STRIKING THE RIGHT BLEND

Precisionscreen’s expansive range of blending systems is drawing positive reviews from clients around Australia.

40

QUARRY PLANNING

Steve Franklin explains quarry planning: what works, what doesn’t, and why.

44

NZ QUARRY CONSENT

NZ is considering changes to its consent process, and a leading advocate body is eager to include quarries.

OFFICIAL JOURNAL OF THE INSTITUTE OF QUARRYING AUSTRALIA JUNE 2024

16

WA475-10 The next generation loader

The newly designed WA475-10 features next-generation technology developed with input from customers like you to deliver improved productivity and lower fuel costs. Ideal for quarry applications, this gentle giant is a unique solution for tomorrow’s challenges.

Up to 30% more fuel efficient * 8% more breakout force* 20% more boom lift force*

Call us today 1300 566 287 to find out more

Scan the QR code to learn more.

IN THIS ISSUE

NZ

Screenmasters

22 Terrific tech

John Deere has revealed a new partnership with a leading technology company to bolster its offering for quarry customers.

24 Top-tier training

Komatsu prides itself on providing a first-class training pathway for its workers.

28 Training tailored for success

The Lincom Group has unveiled a new technical institute.

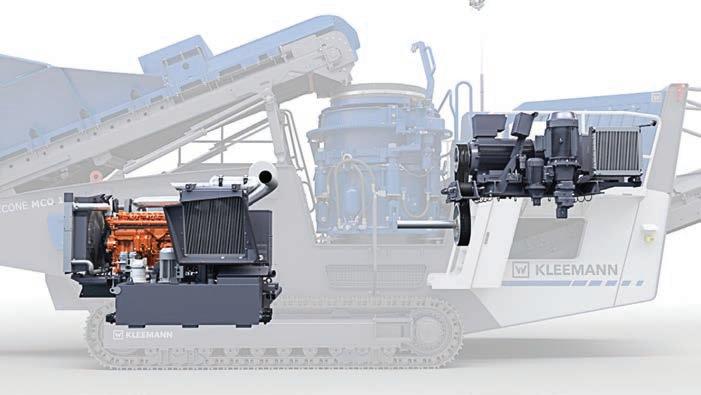

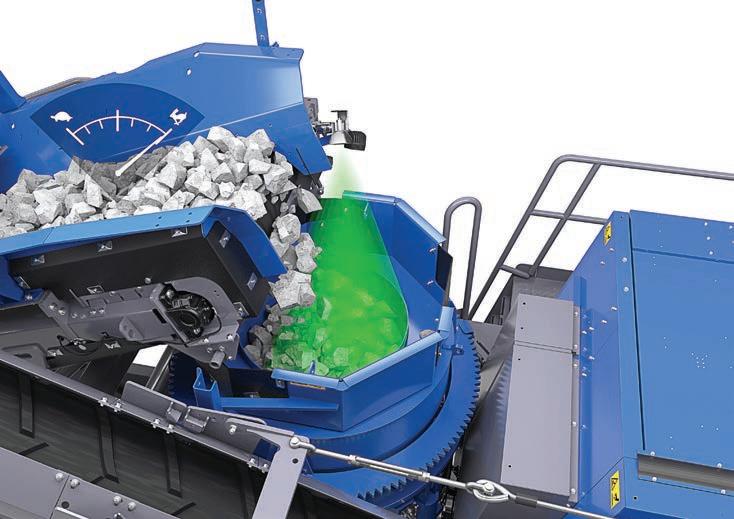

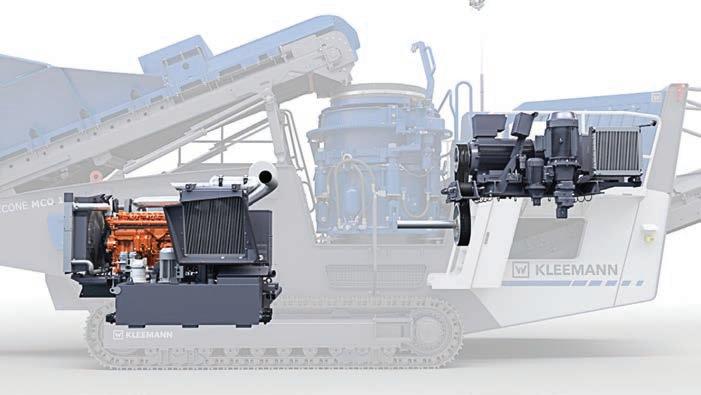

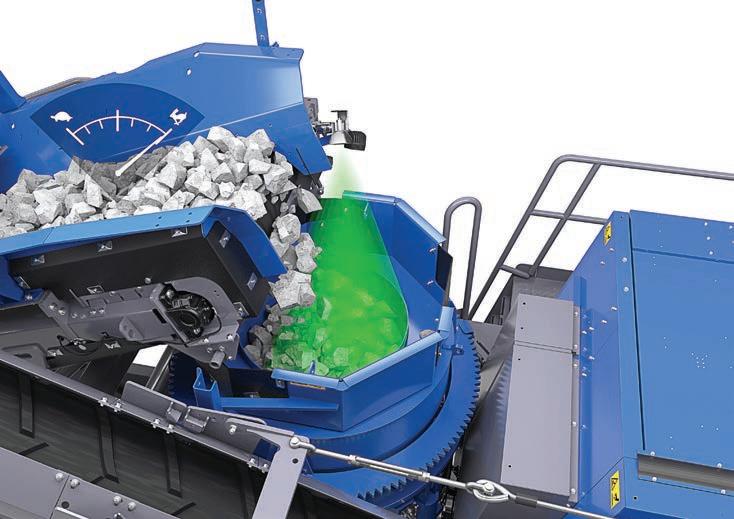

34 KLEEMANN’s cone crusher

The MOBICONE MCO 11 PRO mobile cone crusher has been built with flexibility and sustainability in mind.

36 Pioneering sustainable construction practices

Volvo Construction Equipment has unveiled its first zero-emission machines to the Australian Market.

38 Expertise to depend on Australia Drilling Attachments provides customers with the ideal drilling attachments.

44 Rapid crushing

How Cedarapids’ cone crusher series became a trusted brand in aggregate production.

Quarry June 2024 3

STRIKING THE RIGHT BLEND 16 QUARRY PLANNING 40 NZ QUARRY CONSENT 44 STRIKING THE RIGHT BLEND

expansive range of blending systems is drawing positive reviews from clients around Australia. Quarry looks at how the Brisbane manufacturer made it happen. 18 32 26 40 CONSENT CONCERNS

Precisionscreen’s

is considering changes to its consent process. How will the changes affect quarries? THE BATTLE FOR BORAL Seven Group Holdings and Boral have been in negotiations over a takeover. CREATING THE FUTURE OF CRUSHING

has delivered a range of crushers and screens. WHAT MAKES A QUARRY PLAN SUCCESSFUL? Steve Franklin explains what works, what doesn’t, and why. FEATURES 04 FROM THE EDITOR 06 FROM THE PRESIDENT 08 NEWS THIS MONTH 14 PRODUCT FOCUS 46 IQA NEWS 50 GEOLOGY TALK EVERY MONTH JUNE 2024 VOLUME 33, ISSUE 6

TIP TOP TRAINING

Ancaro Imparo is an Italian phrase, often attributed to Michelangelo who supposedly said it while working on the St. Peter’s Basilica. In English it means “I am still learning”, a reminder that even the masters are finding out new tricks.

When it comes to quarries it’s even more important to be well informed. This knowledge pays off, as understanding how to make the most out of new (or existing) equipment will allow you to make the most out of the day.

As quarries are often in remote locations, learning how to properly care for and maintain the expensive, vital equipment can also bolster a site’s self-reliance. There is also the matter of safety – if you don’t know what to do, you may be putting yourself or other people at risk.

As technology marches onwards, new skills become relevant.

Learning how to access and use the Internet of Things and Industry 4.0 equipment is becoming more important in the modern industry.

The Institute of Quarrying Australia (IQA) prides itself on

offering comprehensive courses for the quarrying sector, offering education for all manner of topics, from regulation, to leadership, or emergency management.

In fact, educating and connecting the industry is the IQA’s entire purpose. Companies such as Boral, Hanson, Holcim, Delta Rent, and more have taken advantage of the Institute’s corporate training and workforce development programs. Its training provides technical and non-technical skills, and can help ensure businesses meet their duty of care and competency equirements.

Original equipment manufacturers are also embracing training for their customers. They have an in-depth understanding of their own equipment, letting them provide specialist advice for customers. Some can even tailor make training courses specifically for individual quarries or customers.

Education is a lifelong journey, so embrace the opportunity.

William Arnott Editor

Published by:

379 Docklands Drive

Melbourne VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chief Executive Officer

John Murphy john.murphy@primecreative.com.au

Managing Editor

Paul Hayes paul.hayes@primecreative.com.au

Editor

William Arnott william.arnott@primecreative.com.au

Journalist

Adam Daunt adam.daunt@primecreative.com.au

Business Development Manager Les Ilyefalvy les.ilyefalvy@primecreative.com.au

Client Success Co-ordinator

Janine Clements janine.clements@primecreative.com.au

Art Director

Michelle Weston

Subscriptions

T: 03 9690 8766

subscriptions@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published. © Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

EDITORIAL 4 Quarry June 2024 UNDERSTANDING HOW TO MAKE THE MOST

NEW

ALLOW

OUT OF

(OR EXISTING) EQUIPMENT WILL

YOU TO MAKE THE MOST OUT OF THE DAY

Brawn. And brains.

