Rehoming operational pump equipment

Desal upgrade delivers historic first flow for rural town

ZOOS VICTORIA gets water recycling seal of approval

Rehoming operational pump equipment

Desal upgrade delivers historic first flow for rural town

First and foremost – welcome to 2024. I hope you all have had a great start to the year.

The weather lately has been fantastic and I think it’s safe to say we have all been revelling in the warmth despite autumn kicking off. Although still close to the beginning of 2024, the industry has hit the ground running and has been busy with a number of events and conferences.

Pump Industry Australia Incorporated C/-340, Stuarts Point Road Yarrahapinni NSW 2441 Australia Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com www.pumps.org.au

PIA Executive Council 2023

James Blannin – President De.mem – Stevco

Joel Neideck – Vice President TDA Pumps

Kevin Wilson – Treasury/Secretary (outgoing) Executive Officer

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Steve Bosnar – Councillor Franklin Electric/Pioneer Pumps

Jamie Oliver – Councillor Grundfos Pumps

Mat Arnett – Councillor Ebara Pumps

Michael Wooley – Councillor Tsurumi Pumps

Luke Biermann – Councillor Mechanical Seal Engineering Pty Ltd

Tim Yakup – Councillor Regent Pumps

Alex Caladoukas – Councillor Pump Strategy

Keith Bowen – Councillor Xtron Pumps Australia

The Pump Industry Association (PIA) had a small presence at the recent Water Industry Operations Conference and Exhibition, held in Bendigo from 28-29 February. This year’s show, the 85th WIOA event in Bendigo, boasted a record number of visitors, and attendees were able to view some fantastic pump displays. Visitors were also given the opportunity to test equipment and other peripheral equipment and services.

Also in Victoria, the Australasia’s Processing and Packaging Expo (APPEX) event was held at the Melbourne Convention and Exhibition Centre from 12-15 March, with more than 400 exhibitors representing various sectors, including machinery, ancillary equipment, materials and packaging, food processing and industry services. This show had a wide range of equipment and services from overseas and locally, everything from plastic containers, food vacuum systems and, of course, pumping equipment, mainly the hygienic variety.

In news closer to home, the PIA’s search for a replacement for Kevin Wilson – our long time secretary/ treasurer – is ongoing. The role is a paid position, and we would love to hear if you or anyone you know is interested in being involved with helping the PIA grow.

As usual the PIA will look to run some breakfast networking events in various states and if you would like to host or know of a good company that can cater to 30-plus people, please let us know.

Also, we would love to hear from members and non-members alike on what the PIA can provide to its membership base to offer more value. We are currently looking at creating a forum for pump/application questions and are investigating the best platform to try and launch this on.

On the project side of things, the New South Wales Government and Kempsey Shire Council are contributing a combined $7.814 million to a jointly funded wastewater and treatment plant in Kempsey, with the proposed new facility expected to meet the needs of the region’s future population.

I and the team at the PIA hope you have had a great start to the year and that 2024 is a great year for the pump industry as a whole.

Scan to subscribe to Pump Industry Magazine’s weekly newsletter – delivered to your inbox every Thursday afternoon.

Cover image: New Zealand Fur-seal. Image credit: Zoos Victoria

ABN: 36 426 734 954

C/- The Commons, 36–38 Gipps St, Collingwood VIC 3066 P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Editor: Rebecca Todesco

Assistant Editor: Sarah MacNamara

Journalist: Kody Cook

National Media Executives: Rima Munafo, Brett Thompson, Ryan Sheehan

Design Manager: Alejandro Molano

Designers: Danielle Harris, Jacqueline Buckmaster

Marketing Manager: Radhika Sud

Marketing Associates: Rhys Dawes, Bella Predika, Georgia Rogers

Digital Marketing Assistant: Emily Gray

Publisher: Chris Bland

Managing Editor: Laura Harvey

ISSN: 2201-0270

This document has been produced to international environmental management standard

This magazine is published by Monkey Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion.

by a certified

printing company.

SA Water made changes to the design for its proposed desalination plant at Billy Lights Point in response to feedback and scientific analysis.

The utility said it reworked the design to reflect its commitment to minimising impacts to the coastal and marine environment following early engagement and analysis.

The proposal involves building a small-scale plant designed to provide long-term water security for the people of the Eyre Peninsula and ensure the ongoing health of the Uley South Basin, which provides the majority of the region’s drinking water.

The design changes include using a trenchless construction method for the installation of the plant’s intake and outfall pipes (where seawater will be drawn in and concentrated seawater will be dispersed), and the placement of these pipes in a deeper area off the coast of Billy Lights Point within a higher flushing zone.

SA Water Senior Manager of Capital Delivery, Peter Seltsikas, said the work forms part of a comprehensive process with early contract involvement partner ACCIONA.

“We have listened to and responded to feedback from the Project Reference Group and other key community groups, our regulators and various other government agencies, which highlighted the importance of minimising disturbance to the Billy Lights Point coastline and avoiding the shallow waters of Proper Bay,” Mr Seltsikas said.

“We will need to conduct additional geotechnical studies to refine the scope of the trenchless construction method, and from early next month, we will use a barge and small drill rig off the coast of our existing nearby wastewater treatment plant to collect soil and rock samples from the ocean floor.

“This will enable a better understanding of the site’s geology to determine the exact type of construction method, which could include directional drilling or tunnelling.”

The geotechnical work is expected to take several weeks to complete. SA Water said the results will help inform a detailed concept design, which will be incorporated into its development application for the project, to be lodged with the State Commission Assessment Panel in early 2024.

“The Uley South Basin is the primary source of drinking water for Port Lincoln and the lower Eyre Peninsula, but the Basin is under stress so a desalination plant is essential to augment supply,” Mr Seltsikas said.

“A combination of long-term lower groundwater recharging of the Basin and ongoing extraction rates to meet community demand means the aquifer’s water levels are likely to reach historically low levels by the mid-2020s.

“We need to build the desalination plant at Billy Lights Point to protect the health of the Basin and provide an alternative climate-independent water source to deliver drinking water to the local community.”

SA Water said it will also be undertaking further hydrodynamic modelling within the preferred marine zone and a re-run of the particle tracking model to support the geotechnical studies, which will add to existing knowledge of mussel spat movement and narrow down the exact alignment and location of the intake and outfall pipes.

“We are planning to place the pipes in a zone to the east of Billy Lights Point, up to 1.5km offshore and more than 2.5km from existing mussel leases,” Mr Seltsikas said.

“This location is near a commercial shipping corridor which extends from the marina to Cape Donnington, and is within water around ten to 15m deep.

“The outfall for our Port Lincoln Wastewater Treatment Plant sits outside of this zone further to the south, and our extensive monitoring to date has demonstrated no negative impact to the local marine environment from this marine infrastructure.”

Not your average pump drive

• The benchmark in Elastomeric Couplings for Pumps

• Engineered materials and patented designs to increase longevity and reduce reactive load on equipment

• Flexible enough to accommodate moderate misalignment and vibration

• Split elements for ease of in-situ replacement

• Stocked in Australia for quick and stress free access

• Coupling and Shaft Guarding

• Configurable to fit most applications

• Powdercoated steel and Polyethylene variants

• Multiple sizes and styles

• Off the shelf availability

The failure of two cooling pumps was identified as the likely cause of an incident that took place in Corio.

Fire Rescue Victoria (FRV) was called to an incident at Viva Refinery on Refinery Road, Corio in January. Firefighters arrived within six minutes to find a larger than normal burn off flare, issuing more smoke and flames than usual.

The issue is believed to have been caused by the failure of two cooling pumps after seaweed became blocked in the system.

Another pump remained in operation and work to rectify the fault was successful.

A Community Advice Notice was issued for smoke in the area at the time.

Flowrox™ pumps for transferring, dosing and metering

The world’s toughest pumps are all about ensuring your productivity and profitability even in the most demanding applications and conditions.

Flowrox industrial pumps serve a wide range of industries, performing especially well in processes involving abrasive, corrosive, highly viscous or crystallizing media with high solid content, up to 80%.

We provide solid performance around the world for the most heavy-duty pumping applications.

The New South Wales Government and the Kempsey Shire Council are contributing a combined $7.814 million to a jointly funded wastewater and treatment plant in Kempsey.

The next phase of work will deliver designs for an upgraded and centralised sewage treatment plant to replace the three existing plants at West Kempsey, South Kempsey and Frederickton which are no longer fit for purpose.

$1,953,500 from the New South Wales Government’s Safe and Secure Water Program has now been confirmed to bring the project one step closer to being tender ready, with the remaining $5,860,500 coming from Kempsey Shire Council.

The proposed new Central Kempsey Wastewater Treatment Plant is expected to be able to meet the needs of the region’s future population and keep up with stringent national effluent quality requirements.

The New South Wales Government said the new plant will offer a modern and sustainable approach to wastewater management in Kempsey and will improve environmental impacts on the Macleay River and surrounding communities.

