COVER STORY

ELEVATE APAC 2023

KÖrber’s first ever in-person Elevate conference is coming to Australia’s shores

Best-in-class narrow aisle material handling for 3PLs

TAKING SUPPLY CHAIN’S PULSE

MHD

Supply Chain Solutions

CONTACT

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Edward Cranswick

Journalist: Joseph Misuraca

Business Development Manager: Beth Jarvis

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Louis Romero, Kerry Pert

Client Success Manager: Janine Clements

FOR ADVERTISING OPTIONS

Contact: Beth Jarvis

beth.jarvis@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST)

1yr (6 issues) for $78.00

2yrs (12 issues) for $120.00 – Saving 20%

3yrs (18 issues) for $157.50 – Saving 30%

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

ELEVATING OUR PERFORMANCE

The new issue of MHD Supply Chain Solutions is all about performance – and how to elevate it.

What could be better than our March cover story focusing on the Körber Supply Chain Software’s Elevate APAC 2023 – scheduled for May? The first in-person Elevate APAC Körber has run – following its successful pandemic virtual conference in 2021 – will thematically focus on the key pain points and challenges facing the supply chain industry in 2023 and beyond.

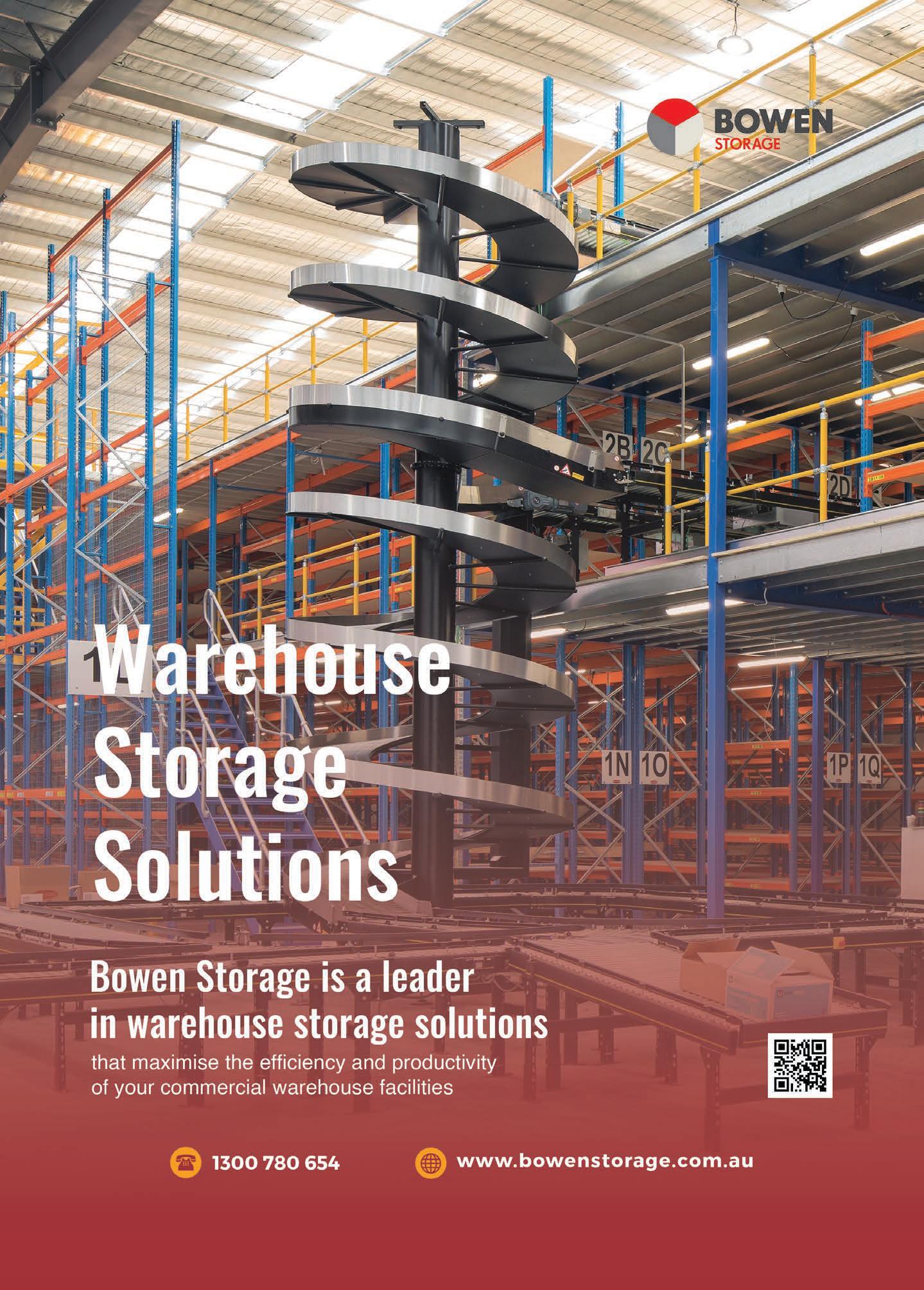

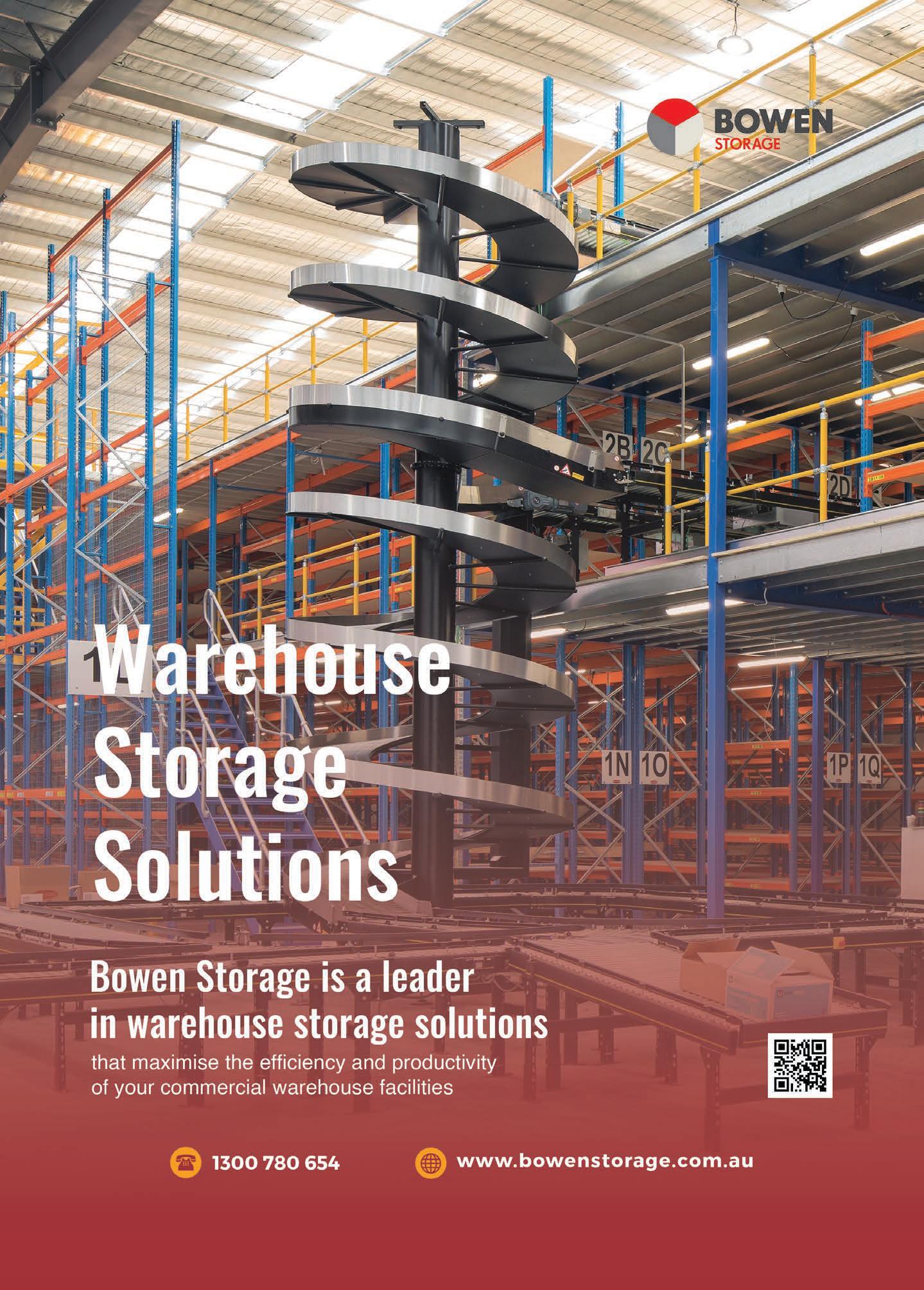

With businesses holding more inventory in their warehouses and DCs than ever and industrial vacany rates at an all-time low, it’s essential that business owners optimise storage space and throughput in their facilities to fit more product. In this issue Greg Phillips, National Sales Manager at Bowen Storage, explains what range of affordable nonautomated, semi-automated and fully-automated smart solutions the family-owned company has to offer.