MOBICONE MCO 90 EVO2 WITH SPECTIVE CONNECT

EFFICIENT, INTELLIGENT AND TOUGH. SPECTIVE CONNECT gives you access to all important information on your smartphone – for more efficient operation. Intelligent overload systems ensure stable processes even under challenging conditions. The cone crusher combines high performance with best product quality and stands out with exemplary team capability: In combination with the MOBICAT MC 110 EVO2 jaw crusher, it ensures optimum throughput. Your team player in hard rock: the MOBICONE MCO 90 EVO2.

www.wirtgen-group.com/mco-90-evo2-kleemann

A WIRTGEN GROUP COMPANY

WIRTGEN AUSTRALIA PTY LTD · National Ben Lefroy +61 448 030 420 · WA Greg Lewis +61 448 033 441 · QLD/NT Adam Lane +61 459 031 778 · NSW Linn Smith + 61 418 276 649 · VIC/SA/TAS Kyle Fredericks +61 447 539 302 · sales.australia@wirtgen-group.com · www.wirtgengroup.com/australia

MCO 90 EVO2

IQA NATIONAL CONFERENCE OCTOBER 2024

Registrations for the IQA conference to be held in Adelaide from 15-17 October 2024 have opened.

With the theme of Innovate and Create, the conference will shine a spotlight on new ideas and concepts in the industry including sustainability, reducing operating costs and driving progress through digital transformation.

We have a line up of impressive speakers, including our keynotes Claire Madden, Author and Social Researcher and Stefan Hajkowicz, Principal Scientist in Strategy and Foresight, CSIRO. Early bird conference registrations are available until June 2024.

IQA NATIONAL AWARDS

The prestigious IQA National Awards will be presented at the Conference. I strongly encourage you to nominate outstanding leaders in the categories on the IQA website.

Nominations are open now and welcomed for both IQA members and non-members, excluding the President’s Medal.

NEW LEADERSHIP AT IQA

It is my pleasure to announce that Jane Schmitt has joined The Institute of Quarrying Australia as our Chief Executive Officer.

Jane brings significant experience from various sectors in addition to a professional background as a lawyer, business strategist, senior executive and board director. Her strong relationship skills, professionalism and commitment to excellence are highly regarded and will be important assets for IQA.

As CEO, Jane will continue our core focus on educating and connecting people engaged in the extractive and associated industries, while ensuring that IQA stretches out into new opportunities to enhance our membership offering.

Jane’s extensive skills and experience will help propel IQA forward through close partnerships with members, stakeholders, and other like-minded organisations. Jane officially commenced in her new role from 1 May 2024. I am delighted to welcome her to IQA team.

SPOTLIGHTING SAFETY

A safe industry is a thriving industry –which is exactly why the IQA has long been a champion of supporting safety throughout the sector.

Our vision is to see thriving communities supported by a sustainable industry.

To do that, we need to support industry participants with compliance and regulation, build a diverse and skilled industry workforce, and foster a strong industry connectivity.

To deliver this, we will need to work collaboratively with regulators to develop a coordinated approach to regulation implementation and support bestpractice when it comes to compliance and regulation.

This relies on industry participation –the right outcomes won’t happen without a listening to quarries and engaging with the realities on site.

That’s part of why the IQA, in conjunction with Resources Safety & Health Queensland, will encourage the industry to explore issues relating to safety at this month’s Annual Queensland Quarrying and Mining Safety & Health Conference.

On Friday, 14 June, at the Brisbane Convention & Exhibition, the resources industry will come together to discuss the important safety and health issues relevant to the quarrying and mining industries.

A trade exhibition will also be held in conjunction with the conference.

I invite you to come along and trade ideas, learn about the latest safety equipment and regulation, and to keep safety front of mind.

Future events will be hosted in other states to ensure the geographically diverse industry can come together and share their knowledge.

Duncan Harris President Institute of Quarrying

Australia

AS CEO, JANE SCHMITT WILL CONTINUE OUR CORE FOCUS ON EDUCATING AND CONNECTING PEOPLE ENGAGED IN THE EXTRACTIVE AND ASSOCIATED INDUSTRIES,

and

www.quarry.com.au

The IQA’s Strategic Plan 2023 to 2026 embodies the following vision, values and strategic priorities:

Thriving communities supported by a sustainable industry

Operational Priorities:

• Deepen industry participation

• Sustainable revenue streams

• Highly capable team

• Technological innovation

• Effective engagement

• Great governance

Strategic Priorities:

• Support industry participants with compliance and regulation

• Build a diverse and skilled industry workforce

• Foster strong industry connectivity

IQA Contacts:

Phone: 02 9484 0577

Email: admin@quarry.com.au

Chief Executive Officer

Jane Schmitt

Deputy President

Sarah Bellman

Company Secretary

Rod Lester

For all education, member and branch enquires please email: admin@quarry.com.au.

6 Quarry June 2024 The Institute of Quarrying Australia Educating

connecting our extractive industry

PRESIDENT’S REPORT

Quarry design services

We work with quarry operators to maximise the value of their resources through effective quarry planning, conducted by highly experienced, qualified mining engineers. Our integrated team provides an end-to-end solution that results in the highest NPV pit design that is geotechnically and operationally sound. Ask us how we can help with your next quarry design.

+61 7 2139 5924 • L2, 127 George Street Brisbane Q 4000 Australia • eltirus.com KNOW WHAT’S IN THE GROUND | EXTRACT IT SUSTAINABLY | ENSURE COMPLIANCE

CDE SET FOR ‘GLOBAL REVEAL’ AT HILLHEAD 2024

CDE has revealed that it will return to Hillhead later this year for a major product showcase that will include a ‘global reveal’.

The sand and aggregate wet processing solutions specialist will deliver the reveal at its stand – A11 –on June 25 at 10.30am.

The company has confirmed it will present the AggMax 252SR scrubbing and classification system and the latest generation of the FreeFlow, the fully-mobile

washing solution for aggregate and sand classification.

“Our plans for Hillhead this year really reflect our commitment to innovation and our desire to elevate the industries and sectors we operate in,” CDE UK and Ireland director of business development David Kinloch said.

“Alongside the AggMax – the backbone of the CDE process and the driving force behind countless natural processing and waste recycling

“OUR PLANS FOR HILLHEAD THIS YEAR REALLY REFLECT OUR COMMITMENT TO INNOVATION AND OUR DESIRE TO ELEVATE THE INDUSTRIES AND SECTORS WE OPERATE IN.”

DAVID KINLOCH

solutions around the world – will be the latest generation of our FreeFlow and the global reveal of our newest product innovation.”

The company will also debut its most efficient water management solution to date, which it says promises greater functionality, improved maintenance access and safety, speed, automation, and material versatility to offer operators the best value per ton processed.

The FreeFlow is designed and built onto the bed of a semi-trailer for optimal mobility, the plant helps achieve maximum in-situ material recovery and boasts integrated water storage and recycling.

The AggMax combines prescreening, scrubbing, organics removal, sizing, stockpiling, fines recovery, and filtrates removal on a compact chassis.

CDE will be joined at Hillhead by strategic partners Molson Washing, the specialist materials processing division of Molson Group, as well as Siemens Financial Services, to provide customers with expert guidance to support their investment in the latest wet processing technology.

The company is encouraging customers who want to know more information about CDE and its wet processing solutions, to visit its stand A11, close to the registration pavilion. •

HOLCIM ANNOUNCES LATIN AMERICA ACQUISITION

Holcim has expanded its global portfolio by signing an agreement to acquire Latin American concrete producer Tensolite.

Tensolite specialises in precast and prestressed concrete construction systems, with plants and a distribution network in Argentina, Paraguay, and Uruguay.

“By acquiring Tensolite, we are further expanding our Solutions and Products portfolio in Latin America and globally,” Holcim regional head for Latin America Oliver Osswald said.

“Due to its leadership in innovative precast and pre-stressed construction systems, Tensolite will be an important part of our continued expansion into the most attractive markets, while offering

synergies with other business units such as our network of yard stores, Disensa.

“I am excited to further grow Tensolite and to welcome all 155 employees to the Holcim family.”

The acquisition forms part of Holcim’s Strategy 2025 to expand its solutions and products business to 30 per cent of Group net sales. The acquisition is subject to customary regulatory approvals and clearance but is expected to close in later in quarter two of this year.

Tensolite was founded in 1979 and has become known for its concrete construction systems and customised projects including large civil works including grandstands and walkways. •

NEWS 8 Quarry June 2024

The acquisition forms part of Holcim’s Strategy 2025.

David Kinloch is the UK and Ireland director of business development for CDE.

Image: CDE Group

Image:

Holcim

HEIDELBERG MATERIALS APPROVED FOR MICK GEORGE ACQUISITION

Heidelberg Materials has been given the green light to proceed with its acquisition of Mick George Group after making some concessions to the Competition and Mergers Authority.

