MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766 Website: www.primecreative.com.au

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Edward Cranswick

Journalist: Joseph Misuraca

Business Development Manager: Beth Jarvis

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Louis Romero, Kerry Pert

Client Success Manager: Janine Clements

Contact: Beth Jarvis beth.jarvis@primecreative.com.au

Australian Subscription Rates (inc GST)

1yr (6 issues) for $78.00 2yrs (12 issues) for $120.00 – Saving 20% 3yrs (18 issues) for $157.50 – Saving 30% To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

And just like that, another year comes to an end. It’s been a whirlwind year in supply chain and logistics. Just as we emerged from under the shadow of COVID-19, war broke out in Europe and governments across the world had to face new economic and fiscal challenges, with historically large government debts and inflation climbing to heights not seen in decades.

The MHD team had the great pleasure of attending numerous industry events in 2022 and meeting – often for the first time in person – leading industry players we’ve been writing about for years.

The sense of energy has been palpable, and as new challenges have popped into view, new product- and solutions-providers have been there to meet them.

Indeed, in this edition we spoke to the team from BALYO about how they’re making the entry into automation easy by fitting out Linde forklifts with add-on technology that turns them into AGVs – a boon for companies struggling with labour shortages and rising costs.

Also, in this edition you’ll read how Marcus Lethlean and his company Mediport have enabled effective interstate movement of pharmaceuticals with active cold chain transportation – helping to save costs and strengthen supply chain resilience in an essential sector.

And in our Cover Story for this month, we talked to leaders from the Supply Chain & Logistics Association of Australia (SCLAA) for their reflections on the year, the recent attendance record-breaking ASCL Awards in November, and what is to come in 2023. Getting back in touch with industry colleagues and partners has been vital this year, and the SCLAA has supplied the backbone of industry engagement.

From the team at MHD we wish you a wonderful Christmas and New Year. See you in 2023.

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Edward Cranswick Editoredward.cranswick@primecreative.com.au

DHL Supply Chain has announced a $150 million investment in warehouse robotics solutions and automation at its Australian warehouses, which will offer several benefits.

The contract logistics solutions provider notes this initiative will support faster delivery to customers, improve operational efficiency, and reduce employee workloads.

It adds this is the largest investment in robotics and automation it has made in Asia-Pacific, with 1000 robots to be deployed by 2025.

“This is a very exciting announcement, reinforcing our commitment to the Australian market and continuous technological innovation,” Oscar de Bok, Chief Executive Officer at DHL Supply Chain, says.

“Global supply chains have been under immense pressure these past few years, and some disruption may persist. But we have invested in supply chain digitalisation worldwide, and by leveraging this global expertise, we will continually develop innovative solutions to help our customers overcome any challenges on the horizon.”

In addition to the investment in

robotics, DHL Supply Chain aims to grow its Australian workforce over two years and will provide retraining and development opportunities to existing employees.

“This investment in robotics will provide more resilient, flexible, and scalable supply chain solutions to our customers, who will be better equipped to service their own customers independent of the sector in which they operate,” Steve Thompsett, Chief Executive Officer, Australia and New Zealand, DHL Supply Chain, says.

“One thing that’s especially important to note is that this investment has been made with three bottom lines in mind, and deepens DHL’s overarching commitments to environmental, social, and governance goals,” he adds.

“For example, one of the robotic picking systems we are deploying uses one sixth of the energy of a standard household toaster. The solutions will also significantly reduce our employees’ time on routine or physical tasks, allowing more time to develop the skills that advance their careers and work on meaningful and interesting projects.”

These robotic solutions will be able to locate and deliver items to pickers faster and will allow workers to despatch more

customer orders per hour compared to a manual environment.

The robotics solutions DHL Supply Chain will deploy by 2025 include: Deployment of Assisted Picking Robots in a multi-customer environment;

• State-of-the-art picking platform, which increases storage density and order processing;

• Goods-to-Person robots, which support teams’ ability to pack more customer orders;

• Automated inventory management robot, which was developed by an Australian DHL employee; and Point-to-point picking robots, which support a diverse range of picking strategies.

Cconstruction delays and rising costs have together reduced Australia’s 2022 supply pipeline of new industrial and logistics space by 600,000 sqm, according to CBRE.

“Occupier demand continues to outstrip supply in most capital cities,” Cameron Grier, CBRE Regional Director, Industrial and Logistics, Pacific, says.

“Developers are simply not able to

bring on space swiftly enough, with long delays in planning approvals in some states and construction delays caused by wet weather and labour shortages,” he adds. “For some projects, this is adding up to delays of six to 12 months.”

CBRE Research’s Q3 2022 Industrial and Logistics report notes a downgrading of the outlook across the five major cities from 2.7 million sqm to 2.1 million sqm.

It also outlines record rental growth of 6.7 per cent quarter-on-quarter for super prime assets, with rents across all grades rising by 16 to 19 per cent year-on-year nationally, headlined by just shy of 30 per cent for Sydney’s newest facilities.

“Coupled with the lack of supply being brought to market, when you overlay some 40 per cent increase year-on-year in construction costs and softening cap rates, it’s putting

When consolidating its multiple Brisbane sites into the new Heathwood DC, Asahi made the decision to upgrade from previously very labour-intensive operations to a fully automated warehouse solution, eliminating manual handling of pallets.

With the introduction of a satellite ASRS solution, Dematic helped Asahi maximise storage capacity, reduce operating costs, and improve efficiency and productivity to better meet the needs of its customers.

Read more and watch the video at Dematic.com

even further upward pressure on rents to hit the new return hurdles of investors,” Cameron says.

A total of 654,000 sqm of new supply came online in Q3 to bring the year-to-date figure to 1.4 million

sqm – all but matching the long-term average of 1.5 million sqm – although the overall pipeline for 2022 has been downgraded, notes CBRE.

It adds construction delays stemming from wet weather and labour shortages, and rising costs based on material shortages and supply chain disruptions have delayed some projects by up to one year, with some cancelled altogether.

“Q3 was another quarter of recordbreaking rental growth in Australia’s industrial and logistics market,” Sass J-Baleh, CBRE’s Head of Industrial and Logistics Research Australia, says.

“To bring the Australian market to a state of equilibrium, around 3.7 million sqm of space is required and only 2.5 million sqm is currently under construction,” she adds. “Therefore, we can expect strong real rent growth to continue over the next three years, averaging at just over six per cent per annum.”

Australia’s national industrial and logistics vacancy rate sits at a world-

low of 0.8 per cent, with Sydney’s rate the lowest in the country at 0.3 per cent and Brisbane’s the highest at 1.4 per cent.

Of the forecast 2023 supply pipeline of 2.5 million sqm, 41 per cent is already the subject of precommitments.

Weighted-average net face rents for super prime facilities have risen by 19.2 per cent year-on-year, with the national average now sitting at $134 per sqm following Q3’s further climb of 6.7 per cent.

There have also been considerable rises for older facilities, with weighted-average net face rents for prime-and secondary-grade assets up by 18.6 per cent and 16.0 per cent respectively this year.

Sydney and Perth have recorded the largest 2022 rises to date, 29.6 per cent and 24.3 per cent year-on-year for super-prime assets, with Perth’s Q3 rise of 9.3 per cent the nation’s biggest.

CBRE says construction delays and rising costs combined have reduced Australia’s 2022 supply pipeline of new industrial and logistics space by 600,000 sqm – almost a quarter of the original forecast.

According to Colliers, increasing industrial demand outstrips supply while prime rents are forecast to grow by 30 per cent or more by 2025 in 10 industrial submarkets.

