manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS

manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS APRIL 2024 >> INSIDE >> Endeavour Awards profile 32 SICK sensor technology 28 Official Industry Partners: sem conductor MANUFACTURING TECHNOLOGY FROM to LiDAV from Advanced Navigation 48

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Journalist: Phillip Hazell phillip.hazell@primecreative.com.au

Production Coordinator: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Cat Zappia

Sales/Advertising: Emily Gorgievska

Ph: 0432 083 392 emily.gorgievska@primecreative.com.au

Subscriptions

Published 11 times a year

Subscriptions $140.00 per annum (inc GST) Overseas prices apply

Ph: (03) 9690 8766

Copyright Manufacturers’ Monthly is owned by Prime Creative Media and published by John Murphy.

All material in Manufacturers’ Monthly is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Manufacturers’ Monthly are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2024

Articles All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head

In April’s cover story, we look at BluGlass Limited, a homegrown semiconductor manufacturer. We will see how the company developed overtime, from their humble beginnings at Macquarie University, to the commercialisation of their products. Also in this issue, we check-in with Endeavour Awards nominee, Verbotics, who specialises in software programming for robotics. Later in the issue, we catch up with SEMMA, who offered their thoughts about the recent land taxes in Southeast Melbourne. Finally, in this month’s Engineering Focus, we explore Advanced Navigations LiDAV tech, which is enabling vehicles to navigate autonomously.

Office 379 Docklands Drive Docklands VIC 3008 P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au Sydney Office Suite 3.06, 1-9 Chandos Street St Leonards NSW 2065, Australia P: +61 2 9439 7227 Printed by: The Precision Group 83-89 Freight Drive. Somerton Vic 3062 Ph: (03) 9794 8337 manmonthly.com.au twitter.com/Manmonthly facebook.com/Manmonthly linkedin.com/showcase/manufacturer’s-monthly/ For daily news visit manmonthly.com.au 26 32 Behind the cover APRIL 2024 06 Editor’s Note 09 Weld Comment 12 Manufacturer Focus 17 News 26 Aluminium manufacturing 28 Sensor technology 30 Events and conventions 32 Endeavour Awards Profile 34 Automation components 36 Defence insight 38 Welding in manufacturing 41 Materials handling in manufacturing 44 Association comment 46 ERP solutions 48 Engineering Focus 53 What’s New 54 Last Word Manufacturers’ Monthly Contents manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS APRIL 2024 >> INSIDE >> Verbotics automation software 32 SICK proximity sensor 26 Official Industry Partners: sem conductor MANUFACTURING TECHNOLOGY FROM to LiDAV from Advanced Navigation 48 4 Manufacturers’ Monthly April 2024

Responsibly sourced Lower-carbon Aluminium your projects.

Choosing lower-carbon aluminium in your next project can significantly reduce the embodied energy of your aluminium products. LocAl® Green (8kg CO2e/1kg AL*) and LocAl® SuperGreen (4kg CO2e/1kg AL*) are the responsible choice for a locally extruded, lower-carbon option in your next project.

FOR MORE INFORMATION VISIT lowcarbonaluminium.com.au POWERED BY * Kilograms emitted per kilogram of aluminium produced - Aluminium Smelting and Casting COME SEE US AT AUSTRALIAN MANUFACTURING WEEK

Charting the course of manufacturing through strategic support

The resilience and innovation characterising Australian manufacturing is particularly inspiring. This month, we reflect on the transformative journey our industry is undertaking, fueled by strategic grants and initiatives that are not just reshaping the landscape of manufacturing but are also fortifying our nation’s economic and social fabric.

Our story begins with the visionary CUREator program led by Brandon BioCatalyst, which vividly illustrates the profound impact of targeted investment in life sciences. The recent allocation of $3 million towards pioneering projects aimed at combating antimicrobial resistance (AMR) underscores a deep commitment to advancing healthcare solutions through manufacturing. It’s initiatives like these that exemplify the sector’s capacity for innovation, addressing global health challenges right from our backyard.

From its inception with a $40 million boost from the Federal Government, CUREator has been a beacon of progress, facilitating the bridge between ground-breaking research and tangible commercial success. The development of the Spritz-OM nasal spray, a potential revolution in paediatric healthcare, is a testament to the power of collaborative innovation. It’s stories like these that should fill us, in the industry, with pride, showcasing how our sector is directly contributing to improving lives while pushing the boundaries of science and technology.

The narrative of transformation extends beyond biotechnology. The Queensland Government’s Made in Queensland (MiQ) program exemplifies the tangible benefits of government support in traditional manufacturing sectors. The grant awarded to CSF Industries, enabling the acquisition of Shotblaster equipment, represents more than just an expansion in capacity; it signifies job creation, economic growth, and innovation within local communities. It’s initiatives like MiQ that reaffirm the enduring strength and adaptability of Australian manufacturing.

In the realm of pharmaceuticals, the ambitious undertaking by Noumed to establish a $100 million manufacturing facility at Salisbury is a striking illustration of the strategic direction in which our industry is headed. Supported by significant federal funding, this venture not only promises to bolster our sovereign manufacturing capabilities but also brings us one step closer to self-reliance in healthcare – a goal more pertinent today than ever before.

Moreover, the Queensland Government’s commitment through its Battery Industry Strategy, investing $570 million in clean energy manufacturing, highlights an exciting frontier for our industry. This strategic vision not only aligns with global sustainability efforts but also paves the way for a new era of skilled job creation in the clean economy sector. It’s forward-thinking approaches like these that ensure our industry

remains at the cutting edge of global trends and opportunities.

Lastly, the New South Wales Government’s Net Zero Manufacturing Initiative shines a light on the path to sustainability. With $275 million dedicated to grants for developing clean technology, this initiative embodies a holistic approach to innovation, securing jobs, and fostering economic growth. It is precisely this kind of leadership and investment in future-ready projects that will enable our manufacturing sector to thrive in the renewable energy landscape.

We in the industry should not be just mere bystanders but ardent supporters of our industry’s journey towards innovation, sustainability, and global competitiveness. Through these strategic investments and grants, we’re not merely funding projects; we’re investing in the very future of Australian manufacturing. These initiatives are a clarion call to all stakeholders within our sector to embrace change, innovate relentlessly, and pursue excellence.

It’s with a sense of pride and anticipation that we can look forward to the continued growth and achievements of Australian manufacturing. Together, we are not just navigating the challenges of the 21st century; we are setting the standards for innovation, job creation, and economic resilience. Here’s to the bright future that lies ahead, shaped by our collective efforts and the strategic support that fuels our journey.

6 Manufacturers’ Monthly April 2024 Image: Inna/Adobe.Stock NEWS EDITOR’S NOTE SYED SHAH – MANAGING EDITOR, MANUFACTURERS’ MONTHLY

WHERE AUKUS MEETS THE QUAD Department of Jobs, Tourism, Science and Innovation GOVERNMENT OF WESTERN AUSTRALIA PARTNERS ORGANISER Defence Security Industry Commerce LEARN MORE WWW.IODS.COM.AU The AUKUS and Quad international partnerships will transform Indian Ocean security, commerce and Australia’s industry capability. Conference and Exhibition Do Business In Great Waters FIND OUT HOW – JOIN THE PROGRAM AT IODS 2024 Contact the IODS Conference and Exhibition team expo@amda.com.au

SIMPLE. STREAMLINED. SECURE.

Introducing the world’s first touchscreen photoelectic proximity sensor - the W10 - combining reliable detection with an intuitive operation. Designed around the User, the W10 was optimised for four key application categories. From basic presence detection, to the most optically challenging applications, the W10 provides world-class performance and user experience accompanies you as an expert sensor partner on the way towards highly automated and autonomous mobile machines. The W10 is an all-round solution which offers unparalleled flexibility. A single sensor can be put into stock instead of many different ones with similar properties. For more information, please vist www.sick.com.au/w10 or call 1800 334 802.

Weld Australia urges investment in network of Indigenous welding schools

Weld Australia is urging the Federal Government to invest in a national network of Indigenous Welding Schools to help create real skills and real jobs for Indigenous Australians – and close the gap.

Now is the time to ensure Indigenous Australians have the skills needed to secure meaningful jobs. According to the Productivity Commission’s recently released first review of the National Agreement on Closing the Gap, governments are not adequately delivering on their commitment to the Agreement.

Despite some pockets of good practice, progress in implementing the Agreement’s Priority Reforms has, for the most part, been weak and reflects

tweaks to, or actions overlayed onto, business-asusual approaches. The disparate actions and ad hoc changes have not led to improvements that are noticeable and meaningful for Aboriginal and Torres Strait Islander people.

The Indigenous Welding Schools initiative not only aligns with the national socio-economic targets of the Closing the Gap agreement—enhancing education, employment, and community development for Indigenous Australians—but also offers a tangible

solution to the pressing need for skilled labour in the welding industry.

Over the past fi ve years, Weld Australia has approached every government in a bid to secure funding to create a national network of Indigenous Welding Schools that use the latest augmented reality and advanced welding systems. We have been largely rebuffed by governments of all persuasions.

However, we know that the Albanese Government is genuinely committed to closing the gap for

9 manmonthly.com.au Manufacturers’ Monthly

COMMENT GEOFF CRITTENDEN – CEO, WELD AUSTRALIA

Images: Weld Australia

Indigenous Australians. Weld Australia has written to the Albanese Government, urging it recognise the value and necessity of the Indigenous Welding Schools concept. It represents a strategic investment in the future of industry and the empowerment of Indigenous communities, promising real skills for real jobs.

The Indigenous Welding Schools program would be predominantly run by Indigenous educators and trades people who would mesh the practical demands of the welding trade with a culturally appropriate curriculum, pastoral support, and employment pathways to deliver gate-ready welders to industry. Students would graduate qualified and certified to the internationally recognised welding competency standard ISO 9606.

The model and technology would be identical to that deployed by Weld Australia in its highly successful existing programs: the VET Centre of Excellence in seven Corrections Victoria prisons; and the NSW Advanced Manufacturing Schools Outreach Program, implemented in over 65 schools.

Australia is facing a looming shortage of skilled welders—70,000 additional welders will be needed in the next 10 years. Demand is being driven by Defence, Infrastructure and Resource projects and exacerbated by supply chain issues promoting growth in local companies. The upcoming renewable energy boom will further overheat the market. Welding-specific VET training and employment pathways for Indigenous Australians could help alleviate some of these skills shortages for industry and close the gap for Indigenous Australians.

A national network of Indigenous Welding Schools could help progress three of the 19 national socioeconomic targets outlined in Closing the Gap:

• Students reach their full potential through further education pathways

• Youth are engaged in employment or education

• Strong economic participation and development of people and their communities

A bright trade future

Munster Services Group is a Queensland owned and operated trade services business with over 115 employees and facilities in Slacks Creek, Underwood, Stapylton and Maroochydore. They maintain Queensland’s vital water and wastewater infrastructure, service heavy industry and manufacture water treatment equipment.

As an employer, Munster seeks people with the right attitude and a keen interest in learning and developing, who are reliable and trustworthy. As a result, without seeking to achieve any target, Munster has a diverse workplace, with more than 22 national backgrounds in the team and a First Nations representation of around nine per cent.

Last year, Munster engaged in the First Nations Engineering Skills Set Program with DGT Employment and Training in Meadowbrook, funded by the Local Jobs Program and supported by DATSIP to provide training and work experience to unemployed locals keen to enhance their career opportunities.

Islander man. Pilot wanted to change careers, from a forklift operator to working as a boilermaker or mechanical fitter.

Pilot is undertaking a Certificate III in Engineering through TAFE Queensland and is a first-year mechanical fitting apprentice at Munster. He has proven to be a reliable and hardworking employee, with a bright trade future in one of Queensland’s key skill shortage areas.

According to Pilot, “I chose a career in engineering to gain a different experience and trade in a new line of work. I spent a majority of my working life in the warehousing industry doing picking and packing and forklift high reach driving.”

“I love working hands-on with tools, learning more about the different types of tools used in the industry, and how machinery works. I enjoy the assembly and disassembly of working machinery parts, learning how they work and the importance of their function. It’s also great learning about the different networks and site repairs and maintenance in the field.”

Equipped with our patented multi-position tiller arm the Combi-CS offers safer operation, maximum operator visibility and narrow aisle performance. The tiller can be turned to the left or right, allowing the operator to remain at the side, providing full visibility of the load and forks, while maintaining full steering control, enabling greater awareness of their surroundings which enhances overall safety. Standing to the side of the stacker eliminates the risk of being trapped or crushed while allowing the Combi-CS to operate in very narrow aisles.

Through support of this program, Munster employed John Pilot—a 40-year-old Torres Strait

“The advice I would give other First Nations people considering a career in engineering is that it’s interesting and enjoyable as well as challenging. There’s plenty of ways to expand your qualifications. It’s an industry that is booming and there is plenty of opportunity for growth and moving up in the engineering industry and once your qualified there’s good money to be earned.”

“I encourage anyone who keen to get started in engineering to stick with it. It’s well worth it,” said Pilot.

10 Manufacturers’ Monthly April 2024

John Pilot, a first-year mechanical fitting apprentice at Munster Services Group.

COMBI-CBE

The fully electric multi-directional forklift designed for the safe and efficient handling of long and bulky loads. Suitable for guided aisles, long loads, narrow aisles and palletised goods.