The New South Wales Government is also funding more than $3 million worth of projects across other parts of the North Coast in the hopes that it will help boost drought resilience and future-proof critical water and sewerage services, including:

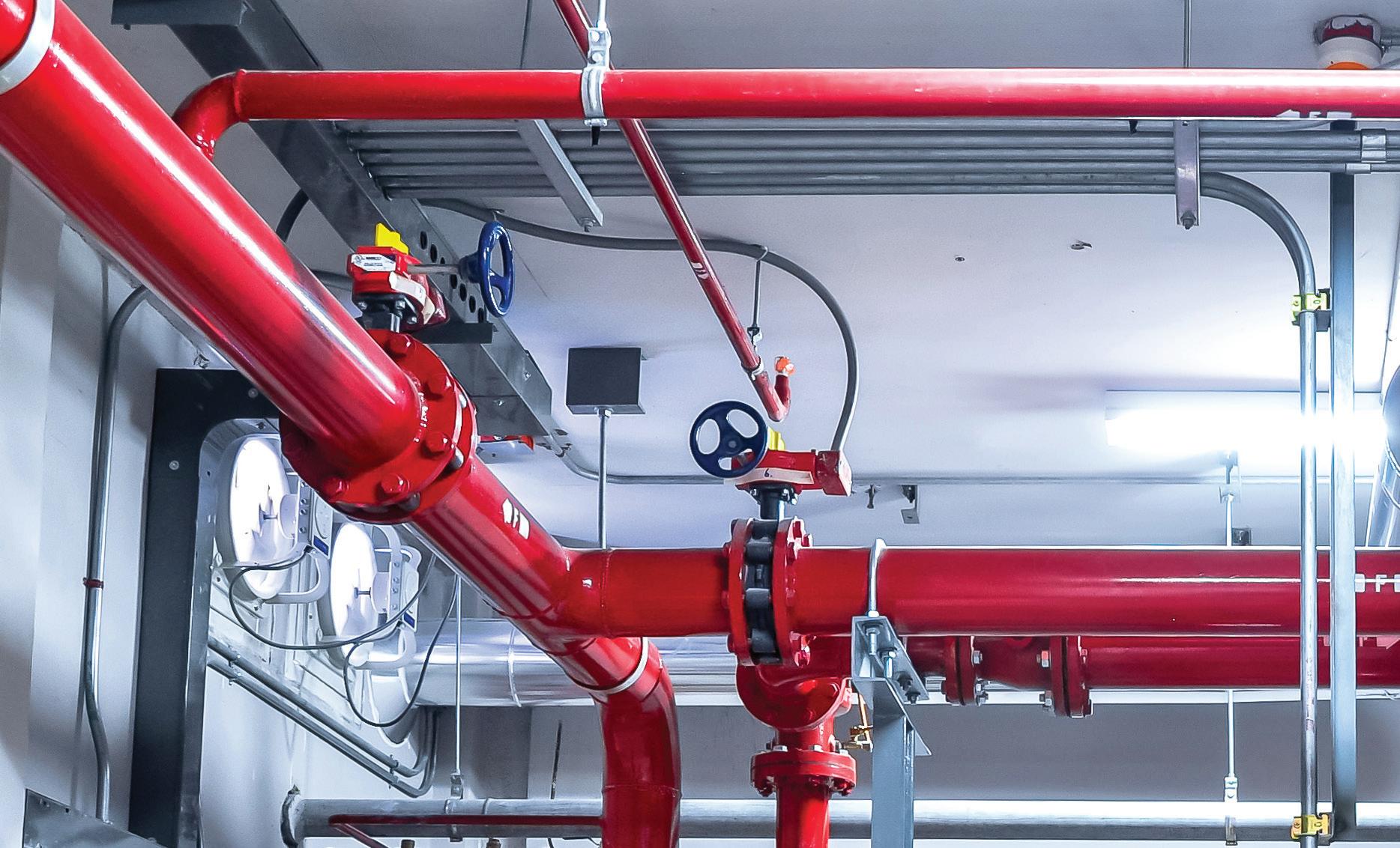

Pumping systems and equipment at wastewater treatment plant. Image credit: New South Wales Government.

• $2.31 million towards the newly completed $2.62 million Nambucca Drought Response project which has delivered an upgrade to Nambucca Shire Council’s treatment plant with a high-tech disinfection system to secure the region’s safe water supply

• $392,000 towards the completed $811,000 concept designs and pre-tender works for the Evans Head Sewage Treatment Plant Augmentation as part of Richmond Valley Shire Council’s long-term plans to double the plant’s capacity to cater for population growth

• $230,000 to drill two new bores in Bonalbo with one already commissioned to supplement the town’s existing water supply during drought. The funding also installed two new bores in Tabulam, ready to be commissioned if and when they’re needed

• $115,000 to deliver detailed designs of the proposed Dorrigo Water Treatment Plant upgrade, with the other funding half coming from Bellingen Shire Council

• $62,500 to bring the replacement Grafton North Sewage Treatment Plant to tender-ready phase, with Clarence Valley Council funding the remaining $187,500

New South Wales Minister for Water and New South Wales Minister for the North Coast, Rose Jackson, said Kempsey is a growing community that continues to attract thousands of visitors every year, which is why the New South Wales Government is working to ensure the town is better equipped with 21st century infrastructure to unlock economic opportunities moving forward.

“The proposed new Central Kempsey Wastewater Treatment Plant will produce much higher quality effluent that will be maintained to the top industry standard, which is crucial in an environmentally sensitive region like the MidNorth Coast.”

Kempsey Shire Council Mayor, Leo Hauville, said, “The three existing wastewater treatment plants have serviced the Kempsey area for many years. Over the coming years they will be replaced with modern and more efficient equipment.

“Slimming down from three plants to one will provide better service to the community. It’s great news that our incredibly dedicated Water and Sewer staff will have the necessary modern facilities with sewage management for the Kempsey area at the one location.

“Planning work is already underway to ensure we are ticking all the right boxes and getting the details right from the outset. We’ll continue to keep locals informed every step of the way.”

The Western Australian Government has announced that a pivot irrigation development will be supported by a 420-hectare land transfer to the Yawuru people.

The land will be used for fodder production for the Roebuck Export Depot and Kimberley fodder market.

It will be transferred to Nyamba Buru Yawuru Limited (NBY) in conditional freehold. The pivot irrigation development will create local jobs and supply fodder to support the Kimberley pastoral industry.

The land transfer is subject to the successful negotiation of an Indigenous Land Use Agreement and will support the diversification of NBY’s agriculture operations to generate new and sustainable income for the Yawuru community.

The conditional freehold tenure will give Yawuru long-term secure ownership, along with their Native Title rights, over the land area in a boost to attract more investment into NYB’s business proposals while also improving the economic viability of ongoing livestock production activities.

Western Australian Lands Minister, John Carey, said, “I want to acknowledge NBY for developing new business ventures that benefit their communities, sustain their cultural heritage and provide more opportunities and better outcomes for traditional landowners.

“The Cook Government is committed to working with Traditional Owners to ‘close the gap’ by supporting social,

cultural and economic opportunities for communities and Aboriginal businesses.”

Kimberley MLA, Divina D’Anna, said, “This is a great outcome for the Yawuru community and demonstrates the Cook Government’s commitment to supporting new opportunities for Aboriginal communities in the Kimberley.”

Ms D’Anna said that subject to the successful negotiation of an Indigenous Land Use Agreement, the land transfer will provide NBY new commercial and business opportunities to benefit their local community.

The Northern Water Supply Project (NWSP) in South Australia has advanced to its next phase of study, with BHP joining the State Government and other industry players on the project.

The desalination pipeline proposal is being developed in partnership between government and industry to be a multiuser facility, available to many sectors and businesses in the state’s Upper Spencer Gulf and Far North regions.

The studies will examine the construction of a 260mL per day desalination plant on Eyre Peninsula and a 600km pipeline to transport desalinated water to the Far North.

BHP’s Asset President Copper South Australia, Anna Wiley, said, “The Northern Water Supply Project is strategic infrastructure with the potential to benefit multiple sectors and businesses.

“We are pleased to partner with government and others in industry to progress further studies as we work towards a commercially sound, multi-user water project.”

Ms Wiley said that global demand for copper is growing fast, and the opportunity for South Australia is significant.

“BHP has created an integrated copper province that we hope will bring the scale required to economically and sustainably produce and process more copper here in South Australia and deliver it to global customers.

“The Northern Water Supply Project will support our South Australian copper operations and growth ambitions.”

