Pump Industry Australia Incorporated

Kevin Wilson – Secretary PO Box 55, Stuarts Point NSW 2441 Australia

Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com

Ron Astall – President United Pumps Australia & Astech Consulting Services

John Inkster – Vice President Brown Brothers Engineers

Mike Bauer - Councillor Dynapumps

Geoff Harvey - Councillor Davey Products Pty Ltd

Tony Kersten - Councillor Grundfos Pumps Pty Ltd

John Link – Councillor Link Pumps

Martin O’Connor – Councillor KSB Australia

Alan Rowan – Councillor Life Member

Keith Sanders – Councillor Australian Industrial Marketing & Life Member

President’s welcome

The importance of energy efficiency is obvious. We already have in place “MEPS” (Minimum Energy Performance Standards) for electric motors, MEPS for fans is not far away and MEPS is in the planning stage for centrifugal pumps. Sustainability Victoria is the driving force behind these initiatives and those of you who attended our energy efficiency seminars and our recent PIA Exhibition and seminar last October should be well aware of these developments.

So from a pumping perspective, we already have mandatory electric motor efficiency standards, and similar standards for pumps are on the way.

Does this mean job done? Not even close!

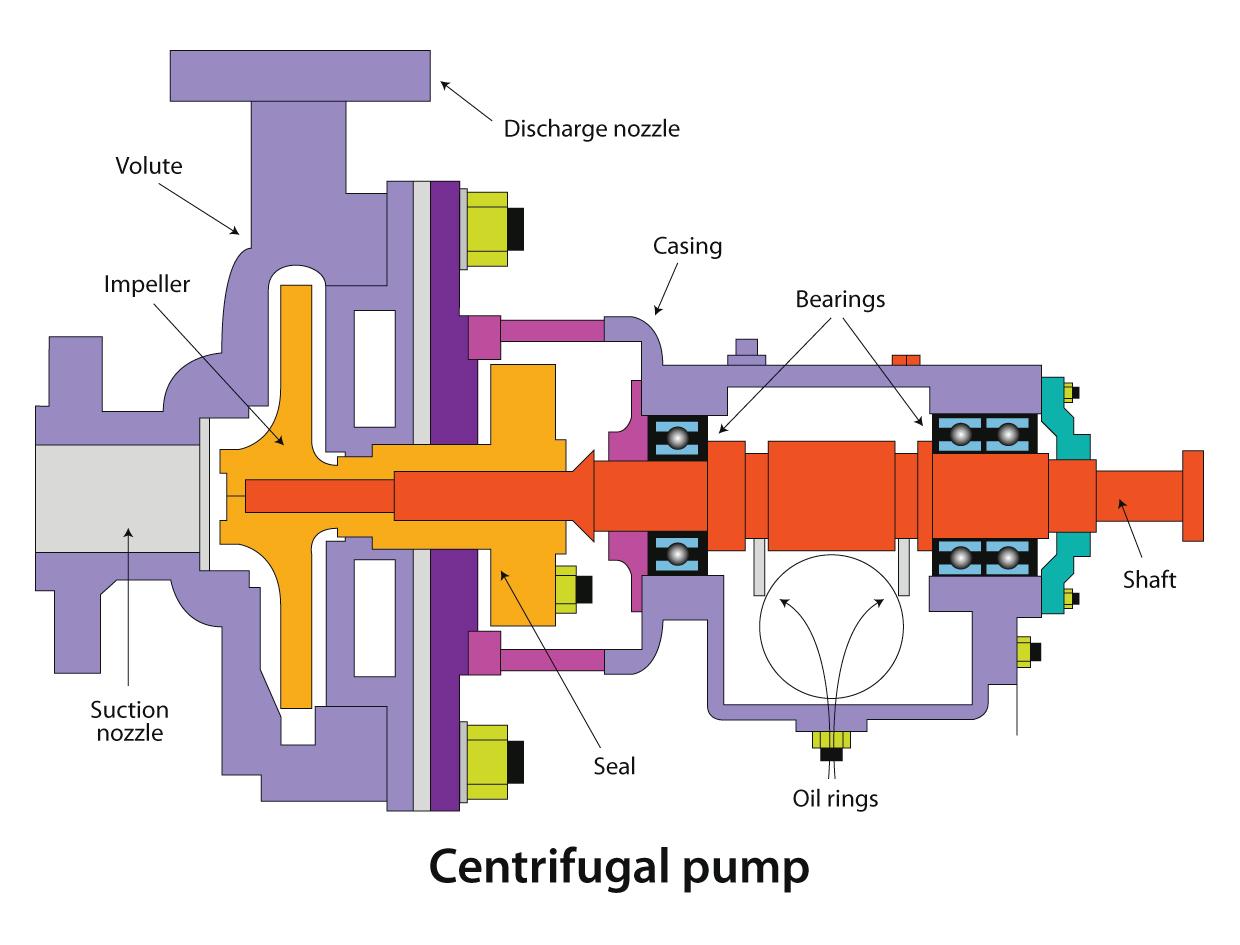

Aiming for more efficient pumps is a no-brainer, but pumps - particularly centrifugal pumps - are pretty unique in that their power consumption is hugely influenced by the system into which they are installed. Unlike a stand alone appliance that may receive an energy rating, pumps are slaves to the system and to the specifier. In his presentation to PIA last October, Sustainability Victoria’s Ian McNicol correctly highlighted that pumps are only one facet of total pumping system efficiency.

A poorly designed system incorporating an efficient pump is still a poor system. A well designed system with an efficient but incorrectly sized or throttled pump is still a poor system.

The real issue is minimising power consumption. A friend of mine was designing a transfer pumping system and asked my advice on pump selection. Originally he wanted to limit himself to 50mm poly pipe because this was cheaper. This would have meant around a 200kW pump for the pipeline length involved. Of course common sense intervened and we found a compromise with 100mm pipe

requiring only a 30kW pump. His annual running costs were obviously much lower and in this instance the capital cost was also better. Interestingly, because larger pumps are typically more efficient than smaller pumps, the 200kW unit would have had a better pump efficiency than the smaller 30kW unit.

The point of this example is that pump efficiency is far less important than the overall system efficiency. Again, the real issue is minimising power consumption.

This brings me to the excellent presentation from John Macdonald from AusIndustry at our February General Meeting; in particular; the Clean Technology Investment Program.

This program is an $800 million competitive, merit-based grants program that supports Australian manufacturers to invest in energy efficient capital equipment and low emission technologies, processes and products. The program will provide funding over a seven year period from 2011-12 to 2017-18.

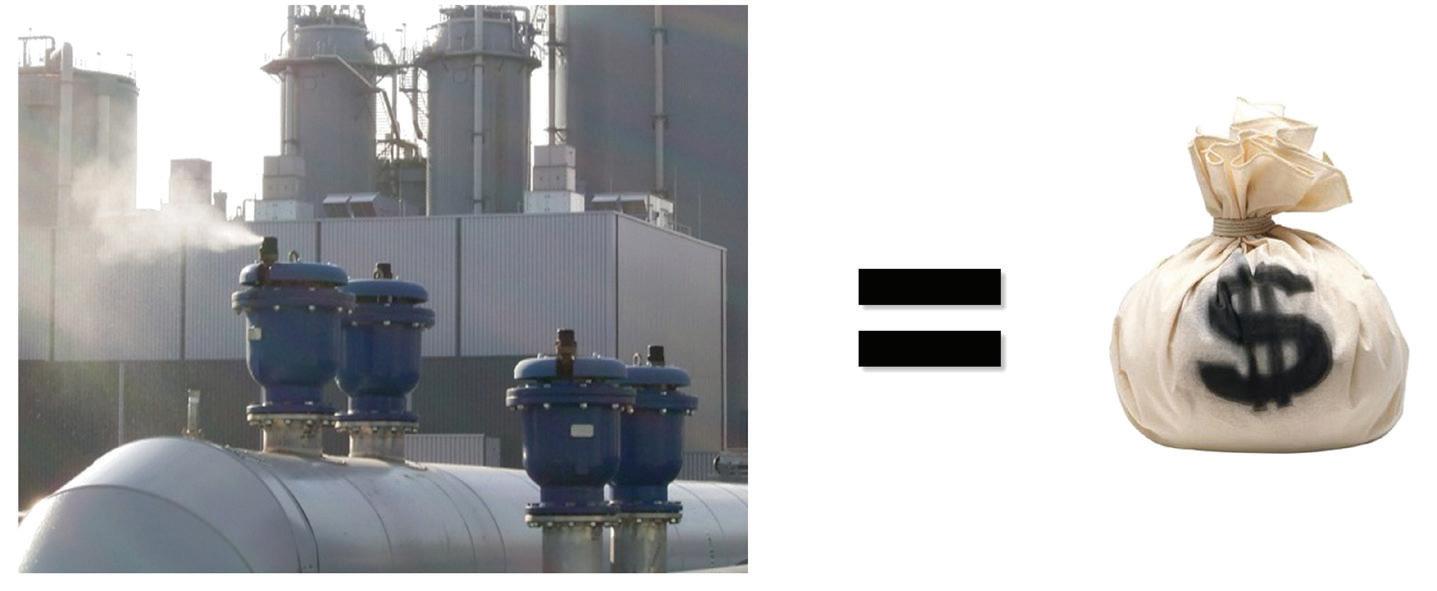

As pumps are often responsible for the bulk of industrial energy consumption, this program could be of benefit to many pump users and would potentially assist in covering upgrade costs for inefficient or worn pumping systems. I encourage pump users to investigate this program and the pump industry to let their customers know that this is available. http://www.ausindustry.gov.au/ programs/CleanTechnology/CleanTechnologyInvestment/Pages/default.aspx

The challenge for us all is to encourage better system design and to correctly specify the most efficient pumps available.

Ron Astall President, Pump Industry Association

1

PUMP INDUSTRY

Editor’s welcome pumpindustry

This magazine is published by Monkey Media in co-operation with the Pump Industry Association (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publishers discretion.

Published by Monkey Media Enterprises

ABN: 36 426 734 954

GPO Box 93, Melbourne VIC 3001

P: (03) 9440 5721

F: (03) 8456 6720 monkeymedia.net.au info@monkeymedia.net.au pumpindustry.com.au magazine@pumpindustry.com.au

Design by Linda Tucker

Happy Places Design www.happyplaces.com.au

ISSN: 2201-0270

Welcome to the third edition of Pump Industry magazine. I’m delighted to say that the strong growth trajectory for the magazine has continued with this issue. We’ve gone from 48 pages in issue 1; 56 in issue 2 and the edition you are now holding in your hands, or browsing online, is 72 pages - and there has been a corresponding increase in advertising take up from issue to issue as well.

Particularly pleasing has been our strong growth online, with hundreds of unique visitors every week and web traffic continuing to increase. We’ve noticed that people are using hundreds of different search terms to find us, ranging from ‘api pumps’ to ‘zinc slurry pumps’ and everything in between. Usually, they are not looking for us at all, but are pump professionals seeking out information to help them do their job better.

Inspired by this, we are working to ensure that pump users who come across the site can find what they are looking for, so we are creating special new mini-sites, called channels, within the website, focussed on particular issues. Some of the first channels we are rolling out include;

• Pumping LNG

• Pumps in building services

• Mine dewatering

• Reliability, and

• Motors and drives with plenty more to come after that. These ‘websites within a website’ will include their own email newsletters to which readers can specifically sign up and exclusive sponsorship options for related companies.

Our readers are becoming increasingly sophisticated in the way they consume information. I’ve been told by many readers that they enjoy being able to access Pump Industry in a variety of ways; they love to get the print issue and will savour taking some time out to read it in-depth, then may pass it round to colleagues or keep in on hand on their desk for months. But they also enjoy being able to access information at any time on the website and to be able to search through all our content at once. And as well as getting their news regularly from the email newsletter, savvy readers are also getting our content daily through social channels such as Twitter and LinkedIN.

This ties in perfectly with the feedback I’ve get getting from advertisers, who are looking for integrated solutions to get their message out to the pump industry, and end users of pumps. So we will continue to expand our offerings and ensure that as well as print advertising, companies can also reach our readers through a range of other options including; online advertising; providing useful content to drive traffic to their websites and enhance their SEO and we will also work with companies to make use of the social media marketing opportunities available.

I appreciate all the feedback I’ve got so far, and if you’ve got any ideas, I encourage you to drop me a line.

But that’s enough about us and the business of publishing, please now enjoy 70 further pages, all about pumps!

Chris Bland Publisher and Editor

PUMP INDUSTRY 2

Inside Sydney Water: in-depth interview MAY 2013 ISSUE 3 Reliability getting the best out of your pump systems Building services pump selection in the HVAC industry Seals or sealless pumps? Australia’s Number 1

Cover shows a typical rooftop pump system used in HVAC applications.

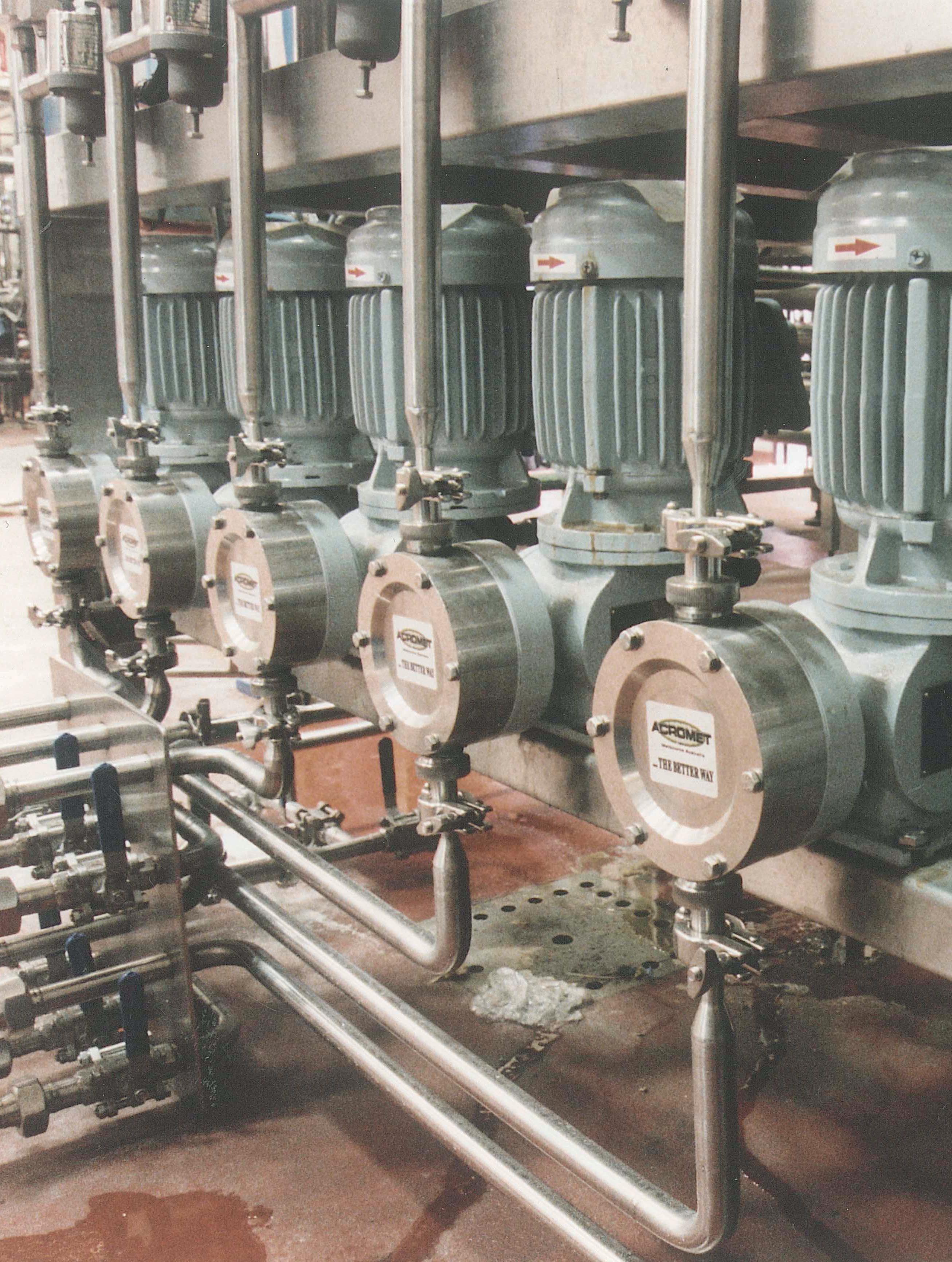

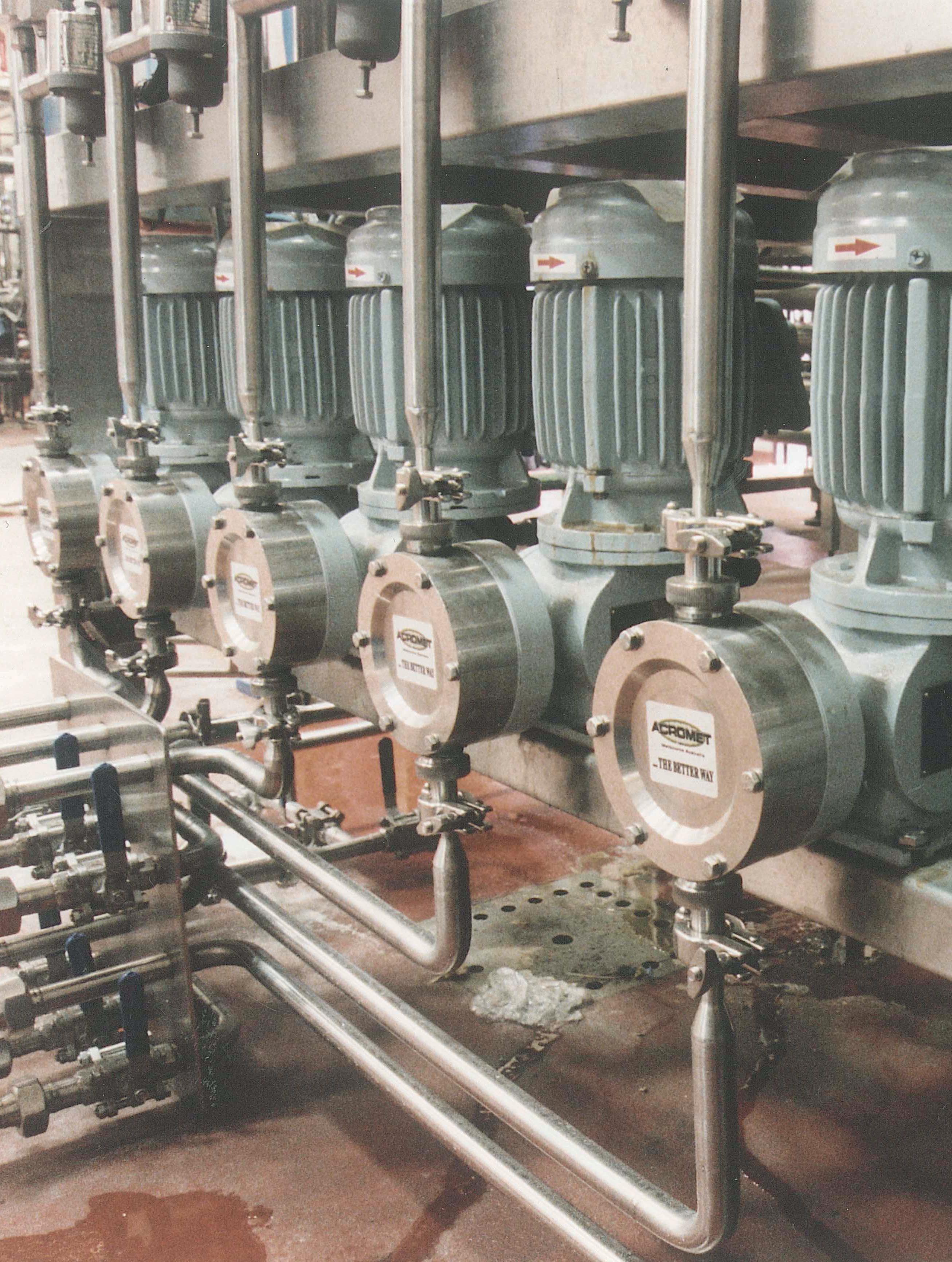

Celebrating 50 years of Service To Australian Industry P O Box 1105, Clayton South, Vic 3169 www.acromet.com.au Email: chemex@acromet.com.au Ph: (03) 9544 7333 Fax: (03) 9543 6706 Robust Pumps Reliable Service Total Commitment Chemical Metering and Process Transfer Pumps

pumpindustry

MAIN FEATURES

Reliability

Fighting black oil and understanding bearing housing upgrade opportunities - by Heinz Bloch......................................................20

