Over the past year, Lightforce Group has cemented its status as a premier designer, innovator, and manufacturer of military and law enforcement solutions, showcasing our dedication to South Australia’s manufacturing goals.

Join us at the 2024 LandForces International Land Defence Exposition! Visit Site A069 to discover our groundbreaking solutions and engage in impactful discussions.

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Mike Wheeler

Assistant Editor: Phillip Hazell phillip.hazell@primecreative.com.au

Journalist: Jack Lloyd jack.lloyd@primecreative.com.au

Production Coordinator: Michelle Weston michelle.weston@primecreative.com.au

Head of Design: Blake Storey

Design: Cat Zappia

Sales/Advertising: Emily Gorgievska Ph: 0432 083 392 emily.gorgievska@primecreative.com.au

Subscriptions

Published 11 times a year

Subscriptions $140.00 per annum (inc GST)

Overseas prices apply

Ph: (03) 9690 8766

Copyright Manufacturers’ Monthly is owned by Prime Creative Media and published by John Murphy. All material in Manufacturers’ Monthly is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Manufacturers’ Monthly are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2024

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive

Docklands VIC 3008 P: +61 3 9690 8766

enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 11.01, 201 Miller St, North Sydney, NSW 2060

Printed by: The Precision Group 83-89 Freight Drive. Somerton Vic 3062

Ph: (03) 9794 8337 manmonthly.com.au

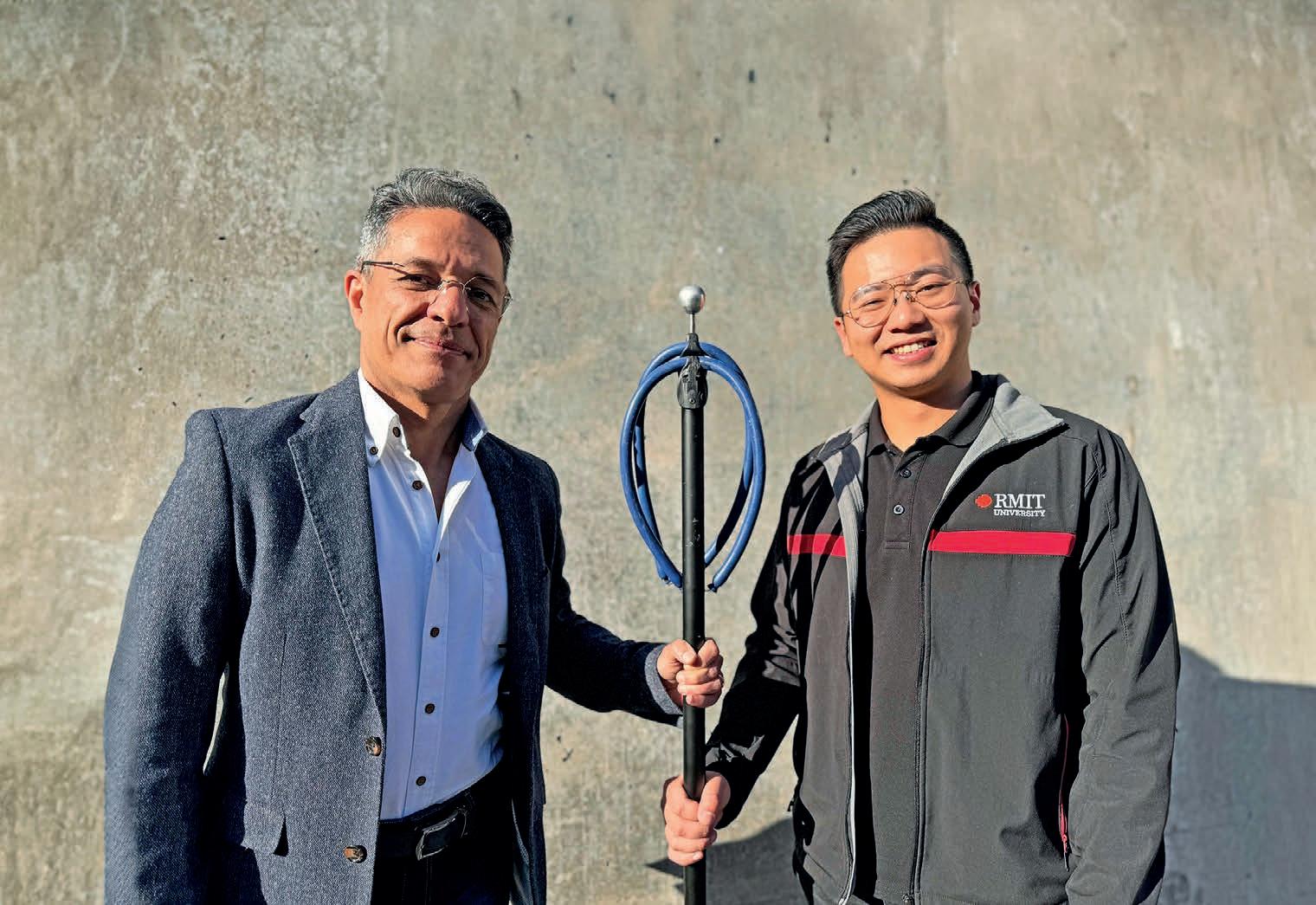

Welcome to the September edition of Manufacturers’ Monthly. In this issue’s Manufacturer Focus, EMVision creates portable brain scanners for rapid stroke diagnosis, aiming to improve speed and accuracy in diverse settings. Learn more about the company’s inception and journey towards commercialising their product. Later in this edition, we speak with representatives from the Australian Foundry Institute who have raised concerns about issues facing the industry. Finally, in this month’s Engineering Focus, we speak with RMIT engineers, who are developing a modified speargun for cost-effective seabed soil testing. Happy reading!

Dear Readers,

As we step into the September edition of Manufacturers’ Monthly, it’s an opportune moment to reflect on the evolving landscape of Australian manufacturing and the exciting developments shaping our industry.

This month, our coverage highlights the strides being made in defence, sustainability, and local manufacturing – each contributing to the growth and innovation of our sector.

In the defence sector, the Federal Government’s commitment to bolstering Australia’s maritime capabilities continues with the ongoing development of the medium landing craft.

This $2 billion project, with vessels designed by Birdon and built by Austal, is a cornerstone of our defence strategy. It represents not only an investment in national security but also a substantial boost to our shipbuilding industry, promising to sustain jobs and stimulate economic activity well into the future.

As these vessels prepare to enter service, they

will enhance our operational flexibility and support regional humanitarian missions, reinforcing Australia’s role as a key player in maritime defence.

On the sustainability front, RMIT University’s groundbreaking work in low-carbon concrete is setting new benchmarks for the construction industry.

The innovative concrete, which reduces cement usage and increases the recycling of coal ash, is a major step forward in addressing environmental impacts.

By cutting CO2 emissions and offering long-term durability, this advancement not only supports Australia’s climate goals but also paves the way for more sustainable building practices globally. The integration of such technologies is crucial as we head towards a greener future in construction.

Then there is Victoria’s manufacturing sector, which is receiving a boost from the Made in Victoria – Manufacturing Growth Programme. This initiative, aimed at enhancing

competitiveness and driving innovation, is supporting nine SMEs with grants to upgrade technologies and improve productivity.

This investment highlights the state’s commitment to fostering growth and creating highly skilled jobs.

As these businesses advance, they will contribute to a more robust and dynamic local manufacturing ecosystem.

Lastly, the effort to save Silver Fleece, an iconic Australian knitting mill, reflects the resilience and dedication inherent in our industry.

Spearheaded by the Australian Fashion Council and Sunset Lover, this initiative aims to preserve a legacy of Australian craftsmanship while addressing rising demand for sustainable products.

The revival of Silver Fleece not only safeguards local jobs but also champions the value of supporting Australian-made goods.

These stories encapsulate the spirit of progress and innovation that defines our industry.