Features include:

• +/- 100mm side shift

• Load sensing steering

• 4-way lever positioning of wheels

• System communication via CAN-BUS

• 2-wheel electric drive

• Powered by AC technology

• Lithium option available

combilift.com

Capacity 2500 kg - 3000 kg Lift Width 1500 mm Engine Type Electric Machinery Type Multi Directional

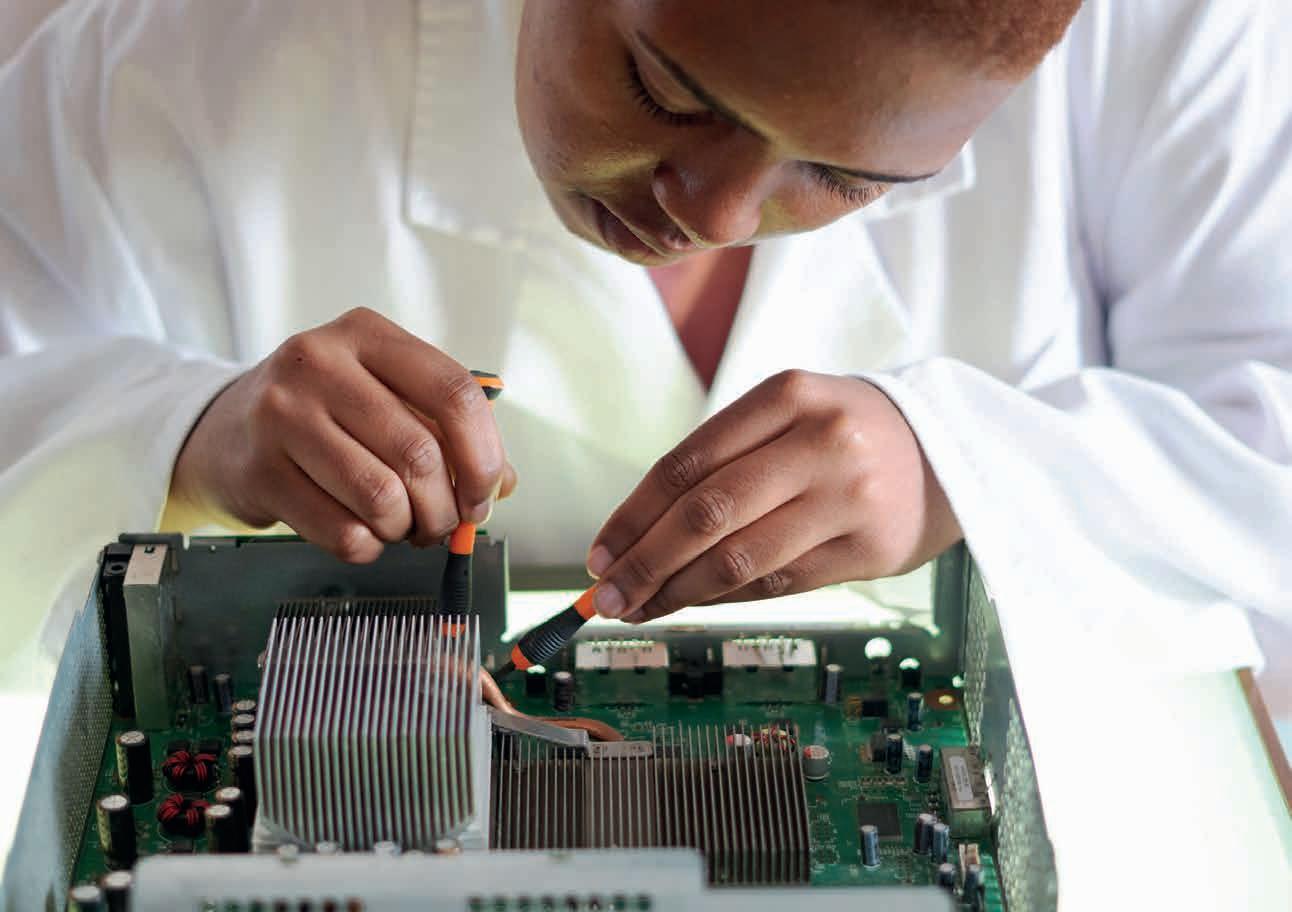

From technology to products

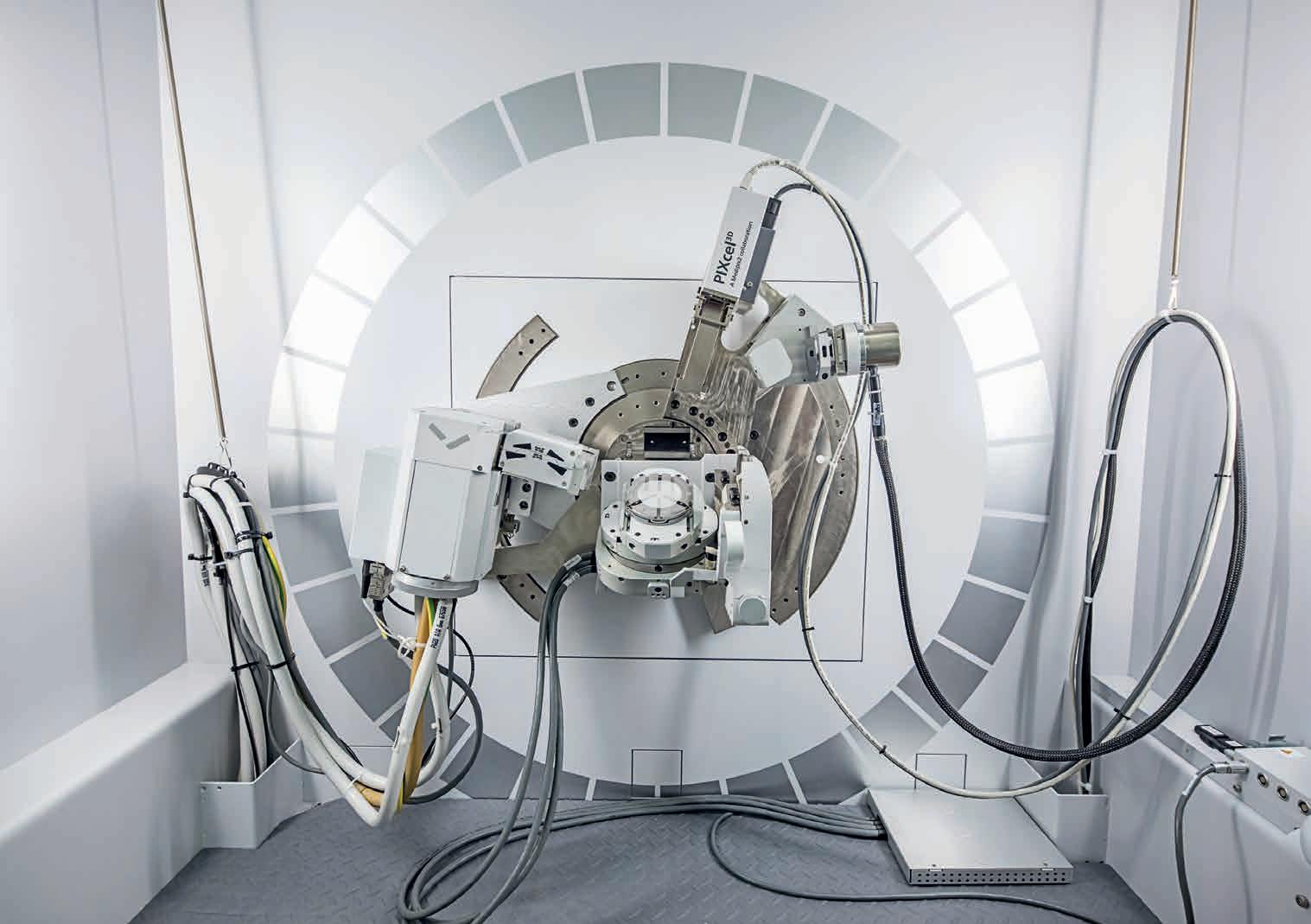

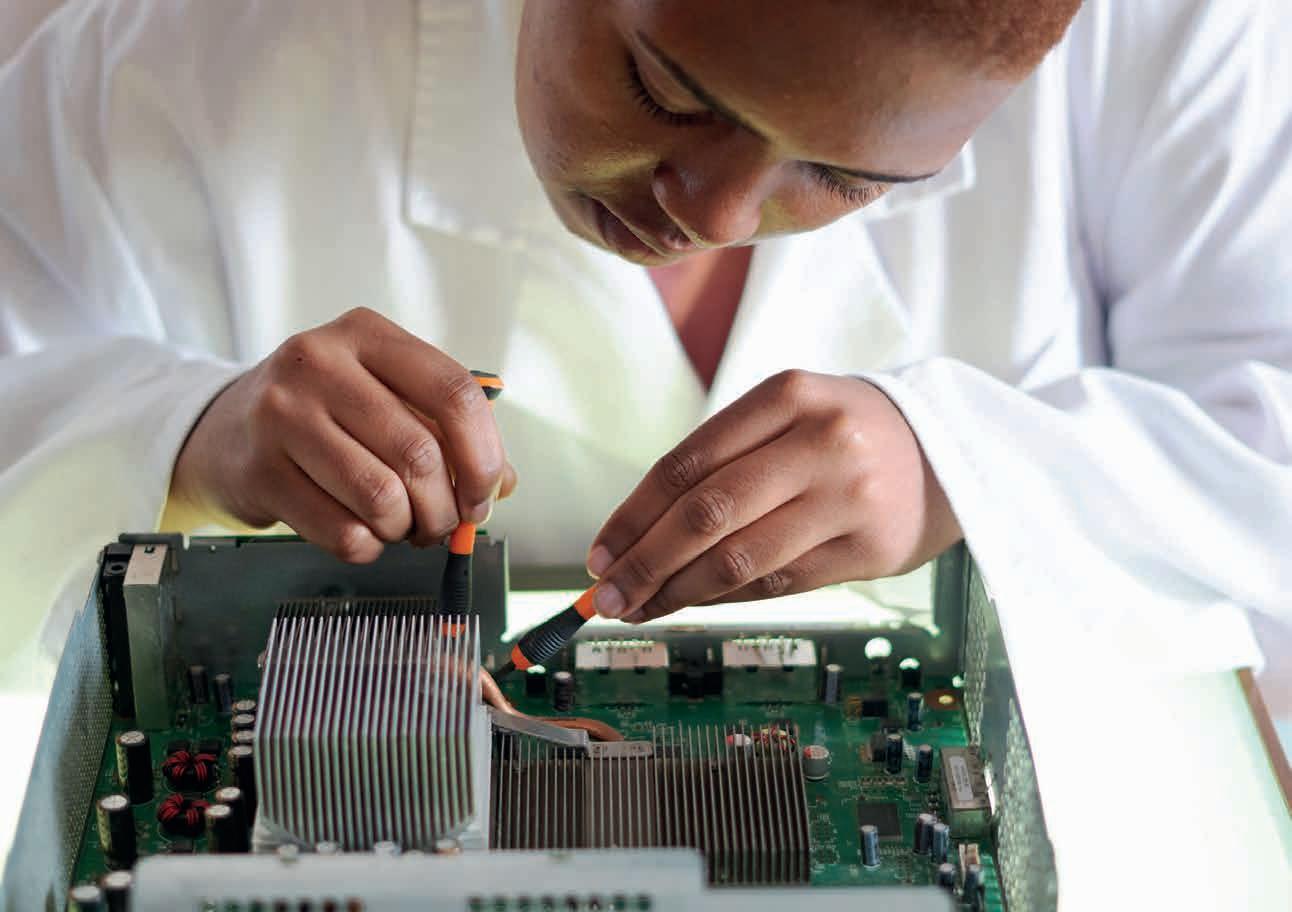

BluGlass Limited, a Silverwater-based semiconductor manufacturer, recognised potential for growth since its humble beginnings at Macquarie University. Before its official inception, the company pioneered experimental technology, but are now producing its own products using the same revolutionary tech. Manufacturers’ Monthly reports.

BluGlass Limited is an Australian technology company specialising in the development of novel semiconductor materials and devices for the semiconductor industry.

The company specialises in a unique form of semiconductors called compound semiconductors.

BluGlass’ pioneering technology, known as remote plasma chemical vapor deposition (RPCVD), provides numerous advantages to its customers.

This technology enables the production of highquality semiconductor materials, such as gallium nitride (GaN) and indium gallium nitride (InGaN), with significant advantages over traditional deposition methods.

“Most people are very familiar with silicon, the standard semiconductor that companies like Intel and AMD use in computer chips,” said Ian Mann,

chief operations, and technology officer at BluGlass.

“Whereas silicon is a single element semiconductor, compound semiconductors are made by combining two or more elements, and have several advantages over silicon chips, providing greater power, speed, stability, and light.

“The type of semiconductor BluGlass is manufacturing is called gallium nitride or GaN for short; in particular we’re focused on making GaN lasers.”

History

BluGlass Limited was founded in 2006 as a spin-off from the III-V semiconductor research group at Macquarie University in Sydney.

The company was established to commercialise ground-breaking research in the field of