In Prological’s monthly ‘Logical Outlook’ column, Peter Jones, Managing Director of Prological, discusses the results of Prological’s new survey, which research helps us understand industry sentiment on a variety of different issues. As Peter notes in the article, overwhelmingly there is a concern about supply chain talent scarcity – in part caused by the COVID border closures ceasing skilled-migrant intake. Be sure to read the full piece and Prological’s new white paper for all the key insights.

But what can we do now? The answer might be: technology. In this March issue we also interview 3PL BrandLink on its use of Combilift narrow-aisle materials handling equipment to get the most out of its footprint – and why it prefers Combilift to supply its MHE needs.

Happy reading. See you next month.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Edward Cranswick Editor edward.cranswick@primecreative.com.au

AUSTRALIA’S LEADING FORKLIFT COMPANY

FOR ALL YOUR MATERIAL HANDLING NEEDS

MINI EXCAVATORSSKID STEER LOADERS SCISSOR LIFTS

ELECTRIC VEHICLES

ELEVATED WORK PLATFORMS

SWEEPERS AND SCRUBBERS

TOYOTA FORKLIFTS & WAREHOUSE EQUIPMENT

Known for market leading Toyota forklifts and warehouse equipment, Toyota Material Handling is also proud to o er an unparalleled range of products suitable for Australian businesses. With a huge range of forklifts, elevated work platforms, scrubbers and sweepers, Taylor-Dunn electric vehicles, plus Huski skid steers, scissor lifts, and mini excavators available, chances are we’ve got the equipment that will suit. So, if you’re looking to buy hard working, fully backed equipment for your business, Toyota Material Handling has all you need to add value to your operation. That’s the Toyota Advantage.

ON THE COVER

MHD discusses the upcoming Körber Elevate APAC 2023 conference – and the themes and subjects attendees can expect.

COVER

REGULAR

MATERIALS

INDUSTRIAL

41

Argon & Co, the global management consultancy that specialises in operations strategy and transformation, has announced that Intent Group has become Argon & Co in New Zealand.

It says Intent Group brings a strong team of experts, specialising in operational transformation, and manufacturing excellence across a broad range of industries, as well as deep knowledge of the local market.

“We have been working on the New Zealand integration for the last few months, our teams have led the way and are already in the mindset of one business,” Paul Eastwood, Managing Partner of the ANZ business, says.

“Intent Group has an incredible history and reputation in the local market and a legacy we are honoured to inherit. Together we begin a new

chapter with the goal to build a leading global management consultancy specialising in operations strategy and transformation.”

Intent Group’s integration reinforces existing capability in New Zealand (NZ) and enhances the ANZ business, with a combined team of more than 100 consultants across Sydney, Melbourne, and Auckland.

“Argon & Co NZ is now a reality, with a significant team focused on operational transformation,” Ian Walsh, Intent Group founder who has become Partner of the Argon & Co NZ business, says.

“Our purpose remains on making a difference for organisations of all sizes and locations throughout NZ and drive outstanding performance outcomes. With this integration, we have access not only to a greater team of experienced

INTENT GROUP BECOMES ARGON & CO COLLIERS’ OUTLOOK ON VACANCY RATES IN 2023

Colliers’ Gavin Bishop, Managing Director Industrial, tells MHD what occupiers and investors can expect as vacancy rates and rental prices continue to change.

Despite a pickup in supply, demand continued to outweigh the availability of stock for lease and vacancy rates continued to fall throughout the year. The national vacancy rate currently measures 0.6 per cent, which is down

from 2.7 per cent at the same point in 2021.

The supply and demand imbalance is expected to persist over the short to medium term, which will continue to drive rents higher. At a national level, prime rents are forecast to grow by eight to 10 per cent in 2023 which remains well above historical averages.

From an investment perspective, deals are still proceeding within the current environment, with the emergence of a two-tiered market with regard to pricing with sharper yields occurring for assets with shorter leave expiry profiles, providing the ability for investors to capture imminent rental growth upside.

Assets with a short WALE are expected to be aggressively pursued in 2023 as buoyant rental growth will result in investors seeking positive rental reversions. If economic

consultants but also the world’s best methodologies and digital capability.”

Chris Foord, Associate Partner of Argon & Co NZ, adds that it has been a lot of fun getting to know the Intent team over the last five months and engaging both existing and new clients together to support them deliver. “Together we are truly better.”

conditions change throughout 2023, it is expected the flight to quality theme will re-emerge and demand for core prime long WALE assets will be highly sought after.

Leasing demand is expected to continue to gravitate towards the precommitment market in 2023 as vacancy rates are expected to remain at close to all-time lows given lease renewal rates over 95 per cent.

On top of this, an increase in development-ready land availability in certain markets will continue to support precommitment and speculative lease activity, especially in Sydney where land availability will increase over the next two years as servicing and infrastructure works are completed in the Mamre Road Precinct.

Gavin Bishop, Colliers Managing Director, Industrial

Online Groceries Fresh & Fast

For RedMart, Singapore’s largest online grocery retailer, order fulfilment speed, reliability, accuracy, and productivity are key in delivering on customer promises, especially during the pandemic, when online visitors increased 11-fold.

Optimising capabilities through leading-edge logistics automation from Dematic, RedMart’s online fulfilment centre features robotic shuttles, ergonomic pick stations, intelligent conveying, and high-rate despatch sortation – all across five temperature zones and managed by sophisticated software, making grocery fulfilment easy, accurate, efficient and safe.

Read more and see it in action at www.dematic.com/redmart

02 9486 5555

KÖRBER SUPPLY CHAIN AND BALYO FUTURE PROOFING SUPPLY CHAINS

As the supply chain environment rapidly evolves, automation should be the top agenda item for global logistics leaders. Körber Supply Chain has partnered with BALYO – technological leaders in the design and development of innovative robotic solutions for material handling forklifts – to help businesses future proof their supply chains.

A growing shortage of labour, an explosion in demand from online retailers and an increase in industrial property rises have combined to make the transportation-and-warehousing industry the sector with the thirdhighest automation potential.

To meet these challenges, Körber Supply Chain partnered with BALYO – a technological leader in the design and development of innovative robotic solutions for material handling forklifts. Working alongside BALYO, this partnership willprovide businesses worldwide with the latest technology in autonomous material handling equipment.

Future proof your supply chain with autonomous robots

Technology is the great enabler of more efficient supply chain operations. Companies need to address the gaps in their infrastructure and accelerate their migration to automation and artificial intelligence or risk being left behind.

By integrating BALYO’s range of robotic forklifts to overcome warehouse challenges associated with full pallets, bulk movements and heavy goods, your organisation will be future proof for years to come by being one step ahead in this rapidly changing world.

The result of adopting state-ofthe art technology is flexibility, agility, and scalability – allowing you to predictably increase throughput and productivity alongside company growth.

Robotic forklifts focused on real human needs

Today, we are seeing a shift in our warehouses. Robots are increasingly supporting businesses around the globe to face challenges in goods movements in the warehouse. As a leading integrator and developer of advanced forklift robots, BALYO’s vision is to let companies focus on humans through designing, installing, and operating simple and affordable technologies, systems, and services.

The robotic forklift range allows full autonomous pallet movement within warehouses. This is achieved thanks to a robust product range, embedded in a full user journey. The most basic robot offered is a tugger that is able to pull trailers of up to seven tonnes in weight. Scaling up from there, BALYO has a range of horizontal transport stackers and counterbalanced stackers. These

stackers are able to transport and place pallets of up to 1.6 tonnes up to four metres high.

One of the most popular products in the BALYO range is the automated reach truck. It manages Australian pallets (along with 30 other global pallet types), offering storage and retrieval solutions up to 11 metres high, while working in aisles as narrow as just three metres wide.

Perhaps the most coveted BALYO solution is the Very Narrow Aisle (VNA) robot. The VNA robot provides storage and retrieval solutions at the highest density and up to a height of 17 metres – the highest available solution in the world. Thanks to deep rooted partnerships with OEMs, BALYO is also uniquely positioned to flexibly build the base truck unit to meet a wide variety of aisle widths.

Robots built for efficiency and safety

The unique thing about BALYO solutions is that they begin with original equipment manufacturer (OEM) base trucks that are designed and produced at a huge scale. By adding autonomy to them, BALYO brings two distinct advantages:

• The ability to have easy service, spare parts, and maintenance ready to hand; a local partner network that brings a level of ease to clients.

• BALYO’s solutions enhance employee safety and efficiency; and their robotic lift trucks overcome labour shortages.

The modern artificial intelligencepowered robots are capable of acting as dependable assistants. They allow workers to be more efficient, while also being suited to hazardous environments. Rather than replacing employees, Körber and BALYO solutions enable them to carry out more valuable tasks while working alongside the robots.

A safer work setting is provided through smart safety and stop-andgo features. BALYO’s robots scan the environment in real time for obstructions and instruct the trucks or tow tractors to move or stop accordingly. The cutting-edge SLAM navigation allows for the robots to navigate in a changing environment without the need to add additional infrastructure such as reflectors or QR codes.

BALYO’s strict safety standards (based on ISO 3691-4) will bring customers the highest levels of reassurance, even when working in an environment surrounded with personnel. On top of that, the whole range of AGVs is dual mode, meaning it can be used both in automatic mode or in manual mode.

Robotic user journey with Körber and BALYO

Established 17 years ago, BALYO has offices in three continents and has deployed more than 1000 robots worldwide. Pascal Rialland, CEO of BALYO, believes the collaboration with Körber Supply Chain – who has assisted many companies to integrate automation in their warehouses – will develop an industry leading partner network that meets local and global needs for sector verticals and logistics customers.