Heidelberg Materials announced its intention to acquire earthmoving and demolition waste recycling contractor Mick George Group in 2022 before the CMA launched an investigation last year into whether the deal would impact the building materials market in England’s East and the East Midlands.

Heidelberg Materials had publicly said the acquisition was targeted at its circular economy approach.

“With the acquisition of the Mick George business, we are clearly moving towards establishing a truly circular materials and services offer in our UK business,” Jon Morrish, member of the managing board, said at the time.

The CMA had previously indicated publicly that it would be open to the two companies putting forward a resolution.

“In many areas where both businesses are active, sufficient competition will remain. But in some local markets, where

there are not enough strong alternatives to the merging business, the deal could limit customer choice,” CMA Senior Director for Mergers Colin Raftery said at the time.

“Unless the companies put forward a solution, we will need to take a deeper look into the potential impact of reduced competition in these local areas.”

Heidelberg and Mick George will divest parts of both businesses to Essexbased Brice Aggregates and Peterborough-based P J Thory. Heidelberg Materials and Mick George’s proposal was approved by the CMA, which allowed the acquisition to proceed.

Brice Aggregates will be the upfront buyer of Heidelberg Materials’ Needingworth quarry, while PJ Thory Holdings will buy the remaining divestment sites, according to the CMA report.

This includes readymix concrete businesses in Northampton, Market Harborough, Wellingborough, St Ives (Peterborough) and Ely. Also divested were the Earls Barton Quarry, Watlington Quarry and Kettering’s Ringstead Grange Quarry. •

KEEP IT SAFE KEEP IT CLEAN!

During planned plant maintenance and shutdowns, conveyor belt cleaners, skirts, impact beds and other conveyor accessory maintenance is often overlooked, or service is performed by people who are not trained to service the equipment.

Unless conveyor accessories perform at optimal levels, belt damage, carry-back and spillage can result.

ESS provides competency-based technicians to specifically monitor and maintain conveyor belt cleaning, sealing and support systems.

ESS technicians inspect conditions and produce a condition report and maintenance plan that can be actioned by plant staff, contracting companies or ESS technicians.

ESS offers a range of flexible maintenance, monitoring and training services to ensure optimum performance from the plants conveying systems.

ESS Maintenance and Monitoring Services Include;

• Installation and Commissioning

• Service and Maintenance

• Inspection and Reporting Services

• On-site troubleshooting

• Site Compliant Vehicles and Equipment

• Maintenance Contracts

• Conveyor Accessory Maintenance Training

Heidelberg Materials had publicly said the acquisition was targeted at its circular economy approach.

Image: Mick George

Heidelberg Materials had publicly said the acquisition was targeted at its circular economy approach.

Image: Mick George

MARTIN ENGINEERING NOTCHES MAJOR MILESTONE

Martin Engineering has celebrated a major milestone in its history, which changed the course of air cannon technology.

It has been 50 years since the USbased company invented the world’s first low-pressure air cannon.

It launched the Big Blaster in 1974 which was devised and developed by Carl Matson, a member of Martin’s senior team and cousin of the firm’s founder Edwin F. Peterson.

The patented technology was designed to dislodge stubborn material stuck to the inside walls of hoppers and silos by firing precisely timed bursts of compressed air to keep bulk material flowing and preventing the growth of serious build-ups and blockages.

The invention was originally aimed at quarrying applications in the same way the Vibrolator, the Martinpatented industrial ball vibrator, had found success in the quarrying industry since 1944.

Martin air cannons became a key invention for sectors such as cement. It signalled an end to workers having to access the interior of preheater vessels to manually break off hefty material build-ups using a highpressure water jet – one of the most unpleasant and hazardous jobs on a cement plant.

“From the very beginning, our air cannons were specifically designed to produce a quiet but powerful, high-velocity discharge of plant-compressed air to dislodge

“SINCE THE LAUNCH OF THE BIG BLASTER 50 YEARS AGO WE HAVE CONTINUED TO INNOVATE, INTRODUCING SMARTER AND EVER MORE POWERFUL AIR CANNON SYSTEMS THAT IMPROVE EFFICIENCY, PRODUCTIVITY AND SAFETY.” BRAD PRONSCHINSKE

buildups and enhance material flow,” Martin Engineering’s global air cannon product manager Brad Pronschinske said.

“They were developed to be capable of handling the high temperatures, harsh gases and abrasive, corrosive materials associated with heavy industries, and yet have low maintenance requirements and low costs.

“Since the launch of the Big Blaster 50 years ago we have continued to innovate, introducing smarter and ever more powerful air cannon systems that improve efficiency, productivity and safety.”

The company has continuously upgraded and innovated to ensure its air cannons are at the forefront of the industry. By the 1990s Martin Engineering had developed an extreme heat and velocity version of the Big Blaster, the XHV, with an all-metal construction capable of withstanding the harshest of conditions. In the 2000s Martin became the first to introduce safer positive-pressure firing valve with its Tornado air cannon.

“We’re especially proud that Martin air cannons have become so important in reducing the health and safety risks associated with clearing blockages manually – such as working in confined spaces, working at height, falling materials, and working in hot and dusty environments,” Pronschinske said. •

PETE ANDREW TO STEP DOWN FROM HILLS QUARRY PRODUCTS

Peter Andrew has announced he will retire from the industry after more than two decades as part of Hills Group and Hills Quarry Products.

The group director of Hills Quarry Products will step down from his position at the end of the year but maintain an advisory role through 2025.

Peter Andrew began his journey with the company in 1999 before becoming the business development manager for Hills Quarry Products’ aggregate and concrete business in 2007.

He is a member of the Institute of Quarrying and the Institute of Waste

Management, represents the company at the Mineral Products Association, and is a representative on the board of QSRMC.

In a statement, Andrew reflected fondly on his time at the company and within the wider aggregates industry.

“It has been an honour and a privilege working with the talented and dedicated team within Hills Quarry Products,” he said.

“With a framework for future growth in place and the team as strong as it has ever been, now is the right time to announce my plans to step down.

“I will be working with my replacement and the wider Hills Quarry

The group director of Hills Quarry Products will step down from his position at the end of the year.

Products team to ensure a smooth handover and seamless transition for our customers. •

NEWS 10 Quarry June 2024

Martin Engineering business development manager Mike Masterson and product manager Sid Dev working at the air cannon test stand.

Image: Martin Engineering

Image:

Peter Andrew

THOUSANDS ATTEND WIRTGEN GROUP TECHNOLOGY DAYS

Kleemann hosted a successful Wirtgen Group Technology Days, which saw more than 2,000 guests from over 100 countries attend the headquarters.

The two-day event highlighted the Wirtgen Group’s achievements in digitalisation and sustainability through machines and technology for construction projects and industries.

The event had around 70 exhibits from Wirtgen, Vögele, Hamm, Kleemann, Benninghoven, CIBER and John Deere including 11 world premieres.

“Innovation is in our genes. As we are aware from the feedback we receive from our customers, there is increasing demand for smarter, safer

and more sustainable solutions in markets around the globe,” Wirtgen Group chief executive officer Dr Volker Knickel said.

“We have concentrated our efforts on this, and can now present stateof-the-art machine technologies and digital systems with which we support and assist our customers in all aspects of the digital transformation.”

Kleemann presented the new MSS 502i EVO scalping screen with an alternative, fully electric drive option.

Asphalt production offers the greatest potential when it comes to reducing CO₂ emissions. In response to this, the company group also presented the new generation of burners from Benninghoven, which supports the

“INNOVATION IS IN OUR GENES. AS WE ARE AWARE FROM THE FEEDBACK WE RECEIVE FROM OUR CUSTOMERS, THERE IS INCREASING DEMAND FOR SMARTER, SAFER AND MORE SUSTAINABLE SOLUTIONS IN MARKETS AROUND THE GLOBE.”

DR VOLKER KNICKEL

use of up to four different fuels at the same time. This means, for example, that an asphalt mixing plant can be flexibly operated with the most appropriate energy source – including, for the first time, exclusively with green hydrogen.

The event also included several product demonstrations, which showcased technology in action from the Wirtgen Group. The demonstrations highlighted how Wirtgen’s production system solutions, including the use of low-temperature asphalt, concrete, and asphalt recycling, can deliver environmental and economic benefits by ‘doing more with less’ and allow companies to be ‘smarter, safer, and more sustainable’.

“This enables our customers to realise more construction projects with fewer resources, build and rehabilitate more infrastructure and simultaneously increase their profitability,” Knickel said.

He said that digital assistance systems and process automation will also contribute to offsetting the shortage of qualified personnel throughout the industry

“This also means that less experienced machine operators will be in a position to deliver qualitatively identical results to those a skilled specialist would achieve.”

Kleemann hosted the two-day event at its headquarters and conducted a tour of its production facilities.•

• Applications:

•

•

• Grain

•

• High-precision

From left: Kleemann GmbH CEO Alexander Knam and Wirtgen Group CEO Volker Knickel.

From left: Kleemann GmbH CEO Alexander Knam and Wirtgen Group CEO Volker Knickel.

