SEPTEMBER

MATERIAL GAINS

Toyota Material Handling Australia launches new state-of-the-art facility in Melbourne

ALL IN ONE CLEANING

Conquest Equipment launches new combination sweeper scrubber

FORKLIFT SURVEY SNAPSHOT

Discover the key takeaways from the recently conducted MHD forklift survey

Learn what factors customers rank #1 when it comes to shopping online

Delays happen, but a bad customer experience should not.

We surveyed more than 2,200 consumers, across eight countries to learn more about their expectations between clicking ‘buy’ and when the product reaches their door.

To learn exactly what today’s customers expect and gain insight on how to make a loyal customer for life download our 2023 State of Shipping and Returns report.

koerber-supplychain.com

MHD

Supply Chain Solutions

CONTACT

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Edward Cranswick

Journalist: Joseph Misuraca

Business Development Manager: Beth Jarvis

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Louis Romero, Kerry Pert

Client Success Manager: Janine Clements

FOR ADVERTISING OPTIONS

Contact: Beth Jarvis

beth.jarvis@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST)

1yr (6 issues) for $78.00

2yrs (12 issues) for $120.00 – Saving 20%

3yrs (18 issues) for $157.50 – Saving 30%

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

NEW CHALLENGES, NEW SOLUTIONS

As we launch into this fresh edition of MHD Supply Chain Solutions, I am buoyed by the new solutions I’ve recently encountered in the wonderful world of logistics and supply chain. The future of our industry gleams with promise, and every story we present this month mirrors this enthusiasm.

Our conversation in this issue’s Cover Story with Toyota Material Handling Australia (TMHA) President & CEO Steve Takacs offers an illuminating look at their state-of-the-art facility in Melbourne. As I delved into the narrative, I couldn’t help but feel the momentum of an iconic brand taking another leap forward. The journey of TMHA, their dedication to innovation, and their constant pursuit of excellence make for an insightful read.

Food wastage remains an undeniable global challenge. Yet, in the midst of this adversity, visionaries emerge with hope and solutions. Escavox CEO Luke Wood shares his insights on tackling this pressing issue with pioneering food visibility technology. It’s a story that doesn’t just touch upon innovation, but also our shared responsibility in a world striving for sustainability.

In our industry, the strength and intricacy of supplier relationships are the bedrock of success. Prological’s Peter Jones delves deep into the essence of these ties and their pivotal role in procurement. His wisdom serves as a testament to the complexities and rewards of building robust partnerships in our ever-evolving sector.

And then there’s the realm of industrial and logistics property, a universe teeming with stories of growth, challenges, and opportunities. Our chat with Centennial’s Paul Ford, paired with insights from Leedwell’s dynamic duo Steve Smith and Henry Treloar, unravels the mysteries of the ‘mid-space’ market, the intricacies of refurbishing versus redeveloping warehouses, and what the future holds for Adelaide.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

While these are the linchpins of this month’s edition, know that each page carries tales of tenacity, vision, and ingenuity – so be sure to read all of them.

Until next month – happy reading!

Edward Cranswick Editoredward.cranswick@primecreative.com.au

Every forklift we sell is built with the same precision and famous advanced manufacturing technologies as Toyota’s automotive products. But we don’t just say it, we’ve demonstrated it for over 50 years. That’s why when you choose to partner with Toyota Material Handling, you’re choosing our legendary quality, durability and reliability. You also get the ongoing support of Australia’s most dedicated service and parts network, and that’s just part of the Toyota Forklift Advantage.

1800 425 438

toyotamaterialhandling.com.au

SOLUTIONS FOR EVERY PALLET ®

ARGON & CO ANZ LAUNCH RENEWED SUSTAINABILITY SERVICE OFFERING

With more than 500 consultants spread over 16 offices globally, Argon & Co, leader in strategy and transformation of operations, is very pleased to announce the launch of ESG and Sustainability as a service offering in ANZ.

At Argon & Co, conducting business in a socially responsible way is engrained in our DNA. We believe this is a driver for business success, we will strive to make the planet, our environment and our communities a better place than when we began. Argon & Co ANZ is a carbon negative consultancy and currently being certified as a B-Corp organisation, we value giving back to the community, we have taken the 1 per cent pledge and as a team have support charities such as Oz Harvest, The Smith Family, Drought Angels and Red Nose.

Our sustainability service offering expands our existing strategy and transformation expertise. We assess and design ESG strategies, sustainability assessments & benchmarks and ESG due diligence frameworks. We leverage our existing expertise to drive sustainable operational improvements in every aspect of the end-to-end value chain and leverage our understanding of ESG regulations by supporting sustainable culture and providing learning & best practice.

In the face of unprecedented climate change challenges, consumer awareness and regulatory requirements, we know embracing sustainability is no longer a choice but a necessity for companies seeking to balance commercial growth with corporate responsibility. Despite this urgency, present-day leaders grapple with crucial questions: how to surmount sustainability obstacles and make impactful decisions? Where to

start? How to translate ESG strategy into meaningful action. At Argon & Co we empower companies to achieve lasting success through sustainable practices. We leverage our deep supply chain, operations and transformation expertise to assess, design, and embed effective solutions that drive positive impact and promote a thriving future for our communities, the planet and businesses.

Paul Eastwood, Managing Partner ANZ states, “The launch of sustainability as a core service offering in ANZ will mark a pivotal moment in our commitment to creating a greener and more sustainable future for businesses across ANZ. With the pressing challenges of climate change, sustainability is no longer just an option, but an imperative for companies seeking to thrive in a rapidly evolving world. By integrating sustainability as a core element of our expertise, we aim to empower our clients to navigate the complexities of sustainable practices, transform their operations, and forge a lasting positive impact on the environment

and society.”

Frans Verheij, Former ANZ Partner recently returned to lead the development of Argon’s sustainability proposition comments, “It is not hard, we need to look after our planet and our communities for future generations, I don’t want to imagine a world where my grandchildren are unable to enjoy the planet and social relationships I have. And if that is not enough; with consumer awareness increasing, resources becoming scarce, regulatory requirements increasing and sustainable business models being most cost effective, it makes good business sense to act now on ESG and sustainability. Together, we have no choice but to create a path towards a more sustainable and socially responsible world.”

The new ANZ Sustainability service offering further strengthens Argon & Co’s global sustainability capability, bolstering our expertise and reach to cater to the evolving needs of clients and the broader market.

Argon & Co

Supply Chain of the Future

Dematic AGVs help keep the beer flowing at Tooheys Brewery.

When Lion Beer Australia started thinking about what its supply chain of the future might look like, they knew they needed to improve productivity to keep up with demand, and adopt processes and technologies that would deliver optimum services for Lion’s people, brands, production facilities and suppliers.

The fleet of Dematic AGVs at Tooheys are helping achieve just that — giving Lion dependable seamless performance for its end-of-line process, keeping product moving accurately and safely to the end consumer.

See the video and read the full story at Dematic.com/lionbeer

Scan to watch the video!

Dematic.com/lionbeer

02 9486 5555

info.anz@dematic.com

TooheysDHL SUPPLY CHAIN AND LOCUS ROBOTICS EXPAND PARTNERSHIP TO INCLUDE AUSTRALIA

DHL Supply Chain and autonomous mobile robots (AMR) specialists Locus Robotics, have announced the deployment of fully integrated LocusBots in a first for the Asia-Pacific region.

The multi-customer digital solution LocusONE adheres to the complex quality assurance profiles and regulations for medical device customers Cardinal Health and Terumo.

LocusONE, the industry’s first data science-driven warehouse automation platform for enterprise-wide AMR deployments, brings immense value by providing powerful insights that drive informed decision making. LocusONE transforms complex information into actionable intelligence to enable greater success in an increasingly data-centric world.

