Woodhouse Timber boosts efficiency with BHD’s optimised storage solutions.

Argon & Co integrates AI to enhance sustainable supply chains efficiently.

TACKLING PEAK PERIODS EMBEDDING SUSTAINBILITY

Vanderlande automates warehouses to tackle peak-period challenges, optimise space, and enhance efficiency.

To address the rapidly evolving e-commerce landscape, fashion 3PL Radial partnered with Dematic to implement an advanced Bin-to-Picker AMRs solution with intelligent software, designed to signi cantly reduce order processing times and operational costs. The result is enhanced supply chain ef ciency, allowing Radial to meet customer demands swiftly and accurately.

With improved inventory management, increased order accuracy, and higher customer satisfaction, Radial enjoys a scalable, robust ful lment system that adapts to market changes and seasonal peaks, setting a new standard in e-commerce ful lment.

Learn more at dematic.com

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Mike Wheeler

Editor: Phillip Hazell

Journalist: Mannat Chawla

Business Development Manager: William Jenkin

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Danielle Harris, Jacqueline Buckmaster

Client Success Manager: Justine Nardone

FOR ADVERTISING OPTIONS

Contact: William Jenkin william.jenkin@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST)

1yr (11 issues) for $99.00 2yrs (22 issues) for $179.00

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

The past few months have seen significant shifts in infrastructure, logistics, and freight transport – changes that reflect the evolving demands on industry and the need for more sustainable, efficient, and resilient supply chains.

The WA Government’s decision to formally cancel the Roe 8 and 9 Perth Freight Link project marks a decisive shift in urban and regional planning. By removing the road reservation and rezoning areas for mixed-use development, the government is prioritising long-term sustainability, housing, and community development over outdated infrastructure plans. While controversial, this move reflects a broader trend in industry – where adaptability and futureproofing take precedence over legacy projects that no longer align with economic and environmental priorities.

Similarly, the proposed return of WA’s freight rail network to public hands highlights a growing recognition of rail as a critical component of a modern, efficient, and environmentally responsible freight system. With record grain harvests and increasing demand for reliable transportation solutions, government intervention could provide the necessary flexibility and investment to revitalise rail networks, reduce road congestion, and support key industries more effectively. This is not just about ownership – it’s about ensuring infrastructure keeps pace with industry growth.

On the corporate front, FedEx’s decision to spin off its freight division into a separate publicly traded company

underscores a fundamental shift in global logistics. As markets evolve, so must businesses. By tailoring investment and operational strategies to the distinct needs of parcel and freight logistics, FedEx is positioning itself for more agile growth, improved customer service, and greater shareholder value. This kind of structural adaptation will likely become more common as companies seek to refine their focus and strengthen their market positions.

Closer to home, the A$400 million investment in Port Botany’s rail infrastructure demonstrates the importance of strategic, future-focused investment in Australia’s supply chains. By increasing rail capacity and reducing truck movements, this project aligns with global trends of moving freight more efficiently while cutting carbon emissions. Each of these developments – from urban planning reforms to infrastructure investments – reflects a fundamental truth: the supply chain and logistics sector must continuously evolve. As we navigate these changes, it will be important to strike a balance between meeting today’s needs and planning for long-term resilience. While challenges remain, ongoing investment and innovation in the industry will help create more efficient

Phillip Hazell Editor, MHD Supply Chain Solutions

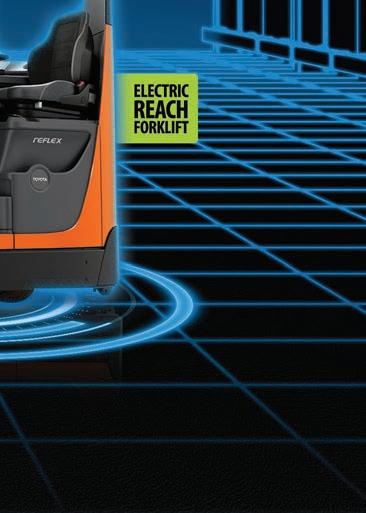

TRUSTED TOYOTA MANUFACTURING

For over 60 years Toyota has been at the forefront of the materials handling market. From our patented System of Active Stability™ safety technology to our exclusive I_Site telematics system, our spirit of innovation drives our continuous improvement. We’re also proudly committed to a sustainable future with one of Australia’s most comprehensive ranges of zero operating emissions forklifts designed to be up to 99% recyclable, and that’s just part of the Toyota Forklift Advantage.

*System of Active Stability available only on selected Toyota Forklifts.

PROUDLY DISTRIBUTED BY TOYOTA MATERIAL HANDLING

14 BHD Storage Solutions teamed up with Woodhouse Timber to maximise warehouse space, streamline operations, and boost logistics efficiency.

20 Argon & Co supports businesses in integrating sustainability into supply chains.

24 Addverb transforms 3PL logistics with robotics and AI, enhancing scalability, operational flow, and end-to-end visibility.

30 Vanderlande strengthens supply chain performance with automation, omnichannel strategies, and AI-driven logistics.

27 Jungheinrich’s POWERLiNE series improves warehouse operations with lithiumion technology, ergonomic design, and automation.

34 Toyota Material Handling Australia supplies 49 forklifts to Refresco, ensuring safety, reliability, and performance across its beverage supply chain.

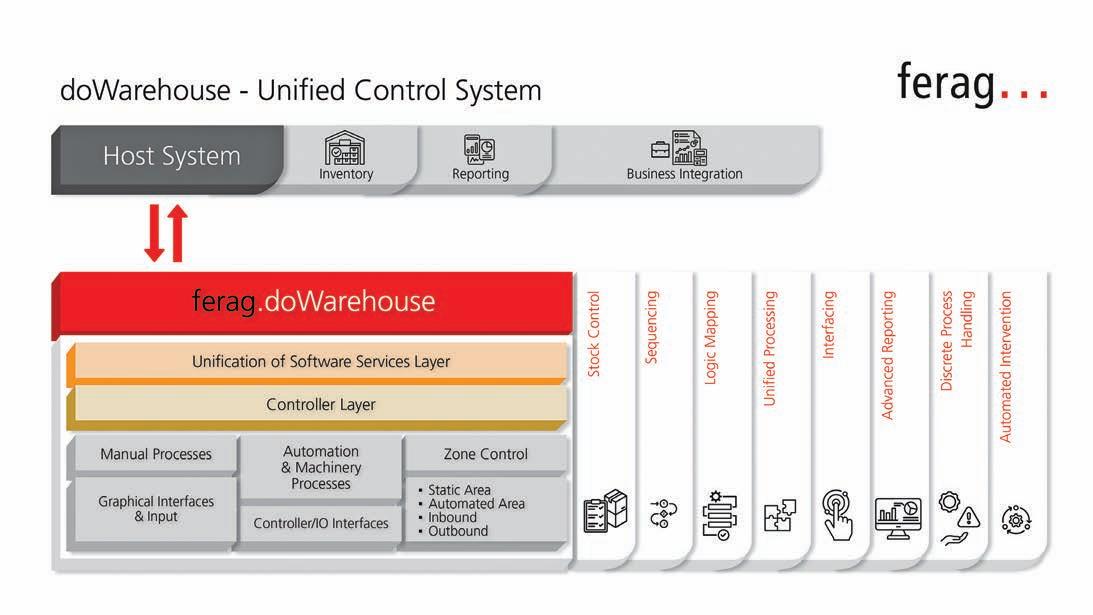

36 Ferag evolves from print specialist to intralogistics leader.

As part of its expansion, Woodhouse Timber partnered with BHD Storage Solutions, installing 196 cantilever columns to maximise capacity, reduce costs, and improve inventory management efficiency.

03 Ed letter

06 Industry News

40 Special Feature: Australia’s ports face congestion challenges, prompting major investments in rail, infrastructure, and cybersecurity to boost efficiency and resilience.

44 Industry Insight: Lessons from a recent World Economic Forum report provide insights on how nations can enhance competitiveness.

47 Special Feature: Australia’s logistics sector overcomes vast distances with infrastructure upgrades, drone advancements, and innovative last-mile delivery solutions.

50 People on the Move

53 Association Commentary: SCLAA

56 Association Commentary: ASCI

58 Product Showcase

Perth Markets Group Limited (PMGL) completed its latest multi-tenant cold chain warehouse in late December 2024.