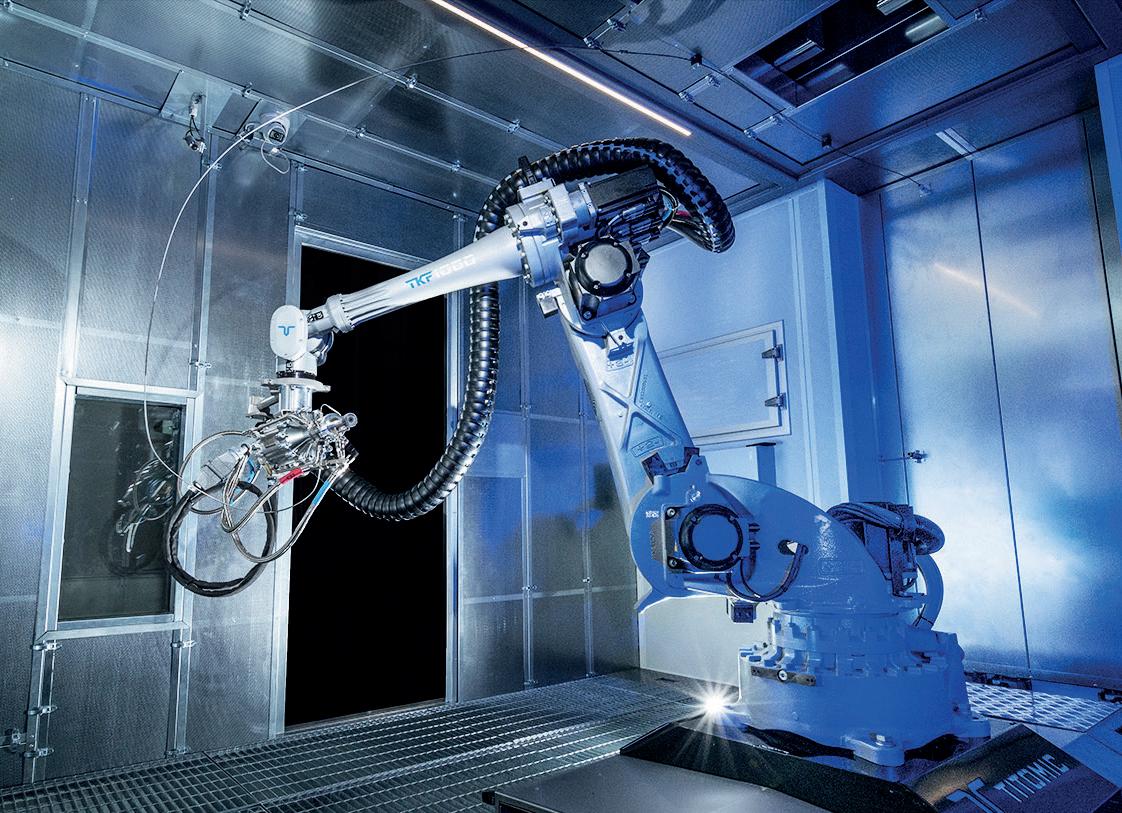

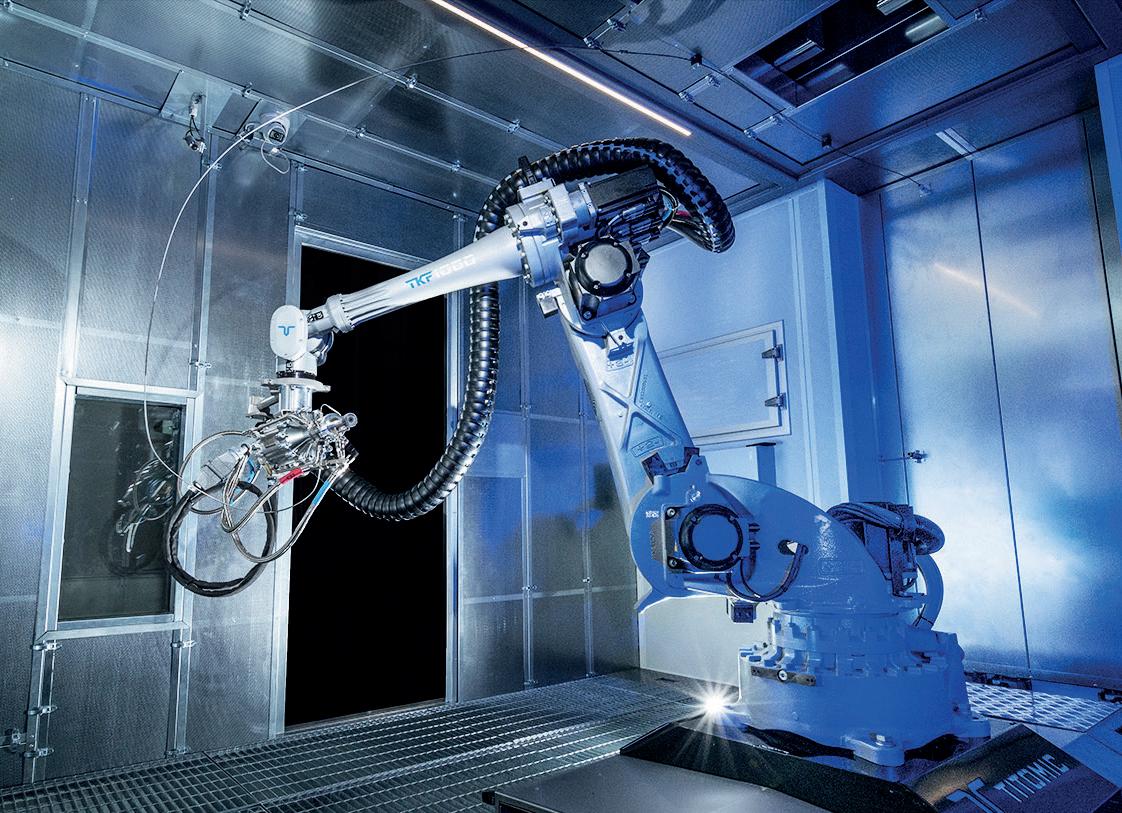

Titomic Kinetic Fusion® provides rapid, no-heat metal repairs and cost-effective titanium manufacturing for defence applications. This technology is enabling new manufacturing capabilities, including the ability to fuse different metals without heat, manufacture titanium without size restraints, and much more.

TKF1000

Create large, strong multi-metal parts

MULTI-METAL, SINGLE-PIECE PARTS

BALLISTICS SHIELDING

TOOLING

STRUCTURES

D523/D623

For versatile in-field battle damage repairs

METAL DEPOSITION

Across Australia, and in particular the building and construction industry, the need to boost productivity is more critical than ever.

Nationally, labour productivity growth has been slowing since the mid-2000s.

According to Treasury reports, the decade to 2020 experienced the slowest productivity growth in 60 years, falling to a yearly average of 1.2 per cent. By comparison, the late 1980s to early 2000s saw a labour productivity growth rate of around 3 per cent.

While this downward trend is roughly in line with the average OECD labour productivity growth rate of 1.4 per cent, Australia has dropped from number 20 to 41 globally in terms of workplace productivity. The slowdown in productivity growth has concerning implications for our economic growth, real wages, and overall living standards, which are key to prosperity.

The construction industry ranks among the

lowest in terms of productivity performance: even an increase to the national average would deliver billions of dollars to the economy. What’s more, Australia’s state and federal governments have a pipeline of infrastructure, housing, and energy projects that are not achievable with our current productivity performance. Solving the productivity problem is paramount to their success.

Labour productivity is a major contributor to economic efficiency and rising living standards. Over the past 30 years, labour productivity has accounted for around 70 per cent of the growth in Australia’s living standards, as measured by real gross national income (GNI) per person. For living standards to improve, we need sustained labour

productivity growth – defined as the ratio of output to labour input.

In the construction sector, lack of productivity gains is one of the greatest challenges to project completion, resulting in only 50 per cent of project owners meeting delivery deadlines. Poor productivity is placing increased pressure on businesses that are already feeling the squeeze of rapidly escalating labour and supply chain costs, high inflation, and long wait times for equipment and materials. Improved productivity performance is crucial to delivering on the Federal Government’s pipeline of $120 billion infrastructure spend and $800 billion of investment in renewable projects by 2050.

On a broader level, Australia’s capacity to navigate economic challenges and capitalise

on opportunities hinges on having dynamic, productive, and innovative businesses. Weak productivity hampers the economy: in fact, the past 30 years of slow productivity growth has equalled approximately $47 billion in lost opportunity.

A driving factor behind the productivity slowdown is a decline in business dynamism. This has slowed the rate of technological adoption and innovation and inhibited resource allocation to more productive companies. As a result, there are a growing number of zombie firms – businesses that are unprofitable but remain in the market, sometimes with government support. At the same time, increased market concentration has led to reduced competition and higher price markups.

Recent years have also seen large structural changes in the economy, with shifts towards the services sector, which typically has slower growth according to traditional productivity metrics. The ongoing impacts of COVID-19 on productivity remain uncertain, as working-from-home models could enhance productivity in some sectors while worsening pre-existing challenges for productivity growth in others.

According to the Federal Government’s projections, the current productivity growth rate of 1.2 per cent will erode relative living standards— with GNI per person forecast at $32,000 lower than an LP rate of 1.5 per cent. However, we are unlikely to see an increase in Australia’s LP rate without additional government policy drivers aimed at addressing barriers to business dynamism, driving technological transformation, and incentivising businesses to improve productivity performance.

In the construction industry, while the number of workers has increased in the past decade, output per worker has reduced. On average, people are working two hours less per year with 25.4 per cent lower output – calculated as construction work completed divided by the number of workers. For example, worker output in 2023 was $180,100, compared with $196,800 in 2018. With demand for skilled workers continuing to outpace the available supply, greater productivity is key to raising worker output.

In the welding industry, productivity is equally imperative to driving innovation and growth. Welding businesses that maximise efficiencies and optimise operations benefit directly from cost savings and better use of resources. Labour, equipment, and materials can be more effectively allocated to minimise waste and energy consumption. Productivity gains lead to faster project completion times – enabling companies

to exceed client expectations and ensure repeat business.

Our recent member survey revealed that twothirds of Australian welding businesses rate the productivity of their staff as good or excellent. However, more than 42 per cent of welders are spending eight hours or less on site every day, and one-quarter spend less than two hours of their shift doing actual welding. The factors most likely to impact on the productivity of welding staff are materials handling and staff shortages.

A clear pathway to productivity is through technology. When companies are focused on improving their processes, they naturally innovate – implementing the latest technologies in a bid to streamline operations. However, Australian companies generally lag their global competitors in digital adoption and unfortunately the welding sector is no exception. Uptake of advanced welding technology remains relatively slow, and this lack of tech adoption is impeding our ability to navigate the current challenges facing the industry.

Most welding businesses are still not leveraging robots or collaborative robots, known as cobots. These are robotic arms equipped with sensors so they can safely work alongside humans, unlike traditional industrial robots, which are a potential hazard to human workers. They are designed to take on mundane and repetitive tasks, freeing up workers to take on high-value tasks.

By leveraging the benefits of cobot welding, businesses can increase their productivity and reduce labour costs, while improving the quality of their welds. Given that the major barriers to productivity are materials handling and a lack of skilled staff, there is an opportunity for welding businesses to harness the capabilities of advanced welding technologies to overcome these issues.

To address the productivity challenge in Australia’s welding and fabrication industry, Weld Australia is seeking grant funding for a productivity-based training scheme. Under the program, fabrication companies would be supported to conduct their own staff training at little to no cost – with Weld Australia providing advanced learning resources, training for the instructor, and accreditation for the training facility. We would also quickly certify production welders according to ISO 9606 or AS/ NZS ISO 1554–so that businesses don’t have to wait three or more years for a Certificate III or IV trained welder.

Weld Australia is also undertaking research into welder productivity, which is defined by the number of arc-on-time per welder per shift. In Australia, our member reports show that the average arc-on-time is around two hours – compared with approximately fi ve hours per welder per day in countries like the United States and Germany, which have similar Workplace Health and Safety Standards.

Our research will investigate the reasons behind this marked difference in productivity, with the objective of identifying potential solutions such as using robots and cobots, and trades assistants for tasks such as griding, set up and cleaning.