“At DHL Supply Chain Australia, we are leading the industry in automation research and development to create truly scalable, efficient and effective solutions for our customers,” says Steve Thompsett, CEO of DHL Supply Chain Australia & New Zealand. “It’s important for us to innovate and to consistently optimise our customers’ supply chains.”

Cardinal Health — a global manufacturer and distributor of medical products — leverages DHL for supply chain and logistics for its customers in Australia.

“We’re glad to see DHL investing in automation and building capacity to be more efficient in the future,” says Jane Crowe, managing director, Cardinal Health. “Cardinal Health has led the way as early adopters of Locus Robotics in healthcare in North America, and it’s fantastic to see investment in the same technology in Australia. Automation drives efficiency, improves employee safety and increases picking and packing accuracy. I look forward to DHL realising similar benefits to its operations, because it will also benefit our customers.”

“Investment in technology for the medical sector is moving forward. DHL’s investment in automation and digitalisation is crucial for Terumo Australia as it enables us to respond faster to increasing supply requirements, aligning with rising demand,” says Terumo Managing Director Jeff Soo. “We’re pleased to see the enhancements in productivity and capacity that this solution brings.”

“We are thrilled to expand our global partnership with DHL Supply Chain into the region,” says Rick Faulk, CEO, Locus Robotics. “This collaboration represents a significant step towards enhancing capacity, optimising operational processes, and elevating DHL’s customer experiences. Together, we are paving the way for a more intelligent, agile, and sustainable supply chain future.”

This automated solution is GAMP 5 (Good Automated Manufacturing Practice) validated and is certified for medical and pharmaceutical distribution. This solution is part of the largest investment in robotics and automation DHL has made in Asia-Pacific, with 1000 robots to be deployed across several sectors by 2025. And it further cements DHL’s position as a market leader in Life Sciences and Healthcare supply chains in Australia.

DHL is the largest customer of Locus Robotics worldwide. This expansion builds on the partnership that began in 2017 in North America.

Assisted picking robots help reduce time spent on manoeuvring pushcarts through warehouses, lowers physical strain on employees, and increases picking efficiency. Assisted picking robots display images of goods to be picked, calculate optimal navigation routes, and reduce required training time. DHL Supply Chain is growing its Australian workforce and is providing continued development opportunities for employees.

DHL’s strategy will see continued investment in launching industry leading innovative solutions for medical devices, cold chain, pharmaceutical and consumer health customers.

DHL now has robotic solutions in all key geographies (North America, Latin America, Europe, United Kingdom, Asia Pacific), and plans to deploy up to 5,000 bots in the years to come.

HANGCHA FORKLIFTS AND BARGWANNAS JOIN FORCES IN NEW MOTORSPORT PARTNERSHIP

The Sandown round of the TCR Australia Series at Sandown in September can be seen on Stan Sport in Australia.

“We are really proud to confirm our new partnership with Hangcha Forklifts,” said Ben Bargwanna.

“The team at Hangcha are very enthusiastic about going racing. Their business is material handling equipment, and like us, they love machines. We feel that there is a really cool synergy and we are looking forward to delivering great results, on and off the track.”

Jason and Ben Bargwanna are pleased to confirm a new partnership with Hangcha Forklifts in a multi-race category partnership program.

Regarded as one of the leading manufacturers of forklifts in the world, Hangcha Forklifts opened its support with Ben Bargwanna, supporting his entry in the final 3 rounds of the S5000 Australian Drivers’ Championship at Sydney Motorsport Park that took place the weekend of 29-30 July, then on to Tailem Bend and the final at the Adelaide 500 in what will be his fourth round in the V8-powered open wheel championship.

The striking blue and red colours with the Hangcha Forklift logos that flank Bargwanna’s #71 S5000, were unveiled at the CeMAT trade show at Sydney Olympic Park on Tuesday 25 July.

Adding to Hangcha Forklifts support of the Bargwannas will be a new entry in the TCR Australia Series.

Ben Bargwanna will continue to drive his Burson Auto Parts Peugeot 308 under the Garry Rogers Motorsport

banner, while a new Peugeot entry will be added to the GRM stable from the fifth round at Sandown in September and throughout the two TCR World Tour events at SMSP and the Bathurst international.

The driver of the new Hangcha Forklift Peugeot TCR entry will be confirmed in due course.

Hangcha Forklifts was founded in 1956 in China and is ranked inside the top 10 material handling equipment manufacturers in the world.

Hangcha’s sales network consists of more than 70 dealers across 140 countries in Europe, Africa, Asia, Oceania and Latin America.

The brands’ portfolio of forklifts include a complete range of material handling equipment, including combustion forklifts, electric forklift trucks and a full range of warehouse equipment from electric pallet trucks to reach trucks.

All of the S5000 racing action can be seen on Foxtel and Kayo for Australian viewers, Sky Sports in New Zealand and via the Supercars Superpass around the world.

“This is an exciting new partnership to the Australian motorsport scene and we are proud to introduce the team at Hangcha Forklifts to the sport,” said Jason Bargwanna.

“There is great potential for both Hangcha, Ben and Bargwanna Motorsport in this new partnership. Their international reach and our local strengths give us all of the bases covered.

“Hangcha Forklifts is proud to partner with the Bargwanna team in their varied motorsport competitions,” said Daniel Anderson, National Sales Manager, Hangcha Forklifts.

“The surname Bargwanna needs no introduction on the Australian racing scene. Jason has conquered the biggest races, and now his son Ben is rising through the ranks.

“Like Hangcha, the Bargwannas are fast moving and passionate about their business, and for us, that makes them the perfect partners. We have some amazing and innovative products in our range and when quality is at the forefront of your minds, we can’t think of a better environment than the intensity and competitive nature of the racing to stand behind our brand and our products and grow the brand in Australasia and beyond.”

COLES SIGNS LANDMARK AGREEMENT

Coles and Origin have signed a landmark agreement, which will see the companies co-invest in renewable energy and battery assets at up to 100 Coles supermarkets and liquor stores nationally.

Over the next three years, Coles aims to install 20 megawatts of solar panels on top of 100 stores across the country, with batteries to be installed at one third of the stores to capture and store excess renewable electricity generated on-site.

Coles Head of Energy Jane Mansfield says this important alliance will help the retailer lower emissions, reduce electricity consumption from the grid and bring down operational costs – with 20 sites to be completed by next year.

“This alliance with Origin is an important step towards achieving our 100 per cent renewable electricity target by June 2025,” she adds.

“Not only will this investment

in renewables help us reduce our emissions, it will also lower our operational costs and allow us to meet more of our energy needs from our own on-site solar generation.”

Coles’ rooftop solar, batteries, and energy assets such as in-store heating, cooling and refrigeration systems will be connected to Origin’s virtual power plant to help ease pressure on the energy grid during peak periods of demand.

Solar panel installation is currently underway at six Victorian stores, with installation at all 100 Coles supermarkets, Vintage Cellars, Liquorland and First Choice Liquor Market stores expected to be completed by 2026.

Origin Zero Executive General Manager James Magill says Origin is thrilled to be working with Coles to support its transition to cleaner and smarter energy solutions.

“This is a landmark alliance between

two of Australia’s leading retailers across supermarkets and energy which will see the companies co-invest in renewable energy and battery assets to help deliver greater emissions reductions for Coles,” he adds.

“This also marks Origin’s largest customer aggregation agreement providing Frequency Control Ancillary Services, allowing us to orchestrate 10 megawatts of flexible energy use across heating, cooling and refrigeration assets at select Coles stores, which helps to support stable and safe operations of the grid.”

Coles already has installed solar panels on 87 stores across the country. Other cleaner energy initiatives by Coles to help reduce emissions include electrification of gas assets, the trial of an electric delivery truck, as well as purchasing renewable electricity from wind and solar farms around the country

TOLL INTRODUCING HYDROGEN-POWERED TRUCKS

Toll Group has announced the introduction of its first hydrogen-powered long-haul truck in China, marking a significant milestone in its commitment to sustainable transportation solutions.