The new facility, known as S2, is located at PMGL’s 51-hectare Canning Vale site and aligns with the company’s commitment to developing infrastructure that supports Western Australia’s fresh produce industry.

The warehouse is a purpose-built standalone facility spanning more than 3,500 square metres. It features twostorey internal offices, 9.1-metre-high cool rooms with motion sensor highperformance rapid doors, and recessed rear-loading docks equipped with dock levellers, restraints, and shelters. With full drive-around road circulation, the warehouse is designed to enhance logistics efficiency and facilitate seamless distribution within the retail and fresh produce supply chain.

PMGL Chief Executive Officer, Scott Gibson, highlighted the significance of

the new development.

“As Western Australia’s only fresh food wholesale market, it is integral we continuously grow and deliver infrastructure that supports, strengthens, and meets the demands of the fresh produce supply chain,” says Scott.

PMGL Chief Property Officer, Shaun Atkins, who oversaw the development and leasing of the warehouse, emphasised its strategic value.

“These warehouses are incredibly important to the growth and success

of our tenants – it gives them the opportunity to consolidate their site operations, deliver efficiencies and underpin continued expansion in the future,” says Shaun.

The completion of the S2 project forms part of PMGL’s ongoing investment in infrastructure to support WA’s growers, wholesalers, and fresh food retailers. Further opportunities will be made available following a strategic review of the precinct’s master plan. ■

Hardware that makes technology last longer on the Moon is among a suite of Australian space projects being backed by the Australian Government.

Five projects will share in the $3.6 million Moon to Mars supply chain capability grants, building on homegrown expertise and getting more Australian-made products and services into space.

“These investments will help further embed us in the global space supply chain, working on the global Moon to Mars mission,” Ed Husic, Minister for Industry and Science.

Among them is South Australian company entX, which will receive $1 million to develop a radioisotope heater unit. The unit will help payloads withstand the low temperatures on the moon, extending their lifespan.

“Through this investment, we are

• Advanced Navigation (NSW) –$856,077 to develop a space-grade navigation system for launch and space service providers. This will ensure the navigation trajectory of rockets is maintained correctly and safely.

helping Australian companies gain crucial space heritage and grow strong customer bases – which will generate more opportunities for Australia to collaborate on the global stage,” says Enrico Palermo, Head of the Australian Space Agency.

The other projects being supported are:

• Space Services Australia (ACT) – $556,189 to enhance its digital platforms that allow companies to test satellite models based on specific space events. This will improve the ability to respond, protect and extend the duration of their technologies.

• Fleet Space Technologies (SA) –$994,956 to develop a cutting-edge gravity measurement instrument that will improve exploration for critical minerals.

• Element Robotics (VIC) – $257,479 to expand its technology which simulates missions and operations on the surface of the Moon. ■ These projects will get more locally made products into space. Image: AdobeStock /pe3check

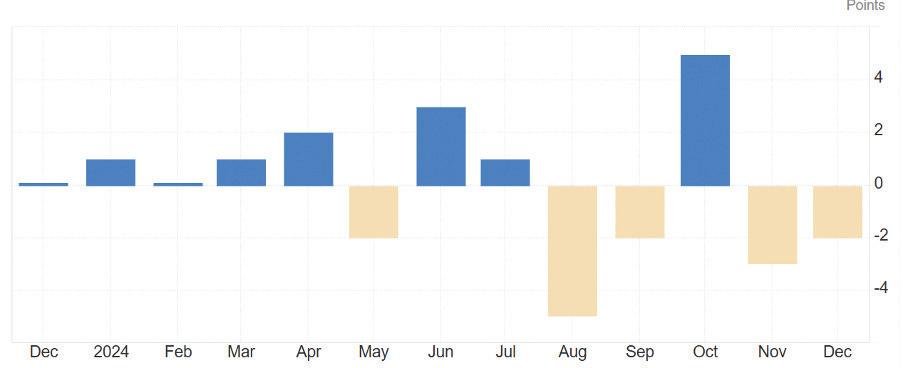

Australia Post has set a new record for its busiest peak period, with almost 103 million parcels delivered from 1 November to 31 December 2024 (up 3.1 per cent from last year), according to its latest quarterly Inside Australian Online Shopping Report.

Across the country, Health and Wellness were the crowd favourites, with a 20.5 per cent increase in the number of online purchases year-onyear (YoY). They were followed closely by Athleisure and Tools & Garden, which increased 15.8 per cent and 14.6 per cent, respectively.

In November and December, 2,800 parcels were delivered to Australian households every minute, and 7.6 million Australian households made at least one online purchase, representing

a 2.4 per cent increase from last year.

While shoppers in each state and territory snatched bargains in the online sales events, it was Northern Territory (up 12.4 per cent), Tasmania (up 11.4 per cent), and South Australia (up 8.9 per cent) that saw the strongest YoY growth. Nationally, the three top suburbs for online shopping were Queensland towns Mackay and Toowoomba and Victoria’s Point Cook.

“On its busiest day, 9 December, Australia Post delivered over 3 million parcels, and 2 million deliveries per day for more than 30 days,” says Gary Starr, Australia Post Executive General Manager Parcel, Post, and eCommerce services.

“The record volume of deliveries reflects Australia Post’s ongoing investment into new and upgraded

4.6 million

Aussies used the Aus Post app to track their parcels in November and December. Image: Australia Post

parcel facilities, technology and fleet as well as a commitment to improving services for online shoppers”

More than 4.6 million Aussies used the Aus Post app to track their parcels in November and December, with a record 57 million visits in December alone, meaning more customers were able to simply manage their delivery experience than ever before. ■

The WA Government has cancelled the Roe 8 and 9 Perth Freight Link project by amending the Metropolitan Region Scheme (MRS). The amendment removes the road reservation, protecting key environmental and heritage areas for Parks and Recreation.

The finalisation of the MRS amendment follows an engagement program with stakeholders. Image: AdobeStock/Imagevixen

be rezoned for urban uses, which allow opportunities such as housing, local open space, recreation, private education, and commercial and mixeduse, which will be determined through subsequent stages of planning.

“This amendment marks a significant milestone in the WA Government’s 2017 election commitment to scrap the destructive Perth Freight Link project,”

says Planning Minister John Carey.

“The road reservation has long been a barrier to planning for the Fremantle/Cockburn area, and the finalisation of this amendment provides certainty to all stakeholders and the community that this road can no longer go ahead.

“The inclusion of urban-zoned land also enables a mixture of other local uses to be contemplated through subsequent stages of planning, with opportunities to boost housing supply and rejuvenate parts of the corridor.”

Despite opposition from the WA Greens, who introduced a disallowance motion on the final day for the MRS amendment, the Bill has been passed, officially ending the Roe 8 and 9 Perth Freight Link project.

The finalisation of the MRS amendment follows an engagement program with stakeholders including local governments, community groups, local education providers, recreation groups and the broader community. ■

Built for versatility, the Cruiser 360 demonstrates flexibility by moving items in X, Y, and Z axes for seamless storage.

Upgrades to Thomas Road will include duplication of 4.5 kilometres between Kargotich Road and South Western Highway Image: AdobeStock/Jana Schönknecht

Aroad project in Perth’s south has reached a critical milestone, with a contract now awarded. The $1 billion Tonkin Highway Extension and Thomas Road Upgrade Project will see the transformation of the southeast of Perth, delivering a 14-kilometre extension of Tonkin Highway as well as upgrades to Thomas Road.

The extension of Tonkin Highway will include a four-lane dual carriageway from Thomas Road to South Western Highway, including several grade-separated interchanges, underpasses and roundabouts.

“This project will deliver significant benefits to Western Australia’s freight and logistics network, by creating a high-standard north-south transport link, improving road safety, freight efficiency, and connectivity for residents, businesses, and commuters,”

says Catherine King, Federal Minister for Infrastructure, Transport, Regional Development and Local Government.

The project will also cater for the recreational needs of the area with several equine underpasses, and a new principal shared path along the entire 14-kilometre extension.

It will also benefit local communities in Byford, Armadale, Kelmscott and Gosnells, which currently contend with large volumes of heavy vehicles on local roads, travelling to and from the South West and Wheatbelt regions.

Upgrades to Thomas Road will include duplication of 4.5-kilometres between Kargotich Road and South-Western Highway, new principal shared path and upgrades to a number of local intersections including Kardan Boulevard, Masters Road and Plaistowe Boulevard.