Oil Mist lubrication by Don Ehlert and Marty Williams................26

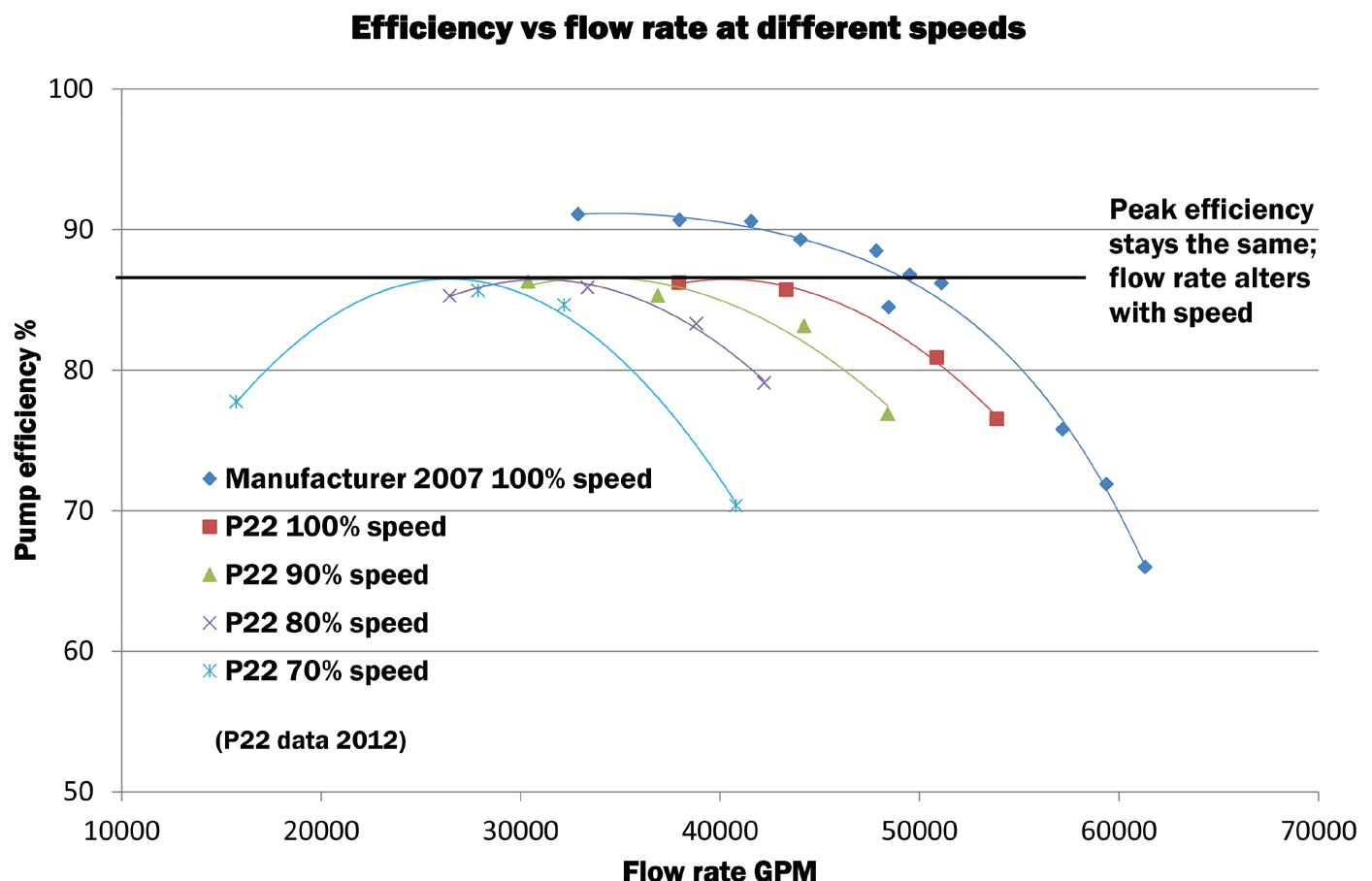

Thermodynamic performance testing and monitoring by Malcolm Robertson...................................................................30

Is your pump reliability in the balance by Christopher Morse....33

Interview: Inside Sydney Water

In this ongoing interview series, we talk in-depth with the end users of pumps across a range of industries and applications. This edition we interview Bruce Maunder, Sydney Water Senior Specialist in Pumping Systems, to get an inside view of Sydney Water.

The Australian office building market...........................................50

Pumps key to Darling Quarter’s sustainable success.................52

Centrifugal pump selection in the HVAC industry........................54

Let’s play the Mechanical Seal Game

by

Larry Bachus, aka The Pump Guy

OK kids, let’s play the Mechanical Seal Game. To play this game we need one industrial process plant. A paper mill, oil refinery, thermo-electric power plant, pharmaceutical/chemical plant, or municipal water plant will do.

PUMP PIONEERS

Bruce Ellis

In the ongoing Pump Pioneer series, Chris Bland catches up with Bruce Ellis who started in the industry almost 50 years ago and whose career included many years as Managing Director of Mono Pumps

CONTENTS

34

20

56

Building Services 50

43 46

60

President’s welcome...................................1 Editor’s welcome.........................................2 Contracts awarded......................................6 News briefs..................................................8 Calendar of events....................................12 Index 72

Modernising an Australian icon

The Snowy Mountains Hydro-electric Scheme is one of Australia’s most iconic engineering achievements. The scheme is now undergoing a $400 million modernisation program. The program is introducing advanced controls and protection systems technology across the entire Scheme.

Innovation for SA water pumping station

Paringa is a small town in the Riverland area of South Australia famous for its vineyards, almond, citrus and stone fruit orchards. Over the last five years, the region has been subject to strict water restrictions imposed by drought conditions.

Local capability key to emergency mine dewatering

In June 2012 Gippsland in Eastern Victoria faced some of the worst floods in recent memory. On June 6, the Morwell River dramatically burst its banks, sending floodwaters into the Yallourn open cut coal mine, damaging a coal conveyor and slowing production, then two weeks later, the mine flooded again.

Gosford council’s sewage pump station upgrade program

Gosford City Council, on the New South Wales Central Coast, is currently investing between five and seven million dollars each year to improve the performance of many of its 185 sewage pump stations. Since 2009 over 40 of its ageing pump stations have been completely upgraded, refurbished or seen their pumps replaced. 46

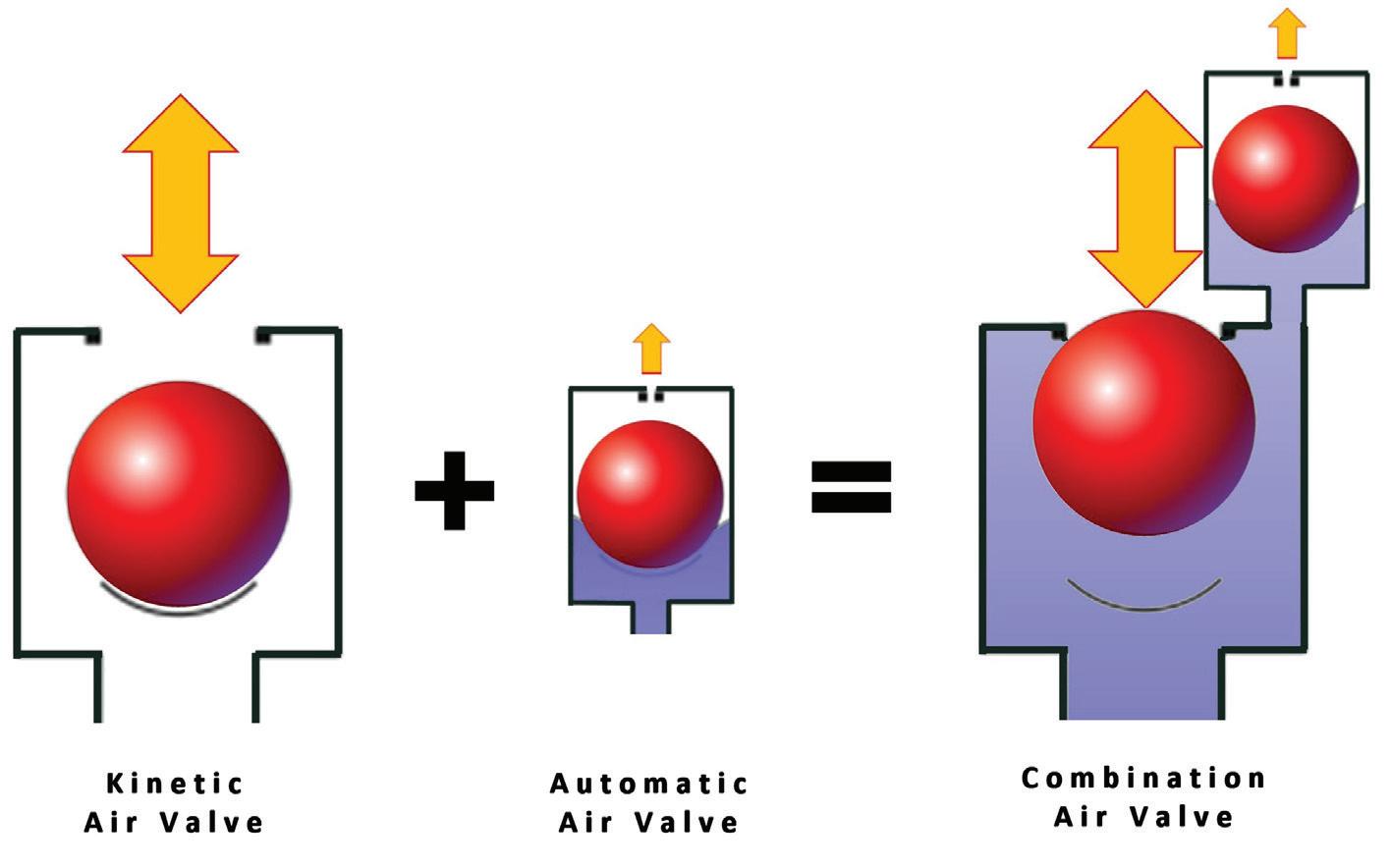

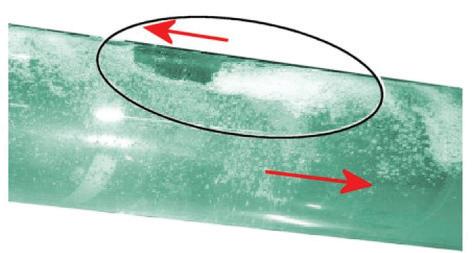

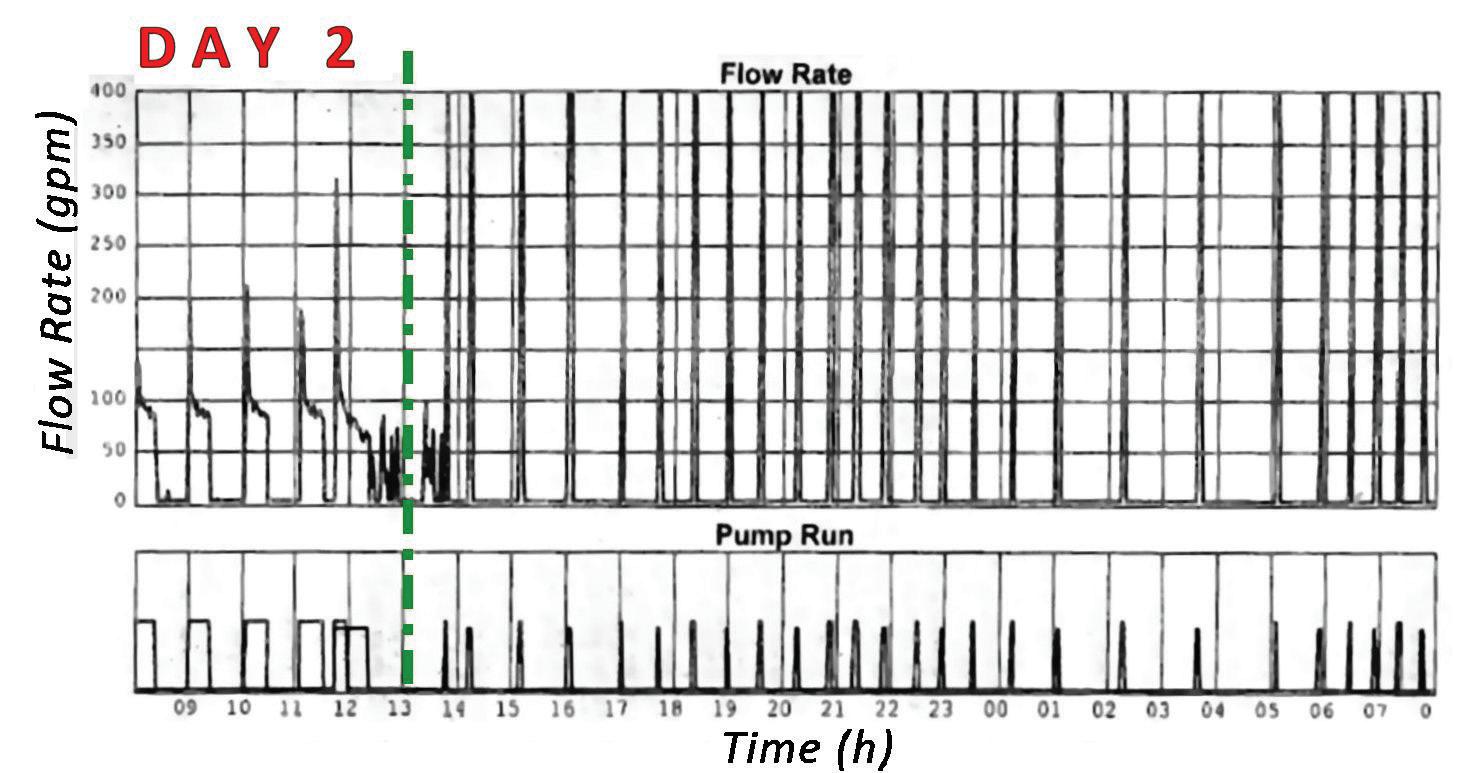

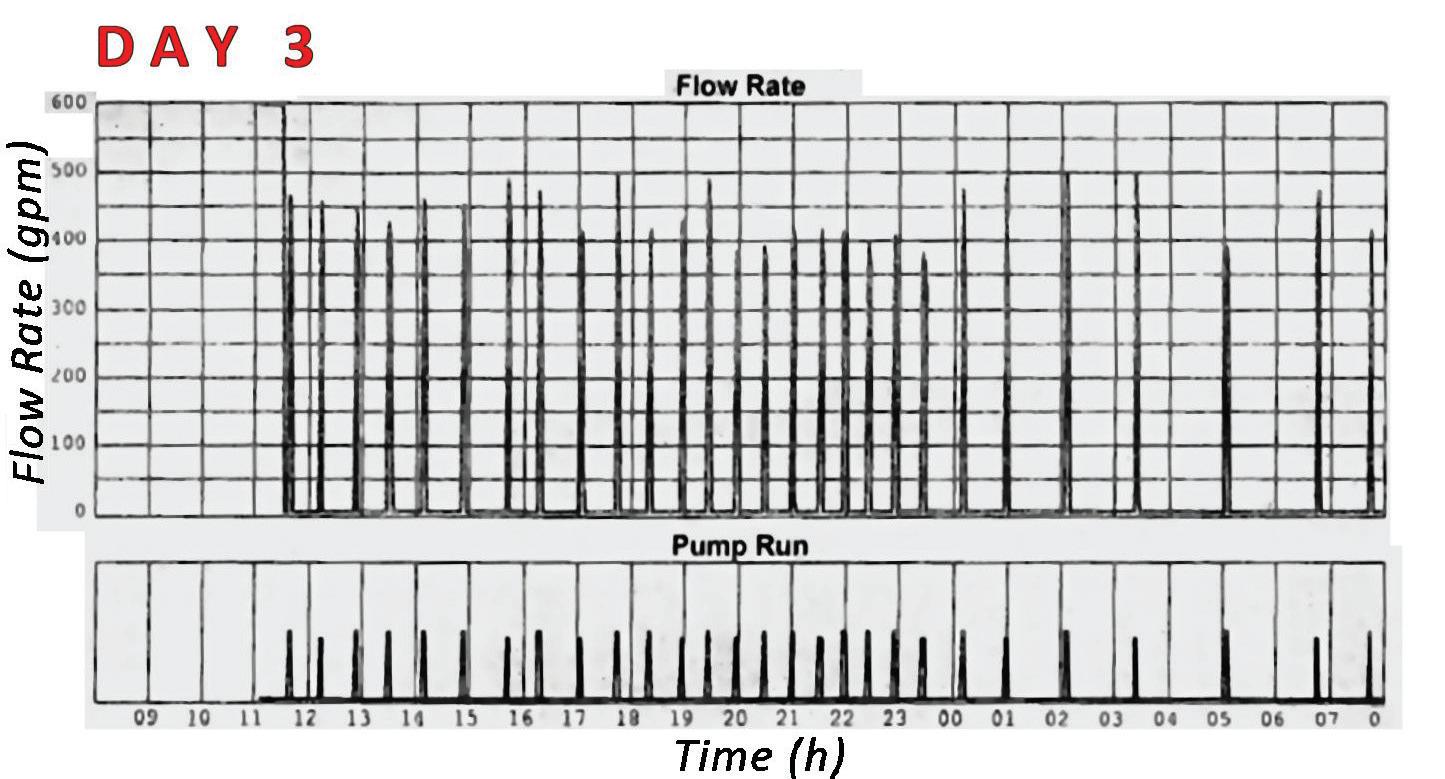

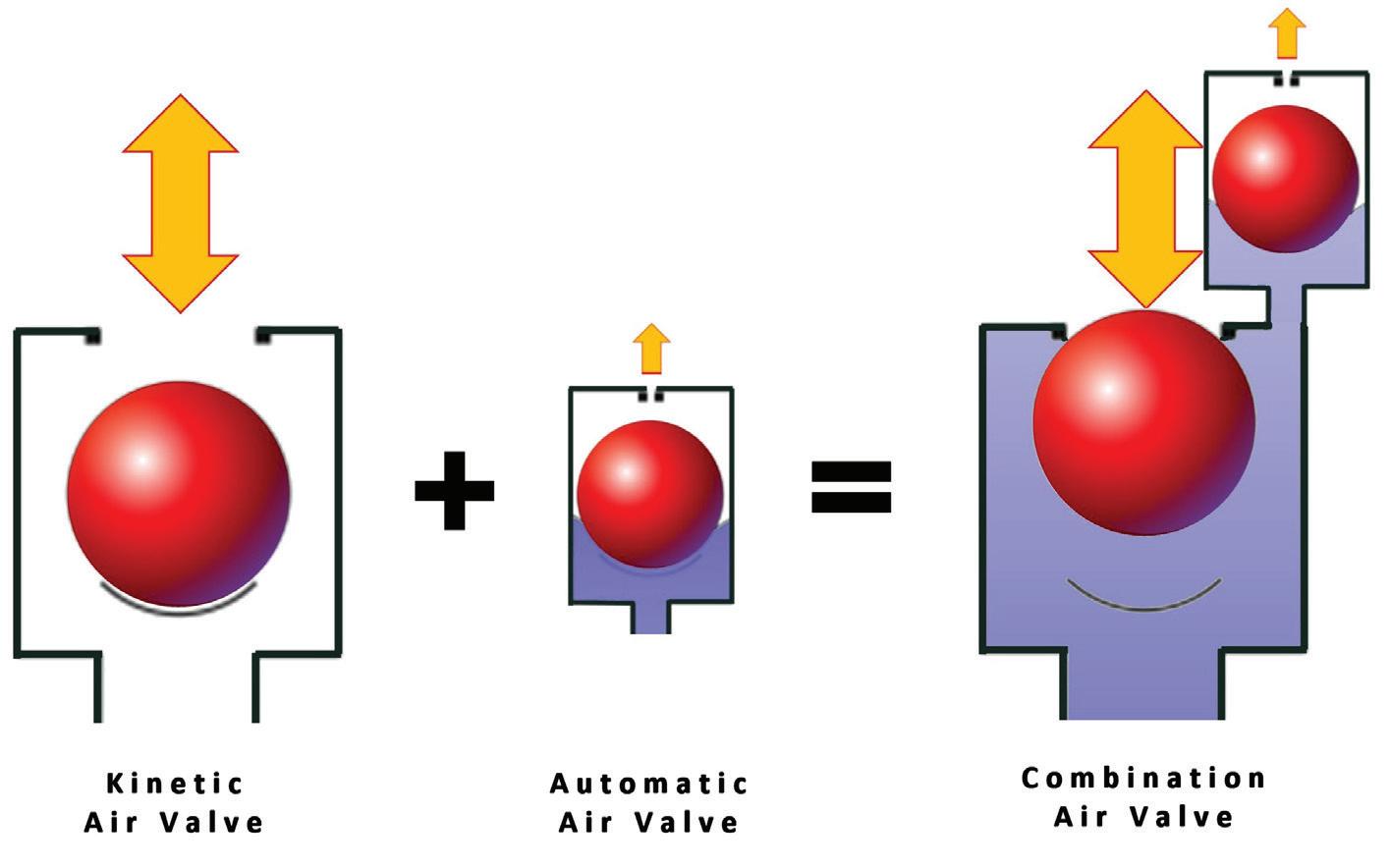

using air valves

48

In our environmentally sensitive world, the need for air release from liquid transfer systems to improve system efficiency is gaining momentum.