South Sydney is leading at 39.5 per cent, Central West Sydney (36.9 per cent), Outer East Melbourne (36.6 per cent) and City Fringe Melbourne (35.6 per cent).

“This is the highest level of growth since we started recording industrial rent data in 2005 and is well above the long-term average of 2.4 per cent per annum,” Gavin Bishop, Head of Industrial Capital Markets, Colliers, says.

“Sophisticated capital is increasingly seeking to optimise rents in the

context of high land values and lack of supply in infill markets with multilevel warehousing, and Goodman, LOGOS, ESR, Hale Capital Partners and Charter Hall are all currently seeking to construct multi-level facilities,” he adds.

A lack of leasing options and robust levels of occupier demand indicate that rental growth of more than 30 per cent in certain industrial markets by 2025 is likely, notes Colliers.

Gavin says this will happen since average industrial prime rents increased nationally by almost 19 per cent in the 12 months leading up to the end of September 2022.

Notable current multilevel warehousing projects due to be delivered within the next five years in Sydney include Goodman’s 45 Burrows Road, Alexandria (16,078 sqm), Charter Hall’s 520 Gardners Road, Alexandria (27,509 sqm), and Hale Capital Partner’s 42-52 Raymond Avenue,

Matraville (19,461).

“Of the multi-level industrial assets currently marketed for lease in Sydney, net face rents well in excess of $300 per sqm are being achieved for up to three levels, and the Qantas lands Colliers sold to LOGOS in 2020, which adjoins Sydney’s International Airport, will likely see Australia’s first four-to-five storey warehousing,” Gavin says.

“The Melbourne market will likely track the success of multi-level developments in South Sydney before looking to roll these out in areas like Port Melbourne over the next two to three years,” he adds.

Multi-level and larger industrial facilities answer the call for new space with vacancy rates in several Sydney areas under one per cent while also offering substantial occupancy savings as land-tax and council rates are shared across each level, notes Colliers.

It adds statutory costs account for around 55 per cent of total outgoing

costs on average, which can result in a large saving to tenants.

“Larger industrial facilities will help facilitate net take-up for 2023, which we are forecasting will be in the order of 3.2 sqm nationally, due to the impact of a shortage of leasing options and moderating demand from the retail trade sector as consumer consumption eases with the rise of the cost of living,” Luke Crawford, Director Research, Colliers, says.

“With regards to speculative projects, between now and the end of 2023, there is approximately 1.6 million sqm in the pipeline along the East Coast, dominated by the Melbourne market,” he adds.

“Of this amount, almost 50 per cent is committed with the bulk of uncommitted space stemming from 2023 likely to be committed closer to completion.

“Given rents are increasing on

a weekly basis at present, select developers are not wanting to lease the space months before completion as they believe they are missing out on rental growth, while others are happy to lease the space to provide outcome certainty.

“Since the substantial speculative pipeline over the next 18 months is far exceeded by the level of active tenant requirements, it is unlikely to significantly impact vacancy rates.”

FedEx Express ANZ is collaborating with Starshipit, a shipping and fulfilment platform, supporting small and medium enterprises (SMEs), which allows e-tailers to tap into the international e-commerce market.

It notes merchants integrating FedEx and Starshipit will enjoy enhanced shipping and fulfilment automation, with access to a premium delivery experience for their customers at competitive rates.

“Our recent e-commerce research shows that e-tailers are increasingly looking for digital solutions which strengthen their delivery capabilities and allow them to grow their exports by tapping more international customers,” Peter Langley, Vice President of FedEx Express Australasia.

“Our collaboration with Starshipit is yet another example of how we are strengthening our capabilities within the e-commerce ecosystem to help small- and medium and e-commerce businesses in Australia and New Zealand,” he adds.

Starshipit customers can generate FedEx shipping labels and use additional features, such as Express Shipping Services and International Shipping Documentation Service, without leaving the Starship platform, notes the express transportation company.

“Our integration with FedEx makes streamlining shipping and fulfilment easy for e-commerce retailers,” Hakan Steele, Partner Manager at Starshipit, says.

This simple and easy-to-use integration of FedEx and Starshipit accounts enable e-tailers easy and automated access to process orders.

“Using Starshipit and FedEx together empowers retailers to save time with automation and deliver great shipping experiences,” he adds.

This simple and easy-to-use integration of FedEx and Starshipit accounts enable e-tailers easy and automated access to process orders.

FedEx says e-commerce in ANZ is expected to annually grow at five per cent and six per cent, respectively.

The latest e-commerce trend report it commissioned also indicates Australian

SMEs are using e-commerce more and agree the pandemic-driven utilisation of e-commerce is permanent.

It notes eight in 10 SMEs believe e-commerce will become more important in their business over the next three years, with nine in 10 SMEs believing they are well positioned to capitalise on this growth. Seventyseven per cent agree e-commerce will continue to become even more important in the future.

Market leading expertise to maximise the potential of industrial property. Experts choose experts.

We look forward to accelerating the success of our clients in 2023.

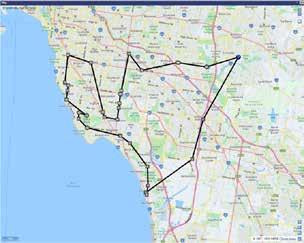

Coles is Australia’s first major retailer to offer drone delivery directly from its store to customers’ homes after launching a pilot service in South East Queensland with global, on-demand drone delivery company, Wing.

From Wednesday November 2, its customers in the Gold Coast suburbs of Ormeau, Ormeau Hills, and Yatala are now among the first to pilot the storeto-door drone delivery model, offering grocery delivery in minutes, directly from the Coles store at Ormeau Village Shopping Centre.

“We are delighted to be expanding our drone delivery pilot program with Wing to our Queensland customers,” James Geddes, Coles Head of Network Development and Customer Delivery, says.

“The service will provide a convenient and effective way of delivering everyday

essentials to our customers’ homes in a matter of minutes,” he adds.

Coles notes it has a dedicated fleet of Wing delivery drones co-located in its store car park. Its team members can process and pack orders while Wing staff can load the drones and oversee operation of the delivery service.

The grocery giant says the service will gradually expand to include other nearby suburbs, delivering 500 of its most popular grocery items including bread, fresh produce, convenience meals, snacks, healthcare items, and household essentials.

“We’re excited to be teaming up with Coles on this Australian first store-todoor drone delivery service, helping to expand the delivery options available to Coles customers by bringing affordable, sustainable, and fast drone delivery to the skies of South East Queensland,” Simon Rossi, Australian General

Manager, Wing, says.

“Since launching our drone delivery service in Logan a few years ago, we’ve heard from customers across South East Queensland who are keen to see drone delivery expand to their region,” he adds. “We’re delighted that through this pilot program with Coles, for the first time, drone delivery will be available to residents in the City of Gold Coast.”

As part of the expansion into South East Queensland, Wing will also soon offer Coles items for delivery from the rooftop of Grand Plaza in Logan, Queensland, where it has been operating a drone delivery service for selected on-site businesses for more than a year.

The Gold Coast area is the third Australian region where Wing drone delivery will be available, having previously been available to residents in parts of Canberra, ACT, and Logan, QLD, since 2019.

The Inside Construction Expo is scheduled for 20-21 September 2023 at the Melbourne Convention and Exhibition Centre where it will help construction and other related industries “engineer the future.”

The construction industry is a critical pillar of the Australian economy, producing upwards of $437 billion in revenue and approximately nine per cent of the nation’s Gross Domestic Product in 2022.

The sector has a projected annual growth rate of 2.4 per cent over the next five years and as it grows, so does the requirements of lifting, handling and transportation and building automation. The boom of the construction industry directly affects and assists the supply chain and logistics industry.

