pumpindustry

Everything you need to know about valves State of the Industry: changes ahead for 2016

The dos and don’ts of pumping fuel oil

SUMMER 2016 ISSUE 14

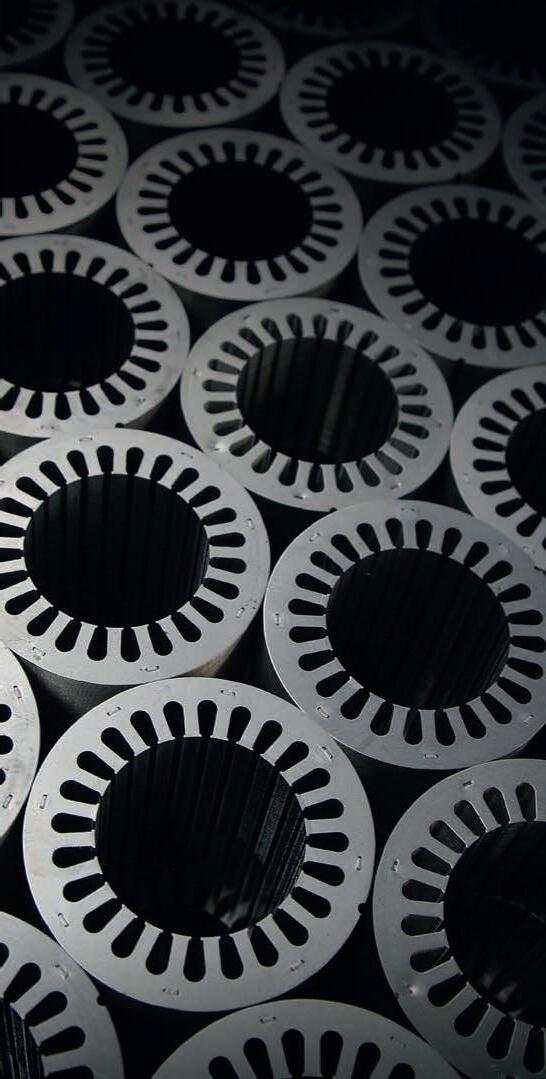

HIGH QUALITY MOTORS ON DEMAND ON BUDGET QUALITY. SERVICE. RANGE. LOW VOLTAGE MOTORS 0.06kW to 1400kW SINGLE PHASE 0.09kW to 3.7kW HIGH VOLTAGE 355kW to 10 MW www.techtop.com.au info@techtop.com.au Melbourne: 03 9753 2222 Brisbane: 07 3106 5111

Pump Industry Australia Incorporated

Kevin Wilson – Secretary PO Box 55, Stuarts Point NSW 2441 Australia

Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com

Ron Astall – President United Pumps Australia & Astech Consulting Services

John Inkster – Vice President Brown Brothers Engineers

Keith Sanders – Councillor Australian Industrial Marketing & Life Member

Alan Rowan – Councillor Life Member

Frankie Camilleri – Councillor John Crane

Ashley White – Councillor Davey Products

David Alexander – Councillor KSB Australia

David Brooks – Councillor Flowserve Australia

President’s welcome

Welcome to a new year, and a new issue of Pump Industry.

2015 was a busy year, building on the hard work from 2014, with the essential input of PIA secretary Kevin Wilson and our three part time Executive Officers, Keith Sanders (Marketing and Statistics), Alan Rowan (Publications and Training) and Ken Kugler (Standards). Thanks to these gentlemen for an excellent and productive year.

As in 2014, the common themes were education and improvement. PIA’s vision is to continue our focus on education and training with ongoing seminars, conferences and workshops.

Our cooperation with Chris Bland, Laura Harvey and Aaron White of Monkey Media is highly valued and we continue to receive positive comments from pump users on the relevance and quality of this Australian publishing initiative.

When visiting a customer in New Zealand last November I was surprised to see a copy of Pump Industry on his desk. We agreed that there were too many photos of me in the magazine, but he remarked that he considered it to be a great read and that he always looks forward to the next issue.

You can read elsewhere in this issue more detail on some of our key achievements during 2015, including our new relationship with the Hydraulic Institute; but one achievement that I particularly want to highlight is the

roll out of the PIA’s Installation and Commissioning Training Program. Congratulations go to Alan Rowan and his team of Ken Kugler, Keith Sanders and Fred Van Ross. I know it has been a hard slog and that the workload will continue with ongoing refinements and improvements. Well done!

You can also read about John Link being awarded PIA life membership. It was a particular pleasure for me to be able to officiate at this time. His generous approach to life and work continues to be an inspiration.

John’s role in assisting with our Installation and Commissioning Training Program is consistent with his ideal of an educated and competent industry, an industry where sound engineering, ethics and a level playing field prevail.

While I have used this before, I think it is appropriate to again mention a quotation from Astronaut John Glenn Junior – the first American to orbit the earth, a US senator and later the oldest ever Astronaut when he flew again in the Space Shuttle.

“As I hurtled through space, one thought kept crossing my mind - every part of this rocket was supplied by the lowest bidder.“

An educated and competent industry is important if we are going to rely on the ‘lowest bidder’.

Ron Astall President, Pump Industry Australia

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 1 PUMP INDUSTRY

3,345

Editor’s welcome

Welcome to the first edition of Pump Industry for 2016.

by Monkey Media Enterprises

ABN: 36 426 734 954

PO Box 3121

Ivanhoe North VIC 3079

P: (03) 9440 5721

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au

pumpindustry.com.au

magazine@pumpindustry.com.au

Publisher and Editor: Chris Bland

Managing Editor: Laura Harvey

Marketing Director: Amanda Kennedy

Marketing Consultant: Aaron White

Marketing Consultant: Jordan Harbinson

Associate Editor: Michelle Goldsmith

Associate Editor: Emily Thomas

Journalist: Jessica Dickers

Designer: Alejandro Molano

Creative Director: Sandy Noke

ISSN: 2201-0270

It has become somewhat of a tradition that in the first issue for the year, we bring you an overview of how the industry has performed over the previous year, and what’s in store for the year ahead.

This year, we’ve conducted our most comprehensive survey yet, speaking to countless pump industry professionals to gain their insights into the challenges they’re facing and the successes they’ve had.

Overall we found our respondents to be feeling positive about what lies ahead; while there’s no denying that 2015 has been one of the most difficult years our industry has faced, our respondents feel that the tide is starting to turn and that the year ahead will be better than the year gone. Sectors experiencing growth, including water and wastewater, and domestic

This magazine is published by Monkey Media in cooperation with the Pump

not necessarily the views of either the publisher or the PIA. Neither the

advertisers.

All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions

providing content to the publisher, you authorise the publisher

with other content in any of its publications and in any format at the publisher's

and commercial construction, will provide benefits to the industry; and the increasing need for energy efficient products and the service of existing equipment are also expected to keep the industry busy.

The full results of the survey and our analysis of your responses make for compelling reading – turn to page 30 for the full story.

The start of 2016 also marks the start of an exciting new period for the PIA. Last November I attended the PIA’s Annual General Meeting, where I had the chance to learn a bit more about some of the new initiatives the PIA has underway. These include a fully revamped website, and a new partnership with the US Hydraulic Institute, which will lead to increased knowledge sharing – a clear benefit for all PIA members.

Chris Bland Publisher and Editor

2

Cover image highlights our feature on pumping in the oil and gas industry.

Published

Industry Australia Inc. (PIA). The views contained herein are

publisher nor the PIA takes responsibility for any claims made by

comply with the publisher’s editorial policy which follows. By

to reproduce that content either in its original form, or edited, or combined

discretion.

must

SUMMER 2016 ISSUE 14 Everything you need to know about valves State of the Industry: changes ahead for 2016 The dos and don’ts of pumping fuel oil

pumpindustry

Authorised Australian Distributor for

Head Office: 88 Wedgewood Road, Hallam VIC 3803, Australia Phone: (03) 9796 5001 Fax: (03) 9796 3499

SOLID HANDLING PUMPS & MIXERS FOR PROCESS INDUSTRIES

RECESSED IMPELLER RECESSED IMPELLER

SCREW CENTRIFUGAL SCREW CENTRIFUGAL

CHOPPER PUMP CHOPPER PUMP

VERTICAL BEARING VERTICAL BEARING

SUBMERSIBLE SCREW CENTRIFUGAL SUBMERSIBLE SCREW CENTRIFUGAL

Large internal passages for handling solids up to 200 mm

Replaceable wear element, extra-thick castings and hard metal construction for abrasion resistance.

Foot mounted casing provides true back pull-out.

Available in horizontal, vertical dry pit, vertical bearing, vertical cantilever and submersible designs.

Gentle, low shear pumping action minimizes product damage and prevents emulsification.

Single channel open impeller for solids up to 178 mm diameter

High efficiency reduces power costs.

High flow/low head hydraulic characteristics.

Low NPSH.

Available in horizontal, vertical dry pit & submersible designs

Simultaneously chops and pumps solids. Eliminates the need for grinders.

External and internal cutting actions.

Patented high efficiency, anti-fouling impeller.

Available in horizontal, vertical dry pit, vertical bearing, vertical cantilever and submersible designs.

Economical solution for general duty in industrial sumps

Reliable self-priming independent of pit depth.

Optional sealed columns for harsh environments. Standard designs for pit depths up to 14 feet, custom versions to 20 feet+.

Recessed impeller, chopper and process pump wet-ends available.

For submerged operation in tanks or sumps. Chopper, recessed impeller, and screw centrifugal designs available.

Capacities up to 910 m3/hr

Heads up to 61 metres

Temperatures up to 150°C

Solids up to 200 mm diameter

Capacities up to 2730 m3/hr

Heads up to 60 m

Temperatures up to 150°C

Solids up to 178 mm diameter

Capacities up to 1408.4 m3/hr

Heads up to 39.624 m

Temperatures up to 150°C

Capacities to 681.36 m3/hr

Heads to 91.4 metres

Temperatures up to 204°C with jacketing

Capacities up to 2730 m3/hr

Heads up to 60 m

Temperatures to 110°C

152 mm diameter maximum solids size

ST SERIES TOP ENTRY MIXERS

ST SERIES TOP ENTRY MIXERS

Three drive sizes cover this series which feature a third lower output bearing which helps isolate hydraulic loads from the gearbox.

2.24 to 14.91 kW

Typical mixing volume: 18.93 to 132.49 m3

service@pumpdoctor.com.au s a les@ p um p d oc t o r. c o m.au www.pumpdoctor.com.au

> > >

> > > > > >

> > > > > > > >

> > > > > > > >

> > > > > > > > > >

> > > > > > > >

Head Office: 5 Brigden Gate, Halton Hills, Ontario L7G 0A3 Canada. Phone: (905) 693-8595 Fax: (905) 693-1452 For more information visit www.haywardgordon.com

STATE OF THE INDUSTRY

Recently Pump Industry undertook the most comprehensive survey we’ve ever conducted in order to present a detailed analysis of the industry’s outlook for 2016.