It notes the launch of the hydrogen truck is part of its broader sustainability strategy and commitment to achieving net-zero emissions by 2050.

“Toll Group is committed to driving positive change in the logistics sector by adopting cutting-edge technologies and sustainable practices,” says Jonathan Kottegoda-Breden, Asia Logistics President at Toll Group.

“The hydrogen-powered longdistance trucks build upon our battery-electric last-mile fleet to offer a holistic sustainable transportation

solution for our customers in China who are looking to reduce their carbon emissions.”

The hydrogen truck will be deployed for deliveries between warehouses in Shanghai. The prime mover will be able to travel 300 kms per trip – a testament of the efficiency and viability of this clean energy solution for longdistance transportation.

Toll expects the new technology to save up to 149 tonnes of CO2 emissions annually as it aims to transition its full fleet of prime movers to hydrogen vehicles in China over the next two years as hydrogen refuelling infrastructure develops across the country.

These are important initial investments, and hydrogen has

the potential to help decarbonise the long-distance, heavy transport fleet across key countries in Toll’s network.

The launch of the hydrogen vehicle follows Toll Group’s announcement last year that it will invest in two hydrogen-powered electric prime movers in Australia.

More broadly in China, Toll is on track to transition the final 50 per cent of its last-mile fleet to battery-electric vehicles before 2030.

The investment in a zeroemissions fleet aligns with the local government’s environmental and sustainability goals and demonstrates Toll Group’s commitment to reducing emissions and driving positive change to create a more sustainable future.

DHL AUSTRALIA LAUNCHES RAP

DHL Australia has announced the launch of its inaugural Reflect Reconciliation Action Plan (RAP), as it joins a network of more than 2,200 organisations that have committed to the program.

The four DHL divisions across Australia: DHL Express, DHL Global Forwarding, DHL Supply Chain, and DHL eCommerce are incredibly proud to embark on this reconciliation journey because it strengthens DHL’s commitment to playing a leading role in driving sustainability and leveraging core capabilities to make a lasting social impact.

“I believe that by educating ourselves and respectfully communicating and collaborating with the Elders and representatives of the indigenous communities we operate in, we

can build strong relationships with our First Nations Peoples,” says Phil Corcoran, Managing Director, DHL Express Australia and Papua New Guinea.

“By fostering those relationships and upholding those shared values, we will create a lasting impact that will enable a better future for ourselves and future generations.”

The contribution of First Nations peoples, businesses and communities will be integral to DHL’s future success. Its vision for reconciliation is clear: to have a workforce that is representative of Aboriginal and Torres Strait Islander communities across Australia and engage with First Nations businesses throughout the supply chain, supporting local businesses to thrive.

“At DHL Supply Chain, we are committed to educating ourselves throughout our journey towards reconciliation,” says Steve Thompsett, CEO of DHL Supply Chain Australia.

“Diversity and inclusion are key to maintaining and growing our strong team and culture, and I’m excited to strengthen our ties with the First Nations community.”

DHL Australia’s four CEOs: Phil Corcoran, Managing Director, DHL Express; George Lawson, Managing Director DHL Global Forwarding; Steve Thompsett, CEO, DHL Supply Chain; and Denise McGrouther, VP, Managing Director, DHL eCommerce look forward to reflecting over the next 12 months to better understand the opportunities and relationships that will create positive impacts in local communities.

PATRICK TERMINALS INVESTS IN HYBRID STRADDLES

Patrick Terminals has announced an investment in 10 Kalmar hybrid straddles for its Melbourne terminal, positioning it as the first container terminal operator in Australia to invest in this technology.

It says these new straddles are expected to be commissioned in 2024.

“We are proud to be the first container terminal operator in Australia to invest in the Kalmar hybrid straddles and set new benchmarks for more environmentally friendly container handling,” says Patrick Terminals CEO Michael Jovicic.

“As a leader in the industry, we understand the importance of reducing our carbon footprint and promoting environmentally responsible practices.

“Together with our trusted partner, Kalmar, we have a shared dedication to building a more sustainable industry. By investing in these hybrid straddles, we are making a

strong commitment towards our decarbonisation journey.”

This investment is part of Patrick Terminals’ commitment to reducing its carbon footprint and promoting sustainability. The new Kalmar hybrid straddles can reduce fuel consumption by up to 40 per cent, compared to equivalent diesel-powered machines and will support Patrick Terminals’ decarbonisation strategy.

“Kalmar is very pleased to continue the excellent collaboration with Patrick Terminals,” says Sales Director APAC Horizontal Transportation Kalmar, Allan Baker.

“We are delighted with the order of the first 10 hybrid straddle carriers for Patrick Terminals, Melbourne. The hybrid straddles, which can cut fuel consumption by up to 40 per cent compared to equivalent diesel-powered machines, will play an important role in supporting Patrick Terminals

with their decarbonisation strategy.”

The new hybrid straddles from Kalmar are designed to be highly efficient and reliable, with low emissions and noise levels. The hybrid straddles feature advanced technology that enables them to operate on electric power, reducing dependence on fossil fuels.

AUSPOST REPORT REVEALS SHOPPERS MORE SELECTIVE

According to Australia Post’s new quarterly Inside Australian Online Shopping Report1, Australians are being more selective with where and when they spend their money as costof-living pressures continue to bite.

The national parcel delivery company notes with consumer buying confidence at low levels2, Aussies across the country – particularly younger generations – are becoming ‘strategic shoppers’ – looking for ways to maximise the value of their dollar and increasingly take advantage of key sales events.

Australia Post Executive General Manager, Parcel, Post and E-commerce Services Gary Starr says that while an increasing number of households made an online purchase in the fourth quarter – compared to the last year – it is clear that cost-of-living pressures are taking effect.

“Aussies are now more cautious and selective with where and when they spend their money, which is why online shopping carts are averaging smaller than last year,” he adds.

“Our love affair with online shopping hasn’t waned, however, cost-of-living pressures are creating short-term headwinds. This is an opportunity for retailers to entice customers via sales

events, subscriptions or other forms of rewards that create loyalty and repeat purchases.”

While online retailers have reported a slow start to 2023, May bucked this trend, up 5.7 per cent compared to last year, which was largely driven by May sales events.

Despite a softening overall in online purchases, household participation in online shopping continues to grow steadily, with 9.4 million households, or 82 per cent of the Australian population, making an online purchase during the 2023 financial year.

Over the last quarter of financial year 2022-23, the Report identifies on average 5.5 million households made an online purchase each month, an increase of 3.9 per cent compared to the equivalent quarter last year. However, consumers are spending less online overall, with online spend down 3.1 per cent compared to last year.3

An Australia Post consumer survey conducted this year revealed 85 per cent of Aussies aged 18 to 34 plan to shop – or have shopped – during dedicated sales events4. This was apparent in the Report with number of online purchases for EOFY sales up 4.3 per cent compared to the same period last year.

Customer loyalty programs and

bundling services proving popular with online shoppers, with one in four consumers turning to online retail subscriptions as part of their cost saving practices.

Regional Australia continues to see strong year-on-year (YoY) growth in online shopping, increasing 4.2 per cent YoY in the last quarter, compared to just 0.7 per cent YoY in metro areas.

The Northern Territory led the charge in this last quarter, with an increase of 9.3 per cent YoY in online sales compared to last year, with residents seeking to tap into the convenience and accessibility of online shopping.

In support of changing consumer needs, Australia Post has continued to invest in new parcel facilities, fleet and technology including the installation of more than 700 parcel lockers and the Australia Post app, which allows customers to easily track parcels and manage their deliveries and collections, all from their mobile device.

1 Australia Post parcel delivery data analytics and other sources of data. 2 ANZ-Roy Morgan Consumer Confidence, June 2023.