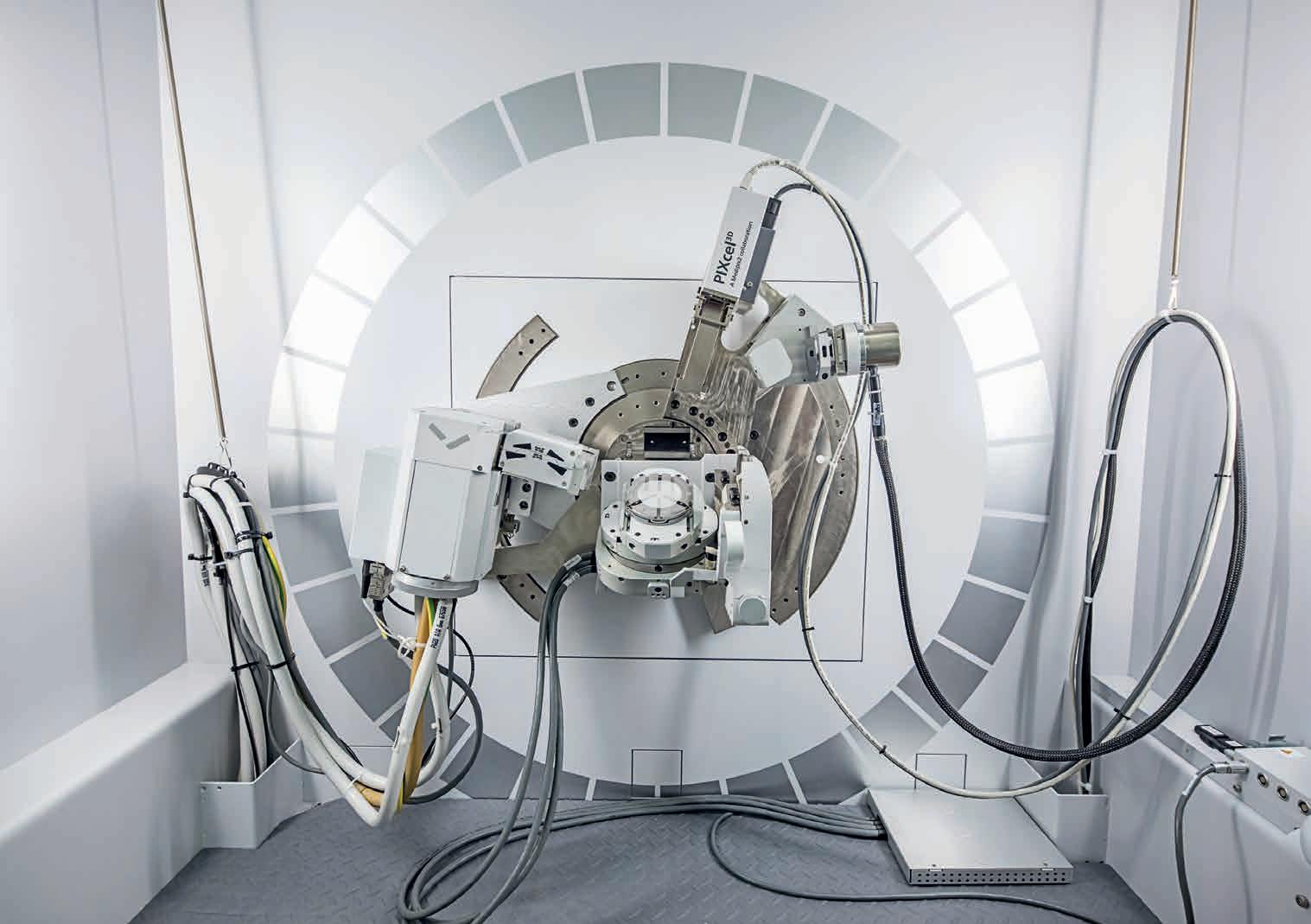

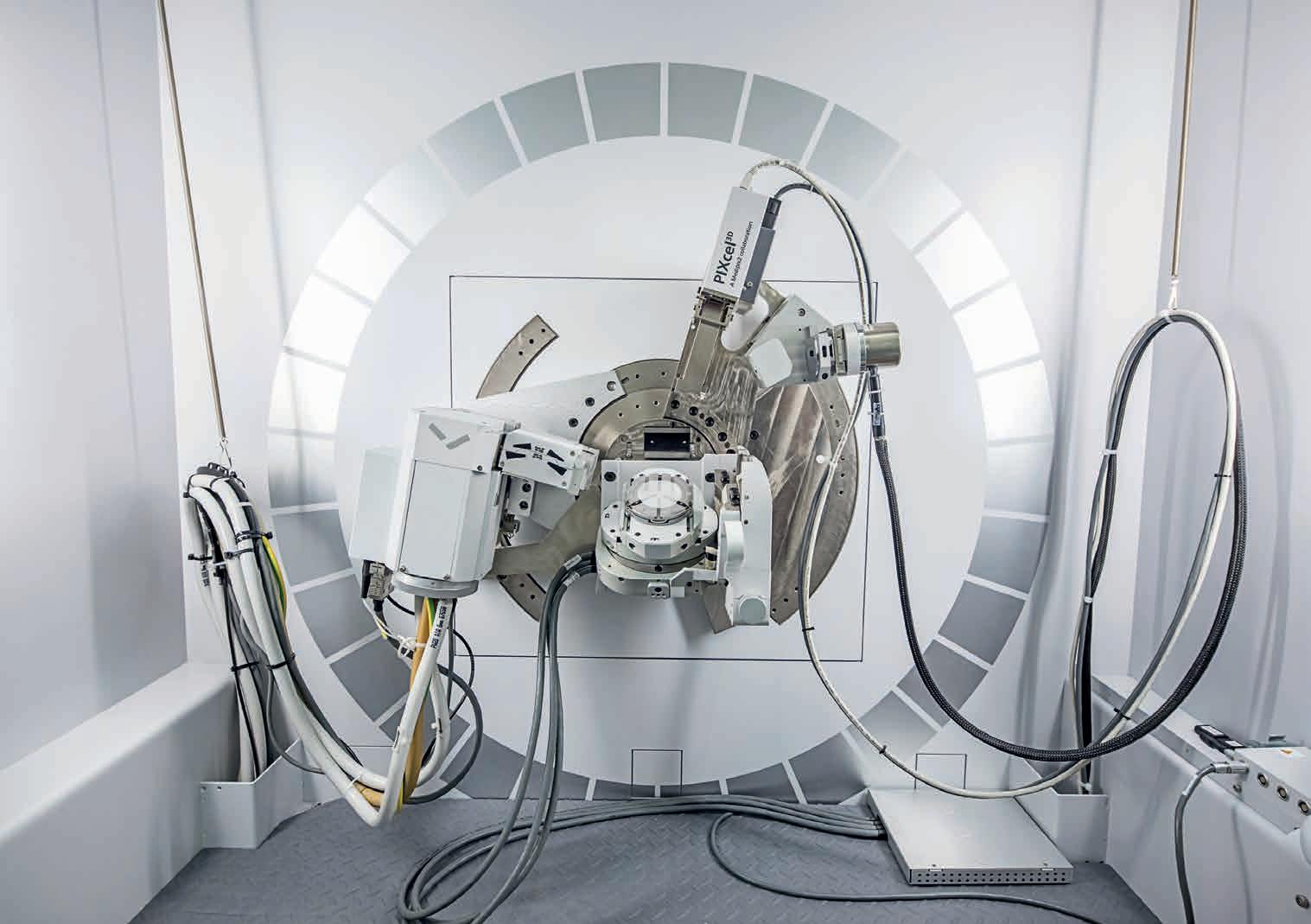

semiconductor materials, particularly focusing on the development of innovative deposition technology, RPCVD, a manufacturing reactor that grows semiconductor materials at atomic scale on specialised wafers.

This technology was designed for the manufacture of semiconductor materials, particularly gallium nitride (GaN), which is commonly used in lightemitting diodes (LEDs) and other electronic devices.

By 2007, its new state-of-the-art semiconductor deposition and demonstration facility located in Silverwater was officially inaugurated.

Shortly after Mann joined BluGlass in 2010, the company underwent a significant pivot from focusing on equipment manufacturing to optimising its proprietary RPCVD technology.

By leveraging its innovative technology, BluGlass

12 Manufacturers’ Monthly April 2024 MANUFACTURER FOCUS

Images: BluGlass

transformed into a technology-driven company.

By 2015, the company had conducted validation studies and demonstrations to showcase the effectiveness of its RPCVD technology for GaN deposition.

BluGlass also expanded its intellectual property portfolio during this period, securing patents related to RPCVD technology and semiconductor device manufacturing processes.

“We started out as a technology company, focused on selling our equipment and licensing our unique IP as our go-to-market approach for the first half of my tenure at BluGlass,” Mann said.

“As we continued to build our technology capability, both at the equipment and device level, demonstrating LEDs, lasers, microLEDs and power and electronics; while helping customers solve complex challenges, we realised that we had a unique competitive advantage with our equipment and foundry services business.”

“We realised we could capture greater market share and create more shareholder and economic value by pivoting our model and using these capabilities to our advantage, to make devices and provide them direct to customers.”

Manufacturing capability

Since 2019, BluGlass’ primary manufacturing focus has been developing and commercialising their visible laser portfolio.

In 2022, the Company acquired a full-suite laser fabrication facility in Silicon Valley to bring its downstream manufacturing supply chain in-house. BluGlass’ semiconductor manufacturing involves multiple-steps to turn the GaN wafers into laser devices ready for customer integration, which relies on facilities located in New South Wales, California, and New Hampshire.

As Mann explained, BluGlass “grows” its semiconductor materials using large and complex machines located in the company’s Silverwater facility in Western Sydney.

“These deposition systems physically grow the semiconductor materials in precise atomic structures to create the building blocks for the electronic circuits on the wafers,” he said.

“We specialise in designing specific material stacks or layers crucial for producing high-quality lasers.”

Once the materials have been produced, the wafers are then sent to its facilities in California for the microfabrication process.

“We prepare and polish the wafers, add metal contacts at the chip level for electrical connections, and cut the wafers into individual chips or bars (multiple chips) to transform those materials into lasers.”

When the lasers have been manufactured, they are then sent to New Hampshire to be packaged and reliability tested.

“Now, packaging is not putting it in a box. Highpower diode lasers require sophisticated packaging designs to protect the device in its operating environment, while managing the heat dissipated during use through specialist sealed containments and thermal heatsinks, while also preparing the device for customer integration,” said Mann.

The Company is now one of only a handful of manufacturers globally with this full-suite capability to manufacture this critical enabling technology, underpinning global megatrends.

The industry

BluGlass has established two crucial customer relationships. One notable partnership is with Applied Energetics, a company specialising in ultrashort pulse laser systems.

“They supply advanced laser systems for defence, aviation, and national security applications and are a key commercial partner,” said Mann.

Additionally, BluGlass is engaged in a collaboration and customer relationship within the US$2B US Microelectronics Commons initiative, stemming from the CHIPS Act in the US.

The initiative, supported by the US Department of Defence (DoD), focuses on advancing technology areas, with BluGlass specifically being supported by

the “lab-to-fab” pathway.

Lab-to-fab aims to facilitate a pathway from laboratory development to commercial manufacturing for semiconductor projects, helping manufacturers overcome the challenges typically encountered during this transition phase.

“Because we have a US presence, we were eligible for the commercial lab-to-fab pathway,” said Mann.

“It’s a multi-year programme, of which we’ve secured the first-year contract. As an approved commercial manufacturing partner in the Microelectronics Commons, in addition to the core program, we are working on DoD’s call for projects now. That is aimed at advancing next generation semiconductors for quantum intelligence and computing, and artificial intelligence.”

“That’s a major undertaking. Both the core development, and if we are successful in securing additional projects, this work will both accelerate and fund our roadmap and, more importantly, embed us into an ecosystem of potential customers and partners.”

The workforce

BluGlass’ workforce is currently divided between the US and Australia; with the majority now employed in the US.

