21 minute read

CONNECTING THE DOTS

Hino Australia recently introduced its sophisticated integrated telematics program called Hino Connect as standard equipment on the new 700 Series heavy duty models sold in Australia. Paul Matthei takes a deep dive into this clever technology which has the potential to maximise efficiencies in truck operation.

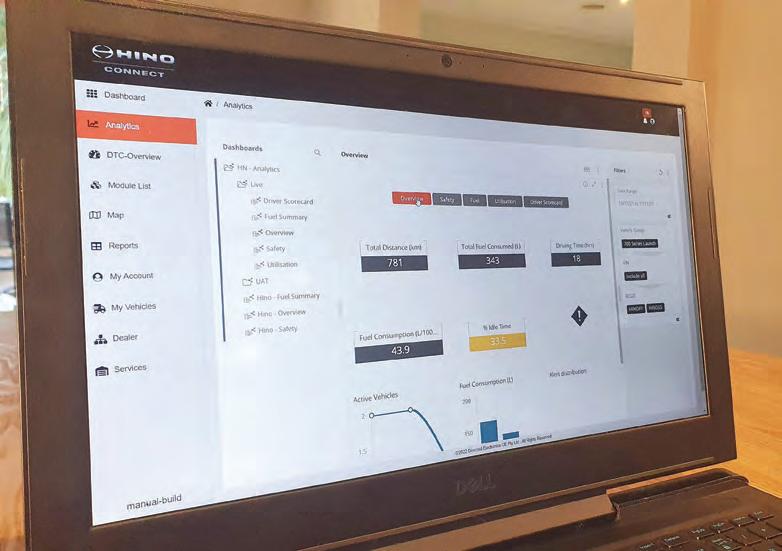

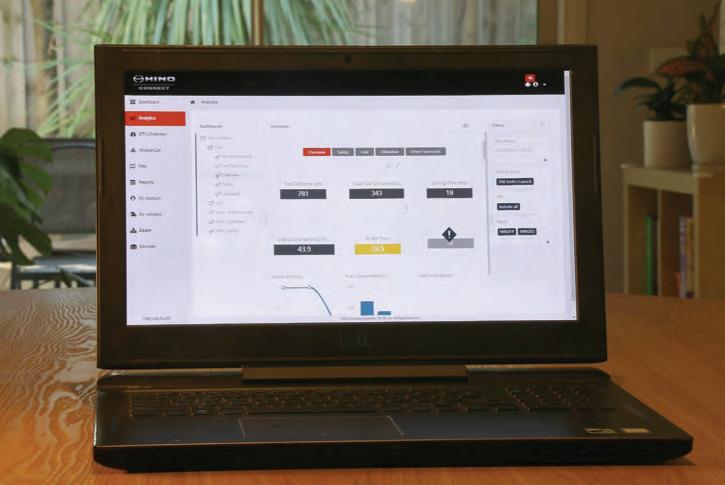

Now standard across the 500 and 700 Series ranges, Hino Connect is an integrated telematics system that combines key performance data tracking in real time, remote diagnosis of vehicle faults and 24/7 alerts delivered to the truck’s owner and their Hino Connect specialist for priority repairs and service support.

According to Hino, this is a complete business intelligence solution designed to reduce costs, optimise driver and vehicle performance, improve safety and enable the operator to make informed decisions.

In effect, the system acts like an invisible umbilical cord between the truck, its owner and Hino Connect, with real-time data accessible at all times. This business intelligence enables the asset manager to monitor key aspects such as driver behaviour, safety and vehicle utilisation either via the Hino Connect portal or an app on a smart device.

The Hino Connect package includes a complementary 12-month subscription for Business Intelligence Access which entails vehicle utilisation, maintenance support and Application Programming Interface (API) data integration for full fleet visibility.

Other features include key performance data tracking in real-time, remote diagnosis of vehicle faults and 24/7 alerts delivered to the operator and their Hino Connect specialist for priority repair and service support.

In the unlikely event of a severe vehicle fault being detected, an alert is delivered straight to the driver as well as the vehicle’s owner and their Hino Connect Specialist.

Hino describes it as the total business intelligence solution designed to reduce costs, optimise driver and vehicle performance, improve safety and help

the vehicle owner make informed decisions.

In addition, there is a complimentary five-year subscription to Remote Diagnostics + Hino Connect Specialist Support which includes the aforementioned vehicle engine control monitoring, severe fault alerts and case management support. Hino Connect is an important element of the all-new 700 Series that the company believes will help it snare a larger share of the heavy-duty market.