Together, the Körber-BALYO mission is to become the long term local and global partner of supply chains around the world – by bringing innovation to warehousing, lowering the cost of pallet movements, and improving safety inside the facility.

“Körber’s expertise in warehousing and logistics, and their global presence, reinforces the complementary nature of the two companies,” Pascal says. He adds that the partnership with Körber Supply Chain is a major asset for deploying

BALYO’s complementary solutions to its customers.

The time for autonomous material handling is now

Every warehouse is different and features a particular set of unique processes to tackle different challenges. The expertise of both BALYO and Körber Supply Chain will take customers on a journey to help figure out how automation is feasible and applicable to unique operations. Multiple models are evaluated, and the best one – with the best return on investment –will be the key to taking each business to the next level.

The time for companies to assess their supply chains and embrace automation and robotics is now. Adopting technology today will provide significant improvements in productivity and efficiency, while reducing labour costs and improving customer satisfaction.

After the disruption our supply chains have witnessed over the last few years, we must now begin to recover. Recovery is the chance to reshape and enhance existing processes. Robots are an important improvement on how we used to work. They give us the opportunity to revolutionise our facilities and make them truly progressive and sustainable long into the future.

E2OPEN’S REPORT REVEALS IMPROVED CROSS OCEAN TRANSIT

E2open has released its Q4 2022 edition of its Ocean Shipping Index – a quarterly report that offers data-driven insights to better manage the movement of goods around the globe.

The connected supply chain SaaS platform also focuses on key lanes between Asia, North America, and Europe.

The e2open Ocean Shipping Index Q4 2022 Report shows that as of January 1, 2023, it takes a company an average of 63 days to deliver goods to truck or rail carriers after booking with an ocean

carrier and completing the cross-ocean journey, saying this is a dramatic eightday global average decline from the same quarter last year.

“While it is the most cost-effective transportation mode, ocean shipping has been in a constant sea of change,” Pawan Joshi, Executive Vice President, Products & Strategy, for e2open, says.

“A company’s constrained ability to predict the impact of external factors like shifting transit times, port congestion, and capacity fluctuations has complicated once-simple ocean shipping.”

Based on information from e2open’s

business network, encompassing 420,000 connected enterprises managing 13.5 billion transactions and tracking 71 million containers annually, the e2open Ocean Shipping Index provides a data-driven reference for shippers to understand how long it takes to move goods internationally as well as the factors that contribute to observed delays.

Companies can use this data to make informed decisions on when to book ocean freight.

“The latest edition of the index highlights ongoing changes and provides

Get the Industrial Capital MarketsInvestment Review 2023

For the latest market trends, insights and outlook for the year ahead.

valuable insights on global shipping lane trends,” Pawan adds. “Incorporating these insights and trends at the moment of decision-making is key to unlocking immediate value and supporting resiliency across the end-to-end supply chain.”

The e2open Ocean Shipping Index is unique because it captures booking information at the start of the logistics timeline to provide a better view of total shipment time.

This report is one of several benchmark reports available from e2open to help companies navigate increasingly complex global supply chains.

MAB CORPORATION’S LAST ALLOTMENT SELLS

CBRE’s Daniel Eramo, Joe Brzezek, Jake George, and Corey LeFavi brokered the sale of MAB Corporation’s last remaining allotment in its Alliance Business Park development in Epping for $10.94 million.

The 11,950 sqm Comprehensive Development Zone land offers three street frontages to Edgards Road, O’Herns Road, and Trafalgar Road.

“Although the buyer depth for land decreased throughout the last quarter of 2022, there is still a flight to

quality for qualified and experienced groups seeking versatile sites within core areas, who are prepared to continue to pay strong rates,” Daniel says.

Alliance Business Park is a 96 ha $144 million industrial and commercial hub and national businesses Mainfreight and Gallagher occupy it.

“The sale of the last lot signifies a strong result and marks the successful completion of the sales campaign,” Michael Martin, MAB

General Manager Commercial and Industrial, says.

“The sale demonstrates there is still solid underlying demand for well-located industrial land in Melbourne’s North, with good exposure and access to transport infrastructure.”

The estate which was sold to a local industrial developer features a 3.6 ha basin including a 700m walking track with cyclist and pedestrian access to the Craigieburn Bypass Trail, notes CBRE.

VANDERLANDE’S ACP SOLUTION SUPPORTS EFFICIENCY AT LIDL KØGE

Lidl is part of the Schwarz Group, one of the world’s largest retail groups, which operates over 13,000 stores across the globe. Lidl’s distribution centre (DC) in Køge, Denmark, outperforms traditional order fulfilment methods by using Vanderlande’s state-of-the-art automated case picking (ACP) solution. At its heart, the ACP solution uses ADAPTO, the shuttle-based automated storage and retrieval system (AS/RS).

This results in:

• enhanced ergonomics and safety

• higher and faster pick accuracy

• increased scalability

• and the ability to supply all Danish Lidl stores.

Lidl’s end-to-end automated case picking (ACP) warehouse solution effectively handles both incoming and outgoing goods and guarantees storefriendly deliveries across multiple store formats.

The ACP system takes over the commissioning and provision of store pallets in an area of only 6,400 sqm saving considerable space. This automates the commissioning processes on site, decreases lead times and further improves the quality of the store pallets.

Vanderlande’s shuttle-based automated storage and retrieval system (AS/RS) with built-in sorting and sequencing capabilities – ADAPTO –

is implemented. Through this, the requirement for costly conveyance technology, sequencing buffers and buffer lines is minimised. ADAPTO

reduces the initial investment costs and delivers a more effective use of space in comparison to similar concepts.

Comprehensive analysis by

specialists from both companies on the site’s workstations means that they comply to the highest ergonomic standards.

WELCOME TO 2023: CONQUEST

Conquest Managing Director Michael Mathews offers his reflections on the year past and ahead –and the recovery opportunities and challenges in store.

We have been able to welcome a return to normality: connecting faceto-face with each other, regaining our freedom to travel, and experiencing a gradual lifting of operational restrictions. However, we have all had to react to a new set of challenges, with inflation, manufacturing/freight delays, and energy scarcity.

I’m proud that the team at Conquest has been able to show resilience and agility in rising to these challenges and provided new products and services that have met the ever-changing needs of our customers.

The foundation of what we do at Conquest will always be about genuinely caring for our customers. We are resolute in our belief that partnering with our customers means more than just providing a product or service. We have invested in our CARE program to ensure that your valuable feedback is heard and integrated into our business. Our pillars: freedom

of choice and reliability, ensure that what we do, and how we work, aligns with what’s important to you and your operation.

A key focus for 2022, was alleviating the pressure of global supply delays for our customers. Through the leveraging of our key supplier relationships in Europe and North America, we were able to boost local machine and spare parts inventory in each of our capital city warehouses to up to eight weeks of supply. This has seen delays incurred through manufacturing and freight, largely negated for our customers.

Our short-term hire fleet has seen rapid growth, commensurate with the ever-increasing demand for emergency cleaning solutions and the temporary augmentation of existing fleets. Conquest Hire now provides the largest range of industrial and commercial floor cleaning equipment in Australia.

An exciting development for us this year, was our expansion into the area of robotic cleaning. Automation will play an increasing role in how we operate efficiently in all our industries, and we are proud to offer an innovative product at the forefront of this technology. The

Michael Matthews, Conquest Managing DirectorAvidbot NEO 2.0 is the most intelligent autonomous product on the market, delivering an exceptional clean through real-time obstacle avoidance and dynamic path planning.

Looking forward to 2023, we have an exciting new range of products and initiatives in the pipeline to ensure we remain able to meet all your floor cleaning needs.

I want to send my sincere thanks for your continued support and best wishes for the year to come.

Michael Mathews is the Managing Director of Conquest.

VINPAC INTERNATIONAL USING DEMATIC’S AGVS

Vinpac International, Australia’s largest contract bottler, has selected Dematic’s Automated Guided Vehicles (AGVs) to help boost productivity and efficiency at its South Australian facility.

Founded in 1975 to provide contract bottling services to customers in the Australian wine industry and beyond, Vinpac bottles more than 10 million nine-litre cases annually and distributes to more than 500 customers. It operates out

of the Barossa and McLaren vale wine regions in South Australia.

“We are absolutely thrilled to be making an investment in three AGVs for the future growth of our Angaston facility,” Andrew Holdback, Group Operations Manager at Vinpac International, says.

“The safety of our team is paramount, so the deployment of these AGVs will help to enhance the working environment for our valued team members and will deliver the

best level of service possible to our customers.”

The advanced, self-charging Dematic Counterbalance (CB) AGVs are designed to increase efficiency, productivity, accuracy, and safety in manufacturing and DCs, achieving this with high-precision laser guidance and the latest safety scanner technology, notes Dematic. AGVs increase productivity and reliability because they are capable of working 24/7 every day for the

year. This is in addition to improving efficiency and accuracy of operations, thereby minimising mistakes, and workplace accidents, which provides significant improvements in occupation health and safety standards.

“We are very excited to be working with Vinpac on this project,” Tony Raggio, General Manager for AGVs at Dematic, says.

“The Vinpac AGV system will transfer finished goods from production lines to conveyors and manage the empty pallet stacks to/from the palletisers and de-stackers.”