To add another perspective to our State of the Industry analysis, we spoke to Ivan Fernandez, the Industry Director at Frost & Sullivan’s Industry practice in Sydney.

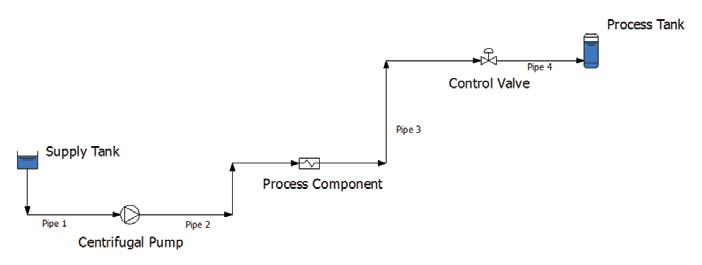

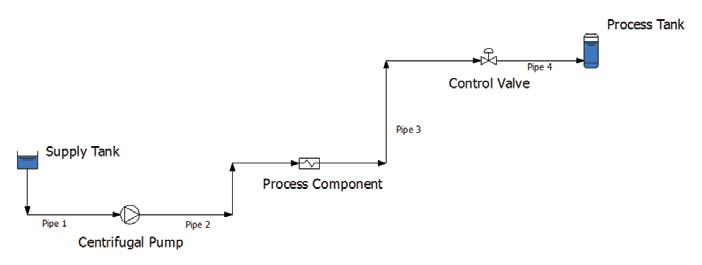

PUMP SYSTEMS

at the total piping system

In the first of a regular series of columns on overall piping systems, Ray Hardee discusses how the various elements making up a total pumped system work together to meet system requirement.

OIL & GAS

ASK AN EXPERT

4 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au

State of the Industry in 2016: adapt, diversify, survive 30

Analyst weighs in ...................................................... 38

Looking

.......................... 40

The dos and don’ts of pumping fuel oil ................... 42 Getting out of hot water 45

Progressive cavity pumps ........................................ 46 CONTENTS PIA NEWS The new face of the PIA ...........12 PIA MEMBER NEWS Sulzer launches new process pump range ..............................16 New centrifugal pump range by Gorman-Rupp .....................17 Operating pumps at partial capacity: causes of vibration ...18 INDUSTRY NEWS Produced water treatment 20 Improved safety in explosive atmospheres ...........................22 Drive solutions for the water world.............................................. 23 From humble beginnings to dramatic expansion..................24 Efficiency and flow monitoring ................................26 Not to be sniffed at 27 Optimised water solutions ......28

REGULARS

considerations by industry

are vital components of pumping systems and pipelines in near-countless different industries.

This article presents some conventional and innovative ways to apply check valves in hydraulic circuits. The author has successfully used all the configurations in various projects.

A beginner’s guide to the right actuator

A valve, in its most basic form, consists of a body and an internal moving component (closure element), which shuts off or restricts flow through the valve.

REPAIR AND

and tricks for maintaining your

you following maintenance best practices?

to know your pump system:

speed and system head

caught up with Bob Pullen to reflect on his years as a pioneer of the Australian pump industry.

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 5 pumpindustry VALVES Selecting valves:

and application ......................................................... 48 Valves

Check valve applications 52

................. 56

MAINTENANCE Tips

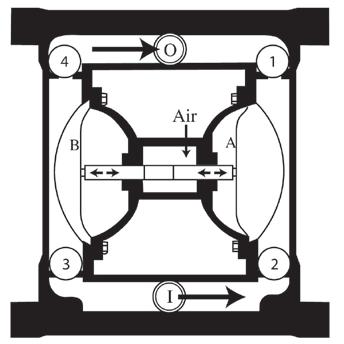

AODD pump ............................................................. 60 Are

.... 63 TECHNICAL Getting

specific

67

President’s welcome ................... 1 Editor’s welcome ......................... 2 News ............................................ 6 Pump pioneers .......................... 68 We

Pump school .............................. 71 Which pump do I choose? Editorial schedule ...................... 72 Advertisers’ index ..................... 72

Pumpserv appoints new sales representative

Ross Shaylor has recently joined the team at Pumpserv as their new Sales Representative. Ross has a long history in industrial sales and started in the pump industry in 2010, initially working for Ebara Pumps as NSW Area Manager before moving to Brown Brothers Engineers. Ross has a proven track record of developing and maintaining positive relationships with key stakeholders. Continually looking for opportunities to expand his knowledge and understanding of pumping and industrial applications, Pumpserv is an ideal business for Ross to expand his knowledge base.

Pumpserv is a distributor of all major pump brands in Australia, and offers everything from design, supply, installation to service. Currently Pumpserv manufactures for other local and international pump companies, designing and manufacturing stainless steel base plates, as well as small to large stainless steel manifolds for varying pump system configurations.

Pumpserv’s engineering workshop capabilities range from pump refurbishment to multiple pump station assemblies and electrics. Infield pump service work is also offered by Pumpserv, particularly for golf courses.

Harcourt finds new contractor after disputes

Coliban Water (VIC) has announced the construction company that has been awarded two contracts for the remaining Harcourt Rural Modernisation Project pipeline works.

Leed Engineering and Construction has been awarded the contracts for the backbone and reticulation network pipeline works.

Phone: +61 3 9720 1100 Email: sales@crusaderhose.com.au

www.crusaderhose.com.au

6 pump industry | Summer 2016 | Issue 14

NEWS

FLEXIBLE RISING MAIN 22

Bayswater VIC 3153

Industry Place

Australia

FLEXIBORE

Flexibore reduces head loss, improves flow rate and eliminates iron bacteria build-up due to swelling under pressure. SWELLING ELIMINATES BUILD-UP

FLEXIBORE

A delivery program for completion of the pipeline, property reinstatement and the installation of customer connection points was developed in December 2015 and construction on the remaining works began in January 2016.

The Harcourt Rural Modernisation Project aims to upgrade irrigation channels to the Harcourt region and provide Harcourt residents with year round access to water through a piped system.

The piped system will replace the existing concrete and earthen gravity channel system.

The project includes approximately 65km of pressurised pipeline, two pump stations located at Faraday and Barkers Creek Reservoir and a balancing storage tank.

The project was put on hold in 2014 after disputes with previous contractor Redline Group, but work recommenced on the Barkers Creek and Faraday pump stations in November 2015.

Project superintendent, Mick Dunne, said the corporation was continuing to work towards having the project completed in time for the 2016/17 rural season.

Mr Dunne said, “With these two key contracts now awarded, and work already underway on the two pump station sites at Barkers Creek and Faraday, the project is progressing.

“While this procurement phase has been underway, we have been busy working behind the scenes with customers to ensure they are ready to connect to the new pipeline system when the project is completed next year.

“We are still working toward having the pipeline ready to deliver water to our 160 customers in time for the 2016/17 rural season,” Mr Dunne said.

To date 95 per cent of the backbone pipeline has been installed, with 17.7km out of the 19km and 25.4km out of the 44km (55 per cent) of the network pipeline now installed.

Hydroflo has a new home

The team at Hydroflo have a new and improved facility, with 10 tonne crane capacity and pump test facilities to 300kw.

You can now find Hydroflo at 115 Munibung Road, Cardiff, New South Wales.

For any enquiries you can contact the team on 02 4922 9020, and for more information about Hydroflo and the products and services they offer, head to www.bcip.com.au.

ONGA®

SSS SERIES

• All Stainless Steel construction wet end

• 4 models – 0.55 kW to 2.2 kW

• Flow rates to over 500 LPM

• Ideal for water transfer, irrigation, wash down and mild chemical use (Viton seal kit required)

• Liquid temperatures up to 85°C

PVMI MULTI-PUMP SYSTEMS

• Up to 6 pumps

• Full 304 Stainless Steel wet end (316 available)

• Individual Variable Frequency Drives

• PLC Master Controller

• 316 Stainless Steel manifolds

• Main and individual isolators

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 7 NEWS

www.onga.com.au www.southerncross.pentair.com

Global pump manufacturers ranked

Arecent survey by Timetric’s Mining Intelligence Center (MIC) has revealed the top global pump manufacturers in the mining industry, with one Australian company among the ranks.

Weir Minerals, Xylem and Kirloskar ranked as top three global pump manufacturers in the survey, accounting for 47 per cent of the total nominations.

The survey asked over 630 mine managers and senior decision-makers across more than 500 mines globally, to nominate the leading manufacturers (in first and second place) for different types of mining equipment, including pumps and submersibles, regardless of their own supplier.

With more than 240 votes and nominating 50 different manufacturers, combining nominations as the first and second leading company, respondents nominated Weir Minerals as the leading manufacturer of mining pumps, dewatering pumps and submersibles, receiving 24 per cent of the total nominations.

This was followed by Xylem with 14 per cent of the total nominations, and Kirloskar in third place with 9 per cent. AllightSykes was next with 5 per cent and KSB received 4 per cent rounding out the top five manufacturers.

The results show the strength of Weir Minerals in penetrating the market in five of the six regions,

where they received more than 20 per cent of the votes.

Xylem, however, is the only other top manufacturer that received nominations in every region, with the most mentions in Latin America of the leading manufacturers.

Australia, Asia and Africa appear to be more competitive markets for the leading players as four out of five of the top manufacturers received nominations in each of these regions.

Australian based company, AllightSykes, was mentioned the most in Australia, but was also considered as a leading manufacturer in Asia and Africa.

Timetric’s Senior Mining Analyst, Nez Guevera, said, “Conditions in mining industries around the world remain challenging as the fall in commodity prices have far-ranging impacts that will continue to weaken the unit sales of new mining pumps.

“However, there are opportunities for growth with the demand for replacement pumps, a bigger focus on recycling and reusing water, and investments made towards productivity improvements.”

8 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au NEWS

Comprehensive Pump Support Reliable & Responsive Service

Engineered Pump Rebuilding

Since 1969, Hydro has built its worldwide pump service organization by bringing a high level of engineering expertise and quality service to the pump aftermarket. Hydro Australia works with our customers to evaluate and understand the root causes of pump degradation or failure and to provide unbiased engineering analysis, quality workmanship and responsive field service for improved plant operation.

Certified Service Centre

Hydro Australia has always been committed to Quality and Occupational Health & Safety. Hydro Australia holds the AS:NZS ISO 9001:2008 certificate in addition to the AS:NZS 4801 and AHSAS 18001 certificates.

Turnkey, Field Service and 24/7 Emergency Response

Hydro Australia’s Field Service team has extensive knowledge of pumps from most major manufacturers and provides turnkey service, installation / start-up supervision, field machining, vibration analysis, laser alignment, pump system troubleshooting and emergency field response 24 hours a day, 7 days a week.

Pump Parts

When you require a part and are facing a long lead time, Hydro Australia can meet your needs in a reduced time frame through our reverse engineering, patternless casting and integrated manufacturing processes. Hydro's engineers review and evaluate all parts to offer important upgrades and apply new technologies that will reduce wear and improve reliability.