Hino’s General Manager of Service and Customer Support, Gus Belanszky, walked me through the details of Hino Connect, beginning by explaining that the mobile device app is a complementary adjunct to the web portal.

“You can’t get the full level of detail through the mobile app so it is pretty much a companion application to the web portal; so through the web portal you can get the advanced granular information about what’s going on,” says Gus.

He then proceeded to analyse my driver behaviour metrics during the recent test drive I undertook in the SS 2848 pulling a loaded fridge van with a gross combination mass (GCM) of around 40 tonnes.

“In there I can see that you have four over-revving events while moving and three excessive idle events,” says Gus. “We can actually go in and see the impact of these idle events in terms of what amount of fuel the engine consumed during these idle events.

“If you had a fleet of vehicles you could see who your main culprits were and use this information to target those in need of some driver behaviour adjustment training.”

In my defence, I explained that the hot summer’s day I picked up the SS the good folk at Sci-Fleet Eagle Farm had started the engine sometime before I arrived to pre-cool the cab for me.

As for the over-revving events, I ventured this probably occurred on the descent from Cunningham’s Gap as I was attempting to achieve maximum retardation from the amazingly effective Intarder auxiliary braking system while selecting the most appropriate gear to optimise the journey time, just what every professional driver should do.

Sure enough, further investigation by Gus pinpoints the GPS positioning of the truck during these events on the eastern side of Cunningham’s Gap, very impressive. Similarly, the major idle event was traceable to the northern side of the Brisbane River near the Gateway Bridge, pretty close to Sci-Fleet Hino at Eagle Farm.

“Everything in the Hino Connect analytics is interactive,” says Gus. “If I right click I can drill down to find information every hour on the day you were driving the truck. I can see there is

data here showing the excessive idling occurred for half an hour from 1pm.”

“How’s that!” I exclaim. “I arrived to pick up the truck at 1.15 and drove out the gate at about 1.30.”

Gus adds that there are a lot of very useful metrics available whether you’re tracking an individual vehicle or a fleet of vehicles.

“You can filter down to which trucks you want to look at by the registration number and various date ranges either on a macro or micro scale,” says Gus. “This is going from looking at pre-built reports to actually being able to look at the data and drill down into it.”

After being shown how to access all this information, it was easy to appreciate the relative simplicity of gaining the information, even for someone like myself who’s not known for being overly tech-savvy.

In addition to the Hino Connect web portal, the mobile app is a useful tool for drivers and operators to access the most salient information while on the road or otherwise away from access to the web portal.

“The great thing about this system is that we’ve managed to keep it as simple as possible to use for those who just want the basic information while still having some really advanced tools for the likes of fleet managers who want to drill right down into the nitty gritty of fuel consumption and driver behaviour, for example,” says Gus. “The mobile app is simple to use yet can still access the high-level information like data on fuel use and driver alerts.”

Gus reiterates that there is an almost endless amount of data that can be extracted, and that the entire system has been developed in-house by Hino with no third-party add-ons.

“We’ve worked with the Hino team in Melbourne who directed the project and the engineers in Japan to develop the system and we’re getting good accurate data which is ultimately a value-added addition for our customers,” says Gus.

As I reflect on this information, it strikes me that the Hino Connect system appears to be much like the Hino trucks themselves: Highly reliable and functional without being unnecessarily complicated to use.

SUBSCRIBE & WIN

SUBSCRIBE to Powertorque magazine or register to receive our eNews letter and go in the draw to WIN one of Two Fantastic GME Product PRIZE PACK’s valued at $950.00 each

PRIZE PACK CONSISTS OF A BRAND NEW OFFER FOR THE TRANSPORT SECTOR:

A personal location device ideal for those working in remote and isolated areas where reception is poor. In the event of an incident press the button and your location is known and help can be arranged.

The latest from the XRS radio range compliments the offer to give 2 lucky winners the best communications package on the market.

MT610G. SAFETY MADE SIMPLE.

This Australian Made Personal Locator Beacon (PLB) transmits an emergency distress signal and is GME’s most compact and lightweight design ever, with a 7 year battery life and a 6 year warranty. XRS-390C. RUGGED RADIO. REDEFINED.