• Robust peristaltic pumps for handling abrasive slurries

• High precision pumps for chemical dosing applications

• Simple, reliable and safe maintenance for low operating cost

vogelsang.info/au/hicone

vogelsang.info

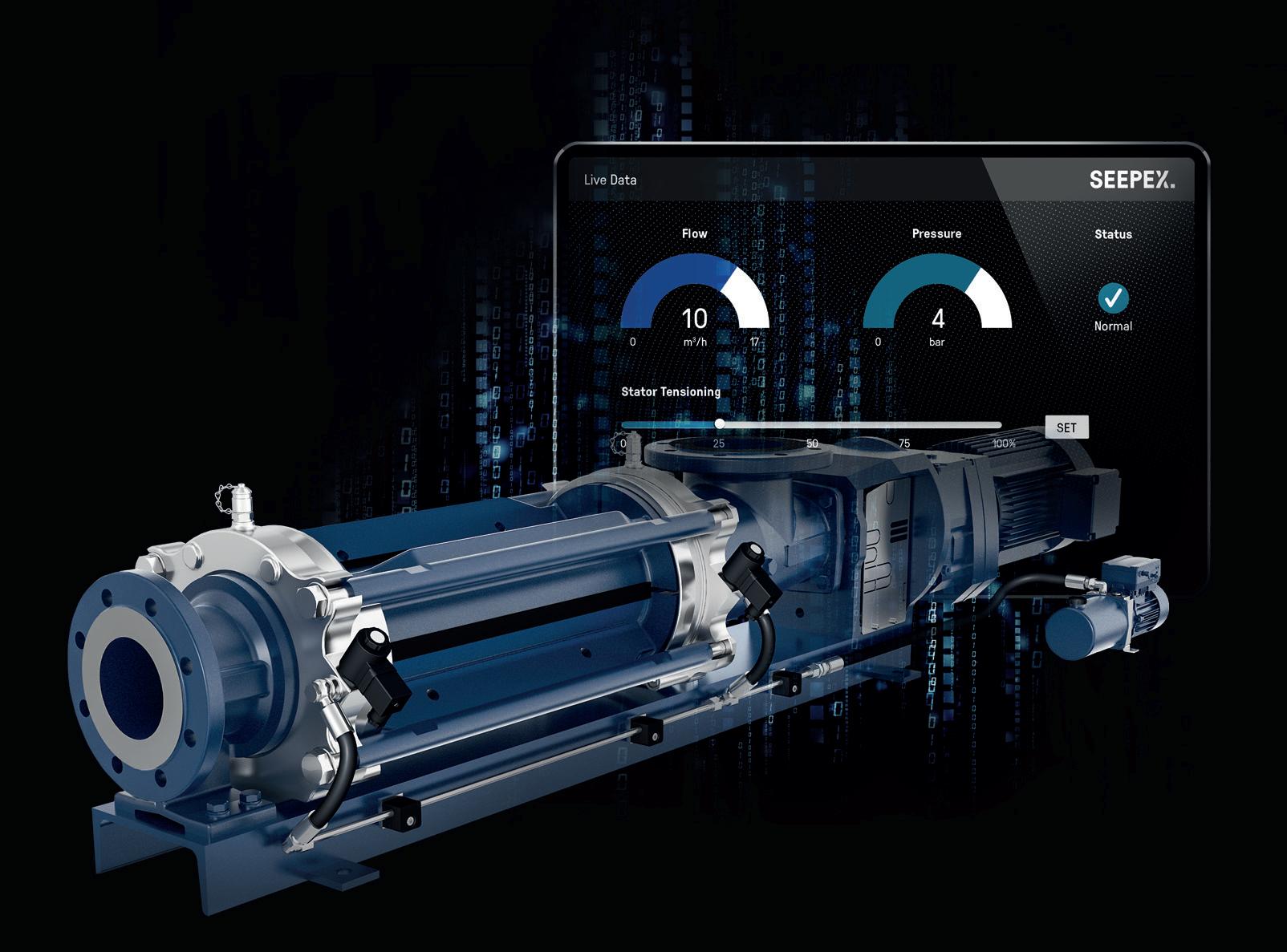

Multiplied service life and significantly reduced life cycle costs: With its conical rotor and stator geometry, an innovative adjustment system, and its intelligent automatic start-up, the new HiCone ® stands for maximum efficiency. Start for a new era with Vogelsang and be one of the first to benefit from the advantages of the superior HiCone ®

Pump facilities and water tank infrastructure across South Australia have received a makeover, as seven vibrant new murals were added to SA Water infrastructure assets in 2023.

From Minlacowie on Yorke Peninsula to Loxton in the Riverland and Lochiel Park in Adelaide’s north-east, these murals are welcome additions to the utility’s growing gallery of public art.

SA Water’s Manager of Brand and Community Marketing, Kellie McDonald, said that SA Water has collaborated with many artists, community groups and councils to bring these artworks to life over the past year, who all bring colour, culture and creativity to the masterpieces.

“Each of these projects was made possible through the hard work and fantastic support of various councils and community groups,” Ms McDonald said.

“These collaborative efforts have transformed blank walls into eye-catching canvases, showcasing a local connection to water including with Traditional Owners, and the rich tapestry of South Australian culture such as elements of local history, nature and community spirit.

“From a vibrant night scene to Aboriginal art celebrating the region’s cultural heritage, each mural tells a unique story that resonates with the local community.”

The murals painted on SA Water infrastructure in 2023 include:

• Loxton water pump building – showcasing birds native to the area, including the Regent Parrot, Mallee Ringneck and Willy Wagtail, this mural celebrates the picturesque Riverland landscape and the local feathered friends, captured by a local Loxton artist

• Swan Reach pump house – residing on the bank of the River Murray, this pump house has transformed into a starry mural of Australia’s only dark sky reserve. The sparkling night sky over the river glistens in the background, while the region’s iconic birds, including the Australian Pelican, Blue Wren, Mallee Ringneck and laughing Kookaburra take centre stage in the foreground

• Wool Bay water tank and neighbouring shed – this mural depicts the Narungga connection to the land and waters, power of the landscape over time, highlighting agricultural scenes, the natural elements and iconic local historical sites

• Lochiel Park water tank – a family of Black Ducks, a Purple Swamphen and an endangered Southern Purple Spotted Gudgeon have now taken up residence on this water tank, thanks to a working party of five local artists. The design embraces the local wetland environment, with a few subtle acknowledgements to the local groups and wildlife that frequent Lochiel Park

• Minlacowie water tank – recognising the region’s Traditional Owners, the Narungga people of Yorke Peninsula, this 6m-high tank is now a kaleidoscope of colour, displaying the four Narungga totems, the shark, eagle, kangaroo and emu. This mural recognises the value of the Narungga people’s knowledge, experience and contribution to the region

• Oodnadatta water fountain shelter – next to the iconic Pink Roadhouse stands an SA Water drinking fountain, providing free access to high quality water from Oodnadatta’s new desalination plant. A mural on the shelter surrounding the fountain was designed by a local year eight student, and all school students picked up a paintbrush to help bring the design to life. This mural tells the story of the flow and activity of water amidst the scorching outback landscape, and its importance to the Oodnadatta community

• River Torrens outlet wall – where the river meets the sea stands a striking mural with fairy floss coloured skies, playful pups on the beach, and an important message promoting the protection of the Hooded Plover’s nesting sites in the surrounding sand dunes. The mural was designed by an Adelaide Hills artist, who welcomed the local community to let their own creativity flow, to help transform this cement canvas into a treasured community masterpiece

“These SA Water assets continue to play an important role in delivering safe, clean drinking water to homes and businesses around South Australia, and now also provide a visual connection to their communities,” Ms McDonald said.

A well-known seals and pumps supplier has joined forces with another industry leader and is operating under a new name to provide high-quality products and exceptional service.

If you really want to have a good day and you’ve got a tricky issue dealing with pumps or rotating equipment, give AESSEAL NSW a call.

Having been a trusted supplier to the New South Wales market for decades and trading as Stevco Seals and Pumps and Australian Engineering Sales & Service (AESS), end users may already know and value the quality of design, manufacturing, service repair and leading-edge mechanical seal technology the company provides.

Now, it’s even better.

Since March 2022, the company has joined forces with AESSEAL, the world’s largest homogeneous designer and manufacturer of mechanical seals and a group that is setting its sights on being the best reliability company in the world.

The resulting company – AESSEAL NSW – is not just bigger; it’s better.

This alliance makes the entire product and service portfolio of both AESSEAL and AES Sealing products available to serve the Australian sealing market to the highest global standards. What does this mean for customers?

AESSEAL is a company centred on reliability, service and environmental responsibility, with numerous awards and a reputation second to none in an industry sector that is sometimes accused of taking customers for granted.

In case you missed the name change and aren’t sure where to get the exceptional quality of service, below you’ve got AESSEAL’s number.

Give AESSEAL a call on (02) 4629 6500 and let it show you what service at the next level looks like, or visit www.aesseal.com

For those working in the pump industry, John Inkster has been a familiar face and has been involved in the industry for 38 years, including a stint as the President of the Pump Industry Association. Pump Industry Magazine caught up with Mr Inkster ahead of his retirement to reflect on some of the highlights and changes he has experienced throughout his career, and find out what’s next for him post- retirement.

Following the announcement of his retirement at the end of April, the last few months have been a whirlwind of activity for Mr Inkster. As is important when things come to an end, Mr Inkster took some time out of his busy schedule to reflect on his 38-year career in the industry

The path to pumps

When asked to think back to the steps he took in his career, Mr Inkster said there was a very clear path that led him to the pump industry.

Prior to joining Brown Brothers Engineers in February 1986, Mr Inkster worked for a firm of engineering consultants in New Zealand called Royds Sutherland and McLeay – now known globally as Stantec.

“When I was working for that firm of engineering consultants, I was doing design and project management of rural water supply schemes in New Zealand, both on the north and south islands. In the later years there, I was more involved in pre-feasibility and feasibility studies for irrigation that were afforded by large hydro schemes.”

It was during this time that Mr Inkster spent two years in Western Samoa as part of New Zealand's Bilateral Aid Program with the Government of Samoa, where he was involved in building small, village-based water supply schemes primarily throughout the island of Upolu and Savaii.

It was through this engineering background and working with consultants and consultancy that Mr Inkster had an early introduction to pumps.

“I wanted to get away from project management and into a management role. An opportunity came up in Christchurch, New Zealand, for General Manager – Pumps Division at Brown Brothers Engineers. I applied for the role and was successful in getting it and, 38 years later, here we are.”

With his background in engineering consultancy and prior work with local authorities, Mr Inkster said it was a natural progression for him to go and work for Brown Brothers since he had a bit of a head start when entering the industry.

“I was often dealing with the same people; I was still liaising with the local county clerks and county engineers, so it was a bit of a logical, natural progression.

“I grew to enjoy the industry and the rest is history. That's the connection – that’s where it all came from.”