HAZEMAG allmineral Australia 2/6 Meares Way, Canning Vale, WA 6155

For more information, contact JACO BOTHA

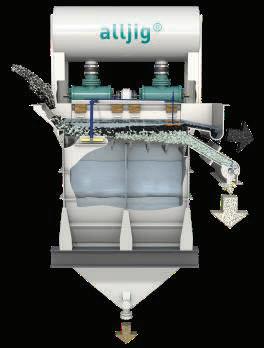

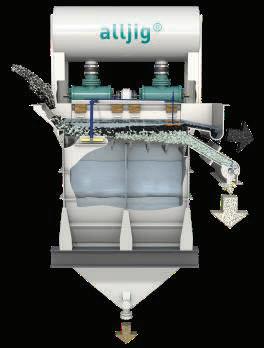

or +61 439549 182 For fullproductrange, scan QR code or visit www.hazemag.com www.allmineral.com alljig® With its broad feed-in spectrum, the alljig® ensures efficient sorting of a wide variety of primary and secondary raw and waste materials featuring different densities. The water- and air-pulsed alljig® is a smart, reliable and economical solution.

info.australia@allmineral.com

jaco.botha@allmineral.com

gravel, sand, coal,

broken stone,

ore, salt, industrial minerals,

shredded material, non-ferrous metals, slag, construction waste, recycling materials.

Throughputsranging from 1 to 700 t/h.

sizes

from 0.1 to 150mm.

wear free.

Jig generated stroke practically

operation.

Easy to configure even during

separation. Image: WG Tech Days

SIBELCO ANNOUNCE ACQUISITION AND NEW CHAIRMAN

across the United States, Canada, and Mexico, which process two million metric tonnes annually.

“We are excited that our offer to acquire SMI has been accepted. This transaction, once completed, will significantly strengthen and expand our operating footprint in North America with a resilient, key mineral platform at scale,” Sibelco chief executive officer Hilmar Rode said.

“The inclusion of a major glass recycler in North America into the Sibelco group will be an important step in the development of our activities in this segment outside of Europe, positioning Sibelco as a glass recycling leader in both Europe and North America.

“WE SEE SIGNIFICANT OPPORTUNITY TO DEVELOP THE SMI BUSINESS FURTHER, WHICH SHOULD PROVIDE OUR CUSTOMERS WITH BETTER ACCESS TO

QUALITY PRODUCTS OVER TIME.”

HILMAR RODE

its business portfolio. In 2022, the company spent $49 million via shares and project investment in mineral and silica mines developer Diatreme.

It follows a major shift in the company’s board composition with Depuydt revealed as the new chairman to succeed long-time chairman Bert De Graeve.

De Graeve will end his tenure at the April general meeting after nine years in the position which started in May 2015.

Depuydt, who was previously Ravago Group’s chief financial officer and chief operating officer, has been on the Sibelco board since May 2023.

Sibelco has revealed two key changes to its board and wider business which will form a major part of its strategy moving forward.

The company has recently announced the acquisition of North American-based Strategic Materials Inc (SMI) and the elevation of Paul Depuydt to board chairman.

The acquisition of SMI marks Sibelco’s entry into the North American glass recycling sector and expands its presence beyond Europe in that space. The acquisition includes SMI’s 42 plants and office locations

INDUSTRY

“We see significant opportunity to develop the SMI business further, which should provide our customers with better access to quality products over time.”

SMI chief executive officer Chris Dods welcomed the move.

“SMI could not have found a better match. Bringing together two longstanding glass recycling leaders from two different continents will elevate SMI’s operational capabilities and product offerings, ensuring continued longevity for our people, partners, and planet,” he said.

It comes on the back of Sibelco spending significantly to expand

The asphalt industry has farewelled Mel Green, a key figure who played an important role in advocacy and business level for the sector.

The Australian Flexible Paving Association (AfPA) advised Green passed away on April 29, 2024, after an extensive career in the asphalt industry.

Green served as national chairman of the AAPA (now AfPA) as well as its council, executive committee and the Victorian branch.

Ray Farrelly OAM, former AAPA chief executive and life member, reflected on their time together with the association.

“During his period of involvement on the AAPA national executive and as vice chair, and chairman, he played a key and passionate role in the growth of the

associations co-operative interaction and influence with governments at national and state level, leading innovating delegations to Canberra and most states, and the hosting in each, of working dinners with government ministers and opposition spokesmen, concurrent with supportive meetings with the heads of key government departments,” Farrelly said.

Green’s extensive career saw him start with Pioneer Asphalt in NSW before moving to Melbourne, where he left a legacy.

Green held senior roles with Readymix Asphalt and was involved in the merger that created CSREmoleum before helping establish Alex Fraser Asphalt.

Several industry figures came forward with public reflections on their time spent

The Sibleco shareholders’ meeting also confirmed Maxime Jadot, Séverine de Sadeleer, Curd Vandekerckhove and Paul Cornet de Ways-Ruart as new board members.

“We are delighted to welcome Paul and our new board members at such an exciting and challenging time for Sibelco,” Rode said.

“I would like to express my sincere thanks to Bert De Graeve and other retiring board members, whose leadership and guidance over the past years have been invaluable for Sibelco.”

Subject to receipt of U.S. regulatory clearances and the satisfaction of other customary closing conditions, the transaction is expected to close towards the end of Q2 2024 or early Q3 2024..•

with Green with several posting their memories of the industry icon.

“Mel was at the forefront of asphalt recycling in the last century in Victoria and could see the benefits of recycling and as a group, we constructed trial sections of 100 per cent recycled asphalt using both foam bitumen and emulsion technology,” civil engineer Barry Schmidt posted.

“At Alex Fraser he pushed plant mixed recycling to new limits incorporating RAP and glass.”

Skillsy general manager Rachael Rooney posted: “Mel was such a delight to work with. I still remember his tenacity and sense of humour from working with him over 20 years ago. A sad day to lose another great one.” •

NEWS 12 Quarry June 2024

Paul Depuydt will become the chairman of Sibelco’s board. Image Sibelco Group Image: Sibelco Group

ICON REMEMBERED FOR INSTRUMENTAL IMPACT

NEW FACILITY TURNS PLASTIC BAGS INTO BUILDING MATERIALS

THE FACILITY WILL PROCESS HARD AND SOFT PLASTICS INTO RESIN8, WHICH CAN BE USED IN CONCRETE, MASONRY BRICKS, BLOCKS, PAVERS, AND ASPHALT.

operational – transforming used plastic into innovative, eco-friendly building materials for Australia, creating a circular economy solution,” CRDC Australian managing director Shane Ramsey said.

The RESIN8 product is currently being trialled by Hobsons Bay Council as part of its road maintenance project. The trial will see 1,350 kilograms of soft plastics will be turned into asphalt.

The state government is considering potentially incorporating RESIN8 into major infrastructure projects, including roads and buildings.

“This is a major step forward in diverting plastic and e-waste from

The first-ever soft plastics and recycling facility from CRDC Global in Australia has been hailed as a “major step forward” for building materials down under.

The facility was opened in Tottenham in Melbourne’s West recently after CRDC Global, in partnership with Australia and New Zealand Recycling Platform

QUARRY PUMPING EXPERTS

Victorian Environment Minister Steve Dimopoulos (centre) attended the event.

Victorian Environment Minister Steve Dimopoulos (centre) attended the event.

Image: CRDC Global

Western Australia PERTH KARRATHA ALBANY KALGOORLIE Victoria MELBOURNE GEELONG South Australia ADELAIDE Tasmania HOBART BURNIE New South Wales SYDNEY HUNTER VALLEY Queensland BRISBANE MACKAY Northern Territory DARWIN

PRODUCT FOCUS

DELTA DELIVERS NEW GENERATION RENTAL HIRES

Sometimes, quarry operators need an extra machine to get a job done without the risk of a full-scale financial investment.

A rental hire can help quarries add the missing piece to their fleet without that risk.

Delta Rent operates one of Australia’s largest earthmoving equipment rental fleets, featuring more than 450 high-performance machines.

The company can provide quarry operators with complete fleet packages comprised of new-generation, low-hour machines with an extensive range of attachments to suit their project specifications. Nothing in Delta’s fleet is over 6000 hours to ensure operators receive the latest and best equipment.

Delta Rent has some of the latest industry machines available for hire, including the HD785 and HD605 Komatsu rigid haul trucks, Hitachi and Komatsu excavators from 60t to 125t, and Hitachi Komatsu and Volvo excavators from 30t to 60t. Delta also has Hitachi excavators from 8t to 30t for smaller-scale jobs.

In line with an industry continuously embracing technology, Delta Rent’s fleet has full GPS tracking and telematics reporting supported by the OEM.

Delta Rent, committed to fast service, offers all customers round-the-clock support and transport and logistics support to relieve the pressure of organising machinery on-site.