The AGVs are capable of lifting loads of up to 1500 kg to a height of four metres. They are powered by high-amp hour, maintenance-free batteries, and can drive themselves onto charging floorplates at times of inactivity to recharge as required.

FTA DIRECTOR ON INFLATION AND FREIGHT RATES

Sky News’ Business Weekend featured Anthony Scali, Managing Director at Nick Scali, outlining the significant cost savings able to be passed on to consumers with the lowering of international shipping freight rates.

While tempering this enthusiasm with a prediction of freight rate increases in the months ahead (refer to the below commentary), I had the opportunity in the same story to share concerns about other inflationary impacts in context of rapidly increasing Terminal Access Charges and ancillary fees paid to stevedores and empty container parks that exceed $600 million per annum.

Data compiled by Freight & Trade Alliance (FTA) and the Australian Peak Shippers Association (APSA) will be presented to the Federal Government as evidence of this claim.

FTA and APSA are escalating advocacy for regulation, as also recommended in the Productivity Commission’s inquiry of Australia’s Maritime Logistics System, to address this cost recovery model imposed on transport operators

(both road and rail) who have no ability to influence service or price.

After years of record high freight rates leading to multi-billion-dollar profits for foreign owned shipping lines, it is now a welcome relief for importers and exporters to see freight rates significantly reduce.

But how long will it last before we see the pendulum swing again in favour of the carriers?

We imagine that shipping lines will look to again take control of the situation within alliances to increase blank (cancelled) sailings by agreement. In a period of adverse economic times and a corresponding reduction in demand, this appears to be how major shipping lines are remaining confident that rates will not fall below costs.

If the contentious EU Consortia Block Exemption Regulation is renewed and at an Australian level, the Part X of the Competition and Consumer Act is retained for an extended period before its inevitable repeal, we can expect a bounce in spot rates in the months ahead.

Recent developments would suggest that shipping lines will fiercely protect their exemptions from competition law. Rather than jeopardise the continuation of broader Block Exemption privileges, we witnessed the stunning announcement of a major split in a global shipping line consortium. Perhaps this was a pre-emptive, and arguably pragmatic decision, noting that this alliance was named by the EU Commission as breaching the 30 per cent market share limit.

Importantly, the ongoing turbulent operating environment places an increased dependence on freight forwarders to provide contract cargo, which shipping lines generally prioritise for loading over spot rate cargo.

Continuity of professional logistics services also includes the ability to seamlessly move between shipping lines to achieve competitive rates, ascertain equipment availability, forecast capacity restraints, manage domestic transport requirements, as well as meeting cross border customs and biosecurity needs.

The advanced, self-charging Dematic Counterbalance (CB) AGVs are designed to increase efficiency, productivity, accuracy, and safety.

The advanced, self-charging Dematic Counterbalance (CB) AGVs are designed to increase efficiency, productivity, accuracy, and safety.

GS1 AUSTRALIA DEVELOPS EDI FOR WOOLWORTHS

GS1 Australia is a long-time partner of Woolworths Group and works closely with its eBusiness Team. It partnered with MessageXchange and Colladium to develop an electric data interchange (EDI) certification and selftesting service.

Woolworths has a set of message implementation guidelines (MIGs) that define how suppliers should trade electronically with them via EDI.

These guidelines outline the document or message types to use, including purchase orders, purchase order responses, purchase order changes, advanced shipping notices and invoices, as well as when to use them, i.e., only use if supplying direct to store or if supplying to a DC, along with the structure and business rules of each message.

With more and more suppliers choosing EDI to trade with Woolworths electronically, onboarding suppliers to EDI with the existing resources and ensuring suppliers’ EDI documents

are built as per the MIGs presented a challenge to Woolworths’ eBusiness team.

“To support our suppliers, we would raise test purchase orders and send them to the suppliers,” Derong Yu, eBusiness Lead at Woolworths, says.

“The suppliers would need to send back messages, like a purchase order response or an invoice for validation. If the messages failed, we would check the message and provide specific feedback to the suppliers.

“The suppliers would then need to make changes on their end and retest it again – it involved a lot of backand-forth and could take weeks or even months to complete the end-to-end EDI accreditation testing.”

Woolworths was keen to adopt this. “We trust GS1, and we know they would partner with the right provider to get this solution delivered,” Yu says.

“We saw this as a way to enhance our suppliers’ EDI onboarding experience and bring real efficiencies to our EDI

accreditation process.”

The teams from each organisation worked together to determine a streamlined process for suppliers and design the EDI Certify solution accordingly.

This was based on the current EDI documents exchanged and business requirements working with Woolworths including numerous scenarios such as accepting, rejecting, or changing orders, fully or partially shipping orders, invoicing, and checking logistics labels.

The MessageXchange and Colladium teams configured the EDI Certify system to guide suppliers through the Woolworths EDI self-certification process, enabling suppliers to generate an order with supplier-specific details such as vendor number and products, as well as validate suppliers’ outgoing messages for Woolworth’s required scenarios with real-time feedback is a key feature.

Most importantly, the processes simulated real-life scenarios. Woolworths also added in other documentation, including labelling guidelines, so that suppliers have all the information they require, in context, and at the time that they need it.

“The EDI self-certification gives us the confidence that the suppliers are ready when it comes time for the endto-end EDI accreditation testing and onboarding to our live systems,” Yu says.

“We’ve seen the quality of EDI messages during the end-to-end testing is now much better and the EDI accreditation testing process is smooth.”

Once the issues are fixed, they can retest messages without relying on Woolworths’ eBusiness team.

With the EDI Certify service, suppliers are now able to generate EDI purchase orders based on the information they input, self-test their messages to Woolworths anytime to get all issues identified upfront.

Woolworths has seen huge efficiencies in its end-to-end testing process – what sometimes took weeks or months, now takes days.

National vacancy rate dips to record low 0.6%

Still the lowest of record Globally.

The national vacancy rate has further fallen since H1 2022 and now stands at a new record low of 0.6%, with the downward movement recorded for all major markets across Australia.

Scan the QR code to unlock the latest insights in CBRE’s Industrial & Logistics H2 2022 Vacancy Report.

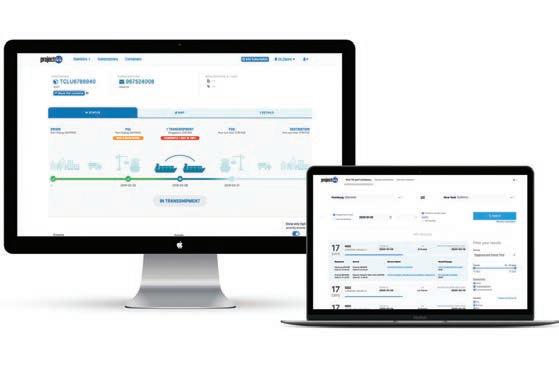

FIND YOUR RHYTHM AT ELEVATE 2023

Having been hosted in the Americas for more than 10 years, Körber’s unmissable Elevate event is coming Down Under. Join Körber’s APAC team at the region’s first in-person Elevate in Melbourne. MHD gives an overview of Elevate APAC 2023 and why it's a must-attend for businesses wanting to stay ahead in innovation, optimise processes, and gain valuable insights to achieve new levels of success today – and into the future.

For the first time ever in Australia, Elevate APAC will take place in-person, building off the success of the virtual

After the success of Körber’s Elevate APAC virtual event in 2021, this year’s Elevate will be bigger and better and held in-person for the first time in Australia.

Held this year on 02-03 May in Melbourne, the agenda will be packed with Körber customer stories, product information, opportunities to network with peers, and meet with the Körber APAC and Global team,

and partners. Furthermore, Körber has exciting new content this year focused upon its newly acquired Order Management and Transportation Spend Optimisation solutions. Industry-leading experts will provide actionable insights for Supply Chain’s biggest and most important trends. There’ll be a deep dive into Körber’s suite of supply chain products and solutions, the

opportunity for attendees to see Körber products in action and learn about real-life transformation stories. Plus there’ll be specialty sessions hosted by Körber’s vast network of complementary supply chain technology partners.

"After 10 years of Elevate in the US, we are extremely excited to bring the first in-person Elevate to the APAC region," says Anthony

Beavis, Managing Director ANZ at Körber Supply Chain Software. "The two-day event will offer attendees a full schedule of product updates, industry insights and networking opportunities. It's the perfect opportunity, as an industry, to learn to grow together in one location."

If you are a Körber customer or someone looking to conquer supply chain complexity, you will not want to miss Elevate 2023.

ELEVATING PERSEPCTIVES

To enrich customer and industry knowledge around the challenges, complexities, and opportunities that face supply chain today, last year Körber launched Körber Perspectives – an integrated effort to deliver learnings, insights, stories, data, and solutions to help businesses.

Elevate APAC 2023 will build off the ongoing themes and learnings identified in Körber Perspectives – providing the opportunity to share perspectives face-to-face in Melbourne.

Some key challenges Elevate will address include:

• Heightened customer expectations around selection, quicker shipping,

and lower costs;

• Labour hiring and retention difficulties;

• Sustainability as a top-of-mind priority for consumers, businesses and governments, as manufacturing and supply chain become a major target of change;

• Facilities being pushed to their breaking points, seeking ways to quickly improve and adapt to rising expectations; and

• Technology continuing to provide supply chains with more data, but choosing siloed technology that doesn’t communicate with the entire supply chain network, leading to difficult decision making and disconnects between different sides of the business.