These two projects could help raise the welding capacity of the Australian industry by enabling us to match international productivity standards. If you would like to be involved in Weld Australia’s Productivity Improvement Projects, please contact Cornelis Van Niekerk (business manager, Weld Australia) via c.vanniekerk@weldaustralia. com.au or 0409 609 031.

The Federal Government has accelerated the $2 billion build of 18 medium landing craft for the Army’s new littoral fleet which is set to be designed by Birdon and built by Austal.

The first of the vessels will be built at the Henderson Shipyard in Western Australia and is expected to be delivered in 2026.

“This pipeline of work will result in opportunities for the Australian defence industry and support

a highly skilled shipbuilding workforce for years to come,” said minister for Defence Industry, the Hon Pat Conroy MP.

These vessels are an essential component of Army’s transformation and optimisation for littoral manoeuvre.

They are set to support a strategy of denial, which includes deploying and sustaining modernised land forces with long-range land and

The Federal Government has awarded Thales Australia with a $45 million contract to build an additional 15 Bushmaster Protected Mobility Vehicles.

The company will build the Bushmaster vehicles in Bendigo, supporting hundreds of jobs in the local economy and more jobs across the supply chain in Victoria.

The additional 15 Bushmasters will facilitate command and control of Army’s High Mobility Artillery Rocket System long-range fires regiment.

Minister for Defence Industry, the Hon Pat Conroy MP, said the investment is another step toward a future made in Australia.

“I am delighted to be back in Bendigo to announce a further $45 million investment in the region, with the production of an additional 15 Bushmaster protected mobility vehicles,” said Conroy.

This supports the Federal Government’s $1.6 billion investment to accelerate the delivery of the first land-based long range fire capability for the Australian Defence Force.

maritime strike capabilities across our region.

The Landing Craft Medium can transport up to 90 tonnes, equivalent to one main battle tank, or one infantry fighting vehicle and two Bushmasters.

These landing craft will be supported by Amphibious Vehicle Logistics, which can navigate over beaches and through waterways.

“These new vessels will enable the ADF to deploy and sustain land forces to beaches, rivers and ports in Australia and across our region, enhance our ability to work with regional military partners, and support communities across the Indo-Pacific with humanitarian and disaster relief operations,” said Conroy.

The local build of the medium landing craft is in addition to up to eight heavy landing craft, which will also be built by Austal at Henderson.

The $2 billion project is expected to create 1,100 direct jobs and more than 2,000 indirect jobs.

This project is a part of the Federal Government’s investment of $7 billion towards littoral manoeuvre vessels.

Bushmasters are currently in use in nine countries and are renowned for their high level of protection and mobility for troops.

Notably, it has seen service in Ukraine through

medical evacuation, command and control, and fire support roles.

This contract will continue Bendigo’s more than 20-year history of producing these vehicles.

At the launch of the GSEM Jobs and Skills Roadmap, Federal Skills minister, Brendan O’Connor, said that the Greater Southeast Melbourne region is the key to a future made in Australia.

The roadmap was launched at Parliament House in Canberra and will help O’Connor assist regions right across the country.

“It will help inform me about how other regions of Australia can take the best approach to ensuring that we have successful economies, good jobs,

and of course, ultimately, a successful nation,” said O’Connor.

“Planning for skills needs is critical at a time when the economy and labour market are rapidly changing.”

O’Connor described GSEM as critical to Australia’s manufacturing sector and invited the region to continue to engage closely with Jobs and Skills Australia and the national Jobs and Skills Councils.

The minister said that the region and the federal

government understand the need for greater collaboration to address workforce requirements.

“We understand the importance of improving equity, inclusive growth, and reducing disadvantage in our VET (Vocational Education and Training) sector.”

O’Connor also invited GSEM to engage with the government to help ensure better analysis of the labour market and to better understand trends in local economies.

One of the world’s largest manufacturers of 4WD accessories, ARB, has opened a new $25 million global headquarters and Research and Development Engineering Centre in Kilsyth, VIC.

The Victorian Government supported the expansion, as the facility has the potential to foster local jobs, investment, and innovation in the automotive sector.

The 5,100 square metre Centre is adjacent to

ARB’s new state-of-the-art showroom, where the company continues to manufacture 4WD equipment.

Bringing ARB’s HQ, R&D centre, showroom, and manufacturing facility together at Kilsyth is creating up to 70 new local jobs for Melbourne’s east. Established in Melbourne in 1975, ARB has grown into a company with an export network that extends across more than 100 countries.

The Kilsyth hub is now home to 600 staff, including 85 engineers, with the company’s employee numbers growing to over 2,000 across Australia and internationally.

Victoria’s $33.5 billion manufacturing industry is a driving force of Victoria’s economy. The sector is made up of over 23,000 businesses, supporting more than 260,000 jobs, and exporting goods worth $23.9 billion.

Almost $2 million from the Australian Renewable Energy Agency (ARENA) will support 10 businesses to undertake feasibility studies to deploy energy efficiency and renewable energy initiatives.

It will help Brown Family Wine Group’s vineyard electrify their operations, O’Connor Beef deploy new technology that captures biogas during wastewater processing, and Real Pet Food Co better manage heat from manufacturing processes and reuse it.

The funding will help hard to abate businesses across manufacturing, wine, meat, and water, in making every Watt count.

Assistant minister for Climate Change and Energy, Jenny McAllister, said this funding is an example of how ARENA is partnering with Australian industry.

“With ARENA’s expertise, these grants will not only help businesses scope and pioneer clean energy innovation but demonstrate the technology to help Australian industries decarbonise and become more competitive,” said McAllister.

The projects supported with the new grants include:

• $399,503 to investigate renewable energy initiatives and a covered anaerobic lagoon to treat wastewater at the G&K O’Connor meat processing facility in Pakenham, Victoria.

• $250,400 to develop a heat energy recovery system at Real Pet Food Co’s manufacturing sites

in Queensland and New South Wales.

• $244,677 to improve energy efficiency and examine electrification options at Quantem in Port Botany, West Melbourne and Brisbane.

• $242,924 to modernise refrigeration infrastructure at the George Weston Food small-goods facility in Castlemaine, Victoria.

• $205,000 for site-wide energy efficiency and electrification projects at the Beston Global Food Company dairy factory in Jervois, South Australia.

• $149,850 to develop a decarbonisation roadmap at three of Unilever’s hygiene and food manufacturing sites across New South Wales and Victoria.

• $147,800 to examine options to harness energy from waste through biomass processing at the Bindaree Beef meat processing facility in Inverell, New South Wales.

• $117,515 to optimise energy efficiency across the Grampians Wimmera Mallee Water pipeline in Western Victoria.

• $116,397 to identify low emissions and energy efficient technologies at the Brown Family Wine Group winery in Milawa, Victoria.

• $110,000 to investigate a geothermal heating system to provide process heat at the Paper Australia barramundi farm in Latrobe Valley, Victoria.

For over three decades, we have played a vital role in the design and manufacture of defence equipment in Australia.

From selecting the best design and validation software to deployment and configuration, consulting on simulation and data management, we ensure the design and engineering teams in defence are proficient and ready to use these tools from the outset. Tailored training programs elevate the skills of personnel, ensuring teams are adept with the latest technologies and methodologies. This holistic approach enhances their capability to develop cutting-edge solutions and maintain a competitive advantage.

The second Australian-built Parramatta River Class ferry, named John Nutt, has sailed towards the sails of the Opera House.

John Nutt completed her maiden landing at the Man O’War steps following a successful three-day voyage across Bass Strait.

The ferry is the second of seven new Northern

Beaches designed vessels being built by Hobartbased shipbuilder Richardson Devine Marine.

The first vessel in the fleet, Frances Bodkin, has been in service since April.

A team of 60 people is working to build the remaining fi ve, which are expected to progressively enter passenger service over the

The Federal Government will invest more than $100 million to boost the ADF’s arsenal of drones, ensuring Australian military personnel are provided with cutting-edge lethal and non-lethal capabilities.

As a part of this $100 million investment, the Government announced the acquisition of two small uncrewed aerial systems (SUAS), the Quantum-Systems Vector 2-in-1 and the Sypaq Systems CorvoX.

These systems will bolster the ADF’s ability to carry out surveillance and reconnaissance and augment the ADF’s existing stock of drones.

The systems have capabilities across land and littoral operations and can support the Australian Army and Royal Australian Air Force in confined areas, including small marine craft, and urban environments.

Both systems can be deployed as a complement to crewed systems.

Minister for Defence Industry, the Hon Pat Conroy MP, said Defence’s partnership with these two companies shows how the Federal government is investing in capabilities the ADF needs to keep Australians safe.

“The delivery of these uncrewed aerial systems in 2025, within a year of project approval, is a significant demonstration of Defence and industry’s strong partnership, and intent to

course of the next 18 months.

Member for Parramatta, Donna Davis, said these ferries are intended to meet the growing population across the Sydney Olympic Park precinct.

“These new ferries, and the more frequent timetable on the popular F3 route, are a big win for anyone catching the ferry to work, school, or events around Sydney,” said Davis.

“The population right across the Sydney Olympic Park precinct is growing, and we need more public transport services to meet demand.”

The Australian-made fleet is set to be more reliable and comfortable than prior models, with upgraded safety systems, greater accessibility, and sleeker design.

The seven new vessels will replace the RiverCat and SuperCat vessels, which will be retired after 30 years of service.

The John Nutt vessel will now be handed over to operator Transdev for final checks to ensure she’s in ship-shape before the first passengers board in July.

enhance the speed at which we introduce capabilities in support of current and future Defence requirements,” said Conroy.

The partnership with both Quantum Systems and Sypaq Systems is expected to create at least 30 highly skilled jobs in Brisbane and Melbourne.

The two new SUAS will be delivered in 2025 as Defence continues expediting the acquisition of new drones while continuing to trial low-cost,

expendable uncrewed and autonomous systems.

This approach will add to the more than 20 drone systems already acquired including models that have been in service for more than a decade and platforms with multiple payload options.

