12 minute read

News@MM

The federal and Victorian governments have signed off on a final agreement which will see vaccine manufacturer Moderna produce mRNA vaccines in Australia for the first time.

A new manufacturing plant capable of producing 100 million doses every year will be built in Victoria, with works expected to begin by the end of this year.

Scott Morrison said the deal is a “shot in the arm” for Australia’s pandemic defences.

“This will be the first mRNA production facility in the Southern Hemisphere, and will ensure Australians have quick and easy access to these lifesaving vaccines,” he said.

The agreement come a few months after an in-principle agreement was signed at the end of last year.

The precise location for the new plant will be determined between the Victorian government and Moderna.

Moderna Australia and New Zealand general manager Michael Azrak indicated it has much more in mind for the facility than just COVID-19 vaccines, with plans to develop a number of other respiratory treatments and vaccines.

“Moderna is backing the development of a world class mRNA industry in Australia,” he said.

“In addition to local manufacturing, we’re going to partner with local researchers and institutions to deliver collaborative R&D that will develop the next generation of mRNA treatments.”

Australia will be one of only a handful of locations manufacturing mRNA vaccines around the world, including the US and Europe.

Boeing Australia recruits local advanced satellite manufacturers

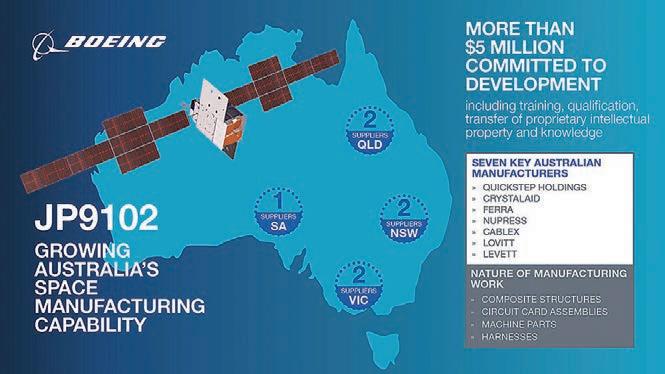

Quickstep Holdings, Crystalaid, Ferra, Nupress, Cablex, Lovitt, and Levett have signed memorandums of agreement to be part of Boeing’s advanced satellite manufacturing team, which will support Australia’s growing space industry and create almost 100 highly skilled jobs under JP9102.

“These seven local suppliers will manufacture a wide variety of products from complex bus, payload and solar array composite structural assemblies to circuit card assemblies, harnesses, and various mechanism and machine part assemblies,” JP9102 program manager Kathryn Burr said.

Boeing has committed over $5 million to an 18-month development program commencing in February to train, qualify and transfer proprietary intellectual property and knowledge to its Australian manufacturing partners.

“We are investing in these partnerships ahead of the JP9102 down-select decision,” Burr said. “We are helping these suppliers to build the capability they need to be part of Australia’s space sector and our broader supply chain for Boeing Defence Australia and Boeing Space and Launch.”

Mark Burgess, CEO and managing director of Quickstep Holdings, said Boeing’s JP9102 Australian industry solution is a comprehensive manufacturing opportunity for the nation.

“Boeing’s proposal is directly aligned to the requirements of the National Space Manufacturing Roadmap and would create more than 50 jobs at Quickstep and, importantly, create the capability for Australian industry to build and test satellite structures locally,” Burgess said.

Circuit card assembly supplier, Crystalaid Manufacture, views its JP9102 collaboration with Boeing as an opportunity to focus on business and technical improvements.

“This is a magnificent opportunity for our business to be mentored by one of the best design, production and logistics organisations in the world and supports Crystalaid and its parent company, Grabba Technologies,” Grabba Technologies executive chairman Ross McKinnon said.

Melbourne-based manufacturer of electrical wiring interconnect systems, Cablex, anticipates creating up to 40 additional high-tech, highly skilled new jobs with flow on effects to its Australian supply chain and potential export opportunities.

“With Boeing’s support, we will leverage and evolve our existing capabilities in electrical wiring and interconnection systems, electromechanical assemblies, avionic bays, consoles and electrical enclosures to create a world-class space and satellite manufacturing capability,” Calex CEO Michael Zimmer said.

Regional NSW manufacturer of specialised engineered components, Nupress, emphasised that Boeing was not only helping local suppliers to build capability in anticipation of the JP9102 outcome, but also providing opportunities to be part of Australia’s growing space sector.

“The Boeing team worked closely with Nupress to bring AIC and sovereign capability to Australia for satellite manufacture, with the technology transfer to provide employment opportunities for regional Australians,” Nupress CEO Craig McWilliam said.

