The PM620 features a C18 Cat engine, designed by Caterpillar.

ROAD BUILDING WITH A

STRONG FOUNDATION AS ONE OF THE MOST IMPORTANT ROAD CONSTRUCTION PROCESSES, ROAD PROFILING MACHINES ARE ESSENTIAL TO ACHIEVING A SMOOTH SURFACE FOR ASPHALT. HASTINGS DEERING EXPLAINS WHY TECHNOLOGY, PRECISION AND SERVICE SUPPORT ARE KEY TO CREATING A QUALITY ROAD PROFILE.

S

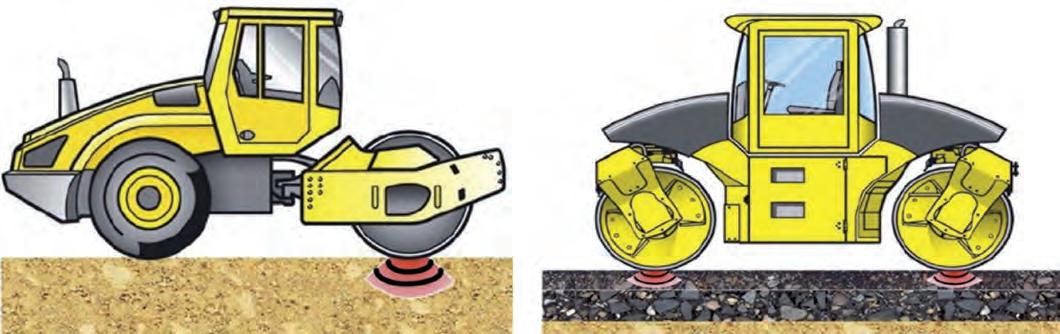

imilar to icebergs, there is so much more to a road pavement than what the driver sees on top. Laying out a strong foundation for a road pavement is critical to ensure the pavement is smooth and level, giving drivers a safe surface to move upon. As each road comes to the end of its life, its replacement with a new stronger pavement begins by getting rid of the old one. The industry has used road profiling machines to remove pavements for decades. As technology enables increased precision and productivity and the ability to recycle pavement materials becomes more attractive, road profilers have grown in popularity. Greg Ellis from Ellis Profiling in Queensland entered the road industry about 30 years ago. While working for an original equipment manager (supplier OEM) he saw an opportunity to start an operational business and began Ellis Profiling in 1997. “Profiling is the core of our business, most of our customers rely on contractors 14

ROADS JULY 2020

to do road profiling works because it’s a specialised area of road construction,” Mr. Ellis says. “It’s expensive equipment and the technology changes frequently so contracting in experts for profiling jobs can be more efficient.” In total, Ellis Profiling has 18 different road profiling machines of varying sizes.

we thought the availability of Cat service people across the state was important,” Mr. Ellis says. “The machine is working regularly, and we need to know that we can get the machine back up and running when and if we need it.” As he was happy with the first machine, Mr. Ellis recently purchased a second road profiling machine from Hastings Deering,

“THE TECHNOLOGY ON THE CAT MACHINE ALLOWS US TO MILL OUT HUMPS IN THE ROAD WITH A LEVELLING SYSTEM CALLED SONIC-SKI, WHICH LEVELS OUT ABOUT EIGHT METRES.” Two years ago, Mr. Ellis was looking for a new machine and after extensive research decided to purchase a Cat profiling machine from Hastings Deering. One of the deciding factors for Mr. Ellis was the level of service Hastings Deering offered alongside the profiler. “The machine was mechanically sound, the technology is up to date, the warranty was impressive and as we will have the machine working in rural Queensland,

the Cat PM620. “We are able to cut a profile surface from zero to 330 millimetres deep with the PM620. We are also able to mix or pulverise material and leave it on site,” he says. “The technology on the Cat machine allows us to mill out humps in the road with a levelling system called Sonic-Ski, which levels out about eight metres.” The Cat PM620 also has the ability to use GPS levelling systems to cut automatically,