3 CommBank IQ: First 5 months of 2023.

4 Australia Post Consumer Segmentation Survey, Feb 2023

WOMEN IN INDUSTRY AWARDS 2024 IN SYDNEY

Prime Creative Media’s Women in Industry Awards will be held on Thursday June 20, 2024, in Sydney following its record-breaking night in Melbourne this year.

WIIA are held annually to celebrate the women who work tirelessly to advance the mining, engineering, road transport, logistics, rail, bulk handling, infrastructure, and waste management industries.

This award ceremony celebrates the achievements of outstanding

women who drive change, create new possibilities for the next generation, and smash glass ceilings across various industries, including logistics, manufacturing, construction, transport, and engineering – to name a few.

These may be women you work with, women whose achievements are inspiring you from afar, or women who are providing you with invaluable guidance and support. WIIA believes their dedication and exceptionalism should be celebrated.

In 2023, the Women in Industry Awards saw a record 160 nominations across 10 categories with 95 per cent growth in 2022.

Thirty-two individual media mastheads have marketed the event while four sponsors have signed for the 2024 edition, including Atlas Copco, SEW-DRIVE, Fulton Hogan, and Paccar.

To find out more about the Women in Industry Awards, please visit: www.womeninindustry.com.au

A LEGACY OF ROLLING SOLUTIONS

Richmond

forging an exclusive partnership with ForwardX Robotics, a frontrunner in the Autonomous Mobile Robot (AMR) space. With the warehouse automation market poised to hit $60B (AU) by 2027, integrating smart warehousing solutions is non-negotiable for businesses aiming for an international edge. As part of this collaboration, customers can witness the prowess of the next-gen AMR solutions like the Flex, Max, and Apex series at our Melbourne demonstration centre, ensuring they’re equipped for the future.

In an era defined by rapid technological advancements and a pressing need for innovative material handling solutions, Richmond Wheel and Castor Co emerges as a beacon of excellence. As a family-owned company with Australian roots, we’ve been at the forefront of rolling solution design, manufacturing, and supply for over six decades. Our vast network of showrooms, stretching from Australia to New Zealand, is a testament to our reach and commitment.

Our journey began over 60 years ago, and today, our precision-engineered products play a pivotal role in sectors as diverse as manufacturing, transport & logistics, mining, retail, and hospitality. On any given day, thousands of our partners and clients rely on Richmond’s solutions to facilitate their material handling needs. With a portfolio boasting over 8000 products, our creations span both

domestic manufacturing in Australia and collaborations with our esteemed international manufacturing partners.

Richmond’s commitment to bespoke solutions is evident in our extensive custom-made product line tailored to fit the needs of any retailer. Our stateof-the-art manufacturing capabilities encompass CNC machining, fabrication equipment, and cutting-edge CAM and robotic technologies. This ensures our customers receive the perfect solution, even for the most intricate material handling challenges. From heavy-duty castor wheels for shipping containers to conveyor systems catering to food & beverage producers, we have it all. Our notable collaborations over the years, featuring names such as Qantas, Coles, Boeing, Downer, John Holland, BAE Systems, and Tip Top Bakery, underscore our industry standing. Recently, Richmond Rolling Solutions expanded its horizons by

Our innovative zeal doesn’t end here. Teaming up with ForwardX Robotics, we’ve introduced the Flex 60-T, tailormade for Australian Z & A Base roll cages and logistic trolleys. This AMR, fitted with a sophisticated docking and towing system, heralds a new age in logistics operations. From retail settings and hospitals to distribution hubs, this innovation promises efficiency, costeffectiveness, and most importantly, enhanced safety.

In the rolling solutions arena, Richmond Wheel and Castor Co is not just a company; it’s an institution. Our 60-year journey has been driven by innovation, commitment, and an unwavering focus on our customers’ needs. And as the world continues to evolve, so will we, ensuring that Australia remains at the forefront of the rolling solutions. ■

Wheel and Castor Co, Australia’s premier rolling solutions provider, discusses its history and why it has become renowned for its innovation and dedication to excellence in the rolling solutions space.Richmond Rolling Solutions has expanded its horizons by forging an exclusive partnership with ForwardX Robotics. The Flex 60-T, tailor-made for Australian Z & A Base roll cages and logistic trolleys.

MHD FORKLIFT SURVEY SNAPSHOT

Recently, MHD polled respondents on various questions relating to forklifts and forklift preferences. Here’s a breakdown of what we found.

In the fast-paced environment of warehousing and logistics, the humble forklift remains a linchpin of operations. Our recent survey dived deep into the industry’s preferences, operations, and future perspectives. Below are our key takeaways.

INDUSTRY VOICES

The diversity of survey respondents paints a rich tapestry of the supply chain landscape. A significant share of the respondents, at 24.69 per cent, were Logistics Managers, followed closely by Operations Managers at 17.28 per cent. Warehouse/DC Managers comprised 16.05 per cent of the survey, thereby ensuring that the survey was firmly rooted in the real-world operations of logistics and warehousing.

BUY VS LEASE

When it comes to forklift acquisition, there seems to be a split. While 45.68 per cenbt prefer to buy outright, a slightly larger 59.26 per cent favor leasing. It might point to the industry’s evolving mindset towards cost-saving, flexibility, and asset management.

LEASING DYNAMICS

Most companies leasing their forklifts prefer going through either the supplier/distributor (46.91 per cent) or direct from the manufacturer (44.44 per cent). However, there’s still a niche group (27.16) who opt for pure leasing companies, suggesting a more personalised arrangement.

EQUIPMENT LIFECYCLE

The majority (50.62 per cent) typically purchase or lease new forklifts between one to four years, indicating a mix of trust in forklift durability and a desire for modern, efficient machines. Meanwhile, 44.44 per cent go longer than four years, which might point

to confidence in their equipment or a longer depreciation schedule.

ESSENTIAL FORKLIFT ATTRIBUTES

Safety, unsurprisingly, takes the lead as the most voted-for essential attribute (72.84 per cent), a testament to the industry’s growing focus on safety standards. Following closely are performance (59.25 per cent) and reliability (64.20 per cent), reflecting the practical needs of the warehouse floor. Attributes like ergonomics, purchase price, and operator comfort also featured prominently, indicating a holistic approach towards evaluation.

MAINTENANCE AND SERVICE

Interestingly, a significant 41.98 per cent of respondents have a service contract with their supplier/distributor. This shows a trend toward outsourcing and trusting the expertise of suppliers. Manufacturer service contracts and independent service companies also have notable portions, showing varied preferences based on unique business requirements.

SAFETY FIRST

A resounding 87.65 per cent and 88.89

per cent of respondents use beepers and flashing lights respectively, as part of their safety features. Seatbelt linked ignition locks also feature heavily, showcasing the industry’s proactive measures towards ensuring operator safety.

FORWARD THINKING

The industry appears receptive to future innovations. A significant 62.96 per cent expressed interest in alternative fuel sources, such as hydrogen fuel cells and lithium-ion batteries. This suggests a forward-looking perspective, conscious of environmental sustainability.

However, the verdict is still out on the preference for a ‘one-stop-shop’ for all forklift and warehousing needs. While 39.51 per cent liked the idea, 60.49 per cent preferred dealing with specialised entities.

CONCLUDING THOUGHTS

The industry’s future seems to lie in a mix of safety, innovation, and adaptability. As the logistics and warehousing sector continues to evolve, it’s heartening to see a balance between sticking to triedand-tested practices and an openness to change. ■

MATERIAL GAINS

MHD speaks with Toyota Material Handling Australia (TMHA) President & CEO Steve Takacs about the business’s new flagship Melbourne branch, and how the state-of-the-art facility will help elevate the brand to the next level.

This past June, following 12 months of construction, Toyota Material Handling Australia (TMHA) celebrated the opening of its new Melbourne branch in Dandenong South. According to TMHA President & CEO Steve Takacs, the new facility was an important step in supporting a key growth region for the company.

“Victoria’s population is growing, and the industrial needs of the state are growing as well,” Steve says. “So, we’ve built this new branch to facilitate the next 25 years of growth.”

