1300 365 088 sales.au@ifm.com www.ifm.com/au To protect, you need to predict. Has your business unlocked the value of predictive maintenance? Special guest speakers from ifm global headquarters unpack the possibilities to be found in moneo. manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS JUNE 2023

Are you happy with the maintenance program at your plant?

The modern plant needs more than condition monitoring to ensure assets are healthy and meeting production demands.

To support a successful predictive maintenance program you need realtime streaming analytics.

ifm’s moneo is an easy to use, self service software platform that simplifies the integration of Industry 4.0 concepts into existing systems.

The in-built DataScience Toolbox enables operators and engineers to leverage their knowledge of equipment with the benefits of AI-assisted predictive analytics and machine-learning techniques. This empowers businesses to identify and remedy anomalies before they become expensive, big problems.

Simple No data science expertise necessary. Easy to implement for production and maintenance personnel. Tunable Fine tune the alerts as desired to optimise your preventive maintenance programs. Easy to train Train your models quickly with a sample of normal operating data. No need to simulate or replicate fault conditions. 1300 365 088 sales.au@ifm.com | www.ifm.com/au To protect, you need to predict.

Ego story The Pharmaceuticals manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS INSIDE >> 32 JUNE 2023 ifm unlocking digital transformation 28 Onshoring with additive 41 Official Industry Partners

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Billy Friend billy.friend@primecreative.com.au

Journalist: Mignon D’Souza mignon.dsouza@primecreative.com.au

Production Coordinator: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Kerry Pert, Tom Anderson, Louis Romero

Sales/Advertising: Danny Hernandez

Ph: 0431 330 232 danny.hernandez@primecreative.com.au

Subscriptions

Published 11 times a year

Subscriptions $140.00 per annum (inc GST)

Overseas prices apply

Ph: (03) 9690 8766

Copyright Manufacturers’ Monthly is owned by Prime Creative Media and published

,

Defence is its own world, so manufacturers need

adapt to certain skills and practices to fit in, better yet, to thrive. Elexon Electronics is undergoing an agile transformation to strengthen its defence offering. The global electronics player has been on a journey to become more prevalent in Australia’s defence space. Part of this is applying a Lean manufacturing approach, but applies it across its entire business, not just manufacturing operations. Elsewhere, Markforged continues to excel in its Defence

applications. In fact, Naval Sea Systems Command (NAVSEA) has installed Markforged additive manufacturing equipment aboard nine surface ships, including three aircraft carriers, and aboard four submarines.

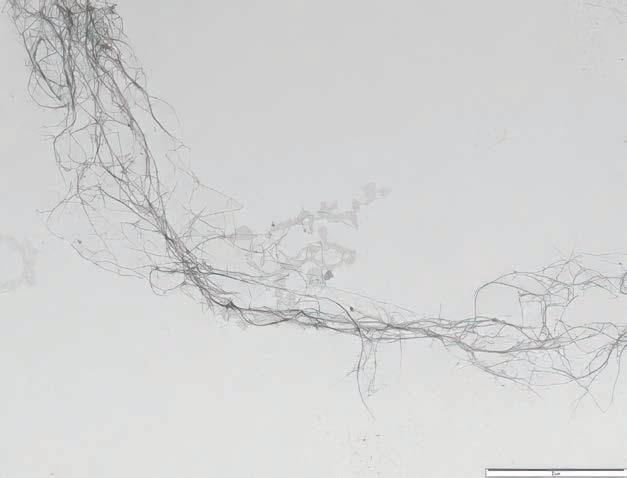

Elsewhere in this insightful edition, we learn about how one company is using high-tech medical gels from Indigenous spinifex grass. The cellulose found in spinifex is the longest, thinnest nanocellulose that has been found in nature ¬–the fibres are three to four nanometres thick, about 20,000 times thinner than a human hair.

We hope you enjoy the latest in manufacturing news and insights. Happy Reading!

4 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au 6 Editor’s Note 8 Comment 10 News 20 Manufacturer Focus 24 Engineering Focus 28 Sustainable Materials 30 Digital Transformation 32 Skills & Training 36 Energy Chains 38 Procurement & Supply Chain 40, 49 Compressors 43 Additive Manufacturing 46 Events 52 What’s New 54 Last Word For daily news visit manmonthly.com.au Inside JUNE 2023 18 Behind the cover Ego story The Pharmaceuticals manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS >> INSIDE >> 32 Onshoring with additive 41 Official Industry Partners ifm unlocking digital transformation 28 In the June edition of Manufacturers’ Monthly

we explore the world of Defence, specifically

businesses are upskilling staff and improving processes to

the market.

to

how

enter

22

by John Murphy. All material in Manufacturers’ Monthly is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Manufacturers’ Monthly are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2021 Articles All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format. Head Office 379 Docklands Drive Docklands VIC 3008 P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au Sydney Office Suite 3.06, 1-9 Chandos Street Saint Leonards NSW 2065, Australia P: +61 2 9439 7227 Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337 manmonthly.com.au twitter.com/Manmonthly facebook.com/Manmonthly linkedin.com/showcase/manufacturer’s-monthly/ Manufacturers’ Monthly Contents

BY Cleaner, Greener. Lower-carbon aluminium for your projects. Choosing lower-carbon aluminium in your next project can reduce the embodied energy of your aluminium products by up to 75%* LocAl® Green (8kg CO2e/1kg AL) and LocAl® SuperGreen (4kg CO2e/1kg AL) are the responsible choice for a locally extruded, lower-carbon option in your next project. FOR MORE INFORMATION VISIT: lowcarbonaluminium.com.au * When compared with global average CO2e for primary aluminium production, Scope 1 and Scope 2 ex smelter.

POWERED

Editor’s Note

Bright skies ahead

WHY do we love manufacturing? Partly it’s the people. Partly it’s the tech. Partly it’s the cruciality of its existence. Those realities came together when I attended all four days of the Australian Manufacturing Week last month.

The aisles were abuzz with industry chatter, as well as like-minded people catching up face to face. The event left no stone unturned, covering every aspect of manufacturing technology, from the largest machine tools down to the smallest precision cutting tools, as well as state-of-the-art support systems, software and accessories, and the myriad services that are essential to any manufacturing operation.

really stood out this year. As did the positive tone that we are indeed enjoying somewhat of a manufacturing resurgence as a country.

the Ai Group’s recent Australian CEO expectations for 2023 report, which gave insight into the challenges facing all industries, including manufacturing, as well as the expectations for 2023.

It appears the overall consensus from CEOs is that 2023 will be a positive year, after encouraging trends were identified in the later months of 2022.

Business conditions, turnover, employment and investment all improved through 2022 but challenges around supply chain, inflation and chronic labour shortages still created headaches.

Ninety per cent of CEOs expect to be affected by staff shortages and will undertake a range of training programs to

It will be important for manufacturers to find ways to make the industry more appealing to those already within it as well as newcomers. A myriad of suggestions spring to mind, but the main focus for retaining staff has to be around listening. More manufacturing businesses are deploying continuous improvement methods, which hopes to make those on the factory floor feel more connected to the decision makers in the office upstairs.

Whilst many within industry are nervous about inflation and interest rates continuing to rise, business results are still expected to improve as we emerge from the COVID pandemic.

Forty-nine per cent of CEOs expect

impacting their business and 88 per cent plan to invest to reduce their vulnerabilities in 2023.

Manufacturing was most affected during 2022 by supply chain issues with 88 per cent in total saying they faced supply issues throughout the year.

More businesses are taking a holistic approach when creating value chains with long term resistance, establishing resilient risk management operations capability. That capability should be technologyled. We are seeing businesses succeed by leveraging platforms that support applied analytics, artificial intelligence and machine learning. It should also ensure end-to-end supply chain transparency.

BILLY FRIEND – Editor, Manufacturers’ Monthly

MM_PressAd.indd 6 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

Victorian Minister for Industry and Innovation Ben Carroll welcomes the crowd at Australian Manufacturing Week.

Are you looking to innovate faster and reduce supply chain issues by 3D printing everything from prototypes to end-use parts?