13 manmonthly.com.au Manufacturers’ Monthly

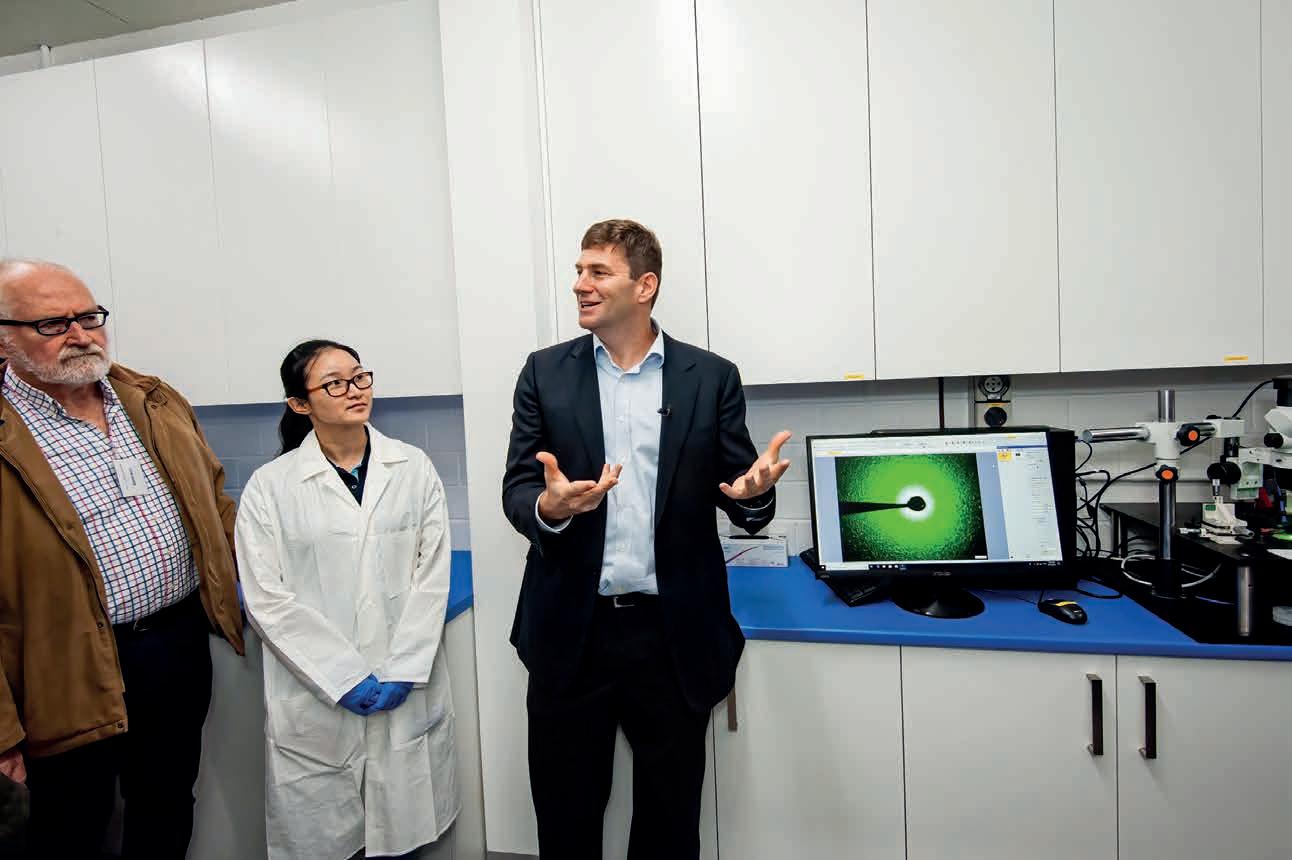

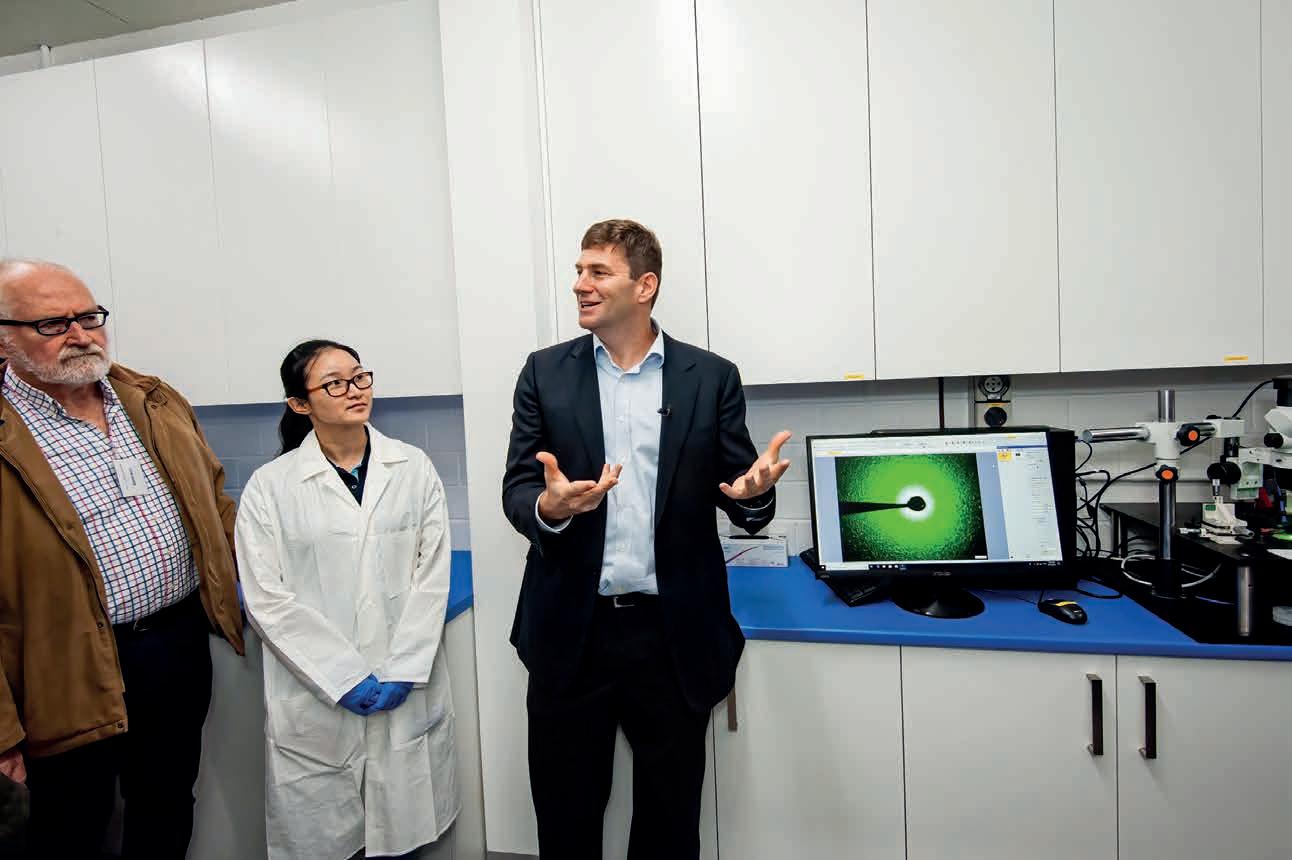

Below, Ian Mann leads an open day event at BluGlass’ facility in Silverwater.

MANUFACTURER FOCUS

As the company has grown, BluGlass has consistently expanded its US workforce.

“Our industry leading team in Australia is well established. Since the fab acquisition, we have been adding highly skilled expert staff in the US. We are very fortunate with the depth of talent now available to us in Silicon Valley, which simply does not exist domestically right now,” said Mann.

“Because of the existing capability in Australia, and now the US, we have sufficient capacity installed to fulfill the next several years of our roadmap with the right staff, and equipment.”

“We figured out a good way to collaborate with our overseas colleagues in New Hampshire and California, which is enabling us to embrace the best of all worlds.”

Hiring top talent has been challenging in both the US and Australia.

Due to the highly competitive market in the US, BluGlass is compelled to face industry giants who are hiring specialised workers at an extreme rate.

“There are a lot of people who’ve got good experience in the US and have worked at other companies. But they’re also in demand,” Mann said.

“With the prolific nature of companies like Apple, Google, and Facebook when it comes to hiring there’s a lot of competition out there for specialty skills.”

“The nice thing there is that those potential employees don’t need a lot of training, they most likely already have relevant experience, and they can hit the ground running.”

In Australia, the challenge is semiconductor hardware engineers are hard to find.

“We’re using a lot of sophisticated equipment for semiconductor manufacturing requiring strong skills in engineering, process scientists, material scientists, and physicists,” said Mann.

“But sometimes to get people who know the ins and outs of this high-tech vacuum equipment, they often need to be sourced from overseas, as there doesn’t tend to be a lot of that existing hardware engineering talent within Australia.”

“We’ve had success hiring out of the automotive industry here, and upskilling in our equipment, but it then takes time to perfect the skills,” Mann explained.

To ensure that its workforce remains strong, BluGlass has instilled a strong culture of loyalty within the company.

“The unique aspect of our hiring process in Australia is that we really build in strong loyalty, which is demonstrated by low staff-turn over,” said Mann.

BluGlass is also actively involved with multiple leading universities, offering internships, and collaborating on grants.

“That’s been a very successful approach for us from a number of schools,” said Mann.

“Given that we’ve been around for a while, we know

14 Manufacturers’ Monthly April 2024

RPCVD is a manufacturing reactor that cultivates semiconductor materials on specialised wafers at the atomic scale.

a lot of the universities, and we’ve often offered industry linkage grants, or had activity with them.”

“It’s a great way to meet some of the top upcoming talent and you get them involved either through an internship or through a collaboration, to create more skills and hands-on know-how, right here onshore.”

BluGlass is aiming to help the growth of semiconductor industry in Australia, which could entice skilled workers from overseas.

“We would love to see the semiconductor industry here in Australia grow not just for the benefit of BluGlass, but for the whole industry,” said Mann.

Visions for the future

BluGlass’ existing and next-gen laser products heavily focus on ultraviolet (UV) laser technology.

BluGlass recognises the potential for UV in diverse applications such as sterilisation, water purification, and quantum technologies.

“These are very short wavelengths, they can be used in a lot of exciting applications, such as quantum sensing applications for aviation and defence, quantum computing including for AI or utilised in advanced sterilisation and bio-medical applications,” Mann said.

Despite the challenges in manufacturing UV lasers, BluGlass also aims to extend its existing capabilities within visible wavelengths, ranging from violet to blue, through to green.

for innovative projects, willing to tackle difficult technological advancements.

“Things like water purification, that’s a rich area for innovation, but making UV lasers is very challenging,” said Mann.

“Once we’ve established our footprint in visible lasers, we will then start extending our development into these other wavelength areas.”

While this strategy may require more time and innovation, BluGlass is confident in its ability to explore new products and applications with its experienced and innovative team.

“That’s our vision and we do think that we can

“We’re willing to do some of the harder technology development, at the same time, extracting a higher profit margin for that.”

“Additionally, our lasers will potentially be designedin next-generation technologies that supersede existing markets, while opening new ones.”

Mann believes that BluGlass’ commercialisation phase is coming to fruition after collaborating with DoD and with other industry giants including General Electric, Coherent and Wolfspeed as part of its Hub in the Microelectronics Commons

Renowned for their expertise in visible lasers, BluGlass is expanding its focus to encompass additional wavelengths.

15 manmonthly.com.au Manufacturers’ Monthly

To maintain a robust workforce, BluGlass has fostered a culture of loyalty among its employees.

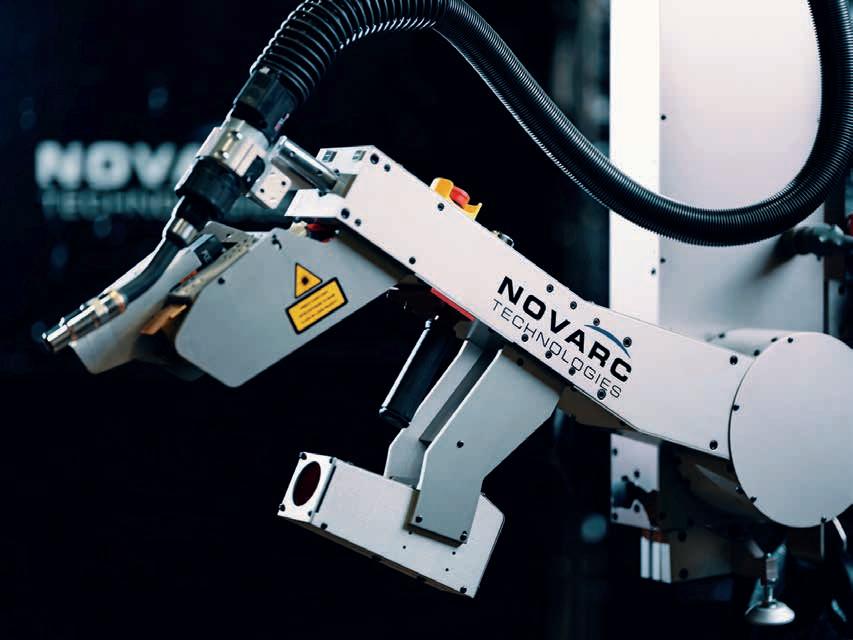

the ONLY Autonomous Spool Welding Robot

With

Space Machines has Australia’s largest satellite ready for launch

Local space company Space Machines has announced the completion of Optimus, the country’s largest private satellite to date. This pioneering Orbital Servicing Vehicle is set to launch with SpaceX next month.

The completion of Optimus marks a major milestone for Australia’s sovereign space capabilities and reinforces Space Machines’ commitment to developing innovative space solutions that are built on local soil.

As the first Australian commercial satellite capable of providing existing space infrastructure and satellites with life-extension services,

inspections and assistance on-orbit, Optimus heralds the beginning of a new era in space sustainability.

Space Machines chief executive officer, Rajat Kulshrestha said “Together, we are paving the way to provide innovative services that extend satellite lifetimes, reduce space debris, and sustainably scale space activities for the benefit of all.” Optimus carries groundbreaking technology payloads from partners and suppliers, including Advanced Navigation, which has developed a revolutionary Digital Fiber Optic Gyroscope (DFOG) Inertial Navigation System.

Global provider of on-orbit refuelling services, Orbit Fab, is supplying critical position and orientation data through its fiducial markers to ensure safe and reliable on-orbit operation.

Space Machines’ Optimus will launch as part of SpaceX’s Transporter-10 mission no earlier than March 2024 from Vandenberg Space Force Base in California.

Space Machines Company also appreciates the ongoing support from government agencies including Investment NSW, the Australian Space Agency, Defence Space Command, and the Government of South Australia.

17 manmonthly.com.au Manufacturers’ Monthly Space Machines aims to develop a next-generation fleet of in-space infrastructure servicing vehicles. Image: Andrei Armiagov/stock.adobe.com NEWS