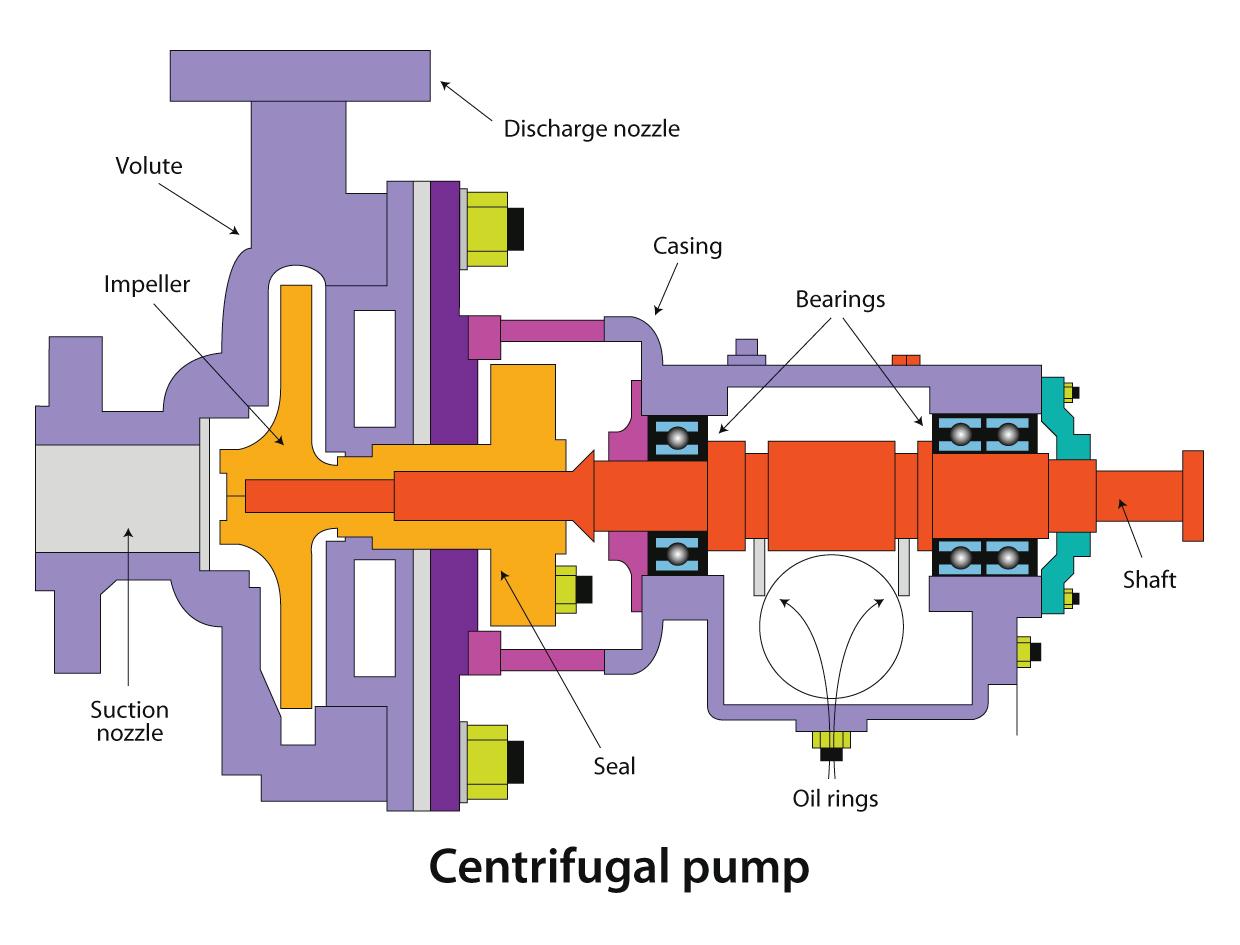

Understanding pump curves

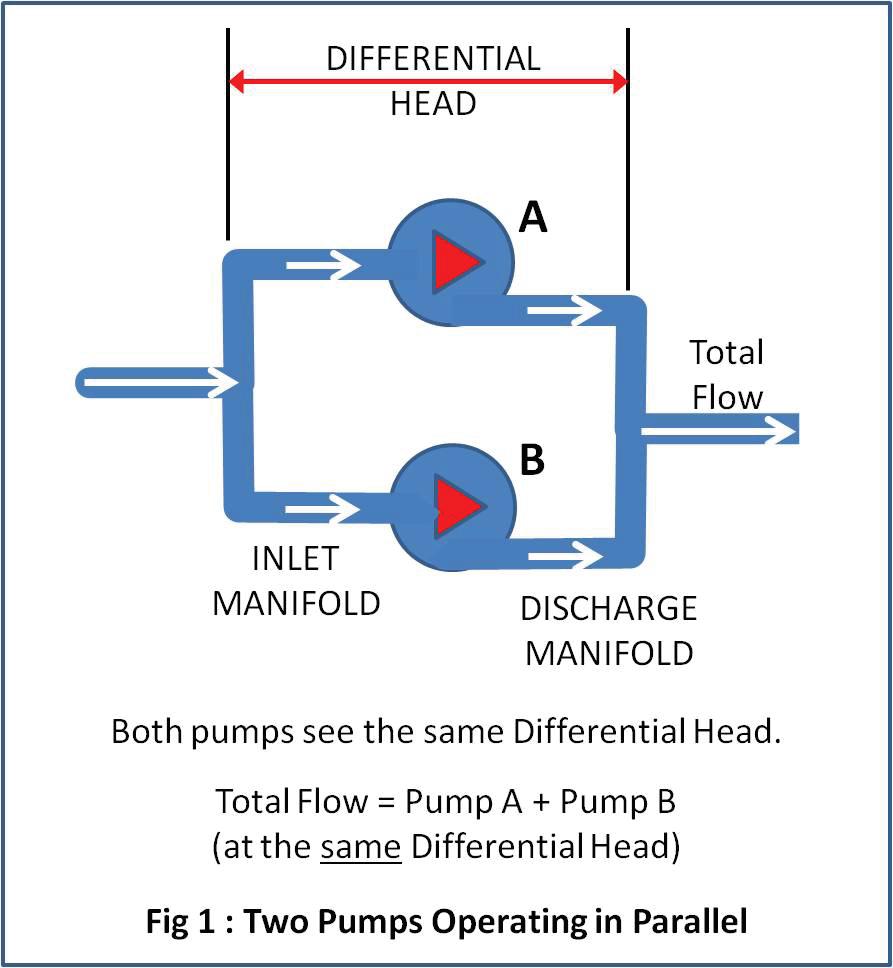

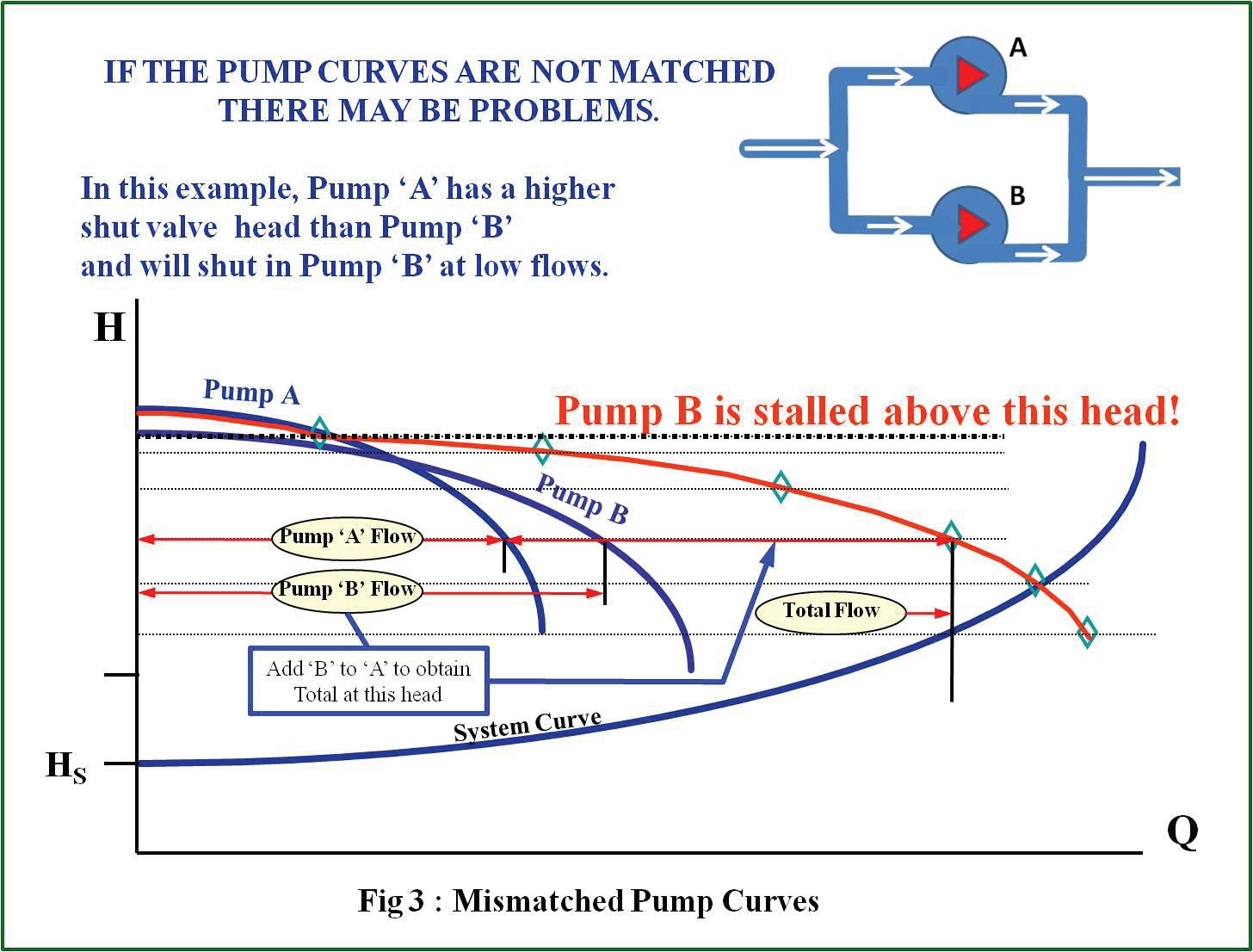

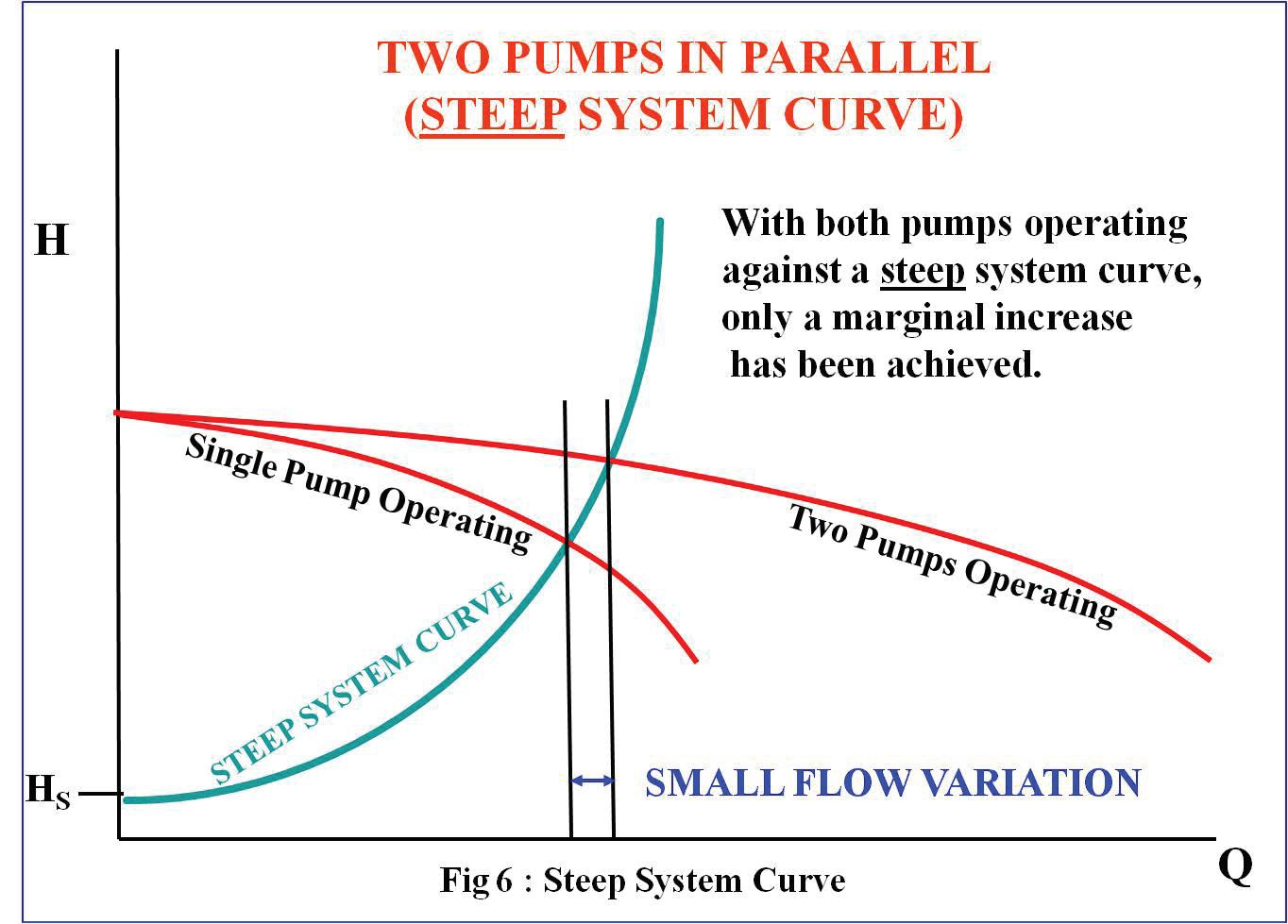

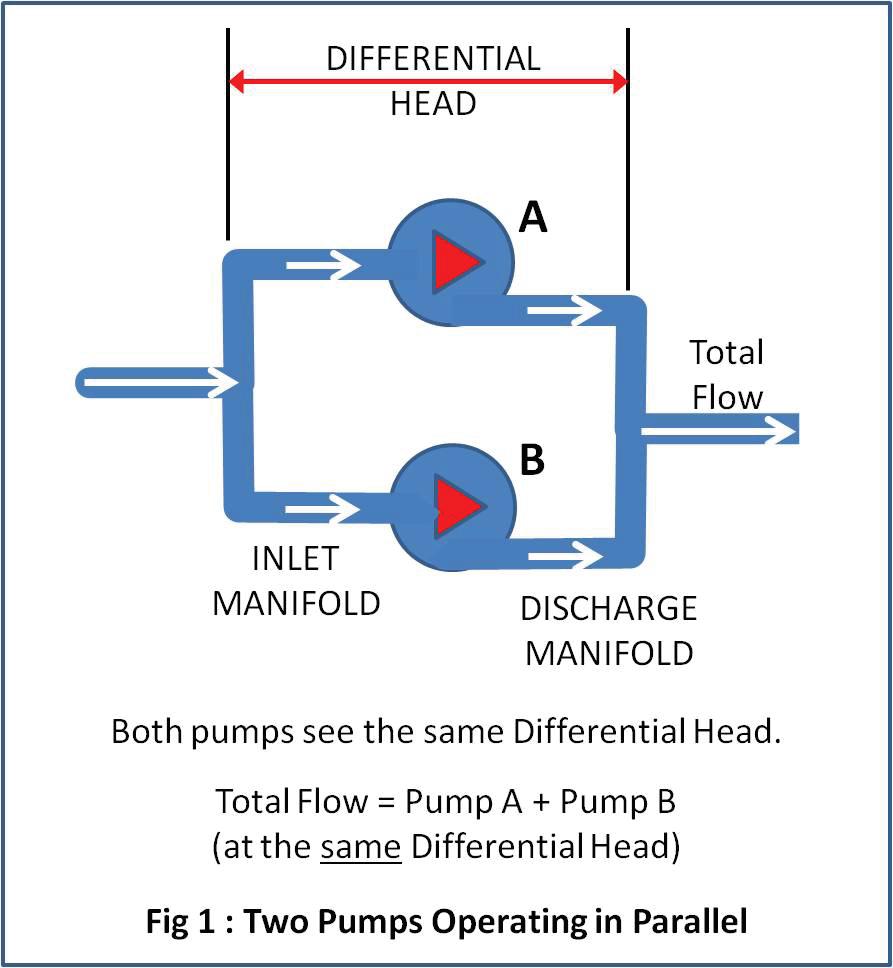

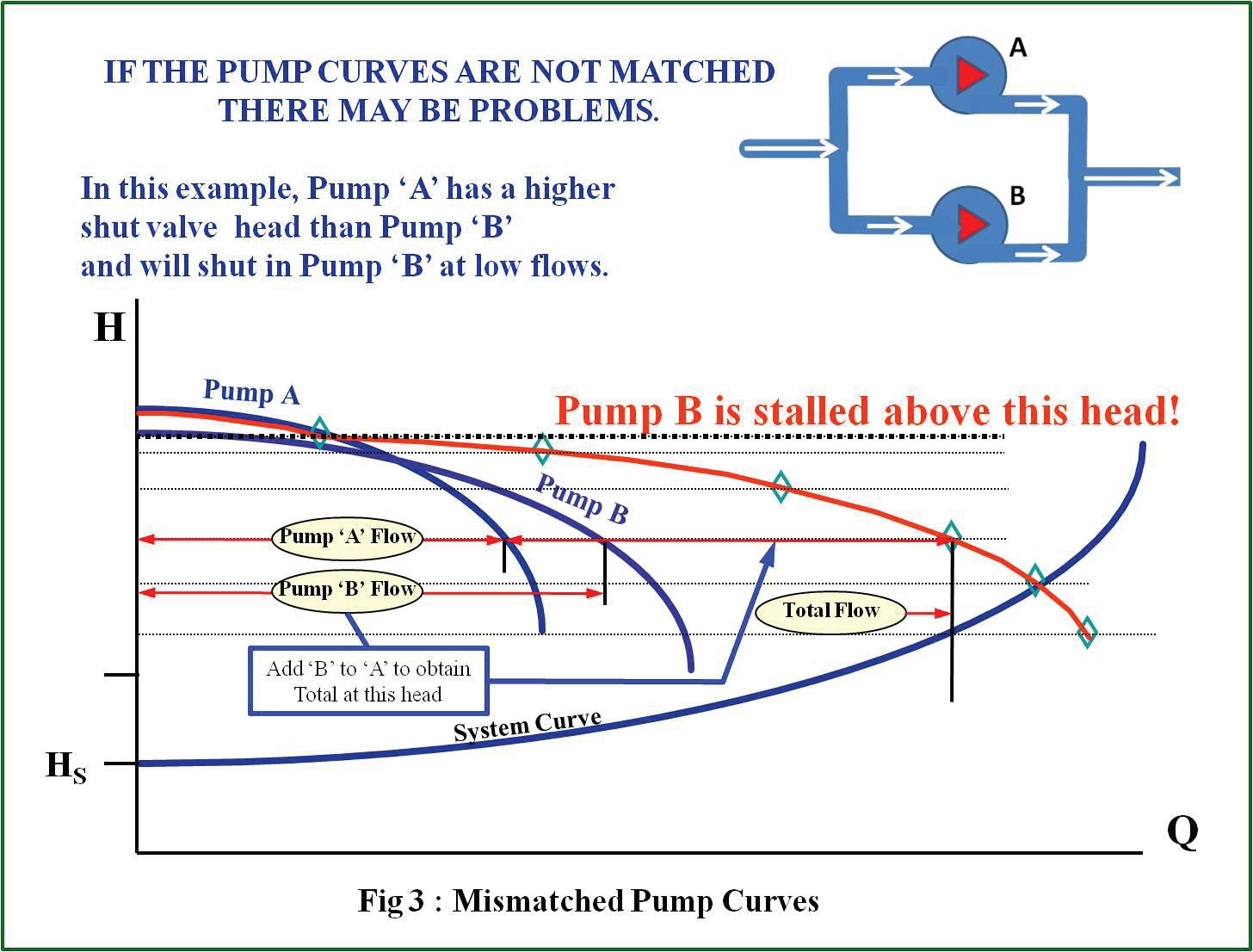

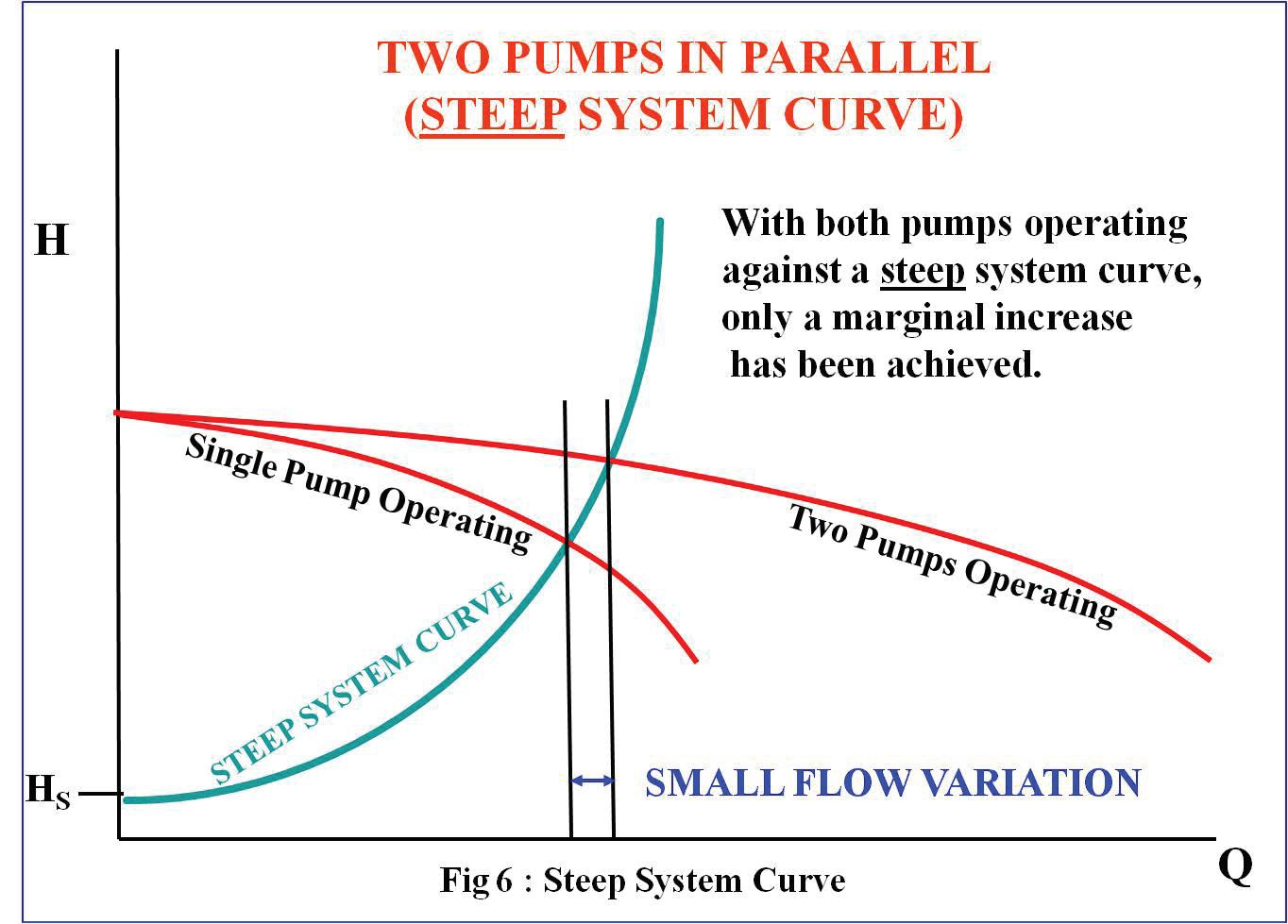

Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability.