We got you covered!

At Markforged we are on a mission to bring industrial manufacturing to the point of need. To help manufacturer reduce lead time we are offering a Complimentary 3D Printed Part*, for a limited time only, to encourage manufacturers to improve their production processes. See for yourself the unmatched surface finish, strength and precision of our 3D printed parts in metals and continuous-fiber reinforced composites.

Claim your Complimentary 3D Printed Part* by simply scanning the QR code and filling out the form. Our Engineers will be in touch!

* T&C Only organizations with relevant use cases qualify for the Complimentary 3D Printed Part at the discretion of the Markforged Application Engineer. By subscribing to the Complimentary 3D Printed Part campaign you agree for Markforged to use the part for marketing purposes. Offer valid in Australia. Get

your Complimentary 3D Printed Part*

MM_PressAd.indd 2 4/3/23 10:11 AM

Comment

DISTRIBUTED in March 2023

and completed by over 130 companies, Weld Australia’s 2023 Member Survey results demonstrate that Australia’s welding and fabrication industry is facing a whole raft of challenges that will make the delivery of the Federal Government’s plans for a renewable energy revolution almost impossible—from labour shortages that are inhibiting the growth of the welding industry, through to rising material and labour costs.

The Federal Government must step in and provide real support to industry to make the renewable energy revolution a reality.

Skilled labour shortages

When asked to select their top two factors, 60 per cent of respondents indicated that labour shortages are most likely to inhibit the growth of their business in 2023. When asked what their main concern is right now, 45 per cent confirmed that labour shortages was on the top of their list.

50 per cent of welding workshops are operating at 80 per cent of their capacity

or below. When asked why this is, a lack of skilled workers was the overwhelming answer.

With a considerable volume of work being onshored and a greater sentiment in the market to ‘buy local’, Australian fabrication companies are so strapped for skilled welders that they are operating well below capacity. They are being forced to turn down jobs because they simply don’t have the manpower to complete the work.

How then, will Australian fabricators cope with the influx of work required to make the Federal Government’s renewable energy revolution reality?

The Federal Government has legislated emissions reductions targets of 43 per cent (on 2005 levels) by 2030 and net zero by 2050. These targets will necessitate the construction of new infrastructure on a massive scale. Australia’s existing renewable energy generation of 64GW is forecast to grow to over 218GW by 2050. This will comprise 90GW of wind, 39GW of solar, 18.7GW of water, and 35.9GW of battery storage.

It is expected that over 11,000 wind towers will need to be produced, each

requiring 500 tonnes of plate steel for onshore towers, or 750 tonnes for offshore wind towers. To connect all this new generation to consumers, AEMO estimates more than 10,000km of new transmission lines and 25,000 transmission towers (at 30 to 60 tonnes of steel per tower) will need to be constructed.

All this the renewable energy infrastructure will require a veritable army of skilled workers, including welders. Australia will have a shortfall of at least 70,000 welders by 2030.

And yet, 45 per cent of survey respondents (compared to 47 per cent in 2022) have a pipeline of work that extends for six months or longer—this protracted pipeline is necessary in the face of ongoing skills shortages. Another 33 per cent of respondents have a pipeline of work that extends between three and six months. By way of context, this is a marked increase on Weld Australia’s 2020 member survey results; the most common answers were less than one month (at 28 per cent), one month (19 per cent), and two months (16 per cent).

Government support vital to making the renewable energy revolution a reality

While our governments can wish, and hope, and make public pledges about Australia’s transition to renewable energy, at the moment, we simply do not have the sovereign manufacturing capability to make this a reality.

According to the results of our survey, at 62 per cent, the majority of the Australian welding industry supports the Government’s carbon emissions reduction targets.

However, 75 per cent of the welding and fabrication industry believes that Australia’s governments are not doing anywhere near enough to support industry in achieving these targets. Our governments will need to consider policy and funding opportunities, reduce red tape and regulatory barriers, and support local investment to enable the renewable energy transition.

Australia’s Federal and state governments can wish their renewable energy policies into existence, but without a massive investment in

Weld member survey reveals labour shortages will make manufacturing the renewable energy revolution almost impossible without government support

8 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

GEOFF CRITTENDEN – CEO, Weld Australia

fabrication and steelmaking facilities, skills and training in each state, and real, practical support for local industry, it will not be achievable.

The welding industry is already investing in its own sustainability performance and credentials, and has made significant headway in the last 12 months. Some of these measures include: installing LED or sensor lighting (80 per cent; up from 53 per cent in 2022); waste reduction programs (78 per cent; up from 46 per cent in 2022); recycling, upcycing and repurposing programs (75 per cent; up from 46 per cent in 2022); and implementing a net zero carbon plan (50 per cent; up from 13 per cent in 2022).

Overcoming labour shortages

In the meantime, the welding industry is already taking steps to help overcome these labour shortages. 60 per cent of respondents indicated that they are training or upskilling their existing staff, another 55 per cent are either increasing wages or improving employee benefits, and 32 per cent are leveraging different

talent pools, such as apprentices, females and prisoners.

Another 57 per cent are either investing in automation and technology, or changing their operational processes. Given these figures, it is little surprise that investment priorities for 2023 include staff training and development (32 per cent), business process improvements (30 per cent) and plant and equipment (25 per cent). Some fabricators are also looking to advanced welding technology to help overcome skilled labour shortages, including investments in Industry 4.0 (40 per cent), robots (36 per cent) and cobots (35 per cent).

The welding industry strongly supports investment into TAFE to help combat labour shortages; 21 per cent support free TAFE for apprentices, 14 per cent support increased funding to upgrade TAFE facilities, and 64 per cent support both options.

Rising costs

Australia’s welding industry is also concerned about rising labour costs and rising material costs, with 50 per cent and

45 per cent (respectively) of respondents indicating that they could inhibit their business growth this year.

Only 47 per cent of respondents indicated that their gross profit margin had increased over the last 12 months to help cover these rising overheads. Alarmingly, the welding industry expects these overheads to continue to rise this year, with 82 per cent expecting even higher materials prices and 85 per cent expecting even higher energy prices.

Despite these concerns, market sentiment remains very positive. 88 per cent of respondents rated the prospects of their business as either strong or steady – a 6 per cent increase on 2022 levels. On average, respondents are 90 per cent confident that their business will be in operation in 12 months’ time (a 23 per cent improvement compared to 2020).

National manufacturing summit

Given the sheer volume of challenges and opportunities on the horizon in the renewable energy industry,

Weld Australia, in conjunction with the Australia Institute’s Centre for Future Work, will host the 2023 National Manufacturing Summit at Old Parliament House on 2 and 3 August. With the theme of Renewable Energy: Challenges and Opportunities, the aim of the Summit is to help industry leverage the opportunities currently available in the renewable energy sector, and translate these into action.

The Summit will gather industry leading representatives from all the major stakeholders in Australia’s manufacturing sector—business, unions, universities, the financial sector, suppliers, and government—to discuss the sector’s prospects, and identify promising, pragmatic policy measures designed to support an industrial turnaround. Government Ministers and international experts will delve into the challenges and opportunities of the renewable energy revolution.

Register now for the Summit via: manufacturingsummit.com.au.

manmonthly.com.au Manufacturers’ Monthly JUNE 2023 9

Industry needs real support from the Federal Government to achieve renewable energy targets.

Bedford to open $45 million advanced manufacturing hub

Bedford, Leyton Property and Leyton Funds are partnering to create a state-of-the-art manufacturing hub in Adelaide’s north, unveiling plans for what is believed will be Australia’s largest social enterprise site.

The hub will offer employment opportunities to people of all abilities and will specialise in the advanced manufacture of furniture and the supply of components to the commercial joinery and construction industry.

The development will be located on what is expected to be one of South Australia’s largest commercial greenfield development sites on Main North Road in Salisbury South.

“The investment will significantly increase Bedford’s manufacturing capability to deliver a world-class commercial product to the market. This will include an investment in the latest automation and robotics technology,” said Bedford COO of Social Enterprises Sam Hunter.