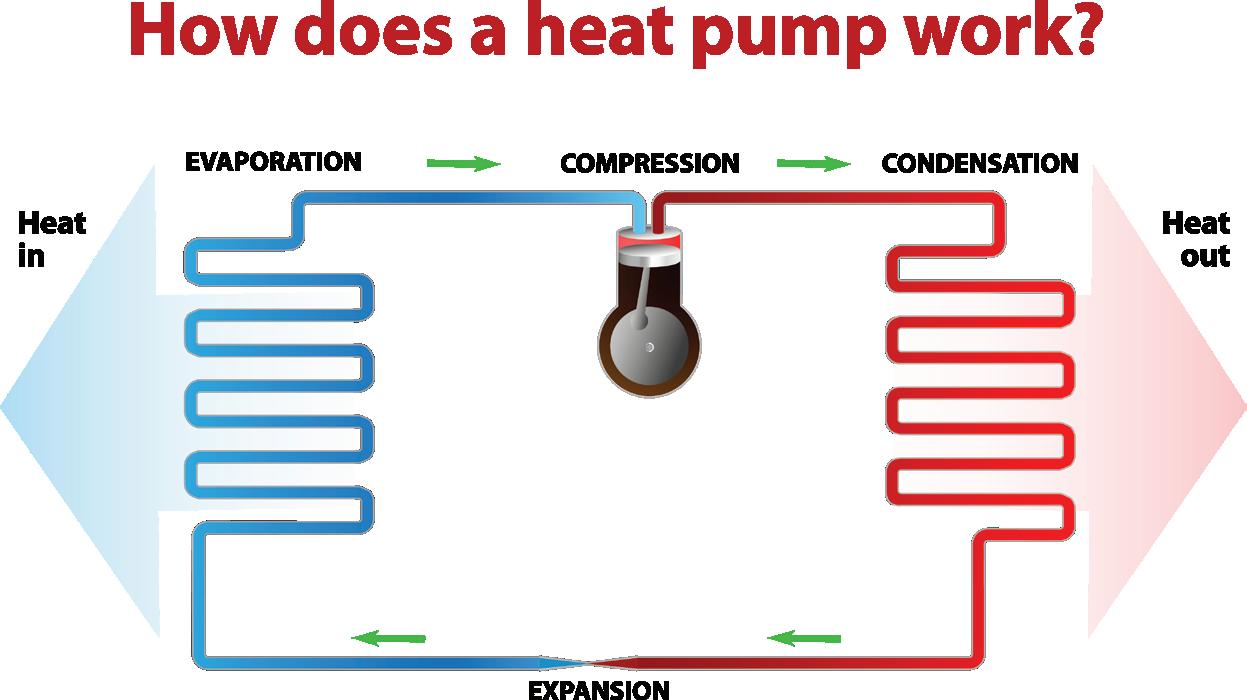

As with many industries, the pump industry has undergone significant changes in recent decades and Mr Inkster pinpoints the introduction of variable speed drives (VSDs) in the 90s as one critical turning point for the industry, as well as the evolution that the increase in smart pump technology has triggered.

“These pumps nowadays are very smart – they've all got engineering degrees or they're very IT-literate. Pumps and pump controllers themselves are very intelligent, offering significant efficiency improvements with energy costs and so forth, and that applies to motors as well. We're all very energy conscious and that reflects in our industry.”

Mr Inkster said that when he first entered the sector 38 years ago, he could never have predicted where the industry would be today, almost four decades later.

“It's not just our industry – technology has taken off everywhere. With smart pump technology and the intelligence of pumps, they can talk to each other.

“I'll often say when we go to hotels now, there's no reason why the pressure in the shower or the flow in the shower should be poor. That's a bygone era that should no longer apply. The technology is there now to make sure that it doesn't matter whether we're on the third floor or the 80th floor, we should enjoy good pressure and flow at all times because of the technology we've got now.”

Having witnessed so much innovation and transformation across the industry throughout his career, it’s hard for Mr Inkster to single out the biggest change.

“In life, nothing stays the same and the same applies to business. It's constantly evolving, and probably what I'm seeing more of nowadays is a consolidation of companies and industry.

“We're seeing a lot more activity in the mergers and acquisitions sector now. We've been part of that ourselves, with acquisitions and being acquired ourselves.”

As with most industries, significant change is not without its challenges, a factor that Mr Inkster himself has observed, highlighting that enticing young people to the industry continues to be the biggest obstacle.

“It's not a sexy industry; it's just the pumps are there and they're inside a shed or they're under the ground – you don't see them – so getting young people to come into the industry and then retaining those people is a challenge.

“Everybody's having problems in employing people at the present time; there seems to be a shortage of skilled people in every sector. In the industry, there's a lot of older people now nearing retirement like myself, and I just don't see that there's younger people coming in to replace them.”

Mr Inkster also flagged that training is a big challenge for the industry, with significant changes in the way companies are training nowadays compared to when he first entered the industry.

“Many years ago, probably decades ago, a lot of the companies would do a lot of training for several weeks, but that doesn't really happen now. Some of the larger pump companies in Australia probably do their own internal pump training, but you have to be a large organisation to do that, with the capacity and resources to do it. A lot of businesses don't have those resources.

“Attracting people to the industry, retaining them and having training protocols in place for them are the biggest challenges facing the industry.”

Reflecting on his time in the industry, Mr Inkster said that although he doesn’t have a favourite project he’s worked on, he’s always enjoyed the acquisition aspect of the industry

“I mark highlights by virtue of stepping stones that the company's made as opposed to winning this project or that project.”

In keeping with this theme, one of the clear highlights for Mr Inkster was the decision to move across the pond and “dip a toe in the water in Australia” with Brown Brothers Engineers.

Mr Inkster said they were invited to make the move by Goulds Pumps Inc who owned Lowara at that time.

“They asked us if we would like to do something in New South Wales and being a young guy, I said, ‘Yep, let's do it.’"

Mr Inkster said that establishing a branch and establishing Brown Brothers Engineers Australia in Sydney in late 1994 was a key highlight for his career. The establishment of a Melbourne office followed in 1996 once again, at the request for a Goulds Pumps Inc; at the same time Brown Brothers Engineers picked up Tasmania – giving them access to most of the eastern seaboard.

In May 2004, the company acquired an industrial company called Kelair Pumps Australia, and then in 2007, it acquired Lowara Pumps Queensland (LPQ), making Brown Brothers Engineers the distributor for Lowara on the eastern seaboard of Australia as well as New Zealand where it had been selling Lowara since 1990.

“Those movements would be the highlights. The next highlight for me later in my term was the acquisition of Brown Brothers and Kelair by AxFlow – a Swedish company – at the end of September 2018.”

“What has been hugely successful about the move is the fact that we did it and we maintained it and now we're a significant entity within the industry in Australia. It doesn't happen very often, but that was a huge achievement.

“One of the takeaways from everything is that up until now it's always been a Kiwi who has been Manager, General Manager or a CEO of Brown Brothers and for the first time in the history of the company, we now have an Aussie.

“This is how things don't stay the same, they change.”

Looking to an industry role model

Throughout his career, Mr Inkster developed strong working relationships and friendships with a lot of people across the industry – some of which he described as “real characters”. Of these people, one who had a significant impact on Mr Inkster was his boss, Ted Mace.

“Ted was a big influence on my career, and he and I had a very close relationship; there was a lot of trust between us. He had a huge impact on my life.”

Mr Inkster said that Mr Mace supported what the Brown Brothers team was trying to do by establishing itself in Australia and then in Victoria, and that he understood what was required to achieve it.

Looking back, Mr Inkster said it’s easy for him to pinpoint what his biggest takeaway from his career in the industry has been: the opportunity to work closely with a great bunch of people, forming lasting relationships – relationships that Mr Inkster knows will go beyond his retirement from the industry.

“When you've been in a position like I have for such a long time, it's the people you meet on the journey that make the job so enjoyable. And I enjoy the company of other people.

“Pumps don't talk back to you, but you can have a conversation with a person.

“The big takeaway from my time is just the opportunity to have worked with a great bunch of people and to know them very well. We've been very blessed within our organisation with a stable workforce and we're a very family-orientated company, we're not openly corporate.”

During his career, Mr Inkster spent four years as the President of the Pump Industry Association (PIA).

“When I came across to Australia in January 2000, nobody knew who I was and I didn't know who anybody else was. There's a lot of people in the industry and Brown Brothers, at that stage, was still in its infancy.

“We'd been there for five-plus years, so I joined the PIA so I could actually get to meet other people, other industry colleagues, and it worked very, very well for me. Then people got to know who John Inkster was and who Brown Brothers Engineers were because it was a New Zealand company.”

Mr Inkster is optimistic for the future, and hopes that there will be more young men and women attracted to the industry, fully trained and leading to better opportunities of retaining them.

“I hope we can teach them somehow that it is a good industry to be in. It's an essential industry, I think we're going to see a lot more innovation in time. I would suggest that in years to come, maybe five plus years, we'll be seeing products on the market that are not available now. The pumps will still be there, but how they work and the technology associated with them – they're going to get smarter and smarter.”

Despite his plans to retire at the end of April, Mr Inkster’s departure from the industry appears to be more gradual; he will be attending the next Managing Directors meeting in Stockholm in June for a more formal handover process.

Travel – both for work and for personal reasons – is at the top of Mr Inkster’s retirement agenda.

“This isn’t the first time I’ve been asked what I'm going to do in retirement, but millions of people do it around the world every day, every week, every month, so I'll do the same. My wife and I want to do a bit of travel, and this time she can have some travel where I don’t say, ‘We've got a flight tomorrow morning,’ and we're only there for a day and a half. Now we can go and we can actually relax, without me having to be somewhere else at a certain time.

“It used to annoy her a lot, but it just went with the territory. Now we can travel at our leisure and we do have a big trip to Europe planned in September.”

Family will also firmly take front seat in Mr Inkster’s retirement, with plans to investigate his family tree and visit family down in Melbourne. Even with all these things to keep him busy post-retirement, Mr Inkster has no intention of becoming a stranger to the people he met throughout his career.

“When I retire, most of all, I will have fond memories of the people I worked with. There's some great people and we had some great laughs and great times – visiting factories overseas in Europe and the US – and the enjoyment of meeting all those other people. I have many, many great memories.”

