AUSTRALIA’S ONLY SPECIALIST ROAD MANAGEMENT, CONSTRUCTION AND CIVIL WORKS MAGAZINE Official media partners of DECEMBER 2022 Inside SAMI Bitumen Technologies’ journey to a monumental milestone AGAINST ALL ODDS ROOM FOR OPTIMISM InEight’s digital tools are helping project owners and contractors to weather the storm of supply chain and skilled personnel shortages LOOKING AHEAD Industry leaders throughout the sector detail what’s to come in 2023

COVER STORY

16 Against all odds

How SAMI Bitumen Technologies reached its one million-tonne milestone for the Port of Brisbane Bitumen Import Terminal.

ROADS REVIEW

20 Roads Review

33 Speed test

How Coffey Testing’s remote testing laboratories have transformed onsite construction materials testing.

35 Sustainable storage solutions

Atlas Copco’s new ZenergiZe range makes on-site energy storage quieter, cleaner, and greener.

SUSTAINABILITY

37 Recycled First

The Recycled First Policy and Alex Fraser are providing industry with an incentive for sustainability.

41 Bitumen’s carbon capturer

A deep dive into Puma Bitumen’s innovative and sustainable ‘Bio-Binder’.

MACHINERY & EQUIPMENT

44 Re-inventing the standard Astec’s SB-3000 Shuttle Buggy grants operators access to much more than just power and manoeuvrability.

47 Rolling out sustainability Dynapac CEA’s Chris Parkin provides an update on the company’s alternative fuel solutions, and how they were received at bauma in October.

R&I SHOWCASE

50 What are you capable of?

How the Roads & Infrastructure Contractor Capability Showcase in 2023 is supporting connections throughout the industry.

NATIONAL PRECAST SECTION

52 Self-cleaning precast A look at National Precast Supplier member ECOTONE’s new range of revolutionary coatings.

AFPA SECTION

AfPA article 56 AfPA Member Profile

Neil “Snowy” Blair, Rockit Asphalting Manager, shares some insights from his experience in the pavement industry with Roads & Infrastructure.

CONTRACTS & TENDERS

A summary of the contracts awarded for major infrastructure projects across Australia.

REGULARS

DECEMBER 2022 CONTENTS

54

58

4 Editor’s note 6 News

MRPV CEO Allen Garner says suppliers of recycled and reused materials, such as Alex Fraser, play a vital role in the shift to a Victorian circular economy.

A BRIGHT FUTURE

THERE’S NO DOUBT that the last two years have been among the most difficult for the roads and infrastructure sector.

Lasting economic impacts from the COVID-19 pandemic, severe supply chain challenges and skilled personnel shortages have forced many companies across the industry to adapt in order to survive.

These challenges will endure for a while, but our sector has proven to be extremely resilient. As the industry looks ahead, and as we learn in the last edition this year of Roads & Infrastructure magazine, there’s still plenty to look forward to in 2023.

In this edition, UAA and MECON Insurance provide an insight into the current state of the insurance market. In particular for the construction, and plant and machinery insurance industries. Stan Alexandropoulos, Underwriting Agencies of Australia (UAA) Group Chief Operating Officer and MECON Insurance Chief Executive Officer Glenn Ross say that despite current challenges, 2023 looks set to be an exciting year for both sectors.

Construction project management software provider InEight is developing digital platforms that aim to ease the existing pressure already on construction companies. Tools such as the ‘digital twin’ are helping contractors and project owners to minimise mistakes, while delivering quality project outcomes.

Also in this edition, we learn more about Alex Fraser’s Green Roads Construction Materials, as well as how Victoria’s Recycled First Policy is supporting the sustainable procurement in infrastructure projects. In this year alone, Alex Fraser has supplied more than 400,000 tonnes of recycled material for projects across Victoria. Peter Murphy, Alex Fraser Managing Director, says the policy and Alex Fraser’s development is laying the ground-work for a sustainable future for the infrastructure sector.

In our cover story, we sit down with SAMI Bitumen Technologies’ senior management team to learn more about a momentous achievement for the company. SAMI’s Queensland team is celebrating a one-million tonne milestone for its Port of Brisbane bitumen terminal, an achievement that is the result of more than a decade’s worth of works. Queensland State Manager Phil Stevens explains what the milestone means for the company, as well as how the breakthrough was achieved.

Thank you to all who have read and contributed to Roads & Infrastructure magazine throughout the year. We look forward to working with industry in 2023.

Happy reading!