Pump Testing - Managing Risk

Ensure your pump will perform as required. Hydro’s 5000HP Performance Test Lab, located in the United States, is compliant to API610 and Hydraulic Institute standards and can test horizontal, vertical, and submersible pumps.

Training

Hydro teaches practical solutions and troubleshooting techniques for common pump problems and offers specialized hands-on training programs. View upcoming courses online at www.hydroinc.com.

Call Hydro Australia at (03) 51650 390 with your pump service inquiries or contact Ross Bertolimobile: (0418) 581190 email: ross@hydroaustralia.com.au.

A Hydro Company Hydro Australia, Pty. Ltd. Hydro Australia Pump Service Centre Morwell, Victoria 3840 www.hydroaustralia.com.au (03) 51650 390

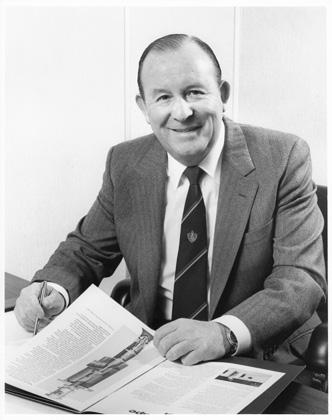

Vale Bob Moore

PIA Life Member, Robert J ‘Bob’ Moore sadly passed away on 5 November aged 88.

Bob was one of the true elder statesmen of the industry, having started working in pumps in 1955, and regarding himself as a lifelong “pump man”. He was a friend and mentor to many in the industry from the time he started in the industry in the 1950s until well past his retirement in the late 1980s.

Bob held a number of roles during his time in the pump industry, including stints at a number of leading Australian pump manufacturers including Kelly and Lewis and FN Bethune.

Bob was involved in the founding of the PIA (then APMA) in the 1960s and served as President of APMA 1975/76 and Chairman of the BPMA 1986/87.

His passion for pumps led him overseas, working as Managing Director for Mather and Platt’s Machinery Group based in Manchester UK. Later, he became Managing Director of Britain’s second largest pump company, SPP Group, and led a management

buyout of that particular company. This was followed by the successful floating of the company on the London Stock Exchange.

Bob’s extensive career reflects his passion and dedication to the pump industry both in Australia and abroad, and he inspired many in the industry with his skill and expertise.

After his retirement, Bob remained socially active with the industry through his relationship with the PIA.

He also continued his involvement with the industry through the writing and publication of two non-fiction works – Toss of a Coin, a reflection on his career in the pump industry, and Kelly and Lewis: a fine old engineering company - it’s rise and demise, which covers the history of Kelly and Lewis, the company where Bob spent more than half of his career.

You can read more about Bob’s career and life in Pump Industry’s profile of him, which can be viewed online at www.pumpindustry.com.au/ robert-j-bob-moore.

Vale Peter Snow

Peter Snow arrived on the Australian pumping scene when he came to Australia from the UK in the early 1960s from Mather & Platt (M&P), around the time that M&P acquired Kelly & Lewis. Peter resided in Sydney and was in charge of sales of M&P electric motors.

In the later years of his life he was employed by Weir Engineering and was heavily involved in both motor and boiler feed pump applications and sales. He was well known for his technical expertise and widely respected in the power generation field, particularly within the Electricity Commission of NSW and the State Electricity Commission of Victoria (as they were then known).

Peter also worked for Ingersoll-Rand during the 1970s where he headed the utility division in Sydney. Colleagues

from those days remembered Peter as a gentleman who was only too happy to pass on his knowledge to young engineers starting out.

Outside of work Peter was a very keen golfer and was a member of the Roseville Golf Club in Sydney for 48 years.

Sadly Peter passed away in hospital on 29 August 2015, aged 87. His birthday was only a couple of weeks earlier on 8 August. His passing followed his twin brother, who passed away only a few months before Peter did.

Peter never married but his brother had one daughter. His niece travelled from the UK and delivered Peter’s eulogy, which featured a touching mix of humour and solemnity.

10 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au

Bob Moore.

NEWS

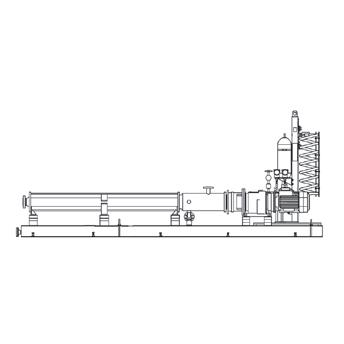

New pumps for QLD pump station

Three new KSB pumps have been installed in the City of Logan’s largest wastewater pump station in Queensland.

The three 8.4 tonne pumps were then lowered into a 20m-deep concrete dry well in the pump station.

Logan City Council Roads and Water Infrastructure Committee Chairperson, Don Petersen, said the 25 tonnes of infrastructure – valued at approximately $450,000 – were part of a major upgrade of the Alfred St wastewater pump station at Slacks Creek.

“The Alfred St pump station is really the workhorse of Logan’s wastewater network,” Mr Petersen said.

“It’s responsible for pumping 84 per cent of the city’s wastewater to the Loganholme Wastewater Treatment Plant for processing.”

Recent upgrades of the pump station valued at $6.8million have included replacement of switchboards, refurbishment of wet and dry wells and improvement of staff access for maintenance.

The City of Logan Council’s water infrastructure alliance has invested 22,500 working hours in the task.

“The three new pumps installed at Alfred St pump station replace three older models that were at the end of their useful life,” Mr Petersen said.

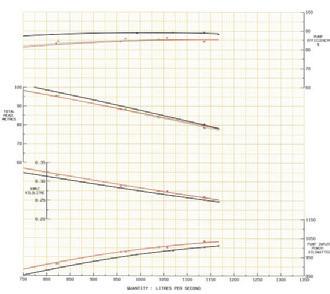

“Our new pumps are state-of-the-art and each can move around 1,300 litres of wastewater per second, lifting it 33 metres. They are an impressive 3m high and 1.5m in diameter.

“Council took the specification of the pumps very seriously as we want them to work efficiently and support the smooth operation of the city’s wastewater network for many years to come,” Mr Petersen said.

Mr Petersen said an engineer from the Logan Water Infrastructure Alliance visited the KSB factory in Germany to verify the pumps’ performance and witnessed them being readied for their six-week journey by ship to South East Queensland.

IRRIGATION & INDUSTRIAL

SUBMERSIBLE PUMPS & MOTORS

Moving Water Is Our Business

Franklin submersible pumps and motors are ideal in the most demanding applications and offer unmatched reliability, service, and availability.

Konichiwa Tsurumi

Our latest Pump Industry selfie comes to us from Japan, where Tsurumi Pump President Osamu Tsujimoto was spotted reading our magazine.

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 11 NEWS

2079_Franklin New Pump Ad_FE807.indd 1 20/3/12 6:28:02 PM

FE942 06/13 www.franklinwater.com/au 1300 FRANKLIN (372 655)

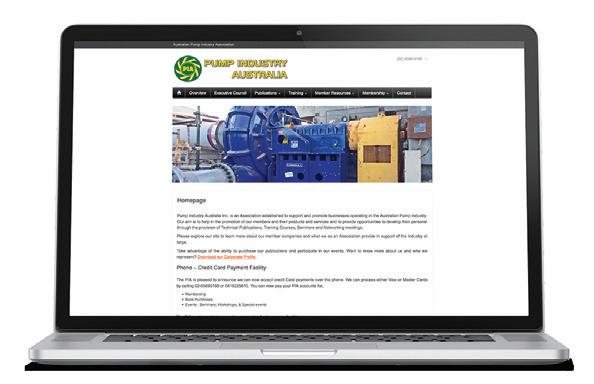

The new face of the PIA

Last November the PIA gathered for its annual general meeting and dinner, an evening which was well attended by the association’s membership. Attendees learned about a range of new initiatives for the association, which will be rolled out across 2016.

The PIA was particularly excited to announce a new alliance with the Hydraulics Institute (HI), which will see the two associations working together to provide mutually beneficial outcomes for their members.

During 2015, the PIA signed a Memorandum of Understanding with the HI covering a range of activities, including:

• The sale of HI publications through the PIA website

• The promotion of HI webinars through PIA website

• The involvement of HI personal in selected Australian seminars

• Access to HI online training programs via the PIA.

The PIA sees this as a significant step in providing members with access to wide ranging information and data from a highly recognised international source.

In conjunction with the HI partnership, the PIA has also launched a revamped version of its website, which has been designed to better promote the Association and its members.

The new-look site, which is now mobile friendly, features an online store offering a wide selection of pump industry related publications. This includes a selection of HI publications, which are now available under the agreement outlines above. The PIA website also features links to other sites which might be of value to members, newsletters, and access to a new members only section of the website.

In addition to this, there is a calendar listing all upcoming meetings and events, as well as a section listing all members and Life Members. The members section has been improved and includes sections containing past AGM minutes, technical papers, industry statistics, and much more.

Head to pumps.asn.au to check out the new site.

12 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au

PIA NEWS

Ron Astall delivers his President’s Report at the AGM.

ANGUS FLEXIBLE PIPELINES PROVIDES INNOVATIVE LAYFLAT HOSE SOLUTIONS FOR A WIDE RANGE OF FLUID TRANSFER APPLICATIONS

Wellmaster is the Industry Standard Flexible Rising Main for all types of ground water extraction and well-monitoring operations.

OVER 70,000 installations worldwide

Flexible Rising Main

Wellmaster Approvals:

Reg 31 UK

NSF 61 USA/Canada

DVGW W270 Germany

DM174 Italy

Institut d’Hygiene Switzerland

AFNOR France

AS 4020 Australia/NZ

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 13 PIA NEWS

9/67 Depot Street BANYO Qld 4014 M: 0400 243 175 Ph: 07 3256 7624 Angus Flexible Pipelines Australia Pty Ltd

John McAndrew presented to attendees during the AGM (top left); before members enjoyed the chance to mingle with clients and colleagues afterwards.

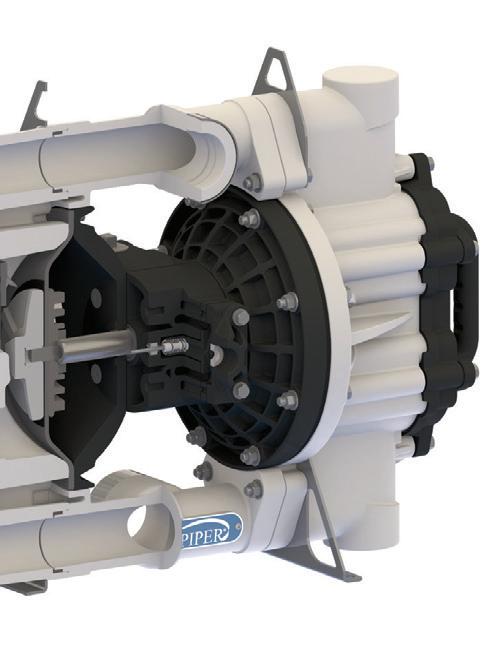

www.pumpindustry.com.au PIA NEWS THE AWAKENING OF A MPump Pty Ltd NEW TECHNOLOGY sales@Mpump.co THE WORLDS MOST ADVANCED AODD FOR DISTRIBUTION OPPORTUNITIES: AUSTRALIAN BY DESIGN

PIA ANOINTS NEWEST LIFE MEMBER

At the PIA’s annual general meeting in November, John Link was named the newest Life Member for the Association.

