5 minute read

Material Handling

CAPS Australia, proud distributors of the complete range of IngersollRand equipment in Australia, is pleased to showcase the allnew Zero Gravity Intelligent Air Balancer.

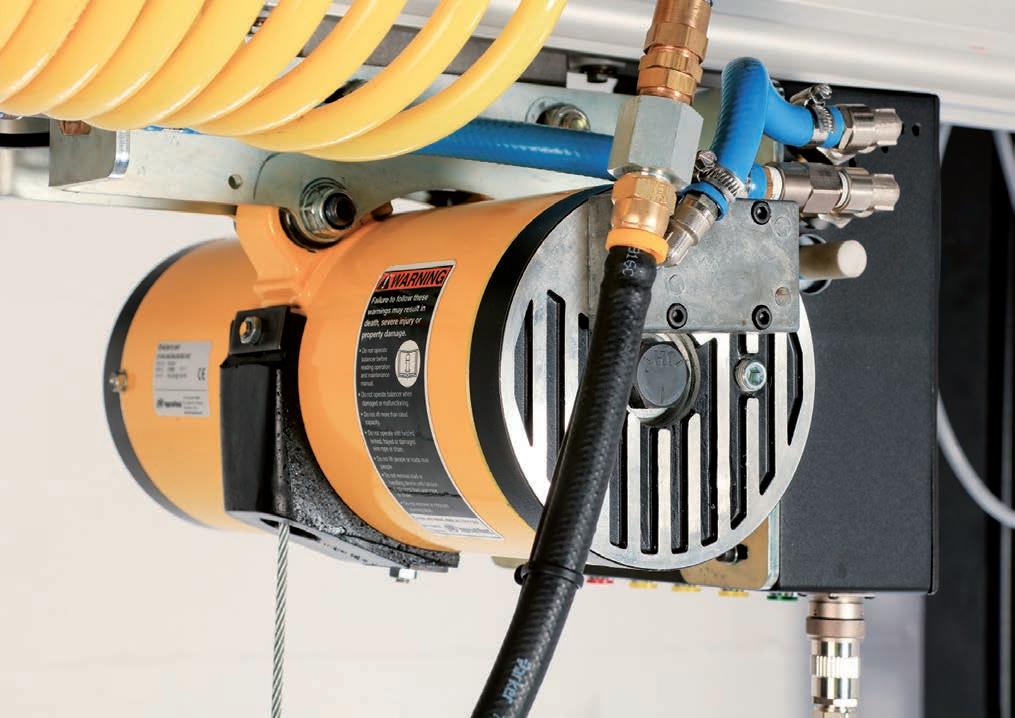

THE new Zero Gravity Air Balancer from IngersollRand shows off improved ergonomics, increased operator comfort and manoeuvrability productivity. It allows up and down movement by action on the handle or directly on the load if it’s already lifted. This all new Zero Gravity control kit is designed to be installed on a standard Ingersoll-Rand BW air balancer to extend the product’s possibilities.

New intelligence to a proven workhorse

Ingersoll-Rand has taken the proven technology of the Ingersoll-Rand air balancer and added to it electronic controls designed to expand its lifting capabilities. Ingersoll-Rand’s Zero Gravity Air Balancer control kit has been designed to be installed on any new or existing Ingersoll-Rand air balancer. The control kit offers an intuitive solution for improved ergonomics operator comfort, manoeuvrability and productivity.

The zero gravity balancer consists of three main components: • the standard Ingersoll-Rand air balancer; • the new zero gravity control box; and • the new inline handle.

In order to suspend the balancer, Ingersoll-Rand have provided new mounting brackets which allow you to use different types of suspension kits such as a trolley mount or hook mount kit. In addition to that you will see that the inline handle comes with a standard bottom hook connected to the bottom of the inline handle. The Zero Gravity Air Balancer features a force sensing handle that measures calibrated spring compression by a potentiometer. This feature causes the load to move up and down according to the direction you slide your hand.

Ingersoll-Rand’s Zero Gravity Air Balancer is now available at CAPS Australia.

Multiple ways to control

The handle itself is equipped with an emergency stop button, two programmable input and output buttons for external integration, and an on off button. The handle has a free plug for external controls located off the back side, along with a locking plug located on the top. This is used to connect the bouncer to the control box.

The zero-gravity balancer offers two ways of controlling the vertical movement of the balancer. The first of these two ways is by utilising the intuitive inline handle controls positioned directly above the hook. This feature allows the operator to simply pull up on the handle or push down on the handle to actuate motion.

The operator can move the load up and down with the intuitive slide handle and without the use of buttons. The second way in which

MaterialHandling

to control the up down vertical movement of the zero-gravity balancer is by direct action on the load itself. Controlling the vertical travel in this way analyses the pressure sensor reading within the control box to open and close a series of valves. These valves are used to regulate the air added to and taken from the air balancer. As an example; the force required by an operator to lift a 25kg load only requires 25 newtons.

When the Zero Gravity Air Balancer interacts with different capacities, two things remain constant; speed and the ergonomics.

Increased productivity

This product is designed with instant load calculation that requires no adjustment when adapting to different loads.

The speed in which the load is raised or lowered solely depends on the force used on the handle. The vertical up and down speed is proportional to the effort the operator applies to the handle. The up and down vertical movement has a maximum speed capability of 90 metres per minute.

The Zero Gravity Air Balancer features multiple ways to control lifting operations.

Safety features

In the situation where the system loses air pressure or electricity, the load will always remain stable and suspended. This ensures that your load will not drop, and the product is safe for the operator.

Several parameters can be easily adjusted in the Zero Gravity Air Balancer control software by simply connecting a laptop via standard USB cable. The Zero Gravity Air Balancer combines the low maintenance and low air consumption features of an air balancer and adds to it electronic controls that extend the air balancer lifting capabilities.

Want to find out more?

CAPS Australia is a privately owned and proud Australian company intent on remaining at the forefront of compressed air, gas and power generation solutions. We have 42 years of experience in the Australian market and our 10 branches reach right around the country with over 160 employees.

We have 60 service technicians covering the full national footprint with a 24/7 service offering including a vast inventory of genuine OEM brand spare parts.

CAPS is an independent company with the flexibility to search globally for the best products and technologies that best serve the Australian market’s needs. CAPS has many world-renowned partner brands including Ingersoll Rand, Kohler, AIRMAN, Sauer, Pedro Gil, Next Turbo Technologies, Lamson and many more.

If you’re interested in finding out more about this revolution in intelligent lifting equipment, please contact CAPS today. Call 1800 800 878 or visit their website at www.caps.com.au.

DataSuite: Central Innovation’s digital continuity solution

Would you like to have an error free flow of data between CAD designs and your production systems? Central Innovation’s DataSuite may be the solution for your business to ensure digital continuity.

Moving data from one system to another is a complex, often manual task that is slow, monotonous, and prone to human error. The errors can be disastrous, causing significant losses in profits and productivity.

DataSuite automates this process, providing a common language between systems to allow data to flow seamlessly across platforms, removing the chance of human error and increasing the options for process automation.

DataSuite has many flexible options for robust, reliable automation of business rules, triggers, and standard data flows. Talk to us today to see how DataSuite may ensure that your business decisions are based on accurate information.