A glossary of pump terms, from A-K

Pump School 69

PROJECTS

66

TECHNICAL

11 31 17

News

Crossley.....................................................11

PIA Member

Welling &

Regal Beloit................................................................12 Xylem...........................................................................14

Acromet.......................................................................16 Emtivac.......................................................................17

Pump Systems Ltd...............18 Product showcase Fire Equipment Australia..........................................59 CONTENTS 44

New member profile:

40

Saving energy

62

CONTRACTS

OIL & GAS

Wood Group PSN awarded Caltex contract extension

Wood Group PSN has secured a contract extension from Caltex to deliver integrated maintenance services at its two Australian refineries – Lytton in Brisbane and Kurnell in Sydney. Effective from June 2013, the $45 million, 18 month contract marks the continuation of a three year contract first awarded to WGPSN in 2010.

Osmoflo to provide off-shore desalination for Ichthys

Contracts for the provision of shipmounted plants which will supply potable and process water to crews involved

Correction

In the February 2013 edition, an incorrect image was used on page 47 illustrating typical low emissions packing for rotary style control valves. The correct image is provided below.

in the recovery of liquefied natural gas (LNG) and hydrocarbons from the Ichthys field in the Timor Sea have been awarded to leading Australian desalination specialist, Osmoflo.

Leighton Contractors awarded Ichthys onshore LNG contract

Leighton Contractors’ Services Division has been awarded a four year, $280 million operations and maintenance contract by JKC Australia LNG (JKC) for the Temporary Site Facilities Works at Blaydin Point, Darwin, Northern Territory.

AusGroup awarded Allseas contract for Wheatstone LNG

AGC Industries has been awarded a supply and fabrication contract for offshore pipeline and subsea construction by Allseas Construction Contractors Australia as part of the Chevron-operated Wheatstone Project.

GE awarded $620 million services contract for QGC

GE Oil & Gas has received a US$620 million, 22-year contractual service agreement (CSA) to provide a broad range of advanced technology services for QGC’s Queensland Curtis LNG (QCLNG) plant.

ABB wins Ichthys order

ABB has been appointed the main electrical contractor (MEC) for a new semisubmersible central processing facility (CPF) at the Ichthys oil and gas field in the Timor Sea off Western Australia. The order is valued at $15 million.

Featured project

More pump contracts awarded on Ichthys

Inpex has recently awarded further pump contracts for both the offshore CPF and FPSO and the onshore gas processing plant on the Ichthys LNG project.

Renroc Group (Pumps & Engineering) was awarded a contract for a number of API 610 Centrifugal Pumps for the Central Processing Facility (CPF) and the FPSO. The scope of supply for the orders to Renroc includes the design, manufacture and installation of pump packages on the CPF and FPSO. The pumps will be delivered in 2013.

The contract for two sewage pumps has been awarded to Ruhrpump Australia and includes the design, manufacturing, testing, certification painting, documentation and operation spares, preservation, packing and transportation of 12 submerged motor sewage pumps with a capacity of 14m3 and a head of 19 m and 12 submerged motor sewage pumps with a capacity of 25 m3 and a head of 27m .

These two wins for Australian companies stand in contrast to the number of pump contracts being awarded to international suppliers.

The project also awarded the design, manufacturing, testing, certification painting, documentation and operation spares, preservation, packing and transportation for various non API “Vertical Centrifugal Type Pump” to Flowserve GB.

• Motor or wall mountable

• Fully programmable on site

• Software specifically designed for pump operation, control and protection

• High level hardware design

• More flexibility and cost savings

• Energy savings up to 70%

• Simple mounting “clip and work”

• Multi-pump capability up to 8 pumps

6

Melbourne: (03) 9793 9999 Sydney: (02) 9671 3666 Brisbane: (07) 3200 6488 Email: info@brownbros.com.au Web: www.brownbros.com.au

HYDROVAR, the modern variable speed pump drive taking pumping to a new level of flexibility and efficiency. Call us today for a Hydrovar technical brochure to see how we can deliver your pumping solutions. DELIVERING PUMPING SOLUTIONS 04/13

RECENT

AND TENDERS AWARDED

MINING

Monadelphous Iron Ore contract Engineering group Monadelphous has been awarded a major iron ore contract for Rio Tinto’s Western Turner Brockman Project in the Pilbara region of Western Australia. The contract is for the supply and installation of structural, mechanical, piping, electrical and instrumentation works for the construction of the Western Turner Brockman iron ore plant.

EPC contract awarded for Carosue Dam Tertiary Crushing

GR Engineering has been awarded a contract from Saracen for the engineering, procurement and construction (EPC) contract for the Carosue Dam Tertiary Crushing Project near Kalgoorlie in Western Australia.

Ausenco to manage Newcrest projects

Ausenco Limited has secured an initial three-year contract to manage a portfolio of projects at Newcrest Mining Limited’s Lihir gold operation in Papua New Guinea. Ausenco will provide project delivery services to support ongoing capital projects, with the services delivered under an EPCM contract working closely with the Newcrest team.

Macmahon awarded largest ever mining contract

Macmahon Holdings Ltd has been awarded its largest single mining contract, worth $1.8 billion, to deliver open cut mining services as part of the Christmas Creek Mine expansion for Fortescue Metals Group Ltd.

WATER

Tenix awarded Nambour STP Upgrade

Tenix has been awarded a $40 million contract by Unitywater to design, construct and commission a major upgrade to the Nambour Sewage Treatment Plant (STP).

Gosford Council awards pump station tender

Gosford Council has awarded the tender for the refurbishment of a sewer pump station at Hardys Bay. The tender was awarded to local company Carey Constructions Pty Ltd, who beat out four other tenderers.

ONLINE

Keep up-to-date with all the latest news

You can get all the latest news daily online at the pump industry website. Sign up for the free newsletter so you don’t miss anything.

Get the latest contracts and tenders awarded at; pumpindustry.com.au/category/awarded/

See the latest open tenders at; pumpindustry.com.au/category/tenders/

Sign up for the free online news at; pumpindustry.com.au/subscribe/

Or just visit the home page and follow the menu options.

Got any news?

If you have any news, such as people movements, new staff, contracts awarded, projects completed etc, please submit to the editor at

Inpro-Seal compound labyrinth bearing seals and air purged product

magazine@pumpindustry.com.au

Full details at www.pumpindustry.com.au

seals. Manufactured in

suit your application. Stevco are authorised agents for We offer a comprehensive range of mechanical seals from simple pusher styles to single, double and split cartridges, and custom engineered sealing systems. We supply seals for pumps, mixers & reactors and for duties including water, chemicals, hydrocarbons, pharmaceutical, sewerage, paper pulp and food & beverage. Contact us to discuss your sealing needs. Melbourne (03) 9408 3875 vicsales@stevco.com.au www.stevcovic.com.au sealing news sealing news Mechanical Seal Solutions Available from... 7

high quality bronze or stainless steel to

Sterling Pumps

Sterling Pumps has moved, the new facility incorporates new pump manufacture, pump repair and submersible motors rewind. Capacity is increased with four CNC lathes and machining centres, and a fabrication bay that includes robot welding. A 10 ton overhead crane services the full length of the workshop including the test bay.

The test bay is designed to service submersible pumps and vertical pumps with a 15m deep 2m diameter pit, end suction pumps are serviced by surface tank water. They have 300kw available on site which can be expanded to 1Mw with additional generator power.

New address:

Sterling Pumps Pty Ltd, 14 Sharnet Circuit, Pakenham, VIC 3810

Ph: (03) 9729 5044

Pump Doctor

Pump Doctor has moved to new premises located at;

88 Wedgewood Road, Hallam VIC 3803

New Ph: (03) 9796 5001

New fax: (03) 9796 3499

Power Pumps & Engineering

Power Pumps have opened a branch in QLD and have appointed Malcolm Maxwell as General Manager. The new address is;

Unit 5, 35 Notar Drive Ormeau QLD 4207

Grundfos buys BKB

Grundfos has announced that they will acquire long term local Australian partner, B.K.B. Pumps & Tanks Pty Ltd.

The new business will merge the resources of B.K.B. Pumps and Tanks Pty Ltd with Grundfos’ Australian Commercial Building Services (CBS) team to create a new entity with national reach and industry leading capabilities and resources. The move will further strengthen Grundfos’ position in the Australian commercial buildings market.

The new entity will be called B.K.B. Building Solutions Pty Ltd (B.K.B.). B.K.B. will operate independently to Grundfos Pumps, with its own Management Team and Board of Directors. The two existing major shareholders of B.K.B. Pumps & Tanks Pty Ltd, Mr Bala and Mr Jeya Thuraisingam, will remain part of the B.K.B. Management Team as General and Deputy General Managers respectively, allowing the company to benefit from their vast experience within the industry.

Grundfos separately announced they will be supporting and selling the DAB brand in Australia and New Zealand. The DAB brand has been owned by the Grundfos Group for over 15 years and this change is seen a natural development.

New conditioning monitoring book from Ray Beebe

A new book by Ray Beebe, ‘Steam Turbine Performance and Condition Monitoring‘ is now available.

Written for the plant engineer, this book shows how to apply condition monitoring by performance analysis to steam turbines. Its aim is to assist to assist with performance problem solving and in decision making on steam turbine maintenance.

With a foreword by distinguished turbomachinery engineer Heinz Bloch, this book should be owned by every power plant engineer and is a worthy companion to Ray’s previous two books Machine condition monitoring (1988, rev 2009) and Predictive maintenance of pumps using condition monitoring (2004).

The book is available from the reliabilityweb.com bookstore.

8

AUSTRALIA UNITED PUMPS AUSTRALIA ISO 9001 CERTIFIED AS2417 ISO9906 API 610 Hydraulic Institute Performance Testing Inspection and trouble-shooting Case build up and re-machining Axial split case facing and reboring Axial thrust balancing Shaft and bearing upgrades Mechanical Seal upgrades to API 682 Custom Spare Parts Rotating Element balancing ASME & AS1210 qualified welding Hydrostatic Testing 31 Western Avenue, Sunshine, Victoria 3020 Phone: +613 9312 6566 Fax: +613 9312 6371 Email: unitedpumps@unitedpumps.com.au http://www.unitedpumps.com.au/ Efficiency Improvement Reconditioning Restore Clearances Re-Engineering Repair, Re-Manufacture For ALL types of Centrifugal Pumps NEWS BRIEFS - Keep up-to-date at www.pumpindustry.com.au Office

moves

John Weaver to head Xylem Water Systems Australasia

Widely experienced water industry professional John Weaver has taken up a new appointment as General Manager for Australia and New Zealand of the Applied Water Systems Division of international water business Xylem Water Systems Australia Pty Ltd.

He is based at the company’s headquarters in Mentone in Melbourne’s south.

John has had almost thirty years of experience in senior marketing and management roles with the last fifteen years engaged with leading Australian water businesses.

“I look forward to renewing contact with the many people in the water products sector that I have met and dealt with in my career in the industry” John says.

John Weaver’s contact details are care of Xylem Water System Australia Pty Ltd Unit 3/1 Federation Way Chifley Business Park Mentone 3194. Telephone 03 9551 7333 or 0438 770 716 or email john.weaver@xyleminc.com.

Update on water industry initiatives

By R N (Bob) Herbert AM

As the Australian Government’s Water Supplier Advocate, I have been appointed by the Minister for Industry and Innovation to promote capable and competitive Australian firms and increase their ability to win more work in the water sector.

Fifty years ago, we changed the direction of the industry Literally.

In partnership with waterAUSTRALIA, I am leading Water Industry Capability Teams. There are over 320 members in these Teams, working together to market their offerings and increase their access to customers through targeted showcasing, trade shows and international water missions.

Under the Australian Water Supplier Compact agreement, I am also working with waterAUSTRALIA, the Water Services Association of Australia (WSAA) and the Industry Capability Network (ICN) to address barriers and increase suppliers’ access to opportunities in the urban water sector. Initiatives under the Compact are already underway including showcases of energy efficient and sustainable solutions to the water utilities to help them address some of their most pressing challenges and, in-turn provide valuable opportunities for capable Australian firms.

Turning to the international market, water missions to the US and Singapore over 2011 and 2012 have generated over 210 million in new leads. As a result of this success, I will be working closely with Austrade and waterAUSTRALIA to lead a trade mission of Australian water suppliers to China in June this year to promote how Australian innovation can help solve China’s water management challenges.

There is no better time to take advantage of the wide range of initiatives in place to support Australian industry. I encourage all Australian firms to be involved and have a say in the future direction of the water sector.

For more information about the Capability Team’s members, please visit directory.wateraustralia.org/

10 NEWS BRIEFS - Keep up-to-date at www.pumpindustry.com.au

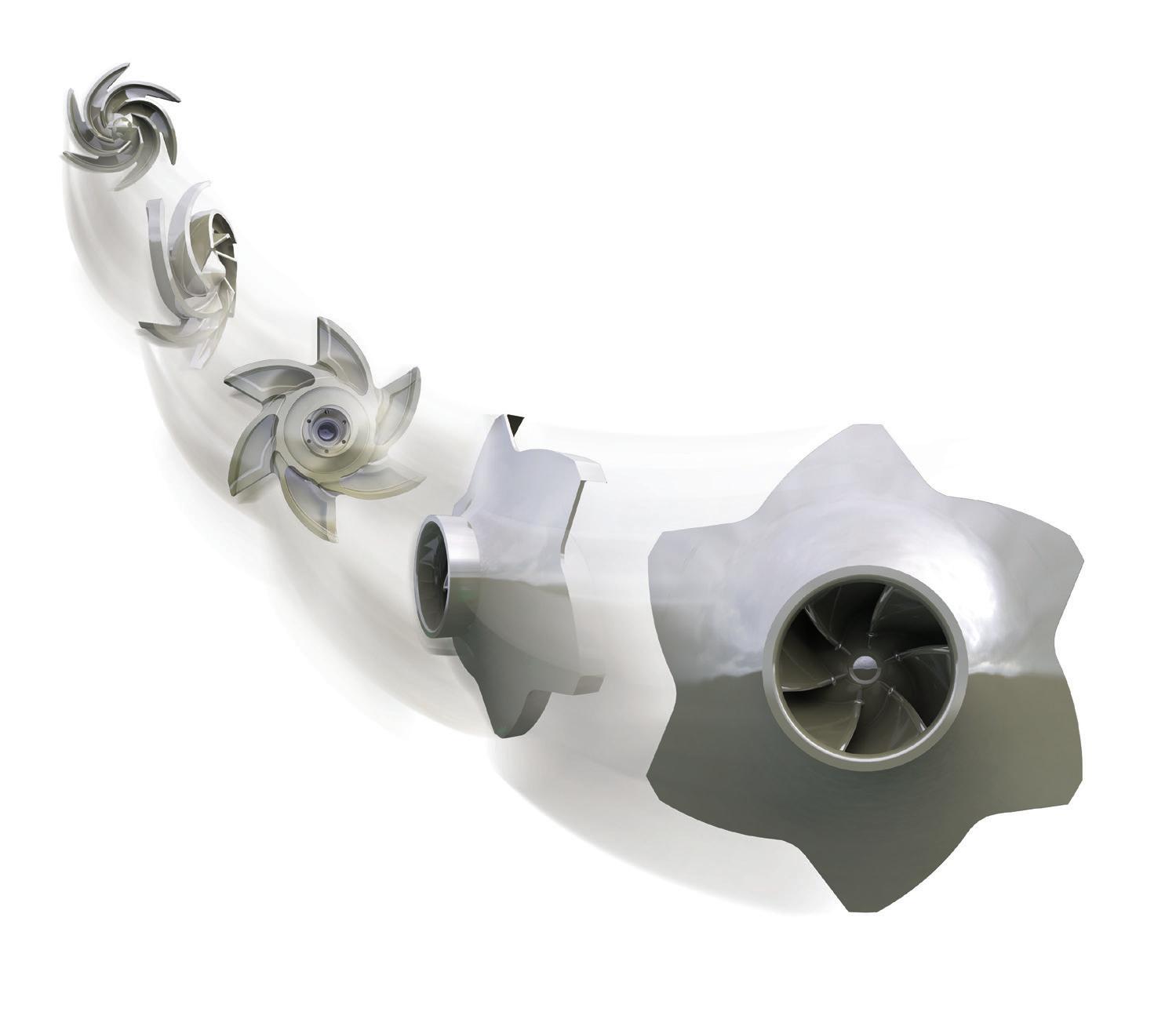

Experience In Motion flowserve.com/rvimpeller In 1962, Flowserve introduced the Durco® reverse vane impeller and forever changed the chemical process pump landscape. Its revolutionary design moved the wear surface from the casing to the rear cover This change had huge implications on the pump’s per formance, reliability and total cost of ownership, and has made the Durco Mark 3™ pump a favorite of leading chemical processors the world over The Durco reverse vane impeller is still impacting the industr y today with the Durco Mark 3 ANSI/ASME pump and the newly released Durco Mark 3 ISO chemical process pump See how at www.flowser ve com/r vimpeller For Enquiries, please contact telephone number 1300Flowserve or email to Pumpsales_Australia@flowserve.com

New lease of life for Lister Petter

You could have been forgiven for thinking that Lister Petter had gone out of business, and for a while there it was looking like it might, but for a couple British Industrialists who had the foresight to purchase the company with a view to returning it to its former glory.

One part of that plan was to establish an Oceania Regional Office within the region and it was decided that New Zealand was the place. That done Lister Petter set about a review of their distributors worldwide, that review found that whilst Australia was once a Lister Petter heartland many new players had entered the market and the Lister product had lost some of its glory.

In August 2009 Melbourne based company Welling & Crossley were appointed as the new Lister Petter distributor in Australia. Welling & Crossley are a well known manufacturer and distributor of Generating Sets around the country and a big time user of Diesel Engines. Their national distribution networks gave an immediate new market to the Lister Petter product and with the appointment of Mike Edwards (formerly having worked with both of the market leading brands

of small Japanese engines) as National Sales Manager for the new Lister Petter division everything was in place.

“I’ve spent most of my working career putting these guys out of business, I guess it’s Karma that I’m now heading it up and re-establishing the brand,” says Mike.

