MHD Supply Chain Solutions is published by Prime Creative Media

11-15 Buckhurst Street, South Melbourne VIC 3205

Telephone: (+61) 03 9690 8766 Website: www.primecreative.com.au

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Edward Cranswick

Journalist: Joseph Misuraca

Business Development Manager: Beth Jarvis

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Louis Romero, Kerry Pert

Client Success Manager: Janine Clements

Contact: Beth Jarvis beth.jarvis@primecreative.com.au

Australian Subscription Rates (inc GST)

1yr (6 issues) for $78.00

2yrs (12 issues) for $120.00 – Saving 20% 3yrs (18 issues) for $157.50 – Saving 30%

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

These past few months have been particularly interesting ones in supply chain and logistics. The year has seen industry events and awards nights ramp back up, and with them – it seems – an even greater appetite has emerged for new solutions to the challenges facing supply chain.

With industrial property vacancy rates at historically low levels, and with no signs of letting up, players in the space are under pressure to do more with less. In this connection, you’ll read in this issue of CBRE’s work helping clients to afford new fit-outs for their properties, in order to get more productive use out of the same footprint – and how such fit-outs can be financed.

Conquest Equipment is also helping its customers to more effectively utilise existing square footage – and to maintain industrial spaces in a state of cleanliness more generally. The leading industrial cleaning equipment solutions provider recently became the primary vendor –in the Australian industrial cleaning market – of Canadian innovator Avidbots’ autonomous cleaning robots. This marks Conquest’s first foray into the automated cleaning space, providing customers with the opportunity to more effectively and efficiently clean warehouses and thereby improve overall productivity.

Elsewhere in this issue, you’ll read of Nokia’s solutions in providing 5G connectivity within warehouses as a way of better linking up people and equipment to streamline activities, providing the low latency information transfer capabilities necessary to implement full Industry 4.0 functionalities.

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Another thing that has become apparent over the past 18 months is the increased premium put on planning – particularly planning that accounts for disruptions to inventory management. It’s an area that Reto Fuhrer of RF Supply Chain Expertise – a boutique supply chain consultancy with global experience – thinks has much potential for improvement. Check out our profile and interview with Reto to find out more.

Happy reading. See you next month.

Edward CranswickEditor

edward.cranswick@primecreative.com.au

CBRE’s Daniel Eramo and Todd Grima negotiated a deal on behalf of Melbourne Airport and Honda Australia to grow the airport’s Business Park precinct with a 22,800 sqm facility.

The investment management firm says Daniel acted on behalf of Melbourne Airport while Todd acted on behalf of Honda Australia.

Melbourne Airport notes its new facility will become the company’s national parts DC, replacing two nearby facilities, and it includes 500 sqm of office space and sits on a 40,910 sqm site.

It adds that construction of the new DC started in June this year with Honda expected to move into the purpose-built facility in Q3 2023.

Andrew Gardiner, Melbourne Airport Chief of Commercial Property and Retail, says he welcomes Honda to the estate, adding that he was thrilled to have another international brand recognise the value of the airport’s location.

“Honda is a global brand known for its automotive, motorcycle and power equipment products, and we are pleased

that we are able to offer them our unique location to support their local business objectives,” he says.

“While our main business at the airport is of course aviation, our commercial property business also underpins our success, and that was particularly apparent throughout the pandemic.”

Melbourne Airport says Business Park is Australia’s largest business park, spanning more than 500 hectares.

The airport offers tenants like Honda fast access to air freight, on-site 24/7 security, and close connections to arterial roads so that they can get their products to their customers quickly and easily, notes Andrew.

Stephen Collins, Honda Australia’s Chief Operating Officer, says the company was excited to be moving ahead with the next phase of its business transformation plan.

He adds that Honda is now making significant investments across the broader business to strengthen local operations.

“We will be bringing our automotive,

BPS Global Australia says it has partnered with Harvey Norman Commercial Division (HNCD) to deliver a range of automation technology at its new $14 million facility at Crossroads Logistics Centre.

AMP Capital owns the state-of-the-art facility in Casula in Sydney’s southwest while Dexus is leasing the building to HNCD.

The property is 18,000 sqm and will be completed in early 2023. BPS Global Australia is working with HNCD to cater for a rapid rise in growth and demand by installing and using the latest automation.

“We’re delighted to deliver a full range of state-of-the-art technology for Harvey Norman Commercial Division as the organisation expands its fulfilment capabilities with a brand-new facility in Sydney,” Malcolm Druce, Managing Partner at BPS Global Australia, and Project Manager for HNCD, says.

“As part of Harvey Norman Commercial Division’s commitment to innovation, they have invested heavily in automation technology that will transform its operation and increase efficiencies, accuracies, and speed for its end consumers,” he adds.

HNCD provides an extensive selection

Melbourne Airport’s new facility will become Honda’s national parts DC, replacing two nearby facilities.

motorcycle and power equipment parts warehousing and distribution together at the new, purpose-built facility,” he says. “As ‘One Honda’ in Australia, we will have greater scale to realise our full potential and best serve our diverse range of customers.”

“The process undertaken identified Melbourne Airport as the ultimate location for Honda’s new distribution centre,” Todd says. “It ensured the right building solution could be delivered and matched with competitive market terms.”

of brand-name products to builders, developers, architects, and designers, notes BPS. It is also responsible for delivering business reward products via frequent flyer scheme and company incentives.

It says this division has seen record growth and as a result HNCD has invested in automation at its new facility to significantly expand its Stock Keeping Unit (SKU) capacity.

“We’ve experienced rapid growth across our service offerings in the past couple of years and have made the decision to invest significantly in our supply chain capabilities,” Alan

For RedMart, Singapore’s largest online grocery retailer, order fulfilment speed, reliability, accuracy, and productivity are key in delivering on customer promises, especially during the pandemic, when online visitors increased 11-fold.

Optimising capabilities through leading-edge logistics automation from Dematic, RedMart’s online fulfilment centre features robotic shuttles, ergonomic pick stations, intelligent conveying, and high-rate despatch sortation – all across five temperature zones and managed by sophisticated software, making grocery fulfilment easy, accurate, efficient and safe.

Stephenson, Proprietor HNCD, says.

“By partnering with BPS Global Australia, we’re confident we have selected the right automation and tech suite for our operation and look forward to delivering the very best experience and service for our customers.”

BPS says the facility will be able to store more than 60,000 SKUs across 18,000 sqm, compared to 20,000 SKUs across 12,000 sqm at its current facility in Taren Point.

HNCD has invested in Autonomous Case-handling Robots by Hai Robotics, automated packing machinery by CMC, very narrow aisle trucks by Toyota Materials Handling and a state-of-theart Warehouse Management System by Thomax Technology.

Paul Graham, Group Chief Executive Officer and Managing Director says despite the growing headwinds this was a solid result.

“I am immensely proud of how our people have met the challenges of a global pandemic and still delivered essential services to all Australians,” Paul says.

“Not only did our team work tirelessly to keep themselves and their communities safe, but this was achieved in an environment of evolving restrictions,” he adds. “I’m pleased we were able to deliver a record number of parcels and expand our range of services, connecting all Australians during this difficult time.”

AusPost says is expected to remain in FY23 due to elevated volumerelated costs and COVID-19 related workforce impacts.

“While it’s clear more Australians are buying goods online following the pandemic, we don’t expect to see the same level of e-commerce growth,” Paul says.

“This has been demonstrated in our second-half results and, going forward, we anticipate growth to be moderate,” he adds.