Adjacent to the new advanced manufacturing facility will be a first-class Food and Beverage hub with hospitality retail offerings including:

• Commercial kitchen Beverage production facilities

• Public entertainment area

The hub will be home to Bedford’s first social enterprise called Cultivate Food & Beverage, which recently opened its first site in Brooklyn Park. This social enterprise has a unique offering, delivering a full supply chain solution to medium and large size food and beverage producers with a national footprint.

Approximately 100 jobs are expected to be created during construction. The centre will provide ongoing employment for more than 200 people when complete.

Bedford CEO Myron Mann said that, pending council approval, construction was expected to begin later this year and be completed in 2025.

“Bedford has a long and successful history of manufacturing in South Australia,” said Mann.

“This investment in our future will enable us to grow, innovate and manufacture at scale while remaining true to our purpose to provide choices in skill-building and career pathways.

“As a social enterprise it will be a vibrant place to work, offering highvalue roles and transferrable skills for employees of all abilities. Jobs will include joiners, machine operators, production workers, chefs, supervisors and apprentices, in a supportive and inclusive environment.

“The site has been strategically chosen for its freight route among other strategic reasons. It will support Bedford to maintain and grow our existing manufacturing contracts and provide opportunities for new partnerships, in particular food and beverage producers north of Adelaide and across the state.

“We are pleased to work with Leyton Property as our development partner and Leyton Funds as our long-term investment partner to help us bring our vision for the site to life.”

“Leyton Property is thrilled to be working with Bedford on this exciting property development,” said Leyton Property managing director Hamish Brown.

“As a real estate asset, this will be an exceptional new industrial property, well located and highly accessible with a strong tenant in the Bedford Group.”

“We will co-invest with Bedford to own this premium grade industrial property together. This project fits with our investment objectives as well as supporting long-term social benefits,” said Leyton Funds managing director Warwick Mittiga.

“As a social enterprise, it provides a platform to support Bedford to grow employment pathways.”

Bedford’s investment forms part of its five-year masterplan announced in November 2022.

Bedford engaged property advisory firm Broadway Property to source and secure the site and guide the joint venture partnership arrangements.

10 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

News @MM

Proposed design for Bedford’s new advanced manufacturing hub.

Skills and training investment to meet critical challenges

The Federal Government has offered $3.7 billion for a five-year National Skills Agreement (NSA) to be negotiated with states and territories, in addition to $400 million to support another 300,000 TAFE and VET Fee-Free places.

Subject to successful negotiation of the NSA, this will take total Commonwealth investment in state and territory training systems to $12.8 billion over five years.

Subject to successful negotiations, funds will be available in line with the vision and guiding principles agreed at National Cabinet prior to the Jobs and Skills Summit, to support major reform areas including:

• Foundation skills: a coordinated effort to ensure that Australian adults lacking language, literacy, numeracy and digital skills can gain essential skills for work, career progression and successful completion of a vocational education training course or an apprenticeship. Lack of foundation skills is estimated to impact three

million Australians.

300,000 Fee-Fee TAFE courses: in essential sectors such as care and support (aged, disability, veterans and early childhood and education), clean economy, manufacturing and sovereign capability (including defence industries), construction, agriculture, hospitality, tourism, cybersecurity and technology.

• Closing the Gap for First Nations students and apprentices – working closely with First Nations people, their communities and training providers to support skill development that works for them and supports their career opportunities.

Women’s participation and gender equality – coordinated effort to support women to successfully enrol and complete VET courses and apprenticeships, with an emphasis on accessing skills in better paid occupations including trades traditionally dominated by men. Men

will also be encouraged to participate and gain skills in fields where women have been historically overrepresented, such as care. Completion rates and support for students who face barriers: coordinated national effort to lift completion rates and improve outcomes for VET students and apprentices, with a focus on students facing barriers and historically underrepresented in the workforce, including those with a disability.

Centres of Excellence: TAFE Centres of Excellence to partner with industry, universities, and governments to address critical challenges in our economy such as transition to a clean economy, manufacturing and sovereign capability and care and support.

TAFE at the heart: supporting highquality vocational education and training, curriculum development, research and innovation through

leadership networks and collaboration.

VET Workforce capability: to be developed in partnership with the sector a VET Workforce Blueprint will strengthen the sector and support a high-quality VET workforce, which teaches up to date industry relevant curriculum.

Strides have already been made through the government’s partnership approach, with delivery of a 12-month agreement that has created 180,000 Fee-Free TAFE and Vocational Education Training places this year.

Australia is facing an acute skill shortage, with the number of occupations experiencing a skills shortage almost doubling from 152 in 2021 to 286 in 2022. Furthermore, 60 per cent of total employment growth is in jobs for which VET is the primary pathway. All governments have committed to working in partnership to negotiate the NSA to be in place by 1 January 2024.

AEROSPACE STANDARDS AS9100D CERTIFIED ELECTRONICS DESIGNER AND MANUFACTURER EXPECT EXCELLENCE + Aerospace Approved Supplier (AS9100D) + Acoustic and Ultrasonic Systems + Industry 4.0 Factory + PCB Assemblies for Satellite Communication + Engineering and R&D + Blast-proof Monitoring Systems + IoT CONTACT: sales@elexonelectronics.com | t: +61 7 3205 8450 | www.elexonelectronics.com manmonthly.com.au Manufacturers’ Monthly JUNE 2023 11 News @MM

Flexible gold sensor unlocks new generation of medical implants

A thin, flexible gold sensor engineered at The University of Queensland (UQ) is both flexible and sensitive enough to enable a more streamlined future for electronic medical implants and real-time sensing applications.

Using a brand-new engineering method, researchers at UQ’s Australian Institute for Bioengineering and Nanotechnology (AIBN) were able to produce the small film-like sensor.

The intricate approach used by Dr Mostafa Kamal Masud and PhD candidate Aditya Ashok represents a breakthrough in the field of flexible nanoarchitecture and, ultimately, suggests a new way to miniaturise and improve medical devices for diagnostics, biological sensing, and

neurological exploration.

“Although modern implanted electronics have developed rapidly over the past 60 years, most commercially available devices are still built on relatively similar – and limiting – design concepts such as thick ceramic or titanium packaging,” said Dr Masud.

“We are offering a new route toward miniaturised, flexible, implanted medical devices that will diagnose and treat chronic diseases and help improve the lives of millions of people.”

The film-like sensor designed by Dr Masud and Ashok represents a novel approach to the field of mesoporous materials, which are highly porous substances with traits that benefit

diagnostics, catalysis, and drug delivery.

Using a novel hybrid fabrication process under the guidance of senior AIBN group leader Professor Yusuke Yamauchi, Dr Masud and Ashok were able to synthesise a mesoporous gold film that acts as an electrode for biosensing and bioimplant applications.

The flexibility and sensitivity of the gold film make it an ideal wearable system for real-time monitoring of body glucose, while Dr Masud said there was strong potential for implanted nerve recording applications.

“The demand for a simple and robust fabrication process with this kind of flexible electronics is enormous,” Dr Masud said.

“Our aim here is to see this sensor embedded in wearable devices – but the potential and possibilities in this field are vast. We’re going to be exploring more in our coming projects.”

The research was published as an inside cover feature for the nano-micro journal Small.

Dr Masud and Ashok acknowledge Dr Hoang-Phuong Phan from the School of Mechanical and Manufacturing Engineering at the University of New South Wales as a key collaborator in their broader work.

This includes research on implanted bioelectrodes, as published in the journal Proceedings in the National Academy of Science.

progress operated and assets. 12 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

@MM

The gold sensor researchers have used for electronic medical implants.

News

$4.1 billion funding for local missile manufacturing

The Federal Government funding will acquire more long-range strike systems and manufacture longer-range munitions in Australia, delivering on the priorities of the Defence Strategic Review.

A key recommendation of the Review is the need to accelerate and expand weapons systems, including land-based maritime strikes and long-range missile launchers.

