6 minute read

Sustainability framework

ASPHALT SUSTAINABILITY FRAMEWORK

THE AUSTRALIAN ASPHALT PAVEMENT ASSOCIATION (AAPA) IS PROVIDING A PATH FOR THE ASPHALT INDUSTRY TO PROMOTE THE SUSTAINABILITY OF THEIR OPERATIONS AND REDUCE CLIMATE IMPACTS OF THE INDUSTRY. AAPA EXECUTIVE DIRECTOR FOR QUEENSLAND AND NORTHERN TERRITORY, ROBERT VOS EXPLAINS.

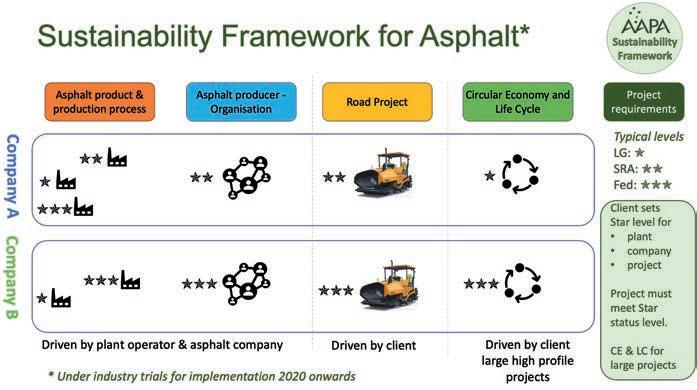

In the form of a simple toolkit, the Sustainability Framework for Asphalt (SF4A) created by AAPA, is a points-based system publicly reporting in three-star bands. This will allow for ease of choice by clients, with targets to achieve at plants and overall goals at organization and project level.

The SF4A is based on international circular economy aspects allowing member assessment and reporting to criteria matched with UN Sustainable Development Goals (SDGs), environmental impacts, promotion of recycling and waste reduction and other green principles.’

DRIVERS FOR CHANGE ARE GROWING IN AUSTRALIA Asset owners, infrastructure clients, asphalt companies and other stakeholders are increasingly requiring sustainability in procurement, production and delivery for the roads sector. There are a variety of approaches at local, state and federal level, to some extent linked with the size and complexity of a project, as well as the priorities of the asset owner.

Purchasing policies of Australian federal, state and local government have already begun setting criteria and expectations when projects are evaluated. All stakeholders are seeking clear and understandable assessment processes that assist in evaluating bids for infrastructure projects.

The asphalt sector has welcomed the increasing attention for sustainability initiatives and the role asphalt can play in providing solutions to society. It recognises the benefits of a consistent approach across

The framework is a points based system ranked against sustainability critera. projects and jurisdictions.

To assist members and clients, AAPA has produced an easy to use toolkit for asphalt producers to assess plants, organisations and projects against sustainability criteria. It draws on the work done in Europe (EAPA’s guidance on Environmental Product Declarations (EPDs)) and the US (NAPA / FHWA Sustainable Pavements initiatives).

LEARNING FROM OTHERS – PCRS AND EPDS With valuable work done across Europe, America and Asia, AAPA sought the best to gain and use recognised international practice through its International Knowledge Transfer visits and interaction with members of Global Asphalt Pavement Alliance (GAPA). This included tracking the development of Product Category Rules (PCR) undertaken in the USA and Europe and learning from GAPA members on the key points in gaining acceptance of the Environmental Product Declarations (EPD) generated.

This regional PCR appendix was ratified in 2019 by EPD Australasia, which registers Australian and New Zealand EPDs developed according to ISO 14025 and EN 15804, and formed the first step in providing a harmonised approach to measuring environmental performance of asphalt. A harmonised assessment of asphalt products creates a level-playing field that will increase innovation.

BUILDING THE TOOLKIT – INTERNATIONAL AND AUSTRALIAN RESOURCES The next step was to develop the bigger SF4A toolkit, again capturing best international practice and experience, with

current Australian practice being applied to road infrastructure projects.

On the international front, attention was given to the NAPA and USA FHWA publications on Sustainable Pavements, and the Dutch (Rijkswaterstaat) approach to assessing sustainability performance of road projects and contractors.

In Australia, current practice for government and toll company projects valued above $100m is the use of Infrastructure Sustainability Council of Australia (ISCA), Infrastructure Sustainability (IS) Rating Scheme. AAPA members have supported the development of the ISCA materials calculator, a subset of the IS Rating Scheme, which uses a life cycle assessment approach and aligns with the methodology used for EPDs.

We developed the SF4A to be complimentary to the IS Rating Scheme, providing support from small to very large road construction projects. This will enable asphalt producers to be recognised for their sustainability activities, and to improve day to day operations.

The AAPA Board endorsed the “Sustainability Framework for Asphalt (SF4A)” as a project of national significance due to the sustainability benefits across social and environmental themes. Direct funding support for the project was received from Queensland Transport and Main Roads (TMR) as part of the AAPA and TMR Strategic Alliance.

The project commenced in February 2019 under the management of Rob Rouwette of start2see, a consultancy specialising in environmental life cycle assessments. Also involved were asphalt producers, road authority representatives, consultants and toll road operators from more than four states.

Feedback from participants reinforced the “Five starting points for our Sustainability Framework” which was endorsed by the funder and the AAPA Board. These points

The framework will enable asphalt producers to be recognised for their sustainability activities.

are embedded in the toolkit with support gained at the AAPA 2019 conference where the importance of Circular Economy principles was reinforced. Reuse, recycling, waste reduction and use of non-industry waste are important aspects of asphalt manufacturers’ future and are part of the toolkit scoring system.

PUTTING THE TOOLKIT INTO PRACTICE The first two components of the Sustainability Framework for Asphalt (SF4A), Plant and Organisation, are part of the implementation phase. The third component, Road Project, is in draft form and delayed due to movement restrictions as a result of COVID-19.

The toolkit takes the form of a macrobased spreadsheet which guides assessment criteria and scoring for Plant, Organisation and Project leading to point-based ranking and the awarding of three levels of STAR categories based on the points achieved. Projects will require minimum star ranking from plant and organisation to allow participation with client applied weighting to accommodate changing priorities in local requirements or limitations.

The figure above provides a conceptual comparison of a project where both contractor A & B would be able to bid for typical Local Government (LG one star) and State Road Authority (SRA two star) but only B would be capable to tender using only one plant for Federal (very large) projects (Fed three star). The toolkit has ratings based on specific categories with indicators against key performance measures for environmental, health and safety, social and efficiency outcomes.

STATUS AND BENEFITS The toolkit has been applied by five major asphalt companies across the eastern states of Australia to allow evaluation of the results from about 15 plants covering rural and urban locations, small and large capacity.

After the review the scoring has been fine-tuned with tweaks added and some indicators reassessed. For the asphalt member participants, measuring and understanding the benefits of intervention on energy reduction and operational efficiencies have already been reported and acted upon.

The final phase will apply the SF4A toolkit to past and pending projects, seeking further feedback to optimise the indicators before full-scale implementation. AAPA will drive promotion of the benefits of the SF4A in delivering more sustainable asphalt road projects. AAPA members believe this will open additional opportunities for road authorities to understand, measure and gain sustainable benefits through applying the toolkit and star-rating system.

With the support of industry and road authorities, the Sustainability Framework for Asphalt provides an important toolkit for the open and transparent evaluation of key sustainability indicators in the procurement of road projects. Consequently, this will accelerate the asphalt sector’s drive to best practice and continuing improvement.