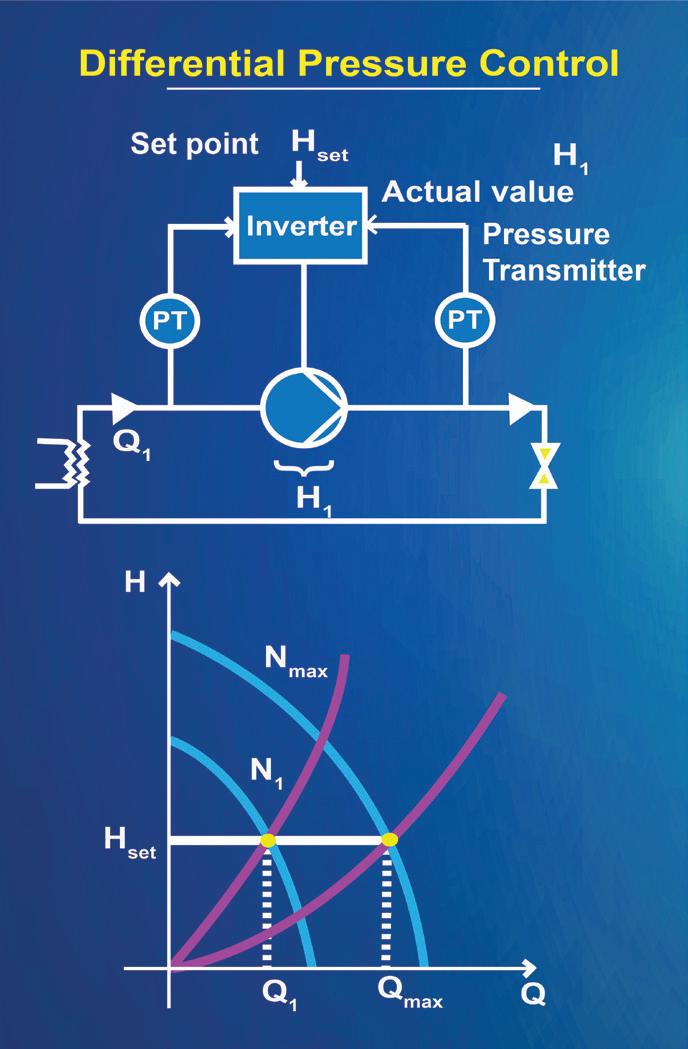

Ebara Pumps Australia has introduced energy saving pumps – K series equipped with a new variable frequency drive E-SPD+ (plus) to the Australian market. This new product allows users to save on energy costs with optimised operations according to the system’s requirements and contribute to a sustainable society.

With rising energy costs and concerns about climate change, energy efficiency and environmental conservation have become increasingly significant topics in the world.

Pumps are everywhere and sustain our lives and industries by means of supplying water and other mediums. Surprisingly, pumps account for over ten per cent of the world’s energy consumption. Due to this, the Ebara Group aims to achieve net zero greenhouse gas emissions by 2050 and contribute to the creation of a sustainable society.

Thus, Ebara Pumps Australia has introduced a new variable frequency drive E-SPD+ (plus) to provide energysaving solutions to the pump market. The E-SPD+ (plus) is mounted on the terminal board of electric motors from 2.2kW up to 11kW, and can be used with horizontal and vertical Ebara centrifugal pumps. It’s capable of varying the speed of pumps continuously and operating on any duty points, consequently optimising performances and energy consumption according to the system's requirements.

The model ranges of E-SPD+ (plus) are as follows:

• E-SPD+2200MT: 230V single phase input/three phase output with up to 2.2kW nominal power

• E-SPD+4000TT: 400V three phase pumps input/three phase output with up to 4kW nominal power

• E-SPD+11000TT: 400V three phase pumps input/three phase output with up to 11kW nominal power

The special features of the new solutions are:

• Innovative LCD display for viewing and changing operating parameters and for keeping track of the history of the key parameters, faults and alarms. Its cover can be rotated 180° for easier reading

• System protection against over currents, input voltage fluctuations, dry running and losses in the system

• Easy installation and programming thanks to the highly-intuitive and user-friendly software

• Connectivity is provided by four configurable digital inputs, two ports for configurable digital outputs, two ports for analogue 4-20mA inputs, one port for 0-10V input, and one port for motor thermistor PTC input

• Two RS485 ports for communication and parallel operation of up to eight pumps

• Connecting to monitoring systems with ModBus connection Finally, E-SPD+ (plus) is available as energy saving pumps K series vertical multi-stage inline pumps EVMS-K, horizontal multi-stage electric pumps MATRIX-K and self-priming pumps

JEX-K. K series enables it to be applied to different types of systems and used in various applications.

Pump control systems:

• Fixed speed

• Constant pressure for pressure boosting systems

• Differential pressure for circulation systems

Applications:

• Water supply

• Pressure boosting

• Irrigation systems

• Filtration and reverse osmosis

• Industrial cooling or heating systems

• Fountains

Thanks to the cutting edge technology of E-SPD+ (plus) and a new variety of energy saving pumps, K series enables Ebara to move toward reaching carbon neutrality goals to contribute to a sustainable society.

New generation inverter with air cooling, installable on the motor terminal board, which can be used with horizontal and vertical EBARA centrifugal pumps, and mounted on motors from 2.2kW up to 11kW. Inclusive of two RS485 ports for communication and parallel operation of up to eight pumps, and for connecting to monitoring systems with ModBus connection. Versatility of this solutions can be applied to di�erent types of system and applications.

Features

Simplicity

Assisted set-up, thanks to particularly user friendly software

Innovation

LCD display for ease of set-up, fault identification and alarm monitoring

Safety

Integrated protections for major common issues

Flexibility

Installable on horizontal, vertical

Pumps Australia Pty Ltd

Pumps Australia Pty Ltd

likely to attract the attention of the industry.

As such, the Australian industry has come to rely on Franklin for the quality, reliability and performance it provides.

Franklin’s commitment to serving the industry is demonstrated to its customers daily through the company’s Five Key Factors for Success:

• Quality

• Availability

• Service

• Innovation

• Cost

Since 1962 Franklin has been dedicated and committed to providing reassurance to the Australian industry through the abilities of highly-qualified individuals, able to resolve situational problems and to fix your pumping needs.

Abattoir in Northern Victoria

Franklin continues its ongoing work to supply high-quality solutions around the country.

A recent build for an Abattoir in far northern Victoria put the teams’ skills to the test, with the build of a Sextuple EV Booster Pump-Set, with space on the skid for a future pump install.

This complex system was supplied as two Triplex Pump Sets for ease of freight and installation. In addition to this was Franklin’s DrivE-Tech VFD Controllers, which

are intercommunicated to form a multi-pump constant pressure system. The drives enable control of pumps individually – allowing for energy efficiency and better operational performance.

Franklin is proud of its ongoing support to local communities. A key relationship underscoring this dedication and support is Franklin’s partnership with the Williamstown Seagulls Football Integration Development Association (FIDA). According to Franklin, this partnership is at the forefront of what it stands for as a company.

In the past Franklin has provided ongoing support to the team and its coach, Glenn Evans.

Speaking about Franklin and the partnership, Mr Evans said, “We are grateful for Franklin's contribution to the club.”

Franklin looks forward to continued endeavours from the team and hopes they can pursue their goals into the future, with Franklin Electric playing a small part of such successes –now and into the team’s future.

Based in Dandenong, Victoria, the team at Franklin strives to meet the current and future needs of its industrial water systems customers, providing not only an extensive range of reliable water pump and submersible motor products, but also delivering great customer service.

As the world’s driest inhabited continent, Australia has always faced challenges in terms of meeting its water consumption needs and the twin challenges of climate change and population growth only compound the country’s inherent water scarcity.

ifm’s IO-Link solution is helping innovative wastewater treatment companies, like Aerofloat, tackle these challenges –saving time, money and water.

Each state and territory has its own regulatory frameworks when it comes to recycling water, with criteria governing wastewater handling including the wastewater source, site constraints, treatment methods and the quality of effluent needed for proposed end-uses of treated water.

Accounting for these factors means there is no one-sizefits-all solution.

Senior Applications Engineer at ifm, Grant Smith, said that the challenge for wastewater treatment operations is to run plants effectively along the entire cycle – producing a result that is economical, effective, safe and in line with environmental regulations.

“At ifm, we understand the customers’ needs and focus on offering scalable solutions that are the best fit for the application,” Mr Smith said.

“We offer solutions for water and wastewater treatment plants, including physical hardware. We take a consultative approach, which helps us understand the customers, and we know that every application and project is different.”

Pressure sensor innovation

Mr Smith said ifm has supplied various IO-Link Solution wastewater treatment projects, providing hygienic pressure sensors that continuously detect the tank’s pressure, temperature, level and flow.

IO-Link is a short-distance communications network that connects smart sensors and actuators back to an industrial control system, allowing for richer and more transparent data monitoring.

ifm’s National IoT Business Manager and Digital Strategy Leader, Freddie Coertze, said that where traditional sensors

would each have to be wired through separate channels, IOLink has just one channel with all the information about an operation, including variables such as pressure, temperature, level and flow.

“In the past, conversion losses and EMC interference during the analogue signal transmission of the level caused inaccuracies and errors. IO-Link utilises purely digital transmission of the measured values. That way, the exact measured value is transmitted to the controller, eliminating any risk of signal interruption,” Mr Coertze said.

With IO-Link, screened cables and associated grounding and expensive analogue input cards are no longer necessary. Instead, data can be transferred via industry-standard cables.

Fronting the charge

ifm has collaborated with water treatment companies using sensor and control systems for many years. One such enterprise is Aerofloat, an Australian industrial wastewater treatment specialist that ifm has been working with to help provide customers with affordable, Australian-compliant treatment services.

Aerofloat’s General Manager of Engineering and Operations, Michael Anderson, said that the company is committed to innovation and sustainable solutions, with several patented technologies, and an R&D focus.

“Relationships like the one we’ve built with ifm are critical. We’ve done some reliable wastewater treatment plants exclusively fitted out with ifm instruments.”