Complemented by investments to replenish our guided weapons and explosive ordnance (GWEO) stocks and to establish sovereign missile and munition manufacturing facilities in Australia.

The Federal Government is moving immediately to respond to the Review and commit real funding to these programs and capabilities.

This investment in key capabilities will see the Australian Army’s current range for artillery grow from 40 kilometres to in excess of 500 kilometres.

$1.6 billion for long-range strike capabilities

This investment will grow the ADF’s ability to accurately strike targets at longer ranges and expand our acquisition of long-range missile systems, including: Accelerating the delivery of additional High Mobility Artillery Rocket Systems (HIMARS) and associated battle management and support systems; and accelerating the acquisition of Precision Strike Missiles (PRISM) to deliver multi-domain strike effects.

$2.5 billion for Guided Weapons & Explosive Ordnance Enterprise (GWEO) Investment in the GWEO Enterprise will fund:

• Manufacturing guided weapons and their critical components to improve our self-reliance, with concrete, costed plans presented for Government consideration by the mid-2024 to: Manufacture selected long-range strike missiles and increase local maintenance of air defence missiles; and

Manufacture other types of munitions, including 155mm artillery ammunition and sea mines Critical enablers needed to underpin an expanded GWEO Enterprise, including increasing our testing and research capabilities and rapidly expanding our storage and distribution network to accommodate a growing GWEO inventory; and

• Acquiring more stocks of guided

weapons, supplementing other Defence weapons acquisitions programs.

This announcement is part of the Government’s $19 billion commitment over the forward estimates to achieving the priorities as set out in the Government’s response to the Review, and will see more than double the investment for GWEO than what was previously provisioned.

National aluminium routing solutions

As one of Australia’s leading national steel and aluminum distributors, BlueScope Distribution has the product range, processing capability, and technical expertise to deliver on your project requirements. Our national aluminium routing capability enables us to profile complex shapes with precision, ease and accuracy. Combined with our extensive aluminium product range and experienced programmers, we work closely with your business to deliver aluminium solutions that

manmonthly.com.au Manufacturers’ Monthly JUNE 2023 13

The ADF will strengthen its missile capability.

Your single source steel and aluminium product, processing and service solutions provider

you the

to do what you do best. Talk to our team about your aluminium processing requirement including, profile cutting simple or complex custom shapes, milling, holes, material labelling and coding, and much more! For more information visit bluescopedistribution.com.au Steel. Aluminium. Knowhow.™ BlueScope Distribution® is a registered trademark of BlueScope Steel Limited. © BlueScope Steel Limited May 2023 ABN 16 000 011 058. All rights reserved. 13 72 82 News @MM

give

freedom

News @MM

Mars Wrigley invests $28.8 million in local manufacturing

The investment at Mars Wrigley’s Ballarat factory comes as its sustainable packaging hits shelves nationwide, building on more than $67 million invested since 2021.

In a world first for the company, Mars Wrigley’s MARS BAR, SNICKERS, and MILKY WAY will switch to new packaging which can be recycled via traditional kerbside recycling bins.

Available on shelves from 10 April, the new paper-based packaging is a result of extensive research and development trials from Mars Wrigley’s manufacturing site in Ballarat and is set to eliminate more than 360 tonnes of plastic from the company’s value chain – enough to stretch from Melbourne to London and back.

This latest investment will enable Mars Wrigley to continue modernising its manufacturing operations through key equipment upgrades, paving the way for further development of sustainable packaging solutions and enabling greater innovation across its filled bar and Bitesize portfolios.

Andrew Leakey, general manager of Mars Wrigley says, “I’m proud that we are leading world-class innovation

in packaging and sustainability from Australia in what is a world-first for us as a business.

“We are the first Mars Wrigley market in the world to launch a recyclable paper-based packaging at this size and scale, and it speaks volumes to the commitment of our team locally who have been working on this project for almost three years.

“When we embarked on this journey, there wasn’t a playbook or roadmap for us to follow but we were committed to finding a solution and cementing our position as a leader in sustainability.

“We trialled many different materials and approaches before we landed on our paper-based solution, but one thing that was non-negotiable for us was to ensure that consumers could recycle our packaging within our current recycling infrastructure. Seeing our bars on shelf now is an incredibly proud moment for me.

“Continued innovation and investment in sustainable solutions is critical to ensure that we can meet our 2025 packaging targets and commitments, as well as continuing to build Australia’s modern manufacturing

capabilities and the future of Australianmade products.”

With Australia’s 2025 National Packaging Targets only a mere two years away, continuing to drive forward innovation in sustainability relies on the collaboration of business, industry and Government.

Mars Wrigley worked closely with Amcor, a global leader in developing and producing responsible packaging solutions, over the last three years to find a suitable material that would maintain the freshness of the product, whilst being recyclable in Australia’s existing recycling infrastructure.

Manufactured in Australia, the new packaging has enabled Mars Wrigley to reduce its virgin plastic use.

Richard Smith, Amcor’s director of sustainability, Asia Pacific says, “We are proud to be partnering with our customers to deliver innovative sustainable solutions to the local market, helping Australian brands to meet the National Packaging Targets.

“We want to be part of the solution, advancing the development of our packaging technology to create a local circular economy for flexible packaging.

We are excited to continue innovating with Mars Wrigley to meet Australian consumers’ changing needs.”

Brooke Donnelly, Coles’ general manager of sustainability welcomes the introduction of Mars Wrigley’s alternative packaging onto supermarket shelves and believes business innovation and collaboration are necessary to drive forward sustainable solutions for consumers.

“It’s encouraging to see Australian manufacturers take steps towards providing sustainable alternatives to plastic packaging. In order to drive further innovation and achieve mutual sustainability goals, it’s important for organisations to collaborate and work together. With businesses increasingly measured on their impact on society and the environment, sustainable innovation can be a key driver of both societal and commercial success”

As part of the company’s commitment to its $1 billion Sustainable in a Generation plan, Mars Wrigley has said it is committed both in Australia and globally to supporting and creating a circular economy where packaging never becomes waste.

14

Mars Wrigley’s recycled wrapper chocolate bars.

Global pharma manufacturer solidifies Australian biotech foothold

Contract development and manufacturing organisation (CDMO) PCI Pharma Services (PCI) announced the operational launch of three new state-of-the-art automated sterile fill-finish machines at its Melbourne and San Diego facilities.

“As the capacity for CDMOs worldwide to take on new projects shrinks, we’re excited to be able to offer integrated

sterile fill-finish capabilities, alongside our clinical packaging facilities, to new and existing clients in Melbourne and San Diego,” said Brad Payne, chief operating officer, PCI Pharma Services.

“Our increased capacity, stockpile of standardised components, including glass, and technical expertise means we can start running batches as soon as needed.

This will cut down on the wait times many local biotech and pharmaceutical companies are facing and begin to help alleviate the global capacity shortage for sterile drug product and downstream packaging.”

The new innovative machinery from Cytiva can be used to fill various sterile medications into vials and syringes for small-to-mid-scale client needs.

The equipment, paired with PCI’s end-to-end services, accelerates company’s drug proof of concept studies, and drastically decreases the average turnaround time from proposal signing to the injectable product’s distribution.

The Microcell Vial Filler at Melbourne further enhances the early-stage services offered and brings additional capacity to Australia—the world’s leading Phase I environment.

These advanced machines expedite the filling process with automation and

remove the need for human intervention in a sterile environment, creating compliance advantages over standard equipment.

“There are less barriers to entry to start a clinical trial in Australia, as well as significant cost benefits, and with Melbourne being an especially popular place to conduct phase I trials, we knew we needed to bring this capability and added capacity to the local market,” said Tim Roberts, chief commercial officer, PCI Pharma Services.

“In addition, we are then able to take our clients through their lifecycle journeys with the expansions and advanced capabilities in our New Hampshire and Madison campuses. With successful recent inspections at our Bedford facility by the Brazilian (ANVISA) and Japanese (PDMA) regulatory authorities, our global reach to supply life-changing therapies to patients quickly and safely is wider than before.”

manmonthly.com.au Manufacturers’ Monthly JUNE 2023 15

News @MM

PCI Pharma Services has three new machines at its Melbourne facility.