John joins a prestigious group, with Life Membership only having been granted to 16 other members.

John started his first business – a crop spraying business – in 1959, before moving into pumps. According to John, “I think I was about the first person to set up a pump company whilst never having worked for an established pump company. Most of what I knew at the time was from the practical use of pumps when crop spraying.”

Over the 1980s and 1990s John’s business

went from strength to strength and grew into the business it is today.

“I have always been very passionate about my customers, employees and business,” said John. “Currently I have eleven employees, who I consider to be friends, and I run Link Pumps as a family business with pleasant customers who appreciate the informal friendliness of our service.”

John’s friends in the industry are many, and there are many who know they can turn to John for advice or assistance when they have a challenging pump that has them stumped.

Congratulations on achieving PIA Life Membership John.

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 15 PIA NEWS

PIA Life Members Keith Sanders, Geoff Daniels, Bill Aitken, John Link and Bill Coulter.

PIA President Ron Astall presents John Link with his Life Membership.

Sulzer launches new process pump range

Sulzer has launched a new innovative SNS end suction single stage process pump range. It is designed to exceed the highest standards of performance and reliability, as well as the requirements of the ISO5199 standard.

The new pump range was developed for pumping applications in the pulp

and paper, water and wastewater, chemical processing, power, oil and gas, hydrocarbon processing, and general industries.

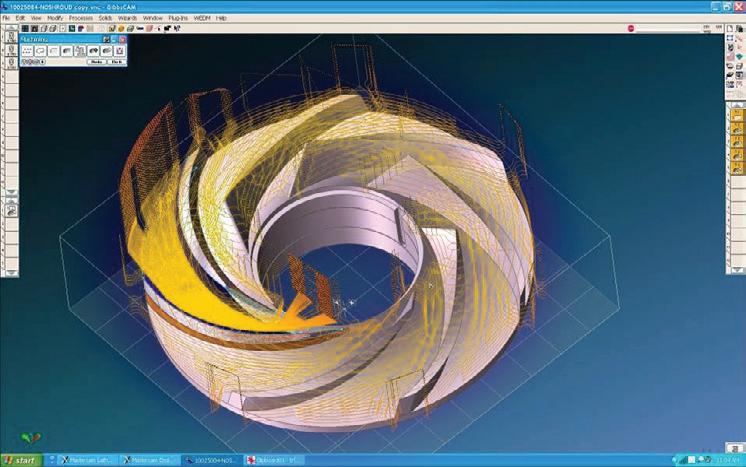

The SNS process pumps are designed to pump clean and slightly contaminated liquids, viscose liquids, and fibrous slurries. The unique hydraulic design ensures efficient

pumping with a low net positive suction head required across the whole pump range.

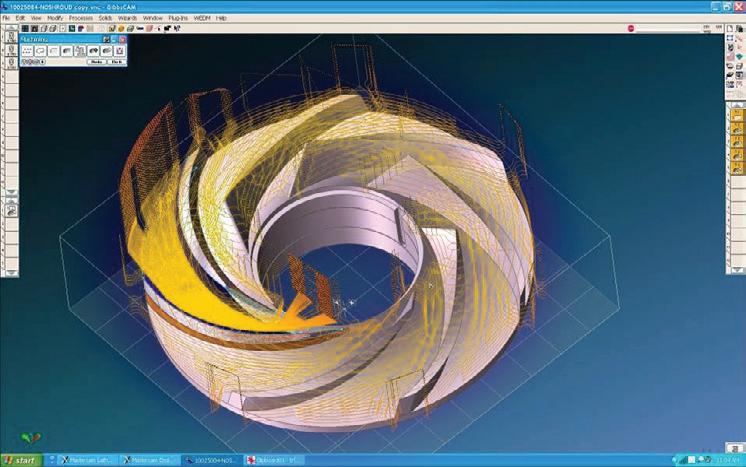

State-of-the-art simulation technology was used for designing the reliable and highly efficient impeller, casing, and shaft sealing. This resulted in very efficient hydraulics with improved shaft sealing conditions to ensure high reliability. Optimised patent-pending balancing holes in the impeller, together with a new design for the sealing chamber, guarantee ideal conditions for maximising the lifetime of the seal.

The innovative mechanical shaft seal solution provides easy assembly and maintenance. At the same time, it reduces the total cost of ownership by cutting down operation, maintenance, and downtime costs to a minimum. The compact pump design minimises shaft deflection and extends the shaft seal lifetime while decreasing unexpected shutdowns and overall maintenance costs.

Sulzer’s heavy-duty, rigid, and compact bearing units are leakage-free, which minimises unexpected shutdowns and reduces the maintenance costs. Standardised base plate, back pull-out design and flexible spacer coupling with an electric motor of standard feet make the installation quick and easy, thus bringing down the installation cost.

Due to the unique design, innovative features, and inventive standardisation of the SNS series, service and spare part inventory costs are also lower than they were previously.

The new SNS process pump is also the most efficient process pump range on the market, exceeding European Union requirements for energy-related products.

“With the new SNS product line, Sulzer provides its customers with very cost-effective pumping solutions, both on initial investment and on energy consumption. This represents a significant contribution to improve our customers’ profitability and environmental footprint,” said Cesar Montenegro, Division President Pumps Equipment at Sulzer.

16 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au PIA MEMBER NEWS | PARTNER SOLUTIONS

Sulzer Australia Pty Ltd Phone 03-85813750 jonathan.fullford@sulzer.com www.sulzer.com TCO savings 21% MEI 0.7 ErP 2015 Modern industry demands more energy efficient pumping solutions so we’ve broken the conventions in the name of efficiency. The revolutionary design increases efficiency, lowers energy consumption and minimizes total cost of ownership. You just have to decide what to do with the savings you make? NEW Sulzer SNS pumps – Efficiency by design How Will the Savings Make You Feel? For more information on the new SNS pump series, visit www.sulzer.com/en/Products-and-Services.

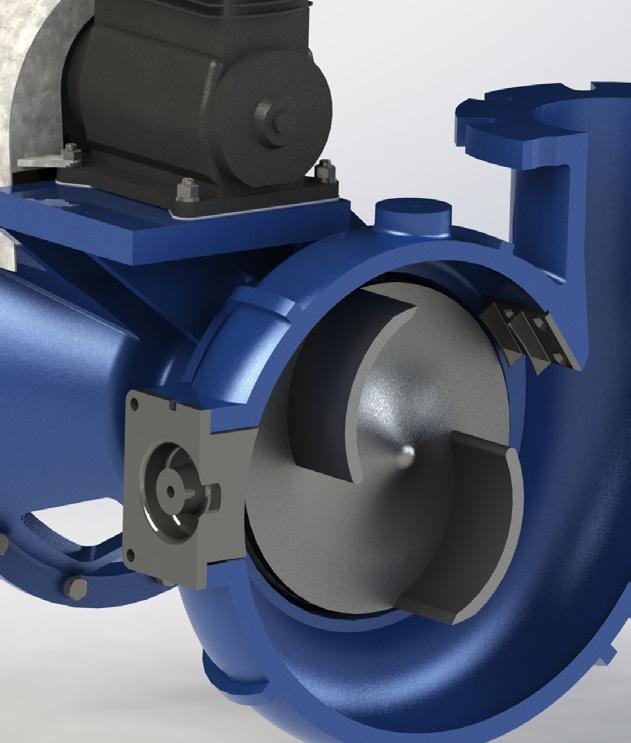

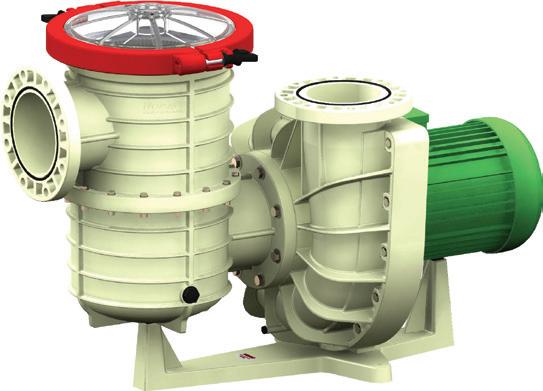

New centrifugal pump range by Gorman-Rupp

Gorman-Rupp has announced the release of a new range of centrifugal end suction pumps through Australian distributor, Hydro Innovations. Called the 6500 Series, the range contains six solids handling models and three effluent pump models.

The range has been designed to have a very low lifecycle cost and minimal service requirements, making them ideal for delivering an excellent ROI. The Smart Scroll® volute allows installers to position the discharge in any one of eight positions, which increases flexibility in pump installation to help reduce installation costs.

Pumps are fitted with SiC/SiC oil lubricated seals, with separate oil chambers for seal and bearing oil and separate sight glasses so that operators can tell at a glance that oil levels and clarity are right in each chamber. The chambers are also separated by an atmospheric vent that keeps water pressure away from the bearings if a mechanical seal fails. Oversized bearings and alloy steel shafts (with options for stainless steel) add to the reliability, as does the double volutes designed into the higher head models.

Solids handling models have minimum 76mm spherical solids handling capability, flow rates from 20 litres per second (LPS) through to 900 LPS, and heads to 120 metres. They also have a side access (clean-out) port for easy access to pump interiors for inspection and blockage removal, while pusher bolt capability assists in the removal of the suction flange. Effluent models range in flow from 20 LPS through to 350 LPS, with heads to 155 metres.

For more information on these pumps, contact Hydro Innovations on 02 9898 1800 or by emailing info@hydroinnovations.com.au.

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 17 PIA MEMBER NEWS | PARTNER SOLUTIONS

Operating pumps at partial capacity: causes of vibration

By Dr Gary Dyson, Managing Director, Hydro Global Engineering Services (UK) and Chandra Verma, Chief Design Engineer, Hydro Australia

It can be common for pumps to operate at low flow. This is inevitable in many cases, as the nature of many process operations place varying demands upon the equipment.

Whilst operating at low flow, a machine is under much greater duress than at most other operating flows. To understand why operating at extreme low flows can cause pump problems, it is instructive to analyse the nature of the flow through the machine.