The addition of these seven Australian manufacturers boosts Boeing’s strong local satellite manufacturing capability, with additive manufacturing partnerships with RMIT and Titomic already in place.

Seven local manufacturers have agreed to join Boeing’s advanced satellite manufacturing team

News @MM

Potential $7 billion uplift in Australian manufacturing from 5G

A new report from Deloitte Access Economics has broken down how mobile use cases in manufacturing will be enhanced through 5G in Australia.

Commissioned by the Australian Mobile Telecommunications Association (AMTA), the report examines the economic impact of adoption levels of 5G-enabled technologies and innovations, and the policy and regulatory principles required to support accelerated adoption.

While Australia has been a world leader in mobile telecommunications for decades and is currently ranked 3rd globally, it is at risk of falling to 9th by 2025 due to lack of business readiness for change and a policy regime that needs to be recharged, according to the AMTA.

The report found the top five use cases planned in the next 12 months: • Sensors and data analytics; • Location tracking machines and products; • Remote monitoring of stock and production assets; • Mass customisation; and • Factory automation.

The report’s economic modelling estimates 5G will increase Australia’s GDP by $67 billion by 2030 based on the current trajectory for adoption, however an additional $27 billion can be realised by maintaining Australia’s global leadership position through accelerated adoption – a 40 per cent uplift in economic benefit over nine years.

John O’Mahony, partner and technology, media and communications lead at Deloitte Access Economics said technology adoption is an intense race, and the earlier Australian business can develop and see the potential for 5G applications, the larger the productivity benefits.

“With nearly 90 per cent of businesses facing barriers to 5G adoption, Australia can only unlock the significant economic dividend by lifting business readiness and re-energising the policy regime and framework for 5G.”

CEO of AMTA, Louise Hyland said Australia’s mobile telecommunications sector has invested billions in the 5G rollout over a number of years to establish itself as a global leader, generating significant opportunity for Australia’s economy and industries in the process.

“We know there are significant economic benefits to be gained from the adoption of 5G across industry, including innovation, jobs, productivity, and global collaboration & competitiveness,” Hyland said.

“Australia’s world-leading 5G rollout has seen three live networks established and operational 5G base stations at almost 4,000 sites at the end of 2021 with significantly more brought online since, while trials of 5G technology are being undertaken by industry and supported by the Australian Government’s 5G Innovation Initiative.”

“But in reality, that opportunity only has value if the potential can be realised, and that’s why we are calling on industry and government to now play their role in driving an enhanced rate of 5G adoption.”

Deloitte has reported how mobile use cases in manufacturing will be enhanced by 5G.

News @MM

Advanced digital design and visualisation technologies are at the heart of the landmark new initiative, Innovation Central Adelaide – being launched virtually by Defence Industry minister, Melissa Price.

Jointly driven by Flinders University and the global technology company, Cisco, Innovation Central Adelaide has been established at Flinders University’s new Digital Transformation Laboratory at the Tonsley Innovation District, also being opened by Price.

A space designed to nurture innovation and growth by solving real business problems for small and medium sized enterprises, it represents the realisation of a national advanced technology network, complementing sister facilities in NSW, WA and Queensland.

“The partnership between Flinders and Cisco expands the co-Innovation footprint of Innovation Centrals in Sydney, Perth and Brisbane, bringing together researchers and industry to facilitate collaboration and create opportunities to solve real world problems, through technology innovation,” Flinders University vicechancellor Professor Colin Stirling said.

“It further reinforces the world-class expertise that Flinders researchers are contributing to the evolution of advanced manufacturing in South Australia, supporting jobs and the economy.”

Flinders University pro vicechancellor of Research Innovation, Professor John Spoehr, said Innovation Central Adelaide will provide a hightech treasure chest to South Australian firms, and turbo charge students’ realworld learning.

“We have companies champing at the bit to do better, but they lack capacity,” Spoehr said. “Innovation Central Adelaide gives them that capacity, supporting them to apply cutting edge design processes, rapid prototyping, simulation, and high-tech visualisation technologies that would otherwise be beyond their reach.

“In addition, companies will be able to experiment with a range of robotics and automation technologies.”

As part of a network similar facilities throughout Australia, Innovation Central Adelaide will support product and service development by facilitating the uptake of digital technologies in South Australian companies.

“This important collaboration is unlocking a treasure chest of technology which will help accelerate advanced manufacturing across our state,” Spoehr said.

“At the same time, it will equip students to be industry-ready with the digital skills required in the knowledge economy that help to solve real-world industry problems.”

Cisco Australia and New Zealand vice president, Ben Dawson, said the partnership with Flinders University will see Flinders join the National Industry Innovation Network (NIIN). NIIN is a Cisco-led industry and university alliance aimed at solving industry challenges through the adoption of technology solutions.