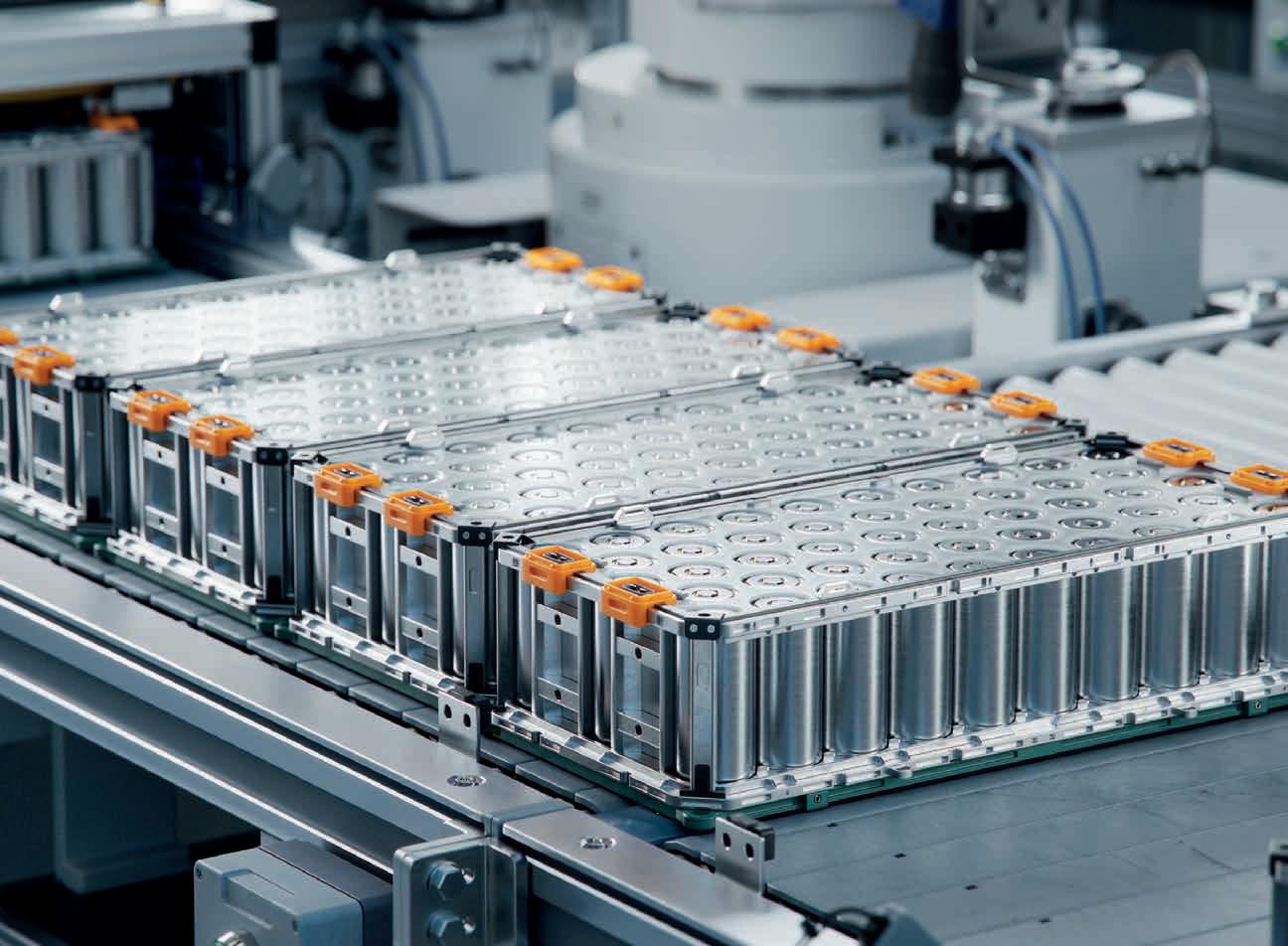

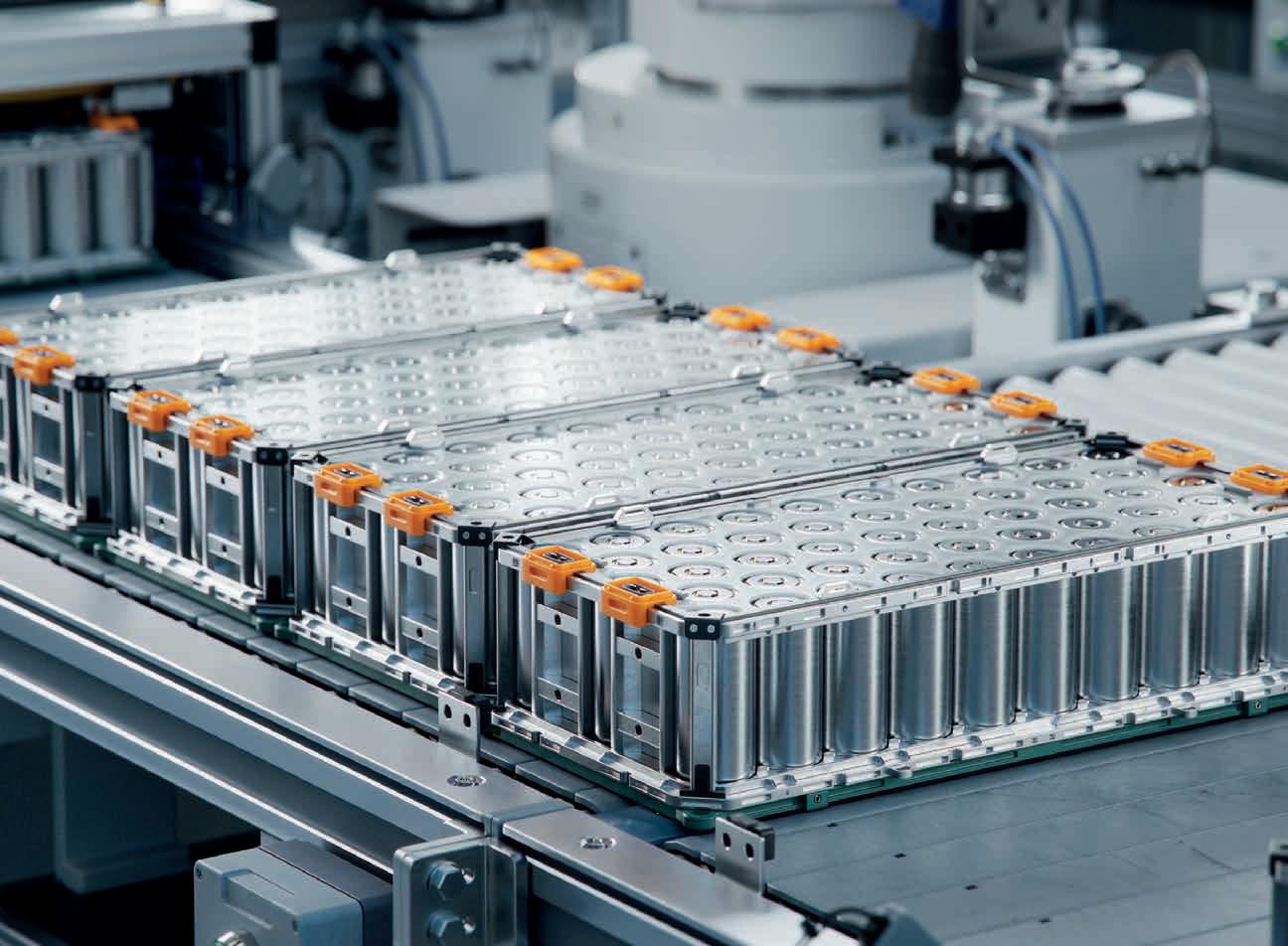

Vanadium battery manufacturing agreement signed for Townsville

Vecco Group, Sumitomo Electric and Idemitsu have signed a collaboration agreement to market, sell and deliver the batteries, from North Queensland.

Vanadium flow batteries are set to be manufactured out of North Queensland, under a new agreement between three major companies.

Idemitsu Australia, Sumitomo Electric Industries and Vecco Group (the group) have signed a Collaboration Agreement to build a complete manufacturing supply chain, from mining to energy storage.

Vanadium flow batteries are set to be a key part of Australias energy storage mix with demand rapidly increasing around the globe.

Queensland Premier Steven Miles said, “Today’s announcement shows how our 75 per cent emissions reduction target by 2035 secures investment in new blue-collar clean economy jobs across our regions.” Under the non-exclusive agreement, Idemitsu

Vecco

plans to market, sell and deliver vanadium flow batteries to Australian customers using Sumitomo Electric hardware and Vecco’s electrolyte made from vanadium mined in Queensland’s northwest minerals province.

Vecco Group will mine and refine high purity vanadium at their Julia Creek mine and manufacture battery electrolyte in Townsville. Detailed design for a commercial production facility is underway.

To cater for the growth expected under this new agreement, Vecco has now secured a 3.2-hectare site at Cleveland Bay Industrial Park (CBIP), in the Townsville State Development Area, for its commercial production facility.

Resources minister and Townsville MP Scott Stewart said, “There is potentially $500 billion dollars of critical minerals in the Northwest Minerals Province and vanadium is one of the commodities Queensland can supply to the world.”

Vecco Group received support from the Industry Partnership Program to establish Australia’s first vanadium electrolyte manufacturing facility which is currently operational in Townsville.

Vecco Group managing director Tom Northcott said, “Over 7.4GWh of vanadium flow battery projects globally are currently under construction or have been announced in the last 12 months.”

“The decision for Idemitsu to market and deploy vanadium flow batteries using Sumitomo and Vecco products acknowledges the scale of the opportunity,” said Northcott.

An end-to-end vanadium flow battery manufacturing supply chain means Queenslanders will be making batteries in Queensland from critical minerals mined in Queensland. That means more blue-collar mining and manufacturing jobs in North Queensland providing the batteries needed for renewable energy.

18 Manufacturers’ Monthly April 2024

NEWS

Image: IM Imagery/stock.adobe.com

has secured a 3.2-hectare site at Cleveland Bay Industrial Park in Townsville to meet the expected growth from the new agreement.

$11.1bn investment to deliver Navy’s enhanced lethality surface combatant fleet

The Federal Government’s blueprint for the Royal Australian Navy’s enhanced lethality surface combatant fleet will deliver direct investment to grow a capable, resilient, and competitive sovereign defence industrial base and support Australian jobs.

The Government has committed to increase Defence’s funding in the 2024-25 Federal Budget by $11.1 billion over the next decade to ensure the enhanced lethality surface combatant fleet is funded.

Australian shipbuilders and industry will be at the centre of delivering this future fleet. The Federal Government is providing a clear pipeline of work and setting the conditions for job creation, technology investment, export opportunities, supply chain resilience, infrastructure enhancement and economic prosperity.

Over the next ten years, this investment will support more than 3,700 direct jobs and deliver the critical infrastructure required at the Osborne shipyard in South Australia and Henderson shipbuilding complex in Western Australia.

Deputy prime minister, the hon Richard Marles MP said “After inheriting the oldest surface fleet Navy has operated in its history, this blueprint will see Navy equipped with a major surface combatant fleet

over twice as large as planned when we came to government, with more surface combatants in the water sooner.”

Combined with more than 4,000 estimated jobs created to build the new Submarine Construction Yard in South Australia and the more than 4,000 direct jobs to build conventionally armed, nuclearpowered submarines in Australia, Osborne will be at the epicentre of a naval shipbuilding jobs revolution in this country.

“The delivery of an enhanced lethality surface combatant fleet and sovereign shipbuilding industry will help secure Australia’s economic prosperity and trade, and help keep Australians safe,” said Marles.

Government invests $3.4m for Defence Industry Manufacturing grants

The Federal Government is investing $3.4m in innovative Australian businesses to support the delivery of cutting-edge defence capabilities while creating highly skilled jobs and boosting local manufacturing.

The latest round of the Defence Global Competitiveness and Sovereign Industrial Capability Priority programs will provide 50 per cent matching grants to 10 businesses, creating more than 50 jobs and helping to drive exports.

Grant recipients include a New South Wales company developing state-of-the-art counter-drone technology, a South Australian producer of composite structures for guided munitions and hypersonic vehicles. It also includes a Queensland business that manufactures complex components for use in precision guided munitions and hypersonic vehicles.

This vital assistance adds to more than $100m already awarded to over 230 Australian businesses under the two grant programs which support delivery of capabilities prioritised in the Government’s

response to the Defence Strategic Review. Some of the latest recipients are:

• Aerobond (SA) receiving $849,876 to acquire and commission a 5-axis computerised numerical control machining centre, composite filament winding machine and related manufacturing capabilities for production and integration of composite structures and electronics in support of guided munitions, hypersonics and integrated defence systems.

• U-Neek Bending Co (VIC) receiving $631,833 to acquire and commission a Trumpf TruLaser Weld 5000 system for welding complex metal parts used in aerospace, land combat vehicles and munitions.

• Advanced Navigation (NSW) receiving $278,756 to acquire a wire bonder and associated equipment to establish a photonic chip assembly and characterisation capability, for use in inertial navigation and navigation Doppler Light Detection and Ranging (LiDAR) systems.

• Protonautics (QLD) receiving $245,267 to acquire

Consolidation of the Henderson precinct is currently underway, as recommended by the Defence Strategic Review. Successful and timely consolidation will enable eight new general-purpose frigates to be built at the Henderson precinct and will also enable a pathway to build six new Large Optionally Crewed Surface Vessels in Western Australia.

Minister for defence industry, the hon Pat Conroy MP said, “The innovation and ingenuity of our dynamic defence industry is critical to the Albanese Government’s plan to deliver four times as many warships in the next 10 years compared to what had been planned by the previous government.”

and commission a computerised numerical control multi-tasking turning centre, measurement probes and non-destructive test capabilities to support the manufacturing of components for precision guided munitions and hypersonic vehicles.

Minister for defence industry, Pat Conroy stated, “The Government is committed to making sure Australian Defence Force personnel are equipped with the capabilities they need to keep Australians safe and protect our national interests.

19 manmonthly.com.au Manufacturers’ Monthly

Rafael Ben-Ari/stock.adobe.com

Image:

The Navy’s future surface combatant fleet will feature upgraded Hobart class air warfare destroyers, Hunter class frigates, new general purpose frigates, and Large Optionally Crewed Surface Vessels.

Image: Ryan/stock.adobe.com

These programs prioritise capabilities outlined in the Government’s response to the Defence Strategic Review.

Global pharmaceutical manufacturer arriving in South Australia

Global pharmaceutical company, Noumed, has made groundbreaking construction towards its $100 million pharmaceutical manufacturing facility at Salisbury, creating 250 construction jobs and 180 ongoing jobs upon completion.

Noumed Pharmaceutical, part of the United Kingdom’s Noumed Life Sciences, is building its first Australia manufacturing plant in Salisbury after receiving $20 million to support construction under the previous Federal Government’s Modern Manufacturing Initiative.

An integrated generics pharmaceutical company, the local facility will produce onshore, 40 million units of tablets, liquids and creams a year, which will replace products currently manufacturing in the United Kingdom.

The 43,000m² facility, which is two and a half times the size of Adelaide Oval, will enhance Australia’s sovereign supply into the pharmacy network and will be one of Australia’s largest drug manufacturing investments in recent years.

Noumed is located at the Nexus North Industrial Estate, next to Mayne Pharma and close to other medical manufacturers including ophthalmic equipment makers Ellex Medical.

One million AI introduction scholarships now available to Australians

Artificial intelligence scholarships are now on offer to one million Australians, in a bid to increase the nation’s literacy of a technology estimated to be worth $4 trillion to the economy by the early 2030s.

The free ‘Introduction to Artificial Intelligence’ microskill course is provided by the National AI Centre (NAIC), coordinated by Australia’s national science agency, CSIRO, and the Institute of Applied Technology Digital (IATD).

The course will provide a non-technical introduction to AI fundamentals and is designed for people at the beginning their AI literacy journey.

With many small to medium enterprises (SMEs) grappling with the challenge of adopting AI the course is an opportunity for business owners to deepen their understanding.

NAIC director Stela Solar said, “SMEs make up over 98 per cent of Australia’s economy, and ‘Introduction

to AI’ is their opportunity to learn how they can use this revolutionary technology to enhance their operations, services, and market competitiveness,” Ms Solar said.

Minister for industry and science Hon Ed Husic said, “This is practical and pragmatic support for small businesses, who don’t have the same access to tech know-how as big business, but have just as big a need to improve productivity.”

This makes it ideal for workers seeking to upskill, individuals starting their career in AI, and small to medium business owners.

Council of Small Business Organisations Australia (COSBOA) chief executive officer Luke Achterstraat said, “This microskill course will help build confidence and competency for small businesses as they navigate the AI landscape.”

Director of IATD operations Helen Fremlin said, “No programming or computer science background is required for students to enrol, and the virtual nature of this course facilitates an easier path for Australians to upskill in AI, whenever and wherever they choose.”

20 Manufacturers’ Monthly April 2024 NEWS

Image: Shuo/stock.adobe.com

Image: IM Imagery/stock.adobe.com

Students will receive a certificate of completion upon finishing the course.

The local facility will annually manufacture 40 million units of tablets, liquids, and creams onshore.

NSW Government grants $275m for Net Zero Manufacturing Initiative

The NSW Government has announced $275 million in grants under the Net Zero Manufacturing Initiative, to secure NSW as the place to develop and manufacture clean technology and create new jobs in the process.

The Net Zero Manufacturing Initiative will support workers, small businesses, manufacturers, and innovators to take advantage of the transformation of our energy grid.

NSW Premier Chris Minns, said, “These grants will bolster local manufacturing in the renewables and clean-technology industries, ultimately delivering more local, secure jobs.”

The move to net zero will also transform our economy, and these grants will ensure NSW manufacturing is part of this revolution.

Minister for climate change and energy, Penny Sharpe said, “These grants are all about ensuring NSW manufacturing is part of this revolution. They will lead to new secure, long-term jobs that are good for the planet but also build wealth in local communities and give NSW security and sovereignty of the renewable energy supply chain.”

The initiative will deliver more local, secure jobs

across the state, and support the diversification of our regional economies.

This investment areas include future energy systems and storage, transportation, built environment, biomanufacturing, power-fuels including hydrogen and agricultural technologies.

The Net Zero Manufacturing Initiative will offer the grants to three markets.

Renewable Manufacturing: increasing capacity to make the components for renewable energy projects, which will alleviate supply chain constraints and increase local content capability.