News @MM

Coles opens first Automated Distribution Centre in QLD

The state-of-the-art facility in Redbank is the first Australian Automated Distribution Centre (ADC) that uses the global leading Witron technology and is the largest of its kind in the Southern Hemisphere.

Prime minister Anthony Albanese MP, Queensland premier Annastacia Palaszczuk MP, Coles Group chairman James Graham and Coles Group CEO Steven Cain officially opened the ADC at Goodman’s Redbank Motorway Estate in Queensland earlier this week,

This is the first of two Witron facilities to open here and comes after Coles Group’s biggest investment into technology in the company’s 109-year history.

More than one billion dollars is being invested, with the second ADC opening in Kemps Creek, NSW in 2024.

Prime minister Albanese said the world-leading technology will help advance supermarket supply chains.

“This technology is not only a first for Australia, but also a win for the state of Queensland. As we’ve seen during the pandemic and natural disasters, resilient supply chains are essential when it comes to feeding our nation and providing Australians with essential supplies.

“Coles is one of the biggest employers in this country and its team was pivotal in ensuring food security during challenging times. A facility like this one in Redbank shows how retailers and manufacturers can look to the future to improve the productivity, safety and sustainability of their operations for all Australians.”

“The decision to invest in and build this Australian-first facility here in Queensland is a testament to the strength of the Queensland economy,” premier Palaszczuk said.

“Coles’ investment will drive productivity growth in Queensland while ensuring food security to one of the fastest growing regions in the country.

“It’s great to see Queensland lead the way with the arrival of world leading technology at the Redbank Distribution Centre. The distribution centre will be powered by renewable electricity provided by Queensland’s publicly owned energy company CleanCo.”

The ADCs are designed to create safer and more sustainable outcomes for team

members and suppliers, and better onshelf availability for customers.

The state-of-the-art facility in Redbank is located 30 kilometres southwest of Brisbane and will service 219 Coles supermarkets in Queensland and Northern New South Wales, as far north as Port Douglas and as far south as Laurieton in NSW.

When operating at full capacity, the site can process up to four million cases per week, the equivalent of 32 million units sold in stores. Over the course of a year, this is around 1.6 billion sales units.

Coles CEO Steven Cain said this was one of the most significant moments since Coles was founded in 1914 and five years in the making.

“Modernising our operations is how we improve efficiency and availability in our stores and deliver higher service levels for our customers, team members and suppliers,” Cain said.

“Our new ADCs can process twice the number of cases and hold twice the number of pallets compared to one of our

current DCs. The ADCs enable us to half our current total footprint, leading to a more productive and sustainable business model.

“Over 90 percent of the cases processed in these automated distribution centres will be processed fully by automation or ergonomically which will be a step-change for the safety of our team as it eliminates almost 18 million kilograms of manual handling in the supply chain each week once the ADC is running close to full capacity.”

Coles Group chairman James Graham said he would like to thank all those involved for their dedication to this very important project.

“I’m proud of our team, partners and suppliers who’ve worked together for over five years to create this state-ofthe-art facility. Over 3,000 people came together, contributing more than 2.5 million work hours to plan and design the facility, construct the building and install and commission the automation,” he said.

The Redbank ADC has LED and sensor

lighting to reduce energy consumption and is fitted with a 180,000 litres of harvested rainwater storage for toilet flushing and landscape irrigation. There are plans for 3.5-megawatt solar installation which will be among the largest rooftop solar solutions in the Coles network. To minimise food waste, the edible food that can’t be sold in the ADC will be donated to Coles community partner SecondBite.

WITRON Logistik + Informatik CEO Helmut Prieschenk said Coles has partnered with the market leader in warehouse automation systems for major food retailers globally.

“We have been engaged to build 93 automated distribution centres in 13 different countries, with the latest for Coles being the largest ambient system Witron has ever built,” Prieschenk said.

“Witron will work with Coles to provide a technology focused, multidisciplinary team for day-to-day operations, technical expertise and maintenance support.”

16 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

Anthony Albanese at the launch of Coles’ Automated Distribution Centre.

Australian manufacturer Tritium enters Malaysian market

KuroEV, a Malaysian electric vehicle (EV) charger, installer and management services provider, has purchased Tritium fast chargers to be deployed across Malaysia.

With only 600 charging stations currently available for the over 10,000 EVs registered in the country, Tritium’s entry into the Malaysian market comes at a crucial time.

The Malaysian government has recognised the need for increased EV charging infrastructure and has pledged to build 10,000 EV charging stations by 2025 in partnership with the private sector.

This initiative is part of the government’s broader goal to achieve net-zero emissions by 2050, which includes targets for 30 per cent renewable energy capacity by 2025 and maintaining 50 per cent of the nation’s land as natural forest.

“We are excited to partner with KuroEV to bring Tritium’s world-

leading charging technology to the Malaysian market and expanding our footprint in the Asia Pacific region,” said Tritium CEO Jane Hunter.

“Our fast chargers will provide reliable, high-quality charging solutions to EV drivers in Malaysia, and we look forward to supporting KuroEV in their efforts to create a comprehensive charging network across the country.”

KuroEV plans to deploy Tritium chargers at various locations throughout Malaysia, including offices, shopping malls, and commercial hubs.

The company also intends to create its own charging network in the future, featuring solar, on-site energy storage, EV charging, cafes, and other premium services available at their sites.

“We are delighted to work with Tritium, a global leader in EV fast charging technology, to offer the latest fast charging solutions to our customers in Malaysia. With Tritium’s

fast chargers, we can provide a seamless and reliable charging experience to EV drivers across the country, helping to accelerate the transition to a cleaner and more sustainable future,” said KuroEV Founder Ken Too.

“This investment is just the first step in our plans to create a worldclass charging network that combines solar, storage, and other innovative

technologies to offer a truly premium charging experience.”

KuroEV offers affordable lease-toown options to help businesses install chargers and launch charge point operator businesses.

Founded in 2001, Tritium designs and manufactures proprietary hardware and software to create advanced and reliable DC fast chargers for electric vehicles.

manmonthly.com.au Manufacturers’ Monthly JUNE 2023 17 News @MM

Tritium has now entered the Malaysian market.

Federal Budget lays foundation for Industry Growth Program

Treasurer Jim Chalmers released the 2023-24 Federal Budget in Canberra last night, which includes an investment of over $500 million into the future economic growth in science and industry.

At the centrepiece of this industry investment is the new $392 million Industry Growth Program, which will offer advice and grants to start-ups and small-to-medium businesses, to help them commercialise their ideas and grow.

According to a media release by minister for industry and science Ed Husic, “This will enable emerging businesses to become the big employers of the future, backing our innovators with investment and advice so they can make the jump from brilliant idea to business plan to a growing enterprise.”

Through grants and mentorship, Australia’s new Industry Growth Program will expand the pipeline of investmentready projects for the $15 billion National Reconstruction Fund to consider in coming years.

This end-to-end approach will maximise the return on taxpayers’ investments and provide a clear pathway for our entrepreneurs to turn their ideas into thriving businesses in Australia instead of overseas.

Support for critical minerals including rare earths that are crucial components of low-emissions technologies such as batteries, electric vehicles and solar panels, also attracted new support.

Minister for Resources Madeline King said: “We’re developing the critical minerals industry…to make batteries and other green technologies – an integral part of our plan for Australia to become a renewable energy superpower.”

Budget funding includes: $57.1 million for the established Critical Minerals International Partnerships Program. This is aimed at stepping up international engagement, to attract investment from like-minded partners and accelerate projects of strategic interest

And $21.2 million to ensure the ongoing operations of the Critical Minerals Office – which is driving policies, programmes and international engagement.

Additionally, the Government will invest $101 million in the responsible development of Australia’s quantum and artificial intelligence industries.

This funding will work in tandem with Australia’s first National Quantum Strategy, which the Government announced last week, and the Government’s $15 billion National Reconstruction Fund.