Off the back of a range of new product launches over the past few years across the Toyota Material Handling and Huski Construction Equipment brands, TMHA plans to continue growing its range – a driving force behind the move to a larger integrated facility.

“There’s no doubt that when you look at the physical size of the new building that that we’ve allowed for significant growth,” Steve says. “Better yet, all that growth – from our storage capacity to our service, rental, and sales departments –will all be accommodated within

the one building.”

Steve says that according to his Japanese colleagues within the company, the new Melbourne facility is the single largest Toyota Material Handling branch in the world – a distinction of no small significance given Toyota’s position as the world’s biggest forklift company.

“I was speaking with the Toyota Material Handling Global President, who has seen quite a few of these branches around the world, and he said this was the biggest he’d seen,” Steve says. “And while the American market is obviously a lot bigger, the brand is represented by a network of dealers over there. Here, we’re a single entity – hence the huge footprint of this branch.”

The ambitious upgrade is a bold step, one Steve says represents TMHA’s commitment to not just its customers, but its valued people, too.

“We’re a tier-one business,” he says. “That means treating our customers to a tier-one experience, and it also means looking after our people with a tier-one facility. So, I’m wrapped that we’ve been able to move out of our older building, and

move them over to this state-of-theart facility.”

The new branch is kitted out with well-appointed lunch rooms, meeting rooms, training facilities, and even little details like automatic warm water taps to help employees brave the cold Melbourne winters. It’s also important, Steve says, that the facilities cater equally to all levels of the business – whether that’s upper management, warehouse staff, or the service team.

“I started as a serviceman almost 38 years ago, so that’s one area of the business that I hold close to my heart,” he says. “It’s important to me that we care for the service team, and to make sure that they’re kept happy, healthy, safe, and that they feel valued.

“It’s no secret that there’s a shortage of skilled tradespeople in the industry today, so we want to look after and retain those we do have. And I think it’s very important that this facility enables that.”

CELEBRATING TOGETHER

With AFL legend Simon Madden leading proceedings, the facility’s grand opening featured guided tours, musical performances, a catered lunch, and a traditional Japanese kagami-biraki sake barrel breaking ceremony.

The 340-strong list of attendees included a range of guests of honour, including Toyota Industries Corporation Executive Officer, Yoichiro Yamazaki, and Consul-General of Japan in Melbourne, Junji Shimada. But Steve says it was just as important to share the momentous occasion with TMHA’s valued people.

“Having our people front and centre – our service staff in particular – was just fantastic,” Steve says. “There’s no hierarchy in our business, our service team is just as important as the CEO. Having everyone there on an

equal standing, celebrating together, was a really proud moment.”

Also among the guests of honour was Australian transport legend Lindsay Fox, with whom Steve has shared a more than three-decadelong relationship.

“The first time I met Lindsay, I was actually laying under a forklift repairing it, and he wandered over and said hello,” Steve says. “That speaks to the kind of man he is.

“Since then, I’ve dealt with him on various occasions over the years. He and his business are hard negotiators, but they’re honourable. For him, a handshake is just as good as a signed document – and that’s something to admire.

“It’s part of what has made Lindsay an Australian icon. I don’t think there are too many people in Australia that haven’t heard the name Lindsay Fox. So, to have him come along and sing the praises of Toyota as a company that makes every effort to over-deliver on our promises, was outstanding.”

FULLY LOADED

The new Dandenong South facility occupies a 32,600sqm site, with the

building itself taking up 16,350sqm – a 34 per cent upgrade on the old TMHA Melbourne headquarters. But Steve says the upgrade is about more than sheer size.

“The old facility had three different landlords, and three different buildings that we were working between,” he says. “The buildings were joined physically, but we had needed to cut holes in walls to make it work. Dynamically, it wasn’t a smooth facility to operate – it could be clunky to work out of, and to move gear around.

“This new facility provides a range of added efficiencies, where one area flows seamlessly into the next.”

From a 28-per-cent-larger workshop area to cutting-edge painting equipment, to a new 300sqm dirt demonstration area for Huski earthmoving machinery customers, Steve says the new facility is fully kitted out to support the diverse needs of TMHA’s ever-growing customer base.

“We have fully functional sealed and pressurised spray paint and preparation booths for as-new paint jobs and refurbishes,” he says.

“We have a full metalworking

facility with four fabricators working in there, and we can do our own hydraulic work here too – whether it’s the type of work that a hose-fitting company might do; or repairs to lift cylinders and hydraulic cylinders – we can now do it all in-house.”

SEE FOR YOURSELF

Steve says that as well as elevating TMHA’s ability to import, deliver, and service its range of in-demand products, the new facility also serves as a bold statement of the company’s values, ambitions, and future plans.

“In Japanese, there’s a saying – genchi genbutsu – which roughly translates to ‘go and see for yourself’,” he says. “Our new Melbourne branch gives us the ability to bring customers in so they can see for themselves the infrastructure that we have in place, and the depth of that infrastructure.

“When they first walk in, they’ll see a wall decorated with plaques celebrating our longest-serving members of staff – so they’ll get a sense of how our employees are looked after, and the longevity of service that yields.

“And when they progress through

the facility, visitors will see first-hand that we’re not a backyard operation. We’re a modern tier-one business that can deal with any material handling issue or supply need.”

INTEGRATION AND INNOVATION

As the new facility stands proudly in Dandenong South, TMHA Vice President and COO Cameron Paxton can’t help but reflect on the sheer amount of thought, planning, and passion that went into every square

metre of the development.

“It’s not just a building; it’s a culmination of years of dedication, hard work, and understanding the core essence of what Toyota Material Handling Australia stands for,” Cameron explains. “The intention behind every design aspect was to create a space that seamlessly integrates our operations while innovating for the future.”

Cameron stresses the importance of proactive, forward-thinking strategy in their operations. “As

we’ve witnessed over the past few years, supply chain disruptions can be unprecedented and require swift adaptability. Our new facility, with its integrated design, allows us to nimbly pivot according to market needs, making us resilient in the face of any logistical challenge.”

Sustainability, too, has been placed at the heart of the Dandenong facility. With climate concerns taking centre stage worldwide, TMHA wants to be part of the solution, not the problem.

“Incorporating eco-friendly

measures was non-negotiable for us,” Cameron shares. “From rainwater harvesting systems to energy-efficient LED lighting, we’ve made every effort to reduce our carbon footprint. Our ambition is to set a benchmark for environmentally conscious operations in the material handling industry.”

But innovation and sustainability aside, Cameron consistently circles back to the theme of ‘people’. Whether it’s their customers, partners, or the heart of TMHA — its own people — the VP reiterates

that their new facility is not just bricks and mortar but an emblem of commitment to those they serve.

“Our people are our greatest asset. Steve mentioned the importance of well-being, and I couldn’t agree more,” Cameron says. “Our new training programs, launched in tandem with the facility, are designed to provide our team with up-todate skills, ensuring they remain at the forefront of the industry. The investment in our people isn’t just financial; it’s about creating a sense of belonging and pride.”

As for customer relations, the Dandenong facility’s spacious design allows for immersive experiences that were previously unimaginable.

“When our customers visit, they won’t just be observing; they’ll be experiencing,” he says. “TMHA’s offerings come to life in this facility. From hands-on trial sessions with our equipment to intricate demonstrations of our tech capabilities – we’re enabling a holistic customer journey,” he elaborates.

In speaking about the facility, it’s evident that for Cameron Paxton it’s more than just a logistical decision –it’s personal. Reflecting on his own journey with TMHA, he expresses gratitude for the collective vision that

brought the facility to life.

“I remember walking through the halls of our old buildings, proud of what we had achieved. But looking at Dandenong South, there’s this overwhelming sense of pride – not just in the infrastructure, but in the collective spirit that built it,” he says. “It’s a testament to our values, to our commitment to the Australian market, and most importantly, to every individual who calls TMHA their professional home.”