With investments in new and existing infrastructure projects in every state and territory, the Australian government’s national rolling 10-year infrastructure investment pipeline will increase from $110 billion to $120 billion, significantly boosting the sector.

Featuring an exhibition, conference, and awards across the two days of the expo, the 2023 Inside Construction Expo: ‘Engineering the Future,’ presents an ideal environment to focus on and discuss answers to the significant challenges facing both the construction

The conference will focus on major projects and civil construction, with the conference and world-class exhibition providing a platform for construction equipment and companies.

industry and by extension the supply chain and logistics industry.

With focus on the skills shortage in the construction sector, the continuing digital transformation of the construction industry and the overall safety values in the construction industry, the expo is an opportunity for the whole industry to connect.

The conference will focus on major projects and civil construction, with the conference and world-class exhibition providing a platform for construction equipment and companies, alongside industry leaders, to present ideas and

equipment that are best suited to the current concerns in the industry.

The centrepiece to the event will be about Victoria’s Big Build, expanding out to showcase construction on other significant infrastructure taking place around Victoria.

With the exhibition spanning 15,000 sqm across 10 bays at the Melbourne Convention and Exhibition Centre, Inside Construction Expo provides the best opportunity to meet with your target audience.

If you specialise in one of the following areas, Inside Construction Expo is right for you.

Site Equipment

• Construction Technology

• Lifting, Handling & Transportation

• Subsurface, Quarrying & Mining Plant, Machinery & Vehicles

• Urban Design & Landscaping

• Sports & Playgrounds

• Building Envelope

Building Interiors & Finishes

• Building Automation

• Construction Tools

• MEP Services

Heating, Ventilation & Air Conditioning

For more information visit www. insideconstructionexpo.com.au

NSW Ports says it has outlined its strategy for moving more freight by rail to enhance efficiency while reducing emissions and road congestion at the Australasian Railway Association Rail (ARA) Freight Conference.

Port Botany is Australia’s only container port with on-dock rail at each container terminal and moves more containers by rail than any other port in the country.

Jonathan Lafforgue, NSW Ports General Manager of Operations and Environment, says Port Botany’s rail moved more than 400,000 TEU a year – up 64 per cent since 2014.

He adds NSW Ports had the right strategy in place to continue optimising and growing rail capacity.

“NSW Ports is investing in extra rail capacity to address long-term demand in a sustainable way, by reducing CO2 emissions and the use

of trucks, as trade volume increases,” Jonathan says.

“Together with Patrick Terminals, we are investing $190 million to substantially boost on-dock rail capacity, which will deliver faster turnaround times, more rail windows for operators and allow more containers to be moved by rail to and from the terminal without the need for double handling.”

NSW Ports says Jonathan spoke at the

ARA conference about the need to build and optimise rail freight connectivity to enhance the sustainability, efficiency and productivity of the nation’s supply chains.

Part of its strategy to maximise the capacity and efficiency of rail freight includes:

Expanding Port Botany’s on-dock rail capacity to meet future container growth demand

• Increasing the two-way loading of trains, including with empty containers, to improve rail

utilisation and efficiency, and reduce CO2 emissions

• A mode shift incentive scheme, funded by Transport for NSW, to incentivise regional exporters to use metropolitan intermodal terminals for the “last mile” journey to Port Botany and collection of empty containers

• Working with businesses, rail operators and Transport for NSW to improve access to the shared metropolitan rail network for trains destined for Port Botany

Port Botany is Australia’s only container port with on-dock rail at each container terminal and moves more containers by rail than any other port in the country.

“Utilising Port Botany’s dedicated freight rail lines and on-dock rail terminals more strategically, by boosting two-way loading of trains and optimising the benefit of intermodal terminals, will help ensure we continue to meet the growing needs of businesses and their customers,” Jonathan says.

“A mode shift incentive scheme is one way to kickstart this process, with jurisdictions such as Victoria and Western Australia showing that such schemes can successfully increase the volumes of freight on rail.”

With booming membership in 2022, record attendance at its Awards and networking events, and new programmes and initiatives in store, the Supply Chain & Logistics Association of Australia has had a great year – and is gearing up for an even greater one in 2023. MHD spoke to Sue Tomic, Chair of SCLAA, Stephen Lakey, Independent Director & Chair of the 2022 ASCLA Awards Committee, and Rakesh Bandipelli, State Director of the Victorian and Tasmanian Division, for their reflections on the year that was, and the year to come.

oming out of the COVID lockdowns, we hit back with a vengeance with our Awards night in March,” says Sue Tomic, Chair of the Supply Chain & Logistics Association of Australia (SCLAA). “Our March Awards set a record for attendance, and our November Awards broke that record again.”

As Sue remarked in her speech at the November Australian Supply Chain & Logistics Awards, the only reason there weren’t more than 450 people in attendance was because they’d maxed out the venue’s space.

And what was true of SCLAA’s Awards nights was true of SCLAA in general in 2022, with outstanding growth in memberships and numbers of events – to speak nothing of qualitative improvements such as a successful rebrand at the start of this year and a new slate of membership offerings; measures which have solidified SCLAA’s reputation as the most vital industry association for supply chain and logistics.

“After the disconnection of the pandemic, we found that people were very keen to get into face-to-face networking and face-to-face connection with their industry peers this year,” Sue says. “Our National Partnership grew by 67 per cent – not a bad result – and we saw great benefits from streamlining our membership categories. Our Platinum National Partner category, for instance, incorporated attendance at a tier one event – be it the Awards, Women in Logistics, or various of our conferences throughout the year – and they had a

really great take-up.”

Indeed, over 2022 SCLAA hosted 43 events around the country, 60 per cent of which were free of charge to SCLAA members, and attracted a total of 1700 attendees.

It’s not too much to say at this point that SCLAA events are the events to get decision makers in a room to thresh out the topics, challenges, and opportunities facing the industry.

For Stephen Lakey, Independent Director of SCLAA, the success of the SCLAA this year was correlated with the growth in supply chain’s importance – or rather, the more accurate perception of its importance – for the economy and society as a whole.

“The challenges of the past few years have really brought home to people how

important a well-functioning supply chain is, and what happens when it breaks down,” Stephen says. “De-risking supply chain is now front of mind for everyone, building resilience is front of mind, global freight flows are making the headlines, everyone is thinking about technology’s role in improving visibility; all these things have been magnified in the public’s mind. And when we turn to SCLAA in particular, what we’ve seen at the Awards and at our various events is that the status of supply chain has lifted, and that’s translated to stronger membership numbers for us, and greater industry engagement.”

With the Cricket World Cup fresh in his memory, Rakesh Bandipelli, State Director of the Victorian and Tasmanian Division of SCLAA, had a nifty simile

ready-to-hand: “I feel like being in supply chain is like being a referee on the cricket field, people pay attention when something goes wrong.”

The sports stadium might be the apt analogy in other respects, too, with the level of energy at the November ASCL Awards reaching such peaks, Stephen says, that the MC had at times to urge quiet amidst all the excitement.

“The November awards really were a great example of networking in action,” he says. “It took us a bit by surprise how much people were getting up, talking to each other, taking the opportunity to connect with people from within their own industries, organisations, and companies that they hadn’t seen in three years.

“We used the Whispir platform at the Awards, which was a real hit. With this system people could send messages and search other attendees to find where they were seated – I think that heightened the success of networking at the Awards.”

An essential function of SCLAA in 2022, and moving ahead into 2023, is facilitating the sharing and crosspollination of ideas within supply chain and logistics.

“Oftentimes in the industry – because it’s so broad and encompasses so many sectors – it’s a matter of learning what each other are doing, sharing knowledge, and applying it,” Rakesh says. “SCLAA provides the platform that brings people and industries together, allowing problems to be solved in unexpected ways. I think that’s vital, because one person or corporation doesn’t, and cannot, know it all.”