The Federal Government is investing more than $10 billion on drones, including at least $4.3 billion on uncrewed aerial systems and $690 million on uncrewed tactical systems for the Army.

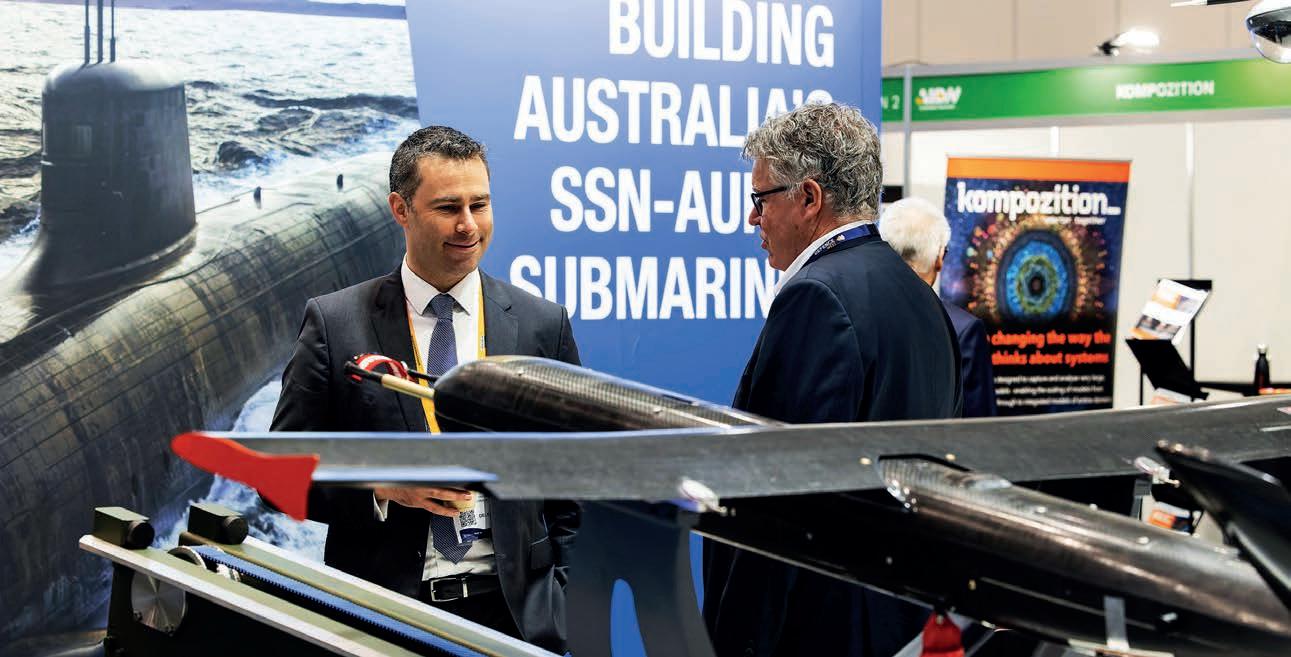

Austal Limited have entered a Memorandum of Understanding (MOU) with Civmec Limited to form a Joint Venture (JV) that will submit a proposal to the Commonwealth of Australia to support the LAND8710 Phase 2, Landing Craft Heavy (LC-H) project.

The LAND8710 Phase 2 (LC-H) is a proposal that has the potential to deliver enhanced transport and littoral manoeuvre capability to the Australian Army and thus enable greater reach over the Indo-pacific region.

The JV is planning to contract directly to the Commonwealth to undertake shipbuilding tasks for the LC-H project within the assembly hall at Civmec’s Henderson facility.

CEO of Austal, Paddy Gregg, said the company is excited by what the partnership could mean for sovereign shipbuilding, especially in WA.

“It would provide the Commonwealth with immediate access to a larger pool of skilled shipbuilding workers that can transition across multiple projects via a ‘consolidated Henderson’ model,” said Gregg.

“It will allow the Commonwealth to continue to leverage Austal’s naval shipbuilding experience and track record of delivery for the Commonwealth, including the upcoming Landing Craft-Heavy program.”

Civmec’s executive chairman, Jim Fitzgerald, said the JV will be an important step in ensuring the continuation of shipbuilding at Henderson.

“By combining Civmec’s Henderson shipbuilding facilities, which include the largest heavy engineering facility of its kind in Australia, our systems, steel manufacturing expertise and 4,000 strong labour force, together with Austal’s naval shipbuilding experience and long track record of

delivery, the JV would be very well placed to deliver efficient Continuous Naval Shipbuilding in Western Australia to Defence,” said Fitzgerald.

The MOU will see both Austal and Civmec developing the structure, delivery process and detailed scope of the JV.

This will help in preparation to submit tenders to the Commonwealth for LAND8710 Phase 2 (LC-H).

The iconic South Australian knitting mill, Silver Fleece, has been saved by the sustainable fashion company Sunset Lover, who has officially secured all its assets.

Co-founders of Sunset Lover, Dean and Melanie Flintoft, were behind announced the acquisition, which was made possible by a successful 48-hour capital raising media campaign.

The quick and successful capital raise not only signals a strong comeback for Silver Fleece but also paves the way for new business partnerships and strategic growth opportunities.

Sunset Lover will now work alongside existing clients like Cricket Australia and private and public schools nationwide, something the Flintoft’s can’t wait for.

“We get the ‘keys’ today and will immediately reassure all existing customers of our renewed operations, well-capitalised status, and continued commitment to excellence, whilst concurrently building a new portfolio of clients to further strengthen our position and get the mill operating at 100 per cent capacity,” said the Flintofts.

Silver Fleece is a renowned Australian brand with a remarkable 73-year history that is dedicated to producing high-quality, locally made products with a focus on sustainability and ethical practices.

The Flintofts said that moving forward it will also offer Australian yarn and a full ethical traceable

production process for all clients.

“Our ethos is to manufacture exceptional, proudly Australian-made products. With our industry experience and commitment to sustainable fashion moving forward, and the overwhelming response to our capital raising campaign - we are confident that we can revitalise Silver Fleece and make our investors happy because Australians do care about where ‘their clothing’ is made,” said the Flintofts.

The pair also announced the upcoming Sunset Lover Resort 2024/25 collection will launch the first capsule under this innovative collaboration with Silver Fleece, representing a significant milestone in the brand’s journey towards innovation and excellence.

“This is a dream partnership for Sunset Lover because Silver Fleece 100 per cent aligns with sustainable Australian made fashion. It will showcase the blend of craftsmanship and sustainability that this knitting mill can produce. We can’t wait to bring other Australian companies into the fold that care about Australian manufactured garments like we are,” they said.

Luxury fashion brands, corporates, government, healthcare, sporting clubs and schools are on the immediate client hit list with Silver Fleece being one of the few options left for Australian made knitwear.

Silver Fleece is equipped with state-of-the-art Shima Seiki Japanese knitting machines, known in

the industry as the best in the world.

Over the coming months the new owners will introduce a brand new Shima Seiki Wholegarment knitting machine to improve the capabilities and efficiency of the factory.

This will help to further leverage the recent fundraising campaign which undeniably demonstrated Australians’ passion for sovereign manufacturing.

“The iconic Australian-owned mill that honours the beautiful Australian artisan craft of knitting wool has been preserved and we would like to offer our heartfelt thanks to everyone, including people like the CEO of the Australian Fashion Council, Jaana Quaintance-James who believes in this craft like we do - we won’t let you down!” said the Flintofts.

Silver Fleece, which was established in 1951 and has a rich lineage of Australian craftsmanship, will resume ‘business’ today under the new management.

The 20 skilled staff and technicians whose jobs have been saved are primarily women and include younger employees eager to learn and preserve the artisan craft.

The Adelaide-based knitting mill entered administration last month, with a general meeting on 26 June 2024 resolving that the company be wound up.

Pfizer Australia has announced a major upgrade to its facility in Melbourne to make it one of the most advanced pharmaceutical production facilities in Australia’s fight against antimicrobial resistance (AMR).

Pfizer has invested AU$150 million to offer advanced pharmaceutical production facilities in Australia for new antimicrobial treatments aiming to help address rising levels of antimicrobial resistance, considered one of the biggest threats to global health.

Pfizer Australia & New Zealand managing director, Anne Harris, said the company is thrilled with reaching this milestone.

“We are thrilled to reach this important milestone in our investment to support the development and delivery of new antimicrobials at our Melbourne site, and to be investing in Australia’s advanced manufacturing capabilities,” said Harris.

The Hon Natalie Hutchins MP, Victorian minister for Jobs and Industry, visited the site to mark the milestone installation of key technology known as lyophilisers.

AMR has been described as ‘the silent pandemic’ and is considered by the World Health Organization to be a top 10 area of public health concern.

AMR makes infections harder to treat, increasing the risk of disease spread, severe illness and death, with annual deaths from AMR predicted to rise to 10 million by 2050.

Without intervention, it is estimated that by the same year, 10,000 Australians will die each year from drug-resistant infections.

“A key strategic pillar of Pfizer’s product innovation work is our effort to help slow the spread of antimicrobial resistance, one of the biggest global health threats of our time. We are also pleased to be providing 500 advanced manufacturing jobs at our Melbourne site,” said Harris.

Investment in the Melbourne site has included the construction of a new separate facility that hosts two newly installed freeze-drying machines known as lyophilisers, which are used in the antimicrobial manufacturing process.

The site has also been selected for a trial of Artificial Intelligence (AI) technology designed to

work and be operational by mid-2025, with commercial manufacture commencing in 2026. Medicines currently manufactured at the Melbourne site – which include those for treatment of cancer as well as antimicrobials, anaesthetics, antiinflammatory and other medicines – are exported to

Sydney-based MedTech manufacturer, EMVision, creates portable brain scanners for rapid stroke diagnosis, aiming to accelerate diagnostic speed and accuracy in both rural and urban settings.

EMVision Medical Devices are developing portable, light-weight brain scanners designed to rapidly diagnose strokes and other time-sensitive medical emergencies.

The technology aims to reduce the inequality between rural and metropolitan stroke outcomes by bringing advanced neurodiagnostic capabilities directly to patients through lightweight, affordable neuroimaging devices.