Delta Rent operates one of the largest earthmoving equipment rental fleets of more than 450 high performance machines in Australia. It offers:

New generation, low hour machines – nothing over 6,000 hours

Complete fleet packages to suit site production outputs and safety specifications

• 24/7 service 365 days a year

• Fast delivery and rapid response services

• Full OEM GPS tracking and telematics reporting

• Large range of attachments available for hire

• Transport and logistics support

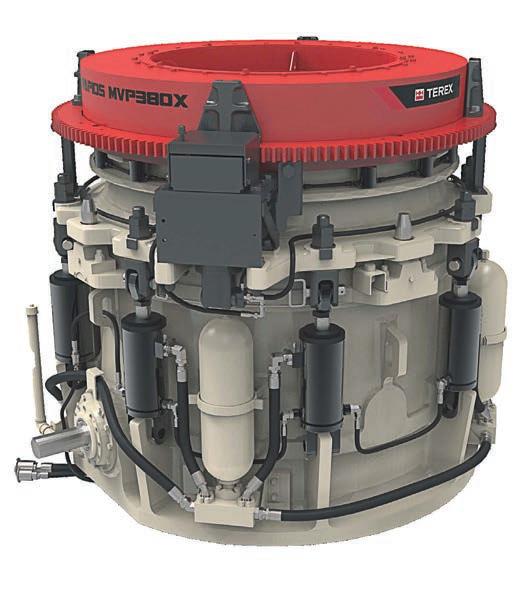

TRUSTED CRUSHER GETS UPGRADE

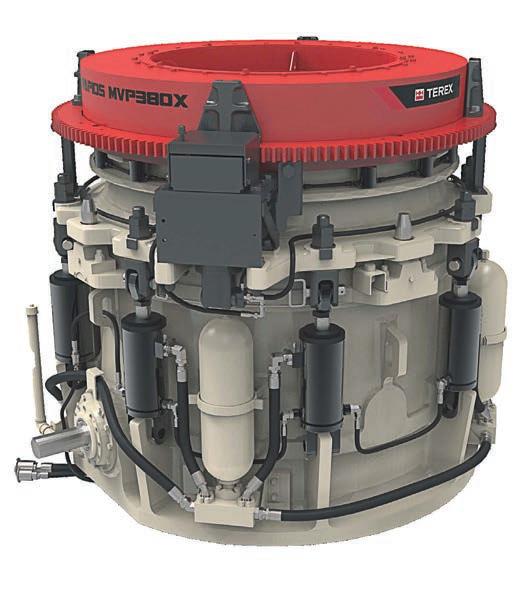

Terex Cedarapids has updated its MPVX cone crushers with a series of new features, including new ACE8 Advanced Automated Cone Controls, a hydraulic clutch and a bowl float monitor, to tackle the challenges quarry operators face every day.

Terex understands quarries are facing increasing pressure to cut costs, increase productivity and meet stringent requirements.

To achieve this, operators need crushers that maintain their productivity and limit downtime.

This is why the MPVX cone crushers have been outfitted with new ACE8 Advanced Automated Cone Controls, a hydraulic clutch and a bowl float monitor for reliability.

The new ACE8 control system will improve the crusher’s performance and reliability, ensuring it lasts the journey. The electronic bowl float monitoring system, which comes standard on the MPVX series, enhances cone protection.

The new hydraulic clutch acts as an anti-spin mechanism. The one-way clutch prevents the cone head from spinning within the empty chamber and prevents excessive wear.

With these features, the updated MPVX cone crushers will keep operators reliably crashing every day.

For more information, visit terexmps.com

To submit new product and equipment releases, email: les.ilyefalvy@primecreative.com.au

Its fleet specifics:

• HD785 and HD605 Komatsu Rigid Haul Trucks

• Hitachi and Komatsu excavators from 60t - 125t

• Hitachi, Komatsu and Volvo excavators from 30t to 60t

• Hitachi excavators from 8t - 30t

For more information, visit deltarent.com.au

14 Quarry June 2024

Delta Rent

Image:

Image:

Terex

Industry leading solutions

Delta Rent operates one of the largest earthmoving equipment rental fleets of more than 450 high performance machines in Australia.

We understand that production is key for quarry owners and operators. In particular, the importance of high optimisation rates for the heavy plant and machines required to process raw materials and meet demand.

24/7 service Australia wide

Our late model, low hour and meticulously maintained fleet – combined with expert 24/7 advice and analysis from an experienced and professional sales team – ensures our clients maximise production output without compromising quality, safety or environmental performance standards. Expert advice and analysisPurpose built fleets tailored

deltarent.com.au

SHAPING TOMORROW

Late

low

GPS

hardwired

1300 793 071

to quarry site requirements OEM backed support, service and technicians

model,

hour fleet

systems

24/7

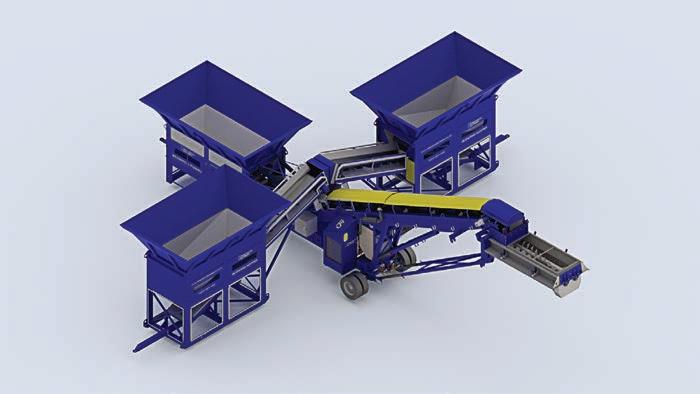

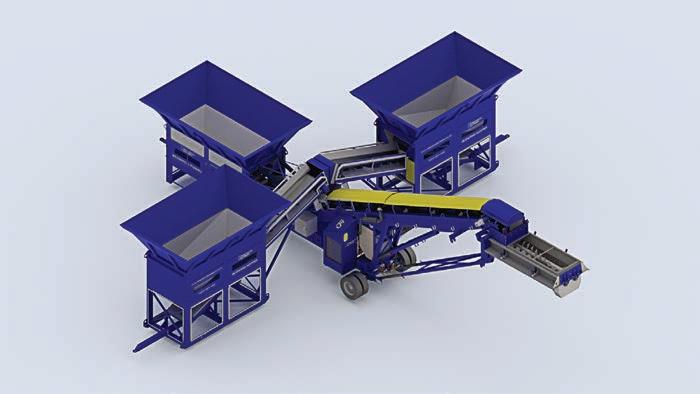

STRIKING THE RIGHT BLEND

Precisionscreen’s expansive range of blending systems is drawing positive reviews from clients around Australia. Quarry looks at how the Brisbane manufacturer made it happen.

Striking the right balance for blended products can be a tough task for operators.

Blended material needs to suit specific requirements, and in some cases versatile equipment is needed to handle multiple products to produce the final material.

Glencore wanted to enhance its pugmill setup. It was being used for a slurry application but needed to blend three products for cavity filling in its Mount Isa mine. Similarly, Mort & Co was looking to blend a manure product with three additional blend-ins.

Precisionscreen chief operating officer Jonny McMurtry told Quarry the two projects, which deliver vastly different end products, show the versatility of Precisionscreen’s blending equipment.

“Blending applications is a particularly growing field and interest from a couple of different markets including mining and agricultural,” he said.

“There’s also demand from open-cut mines and quarry-based applications as well.

“[Whether] that is blending multiple products, or some customers are just [looking] to blend two to three types of

sand or couple different aggregates. [These projects] are an extension on products that we already produce. It is just updating and adjusting our control systems mechanisms and specifications to match what the market wants and needs.”

Precisionscreen’s blending hopper enables operators to add in extra quality control without creating an operational headache. The

hopper works with Precisionscreen’s pugmills and is operated via the same control system.

In effect, this connection means the blending hopper and pugmill can be operated by just one worker.

“All of those blends are controlled by the PLC system onboard the pugmill unit. It takes the legwork away from the operator as it is all controlled and digitally monitored from the

16 Quarry June 2024 COVER STORY

Images: Precisionscreen

Precisionscreen has a focus on providing efficient, localised service.

Precisionscreen designed and manufactured an independent, three hopper system.

control system,” McMurtry said. “We design the control systems on the pugmill with the operator in mind. Even though we’re adding on different circuits and extra units to be controlled by the PLC pugmill, it is still that single point of control once it is coupled up to the PLC pugmill unit.

“It will hydraulically and electronically operate off the pugmill powerpack and control system and it will read on the screen as part of the pugmill control system.

“The operator will see how much material is going through the pugmill plant as the main screen and function, but then it will tell them how much material is passing through the hopper bins and how they are being controlled from the pugmill system.”

The Australian company manufactures all its blending hoppers using a robust, heavyduty frame and triple-sealed bearings to withstand local conditions. Precisionscreen can design the blending hopper in various sizes, belt widths and number of bins to match the customer’s volume requirements.

The blending hopper is hydraulically controlled and feeds into the PLC controlled pugmill and enables the blending of multiple products.

For Glencore, Precisionscreen added two additional blending hoppers onto its existing pugmill set-up, which fed onto the pugmill’s main conveyor belt.

McMurtry explained to Quarry that the Mort & Co solution required a tailored engineering approach. Precisionscreen designed and manufactured an independent, three hopper system for the feedstock company which is controlled by the PLC system to blend the three products with the main product.