The NIIN is co-funded through Cisco’s Country Digital Acceleration (CDA) program, a $61 million investment to accelerate Australia’s digital capabilities in industries of national significance.

“The partnership with represents new research and innovation opportunities that will transform advanced manufacturing with the application of digital technologies to increase efficiencies and scale across industries,” Dawson said.

“This world class co-innovation commitment furthers our collaborative approach to innovative teaching and learning and opens the door for world leading research.”

(L-R) Flinders University professors Robert Saint, John Spoehr and Trish Williams, and Cisco vice president Ben Dawson.

Food and beverage manufacturing sector receives a boost

The federal government has forked out $33.4 million for an Australian-first manufacturing precinct at Sunshine Coast Airport.

Minister for Industry, Energy and Emissions Reduction Angus Taylor has announced support for the $112.8 million Turbine Collaborative Food and Beverage Manufacturing Precinct under the Collaboration Stream of the Morrison government’s $1.3 billion Modern Manufacturing Initiative.

The precinct will be home to local food and beverage companies that will be able to utilise shared warehousing and logistics, an education and training centre, as well as a collaborative high-tech manufacturing facility.

It will bring together beverage company Lyre’s Spirit Co, the Queensland Drinks Accelerator and ingredients company Doehler Australia, with the Food and Agribusiness Network and University of the Sunshine Coast.

It’s expected the project will see 131 new jobs during construction and support 687 once operational with $200 million in economic benefits.

Minister Taylor said the Sunshine Coast is home to incredibly innovative manufacturers especially when it comes to amazing food and beverage products.

“Food and beverage manufacturing is the largest manufacturing sector for the Australian economy. One in four people employed in manufacturing are employed in our food and beverage sector and it contributes $27.5 billion to our economy,” Taylor said.

“This funding will support some of the most innovative producers leverage technology to increase their production, while meeting growing export demand and creating new local jobs across the region and beyond.”

News @MM

New renewable carbon solution could decarbonise steel industry

BIOCARBON, a manufacturer based in Sydney, has found a viable solution to decarbonise the steel industry via its manufacture of a 100 per cent renewable carbon material that can directly replace fossil carbon in Electric Arc Furnace (EAF) steelmaking.

BIOCARBON’s new sustainable carbon neutral product hopes to enable steelmakers to decrease their carbon footprint without incurring large capital costs for modifying their equipment or processes.

The business is set to run a commercial trial of the novel product at Molycop’s steel plant in Newcastle, Australia.

The initiative is being supported by the federal government’s Department of Industry, Science, Energy and Resources through its Entrepreneurs’ Program, which recently awarded BIOCARBON a $293,840 Accelerating Commercialisation grant.

The initial trial will utilise 75 tonnes of the renewable carbon product (BIOCARBON bricks) in the production of 8,500 tonnes of steel. The University of New South Wales has tested the renewable carbon material for its efficacy and the product underwent an initial trial in Molycop’s EAF ahead of the now fullscale industrial trial set to take place in May.

BIOCARBON’s product is made from low value woody biomass streams, which are converted to a high-grade raw carbon product through a thermochemical reaction called pyrolysis. The raw char product produced through this process is high quality with lower ash content and higher carbon content than the fossil coke presently used in EAF steelmaking.

The added advantages of this sustainable product include converting a waste stream into a value-added raw material and reducing the volume of timber waste going to landfill. Just in NSW, over 22 million tonnes of woody biomass waste is underutilised annually and this scale of available raw material is well surpassing EAF sector requirements in Australia.

“The renewable carbon replacement trial at Molycop will demonstrate proof of performance of the product in making green steel at full-scale, against existing fossil carbon metrics,” BIOCARBON CEO Chad Sheppeard said.

“Coupled with green electricity, a simple change in the choice of consumables for EAF operations worldwide to our product will enable a major segment of the steel sector to become carbon neutral, with the possibility of 100 per cent decarbonisation in the future.”

Following the success of the trial, BIOCARBON expects to establish commercial product offtake agreements, allowing the business to attract investment and scale its production capacity at a facility at Bulahdelah in the Hunter/Mid North Coast region.

Member for Mackellar Jason Falinski said, “the green technological revolution is happening right here on the Northern Beaches. We are proud to be supporting companies like BIOCARBON, taking their innovative technologies to the next level through the commercialisation process.”

We are exhibiting! INDOPACIFIC 2022

Talk to our expert Industry & Defence staff on how RS can support your MRO needs.

RS will showcase the latest technology from our leading brands plus highlighting our range of procurements solutions and business services to support the high demands of the Defence Industry.

Visit us at Booth: 3J7

au.rs-online.com