To help combat these issues, supply chains need to carefully plan and execute on technologies that help build a strong, end-to-end supply chain network that can help support growth and adapt to ever-changing market conditions.

Körber Perspectives aims to help businesses understand these complexities and provide information that could be key to addressing them in the future. Since the initiative began, Körber Perspectives has identified six key pillars of focus –around which Elevate APAC 2023 will be structured:

• End Customer Experience

• Labour Engagement

• Digitisation

• Facility Optimisation

• Sustainability

• Agility and Resilience

END CUSTOMER EXPERIENCE

With the rise of e-commerce, many businesses have had to transform their warehouses to handle online orders in addition to the regularly scheduled inventory shipments. This means that warehouses need more information than ever before to ensure they can meet the needs of customers.

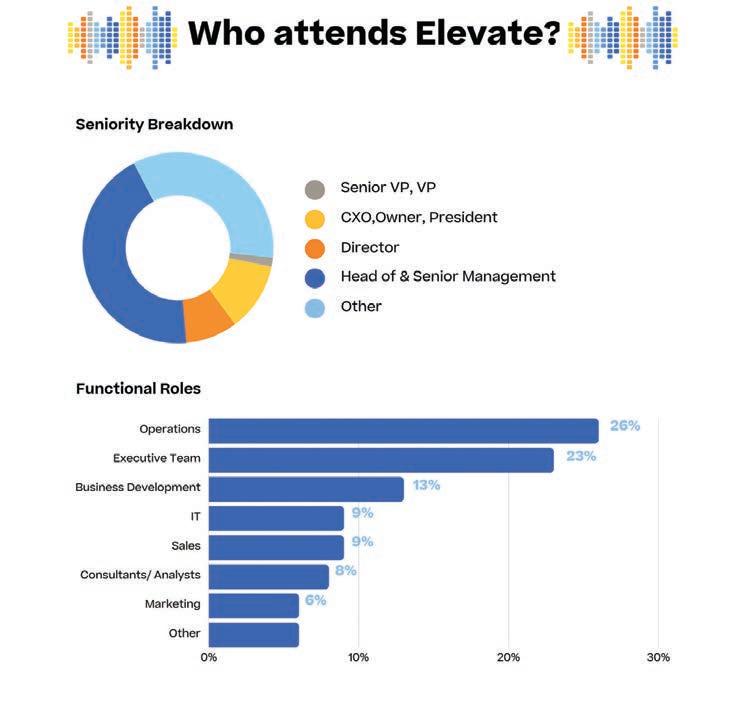

Elevate APAC 2023 will build off the ongoing themes and learnings identified in KÖrber Perspectives – providing the opportunity to share perspectives face-toface in Melbourne.A breakdown of Elevate attendees by profession. End Customer Experience is one of the key pillars of Elevate 2023.

The Challenge

Over the past 10 years, customers have developed a desire to have what they want, when they want it – even when the distribution centre holding that item is across the country. Last minute orders can put high stress on warehouses, as shipping windows and cut-off times become increasingly important.

The Opportunity

With these new expectations, many companies find themselves facing tough decisions. Do you hire more workers? Increase overtime? Or do you pass the cost on to the customer themselves? Choosing the right technology can help address these issues without putting an undue burden on the operation.

LABOUR ENGAGEMENT

Finding and retaining labour is one of the biggest challenges facing the supply chain today. Choosing the right technology to attract and support your workforce may be the solution.

to work more safely, enthusiastically, and productively. Introducing the right technology, in the right place, and connecting it with the workforce, can enable organisations to build the supply chains of the future.

DIGITISATION

Today’s supply chain is full of complexity – balancing customer expectations, company demands, and consistently changing markets. Knowing what is happening in your supply chain is key to staying ahead of the competition, which is why digitisation is so important to supply chain success.

The Challenge

To meet the complex demands of both the industry and today’s consumers, the need to optimise warehouse and DC facilities has become more than a competitive advantage – it is a business necessity. Gone are the days when large batches of the same product could be moved by a single forklift and loaded onto a truck for delivery within minutes, and operations needs to adapt.

The Opportunity

The Challenge

Supply chains are under increasing pressure to be smarter, more productive, and more efficient. Technology can help, but selecting the wrong technology – or multiple pieces of technology that don’t communicate – can actually make improvements more difficult to achieve.

The Opportunity

Technology is not designed to, and never will, replace human intervention. People will always be able to do things that robots cannot. However, there is currently a huge amount of latent potential to combine human skills with automated technology, allowing warehouses to stay competitive within the challenging environment that supply chains face today.

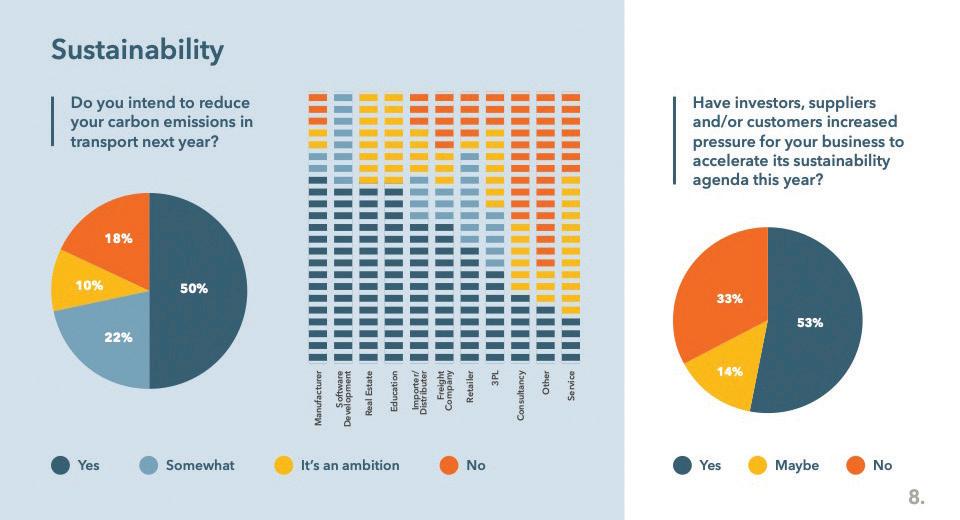

SUSTAINABILITY

The Challenge

Warehouses across the globe are struggling to find the staff they need to meet demand, especially as e-commerce continues to grow. Even when staff are found, it can be difficult to keep staff engaged and retain them amidst enticing offers from other companies looking to solve their labour shortages.

The Opportunity

Against these forces, technology offers a solution, unlocking new operational savings while supporting employees

Data is a valuable resource for any company to be able to gain insights, support planning, and make informed decisions. Selecting technology that integrates and provides powerful, easy-to-use and accessible data will elevate your supply chain.

FACILITY OPTIMISATION

Warehousing today looks wildly different from days past. Processes have changed, customer demands have heightened, and technology is being leveraged like never before. Getting the most out of your facility will be the key to keeping up- today and in the future.

Sustainability front-of-mind in today’s society and governments and consumers are coming to expect more from businesses. While emissions are the starting point for many operations, integrating sustainability fully into the supply chain will be key to managing expectations in the future.

The Challenge

The urgency of solving the climate crisis has never been higher, and people’s awareness of their impact on the planet is growing. Global forces are imposing more and more regulations on businesses to become more sustainable. But as the supply chain makes efforts to cut their CO2 emissions and carbon footprint, it also needs to keep demanding customers satisfied.

The Opportunity

Sustainability is more than the environmental impact as we know it. That’s why the supply chain must start taking a more holistic approach to their operations, both in and out of their warehouse. This will not only help operations meet increasing regulations, but also provide the chance to earn customer loyalty as a brand that aligns with their values.

AGILITY AND RESILIENCE

From natural disasters, to pandemics, to unexpected disruptions caused by blockages in ports or highways, there’s always something around the corner for today’s supply chain. Choosing the right technology can help mitigate the risk and prepare your operation for what comes next.

The Challenge

Supply chain operations are critical for any business, but they are susceptible to disruption from both operational and environmental factors. It’s crucial to build agility and resilience into your operation so you can overcome the unexpected when it arrives- and it will arrive.

The Opportunity

Agile supply chains are successful because they can adapt strategically. They are able to react to external trends and changing customer demands while navigating the challenges of today’s supply chain. This can be achieved through careful planning, robust but flexible processes, and investing in technology that can adapt with you.

DON’T MISS ELEVATE APAC 2023

With a successful 10-year history in America – and more recently in Europe – Elevate has established itself as a must-attend annual event for customers and partners. The 2023 event will feature keynote speakers, panel discussions, and networking opportunities that will focus on the latest industry trends, cutting-edge technologies and solutions to tackle pressing supply chain challenges. Find your Rhythm at APAC Elevate 2023 and solve supply chain complexity with industry experts. ■

Don’t miss your chance to register for Elevate APAC 2023. Use the accompanying QR to secure your ticket today.

After 10 years of Elevate in the US, we are extremely excited to bring the first in-person Elevate to the APAC region. The two-day event will offer attendees a full schedule of product updates, industry insights and networking opportunities. It's the perfect opportunity, as an industry, to learn to grow together in one location.Learn how to build Agility and Resilience at Elevate 2023.