“We are also delivering on our election commitment to establish a Powering Australia Industry Growth Centre, with a $15 million investment to support local manufacturing of renewable energy technology,” Husic added.

The Budget focuses on Australia’s potential as a renewable energy superpower, with $2 billion allocated for a new Hydrogen Headstart program to scale

up development of Australia’s renewable hydrogen industry.

Chalmers said, “Australians have shown resilience in the face of heightened global uncertainty, persistent inflation and higher interest rates, which are combining to slow our economy.

“The best response to these challenges is a responsible budget that strikes the right balance between easing cost of living pressures, securing the essential services people rely on and laying the foundations for future growth.

“It does this while strengthening our fiscal position, with a budget surplus now forecast in 2022 23, and lower deficits and debt compared to recent budgets.”

Overall, the Federal Budget aims to: Deliver cost of living relief,

• Strengthen Medicare, Invest in a stronger and more secure economy, Broaden opportunity, and

• Strengthen the nation’s finances and funding priorities.

18 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au News @MM

Biological environmentally Driving GearFluid to

Jim Chalmers announced an investment of $392 million in an Industry Growth Program.

Biological and environmentally friendly

1 Sustainable biomass made from green and food waste, among other things

2 Processing and synthesis of the biomass into the basic oil for the GearFluid

3

4

Mixing in high-quality additives creates the finished GearFluid

Filling the gear units and canisters with GearFluid by SEW EURODRIVE

Data driven Condition Monitoring makes for the most sustainable Asset Management and Maintenance

Driving the world

SEW-EURODRIVE –

less CO

emission

conventional polyglycol lubricants www.sew-eurodrive.com.au

2

3

GearFluid by

84%

2

compared to

1

4

Manufacturing Focus

Innovation and empathy: Inside a dermatology success story

Billy Friend sits down with managing director of Ego Pharmaceuticals Alan Oppenheim to learn about the company’s journey from developing formulas in bathtubs to its recent factory expansions supporting the production of 9 million kilograms of pharmaceutical products every year.

20 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

Manufacturer Focus

AFTER Alan Oppenheim finished his morning play at preschool, he would be taken across the road to Ego Pharmaceuticals’ first factory, where he would sit on a table, watching Pinetarsol Solution be put into glass bottles and labelled by the company’s second ever employee, Eunice.

“Sometimes I would get a label and attempt to put it on the bottle myself,” he said. “Four year olds aren’t particularly ambidextrous, and you need to get the label straight, so I suspect almost every label I put on Eunice had to take off and start again. She could label bottles faster than a machine could. When my father bought the first automated machine, it was surprising how slow it was compared to Eunice.”

Alan’s father, Gerald Oppenheim, founded Ego in 1953 with his wife, Rae, after they saw a need for products to restore and maintain healthy skin. Gerald’s father Erwin was a successful dermatologist himself in Germany – the family had emigrated to Australia in 1939, when Gerald was 13 years old. In the laundry of Gerald and Rae’s suburban Melbourne home, they developed Ego Pine Tar Bath Solution, later called Pinetarsol, which remains one of Australia’s most widely used itch and inflammation skin treatments.

As a chemist, Gerald was uniquely positioned to formulate innovative

products that people needed to treat their skin. Rae, being a nurse, communicated the benefits of the products to dermatologists across Australia. When Alan suffered cradle cap as a baby, his father formulated a product to ease the skin condition, which remains the only product of its kind around the world. From the beginning, the husband and wife team established Ego as innovators in the scientific development of dermatology products.

Gerald grew the business by working with dermatologists, visiting them at different conferences around the country. The professionals understood the value of the products, but the trouble was you could only get a small amount of sales from this. In the mid 1970s, Ego begun to enter some pharmacies. In 1975, the trajectory of the company changed when Gerald was asked by Melbourne’s Queen Victoria Hospital to develop a specialist bath oil for its dermatology patients.

“The aptly named Dr. David Nurse wanted a bath oil for children with eczema in hospital,” he said. “My father formulated a bath oil with minimal chance of irritation as a service line for the Queen Victoria Hospital. We made a bucket full of the product and we labelled it QV bath oil. Everyone thought it didn’t matter at the time because it was just a service line, kind of a nuisance in the back

manmonthly.com.au Manufacturers’ Monthly JUNE 2023 21

Alan Oppenheim on a tour of Ego’s facility with Minister Ben Carroll.

Manufacturing Focus

corner. Then years later, patients loved the product and went to the pharmacy after leaving the hospital to ask for some QV bath oil. The pharmacies didn’t know the product existed, but the feedback was relayed to my dad and he had some bottles printed, did a pharmacy run and transformed the business.”

Ego’s QV Bath Oil, named in honour of the hospital, is a household name over four decades on. But that product just scratches the surface of Ego’s production today. Last year, Ego produced an equivalent of 50,000 full bathtubs of product, including 2.4 million kilograms of QV Gentle Wash alone. The Australian manufacturer produces over 120 products for all types of skin needs, sold in many different sizes, targeting anything from eczema, to head lice to anti-aging:

• SunS ense® - In 1988, Ego was the first company to use a combination of a physical blocker and UV absorber in sunscreen and make it cosmetically acceptable.

DermAid® – To the best of the company’s knowledge, it was the first company to produce a dissolved hydrocortisone cream.

Aqium® – Dr Jane Oppenheim created the hand sanitiser market in Australia when Ego launched Aqium in 2000.

Ego continues to make Aqium in its $20 million facility designed to make flammable alcoholic products to world class pharmaceutical quality. During COVID- 19, Ego increased production by more than 100 per cent to meet the rapidly rising demand.

• MOOV® Headlice - Ego was the first company to have a headlice product that had been clinically tested to the international GCP Guidelines for clinical trials.

• QV® Dermcare - Ego was the first company to introduce products with ceramides into Australia at a cosmetic level. This was the QV Intensive with Ceramides range, which was rebranded to QV Dermcare in 2021. The tried and tested formulas have global reach, with exported product equating to about 50 per cent of the business. Ego is sold in over 15 countries beyond Australia and New Zealand – the UK, Asia, and Middle East being the top buyers. Today, Ego employs 517 people (54 per cent female, 46 per cent male) in Australia, but over 700 in total globally.

To support this growth, Ego’s facility underwent a $25 million facelift over the COVID pandemic, including installation of new LED lights, sprinkler system, fire detection system, solar panels and

replacing air conditioning systems with one centralised lower energy system.

Air conditioning in pharmaceutical production is different to other manufacturing sectors, because it needs extremely clean air in the clean rooms, using fine filters.

Dr Jane Oppenheim, scientific and operations director at Ego, was in charge of the upgrade which was completed in the middle of last year. Jane explained Ego is determined to have expertise inhouse and not just rely on contractors for its continued expansion.

“When I took over the engineering team, we had two engineers with some electricians and fitters. We now have a team of over 50,” she said. “Over time, we’ve been able to develop the engineering team to really run the project.”

Ego has worked with the same one company on all of its structural engineering consulting for 15 years, developing a functional team of external and internal engineers who understand how each other work. Jane credits this as the main reason why Ego has delivered so many projects on time and on budget, including the 50 million, five-year facility called Oppenheim Way in Dandenong South.

“We bought the land as a team. We rezoned it as a team. We did a master plan as a team and we built the main office building as a team,” she said. “It is our Global Support Centre where a lot of the new manufacturing will be done. We’ve recently started the first expansion of this which is very exciting.”

From making its formula in bathtubs, Ego has progressed to become a local manufacturing powerhouse for the people of the world. This year, the company has announced it is expanding production capacity by 50 per cent as part of a $35 million project.

The project will add new cream and filling lines to Ego’s Braeside manufacturing facility and extend its distribution centre in Dandenong South, increasing capability and capacity to support local and fast-growing export markets.

“Keeping our high-technology manufacturing in Australia has and always will be important to us,” he said. “This grant will help us further in creating good jobs to support our local economy as we continue to grow and will enable Ego to transform more lives through the science of healthy skin across many nations.”