Australia Post says its Full year group revenue for FY22 was $8.97 billion, which is up 8.5 per cent from FY21 and attributes strong first-half parcels revenue to driving the growth.

It notes e-commerce returned to normal growth rates and letters volume continued to decrease in the second half of FY22.

Sales of surplus assets and revaluations, as well as favourable bond rate movements supported Full year Group profit before tax of $55.3 million, including letters losses of $255.7 million, notes the national postal service.

It says after a strong first-half profit, the second half incurred a loss of $144.5 million, which it adds is considerably higher than in previous years.

Operational costs increased by 9.2 per cent on last year, some of which

He says despite the significant financial headwinds, Australia Post is focusing on business efficiencies, while continuing to invest in its network and technology, to better meet the needs of its customers.

Australia Post says more than $1 billion has been invested in it over three years to better service customers, with $427 million invested in new parcel facilities, fleet, and technology in FY22.

It adds that it invested an additional $17.1 million into the Licensed Post Office Network, bringing the total paid to Licensees in FY22 to $536.6 million, supporting the important role of Post Offices in communities across Australia.

WiseTech Global, provider of logistics execution solutions says it has partnered with ZIM Integrated Shipping Services, a global container liner shipping company to improve customer experience by connecting data via systems.

It notes that while supply chain visibility is increasingly important for logistics businesses, access to realtime, operational data is what drives critical decision making in an everchanging industry landscape.

CargoWise ZIM data connection now provides CargoWise customers with direction electronic messages for schedules, booking, tracking, verified gross mass, shipping instructions, and bill of lading data.

“ZIM makes digitisation a priority, and providing our customers with an easily accessible, digital way to connect directly gives us the ability to provide the best-in-class multiservice care we are known for,” Karin Schweitzer, VP Global Customer Service ZIM, says.

“As a platform used by some of

the world’s largest global freight forwarders, we’re pleased to be working with WiseTech Global and CargoWise,” she adds.

She says this connection will serve both companies as mutual customers will get faster and more reliable confirmations and information regarding their shipments.

Removing the limitations of using a third-party connection, CargoWise is broadening the scope of connectivity customers can access while on the platform, enabling both freight forwarders and carriers to exchange relationship-specific information that helps with process automation, reporting and visibility, notes WiseTech.

“ZIM is an important addition to CargoWise’s extensive carrier connectivity network,” Ashley Skaanild, Regional VP – Logistics Data and Connectivity, WiseTech Global, says.

“This collaboration empowers CargoWise customers with unparalleled, rich data at their fingertips through one integrated

platform,” she adds.

She says ZIM and WiseTech will continue to build on the benefits of their partnership as they work together to enhance connection with even more functionality, like contract and spot rates.

“It’s exciting that we’ve reached a milestone with our ocean carrier connectivity – over 95 per cent of ocean cargo managed by our customers through the CargoWise platform can be booked through a direct connection to ocean carriers and NVOCCs.

“This is extremely beneficial to all parties. We’re streamlining the supply chain by enhancing cross-border operations and providing access to essential information via electronic exchange of data. This is the future of the logistics industry.

Ashley says the companies’ vision is to be the operating system for global logistics, and their focus will continue to be to scale and build out the Cargo Wise ecosystem to provide their customers with leading solutions that meet their diverse needs.

Experts across all industrial property types in Australia

factories, manufacturing

warehouses, cold-storage and data centres.

Simon Andreatta

Accelerating

As the labour market tightens, demand for supply chain and tech talent is at an all-time high. With the skills shortage posing a major threat to organisations’ resilience, efficiency and profitability, Körber Supply Chain takes a deep dive into what’s driving the labour shortage and how businesses can better retain, attract and upskill their workforce.

According to recruitment firm Hays, more than 91 per cent of Australian and New Zealand businesses are currently experiencing a skills shortage. The Hays Salary Guide 22/23 revealed 83 per cent of responding businesses stated the insufficient supply of local skilled professionals will hinder growth and operations this year – the highest level the recruiter has recorded in the 43 years it’s been producing its report.

The talent crisis is being felt around the world, in every region and

sector. In supply chain and retail, the pursuit of customer satisfaction and efficiency is the driving force for many businesses, and as a result sourcing and retaining labour has become extremely challenging.

“The supply chain is facing competing customer demands for faster delivery, and more product choice, all against the backdrop of unprecedented labour shortages,” Anthony Beavis, Managing Director APAC at Körber Supply Chain tells MHD

Finding and retaining labour is one

of the biggest challenges facing supply chain businesses today. In a recent Körber Master Class Survey, 73 per cent of respondents indicated that it takes at least 30 days to fill an open warehouse position.

Not only is there a worldwide shortage of staff, but it is also becoming increasingly difficult to attract workers into a warehouse environment that can be both physically demanding and dangerous.

Combine this with low pay and the constant pressure for efficiency and

Employees are motivated when they feel valued and can create impact.

consumer satisfaction, and you have a perfect storm of worker disinterest and dissatisfaction.

However, according to Körber’s Anthony Beavis, the skills shortage presents an opportunity to redefine the way we work, including the way we value our employees.

“Without productive, efficient and motivated teams a supply chain operation simply cannot serve its customers. We know that employees are motivated when they feel valued and can create impact. To compete for talent in today’s environment, we need to make sure all employees feel valued by using technology to create an optimised environment for them to thrive in,” Anthony says.

Against these challenges, technology offers a solution, unlocking new operational savings while supporting employees to work more safely, enthusiastically, and productively.

Introducing the right technology, in the right place, and connecting it with the workforce and the warehouse system, will enable organisations to build the supply chains needed for the future.

With warehouse managers under increasing pressure, they now must find, train and engage staff to manage the demands of growing customer expectations, expanding product lines and unexpected peaks.

Today, Körber customers around the world are leveraging the benefits of advanced technology to improve efficiency and productivity and increase employee safety and engagement.

One highly agile and flexible solution is voice-directed work (VDW). During the early stages of the pandemic, one of Australia’s largest retailers worked with Körber to become the first Australian retailer to deploy Android Voice based systems throughout its

“ Any solution needs to match the scale of your operation, and offer benefits from both a safety and an efficiency perspective, encompassing the requirements of both your business and your workforce. ”

Anthony Beavis, Managing Director at Körber Supply Chain, explores how businesses can better retain, attract and upskill their workforce.

retail fulfilment operation.

The Android Voice solution guides employees with online and instore order fulfilment – improving productivity, reducing errors and safety incidents, as well as

Voice technology has proven to improve productivity by 35 per cent and reduce training time by 50 per cent.

decreasing training time.

By blocking out the noise of the warehouse and streamlining worker activities, VDW can improve accuracy, productivity, and safety across various functions in the warehouse including picking, putaway, replenishment, cycle counting, receiving, inspection and line loading.

In some use-cases, VDW has proven to improve productivity by 35 per cent, accuracy by up to 85 per cent, reduce training time by 50 per cent and importantly, reduce employee turnover by 50 per cent.

A further opportunity to tackle labour challenges with technology is the use of Automated Mobile Robots (AMRs). In the APAC region, Körber has been working with several major logistics providers and retailers to boost efficiency and help tackle labour shortages with agile and flexible automation.

Equipped with a combination of sensors, vision systems, and sophisticated mapping software that allows AMRs to respond in real time to changes in the environment, these robots can move independently

around the warehouse, avoiding people and objects.