What is abundantly clear, from our conversations with Steve and Cameron – and from the design of the facility itself – is that TMHA is focused on the people at the heart of materials handling.

“When I first started with TMHA nearly 27 years ago, sales were purely transactional,” Cameron says. “Customers purchased or rented a forklift, and price was arguably the most important criterion. Now, one of the biggest considerations is having a service infrastructure in place to meet their ongoing needs. This is where TMHA excels. With over 20 branches, numerous residential customer locations, and more than 500 devoted service staff, we have an unprecedented network all designed to keep Australia moving.”■

ACQUIRING INDUSTRIAL INTELLIGENCE WITH DATA

Since Colliers and data platform company, SA1 Property, forged a partnership in April 2023, the two companies have made strides in collating valuable and insightful information on industrial markets. MHD spoke to Colliers Managing Director Gavin Bishop and SA1 founders, Aaron Bates and Stephen Clark, to find out more.

Data analytics and visibility have become essential tools to helping businesses identify gaps, opportunities, and for collating and obtaining substantial and detailed information about the industrial market.

This is why Colliers has been working with the data platform company SA1 Property since April 2023. Together, these businesses are making it easier for occupiers to decide what type of industrial facility they’d like to invest in, buy or rent –whether it’s a warehouse and office, or a DC.

Aaron Bates, Director, Property Strategy and Stephen Clark, Director, Location Analytics at SA1 Property founded the software enterprise back in 2018. Over these past five years, they’ve cooperated with an eclectic mix of clients ranging from local government to machine learning professionals, asset managers, and more recently, with Colliers’ agents.

USING DATA FOR OPTIMAL OUTCOMES

Colliers’ partnership with SA1, has allowed the team to provide the best possible data of Australia’s industrial property markets by engaging with both institutional and corporate clients

and using this information, in addition to their own Colliers’ owned data and internal platforms to assist them when they’re making important propertyrelated decisions.

By leveraging the SA1 platform together with Colliers’ unmatched data, Gavin Bishop, Managing Director, Industrial & Head of Industrial Capital Markets Australia at Colliers, says it has allowed teams to offer a point of difference to their clients, who have recognised the value.

He continues: “Our clients have been able to make informed property decisions that achieve strong outcomes. We’re continually evolving the capabilities and offering of our experts and ensuring we maintain up-to-date information on the market for our clients. This partnership is a value add for clients in addition to what Colliers is already doing, and the internal data and platforms we have.”

SA1’s main goal when it started five years ago was to create the best data analytics platform for the Australian industrial property market. Many investors and developers in this sector use the company’s SA1 Pro program –a spatially enabled platform.

“We provide physical and locational intelligence on the industrial property market,” explains Aaron. “This

brokers strong advantages when dealing with investors and developers in this space.”

When he and Stephen founded the digital enterprise, they’d noticed there were no other players in this niche industry.

“We saw there was demand for a curated collection of data and insights and centralisation of information in a singular place, and we knew if we didn’t seize this opportunity first, somebody else would,” adds Stephen.

“We save users time by collecting and verifying the information and handle location intelligence for them, which is critical to industrial occupiers when they’re determining where they want to go.”

The data may validate what the

users already know and think about their assets and locations or may result in identifying unrecognised value to segments of the market. It can also help with client discussions because they can refer to this independent source of information.

SA1 covers the entire eastern seaboard except for Tasmania, and has detailed information on the cities of Brisbane, Sydney, and Melbourne, and gives users access to a digital database of major owner assets and industrial occupiers with 7000 occupiers, across more than 4000 different entities classified by sector.

GAINING RESULTS FOR CLIENTS

Colliers is using its own in-house data platforms together with the SA1 platform to secure various sale and leasing appointments to show clients the value these solutions can add to a campaign process and the opportunities they can provide.

It has used the bespoke reports during sale and leasing campaigns for properties and portfolios and continues to drive enduring value for its clients by using the combination of SA1-related data and its own.

“We’re showing clients our unique view of the market with the data we have populated and extracted, which is helping them make informed decisions during the property process and benefitting their teams,” says Gavin. SA1 notes while it deals with thousands of industrial occupiers –including tenancy sizes and tenure – it also analyses and spatially enables transaction data, as well as deploying a location benchmarking system.

“There were requests for this location benchmarking system,” explains Stephen. “These were due to the diversity of industrial occupiers having different location drivers.

“This is why we presented a deep library of various topics that are benchmarked and rated throughout each market.

“It helps them look at the benefits and understand the locational strengths of their assets. Alternatively, if they have a theme, or multiple themes they want to target for a site selection activity, they can use the rating system to find the best location for their purpose.

“The platform brings together third-party content from leading software and information providers, including ESRI (for geographic information system software), Aerometrex for aerial imagery, and Geoscape for building footprints. The system also allows additional data to be added interactively to the map – both ours and that of the government’s.”

The platform, paired with the industry experience and data that the Colliers experts have internally, provides clients with an array of information to understand the current market conditions and aid business decisions.

PROVIDING MARKET OVERVIEW

The SA1 platform is benefiting Colliers and providing it with significant value for its clients by producing stronger insights, improving business operations, and converting opportunities.

“Combined with our Colliers data, we are able to show clients a full view of the given market, sharing valuable insights on how they can take advantage of the conditions and drive stronger results,” says Gavin.

“It’s allowing Colliers experts to present our own data in ways that make it easier for clients to understand and act on. Some of the SA1 capabilities enable them to rank properties we’re selling or leasing against other assets and locations and our experts can then complete a full competitive analysis of assets and market providing the best outlook for the client.”

It also means Colliers can compare different sub-markets, assessing their respective land supplies and take-up and vacancy rates.

“Since we forged a partnership with Colliers, we’ve helped agents who’ve managed multiple transactions by providing them with insights into assets beyond benchmark and identifying prime locations to work on,” notes Aaron.

“I’ve been cooperating with the Colliers Melbourne and Sydney teams to find ways to present and analyse the data they have, and the platform provides.”

Colliers says the SA1 platform has further elevated what it was already offering its clients.

“Colliers has a unique geographic footprint in Australia with major metropolitan markets and regional markets,” adds Stephen.

“We want to work with Colliers to move into the regional markets to better understand them. We can analyse and identify opportunities there and provide better coverage of those areas.”

“We look forward to working with SA1, and our Industrial experts to continue evolving our own data and the use of the platform to continue providing clients with market leading solutions,” Gavin says.

“The introduction of SA1 – and it being used by our teams – is a natural consequence of the data-centric approach we already took at Colliers. We already have exclusive internal data platforms and outputs we are providing our clients, and working with SA1 just bolsters that unique data value proposition.” ■

Reach out to learn more about the industrial market and how we can maximise the potential of property for you with our data-centric approach.

Aaron Bates, Director, Property Strategy at SA1 Property.

Aaron Bates, Director, Property Strategy at SA1 Property.

HOW TO MANAGE SUPPLIER RELATIONSHIPS

Prological Managing Director Peter Jones discusses the essence of supplier relationships and their importance in the procurement process.

In supply chain and logistics, nurturing supplier relationships is often touted as a crucial component of effective procurement. While many businesses claim proficiency in managing these relationships, the reality is that the effectiveness of their management can greatly vary.

Peter Jones, Managing Director of Prological, provides a nuanced take on this. “Most businesses believe they excel at managing supplier relationships,” he begins. “But for many businesses, good relationship management means simply adhering to company policies.”

Yet, this understanding can sometimes be limiting.

“For example, many companies have policies that prohibit employees from even accepting a coffee treat from a supplier due to concerns about bias or undue influence. To them, that level of control signifies sound supplier management. They might argue that their monthly or quarterly meetings and checklists ensure suppliers meet their obligations.

“Adherence to policy is of course important, but it needs to be a policy that is good for the business and the people in the business, too.”