Minister for industry and innovation and manufacturing sovereignty Ben Carroll told Manufacturers’ Monthly the state

22 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

Ego has set its sights on new cream and filling lines to increase production at its Braeside manufacturing facility.

Managing director Alan Oppenheim with minister Ben Carroll and scientific and operations director Dr Jane Oppenheim.

government’s support of the expansion will create 90 new jobs.

“Ego Pharmaceuticals’ decision to expand its operations in Victoria demonstrates the strength of our nationleading advanced manufacturing industry and highly skilled workers,” Caroll said.

A demand for quality control

Quality control is integral in the pharmaceutical world. Before he became managing director, Gerald was the scientific director himself, directly involved in projects such as significantly upgrading the businesses’ water purification standards.

Ego’s products are not sterile, but the goal is to produce products with very little bacteria in them. Australia’s Therapeutic Goods Administration audits processes on a frequent basis, and Ego decides to make all of its products to international pharmaceutical standards (even though some products aren’t classed as therapeutic and therefore wouldn’t require as such).

“Our job is to produce and supply a product that is really clean with really low levels of bacteria,” Alan said. “The most important ingredient for that is the water. Water at room temperature doubles in bacteria about every half hour, which is

Manufacturer Focus

really, really fast. When we’re putting water in our products, or rinsing our tanks, we are using our purified water systems that makes reverse osmosis water. We don’t go sterile because that’s a whole another level of cost, but the level of bacteria in the water is really critical and really low.”

To test the level of bacteria, chemists can’t just duck into a lab and resolve a sample in five minutes. In a microlab, staff have to grow the sample in an incubator and wait for 48 hours for the results, which is why it’s critical for bacteria levels to begin low, and if they are concerning at all, to get onto it early.

“For the purified water system, the most important ingredient is TLC –tender loving care – by the engineers who understand it and work closely with microbiologists,” he said. “Improvements might come from a particular tap where the water comes out, or it might be the system or a whole range of things. We do a lot of work to ensure the bacteria levels stay really, really low.”

The people behind the product Dr Jane Oppenheim has been working on Ego’s mixers for more than a decade, having purchased the first machine from Germany around 15 years ago. This machine is a two-tonne, computer-

controlled mixer which makes batches of emulsions such as sunscreen and antifungal cream. Ego has another two-tonne mixer for making its Aqium Hand Sanitiser, which is flammable, thus requiring completely different engineering because of the alcohol in the formula.

When touring Ego’s facility in Braeside, Victoria, it was clear to see the company recognises the impact particular staff have had over the years. It was impossible to miss the new arrival – Ego’s gigantic new mixer, which is named after one of its dedicated employees – ‘Ravi.’

The machine weighs eight tonne empty – so big it couldn’t be shipped in a container and had to be transported in wooden crates – and came with two whole shipping containers of cables and valves.

“We then had two structural engineers, civil engineers and one computer engineer from the supplier come out from Europe with many of our engineers all working together,” he said. “We had to raise the ceiling, and literally take the roof off and raise the roof to fit it in.”

The mixer makes five tonne batches of emulsions. The oil ingredients and oil soluble ingredients are put into one container, while the water soluble ingredients are in another container. The ingredients are heated and mixed

together, cooled and emulsified.

“The huge motor which runs the emulsifier pushes the mixture through a very fine gap to make sure that the droplets of oil in the water mixture are really small which increases the stability the product for the long term,” he explained.

The machine’s namesake – Ravi – has worked with Ego for 28 years. Described by Jane Oppenheim as “just a really, really good sort,” Ravi has been integral to Ego’s manufacturing operations, including working a way to increase from two batches a day to three batches per day.

“Whenever I step into manufacturing, Ravi has always a good reason for change,” Jane said. “He looks at what we can do differently in the future. He gives me the floor credit and I give him the management credit, so together we are able to convince most people of plans to better production and efficiency.”

Alan Oppenheim explained that the company’s values – including considering staff as family themselves – stemmed from his family heritage.

“When you’re running a small business you don’t usually have time to put them on paper, but my mother and father lived these values – quality, our people making the difference, innovation, ethics, service and helping our customers.”

manmonthly.com.au Manufacturers’ Monthly JUNE 2023 23

Ego Pharmaceuticals hold consistent ambitions to upgrade its equipment and processes.

Engineering Focus

High-tech medical gels from Indigenous spinifex grass

Manufacturers’ Monthly sits down with Tim Case, interim CEO of Trioda Wilingi and Dr Jane Fitzpatrick, CEO of ANFF, to discuss how the medical device company harnesses the abundantly available native spinifex grass to develop innovative medical gels.

24 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

Spinifex grass is a resilient plant that grows abundantly in the arid Australian outback.

Engineering Focus

THE Australian outback is home to some of the world’s most unique and hardy plant life. Among them is spinifex grass, a tough and spiky plant that can survive in the harshest of conditions. The humble grass, found predominantly in the arid regions of Australia, is proving to be a game-changer in the field of medical research.

For centuries, the IndjalandjiDhidhanu people – Traditional Owners of the upper Georgina River region of Northwest Queensland – have used spinifex grass for a variety of purposes, including as a source of medicine, to build shelters and using resin from the grass as an adhesive to attach spearheads, and seal water vessels. But it wasn’t until recently that scientists discovered the potential of spinifex in the field of nanotechnology.

Unleashing the potential of spinifex grass

Spinifex has a unique chemistry that allows for the production of stronger, longer, thinner, and more flexible nanofibers. The nanotechnology research on spinifex grass and its properties has been twelve years in the making.

Dr Jane Fitzpatrick, chief executive officer of the Australian National Fabrication Facility (ANFF) said, “The Traditional Owners approached the University of Queensland with an idea about spinifex grass – they know it’s tough and hardy, grows well, and they’ve been

using it for thousands of years for several applications.”

In 2008, the Dugalunji Aboriginal Corporation (DAC, a parent company of Bulugudu Ltd), and the University of Queensland were awarded a discovery grant by the Australian Research Council (ARC) to explore the Aboriginal and Western scientific knowledge of spinifex grasses.

Bulugudu Ltd, led by Colin Saltmere AM, was established to further explore the potential of the nanocellulose fibres in spinifex grass.

Tim Case, interim CEO of Trioda Wilingi said, “A key part was to characterise the cellulose nanofibres in spinifex grass and that’s where ANFF stepped in. ANFF had research equipment and capabilities, and in collaboration with the Australian Institute for Bioengineering and Nanotechnology (AIBN), helped characterise the spinifex nanocellulose fibres.”

ANFF’s involvement in the project

ANFF was founded in 2007 to provide open access to micro and nanofabrication equipment and capabilities to develop new products and provide improvement to current production methods. From a technical perspective, ANFF’s support revolved around the characterisation of the nanocellulose fibres from spinifex grass.

The late Dr Ian Griffiths, previous CEO of ANFF, was instrumental in recognising

the potential of spinifex nanofibers in medical gels and began negotiations to commercialise the product, which eventually led to the establishment of Trioda Wilingi. The investment opportunity was developed and led by ANFF-C, the new commercialisation arm of ANFF, which is part of Australia’s National Collaborative Research Infrastructure Strategy (NCRIS) funded by the Australian Government’s Department of Education.

“We provide expertise and equipment to people who want access to fabrication

equipment. In the initial stages, when you’re only testing ideas, some of this equipment is expensive ¬– so it makes sense to have the capability to rent the equipment for an hour or so, for research all the way through to industrial processes,” explained Dr Fitzpatrick.

“We identified that there were many great ideas that weren’t getting very far beyond their initial stages of research. Therefore, we developed our commercialisation support platform or ANFF-C. With this, we support early-stage entities that are trying to get out into the

manmonthly.com.au Manufacturers’ Monthly JUNE 2023 25

Trioda Wilingi interim CEO Tim Case (far left) with ANFF CEO Dr Jane Fitzpatrick and Bulugudu director Colin Saltmere AM (centre)

Spinifex medical gels can be applied to wounds to create a strong, flexible, and water-resistant seal.