Many are fitted with screens that help assist warehouse workers, with details of what needs to be picked or put away. Ideal for scaling up and scaling down, they help organisations rapidly meet peak demands and can move goods more efficiently around the warehouse than traditional picking methods.

They also reduce the steps and movement that warehouse staff have to make, which not only improves productivity but reduces the risks of slips and falls, repetitive strain injuries and fatigue or fatigue-related accidents.

During the challenges of the pandemic, a record number of retailers and logistics providers explored the use of AMRs in their operation. Most recently, a major Australian department store retailer announced it will work with Körber to deploy more than 200 AMRs at its new national distribution centre.

This major commitment to AMR technology will make the leading retailer the first in the world to boast three different AMR technologies – Geek+ RS8 Shuttle, P800s and Körber’s sortation solution,

Technology can be used to fulfil the needs of both the customer and the employee.

the site will also be the largest Geek+ RS8 Shuttle implementation in the Southern Hemisphere.

Rather than be a cause for conflict, technology can be used to fulfil the needs of both the customer and the employee. With careful planning and consideration, the introduction of selected technologies can be a costeffective way to improve product quality and choice, while simultaneously driving safety, productivity, and worker engagement.

“Any solution needs to match the scale of your operation, and offer benefits from both a safety and an efficiency perspective, encompassing the requirements of both your business and your workforce,” Anthony Beavis says.

Another major Australian retailer is working with Körber Supply Chain to deploy advanced technology to not only improve fulfilment capabilities but benefit the wellbeing of its team members.

As the organisation grows, the retailer maintains focus on its team members and their wellbeing. As a result, it has explored technology that enables it to not only fulfil at an increased speed and

rate but improves the environment for its team members.

“At Körber, we look at technology with a much wider lens and as such it has been great to deliver some further benefits for our customers around sustainability, employee wellbeing and occupational health and safety,” Anthony says.

Whether an organisation needs to respond to peak demand or manage crises, increase employee awareness and social distance, expand product lines, or adapt to new regulations – technology is available to support.

“Whether your organisation is national or international, single warehouse or multi-distribution centre, single channel or omnichannel, there is the technology to match and scale to your needs,” Anthony says.

However, whatever technology is deployed, labour will always remain the cornerstone of any operation.

“That is why the needs of your workforce must be considered in every technological decision. Using technology as a tool to augment and support employees to do their jobs better is the secret to keeping them safe and on side,” Anthony concludes.

■

Is your organisation experiencing a shortage of labour in supply chain or logistics roles?

The impact has been twofold –there is a shortage of available labour but more severe is the reduction in capability and accountability across the temporary workforce. For every 10 applicants we experience an average of two or three we want to retain for the next day. For 12 months now, labour supply has been limited particularly where MHE licensing is involved.

What is your organisation doing to alleviate the labour shortage issue?

We have successfully converted a percentage of our higher performing temporary staff into permanency and concurrently de-risked the labour shortage by offering a wider spread of hours to the temporary workforce. We have also moved away from a high reliance of MHE licensed operators and increased the spread of labour hire agencies across our business.

Moving into peak period, do you think this issue is going to get worse and if so, what plans do you have in place to help with this challenge?

Last year escalated from mid-July and this year was the same as more businesses hit their “peak”. As a result, this year we began recruiting earlier to gradually pick our way through and find the talented workforce.

How do you think the industry can do more to attract a wider pool of talent to help solve this issue?

By allowing the aged workforce with the correct skills, aptitude, and attitude back into the workforce. We must also be allowed to maintain a flexible industrial workplace platform to allow supply chains to become more efficient from a labour perspective.

The importance of attracting and keeping female talent in supply chain has been an increasingly hot topic over recent years. Prological’s Michelle Powell and Kelly Borskjaer discuss their experiences in the industry, what needs improving, and what is already being done well.

Much has been made of the importance of getting more women into supply chain. However, how this is best done – and the importance of taking active steps to achieve a more even male-tofemale ratio in the industry – is still a matter up for debate.

Prological’s Michelle Powell, Senior Analyst, and Kelly Borskjaer, Bid and Brand Manager, are two leaders in their field who spoke to MHD to share their perspectives on this vital issue: how the industry has developed, and what work still needs to be done.

Michelle, who has worked in the industry for almost two decades, says there has been a big shift in the composition of the work force.

“I studied science and engineering at university and was used to being almost exclusively with boys early on,” Michelle says. “But to

be honest, it wasn’t something I thought too much of. I’m fortunate in that I had great experiences during my entire career primarily due to supportive direct line managers.”

Michelle spent almost 16 years at Kimberly-Clark, which she credits with having a “progressive culture”.

“During my tenure there definitely was a shift towards more women in the industry,” she notes. “When I started out, I might have been the only woman in a room full of ten people. But 16 years later there were many more women employed with engineering or science degrees, particularly in the technical and quality assurance or planning areas where I worked. So, there was a big shift in terms of the composition of the workforce.”

What accounts for this change, in Michelle’s view?

“I think the change stems from having visibility of the opportunities available from an early age,” she says. “I went to a girls’ school, finishing in 1990. One thing I remember is really wanting to study engineering drawing – and not having the opportunity to do that.”

But Michelle says this is the only real hurdle she can recall in her career.

“Once I got to university, and then into the workforce, it just completely changed. I didn’t feel restricted. I didn’t feel any negativity or that I was limited in any way because I was a female.

“My impression is that school has definitely changed, girls are encouraged more to do whatever they want at an early age – and especially STEM subjects. It’s all over the media, and government is pushing for more young women to

pursue careers in STEM. The opportunities that are open for women is so much more visible now than it was in the past, which is great.”

Kelly Borskjaer is relatively new to supply chain, having joined Prological in March of this year to work on bidding and proposals processes, after working 20 years in the engineering and consulting sectors.

“Coming from the engineering services field, I would say that sector is still very male-dominated,” Kelly says. “But my impression is that a large part of that has to do with where one starts one’s career progression – up until recently, young women haven’t been encouraged in pursuing a career as, say, a technician, which is where you start before becoming a service manager, then a general manager. I’ve only been in supply chain a short time, and my general impression is that it’s quite similar. But like Michelle, this doesn’t strike me as unusual. The difference is that these days there’s more of an active push and visibility around women being in the sector as a viable career path from an early age.

“But speaking from my own experience across the engineering and consulting fields, and now in supply chain, I’ve never felt there has been a barrier to my progress.”

Michelle notes that part of reason she has never felt hamstrung in the industry is because her experience at KimberlyClark was very positive on a cultural level.

“The policies they had around maternity leave and pay were always good,” she says. “Pay was based on job description. I do remember, after returning from 12 months of maternity leave, my pay had fallen below the midline. But fortunately, my boss went right in to bat for me and the issue was rectified. So, company culture is really important, and so long as an awareness of and emphasis on having a female-friendly culture is front-of-mind, that’s the main thing.”

Michelle adds that at the end of the day, it should just be a true meritocracy.

“Firstly, you’ve got to have women who want to do the job. That’s where the issue starts. Now, it might be a case of women not being sufficiently aware or feeling enabled to do these jobs – in which case I’m all for opening those avenues. But we must also realise that women, and increasingly men, may have different priorities at different times of their lives – structural change is important in

When it comes to shifting the ratio more towards women in the industry, measures should be squarely focused on promoting the attractiveness of the industry and opening up pathways for their meritocratic advancement. That’s where companies in supply chain should be putting their focus.

”

supporting that family-life balance that we all are looking for, but time out of the workforce can definitely impact on career trajectory.”

