he trucking industry has always been in flux, constantly changing and developing to cope with the inevitable growth in size and complexity of the freight task. At the same time as this openness to change and development, there is also an innate conservatism which has characterised the development of our culture.

Every now and then some ‘outside the box’ thinking, or a major change in the nature of the freight task brings out the industry’s capacity for innovative thinking to solve an issue and, more often than not, creates a workable, and, hopefully profitable, solution.

This period seems to be building up to being one of those flexion points. This is where the trucking industry has to come up with new solutions and learn to live with some new realities in order to move forward into the 2030s.

The issues are starting to pile up. The average age of truck drivers continues to increase at a substantial clip. The experienced drivers are well into retirement age, as the baby boomers are now in their seventies.

That population is still the knowledge base in the industry, an industry which struggles to get young school leavers to even consider it. At the same time attempts to make us a more attractive proposition have been unsuccessful, poorly thought out and poorly funded.

Meanwhile, on another front, the trucking industry is set for major upheaval with the planned transition away from carbon to the bright sunlit uplands of a carbon free trucking industry.

The fact of the matter is, the freight task in the 2030s will be much bigger than it is now. The pressure to get away from carbon will be intense. There will be little progress towards that scenario if we don’t get our heads around how to survive in this brave new world. The consequences if we don’t, will be the road transport industry being a drag on economic growth and an impediment to progress.

It is simply a matter of asking ourselves whether we are ready for change and willing to make the difficult decisions which are becoming imperative. It’s pointless trying argue about change, because it’s coming whether we are like it or not.

Denial is not an option, drivers are aging and the replacement numbers are too low. The idea that autonomous trucks are going to be a solution any time soon is unthinkable in Australia, apart from a few major highway exceptions.

PUBLISHED BY

Prime Creative Media Pty Ltd

ABN 51 127 239 212

379 Docklands Drive, Docklands VIC 3008 Australia

Telephone: 03 9690 8766

Fax: 03 9682 0044

Email: enquiries@primecreative.com.au

Chief Executive Officer: John Murphy

Managing Editor: Geoff Crockett

Editor: Tim Giles

Journalist: Alex Catalano

Contributor: Bob Woodward

Correspondent: Will Shiers (UK)

Advertising Manager: Trevor Herkess: 0411 411 352, trevor.herkess@primecreative com.au

Client Success Manager: Salma Kennedy, salma.kennedy@primecreative.com.au

Production Manager: Michelle Weston

Circulation & Subscriptions Manager: Bobby Yung

Head of Design: Blake Storey

Designers: Cat Zappia, Jacqueline Buckmaster, Danielle Harris

Official Media Partners:

REGISTERED BY Australia Post - ISSN 1445-1158

SUBSCRIPTION

03 9690 8766

subscriptions@primecreative.com.au

Instead, trucking needs to turn its attention to a more rational and collaborative distribution system which avoids the level of empty or partially loaded running we do today and consolidates loads onto bigger, more productive trucks. At the same time we need to be attuned to the preferences of Generation Z, not the boomers.

There is no debate to be had about zero emissions. The ball is rolling globally and burying our heads in the sand will simply see us left behind by the rest of the world and become an economic back water.

EDITOR

PowerTorque Magazine is available by subscription from the publisher.

The right of refusal is reserved by the publisher.

Annual rates: AUS $60.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

PowerTorque Magazine is owned and published by Prime Creative Media.

All material in PowerTorque Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in PowerTorque Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

DAF is versatile and an all-rounder with the perfect combination of superior comfort and luxury for the driver and maximum vehicle efficiency for the operator. So, you need a prime mover with superior robustness and high payload? There’s a DAF for that!

Whether your needs are long-distance haulage, city distribution, construction transportation, bulk or tank transport, the versatility of DAF keeps you moving, and that’s good for business. DAF.COM.AU

Dozens of smart new road transport and distribution operations popping up around Australia are moving away from the traditional trucking model.

This year’s Rural Transport Rising Star, Luke Cannon, has come a long way in a few years from a livestock truck workshop, through to truck driving, to handling a busy livestock transport fleet like Fraser’s.

The winner of the Truck of the Year Australasia 2024, the Western Star X Series was a long time in the making. It’s here now and PowerTorque has looked into the origin story of this ground breaking range of trucks for the Australasian market.

Looking at the realities which will face transport operations as they migrate across from fossil fuel dependency to the zero carbon economy, one of experts in the field examines some possible scenarios.

The National Heavy Vehicle Regulator has been active in New South Wales for over two years now, so we spent the day at the Mount White Checking Station to see how the transition has changed the interface between the trucking community and its regulator.

Descending from a long line of shearers and sheep farmers, Mark Williams is a primary producer and shearer based outside of Goulburn in New South Wales.

Volvo’s engineers have managed to squeeze out 780hp from its new 17-litre engine, which is just enough for the FH16 to knock arch-rival Scania off the top spot to become Europe’s most powerful production truck.

It’s a perennial question on many and varied topics, but the question, ‘does size matter?’ is also relevant in the truck world. There’s cab size and engine size and many other things to consider.

28 FROM LOGBOOKS TO LEGAL

Navigating contracts and onboarding in the trucking world can be confusing at the best of times. The team at Clear Employment Relations Advice Team explain the ins and outs.

60 NHVR PROVIDES INDUSTRY ‘HEALTH CHECK’

NHVR Chief Operations Officer Paul Salvati addresses the newest iteration of the National Roadworthiness Survey, which hopes to drive safety and efficiency improvements across Australia’s heavy vehicle fleet.

64 CHAMPIONING FAIR TOLLING FOR HEAVY VEHICLES

NatRoad CEO Warren Clark says the recently released NSW Independent Toll Review leaves plenty to be desired when it comes to meaningful reform for a sustainable transport system.

78 REASONS TO GO DIGITAL

Nobody wakes up each morning and hopes to spend the day filling out and filing paperwork. Relying on paper and manual processes limits your ability to become more efficient, have better safety outcomes and boost your bottom line.

80 IMPLEMENTING SAFETY MANAGEMENT SYSTEMS FOR TRANSPORT OPERATORS

Adding a safety management system to your fleet can have major benefits aside from just meeting legal and regulatory standards.

82 SAFETY IS A TEAM EFFORT

Regular PowerTorque contributor Bob Woodward reminds us that safety is a team effort and we all need to engage as part of the team. He also highlights the safety capabilities of the unused potential in some truck systems.

• Supporting drivers for more than 50 years

• Seating – on a higher level

The new Volvo VNL Autonomous was shown off at the ACT Expo in Las Vegas, developed in partnership with Aurora Innovation, which created the autonomous technology inside the truck.

It is currently slated for use across the United States, with a view to expand distribution worldwide.

“We are at the forefront of a new way to transport goods, complementing and enhancing transportation capacity, and thereby enabling trade and societal growth,” says president of Volvo Autonomous Solutions Nils Jaeger.

“This truck is the first of our standardised global autonomous technology platform, which will enable us to introduce additional models in the future, bringing autonomy to all Volvo Group truck brands, and to other geographies and use cases.”

The VNL Autonomous includes redundant steering, braking, communication, computation, power management, energy storage and vehicle motion management systems.

Chinese heavy vehicle manufacturer FAW Truck exports its trucks to 80 countries and regions around the world, and has now landed in the Australian market.

The JH6 Prime Mover has received approval under Australian Design Rules, and freatures a high end, bold and generous appearance.

Soon to be made available as a 6x4 prime mover, multiple

Mack has released its “gamechanging” new range of Euro 6 offerings for the Australian market.

A whole new range of Mack drivetrains has been revealed that includes an all-new range topping 780hp 17-litre MP11 engine and a stump pulling 3800Nm of torque.

The new Mack Trucks Euro 6 range is now available to order with the first vehicles expected to hit the road in early 2025.

Mack says the Super-Liner has already held the title of Australia’s

most powerful conventional truck for more than a decade, with this new model set to elevate its offering.

The arrival of the new MP8HE (high efficiency) engine platform will help evolve Mack’s powertrain, with the 2800Nm of torque increasing the output from Mack’s standard MP8 engine.

