SAMIFALT I-BRID: RESEARCH MEETS INNOVATION IULIAN MAN, SAMI BITUMEN TECHNOLOGIES TECHNICAL SERVICES MANAGER, SPEAKS TO ROADS & INFRASTRUCTURE ABOUT THE COMPANY’S LATEST BINDER SAMIFALT I-BRID CREATED IN PARTNERSHIP WITH RMIT UNIVERSITY.

T

he Australian Bureau of Meteorology found that 2019 was Australia’s warmest year on record, with the national mean temperature for the year placed at 1.52 degrees Celsius above average. Climate predictions, by the CSIRO and the Australian Government, show that this increasing trend will continue for the rest of the century. Across four major clusters, estimations show that later in the century if a high emissions scenario becomes reality, the country could see from 2.7 up to 5.3 degrees Celsius of warming. Warming of this nature pose challenges to the road building industry. It must adapt to develop asphalt mixes that can perform under increasing temperature conditions and with increase of channelised loading expected on road surfaces with the concomitant evolution of autonomous vehicle technology. Since its establishment more than 40 years ago, SAMI Bitumen Technologies has been continuously developing bituminous binders in order to cater to a wide range of traffic and climate conditions.

26

ROADS JULY 2020

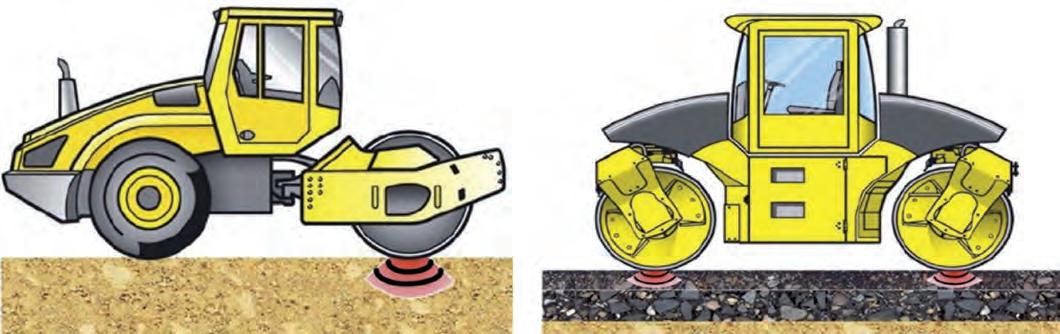

It’s latest new generation hybrid binder, SAMIfalt I-Brid, was developed as a result of substantial research work led by Kanjana Yindee, National Laboratory and R&D Manager SAMI Bitumen Technologies. This was in partnership with Royal Melbourne Institute of Technology (RMIT), one of the leading universities in Australia for asphalt and bitumen technology. Iulian Man, SAMI Bitumen Technologies Technical Services Manager, says the binder displays excellent performance over a wide range of service temperatures. “You can use this product in very hot climates, especially in northern Australia but also in cooler climates such as Victoria or Tasmania,” Mr. Man says. He says under hot ambient conditions the wearing course of pavements tend to

soften up and therefore there is a need for a bituminous binder that would impart deformation resistance under heavy traffic loading. “In contrast, in cooler areas, as the pavement has a tendency to stiffen up under low temperature conditions, cracking may be a problem and therefore the binder used in the wearing course needs to be flexible and resilient” Mr. Man says. “With I-Brid we are able to cover a very wide range of service conditions when it comes to ambient temperatures, with the binder imparting rutting resistance at high service temperatures and cracking resistance at low and intermediate temperatures.” Essentially, the binder is a combination of innovative plastomeric and elastomeric

“WITH I-BRID WE ARE ABLE TO COVER A VERY WIDE RANGE OF SERVICE CONDITIONS WHEN IT COMES TO AMBIENT TEMPERATURES, WITH THE BINDER IMPARTING RUTTING RESISTANCE AT HIGH SERVICE TEMPERATURES AND CRACKING RESISTANCE AT LOW AND INTERMEDIATE TEMPERATURES.”