This unit is the first UHF CB radio to feature a built-in GPS receiver, offering true location awareness without relying on a smartphone for location data. It is GME’s toughest radio yet, dust and waterproof, and backed by GME’s 5 year warranty.

To subscribe to Powertorque magazine at the SPECIAL

promotion price of $60.00 p.a for Australian Residents:

1. Follow the link https://powertorque.com.au/gme/?utm_ source=Print&utm_medium=PowerTorque&utm_campaign=GME_subs 2. Or use the QR Code 3. Fill in the missing word to enter the draw.

FROM TWO TO22 WHEELS

You might think that many years of professional dirt bike racing and managing Motocross and Supercross teams at the top echelon would be a tough gig to follow. However, Paul Mattthei discovers that Troy Carroll has made the transition from managing two-wheelers to 22-wheelers like a duck to water.

Troy Carroll has been messing around with a variety of vehicles ranging from motorcycles to trucks all his life.

“As a professional Motocross and Supercross rider I managed to win 24 Australian Championships and represented Australia several times at international events,” says Troy. “When I retired from racing in 2010, I started managing the NPS Monster Energy Kawasaki racing team.

“We mostly had two riders, and at one stage three, and were travelling all over Australia during the racing season then travelling to the USA for training during the off season.”

He did this for a total of seven years until 2017 when he decided to hang up the riding boots and pursue an entirely different career.

“It got to the stage where I was simply burnt out from all the travelling and I knew I had to walk away from it,” Troy says. “The hardest part was being away from my wife and kids; even when they were travelling with me, most days I was away from six in the morning to six or seven at night.”

Troy explains that he knew it was time to quit during his last season of the Supercross in 2017 which went for six or seven rounds.

“I was basically hiding away in the transporter and not coming out until the guys raced, I just didn’t want to be there and that’s when I knew for sure that it was over. When Kawasaki asked me to renew the contract, I had to tell them I was out.”

Troy subsequently sold all the equipment including the race transporter semi-trailer, but somewhat fortuitously something made him hang onto the prime mover, a black Freightliner Argosy.

Perhaps this was partly due to the fact that his father Vince had worked in the trucking industry for over 40 years, meaning trucks were in the blood.

“The prime mover was sitting there and one of my mates suggested I get hold of a trailer and start delivering for him,” Troy says. “I basically got my semi license the day before I left, and my first trip was from Brisbane out to a mining company’s site at Roma Logistics Hub in central Queensland.”

This was the start of a very steep learning curve for Troy that four years down the track sees him at the helm of his very own trucking company, Carroll Group Australia.

“When I started driving, I didn’t know anything about things like Basic Fatigue Management (BFM) or Chain of Responsibility (CoR), but I have certainly learnt all about these regulations and the many others since then,” Troy says, adding that it was quite a shift going from being the hero of a sport to driving a truck.

However, he soon realised that if he kept driving it would mean lots of time away from his family, the very reason he had left the Motocross world behind.

“I started driving in November 2017 and then in January 2018 I put a driver

Troy Carroll, started his Carroll Group trucking operation after retiring from a successful moto-cross and supercross career.

in the truck while I took my family and parents away for a big holiday in Singapore and Thailand,” Troy says. “And I thought, ‘how good’s this, I’m making money while I’m away on holidays’.

“So when I came back I decided to shift things up a gear and started doing courses to learn everything I needed to know about running a trucking business.”

Troy adds that keeping up with compliance has become a huge thing for the company – which prides itself on maintaining the highest possible standards in safety and compliance.

“This goes hand-in-hand with the type of work in which we specialise; that is general freight going to mining

and gas exploration companies where safety and compliance are of the highest order,” he says.

FAMILY AFFAIR As the business developed, Troy’s father Vince came onboard with his own truck as a subcontractor. Vince has a wealth of experience in the industry, having founded and managed Carroll Truck Sales Toowoomba for many years before selling it. Prior to that he was operating grain tippers and running refrigerated produce to the Brisbane markets.

“I then bought his truck and he started driving for me for a while, and we added a third truck to the fleet,” Troy says. “As we got bigger, I realised I needed someone I could trust to manage the financial side of things, so I asked Dad to join me in the office as our Financial Controller.

“From there the business has continued to grow and we now have 23 pieces of equipment, and we have another three new trucks on order to be delivered this year,” Troy says, adding that additional flat top, curtain side, side-loader and drop deck trailers with ramps will be acquired in due course.