Kelly agrees with this assessment, saying that awareness of the sector and an inclusive culture will be the primary determinants in getting those women who want to be working in the field working in the field.

“These sorts of questions can’t ever be boiled down to just one single factor,” Kelly says. “No doubt, there are still some people out there who think only people who look like them can do the same job – but they’re becoming less and less common in my view.

“But we should also be aware that supply chain and related industries will need to work hard to improve their attractiveness to women. For instance, there are industries which are simply more female dominated, and so in terms of competition for talent – supply chain might out-compete for attracting male talent, and other industries out-compete for attracting female talent.

“For example, I had a young woman working for me in the last engineering firm I was at. She was great, she loved the work – but,” Kelly laughs, “she was tapped on the shoulder by Louis Vuitton to come work for them. Between maybe a free air conditioner and a free handbag … what’s a girl to do?”

Kelly notes that at the board level across all sectors, including supply chain, there is a push to get more women in at the top.

“Given previous generational dynamics, I think it is important that mentoring processes are in place to ensure women who want to take that step up to the C-Suite roles can build the experience necessary for these roles.”

“I agree,” Michelle says. “Setting quotas on a process that’s quite multifactorial can create unnecessary angst in the workplace. No one who has earned their position on merit wants to feel undermined by any perception that they were promoted for non-meritocratic reasons.

“As Kelly says, when it comes to shifting the ratio more towards women in the industry, measures should be squarely focused on promoting the attractiveness of the industry and opening up pathways for their meritocratic advancement. That’s where companies in supply chain should be putting their focus.”

Colliers has currently appointed agents to several major developments in South Australia. Paul Tierney, National Director Industrial, is based in Adelaide – where he has witnessed vacancy rates hit historic lows and observed how the city’s industrial market has grown and evolved over the last two decades. He explains how the company is servicing the SA industrial market as it reacts to external forces and the changing economic environment.

Colliers Industrial property is currently dealing with changing market dynamics on both the sales and leasing fronts. National figures show this year there’s been an even split between leasing and sales revenues – an uncommon occurrence.

Paul Tierney, based in Adelaide, is National Director Industrial at Colliers. He has lived in the City of Churches for the past 22 years and developed strong ties with SA investors, occupiers, and clients.

Adelaide’s industrial property market is smaller in size compared to the east coast markets of Sydney, Melbourne, and Brisbane. Paul and the SA team have extensive experience as specialists in the industrial market locally, supported by the National Industrial Team and broader business.

“We interact with interstate occupiers and clients that own and occupy property, but over 70 per cent of our market base is privately owned” Paul says. “We are trusted advisers to our clients. Our clients seek expert advice supported by data from us for leasing, brokerage, and sales as well as land division and developments.”

Industrial leasing focuses on existing vacant and design and construct opportunities while industrial sales focus on owner-occupier, vacant possession, and investment sales.

“Within Colliers, we have two key internal teams in the industrial business

– the Capital Markets and the Occupier Teams,” Paul explains. “I sit on the National Capital Markets and Occupier Teams. I meet with my colleagues regularly to discuss national market trends and the impacts they have on occupiers and investment sales in South Australia.”

He suggests more than 50 per cent of tenant and occupier demand is warehousing and logistics related. There is also growing interest and enquiry from advanced and, to a lesser extent traditional, manufacturing and other professional service providers who need to own or lease industrial assets.

“Our market is broken up into five key submarkets,” Paul says. “There’s the outer north, Edinburgh, Direk, and other nearby suburbs. Then there are the traditional markets of the inner north (Wingfield, Regency Park, and Gilman). There’s the west near the airport, and the inner south, including Edwardstown, and the outer south Lonsdale and Seaford.”

South Road is the main arterial corridor linking north and south Adelaide which is currently undergoing a significant upgrade over a staged process. Ultimately this arterial corridor will be the critical spine of Adelaide.

“Twenty-odd years ago, when I moved to Adelaide, the core industrial market was in inner-northern areas. It has now grown with emerging markets in the outer north and outer south becoming more popular.

Land values have improved and continue to keep growing

with pressure from higher and better uses in near city markets.”

Average land values on near city suburbs range between $700 to $1000 per sqm. The further you move away from the CBD the more affordable the land becomes, with pricing in the outer north and outer south now ranging from $175 to $200 per sqm upwards.

Development and opportunities follow infrastructure, notes Paul. With pressure on land from higher and better uses such as residential and commercial we are witnessing a migration of industrial occupiers to infill development locations in the traditional markets and expansion to the emerging industrial markets.

The upgraded South Road will provide development opportunities for higher and better use, but also makes movement of

product through the state and capital city a lot easier.

“Certain major routes that get used are susceptible to congestion,” Paul says. “South Road will reduce the congestion and improve traffic flow through some key residential suburbs in the east and west, particularly with the central corridor.”

“It will also mean that we can move product between southern and northern facilities. These warehouses and DCs will be smaller. This is important as e-commerce rapidly grows and customers want their purchases within a matter of hours and days, not weeks. We anticipate more of these smaller DC facilities that can quickly distribute items moving forward.”

Once connectivity to the ports and terminals in Adelaide is improved, containers will move more easily and can be transferred more directly from the port to rail and road networks. The investment in road, rail, and port infrastructure is crucial to this process.

Colliers was involved in the Walker Corp Development, The Vicinity Industrial Base from the outset. This was a 90-hectare parcel of land. Paul explains, “the first 10 years were a bit slow because of the amount of availability within the inner north, which is where occupiers had a preference to be because of the network and transport operators.

“With the development of the Northern Connector linking the South Road, Port River Expressway and the Northern Expressway, Stages 2 and 3 sold out within 12 months, with Stage 3 not even being formally released to the market due to pent up demand. This is a clear indication of how improved infrastructure supports new development and allows occupiers to relocate to these emerging suburbs.”

With the lack of supply of existing leasing stock, pre-commitments are key to satisfying occupier demand. The Adelaide market does not have

speculative development like other eastern seaboard markets.

With the current vacancy levels many of the existing opportunities have short term occupiers renting these premises adding more pressure to supply, Paul explains. New vacancy coming to the market is generally snapped up quickly due to increased demand for warehousing and logistics facilities. The focus is more towards a flight to quality, steering clear of these old and inefficient buildings.

“Internal clearance for those older buildings is often six to seven metres, whereas most new buildings have springing heights of 10 to 12 metres, and maximum internal clearance up to 13 to 14 metres. Efficiency in automation and supply chain technology is forcing these changes.”

Paul notes that with this trend continuing businesses can expect to see “dark warehouses.” These are fully automated warehouses that require limited human operators.

While multi-storey warehousing will be coming to the more land constrained markets of Sydney and Melbourne, these facilities will only possibly appear near Adelaide’s main airport and where land pricing and supply are constrained.

Colliers has two new leasing development opportunities in Wingfield. 2 Francis Road for Charter Hall, called the Wingfield Industrial Estate, will be developed in two separate warehouses providing more than 14,000 sqm and will offer ESG initiatives to attract larger corporate occupiers. With strong leasing enquiry Colliers anticipates these warehouses will be pre-committed and developed in 2023.

“The other development is Wingfield Logistics Park, a 13-hectare site that Fife Capital is developing including a pre-commitment to Blue Star Logistics. The further development of two larger 9000 sqm buildings due for completion in late 2023 are already attracting strong interest from the market and we would expect these to be leased before

practical completion. Further stages within Wingfield Logistics Park can accommodate pre-commitment occupiers to the estate.”