“The extension of Tonkin Highway

will be a game-changer for the movement of freight to and from the South-West and Wheatbelt and provide a safer road network for people living in suburbs like Byford, Armadale, Kelmscott and Gosnells who currently contend with large volumes of heavy vehicles on local roads,” says Rita Saffioti, WA Deputy Premier and Minister for Transport.

Construction of the project is scheduled to commence in mid-2025 with completion anticipated by late2028 and is set to support around 4,400 direct and indirect jobs, marking a boost for the local economy.

The contract to deliver the project has been awarded to the Tonkin Extension Alliance consortium which includes BMD, Civcon Civil and Project Management, Georgiou Group, BG&E, and GHD. ■

Through multidirectional movement and sequencing, Vanderlande’s shuttle-based automated storage and retrieval system (AS/RS), ADAPTO, delivers goods fast and accurate in the appropriate order, enabling same-day deliveries.

Learn how Vanderlande customers bene t from FASTPICK to e ciently handle both their e-commerce and store orders.

> vanderlande.com

DB Schenker has opened a new facility in Sydney’s west. With a strong presence across Australia and New Zealand, DB Schenker has been expanding and introducing initiatives to pursue our broad sustainability ambitions across our sites and facilities.

The Sydney warehouse, over 17,000sqm, has been built to a 5-star Green Star rating, designed to meet the highest standards of sustainability and operational efficiency. This certification indicates that the

site is future-ready, protecting the community’s biodiversity and ecosystems and contributing to market transformation and a sustainable economy.

Features of the site include solar panels and water heating, as well as rainwater collection and reuse. It was also ensured that facilities encouraged emission-reduced commuting through EV charging stations, bicycle parking and car share spaces.

“The opening of this new site shows our dedication to serving the

region by providing the right space and operational facilities in much needed locations for our customers, teams, and the community,” says Craig Davison, CEO Australia and New Zealand Cluster.

This new facility represents a milestone in our efforts to enhance our logistics capabilities and the custom fit out allows us to better serve our customers in the Hi-Tech Electronic segment with improved efficiency and reliability,” adds Craig. ■

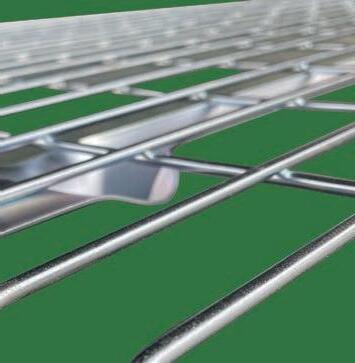

Woodhouse Timber partners with BHD Storage Solutions to optimise warehouse efficiency, expanding storage capacity and reducing unproductive floor space.

Woodhouse Timber, a familyowned timber wholesaler established in 1983, partnered with BHD Storage Solutions to enhance its storage infrastructure.

Founded by Chris Woodhouse, the company has evolved from a small Brisbane warehouse into a prominent national timber wholesaler in Australia.

Initially focused on dressed timbers and interior mouldings, Woodhouse transitioned to using plantation timber from New Zealand, placing an emphasis on sustainability. Its flagship product, Weatherproof, is known for its distinctive pre-primed pink finish, designed for exterior use.

The company has evolved under the leadership of the Woodhouse family, leveraging new technologies and operational efficiencies to improve its warehousing and logistics.

Woodhouse Timber’s transition to second-generation leadership has shaped its direction, combining industry experience with modern innovations. Mark Woodhouse serves as Managing Director and Drew is the Director of Warehouse Operations and Health and Safety. The shift in leadership brought a fresh perspective, particularly regarding innovation and efficiency in warehouse management.

“My brother and I grew up in the business, working in all facets from a young age,” says Drew. “This helped us gain a deep understanding of its operations. With changes in technology and warehouse management solutions, we saw an opportunity to improve our storage infrastructure.”

One of the key changes the new leadership brought was a focus on warehouse technology and efficiency.

“The changes in technology and growing up in that world really gave us an opportunity to look into, and explore ways, we can develop our warehouses with the new technology and the new things that are coming out,” says Drew.

Despite the company’s growth and evolution, its core values remain unchanged.

“We are a family business. Work-life balance is something that we strongly

push to our staff members,” Drew says. “We do find we get the best out of our family here at work by ensuring staff are supported and get to have that proper work-life balance.”

To manage its increasing inventory efficiently, Woodhouse Timber turned to BHD Storage Solutions.

BHD Storage Solutions provides a

range of warehouse storage systems designed to maximise space and improve operational efficiency. With more than 30 years in the industry, the company supplies pallet racking, cantilever racking, shuttle racking, mobile racking, and mezzanine systems to businesses across Australia.

Its pallet racking systems allow for various configurations depending on storage needs, while cantilever racking

is suited for long or bulky items such as timber and steel. Shuttle racking offers a semi-automated solution for high-density storage, and mobile racking eliminates unnecessary aisles to increase capacity. Mezzanine and platform systems enable businesses to expand usable storage space without extending their warehouse footprint. Beyond storage products, BHD provides installation, maintenance, and repair services to ensure compliance with safety standards and operational reliability. The company also offers project management for large-scale warehouse fit-outs, safety inspections, and relocation services for businesses moving storage infrastructure to new sites.

The company’s collaboration with Woodhouse Timber began in 2019 when David Seale, BHD’s Business Development Manager, connected with Drew. In recent years Paul Friske, Woodhouse’s General Manager of Operations, has been the one collaborating with David for the successful expansion and install of racking in Brisbane, Melbourne and Adelaide.

“That began a few years ago in

Brisbane,” explains Drew. “We realised we weren’t utilising the full potential of our warehouse space. Our first experiment was with six-metre and nine-metre racking. We learnt a lot from that experience which we used when installing additionally racking in Brisbane and new racking solutions into Melbourne and Adelaide.”

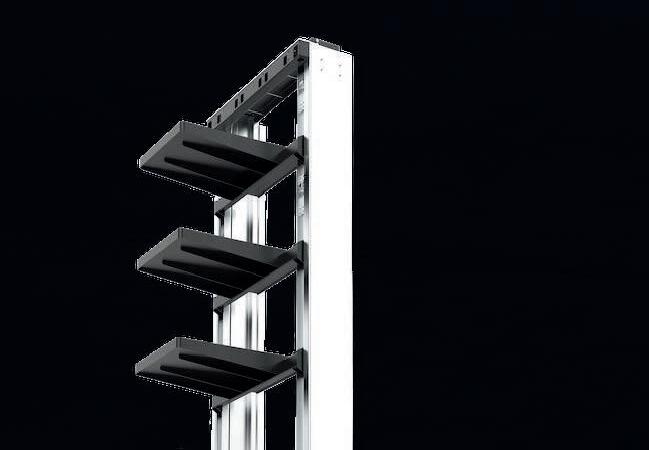

BHD designed and implemented a storage solution featuring 9,000 mm high double-sided cantilever columns, surpassing the standard 5,800 mm height. This design reduced floor space requirements by 37 per cent and, with the use of narrow aisle forklifts,

decreased unproductive floor space by 35 per cent compared to standard aisle configurations.

Consequently, Woodhouse Timber saved approximately 1,500 sqm of floor space, translating to an estimated cost saving of $1.5 million in land and building expenses.

The partnership has continued to expand over the years.

As Drew explained, Woodhouse Timber’s previous racking provider did not meet its standards.

“We had issues with our first racking supplier, the installation process was problematic. The installers caused

delays, and the product didn’t arrive on schedule. With BHD, we haven’t experienced any of those issues,” he says.

“They have a direct relationship with the manufacturer, which means they go straight to the sources so that is a major advantage. With BHD, you get clear and honest time frames for production, delivery, and installation.”

In 2024, BHD installed an additional 196 cantilever columns, each measuring 9,000 mm by 410 mm, covering 90 per cent of the warehouse floor space. This expansion further maximised storage capacity and reduced annual storage costs per metre.

Woodhouse Timber has continued integrating BHD’s storage solutions into its operations. The most recent development, Stage 2 in Dandenong South, marks another advancement in warehouse efficiency.

The company has operated its Dandenong South warehouse for about four to five years, identifying it as a key location due to the independent market in the area. Initially, the company racked out half the warehouse to assess its needs, later deciding to expand further to maximise storage and efficiency.