Welling & Crossley believes there is still a place in the market for a solidly built, hardworking, old fashioned diesel engine in Australia. Many of the recent comers and larger companies have been obsessed with emissions controls and making engines for the USA and European markets, but here in Australia we still use diesel engines in the outback, hundreds of kilometers from nowhere, and the need for reliability is paramount. And Lister Petter “doesn’t make throw away engines, you can rebuild them more

than once and more importantly you can afford to!” says Mike.

That’s not to say Welling & Crossley haven’t added a little technology to the old Lister Petter reliability, they are fitting them with state of the art Murphy irrigation control gear and with their own brand of fully programmable generator control gear. You can make them start or stop anyway you like.

Welling & Crossley are offering a full range of both Air Cooled and Water cooled Engines, Generating Sets, Fire Pump Engines and purpose built generators for Electric Submersible Bore Pumps and Center Pivot Irrigators.

For more information on the Lister Petter range contact Mike Edwards at Welling & Crossley on 1300 524 485 or email

11

medwards@wellcross.com.au.

PIA MEMBER NEWS

Who is Regal Beloit?

Regal Beloit Corporation is a leading manufacturer of electric motors, mechanical and electrical motion controls and power generation products serving markets throughout the world. Regal Beloit is headquartered in Beloit, Wisconsin, and has manufacturing, sales and service facilities throughout the United States, Canada, Mexico, Europe and Asia.

Regal Australia brings together the strength and experience of three of Australia’s leading suppliers of engineered industrial products. CMG, OBA and Transmission Australia are now in a position to offer industry an unparalleled range of products under the Regal Australia banner.

Their products are efficient and innovative; they conform to Australian design, performance and engineering standards. Regal Australia sources products from Regal manufacturing facilities and

represents some of the world’s leading industrial manufactures.

Regal Australia embraces the company core values of Integrity, High Energy and Performance and has adopted the initiatives of customer care, globalization, innovation, sustainability and simplification.

The company business statement is that “We convert power into motion to help the world run more efficiently” has direct links to our core values and initiatives.

Event Calendar

PIA Events

PIA General Meeting 14 May 2013 – Adelaide

PIA Fire Pump standards seminar 15 May 2013 – Adelaide

PIA General Meetings 13 August 2013 - Sydney 12 November 2013 (AGM)– Melbourne

For more information or to register for PIA events, visit pumps.asn.au or email pumpsaustralia@bigpond.com

Other Events

OzWater

Perth 7-9 May 2013 www.ozwater.org

Auspack Plus

Sydney 7 - 10 May 2013 www.auspackplus.com.au

National Manufacturing Week

Melbourne 7-10 May 2013 www.nationalmanufacturingweek.com.au

APPEA

Brisbane 26-29 May, 2013 www.appea.com.au

PACIA

Melbourne 4-6 June 2013 www.pacia.org.au/events/

WIOA Queensland

Gold Coast 5-6 June, 2013 www.wioa.org.au

Pumps and Compressors

Perth 25-26 June, 2013 www.idc-online.com/

IPWEA

Darwin 11-15 August, 2013 www.ipwea.org.au

WIOA Victoria

Bendigo 4-5 September, 2013 www.wioa.org.au

12

2012SB300 PIA MEMBER NEWS

more online visit www.pumpindustry.com.au for exclusive online-only content and sign up for free

Read

DYNAMIC .

As a corporation, we are becoming a more dynamic enterprise - continuously innovating and growing to reach more customers in more markets. And we are doing so with the confidence that comes with our years of industry experience.

As a corporation, we are becoming a more dynamic enterprise—continuously innovating and growing to reach more customers in more markets. And we are doing so with the confidence that comes with our years of industry experience.

BOLD.

Regal-Beloit Corporation, the parent of CMG Engineering Group, is in the midst of simplification. We are streamlining our business processes, standardising our computer systems, and improving our communications - all with the idea of making it easier for customers to do business with us.

Regal-Beloit Corporation, the parent of Marathon Electric, is in the midst of simplification. We are streamlining our business processes, standardizing our computer systems, and improving our communications – all with the idea of making it easier for customers to do business with us.

As we bring life to the new Regal identity, our brand boldly reflects our corporate objective to become a more focused, integrated and customer centric company.

As we bring life to the new Regal identity, our brand boldly reflects our corporate objective to become a more focused, integrated and customer centric company.

As a premier Regal brand, Marathon Electric will continue as a dynamic and customer focused brand serving partners around the world. The Marathon Electric brand promise remains providing customers with a vast array of efficient solutions for commercial and industrial applications performing every day for the long run.

13 1

Identity

“Regal”

Our New Corporate

is Simply

SIMPLE.

2012SB300 1-20.indd 1 3/6/13 8:39 AM Sales: 1300 888 853 www.regalbeloit.com

Xylem - a global water technology company

On October 31, 2011, Xylem completed its spinoff from ITT Corporation, and began a new chapter as a leading global water company.

Xylem’s market-leading product brands, applications expertise and technological strength enable the transport, treatment, testing and efficient use of water in public utility, residential and commercial building services, industrial and agricultural settings. The company serves customers in more than 150 countries to address critical water issues such as growing water scarcity, aging infrastructure and more stringent environmental regulations. On November 1, 2011, Xylem begun regular trading on the New York Stock Exchange under the ticker symbol XYL, and was listed on the Standard & Poor’s 500 Index.

This is a unique company, the product of more than 100 years of experience in the water business and the collective work and expertise of nearly 12,000 employees and strategic partners around the world. While the name has changed with the spinoff, customers will find in Xylem the same commitment to providing local service to meet their specific needs while leveraging our global network, technological strength and applications expertise.

Xylem serves a $30 billion segment of the global water equipment and services market through a distribution network consisting of a direct sales force and independent channel partners. The company’s products and services address the full cycle of water and are key in the collection, distribution and use of water. Well-known and respected

product brands such as Lowara, Goulds Water Technology, Bell and Gossett, Flojet, Flygt, Godwin, WTW and YSI, among others, will continue their place in the water industry as a part of the Xylem portfolio.

Xylem in Australia and New Zealand is split into two divisions. The Water Solutions team focusing on the Flygt, Godwin, Wedeco and other waste water brands with the Applied Water Systems team focusing on Lowara, Goulds, Vogel and other clean water brands.

Xylem’s ANZ Director Richard Buckwell says “we are committed to supporting the large range of product supplied by Xylem across the region by our two divisions. The two teams work closely together to provide a total solution to fulfill the needs of our customers. A good example of that solution package is the Sydney Airport project where we provided equipment to treat and recycle storm water

runoff for non-potable uses like cooling towers, washing vehicles and landscape irrigation. This saves the airport about 350 million litres of fresh water a year – enough water to fill 140 Olympic sized swimming pools.”

The name Xylem is derived from classical Greek and is the tissue that transports water in plants, highlighting the engineering efficiency of our water-centric business by linking it with the best water transportation of all -- that which occurs in nature. For more information, visit http://www.xyleminc.com.

Pump

14

PIA MEMBER NEWS

Residential Contact: Water Solutions – Greg Pratt, Sales and Marketing Director 08 9475 1922 www.xylemwatersolutions.com/scs/ australia Applied Water Systems – John Weaver, General Manager – 03 9551 7333 australia.xylemappliedwater.com/

Pump Selection Guide

Commercial Water

Residential &

Lowara

The sealless alternative

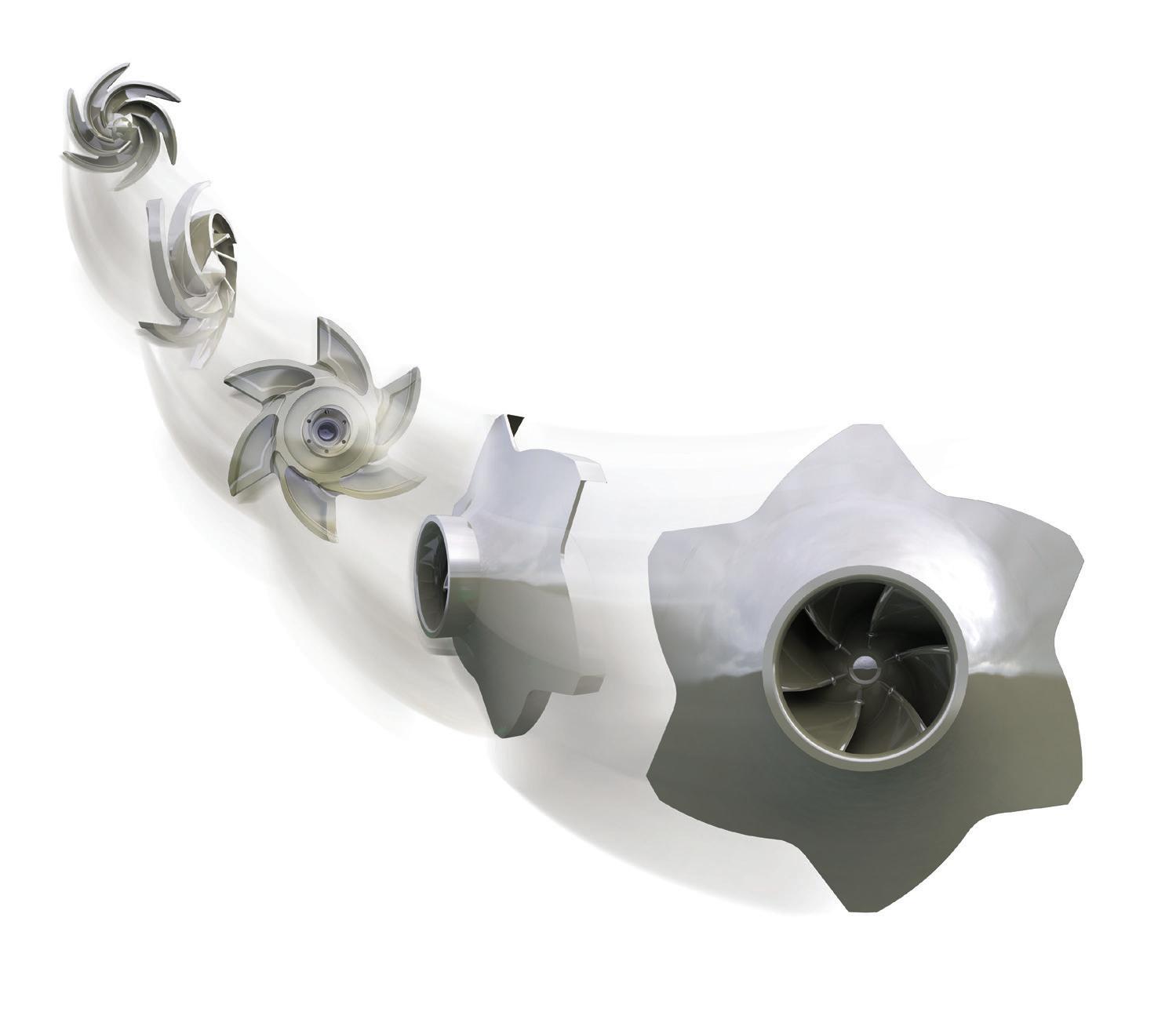

Mag-drive pumps offer a sealless alternative to mechanical seal pumps. Instead of a coupling between the driving motor and the pump shafts to power the impeller, the drive shaft is surrounded by magnets, allowing the magnetic field to be transferred to the impeller shaft through a completely enclosed shell through which the fluid passes.

Sealless pumps have the benefit of zero leakage as well as reduced wearing and maintenance issues. As a result, sealless pumps are particularly useful for pumping fluids that you particularly don’t want to leak, ie corrosive, toxic and noxious liquids. Acromet, a provider of innovative pumping solutions, are one of the foremost experts in handling this type of fluid.

Acromet has an extensive range of MagDrive pumps that are designed to meet the high demands of corrosive, toxic and noxious liquids that are widely encountered throughout all industries from Agriculture to Zinc Mining and everything in between.

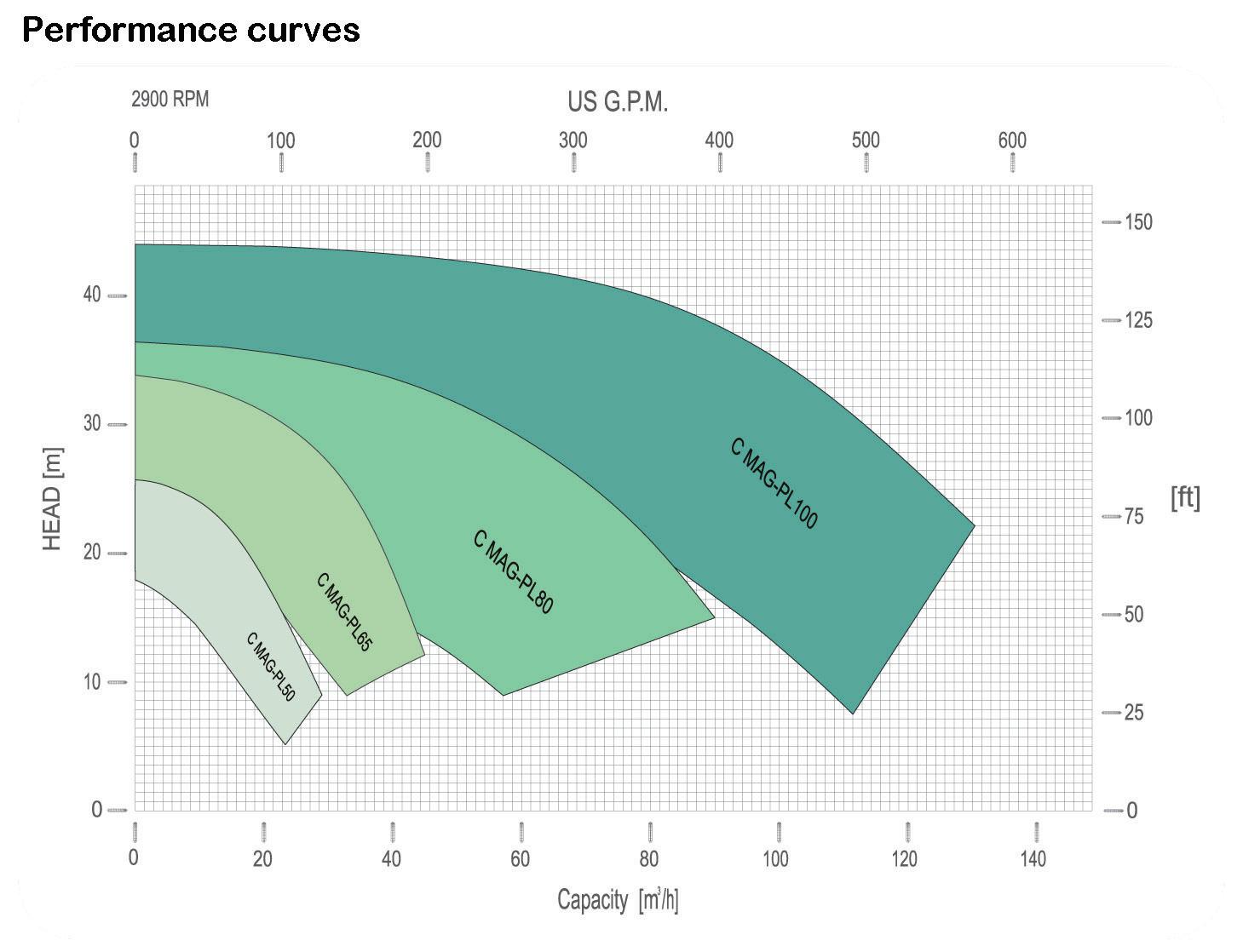

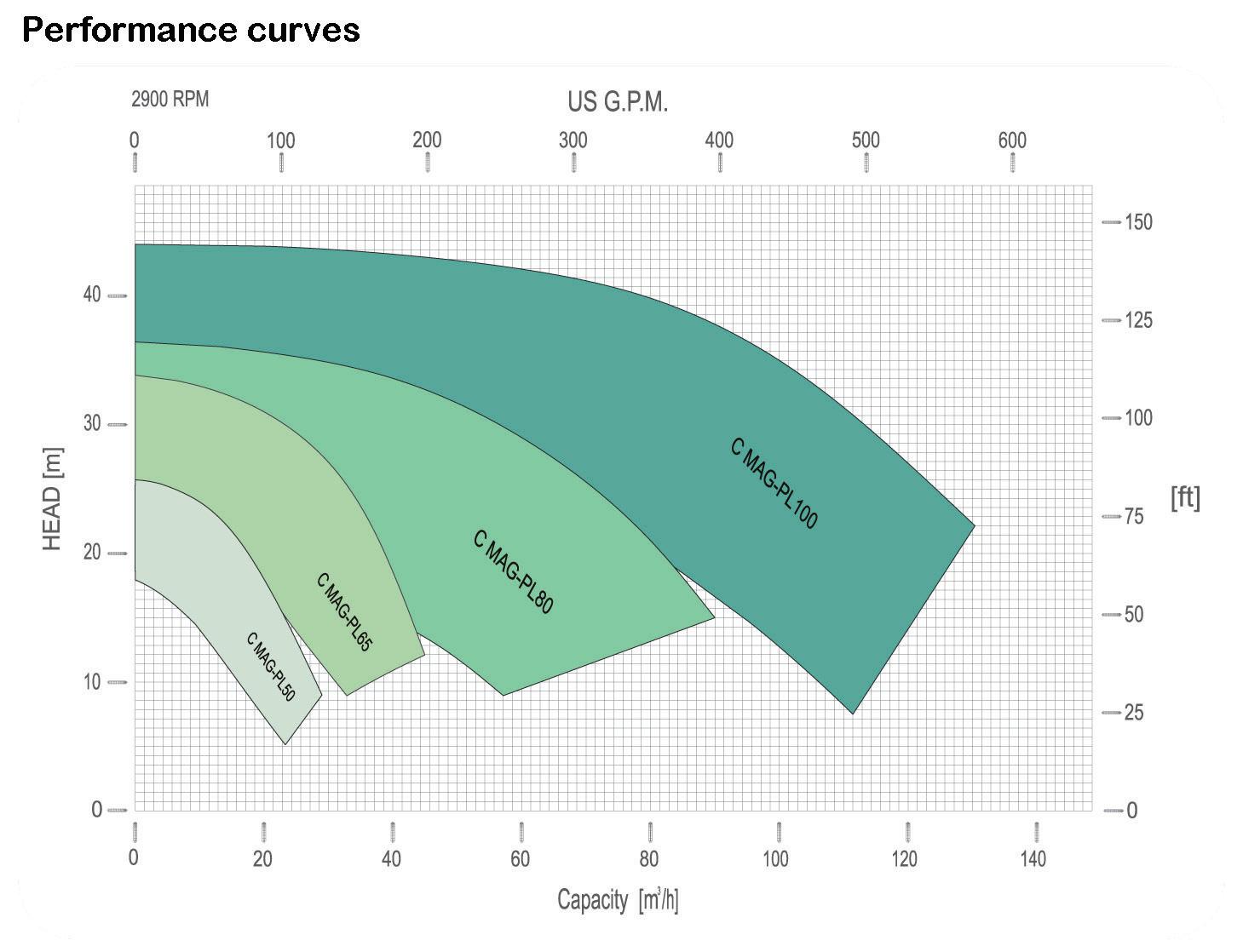

This issue we take a closer look at the C MAG-PL Series.

This pump demonstrates how the separation of liquid chamber/atmosphere by means of an isolation shell is the best solution to pump aggressive chemical, high purity liquids and liquids difficult to seal.

The hermetic sealless design is the best solution for the chemical and pharmaceutical industry.

The pump is constructed with closecoupled motors drivers, which are conventional motors drivers mounted directly to pumps frame. No base, coupling or guards are required for this mounting style. It uses universal flanges connections that meet DIN PN16 and the ANSI 150#.

Operating Limits

• Flow up: to 140mc/h

• Head up: to 44m

• Max system pressure: 16 bar

• Max viscosity: 200 cSt

• Temperature ratings:

• from 85°C

• to 120°C

• Electric motors: from 1,5 to 18,5 kW

• ATEX II - / 3G cbk II C T5

PIA MEMBER NEWS

For more information visit www.acromet.com.au

16

Major vacuum pump export to Saudi Arabia

Emtivac Engineering has recently completed a large project with eight liquid ring vacuum pump units for a new Alumina Refinery in Saudi Arabia.

There are 3 x 500 kW units for Pan Filters and 5 x 280 kW units for Disc Filters. The heavy duty liquid ring vacuum pumps are Emtivac N2BE/HE units with Ductile Iron End Castings. The N2BE/HE vacuum pumps were selected due to their unique high efficiency design and low operating speeds at the duty points requested. Gearboxes are water cooled Siemens/ Flender units with sunshades and electric motors from WEG. The entire skid is designed to withstand the harsh environmental conditions in the Saudi desert and the caustic process conditions.

All engineering design & fabrication of baseframes, piping and vessels was carried out by Emtivac and other local Dandenong businesses. Base frames were heat treated and machined after fabrication.

The project specifications and QA requirements were very stringent and a specific project manager was allocated for the duration of the project to ensure all the customer’s requirements were met.