Colliers has identified trends in SA that mirror those occurring nationwide, with a particular focus on infill development options.

“There’s appetite for land-rich sites, especially short-term leases, however long WALE assets are still attractive to REITS and syndicated purchasers,” Paul explains. “We are still experiencing strong demand from offshore and onshore capital seeking investments in the industrial asset class. Limited opportunities in this sector are helping to hold yields relatively firm. We anticipate investor activity to grow as inflationary pressure and interest rates ease.”

Investors are attracted to South Australia not only for the value proposition comparative to the eastern seaboard, but also because of the removal of stamp duty on commercial property transactions.

“Taking five per cent off your purchase costs at the upfront has a massive impact on investors, and with the softening of yields, I think it will keep attracting them to South Australia.”

In line with the national trend the Adelaide industrial markets are witnessing sustained rental growth. This rental growth is supported by limited supply and the opportunity for some older facilities to be refurbished and repurposed to accommodate modern warehousing and logistics demand.

A good example of this is 7 Brandwood Street, Royal Park which Colliers sold to Centennial last year. The 12,000 sqm building is being refurbished with completion in late 2022. It anticipates the building will be fully leased prior to practical completion of the refurbishment.

“We’ll see a lot more of these refurbishment opportunities as sites are brought to market, particularly in areas like Regency Park and Wingfield. We may even see speculative development of larger facilities to cater for the increased demand.

“Given the demand and the lack of supply, it’s the ideal time for developers if they’ve got that appetite to do it here.” ■

A family-owned Queensland nursery wins free TMHA electric pallet jack after forklift purchase.

Afamily-owned contract growing nursery business has enjoyed a welcome bonus after becoming a customer of Toyota Material Handling Australia (TMHA) for the first time.

Growing Solutions Australia, based in Cabarlah, Queensland, wanted to purchase its first forklift and chose the superb safety and reliability of TMHA by opting for a Toyota 8FG18 counterbalance forklift to best complement the business.

However Growing Solutions Australia owner Jamie Currie got more than he bargained for after ordering his new forklift, with TMHA area sales manager Max Reindl assisting Jamie to enter into a competition to win an LHE150 electric pallet jack.

As luck would have it, Growing Solutions Australia proved to be a winner in TMHA’s Grower’s Prize Giveaway promotion with Jamie particularly pleased at the result.

“We don’t win a lot of things but it was brilliant to get the phone call,” he says. “Max recently delivered the product and went through the product familiarisation, and now we have not only a forklift but a brand-new electric pallet jack.”

“Sometimes you’re just happy with the meat tray at the pub, but this time we won an electric pallet jack, which is great!”

Having started Growing Solutions Australia five years ago with his wife, Jamie had previously been using an old forklift that came with the Cabarlah nursery when he

purchased it.

However the need arose for a replacement, with Jamie canvassing the products of multiple brands but eventually settling on Toyota.

He says the advice of friends helped him make what was a simple choice in the end.

“One of my mates who also owns

Growing Solutions Australia was the winner in TMHA’s Grower’s Prize Giveaway promotion, receiving an LHE150 electric pallet jack as prize.

a forklift bought it through the same salesman, Max Reindl,” Jamie notes.

“I was talking to him, asking what forklift he got and he said, ‘I just got one recently, I bought it through Toyota, I’ll text you his details.’ It was as simple as that, he texted me his details and from there we made a very

simple purchase.

“Knowing that a colleague also purchased one through Max, knowing that it was a Toyota and knowing the Toyota comes with all these different benefits and its reputation, it was a simple decision for me.”

Jamie sung the praises of the TMHA team led by Mr Reindl, who facilitated a purchase process that was made as simple as possible.

“The whole purchase process was extremely simple,” he says.

“It was quote, the rep came out and saw me, met with me, discussed the machine, selected the machine, quoted, ordered, paid, delivered. They’re just simple to work with.”

Product familiarisation was also carried out upon delivery of the new machine - a process that was repeated a couple of months later with the arrival of the free electric pallet jack.

Having moved from an older competitor’s forklift, Jamie says the Toyota 8FG18 machine offered a significant step up in features and usability, making for a simple-tooperate machine.

“I’d just say that from the machine that I’ve moved from, from a business owner’s point of view there’s obviously the safety features, and it’s just a very smooth and easy machine to operate.”

With its class-leading safety features including Toyota’s exclusive System Of Active Stability, legendary reliability and excellent customer service, it comes as no surprise that Jamie has been pleased with his decision to switch to Toyota forklifts.

Additionally the prize of the LHE150 electric pallet jack was an added bonus as it features a compact design perfect for light applications, and a maintenance free lithium-ion battery for fast charging.

When asked if he would recommend TMHA to others in the industry, Jamie didn’t hesitate to say that he would “100 per cent” encourage others to jump on board.

“My response is very clichéd but if you look at people sharing their positive experiences in the media, mine is pretty much the same,” he says.

“From making contact with the rep, to the rep coming out and responding straightaway, to delivering and having the machine, it was all made very simple.

“And with the quality of the product - in my opinion, if I compare it to the quality of other products out there, it was a no-brainer for me to go with Toyota.”

Jamie and his wife started Growing Solutions Australia five years ago to work as a contract grower with businesses in the nursery, horticultural and agricultural industries.

The family-owned Queensland business now boasts eight employees from the local area across fulltime, apprentice and casual staff, predominantly working with wholesale nurseries in producing young plants.

■

For more information visit ww.toyotamaterialhandling.com.au

Leading forklift retailer Toyota Material Handling Australia (TMHA) has broken ground on a new home for its operations in Victoria, with the state-of-the-art facility to provide a range of functions for the company.

Located in Dandenong South in Melbourne’s south east, the new facility is approximately 5km away from the existing facility on Abbotts Rd and will offer a broad scope of capability for TMHA.

Having been in planning for five years from board approval to acquisition of land to commencement of construction, the new site sits on 32,600m2 of land - a significant 81 per cent increase over the outgoing facility.

The building area will take up half of the available land with 16,350m2 set aside for the facility itself - a 34 per cent increase over the previous building.

At 12,827m2, the new warehouse and workshop area is 28 per cent larger than before, while a new 300m2 ‘dirt’ demonstration area will allow for prospective customers to demo its HUSKI Construction Equipment range of earthmoving products.

In addition, the new facility will feature state-of-the-art sealed and pressurised paint and preparation booths.

TMHA GM Corp Compliance & Project Development Bob Walmsley says the new site would allow for a greater level of usability and innovation for the brand.

“With features like a dedicated dirt demonstration area, paint booths and support for parts and service, our new state-of-the-art facility will offer more for our valued Victorian customers.

“We all can’t wait to experience the fruits of this investment from TMHA and look forward to seeing the completed hub next year.”

Along with facilitating sales and rental of TMHA forklift and allied equipment, the new facility will serve as a regional base for major and corporate accounts operations, will hold inventories of new material handling and Huski construction equipment, and will offer full support coverage for parts, workshop and field service, and training facilities.

The purpose-designed new facility and the land it is built on is wholly owned by TMHA.

TMHA is also exploring other opportunities to expand its branch operations through regional Victoria. Construction of the new facility is expected to be completed in the first quarter of 2023.

A leading global tax services and software provider has signed a reseller agreement with Geotab. Find out more here.

use of telematics data as a valuable data source in helping clients solve tax problems across a range of taxes globally, from fuel taxes in trucks to income taxes on company cars.