Based in Macquarie Park, Sydney, the company manufactures emu, an in-hospital bedside scanner designed to improve the speed and accuracy of brain imaging.

Scott Kirkland, CEO of EMVision explained that the emu scanner can quickly and easily be brought to the patient’s bedside instead of moving a criticallyill or unstable stroke patient to a CT Machine or MRI.

“Our emu scanner offers advanced neurodiagnostic capabilities, perfect for rural emergency departments and wards,” he said.

“In settings where traditional tools like CT and MRI may be inaccessible and specialised operators are scarce, this capability is invaluable.

“Given the critical time sensitivity of stroke diagnosis, emu allows nurses to perform scans, with expert guidance via telehealth opening the door to earlier triage, transfer and treatment decisions — potentially making the difference between a life of disability and a full recovery.”

In addition to the bedside scanner, EMVision recently unveiled its First Responder prototype, a portable scanner, weighing about 10 kilograms.

“It’s designed for pre-hospital deployment, making it suitable for use by paramedics, emergency physicians in both road and air ambulance services,” said Kirkland.

EMVision was founded in 2017, originally spun out from the University of Queensland, where cofounders, Scott Kirkland and Ryan Laws, acquired the original patent portfolio from research led by Professor Stuart Crozier, EMVision’s Chief Scientific Officer, and Professor Amin Abbosh.

“The University of Queensland had prototypes for three different types of scanners: a torso scanner for assessing liver fat and scarring (fibrosis), a skin scanner for assessing and diagnosing potential melanomas, and a brain scanner for identifying

potential bleeds or blockages in the brain,” said Kirkland.

“Our preliminary research led us to focus on the brain-scanner technology, due to the significant global health and economic burden of stroke.

“One in four adults will experience a stroke in their lifetime, and many of those result in some form of permanent disability.”

Now, with 36 staff members in NSW and Queensland, EMVision intends to lessen the burden of time sensitive emergencies that impact patients and their families.

In stroke care, the “golden hour” refers to the critical window immediately following stroke onset, during which, prompt medical treatment can improve patient outcomes.

“Bringing neurodiagnostic technology to the patient, rather than transporting the patient to a CT or MRI, can save crucial time,” said Kirkland.

“Approximately two million brain cells die every minute during a stroke. Faster diagnosis and treatment can lead to better outcomes. Every minute saved through accelerated treatment matters.”

The engineering

The emu bedside unit is a trolley-mounted system with an articulated arm connected to a helmet, which fits over the patient’s head.

The unit features Integrated antennas that surround the head and capture data from the scan.

The unit can be operated by medical staff with minimal training, enabling timely assessments of suspected stroke and stroke subtypes.

By utilising electromagnetic sensing and imaging technology, the device transmits low-energy radio waves from the ring of antennas.

As these waves pass through tissues, they create distinctive signatures indicative of healthy brain or brain pathology.

It is changes in the dielectric properties of brain tissue that provide these critical insights, and inform if a stroke is present or not, and if a stroke is present, whether it is a bleed (hemorrhagic stroke) or blockage (Ischaemic stroke).

The First Responder unit has a lighter miniaturised design and expanded antenna coverage, allowing complete cranial vault coverage in a single scan.

“One antenna emits a radio frequency signal, while the remaining antennas listen for the signal as it transmits, reflects, and scatters,” explained Kirkland.

“An AI model then analyses these interactions to assess the relative dielectric values of the tissue being imaged.”

Kirkland noted that the process is swift, with their emu device averaging a completed scan time of about fi ve minutes in clinical studies.

Commercial pathway

EMVision has recently completed enrollment for a larger multi-site study involving hundreds of patients at Liverpool Hospital, Royal Melbourne Hospital, and Princess Alexandra Hospital, using the production equivalent emu device.

“We have reported very encouraging interim findings and are meeting our study objectives,” said Kirkland.

EMVision has also collaborated with the Australian Stroke Alliance, which is leading advancements in golden hour stroke care, including with their mobile stroke unit program in Melbourne.

“A mobile stroke unit (MSU) is a multimillion-dollar truck, equipped with a CT scanner and specialist team, that are deployed to treat suspected stroke patients at the scene, ideally within the critical first hour, to achieve excellent outcomes.

“We work closely with the Australian Stroke Alliance to ensure our solutions are clinically useful, can be suitable for broad use and to support our local rollout strategy.”

Kirkland explained that EMVision has already received interest from local and global prospective end users.

“The clinical enthusiasm for this technology is very strong so far, as it offers the potential for early stroke diagnosis in a point-of-care manner otherwise not widely available,” Kirkland added.

“We exhibited at the Radiological Society of North America conference in Chicago last November, one of the largest global imaging conferences.

“Our technology stands out because it is unique in its field, particularly compared to CT and MRI machines, which at their lightest, weigh around 500 kilograms.”

The company plans to enter key international markets, focusing initially on the United States, where they are pursuing FDA approval, as well as Australia and thereafter parts of Asia and Europe.

“Our bedside device will follow the FDA’s de novo pathway in the United States, signifying it as the first of its kind product,” said Kirkland.

“Under this pathway we run studies to demonstrate its safety and efficacy from first principles.

“Once emu is approved, it will serve as the

predicate device for our new First- Responder model, accelerating its path to market.”

The first generation of the technology, the emu bedside iteration, is anticipated to hit the market next year and will be targeted for use in rural and regional emergency departments alongside ICUs and stroke wards in city centres.

The second generation, first responder system, has yet to have a confirmed release date but is expected to be available shortly after the emu device.

The EMVision supply chain EMVisions plans to retain manufacturing locally and has established a pilot production line at Macquarie Park.

Under the current configuration, it is capable of building, testing, and releasing up to three of its emu devices per week.

“There are several reasons why we’re not pursuing markets with cheaper labour for manufacturing our product,” explained Kirkland.

“First, as a medical device, it requires the highest possible quality standards, and Australia has an excellent reputation in that regard.

“We believe there is a significant opportunity to continue to produce the device here and export it globally.”

While manufacturing locally, EMVision sources components from global and local suppliers.

The next steps

As EMVision Medical Devices pushes forward with its innovative brain scanning technology, the potential for transforming stroke diagnosis and treatment is immense.

By focusing on both its portable and bedside solutions, the company is poised to address critical gaps in rapid, accurate stroke assessment, whether in metropolitan hospitals or rural clinics.

In July, Lightforce Group announced the supply of 120 advanced, customisable night vision and thermal imaging systems to the ADF’s Dismounted Combat Program, along with ‘train-the-trainer’ instruction.

This development is just another in a series of contract wins for the Adelaide headquartered global business after it announced its intentions in 2017 to formally enter the defence manufacturing market.

The story of the Lightforce Group is an interesting and inspiring one. After three decades building arguably the best rifle scopes and lighting systems for militaries and hunters all around the world, the Lightforce Group brought together four of its

leading brands, Nightforce Optics, Horus, Gunforce and Lightforce Australia, to create its defence manufacturing arm, Force Ordnance. This story begins much further back in the early 1980s in the South Australian country town of Cleve when the company was founded by local dentist Dr Ray Dennis.

After searching the retail market for a high quality and robust spotlight for to eliminate feral pests and finding nothing suitable, Ray decided to build one himself…and the rest, as they say, is history. Being

a man of vision and foresight, Dr. Dennis recognised the potential demand for the lightweight, portable and handheld spotlight which lay before him. Enter Lightforce. It was a system powerful enough to use for professional purposes yet priced within the grasp of the enthusiast and sportsman. Ray soon produced his first commercially manufactured lighting system. Based on original designs, his lighting systems found such favour among professionals and sporting enthusiasts alike that production was increased,

and improvements incorporated. This brought greater diversity to the range, ensuring the growing success and popularity of the brand. Fast forward a couple of decades, and whether it’s in the frozen Arctic tundra to the scorching heat of the Australian Outback, Lightforce’s products are trusted on all seven continents. Lightforce Group now exports to more than 50 countries and has manufacturing facilities in Adelaide, South Australia, and in Idaho in the USA. A large proportion of Lightforce Group’s production is exported worldwide to major markets in Europe, Scandinavia, Africa, Southeast Asia and North America.

Lightforce’s first foray into the formal defence manufacturing sector came in 2021 when it announced Force Ordnance as a “systems integrator’’ and developer of the QTD1 Long Range Rifle - a completely Australian designed and manufactured sniper rifle including patented technology which allows users to switch out barrels in seconds without compromising accuracy.

At the company’s Hindmarsh facility products are designed, built and tested, with ex-special forces and law enforcement staff - including expert long range precision shooters - on board to guide the design process. Its weapons manufacturing credentials reside substantially in Ace Precision Rifle Systems (APRS) which has been building premium rifles in Adelaide for the past 15 years. Using the

finest components machined to exact tolerances, APRS produces the highest quality precision rifles and offers a full gunsmithing service.

In 2022, Lightforce Group grew its presence and influence in the local and international defence and law enforcement sectors with a series of wins that saw its world-renowned automotive and hunting lights being applied to illuminate the fields of battle and shine a light on crime. Locally, the Australian Defence Force’s trial of Australian Expedition Vehicles included Lightforce’s infrared and white light combination HTX2 lights, signalling the company’s first local win. Other clients included the Australian Customs & Border Protection which fitted their 41-foot MMI Interceptor boats with Lightforce ML240mm lights, as well as a number of state police agency vehicles that have been fitted with infrared Striker lights.

Internationally, Lightforce partnered with the armed forces of the Philippines for the provision of driving lights on military vehicles whilst in the US, several defence and police bodies are still shining a brighter light on suspects thanks to the Adelaidebased manufacturer. These include the Maryland Police, the US Marshall Service and the Georgia State Patrol who are all using Lightforce white and Infrared lights on their respective patrol and SWAT vehicles.