The fully integrated 70-inch walkthrough sleeper will also be available for order with Euro 6 Super-Liner and Titan products, with single and double bunks included.

configurations of the vehicle will be integrated with an eye towards excellent performance.

The JH6 is known for its fuel efficiency, light weight and low maintenance cost, forging a high cost performance truck with high efficiency, reliability, safety and comfortability.

The company has now reached more than 80 million unit sales worldwide.

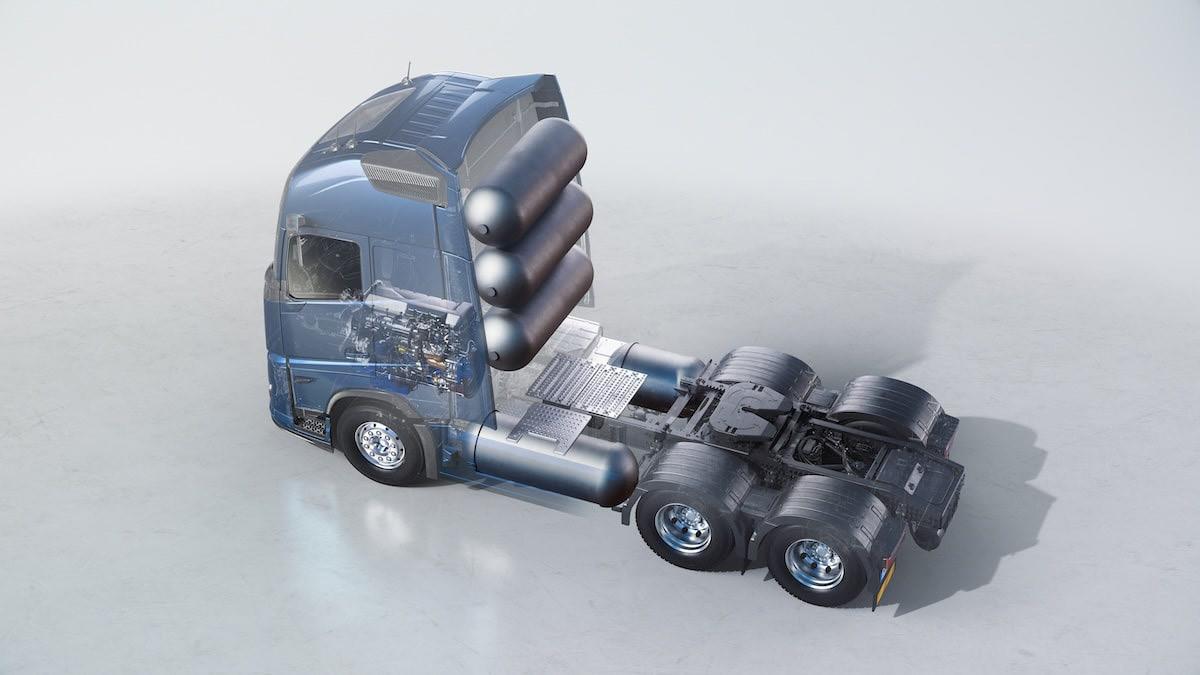

has announced plans to globally manufacture hydrogen trucks in an effort to diversify its investment in zero emissions heavy vehicles.

global manufacturer says on-road tests with the hydrogen combustion engine trucks will begin in 2026, with Volvo planning to commercially launch the vehicle by the end of the decade.

move comes due to the ability that trucks running on green hydrogen have to decarbonise transport, with Volvo also citing the suitability of the technology over longer distances as a key advantage. develop the technology, Volvo has signed an agreement with

business, with the Corowa-based company farewelling the transport industry.

Initially founded in 1988 by brothers Greg and Ray Milthorpe, the two diesel mechanics used their collective experience at Corowa Truck and Trailer Repairs to pioneer

Greg Milthorpe says the operator managed to reach an impressive milestone.

“We’ve nurtured Milthorpe for about four decades now – from its modest inception, it has steadily expanded into a family-owned business, with my sons, Steve,

Rodney and Chris now integral parts

“However, as we embark on this new chapter, we eagerly anticipate embracing the joys of family life and relishing in newfound leisure.”

Ray’s recent retirement, coupled with Greg’s desire to follow suit, means the family business will gracefully exit the industry.

Meat and Livestock Australia has launched a new information resource for drivers and workers in the livestock transport industry, known as the MLA Transport Hub.

MLA consulted heavily with the Australian Livestock and Rural Transporters Association, operators and other relevant industry bodies to launch the service.

It says it will help to unify rules and guidelines across the industry to provide the best outcomes for the animals being transported.

“Transporting and handling livestock is a specialist task and one which the whole supply chain relies on to be performed safely, efficiently and professionally,” says ALRTA vice-president Athol Carter.

“Well planned and managed livestock transport delivers the best results for people and animals, higher profits and ensures the sustainability of the industry.”

MLA project manager Sharon Dundon says the information hub will be continually updated with new information for drivers and workers who work with animals, giving them transparency and a source of information for the industry.

“There’s nothing that exists that pools and brings all that information together,” she explains.

“This ranges from practical hands-on information to scientific information.

“A core part of the hub will be information around preparation for livestock for their intended journey and all the things you need to consider.

“We’ve been working with the Australian Livestock and Rural Transporters Association and TruckSafe, as well as operators that do livestock transport around what things they consider as best practice.”

UD Trucks is celebrating the 20th anniversary of its popular Quon model, first introduced in 2004.

As the successor to the renowned BigThumb model, UD says the Quon set a new industry benchmark through its integration advanced technologies and world-first innovations.

“Bringing the Quon to market 20 years ago was driven by UD Trucks’ Better Life purpose, enabling us to deliver a truck that’s better for people, our planet and for business,” says UD Trucks Australia vice president Philippa Wood.

“Quon has been at the forefront of addressing evolving challenges, setting new standards and delivering exceptional performance and success to our valued customers

across Australia – and many other markets worldwide.

Quon range to date and we will continue to go the extra mile and

The Australian Livestock and Rural Transporters Association and TruckSafe are developing a new Animal Welfare Accreditation program for the safe road transport of livestock. It will be developed in partnership with National Transport Insurance and will aim to support consigners, transporters and consignees meet their driver and animal welfare obligations.

Smith says the agreement has been reached after several months of consultation.

“This is necessary given the importance our members place on the safe and humane transportation of animals,” she says.

“It is an exciting time for ALRTA and its members, having developed the original TruckCare accreditation scheme that eventually formed part of

MAN Truck and Bus is taking an ambitious step forward in its truck production, announcing its intention to launch a series of hydrogen combustion powered trucks in 2025.

By 2025, this initially planned series of around 200 MAN hTGX units is expected to be delivered to Germany, the Netherlands, Norway, Iceland, and selected non-European countries.

The company says that this model will provide a zero-emissions option for transporting heavy freight across the construction, tank transport or logging sectors.

The initial axle configurations of the MAN hTGX, 6×2 and 6×4, are expected to allow for high payloads and maximum ranges of up to 600 kilometers.

The H45 hydrogen combustion

engine used in these trucks will have a power output of 383 kW or 520 hp. Refueling the vehicle with compressed hydrogen (CG H2) at 700 bar and a tank capacity of 56kg should take less than 15 minutes, MAN says.

The Mercedes-Benz eActros 600 has begun its gruelling journey across Europe, as Daimler Truck undergoes its ‘most extensive truck test run’ in the company’s history.

Two flagship electric eActros 600 are travelling across more than 20 European in a test of the capabilities of electric batteries for long haul trucking. Both models will be completing 13,000km each, towing 40 tons total.

Head of global testing at Mercedes-Benz Trucks Christof Weber says the company is looking to improve its knowledge of the wide range and routes and climates that a long haul electric truck will face.

“We have put various prototypes of the eActros 600 through their paces over the last few years,” he says.

“Whether in the North of Finland or the South of Spain, the vehicle has long proven what it can do. With series development, we are now on the finishing straight.