Ryan, a leading global tax services and software provider, has announced that it has signed a reseller agreement with Geotab, a global leader in IoT and connected transportation. This agreement will allow Ryan to serve as a one-stop shop to its clients. Through a subscriptionbased product offering, Ryan’s clients will now benefit from both Geotab’s telematics insights and Ryan’s specialist tax advisory and compliance services.

Ryan’s clients worldwide will be able to purchase Geotab’s awardwinning telematics device solutions. Combined with Ryan’s full suite of services, comprised of tax, consulting, and integration services, including existing integrations with enterprise platforms, the agreement enables Ryan to provide its clients with a telematics and tax cross-border offering that uses telematics data to solve complex tax challenges while making strategic business decisions.

“We are excited to embark on this new commercial journey with Geotab,” says G. Brint Ryan, Ryan Chairman and CEO. “This partnership will provide us with even more opportunities to assist our global clients. We’re seeing the

“These technologies allow clients to achieve better tax outcomes as well as more robust tax risk management. Combining the power of Geotab’s industry-leading telematics data with the experience and knowledge of a leading tax services firm will help our clients understand how they can use telematics to drive strategic business decisions and favorable tax outcomes.”

Geotab has shown no signs of slowing down, despite the pandemic. In August, Geotab announced it had surpassed three million subscribers across the globe, demonstrating the continued high demand for data intelligence to support rapid transformation of industry, including fuel and operating efficiency, safety, sustainability, and predictability.

“The unique intersection of Geotab’s telematics technology and Ryan’s tax

In August, Geotab announced it had surpassed three million subscribers across the globe.

services will provide Ryan’s clients worldwide with the opportunity to connect their vehicles to the cloud and, as a result, have better insight into their fleets and any related taxes,” says Neil Cawse, Founder and CEO of Geotab. “By taking advantage of Geotab’s telematics offering and the set of tax, consulting, and integration services from Ryan, clients will be able to make better decisions and save time and money, which can help advance their positions in their respective industries.”

For Geotab, which recently marked its 22-year anniversary, surpassing three million connected vehicles, and forming new and interesting strategic partnerships in diverse fields – as illustrated by the Ryan partnership – is indicative of the significant impact its high-quality data insights contribute to organisations across the world as they optimize operations, build safe and intelligent communities, and continue working towards their various business goals. ■

Hear more from our experts on our latest episode of Talking Property

the Fit Out of

No two logistics problems are alike. Neither are their answers. Each requires a point of view. A new angle. Together, we’ll look for an integrated solution, guided by data and insights. We’ll gain a deep understanding of your business, and consider every part of your commercial real estate strategy, so you can realise anything.

Stockland is developing logistics parks in the ever-growing areas of Sydney’s west and south-west. Tony D’Addona, Stockland Executive General Manager, Workplace and Logistics, gives insight into what’s going on in this space – and what opportunities will become available as sites like the Western Sydney Aerotropolis open in the coming years.

consideration is supply of employment lands,” says Tony. “Changing land uses over time, which we understand as a creator of masterplanned communities, have seen a reduction in employment lands – that is areas zoned for industrial or similar purposes – when they are rezoned for other purposes.

“When you combine these factors with the time it takes to rezone employment lands elsewhere, and provide the infrastructure for development to progress, supply has just not kept pace with demand.”

As two councils in Sydney’s south west gave the green light for the diversified property group to develop its Leppington Business and Ingleburn Logistics parks, Stockland has strengthened its presence in the west and south west where the Western Sydney Airport and Western Sydney Aerotropolis are set to become economic catalysts for the broader region.

In a constrained market with elevated occupier demand, Stockland is providing much-needed supply for customers who are looking for strategic locations in growing areas with access to working populations and key infrastructure.

While still making up ground on its Asian and European counterparts, Australia’s e-commerce market is growing rapidly. It’s a major factor

in driving demand for logistics space as online distribution requires a significantly larger footprint particularly when compared to traditional bricksand-mortar operations.

The change in consumer behaviour brought about by the restrictions and lockdowns during the COVID-19 pandemic show no signs of abating.

Disruptions in supply chain have also created a step change in the way businesses strategically manage their inventory. There is a growing trend from a ‘just in time’ to ‘just in case’ with businesses preferring to hold more stock to mitigate supply chain risks, meet unexpected demand spikes, and potentially lock in material costs. Onshoring of manufacturing is also expected as a consequence of the pandemic and deglobalisation.

“Apart from the obvious demand drivers at play, another key

It’s these factors that have led to previously unseen rental growth and record low vacancy rates and highlight the importance of a healthy, functioning logistics sector with the right facilities in the right locations.

For example, Stockland’s Leppington Business Park and Ingleburn Logistics Park in south west Sydney are masterplanned estates that offer premium warehouses with ancillary offices, 5 Star Green Star ratings, and connections to key road and transport networks.

As the Western Sydney Aerotropolis nears completion, the airport and its surrounding lands will play an important part in delivering growth by supporting employment, population, infrastructure, and road upgrades which will further increase the attractiveness of the region.

These market conditions are influencing Stockland’s customers – some need to

evolve their operations with bigger and more modern spaces, others want to downsize or take advantage of better locations, and some need to move to interim sites while they wait for their new premises to be completed.

“Many of our customers are looking to expand or diversify their operations into secondary markets,” says Tony. “We are working collaboratively with current tenants to place more than 150,000 square metres of demand across our portfolio and development pipeline.”

This highlights a point of difference. Stockland works in close partnership with its customers to leverage its diverse portfolio of assets and to ensure a smooth and effortless transition between spaces.

“Population growth within the Western Sydney region plays a major role in influencing the demand for logistics assets, with an anticipated growth rate faster than that of Sydney as a whole,” says Tony.

“A further contributor to population growth will be the increased migration cap, with roughly 35,000 permanent migration visas will be made available in the coming year to help ease critical workforce shortages.

“There will be a need for a thriving logistics market to service this surging population,” he continues.

“The region is incredibly well located

in regard to key infrastructure and the road and transport network.

“There is motorway access to key industrial hubs in the west, north west, and infill locations, the M5 delivers direct access to the existing airport and the ports, and it’s close to the Western Sydney Aerotropolis, as well as corridors to Melbourne and the ACT.”

As businesses grow and require bigger footprints, or more modern facilities, growth areas like Western Sydney are more desirable.

“While we are seeing customers migrate towards Western Sydney, we are also seeing major redevelopment potential in our infill locations,” Tony says.

“Many of our ecommerce customers operate a B2C model. Their customers are individual consumers, so they

Logistics space is critical for customers who are looking for strategic locations in growing areas, with access to working populations, and key infrastructure.

are targeting ‘middle and last mile logistics’ locations, close to major population centres. They may be using smaller trucks and vans and are happy to pay more for less space closer to the city.

“While the traditional logistics operators operating B2B models are more likely to gravitate west towards bigger warehouses, more hardstands, and are generally using heavier vehicle types.

“If the pandemic and current market conditions have taught us one thing, it is that logistics assets need to be viewed as critical infrastructure for our cities, integral to their ongoing productivity and the liveability of our communities.”

“Our western Sydney developments will generate job opportunities throughout construction, and as tenants and their employees move in”. ■

Argon & Co is a global management consultancy that specialises in operations strategy and transformation. With expertise spanning the supply chain, procurement, finance and shared

services, we work together with clients to transform their businesses and generate real change. Our people are engaging to work with and trusted by clients to get the job done.

VisionNav is a company on the rise off the back of the utilisation of advanced technology. MHD learns about the navigation technology behind VisionNav’s range of autonomous industrial vehicles.