Rather than relocating, Woodhouse chose to increase product capacity within the existing space, allowing them to stay in Dandenong South longer while improving logistical efficiency. The expansion has helped the company become more entrenched in Victoria’s market, reinforcing its commitment to providing fast, flexible, and frequent service.

Feedback from warehouse staff has been positive, despite initial skepticism about the changes.

“Now they’ve got the hang of things, they couldn’t be more excited to get the racking in,” says Drew.

Since 2019, Woodhouse has installed 731 double and single cantilever racks across its facilities, enhancing stock accessibility and accommodating its product range.

Efficiency is at the core of Woodhouse Timber’s operational strategy.

“The racking system forces our team to stay on top of things,” says Drew. “Before, we had products stored on the floor, which led to inefficiencies when replenishing stock. Now, we have

operations.”

The company also implemented a warehouse management system (WMS) alongside BHD’s racking solutions.

“It was a big learning curve, but once we had both systems in place, our efficiency and output skyrocketed,” Drew adds. “It’s an investment that continues to pay off.”

BHD’s reliability has been a key factor in Woodhouse Timber’s continued partnership.

“In Adelaide and Melbourne, BHD even completed their installation ahead of schedule by two days,” Drew says. “That kind of reliability makes a huge difference in our planning and logistics.”

“The structured storage system has improved workflow and efficiency, and we haven’t had any issues with the racking itself,” says Drew.

Looking ahead, Woodhouse Timber plans to continue working with BHD on future warehouse expansions.

“We still have a few facilities that haven’t been fully racked out yet,” Drew explains. “Beyond that, we’re always open to innovative storage solutions that can help us improve efficiency further.”

While expansion into new markets isn’t currently on the agenda, Woodhouse Timber is committed to optimising its existing warehouses.

“Our goal is to make the most of

our current spaces and refine our processes,” Drew says. “Our vision is to be fast, flexible, and frequent – and having the right storage solutions in place is key to making that happen.”

The continued partnership between Woodhouse Timber and BHD Storage Solutions showcases the importance of strategic storage solutions in warehouse efficiency. Through innovative racking systems, efficient space utilisation, and a good supplier relationship, Woodhouse has been able to grow and streamline its operations, ensuring it remains a leader in the Australian timber industry.

The efficiency gains have had a ripple effect across the company’s supply chain. Reduced storage costs have allowed for reinvestment in logistics and transport solutions, helping the company meet its goal of being “fast, flexible, and frequent,” says Drew.

As Woodhouse Timber moves forward, its partnership with BHD Storage Solutions remains integral to its growth and operational efficiency.

The two companies continue to explore new ways to optimise storage, ensuring that Woodhouse Timber remains at the forefront of Australia’s timber wholesale industry. ■

Argon & Co helps businesses optimise supply chains by leveraging AI-driven insights, reducing waste, and embedding sustainability for efficiency and resilience.

upply chains are under increasing pressure. As consumer demands rise and global disruptions continue to test resilience, businesses must navigate a delicate balance between service, efficiency, cost, and sustainability.

Yet, for many companies, while they understand sustainability and its implications, it remains an afterthought rather than a core driver of supply chain strategy.

“Sustainability for me is nothing new. It’s all about conserving every single resource that you have –materials, energy, people, logistics. Obviously, carbon is first and foremost, but sustainability is much broader than that,” explained Sean Mitchell, Associate Partner at Argon & Co.

As a global management consultancy, Argon & Co helps businesses in the industrial sector optimise their operations, cut waste, and embed sustainability at the core of their supply chains. From reducing carbon footprints and minimising excess inventory to

leveraging AI-driven analytics for smarter decision-making, Argon & Co’s approach is clear: efficiency and sustainability go hand in hand.

As part of his role, Sean develops and implements strategies to help industrial sector businesses optimise their supply chains, improve sustainability, and enhance operational efficiency by leveraging data-driven insights, automation, and resource conservation techniques.

“We work with companies to identify pain points in their supply chain, streamline operations, and reduce inefficiencies that contribute to waste –be it energy, time, travel or materials,” says Sean.

“By optimising processes – whether in manufacturing, warehousing, or logistics – we help companies reduce their carbon footprint while improving overall efficiency.”

While many businesses acknowledge

sustainability’s benefits – lower carbon emissions, reduced waste, and improved efficiency – turning awareness into action remains a challenge.

Several key barriers prevent companies from making meaningful progress in embedding sustainability into their supply chains.

Supply chains today are under immense pressure to transform. As consumer expectations rise, regulatory frameworks tighten, and climate concerns intensify, businesses are compelled to rethink their operations –not just for efficiency and cost savings, but to embed sustainability into their core strategies.

Most industrial businesses are aware of sustainability and its benefits –lower carbon emissions, reduced waste, and improved operational efficiency. However, when it comes to execution, gaps remain:

• Measurement and visibility issues: Many businesses lack comprehensive data on their environmental impact, making it difficult to track and

Businesses are increasingly leveraging AI and green logistics to reduce their carbon footprint and improve operational efficiency. Images: Argon & Co

improve sustainability performance.

• Short-term cost vs. long-term gains: Decision-makers often prioritise immediate cost savings over the longterm efficiencies that sustainability strategies can deliver.

• Complex supply networks: In global supply chains, businesses rely on multiple suppliers – each with their own sustainability policies (or lack thereof), making alignment difficult.

“The average client we work with understands that their processes lack sustainability, but they don’t know how to tackle it. The challenge isn’t just about making supply chains ‘green’ – it’s about making them resilient, efficient, and adaptable to the future,” says Sean.

An essential capability in sustainability management is visibility – businesses can’t optimise what they can’t measure.

Argon & Co leverages AI-powered analytics and big data to provide realtime insights, helping businesses track

environmental impact and streamline operations.

IRIS, Argon & Co’s AI and big data platform, enables businesses to:

• Process large, complex datasets to gain actionable insights into sustainability performance.

• Identify inefficiencies in supply chains, such as excessive energy use, redundant stock movement, or wasteful packaging.

• Automate processes to eliminate nonvalue-added activities and enhance efficiency.

• Use predictive analytics to improve planning, reducing overproduction and excess inventory that contribute to waste.

• A client in the industrial sector struggled with excess inventory and inefficient stock replenishment, leading to unnecessary waste.

Working with IRIS, Argon & Co helped one of its clients optimise stock levels based on real-time demand forecasting, reducing surplus and improving sustainability.

driven decisions that directly impact sustainability,” says Sean.

“By understanding inefficiencies and eliminating unnecessary waste, companies can cut costs while improving their environmental footprint.”

Beyond AI-powered insights, businesses also need a structured approach to track and refine their sustainability performance over time. scprime, Argon & Co’s benchmarking tool, enables businesses to assess the current state of their sustainability efforts and measure progress toward more efficient, responsible operations. It provides a clear evaluation

Argon & Co helps businesses analyse supply chain inefficiencies and implement data-driven strategies for sustainability and resilience. Image: indyntk/stock.adobe.com

of sustainability maturity across procurement, manufacturing, and logistics while establishing measurable benchmarks for energy use, waste reduction, and process efficiency.

By identifying gaps and offering actionable insights, scprime helps businesses transition from reactive sustainability measures to a structured, data-driven approach that drives continuous improvement.

“scprime helps businesses see exactly where they stand in terms of sustainability. It’s not just about compliance – it’s about continuous improvement and making supply chains leaner, smarter, and more resourceefficient,” says Sean.

While AI and benchmarking tools provide businesses with the data and insights needed to optimise internal operations, true sustainability cannot be achieved in isolation.

A supply chain is only as sustainable as its weakest link. While businesses can implement green initiatives internally, these efforts lose impact if their suppliers operate inefficiently.

Argon & Co helps companies align their

sustainability goals with those of their suppliers by enhancing supplier visibility, ensuring businesses have a clear picture of their suppliers’ carbon footprint, resource usage, and ethical sourcing practices.

The company also establishes collaborative partnerships, where suppliers proactively work to improve sustainability rather than merely meeting compliance requirements. Additionally, Argon & Co implements supplier assessment frameworks to measure and track sustainability performance across the network.

“Sustainability in supply chains isn’t just about what you do within your own four walls – it’s about how you collaborate with suppliers to drive efficiency across the entire network,” says Sean.