Daimler wants to prove that electric trucks can handle the demands of long haul trucking, which could not only be applied in Europe, but in overseas markets too.

Daimler Truck is rolling out the first electric trucks in its new RIZON Truck brand, sending out an order to several companies across California.

The all-electric US class 4 and 5 trucks ‘address a diverse range of customers’, Daimler says, as it looks to continue to develop its commitment to sustainable transport solutions.

While there are still more trucks on order, this batch of 20 e18L RIZON trucks will be delivered to LA Sanitation and Environment (seven trucks), Diamond Environmental (four trucks), Ecorecycling (three trucks), Velocity Truck Rental and Leasing (five trucks) and Goodwill Industries of San Diego County (one truck).

“I’m very excited the first RIZON trucks are now in operation,” said Andreas Deuschle, Global Head of RIZON Truck.

“Our all-new RIZON trucks inherited all this expertise which results in a very mature system: innovative eAxle concept, latest safety features, a wide variety of body applications, and a flexible battery concept.”

Daimler Truck Australia Pacific has opened a new parts warehouse to support its Mercedes-Benz, Fuso and Freightliner truck brands as well as parts division Alliance Truck Parts.

30,000 square metres in size, the facility is based in Truganina, west of the Melbourne CBD. It had been used previously as a shared facility with Mercedes-Benz passenger cars.

Daimler Truck Australia Pacific CEO and president Daniel Whitehead says that the new warehouse will give Daimler customers increased service and will also meet the company’s future sustainability needs and goals.

“This dedicated truck and bus parts warehouse is at the centre of our commitment to our customers across Australia and New Zealand,” he says.

“It was a great opportunity to specify a design that incorporated a raft of environmental elements ranging from double-glazed windows to an impressive solar power array.”

National logistics company Allied Express has enjoyed Isuzu’s offerings, which have helped its fleet offer the versatility it needs for a number of job.

Managing director Michelle McDowell says that while there isn’t necessarily a perfect delivery truck, Allied’s subcontractors seem to prefer the fleet of Isuzu trucks that the company can offer.

“Our fleet consists of a wide variety of trucks, because we do such a gauntlet of different delivery types,” she says.

“Reliability and presentation are very important for Allied Express as our customers put their trust in us to deliver the product on their behalf… it is important for all drivers to keep their vehicles well-presented and for them to be proud of their work.”

$17 million of funding is being put towards five new rest area projects in a joint effort from federal, state and local governments.

Rest areas will be located on the Barrier Highway in South Australia, Newell Highway and Sturt Highway in New South Wales, and in Pingelly, Western Australia.

“The federal government’s Heavy Vehicle Rest Area initiative aims to increase heavy vehicle user safety and productivity through vital new and upgraded rest areas across their journey,” says chair of the Heavy Vehicle

Rest Area Steering Committee Glenn Sterle.

“We want to keep our truck drivers and communities safe and these new and upgraded rest stops will help drivers reduce their fatigue as they keep goods moving across the country.”

These projects will include the construction of new rest areas with dedicated slip and turning lanes, shelters, landscaping, and connecting footpaths, as well as the upgrade of existing ones from light to heavy vehicle classification with all-weather pavement, solar lighting, and amenities.

Hino launched its new zero emissions truck brand, Tern, at the ACT Expo in Las Vegas as a part of a $3 billion partnership with zero emissions technology company Hexagon Purus.

They also unveiled the inaugural vehicle model in the RC8 battery electric Class 8 tractor.

Alemlube Automatic Lubrication Systems next level greasing allows you to:

• Eliminate manual greasing

• Stay on the road

• Deliver on time

• Spend more time doing your own thing

The semi-tractor uses Hexagon Purus’ years of zero-emissions drivetrain development for heavyduty trucks and represents a different option for fleets.

The new vehicles will be manufactured in Hexagon Purus’ new facility in Dallas, Texas, with the RC8 scheduled for serial production later this year.

The model is built on Hino’s XL Series 4×2 chassis and is equipped with Hexagon’s zero-emissions technology, including proprietary battery systems, auxiliary modules and power modules.

The vehicle uses a US assembled Hino chassis, an e-Axle from Dana and Panasonic Energy battery cells.

There are dozens of smart new road transport and distribution operations popping up around Australia and many are moving away from the traditional trucking model and finding new 21st century business models. PowerTorque visits one of them, Motus Transport in Sydney.

The way to develop a new

currently working, then talk to the end user, the customer, and look at the business from their point of view. This is what happened for Andy Harris and his wife Emily.

In 2016 the operation began with Andy hiring a van and Emily processing orders from home. The growth in the intervening years has seen the fleet grow to over 70 vehicles transporting craft beer and other beverages across a large area of NSW and SE Queensland. The business has two warehouses in Sydney and one in Brisbane, as well as warehouses in Canberra, Newcastle, Coffs Harbour and Byron Bay.

Andy says that Motus Transport’s aim is to act as an indispensable partner to customers and an extension of their business, by simplifying the process of transport and delivering great service. The Motus team are a close-knit team of diverse people, dedicated to this vision and share a love for good beer (beverages) and great people.

“We started really small, I was driving a truck myself and then one person said, ‘we’ve got a brew coming out, on this date, you need to have a warehouse’,”says Andy. “I just hired a truck, then went from there.”

The service Motus offers to the brewery is handling all the warehousing and distribution for craft brewers, as beer comes off the end of the production line. The trucks either pick up from the brewery or the brewery delivers it to the Motus warehouse.

It is then stored in a large cool room. It’s not just beer, it’s also sparkling water and and other beverages, delivered on their behalf. Trucks run all around Sydney, to Canberra, Newcastle, Coffs Harbour, Byron Bay and SE Queensland. In terms of storage, they have10,000 square metres in Sydney and another14,000 square metres in Brisbane.

“This year is a bit of a settle down and consolidate, and just make sure that we’re going to get everything right,” says Andy.

Motus means to move in Latin, and the logo includes a wing, which derives from Mercury’s helmet (Mercury was the Roman god of speed). The recently purchased Hino 300 Series hybrid trucks are named after Greek or Roman gods.

Distribution for the alcohol industry was not Andy’s first career choice.

“I said I would never do transport,” says Andy. “My dad owned a transport company here in Sydney. He owned that business and I’d worked in it when I was younger. It was a taxi truck business.

“Later, I went to uni and then I actually got into the alcohol industry, I left my family business in transport and then worked in the alcohol industry for 15 years. I was in sales and marketing and I was once a brand manager for Bundy, looking after key accounts. I met my wife on the first day in the industry she worked in safety, in her

uncle’s pub. Emily was managing the pub while at Uni, then worked in Safety for the like of Kennards Hire and Coke.

“I saw that in the alcohol industry, they’re all complaining to me about transport. I thought, it’s just got to be done better. Now, we’re kind of breathing fresh air into transport. We’re big on customer service, we’re big on our own staff, and the environment is something that you have to be good to. We want to make sure that we do the right thing and hybrids are the first step into that and it’s a relatively low risk. It’s not a massive capital outlay.

“When you’re in it, you can sort of pick where it can be improved. My real customer is pubs, clubs, restaurants. I tell the beer suppliers that we are an extension of their business and make sure that we do what their customers tell us. All of our drivers are a customer service person.

“You’re told when you’re going to deliver it, it’s got to be there at four

and if it’s not there at four, there’s a problem. It’s making sure that we work in with the venues and make sure that we’re doing our job, and if we are late, we tell them and say sorry. I think this industry has gone away from saying sorry, you know, yes, there is traffic and yes, there are other things and people do understand, you’ve just got to let them know.”

The business’ customers are mainly breweries, but they also include wineries or distributors of wine, or multiple beverages. There’s a lot of diversity in the industry, there are not big corporates like Coles or Woolworths influencing buyers. A business owner makes an individual decision on what they put on tap at their pub. They might have contracts with the big breweries, but they still support independent product.

Motus use the Carton Cloud system to run the distribution process, getting the idea from one of their customers, the Pirate Life brewery.

