5 minute read

Software Management

How software can help SMEs grow

ECI Software Solutions provides business management and e-commerce software for growing small and medium-sized companies. Manufactures’ Monthly sits down with ECI’s managing director in APAC, Joe Wrightman, to talk about the company’s flagship software for manufacturers – ECI M1.

BACK in 1992, Bowen and Groves was founded to empower manufacturers with a uniquely flexible ERP that could be adapted to any environment and drive overall business efficiency. After years of making a difference to local SMEs, ECI Software Solutions acquired the Australian company in 2009, bringing with it the flagship manufacturing solution called M1.

The American company headquartered in Texas has offices across the US, UK and Netherlands, as well as Australia which is anchored by ECI M1 and JobBOSS².

The company’s in-depth industryknowledge is reflected by the diversity of its manufacturing customers, working with businesses across an array of different sectors.

“We are completely dedicated to the small to medium market,” Joe said. “We understand the challenges that these businesses face and appreciate their need for a truly costeffective solution that delivers results and enables growth.”

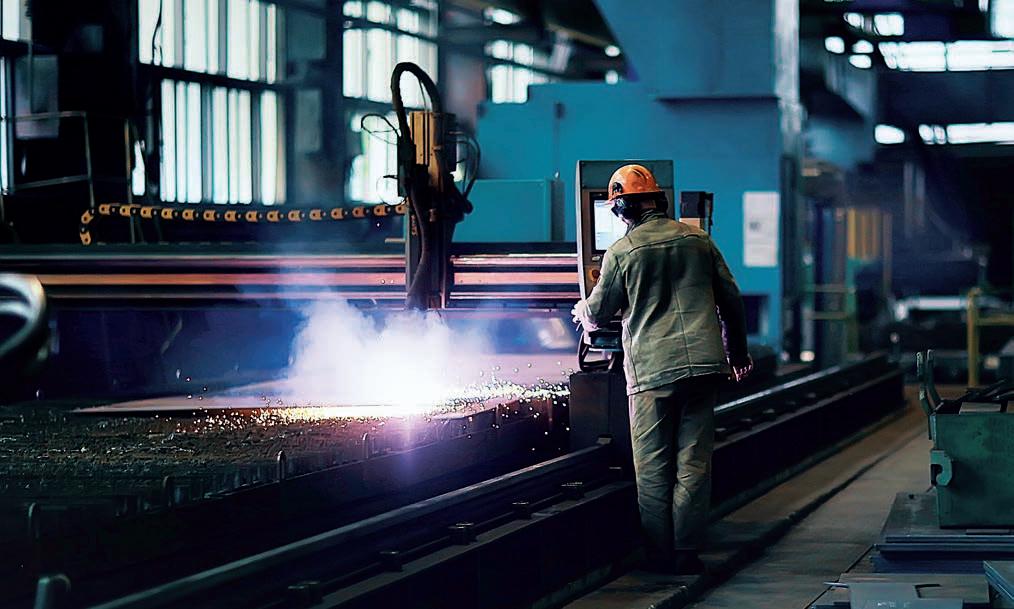

Global turbulence created by the COVID-19 pandemic and the ongoing global supply chain crisis has forced manufacturers to significantly adapt. Combine this with the ongoing labour and material shortages, and manufacturers are facing some big challenges. Now, new technologies are being rapidly deployed and more innovative methods of production being trialled, helping to improve overall service delivery and efficiency.

The ECI M1 solution

ECI M1 is an enterprise resource planning (ERP) solution, designed for small and medium-sized discrete manufacturers, while JobBOSS² is specifically for job shops, custom and make-to-order manufacturers.

Improve visibility across departments

The key to the software is its ability to integrate every department. Those reliant on disparate systems or those that find themselves constantly chasing a paper-trail or having to speak to other teams to source key information.

“ECI M1 is designed to provide a single source of truth, integrating all key business data, meaning, for example, that your sales team no longer need to bother the schedulers or planners when a new order comes in,” explained Joe.

With all information entered into the ERP system, key data is accessible across the entire business. Not only does this increase data accuracy and minimise the chance of duplication, it will help the entire business run more smoothly.

Using the ECI M1 design studio, a simple and flexible customisation tool, businesses can add new fields, create new tables, change input forms, and view information in different ways through search grids, KPI’s and integrated graphical output. The integration of an added new tool called Alora is allowing further machine intelligence and maintenance planning.

“ECI M1 is designed to improve visibility and help manufacturing businesses make sense of their data, allowing teams to pull reports whenever necessary. Over time, this insight can be used to enhance decision making, drive growth and improve profit margins,” explained Joe.

Customer and project data can also be entered as soon as an order is placed. This data will then progress through all phases of the project, eliminating the need for the data to be re-entered at each stage.

Joe Wrightman says ECI M1 helps manufacturing businesses make sense of their data.

Better inventory management

Efficient inventory management is critical for any business, but especially crucial for manufacturers.

Software Management

“Effectively planning and structuring production runs in line with lead times can be a challenge, especially given the ongoing global supply chain crisis and the impact this is having on component and product availability,” Wrightman said. “Having an inventory management system in place, such as ECI M1, will prevent the over or under ordering of stock and enable cash flow across the business. The last thing you want is to end up with thousands of dollars of stock sitting idle in your warehouse.”

Customer support

ECI M1 has rapidly become a global product, having been rolled out in the US, New Zealand and Europe, leading ECI to bolster its customer support team.

“As we’ve become more and more of a global organisation, we found that we needed to expand and change our customer support infrastructure,” Joe said.

“We now have a 24/7 ‘follow the sun’ support structure which allows customers in any location to access expert advice and guidance. ECI’s Customer Satisfaction Score (CSAT) is an incredible 98 per cent in Australia.”

The support team constantly monitors whether a customer’s needs are being fulfilled in a timely manner. ECI also monitors this data throughout the initial sale, installation and implementation phase.

“Looking specifically at the team involved in developing the ECI M1 product, the level of expertise really is insurmountable,” Wrightman said. “We have people who have been with us for 29 years, so their level of understanding of the software and wider industry really is second to none.”

ECI is about to embark on a new initiative designed to educate businesses about how specialist software can help them streamline and strengthen their processes to drive efficiency.

ECI has recently expanded its customer support infrastructure.

Treotham Automation is a leading supplier of high quality components and products to the industrial automation sector

Flexible Cables

Flexible Conduits

Measuring Systems Chain ex Cables

Cable Accessories

Bearings Energy Chains

Safety Products

Gear boxes Connectors

Sensors