Ultimately, Argon & Co’s approach demonstrates that businesses can achieve both economic success and environmental responsibility by minimising waste, reducing costs and carbon footprints, leveraging AI-driven insights to eliminate inefficiencies and optimise resource allocation, and fostering a sustainabilityfocused culture that empowers employees to lead green initiatives.

“There’s no trade-off between sustainability and profitability. The more efficiently a supply chain operates, the lower its environmental impact – and the stronger its long-term resilience,” says Sean.

As businesses navigate an increasingly complex and competitive landscape, sustainability isn’t just about regulatory compliance – it’s about future-proofing operations, building resilience, and staying ahead of industry shifts.

Argon & Co’s expertise in AI-driven analytics, process optimisation, supplier collaboration, and automation ensure that sustainability is embedded at every stage of the supply chain.

By rethinking traditional models and embracing continuous improvement, companies can drive efficiency, profitability, and environmental responsibility – simultaneously.

Discover how Argon & Co can help your business turn sustainability ambitions into measurable results. Get in touch to explore AI-driven insights, process optimisation, and supplier collaboration that make sustainability a strategic advantage: http://www.argonandco.com/en/services/ sustainability/ ■

Advanced robotics and AI-driven automation revolutionise 3PL logistics, ensuring scalability, flexibility, and real-time visibility in supply chain operations.

Addverb revolutionises 3PL automation with robotics, AI, and scalable solutions, enhancing efficiency, accuracy, and supply chain adaptability.

With supply chains evolving at a fast pace, 3PL providers must strike the perfect balance between efficiency, adaptability, and cost-effectiveness to stay ahead. The exponential growth of e-commerce, fluctuating demand patterns, and increasing consumer expectations have made traditional warehousing and fulfilment models inadequate. Automation has emerged as a pivotal solution, revolutionising supply chain operations and setting new industry benchmarks. At the forefront of this transformation is Addverb, a specialist in robotics and automation, driving advancements in the 3PL sector.

Ranmeet Singh, General Manager of Addverb Australia, underscores the critical importance of automation in addressing industry challenges.

“The 3PL sector is undergoing a seismic shift, and the need for realtime visibility means automation is no longer a luxury, it’s a necessity,” he says.

Addverb’s intelligent automation solutions equip 3PL providers with the agility and precision required to

navigate these complexities while ensuring long-term operational resilience.

An example of Addverb’s impact is its collaboration with DHL Supply Chain. With a labour-intensive sortation process required to work almost 24/7, consistent labour shortages, high turnover rates, and the need to develop new technologies, DHL needed to find a solution quickly. Addverb delivered robotic sorting automation solutions to DHL within a span of five months. The solution went live three months later, showcasing Addverb’s in-house manufacturing and integration capabilities.

The results were remarkable: a more than 300 per cent increase in throughput efficiency and accuracy, with the system achieving a throughput of 1,000 sorts per hour and a 99.99 per cent order fulfilment accuracy. The deployment of advanced sortation technology reduced reliance on manual labour, streamlined processes,

and enhanced operational visibility, positioning DHL to manage higher order volumes without compromising on service quality.

Reaffirming Addverb’s expertise in customising automation for diverse operational needs, the company leverages robotics, AI-driven analytics, and real-time data visibility to empower 3PL providers with efficiency and scalability.

Beyond DHL, Addverb has played a pivotal role in transforming Maersk’s logistics operations. As one of the largest integrated logistics providers, Maersk required an advanced automation system to optimise its warehouse operations while maintaining flexibility to handle dynamic supply chain demands. Addverb delivered a multi-faceted automation solution that integrated fixed and flexible automation technologies.

By deploying Automated Storage and Retrieval Systems (ASRS), mobile robots, sorting robots, and innovative picking technologies, Addverb transformed a 330,000-square-foot

facility into an efficient logistics hub. The facility has achieved high-density, multi-deep storage and retrieval of pallet loads with 16,500 pallet positions and dispatches 100,000 pieces per day. The deployment of robotic solutions enabled Maersk to adapt seamlessly to fluctuating demand patterns, ensuring uninterrupted supply chain operations.

Addverb’s proprietary Warehouse Execution System provided Maersk with real-time inventory tracking and intelligent task allocation, minimising bottlenecks and improving order fulfilment accuracy. These advancements underscore Addverb’s ability to customise automation solutions to the unique challenges of 3PL providers, regardless of scale or complexity.

What distinguishes Addverb in the 3PL automation landscape is its holistic approach to warehouse optimisation. Unlike traditional automation providers that focus on isolated technologies, Addverb integrates robotics, artificial intelligence, and data analytics to create seamless, end-to-end solutions.

Additionally, Addverb’s in-house manufacturing capabilities and research and development ecosystem facilitates rapid innovation and customisation.

“We don’t just provide technology; we engineer solutions tailored to our partners’ specific needs,” Atit says.

This agility enables Addverb to cater to diverse 3PL models, whether centralised fulfilment centres, microfulfilment hubs, or hybrid distribution networks.

Another key differentiator is Addverb’s commitment to modular and scalable automation. Unlike legacy systems that require overhauls to accommodate growth, Addverb’s solutions are designed for seamless expansion. This modularity ensures that 3PL providers can adapt to market shifts and business growth without major disruptions or capital investments.

As e-commerce growth continues to surge and consumer expectations for faster deliveries intensify, the demand for intelligent automation in 3PL will only escalate. Robotics, AI-driven analytics, and real-time data visibility will be fundamental in shaping the next generation of supply chain ecosystems. The increasing adoption of technologies such as machine learning, predictive analytics, and digital twins will further enhance automation’s impact, enabling predictive maintenance, demand forecasting, and optimised resource allocation.

Sustainability will also be a crucial consideration. As supply chains strive to reduce their carbon footprint, automation will play a key role in

minimising waste, optimising energy consumption, and improving lastmile delivery efficiency. Addverb’s automation solutions are designed with sustainability in mind, integrating energy-efficient robotics and intelligent workflows that reduce resource wastage and operational redundancies.

Furthermore, the integration of collaborative robotics (cobots) can redefine human-robot interaction within warehouses. Unlike traditional industrial robots that operate in isolation, cobots are designed to work alongside human operators, enhancing productivity while ensuring safety. Addverb’s investment in human-centric automation ensures that its solutions complement human expertise rather than replace it, fostering an efficient and adaptive workforce.

With its expertise and commitment to innovation, Addverb is poised to remain a driving force in the automation revolution. By empowering 3PL providers with intelligent, scalable, and future-ready solutions, Addverb is not just transforming warehouses – it is redefining the logistics industry itself.

As the industry navigates the complexities of modern supply chain management, automation is increasingly recognised as a key factor in achieving efficiency and resilience. Addverb is playing a role in supporting this transformation. ■

Jungheinrich’s commitment to sustainability and innovation drives its development of the POWERLiNE series, tailored to enhance operator comfort, efficiency, and environmental impact.

In today’s rapidly evolving industrial landscape, businesses face mounting economic pressures and growing demands for sustainability. The shift towards more energy-efficient and ecofriendly solutions has driven companies to innovate.

Jungheinrich, a global leader in material handling and warehouse solutions, has responded to this demand by introducing its POWERLiNE series, which is designed to transform warehouse operations while enhancing efficiency, sustainability, and operator well-being.

The POWERLiNE series, which includes the ETV 214i and 216i reach trucks, is based on years of research and development, with a clear vision to provide a more efficient, sustainable, and user-friendly solution for modern warehouse needs.

“The development of the Jungheinrich ETV POWERLiNE is rooted in a thorough understanding of operator needs,” says John Carraro, National Key Account Manager at Jungheinrich Australia.

“Our team in Germany analysed data from 14,000 trucks and conducted numerous site surveys to gain insights into operator behaviour and preferences. Rather than the traditional approach of designing a forklift and adapting it to the operator, we flipped the process.”

The development of the POWERLiNE series was driven by a clear market need.

“Jungheinrich is deeply connected to the Australian market, listening to its needs and developing solutions that enhance safety, productivity, and efficiency,” says John.

As the industry grapples with space constraints and increasing operational costs, warehouse operators require high-performance equipment that maximises storage capacity, boosts productivity, and reduces energy consumption while offering low energy consumption.