The fully assembled skid for the Pan Filter vacuum pump has a total weight of 24,000 kg, special heavy duty shipping crates were manufactured to safely transport the skids to Saudi and to protect the units on site prior to installation.

This project is the largest completed by Emtivac in its 15 year history but the company has just been awarded an even larger project for 2 x liquid ring compressor packages for Flare Gas Recovery at an oil refinery in Malaysia.

17

PIA MEMBER NEWS

Pump Systems Ltd: solids pumping & mixing specialists

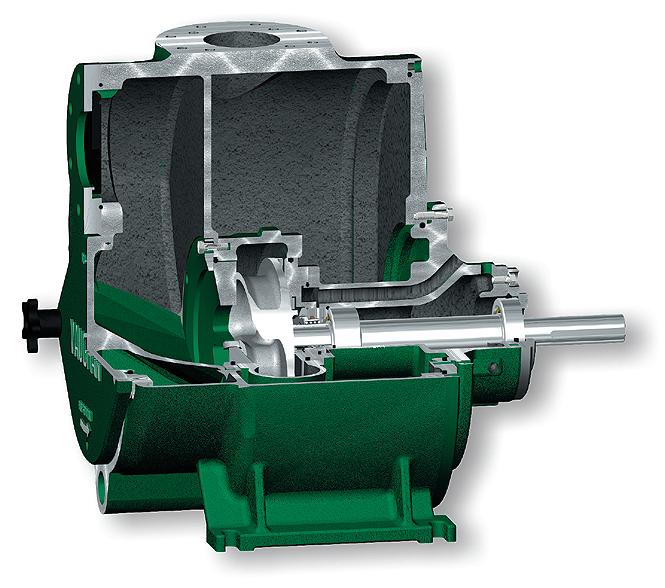

Established in 1984, Pump Systems Ltd is one of Australia and New Zealand’s leading suppliers of sewage pumps and process mixing systems for anaerobic digesters and sludge tanks in the combined municipal and industrial wastewater sectors.

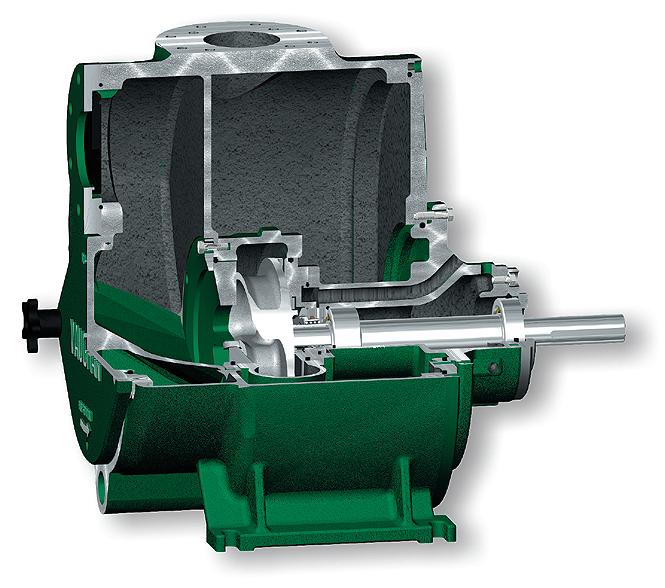

As the Authorised Distributor of Vaughan® Chopper Pumps and Rotamix® Process Mixing Systems for over 20 years, Pump Systems has been involved with the design and delivery of numerous large-scale projects throughout Australia, New Zealand and Singapore, for applications where generic “non-clog” impeller pumps and traditional digester mixing systems struggle to perform or cope with suspended solids in sludge and wastewater.

Designed and developed by Vaughan Company, Inc. in Montesano, USA, the Vaughan Chopper Pump was the world’s first true heavy-duty chopper pump and should not to be confused with other types or brands of chopper pumps, cutter pumps, grinder pumps or macerators. Leading the chopper pump market for more than 50 years, product reliability and positive customer feedback has enabled Vaughan Co. to guarantee the performance and clog-free operation of every unit sold, instilling confidence in the end user through a unique assurance of quality design and dependability. Over the years, the Vaughan Chopper Pump has not only proven its value in problem solving, but has also established itself as the reliable alternative to conventional pumping.

Vaughan Co. is already the producer of the world’s largest chopper pump, but later this year will be releasing a new, even larger 16” discharge model. This revolutionary new chopper pump will be capable of flows up to 3,180 m3/ hr (880 L/s) and will be available in multiple configurations including dry well and submersible designs. The extremely heavy-duty 16W will be ideal for high flow solids pumping applications in large local authority pump stations, influent wet wells, wet weather stations and CSO basins among many others. Vaughan Co. is continuously developing its product range with new configurations, larger sizes, and advances in design and efficiency.

With a proven track record and wealth of industry experience, Pump Systems has supplied hundreds of Vaughan Chopper Pumps for some of the most challenging pumping applications in the region. Local authority and industrial wastewater treatment plants in particular can present major challenges for modern pumping and mixing equipment, an area that is second nature to Pump Systems. Dealing with suspended solids such as rag, plastics, grit and fibrous material is often an ongoing battle for most plant operators due to continuous binding and clogging of pumps, valves and heat exchangers. The Vaughan Chopper Pump eliminates these problems by effectively chopping all solids in suspension as they enter the pump. The conditioned slurry is then easily pumped away without the risk of clogging.

The heavy-duty design of the Vaughan Chopper Pump means that

it is ideal for critical and severe-duty applications, including the pumping of screenings and septage containing raw, concentrated solids. All main components are heat treated to a minimum of Rockwell 60C hardness for impact and abrasion resistance, while externally adjustable cutter clearances allow operators to effectively “delay” the wear process, maximising pump service life. Vaughan Chopper Pumps are ideal for applications where roping and clogging can cause problems for other equipment and processes, such as clarifier scum pits, clarifier underflow to thickeners, transfer and preconditioning of return and waste activated sludge, thickened and digested sludge, as well as dealing with F.O.G. (Fats, Oils and Greases), where organic wastes are processed to enhance methane production in anaerobic digesters. The Vaughan Chopper Pump also plays a pivotal role in the Rotamix System, the world’s most cost effective means of mechanical hydraulic mixing for anaerobic digesters, sludge storage tanks, and other high volume applications.

Pump Systems has Vaughan Chopper Pumps and Rotamix Systems operating throughout Australasia, with installations in municipal wastewater treatment plants and large industrial sites located Christchurch, Dunedin, Auckland, Hamilton, Tauranga, Palmerston North, Sydney, Perth, Queensland, Adelaide, Tasmania and Singapore to name a few. The Vaughan Chopper Pump not only plays a key role in the municipal sector, but has also proven its value across a range of difficult industrial applications including meat, vegetable, seafood and poultry processing, pulp and paper mills, mining, chemical and automotive industries, as well as biogas.

To learn more about Pump Systems Ltd and for further information on Vaughan Chopper Pumps and the Rotamix System, please visit www.chopperpumps.com.au.

18

PIA NEW MEMBER PROFILE

✓ Multiple

configurations

available

including

horizontal

end

suction,

vertical

wet

well,

recirculating,

submersible

and

self-‐priming

✓ Heat

treated

components

for

impact

and

abrasion

resistance

and

externally

adjustable

cutter

clearances

for

extended

pump

life

✓ Flows

up

to

3,180

cubic

metres

per

hour

and

heads

up

to

70

metres

✓ More

than

50

years

of

solids

handling

experience

✓ NON-‐CLOG

PERFORMANCE

GUARANTEE

ON

ALL

PUMPS

Is

your

so-‐called

‘solids

handling’

pump

struggling

to

cope

with

debris

in

your

waste

stream?

A

blocked

pump

in

a

critical

process

can

be

frustrating,

especially

when

it

results

in

expensive

downtime

and

repairs.

VAUGHAN®

Chopper

Pumps

are

designed

and

built

to

eliminate

clogging

problems

by

chopping

and

conditioning

all

suspended

solids

as

they

enter

the

pump.

Sludge

and

sewage

containing

rag,

grit,

plastics

and

fibrous

material,

as

well

as

difficult

industrial

and

food

process

wastes

are

handled

with

ease.

Stop

wasting

time

and

money

unblocking

your

standard

‘non-‐clog’

and

in

the

world’s

leading

chopper

pump.

For

more

info,

19

visit

www.chopperpumps.com.au For

guaranteed non-‐clog

performance, invest

in

a

VAUGHAN®

Chopper

Pump... Pump

Systems

Ltd

-‐

VAUGHAN® Authorised

Factory

Representative

Australia

&

New

Zealand Free

Phone:

1800

121

452

|

sales@chopperpumps.com.au

|

www.chopperpumps.com.au Sick

and

tired

of

pump clogging

problems? THE

VAUGHAN

pump

invest

ADVANTAGE

Fighting black oil and understanding bearing housing upgrade opportunities

By Heinz P. Bloch, P.E. ; Westminster, Colorado, USA

Because rolling element bearings are standard components in most centrifugal pumps, scores of authors have devoted much time and effort to bearing performance issues. Lubricant degradation is among the many topics, although not many articles have dealt extensively with the root causes of oil ring-related contamination and formation of “black oil.” The term “black oil” refers to seemingly random lubricant discoloration that can be experienced over a rather short period of time. Needless to say, any manner of repeated short-term degradation of the lube oil affects bearing reliability. Equipment outages result and time and money will inevitably be spent. That’s why the subject of “black oil” should be important to us. Black oil is the result of one of only two possible events. One of these is rooted in an overheating of the lubricant; the other blackening event is often caused by slivers of black elastomeric material abraded from O-rings. The risk of experiencing considerable wear with dynamic (or moving) O-rings in certain bearing housing protector seals will be pointed out.

Bearing

housings with or without oil rings?

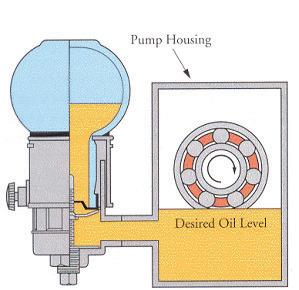

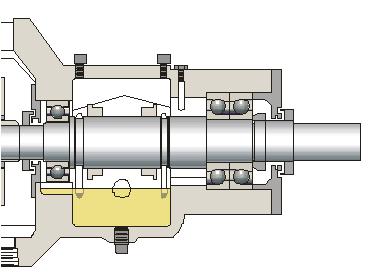

An estimated 45% of oil-lubricated industrial pump bearing housings are furnished with inexpensive oil rings that lift the lubricant from an oil sump (Figure 1). In some applications, oil rings are used to keep the oil volume more uniformly mixed, i.e., to prevent oil stratification. The term stratification describes a layer of hot oil floating near the top of the oil sump.

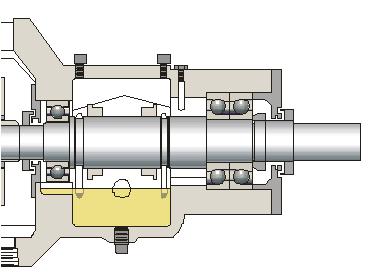

We might assume that perhaps another 45% of oil-lubricated pumps are designed for operation without oil rings. In the typical “without oil-ring” design, the oil level should reach the centre of the lowermost ball, roller or other bearing element. This oil level centering requirement would be difficult to achieve if, as shown in Figure 1, the bearings supporting the shaft had different diameters. We estimate that, in the remaining 10% of oil-lubricated pump bearings, the

lubricant is probably applied by pumparound (“pressurized”) means, or the housings incorporate flinger discs (Figure 2), or oil mist is being used.

To confirm, no oil rings are needed at slow-to-moderate shaft peripheral velocities. Shaft peripheral velocities

Figure 1: Process pump bearing housing with static oil sump and two oil rings

are a function of operating speed (rpm) and shaft diameter, inches or mm. It is found convenient to express peripheral velocity as “DN-values”-- the product of inches of shaft diameter multiplied by shaft rpm. For example, a 70 mm (~2.75 inch) bearing operating with a shaft turning at 1,800 rpm would have a

Figure 2: Bearing housing with thrower (or “flinger”) disc. Accommodating this stainless steel lube thrower disc requires that the thrust bearings be placed in a cartridge. The outside diameter of the cartridge is slightly larger that the diameter of the flinger disc. Note bearing housing seals at shaft protrusions

(Source: AESSEAL plc, Rotherham UK, and Rockford, TN)

RELIABILITY 20

DN-value of 4,960; values below 6,000 are somewhat arbitrarily considered low-to-moderate DN numbers.

In DN < 6,000 designs, both housing geometry and constant level lubricator settings are generally selected to allow lubricating oil to reach the center of the lowermost bearing ball or rolling element. However, if the DN value exceeds 6,000 it will be risky to keep the oil level at the center of the lowermost bearing ball. Potentially excessive friction-induced temperatures would likely result. These temperature concerns led to the decision to lower the oil levels in many of the larger API-compliant pumps operating at 3,000 and 3,600 rpm. In these, oil levels are customarily set well below the periphery of even the lowermost bearing ball. Because oil then no longer reaches a portion of the lowermost part of the bearing, some other means are needed to feed, lift, spray, or splash the lubricant into the pump bearings. Oil rings are often the least expensive component used for lifting oil into the bearings. But oil rings have limitations, and some of these are either little known or not well publicized. Oil ring malfunctions may deprive bearings of oil or simply allow oil to overheat. As mentioned in our introduction, that’s one possible source of black oil. But how and why can oil rings malfunction? What application limits exist?

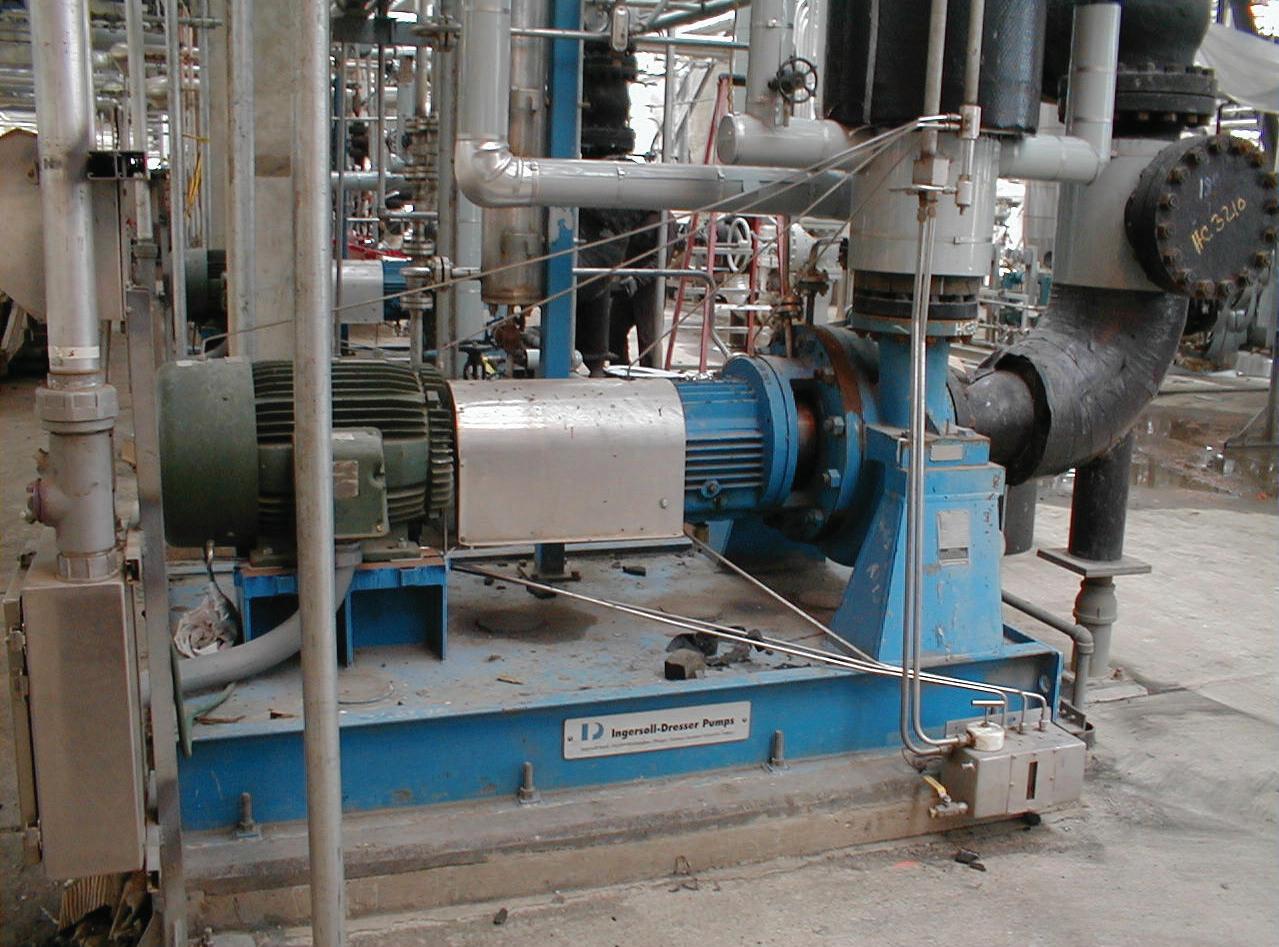

DN-value limitations and attempts to improve on troublesome oil ring lubrication

Oil rings may be unstable for a number of reasons; oil ring instability (“wobbling”) is not a new phenomenon. To ensure proper operation, Ref. 1 cites surface velocity limits around 3,500 to 4,000

fpm (~18-20 m/s) with water cooling. The stipulated water cooling serves to maintain a constant oil viscosity; oil, of course, will become thinner when heated. Without water cooling of the lubricant, Ref. 1 advises users to stay well inside the stable limit for oil rings and not to exceed peripheral velocities of 2,000 to 2,500 fpm (~10-13 m/s).

Another source, a major multi-national oil corporation’s “Lube Marketing Course Book,” suggests a DN value of 6,000 as the threshold of instability for oil rings. As a precautionary rule, both of these authoritative texts warn that oil rings in field situations tend to become unstable whenever DN, the product of shaft diameter (inches) and speed (rpm), enters the region from 6,000 to perhaps 8,000. With its DN value of 7,200, a 2-inch shaft at 3,600 rpm would thus operate in the risky or instability-prone zone, whereas equipment with a 3-inch shaft operating at 1,800 rpm (DN = 5,400) might use oil rings without undue risk of instability. In just one more example, a 3-inch (~76 mm) diameter shaft at 3,600 rpm would operate with a peripheral velocity of 2,827 fpm (~14.4 m/s).

One might not wish to quarrel with pump manufacturers pointing to satisfactory experience with higher peripheral velocities. However, field situations are usually far from ideal. In real-life situations, shaft horizontality and oil viscosity, depth of oil ring immersion, bore finish and out-of-roundness are rarely perfect. The vendor’s test stand experience is of academic value and field experience trumps all else. Reliability professionals must define safe operating ranges and use a good measure of conservatism.

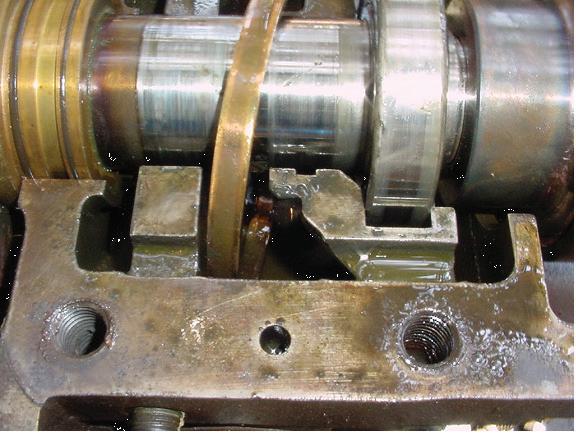

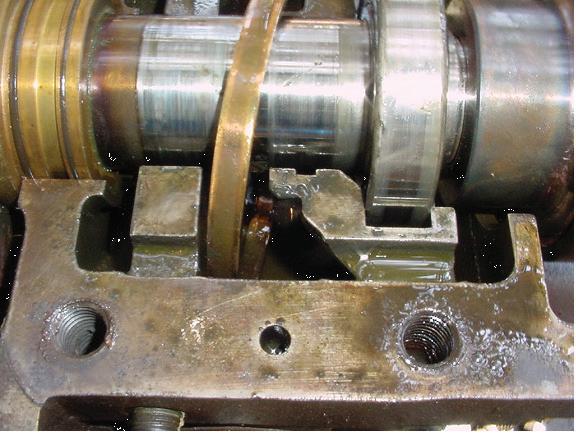

Figure 3: A new oil ring (left) and a badly worn oil ring (right). Oil rings tend to abrade; the abraded particles cause bearing distress (Photo courtesy of TRICO Corporation, Pewaukee, Wisconsin)

Over the years, conservatism was probably sought by a number of pump manufacturers. In the 1990s one major pump manufacturer decided to look into the matter of oil ring instability and black oil formation. The manufacturer’s report was later presented as “Investigations into the Contamination of Lubricating Oil in Rolling Element Pump Bearing Assemblies” at a widely respected Industry Conference in 2000 (Ref. 2). The scope of both the report and the lecture presentation was to relate an analysis of factors affecting the short-term contamination of liquid lubricants in ring-oil lubricated rolling element bearings. “Short-term” was defined as intervals ranging from one hour to several weeks. The analysis dealt with the pump manufacturer’s standard range of centrifugal pumps, and short-term oil degradation had been reported in a number of installations (Ref. 3).