The PLC system can adjust the blending system’s speed based on the volume of material on the main conveyor belt of the pugmill. The feature ensures Mort & Co strike the right blend for its final product.

“The principles and controls of the pugmill system are essentially the same, it was just the additional controls and communications to these additional hoppers have opened new doors,” McMurtry said.

“We can both manufacture and produce units that are applicable to the applications or industries involved and then be able to service and support in the future as well.

“It is one of the big areas that we focus on.”

According to McMurtry, the company has received positive feedback from its customers about the blending systems.

“They are pretty impressed,” he said.

Precisionscreen has received positive feedback.

“This idea is a much more cost-effective solution than something they were looking to import and implement.

“The main thing that interested Glencore in these units was the adaptability. They were able to specify what they were able to do, and we designed, manufactured, and tailored it to their needs.”

Precisionscreen designs and manufactures its equipment at its Wacol headquarters to serve the Australian market as well as overseas customers.

Since it was established more than three decades ago, the company has refined and updated its product line with the latest innovations and technologies. Its ability to offer innovative design with lower lead times, compared to importing from overseas, has seen it generate a diverse range of clients.

The blending hopper, much like Precisionscreen’s pugmill range, has been upgraded over to time to meet the needs of the Australian market, according to McMurtry.

“We’ve been building blending hoppers for around 20 to 30 years, but the new control systems have been adapted and developed over time,” he said.

“On the new blending hoppers, we offer load cells for material volumes or weights passing over the belt. We can have control systems speed up or slow down to match what’s needed in the blending requirements.”

McMurtry said the technology took away the guesswork from operators needing to monitor the material flow across the blending system.

“As opposed to doing some mental calculations throughout the day, if you’re doing batches or certain runs, the PLC control system will record the volume of material going through the pugmill (and) the volume of material that is coming from other units joined to the pugmill,” he said.

“It will give you better information and better control of what is passing through all these units. It is much easier for the companies to understand what their expected output is each day.”

The Brisbane-based company has a specially trained team which enables it to provide strong after-sales support to all customers.

McMurtry said Precisionscreen has a focus on providing efficient, localised service and support.

“Being able to do that in an effective timeframe is pretty important for all (our) customers. Being able to hear their requirements offer standard products adjust them as needed, and then quickly fabricate and manufacture them is important,” he said.

“(With Glencore) we’re Brisbane-based producing for a Queensland mine so we’re able to service and support them in real-time based on their needs and requirements,” he said.

“Being Australian-made equipment, they know they can have that level of support.”

With its focus on service and support, Precisionscreen has designed systems to strike the right blend for its customers. •

For more information, visit precisionscreen.com.au

Quarry June 2024 17

CONSENT CONCERNS ALARM

New Zealand is considering changes to its consent process, and a leading advocate body is eager to include quarries in it.

Regarding New Zealand, one of the biggest concerns of the quarrying sector is the consent process.

Aggregates and Quarry Association of New Zealand chief executive Wayne Scott, the former president of the Institute of Quarrying Australia, is clear in his concerns for the sector.

“New Zealand is endowed with a lot of rock; the country is covered in it, and we’re lucky to have a lot of it, but access to it is getting more and more difficult,” Scott told Quarry

“New Zealand’s rock and sand has always been pretty accessible, so I think people tend to ignore it, but over time, it has become hard to get developments consented.

“It has had an inevitable impact on construction.”

New Zealand’s geography and aspirations makes it a case study for the use of aggregate. It has an extensive road network and a large infrastructure pipeline worth $210 billion, which means its aggregate demand is set to remain consistently high.

This would mean a strong supply of aggregates is required to fulfil the infrastructure plans, but previously, the consent process has been hard and expensive for operators to navigate.

Recently, the New Zealand Government, led by the National Party in coalition with ACT New Zealand and New Zealand First, has proposed changes to the Resources Management Act, which it says will improve the process.

According to the government, among other changes, it will give priority to regionally and nationally significant projects, list projects that will be first to have their consent approved and conditions set by an expert panel, and allow government ministers to refer projects to the fast track if they meet specific criteria. According to reports, in effect, the new policy would allow ministers to effectively consent to projects themselves while expert panels can apply relevant consent and permit conditions.

18 Quarry June 2024 REGULATION

Image: Parilov/shutterstock.com

New Zealand quarries can struggle to gain consent.

“For too long, New Zealanders have had to wait for progress in their towns and cities due to the overly-restrictive RMA,” RMA Reform Minister Chris Bishop said.

“This situation is stifling economic growth and improvements for the environment and the community.

“We have taken the first steps in cutting through this mess of red tape so we can supercharge New Zealand’s infrastructure.”

Scott and the AQA have welcomed the move but have indicated their desire to see quarries included on the fast-track list. They also hope to see changes in the national policy statements on highly productive land and indigenous biodiversity, which have held up some quarry consents.

Scott wrote a letter to the New Zealand Government in February stating that infrastructure projects would require a consistent supply of aggregate and sand.

“Not only do we need some quarries on the fast-track list, we can’t afford to lose

other nearby sources of good rock supply to competing development,” he said.

“All these projects will require aggregates and sand, so some quarries must be on that list.”

In some ways, it is a situation that New Zealand has seen before. The previous Labour Government introduced a fast-track process for “shovel-ready” projects during COVID-19.

Under that legislation, the then Environment Minister David Parkes could refer projects to be fast-tracked to an expert panel for assessment. At the time, the government said applicants could have a “high level of certainty” that the resource consent would be obtained if the project was fast-tracked to the panel.

When the legislation expired in June last year, 42 projects listed had no expert panels appointed.

Scott urged anyone in the infrastructure sector to be cautious about these changes.

“There could be 100 of these (fast-tracked consents). Each will need to be considered by an expert panel with people with the necessary skills, supported by staff from various government agencies to provide all the required information,” he said.

“Even those projects approved under fasttrack processes which get an expert panel are still likely to be quite some months from go to whoa.”

However, more advocacy groups increasingly highlight a need for further quarry application consents.

The New Zealand Infrastructure Commission highlighted a need for aggregate material in 2021.

According to its Infrastructure Resources Study, the commission found the quarry industry faced “significant challenges” in meeting spikes in demand for infrastructure projects.

This was partly due to quarries’ long lead-in times but also because consent conditions,

© 2024 Terex Corporation. All rights reserved. Terex and Jaques are trademarks of Terex Corporation or its subsidiaries. A cost effective design built to the robust standards Terex Jaques is known for: MODULARPORTABLESTATIC mvpx series CONE CRUSHERS E: jaques@terex.com www.terexjaques.com BOLT-IN V SEAT ACE8 AUTOMATION SYSTEM BOWL FLOAT MONITORING

including operating hours and the number of trucks allowed in and out of the site, limited quarries’ ability to increase production.

“We have seen examples of major projects causing significant disruption to aggregate supply, such as Transmission Gully in Wellington.

Local quarries are limited in how much they can increase production, causing shortages for other projects and even for ‘business as usual’ services,” the report read.

“These materials are critical for the future of infrastructure. Increased demand transparency, such as Te Waihanga’s pipeline, are critical to ensure sufficient material is available and there are not wider impacts on the rest of the market.”

According to Scott, the lack of support for the quarrying sector, particularly in highgrowth areas like Auckland, has been a long-term issue.

“In some parts of the country, you can’t even lodge a consent for a quarry at the moment,” he said.

“Auckland, our third biggest population market, is also a high-growth area; a new quarry hasn’t been approved there in more than 10 years.

“The material is having to come from further and further afield.”

Consents are being hampered in some cases by community objections, which can be lodged by anyone, even if they are not residents in the quarry area.

In one recent case in Christchurch, a large quarry consent had been approved, but close to 490 objections were lodged, more than 100 of them from people outside of the South Island.

Most quarry consent applications are appealed to the environmental court, which can be a long-term process.

In Australia, some quarries have faced community-mounted campaigns as they seek extensions for extraction consent or to create new quarry pits.

In Victoria’s northeast, one quarry has been subject to a long-standing community

campaign against it despite providing valuable material for the local area.

Scott said Australia and New Zealand shared some of the same circumstances in that respect.

“There’s no impediment to anyone objecting to a resources management consent; it has become very problematic,” Scott said.

“For local councils, there is nothing in it for them to approve it because they’re only going to alienate their residents or get themselves voted out.

“As an investor, who is going to stump up the money when there is so much risk and a diminishing chance of success.”

The AQA hopes the government’s new fast-track process will help the quarry sector mitigate the issues it has seen with consent applications.

“We need to start making sure we secure supply for the long-term,” Scott told Quarry.

“Or at least know where we are going to get it from. Otherwise, infrastructure is not going to happen.” •

20 Quarry June 2024

REGULATION Image: Salienko Evgenii/shutterstock.com

New Zealand needs aggregate for its infrastructure projects.

Volvo Electric Machinery

Smarter Solutions Start Here

CJD Equipment proudly introduces Australia’s first zero-emission machines, with a focus on addressing climate change and minimising environmental impact.

Wherever and whenever you need to do work, Volvo electric machines will help you get the job done with less noise, fewer vibrations and no exhaust fumes.