The POWERLiNE combines advanced lithium-ion battery technology with an ergonomic and compact design. With fast-charging capabilities, minimal downtime, and maintenance-free batteries, these reach trucks help companies keep their operations running smoothly.

Additionally, the quiet operation of the trucks improves comfort for operators, reduces fatigue, and enhances safety, creating an overall more productive and pleasant working environment.

One of the standout features of the series is the integration of lithium-ion batteries, a technology pioneered by Jungheinrich over 14 years ago. These batteries are more energy-efficient, have a higher energy density, and last longer than traditional lead-acid batteries.

As a result, they require less maintenance and reduce operational costs, making them an attractive option for companies seeking to lower their total cost of ownership (TCO).

Lithium-ion batteries are also environmentally friendly. They produce zero emissions during both operation and charging when powered by renewable energy sources, helping businesses meet their sustainability goals while also reducing their carbon footprint.

This aligns with the growing demand in the Australian market for solutions that contribute to cleaner operations and better air quality.

The batteries are equipped with an advanced Battery Management System (BMS), which optimises power distribution for maximum efficiency. This means less energy is wasted, and operators can rely on consistent performance throughout the day. For businesses operating in multi-shift environments, the ability to quickly charge batteries in just 80 minutes ensures that downtime is kept to a minimum.

The development of the POWERLiNE series was driven by a clear market need. Images: Jungheinrich

models feature spacious cabs that offer optimal visibility of both the loads and the surroundings. This design helps to reduce operator fatigue as it makes it easier for them to navigate narrow aisles and manoeuvre large loads safely.

The integration of ergonomic features, such as adjustable armrests, low entry steps, and integrated shoulder protection, enhancing operator comfort. A spacious cab design ensures that operators have ample room to move, reducing the likelihood of strain or injury.

Features like positionCONTROL optimise retrieving and put-away speeds, ensuring efficient handling.

“The trucks also feature a light bar that provides daytime running lights, improving visibility and contributing to greater safety in the warehouse,” says John.

“The combination of comfort, visibility, and reduced fatigue ultimately supports safer, more focused behaviour, positively influencing safety standards and operator performance”

The trucks are designed to navigate tight spaces without sacrificing lifting capabilities. The design incorporates high-strength steel and a low centre

compact size and high performance allows businesses to maximise storage space, improving operational efficiency and throughput. The trucks are particularly well-suited for environments with limited space, such as warehouses in dense urban areas where land costs are high.

The introduction of liftPLUS and drivePLUS technologies enhances the trucks’ energy efficiency and throughput, providing faster lifting and driving speeds. With a 20 per cent increase in productivity over average reach trucks, the POWERLiNE series enables businesses to get more work done in less time.

Jungheinrich’s commitment to sustainability goes beyond product design, with the ETV POWERLiNE series manufactured using eco-friendly practices at its facility in Europe. The facility operates with green energy sources and recyclable materials, reducing waste and lowering its carbon footprint.

In addition to using recyclable materials, Jungheinrich minimises the demand for raw resources and reduces environmental impact by repurposing components at the end of a truck’s lifecycle. This process is energy-

The POWERLiNE series is the result of 14 years of research and development.

Vanderlande addresses peak-period supply chain challenges with automation, omnichannel solutions, scalability, space optimisation, and AI-driven order accuracy.

s e-commerce continues to thrive and traditional brickand-mortar stores expand their digital presence, businesses face increasing challenges in managing their supply chains effectively. Peak periods such as Black Friday and Cyber Monday exacerbate these challenges, placing pressure on manual warehouses and distribution centres.

Vanderlande, a specialist in automated logistics solutions, understands these challenges and offers innovative strategies to help businesses optimise their supply chains. With a presence in Australia and New Zealand, Vanderlande is spearheading omnichannel warehouse solutions that blend Fastpick systems with shuttle, sorting technologies and AMR technologies.

Vanderlande is currently building

five new warehouse solutions that will go live in Australia this year. These projects highlight Vanderlande’s commitment to driving innovation and supporting local businesses with supply chain solutions.

1. Surging order volumes

During peak events like Black Friday and Cyber Monday, order volumes skyrocket. For brick-and-mortar retailers that have transitioned into e-commerce, balancing both in-store and online sales can be overwhelming. Traditional warehouse operations struggle to meet demand, often leading to delayed deliveries and customer dissatisfaction.

“Retailers are constantly facing the challenge of handling unprecedented spikes in orders. Without a robust

warehouse solution, businesses risk falling behind their competition,” says Vanderlande Sales Director Roald de Groot

Online retailers without a traditional brick-and-mortar setup face greater challenges during Black Friday, as sales can surge during these peak periods. Managing this influx while meeting promised customer KPIs can place pressure on a business.

2. Managing unpredictability

Retailers often lack certainty in forecasting demand. Seasonal variations, consumer trends, and unexpected market shifts make it difficult to anticipate inventory needs. The unpredictability in demand can lead to stock shortages or overstocking, both of which can be detrimental to business operations.

“Understanding market trends and preparing for different demand scenarios is key,” said Katie Budd, Sales Manager at Vanderlande“Our solutions are designed to provide data-driven insights that help businesses stay ahead of uncertainty.”

Even with automation, fluctuations in demand can still pose challenges. The key is understanding how to manage these peaks and implementing strategies to make them smoother and less disruptive during this critical period.

3. Labour shortages and scalability

The traditional approach to handling peak demand is hiring temporary workers. However, labour scarcity, especially in Australia and New Zealand, makes it challenging to scale up quickly. Training new employees on short notice further complicates the process.

“Automation is the best way to tackle labour shortages,” says Roald. “Our solutions reduce dependency on seasonal workers and provide a scalable system that can handle peak volumes efficiently.”

At a certain point, adding more hands in the warehouse won’t be enough. Automation will shift from being a luxury to a necessity to successfully handle these peak periods.

4. Warehouse space limitations

With increasing SKU ranges and order volumes, warehouse space is often stretched to its limits. Conventional storage systems fail to optimise space effectively, leading to

congestion and inefficiencies.

“Warehouse real estate is expensive, and maximising every square metre is crucial. Our shuttle-based storage solutions ensure businesses can store more SKUs in less space, improving overall efficiency,” Katie adds.

Optimising warehouse operations isn’t just about maximising height, though that’s certainly a benefit.

Simple, cost-effective solutions like batch picking or sortation can improve efficiency without adding unnecessary complexity.

5. Order accuracy and speed expectations

Consumers demand fast and accurate deliveries. Mistakes in order fulfillment can result in costly returns and negative customer experiences. Maintaining accuracy while speeding up operations is a challenge during peak periods.

Roald emphasises, “A reliable sorting system makes all the difference. Our automated sorting and sequencing technology ensures that orders are picked and packed with precision, reducing errors and improving customer satisfaction.”

Recognising the critical pain points of modern supply chains, Vanderlande provides tailored automation solutions to help businesses navigate peak periods efficiently. Katie and Roald highlight Vanderlande’s approach in transforming warehouses into high-performance logistics hubs.

“Many of our recent customers are facing similar challenges,” says Roald.

“Our goal is to support them on their automation journey while they’re still in growth mode – before obstacles arise. Identifying the need for change early can be a key factor in future success,” Katie adds

1. Omnichannel warehouse solutions

Vanderlande is developing omnichannel warehouse solutions in Australia that integrate brick-andmortar and e-commerce fulfillment seamlessly. These solutions leverage a mix of Fastpick systems with shuttle and sorting solutions powered by Vanderlande’s sorting technology. In addition to its fast pick and sortation systems, it is focused on tailoring solutions for emerging markets.

This serves as a suitable first-step investment in automation.

2. Scalable and flexible automation

By implementing automated storage and retrieval systems (AS/RS), Vanderlande ensures that warehouses can scale operations without being constrained by labour shortages. Its Fastpick solutions enable rapid order fulfillment, minimising delays even during peak sales periods.

3. Data-driven forecasting and planning

Vanderlande employs advanced data analytics to predict demand fluctuations and optimise inventory management.

Scenario planning ensures businesses are prepared for varying order volumes, reducing the risks of stockouts or excess inventory.

4. Maximising space utilisation

With innovative shuttle-based storage solutions, Vanderlande optimises warehouse space, making it possible to store more SKUs within a smaller footprint. Its systems allow for efficient inventory management, even during high-demand seasons.