Sue adds that SCLAA’s unique capability to bring people from all industry backgrounds and at all levels of expertise together is one of the main benefits of the SCLAA as an association and a key takeaway she’s heard from members in 2022.

“We partnered with major conference providers during the year to offer substantial discounts to our members and opportunities to our Partners to showcase their solutions. At one major industry conference, the organisers said, ‘Wow – I turned around at the conference and SCLAA was everywhere.’ That’s exactly where we want to be. We’re the only association that is truly cross sector. Most other associations

focus on a specific sector – whether it be transport, trucking, shipping, sea freight, and numerous others – whereas we try to bring everybody together, because that’s the only way you can actually produce solutions – by bringing all the players together in a room and nutting out a problem. The fact we are a not-for-profit Association also gives us an edge as we are a neutral representative of the supply chain and logistics industry, working for the benefit of all.

“We have to face it, every sector affects every other sector. If there are issues or problems being experienced in one area, you can be sure those effects will ripple out to cause issues in every other sector. So, SCLAA is the organisation that brings everyone together to tackle our shared challenges and solutions.”

But it’s not only about bringing together industry veterans with decades of expertise. Indeed, Stephen, Sue, and Rakesh all agree that engaging and educating supply chain professionals at all stages of their careers is imperative to bringing good ideas and people into the industry.

Supply chain’s importance in the headlines has raised the profile and status of its professionals, and SCLAA’s Awards nights, mentoring opportunities, and networking events are paying dividends in making supply chain a more exciting and attractive career for fresh young minds. But SCLAA isn’t resting on its laurels.

“We’re very excited in 2023 to be partnering with TAFE, WiseTech Academy, and the Institute of Transport and Logistics Studies (ITLS) at the

University of Sydney,” Sue says. “WiseTech offers all sorts of courses for the beginner – the basics on containers or warehouses, for instance – all the way through concepts around regulatory compliance, customs, forward brokerage and more. TAFE fills its own niche with both blue-collar accreditation as well as middle management in general supply chain knowledge. And ITLS specialises in university undergraduate and postgraduate programmes for business owners, executives and senior managers looking to progress their careers.

“With WiseTech Academy and ITLS, SCLAA is one of the only partnerships where they’ve signed an agreement for us to produce training courses in conjunction with them.”

That means SCLAA will play another essential role in bringing industry knowledge and issues – as well as identifying knowledge gaps – to these training institutions to help them improve what they’re providing by way of curricula to professionals in the industry.

There are too many initiatives and programmes that SCLAA is conducting in 2023 to mention them all here, but for Sue and the SCLAA the next year promises to be a big one.

“One of the main things I’ve really appreciated this year is a renewed sense of optimism,” Sue says. “There’s a real air of optimism about the future, pride in our achievements, and excitement for what’s to come. And SCLAA is ready to go in 2023 and build on that optimism, recognise those achievements, and contribute to solving problems and developing our brilliant members.” ■

Winner: Officeworks

Officeworks won the Automation, Robotics or Emerging Technology Award for its work modernising its Victorian fulfilment network in response to surging online sales sparked by COVID-19, the workfrom-home movement, and customer expectations for faster delivery times.

Since becoming operational, its new Derrimut facility has boosted capacity, can process 100 per cent more orders than possible at its previous facility, and is expected to process 30,000 lines and 10,000 order per day.

Additionally, the facility is solar-powered, helping to deliver Officeworks’ net-zero ambition to use 100 per cent renewable electricity by 2025.

Winner: Mangala Siriwardhane – B dynamic Logisitics

Mangala Siriwardhane won the Industry Excellence Award for his work revolutionising the supply

chain industry.

Since co-founding the B dynamic Logistics business in 2016, Mangala Siriwardhane has been revolutionising the supply-chain industry by delivering much needed agility, innovation, and affordability in a very tough business climate where the supply-chain industry is challenged significantly.

B dynamic was recognised as one of the best places to work in Australia and New Zealand by the Australian Financial Review in 2022.

Winner: Dematic – Leader Computers

Dematic won the Supply Chain Management Award for its work with Leader Computers upgrading the latter’s Lidcombe warehouse – which houses approximately 8500 different products – by providing an AutoStore™ automated storage, goods-to-person (GTP) picking and fulfilment solution. The system at Lidcombe comprises nine AutoStore robots, three GTP ports, and stores 6662 product bins.

Leader’s adoption of the AutoStore solution has enabled them to make intelligent use of their available space, and streamline picking, packing, and replenishment operations, while also allowing room for future growth.

Winner: TT Logistics (Australasia) Pty Ltd

TT Logistics (Australasia) Pty Ltd won the Environmental Excellence Award for its work in 3PL contract logistics.

TT Logistics (Australasia) Pty Ltd has demonstrated strong commitment to environmental excellence in contributing corporate and government initiatives towards a carbon neutral future.

Operationally, Anzen (safety) is TT Logistics’ top priority followed, by quality, flexibility, visibility,

Supply Chain Management Award winner Dematic.

and innovation.

Each of these elements impacts its operation and consequently all 3PL contract logistics activities it performs for its business partners.

BIG DATA, IT AND BUSINESS INTELLIGENCE

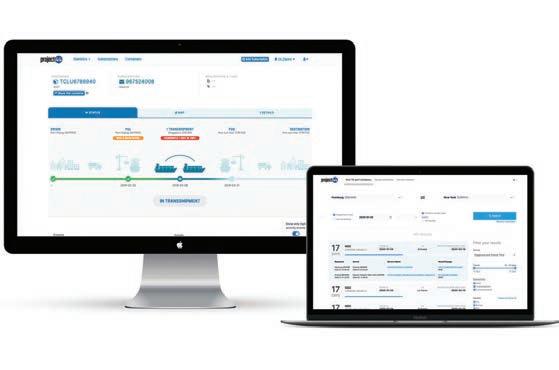

Winner: project44

The Big Data, IT and Business Intelligence Award was given to project44 for its efforts using the world’s best ocean shipping data to untangle the biggest knot in the supply chain: port congestion.

With a mission to make supply chains work, project44 set out to build Port Intel, a trustworthy single source of truth providing better visibility, simplified reporting, and improved flexibility.

Through Port Intel’s comprehensive data capabilities, customers can evaluate and execute the most important supply chain decisions with the highest possible degree of confidence, allowing them to overcome delays and disruptions.

START-UP AWARD

Winner: Ofload

Ofload, the digital end-to-end road freight solution, won the Start-Up Award at the ASCL Awards.

Ofload’s focus is to eliminate waste in transport through technology to support the resilience of small-medium sized transport companies while reducing carbon emissions.

It provides customers a digital cloud-based platform and an endto-end road freight management solution. The platform manages road freight shipments by matching freight requirements to suitable transport companies, eliminating unnecessary waste by ensuring trucks travel full.

Ofload partners with 1600-plus vetted transport companies and, through technology, streamlines the booking process, enabling them to have one point of contact.

Winner: Winning Group

Winning Group won the Training, Education & Development Award at the November ASCL Awards.

The National Training Plan facilitates the development of Winning Services (Winning Group business entity) employees through a growth and development framework created and run by Winning Academy.

Through its ongoing interactive quizzing platform, Winning Group achieved participation results of 87 per cent, a performance rate of 85 per cent, and an improvement rate of six per cent for knowledge improvement (90 per cent pre-campaign to 96 per cent post-campaign).

Winner: ANCA Pty Ltd

ANCA Pty Ltd won the International Supply Chain Award for its achievement in manufacturing a record highest number of CNC machines while dealing with post-pandemic supply chain issues.