Such as projects that include constructing a brand-new facility for the manufacture of solar cells, or supply chain parts for renewable energy transmission.

Clean Technology Innovation: helping businesses get scalable low-emission technologies, marketready.

For example, prototypes of next generation residential batteries, or new laboratory equipment that can test a material’s ability to store hydrogen atoms.

Low Carbon Product Manufacturing: establishing

industrial facilities and manufacturing capabilities that can take advantage of investment in new and emerging low carbon industries.

Such as building a new facility for the manufacture of low-carbon laminate timber or implementing a new production line within an existing biomass facility for manufacturing biodiesel.

The Net Zero Manufacturing Initiative will focus on already lab-proven technologies and the manufacturing of market-ready products that are ready to be scaled up and rolled out across NSW.

This will support NSW’s 5 Renewable Energy Zones and hydrogen hubs, giving them access to more materials produced in NSW.

Minister for domestic manufacturing and government procurement, Courtney Houssos said, “For every one job in manufacturing, three-and-ahalf other jobs are sustained in the supply chain. We want those secure, well-paid manufacturing jobs to be in NSW.”

The investment areas are aligned to the opportunity areas identified through the NSW Decarbonisation Innovation 2023 Study, released by the Office of Chief Scientist and Engineer.

21 manmonthly.com.au Manufacturers’ Monthly

Image: Phattana/stock.adobe.com

The initiative will create additional secure jobs locally and aid in diversifying regional economies.

Hysata welcomes UN climate official to Port Kembla electrolyser facility

Australian electrolyser company Hysata hosted executive secretary for the United Nations executive secretary of the United Nations Framework Convention on Climate Change (UNFCCC) Simon Stiell last Friday in Port Kembla.

Minister for climate change and energy the Hon Chris Bowen MP and member for Cunningham Alison Byres MP joined Mr Stiell for a tour of Hysata’s electrolyser manufacturing facility during his first official visit to Australia.

Hysata chief executive officer Paul Barrett said, “It was a huge honour for Hysata to welcome Mr Stiell, the United Nations’ leading authority on climate change to showcase our high efficiency electrolyser and manufacturing capability.”

“Mr Stiell had some incredibly insightful comments about the urgency of global climate action, and the importance of government, industry and academia working together to solve challenges,” said Barrent.

“Mr Stiell recognises that green hydrogen has a vital role to play in the deep decarbonisation of the hard-to-abate sectors such as chemical and steel manufacturing, high-grade industrial heat and heavy transportation.”

Hysata is an Australian electrolyser company headquartered in Wollongong that is developing a completely new type of electrolyser, featuring the world’s most efficient electrolysis cell.

“We are incredibly humbled the Minister chose

Hysata as an example of Australian ingenuity for Mr Stiell’s first official visit to Australia and being able to showcase the potential of the Illawarra region in the transition to net zero,” said Barrent.

Electricity makes up most of the cost of green hydrogen and therefore, the most efficient electrolyser will deliver the lowest cost hydrogen.

“Mr Stiell recognises that green hydrogen has a vital role to play in the deep decarbonisation of the hard-to-abate sectors such as chemical and steel manufacturing, high-grade industrial heat and heavy transportation,” said Barrent.

Backed by leading global investors, Hysata is moving rapidly towards manufacturing at the multigigawatt scale needed to address climate change.

22 Manufacturers’ Monthly April 2024 NEWS

peter/stock.adobe.com

Image:

According to ARENA, the Port Kembla facility has the potential to transform the economics of renewable hydrogen production.

Victoria revealed as Australia’s $1bn fashion manufacturing capital

Victoria has been named the nation’s biggest clothing manufacturing capital with the sector valued at almost $1 billion, according to Australian Fashion council.

With its eco-system of fibre, manufacturing, retail, and wholesale, alongside repair and second-hand retail, Victoria has the most complete clothing supply chain in Australia.

The Australian Fashion Council (AFC) in partnership with Epson Australia, commissioned RMIT to quantify the true value of the Victorian textile, clothing & footwear (TCF) manufacturing sector.

AFC have announced, as part of a full report due to be released in April, that Victoria’s TCF manufacturing industry is valued at $960 million in economic value and employs 10,300 people.

NSW is the second highest state, employing 9,000 people.

Chair of the AFC Marianne Perkovic said, “Victoria can be a global leader in advanced, sustainable manufacturing, while boosting jobs and developing skills in an industry that generates a huge $960 million.”

Victoria is best positioned to lead Australia’s

transition into a circular and sustainable economy due to its most complete clothing ecosystem, including fibre, manufacturing, retail, wholesale, repair, and second-hand retail.

This initial research shows employment, exports, imports, and revenue in the TCF manufacturing sector have stabilised.

A recommendation from the report is to optimise microfactories. Microfactory technology has allowed small, on-demand and quick-to-market merchandise offerings to inject newfound vitality

CSIRO’s flexible solar cells launched into space aboard private satellite

State-of-the-art printed flexible solar cell technology developed by Australia’s national science agency, CSIRO, was successfully launched into space today aboard Australia’s largest private satellite, Optimus-1, on Space X’s Transporter- 10 mission.

Space program director of CSIRO, Dr Kimberley Clayfield said, “CSIRO’s printed flexible solar cells could provide a reliable, lightweight energy solution for future space operations and exploration.”

CSIRO is exploring the potential of printed flexible solar cells as a reliable energy source for future space endeavours, in collaboration with Australian space transportation provider, Space Machines Company.

“If the space flight test reveals similar performance as we’ve shown in the lab, this technology offers significant advantages over traditional silicon-based solar,” said Clayfield.

Eight mini-modules of CSIROs Australian-made printed flexible solar cells were attached to the

surface of Space Machine Company’s Optimus-1 satellite.

CSIRO renewable energy systems group leader Dr Anthony Chesman said, “Our perovskite cells have been achieving incredible outcomes on earth and we’re excited that they’ll soon be showcasing their potential in space.”

The completion of Optimus is a milestone for local Space Machines Company.

Space Machines Company chief executive officer Rajat Kulshrestha said, “Through perseverance and teamwork, our engineers and scientists, alongside partners like CSIRO, have created something truly ground-breaking.”

This launch is a great opportunity for Australian technology to contribute to global space exploration.

“Based on our research we expect our printed flexible solar cells will stand up to the effects of cosmic electron and gamma radiation which can compromise the performance and integrity of traditional solar cells,” said Chesman.

into the industry.

Managing director of Epson Australia Craig Heckenberg said, “By embracing the latest digital printing technology with localised, demand-driven manufacturing, these nimble entities signifi cantly reduce waste and enhance effi ciency, aligning perfectly with the principles of the circular economy while delivering speed to market.”

The initial report findings are available from www.ausfashioncouncil.com and the full report will be released in April 2024.

“We are also confident these cells will outperform traditional cells in cases where sunlight hits them at non-optimal angles.

The printed flexible solar cell technology was successfully launched into space on 5 March 2024 aboard Australia’s largest private satellite, Optimus-1.

23 manmonthly.com.au Manufacturers’ Monthly

Image: zhengzaishanchu/stock.adobe.com

Image: CSIRO

According to the Australian Fashion Council, Victoria has the highest number of individuals employed in fashion manufacturing compared to any other state.

CSIRO’s recent paper in ACS Applied Energy Materials explores the potential of printed flexible solar cells in space.

Australia’s biggest renewable power deal signed by industry leader

Rio Tinto has signed Australia’s largest renewable power purchase agreement (PPA) to date to supply its Gladstone operations in Queensland, agreeing to buy most of the electricity from Windlab’s planned 1.4GW Bungaban wind energy project.

The agreement, which of follows the announcement last month of PPA for the Upper Calliope solar farm in Queensland, will make Rio Tinto the biggest industrial buyer of renewable power in Australia and is another major step in the work to repower the company’s Gladstone production assets of Boyne aluminium smelter, Yarwun alumina refinery and Queensland alumina refinery.

Under the new PPA with Windlab, Rio Tinto will buy 80 per cent of all power generated from Bungaban wind energy project over 25 years. The project which, is currently in early development, will be built and operated by Windlab at a site in Queensland about 40 kilometres from the town of Wandoan, and 290 kilometres south-west of Gladstone, subject to development and grid connection approvals.

The remaining 20 per cent of the project’s generated electricity will supply Australia’s

National Electricity Market, delivering clean electricity to homes and businesses.

Rio Tinto chief executive Jakob Stausholm said, “This agreement with Windlab builds on our momentum in our work to repower our Gladstone operations and provide a sustainable future for heavy industry in Central Queensland.”

The PPA is the second renewable power deal signed for Rio Tinto’s Gladstone operations, after the recent agreement signed with European Energy to drive development of the 1.1GW Upper Calliope solar farm.

“Competitive capacity, firming and transmission, are critical to developing a modern energy system that can ensure more large-scale renewals development in Queensland and help guarantee the future of Australian industry,” said Stausholm.

Once developed, the combined 2.2GW of renewable PPAs with Windlab and European Energy have the potential to lower carbon emissions by about 5 million tonnes per year and could generate the equivalent of 10 per cent of Queensland’s current power demand.

Windlab chief executive officer John Martin said, “This agreement highlights the importance

of large-scale renewable energy projects in shoring up Queensland’s powerhouse traditional industries, particularly minerals and advanced processing, which employ thousands of people in regional communities across the state and have a key role to play in our nation’s low-carbon future.”

The Bungaban PPA will bring more renewable power into one of Australia’s most important industrial hubs and marks another step towards Rio Tinto’s climate goal of having its global scope 1 and 2 carbon emission this decade. If combined with more renewable power and suitable firming, transmission, and industrial policy, the Bungaban and Upper Calliope PPAs could also provide the core solution to repower Rio Tinto’s three Gladstone production assets.

“Bungaban is a key transition opportunity that will create up to 600 new Queensland construction jobs and inject around $500 million into regional economy through local economy, supply and contacting,” said Martin.

Once approved, construction of the Bungaban project is targeted to start in late 2024 and is expected to produce electricity by 2029, employ up to 600 people during construction and support up to 30 permanent jobs when operating.

24 Manufacturers’ Monthly April 2024 NEWS

Image: Tobias Arhelger/stock.adobe.com

Under the new PPA with Windlab, Rio Tinto has committed to purchasing 80 per cent of the total power generated from the Bungaban wind energy project over the next 25 years.

Australian Innovation goes global

Innovation and quality have powered Australian manufacturer Ozroll from Dry Creek in South Australia to markets across Europe. With an office in Germany and customers in Poland, the Czech Republic, Switzerland, Austria, France, and Spain, Ozroll’s story highlights Australian manufacturing competence and a relentless pursuit of excellence.

Established in 1999, the Ozroll Group has become the Australian market leader in aluminium louvres, plantation shutters, outdoor blinds, and roller shutter manufacture. Further to this, Ozroll offers an exclusive array of 12V drive systems and produces high-quality paints, renders, and textures.

The company’s roots remain firmly planted in Australian soil, with a 14,500-square-metre production facility in Dry Creek and a new 6,000-square-metre Queensland facility. From its inception, Ozroll has been on an upward trajectory, marked by strategic investments in advanced machinery, such as German roll formers, and a strong presence in international trade shows like the R+T in Stuttgart.

A massive post-millennium surge saw Ozroll triple its staff and expand its national footprint. This growth was not just in numbers but also in reputation, as the company became renowned for its quality and rapid production. “We make high-quality parts quickly, and with aluminium louvres, we’ll do pretty much any colour under the sun,” said general manager Jack McDonald.

“Our cyclone rating is huge – we make certain types

of panels that can stand up to 250-kilometre winds,” McDonald said, emphasising the robustness of their products.

Ozroll produces up to 300 roller shutters in a single shift and runs two shifts daily; with its three state-

of-the-art roll-forming machines, its commitment to quality is unwavering.

The company’s innovative spirit is best exemplified by the Ozroll Drive System (ODS), a 12-volt battery control unit that revolutionised automation in

26 Manufacturers’ Monthly April 2024 ALUMINIUM MANUFACTURING

Ozroll’s success story extends beyond innovation and growth; it includes creating jobs and showcasing Australian industry globally.

Capral

With a workforce of over 200 highly skilled employees, Ozroll exemplifies the potential of Australian manufacturing. Images:

the roller shutter industry. The L10 motor, a part of this system, was a game-changer, leading to Ozroll’s international expansion and establishing a permanent office in Frankfurt, Germany.

Adopting Capral’s low-carbon aluminium LocAl marks a new chapter in Ozroll’s commitment to sustainability. “Aluminium is highly recyclable and versatile. We’ve just started purchasing Capral’s new green aluminium LocAl. With such huge reductions in carbon emissions, LocAl is the perfect option for us,” McDonald shares, highlighting the company’s environmental stewardship.

Capral Aluminium, a key partner in Ozroll’s journey, has been instrumental in supporting and facilitating Ozroll’s growth.

“Working with Capral feels like a partnership, which we appreciate,” CEO Chris Parkinson said. T his partnership has been fortified over 15 years, with Capral providing invaluable support in areas

produce aesthetically pleasing, functional, and wellengineered products.

Ozroll’s success story is not just about innovation and growth; it’s also about creating employment opportunities and representing Australian industry on the global stage. With a highly skilled workforce of over 200 employees, Ozroll underlines the potential of Australian manufacturing. “Producing beneficial products and employing local people is very satisfying,” Zwar reflects.

Ozroll’s journey from a local manufacturer to an international player is a narrative of ambition, innovation, and unwavering commitment to quality. With the adoption of Capral’s LocAl green aluminium and a partnership that strengthens its operational capabilities, Ozroll is not just riding the wave of

Following the millennium, Ozroll experienced a substantial surge, tripling its workforce and expanding its presence nationwide.

success; it is creating it.

As the company continues to expand its reach and influence, it showcases the Australian industry’s potential to innovate, grow, and compete globally.

It’s a narrative that continues to unfold, promising new chapters of growth and success in the shade industry under the heat of the Australian sun and beyond.

To learn more about Ozroll’s story in the Crafted with Capral series, follow the QR code below.