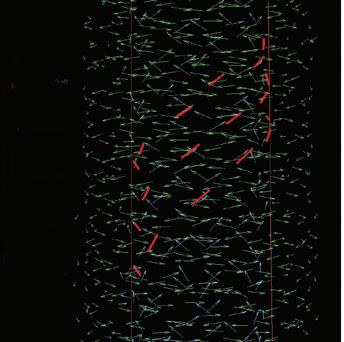

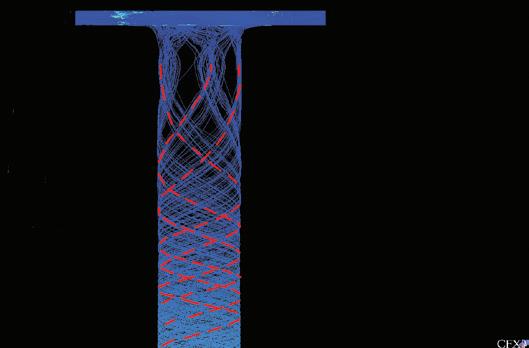

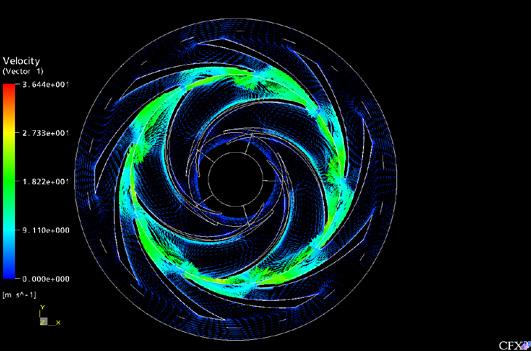

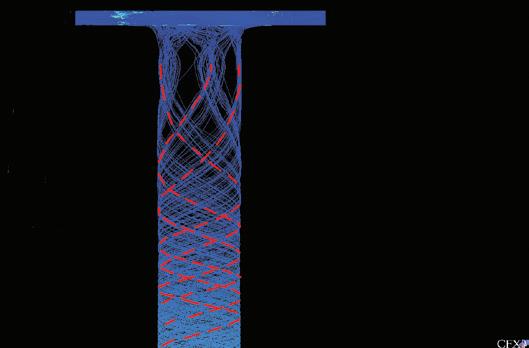

Using computational fluid dynamics, Hydro Australia has been able to model this flow picture. By truly understanding the nature of the flow regime Hydro Inc Engineers have been able to re-design and refine equipment for wider operating regimes and greater mean time between failures.

Hydraulically generated vibration

The days have long passed where pump vibrations were viewed as largely a matter of mechanical balance. Nowadays, we recognise that, even if a pump has near perfect mechanical balance, it will still exhibit remnant vibrations.

The intensity of this remnant vibration turns out to be flow related, with a minimum at or around best efficiency point. Clearly the hydraulic design of the pump has some significance in its vibration behaviour.

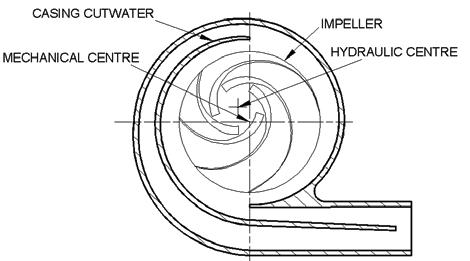

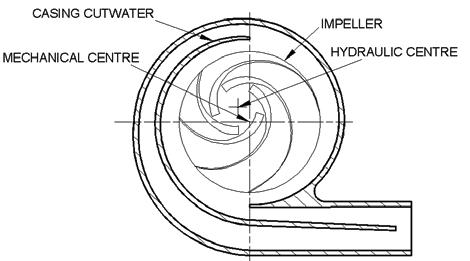

Vibration at “one times” shaft rotational frequency is frequently ascribed to driver misalignment, or mechanical balance. However, this can also be caused by the impeller if it is machined eccentric to its hydraulic centre. The impeller behaves like a hydraulic cam while in the pump, even though it may be in near perfect mechanical balance in air. See Figure 1.

Hydraulically generated vibration – vane pass

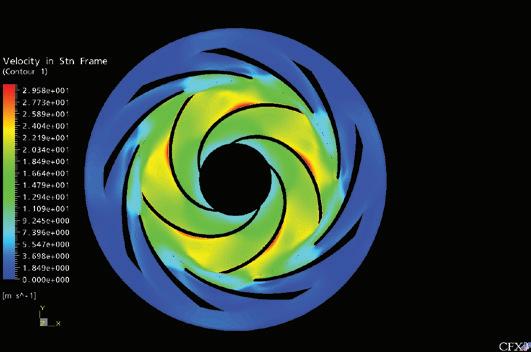

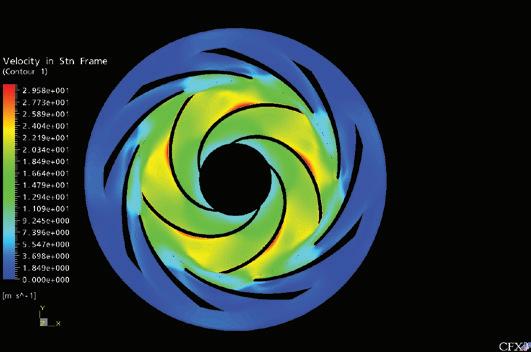

From a hydraulic design standpoint, vibrations at vane pass frequency are always inherent, due to the way impellers generate head.

Each vane had a pressure differential between the top and under side of the van. This pressure differential results in a velocity difference over both surfaces of the vane.

This difference propagates through the passage out into the collector. Thus the collector, and anything connected to it, will experience a fluctuating velocity field once per impeller blade pitch. These result from the turbulent ‘wake’ generated at the trailing edge of the blade, which is fuelled by the two different velocity streams mixing out. See Figure 2.

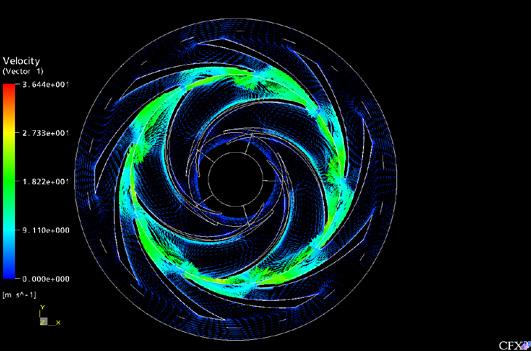

At partial capacity this flow picture greatly deteriorates, as shown in Figure 3. Each passage is filled with slow moving fluid. The diffuser passages are stalled and the velocity is heavily time dependent. Operated in this condition it is easy to see how vibration and heat can become a problem for pumps reliability.

Vibration caused by inlet back flow

This phenomenon is always present within a pump operating at low capacity, and always contributes to the vibration level.

High-energy liquid is expelled from the impeller eye. This expelled liquid dominates the suction passage, occupying

18 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au

PIA MEMBER NEWS | PARTNER SOLUTIONS

Figure 1. Hydraulic cam causing high 1x vibration.

Figure 2. Varying velocity experienced by diffuser.

Figure 3. Complex nature of the flow regime at low capacity.

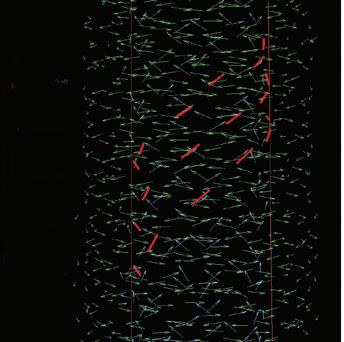

the two-thirds of the flow area from the pipe outer diameter downwards towards the channel centreline (see Figure 4). The extent that the expelled liquid fills the suction channel remains unchanged with distance from the impeller. This flow spirals helically down the periphery of the suction pipe.

Each impeller blade generates individual streams. The tangential velocity imposed on the regime by the impeller dominates the flow causing the helical spiral angle to be approximately equal to the blade inlet angle. This angle does not diminish with distance from the impeller implying that both the tangential and axial components of the velocity decay proportionally to maintain this angle.

The inner third of the suction channel area contains a spiralling core of slower moving fluid. Viscous effects transmit tangential energy from the high-energy peripheral flow and drive this core in a helical spiral counter to the direction of pump rotation. Flow is dominated by the axial component of the velocity and tangential forces exerted by the peripheral flow cause the inner helical flow angle to be approximately double the outer angle. Again the helical spiral angle remains

ABOUT THE AUTHORS

constant. See Figure 5.

Whilst these velocity streams are not responsible in the computational analysis for a vibration component, this cannot be said in a real situation. Pump suction and piping designs contain discontinuities such as splitters, elbows and reducers.

The velocity streams impacting on these features contribute to the vane pass frequency vibration.

Conclusion

Being able to visualise the nature of the flow with a centrifugal pump allows a greater understanding of how these flow impact on the reliability of the equipment.

Vibration is no longer viewed as merely a function of the mechanical balance but is also influenced by the design of the bladed components, the operating philosophy and the precision of the build of the pump.

By using advanced computational techniques it is possible to refine and manage these contributing factors to minimise hydraulically generated vibration.

Dr Gary Dyson is the Managing Director of Hydro Global Engineering Services, based in the United Kingdom and Chandra Verma is the Chief Design Engineer for Hydro Australia, based in Morwell, Victoria.

HYDROVAR

• Motor or wall mountable

• Fully programmable on site

taking

• Software specifically designed for pump operation, control and protection

• High level hardware design

• More flexibility and cost savings

• Energy savings up to 70%

• Simple mounting “clip and work”

• Multi-pump capability up to 8 pumps

1300 4 BBENG

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 19 PIA MEMBER NEWS | PARTNER SOLUTIONS

Figure 4. Internal core of spiralling fluid in suction channel.

Figure 5. Helical spiralling inlet backflow at suction duct periphery.

Ph:

www.brownbros.com.au

®

Call us today for a Hydrovar® technical brochure to see how we can deliver your pumping solutions. DELIVERING PUMPING SOLUTIONS 03/15

, the modern variable speed pump drive

pumping to a new level of flexibility and efficiency.

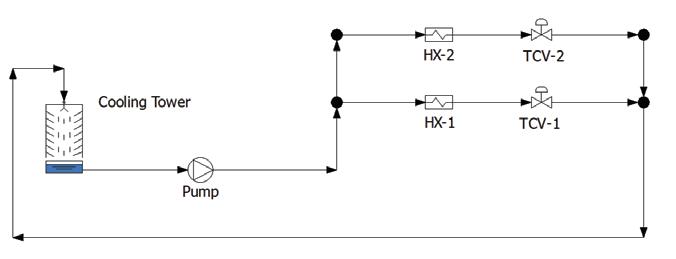

Produced water treatment

The effective separation of oil and water is a vital part of any oil and gas production facility. The preservation of oil droplet size and prevention of emulsion formation is crucial to the effective treatment of oily water.

Feeding of oily water separation equipment, either gravimetric or dynamic, is optimised by low shear pumping equipment. The slow running speeds and gentle action of progressive cavity pumps eliminates problems caused by emulsion formation.