21

RELIABILITY

The presenter described the tests conducted and discussed their results. He then made a number of recommendations (reported here under “presenter”) to which this writer would like to add relevant editorial comments in brackets (as “author’s comment”).

• Unless slightly preloaded, backto-back mounted angular contact thrust bearings allow the unloaded side to skid. The unloaded bearing then gets quite hot (Ref. 3). [Author’s comment: The pump manufacturer had supplied back-to-back angular contact bearings and had inserted a thin shim between adjacent bearing inner rings. Competent users have, since the late 1960’s, insisted on using matched pairs of lightly preloaded or flush-ground backto-back angular contact bearings. Shims are shunned. Moreover, there are applications where the user would be best served by lightly preloaded angular contact bearings with, say, a 15-degree contact angle on one, and a 40-degree contact angle on the mating bearing. This would prevent skidding of one of the bearings.]

• Much of the contamination originated from metal particles being worn off the bronze oil rings (Figure 3) which were erratically hitting the adjacent components (Presenter’s observation). [Author’s comment: Abrasive wear has been known to occur with unstable oil rings. Factors contributing to instability are discussed below.]

• Instead of metallic oil rings, plastic oil rings should be used (per presenter). [Author’s comment: Highperformance polymers are indeed less likely to suffer from abrasive wear than metallic oil rings. However, simply switching to non-metallic rings treats the symptoms; it does not address the cause of the problem.]

• Instead of using mineral oils that were either too light (ISO Grade 32) or too heavy

Figure 4: A “dynamic” (moving) O-ring in close proximity of grooves will abrade if it contacts any of the sharp groove edges shown in this sketch

(ISO Grades 68 and higher), ISO Grade 46 lubricants should be used (per presenter).

[Author’s comment: With ISO Grades 32 and lower, the resulting oil film is often too thin to prevent metal-to-metal contact in rolling element bearings for centrifugal pumps. SKF commented on the matter in Ref. 4]

The various recommendations found in Ref. 2 and the author’s comments deserve to be further examined in terms of root cause problem identification.

Examining the causes of darkened oil

We know from experience that closely observing both new and “used” oil rings will prove very revealing. Abrasive wear of oil rings is easily recognized; a previously chamfered edge is now razor-sharp or burred (Figure 3), or an originally strawcolored lubricant has recently turned dark. Many copper-containing alloys leave a grayish color; pure overheating generally produces free carbon and causes the oil to become black. A good reliability verification technique would include measuring the “as installed” oil ring width and to later compare it with its “as-found” width. Measuring will avoid the cost of analyzing for contaminant composition. Needless to say, abraded oil ring material is suspended in the oil and bearing life is cut short by the abrasion product.

Years of operating and troubleshooting experience confirm that some pump manufacturers’ “old practice” of using low viscosity “thin” ISO Grade 32 oil is flawed. While acceptable for sleeve-type (also called “plain”) bearings, ISO Grade 32 oil is risky for the rolling element bearings found in the average process pump. In many small or mid-size pumps with rolling element bearings, thin oil exacerbates the problem of premature bearing failures.

The presentation based on Ref. 2

Figure 5: Because there are no sharp edges to contact, the two “dynamic” (moving”) O-rings (see arrows) in this bearing housing protector seal will have extremely long life (Source: AESSEAL plc, Rotherham UK, and Rockford, TN)

recommended ISO Grade 46 lubricants. However, we need to look at industry experience overall; we also might examine the position taken by competent bearing manufacturers in the matter (Ref. 4). While oil viscosity is an important parameter, tweaking the oil viscosity selection and substituting ISO Grade 46 (mineral oil) for the previously used ISO Grade 32 will not make much difference. Relatively minor changes in ambient temperatures negate the effect of small viscosity changes; numerous temperature vs. viscosity charts are available to confirm the validity of this concern. Moreover, a renowned bearing manufacturer had determined decades ago that film thickness and film strength limitations rendered ISO Grade 32 mineral oils undesirable for rolling element bearings in many centrifugal pumps (Ref. 4).

Years earlier, this bearing manufacturer had asked users to restrict mineral oil ISO Grade 46 lubricants to bearings operating at temperatures not exceeding 70°C (158°F) and recommended ISO Grade 68 (again assuming mineral oil) for bearing operating temperatures not exceeding 80°C (176°F). However, to simply use more viscous, thicker oils would tend to slow down an oil ring and is not usually recommended.

While black oil can form because oil rings slip, skid, or bounce, black oil can also be found randomly in slower speed bearings that are not using oil rings. In those instances black oil formation is likely the result of the oil level receding by a fraction of an inch, essentially low enough to just barely reach the “bore rim.” We use the term “bore rim” to describe the edge (at the 6 o’clock position) of the bearing’s outer ring bore.

Bearing housing

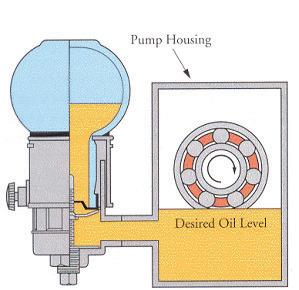

Figure 6: Traditional constant level lubricators sometimes allow the pressure inside the bearing housing to rise above ambient. In that instance, the oil level will be pushed below the Desired Oil Level and oil may no longer reach the bearing’s rolling elements (Source: Trico Manufacturing Corporation, Pewaukee, Wisconsin)

22 RELIABILITY

And here is another concern: Lube oil supplied into a bearing must be allowed to return to the main oil sump. This is accomplished by the small passageway near the 6 o’clock position of the left bearing in Figure 1. Note, however, that this passageway is missing from the same position on the right bearing. This omission is important because it deprives the oil to the right of the thrust bearing set from returning to the sump and freely mixing with the main oil volume. (Note that the same return passage is inexplicably missing from both sides of Figure 2).

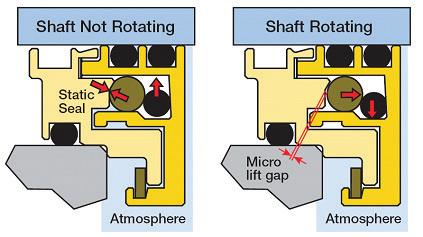

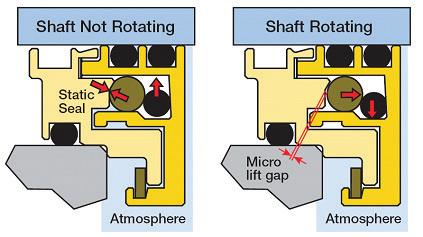

Black oil will also form if bearing housing protector seals incorporate “dynamic” O-rings. Notice that the design in Figure 4 has a dynamic (moving) O-ring located between its rotating and stationary components. The O-ring will be damaged if it contacts either of the two sharpedged grooves. The same failure mode does not exist in a design where an O-ring makes only very brief contact with the relatively large and well-contoured surface of a more advanced bearing housing protector seal design (Figure 5).

Oil level and oil application concerns must be addressed

There have been many instances where the transparent reservoir bulbs of constant level lubricators showed adequate levels of oil which, understandably, led operators and maintenance technicians to assume the oil level in the bearing housing was also at the correct height. Hydraulic laws should convince us that such an assumption is not always correct. The lube oil level in a bearing housing cannot coincide with the level in the base of the constant level lubricator if the internal bearing housing pressure is different from atmospheric pressure. It should be noted that, in a typical non-balanced constant level lubricator the actual oil level in the die-cast base of the assembly (Figure 6) is contacted by ambient air. Ambient air, in most industrial locations, carries water vapor and airborne contaminants, either of which will reduce bearing life. Also, according to

the laws of physics, slightly elevated pressures in the bearing housing will lower the oil level in this housing. The displaced oil volume will be pushed into the die-cast base and the occasional overflow will be seen on the equipment base.

Using a properly pressure-balanced constant level lubricator assembly (Figure 7) goes a long way towards curing the problem. A suitably sized balance line back to the bearing housing ensures this pressure equalization. Together with advanced models of bearing housing protector seals --magnetically closed or rotating labyrinth styles -- a pressurebalanced constant level lubricator makes a fully enclosed oil-lubricated bearing environment feasible. (An advanced rotating labyrinth bearing protector seal

will be almost as good as a dual-face magnetic seal, and we leave it to the reader to determine what constitutes advanced rotating labyrinth seals, Refs. 5 and 6). Compared to non-balanced constant level models, the typical incremental cost of an average-size pressurebalanced constant level lubricator is $40. Just think if you retrofitted 200 pumps with advanced bearing protector seals and pressure-balanced lubricators. Calculate the value of avoiding even a single unscheduled pump downtime event in each of the next five years. And imagine the peace of mind those relatively minor incremental monetary outlays would buy. That would be a tangible and verifiable reliability improvement step for your pumps.

LabTecta®66 Bearing Protectors ‘Eliminate

over 50% of bearing failures’

• Identification mark — Aids correct fitment

• Shut off valve — Prevents chamber breathing

• Twin rotary ‘O’ ring drive — No shaft wear. Retrofittable on shafts previously worn by lip seals

• Repairable — Face shield design allows fast, and most importantly, safe repair of the LabTecta®66. No chemicals or special tools required

• Positive location — Press fit design & ‘O’ ring seal

• Oil retention — Velocity reducing cavity combined with a unique zenith barrier design creating twice the chance of preventing oil egress

• A true non-contacting labyrinth design with a shut-off design that really works

• Proven to increase equipment reliability in pumps, electric motors, fans, pillow blocks, steam turbines and gearboxes

• IP66 certified designs that conform to IEEE Std. 841-2001

RELIABILITY

Figure 7: A pressure-balanced constant level lubricator (Source: Trico Manufacturing Corporation, Pewaukee, Wisconsin)

Visit www.LabTecta.com for a 3-minute video showing statistics and technology

The LabTecta®66 shut-off valve has an axial energizing member. As equipment rotates, centrifugal force causes a temporary micro-gap to be created, allowing the expansion of the oil / gas mixture in the bearing housing. When equipment stops, the centrifugal force ceases and the micro-gap is closed, forming a perfect seal. This stops atmosphere from being sucked back into the bearing-housing, preventing the damage caused by breathing. Shaft Rotating Housing Housing Shaft Not Rotating Shaft Rotating Housing Housing Shaft Not Rotating Essential Micro-Gap When Rotating Effective Vapour-Seal When Not Rotating • Oil expulsion port — Returns oil to sump AESSEAL AUSTRALIA Pty Ltd, Head Office: 12 Counihan Road, Seventeen Mile Rocks, QLD 4073 Ph: +61(7) 3279 1144, Fax: +61(7) 3279 1067 E-mail customer.service@aesseal.net.au LabTecta®66ST LabTecta®66FS LabTecta®66AX 66 www.labtecta.com Get high performing application-specific designs, quickly — Special designs are available to upgrade steam turbines (LabTecta®66ST), axial movement (LabTecta®66AX), oil flooded applications (LabTecta®66FS), split-seal designs for easier installation (LabTecta®66RDS), pillow blocks (LabTecta®66PB), top / side entry (LabTecta®66TE / SE) and inboard / outboard air purge for difficult environments (LabTecta®66IAP / OAP).

RELIABILITY

From an operating and maintenance perspective, don’t overlook that there must always be a partial vacuum in the upper part of the lubricator bulb. If caulking is used to cement the transparent bulb to a metal body in either Figure 6 or Figure 7, it must be realized that this caulking has a finite life. Once it develops tiny aging cracks, rainwater may enter via capillary action. Finally, traditional constant lubricator assemblies are direction-sensitive and should be mounted on the correct side of the bearing housing. The manufacturer’s instruction manuals describe this requirement, as does Ref. 5. The rotation arrow in Figure 6 is important. Constant level lubricators must be mounted on the “up-arrow” side of the bearing housing.

More on the limitations of oil rings

Assume the rolling element bearing housings are routinely furnished with oil rings and the manufacturer is either unable or unwilling to offer superior lube application methods in pumps or other equipment with high shaft (or bearing bore) DN-values. In those instances, the polymer oil rings recommended in Ref. 2 will be a (minor) step in the right direction. Still, it should be kept in mind that all oil rings have limitations which include the following:

(a) a DN limitation, i.e. certain rpmtimes-oil ring-bore values should not be exceeded;

(b) oil rings are viscosity-sensitive, and Ref. 2 merely confirms that oil rings slow down in thicker fluids

(c) oil rings are immersion-sensitive, and disputing it would be denying the effects of viscous drag. This drag is (approximately) proportional to the velocity

(d) oil rings must not be out-of-round or “slightly oval.” Reliability-focused users should not allow more than 0.002” (0.05 mm) ring eccentricity (Refs. 1 and 5). Oil rings bought from the lowest bidder may not have been stress-relief annealed. They will not remain sufficiently round in service

(e) oil rings will run down-hill; they tend to malfunction if the total shaft assembly is not truly horizontal. They will malfunction if allowed to touch the inside of a bearing housing

Industry now has access to and benefits from superb laser-type shaft alignment tools. However, to achieve good alignment the installer typically shims up one end of the pump, thereby jeopardizing shaft horizontality. Also, the user will experience occasions where, in spite of

lubricant delivery via “constant level” lubricators, the oil level is actually lower than the set point indicated on the constant level lubricator assembly. Recall from our earlier comments that understanding how these lubricators function is very important and can save the user much pain.

Needed: a better choice than oil rings and constant level lubricators

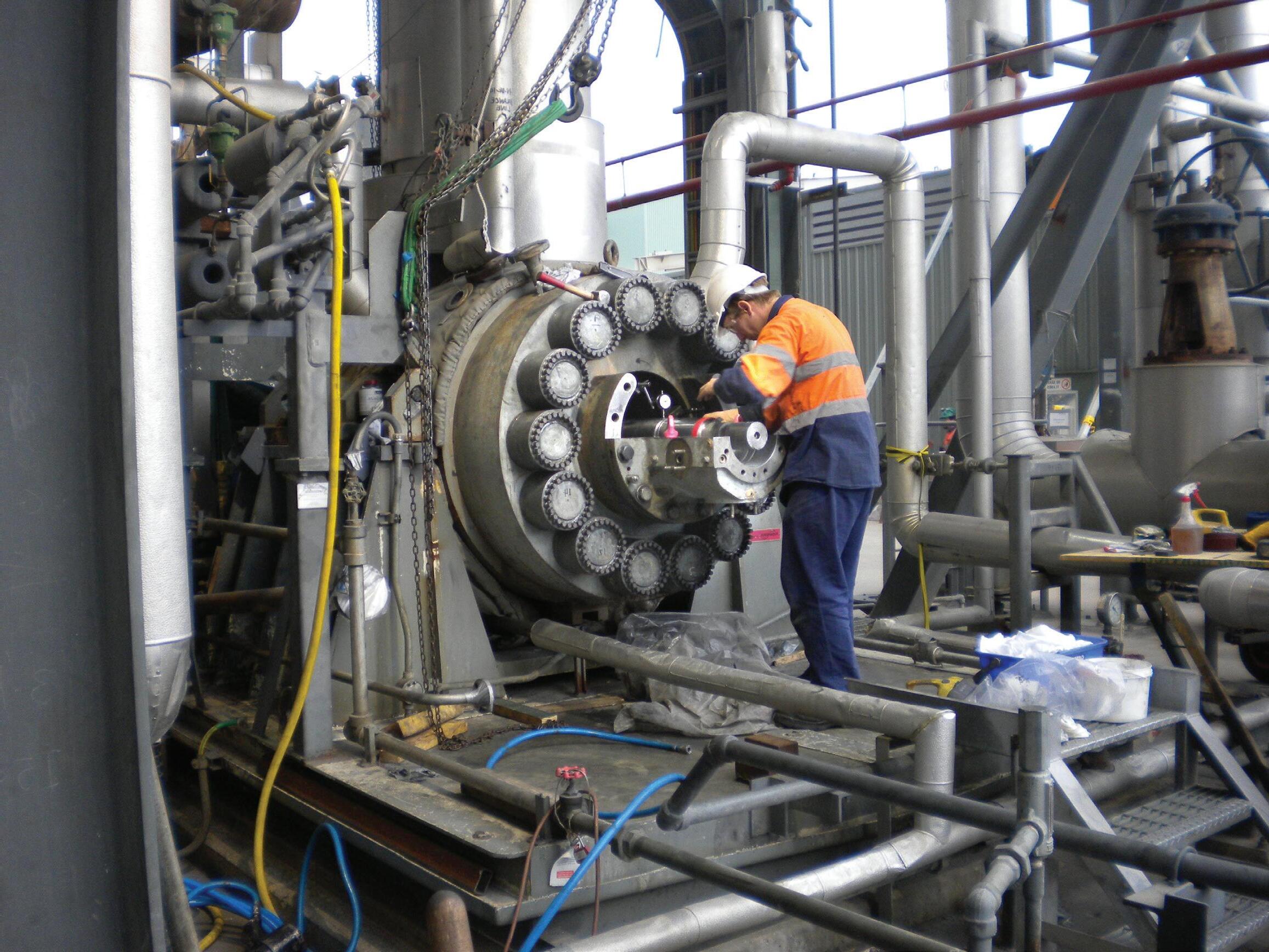

Most 3,000 and 3,600 rpm pumps obtain splash lubrication through the action of oil rings. Yet, oil rings have inherent shortcomings that often make them a poor choice for risk-averse plants, Flinger discs (Figure 2) securely mounted on the shaft seem to offer a better choice than oil rings. Many reputable European pump manufacturers avoid oil rings and use flinger discs instead; some have done so for many decades. Because flinger discs are secured to the shaft, they are not subject to the influence of shaft horizontality, oil viscosity, depth of immersion, shaft surface finish and ring concentricity. These five factors inevitably vary from pump to pump; they result in an infinite combination of variables. Some of these combinations tend to make oil rings prone to malfunction. These malfunctions occur more often than deemed desirable by best-of-class user companies.

Visualize also that oil rings operate at slippage conditions relative to the shaft surface and that abrasive wear often results from this slippage. Slivers or particles of oil ring material have ruined thousands of bearings. Fortunately and unlike oil or slinger rings, flinger discs (Figure 2) are securely fastened to the shaft and avoid slippage and abrasion problems. However, when metal flinger discs are made with diameters larger than the bearing housing bore, a bearing mounting cartridge (Ref. 3, 3rd Edition, pp. 162) may be required to allow assembly without interference. Mounting cartridges are machined to precision tolerances and this adds to pump cost.

In the 1990s flexible discs were developed to get around the need for this added-cost cartridge. They “fold up” while being inserted through a smaller diameter bearing housing bore and snap open after passing through this housing bore (Ref. 5). Needless to say, it is important that the designer-manufacturer selects the proper elastomer and opts for a disc geometry that gives long and trouble-free service life at predetermined permissible – safe -- peripheral speeds. Suitable elastomers are costlier than originally thought, which explains why

“wobbling”

we see few plastic flinger discs in pump bearing housings.

Recommendations and future improvements

Some day, an enterprising inventor or pump manufacturer may turn his back on cost-cutting and will return to ingenuity. He or an enterprising company may then develop a better alternative to oil rings or even flinger discs for rolling-element bearing housings. This alternative may be a smart device just short of the wellproven oil mist, and less costly than the widely known conventional, pressurized, oil pump-around systems. Reconfiguring part of the shaft to serve as the rotor of a progressive cavity pump, or utilizing the principle of magnetically driving a small internal lube pump may be feasible. Direct-driving a housing-internal impeller is clearly feasible for picking up some oil, pressurizing a small stream of this oil, and then spraying it into the bearing rolling elements.

As time progresses and if we are really fortunate, motivated engineers serving on the various API Standards Committees might address the various oil application issues and carefully listen to all sides of the story. Meanwhile, owner-purchasers of process centrifugal pumps should consider paying close attention to well-documented user experience and depend not only on the routine answers offered by some pump manufacturers. Let your equipment manufacturers know that your plant is dealing with real-world issues and that you are interested in lasting failure avoidance measures for chronic maintenance problems. Try to discourage temporary patch-ups and the flawed solutions that don’t cure root causes. Consider rejecting action steps that require maintenance expertise bordering on perfection. Don’t get into the habit of rewarding the lowest bidders by purchasing only from them. If you don’t heed this advice, the long-term experience will almost certainly prove disappointing.

It is important not to miss the bottom line of this article. If the safety and reliability of a plant were dependent on

24

Figure 8: Oil ring with evidence of damage due to

upgrading bearing lubrication of vulnerable pumps, trust neither wobble-prone oil rings (Figure 8) nor lubed-to-centerof-lowermost ball applications. Be a bit more reluctant to put faith in most, if not all, constant level lubricators for really trouble-free lubrication (and trouble-free takes into account human imperfection of operator and mechanics). So, in most cases, try to get away from 18th century oil rings, which would also eliminate questions on oil ring material selection preferences. If at all possible, favor dry-sump oil mist for lubrication and for preservation of standby equipment, whenever this modern oil application method is cost-justified.