5. Enhancing order accuracy and speed

By integrating robotics and AI-driven picking technologies, Vanderlande ensures higher accuracy rates in order fulfillment. Automated sorting and sequencing improve processing speeds,

meeting customer expectations for fast deliveries.

Vanderlande has built a reputation for delivering future-proof warehouse solutions. The company works closely with clients to design customised systems that align with their operational needs. Through advanced automation, predictive analytics, and seamless integration of omnichannel logistics, Vanderlande empowers businesses to navigate the complexities of peak periods with confidence.

Additionally, Vanderlande is always looking for new partnerships to further

enhance its offerings. The company prides itself on its excellent service and maintenance organisation, which provides support throughout the lifecycle of its solutions.

As the retail landscape continues to evolve in Australia and New Zealand, Vanderlande remains committed to providing scalable, efficient, and intelligent warehouse solutions. Whether managing surging order volumes or overcoming labour challenges, Vanderlande stands as a trusted partner in supply chain excellence.

For businesses looking to futureproof their warehouse operations, Vanderlande offers the expertise and technology to stay ahead of the curve. ■

Refresco continues its successful partnership with Toyota Material Handling Australia, ordering 49 forklifts to power its nationwide beverage supply chain, prioritising safety, performance, and reliability.

International beverage supplier and manufacturer, Refresco, has used the performance, dependability and safety of Toyota Material Handling Australia (TMHA) forklifts to ensure its supply chain keeps people refreshed across the country.

Recently, Refresco decided to turn over its fleet of material handling equipment, which forms the backbone of its nationwide manufacturing network, choosing to renew its contract with TMHA after more than five years of safe and reliable performance.

An order for 49 Toyota forklifts has been placed for Refresco warehouses in New South Wales, Victoria, Queensland and South Australia, with the first 26 already delivered to one of its warehouses in Condell Park, NSW.

Refresco regional supply manager for Condell Park, Dave Stanford, has

been working for Refresco under its different iterations for the last 25 years, and for the past five years has been using Toyota forklifts to store and move products around the facility.

When Refresco’s first contract with Toyota expired, the decision was made to renew the contract for another fiveand-a-half years after going through a tender process.

According to Dave, there were several reasons for remaining a loyal Toyota forklift customer, with the performance and servicing of the machines over the last half-decade a significant factor.

“Toyota’s pricing was competitive. We got to know the units over the previous term, and the maintenance on the forklifts was really good,” says Dave.

“We had minor issues over that period and didn’t experience too much downtime with the forklifts – it was good service, and we’ve got a good

working relationship with the national account manager, those are the main reasons we stayed.”

Dave and Refresco worked closely with TMHA’s account manager, Michael Provan, to work out the new order, which consists of a range of LPG forklifts with several modifications fitted to suit the needs of the company.

The order included 32-8FG20 forklifts with standard and drive-in racking, rotators and push-pull attachments; 32-8FG25 forklifts with standard and twin-pallet handlers; and a number of 32-8FGJ35 units with twin-pallet handlers, specified to suit Refresco’s usage requirements.

Safety is paramount to Refresco’s operations, which is why the company fitted safety features including red halo lighting, front and rear blue safety lights and the rear-facing pedestrian

sensor, which alerts the operator to any people or obstacles that might be behind them.

Provan was more than happy to help facilitate the fitment of the accessories, and his facilitation of the purchase helped make the procurement process simple for Refresco.

“Without Michael, it wouldn’t have been a smooth process,” adds Dave. “He did a good job with that – we haven’t seen any issues with delivery, which has been great.”

With the Condell Park forklifts having arrived, Refresco operators have noticed a difference with the newest machines, which offer excellent operator comfort and usability.

“Our new forklifts are a different model to what we’ve had previously,” says Dave.

“They seem to drive a lot smoother; the controls are a lot more accurate. They’re a good forklift – they’re a workhorse.”

Another important factor for Refresco when choosing TMHA was the excellent service experience provided, which is made possible by a network of experienced technicians who can provide speedy and knowledgeable service and repair work.

“Servicing with TMHA is a simple process,” says Dave.

“We email the service team, and we get a reply the same day about when they can come out. It’s never a long wait.

“We have been very happy with the performance of the Toyota machines and the service provided by both Michael and the TMHA technicians who service Refresco.”

Refresco’s Perth warehouse currently has existing Toyota units on contract but is beginning to consider a proposal for new equipment.

Refresco is a global beverage provider for retainers across the world and one of Australia’s largest beverage suppliers and manufacturers, working with brands including Ocean Spray, Prime and supermarket retailers to produce juices, soft drinks and other juices for sale across the country. ■

For more information, call Toyota Material Handling Australia on 1800 425 438 or visit toyotamaterialhandling.com.au

doWarehouse offers more than just Automation. Images: Ferag

Ferag AG’s journey from a Swiss print industry powerhouse to a global player in intralogistics solutions is a story of engineering excellence, adaptability, and customer-centric values.

Founded in Hinwil, Switzerland, in the 1950s, Ferag initially established itself in the printing sector, specialising in conveying systems and post-printing processing. Its innovative solutions quickly gained worldwide recognition, propelling the company to prominence within the publishing industry.

The technical expertise honed in designing high-speed, precise newspaper and magazine conveyors seamlessly translated to warehouse conveyors, where efficiency, accuracy, and reliability are equally critical.

Much like ensuring the timely delivery of publications to readers, Ferag’s warehouse systems are engineered to move products swiftly and accurately, meeting the demands of modern e-commerce and supply

chain operations. This transition was not simply a pivot; it was a natural extension of the company’s commitment to problem-solving and efficiency.

Today, Ferag stands at the forefront of intralogistics, offering solutions that streamline operations and elevate customer experiences across a variety of industries, including retail, fashion, and e-commerce.

Justin Boyd, Managing Director, Ferag, shares how Ferag’s evolution has always been guided by a core principle: reliability.

“A customer came to us with a machine that was no longer supported, requiring a spare part that was no longer produced,” says Justin. “Upholding our customer-centric ethics, we searched everywhere and found

Ferag’s doWarehouse provides actionable insights that drive informed decision-making and continuous improvement.

the crucial spare part we needed… in the Ferag museum. The part, still in perfect condition after decades, fit flawlessly, proving Ferag’s commitment to preserving the past while driving innovation for the future.”

As Ferag expanded globally, it became clear that the company’s future would require not just technological innovation but also strong localised support networks.

“Our local presence enables us to earn trust and form long-term partnerships, something that’s harder to achieve from afar,” adds Justin. “It also lets us understand and meet local requirements and regulations.”

“Having a presence here allows us to tailor our solutions more effectively,

integration and advanced predictive maintenance weren’t as widely prioritised as they are today,” says Justin Boyd.

“Now, businesses demand more than just automation, they need smart, adaptable systems that provide actionable insights and scale with their operations. Ferag’s solutions are built to meet these demands, combining Swiss engineering precision with

With transparency down to the robotic layer, companies can optimise processes and cut costs in today’s fastpaced logistics environment.

By leveraging data science and machine learning, doWarehouse anticipates system failures, identifies bottlenecks, and optimises demand forecasting. This helps businesses improve operational efficiency and adapt quickly, especially during peak

“Our goal is to make human-machine our passion.”

Another innovation in Ferag’s intralogistics arsenal is Skyfall, a pouch-handling system that seamlessly combines sorting, buffering, and picking functions in one platform. Think of it as a dry cleaner’s conveyor belt, but engineered for industrial precision and scalability. Skyfall goes beyond traditional conveyors, acting as an all-in-one solution that eliminates

the need for multiple separate systems, thereby significantly reducing costs and complexity.

What sets Skyfall apart is its energy efficiency. By leveraging gravity and low rolling friction instead of motors, the system minimises energy consumption and maintenance requirements.

“This design not only reduces operational costs but also ensures longterm reliability, making it an ideal solution for dynamic industries,” says Michael Gruber, Director, Customer Service & Support, Ferag.

In addition, Skyfall can handle a range of products, from cosmetics and apparel to electronics and even dangerous goods, making it versatile for a broad array of industries.

apart through a combination of agility, innovation, and an understanding of customer needs.

While the baseline service offering across companies is similar, Ferag stands out by leveraging its software expertise to implement predictive and prescriptive maintenance – tools that not only identify potential issues before they arise but also optimise system performance in real time.