In perhaps its most significant defence contract

win to date, Lightforce Group was selected in 2023 to provide 400 of its world-leading Nightforce precision rifle scopes to the ADF as part of the Sniper Systems component of Land 159 Lethality Systems Project (LAND 159) Tranche 1. The development has paved the way for Nightforce’s MIL-SPEC ATACR 7-35x56F1 scope to bring ADF sniper capability up to Five Eyes nation standards through Force Ordnance. Nightforce Optics are now the chosen optical instrument for superior weapon systems throughout the Five Eyes Special Operations communities, with multiple contracts won in New Zealand, United States, Canada and the United Kingdom. Typical deployments of this optic will include support to patrols, operations, surveillance and other specified tasks as well as Anti-Materiel Sniper Capability (AMSC) for the purposes of providing precision fire against enemy materiel (such as vehicles and equipment) at ranges of up to 2500m in day and night conditions. The ADF is expected to take delivery of the scopes later this year and there are further exciting announcements expected in the not-too-distance future.

Australia’s recommitment to sovereign defence manufacturing capability has well and truly begun and is being driven by businesses like Lightforce Group that are putting home-grown innovation and manufacturing excellence back into the hands of service men and women.

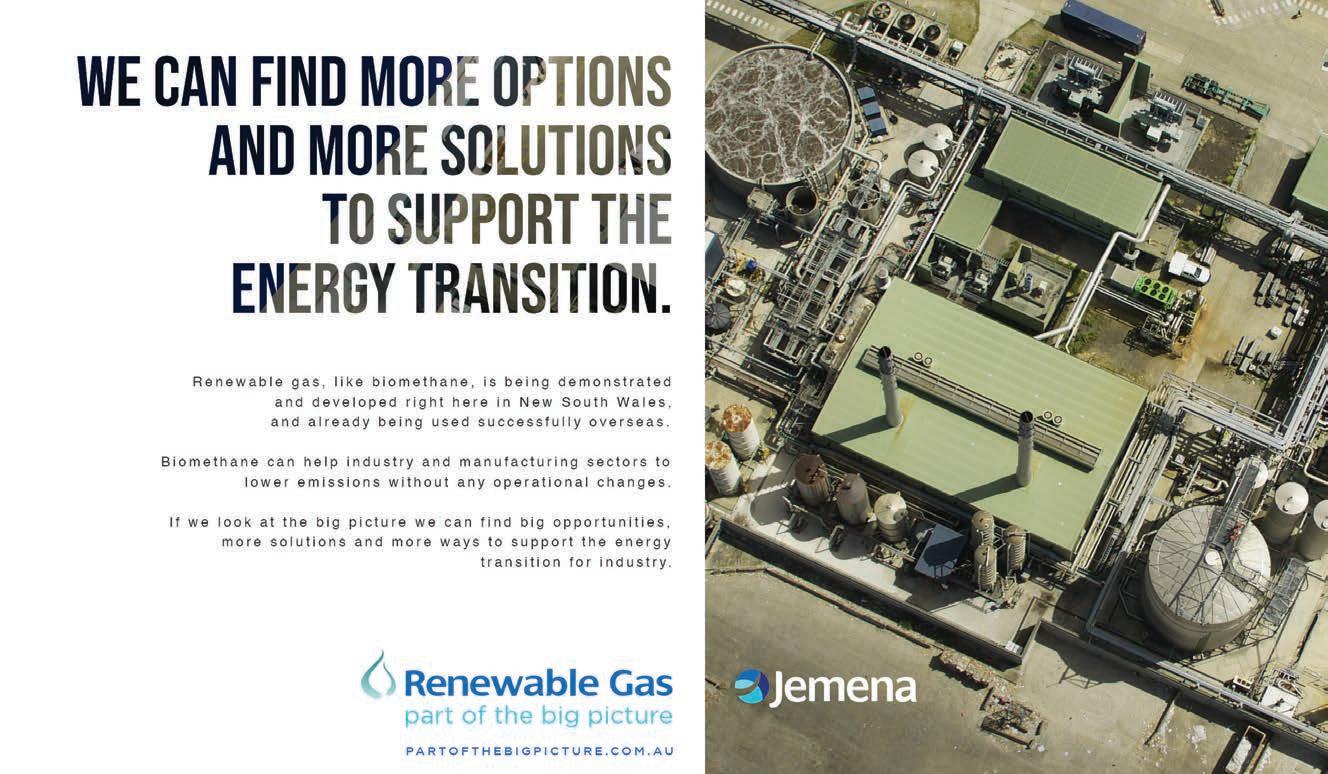

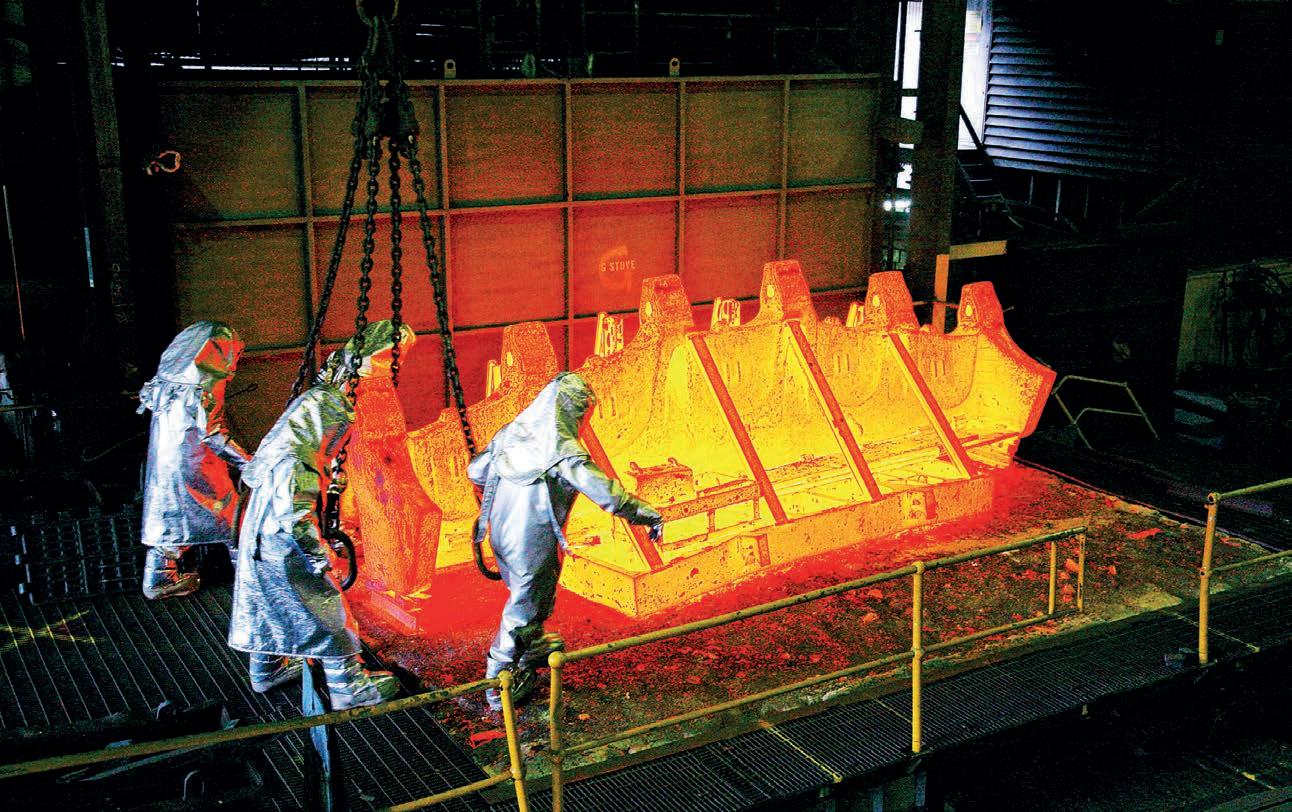

The Australian Metal Casting Industry - a significant sector within Australia’s broader manufacturing landscape.

Castings are a fundamental foundation for all major industries in Australia. Every one of us is rarely more than 5 meters from a metal casting. You don’t buy metal castings in a supermarket but you do need them to build roads and buildings, to irrigate, to mine and process our mineral deposits, to manufacture wind turbines and solar panels, to sow and harvest crops, for all forms of transport, to sterilise medical instruments and to support our Defence industry.

The Australian metal casting industry directly employs 2000+ with annual sales of approximately $1.0 billion. Our businesses are largely small to medium size enterprises producing bespoke products in the low to medium volume market. Our point of difference is technical excellence, quality and reliability.

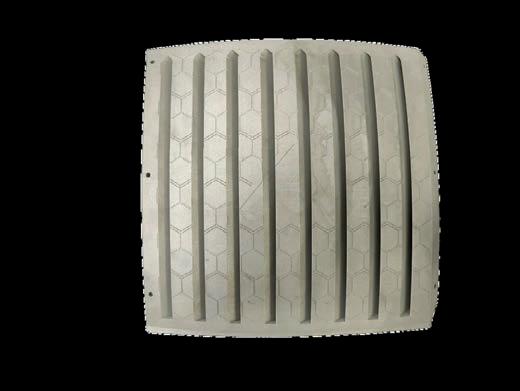

Amiga Engineering leads the charge in defence innovation with its Metal 3D Printed Ballistic Titanium Armour, surpassing the rigorous MIL-DTL-46077G V50 standards.

Amiga Engineering, an Australian leader in advanced manufacturing, is redefining defence protection with its revolutionary Metal 3D Printed Ballistic Titanium Armour. This innovation allows for the creation of complex and groundbreaking armour designs that are unattainable with traditional manufacturing methods. By leveraging advanced 3D printing technologies, Amiga’s armour surpasses MIL-DTL46077G V50 standards, delivering unparalleled durability, corrosion resistance, and lightweight adaptability.

The custom-shaped solutions provided by this 3D printed titanium armour are ideal for vehicles, protective gear, and critical component shielding, all without compromising structural integrity or design. This cutting-edge technology enhances operational efficiency and delivers superior ballistic performance, offering a decisive edge in modern military applications.

While Amiga’s ballistic titanium armour stands at the forefront of defence innovation, the company also distinguishes itself as the only firm in Australia certified to metal 3D print in Scalmalloy—a material prized for its high strength-to-weight ratio, particularly in aerospace applications. Additionally, Amiga is the sole Australian provider of metal 3D printing in Tungsten, a material essential for leading hot edges in hypersonic vehicles and for meeting heavy weight requirements in various industries.