VisionNav Robotics supplies autonomous industrial vehicles and intralogistics automation solutions for a range of clients around the world. Based on 5G Communication, AI, Environmental Perception, Deep Learning, Servo Control technology, VisionNav has developed nine automated product series including automated guided forklifts and tugger trucks for various scenarios.

Following huge success in Asian markets, VisionNav is making an impression in the Australian logistics space, with solutions covering the full stack of intralogistics scenarios, including core scenarios such as 12m high access, 1.9m narrow aisle access, unmanned loading and unloading of trucks, and multi-level racking and block stacking.

At the equipment level, autonomous forklifts move pallets and material

frames (this is also the most common material storage unit) of various sizes.

At the system level, VisonNav uses user management systems such as WMS/MES/ERP, by sending operation instructions to autonomous forklifts to achieve real-time matching between logistics and the information flow.

The Bright Eye system manages the production line area via realtime monitoring and promptly orders autonomous forklifts to provide raw material replenishment, empty pallet recycling, and provide offline support for finished products.

Thomas Wilson of VisionNav says the Bright Eye system is an AI device that’s based on repeatable learning –it can detect the pallet location and the pallet status in real time, he says. “And it sends that information back to the upper system. It can also detect humans within that area, providing additional safety should a human enter that environment.

The Bright Eye system is used for the pallet management between manual forklift drivers and AGVs operating in the same area safely.

“There’s no need for a manual driver to scan a pallet location once he’s removed that pallet from that area,” he says. “We can use the system in conjunction with other vision-nav systems that enables us to complete truck loading of multiple types.”

settings, without a need to modify the site environment and existing business processes.

“The visualized technology uses six degrees of freedom, multi axis movement, and that’s used for accurate and efficient execution of movements such as loading and unloading of trucks, picking and placing of pallets, stacking or putting pallets away into high bay racking,” Thomas explains.

“The technology uses multi sensor configuration for enhanced sensing and accurate identification of objects such as for searching for fork pockets, cage legs or spigots.

The VisionNav self-adjusting algorithm assists the AGV to pick up pallets squarely and in a centralised position, confirming that the first point of contact is correct, which means less pushback to customers on Brownfield sites to meet a perfect world scenario of hard stops, level floors and level racking.

Because of its hybrid nature, the VisionNav technology can adapt to existing sites and operations, lowering system infrastructure costs that are often hidden during the design phase.

VisionNav is capable of building up to 2000 machines per year, which helps to combat the current market supply challenges.

VisionNav is capable of building up to 2000 machines per year, which helps to combat the current market supply challenges.

VisionNav’s highly accurate navigation technology adopts 3D laser hybrid sensors to capture detailed information for indoor and outdoor

“VisionNav can still deliver AGVs within a four to six months period. We have local Australian and New Zealand distributors that can complete those installations, and provide services and support,” he adds. ■

With a diverse portfolio of assets nationally and a strong development pipeline, Stockland offers flexible solutions to evolve with your business.

Find your space to thrive across our leading portfolio.

Position your business for growth, scan the QR code and enquire today.

2022 marks 150 years of DB Schenker globally, and 60 years in Australia.

our first day in business, we’ve kept our beginner’s mentality to find new and better ways to tackle tomorrow’s challenges and elevate lives.

committed to providing innovative supply chain solutions that challenge the status quo.

a global industry leader, we’re proud to support industry and trade in the global

of

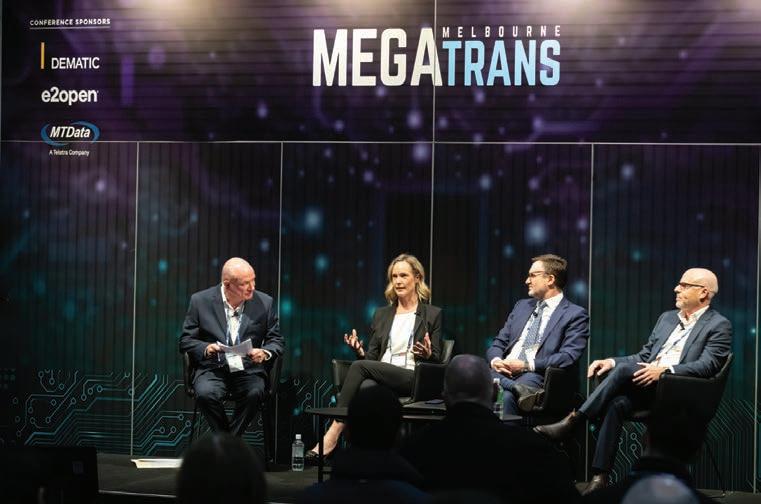

Dematic’s Graham Lawrence, Jason Hill, and Jennifer Horton are some of the directors, project managers and engineers who facilitate project implementation capabilities for the intelligent automated solution company’s clients. They explain how the intricate process works, and why long-standing partnerships with customers are vital to its operations.

Companies looking to optimise their supply chain operations – to reduce their reliance on labour, increase storage and throughput capacity, increase order accuracy and speed, all in a smaller footprint close to customers –are evaluating implementing automation in their logistics operations.

In planning to automate, it’s critical that companies choose the right partner to work with from understanding their business and supply chain operations, their future growth strategies, designing a solution, through to system implementation, system handover and training, and ongoing service and support.

Critical to the success of the automated system – ensuring it is implemented to mutually agreed system deliverables and the project schedule – is the

project implementation.

Dematic has strong project implementation capabilities across Australia and New Zealand (ANZ). Its implementation teams work closely with all parties – including the builder, the company’s host software provider, and other key suppliers involved in the project – to ensure the best outcome is achieved for the customer.

The locally based, in-house experts in project management, engineering, controls, software, and go-live support reduce implementation time, cost, and risk. This includes dedicated project and site managers, engineers specialising in software, mechanical, electrical, structural, controls and systems, all collaborating to achieve the best result.

The Dematic team’s approach covers project safety, scope, timing, budgeting,

When planning to automate, it’s critical companies choose the right partner.

resource management, supply chains, quality assurance, and communications with customer and partner teams.

The process begins with Dematic analysing its customers’ entire operations – not only their supply chains. It looks at the business’s forecast – that is, where it’s going and what changes it needs to make as it moves forward.

It develops a system tailored to the business’s operations but with the necessary flexibility required. This is then handed over to the customer and the project team. Their partnership is constant throughout the entire project management process and helps the customer to become comfortable with using the automated systems to their full capabilities.

The Senior Enginners and Project Managers look at the technical aspects of a project, assessing durations and potential risks. Once the contract has been signed, the dedicated delivery organisation is engaged working closing with the sales and consulting team that designed the solution for the remainder of the project lifecycle.

There are more than 100 people working in the delivery side of Dematic in the ANZ region, including the many different types of engineers. This gives Dematic a diverse and deep understanding about delivering projects and means it doesn’t need to recruit many overseas workers.

“Our customers are dealing with the people who are going to deliver the job in the country,” Graham Lawrence,

Director Projects ANZ/ASEAN at Dematic, says.

Dematic delegates the specific project – which takes anywhere between six months to three years to complete – to the suitable team to work on it.

“It’s all about forming a relationship with the customer and to understand their expectations,” Graham explains. “We have a process based on the Project Management Body of Knowledge, called PMBOK. The Dematic Project Excellence Process is based on this.