Mr Anderson said that because ifm has so many instruments in its portfolio, there are always new products that can be added to Aerofloat’s arsenal in servicing its wastewater plants.

“With IO-Link, we can add a new instrument later without upgrading the control panel. We can quickly and efficiently get the instrument into one of the field modules with a digital system.

“Having that scalability, flexibility and ease of add-on functionality is critical. It not only helps us respond to customer demands but also allows us to adjust to regulatory changes within the industry.”

Are you ready to take your water facility to the next level of performance, quality, and efficiency?

With IO-Link, you can enjoy the benefits of digital communication and data access for your process instruments.

IO-Link is a simple, flexible, and cost-effective way to connect your sensors and actuators to your higher level controller.

Here are some of the advantages of IO-Link for your water facility:

Elevate Your Operation: Harness reliable, precise data.

Save money by eliminating the need for analogue input cards and shrinking your control cabinet size.

Increase your efficiency with bidirectional data exchange between your devices and your controller.

Improve your machine uptime by replacing faulty devices quickly and easily with the automatic device replacement feature of IO-Link enabled sensors.

Don’t miss this opportunity to upgrade your facility with IO-Link, the smart solution for intelligent digital transformation. Contact us today to find out more!

Industry is driven by productivity, productivity is driven by efficiency, and efficiency is driven by integration.

Keeping this in mind, WEG has developed WEGmotion Drives – an integrated and flexible package that combines motors, drives, gears and digital solutions to improve productivity of manufacturing plants.

The results include better reliability, better control of machines and equipment, more intelligence in operational processes and more efficiency for each industry.

With robust technical support, WEG guarantees the efficiency of your process, contributing to increased operational gains.

The main features of WEGmotion Drives are:

• Offering the combination of three innovative products in one integrated package from one supplier

• WEG verticalisation provides full control of manufacturing and quality processes

• Solutions for a range of applications from a wide product portfolio

• Flexibility allows for competitiveness of highly customised packages

• The integrated package assists in driving efficiency and sustainability

With WEGmotion Drives it’s possible to combine the quality of its motors, the strength of its gearboxes and the reliability of its inverters in a flexible and integrated package for the most diverse applications across a wide range of industrial segments.

If your company seeks total process control, regardless of your machine’s design, WEG provides fully integrated and flexible WEGmotion Drives solutions that can maximise the performance of your machines – whatever their application.

WEG. Getting you ready today for tomorrow’s challenge.

To learn more about WEGmotion Drives, scan the QR code:

Optimal control of pump speed helps to significantly reduce energy consumption.

The Grundfos CUE is a variable frequency drive for the effective speed control of any Grundfos pump without integrated drives – irrespective of size or area of application.

Perfectly suited for pump applications in industrial pumping solutions, Grundfos CUE keeps pump speed optimal and reduces energy consumption.

New functionality means that an additional 5-15 per cent of energy is saved in applications with stable flow rates.

Maximum convenience and advanced user interface Grundfos CUE is an integral part of Grundfos iSOLUTIONS. Offering simple installation and operation coupled with extensive control and monitoring possibilities, Grundfos CUE is perfectly suited for pump applications in the water or wastewater network, building services, or industrial pumping solutions.

Dedicated functionality for industrial pump systems

With dedicated functionality for industrial systems, Grundfos CUE ensures fully optimised operation in these applications:

Industrial water supply

• Pipe fill mode improves system reliability, prevents water hammering and is specifically designed for both vertical and horizontal pipe systems to increase system performance and prevent water hammer in the application

• Low flow stop function offers improved energy optimisation, easy configuration and high comfort

• Built-in cascade control of two fixed-speed pumps allows increased flow by simple cascade option of up to two fixedspeed pumps and easy set-up from the start-up guide

Industrial processes

• High overload and constant torque – the torque characteristic is normally set to variable torque for centrifugal pumps. However, Grundfos CUE offers a constant torque characteristic optimised for:

» Higher starting torque

» Screw spindle pumps

» Load shocks in machine tool pumps

• Stop at minimum speed function, which ensures that the pump will stop after a selected time when the controller is in saturation, forcing the pump to run at minimum speed Do you have a fixed-speed pump system running all the time? Contact Grundfos and the team can help you to optimise your installation by adding a CUE frequency driver.

How validated carbon reduction targets can safeguard your business Grundfos is the first water solutions company to receive validation of its long-term 2050 net zero target and near-term 2030 emission reduction targets from the Science-Based Targets initiative (SBTi).

grundfos.com.au

Let’s work together towards decarbonising industry!

A filter housing serves as the frontline defence against contaminants, safeguarding downstream users and equipment. Choosing the wrong one can lead to performance issues, increased maintenance costs and potential system failures.

That’s where Maxaflex Filter Housing Kits come in – a first-class solution designed to set a new standard in filter housing flexibility.

Flexible connectivity for diverse systems

Maxaflex Filter Housing Kits redefine flexibility by seamlessly connecting into a wide array of pumping systems. The range is multipurpose and interchangeable with other filter systems. Whether operating an agriculture site, a water treatment plant, an industrial facility or a residential water supply system, Maxaflex adapts effortlessly to specific requirements.

Low-cost, high-quality assurance

Say goodbye to the trade-off between cost and quality.

Maxaflex offers a budget-friendly option without compromising on excellence.

Backed by Global Water Solutions (GWS) and Southern Pumping – Australian specialists in pumping since 1974 – Maxaflex Filter Housing Kits provide a reliable and affordable solution.

Certified safety and easy installation

Safety is paramount and Maxaflex reinforces this by being certified to Australian and International standards – WaterMark AS/NZS 4020 and ANSI/NSF 42.

Installing Maxaflex Filter Housing Kits is a breeze with complete, ready-to-install kits saving time and effort in the setup process.

Extended lifespan with free grooved filter cartridge

Maxaflex goes the extra mile by including a free grooved filter cartridge in each housing.

Boasting 80 per cent more surface area than standard filter elements, this cartridge ensures a longer lifespan, minimising pressure and flow rate drops over time. It's a cost-effective solution that enhances the overall efficiency of your pumping system.

Experience a new standard in water filtration with Maxaflex, designed for optimal efficiency, durability and versatility.

Upgrade to the Maxaflex Water Filter Housing Kits and elevate your water filtration experience.

Maxaflex Filter Housing Kits – the new standard in filter housing flexibility.

Flexible – connects into more systems and suits multiple filter cartridge types

Economical – competitive pricing without compromising on quality

Safe – certified to Australian standards AS/NZS 4020

Easy – complete kits ready to install

Trusted – backed by GWS and Southern Pumping, Australian specialists in pumping since 1974

Multiple sizes – available in single and dual housings across three size options

Free grooved filter cartridge included per housing – 80 per cent more surface area than standard filter elements, giving longer lifespan, less pressure drop and less flow rate drop over time

Melbourne Zoo is highly regarded for the vast array of species it hosts and its dedicated conservation efforts, but perhaps less well-known is the work being undertaken behind the scenes to uphold the high sustainability standards it prides itself on, including an onsite water treatment plant and VSDs supporting crucial Aquatic Life Support Systems.

Melbourne Zoo is renowned for its rich biodiversity and is located within the heart of the city. As you wander through the world of wildlife, visitors will notice the diversity of species that call the Zoo home – species that are representative of a diverse range of landscapes, from tropical rainforests to the Australian bush.

Melbourne Zoo is also a botanical garden with complex needs and maintaining a microcosm of the world in the one precinct presents its own set of unique horticultural challenges and requirements. In response to this, the Zoo has some groundbreaking systems in place that are being used to conserve water onsite.

As many endangered animals are vulnerable to climate change and habitat loss, Zoos Victoria is determined to be a world leader in environmental sustainability, recognising the key role sustainable practices play in its mission to fight extinction. Zoos Victoria is committed to reducing water consumption, while maintaining the diverse environments for the more than 200 species that call the Zoo home.

Melbourne Zoo’s Zac Saber, is Sustainability Manager at the 160-year-old cultural location, where a large part of his role is water management.

At Melbourne Zoo, 90 per cent of the water used is collected from the Zoo grounds and processed onsite through a water treatment plant. This has considerably decreased the Zoo's use of potable water when its consumption is not needed. The water is captured across the entirety of the zoo – from stormwater drains, wastewater, animal exhibits and moats.

“Our ability to utilise recycled water and avoid potable water use has been a huge achievement,” Mr Saber said.

“Recycled water accounts for approximately 50 per cent of our annual usage onsite by having this plant.”

Among the Zoo’s team of Horticulturists, Plant Operators and Water Technicians, one person looking after the complex water needs of Melbourne Zoo is Irrigation Specialist, Giuseppe Greco.

Hailing from Catania, Italy, where his family still operates an organic citrus farm, Mr Greco’s agricultural roots led him to study Science and Technology, where he produced a thesis on biomass and energy. Mr Greco holds an intimate knowledge of the Zoo’s varied landscapes and the science behind effectively managing its most precious resource: water.

“I make sure we efficiently deliver water to maintain our diverse landscapes to keep them happy and healthy,” Mr Greco said.

Mr Greco explained that the Zoo has a very sophisticated network, starting at what he has dubbed its ‘headquarters’: the water treatment plant.

The recycled water captured onsite is delivered with an automated system to the grounds via a complex irrigation network to all the gardens managed by the horticulture team, as well as to various water bodies across the property, including the Asian elephant pools and Pygmy hippopotamus pools.

“We have a reticulation system of approximately 15,000 sprinklers throughout the Zoo, which I utilise to maintain our gardens and tree collections,” Mr Greco said.

“Some of these trees are listed on the City of Melbourne’s Exceptional Tree Register, so we need to ensure we are receptive to the trees’ needs.”

Mr Greco and the team have developed a modelling system with soil probes and other environmental monitoring devices, some attached to the canopies of trees.