Feeding the oil/water mixtures to the separator using a high quality progressive cavity pump, from a reputable global manufacturer, is a ‘state of the art’ solution for maximising the overall efficiency of the system. No demulsifying chemicals need to be added, so operating costs are substantially reduced. Specifying even wall stator technology reduces internal slippage and shear, while also offering a compact design where space is at a premium.

Flow rates can be regulated via simple speed control which eliminates the need for control valves and spillback lines (as used with centrifugal pumps). The removal of these valves further reduces points of shear in the process system. Semisubmersible, vertically mounted progressive cavity pumps provide a flexible solution in restricted space and when fitted in a can, this configuration will optimise the NPSH available and the process conditions.

Produced water recycle pump

Conveying capacity:

18.2 m³/hr (80 USGPM)

Pressure: 14.9 bar (216 psi)

Material EN 1.4501

API 682 plan 53B seal system

Benefits include:

• Compact design, with even wall stator, saves space

• Flexible installation and use of semi-submersible in-can design, provides compact footprint

• Minimal shear on oil droplets prevents emulsion formation

• Variable flow rate is controlled via simple speed adjustment to optimise efficiency of separation systems

• Pumps can operate with low NPSHr 0.3m (0.98ft) eliminating the need for a separate booster pump

• Eliminates the need for adding chemicals, providing substantial cost savings.

For more information, or to request a free site survey to establish if SEEPEX can help you, contact SEEPEX Australia on 02 4355 4500 or info.au@seepex.com.

Slop oil pump

Conveying capacity:

25.6 m³/hr (113 USGPM)

Pressure: 13.4 bar (194 psi)

API 682 Cat 2 seal 53B system

Flare drum pump

Conveying capacity:

11.28 m³/hr (50 USGPM)

Pressure: 18 bar (261 psi)

API 682 Plan 53B system

20 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au

INDUSTRY NEWS | PARTNER SOLUTIONS

FLOW CHART BASED ON PRODUCED WATER TREATMENT

WATER TREATMENT

APPLICATIONS

1. BE range pumps lift oil from the slop oil tank to the separator

2. BN / BE range pumps transfer product from the knock out drum to the separator

3. BN / BE range pumps transfer product from open and closed drains to the separator tank

4. BN / NS / N range pumps with even walled stator technology transport produced water to hydrocyclones

5. BN / NS / N range pumps transport reject oil back to the upstream separators or water to induced gas flotation (IGF) units

WHY REPLACE WHEN YOU CAN ADJUST?

SEEPEX Smart Conveying Technology extends the life of your stator. Adjustment of the retaining segments takes just 2 minutes and restores 100% pump performance.

Tests have shown up to 3x stator life compared to conventional progressive cavity pump design Join the smart revolution and test our innovation “Smart Conveying Technology”.

SEEPEX Australia Pty. Ltd. Tel +61.2.4355 4500 pvila@seepex.com www.seepex.com

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 21 INDUSTRY NEWS | PARTNER SOLUTIONS produced water oily water water hazardous drains water oil oil RANGE BN knock out drum pump RANGE BE RANGE BN centrifuge / hydrocyclone feed pump RANGE BN open drain pump RANGE BN reject oil pump RANGE BN closed drain pump RANGE BE canned pump RANGE BN reject oil pump 9 PRODUCED WATER TREATMENT FLOW CHART BASED ON PRODUCED

slop oil tank separator centrifuge hydrocyclone closed drain tank knock out drum APPLICATIONS 1. BE range pumps lift oil from the slop oil tank to the separator 2. BN / BE range pumps transfer product from the knock out drum to the separator 3. BN / BE range pumps transfer product from open and closed drains to the separator tank BN / NS / N range pumps with even walled stator technology transport BN / NS / N range pumps transport reject oil back to the upstream

Improved safety in explosive atmospheres

KTR has expanded its ROTEX® coupling line with the new ROTEX® non-sparking for maintenance-free use in potentially explosive environments. This failsafe innovation assures operation in cases of spider element wear while reliably preventing sparking.

The jaw geometry consists of a conductive high-tenacity plastic that is injected onto the hub body which continues to be made of steel or other metals such as aluminium. The newly developed synthetic material prevents any static charging and is also designed to be so hard wearing that even in cases of elastomer wear out, torque will still be transmitted without any danger of sparking. As a result, maintenance work can be postponed to a convenient time frame.

The failsafe and maintenance-free ROTEX® non-sparking is certified under EU directive 94/9/EC (ATEX 95) and thus deemed suitable for the use in explosive atmospheres. The shaft coupling has a compact design and can be axially plugged in. It offers good dynamic properties, excellent vibration damping

and a low moment of inertia.

The ROTEX® non-sparking ensures dampened torsional vibration during power transmission and absorbs shocks generated from imbalanced machinery.

The new explosion-proof ROTEX® non-sparking coupling displaying injected jaw geometry on one side.

The new coupling is also available in various double-cardanic finishes for large shaft misalignments that maintain low restoring forces and ensure sound dynamic properties.

With the double-cardanic design, the centrepiece comes with injected jaw

22 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au

INDUSTRY NEWS | PARTNER SOLUTIONS

geometry

The ROTEX® Non-Sparking is exclusively distributed in Australia and New Zealand by Deanquip. For further information or technical support, please contact +61 3 9729 0201 or send an email to sales@deanquip.com. www.ktr.com Thanks to new material and production technologies the fail-safe ROTEX® Non Sparking can continue to operate if the spider has worn off with no danger of sparking, ensuring a carefree operation in hazardous locations. More safety for hazardous locations Phone: +61 3 9729 0201 www.deanquip.com Your KTR distributor in Australia.

on both sides.

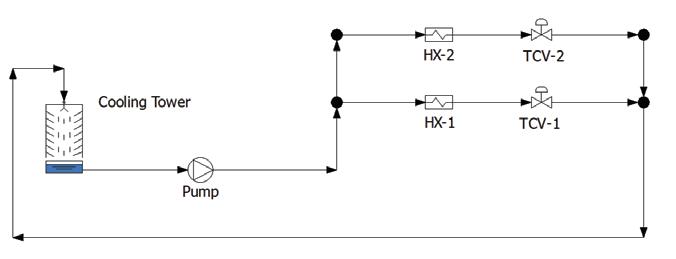

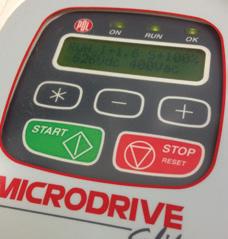

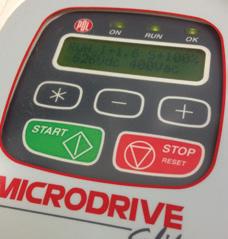

Drive solutions for the water world

FCR Motion Technology is proud to present the Emotron FDU series of pumping variable speed drives from CG Drives & Automation.

Born as Emotron in 1937, Emotron has developed solutions for the control and monitoring of electric motors. With over 30 years of experience in water handling applications, Emotron’s pumping solutions guarantee longer service life, flexibility, system protection and improved cost-efficiency.

The rugged construction of the IP54 FDU variable speed drive is designed to withstand the toughest environmental conditions, with power ranging from 0.75 to 3,000kW. The full featured FDU is designed to regulate the motor speed to control flow, and pressure with an in-built suite of pumping specific features which include:

Multi pump control – The control of up to seven pumps regulating the flow/ pressure of the system, selecting the pump to give them all equal running time. Should one pump fail, the system

automatically selects the next available pump, avoiding unnecessary down time.

Auto rinsing – When running at low speed, sludge can build up reducing the efficiency of the pump. With auto rinsing the system can be programmed to run at full speed at certain intervals or on start up to prevent this sludge building up.

System sleep – This function can be activated in low flow or no flow situations to prevent the pump from overheating and reduce energy consumption.

Damage protection – The built in shaft power monitor uses a unique load curve protection function to detect situations such as dry-running, cavitation, overheating, blocked pipes, etc.

Energy saving – By regulating the speed of the pump to control flow or pressure, the system will only use the power required to deliver the required output, saving considerable energy when demand is low.

Simple descriptive text – Simple descriptive programming parameters and operating units for pressure, flow, speed, etc, can be customised to suit user needs.

FOR ALL YOUR PUMPING APPLICATIONS MOTOVARIO INLINE

• Increased mechanical performances

AND WORM GEARBOXES

• High external radial capacity and mechanical strength

• Reduction ratios between 1.3 and 280

• Specific reinforced seals, taper roller bearings and thrustbearings available

EMOTRON DRIVES, SOFT STARTERS AND SHAFT POWER MONITORS

• Torque control, smooth start and stop modes to avoid water hammering

• Dedicated software for pump control systems

• Programmable timers with real time clock

• Early warnings and safety stops

• Optimized monitoring for energy saving

• Control of up to 7 pumps

• IP20/21 and IP54 rating www.fcrmotion.com

(03) 9362 6800

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 23 INDUSTRY NEWS | PARTNER SOLUTIONS

For more information visit www.fcrmotion.com or call 03 9362 6800.

Universal mounting foot mount, flange

foot/flange

mount and

mount

From humble beginnings to dramatic expansion

Since the relaunch of the Tsurumi product range in Australia four years ago, the results have been nothing short of astonishing. When Aussie Pumps began supplying Tsurumi Pumps, the company found that Tsurumi’s reputation was well known by pump specialists but not necessarily by users such as farmers, consultants and even mine engineers.

“We knew the quality and standing of Tsurumi internationally and shared a desire to make the brand a market leader in Australia. This would match the standing and reputation the product already has in North America, Europe and South East Asia,” said Aussie Pumps Chief Engineer John Hales.

Tsurumi has spent 91 years becoming the world’s number one manufacturer of electro-submersible pumps with an annual production capability in excess of 1.4 million units. This story charts the progress of the dynamic Japanese company.

Humble beginnings

The company started out in 1924 as a manufacturer of agricultural vertical shaft pumps. The primary function was for applications in paddy fields and Japanese horticulture. By 1951 the company had grown into Tsurumi Manufacturing Company Ltd and had produced a two-stage vertical shaft pump for construction dewatering use.

That evolution of agricultural pumps was a huge breakthrough for Tsurumi. It introduced them to the construction market, a vital industry during the rebuilding of post-war Japan.

PUMP HIRE and REPAIRS

Repairs

Our continuous exposure to a wide range of problems and Industrial applications across numerous markets, has ensured we have the know how to handle pump repairs of all sizes and complexities, including re-engineering, testing, laser alignment and condition monitoring.

With each repair job we implement a thorough inspection process and follow strong control and stringent acceptance criteria carried out by a team dedicated to keeping your pump working at optimal performance.

Hire

Link Pumps has been servicing the needs of Australian Industry with pump hire solutions for over 50 years, and as such has built a reputation for being able to solve complex engineering problems and additionally undertake complex setups with complete reliability notwithstanding working to the exacting standards of environmental and occupational health and safety expected by that of our customers and regulatory authorities.