27 manmonthly.com.au Manufacturers’ Monthly

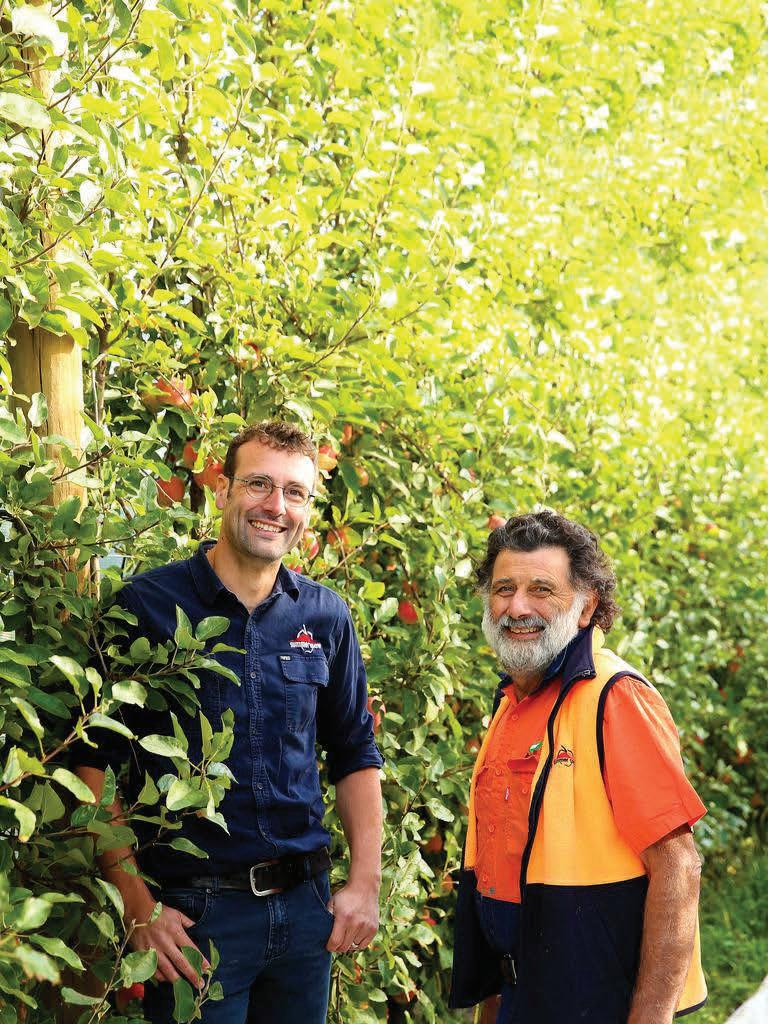

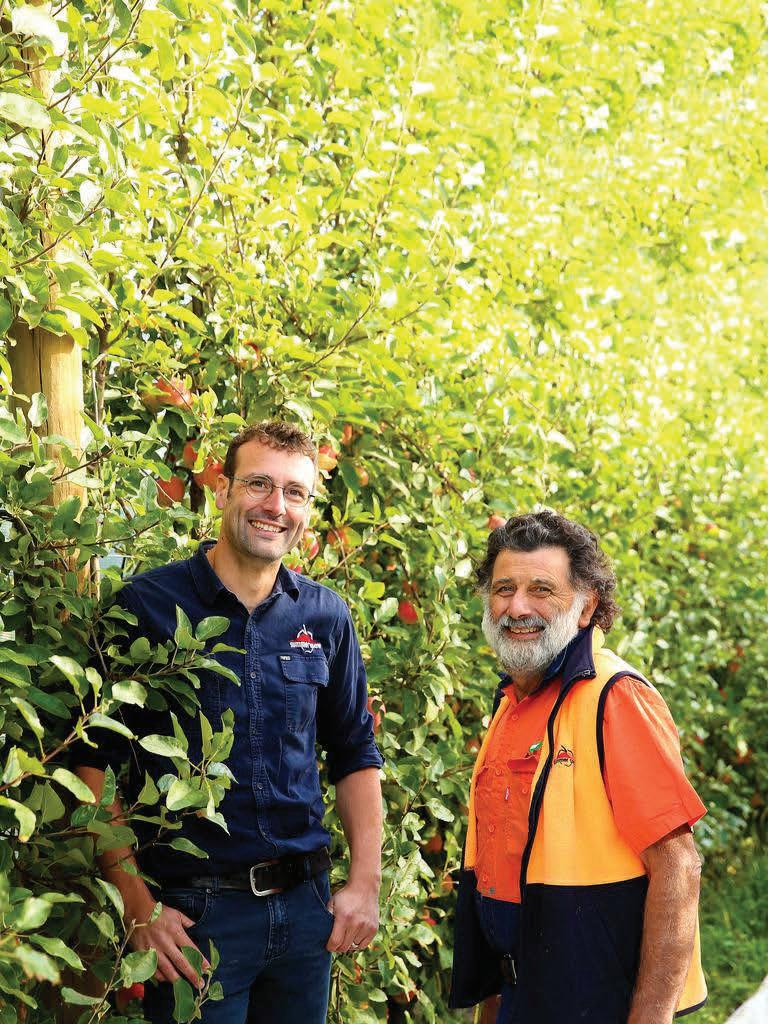

WWW.SEMMA.COM.AU https://au.linkedin.com/company/semma-au View the video on LinkedIn We joined SEMMA primarily to connect us to other support networks in the area. Whether it’s equipment maintenance, installation, automation - SEMMA has it in spades. Nick Russo | Executive Director Bellevue Orchard, Officer VIC Member since 2015 WE SUPPORT , ADVOCATE AND CONNECT MODERN MANUFACTURING: SMART, SECURE, SUSTAINABLE

SENSOR TECHNOLOGY

Versatile object detection

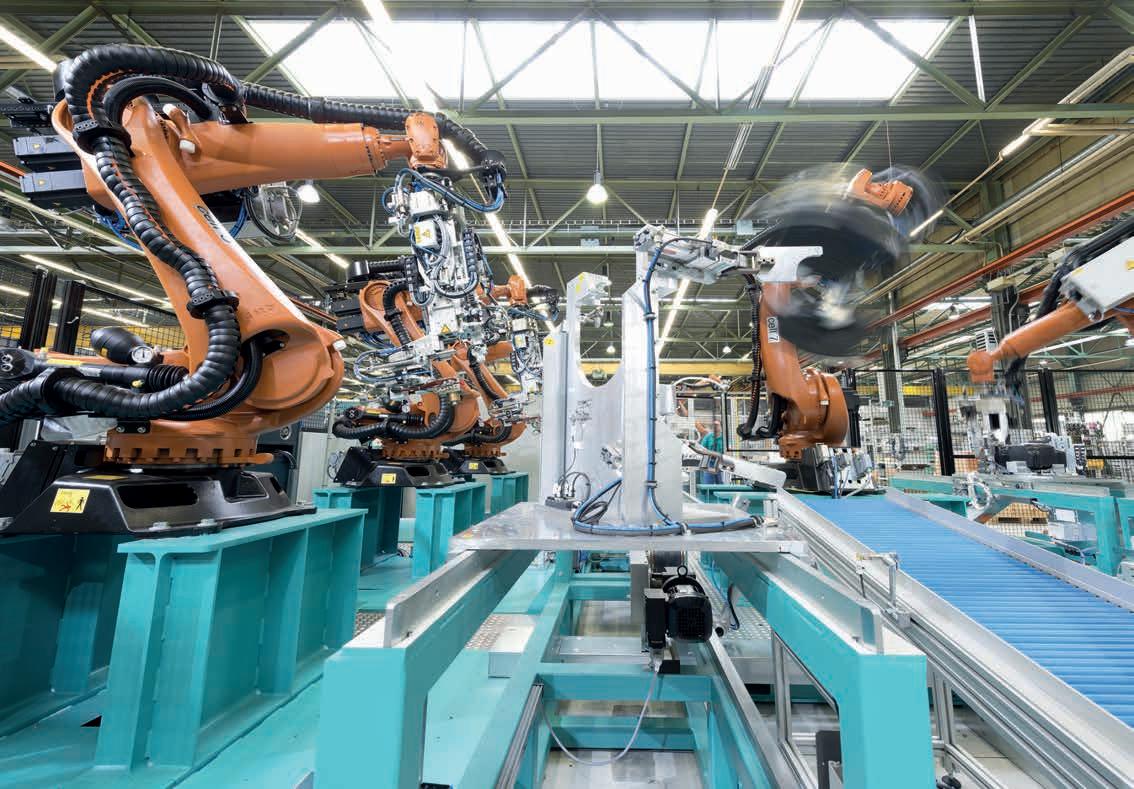

SICK has introduced the W10 photoelectric proximity sensor, a ground-breaking innovation poised to redefine the landscape of automation technology. Manufacturers’ Monthly reports.

Introducing the new W10 photoelectric proximity sensor, SICK introduces a sensor solution designed to tackle a diverse array of automation tasks more universally than ever before.

With just four variants differing in operating distances and mounting options, the sensor series significantly simplifies the typical variety of types.

Leveraging a Class 1 laser light source and precise receiver evaluation line, the sensor delivers precise detection results with remarkable repeat accuracy.

For the first time, a touchscreen interface has been integrated into a sensor of this kind, meeting demanding requirements for intuitive operation, and enhancing the user experience.

Three application-optimised operating modes, along with foreground or background suppression, can be easily activated via the display.

Moreover, situation-dependent teach-in options enable convenient adaptation to individual application scenarios.

Featuring a stainless-steel housing with IP69k protection, the sensor ensures durability even in challenging environments.

With IO-Link functionality, the sensor facilitates remote configuration and seamless integration of sensor data into existing automation networks.

The W10 embodies versatility and high flexibility in application design, offering a multitude of applications across various industrial and innovation sectors, notably in factory and logistics automation.

It excels in the robust and reliable detection of objects with diverse or challenging surface properties such as gloss, colour, or texture.

Laser triangulation sensor with intuitive user experience via touchscreen

The W10 sets itself apart by eliminating the need for traditional setting elements like slide switches, potentiometers, and rotary knobs.

This innovation is made achievable through its touchscreen display, marking this laser photoelectric proximity sensor as the pioneer of its kind.

Irrespective of whether it’s speed, standard, or precision operating modes, foreground or background suppression, individual teach-in settings, preconfigured parameters, or limit values, operators

can intuitively select, access, adjust, and save all settings effortlessly.

The W10 features a screen lock as an added security measure, ensuring settings remain protected from unauthorised access or alterations by third parties. Additionally, aside from on-device operation, the W10 offers convenient configuration via IO-Link, facilitating communication through this interface.

With two digital outputs available, the W10 can efficiently deliver switching signals.

Reliable detection thanks to precise laser triangulation

The W10 integrates a class 1 laser light source renowned for its high precision. Its focused light beam creates a minimal light spot on the object, complemented by a swift and accurate receiver evaluation line.

With the aid of this advanced technology, the photoelectric proximity sensor attains exceptionally precise detection outcomes, coupled with high repeatability.

This holds true for both the short-range version,

28 Manufacturers’ Monthly April 2024

Images: SICK

covering distances from 25mm to 400mm, and the long-range variant, spanning from 25mm to 700mm.

Such capabilities make it ideally suited for accurately detecting objects and positions.

In speed mode, the response time is 1.8ms, ensuring reliable switching behaviour even at elevated machine speeds.

Teach-in option and hybrid and robust design

Through the utilisation of dynamic algorithms tailored for specific applications, the W10 achieves a superior level of reliability and consistent repeatability straight from the factory.

The photoelectric proximity sensor provides personalised teach-in capabilities for specific adjustments.

Apart from the standard 1-point teach, which identifies objects at a set distance, the 2-point teach option allows for the detection of objects with varying heights.

The manual mode broadens the teach options, providing increased flexibility.

Both the short-range and long-range versions of the W10 are offered in two housing variants: one designed for standard mounting with a 1-inch hole, and another for hybrid mounting, allowing installation either via the M18 thread on the front or the 1-inch hole on the side.

Offering two versions, each featuring dual-colour LEDs to signify the operational status, the W10 provides extensive mounting flexibility, catering to typical installation scenarios with ease.

With a stainless-steel housing boasting an IP69k protection rating, all W10 models are exceptionally rugged, capable of enduring harsh operating conditions, aggressive substances, or frequent cleaning cycles.

The

This guarantees optimal operational availability and mitigates prolonged downtimes in various applications.

SICK’s introduction of the W10 photoelectric proximity sensor marks a significant milestone in automation technology.

With its intuitive features and versatile capabilities, the W10 stands out as a pioneer in the field.

29 manmonthly.com.au Manufacturers’ Monthly

Treotham Automation • 1300 65 75 64 • info@treotham.com.au SCAN NOW FOR MORE The leading supplier of the BIGGEST names in Automation E-Chain & BearingsCables & GlandsFlexible ConduitsConnectors Safety Sensors

W10 incorporates a class 1 laser light source known for its exceptional precision.

A MEGA showcase of sustainable warehouse innovation

Melbourne will host a dedicated space for leading manufacturers to help shape strategic plans in meeting the future needs of net zero warehouses. Manufacturers’ Monthly reports.

The Australian manufacturing industry is striving to reach lower carbon emission supply chains and warehouses. Leading professionals will convene at MEGATRANS to showcase and consider the imperative directions needed for the future of sustainable warehouses.

The MEGATRANS2024 expo will showcase offerings from advanced technology companies, grouped by the technologies and services they contribute to sustainable supply chains.

This interactive expo will feature new, leading, and innovative approaches, including those from companies of varying sizes.

To achieve a zero-carbon warehouse, a facility

must have a net-zero carbon footprint, meaning the warehouse has balanced its emitted greenhouse gases with equivalent reductions or offsets to ensure there are no net increases in carbon dioxide.

Net-zero carbon footprints can be achieved using energy-efficient practices and reliance on renewable energy sources, such as solar or wind power.

The objective of meeting zero carbon warehouses helps contribute to a more sustainable and environmentally friendly supply chain.

Businesses and industries are increasingly recognising the importance of addressing issues such as climate change and the prevalence of

implementing broader sustainability strategies to their manufacturing processes.

MEGATRANS is not only an expo showcasing technologies that aid in assisting zero carbon warehouses, but it also highlights new innovations emerging to the manufacturing market.

Manufacturers’ Monthly spoke with Nexobot cofounder and chief executive officer, Dominic Lindsay, a company exhibiting at the event.

Nexobot is a modular system building warehouse robotics to address the growing demands of warehousing and logistics sectors.

As a 2023 start-up Nexobot have developed a robot that travels beneath a barrier, allowing

30 Manufacturers’ Monthly April 2024 EVENTS AND CONVENTIONS

MEGATRANS is an interactive expo featuring companies offering advanced technologies and services grouped by their contributions to the sustainable supply chain.