“We were working with them and they said that this software is great,” says Andy. “We found that Carton Cloud was very much tailored for us. It helped my wife get away from being on the phone all the time. I’d get home after doing deliveries and she’d be doing routing until 11 o’clock at night, before we got it.

“It helped with everything. A lot of transport companies only use about 60 per cent of the software and don’t use 100 per cent. Emily and her customer service team use 100 per cent of that software. It’s quite funny, Emily’s actually taught a lot of our competitors how to use that product. I don’t mind because I know that they’re never going to use it to the extent that we do. Technology is a great thing if you use it properly.”

In the past, Andy’s Dad’s transport business would supply handhelds to every single driver or inbuilt units. Now, drivers at Motus just use their own phone. The system will do invoicing every week which is auto generated. Every item in the warehouse can be barcode scanned, it can also bottle scan. Carton Cloud has evolved with Motus, after starting on

the Gold Coast in Australia. It is now in the US and Canada. Some of the bigger businesses Motus deal with are starting to use it for their own inventory.

We have a lot of younger staff and it helps that the hybrids look very good

then there’s a few semis (700 Series SS)

road, and we’ll start taking a lot more.

working on themselves at the moment.”

“My wife and I, we’re both 39/40, we’ve still got our first driver and he’s probably the oldest in our business at 54,” says Andy. “We do a bit of heavy lifting, the majority of the business, is younger. A lot of people talk about employing younger people.

“It’s just the way we treat them compared to other businesses. We work in the beverage industry. So when it comes down to it, it’s a fun industry to work in. We’re not delivering carpet, we’re not delivering cement, they actually like doing the job, they get to interact with venues,

The flexible and agile Volvo FM Electric. Lower sound and emissions. Excellent ergonomics and visibility. Designed for high-capacity grocery deliveries, container transports, refuse pickups and more within metropolitan areas. To simplify the transition to electromobility, the truck is offered together with solutions for charging, route and range planning and energy status.

Trucks. Driving Progress

pubs, clubs, restaurants.

“Sometimes some of the older drivers are stuck in their ways, but with young people, it’s really easy to train them our way, which we find quite refreshing.”

An issue in Sydney and Brisbane and in the bigger cities, is having enough room to park a fleet of this size, when industrial space is at a premium. So, if Motus drivers treat a vehicle like it is their own, the company will allow them to take it home. Semi trailers and the bigger trucks are parked at home base.

“We trust our drivers, and to be honest, I can probably name on the fingers of my hand when people have abused that,” says Andy. “We try as much as we can to work with them. If they live in the inner west of Sydney we try to have them finish relatively close to their home, which works for them. We implore drivers to talk to us, if they have to look after their kids, or they need to be at sports training or something, we try and work with them.

There’s also a lot of DC work for Motus, going into Coles, Woolworths, Australian Liquor Marketers (part of Metcash), Independent Liquor Group and Paramount liquor. The operation brings in liquor from it’s customers, and consolidates the loads for the required DCs. ALM sell to all the bottle shops and their consolidated loads are bigger than most.

The trucks all have compact small bodies, built to the Motus spec. The city trucks are lower roofed, with the height inside at 1.6 or 2.2 metres, so they can get into loading docks.The fleet have three body specs and they call them Mini Me, Medium Me and then Tautliner. Mini Me and Medium Me are the city trucks, pantechs. The truck bodies have signage on them for Motus’s customers on the van rear doors and Motus signage on the side.

“We try to keep our trucks for about four or five years, but we’ve had some massive growth,” says Andy. “We try to switch them out as soon as we can. There’s some trucks that haven’t done the kms because they’re only going

from here into the city and those we will keep longer. We just liaise with Hino and make sure they’re good. We’ve just had a few bodies redone, when they looked a bit tired after that length of time. We try to move them on and then get newer trucks. I don’t like having tired old trucks.

“For the next few years, we’ll work on our areas and build them out with other beverages, whether it be soft drink, or wine and spirits. We’ve got a bonded warehouse as well, there are opportunities. I see going further North in Queensland would probably be the first step. Wherever there’s an opportunity, we’ll just have

FAW JH6 PRIME MOVER meets your multifaceted needs. Achieve your smooth long-haul transportation.

FAW Truck products are exported to 80 Countries and Regions and has now landed to bring competitiveness into the Australian Market. It’s star product JH6 Prime Mover has a high end, bold and generous appearance. At the same time, multiple configurations of the vehicle are integrated to create the excellent performance. JH6 is known for its fuel efficiency, light weight and low maintenance cost, forging a high cost performance truck with high efficiency, reliability, safety and comfortability.

This year’s Rural Transport Rising Star, Luke Cannon, has come a long way in a few years from a livestock truck workshop, through truck driving, to handling the stressful role of organising loading and delivery for a busy livestock transport fleet like Fraser’s.

PowerTorque spoke to this year’s winner of the Rural Transport Rising Star Award, Luke Cannon, who was presented with his award at the combined Australian Livestock and RuraL Transporters Association and Livestock and Rural Transporters Association of Queensland conference, held in the Goods Shed, in Toowoomba Queensland.

“I’m born and bred in Warwick, Southeast Queensland, lived there my whole life,” says Luke. “At 19 years of age, I approached the Fraser family for a job in the workshop, at Frasers Livestock Transport. I started off in there for a few months. When I got a semi license, I started just helping them out where I could, running dog trailers about. My dad was a truck driver and he was in the workshop at Frasers, at the time.

“Eventually I thought I could stay away for a couple of nights and help out, jump from truck to truck and then eventually I got my own truck and I was driving full time. The workshop was a thing of the past, and then, after a few years, I finally worked my way up and got a brand new Kenworth T 659. That’s the ultimate for me, especially when you’re in your 20s.

“Then after about eight years of driving, a job opportunity came up in the office, so I went in there. I was always pretty handy on computers and with technology. I thought I could bring a few bright ideas to the office and asked if I could have a trial. I was working on the principle, that if it didn’t work out, I’d just go back to driving, which was no dramas.”

Since then Luke has stayed in the office. He started off helping out the operations managers, where needed, now he’s the sale yards logistics manager. His job is to take all the sale yard numbers each day and put together loads, taking in the various customer locations and preferences. Then he will allocate which truck does what load, generates and sends load plans and explains to the drivers how to load the livestock to suit the different destinations.

Not only do they need to have the right number of animals on the right truck, but also they’ve got to be loaded

the right weight distribution.

“Also some of the regular customers have got to take priority.” says Luke. “You want to treat everyone as equals, but it gets very hard there at times. Yes, it’s a big puzzle every day. You sit there in the mornings and wait for the sale yard numbers to come in and you’re all calm and collected, and they just hit you with big numbers.

“Then you’ve got to put it all together in the afternoon as quick as you can, so you can tell the drivers what’s happening and get them going, to give them the information. Then at night time there’s a lot of calls and there’s a lot of planning still going on, checking weights. Plus, there’s a lot of mornings where people can’t find cattle and can’t find paperwork. It’s a very stressful and demanding job, but it’s very rewarding, at the same time.

“You’re catering for drivers needs all the time. Drivers are restricted by their capabilities at times and you’ve got to allow for that. You have to think about cattle weights and who’s coming off first. It’s a very demanding job at times.”

Luke has got to work in a team with the other members of the operations group, who are organising the feedlot livestock tasks. These are booked in earlier, but have also got to happen at the right time with the right truck in the right location. For those dealing with the sale yards, the final decision is up

Frasers business and is still a vital cog in the organisation, still making up the bulk of the business.

“The fellow I work with mainly, is named Steve, he’s in his 40s. He’s drove for longer than I could imagine but he’s been in there about 10 years,” says Luke. “I work closely with Ross and Warwick Fraser, they oversee everything and just keep an eye on things. Other people just help us out where they can and when they can do.”

Having that period of driving experience beforehand means Luke has the skills to know what cattle should weigh, and if a problem situation arises, he has had the experience of handling it himself and knowing what to do, who to ring.

“Honestly, when I first walked into the workshop, I didn’t know where I was going to go,” says Luke. “I do like to be always moving forward and trying to keep building and get better, I just want to build on what I’ve got. I love to move forward and strive for better. You can always come back to what you’re doing, to come back to feeling comfortable.