Metal 3D Printed Titanium Ballistic Armour’s exceptional properties make it increasingly favoured in protective applications. Applications include providing vital protection in aircraft cockpits, safeguarding essential systems with lightweight, corrosion-resistant materials. Beyond aviation, titanium ballistic armour’s durability and resistance to corrosion make it an ideal choice for maritime use, including ballistic hatch covers that secure access points on marine vessels.

Amiga Engineering’s 3D printed titanium armour, offering advanced protection.

Amiga Engineering is also advancing personal protection with the development of body armour plates specifically designed for different shapes,

utilising the precision and versatility of additive manufacturing. Their 3D printed armour plates have been rigorously tested and proven to exceed military specifications by up to 40 m/s, maintaining superior performance with an areal density at 15 mm thickness—less than 5/8 inch.

Amiga’s armour has successfully stopped high-

Amiga’s advanced custom armour, engineered to stop high-calibre rounds, delivers superior protection through tailored, formed designs.

calibre rounds, including 39 API BX, M80 7.62 x 51, and 5.56 SS 109, with its 15 mm thick plates. The company has also developed a vehicle grill capable of withstanding these rounds, underscoring its commitment to robust defence technology. Future

projects include integrating composite layers to reduce weight and exploring the development of bulletproof alternators and other critical vehicle components for both civilian and defence applications.

Amiga Engineering’s innovations will be prominently displayed in the Innovation Precinct at Land Forces 2024, offering a unique opportunity for industry stakeholders to engage with the latest advancements in defence technology.

BlueScope Distribution is your single source provider of steel and aluminium products, processing and solutions.

With a national network of branches, including our National Product, Processing & Solutions Hub, our team can provide customers with world-class plate processing capability, optimised supply chain solutions with diversified transport options, and a dedicated project management team to help deliver projects on time and to specification.

• Complex processing and component manufacture

• End-to-end management of complex steel processing and supply

• Customer specific product in kit form ready for assembly

• Domestic supply and processing of steel for complex and significant projects

In high-tech industries, where high-mix, low-volume production intersects with complex products and rapid technological advancements, achieving precision in inventory management can pose a challenge.

Recognising the role of robust inventory management in overcoming these challenges, Raider Targetry, a force in military training solutions, unveiled an advancement in efficiency through the integration of Fishbowl Inventory, a software solution for inventory management.

Raider Targetry’s CEO & CTO Mick Fielding, alongside Executive Director Cody Webster, envisioned the company’s global potential since its inception.

Fielding emphasised the strategic importance of establishing a solid foundation for products and services to support the company’s growth trajectory, stating,

“When we were looking at building the business, we knew that we needed an inventory management system that would support us today, but also into the growth that we would expect in the future” he said.

“Accurate and efficient tracking of inventory movement from inception to its final consumption point is crucial for effective control and decision-

making processes within a business, ” said Simon Jupe, Fishbowl APAC managing director.

“Investing in a system that enables both signature tracking and inventory tracking facilitates swift resolution in cases where physical transactions diverge from the system records.”

Tim Kelly, Digital Systems Manager at Raider Targetry, expressed the transformative impact of Fishbowl

“Fishbowl’s been game-changing for us in terms of having that single source of truth that everybody can refer to, to understand the status of any particular work order at any point in time,” he said

“Fishbowl’s also been fantastic in terms of helping us to save costs, in particular the labour cost of trying to coordinate all of these different production and work orders.

“The main thing though, that Fishbowl’s really helped us with in terms of productivity is the ease of integration into the engineering software that we’re using.

“Implementing a new inventory management

system is often a big commitment for any organisation. Thankfully, the Fishbowl support team is fantastic, and they’ve made it really, easy for us to configure Fishbowl in a way that’s suitable for our organisation.”

The software’s capabilities extend to meeting regulatory requirements and ensuring compliance by providing accurate records, traceability, and comprehensive reporting features.

Kelly highlighted Fishbowl’s ability to digitally track and trace, serialisation, and manage complete bills of materials, ensuring the delivery of clean and clear, real-time information to the Defence Force.

“In the future, we’ve got an extensive amount of automated purchase order and production order planning coming into play,” he said.

“We’ve got additional integration through the full depth of our bills of materials, and we’re tracking alot of custom fields like NATO stock numbers and those kinds of things too.”

“Fishbowl in particular has a number of features which support what we do. Fishbowl gives us a single source of truth for everything we do within the business, especially when it comes to production, but also supporting our R&D activities,” said Raider Targetry’s Fielding.

“As high complexity, low-volume businesses grow or evolve, Fishbowl software can scale to help our clients meet their changing needs. This flexibility can be essential, especially for companies dealing with diverse and evolving product lines,” said Jupe.

“As a company developing high-tech solutions, we need high-tech business processes that support what we do, and especially those that scale with the business as we expand globally.

“The technology we’re developing has fast iteration cycles. They’re technically complex systems, and we need products that support the business that work in the same manner.

“Fishbowl was a natural fit for us and very much complementary to the tech stack we’d already brought on board. Now that we’ve partnered with Fishbowl, we’re really excited to see where the future will take us, and we have full confidence that we’ve got the right partners in place to get there.”

Raider Targetry’s strategic integration of Fishbowl Inventory represents a paradigm shift in inventory management, reinforcing its commitment to operational excellence, innovation, and global growth.

RSM Australia, an audit and tax consulting firm, has appointed Louis Quintal as the new head of manufacturing.

RSM Australia has appointed Louis Quintal as the new Head of Manufacturing, succeeding Jessica Olivier.

“I’m thrilled to step into this role and drive our manufacturing sector strategy forward,” said Quintal.

“My goal is to expand our capabilities and address the evolving needs and challenges of the sector.”

Olivier, with almost a decade of experience at RSM, has now moved on to become a national executive at the company. Quintal aims to expand RSM’s manufacturing service capabilities.

“Jessica and I are currently managing a handover and transition for projects. Jessica is wrapping up the projects she started, and over the coming months, we will gradually transition other relationships,” he said.

“This includes the one we are working on now, as well as two or three other key relationships.

“It won’t be a hard cutoff; instead, Jessica and I will work together over the next six months to ensure a smooth transfer of knowledge and expertise.”

Speaking on her departure from the role, Olivier said: “For me, the National Executive role is the next step in my career and in a firm where I want to be part of its long-term future.”

“It is also a way for me to lead by example and support others in our firm to follow a similar career path, should they so want.

“I am also excited to work as part of our National Executive to implement our 2030 Strategy, part of which includes servicing our clients with our ability to offer deep industry expertise and client-focused solutions.”

As Olivier transitions out of her role, RSM is ensuring continuity in their projects and client relationships.

“Louis Quintal, Ross Dixon and I have already worked together on the Manufacturing Strategy for FY25 and beyond, and in line with RSM Australia’s 2030 strategic priorities more broadly,” she said.

“In addition, I will continue in my role as R&D Partner and will also remain on RSM’s National Manufacturing committee and as a strong advocate for this sector.”

With a career spanning over 20 years, Quintal began at the RSM South African office, where he spent 18 years before transitioning to the Australian market for the past two and a half years.

Throughout his career, Quintal’s primary focus

has been on the manufacturing sector. In Africa, which has a low-cost base and significant production activity, he built his expertise and clientele in this field.

Once in Australia, he continued to concentrate on the manufacturing sector, further developing his career and client relationships.

This focus on manufacturing has been a cornerstone of his approach, which aligns with RSM’s broader strategy.

“The first step for us at RSM has been building our capabilities and expertise across various multidiscipline service offerings within the manufacturing sector,” said Quintal.

“Our newest areas include the digital space, cybersecurity, ESG, and CFO advisory services.”

Now that RSM have a suite of offerings, its focus is on marketing and branding these services within the industry.

As mentioned in their mission statement, RSM is committed to aiding Australian manufacturing businesses by serving as trusted advisors and providing tailored solutions to boost capability and success in a post-pandemic landscape.

It supports a range of manufacturers, from small firms launching new products to large global entities optimising their operations.

Leveraging its industry expertise and personalised

approach, RSM helps companies with their compliance requirements, cut costs, enhance efficiency, and drive profitability.

“We want to showcase a lot of case studies demonstrating how we’ve helped clients in the manufacturing sector through different stages of their business lifecycle,” said Quintal.

“This includes helping sole practitioners grow into SMEs and supporting them as they continue to expand.”

For example, Prinova, a manufacturer of ingredients and premixes for the food, beverage, and nutrition sectors, established a subsidiary in Australia in 2019 to meet rising demand in the APAC region.

To support this expansion, Prinova engaged RSM to assist with local Australian compliance and payroll, given the absence of a dedicated finance team.

RSM provided services, including advisory on entity establishment, Xero implementation, taxation related to imports and mergers, transfer pricing, and compliance with local regulations.

Quintal explained that RSM wants to effectively partner with clients to drive change and growth.

“Our key objective is to highlight our capabilities and how we can partner with clients to lead change. We aim to be the service advisor of choice, providing proactive and integrated support to our clients as they evolve,” he said.

Having established a strong foundation in manufacturing through his experience in both South Africa and Australia, Quintal’s understanding of the industry has now led him to recognise and address the current challenges faced by Australian manufacturers.

Quintal’s impression of Australian manufacturing

Reflecting on the past two and a half years, Quintal has found the Australian manufacturing market to be challenging relative to the previous markets he served.

The high labour costs in Australia set it apart from the global market and increased cost of energy leading to higher input costs.

Additionally, property rentals rates compared to other countries are higher, making it more costly to manufacture products in Australia compared to regions like APAC.

Further challenges to the sector include geopolitical matters, increased complexity in the regulatory environment, a lack of incentive to make new investments by government in the sector.

Quintal identifies the key challenges for the manufacturing sector as including the adoption of automation and robotics.

Traditionally, the sector relied on labour-intensive machinery, but modern automation presents both challenges and opportunities, says Quintal.