ANCA CNC machines managed to double production output in a very short time and could manage to increase the market share significantly.

ANCA started increasing its resilience and agility by kicking off different projects and initiatives in these areas including dual sourcing activities, system improvements, nearshoring,

localising, and revisiting its logistical arrangements.

These among myriad other initiatives earnt ANCA the International Supply Chain Award this year.

JUDGES’ CHOICE AWARD

Winners:

• Ferry Jie – Edith Cowan University Kyra Dagostino accepted the Judges’ Choice award on behalf of Ferry Jie, celebrating Ferry’s outstanding dedication and contribution to the alignment of Industry and Education across many years, and his active involvement in promoting and developing Outstanding Supply Chain and Logistics Management Education.

• Jacqui McCombie – Globelink International Pty Ltd Jacqui McCombie, Managing Director of Globelink for 25 years, won the Judge’s Choice Award for her work as a strong leader in the industry and for being a supporter and mentor to many, including through the SCLAA mentor program, as well as numerous other selfless contributions to the industry.

FUTURE LEADERS AWARD

Winners:

• Nives Gović

For Nives’ dedication to her career, her role, professional development, and industry involvement. Demonstrated through her public speaking classes, women’s mentorship programs and networking groups,

particularly geared towards AU-NZ women in business as well as the local and global level. Currently Nives is the Commercial Manager for DSV Solutions.

• Doreen Vrankar

For Doreen’s commitment and impact to the industry through developing new procedures, attending and running many seminars and work network gatherings, locally and globally. Doreen’s nomination was strongly supported and she has a reputation for excellent customer service that precedes her. Currently Doreen is Sales & Customer Service Manager at Globelink international.

Peter Jones speaks to MHD about whether the ongoing supply chain disruptions will drive network design towards centralisation or decentralisation, what these two business strategies entail, and their advantages and disadvantages.

As e-commerce continues to exponentially grow and disruptions persist, businesses are needing to modify their network designs – including their supply chain models, warehouses and DCs – to deal with increasing consumer demand and new challenges.

Peter Jones, Founder and Director of Prological Consulting, says the changes made to supply chains to deal with the problems the COVID-19 pandemic posed will not be undone.

COVID-19 has been the disrupter that broke what were already fragile supply chains built on the just-in-time principle. Businesses have, since the GFC, assumed everything would work perfectly (most of the time) from purchase order through to fulfilment at every level of the supply chain globally.

The contributing factors to supply chain disruptions that ran in parallel with the pandemic over the past three years have included changes in the US foreign and geopolitical policies, e.g., withdrawal from the Transpacific Free Trade Agreement in 2020.

“The USA stepped out of several equally important treaties or agreements and moved back from existing agreements for the first time since the end of World War II,” Peter says. “This is not a commentary on the merit of these decisions, but it is an example of long-term stability (70 years of consistent policy) transitioning to something new in a short period of time.”

Other contributing factors are the ongoing ramifications of Britain’s

withdrawal from the European Union (EU). The policies rolled out over the past three years have impacted the UK economy – one of the largest in the world – now having flow on effects to the rest of the world.

“There’s been a bit of sabre rattling from some of the other EU members and the possibility of withdrawal from the European Union.

“China is taking a more Sinocentric view of the world while the RussiaUkraine War is ongoing. Russia and Ukraine are custodians of enormous amounts of globally critical resources, from energy to food to rare earth minerals that are required within the new economy, particularly for battery manufacturing and within the automotive industry.

In response we see businesses

engaging in new thinking and setting up contingency plans to recapture some level of certainty as they move forward.

“I believe that the COVID-19 influence will diminish soon enough. But it’s these other factors that will drive supply chain redesign into the next decade. The impact of these geopolitical influences is going to be much longer lasting and be more far reaching than the impact COVID brought about.”

Businesses can deal with the consequences of these geopolitical elements by developing greater levels of security for their supply chains, and one of the simplest ways of achieving this, is having the source of what is required as near as possible while also having the finished product as close to the customer as possible – for most businesses of scale, this will require more “decentralisation.”

Decentralising can result in shoring up of contracts, spreading critical elements, and de-risking supply chains from several angles. More inventory sits in the whole system as a business decentralises while energy, digital, and industrial relations failures become more manageable because, as in any decentralised environment, there isn’t a single point of failure that can bring a whole system down as is possible in a centralised environment.

“In Australia, post-lockdowns and after some businesses went under, there is now a trend away from centralisation and back towards decentralisation to some degree,” Peter adds.

The challenges are significant. The smaller your business, the more difficult it is to decentralise whereas the larger it is, the easier it is to accommodate. When a business decentralises, it needs more inventory, and it goes from having one facility to having multiple facilities.

Unless a business’s inventory is well controlled, its freight costs will quickly increase due to having to support the service promise via a transport network, sending direct-to-customer goods from a non-facing fulfilment centre or DC, rather than a facing one. This can become costly very quickly.

“There’s a direct correlation between freight costs and inventory control when a business decentralises,” Peter says.

Businesses also need to manage more

facilities so there’s a higher headcount as a ratio to sales. These challenges can be offset by increasing market share or sales within a growth market because of the better service offering a decentralised network offers.

“For businesses that are unable to do this, they’re going to struggle moving forward while businesses that can create an advantage through their supply chain to lift market share are going to have a far more agile, flexible, and responsive supply chain network. This is a key learning that has come out of these years of disruption. Smaller businesses can meet these challenges by finding good 3PL partners to fulfil their service requirements.

“Centralisation is a simpler environment to manage from inventory, staff management, and transport perspectives, and that simplicity is not to be underestimated. For a business to decentralise, it requires some maturity in its people, processes and systems and therein lies the risk.”

In an Australian and New Zealand context, fully decentralising will provide a business with the lowest freight cost possible, and a centralised network will come with the highest freight costs.

“The offset is from a warehousing perspective,” Peter explains. “When you only have one warehouse, centralised, your warehouse costs will be the lowest, but when decentralised, they will be the highest – the opposite to the freight cost equation.

“There are playoffs between warehouse costs and in multiplying a business’s footprint. Freight can offset the costs of warehousing and inventory. A

decentralised network affords a business a significantly higher service capability than a centralised one. There’s no prima facie case to say that decentralised network affords a far lower risk profile to a business plan than a centralised network. You have to do the work to determine the outcomes in each case.”

One of the major benefits of a decentralised network, Peter says, is that it’s more environmentally sensitive than a centralised network.

A decentralised network is environmentally lighter than a centralised one, mainly through reductions in transport emissions.

“By sending large volumes as replenishment orders, they create the option to use sea or rail freight or enabling weight and cubic ratio optimisation supporting good road transport utilisation. For Australian manufacturers, they can send bulk quantities to other states and territories in a decentralised network in a more efficient manner and then do all their last mile deliveries from a local environment.

“There is no one size fits all answer globally or nationally as to the centralisation/decentralisation question. In each business, someone must do the work involving infrastructure costs, inventory and freight for each of the potential options.

“Then the options have to be considered by the sales team (or driven by the sales team) as to the market opportunities various options may bring to increasing market share and ‘owning’ your customers because of the advantage developed in supply chain.

“All businesses need to create an unfair advantage through having a supply chain that serves their customers better than their competitors can.” ■

The Gold Coast may be known for tourist-filled Surfers Paradise, enthralling theme parks, invigorating sunshine, a buzzing nightlife, and pristine beaches, but it’s also home to some of Australia’s prime industrial real estate.

Marlon Crawford, Associate Director, Industrial and Large Format Retail and Matthew Adcock, Industrial Sales and Leasing Executive at Colliers, are the forces behind the sale and leasing of key commercial assets in the sunshine state’s second largest city.