“In high school, I never dreamed that I’d be doing what I’m doing now. Never even dreamed I’d get a new truck and be doing Western cattle work and road trains or anything like that, but the possibilities are endless.”

This year’s Australian Livestock and Rural Transporters Association Conference took place in Toowoomba, as a jointly hosted event with the Livestock and Rural Transporters Association of Queensland.

This year’s ALRTA conference took place in the Goods Shed event venue in Toowoomba, in a region which is home to the largest cattle feedlots in the southern hemisphere, with 617,000 cattle on feed in the local region and 45 per cent of the

“It’s an interesting time for transport and regional transport, at the moment,” said Rachel Smith, Executive Director of the ALRTA, at the event. “We’ve got a very interesting federal government that perhaps doesn’t necessarily look beyond the metropolitan borders.

“This is the situation we’re going to have to play to over the next 12 months, leading into the federal election. We are concentrating on the contribution that rural transport makes to regional economies and jobs, and stressing the need to adequately fund roads to provide safe workplaces for everyone in the rural transport sector.”

This national conference was the first opportunity for Mat Munro, the CEO of the Australian Trucking Association, to return to national conference of the ALRTA of which he was Executive Director for over ten years.

“It’s really nice to be back and good to see a lot of familiar faces and be amongst you today,” opened Mat. “The ATA is working on plenty of big ticket items, as the peak body representing 10 different member organisations. This is really broad mandate, but the first one I would mention is the industrial relations reforms.

“I was with ALRTA when we tore the Road Safety Remuneration Tribunal down the first time and, now, we’ve got something like it back. It’s a little bit different, but it’s also a little bit the same. It carries some of the same risks. We’ve worked really closely with our member organisations, it was a tricky issue for us, because across our 10 member organisations, we had five that were supportive of it and five that really didn’t want it to come back in any form at all.

“We worked with our members and with the government to try to find a way to bring this to function in a way that would actually work. The legislation has passed and we asked government for a whole range of failsafes, so that it can’t do what it did last time. If it gets it wrong, we

can stop it. Rather than, what we had to do last time, drive the trucks up the Parliament House and protest on the lawns to get rid of it.

“I’m hoping we’ve got plenty of other mechanisms to deal with issues this time around. We’ve got automatic understandings for industry associations be part of the consultations. We’ve got very long lead times before anything actually comes into effect, so we can analyse it and see where it’s actually going to have problems.”

The new rules have removed the Heavy Vehicle National Law and Workplace Health and Safety laws from the law’s remit to avoid any overlap in those spaces. If there are issues, the industry can reconstitute the Fair Work Commission panel to have a look at it. If all else fails, there’s now a role for the minister as well.

“If we had some of these those things the first time around, we might have been able to deal with the harm that the orders were causing, rather than striking out the whole legislation and tribunal,” said Mat. “There are things that the tribunal can now do, which will be a benefit.

“In payment terms, for example, we don’t have laws in other spaces that can really deal with those payment terms, waiting times and unfair contracts. There are things that we could do that would be beneficial for this industry, but we have to be really mindful of some of the things that happened last time, where it set minimum rates for one part of the industry and, basically, destroyed that part of the industry.

Eyes wide open, but there’s some opportunities here. We think, we’ve got the balance right this time around.

“The ATA is also looking at the sustainability issue, the low carbon transition and government has set pretty ambitious targets, like 43 per cent by 2030, and net zero by 2050. We can’t meet those targets on our own, we can contribute, but we can’t get there. Our best guess at this point is we might be able to go to between 12 and 15 per cent. We are just not going to turn the fleet over fast enough to meet those targets.”

The ALRTA is an organisation which works with politicians of all stripes, and continues to work to improve their understanding of rural transport’s specific issues. Most recently, the ALRTA has lobbied for changes to the industrial reform to take rural trucking into account

“We actually got concessions through working with David Pocock, and he’s a Teal, because we went and had very sensible conversations with him about the potential impacts of the legislation and the flow-through effects to Australian consumers, who are his constituents,” said Rachel. “There’s, opportunities to work with the government on issues such as rural road funding, ALRTA has been talking to the Australian Local Government Association about revamping the Rural Road Alliance.

“It’s highlighting that Australia is one national economy, we don’t necessarily have state borders or council borders

on the issues. How do we help the government solve some of those problems? Transport, fuel and others, we all have a role to play, because everyone’s hurting in the pocket right now. Whether it’s a business or a consumer.”

The ongoing shortage of resources to local government to achieve the result needed to maintain, let alone develop, our current rural road infrastructure, continues to be a major issue. The problem has been exacerbated by a number of weather events which put those resources under even more pressure.

Another issue which is exercising the dynamics of the relationship between the rural livestock operators, the local councils and the state authorities is effluent. All of the cattle in the feedlots and elsewhere in the vast area to the West of Toowoomba have to be brought towards the coast and get processed in abattoirs, creating environmental issues around the topic of effluent from the animals flowing from trucks onto the roads and roadsides.

Livestock industry lobbying for initiatives to enable the dumping of effluent from the trailers hauling cattle into facilities able to handle the effluent, have had little success. Local government and state government have made positive noises about addressing the issue, but very little of note has come of it. The responsibility for developing a solution to the issue is being passed back and forth between different levels of government. As a result very little progress has been made towards a practical solution.

“Local government can’t afford to do anything, except to advocate and we’ve done that quite strongly,” said Carol Taylor, a Councillor on the Toowoomba Regional Council. “Our group sent a letter to the federal minister and we got a strange reply saying the responsibility lay with the State Authorities for truck wash-down and also for effluent disposal facilities, and that’s where the responsibility lies.

“We need to advocate to the State Governments to find sites and we need to work together, both the livestock transport industry and local government.”

Navigating Contracts and Onboarding in the Trucking World is explained by the team at Clear Employment Relations Advice Team

If you’ve never had a legal headache, count yourself lucky. You never want to have one. In the fast-paced world of trucking, the importance of solid employment contracts and efficient onboarding processes is as crucial as keeping your rigs in top gear. Whether you’re managing a fleet of long-haul truckers or a team of local drivers, ensuring that your employment practices are watertight will save you time, money, and legal headaches down the road. Buckle up as we take a deep dive into the common contract pitfalls and the best practices for onboarding employees, aimed at equipping employers with the knowledge you need to keep wheels turning smoothly.

Common Contract Pitfalls

1. Ambiguity in Terms and Conditions: One of the most frequent mistakes is vague language. Terms like “reasonable notice” or “as required” can lead to disputes. Clearly define working hours, overtime expectations, job responsibilities, and termination conditions. Clear contracts mean no surprises.

2. Failure to Update Contracts: Employment laws and industry standards change faster than a trucker can finish a meat pie. Regularly reviewing and updating contracts is like keeping your truck serviced—it ensures compliance with the latest legal requirements and best practices. Outdated contracts are like dodgy brakes—they can lead to nasty legal prangs and misunderstandings. Keep those contracts fresh and roadworthy!

3. Misclassification of Workers: Misclassifying employees as independent contractors or casual workers can have serious repercussions. Ensure that the contract accurately reflects the nature of the employment relationship. Employees classified incorrectly can lead to liabilities for unpaid superannuation, leave entitlements, and even penalties from regulatory bodies like the Fair

Work Ombudsman. Get it right to avoid costly detours.

4. Inadequate Leave Policies: Trucking work often involves long hours and gruelling schedules. Make sure your contracts outline leave entitlements, including annual, sick, and long service leave. Don’t forget to build in notice and evidence requirements into your employee handbook to ensure you can manage those difficult staff.

5. Inadequate Overtime Policies: Trucking often requires flexibility and long hours. Make sure your contracts clearly state how overtime will be calculated and compensated. Do you just pay an all-inclusive rate? You better have an offset clause in there or you may get a nasty surprise – without this, it doesn’t count as overtime pay. Failure to comply with the Fair Work Act regarding overtime pay can result in significant financial penalties and strained employee relations.