Engineering Focus

market, to develop a product or develop a company.”

Trioda Wilingi was one of those companies.

“With Trioda, we worked with all involved partners like the University of Queensland and Bulugudu to get everything lined up for it to be investable. There are a number of different markets Trioda can go to, but we’re focusing on medical gel end markets that require high-value, low-volume manufacturing.”

Tim Case added, “Trioda Wilingi was the first project under this pilot commercialisation funding by the Federal Government that led to the formation of ANFF-C. It helps find potential commercial applications, funding, and attract external funding – and therefore was pivotal in enabling Trioda Wilingi to

become an investable opportunity.

“We’ve integrated traditional knowledge of the plant and how it grows, with the latest chemical nanotechnology advances, to create the beginnings of a new industry.”

The journey from research to commercialisation

Around three years ago, Mr Case was brought into the project to assist in identifying market opportunities, develop the commercialisation plan and ultimately create an investable opportunity.

“I had previously worked on another project with the late Dr Ian Griffiths. Dr Griffiths was a polymer chemist and he worked with Professor Darren Martin, one of the inventors of the

technology, from The University of Queensland’s School of Chemical Engineering, to identify the potential of using the nanocellulose in medical gel applications,” Mr Case said.

“Medical gel applications for spinifex ticked a lot of boxes, both from a technology perspective and a commercial and scalability perspective – building a solid business case. We sadly lost Dr Griffiths in this time, and we had to pick up on all the hard work he had done – it reminds me of the quote ‘standing on the shoulders of giants’.”

In February 2023, the hard work came to fruition when Australian venture fund Uniseed and Bulugudu Ltd announced an investment of $2.6 million into Trioda Wilingi to develop injectable medical gels from cellulose nanofibres extracted from spinifex grass.

The name ‘Trioda Wilingi’ is derived from the scientific name for spinifex grass – Triodia pungens – and ‘Wilingi’ which means “special grass” in the Indjalandji language. The company’s exclusive global rights to develop the injectable spinifex medical gels have numerous potential applications including osteoarthritis, drug delivery, and cosmetic treatments.

A closer look at the applications and advantages of spinifex nanofibres

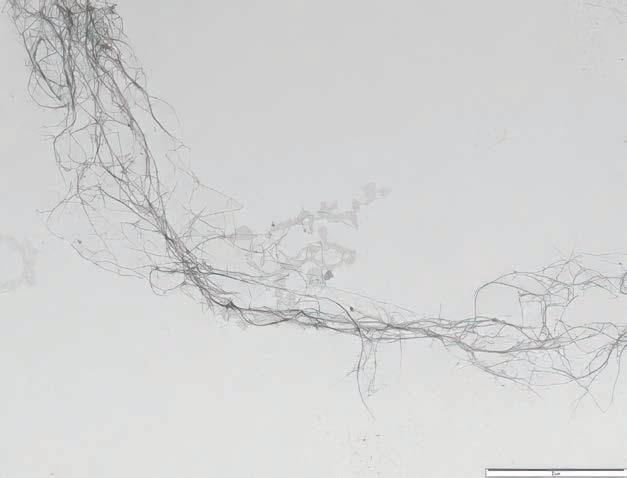

The cellulose found in spinifex is the longest, thinnest nanocellulose that has been found in nature ¬–the fibres are

three to four nanometres thick, about 20,000 times thinner than a human hair. The aspect ratio or the length and width of the fibres is 500:1, which makes them both skinny and strong. This is important because it helps spinifex grass work as an excellent reinforcing agent.

There’s a global demand for cellulose nanofibres due to the vast number of potential applications, specifically in the commodities market. One of them, for instance, is recycled paper.

“When you’re trying to recycle paper, it can only be recycled so many times before the grade disappears,” Dr Fitzpatrick said. “By adding reinforcing agent into that process, you end up with paper that’s better for recycling. Latex is another example – items such as gloves that require strength and reinforcement. Currently, Trioda will be concentrating on medical gels.”

Initial research has shown that the advantage of using spinifex nanofibers for medical gels compared to other materials is its ability to be injected and to last longer.

“As a plant material, spinifex nanocellulose is simple. It can be modified easily with fewer chemical modifications so you can add things to it and there are a number of different properties that allow this cellulose to work,” Dr Fitzpatrick said

Additionally, explained Dr Fitzpatrick, the nanocellulose can be released from spinifex grass without using

26 JUNE 2023 Manufacturers’ Monthly manmonthly.com.au

Spinfex’s unique chemistry makes it an excellent reinforcing agent.

energy-intensive processes to make nanofibres from materials such as wood pulp, carrots, wheat straw, and sugar beet.

Tim Case added, “UQ has developed a process to extract the nanocellulose fibres that is milder, ensuring that you maintain the unique attributes of the spinifex fibres, as well as being more environmentally friendly.”

Next steps for the company

The funding that Trioda received earlier this year will be spent towards taking the research further and perfecting its formulation, according to Tim Case.

“The focus of this current capital raise is on research from some preclinical studies and some animal work as part of that, which is about getting the formula right, ensuring you understand the manufacturing process to, ultimately, produce a quality gel consistently that meets its characterisation criteria. We will then subsequently look to raise further capital and move into clinical trials, ” he said.

“And we are looking to tick boxes from a data perspective, both in terms of what we must do, including from a safety perspective, and also look to support those differentiators that could mean a gel that has great market disruption potential.”

Engineering Focus

In the next five years, Mr Case is hopeful about having numerous other applications under development for spinifex grass. “We’ve had early discussions large international players within the industry and the feedback has been positive – we’re moving forward in the right direction.”

Support to Indigenous communities

“Spinifex grass is an ancient and sacred material to our people. In IndjalandjiDhidhanu culture, spinifex is a sacred thing. It belongs to Country, and to us, that’s what ‘sacred’ means,” according to Colin Saltmere, director of Bulugudu and Trioda Wilingi.

Under the deal that was signed in February, a portion of any future royalty

stream will be allocated to an Indigenous STEM education fund that aims to maximise training, education, and network opportunities for Indigenous Australians.

“We’re hoping this can also lead to an increase in Indigenous participation in STEM and the effect of that over time,” Mr Case said.

“My hope is that Trioda Wilingi is the icebreaker for how spinifex may be used, and not just for medical gels – that way there will be other companies like Trioda Wilingi with other applications for spinifex grass. We are also attempting to demonstrate ways for other indigenous entrepreneurs to navigate ways to commercialise their potential.”

Dr Jane Fitzpatrick said, “With the spinifex medical gels from Trioda

Wilingi, the industry here in Australia is going to have a worldwide market. Simultaneously, the Traditional Owners will be involved in the farming and harvesting and initial processing of the spinifex grass since they’re the ones with the license to do so.”

Additionally, creating a burgeoning industry using local spinifex grass helps ensure that manufacturing capabilities are kept within Australia.

Dr Fitzpatrick said, “Trioda was the impetus that allowed us to develop ANFF-C. Since then, we’ve done several different projects through ANFF-C, but not on the scale of Trioda Wilingi. The formation of ANFF-C has helped us remove barriers for different projects and move them towards the ability to manufacture here in Australia. And that’s really the key in the development pipeline – to keep the innovation and the tech here.”

Tim Case also stresses the importance of regional manufacturing.

“When we start looking at other applications that are high volume in nature, in terms of manufacturing scale, it has the potential to make the employment sector really viable, especially in remote areas such as Northern Queensland where spinifex is harvested. We want to see a strong regional supply chain and viable employment opportunities ¬– with the involvement of Indigenous communities.”

manmonthly.com.au Manufacturers’ Monthly JUNE 2023 27

Spinifex resin has been used as an adhesive to make stone tools.

Spinifex cellulose nanofibres tiny, hair-like structures that interlock with surfaces.

Trioda Wilingi’s novel injectable spinifex medical gels have many potential applications.

Sustainable materials

Driving a sustainable future

VOLGREN built its first bus in 1979 with the promise of creating a more reliable, comfortable and longer-lasting vehicle with lower operating costs than others then what was available at the time.