If oil mist cannot be justified, the author would -- without the slightest hesitation -simply take oil from the drain location at the bottom of the bearing housing (Ref. 5). This oil would be piped to the suction of a small (yet highly reliable) fractional horsepower canned motor pump and generate a few psi of pressure. About two or three gpm (8 to 12 liters) of pressurized, filtered ISO Grade 68 PAO/Diesterbased synthetic oil from the bearing housing drain would be forced through two spray nozzles into the inboard and outboard bearings of the most vulnerable process pumps. Implementation of such a strategy would close the book on issues involving black oil. Spraying oil into the bearings would terminate endless arguments over the merits of maintaining oil viscosity at tight limits, the adequacy of metallic versus plastic oil rings, the maintenance requirements of constant level lubricators, and the ramifications of hot bearings.

References:

1. Wilcock, Donald F., and E.R. Booser, (1957) “Bearing Design and Application,” McGrawHill Book Company, New York, NY 10121

2. Bradshaw, Simon; “Investigations into the Contamination of Lubricating Oil in Rolling Element Pump Bearing Assemblies”, Proceedings of the Texas A&M Pump Users Symposium (2000).

3. Bloch, Heinz P.; “Improving Machinery Reliability,” (1982 and later Editions), Gulf Publishing Company, Houston, TX, ISBN 0-87201-376-6; ISBN 0-87201-455-X; ISBN 0-88415-661-3

4. SKF USA Inc, “Bearings in Centrifugal Pumps, Application Handbook” Publication 100-955 (1995), pp. 20

5. Bloch, Heinz P. and Allan Budris; “Pump User’s Handbook—Life Extension,” (2006) 2nd Edition, The Fairmont Press, Lilburn, GA 30047, ISBN 0-88173-517-5

6. Bloch, Heinz P.; “Pump Wisdom: Problem Solving for Operators and Specialists,” (2011), John Wiley & Sons, Hoboken, New Jersey, ISBN 978-1-118-04123-9

About the author

• 4” 0.5kw to 7.5kw

• 6” 7.5kw to 45kw

• 8” 30kw to 93kw

• 10” 75kw to 150kw

• 12” 93kw to 300kw

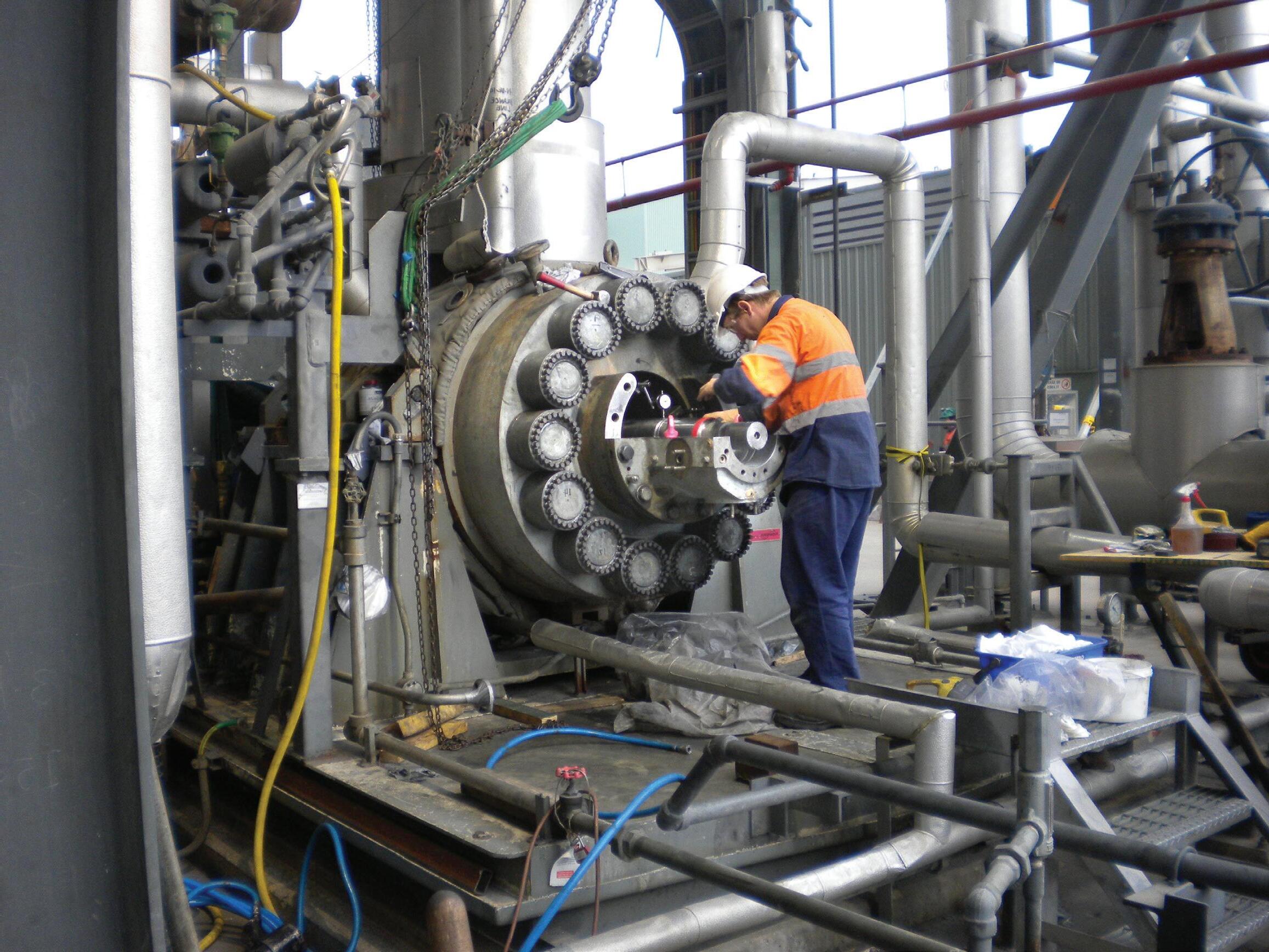

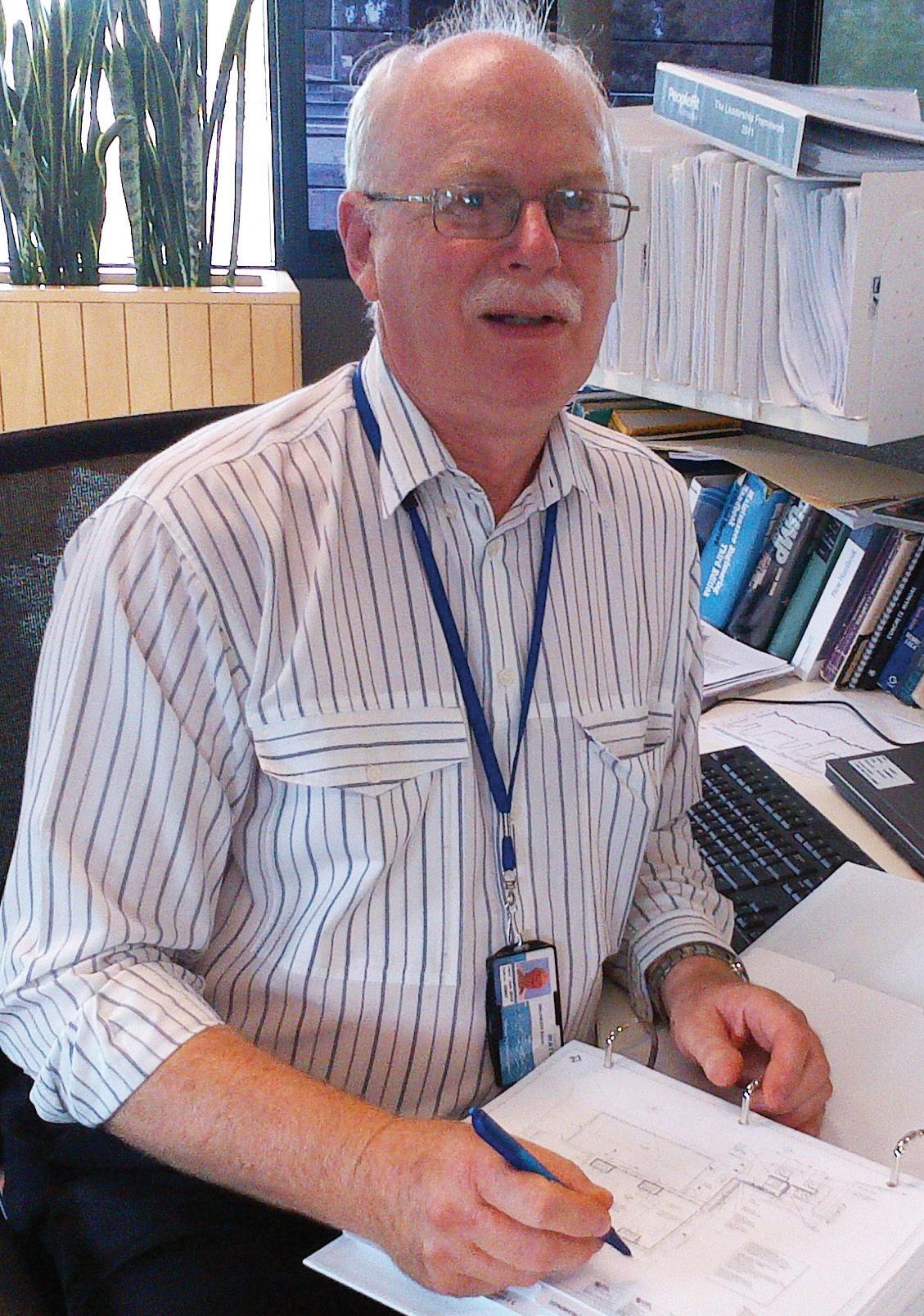

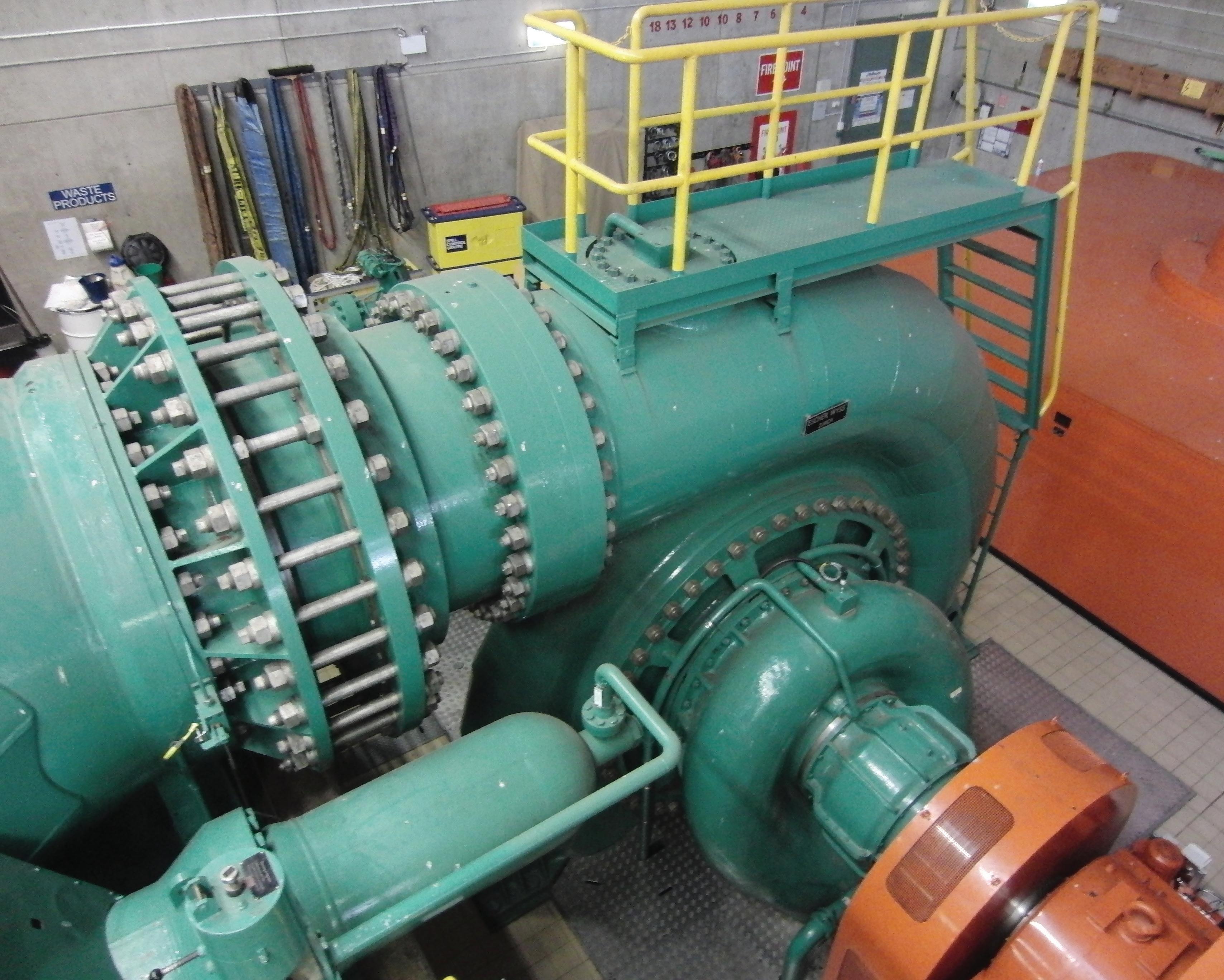

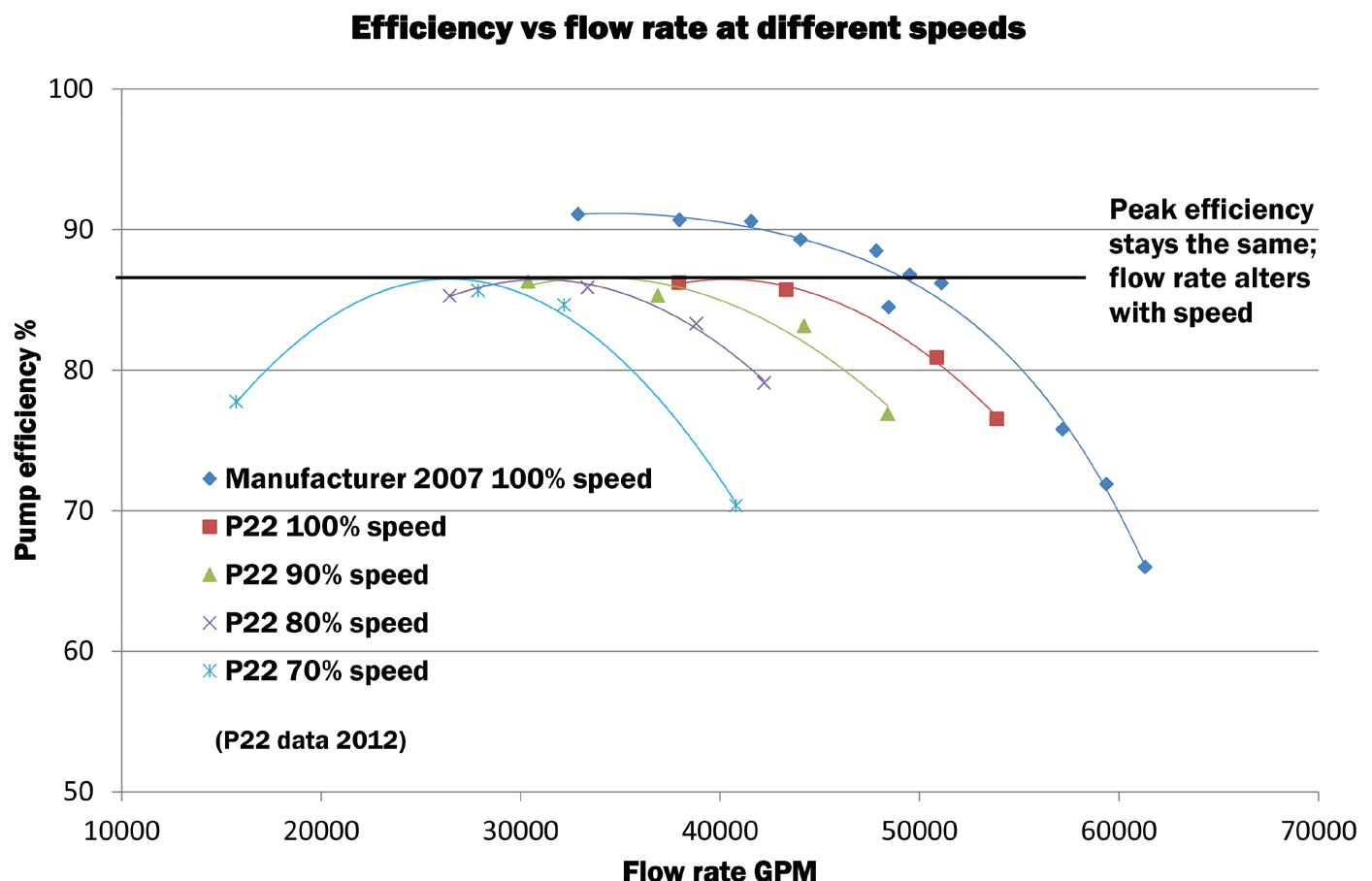

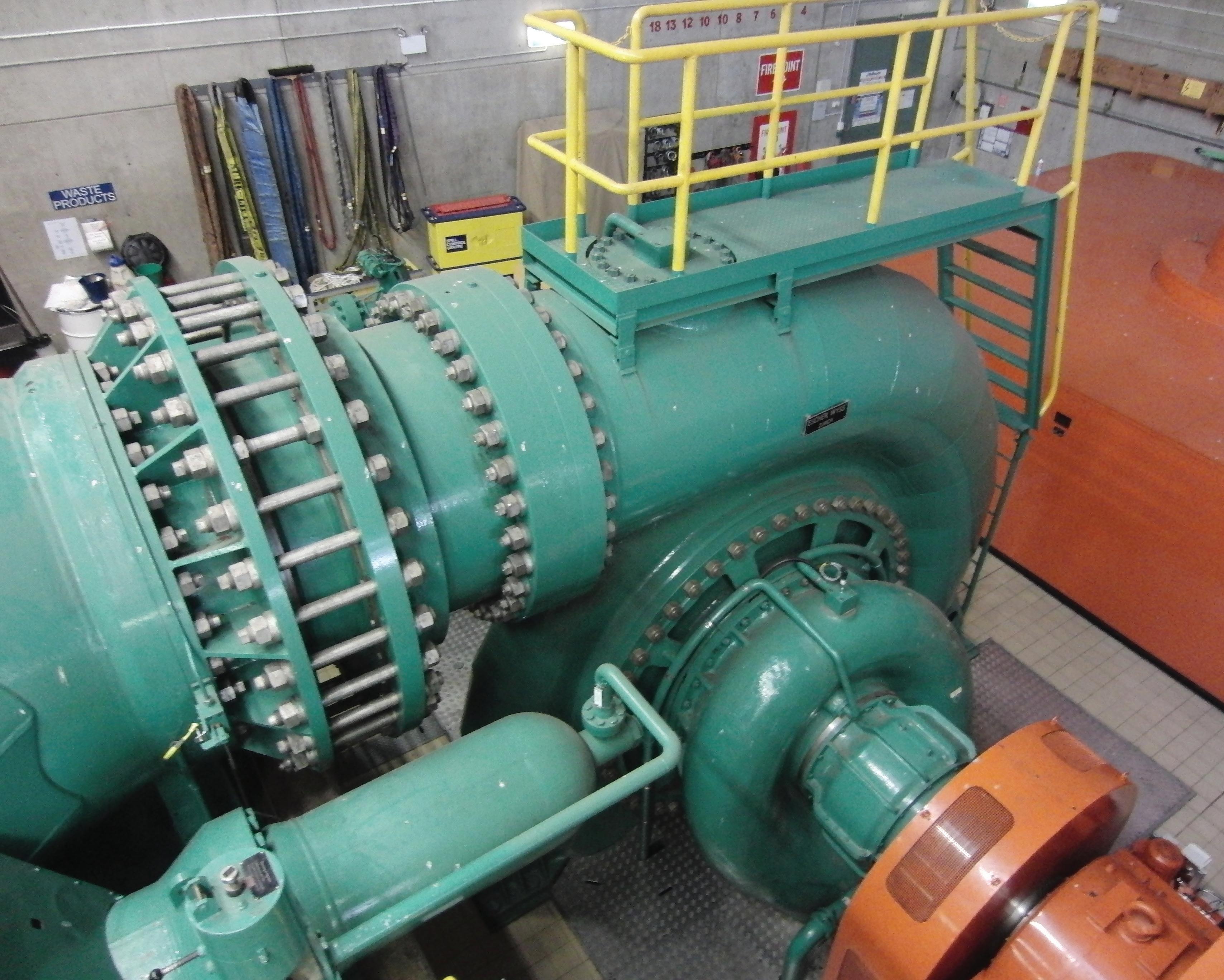

• 14” to 30 “ up to 2500kw