So what do you need to issue your employees at the time of onboarding?

1. A contract relevant to their employment type (i.e. full time, part time, casual)

2. A copy of your employee handbook, which should outline your policies and procedures

3. A detailed job description

4. A copy of the Fair Work Information Statement – you must issue this by law – and make sure it’s the updated version!

5. A copy of the Casual Employee Information Statement (casual employees only)

6. A form requesting their personal particulars (name, date of birth, emergency contact details, driver’s licence details, bank account details and more) and health questionnaire

7. Tax File Number Declaration Form

8. Superannuation Standard Choice Form

9. Contracts, handbooks and job descriptions are business specific and you should chat to a

professional about these to ensure your business is protected. You can download a free resource pack with some helpful items here:

The strength of your workforce is the backbone of your business. By avoiding common contract pitfalls and implementing effective onboarding processes, you lay the groundwork for a stable and productive work environment. Remember, clarity and preparation are your best allies. Investing time in these areas will pay dividends in employee satisfaction, retention, and overall business success. So, keep the rubber on the road and your contracts airtight! Questions? Reach out to advice@clear-er.com.au

THE STORY OF THE TRUCK OF THE YEAR AUSTRALASIA 2024

Winner of the highly-prestigious Truck of The Year Australasia (ToYA) award for 2024, the X-Series is the most-tested Western Star ever. The X-Series boasts our legendary Star durability, features a powerful integrated driveline, an advanced safety package, and superior comfort – even in the most rugged applications.

The winner of the Truck of the Year Australasia 2024, the Western Star X-Series was a long time in the making. It’s here now and PowerTorque has looked into the origin story of this ground breaking range of trucks for the Australasian market.

TStar X-Series began back in 2014/2015, when the team at Penske Australia & New Zealand (formerly Penske Commercial Vehicles) first started looking at a model range to take the brand through the 2020s.

This is a story of bringing new levels of safety and efficiency to the brand, without compromising the qualities the brand had built on over the last 40 years, as the new trucks passed through the design process. The requirements included meeting the latest regulations which were expected to be mandated, as well meeting the expectations of the trucking industry in the coming decade.

Also included in the process were deliberations needed in starting work on any new truck, designing and integrating trucks for as many applications as possible and enabling ever more efficient logistics. It was also important to include the latest and greatest technology and design being developed for the Western Star brand by Daimler Truck in North America in

for the Australasian market.

At that time, when the design process began the date for the next round of exhaust emission regulations to be implemented had not been finalised, but the team also new it was inevitable. As it happens the design process was able to get trucks able to meet the ADR 80/04 limits well ahead of the mandated date for the introduction of November 1 2025.

There was clearly a need for a new engine platform and after treatment to meet the ADR as well as taking Western Star into the fuel usage levels being asked for by the trucking industry at this time. Any new driveline would also have to meet the durability expected in Australasian operations.

“Overall, we launched the X-Series with the goal of having the strongest and most durable Western Star truck to date,” says Kurt Dein, Head of Western Star Trucks at Penske Australia.

“Looking back, we had launched the Constellation from Western Star back in 1998 and had gone through three

days of C15, S60 & Signature ADR80-01 engines through to current ADR8003 which saw the introduction of the Detroit DD platform back in January 2011.

“By that point we had exhausted the architecture and packaging to reach the point where the Australasian market, and the global market was going for the next round of emissions. The next Detroit platform under the Daimler portfolio would include safety systems and we just didn’t have the architecture to run those systems and things like the multifunction steering wheel capabilities, and so forth. We could see where the fleet volume and demand was going, looking for improved emission platform whilst maintaining a very compelling TCO offer.

“The Western Star engineering team came out here to Australasia, and we created that product concept, made a roadmap, and a product definition. We needed to identify what segments we were playing well in, and not so well in. What do we

need from a driver’s fit, from a safety fit and from a fuel packaging fit point of view? Then there was bumperto-back-of-cab (BBC), because 2013/2014 had been the era of truck and dogs, when they went from 52 to 57.5 tonne GCM.

“I was lucky enough to be part of that conversation with key customers, when I was part of a dealership. It was asking, what’s the market after today, and what’s the market need for the future? What key milestones do we need to achieve? If you look at Western Star, we’ve always had a very strong truck, but a heavy truck. We’ve always been a very strong build. The frame rail has been key. We’ve had a steel cabin, we’ve had a big solid brass core cooling package and big stainless steel air cleaners and we’ve never lost a truck because the frame snapped.

“But when it comes to safety, innovation and efficiency, how do you make that lighter? How do you make it stronger? Can you make it last? It was really looking at the frame and working from the frame up on X-Series. It was about achieving the strongest frame rail that Daimler has ever put into one of its products.”

The engineering team worked to improve the cooling package performance in a few key ways. They optimised the radiator packaging and placement to handle the increased heat from lower emissions components. The radiator needed to remain being fitted relatively high for protection and also achieving the high cooling requirement needed.

The team in Australasia worked on extensive testing and simulations, alongside the Western Star team in Portland in the US, to ensure the cooling system could handle the demands of a 220 tonne GCM truck. When working on the cooling package for the 49X, the introduction of the ‘Power Hood’ ensured high airflow and required size of radiator was achieved. When it came to the 48X, the cab needed to be lifted to achieve the same cooling package of the 49X and house the DD16 under such a short BBC configuration. During development, testing of the

cooling package performance in extreme environments was vital, in conditions like the Australian outback to ensure durability.

Overall durability was paramount, with the team noting past issues with turbo failures and overheating that other brands had experienced.

Truck dimensions are also an important factor in suitable design with bumper to back-of-cab fit and space to improve airflow and heat dissipation for the engine and emissions components taken into consideration. It wasn’t just about lighter and stronger, it also had to meet wheelbase and packaging requirements. Square fuel tanks were also a necessity, so

the frame in the right locations to support the tank package and ground clearance.

Western Star has always had the bonnet mounted off the chassis rail ensuring stability in the bonnet and enhancing the durability in the bonnet. The bonnet on the X-Series was to be made of resin to take the weight out of it, but also make it stronger.

“In North America the Western Star is specifically designed and targeted for the vocational segment,” says Kurt. “The conditions of the average vocational market truck in the US is like, ‘welcome to Australia’, and that segment was absolutely achieving, they were mounting equipment off the

logging applications and those heavy mining applications over there. They’re really custom built over there, they don’t have 1000 truck fleet orders of that cookie cutter truck. X Series, predominantly in the US, in the vocational segment, built in Portland, Oregon, and that’s where ours are built.”

The CANbus now fitted in the Western Star brings the brand right up to date, in terms of electronic architecture. It offers a new level of sophistication, the system is programmable and will enable body builders to interface effectively with the truck. It also means the large bank of switches can be utilised for many of the independent body control functions without the need for the body builder to cut and shut anything in the wiring harness. The solution is a simple plug-in interface.

“We can program the functionality in this system, it’s dealer supported and we can even have the chassis rail to suit the body builder requirements in Australia,” says Kurt. “Going forward, it’s exciting what we can offer in that piece.”

Sophisticated electronics and design, alongside the right power and torque figures, fuel consumption and durability was also going to be

Australasia, it’s about getting the requirements in early and making sure that the teams which are designing the driveline for a global market are taking the Australasian requirements into account,” says Bob Gowans, Detroit Business Manager at Penske Australia.

“We feed those requirements in early, seven or eight years before we see the first real trucks. That means that our specifications are on the slate, alongside the Canadian, Mexican and North American requirements, and taken into account. On the engine side, it’s been known for a while that, at some point, the Australian emissions regs would get tightened up. Although we didn’t really know when, it was pretty much a shoo-in that it was not going to be something bespoke in Australia and it would follow the usual route for exhaust emissions legislation.

“On the engine side, the platform since 2007 has been designed to take into account exactly where we’re going emissions-wise in the long term and it was designed with that in mind. We made the block stiff enough to cope with high compression pressures and made the cooling system capable of removing the waste heat that you end up with in certain operating modes.”