In 1955 the company launched the first electro-submersible pumps, the EP Series. Now there was no stopping Tsurumi.

With that technology and a booming domestic market, the company threw itself into the development of a range of new products. This included a newly developed lightweight dry type motor series. The dry motors replaced the conventional oil filled motor, with major features and benefits for users. By 1965,

For all your Pump Hire and Repair needs you can’t go past Link Pumps, so call us now…. We perform, Anytime, Anywhere

4 Ponting Street, Williamstown North,3016

24 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au INDUSTRY NEWS | PARTNER SOLUTIONS

LINKPUMPS

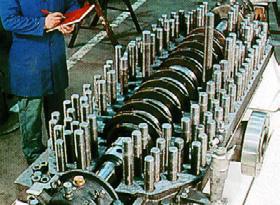

Tsurumi started producing two stage vertical shaft pumps in 1951 for the construction market.

Phone: (03) 9391 9600 Email: sales@linkpumps.com.au

the submersible pumps incorporated built-in circle thermal protectors (thermostats) to protect the motor from overheating.

During this period of rapid growth the company opened an Osaka sales office and a separate branch in Tokyo. In 1965, a Sapporo sales office was added in Hokkaido, and another sales office opened in Fukuoka (on Japan’s island of Kyushu).

In the early 70s a major breakthrough in the introduction of a solids handling impeller was achieved by the company. Unique to Tsurumi at the time, the company introduced the concept of a vortex style impeller which enables the passage of solids without clogging or excessive wear on the pump end.

By now Tsurumi, guided by Mr Tsujimoto as President, was sensing that there was a world outside Japan for the company’s products. In the early 70s Tsurumi started exporting through trading houses and entered the European, North American, South East Asian, Australasian and Middle East markets. That explosion of activity was generated by the company’s quality standards, extremely competitive prices and innovative designs.

By 1979 Tsurumi had established subsidiary companies in Hong Kong, Singapore and the United States. To keep pace, a brand new factory was built on a green-field site in Kyoto. A new plant designed to dramatically increase productivity included an enhanced R&D department and test rigs capable of handling pumps big enough for flood mitigation and municipal sewage applications.

By now Tsurumi had come an awfully long way from vertical shaft agricultural pumps and had developed a range of dewatering pumps, slurry pumps, sewage pumps and even aerators. Driven by worldwide demand they provided realistically priced products that were deemed to be of a level of reliability not found elsewhere.

“The company philosophy is very typically Japanese,” said Mr Hales. “It’s a combination of modern innovation combined with traditional Japanese attention to detail,” he said.

In the year 2000 the Kyoto plant acquired ISO 14001 certification.

International growth

By 2005 Tsurumi had established additional subsidiaries in Germany, Taiwan, Malaysia and Shanghai. Additional subsidiary companies would be established in the coming years in Korea, Thailand and in the Middle East.

Today the Kyoto plant represents a massive development of manufacturing and engineering excellence. Modernized and developed using the most modern robot technology, the production capacity from this one plant alone is over one million units per year.

Tsurumi philosophy

Tsurumi traces its beginnings back to the projects it undertook to improve the harsh conditions in Japanese farming villages, introducing vertical irrigation pumps more than 90 years ago.

During the rebuilding of Japan after the Second World War, Tsurumi was the first domestic company to establish submersible pump technology. During that subsequent period of high economic growth Tsurumi contributed to the expansion of many industrial sectors by assisting in the development of social infrastructure through water related urban planning and flood control projects.

The company’s capability enabled it to participate in major Japanese projects like the Akashi-Kaikyo bridge

(between Honshu and Awaji Island across the Akashi Strait).

The philosophy of the company has always been to be ‘water and people friendly’. Tsurumi encourages creativity, harmony and passion from the President, Mr Osamu Tsujimoto, to staff. The staff are committed to facing the challenges delivered by changing times.

The message for Australia

Australian Pump, a well-established and progressive Australian company, are absolutely committed to bringing Tsurumi to the market.

“Capitalising on the company’s engineering, production, and perhaps more importantly their philosophy, make them an unstoppable force in the pump business” said Mr Hales. “Working with Mr Tsujimoto and the Tsurumi team means we get incredible engineering support. A positive, progressive attitude and access to products that are built to quality standards means Australian customers receive the world’s best.”

Australian Pumps Tsurumi business has expanded dramatically since the establishment of a Tsurumi Pump Bank. This bank puts millions of dollars worth of Tsurumi stock at the disposal of Australian customers.

“Providing the combination of the best product, at the best price and short lead time is our goal,” said Mr Hales.

For further information including detailed catalogues, technical data and material on the huge range of submersible pump products visit www.aussiepumps.com.au or contact Australian Pump Industries on 02 8865 3500.

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 25 INDUSTRY NEWS | PARTNER SOLUTIONS

Mr Osamu Tsujimoto President Tsurumi masterminded the robotised production plant in Kyoto.

Mr John Hales, Aussie Pumps’ Chief Engineer with the latest evolution of Tsurumi dewatering pumps.

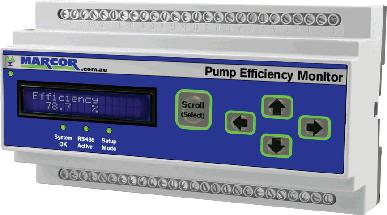

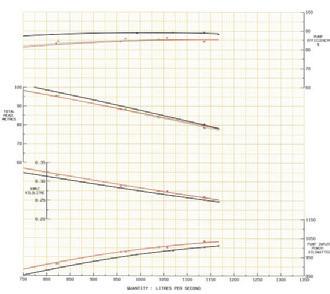

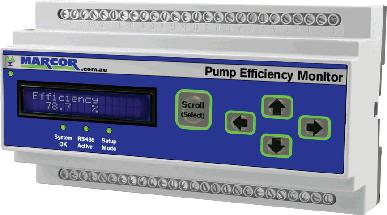

Efficiency and flow monitoring

Some studies have shown that 30 to 50 per cent of the energy consumed by pump systems could be saved through equipment or control system changes. The fact is – monitoring pump efficiency and rate of wear will save you money.

In today’s world where there’s an increased awareness of the need to use energy efficiently and operate in a manner that is sustainable, in the pump industry there is constant pressure on users to reduce energy wastage, reduce costs and reduce pollution.

The saying goes “If you cannot measure it, you cannot manage it”. This is also true for energy wastage and being able to know where and how much energy is wasted, is the first step to reducing energy wastage. The question that needs answering is: If I want to save money, when is the ideal time to rebuild my pump?

Real-time efficiency monitoring or pump tests?

The Marcor Pump Efficiency Monitor measures real-time pump energy wastage and flow rate accurately, using the thermodynamic method as

described in ISO5198. It allows you to manage your pump and pumping system’s performance in real-time rather than relying on periodic pump test results. Any condition that arises which can lead to energy wastage or pump damage, can be responded to immediately.

The Pump Efficiency Monitor was developed to provide pump and asset managers with a reliable tool to accurately measure and monitor energy wastage and to be able to confidently forecast maintenance activities. This efficiency monitor provides all the necessary information to realise significant savings.

For the price of two or three pump tests, pump end users can now monitor the performance of their pump in

real-time for at least the next 20 years. Pump management staff can spend more time managing pumps and pump systems to reduce energy wastage, and less time collecting pump performance data in the field.

The device uses the thermodynamic method for determining the energy losses in the pumped fluid. This method has the advantage of determining percentage energy losses by measuring the changes in pressure and temperature across a pump. It does not require a flow meter reading.

The key parameters the monitor measures are energy wastage (%), pump efficiency (%), cost of pumping (kWh/kl), flow (l/s), head (m) and power (kW).

For more information on how the Marcor Pump Efficiency Monitor can help your business, visit www.marcor.com.au or call 08 8326 7171.

Pump Performance Testing

S In-situ pump performance testing

S Portable pump test equipment

S Real-time pump efficiency monitoring

S Differential Temperature Transmitters (1mK)

S Pump test equipment rental S Reduce your energy bill S Extend the life of your pumps S Reduce greenhouse gas emissions

26 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au INDUSTRY NEWS | PARTNER SOLUTIONS

.com.au Serving the industry - Caring for the environment E: enquiries@marcor.com.au. Ph: 0450 027 110

Let us:

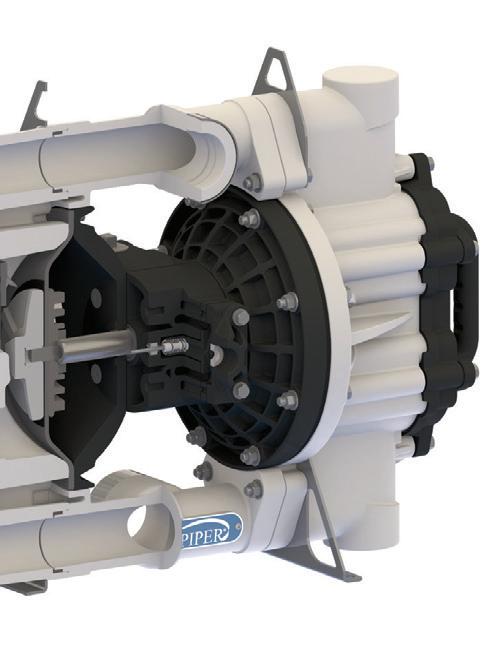

Not to be sniffed at

New to the AllightSykes range of Sykes pumps, the SW has been specifically designed for sewage and wastewater applications. The patent-pending SW range is capable of pumping large solids up to 100mm. It chops and shreds debris, rope, and other types of stringy items that normally partially or fully clog pumps.

The SW pump range boasts an array of new and exciting features to ensure optimum pump performance in times of need. To test and prove this patent pending concept, Sykes Pumps have carried out extensive field trials with various water authorities with excellent results and feedback.

The SW pumps are based on the market leading Sykes heavy duty and robust CP range with significant commonality and interchangeability of key components.

The SW features a fully open non clog design impeller capable of handling large

solids. A shredder claw that is designed to tear and shred stringy material that normally would wrap around the impeller and clog the pump. The cutting pockets in the front wear plate chops and shears large object allowing them to be passed through the pump. The inspection insert is designed to allow easy access to the volute chamber enhancing maintenance and repair activities.

Optional extras include soundattenuated acoustic canopies, road registerable trailers, heavy duty skid base, remote pump monitoring, increased fuel capacities and fuel tank bunding.

For more information on the range of Sykes pumps

freecall 1300 255 444

SEWER & WASTE PUMP RANGE

New to the AllightSykes range of Sykes pumps, the SW has been specifically designed for s ewage and waste water applications.