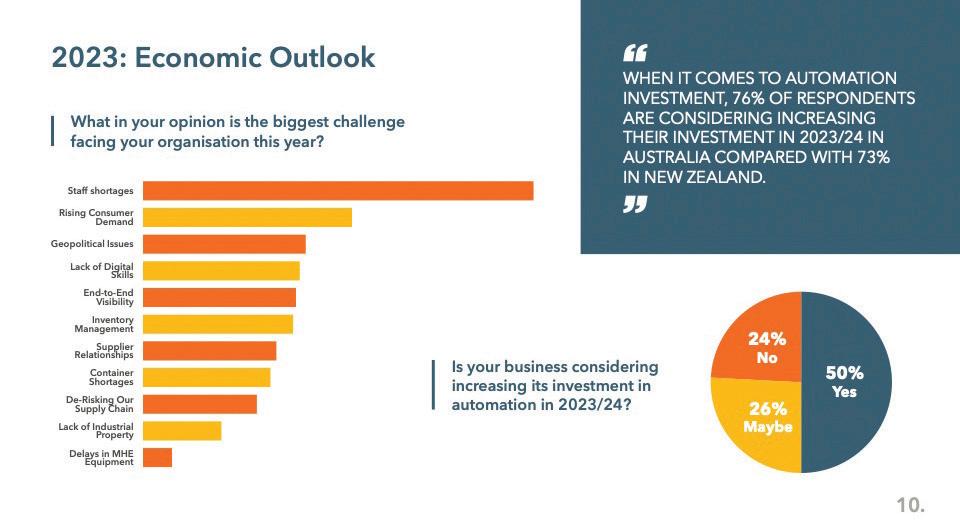

TAKING THE PULSE

In a recent interview, Peter Jones, Managing Director of Prological, discussed the new Prological Supply Chain Pulse Check Survey 2023. The survey addresses five critical areas of concern for businesses, including supply chain uncertainty, sustainability, supply chain visibility, the economic outlook, and skills and recruitment. The survey questioned the importance of such issues to organisations and their businesses’ intentions to address them.

“The impact of recent supply chain induced business pain is driving the renewed focus of addressing the fail points,” Peter says.

One key takeaway from the survey is how concerned firms are with recruiting effective talent in this economic environment. “The current low unemployment rate has made it difficult for businesses to find new employees,” Peter says. “The ‘silly money’ that businesses were recently offering to attract employees during ‘The Great Resignation’ has largely stopped, while employees also seek better life balance. It appears workplace flexibility is the new currency to attract and keep staff.”

On the broader themes of supply chain and the 2023 economic outlook, Peter states that it is difficult for logisticians to draw emphatic conclusions on global macroeconomic factors. However, Peter notes that the apparent experts from banks and consulting firms, government, and superannuation funds are all saying the same thing about the economy – locally and globally: interest rates are rising, and the cost of living has increased. This has resulted in people modifying their spending and this is driving the survey’s result in relation to economic uncertainty.

The results of the survey showed only 28 per cent of businesses are considering reshoring manufacturing. Given the emphasis that was put on this theme in public discourse during the pandemic, is

Peter surprised by this result?

“Many Australian and New Zealand companies have been importers for a long time. Many are part of global conglomerates, making it quite difficult to suddenly decide (during a pandemic) to get into local manufacturing. Having said that, I was still surprised. I thought that with the government talking about supporting onshore manufacturing and the opportunities available, there might have been a higher percentage of businesses considering it. Maybe, the business cases regarding reshoring still didn’t add up, despite the desire, or that reshoring requires a long-term commitment to local manufacturing. A commitment that, while desirable, presented other risks, leading to strategies enabling the ‘riding out’ of this economic storm.”

On the sustainability front, companies are doubling down on their sustainability commitments. “Our governments have been slow to the mark in setting goals, clarity in legislation, or even minimum standards – notwithstanding recent positive changes. In contrast to 15 years of politicisation around decarbonising the economy, energy policy and investment into sustainable energy, businesses have taken a strong lead.”

According to Peter, some businesses

in Australia are well-advanced in their actions, plans and aspirations toward sustainability.

“We no longer see any brief from any client that does not have clear, high-bar sustainability goals set within the context of well-developed boardapproved ESG policy. This has become the norm.”

With respect to supply chain visibility, Peter notes he was “more heartened than surprised” by the results. “Some of the respondents come from the e-commerce businesses,” he explains. “Within e-commerce businesses, visibility has been a focus since the industry’s inception 30 years ago.”

However, he was surprised to see “less than one per cent acknowledging ‘little or no visibility’.” Peter’s daily experience is that “many B2C businesses provide little product availability or order-to-delivery-fulfilment visibility to their customers, mainly because they do not have the systems to do it. He notes that “a large proportion of businesses have as a high priority taking action to provide good quality, value adding, endto-end visibility across the supply chain.

“We believe some of the survey outcomes reflect how e-commerce businesses are now taking up a much bigger proportion of our economy. As

Prological has released findings from an inaugural survey, uncovering trends and future predictions from supply chain, property, and manufacturing experts across Australia and New Zealand. Peter Jones explains to MHD some of the key findings, surprises, and implications.

a result, B2C businesses have started benchmarking their visibility and control capability against their employees’ B2B experiences.

“For example, say a person goes to work at the chemical manufacturing company and tells a story: ‘Yesterday I received an e-commerce order from ‘Amazacom’. I got immediate order confirmation, updates as my order progressed through fulfilment, tracking information upon despatch, and delivery options by the courier.’ Why, the employee asks, can’t they give their own customers visibility and control like this? This question is the subject of many B2B discussions today – and some are finding the required answers.

“Advanced B2C businesses are pushing into new frontiers of visibility, providing control not only to their suppliers, but also enhancing their consumer experience by providing them options as well. The B2C capability we all now experience has not yet reached full maturity. There is more to come, but what we now have has started migrating into the B2B environment, and all will benefit from this development.”

Peter’s holistic read on the outcomes of the survey leaves him optimistic.

“The first key takeaway is that supply chain now has a seat at the table within the C-suite and within boardrooms across the business community.”

He explains that the COVID-19 pandemic has taught us all the

importance of reliable, efficient, and controlled supply chains.

“Prior to 2020, many businesses had created significant exposure to single point failures in their supply chain. Above all, the survey results speak about supply chains being enhanced to reduce risk.

“Supply chain became a central topic of discussion in the boardroom because production lines were stopped, because critical supplies couldn’t arrive, because there was nothing to sell. Similar discussions happened in our homes when we could not buy toilet paper. From the board room to the dinner table, we all became aware that supply chains need to work, and when they don’t both business and families feel the consequences.”

Peter adds the survey showed that businesses have responded to the importance of their supply chains, with 77 per cent of respondents confirming supply chain investment in 2023.

“My final reflection is that we will likely see a much greater distinction between businesses’ capabilities based on supply chain. In the second half of this decade, we will see the impact of those investing in next generation supply chains today and those that are not. The companies that are developing now will stand in great contrast to those who have not developed their supply chains in this season.

“Supply chain has become a

distinctive competency for some businesses. For others it will be that advantage within the next two to three years. For others who are not investing in this period of opportunity, it will become an even greater challenge as the gap between the ‘have’s’ and the ‘have nots’ amplifies and accelerates heading into the middle years of this decade.

“When asked ‘What do you do’? my answer has for 27 years been, ‘I work in supply chain’. For most of my 27 years this answer has often had the follow up question, ‘What sort of chains do you supply?’

“But today I almost always get asked informed questions that display knowledge and interest. As the survey displays, supply chain is front and centre now. At home, we know about it, in business we are working on making them more agile and resilient. In board rooms there is now experience-based knowledge regarding the correlation between supply chain success and business success. The survey demonstrates with great clarity that businesses better understand the importance of supply chain and are rapidly addressing their gaps with commitment and investment.” ■

CAPITAL MARKETS KEY THEMES

In this month’s column, Colliers provides MHD with an in-depth analysis of the pricing of industrial real estate assets and the outlook for 2023.

Despite broader economic headwinds, the Australian industrial and logistics sector continued to show its strength throughout 2022. The key themes for 2022 included:

• Occupier market exceeded expectations - take-up set a new record and vacancy rates plummeted in all markets.

• New rental benchmarks set - rental growth grew by six times the longterm average as occupiers competed aggressively for space.

• Investment activity eased in H2 2022 - the pace of activity in the investment slowed in the second half of 2022 as buyers and vendors worked through a repricing period.

• Yields expansion cycle began –rising interest rates and debt costs had flow-on impacts to pricing. Overall investment volumes totalled $7.9 billion in 2022, and while this is down from the record $16.0 billion in 2021, it is the second-highest

NATIONAL INDUSTRIAL & LOGISTICS INVESTMENT VOLUMES ($10M+)

volume on record. Deals in the current environment are still proceeding; however, the buyer pool has thinned.

The key theme to emerge in the capital markets space in 2022 was asset pricing as yields softened for the first time in over a decade. Inflationary pressure has led to a sharp rise in interest rates globally,

and as a result, industrial and logistics assets are being repriced to reflect higher funding costs. Since the peak in pricing in Q1 2022, prime yields have softened by 85 basis points on average nationally, while long WALE assets have seen closer to 100 basis points of softening over the same period, given that the rental upside cannot

be accessed for some time. Looking ahead, it is inevitable that industrial and logistics asset prices will continue to be impacted in 2023; however, the scale of any movements will depend on a myriad of factors, including the terminal cash rate. Once interest rates stabilise and lenders are pricing debt with more predictable spreads, investment demand is expected to pick up. However, sellers face a price adjustment for the time being, and many are only bringing assets to the market if they need to.