Colliers on the Gold Coast covers a range of services for its clients. It provides appraisals and market updates, as well as delivering sale and leasing campaigns.

Its agents deliver clients an idea of where their asset sits in terms of the current market. Generally, a range is

provided rather than the exact value of the property. What has been seen of late is assets exceeding expectations and transacting above this range. The agents have many different sale methods when conducting campaigns – all tailored specifically to each property.

Fostering relationships is at the heart of Marlon and Matthew’s work – and has resulted in the pair working on some exciting projects.

Marlon tapped a local developer – that the team has a close relationship with –to purchase a site in Burleigh that was earmarked for a future supermarket by German chain, Kaufland. Kaufland chose not to enter the Australian grocery retail sector during the COVID-19 lockdowns, leaving an opportunity to transform the tapestry of the southern Gold Coast large format retail offering.

“It was a daunting time,” says Marlon. “We worked with the developer providing feedback and advice surrounding the highest and best use of the site. A large format retail scheme was crafted with the entire project fully leased to national tenants pre-Christmas 2021.

“Once fully let, the development was sold as a tenanted investment. Having worked on the site throughout the various stages, it’s helpful to carry over that institutional knowledge and experience of a property, even when working with different clients, and in our experience they appreciate the knowledge we bring to the table.”

Another recent campaign in the Burleigh Heads precinct is the strata unit development at 90 Kortum Drive. It is described as a man-cave project, with high exposure fronting Reedy Creek Road. The market response was strong, achieving record rates at that point in time. The project was sold out prior to

completion with more than $11.5 million in sales an excellent result for their client.

While Matthew only onboarded with Colliers several months ago, he has seen what the Gold Coast market has to offer, working closely alongside Marlon throughout the central/south sector.

“I arrived at Colliers shortly after Marlon and Jacob wrapped up the sale campaign for 90 Kortum Drive and began working with potential tenants,” Matthew says.

“We were able to successfully lease multiple units, achieving record rates upwards of $330 sqm net. On the back of that we’ve been able to pick up a handful of units in the new Burleigh Head Quarters development along Burleigh Connection Road.

“Cracking 46-unit development with a mix of trade/retail, showroom, warehouse, and self-storage due to be delivered Q1 2023. On top of the leasing rates and sales touching $6000 sqm across multiple developments, Burleigh seems to be standing on its own as we’re still seeing people happy to pay a premium price due to the lack of opportunities to stay closer to home or that Burleigh lifestyle.

“There’s definitely some people who aren’t willing to match numbers with the Burleigh market though, as we’ve begun picking up some good traction on other and possibly more affordable projects across central Gold Coast like The Links Industrial in Carrara, which is another warehouse development with units ranging from 70-260 sqm.”

Marlon recently transacted two investment sales – one of them 13 Northview Street, Mermaid Waters, which was a unique offering in a tightly held exclusive pocket. The property is located

close to the upcoming light rail expansion on the Gold Coast, and a short stroll to the beach. Built in the 1970s, this 500 sqm besser block building backs onto a canal.

“We conducted an Expressions of Interest campaign and received 165-plus enquiries and 12 offers before the close date,” notes Marlon. “This demonstrates that the market isn’t all doom and gloom, demand is still out there for those quality assets. We ended up achieving a sale price above the previous valuation back in February which some might say was the height of the market.”

Another highlight was 112 Bundall Road, a freehold showroom and warehouse leased to a furniture business. It was sold as a tenanted investment with a very low yield due to being below current market rents. “We had it under contract, then it fell through.”

When speaking with National Storage about the Northview Street site where it has an existing operation, they spoke about the 112 Bundall Road, Bundall site, which sits directly next door to their current Bundall facility.

“I sent them the IM, they inspected the property, contracts were drawn up and it was all wrapped up 10 days from there,” Marlon explains. “National Storage was trading at 99 per cent occupancy, and it was bursting at the seams for more storage space.”

The Colliers Gold Coast agents have noticed the surfing city’s population boom during the past three years due to interstate migration driven by COVID-19 lockdowns.

“The population growth has fuelled demand for industrial property,” Marlon says.

“The government stimulus available and low interest rate environment was encouraging people to get into the market and purchase, there has been decentralisation from capital cities, and groups are more accepting of regional centres – which underpins this demand from our recent campaigns. Demand is still there, but commitment from the market has softened a little.

“I think now investors are factoring in further interest rate increases, the looming market downturn and I guess they are just happy to wait and see what happens over the few months. Interested

investors and renters are making plenty of enquiries about assets in Burleigh. Just like everywhere else, it’s massively undersupplied. There’s a lot of demand, but lack of opportunity.”

“We’re seeing premium rates across land, sales and leasing along the Coast because of this,” Matthew adds. “Rental growth on the Gold Coast can probably thank the high demand.

“In saying that, we are restricted on the Gold Coast due to the land scarcity of centrally located sites, rising construction costs are putting pressure on new stock coming to market, and low interest rates are encouraging investors to park their capital in real estate assets – there are so many factors driving rates upwards. Despite the premium rates here, the Gold Coast is cheap compared to other markets such as Sydney.”

The e-commerce boom and manufacturing problems coupled with supply chain issues in Asia, have prompted local businesses to ramp up their processes locally, which has benefitted the local Gold Coast and national Australian economy.

The Australian industrial market is yet to experience any downturn, notes Marlon, with only yields softening. “Land values, rental rates, and capital value rates will hold the same and probably continue to increase.”

“Trophy assets are still in huge demand with investors,” Matthew concludes. “The only trouble seems to be getting your hands on them.” ■

Contact Colliers today to learn more about the Gold Coast Industrial market and how to meet your property needs.

Supply chain consultancy, Pollen Consulting Group, joined Argon & Co in June 2022. Paul Eastwood, Managing Partner, looks back at what the company has achieved in the past six months, what it sets out to achieve in 2023, and predicts what challenges may lie ahead for the industry.

New Zealand of Intent Group to scale our footprint over there, and it really gives us the team size we’ve needed to compete in that local market.”

When Paul started Pollen Consulting Group, he says part of his vision was to have 100 people that love working for a consultancy business as much as he does. This is a milestone he’s now achieved. In the next couple of years, he aims to increase this number by 50 per cent.

Supply chain and manufacturing specialist, Pollen Consulting Group, joined Argon & Co – the global management consultancy specialising in operations strategy and transformation – in June 2022. December marks the first six months since the Sydney-based SME merged with the British-French business.

The Pollen integration came on top of the 2018 merger between the French Argon Consulting and the UK-based Crimson & Co – which formed Argon & Co. Paul Eastwood, the company’s Managing Partner, says significant progress has been made in the ANZ region in the past six months.

Paul says lots has changed within Argon & Co in the short period since the merger.

The old Argon & Co in Australia led

from a supply chain and planning point while Pollen Consulting Group led from a manufacturing point.

What hasn’t changed is the way the company behaves as a business – the fundamental approach to consulting has remained the same. When Pollen amalgamated with Argon, it continued to provide exceptional quality services to its clients by developing end-to-end solutions. But now, its capabilities have been amplified.

“A lot has changed in terms of capability,” Paul explains. “When we combined the two businesses, we had around 60 people in Australia and New Zealand. We now have 100. Since January, we added those extra 40 people, of which about 20 to 25 of them have been procured due to customer and capability demand.

“We also completed an acquisition in

“We’d like to add 250 new employees and deliver great results along the way. We don’t stretch ourselves or our capabilities too far. We are already supporting new sectors, but we are growing in a sustainable way such that we ensure we are always delivering on what we’re doing now before we take another step to grow the company further.