It’s a project management philosophy and process we’ve had for over the past 20 years which has served well in all our projects, including projects introducing innovations into the region for the first time

“It looks at the whole design process, but also considers the systems engineering approach. We’re not just providing products, we’re providing a system to a customer, which has multiple interfaces to host software systems into their operations, and we integrate multiple pieces of technology and software.”

Systems Engineering is an integral part of the project team. It initially focuses on the customer requirements in the early stages of sales, consulting and solution development. Beyond this, it focuses on executing them and delivering on customers’ requirements.

The engineers hold a series of workshops with clients to discuss what they have and know, and to review the solution layouts.

“We want to make sure it meets

resources. They also look after Dematic’s subcontractors and ensure the work is done safely, and that the equipment’s installed correctly from a technical standpoint.

“It’s a much happier site environment when our safety officers check on our staff and continue to foster a cohesive workplace for everyone,” Jennifer Horton, Director Projects and Sites at Dematic, says. “We’re hitting schedules and maintaining our delivery timeframe.

“When there are shipping delays, we pride ourselves in working through those risks to minimise impacts to the client.”

their needs,” Jason Hill, Systems Engineering Manager APAC at Dematic, says. “We focus on their requirements, potential deviations that might occur, and track them throughout the process. Once we have system and functional specifications, we can execute on these during the project process.

“Before we even get to site, we start by conducting internal design reviews, software checks, and verify equipment performance. We begin with the basics, test each component, and build up with nodal equipment rates through to overall system performance.”

The Systems Engineers provide ramp up and operational support to customers. “We’re looking at the people on the ground, how they’re using the equipment, if they’re able to use the software efficiently, and we’re focusing on improvements throughout the process,” notes Jason.

“Systems Engineering is the bit of glue that holds it altogether,” Graham adds. “Each of the different disciplines has a role to play. Mechanical engineers will design a system and layout, and create a system based on various rates and performance criteria while the controls engineering team will look at how it’s electrically controlled and programmed.”

Dematic provides the inputs, controls, and software for the equipment it installs, and integrates third-party components as and where necessary to optimise outcomes leveraging mature relationships and technical solutions.

Project and site managers are assigned to manage and coordinate implementation

Dematic controls the inputs as much as possible and draws from its own key resources and scale of that support. In the initial stages of handover to the project implementation team, these teams are working with a builder to establish the building parameters and design they need to work around, as well as the timeframe.

The pre-construction phases are based on the engineers finalising the design, procuring the equipment, and preparing it all for ship to site. Once onsite, the teams install the equipment which is then followed by commissioning and subsystem testing before final performance and volume testing with the customer and their products.

“We practise the train-the-trainer approach,” Graham explains. “We train key personnel from the customers’ operations and have formal classroomtype training, and on- the-job training. It involves operating the systems, not only the software.”

The biggest differences between a major and a minor project are the risks involved and the team size, notes Jennifer, but the process itself remains the same. The project manager is responsible for coordinating the project and acting as its leader.

“Dematic is very much a customerfocused company,” Graham says. “We will not walk away from a situation, and we will always work with the customer and support them in their operations to ensure their systems continue to deliver to their business and supply chain requirements now and into the future. Testament to this is the number of repeat customers we have partnered with over the many years we have been implementing systems in ANZ and the broader APAC region.”

■

With vacancy rates at all-time lows, the Australian industrial property market is being forced to think outside the box. MHD speaks with property experts, Leedwell, about speculative developments and the future of the Adelaide and Melbourne markets.

Leedwell has been a major player in the South Australian industrial and logistics market for more than 14 years. Under the guidance of partner, Steve Smith, the same industrial team has been closing deals together for nine years – a testament to its synergy as a group.

Andrew Gerlach of Leedwell says it’s an unusual time for the Australian industrial sector, yet one that remains active and as exciting as ever.

“We’ve never seen industrial vacancy rates under one per cent,” he says. “It’s not just in the larger markets of Melbourne and Sydney – Adelaide has never seen rates below one per cent.”

Take-up in the industrial market has been astonishing in the past two years. In Adelaide, the low vacancy rate is a result – in part – to a lack of developers undertaking speculative development, which can’t be said for eastern seaboard markets where large developers are consistently creating new opportunities and being rewarded with take-up simply overwhelming the supply. With demand at an all-time high in Adelaide, developers have missed a golden opportunity.

“The take-up is moving from a justin-time to a just-in case situation,” Andrew says. “A number of our clients are in planning stages of large developments; however, a lot of that stock won’t hit the market – particularly in western and northern Melbourne markets, and in Adelaide until mid-tolate 2023.”

As supply struggles to keep up with demand for warehouse space in the South Australian market – especially

within 10 kilometres of the Adelaide CBD – a myriad of recent studies indicate the e-commerce shift continues to gather steam, suggesting the demand for automated fit-outs won’t dry up any time soon – if ever.

“It’s not just the big end of town,” he explains. “In the smaller end of the market – the sub-300 sqm units for mum-and-dad type investors or owner occupiers – there are many developments that are coming out of the ground that are having great success.

The market is trying to address the situation of low vacancy, but it does take time for speculative or pre-commitment development so there will be a hiatus of stock for a little while.”

Leedwell has been working closely with groups such as Sector Property on both smaller unit developments and small lot land divisions. Sector Property’s Managing Director, David Loakes, was an early adopter in this market and comments, “this end of the market, in the right locations remains an

opportunity for Sector to bring product onto the market for a broad range of our clients. We continue to review opportunities in Melbourne, but also interstate to satisfy this demand.”

The industrial market is heavily impacted by new, efficient infrastructure, explains Andrew, particularly roads. One clear example is the new Northern Connector expressway in Adelaide, which links Edinburgh Parks with more traditional markets, leading to significant land take-up in those markets. The completion of the Northern Connector resulted in improved land pricing and strong demand from developers to create development opportunities.

“Given the low vacancy rate, we’re encouraging our clients, both private and institutional, to take a leap of faith, measure the demand and look to build speculative developments in both Adelaide and Melbourne – rewards will be reaped by those who take action,” he says.

Owner-occupiers are also a strong market participant. Stock levels of existing buildings or development land for this market is also very low, resulting in participants needing to be more organised to capitalise on the right opportunity, especially given the current market conditions. Andrew explains that these groups should start planning at least 12 to 18 months in advance of a desired purchase.

“The key to that planning is knowing the right location for your business, key elements including supply chain, zoning suitable to intended land use, road restrictions for certain types of truck vehicles and of course, proximity of where staff live compared to the location are critical components of making these decisions.

“Another key consideration is affordability – do you need to relocate to an inner market, or can you go a little further out considering the scarcity of stock? These factors need to be established and planned out early so you can focus on where you want to move

your business.”

Another gem of advice for tenants looking to relocate is to keep an open and mature relationship with the existing landlord.

“Strong landlord and tenant relationships often allow for some flexibility so if you provide plenty of notice of an impending move, you are more likely to receive additional time if a property doesn’t eventuate in a timely manner. As investors, open communication is important as it allows them to plan for any upcoming vacancy and work with potential new tenants to limit down time and protect their income.

For non-income producing product (i.e., vacant land), the higher interest rate environment has momentarily cooled demand as businesses review operational needs and monitor market conditions. Andrew says despite not seeing any decrease in pricing, the levels of activity in market has recently settled, however the outlook remains bright for the industrial market.

“Most of the commentary we’re hearing from investors and developers buying land is that the current lull will not be a long-term issue because demand is so strong from tenants and owner-occupiers that people will reset themselves very quickly,” he says.

“Going forward, we are pretty bullish about the industrial market’s mid-term future.”