WHERE TO NEXT FOR PRICING?

Interest rates which provide a crucial backdrop to real estate pricing, have increased sharply from the first rate rise in May 2022. Going forward, it is forecast that interest rates will peak at ~3.6% by mid-2023, while a number of the big four banks are

anticipating rates will ease in early 2024 as economic growth begins to drag. Nonetheless, interest rate rises will continue to increase funding costs, and flow-on effects will occur to yields and pricing.

Based on the outlook for interest rates and funding costs, our view is that yields will soften a further ~50 basis points by mid-2023 and then stabilise thereafter, taking the national prime yield to just over 5.25%. Prime yields in Sydney and Melbourne are expected to sit closer to 4.75% and 5.00%, respectively, at the same point in time.

Our analysis shows that for every 25 basis point softening of yields, a ~7.0% increase in rents would be needed to preserve asset values. While rents are growing well in excess of this on an annual basis, the softening of yields to date has outpaced rental growth, and prime capital values have fallen on

average by 6.2% nationally since the peak in pricing in Q1 2022. From the pricing peak, prime asset values are forecast to fall ~10.0% by mid-2023 before improving thereafter as yields stabilise and rental growth remains solid to drive an uplift in asset values. For context, the peak-to-trough decline during the GFC totalled 22.9%, and pricing took eight years to recover to its pre-GFC level. This time around, pricing is expected to revert to the pricing recorded in Q1 2022 by the end of 2024.

Despite the uncertainty around pricing, given the lack of genuine benchmark transactions, fundamentals within the sector will remain supportive of further capital inflows in 2023, led by the occupier market.

While rising interest rates and debt costs will remain the key themes on pricing in 2023, the impacts will be mitigated to some extent given low gearing levels through conservative debt management, including highinterest cover ratios, which will mean less pressure on groups to sell. As a result, fewer distressed assets are likely to come to market in 2023 compared to the GFC. Similarly, with higher interest rates impacting levered returns, cashfocused buyers are expected to be active and competitive in transactions. This is expected to see private investors return to the market, particularly as most have been priced out of the market for the best part of two years and would be sitting on funds to invest from selling down assets in recent years.

Buyer demand will likely remain patchy in early 2023 before recovering quickly as capital sources re-enter the sector. Nevertheless, strong occupier fundamentals will continue to entice new market entrants into the sector. More broadly, groups with access to offshore capital are forecast to remain the most active in 2023, while REITs will likely be more selective in their acquisitions. ■

To download the report and find out more scan the QR code. Colliers welcomes any questions about the research and how it can best assist you with your property needs.

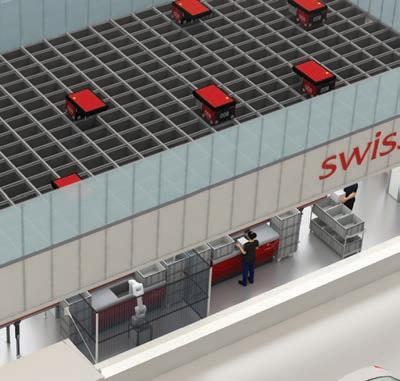

MOVING AUTOMATED FULFILLMENT FROM STRATEGY TO EXECUTION

Rising order volumes and pressure for shorter pickup/delivery times are driving the evolution of e-grocery. Fulfillment times are now measured in hours and minutes, rather than days. The Swisslog e-book shares lessons learned and best practices to help grocers successfully implement MFCs and larger EFCs. Don’t get left behind in the e-grocery evolution. Download the e-book today.

swisslog.com/e-grocery

MASTERING NARROW AISLES

For eight years BrandLink has been using Combilift Aisle Master vehicles to get the best results for its diverse 3PL operation. MHD speaks with BrandLink’s Kevin Butler to learn why he prefers Combilift.

3PL provider BrandLink caters to a unique array of clients, says Kevin

Butler, NSW Warehouse Manager at BrandLink.

Butler, NSW Warehouse Manager at BrandLink.

“We don’t limit ourselves to just one industry, but instead have a diverse client base, servicing customers across both DC and retail distribution, on and off-premise, and the ever expanding direct to consumer requirement ,” Kevin says. “Our facilities undergo regular audits every 12 months to ensure they meet the high standards of our clients. Importantly, we take pride in staying ahead of the curve in terms of technology – and require the best to keep everything running smoothly.”

BrandLink has a workforce of roughly 20 staff in each of its three warehouses – two of which are in NSW and one in Victoria. With 60 staff in total across the three warehouses, the company relies on top-end narrow aisle materials handling equipment to get its various jobs done.

And it relies on Combilift to provide

that equipment.

According to Kevin, the use of effective narrow aisle materials handling equipment is crucial for the success of BrandLink.

“BrandLink has been using Combilift for its material handling needs since the opening of its first site eight years ago,” he says. “The justification for choosing Combilift was due to its excellent customer service, good communication, and the product’s suitability to the company’s needs.”

BrandLink’s machines are serviced by Combilift vendor and partner Adaptalift. “The servicing is excellent,” Kevin says. “If we have breakdowns of our forklift, they’re usually out within the 24-hour period and have it fixed. Combilift has always been a reliable and efficient partner for BrandLink.”

He says the New South Wales warehouse of BrandLink currently

has four Combilift Aisle Masters and one counterbalance machine. By implementing the Aisle Master in its operations, BrandLink has been able to utilise more space and add an extra row of racking in its Erskine Park warehouse, notes Kevin.

“We’ve found Combilift to be a good partner with very responsive customer service,” he says. “If there’s a problem, it gets fixed quickly. Combilift has also been able and willing to trial new ideas with our forklifts and accommodating in setting up technicians to fit the units. For instance, one time we wanted to trial fitting out the forklifts with RF units, and although we decided against it after the trial, Combilift was happy to come back out and remove the unit as well. Overall, I feel like Combilift is there to help BrandLink.”

The recent acquisition of a Combilift Aisle Master OP by BrandLink has

added to the functionality and utility of their materials handling equipment. The Aisle Master OP is a stand-on operated machine – different from the previous sit-down models.

“The new model is more advanced in terms of technology, as it is operated by a joystick, making it easier and more comfortable for the operator to use,” Kevin says. “The main benefit I’d say from the new model is the ease of use and improved safety for operators.”

International opinion agrees, with the Aisle Master OP recently nominated as a finalist for the IFOY Award (International Intralogistics and Forklift Truck of the year), which honours the best products and solutions of the year. The electric stand-on forklift was shortlisted by the Jury in the ‘Warehouse Truck ‘highlifter’ category for its versatile operation in warehousing applications.

Kevin adds that with an extremely tight industrial property market, he thinks premium narrow aisle vehicles of the kind Combilift offers will be increasingly important to get the most out of warehouse footprints.

“Moving forward, the utilisation of warehouses is going to be crucial, especially in the Sydney market where acquiring land and leasing warehouses is very difficult,” he says. “A lot of

companies are going to look towards bringing in more narrow aisles to maximise their available space.

“We had to go through a lot of trouble to get extra space when we acquired our warehouse at Arndell Park. I think a lot of people are going to be working hard to better utilise the warehouse space they already have –as it’s hard to acquire any more.

“I believe that technology, such as the Combilift Aisle Master, will play a crucial role in maximizing space. The OP models are more comfortable and safer to use, with stand-up operation and joysticks, and I think this is definitely the way to go.” ■

AISLE MASTER OP HIGHLIGHTS

• Up to 12m lift height

Up to 2500kg lift capacity

Low floor height of only a 280mm: a single step speeds up order picking compared to an operator having to get in and out from a seated position.

• Aisle widths as narrow as 1.9m while allowing order picking from either side.

• 360 degree visibility

• Truck to rack: indoor / outdoor usage

• Adjustable Joystick control

I believe that technology, such as the Combilift Aisle Master, will play a crucial role in maximising space.By implementing the Aisle Master in its operations, BrandLink has been able to utilise more space.

→L easing & Sales

→I nvestment Sales

→ Development Expertise

→A sset & Property Management

Reliable. Scalable. Secure. Go further with the world’s leading fleet tracking platform.

40,000 + Global customers

2 Million + Connected devices

40 Billion + Daily records

Fleet optimisation

• Improve fuel economy

• Decrease idling

• Reduce Speeding

• Monitor engine data

• Plan maintenance

Compliance

• Vehicle inspections for safety

• Seatbelt use reporting

• Manage driver infractions

• Corporate sustainability programs

Productivity

• Real-time fleet management

• Exception rules

• Trips & activity reporting

• NFC Driver ID

• Easy dispatching

Expandability

• Open-source platform

• Marketplace of Add-ons & Add-ins

• SDK & APIs

• IOX expansion on every device

Safety

• Risk & safety reports

• In-vehicle coaching

• Accident notifications

• Collision reconstruction

• Driving in reverse

Sustainability

• Reduce fuel consumption

• Track CO2 emissions

• Fleet electrification

• EV performance monitoring and reporting

• GO device recycling program

TOYOTA FORKLIFTS DELIVERING FOR BORDER EXPRESS

How Toyota Material Handling helps Border Express to keep running smoothly.

Toyota Material Handling Australia (TMHA) has helped an Australian-owned transport company avoid logistical difficulties, providing support and equipment when it was most needed.