Troy mentions that his 18-yearold daughter has recently started working in the office which means three generations of the family are now engaged in the business, along with 18 employees.

DIVERSIFICATION Late last year the company moved into a new dimension, commencing a thirdparty logistics (3PL) end-to-end service at a new facility at Yatala to complement its existing operations. The site has a huge shed where the goods are temporarily stored after being unloaded from shipping containers, before being trucked to the customer.

“We pick up the containers from the port and bring them here, unpack them, store the products then deliver them when the customer needs them,” he says. “At this stage we are using subcontractors with sideloaders to deliver the containers to us and return the empties, but we plan to purchase our own sideloaders so that we can be in full control of the entire operation.”

Troy elaborates on another future development for the operation, that’s in the pipeline, a full quarantine service that will be used in conjunction with unpacking containers from overseas.

He makes no secret of his desire to keep growing the business over the next eight to 10 years, adding as many facets as practicable along the way to provide the ultimate end-to-end solution for customers.

“I was brought up with a strong work ethic and I am putting every bit as much effort into this business as I did when I was racing,” Troy says. “I try to ensure that all our gear is top notch and looks good and that the service we give our clients is 100 per cent, that the freight is there on time, undamaged and fully compliant.

“I think we’re doing alright,” he says modestly. “In the meantime, we continue to engage companies who have helped us in the past as we believe loyalty and long-term relationships are keys to a successful business.”

CARE FOR EMPLOYEES Troy regards his employees as the backbone of the business and tries to

look after them accordingly. Despite this, he says, the company still has a relatively high turnover of drivers, around three to four per year.

“I think every transport company has the same issue,” says TRroy. “We have a couple of guys who have been with us a fair while, so we try to look after them by giving them the new gear.”

Other niceties the company now fits to its new line-haul trucks include IcePack cab air-conditioners, fridges, microwave ovens and televisions.

“This way the drivers can take their meals with them as a potentially healthier and more cost-effective option compared with buying food at truck stops,” says Troy.

Somewhat unusually for long distance driving work, Troy pays his drivers by the hour rather than a per kilometre rate and he says, depending on what projects are on at the time, they average between 3,500 and 5,500km per week.

“They generally leave on Monday morning and get back Friday evening or Saturday morning, we try to get them home for the weekends wherever possible,” Troy says. “We also stipulate that they don’t drive between 10pm and 5am, unless approved by management, in the interests of optimised safety and effective fatigue management.”

As for the reasoning behind paying the drivers an hourly rate, Troy says he believes they should be paid while they rest in the bunk if they have to wait to get unloaded.

“If they get to a site and there’s a four or five-hour delay I’d rather the driver be happy to get in his bunk and have a sleep knowing he’s still getting paid while he rests,” says Troy. “Sure it costs us more money but I know I’m looking after the driver and he’s getting more money for his family, and at the end of the day we’re all about family here.”

BRAND LOYALTY The company runs several different brands of trucks, with Kenworth being the new kid on the block. In fact, the first Kenworth, a pre-owned T409, was purchased mid last year from Brown and Hurley at Yatala. Since then, two new K200s have also joined the fray.

Troy describes the service from Brown and Hurley Yatala as ‘absolutely fantastic’, saying the company goes above and beyond with its support and the way the trucks are impeccably presented at delivery.

He also has high praise for Volvo Commercial Vehicles Australia (VCVA) which he has been dealing with for the past three years since buying some second-hand Macks ,a Trident and a Super-Liner, and two new Volvos, an FH16 and a Globetrotter.

“The Globetrotter is 120-tonne road train rated and has the big rubber guards, we send it out to Moomba in the Cooper Basin on the Strzelecki Track in the north-eastern corner of South Australia and it is performing very well for us under those harsh conditions, we’ve absolutely had zero problems with it,” Troy says.

“This is the main reason why we have changed to only buying new trucks and we put them all on maintenance plans and turn them over after they’ve travelled 800,000km.

“We used to deal with VCVA at Wacol

but now that we are based at Yatala it’s easier to deal with the Nerang branch. Their maintenance package has been great, and we look at it as a sort of insurance policy that keeps our trucks where they need to be, on the road earning money.”

Troy explains that the company’s move to Kenworth is due in part to Volvo having supply issues with its new trucks.

“Volvo have shut their books to taking more orders, hence the reason we started looking at the Kenworth products; and now that we’ve been so well treated by Brown and Hurley, I think we’ll be buying a lot more Kenworths,” Troy says.