The patent-pending SW range is capable of pumping large solids up to 10 0mm. It chops and shreds debris, rope, and other type stringy items that typically clog pumps. For more information on the Sykes range of pumps, visit our website or freecall 1300 255 444

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 27 INDUSTRY NEWS | PARTNER SOLUTIONS

INSPECTION INSERT CUTTER POCKET SHREDDER CLAW NON-CLOG IMPELLER

experts FREECALL 1300 255 444

to speak to one of our de-watering

visit www.allightsykes.com or

to

to a dewatering experts.

available,

speak

Optimised water solutions

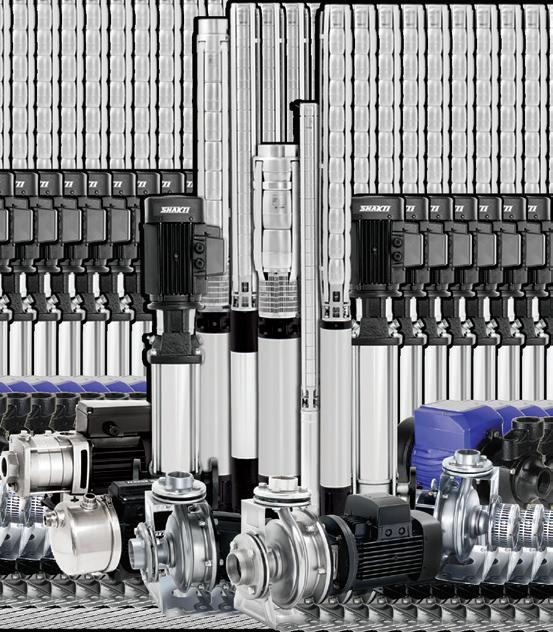

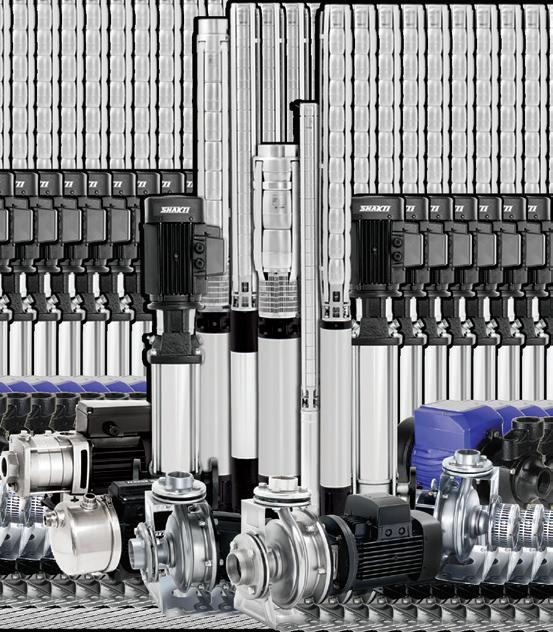

Dating back to 1982, the Shakti Pumps story is one of a company which has gone on to produce stainless steel submersible pumps, energy saving submersible motors, vertical multistage centrifugal pumps, pressure boosters, self-priming, end suction, open well and solar pumps. In the three decades since it was established the company has grown phenomenally and has become one of the few pioneers in the world to produce 100 per cent stainless steel submersible pumps.

The company employs international best practice technology to manufacture its products. This technology includes cutting-edge Japanese and European machines, modern CNC machines and stamping machines.

Thanks to dedicated efforts in R&D and technological innovation, Shakti Pumps has emerged as a leading entity in the pump industry, catering to domestic as well as international markets, with a notable reach of more than 100 countries.

Today, Shakti Pumps is a leader in the global pump industry, thanks to stateof-the art technology and continuous innovation. Their pumps have applications in raw water intake, drinking water treatment, water distribution, wastewater control and flood control, and wastewater treatment.

Shakti Pumps supplies a broad range of equipment and solutions designed specifically for water utility applications. Shakti is at the forefront of promoting and facilitating energy efficient and

sustainable technology, ensuring that water supply and wastewater facilities meet future challenges and regulations.

Shakti domestic pumps are ideal for use in homes, where they are used to maintain water pressure in taps and for general applications like watering gardens and operating fountains.

Shakti Pumps also meet varied agricultural needs, be it drip irrigation, agricultural sprinkler systems or watering crops; and they are used in industries for a variety of purposes including cutting and grinding, firefighting, managing sewage, and the heating and cooling of systems.

Shakti Pumps is a major force in places like hotels, corporate buildings and shopping malls, where heavy pressure and boosting is required. The company supplies pumps with the latest digital technology for cooling, heating and wastewater management.

Shakti Pumps also has a range of solar pumps, ranging in size from 0.37 to 75kW, that are simple and easy to operate, offering 40 per cent more

discharge than other ordinary pumps.

From draining flooded water from areas like basements, car parks and empty cesspools, to managing sewage in a water treatment plant, Shakti Pumps are widely used in the domestic, industrial and commercial sectors.

The range of Shakti Pumps products includes:

• Submersible pumps and motors

• Solar pumps

• Vertical multistage centrifugal pumps

• Pressure booster pumps

• Mono block end suction pumps

• Sewage pumps

• Immersible pumps

• Open well pumps

• Hydropneumatic booster systems

• Self-priming pumps.

28 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au INDUSTRY NEWS | PARTNER SOLUTIONS

more information please visit the company website - www.shaktipumps.com.au.

For

State of the Industry in 2016: adapt, diversify, survive

Recently Pump Industry undertook the most comprehensive survey we’ve ever conducted in order to present a detailed analysis of the industry’s outlook for 2016.

After a challenging 2015, coming off the back of the depressed oil price and the global fall in commodities prices, we were keen to measure and understand our reader’s expectations for the year ahead. Are we expecting the challenges of 2015 to continue? Or is the mood more optimistic, thanks to new opportunities in water, wastewater and energy efficiency?

The data from our respondents suggests it’s a bit of both. When asked how they expect their own company to perform in 2016, our respondents are feeling positive, with 45 per cent expecting their own performance to be better than 2015; and 44 per cent expecting to perform about the same. Only 8 per cent of respondents believe performance in 2016 will be worse than 2015, and the remaining 3 per cent were unsure. These responses are shown in Figure 1.

Interestingly, while our respondents are feeling positive about their own performance in 2016, their thoughts about the industry more broadly aren’t necessarily reflective of this. 49 per cent of respondents believe the industry will perform about the same as 2015, while a much smaller 22 per cent expect the industry as a whole to improve. 18 per cent expect the industry to perform worse than 2015, and the remaining 11 per cent were unsure. These responses are shown in Figure 2.

The discrepancy between personal performance and industry performance could be down to a number of reasons; perhaps our respondents are feeling more positive about their own ability to ride out the challenges of 2015 and prosper more in 2016. Or perhaps the difference suggests that the industry has a slightly less positive view of the broader industry’s performance which is not necessarily justified.

Performance by vertical

To gain an understanding of how the pump industry is performing across

a range of key verticals, we asked our respondents about their performance in these industries in 2015, and we asked our respondents how they expect to perform in these industries in 2016. From the responses we’re able to gain an insight into the best and worst performing verticals, according to our respondents, and gain an insight into which verticals show the most promise in 2016.

Figure 3 highlights the performance of our respondents across several verticals. From the baseline, this graph highlights the verticals in

Our respondents have noted a lack of major projects is having an impact on the pump industry.

30 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au

STATE OF THE INDUSTRY

which businesses overall ‘decreased somewhat’’ or ‘decreased significantly’ (bar below the baseline) and the verticals in which businesses overall ‘increased somewhat’ or ‘increased significantly’ (bar above the baseline).

From this graph we can see that our respondents had a challenging year across a number of sectors, with those involved in mining the hardest hit. As for how our companies expect to perform in 2016, respondents believe that conditions will improve across a number of verticals. While it’s anticipated that

the mining, plastics and rubber and pulp and paper sectors will continue to be challenging markets to operate in, our respondents believe in all other sectors their performance will increase or increase significantly.

In particular, the irrigation, water and wastewater, food and beverage and building services and HVAC sector all seem poised to offer pump company’s significant growth – a trend which continued to present itself throughout the survey.

How do you expect your company to perform in 2016?

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 31 STATE OF THE INDUSTRY

Worse than 2015 About the same as 2015 Better than 2015 Don't know

8% 44% 45% 3% Figure 1.

How do you expect the Pump Industry overall to perform in 2016?

External factors affecting the industry

To gain an understanding of how macroeconomic conditions, such as the value of the Australian dollar, are impacting the Australian pump industry, we asked our respondents to describe their positive or negative impact on the industry.

Analysing the responses, we’ve been able to generate graphs which represent which of the factors will have the greatest impact on the industry (Figure 4) and then order these from the impacts that will have the most negative impact to those that will have the most positive impact (Figure 5).

Figure 4 shows us that the performance of the mining industry, the value of the Australian dollar, the approval of major projects and the price of commodities stand out to our respondents as being the most influential over the Australian pump industry. The agricultural industry and global oil price are seen to have a similar impact on the industry, and further down the list of influencing factors are interest rates and unemployment figures.

How has the volume of work for your business changed in the following sectors in 2015?

How do you expect the volume of work for your business in the following sectors to change in 2016?

Figure 5 provides us with interesting insights into the factors that are proving to be most challenging to navigate; and allows us to compare these to factors which are providing a positive boost to the industry. It’s clear that commodities prices, the global oil price and the mining industry downturn – three factors which are all somewhat linked – are having the biggest negative impact on the industry. On the flip side, the broader agricultural industry and the approval of major projects are seen as critical factors in improving the performance of the pump industry.

This was reflected when we asked our respondents about the key verticals they expect to drive growth in the Australian pump industry in 2016 –water and wastewater came in first, with irrigation third and building and HVAC fifth. Interestingly, while our respondents identified mining as the single vertical have the biggest negative impact on their business, they are clearly expecting things to improve in 2016, with mining identified by 41 per cent of respondents as a key source of industry growth in the year ahead.

32 pump industry | Summer 2016 | Issue 14 www.pumpindustry.com.au STATE OF THE INDUSTRY

Worse than 2015 About the same as

Better than 2015 Don't know 18% 49% 22% 11%

2015

same decrease increase Mining Oil & Gas Pulp & paper Plastics & rubber Chemicals & pharmaceuticals Manufacturing Power generation Building services/ HVAC Food & beverage Water & wastewater Irrigation

Figure 2.

Figure 3.

www.pumpindustry.com.au pump industry | Summer 2016 | Issue 14 33 STATE OF THE INDUSTRY

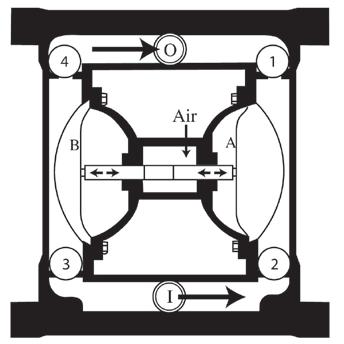

impacts on the industry Performance of mining industry Value of Australian dollar Major projects approved and/or underway Commodities prices Agricultural industry Global oil price Interest rates Unemployment rate Other -20 -15 -10 -5 0 5 10 15 20 25 30