After putting out a new business tender, Border Express settled on TMHA thanks to the performance of its Toyota forklifts and its broad network of aftersales support.

Border Express National Procurement Manager Alec Trikash says there were multiple factors that

saw TMHA come out on top ahead of six other offerings.

“TMHA was selected as the successful tenderer based on a number of factors including reputation, the value proposition that was offered, the network that TMHA has, where it’s primarily TMHA staff instead of agents – particularly in regional areas,” Alec says. “Those were the three primary factors – and the quality of the equipment.”

Having such a diverse geographical reach via their direct branch network,

the extensive scope of TMHA’s network and the expertise of its service technicians was an important factor in Border Express’s decision to partner with Toyota.

“The feedback has been that the service technicians are very responsible and knowledgeable,” Alec says. “So, positive feedback all round regarding TMHA from both the operators and operation management sides.”

With 18 branches across the country, Border Express requires a large fleet

of machines, with approximately 215 total units needed consisting of gas forklifts, electric pallet jacks and reach trucks.

Due to the current global supply chain issues, replacing Border Express’s 215-strong fleet was always going to be a tough ask, however TMHA “bent over backwards” to make the change work.

“Despite the global supply chain issues initially delaying delivery, TMHA senior management stepped in to support Border Express and since then they’ve been fantastic in supporting us,” Alec notes.

“Pulling out all the stops in terms of new equipment, sourcing short-term hire equipment and even additional equipment through a sub hire arrangement.”

Since switching fleets to TMHA, Border Express’s forklift operators have praised their new Toyota forklifts, with Toyota’s System of Active Stability (SAS) being a particular standout.

“It’s been noted – the equipment has received positive feedback from the operators,” Alec says. “There were some adjustments that needed to be made to the equipment and Toyota were very quick and responsive in delivering that – so very happy.”

Developing strong relationships is a key facet of the way Border Express does its business, and TMHA General Manager – Corporate Accounts, Steve Hopkins, says the two companies came together in trying times to achieve the best outcome.

“Border Express is driven by having genuine relationships, it’s not just something they pay lip service to,” Steve says.

“Making an assessment of the marketplace, they viewed TMHA as the most suitable to partner with based on our fundamental values.

“Given that supply chains have been challenged across the world, we’ve worked in unison with Border Express to ensure that any operational distress this could have caused them has been eliminated.”

Toyota’s I_Site Fleet Management System has also unlocked further efficiencies for Border Express, allowing the company to analyse the way forklift operators work and where improvements can be made.

“The machines are fabulous, the fleet management system is excellent and we’ve been getting some great data captured that we can sync back through to our operators to train and help change some of the behaviours, so in that regard the fleet management

system has been second to none,” Alec says.

Since moving to THMA, Alec has found the products, service and value has improved for Border Express, and would happily recommend Toyota to others in the industry.

“Certainly in terms of the level of service, especially the service technicians, they’re very good.

“Also the account managers in each state have really been working well with our operations.

“They’ve been really proactive and have gone above and beyond in terms of the training, inductions, the equipment, and helping us out with things like the pre-delivery reports. We’re very delighted in terms of the overall value proposition.”

Border Express was founded over 40 years ago by the Luff family and is 100 per cent family owned with the third generation of the family now in the business.

It offers parcel and bulk freight services to B2B and B2C customers across the country with a particularly strong regional presence and employs more than 1500 staff throughout Australia. ■

For more freecall 1800 425 438 or visit www.toyotamaterialhandling.com.au

BALYO HELPS CLIENTS SCALE NEW HEIGHTS

MHD sits down with Joshua Couturier, ANZ Sales Engineer for BALYO, and Jian Han Law, Head of APAC Sales, to discuss how their Very Narrow Aisle robots have helped global companies scale up their operations to a staggering 17 metres to face business challenges head on.

2

023 finds Australian warehouses and distribution centres feeling pressure from all sides, from a staggering increased demand for throughput, to rising space costs and let’s not forget the talent shortage that’s clogging up job boards for qualified personnel that has been a problem since the pandemic started.

While it seems like there’s no escape from these woes, organisations are finding ways to use automation to help face these challenges and find surprising new efficiencies at the same time.

BALYO was founded almost twenty years ago with the simple mission of taking standard forklifts and turning them into a robotic workforce. Most people call these AGVs, but BALYO says it dislikes the term. AGVs typically require huge amounts of infrastructure like reflectors and guides while BALYO robots are autonomous. The guidance

is on-board, which means no changes are required to a user’s existing space. Brains and brawn are all selfcontained on the robot. In the past few years, BALYO (and the industry) have become hyper-focused on the vertical space over the horizontal. Companies need to start thinking up, not out; and it’s been building innovations to be the leader in realising 3D environments, owning the concept of precision along the x, y, and z axises.

CREATING STORAGE SPACE WITH VNA

It’s all about cost and efficiency, which means maximising space. Warehouse rents per square metre costs are reaching never-beforeseen levels in Australia so companies need to first start by using all their available space.

For example, implementing VNA

racks can reduce horizontal ground footprint. For all levels users go up in a rack, it’s estimated they gain 30 per cent more storage capacity. Very Narrow Aisle racks are obviously a great alternative to Narrow Aisle racks in terms of storage capacity and density; and combined with shuttle racks, customers get an extremely dense storage capacity.

The highest BALYO has seen, which it says is a world record, is a 16.8m very narrow aisle pick for a company in Singapore called Singapore Storage & Warehouse (SSW). SSW wanted to convert its manual forklifts to autonomous robots without sacrificing reliability and safety.

Thanks to BALYO’s innovative approach to safety, standard OEM forklift controls, and smart perception of pallets, reaching new heights is now possible. After a short test period in 2021 and a commissioning period

MHD WAREHOUSING

of a few months, BALYO successfully ramped up and handed over four autonomous VNAs to SSW, covering 20 seventy-five-metre-long aisles.

“We are very happy to be partnering with BALYO & Linde for this automation project,” Ong Swee Keong, CEO of SSW, says.

“The productivity gains have been impressive, and I am glad that the dedication and hard work put in by everyone in SSW, Linde, BALYO, and our partners for this project has paid off. As SSW continues to transform and grow, we look forward to achieving even more business success with our reliable partners.”

ACHIEVING EFFICIENCY AND SAFETY

In addition to space challenges, warehouses globally are facing very real labour shortages. Finding milk-run forklift drivers is a challenge, finding VNA drivers is 10 times harder. There’s also the efficiency element to consider. Humans make mistakes, robots don’t.

When wrong pallets are shipped to the wrong place with an entire cargo crate packed with the wrong product, fixing that mistake can be costly and crippling for companies. Robots are plugged directly into the WMS and when they scan the wrong barcode, they trigger an alert. Humans won’t always do that, sometimes they’ll just keep going since they are always trying to make up time.

Another great feature of BALYO’s robots is that even though customers are transitioning to an automated system, they are still able to use the robot in manual mode as a regular forklift, giving them flexibility and control over the system when required.

Let’s also not forget about safety. From moving through the aisles to picking the pallets, robots are simply safer. At BALYO every vehicle has 360 degree safety sensors, in addition to cameras and sensors on the mast to ensure perfect alignment during pick and drop. This becomes especially important when users are lifting half a tonne of material at such perilous heights.

Throughput impact is a definite consideration. Travelling speeds and forks movements must be slower at

such heights, to ensure full safety. The answer to optimise slower operations was double-cycling, precise traffic management, and forks anticipation (diagonal movement on-the-fly).

Double cycling is the most important one; it is a pallet movement strategy that aims to reduce the amount of time a robot travels without a load on its forks.

Another challenge BALYO faced was mast bending when dropping at levels above 12 metres. It controlled this with a proprietary algorithm that calculates the correct forks extension based on weight of the load and the forks height.

This allows BALYO to ensure the pallets are always placed in the same position in the racks and on the forks. A similar challenge is the dynamic mast oscillations, which are reduced thanks to a similar algorithm adjusting the forks speed and acceleration during pick and drop phases.

GENERATING ROI AND PRODUCING SMOOTHER OUTCOMES

Some of the people Joshua has spoken to think the answer is an ASRS system. The reality is that under 18 metres an automated forklift is less expensive and provides a much faster and better ROI.

VNA systems are more flexible and scalable. As users’ pallet movement increase, it’s simply easier to add more robots. There’s no change that’s needed to their physical warehouse, they just need to add more robots to the system.

Customers can also move a robot to new locations with ease. They can’t say that with an ASRS system. Once it’s built, it’s not going anywhere.

Easy and repetitive processes are the best place to start. Inbounding and out-bounding of pallets in any rack height can easily be automated. In addition to the VNA, BALYO has a very popular reach truck that can lift up to 11 metres and work in an aisle width of three metres. BALYO will help customers identify how automation can benefit their logistic operations and provide the best fit from its extended range of automated forklifts. ■

Thanks to BALYO’s innovative approach to safety, standard OEM forklift controls, and smart perception of pallets, reaching new heights is now possible.

Sept 2023

Melbourne’s leading construction and major infrastructure event

EXHIBITION SPACE NOW ON SALE

Inside Construction Expo will deliver

Targeted messaging in over 19 industry-leading publications that reach more than 80,000 decision makers across multiple sectors

Digital communications to 28,000+ engaged readers

Premium networking opportunity with industry leaders at the Foundation Awards gala dinner

insideconstructionexpo.com.au

COORDINATING PROPERTY SALES SUCCESS