“Each area behaves differently, but we know how much water goes through the soil layers. The monitoring system provides us with data on the volumes of water needed in particular areas, allowing us to be efficient in our watering.”

Mr Greco said that a day with a 34°C forecast with some wind means there will be a significant amount of water loss from transpiration in the tree canopy.

“For example, the 105-plus years old Ficus tree (Ficus Macrophylla) at Carousel Park has a wide canopy and will lose roughly 1,000L of water on a very hot day.”

To counteract these heat events, Mr Greco and the team proactively forecast the climate and prepare soil before time.

“This site is complex to manage because there are so many different landscapes and water requirements. My role is to ensure we have a system that supports both our habitats and animals.”

The Zoo has a whole range of different pumps that are within the variety of the systems in use, the specs of which are dependent on the system they are feeding and the optimal flow rates required for associated life support systems.

Many of the Zoo’s filtration systems are retrofitted into areas that may not have always been water bodies – as is the nature of a constantly changing 160-year-old zoo – so depending on the differing needs, the Zoo will employ submersible or end-suction pumps.

The Wild Sea Precinct

Mr Saber and his team also manage Aquatic Life Support Systems within the Zoo’s Wild Sea Precinct.

Wild Sea showcases Victoria’s coastal environment and the marine life that calls it home. These species include Australian and long-nosed fur seals, little penguins, fiddler rays, seahorses and other fish species. With an unmissable conservation focus, the area highlights the threats to Victoria’s coastal areas and underscores what people can do to help protect them.

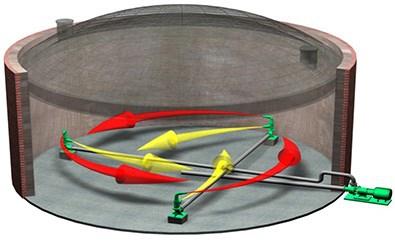

An extensive web of 24-hour life support systems maintain the quality of numerous bodies of water for the animals of Wild Sea. These life support systems are comprised of pumps, chillers, UV Sterilisers, Ozone Generators and filters that process around 1.5 million litres of water several times a day.

Wild Sea is also reusing water onsite with its backwash recovery system. Water that goes through backwash is sterilised through sand filters and injected with ozone.

Once the water is cleaned, it goes into saltwater distribution before filling up the seals and penguins’ systems. One backwash of the systems that services the seals and penguins uses approximately 30,000L of water that is then able to be reused.

Wild Sea pumps in play

Many of the systems in use at the Wild Sea Precinct will have corrosion resistant pumps as saltwater and ozone often eats away at various components. This also prevents any trace metals entering the water as some of these systems have fish and elasmobranchs in them that could be sensitive to any corrosion by-products.

The Wild Seas systems are designed with multiple circulation pumps so ideally the Zoo doesn't lose the entire Life Support System if one pump was to fail. Similarly, the Zoo’s stormwater plant has multiple pumps for the filtration

stages, as this is particularly beneficial for systems that are running submersible pumps as failures are less likely to be identified early.

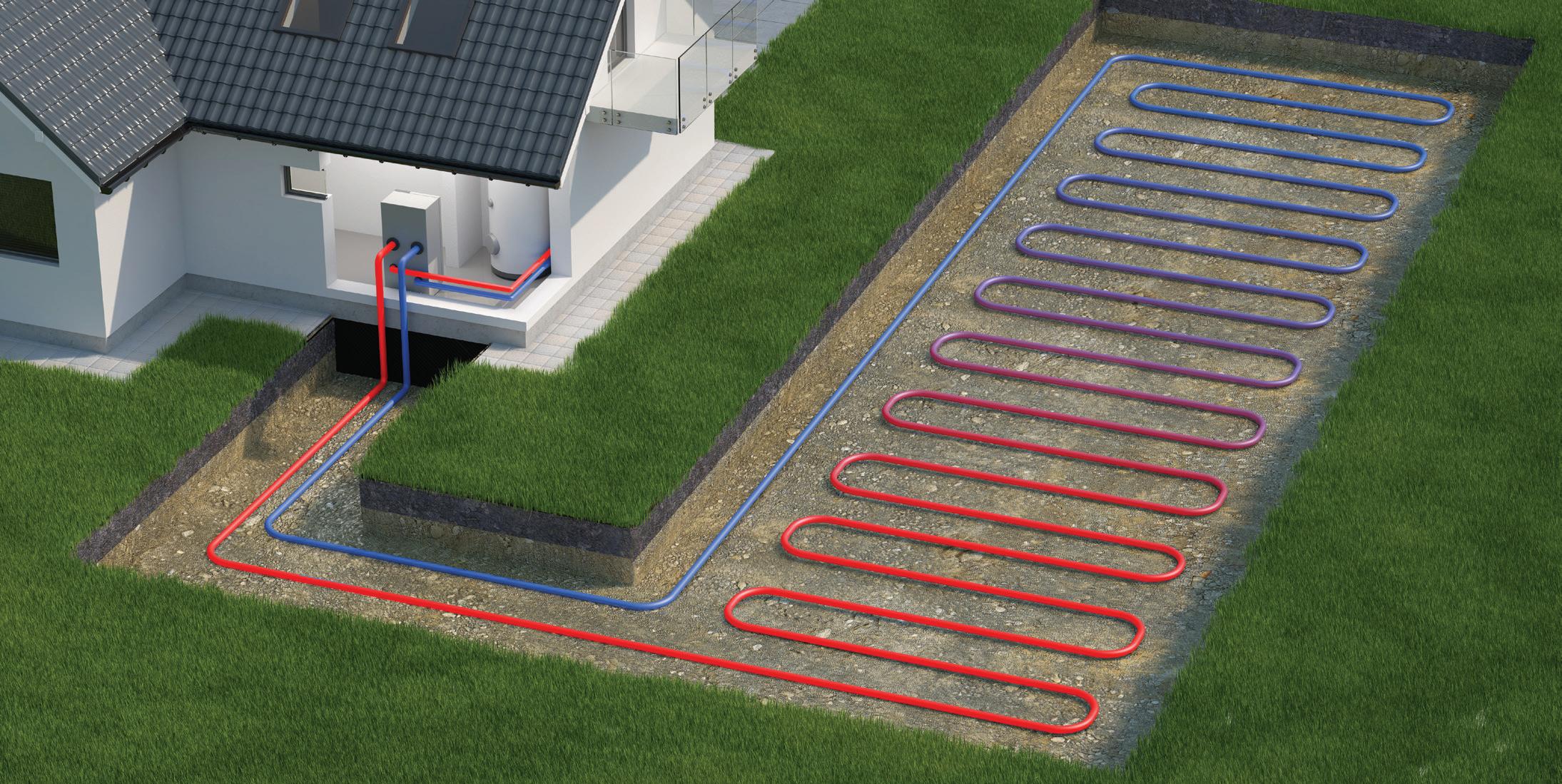

Even with such sensitive and critical systems, the Zoo’s commitment to sustainability is never far off. Most of the circulation and filtration at Wild Sea was designed with VSDs to achieve flow-rates rather than throttling valves – this allows many of the automation processes to be controlled from the Programmable Logic Controller, aids in longevity of pumps, and is beneficial to our energy consumption for the precinct.

While VSDs were less involved in the overall design of the Zoo’s stormwater treatment plant, the pressure pumps and any booster pumps that are built into the system do use VSDs for the same reasons, and would likely be a consideration for any future replacements.

While water circulation and filtration are significant power consumers onsite, Melbourne Zoo strives for best practice in this space wherever possible – it aids the Zoo in aiming for its sustainability targets, but also makes the most sense from an asset management point of view.

The biggest complications faced by the team at the Zoo are critical failures and more often than not, systems are run with multiple pumps either in a Duty-Standby arrangement or they are designed in such a way that a pump failure does not mean the entire plant is down.

Due to the large demand for recycled water at the Zoo, any plant failures must be dealt with quickly to avoid impacting operations and most importantly animal welfare.

Most of the pumps in use onsite have relatively low maintenance requirements – with occasional greasing and

more of a focus on monitoring and inspecting. In spite of this, there are also a handful of critical spares the team would need onsite to keep them out of trouble. The team is equipped to handle ornamental water bodies stopping for a period of time, but there’s no room for complete life support failure.

“Problem solving any plant failures can take precedence over what was planned for the day. Addressing a burst pipe is far more time sensitive than responding to an email!” Mr Saber said.

“Most of our systems are automated with a Programmable Logic Controller (PLC) and Human Machine Interface (HMI) system – from the Wild Seas Life Support Systems through to our organics processing and HotRot Machine, there’s a lot of technology that we use daily.”

“It also helps a lot to have remote access to identify faults. On a big day, I might walk ten kilometres around the Zoo between all of the plant rooms, so having the tools to remotely check if something is running is very useful.”

Many of the upgrades the Zoo has undergone have actually been through software and programming changes. The team didn’t always have the ability to adjust the speeds of some filtration pumps through the PLC systems, and these changes have allowed for slight tweaks resulting in better water quality parameters for the Zoo’s exhibit inhabitants.

Zoos Victoria’s sustainability commitment reflects its identity as an ecologically mindful conservation organisation.

“We do a lot of work in conservation, but also recognise that our power, waste and water will have an impact on the planet. By reducing that footprint, we are better equipped to fight extinction and reduce habitat loss,” Mr Saber said.

“You can’t campaign for the conservation of endangered species if you aren’t practising it in your own backyard.”

In an age where environmental responsibility is no longer a choice but a necessity, Wellington Shire Council made a concerted effort to integrate sustainable design principles, including repurposing equipment, into its $23 million redevelopment of Aqua Energy Leisure Centre in Sale.