Images: James Thomas Photography/Prime Creative Media

packages to be efficiently sorted into designed bins.

With the growing social pressures of business to establish sustainable supply chains Lindsay said, “essentially, we’ve seen the challenges that other people have had in the industry, and we’ve designed our entire business model around avoiding those challenges.”

The viewpoint, from an exhibiting company, of having a dedicated space such as MEGATRANS to discuss strategies that can help achieve net zero warehouses was emphasises when Lindsay said, “I think getting together and talking about strategies is obviously a really good idea but what we really need is spaces to exhibit technologies that are going to help people achieve that.”

Nexobot’s primary goal in participating at the MEGATRANS expo is to establish a strong presence and successfully introduce their product to the market.

The clear objective of Nexobot attending MEGATRANS is to gain exposure in launching their product into the market.

Lindsay said, “MEGATRANS is perfect for us because we’re primarily focused on working with people who are doing any sort of horizontal movement through a facility, and predominantly the moment in parcel sorting, which is exactly where

MEGATRANS is focused.”

Nexobot has just launched with their first customer offering a regional freight carrier a lowcost parcel sourcing solution.

Lindsay said, “We’re basically going to help him sort freight faster, more accurately and safer for his team.”

Another key sector Nexobot plan to intersect is cold supply chains, “we’ve designed the entire solution to work down to zero degrees. We use

the same robot both in a chiller as well as in an ambient facility,” said Lindsay.

Exhibition opportunities for MEGATRANS are still available, use your stand as an opportunity to showcase how you can contribute to achieving zero carbon warehouses. If you are interested in exhibiting and you would like to know more, please visit the official website at www.megatrans.com.au, or contact Emily Robertson on +61 422 103 119.

31 manmonthly.com.au Manufacturers’ Monthly

The integrated event, comprising of a conference, exhibition, and jobs pavilion, offers a chance for aligned suppliers and industry leaders to connect.

MEGATRANS gathers companies offering zero-carbon solutions, from electric industrial equipment to renewable energy solutions.

ENDEAVOUR AWARDS PROFILE

Recognising the development of robotic programming

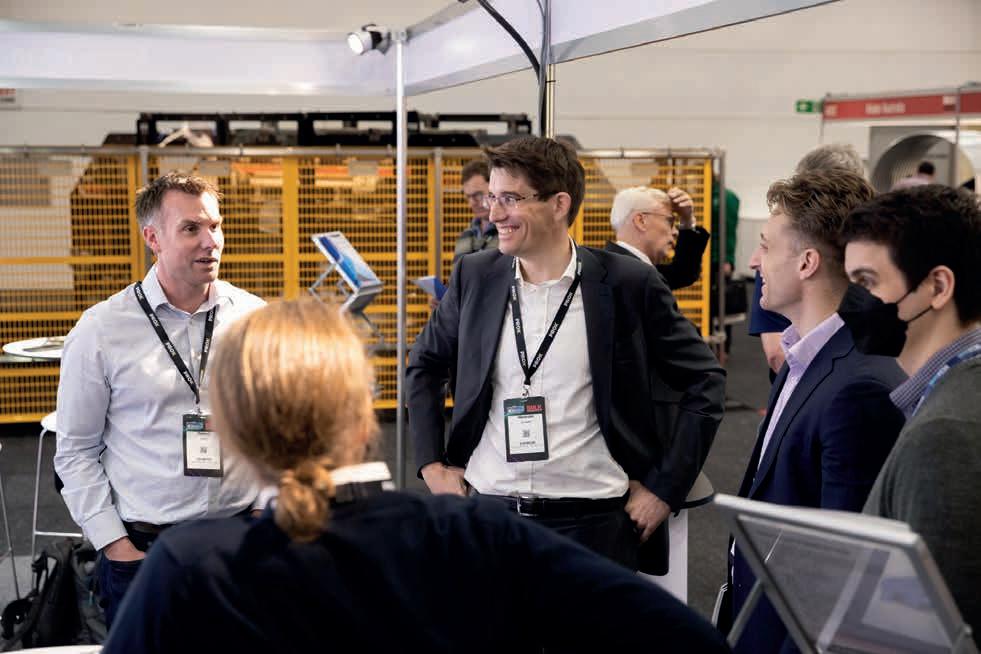

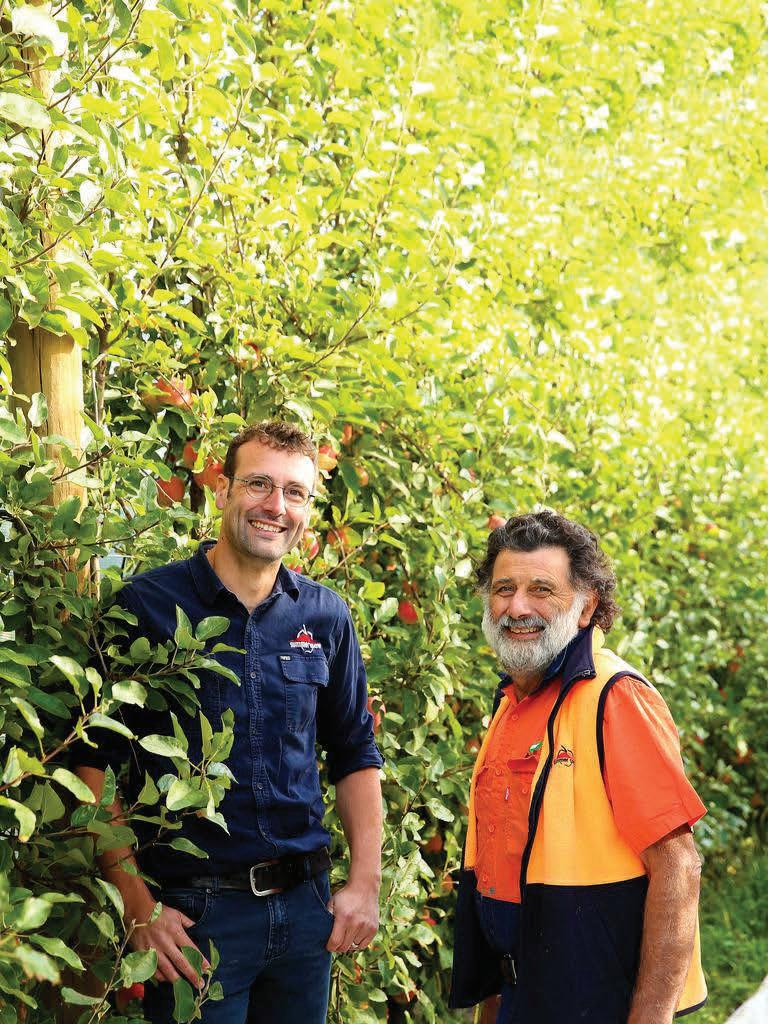

The Endeavour Awards is recognised as the premier awards program within the manufacturing industry. Australian robotic programming software company, Verbotics, was awarded winner of the 2023 Technology Application Award. Manufacturers’ Monthly reports.

The Technology Application Award, proudly sponsored by Beckhoff, recognises technologies designed to enhance manufacturing processes. This category acknowledges technology providers new to the market, catering to Australian manufacturing businesses.

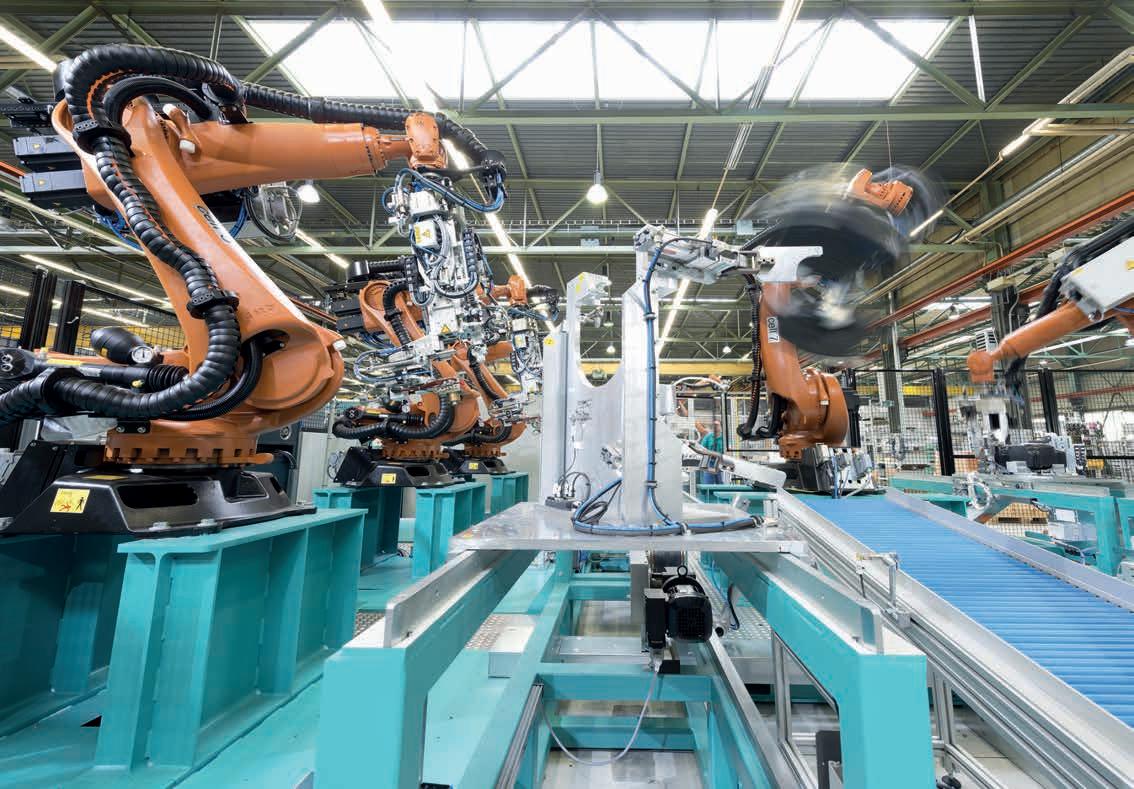

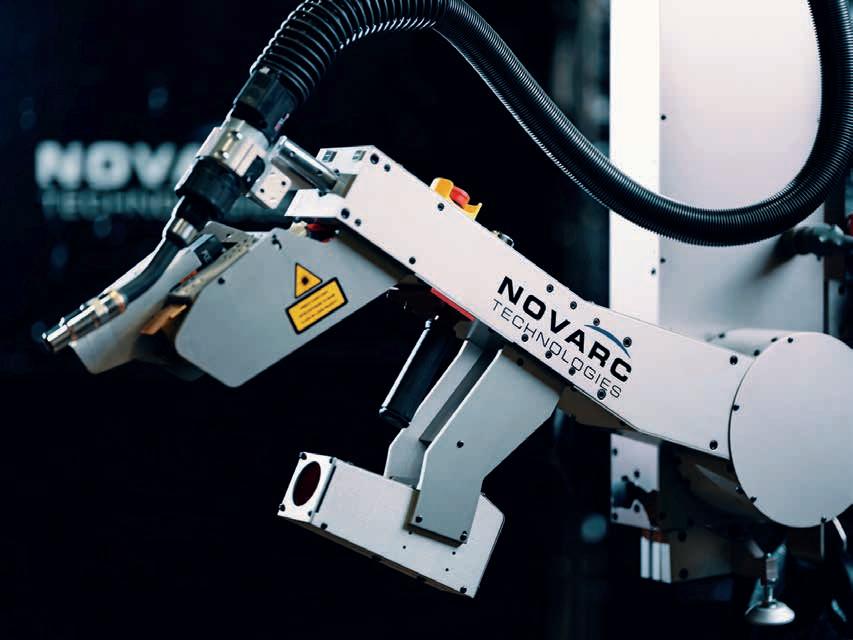

Winner for the Technology Application Award, Verbotics, has been innovating the way robotics are programmed for large and small manufacturers since 2019.

The company provides smart software for manufacturers to automatically program industrial robots, specialising in welding applications. The software produced is constructed directly from computer-aided design (CAD) to generate high quality collision-free welding programs.

Manufacturers’ Monthly spoke to Verbotics cofounder and technical director, Andrew Short, to find out more about the role of robot programming in the manufacturing industry, how Verbotics software programming influences the industry and the future of the company.

Verbotics software programming

Verbotics is a programming software designed to help remove skill barriers, time and effort limitations associated with programming robots.

The application of this technology has been implemented to help make robotic automation more accessible for manufacturers.

Their programming is achieved through a combination of 3D modelling, smart algorithms and intelligent decision making.

“We make smart software that automatically programs welding robots, instead of needing a human to come in and manually program a robot,” said Short.

“You can input a 3D model of what you want to weld, we will automatically identify where the weld paths are, and automatically plan all the robot motions to get the robot to the welds and perform the weld, while optimising for weld quality.”

A critical component of programming is accounting for differences between the simulation and the real world.

Verbotics addresses this accuracy through path finding, a process of using sensing technology to adjust the as-programmed welding path to be in the correct location.

Short said, “critically, we also include path finding.”

“The simulation and the real worlds are never going to match exactly, so we include using robot sensing to figure out exactly where the part is in the real world and adjust the weld path so it is in just the right spot.

A range of companies can benefit from robotic programs, making robotic programs applicable across small and medium sized enterprises (SMEs) to much larger companies.

Software programming uptake

Within Australia, many manufacturers focus on high-mix low-volume manufacturing. This process involves the production of a high variety of products in small quantities.

“Many Australian manufacturers focus on high mix, low volume type production – and their volumes are just too low to offset the cost of programming using conventional methods,” said Short.

High-mix low-volume manufacturing is commonly used in circumstances that are more unique and require specific quality process, such as welding.

Verbotics accommodates to this production type, Short said, “Our software can make it 40 to 50 times faster to program a robot, we move it from requiring a dedicated expert to a smart piece of software that a boilermaker or someone with some CAD experience can use.”

Robotic welding is a technology that many manufacturers would take advantage of if implementation costs were more achievable; robotic programming software’s make this realistic.

Verbotics is compatible with a range of automation robotics, demonstrating the breadth of opportunities for robotic programming across industries.

Short explained how robotic programming can help job training and development.

“With our software, you can take someone who’s interested in robotics and has a welding background, get them to use our software and all of a sudden, they’re now a great welder and they’re also a great welding robot programmer,” he said.