Tom O’Keane Roads & Infrastructure magazine

COO Christine Clancy christine.clancy@primecreative.com.au

GROUP MANAGING EDITOR Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST Leon Cranswick leon.cranswick@primecreative.com.au

DESIGN PRODUCTION MANAGER Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR Blake Storey DESIGN Bea Barthelson

BUSINESS DEVELOPMENT MANAGER Brad Marshall brad.marshall@primecreative.com.au

CLIENT SUCCESS MANAGER Glenn Delaney glenn.delaney@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive, Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

4 ROADS DECEMBER 2022

EXPERTS IN MOBILE PLANT INSURANCE

With over 30 years’ experience, UAA is the largest and most reputable specialist mobile plant and machinery insurer in Australia, New Zealand and globally.

Our insurance products are tailored to produce a hand crafted solution to meet your business needs

The UAA Group has the knowledge, ability and capacity to insure a wide variety of plant and machinery spanning numerous industries.

Our experienced claims team has access to a network of the very best expert industry repairers, assessors and suppliers.

For more information on UAA’s Industrial Special Plant and Procon products, please contact your Insurance Broker or visit www.uaa.com

ProCon

by QBE Insurance (Australia) Limited. ABN

191

Industrial Special Plant and

underwritten

78 003

035, AFSL 239545.

Pty

ABN

302 AFS Licence

J6663

Underwriting Agencies of Australia

Ltd.

86 003 565

238517. Underwriting Agencies of New Zealand Limited (UAA). 4758199, NZBN: 9429040999678.

2022-23 FEDERAL BUDGET OUTLINES 10-YEAR INFRASTRUCTURE PIPELINE

The Federal Government has handed down the 2022-23 Federal Budget, which outlines a $120 billion pipeline for transport infrastructure over the next 10 years.

The investment also includes $250 million to expand the Local Roads and Community Infrastructure Program, which supports local councils to deliver priority local road and community infrastructure projects across Australia, supporting jobs and the resilience of local communities.

In Victoria, the Suburban Rail Loop East project received a $2.2 billion investment for the next five years. Construction on the project started in June 2022 and trains will be running by 2035. The Barwon Heads Road Upgrade – Stage Two received $125 million, with the project expected to support up to 44,000 daily journeys by 2031.

will have the capacity for trains to run up to and over 250kmh, slashing travel times from Sydney to Newcastle from over two and a half hours to just 45 minutes.

As part of the investment, $18 million will be allocated for the establishment of a High-Speed Rail Authority, to support project delivery. The Western Sydney Roads Package also received a $300 million investment.

Queensland’s Bruce Highway Upgrade Program received $586.4 million for further upgrades through Brisbane’s outer northern suburbs, which will aim to increase the safety and reliability of the connection. The Kuranda Range Road, in the state’s far north, received a funding boost of $210 million for further safety and reliability upgrades.

The 2022-23 Federal Budget includes a $2.2 billion investment for the Suburban Rail Loop East project. Image courtesy of Victoria’s Big Build.

and electric bus charging infrastructure in Perth received $400 million and $125 million respectively. While South Australia received $400 million for upgrades to the Dukes, Stuart and Augusta Highways, as well as $60 million for on and off ramps to the Southern Expressway and Majors Road interchange.

In New South Wales, $500 million was allocated for the corridor acquisition, planning and primary works on high-speed rail between Newcastle and Sydney. The proposed line Works on the Victoria Cross Station in northern Sydney are powering ahead, following the installation of the 70-metre-long metro platform and all platform screen doors.

Funding for upgrades across the Bass and Tasman Highways in Tasmania received $540 million. The Budget also included up to $35 million for the TransLink transport hub at Launceston Airport.

Western Australia’s Tanami Road upgrade

Funding was also allocated for the Canberra Light Rail Stage 2A in the ACT, with $85.9 million to support the delivery of the project. Once complete, the light rail will run from the Canberra CBD to Woden via the Parliamentary Triangle. The line will be 11 kilometres long, with 12 new stops along the route.

WORKS RAMPING UP ON NSW’S VICTORIA CROSS STATION

throughout the city, including three minutes to Barangaroo Station, five minutes to Sydney Metro Martin Place Station and nine minutes to Central Station.

The underground station provides new metro rail access to the North Sydney business, education and residential area.

From 2024, the station is expected to

The 50-metre-long and 15-metre-wide mezzanine level, which will form the main entrance and exit to the southern section of the platform, has also been completed as part of on-going works on the station.

More than 11,000 tonnes of concrete has been poured to date.