At its core, the supply chain industry is a human-centric domain. Peter notes the importance of the human touch.

“The supply chain industry revolves around people, and it’s not an exact science,” he says.

According to him, this inherently imperfect landscape necessitates strong interpersonal connections.

“If there’s a solid interpersonal connection, it’s easier to engage in

continuous improvement and address significant challenges,” Peter says.

He illustrates his point with a recent example: “Just three weeks ago, I visited a large New Zealand company with over a billion dollars in annual sales. The company, despite having implemented a stringent procurement-based supplier management process for eight years, found a glaring gap in their approach. While suppliers were meeting requirements, there was no innovation.”

Peter attributes this to the company’s “stringent contracts and lack of interpersonal relationships.”

Peter draws parallels between this

and the way IT departments operated in the late 1990s. He observes that these departments “became overly influential and disconnected from the core business needs.” A similar trend was noted during the Global Financial Crisis (GFC), with purchasing departments gaining significant power.

Diving deeper into the ripple effects of the GFC on supplier relationships, Peter recalls the financial strains businesses underwent during the period. “During the GFC, businesses faced enormous cost pressures,” he says. This led to a dramatic shift in how these businesses approached supplier negotiations, with a heavy emphasis on cost-cutting. “From a supply chain perspective, the emphasis was on negotiating with suppliers for more cost-effective solutions,” Peter notes. This change “altered the nature of the supplier relationships, and it’s taken a decade or more for the balance to be restored.”

In light of these evolving dynamics, Peter emphasises the need for a more balanced approach in managing supplier relationships. “Mature businesses have both formal and informal management practices,” he says. For Peter, there’s a growing understanding in the industry: “There’s a growing recognition that informal interactions are crucial for fostering innovation, continuous improvement, and fostering a genuine partnership.”

The delicate balance between structured corporate policies and the human touch in supplier relationships has long been a topic of debate. As the industry navigates this balance, the

If there’s a solid interpersonal connection, it’s easier to engage in continuous improvement and address significant challenges.

emphasis on human relationships in the supply chain becomes increasingly important.

But how, precisely, does one create or manage an effective supplier relationship?

Drawing parallels between personal and professional relationships, he elucidates, “Outside work, what does a good relationship look like? For instance, during the holidays, I might gift someone based on our relationship’s depth.”

Just as you might treat a close friend to a coffee or a gift, business interactions should embody a similar spirit.

“Similarly, in business, I should be able to naturally engage with key contacts,” Peter explains.

In today’s era of rigorous rules and policies, it seems challenging to operate from a principle-based standpoint. As Peter points out, people prefer the safety of strict rules that delineate boundaries. “Operating on principles means allowing others to exercise judgment, accounting for varying personalities,” Peter says. His belief centres around the idea that relationships, especially with essential suppliers, should mimic the natural flow of personal interactions, while still respecting commercial obligations.

Such an approach can significantly impact how businesses address issues with suppliers.

“Just yesterday, we received an email from a significant IT supplier, expressing discontent over a few

issues.” Instead of a bureaucratic response, Peter adopted a personal touch, understanding the supplier’s grievances and rectifying the issue. This approach stems from his desire to “treat suppliers the way I would want to be treated,” while acknowledging that no process is perfect.

Peter notes that procurement professionals shouldn’t dominate supplier relationship-considerations, as they have a different set of skills and priorities.

“Typically, procurement isn’t responsible for maintaining relationships. They initiate and, when a contract nears its end, review them.”

The true experts, from lawyers to logistics specialists, handle daily management.

Procurement’s role becomes pivotal when issues arise or when contract nuances need understanding.

Even if they’re not responsible for ongoing supplier relationship maintenance, what are the traits of a good procurement professional?

“Good procurement professionals have an eye for detail and understand contract intricacies, approaching them with a sense of fairness.”

Peter identifies a shift in the procurement landscape. Previously dominated by a hierarchical approach, today’s procurement process values relationship-building. Highlighting this evolution, Peter cites the example of non-disclosure agreements (NDAs) now being typically mutual.

Once upon a time, NDAs were often one-sided – foisted by one party on another, creating a power asymmetry that wasn’t conducive to good ongoing relations.

Modern procurement needs a blend of technical know-how and interpersonal skills.

“I do see things moving in this direction,” he notes, recognising the growing maturity of purchasing departments in larger businesses.

Achieving this maturity is more important than ever, as supplier relationships constitute a key part of ensuring supply chain resilience.

Discussing the dynamic nature of sourcing over the last five to ten years, particularly in the post-COVID era, Peter touches upon a noticeable trend.

“There absolutely has been diversification to mitigate risk,” he observes. The focus, he notes, has extended beyond the longevity of partnerships. “While businesses have traditionally relied on longstanding suppliers, the unpredictable nature of external factors, such as global crises or political shifts, forces them to consider risk from a broader perspective.”

But how does this shift impact supplier relationships?

In Peter’s view, the key lies in transparent communication.

“A good buyer will help their supplier understand this and guide them through this journey,” he says, emphasising the significance of strong relationships when navigating these waters. “While businesses must inevitably prioritise their own interests, it’s essential for suppliers to recognise and support this. Discussions about diversification become considerably more seamless when built on a foundation of trust.”

No matter how supply chains evolve in complexity, the essentials of supplier relationship management remain simple: it’s all about fostering and nurturing those invaluable supplier relationships.

“The same goes for supplier relationships as goes for every other relationship,” Peter says. “Treat others as you’d like to be treated. Not necessarily how you are actually treated – but how you’d like to be treated.” ■

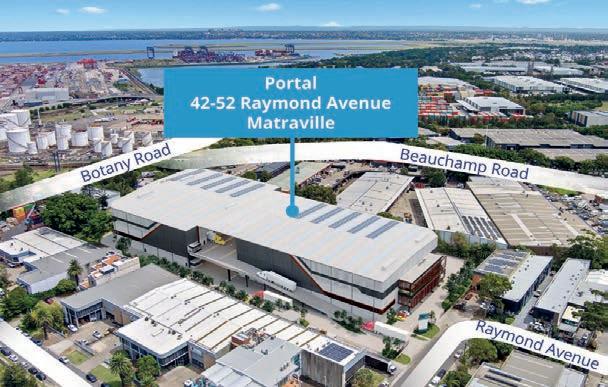

THE ADELAIDE ADVANTAGE

Centennial’s Executive Director and CEO Industrial & Logistics, Paul Ford, along with Leedwell’s Steve Smith and Henry Treloar, talk to MHD about new projects they’re working on, the ‘mid-space’ market in the industrial and logistics property market, the difference between refurbishing and redeveloping warehouses – and the future for Adelaide more broadly.

The refurbishment of Centennial’s $30m Royal Park Distribution Centre in Adelaide showcases the evolving dynamics of Australia’s industrial and logistics real estate sector. Central to this transformation is Centennial’s unique focus on the niche ‘mid-space’ segment of the market.

“Mid space is a term we’ve coined to describe the niche market we target,” says Centennial’s Paul Ford, Executive Director & CEO Industrial & Logistics. “We saw a gap in the industrial and logistics ‘mid-space’ market, typically comprising assets between 1000 sqm and 10,000 sqm, as they were too small for the larger institutions – given they were and still are labour intensive to manage from a leasing or upgrade perspective – and too large and out of reach for individuals and family office investors, yet still in demand from quality occupiers.”

Centennial purchased the 31,120 sqm industrial and logistics facility at Royal Park in 2021, positioned 8.5km north-west of Adelaide’s CBD for $5.4m in 2021.

“Royal Park DC is a prime example of our national strategy of sourcing functional and generic mid-space assets, with flexibility for upgrades and expansion, that offer strong

connectivity to major distribution networks in often land-constrained, inner-ring or urban locations at scale,” Paul says.

Director at Leedwell, Henry Treloar, says the Royal Park DC is an ideal location for occupiers given its proximity to the motorway, and a generic design that offers a wide variety of flexible spaces and usages.

