TECHNOLOGY & EQUIPMENT

PAVING ON

THE MOVE

DESIGNED IN AMERICA AND TAILORED FOR AUSTRALIAN CONDITIONS, ASTEC HAS INTRODUCED THE CARLSON CP100 II AND CP130 PAVERS TO THE LOCAL MARKET. PROVIDING FLEXIBILITY AND A SPECIALISED CARLSON SCREED, IT HAS PROVEN POPULAR WITH CONTRACTORS ACROSS THE COUNTRY.

T

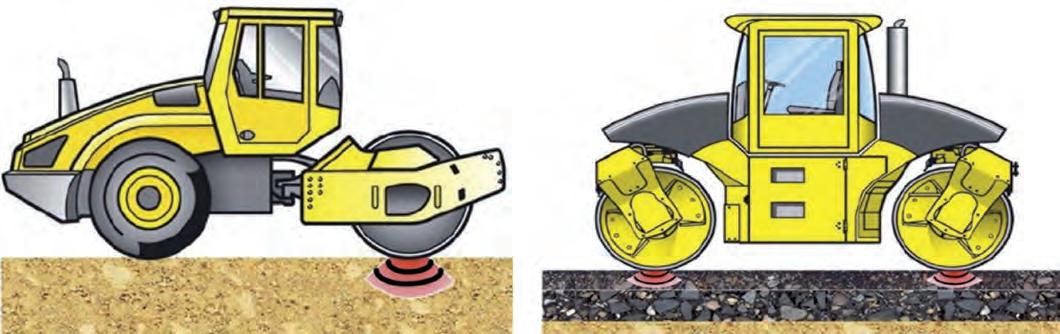

he ISM Raceway in Phoenix, home to two weekends of NASCAR racing each year, attracts thousands of fans and the world’s best race car drivers. When modernisation was needed in 2018, local company Performance Paving needed the right equipment for the job. Company president Tommy Tuttle said the CP100 II paver was chosen specifically for its ability to produce a quality screed and mat finish. As a distributor of Carlson products in Australia, Astec supplies the CP100 II and CP130 to Australian contractors. Travis Colwell, Marketing Manager at Carlson Paving Products, describes the CP100 II as the swiss army knife of paving. He says it is well suited to a variety of projects including municipal jobs, residential roads, carparks and utility works. This versatility allows contractors to work the machine across multiple jobs each day. The paver and screed are designed to meet specifications in states such as Queensland and in New South Wales, where the width requirement for heavy vehicles is a maximum of 2.5 metres. “The EZCSS screed has a transport width of 2.49 metres, so contractors in those states can move machinery around during the day,” Mr. Colwell says. The Carlson EZCSS front-mounted screed is a critical component of the paver. “We have distilled our highway class screed innovation into a smaller platform that can be mounted onto the CP100 II and CP130. This includes highway class mat quality, a two per cent screed taper, adjustable side blocks and more,” he says. “A single slide extension support also means fewer moving components on the screed and, therefore, increased reliability.

34

ROADS JULY 2020

The EZCSS screed’s simplified design makes it ideal use for day in and day out.” For added flexibility, the paver can be configured for two or three operators. “Contractors running smaller crews can have two people running the paver and allocate more labour to other works,” Mr. Colwell says. “The three-operator configuration has a dedicated person on top of the paver and two on the screed. This is used for paving with larger crews.” A two-person set up, removing the operator at the top of the machine, is an important feature in height restricted areas. Mr. Colwell says versatility is also clear in the paver’s control system, a simple LED display operators configure the machine. “We do not support one or another technology when it comes to grading slope automation systems. The contractor can use any system and mount it on to the paver to achieve quality results,” Mr. Colwell says. The CP100 II and CP130 pavers can also be upgraded according to the needs of the

customer and their business. “When starting out you need a machine that can meet the scope of work today. But with the CP100 II and CP130, you can build the machine’s technological capabilities as needed,” Mr. Colwell says. Jorge Boil, Business Line Manager at Astec Australia says CP100 II and CP130 machines are now working in NSW, TAS, QLD and WA. “We have sold a number of these machines across the country. Our customers are using these pavers on jobs from carparks to subdivisions, streets and driveways,” Mr. Boil says. He says customers are finding real benefit in being able to transport the paver to many different jobs during a day, without having to remove any machine components. “I think the CP100 II and CP130 are ideal for any smaller jobs, their pushing power and traction are impressive. Operating the machines in two modes is important for visibility, and the screed really does give a beautiful mat finish,” Mr. Boil says.

The Carlson CP100 II and the CP130 can be upgraded as a business expands to increase the machine’s technological capabilities.