For instance, if a customer needs their products delivered in a specific sequence for easier store restocking, Skyfall can ensure the correct store sequence when loading the truck. This means the goods are unloaded at the store in the correct sequence to be placed on the floor, saving time and storage in the back of the store. This helps optimise the entire supply chain, from the warehouse to the shop floor.”

Complementing Skyfall’s capabilities is Denisort, Ferag’s tilt-tray sorting system designed for high-speed, highaccuracy performance. With a unique 3D architecture, Denisort maximises floor space while maintaining exceptional throughput. Its dynamic dual-tray configuration enhances sorting capabilities, making it ideal for high-throughput environments. Denisort is designed for industries like printing, where high-speed, error-free sorting is critical.

“For instance, in the newspaper industry, where thousands of copies must be sorted and delivered within hours, Denisort’s reliability and long lifespan are invaluable,” says Michael. “The system’s low maintenance needs make it an attractive choice for companies looking for long-term, trouble-free operation.”

Ferag is at the forefront of integrating digital technologies into its materialhandling solutions, empowering businesses with tools that drive operational efficiency and resilience. At the core of this effort is advanced

data analytics, which optimises system performance by delivering actionable insights into operations, forecasting, and identifying potential issues before they escalate.

“Our AI-driven systems enable prescriptive maintenance by learning from past incidents, allowing us to proactively adjust material flows and tune systems to prevent issues before they arise, explains Michael.

With its focus on continuous innovation and R&D, Ferag ensures that its products are not just meeting the current needs of industries but are future-proof, helping businesses stay ahead in an increasingly digital and automated world.

“Scenario modelling is a gamechanger for our customers,” adds Justin Boyd.

“It lets them simulate different operational conditions to optimise layouts, predict bottlenecks, and make real-time decisions – all without disrupting operations. It’s like a sandbox for training, helping managers prepare for real challenges,” adds Justin.

Among the many roles played by digital technologies, safety stands out as a key focus.

“Safety technology, like wearables, ensures workers stay out of hazardous zones by sending real-time alerts,” explains Justin.

“The goal is simple – keep them safe and ensure they go home in better condition than they arrived.”

Ferag’s service offering goes beyond the conventional OEM support, setting itself

“With a young and agile team, Ferag can quickly adapt and implement solutions, exemplified by the rapid deployment of its system monitoring tool toMonitor, which was developed and implemented in just one weeksomething that would have taken years in larger organisations,” says Michael.

As the industry faces a shortage of qualified personnel, Ferag is tapping into the power of remote diagnostics and data analytics to address this gap. These tools help identify potential failures, reduce downtime, and streamline maintenance, benefiting both customers and the environment by reducing the need for spare parts and lowering costs.

“We also customise our support packages for diverse APAC markets, listening closely to customers’ pain points and tailoring solutions to fit their unique logistical challenges,” explains Michael.

Looking ahead, Ferag aims to be a leading force in the intralogistics space across the APAC region, recognised for its innovation, customer-first mindset, and strong local presence.

In line with this vision, Ferag continues to prioritise investments in cutting-edge technology and workforce development. The company understands that advancements in AI, machine learning and the use of data lakes are reshaping the industry and is committed to staying ahead of these trends.

“As the landscape of AI and machine learning evolves, we understand the importance of staying ahead by equipping our team with the latest knowledge and tools,” concludes Michael. ■

Learn more about Ferag and its services by direct contact via email at info-apac@ferag.com

Every hour, thousands of tonnes of goods move through Australia’s ports – fuelling industries, sustaining jobs, and connecting the nation to global markets.

From iron ore in the Pilbara to consumer goods arriving at Port Botany, maritime trade underpins nearly every sector of the economy.

Ports Australia’s inaugural State of Trade report quantifies this impact, highlighting $650 billion in trade value and nearly 700,000 jobs directly linked to port operations – 99 per cent of Australia’s international trade.

Each year, 31,000 vessels move 1.6 billion tonnes of trade, along with 1.25 million cruise passengers. Iron ore leads exports at 36 per cent, followed by coal (14 per cent) and agriculture and food (13 per cent). Mining accounts for 64 per cent of total export value.

On the import side, oil, gas, and fuel represent half of inbound trade by volume, while seven million containers carry essential goods, including building materials and machinery.

Despite their economic weight, Australia’s ports face mounting challenges, leading to congestion and bottlenecks. Infrastructure struggles to keep pace with growing demand, creating logistical headaches across supply chains.

Mike Gallacher, CEO of Ports Australia, emphasised the oftenoverlooked role of ports in sustaining industries and communities.

“This inaugural State of Trade report provides a snapshot of Australia’s port

Australia’s ports drive trade but face inefficiencies; investments aim to ease bottlenecks and improve freight productivity.

industry unlike anything we’ve seen before,” Mike says.

“It highlights the interconnectedness of key industries and supply chains, allowing us to plan for the future.

“Quite frankly, our security relies on our ports. We need to ensure they thrive so they can connect us to the world into the future.”

Gallacher also points out that Australia’s port landscape is highly diverse, with distinct challenges facing regional and capital city ports.

particularly on fuel and vessel sizes.”

Gallacher adds that Ports Australia has already been facilitating knowledge sharing among Pacific nations, particularly regarding sustainability initiatives and best practices.

“There’s the distinction between import-related ports and exportrelated ports,” he says. “For Australia, decarbonisation and fuel security remain key challenges. We need certainty around future fuel types to ensure our ports remain globally competitive.”

Another critical issue is cybersecurity. Gallacher highlights the importance of protecting critical infrastructure to maintain operational continuity.

“This isn’t just an Australian challenge; it’s a global issue. How do we keep our ports secure from cyber threats to ensure they keep running?”

Furthermore, the role of international collaboration cannot be overstated. Gallacher emphasises the need for Australia to work closely with regional partners, particularly in the Pacific.

“We’ve been doing that for the last couple of years. We don’t deal at the government level; we deal at the industry level. And what we see there is a real thirst from our Pacific neighbours to understand the investment we’re making in research.”

To address congestion, an investment of $400 million will be made over the next two years to expand the rail terminal at Port Botany.

The project, starting in June, will introduce five new rail sidings for 600-metre-long regional trains, boosting productivity at one of Australia’s key ports.

“We are a massive geographical landmass, but we are not a large player in the global shipping debate,” he explains. “Where I see an opportunity for Australia is to bring together New Zealand and the Pacific nations so we can work cooperatively as a region in those discussions on decarbonisation and the downstream effects of it,

In addition, NSW Ports is investing $148 million in a new rail facility. Once completed, the upgraded infrastructure is expected to more than double annual throughput, from 400,000 to 1 million twenty-foot equivalent units (TEUs).

Marika Calfas, CEO of NSW Ports, highlighted the significance of this investment:

“This collaboration with DP World continues the growth of on-dock rail capacity at Port Botany, supporting the state’s import and export trade.”

With these investments, the industry aims to ease bottlenecks, improve supply chain efficiency, and reduce reliance on road transport, ensuring ports remain a critical link in Australia’s trade future.

While COVID-19 disrupted industries globally, Australia’s ports remained resilient. Gallacher recalls how ports adapted quickly to health protocols to ensure trade continued.

“During COVID, while air travel virtually stopped, ports never closed,” he says. “All the protocols we put in place ensured operations continued, and we only had one confirmed case among port pilots in the far north of Queensland. That speaks volumes about our preparedness.”

Looking ahead, Gallacher believes preparedness for future global shocks is crucial.

“We need to ensure our ports remain competitive by continuing to invest in infrastructure and improving productivity,” he says. “Ports Australia plays a key role in sharing knowledge across the region, ensuring we stay ahead of emerging challenges.”

Australia’s productivity also

comes into question when compared internationally. While many point to the potential for larger container ships to increase efficiency, Gallacher cautions that bigger vessels bring additional challenges.

“People say we should just go to larger ships, but there are many questions that need to be addressed,” he says. “Is our population demand

strong enough for larger vessels? What would larger vessels mean for congestion in our capital cities? What impact would they have on dredging requirements and on-water changes?”

Gallacher highlights that while bulk exports such as iron ore and coal maintain high productivity, there is always room for improvement.

“There is continual room for improvement on both sides, in terms of organised labour and the port terminal operators themselves,” he says. “We need to ensure that as vessel sizes grow and productivity gains come from larger ships, our rail and road infrastructure is also prepared.”