“The sector needs to focus on achieving efficiencies and producing high-quality products at a lower cost through advanced automation and robotics,” he said.

In addition to addressing labour shortages, Quintal

points out that another challenge is complying with Environmental, Social, and Governance (ESG) requirements.

“Manufacturing processes naturally involve carbon emissions, making it crucial for the sector to adapt to these compliance standards. This is a pressing issue not only in Australia but globally,” he said.

“However, despite all these challenges, I believe that Australian manufacturing, overall, offers highquality products comparative to global competition.

“The higher cost base results in a product quality that often exceeds expectations, which is a key differentiator.”

Quintal has also observed several key trends within the Australian manufacturing industry, namely, automation and improving operational efficiency.

He explained that automation could eventually become a solution to many of the challenges facing the industry and see less of Australian products been sent offshore for processing to only be imported back for consumption.

“The manufacturing sector is broad, encompassing 141 sub-sectors,” said Quintal.

“Food and beverage automation is evolving, while other sectors, such as submarine manufacturing, face unique challenges.”

“The faster automation technology advances, the quicker industries can adapt.”

Quintal said that the challenges of labour charges and cost of living are difficult to address, primarily due to supply and demand in the Australian market.

“The best solution is to embrace and adopt automation, robotics and tools to improve efficiencies and profitability margins,” he said.

“In my view, this is a key factor for the sector at this point.”

While addressing these industry challenges, Quintal is also looking towards the future of manufacturing and RSM’s role within the sector.

He envisions manufacturing becoming one of the leading sectors in RSM business and is focused on transforming RSM’s role in the industry.

Quintal also wants RSM to be recognised as the provider of choice, particularly in terms of service, understanding the client business and instilling change.

“We need to embrace change and build strong partnerships. Personally, I am a hands-on type of person, and I enjoy seeing things evolve,” he said.

“I am passionate about innovation and take pleasure in seeing people grow and benefit from these advancements.”

To achieve this vision, Quintal explained that RSM will be focusing on increasing its presence in industry-specific sectors by partnering with key organisations and sponsoring events.

“For example, we have partnerships with Manufacturers’ Monthly and Robotics Australia,” he said.

“Our goal is to engage with sector-focused bodies and enhance our branding through these sponsorships.

“Our ultimate mission is to not only adapt to changes within the industry but to drive and instil them, positioning RSM as the partner of choice for the manufacturing sector.”

Industry leaders call for strategic government intervention to prioritise local scrap consumption and rejuvenate manufacturing capabilities amidst global competition.

Metal Casting Industry leaders and the Australian Foundry Institute are calling on the government to recognise the challenges facing the metal casting sector in Australia.

The Australian metal casting industry differentiates itself on the global markets with its high-quality product, technical know-how, and the strong partnerships the metal casting businesses form with their customers.

Australian metal casters export ferrous and nonferrous castings to Europe, Asia, North and South America and Africa.

The cast metal industry in Australia heavily relies on recycled materials, primarily sourced from locally produced metal scrap as a feed material, but faces strong competition from international markets like China.

As Keiran Slattery, managing director at Hayes

for both sovereign capability and the wider Australian economy.

“The future of Australia’s metal casting industry hinges on Government action. Without it, we risk losing not just our economic edge but our national security capabilities in the event of crisis,” he said.

Slattery further warned that without federal support, the Australian metal casting industry could lose the ability to recycle domestically generated scrap metal locally. Australian industry can take advantage of the stored energy in scrap to recycle at home but now struggles to compete against global rivals for our scrap resources.

“It is time for the Government to take our calls seriously and create more sovereign capability for our Australian foundries before it is too late,” he said.

Metal casting is a manufacturing process where molten metal is poured into a cavity to form parts and components.

This method allows casters to produce complex and detailed shapes that are difficult to achieve with other techniques.

By using various metals and casting methods, casters can ensure that the final products meet all specified design requirements including integrity, strength and durability.

Non-ferrous metals include aluminium, copper, lead, nickel, zinc, and tin, each of which are valued for their specific metallurgical & mechanical properties.

Whereas ferrous metals are metals that contain iron as their principal element. Iron and steel continue to be vital for the global economy.

Crucially, the metal casting industry supports

Australia’s sovereign capability by ensuring a resilient supply chain for the Australian Defence Force (ADF) and all of the major industries in Australia.

The Australian Foundry Institute (AFI) plays a vital role in representing and advancing the interests of this sector, focusing on enhancing national industrial capabilities, particularly in defence manufacturing.

With more than 100 foundries and die-casting plants across the country, employing thousands of skilled workers, the industry generates around $1 billion for the Australian economy annually.

Essentially, metal casting is key to producing highquality parts efficiently and economically.

“It’s crucial to keep this industry thriving in Australia. While we might import cars or taps, the real concern arises when we face supply disruptions from other countries,” said Slattery.

“The COVID-19 pandemic highlighted this vulnerability, and with current geopolitical uncertainties, the risk of such disruptions remains.

“Maintaining a robust domestic metal casting industry ensures we have the capability to produce essential components when global supply chains falter.”

Additionally, the AFI has raised concerns over the cost of utility prices, which are in turn impacting the production cost in foundries.

Brett Lawrence, AFI national president and

general manager of Australia’s largest iron foundry Intercast & Forge, said: “Utility prices across the Nation with the exception of Western Australia, both from a gas and electricity perspective, have certainly increased substantially.”

“Energy supply is a fundamental building block for manufacturing in particular, and Australia has lost the competitive advantage that local lower energy costs once enabled.”

The non-ferrous metal casting industry relies heavily on metal scrap to create ingots, as opposed to raw materials.

The reason for this is that using scrap reduces the overall cost of feed materials compared to using primary metals, which can be more expensive to extract and process.

Additionally, recycling both ferrous and nonferrous scrap helps conserve natural resources and reduces environmental impact by minimising mining and refining activities by utilising the “stored energy” contained in scrap metal.

“When primary aluminium is produced in a smelter, it requires a significant amount of electrical power to convert alumina powder into solid aluminium forms,” said Slattery.

“However, once aluminium is in its solid state, recycling it only requires about 10 per cent of the original energy cost.

“This makes scrap aluminium highly valuable, especially to overseas markets like China, which imports scrap from around the world.”

As Slattery continued to explain, global competitors such as Japan, Korea and China have benefited from purchasing non-ferrous scrap, as the energy costs have already been incurred during the initial production phase thus avoiding the need to generate that extra energy themselves.

Many Countries have been utilising non-ferrous scrap metal for decades, but now as their demand for non-ferrous scrap increases, Australian metal casters are left with the ‘scraps’.

“China initially lacked primary smelters due to power shortages, so they began importing scrap metal from Australia Europe and America decades ago,” said Slattery.

“Over time, China has substantially increased its domestic electric power generation thus enabling it to build more primary aluminium smelters than any other country, yet they continue to purchase Australian scrap.

“Australia with its abundance of bauxite deposits and competitive mining and refining activities, once produced 10 per cent of the world’s primary aluminium, about 2.5 million tonnes yearly. Now, production has dropped due to high energy costs, even as global demand has risen.”

The pandemic lead to a disruption in global supply chains that forced casting buyers to reconsider

their purchasing strategies. The subsequent scramble to onshore was offset by the rising input costs for those feed materials that had to be imported together with rising energy costs.

Casting Buyers that sourced Australian made product now prefer local suppliers for the security and certainty of a more reliable supply chain.

However, with input costs soaring, profit margins are squeezed resulting in a challenging financial environment.

Slattery and other industry leaders are calling for the Government to recognise the metal casting industry and consider measures to revitalise it.

“We aim to stabilise and potentially grow the metal casting industry with the right support and understanding from the government,” said Amber Maxwell, president of the Australian Foundry Institute, Victoria division.

“We’re not seeking a handout but rather recognition and support of our industry’s expertise, capabilities and critical contribution to our daily lives.

“If our contributions in metal casting aren’t acknowledged and leveraged, there’s a risk that our metal casting businesses could be lost.”

The leaders are ultimately calling for strategic

measures to, boost domestic manufacturing capabilities, enhance sovereign capability and support local scrap consumption

They believe that achieving these goals depends on government intervention and the introduction of incentives to attract the next generation of Australian workers into the industry.

“The ‘Made in Australia’ campaign is a great initiative, but its success hinges on genuine commitment at all levels,” said Maxwell.

“For it to make a real impact, it needs to be supported and understood from the grassroots up.”

This sentiment is affirmed by Lawrence.

“We need to return to grassroots and start discussing the value of manufacturing with students in schools,” he said.

“Victoria has been running a program for a few years now, introducing casting concepts through the ‘Foundry in a Box’ initiative at some high schools. This program provides students with a “hands on” manufacturing experience whilst at the same time engaging them in conversations about pathways and opportunities for what a career in the manufacturing industry offers”

“We’re working to expand this program into other states, as there is significant demand. It’s also important to educate career advisors, as many currently do not understand the opportunities

within the metal casting or manufacturing industry” explained Maxwell

Slattery also explained that there’s potential for innovation within the industry, as the CSIRO previously invested resources into researching alloys.

“Australia was once a leader in metal research, with significant contributions at both state and federal levels,” he said.

“Institutions like the CSIRO conducted extensive research in Victoria, and had facilities such as the CAST in Queensland, receiving funding from both the government and industry.

“Unfortunately, many of these research capabilities have dwindled.”

Previously, major companies invested in alloy research, but those centres are no longer operational.

Slattery said that there’s a need to focus more on developing new materials and improving existing ones.

“Big companies like Rio Tinto had centres focused on alloy development, such as the Research Centre in Melbourne,” he said.

“However, these facilities no longer exist. There is a pressing need to reinvest in research in Australia, particularly in developing new alloys, such as scandium-enhanced aluminium.”

Scandium is a rare metal that, when added to alloys like aluminium, can improve their performance. A small amount of scandium makes these alloys much stronger and more durable, while also making them lighter.

“There are many opportunities to improve alloys in this way. For the Australian casting industry, it’s crucial to highlight our capabilities and capacities to ensure we remain competitive,” says Maxwell.