“In the US there are three versions of DD13, there is a low revving fuel saving version, an extreme fuel efficiency engine and a fuel efficient

needed for, what in the US they’d call,

This means the X-Series here can get the range of ratings needed out of the 13 litre to be able to perform in trucks from rigids all the way up to B-double operation with a mechanically identical engine, with the same injectors, turbo and other components across the engine regardless of rating.

“In the US the DD16 is not seen as a normal line haul engine,” says Bob. “It’s used for what the US regards as extreme applications, heavy logging, heavy haul, moving large pieces of machinery around. That’s what it’s used for over there. Over here it’s an absolutely normal engine to use and it puts you right up there with the most fuel efficient engines on the market, that can cope with those weights.

“It’s only with the introduction of X-Series that it’s available in the Western Star and that engine is designed to give really good usable amounts of torque and power. The feedback we’ve had from customers that the DD15 is great on fuel and it’s reliable. However, when you move to the DD16, which is a very closely related engine, you’ve still got the fuel economy in a newer design. It’s still got the reliability we’re not over stressing the engine. We’ve got more power out by adding almost another litre of displacement to the engine.”

@ 1,800 RPM

1,850-2 ,050

lb-ft @ 975RPM

Extreme duty and heavy hauling for your biggest jobs

Detroit’s most powerful truck engine ever, the DD16 boasts up to 600 horsepower and 2,050 lb-ft of torque. The big bore workhorse provides efficient and dependable power and performance without compromise.

Advanced combustion and aftertreatment technology exceed future emissions requirements whilst retaining exceptional fuel efficiency and uptime.

This power, performance, and efficiency are backed by the most comprehensive warranty and extended coverage packages, ensuring the highest level of support for our customers.

When you buy a Detroit product, you’re buying billions of miles of engineering excellence. Tried and true, Detroit engines are built to ride the roughest roads.

With Detroit, there’s no compromise.

The ESOC875E electronic commercial vehicle oil change system, developed by ESOC in the USA, is transforming the commercial vehicle maintenance landscape in the technological sense.

This system not only reduces labour time and costs significantly but also moves towards greater efficiency and sustainability in commercial vehicle servicing.

Designed to complete oil changes within 10 to 15 minutes, the ESOC875E allows technicians to allocate their time more effectively, marking a pivotal advancement in workshop productivity and environmental stewardship.

Crucially, the system’s fully electronic and metered oil dispensing feature ensures precise control over the oil change process, further enhancing its efficiency and reducing waste.

One of the most appealing things of the ESOC875E’s appeal is its reduction in labour time and costs. Capable of completing oil changes for trucks and commercial vehicles in 10 to 15 minutes, it frees up technicians to perform other tasks, enhancing workshop productivity.

This efficiency is not only about speed but it represents a commitment to ESOC’s mission of developing ‘Green fluid exchange technologies.’

These technologies are designed not only for preventative maintenance of both heavy and light-duty engines but also to minimise truck downtime and ensure the procedures are as quick and easy for the technician as possible.

The universal attributes of the

ESOC875E system is one of its key strengths. With support for multiple truck brand fittings, it has compatibility with a wide range of trucks and commercial vehicles. This versatility ensures that workshops can use the system on a variety of vehicles.

From a technical standpoint, the ESOC875E can exchange approximately 38 litres of oil in 10 to 15 minutes. This is a significant advancement for commercial vehicle servicing workshops that are constantly seeking ways to achieve real cost savings and improvements in time-saving equipment.

The system’s innovative features, such as automatic oil sampling and patented spill-free quick-connect fittings, utilise the latest technology to speed up oil extraction and refilling processes, thereby increasing speed and productivity.

From purging waste oil and refilling with new oil in approximately 15 minutes, requiring 100psi compressed air, to its onboard fluid management system and USB for data transfer and saving, the system is designed for efficiency and ease of use. It also features an onboard computer that records vital information such as vehicle ID, mileage, amount of oil added, and technician ID, ensuring thorough and accurate maintenance records.

The operating instructions

highlight the user-friendly nature of the system. From draining the waste oil to filling the engine with new oil, the process is streamlined and straightforward, reflecting a design that prioritises ease of use without compromising on functionality.

The ESOC875E represents a significant forward leap in commercial vehicle maintenance technology reducing labour time and costs, offering wide compatibility, and incorporating advanced features that ensure speed, efficiency, and environmental responsibility.

It stands out as a perfect addition to any truck or commercial vehicle workshop, changing how maintenance is performed, and offering a more efficient, sustainable, and productive future.

· Protect equipment and boost productivity.

· Covers a diverse range of needs, from trucks to extractors.

· Clear communication and capacity management for efficient operations.

· Global standards with local expertise across Australia and New Zealand.

· Minimise wear and enhance efficiency.

Wood and log hauling is specialised work, and requires safety solutions that may not be otherwise seen in other areas of the trucking world, Alex Catalano investigates.

Nestled out in the middle of Victoria’s picturesque Gippsland region, ANC Forestry is a logging and transport business that operates across all of Victoria, up to New South Wales and even in Tasmania. Its headquarters are just a short five-minute drive out of the main drag of Morwell, and houses its comfy office space, a sizeable workshop where mechanics work away on the trucks and equipment

and a yard filled with resting vehicles and timber as far as the eye can see.

Run by managing director Daryl Hutton, ANC has been in action for 16 years, having grown from a fleet of just five trucks to now 35 along with 60 staff.

It first started in harvesting wood in steep country with cable logging on contracts before moving onto more hauling work, as opposed to harvesting.

“Native logging has been closed down in Victoria, so we’ve had to diversify into carting for other people and products,” Daryl explains.

“We’ve also diversified to rock trucks. We’ve got four rock trucks and trailers, and walking floors. We’re starting now on our next processes, on building other configurations that can cart different product as well.

“We try to innovate and keep

being proactive moving forward.”

Those big logging and hauling jobs call for powerful vehicles, which ANC is in no shortage of.

Walking through the workshop and the yard, it’s hard not to marvel at the sheer size and scale of the Kenworthheavy fleet – especially when they’re loaded as high as they are.

“I’ve only brought new Kenworths for the last 15 odd years,” Daryl says.

“We’ve acquired Volvos and other trucks by acquiring other fleets, but I haven’t bought them new. Kenworth is the truck of choice for logging. It’s tough and robust.

“They have become very expensive. The rates in forestry haven’t increased to keep up with that. Things have to change.”

As challenges in the forestry game continue to arise, ANC has had to continue to diversify its business.

The rock trucks are one part of it, giving the business options in the types of jobs it can take on.

“We’re in difficult times of transitioning out of native forestry into other haulage opportunities. We’re going to be fine, and we’ll make it, but we’ve got to truck smarter,” Daryl says.

“Transport is competitive, and so to keep up with prices, to where things need to be, you can’t just pass the costs on, you have to keeping moving on.

Daryl leans heavily on his prior experience in logging haulage in New Zealand, where he worked for 15 years before making the move over to Australia.

There are different issues which arise across the ditch compared to here, he says. Kiwi operators have to worry more about their road tax, which has to be paid upfront.

They’re also generally unable to be as efficient as logging businesses here, which are able to carry greater

five axle dog trailer still only carts 58 tonnes, whereas we’re at 67.5.

“Our axle loadings are greater, so the trucks are more than capable of carrying it. New Zealand’s log hauling fleet is 90 per cent truck and dog.

“Their terrain is pretty tough and their main roads are tough. Very windy and so many opportunities for a driver to get it wrong.”

Daryl has recently gone through the

Out here, standard is just the starting point. We believe in pushing the limits. For over 60 years, Mack Trucks have outpowered, outlasted and outperformed to earn their best-in-class reputation. With new upgrades to horsepower, fuel-efficiency, driver comfort and safety, Mack is setting the standard once again.

the workshop installing it, his own mechanics are now trained on how to do so, with one truck currently going through the process.

“In our twin steer with the five axle dog trailer, it’s a PBS vehicle which is fitted with PRIMAAX air suspension on the rear of the truck, and that was for payload height,” Daryl explains.