Proven performance

• Same performance as a diesel equivalent

• Outstanding visibility and operator comfort

• Range of Volvo attachments

Innovative battery technology

• Lithium-Ion 48V battery - 40kWh

• Fast Charging possibilities

• Theft protected fixed battery

Less maintenance

• Maintenance-free electric motors featuring auto shutoff to save wear

• Easy ground access to lubrication and maintenance points

Big Enough to Trust, Small Enough to Care

Zero Emissions

• No power consumption when machine is not working

• Low noise level

• No emissions locally

CJD.COM.AU | 1300 139 804 CONTACT YOUR LOCAL BRANCH FOR MORE INFORMATION

TERRIFIC TECH

Technology is the way of the future in the quarrying industry.

Companies are increasingly investing in research and development in their technology, offering technology-based services and services to ensure customers are at the forefront of their respective industries.

John Deere has revealed a new partnership with Leica Geosystems to enhance its offering to the heavy construction and quarrying industries.

John Deere’s senior product manager for grade management, Mark Colvin told Quarry the partnership with bring new technologies and services to construction professionals.

“Working with Leica Geosystems is a tremendous opportunity,” Colvin said.

“(Leica’s) advanced technology solutions, paired with the power and performance of the John Deere construction equipment lineup, makes for a highly productive, efficient and seamless jobsite for our customers.”

Leica Geosystems, which is part of Hexagon, has more than 200 years of history and has made its name in positioning technology, sensors, and software services.

The company has worked across a wide range of sectors including construction, mining, and infrastructure with its product offering.

According to the two companies, their combined technology offering will deliver solutions to improve productivity and reduce material costs and the number of passes required.

The partnership will see Leica Geosystems’ technology, software, and services available

for customers to purchase on select John Deere construction equipment.

The technology will be available with John Deere’s SmartGrade platform. The SmartGrade technology is a fully integrated 3D mastless machine control system which was released in 2019.

The company’s SmartGrade machines are fully calibrated at the factory and have no external masts, cables or GNSS receivers to install or remove, which means John Deere machines are ready for work.

The removal of the external technology means operators can spend more time on their passes and grading without the need to mount and calibrate equipment, which eliminates downtime.

The SmartGrade system has an easy-to-use automation suite which operators can access to streamline common tasks to enhance productivity. The machine presets feature enables the operator to access multiple machine functions, features, and positions from one button.

The auto-articulation feature enables operators to combine front and rear steering. The auto-pass feature is one of the company’s newest additions to the automation suite.

It is used at the start and end of grading passes and enables operators to streamline their input. The technology has been a popular addition to John Deere’s motor grader and dozer line-up.

“The availability of SmartGrade with Leica’s solutions allows John Deere and our dealers to participate and support various jobsites

while meeting the technology needs of our customers,” Colvin said.

It comes on the back of recent data which indicates customers are increasingly investing in technology for their businesses.

A McKinsey report, From start-up to scaleup: Accelerating growth in construction technology, showed that the construction industry – alongside architecture and engineering – has spent an estimated $50 billion in technology between 2020 to 2022.

The estimated expenditure is 85 per cent higher than in the preceding three years.

Most respondents to the McKinsey survey indicated they expected to see similar expenditure in 2023 and in the future.

Leica Geosystems vice president for heavy construction in United States and Canada Troy Dahlin said the partnership was a strong combination of manufacturing expertise and technology.

“We are thrilled to be working with John Deere, a company that shares a similar culture and commitment to innovation, quality, and customer satisfaction,” he said.

“Together, we will bring new levels of accuracy, productivity, and accelerate the implementation of safe and sustainable workflows to the construction industry.

“This is helping our customers succeed in today’s competitive marketplace and enhancing their resilience for tomorrow.”

To see what automation upgrades are available for John Deere motor graders, contact a John Deere dealer. •

22 Quarry June 2024

For more information, visit deere.com.au TECHNOLOGY

John Deere has a new agreement.

Image: John Deere

John Deere has revealed a new partnership with a leading technology company to bolster its offering for quarry customers.

20 June, 2024

JOIN

womeninindustry.com.au TICKETS ARE NOW ON SALE PROUDLY SUPPORTED BY Australia

PRESENTED BY MHD upply

US TO CELEBRATE THE BEST OF THE BEST FROM ACROSS THE AUSTRALIAN INDUSTRIALS SECTOR Celebrate the women who work tirelessly to advance the mining, engineering, road transport, logistics, rail, bulk handling, infrastructure and waste management industries. Thurs

PROUDLY

TOP-TIER TRAINING

Komatsu prides itself on providing a first-class training pathway for its workers.

Quarry looks at how its award-winning program is supporting quarries.

The quarrying sector has a long list of operators who expect knowledgeable service and strong skills from dealers and original equipment manufacturers.

Yet many industries, including quarrying, face a labour shortage as older workers retire.

That is why Komatsu invests heavily in its next generation. The company has an extensive training program that incorporates two multi-million-dollar training facilities in Brisbane and Perth.

When Komatsu opened its training facility in Welshpool, Western Australia, it increased the company’s annual investment in training past $12 million. The Perth facility includes advanced workshop training rooms, a 30t crane heavy lifting bay, and labs dedicated to hydraulics and electronics.

Quarry spoke to Janine Gurney, Komatsu’s general manager for strategic capability and Matthew Tosolini, national RTO and technical capability manager, who work within the Komatsu Apprenticeship Program, and Komatsu employees.

Last year, the company’s efforts in training and development received national attention at the Australian Training Awards. The event

innovations to their training, benefiting apprentices or local communities.

The company received the prestigious Australian Apprenticeships Employer Award for its apprenticeship program. The program is designed with institutions and industry bodies to ensure the program is at the forefront of any industry trends.

Tosolini said the company wanted its apprentices to learn continually.

“We have a strong focus at Komatsu to actively engage in the development of our workforce, whether that’s through our comprehensive apprenticeship programs, strong industry partnerships, or supportive workplace culture, it’s what sets as apart as a leader in the field,” he said.

“As labour shortages continue to be top of mind for our industry, we are immensely proud to contribute to the development of the next generation of skilled professionals and be recognised at such a high level for our training efforts.

“This achievement would not have been possible without the incredible effort of everyone at Komatsu. Thank you to our apprentices, staff, and all those who support

vocational education and training.”

Komatsu’s program is run by specialised trainers who ensure the company’s apprentices can maintain the customer’s fleet and deliver expert knowledge.

As a registered training organisation, the Komatsu Training Academy is held to rigorous standards to ensure learners receive the best education.

This is why Komatsu has invested heavily in both its Brisbane and Perth training academies.

The Komatsu Training Academy provides a range of training that can be customised to the learner. It provides online, on-site, and facility-based training, from fully accredited courses to short and topic-specific courses.

“We have two purpose-built education training facilities now. One is based in Brisbane, it is one of the most advanced technical training facilities for mining, earthmoving and utility equipment in Australiasia,” Gurney said.

“We also have a second facility based in Welshpool, Perth, where Komatsu has invested more than six million dollars in this state-of-the-art apprentice and training facility.

“It is a highly interactive, technically advanced, and globally connected facility designed to establish career pathways into high-technology areas in autonomous and smart construction.”

The company also conducts upgrade programs to continually upskill apprentices and employees to ensure their skills are among the best in the field. These programs have seen light motor vehicle mechanics become mobile plant fitters or diesel mechanics. Additionally, diesel fitters have been trained in digitisation to conduct remote safety checks and diagnoses.

Apprentice mobile plant mechanic Oonagh Keogh has been part of the Komatsu Apprenticeship Program. She initially decided to pursue the program after hearing “outstanding” feedback from others who had participated.

In her time at the company, Keogh was part of a team of apprentices at the Wacol branch that undertook a restoration of a

24 Quarry June 2024 TRAINING

From left: Brendan O’Connor, Skills and Training Minister, Kirstyn Clarke, and Matthew Tosolini.

1976 vintage Komatsu D10A-1 track loader as part of the company’s 100th anniversary last year.

“I really enjoy the work that I get to do and the fact that I can learn new skills every day,” Keogh said.

“I’ve learnt everything from how to use different types of tooling to how to fix a hydraulic or electrical fault.

“Komatsu have provided me with constant support that goes beyond learning and training.”

Gurney said the program was already having a positive impact.

“The current challenges present an even greater need to create an industry-leading, future-focused training facility here in the West,” she said.

“Our award-winning apprenticeship program aims to deliver not just the technical skills but also gives our apprentices those life and business skills to help them thrive not only within Komatsu but the broader industry.”

FT2650

MOBILE JAW CRUSHER

•Up to 25% more capacity

•Production rates up to 400TPH

•Optional hydraulic relief

•Aggregate & recycling applications

Apprentice mobile plant mechanic Harry Newell said he had no regrets about pursuing an apprenticeship with Komatsu.

“I knew Komatsu was industry-leading with a great apprenticeship program, so it just made sense to apply,” he told Quarry.

“Komatsu show me that they care by

supporting my technical and personal growth. If there’s an area that you’re passionate about they’ll provide you with the training and support to achieve your goals.