Wellington Shire is the third largest municipality in Victoria, with an expansive 16 swimming pools across six locations and almost 11,000 square kilometres. This leaves Wellington Shire Council with one of the most extensive outdoor pool portfolios in the state.

Given this portfolio scale, it became imperative from the outset to adopt a sustainable approach to the Aqua Energy Redevelopment, aimed at both cost-saving measures and the efficient repurposing of perfectly functional equipment within its regional pool facilities. With stage one of the redevelopment almost complete, Wellington Shire Council believes that this is what has been achieved, demonstrating a commitment to environmental stewardship and promoting sustainable practices across the organisation and community. Rescuing functional equipment

For Council, the project objective was clear – to create a modern and accessible facility that promotes health and wellbeing and aligns with sustainable practices without compromising on budget constraints.

In November 2023, as demolition crews commenced their work on the centre, the 25m chlorine dosing system, including a pulsar precision control panel and chlorine feeder, found a new purpose at the nearby Heyfield Outdoor Pool.

With a current value of $10,000, the system – designed to automatically regulate water pH and chlorine levels – was a savvy cost-saving initiative for the Council.

The chlorine dosing system was installed alongside the filtration system. Return water is tested using the Pulsar Strantrol unit, which monitors current pool levels and triggers chemical balancing with chlorine or CO₂ for pH stabilisation. The unit undergoes testing and calibration in accordance with manual testing and calibration procedures. After testing and balancing, the set points are locked to maintain chemical levels.

Since its installation at Heyfield Outdoor Pool, routine maintenance on the chlorine dosing system involves recalibrating levels and set points, cleaning testing probes and clearing chlorine feeder and return lines.

The surplus of equipment that resulted from the redevelopment also included a pump system and prior to their removal as part of the redevelopment, the pump system and chlorine dosing system were flushed and meticulously cleaned.

The surplus pump system contained two 3kW Grundfos circulation (couple end-suction) pumps. The Grundfos circulation pumps were sourced in Australia and originally installed by local Gippsland contractor AC pools.

Wellington Shire Council intends to utilise the two Grundfos circulation pumps to replace a single pump at the Maffra Outdoor pool. This change will provide redundancy, ensuring continuous circulation even if one pump malfunctions.

Among the other salvageable items awaiting reuse are solar panels with an estimated value of $100,000. These panels are ready to find their next home, with potential destinations ranging from local recreation reserves to sporting change rooms, aged care facilities, library and customer service hubs –all of which are earmarked for future enhancements.

Wellington Shire Council Mayor, Ian Bye, said Council is committed to finding new and innovative ways to make the most of pool equipment that still has life left in it.

“The decision to repurpose and integrate equipment into smaller pool facilities became a natural choice for us.”

Despite project constraints, such as a partial rebuild of the existing facility and budget limitations, Wellington Shire Council has remained committed to its promise to sustainable practice – most notably, the decision to retain significant existing infrastructure, including air handling units a mere 18 months old.

By focusing on elements such as insulation, airtightness, and ventilation with heat recovery, Aqua Energy Leisure Centre aims to create a healthier and more comfortable environment for visitors while simultaneously reducing the facility's carbon footprint.

Wellington Shire Council’s commitment to enhancing energy efficiency and sustainability is demonstrated in the comprehensive measures implemented across its facilities and assets. A recent initiative involves certifying Project Engineers

in ‘Passive House Building Standards’. This official accreditation in sustainable building design makes it easier for project teams to integrate this crucial aspect into future projects, benefiting the entire community by focusing on energy efficiency, comfort, and affordability.

Additionally, incorporating passive house design principles reduces a building's overall energy demand, making it easier to transition to other heating sources in the future.

In a notable achievement, Council now boasts the highest number of certified 'Passive House' designers across the Gippsland region.

Additional strategies, such as reducing thermal bridges and implementing airtightness testing to enhance ventilation efficiency, are currently being utilised. Incorporating high levels of building insulation along with thermally efficient double glazing, as well as utilising natural daylight and LED lighting, further aids in energy conservation.

levels, while also leveraging natural features like proximity to open spaces, including large red gum trees and nearby Lake Guthridge.

Water-efficient fixtures, the reuse of existing solar panels, and installation of new ones with future expansion capability aim to maximise available rebates.

The $23 million facility upgrade has been made possible thanks to the Victorian Government, including $2 million from the Local Sports Infrastructure Fund and $10 million from the Community Sports Infrastructure Loan Scheme, $950,000 from the John Leslie Foundation, with the remainder of the project funded by Wellington Shire Council. Council is also utilising funds from the Federal Government’s Local Roads and Community Infrastructure Program.

As a key asset for the community, Council placed emphasis on creating a comfortable building environment, characterised by even temperatures, reduced draughts, and lower noise

“Our commitment to sustainable design reflects our dedication to creating a positive impact on the environment while providing a state-of-the-art facility for our community,” Cr Bye said.

"Our focus extends beyond the construction phase, and we are dedicated to maintaining a sustainable approach throughout the lifecycle of the leisure centre."

When reviewing the Wellington Shire Council Plan, it is clear that four strategic directions and priorities have shaped its work over the past four years: Environment and Climate Change, Economy and Sustainable Growth, Liveability and Wellbeing, and Services and Infrastructure. It appears this redevelopment has showcased these elements.

Irrigation Australia is thrilled to present the Irrigation Australia Conference and Exhibition in conjunction with the 9th Asian Regional Conference of Irrigation & Drainage and the 75th International Executive Council (IEC) Meeting.

With less than six months to go, the countdown is on to the Southern Hemisphere’s biggest irrigation event. There is still time to be part of this event and here’s a sneak preview of what attendees can look forward to.

Huge combined event

At least 1,000 delegates and around 100 exhibitors are expected to attend the event from 1-7 September. The event will be held at the spectacular Sydney International Convention Centre in the heart of Darling Harbour.

A unique aspect of this combined event is its size and scope; it brings together world-renowned researchers and policy makers, leading manufacturers, retailers, suppliers, water managers, installers, designers and others from Australia and further afield all under the one roof.

Rich conference program

The conference promises a rich program, with presenters from around the globe, based around the theme: ‘Irrigation’s role in delivering economically viable food security and sustainable urban spaces in an increasingly unpredictable climate’.

The conference themes and sub-themes promote inclusion but also celebrate the significant skills and expertise the irrigation industry offers, along with the benefits of international collaboration.

exhibition approach

In 2024, Irrigation Australia has taken a fresh approach to the exhibition, making some big changes to ensure it is as interactive, fun and productive as possible for both delegates and exhibitors.

In 2024 the event will have:

• More space, with all meals incorporated into the exhibition hall

• Two-hour lunch breaks with plenty of activities, including promotions and competitions

• An ‘interactive zone’ where exhibitors can demonstrate their products

• A networking lounge

• Exhibitor competitions

There’s still time to secure your exhibition space. The exhibition is an unparalleled opportunity for organisations to come face-to-face with customers, to increase visibility and to showcase products and services.

Irrigation Australia is excited to welcome Franklin Electric as its principal partner and major sponsors include Brown Brothers Engineers Australia, Davey Water Australia and Rain Bird Australia.

It is not too late to get involved as a sponsor and there are a range of packages available.

As always, you can look forward to a selection of sideevents: workshops, technical tours, social and networking events. Among these is the ‘Women Working in Water’ Breakfast, which was one of the highlights of the 2022 event. Attendees will also have plenty of time to catch up with old friends and colleagues and forge new connections at the welcome ceremony and the conference dinner, which will feature entertainment by Aus rock band, Classic Oz. Irrigation Australia looks forward to welcoming you!

To find out about sponsorship or exhibitor opportunities, contact Robert Gunn 0497 800 962 or Abdul Khan 0433 159 345, irrigationpartnerships@theeventgap.com.au Visit the event website at https://irrigationconference2024.com.au/exhibition-opportunities/

For the first time in history, residents and businesses in Marla, South Australia, can access safe and clean drinking water directly from their taps, with SA Water’s new desalination plant now operating in the South Australian town.

Located just over 1,000km north-west of Adelaide, Marla is at the junction of the Oodnadatta Track and the Stuart Highway, with around 70 people calling it home.

The town’s water supply has historically been designated as ‘non-drinking’, with residents previously sourcing their own drinking water from private rainwater tanks, water carting or from purchasing bottled products.

The town’s small-scale desalination plant is now producing drinking-quality water for locals to use in their kitchens, bathrooms, laundries and gardens.

A suite of projects

SA Water’s General Manager of Sustainable Infrastructure, Amanda Lewry, said that this project is the utility’s second drinking water upgrade for a remote town in the past 12 months.

“Having delivered a new desalination plant for our customers in nearby Oodnadatta last August, it’s exciting to see yet another of the state’s iconic outback towns enjoying

safe, clean drinking water flowing through their pipes for the first time,” Ms Lewry said.

“Whether it’s greening the garden or topping up the kettle straight from the tap, we recognise the significance this upgrade is already having on promoting health and hydration, along with the positive social and economic opportunities it’s providing.

“Marla’s desalination plant – constructed inside a shipping container to help protect the infrastructure from the sometimes harsh weather experienced in the area – can produce up to 87,000L of water each day.”

Drawing water supply from the largest groundwater basin in Australia – the Great Artesian Basin – the plant’s reverse osmosis technology pushes the sourced supply through a semi-permeable membrane designed to separate the water and salt molecules.

“The purified water continues through the membrane for further cleaning and treatment to make sure it meets the requirements under the Australian Drinking Water Guidelines

(2011), before being stored inside an onsite 539,000L capacity tank, for distribution through a network of pipes to the town.

“The brine byproduct created in the desalination process is diverted in the other direction, to be stored in the large onsite evaporation basin.”

According to Ms Lewry, it took an extensive planning and delivery process to reach the plant’s first water milestone.