“We ran it initially without Base, but we’ve now put Base Air in it. I took it loaded to Mansfield one day, and as I was driving along the long straight I noticed the Base Air works so quickly that you’re not constantly turning the wheel to compensate for the camber changes in the road.

“In a log truck with a high payload, if the road leans slightly to the left, the truck’s going to lean over. It reacts so quickly you don’t need to move. You’re holding the wheel dead straight. That was when I became a true believer that Base Air makes a difference.

“The fact is, that it’s taken the wag out of the dog of a five axle dog trailer, which is quite long, it just sits rigidly behind you now.”

Michael van Tilburg is one of ANC’s drivers, doing around eight to 10 trips

up and back to the local quarry at Hazelwood, carting rocks in his Volvo FMX, configured as a truck and dog.

We had the chance to jump in the truck with ‘Mick’ as he completed one of those trips, and the stability of the trailers was immediately noticeable.

“Even when I’m throwing the truck around the roundabouts, the trailer just sits there,” he says.

“I’ve been in the Volvo officially since the second week of January. The Base Air in it is working all the time but you can’t hear it. It’s pumping air here and there. You don’t see it on the air gauge either when it’s controlling air.”

Warwick Blines has been driving for ANC for seven years, almost always in one of the Kenworths carting logs.

On this day he was fully loaded with a massive stack of pine, locally near Strathford. He’ll run to the mill and back, and head out as far as Melbourne on occasion.

His truck has now been fitted with the Base Air suspension system, which he sees as a big upgrade.

“Every time I saw Daryl after he put the Base Air on I told him how good it

was,” Warwick says.

“Fair dinkum, it felt like a different truck. Just unbelievable. First of all it stays flat. The truck doesn’t move. My sticker says ‘straighten out the road’, it does.

“You don’t get that awful feeling going around corners. Some roads are off camber, and I’m very low tolerance to that. I won’t speed. But if the cab tips over, you get that feeling. It settled the trailer down. I try loaded on a flat road, just turning the steering wheel the dog would swing out on the other side of the road then swing back then come straight.

“When they put Base Air on, the trailer swings out and when you turn back it just stops behind the truck. When it’s empty, it feels like a race car because it stays flat.”

Daryl stresses that ANC prides itself on the safety that it offers its drivers on the job.

In 2015, the business was recognised with a WorkSafe Victoria Award for Safer Logging Systems after developing a restraint system solution alongside a group of other foresting

and trucking companies.

When carting such specialised material as logs, these innovative systems have to be in place to keep everyone safe in the workplace.

“Our local area is unique for slippery logs at certain times of the year. We had an issue with log movement in transit,” Daryl says.

“So we got together to fix the problem by changing the restraint systems by using double purchase systems and the air winches which were available at the time.

“It’s doubled our restraint and it’s mitigated the logs falling off. We haven’t had loads shifting, in however many hundreds of

thousands of loads since.

“We made chain hangers that are spring loaded onto the side so we can hang the chains and the loaders can chuck them over for the driver. The driver doesn’t have to be worried about shoulder injuries.

“The flipside of that means we’ve got guys in their 70s still working for us. There’s no manual handling.

“We had one guy retire on 77, and he had carted logs for 60 years. It was the only product he carted for his whole life.”

Similarly, Daryl believes the Base Air systems offer his drivers considerable safety benefits first and foremost.

“As a fleet owner, it’s another tool that I can provide to get the drivers home safer,” he says.

“We do everything, log trucks are fitted with every safety device you can think of, but the industry still has the odd rollovers. That has been mitigated by EBS on trailers, but there are still times when people get it completely wrong.

“You want to give them the best fighting chance that’s available. For me I find that Base Air ticks one of those boxes.”

It’s a perennial question on many and varied topics, but the question, does size matter? is also relevant in the truck world. There’s cab size and engine size and many other things to consider, but for Tim Giles, or any driver, cab and engine size do make a difference.

20 years is a long time in the world of trucks and trucking.

It is also the time between my very first drive of a MercedesBenz Actros with a MegaSpace cab and my most recent experience with the latest version of the Mercedes-Benz Actros GigaSpace truck.

It’s rather easy to say that the difference between the two is pretty much chalk and cheese. Probably the most important difference between that truck 20 years ago and the one which PowerTorque magazine is testing now, is the fact that this truck is definitely fit for purpose, whereas there were a lot of question marks about the truck which was tested in 2003.

It’s not a good idea to dwell on many details of that MegaSpace, which was brought to Australia for

the 2003 Brisbane Truck Show, apart from mentioning that it was very tall. It had quite a big powerful engine and it had been designed for the major motorways of Europe. As a result, running it around the rough, badly maintained highways of Queensland was a bit of a queasy experience with such a tall cab swinging from side to side as well as forwards and backwards.

The engine was of course the Mercedes-Benz V8 engine which was a great performer, but it drove through a so-called semi automatic transmission which left a lot to be desired and certainly did not come into its own on the climb up Cunninghams Gap towards Warwick.

Thinking back on that test drive, it was a completely different experience

in contrast with spending some time with the GigaSpace truck which was brought over to the 2023 Brisbane Show. The contrast couldn’t have been greater, with this latest truck being a fit-for-purpose design which could suit many tasks in the Australian transport industry, and do a good job

One of the first things anyone would notice walking up to this truck is the sheer height of it. This is a tall truck, which may have a long climb up into the cabin, but it has that feeling of spaciousness once inside the flat floored cabin.

The other size we were looking at is all about that other major component to truck driver satisfaction, engine power. In this case we are dealing with the latest 16L produced by Daimler for Mercedes, the OM 473 six cylinder

in line diesel engine, which has been developed from the global engine of platform developed by the Daimler organisation in the 2000s to go into all of its heavy duty vehicles, across three continents.

Here we are dealing with an engine which provides the driver with 630 hp under the right foot and 3000 Nm (2213 M) of torque to get the job done. This is a well proven engine, which has seen the Mercedes Benz market share rise due, mainly, to its fuel consumption figures and economic performance.

The difference between that first experience 20 years ago and this second experience is another major component which has transformed the truck offering from the whole Daimler

organisation, globally, and that is the Power Shift AMT. In this particular case it’s the 12 speed power shift running through a 1:3.583 rear axle ratio which gives us 1436rpm at 100 km/h out on the highway.

Where the transmission in that 2003 truck was plodding and not very reactive, this latest iteration of the AMT in the Mercedes-Benz is smooth, reactive, easy to use and reliable. The development of AMTs, as a whole, in the intervening 20 years between these two test drives has seen transmissions become much less of an issue. Where, in the past, we would need to discuss them thoroughly during these test drives, now, the population of new truck AMTs has reached a standard where, quite often, the driver doesn’t have to think about the transmission

because they can trust it to do the job without their interference, most of the time.

Cab suspension has come a long way in the intervening 20 years since that first experience. They are much more sophisticated and much more able to handle different road conditions in different situations. It’s no longer a one-size-fits all design aimed to avoid making the German truck driver on the autobahn spill their coffee, but make the driver on the Warrego Highway slightly seasick. Daimler now thinks of itself as a global truck manufacturer and designs components like cab suspensions to suit the many and varied applications into which its trucks are placed.

These sort of cabins are now accessible for operators in Australia. That’s not to say they all function well in all tasks, because the sheer physics and mathematics around such a tall cabin with such a small footprint is hard to overcome. The dynamics are always going to make cab sway more prevalent than on a conventional, truck with a lower cab fitted behind and below the engine.

On this particular drive we took the GigaSpace 630 across from Melbourne and down into Adelaide. The road between the two capitals is not bad, but it’s not that good either and the truck coped easily with the lump and bumps with which it was presented.

For Australian truck drivers a flat floor is not a big deal, but space is always a big deal. The cabin is fantastically tall, but it’s not fantastically deep, therefore you don’t get that one metre wide bunk.

Another revelation on this drive was the MirrorCam, which Daimler introduced a few years ago. It has had a mixed reception, but we are told that the latest version is a step up from its predecessor. To the casual observer, the actual screens, mounted on the A pillars and the outside mounted cameras look the same as they did before.