“We will evolve and move the market dynamics within those sectors, whether that means more growth towards the retail e-commerce side, where we’re seeing quite a lot of businesses need help to unpick what they did to respond to COVID and become more efficient in a long-term sense.

“We’re working with food and beverage businesses and we’re moving into other sectors, such as industrial and chemical. However, what we won’t do is suddenly jump into sectors we don’t really know or understand. We will only work where we can give real advice.”

The Argon & Co team is flexible and

services the whole of Australia, while catering to clients’ individual needs.

If customers have people working with them who have multiple sites in several locations, and prefer to use the same people, Argon & Co has the flexibility to service multiple locations.

“The business has traditionally been heavily weighted towards Sydney – where currently we have 60 people,” notes Paul. “We’ve got most of our team here. We now have just over 15 to 20 people down in Melbourne, with the office having opened in May or June. We continue to grow that office – it’s a priority and a focus.”

Some employees live and work remotely while providing regional support. Another 12 to 15 are based in the Auckland office, which is the main site for New Zealand with an additional eight spread around the North and South Islands.

Over the past six months, Paul says Argon & Co has grown while still retaining the cultural values upon which its original success was built: energy, pride, and humility. These are qualities staff show when working with clients and acting as partners. They proudly live and breathe their clients’ successes, Paul says.

“We’re making sure we don’t lose that entrepreneurial side of growth and thinking,” he adds.

“When you’ve got 50 people, you tend to know everybody and you tend to know everything that’s happening in your business, but as you grow and scale you need to put a little bit more structure around training and development of the team.”

Argon & Co has invested in and launched a graduate program because it sees the importance of growing capability in Australian supply chain, logistics and operations. “This will help us build our longer-term business.”

During these six months, Argon & Co has also moved offices, yet maintained the professional and polished look and the atmosphere it had when it was Pollen Consulting Group.

When Argon merged with Crimson in 2018, it envisioned a global consultancy platform focused on operations strategy and business transformation. At the time, its workforce was 250 to 300 employees. Over the last four years, it has expanded to 470 employees worldwide as part of the

company’s main strategy.

The strategy involved amalgamating with businesses, like Pollen Consulting Group, that share its values, talent, and commitment to excellence. It also means it can create a global footprint by using the underlying growth of the businesses and present service propositions globally, including opening new offices in locations such as Hong Kong, the Middle East, and North America.

Argon & Co’s key focus is to service Australian CEOs and to deliver business transformation. Some of its teams are working on capabilities and on growth strategies in this space. It has 500 staff globally and aims to expand this to 1200 in the next five to seven years.

“Our business has delivered some interesting and exciting projects in the digital twin space, which continues to go from strength-to-strength, as we work on different manufacturing footprints today, different warehouse designs tomorrow, and something completely new the day after.

“Traditionally, testing facilities isn’t easy, so the ability to build a facility in a virtual world before you go and put a lot of money into it has got some exciting value to it.

“We are building digital twins in Simio, the simulation modelling solution. It gives us a platform to create a 3D model of factories while running with real life variability – so you can go and see your future factory, and you can test it and see the risks associated with the design.

“It uses smart data analytics and modelling to replicate real life simulation,

and if you’ve done it 1000 times you learn it will be different every time – in the same way every day is different in a factory or a warehouse. So, it’s a vital tool in forward planning and future proofing your operations.”

In the next six months, Argon & Co plans to return to in-person events and meeting clients face-to-face.

“We’ll help our clients through the next six to 18 months of pressures. There are more dynamics to balance now than ever before. You look at today’s market and you’ve got sustainability coming in from one angle, you’ve got cost inflation, changing customer preferences and behavioural demand patterns, and the external macro impacts of what’s going on in the rest of the world.

“We need to think about having a lean operating model, how to set up the business for the future, and manage to balance all these priorities along the journey. An efficient platform is a sustainable platform.”

Paul says that the next six to 12 months is a defining time for Argon & Co’s clients and that Argon is ensuring it focuses on their needs and supporting them through the challenges and opportunities of 2023.

“I certainly look back over the last six to nine months and think it’s been an incredibly exciting journey, and one that has given me a new sense of energy.

“We’ve created a global management consultancy business. So, when we look back in five, 10 years’ time, we’ll have a global footprint of 1200, 1500, maybe 2000 people – and to know one of our offices in Australia played a key role in developing that is really cool to me.” ■

The growing pressure on companies to act on sustainability means that their supply chains are expected to be greener, too.

Körber Supply Chain on putting sustainability at the heart of the industry.

Over the past few years, Australian companies and their supply chains have been inundated with a growing number of disruptions, fuelled by megatrends such as globalisation, technological advancements and, most concerningly, climate change.

No longer something we can ignore, sustainability has become the key driver for business success and is essential to the positive public image of any organisation.

With increasingly environmentally conscious consumers now playing a central role in forcing companies to embrace sustainable business practices – including managing the environmental and social impacts of their supply chains – the time for our sector to act is now.

According to research by global market research company NielsenIQ, 73 per cent of consumers say they would either ‘definitely’ or ‘probably’ change consumption habits to reduce their impact on the environment. As Australian consumers demand products that are sustainably sourced through a supply chain that has a minimal impact on the natural environment, today’s operations are having to move quickly to ensure their business is more sustainable and ethical.

At Körber Supply Chain, we have seen first-hand how climate change has directly impacted our economy,

livelihoods, and health.

Disruptions caused by extreme weather events have had an impact on all regions and all sectors. Perhaps in no other sector has the impact of climate change been felt more significantly than within the global supply chain.

Here in Australia, the climate risks of greatest concern are rising sea levels, extreme rainfall and wind, increasing intensity of cyclones and tropical storms, and higher temperatures.

These risks have already resulted in coastal recession, flooding of essential public infrastructure, loss of transport access, heatwaves, and an increasing frequency of bushfires.

We all witnessed first-hand the unprecedented nature of the bushfire seasons of 2019 and into 2020. Key infrastructure was closed, including some highways and ports. Production lines were damaged, and consumer spending tumbled. Several key freight routes were closed, heavily impacting the supply of goods – forcing companies to find alternative routes. Further, data from AccuWeather estimates the total damage and economic loss caused by the wildfires to exceed $110 billion

To avoid similar devastation in the future, our supply chains must start to put sustainability at the heart of their operations today.

At Körber Supply Chain we are committed to making the world a greener place by building a more sustainable global supply chain network. For many years we have placed sustainability at the front of our minds and this trend will increase in the future, together with a focus on climate change risks.

As larger companies make public promises to become more eco-friendly, they are also holding their suppliers to the same standards. It is therefore more important than ever before that we all have a sound understanding of our processes and how our suppliers procure their goods.

To facilitate this, there are several practical solutions to make your supply chain more sustainable, reducing both your waste and your carbon footprint, and managing costs – all while increasing profitability. From pushing companies to rethink the use of plastic in packaging and increasing efforts to use recyclable materials, to overhauling vehicle fleets and making the move to electric vehicles, as well as introducing more automation to our warehouses.

Companies of all sizes and industries can introduce a variety of supply chain software and automation options to reach

their sustainability goals. Technologies such as autonomous robots, warehouse management systems, and artificial intelligence, will all play a critical role in allowing the continued functioning of a greener and cleaner supply chain.

Advanced software and automation technologies will reduce energy waste in warehouses, shrink carbon footprint and decrease costs for both energy and materials. With the help of robotics –such as drones, Automated Mobile Robots (AMRs) and artificial data intelligence – businesses can increase productivity, efficiency, and product quality, as well as become more sustainable largely due to increased accuracy and reduction in energy consumption.