“From our perspective, based on inquiry levels, the success of Centennial’s approach stems from the current market trend,” Henry says. “There’s a pronounced shortage of ready-made buildings in the market.

The Royal Park DC had a large hardstand and was strategically located, making it ideal for logistics users.”

The 12,830 sqm distribution centre was fully leased prior to completion of the redevelopment, with global air-conditioning giant Daikin and major logistics group, Allied Express pre-committing.

“Competition for the site from prospective tenants was high, driven by sub-one per cent vacancy rates and limited new developments coming on-stream,” Henry says.

“Demand for

institutional-grade industrial space such as Royal Park will remain strong.”

Centennial undertook an expansive refurbishment programme, stripping away outdated materials to unveil a structure in impeccable condition. The renovated site features re-skinned exteriors, upgraded services, brand-new offices, revamped external pavements, dedicated car parking zones, and landscaping. Upon completion, it bore the look and feel of a brand-new establishment, garnering considerable interest from prospective tenants in a market with less than one per cent vacancy rates.

Steve Smith, Partner at Leedwell, underscores Centennials’ repositioning strategy.

“Centennial’s adaptability and ability to swiftly introduce products to the market is commendable,” Steve says. “For instance, with the refurbished building, the process was much quicker than starting a new development. Furthermore, the Royal Park site had unique

features that weren’t available in other properties at the time, making it a value-added proposition.

“With continued demand for high quality, mid-space requirements, Centennial has an edge over its competitors.”

Paul says Centennial will continue to focus its efforts on acquiring mid-space, near-city and inner ring infill sites to add to its growing I&L portfolio.

“By deliberately targeting undercapitalised assets through offmarket deals, identifying distressed sellers or assets that need specialised management, we will continue to boost our industrial and logistics acquisition and divestment programs and deliver enhanced returns to our investors.”

REFURBISHING RIGHT

“We typically target generic assets that have a solid foundational structure, and options for a range of uses,” Paul says. “Our preference is to regenerate existing land and rebuild existing buildings, reuse materials to reduce waste, and provide functional and flexible space suitable for a range of users.”

With rapid increases in material costs, labour shortages, and the continuing rise of construction costs, the benefits of refurbishing cannot be understated.

While the mid-space market often sees older structures that might not align with today’s efficient operational requirements, if the building’s core structure is sound and the surrounding infrastructure is viable then refurbishing emerges as a viable option that carries significant advantages. These include lower costs, a quicker planning process, marked environmental benefits, and a faster timeline to market. Such speed often leads to quicker leasing agreements, ensuring a prompt return on investment for stakeholders.

However, refurbishing isn’t without its challenges. Paul notes potential disadvantages, such as “the costs of upgrading obsolete infrastructure or exposing unforeseen issues that impact on cost.” He says that many of these challenges can be pre-emptively addressed during a thorough due diligence process.

The environmental and operational advantages of refurbishing extend beyond just cost saving.

“There are several elements,” Paul

adds. “Compliance with the Building Code of Australia is a significant aspect. We would always upgrade to modern fire safety regulations if buildings weren’t up to Code, while other improvements would generally include separating vehicular traffic for safety, updating landscaping, and improving aesthetics and internal features.”

LAST MILE CONSIDERATIONS

Challenges in the Australian logistics domain are as vast as the country itself. Unlike compact regions or those with dense transportation networks like the U.S., Australia’s sprawling geography often disrupts seamless delivery schedules. “To address this, there’s a pressing need for a proliferation of smaller, regional distribution hubs as opposed to a few centralised ones,” Paul says. “This strategic spread could help businesses bridge the geographical divide, facilitating faster deliveries.”

But while demand is robust, supply constraints loom large. Paul highlights bottlenecks, particularly the impending limited supply set against a backdrop of urban renewal initiatives. “There’s practically minimal supply forecasted for the next couple of years, which could translate to promising rental growth,” he says.

LOOKING AHEAD

Centennial’s acquisition of the 406-416 Martins Road, Green Fields – (the Inner North Distribution Centre), with Leedwell and Colliers appointed as leasing agents, showcases its commitment to revitalising underperforming assets. Located in Adelaide’s industrial heartbeat, this site offers 12,000sqm of state-of-the-art office and warehouse space, complemented by a spacious breezeway and an expansive concrete hardstand. But what sets it

apart is its strategic position. Lying on a b-triple gazetted road, it promises unparalleled access to both the Port Wakefield Road and the Northern Connector, ensuring easy connectivity to Australia’s primary markets and metropolitan Adelaide.

“Its flexibility to accommodate dual tenancies with tailored amenities only amplifies its appeal,” Paul says.

“The site will naturally appeal to users within transport and manufacturing industries. And with massive investment in defence and allied industries, we see this site appealing to supply-chain and other groups wanting to take advantage of the site’s characteristics and strategic location.

“Centennial’s proactive approach, combined with the site’s inherent flexibility, allows us at Leedwell to tailor offerings based on tenant requirements,” adds Henry. “From adding sprinklers to accommodating cranes, the Green Fields site exemplifies adaptability.”

Beyond the Green Fields site, Centennial’s philosophy and approach will continue to be undergirded by its focus on mid-space holdings in the industrial and logistics sector. “With a growing portfolio boasting 68 assets across Australia, valued at around $1.5 billion, and an additional development pipeline exceeding $350 million, we’re bullish about the sector’s prospects,” Paul says.

It’s an exciting time for Centennial and Leedwell, as Adelaide’s allure as an industrial hub grows, particularly given Melbourne’s expanding footprint and the subsequent price surge.

“We’ve seen a strong shift of interest towards Adelaide, driven by a quest for more affordable, yet efficient, industrial solutions.” ■

DRIVING GREEN WITH HANGCHA

Hangcha Forklifts is at the forefront of sustainable materials handling. With its new range of lithium-ion forklifts, the company offers an economical, environmentally conscious alternative to old school forklifts.

Hangcha, a name synonymous with resilience and innovation, has journeyed from its humble beginnings in 1956 to become a global leviathan in materials handling. Its ascent from a modest Chinese stateowned enterprise to a leader amongst global materials handling equipment manufacturers is a testament to its relentless pursuit of excellence and a fierce commitment to innovation.

For over six decades, this stalwart has melded courage, passion, integrity,

and innovation, staying true to its ethos of making handling easier.

No longer just the pride of China, where it has garnered recognitions such as spots on the ‘Biggest Enterprises’, ‘Most Competitive’, and ‘Biggest Private Enterprises’ lists, Hangcha has painted a compelling global narrative. Its expansion into Australia in November 2022 underscores its mission to proliferate quality and professionalism.

By recently opening an Australian

branch, Hangcha made a statement of its intent to resonate more closely with its international clientele. Stocking spare parts locally to ensure quicker responses to market demands, the venture aligns seamlessly with Hangcha’s vision: global reach with local touch.

Yet, it’s the recently unveiled line of lithium-battery-powered forklifts that highlights Hangcha’s commitment to sustainable innovation. As Daniel Anderson, National Sales Manager for

MHD MATERIALS HANDLING

Hangcha Australia, elucidates, these machines are not only available for immediate dispatch but are also a testament to the company’s agility during tumultuous times. “Even straight out of the factory, we can deliver in around three months,” Daniel says.

The technological advantage of Hangcha’s lithium forklifts is undeniable. Traditional lead-acid batteries, which typically require weekly watering and an open environment for charging, are now overshadowed by the lithium variant’s longevity of 4000-5000 cycles. Without the constant upkeep or the dangers of acid spillage, lithium batteries pave the way for hassle-free operations. Charging them intermittently doesn’t dent their life expectancy, and they can be conveniently charged indoors.

And this isn’t a luxury reserved for the well-heeled. Daniel emphasises the economic appeal of the lithium models. “The return on investment is almost immediate ... running an