“I honestly enjoy that Komatsu encourages us to participate in charity work as a team.• For more information, visit komatsu.com.au

FT3055

MOBILE JAW CRUSHER

•Production rates up to 700TPH

•50” x 18” pan feeder

•23.6” tracks with dual drive

•Largest crushing stroke in class

DUTY

in australia NOW available for immediate purchase 1300 278 322 enquiries.australia@astecindustries.com astecindustries.com

HEAVY

CRUSHING POWER

Image:

Komatsux

CREATING THE FUTURE OF CRUSHING

Screenmasters has delivered the future of mobile crushing and screening with Keestrack’s hybrid and electric crushers and screens.

The quarrying industry is hurtling towards a greener, cleaner future. Many original equipment manufacturers (OEM) and dealers are trying to create more sustainable practices with greater efficiency for their customers.

Screenmasters Australia is at the forefront of this trend through its partnership with European OEM Keestrack. As part of the long-standing partnership, Screenmasters is bringing Keestrack’s ‘E’ range to Australia and unlocking the next generation of electric Impact Crushers, Jaw Crushers, Cone Crushers, Screens, and Stackers.

“The strong focus by Keestrack on mobile electric-plug-in and hybrid-driven crushers and screens, to reduce emissions and operating costs, is a big plus for end users and the Australian environment,” Screenmasters Australia general manager Andy Blythe told Quarry Fundamental to the ‘E’ range are Keestrack’s innovations in load-sensing hydraulics and drive options.

Keestrack first introduced the hybrid and electric drive options in 2012 and has continuously developed its drives to be among the “greenest” options available. The manufacturer developed the concept further to include a ‘ZERO-drive’ across all of its impact crushers and many of its Screeners, Stackers, Jaw Crushers and Cone Crushers.

This makes the Keestrack ‘E’ range ideal for businesses that want to lessen their environmental footprint regardless of

“A focus on sustainability is at the core of our company as this is the origin of our business,” Keestrack vice president for sales and marketing Frederik Hoogendoorn said.

“As these heavy-duty industries need very powerful drive systems, Keestrack kept on searching for alternative drive systems.

“From load sensing hydraulics, to e-drives and now we are going to ZERO drives. This way, we want to protect the planet and save money at the same time.”

ZERO-drive machines use an electric motor to power most of the mobile crushing and screening equipment without a combustion engine onboard. The electric drive has been developed so it can power some of the necessary hydraulic systems.

“At this point, electric drive systems are the greenest and most effective options on the market, as they are more efficient than conventional hydraulic systems,” Keestrack group president Kees Hoogendoorn said.

“It also makes the end-user less dependent on a specific engine supplier. If there is no electric plug-in available, the end-user can choose his own gen set or select one of the Keestrack (tracked)engine/gen-set units.”

Keestrack’s equipment features loadsensing hydraulics. The hydraulics can sense when a load is present and idle when not required, which saves fuel from being wasted. Keestrack’s internal data indicates this can save four to six litres of fuel per hour, a 25 per cent saving over conventional drives.

Keestrack designed the R5e Impactor to

The R5e has a fully electric version with an electric-driven motor and a conventional hydraulic mode with low fuel consumption.

The K8 Screen is one of the most versatile scalpers on the market due to its big screening area; according to Keestrack, it can make four products in one pass. As part of the ‘E’ range, the K8 screen is available in hybrid electric drive and full electric options.

The screen can perform heavy-duty scalping through to ultra-fine screening, and operators control the equipment with userfriendly controls.

“One of the big elements is that we believe Keestrack equipment is as good, if not the best, in respect to maintenance and service accessibility. The access [for maintenance on the machines] is as good as it gets and sets the standards,” Blythe said.

“In the grand scheme of things, not all machines are equal when it comes to maintaining them. Even simple things, like accessing a bolt to adjust belt tension— there’s nothing worse than taking 30 minutes to do a two-minute job.“

As Keestrack’s Australian dealers, Screenmasters can provide customers with complete support for its equipment across the country.

The company has offices in New South Wales, Queensland and Victoria while its Wetherill Park office in Sydney stocks an extensive range of wear and spare parts.•

For more information, call Screenmasters on 1800 571 464.

Quarry CRUSHING

Images: Screenmasters Australia

Keestrack R6e Impactor.

TRAINING TAILORED FOR SUCCESS

CHe conducted a worldwide search by attending training courses to understand the best practice approach.

“We were told there would be a new refurbishment of the workshop, and as part of that, we would end up with space for a training institute,” he told Quarry

“Stephen Watterson, our CEO, had a clear and ambitious vision for this space and he gave me carte blanche to design a training facility that could support both new and existing customers.”

The company officially opened its new technical institute in April at its Narangba facility in Queensland. The institute will be a key part of Lincom’s offering and aim to help customers understand and utilise their equipment safely and efficiently, as well as troubleshooting any issues they may encounter.

thorough understanding of the equipment’s fundamental systems, coupled with practical tips and techniques for maintenance.

This dual focus helps to ensure that each participant can operate their equipment safely, efficiently, and at peak performance, instilling a sense of confidence in their abilities.

The facility itself consists of two parts: a computer-equipped training room and an interactive room that allows participants to get hands-on with the equipment. The idea is to allow those in training to identify faults, and there are plans to include cutaways to help visualise what is going on inside the equipment.

Evans said training can also take place in the nearby machine depot to help trainees get acquainted with the company’s range of equipment.

to apply what they have learned in a controlled, realistic environment, bridging the gap between theoretical knowledge and practical application.”

Lincom offers training for all brands within its portfolio, including Powerscreen, McLanahan, Morbark, Thor Global and more.

Evans said different customers have different objectives and requirements, so the company has avoided taking a “one-size-fitsall” approach.

Instead, the company offers a range of flexible training programs, designed to align with the client’s specific goals to ensure that each training session is relevant and effective.

“From refreshing the skills of experienced technicians to foundational training for new hires, the technical institute’s tailored programs

28 Quarry June 2024 TRAINING

Images: Lincom Group

Lincom offers training for all brands within its portfolio.

cater to a broad audience, accommodating their individual skill set,” he said.

“I get in contact with our customers and find out what skills and training their fitters might be lacking. Then, we provide specific training, from the very basics all the way up to advanced techniques.

“Everything is based on the feedback we get from our clients, and we use this to design a training plan.”

Each session starts with a discussion on safety. Evans ensures the topic is included in everything related to the training courses. It’s part of the company’s push to ensure the trainees are as safety conscious as possible.

almost 30 years ago, provides specialised equipment for a range of sectors – including quarrying. It has operations throughout Australia, Papua New Guinea, and the Pacific Islands, with its head office based in Southern Queensland.

Many of the company’s customers are in remote areas, where telephone reception is poor and downtime costs are high.

Evans said if the company’s fitters are confident with the equipment and know how to fix it, they’ll be back in business much faster.

“This facility is industry leading,” he said.

“There’re no other players offering this sort of training. The commitment we have put into

Innovating the way to a sustainable supply of concrete sand for construction

KAYASAND.COM

Lincom CEO Stephen Watterson cuts the ribbon to the new training facility.

Lippmann 300c and 400c. These mobile cone crusher plants were specifically designed to take on the most abrasive and toughest materials in aggregates and mining — all with mobile capabilities. Heavy duty cone crushers with an innovative material flow that maximizes capacity and throughput while delivering a consistently high quality product.

• MC400 High Speed Cone Crusher

• CAT C18 Engine

• Direct Drive

• 250mm Feed Opening

T: 1300 859 885 E: sales@triconequipment.com.au www.triconequipment.com.au

CRUSH | SCREEN | CONVEY | WASH | RECYCLE | PARTS | SERVICE

Michael Tripolone 0417 281 795 Paul Knauer 0488 012 384 Chris Mulally 0488 288 374 Cailean Woods 0488 288 191

CRUSH

THE COMPETITION

ONE TOUGH TROMMEL

Effective and efficient.

The MDS M515 Heavy Duty Trommel excels at crafting rip rap and reclaiming rocks entangled with clay and other adhesive materials. Comes complete with fold out stockpiling conveyors and has four hydraulic jacking legs to raise the machine to increase stockpile capacities and lower for transportation. See triconequipment.com.au or call 1300 859 885

Superior’s Telestacker® Conveyor is a material handler’s most effective weapon against costly stockpile segregation. Its variable height, length, and axle positions allow for layered stockpile construction, which is key to achieving partially and fully desegregated piles. The design has been carefully fine-tuned for hard work and dependability in numerous applications.

Call Tricon on 1300 859 885 or see triconequipment.com.au

UNPARALLELED PRODUCTIVITY In dry bulk stockpiling. PHONE 1300 859 885 | SALES@TRICONEQUIPMENT.COM.AU | TRICONEQUIPMENT.COM.AU

THE BATTLE FOR BORAL

Seven Group Holdings and Boral have been locked in takeover negotiations since the start of the year.

If the mark of being truly famous is to be known by one name than few names are more recognisable than Boral in Australian quarrying.

The company attests to being one of Australia’s leading quarry operators, with around 76 quarries, sand and gravel pits in operation.

So, when Seven Group Holdings announced its bid to complete a total takeover of Boral earlier this year, it is fair to suggest it was news that rocked quarrying.