By keeping up with the pace of change and embracing the innovation in our industry, we must leverage the technologies available to us today in order to achieve increased visibility, energy efficiency, and waste minimisation across the entire supply chain operation.

As the demand for eco-friendly products and services grows, so too does the risk of companies overstating their sustainability credentials in order to attract and retain customers and investors. This is known as greenwashing – the practice of misrepresenting the extent to which a product or strategy is environmentally

We all witnessed first-hand the unprecedented nature of the bushfire seasons of 2019 and into 2020. Key infrastructure was closed, including some highways and ports.

friendly, sustainable or ethical.

With so much pressure on businesses to be greener, many organisations are trying to use their credentials on sustainability to gain a competitive edge. Recently, however, Australian companies have been put on notice about greenwashing after the Australian Competition and Consumer Commission issued its first ever fine for greenwashing.

While there has been an increase in investor demand for, and the availability of, sustainability-related products in the Australian market, there has been a growing risk of greenwashing. Greenwashing can take many different forms, ranging from exaggerated or imprecise claims to those intentionally crafted to deceive or mislead. Although initially used in the context of environmental statements, it now extends to broader sustainability concepts. It is therefore important that we, in the supply chain, comply with existing requirements when promoting or offering sustainability-related products.

The growing pressure on companies to act on sustainability means that their supply chains are expected to be greener, too. Research has shown that for most companies the supply chain is responsible for the bulk of their environmental

impact. By their very nature, supply chains often involve energy-intensive production and transportation, as goods are made and moved around the globe. Therefore, organisations can often make the biggest difference by making changes to their supply chain.

As the push for sustainable development gains momentum, driven by key stakeholders such as investors, financiers, regulators and customers – the scope broadens from mitigating climate risk to broader social considerations in line with global targets. As awareness grows about the need for sustainable development practices there is now a mounting focus on a broader spectrum of issues, which includes social and corporate governance concerns.

Developing and operating a sustainable supply chain strategy will help improve investor and consumer perceptions, manage costs and drive innovation, as well as build a resilient supply chain that leads to long-term financial viability.

It cannot be overstated how much making a change today will impact the future of our supply chains. Under pressure from consumers, competitors, and national and international regulations to meet better sustainability standards, supply chains should waste no time in ramping up their efforts to be both more sustainable and more ethical. ■

How a Toyota forklift is making life easier for NSW solar panel specialist.

energy storage technology, Paul was impressed by the batteries used in the Toyota forklift and the fact that he can run the machine inside his hangar without worrying about exhaust fumes.

Paul has outfitted his hangar with a comprehensive solar arrangement that allows the structure to exist off-grid, with all power for the building sourced through solar power.

That means his Toyota forklift essentially exists with zero carbon footprint, due to all charging being done on-site with electricity sourced exclusively through solar power.

Despite being a big investment for a small business, Paul’s forklift has been a great purchase for BlackLab Solar, helping him stay on top of logistics in the warehouse.

Asmall New South Walesbased solar energy specialist has turned to the classleading reliability and safety of Toyota Material Handling Australia (TMHA) forklifts to help his burgeoning business.

BlackLab Solar, based in Rylstone in central NSW, is run by owner and licenced electrician Paul Deegan and specialises in high-quality solar installation and maintenance.

Paul essentially does all of BlackLab’s installation, maintenance and ordering himself – a big enough job on its own, let alone when it’s being done without the right equipment.

After operating for a few years using an older diesel forklift bought from a neighbouring farmer, Paul made the choice to upgrade and purchase a new machine.

A former pilot, Paul was using his

hangar at Rylstone to store solar equipment following a period of heavy rain and needed a forklift that was ideal for indoor operation.

After looking at a couple of options, he quickly settled on an 8FBE20 electric forklift, with the material quality of Toyota products a big reason for the purchase.

“This new one’s been an absolute delight, it’s fantastic,” Paul says. “I wasn’t price-driven, I just wanted the best.

“Compared to the old one it’s a precision machine. You move a lever, and it moves exactly. It’s just great.

“Every time I get on it I just think ‘How good is this?’, because in the old days starting the business I was in Sydney and I had my kids handloading the solar panels, and now I’ll lift six pallets off a truck and it’s done in 15 minutes.”

Being an expert in battery and

Paul has now owned his Toyota forklift for approximately one year, and has been impressed by its precise performance and faultless reliability.

He also spoke highly of his relationship with TMHA and area sales manager Richard Bopping, who has helped to make the ownership experience as seamless as possible.

Paul says there were no current plans to expand the BlackLab business, but if he needed any new equipment, TMHA would be his first port of call, regardless of product.

A qualified electrician for 20 years, Paul started BlackLab Solar after working as both an electrician and pilot based out of Rylstone, including with the Royal Flying Doctor’s Service.

After flying planes for around 10 years, Paul re-entered the electrical industry with an emphasis on solar installation and ongoing service and maintenance, gaining qualification for solar, off-grid, and hybrid installations.

The company has an emphasis on producing solar installations of the highest quality, referencing the Benjamin Franklin quote: “The bitterness of poor quality remains

long after the sweetness of low price is forgotten.”

With the business placing such an emphasis on high build quality, it is no surprise that Paul gravitated towards TMHA, with impeccable reliability and durability a key tenet of the brand’s philosophy.

Toyota 8FBE battery electric forklifts have the latest control technology, coupled with an ergonomically designed operator compartment.

Outstanding energy efficiency has been achieved with new motors and drivers, to improve operating time by 20 per cent compared to the previous model.

Key safety features include Toyota’s System of Active Stability, to reduce the risk of tip-overs, and Active Mast Function Controller to limit mast angle and forklift speed according to load height and weight.

Despite being a big investment for a small business, Paul’s forklift has been a great purchase for BlackLab Solar, helping him stay on top of logistics in the warehouse.

“It’s made a huge difference – I’m

43 years old and I’m almost singlehandedly running a million-dollar business,” he says.

“And having that machine, knowing I can jump on it, get the panels in the back of a truck in 10 minutes and I

know the thing is going to start – I know it appeals to someone like me.” ■

For more information freecall 1800 425 438 or visit www. toyotamaterialhandling.com.au

Combilift has gone from strength to strength in 2022. MHD speaks with Managing Director Martin McVicar and Country Manager Australia Chris Littlewood about the company’s growth, its sustainability achievements, and why pedestrian vehicles are in hot demand Down Under.

022 has been another record year for Combilift,” says Martin McVicar, Managing Director. “We’ve broken previous records in terms of both output and revenue, as well as in our employee numbers – we now have more than 750 people in our manufacturing plant in Monaghan, with another 130 or so overseas.”

Amidst supply chain uncertainty affecting the procurement of components for their path-breaking material handling equipment, Combilift has nevertheless continued to keep up the pace this year in terms of orders and innovation.

Ensuring the seamless supply of its products has involved taking a financial hit, in some cases, says Martin, but is worth it in the long term.

“It hasn’t all been plain sailing,” he says. “Anticipating the continuing supply chain challenges that would affect us this year, in 2021 we made a strategic investment to extend our factory and increase its capacity to supply more inventory on site. Having

that buffer stock of components has allowed us to get through some of the ripples affecting supply chains this year.”

In one instance, when the supply of a particular chip for the vehicle’s display panels appeared to be under threat, Combilift made alternative arrangements to procure the chips from another source – spending US$115 per chip compared with the standard three euros – in order to guarantee its ongoing production and delivery.

“That’s an extreme example, of course, and we haven’t done that in many cases,” Martin says. “It’s just one example of where it has cost us money to deal with supply chain issues or uncertainty – but we always keep our eyes on our longer-term brand promises even if it means taking a short-term hit.”