That said, Troy says he has a high regard for the Volvo Globetrotter and believes that model and the K200 Kenworth will be the mainstay of the fleet for the foreseeable future.

TRAILERS OF CHOICE Troy says Freighter and CIMC are the company’s preferred brands for flat top, drop deck and curtain side trailers. When the time comes to purchase sideloaders, he says he will consult friends who operate them at the port to guide “I ABSOLUTELY LOVE WHAT I’M DOING NOW WHICH MAKES IT EASY TO GO TO WORK EVERY DAY. SEEING THE BUSINESS GROW AND HAVING FAITH IN MY TEAM AROUND ME IS A MASSIVE BUZZ – I REALLY THANK THE PEOPLE WHO I HAVE WORKING FOR ME WHO ASSIST IN WHAT WE DO ON A DAILY BASIS; THEY ARE ABSOLUTE STARS IN THEIR JOBS.”

him with purchasing decisions.

“We have more prime movers than trailers at the moment, so we need to buy more trailers this year,” says Troy.

As the conversation draws to a close, Troy reiterates the key reasons for the success of the company.

“I grew up around trucks in Dad’s truck sales yard and it’s definitely in my blood, but I didn’t know anything about running a trucking company until just over four years ago,” says Troy. “It was a completely different ball game compared to the Motocross glitz and glamour and flying around the world that I was used to.

“So, leaving that all behind and throwing myself into this new career path, boots and all, was probably the biggest turning point in my life. Driving trucks completely changed my mindset in regard to what I was doing with my life and helped me find myself again, that was a huge thing for me.

“I absolutely love what I’m doing now which makes it easy to go to work every day. Seeing the business grow and having faith in my team around me is a massive buzz – I really thank the people who I have working for me who assist in what we do on a daily basis; they are absolute stars in their jobs.”

COVERING

ALL OF THE BASES

Going down the fleet monitoring route requires an operation to commit to the system completely and integrate any telematics system into the entire business. PowerTorque talks to Andy Mickan, National Workshop Manager at Hi-Trans Express about using all of the data created by the truck and trailer assets to improve productivity in the business.

Hi-Trans Express is another example of the kind of convergence happening in the Australian trucking industry, where a sophisticated monitoring set-up can be used across the business to improve all of the functions within the business.

The Hi-Trans business has been around for more than 50 years and operates Australia-wide with its line-haul fleet of Kenworth and Mercedes Benz prime movers. The fleet regularly runs between its company depots in Adelaide, Brisbane, Sydney, Broken Hill, Townsville and Melbourne. It also uses agents in Perth, Darwin and Hobart, servicing customers throughout the country.

A high kilometre, just in time, type operation like this requires a varied fleet which does not miss a beat, to compete in a competitive marketplace. The company has an extensive system monitoring all of the rolling stock, trucks, trailers and dollies to ensure they are up to the job every day.

“It’s a fairly foolproof system,” says Andy. “The way we carry out our maintenance comes from the recording of all of the data from the system. There is 100 per cent monitoring of all of the vehicles, all of the time. On the fleet maintenance system we can see anything.

“We can see into the truck’s computer remotely, see all of the parameters we need.

I can see where it is, set speeds, look at the engine ECU data, then pull down history reports, look at fuel economy, the whole lot.”

The system Hi-Trans Express use is from MT Data telematics and it is used throughout the business, both as part of the maintenance process, but also for operations to organise fleet movement as well as for invoicing customers. The fully integrated system also includes the Seeing Machines driver monitoring equipment, to give the operation a comprehensive view across the business.

“I get reports every day and go into the system to see where we are travelling with kilometres,” says Andy. “All of our kilometres are manifested on trucks and trailers. So we know, if a truck is going from Adelaide to Sydney, we know it’s going to do 1448km and that gets manifested every day. All of that data on every truck, trailer or dolly gets put into our fleet “ALL OF MY PREVENTATIVE MAINTENANCE AND EVERYTHING ELSE IS IN THIS SYSTEM. I DON’T REALLY HAVE TO THINK OF A THING, IT’S SIMPLY A MATTER OF GETTING THE INFORMATION IN AND UPDATING IT. IT’S STRAIGHTFORWARD EASY SYSTEM TO USE AND WHEN WE GET OUR AUDITS, I CAN PULL ALL OF THE INFORMATION OUT AND MAKE HARD COPIES, IF NEEDED.”