The enormous 300-metre-long, 25-metrewide, and 16-metre-high station cavern is also making progress. The giant cavern is the largest railway cavern in Australia and is 40 per cent bigger than any other cavern built on the Sydney Metro project.

During construction, the cavern has been used to piece together segments of the station, with the delivery of all station components needing to be manoeuvred through the entrance to the site.

In the coming months, work at the station will include completing the 100-metrelong and eight-metre-wide main pedestrian walkway that connects the northern end of the station to the metro platform below.

By the end of the year, the station will have 14 new lifts, and work will have progressed on installing the 19 new escalators that will take customers from the platform to various sections of the station.

6 ROADS DECEMBER 2022

NEWS

The Victoria Cross Station cavern is the largest railway cavern in Australia. Image courtesy of the NSW Government.

The Evolution of SHARING KNOWLEDGE

TRANSFORMING THE WAY THE WORLD BUILDS Software for Capital Projects

Learn more at InEight.com/Sharing-Knowledge

BUILDING GREENER ROADS. Australia’s leading provider of sustainable construction materials ASPHALT • AGGREGATES • ROADBASE • SAND VISIT: alexfraser.com.au CUSTOMER SERVICE: 136 135 CONSTRUCTION MATERIALS

MILESTONES REACHED ON $237.5 MILLION CAPE YORK REGION PACKAGE STAGE TWO

The $237.5 million Cape York Region Package (CYRP) Stage Two in Queensland has reached two significant milestones, with a new bridge and hundreds of kilometres of road now sealed.

The CYRP Two is a program of works to deliver infrastructure upgrades on the Cape York Peninsula between 2019-2020 and 2023-2024.

CYRP Two includes $190 million to progressively seal priority sections of the Peninsula Developmental Road, as well as $47.5 million to progressively seal priority sections of community access roads.

Construction of the 90-metre-long Saltwater Creek bridge – located on Peninsula Developmental Road (PDR) next to Musgrave Roadhouse (about halfway between Laura and Coen) – began in June 2021. It is the first bridge to be built under the CYRP.

The bridge is now open to motorists and

WORKS UNDERWAY ON THE SUBURBAN RAIL LOOP AIRPORT LINE

Works are underway at Keilor East, signalling the start of initial and early works for the highly anticipated Suburban Rail Loop Airport Line in Victoria.

When completed, the SRL Airport Line will mean passengers can get from the CBD to the airport in 30 minutes. More than 30 stations across Melbourne will have a direct connection to the airport via the Metro Tunnel.

The first tranche of works on SRL Airport includes the removal and relocation of six AusNet electricity transmission towers between the Western Ring Road (M80) and the existing Albion-Jacana freight corridor.

New towers will create space for a new rail

replaces the low-level causeway, improving safety and flood resilience along this important route.

The completion of sealing from Merluna to York Downs this month marks one of

kilometres of the PDR now sealed. Once CYRP Stage Two is complete, only 145 kilometres of the 571-kilometre PDR will remain unsealed.

CYRP Stage Two is funded by the Federal and Queensland governments on an 80:20 basis under the Roads of Strategic Importance (ROSI) initiative.

Once CYRP Stage Two is complete, only 145 kilometres of the 571-kilometre PDR will remain unsealed.

Image courtesy of the Queensland Government.

bridge over the Western Ring Road, taking trains north to the airport every 10 minutes and connecting more than 150,000 passengers in the City of Moonee Valley area to Victoria’s expanding rail network for the first time with a new station at Keilor East.

The bridge will stand more than 50 metres above the river valley at its highest point. A second construction consortium of John Holland, CPB, KBR and AECOM has been selected as the preferred contractor to

deliver the Sunshine Systems Alliance works package to transform Sunshine Station, rebuild Albion Station, and build twin tracks between Sunshine and the Albion-Jacana corridor, including the elevated rail bridge.

These works will minimise the impact to businesses and pave the way for major construction next year. The State Government is investing $143 million to deliver the first stage of the Sunshine Precinct Masterplan.

The SRL Airport will open in 2029.

roadsonline.com.au 9

NEWS

The Suburban Rail Loop will connect every major suburban and regional line to Melbourne Airport. Image courtesy of Victoria’s Big Build.

FEEDBACK SOUGHT ON DIAMOND PROPOSAL FOR NSW’S PICTON ROAD INTERSECTION

The New South Wales Government is seeking feedback on the preferred option for the Picton Road intersection.

Picton Road links the Illawarra Region with Sydney and the Greater Macarthur Growth area and is one of two major east-west links between the M1 Princes Motorway and M31 Hume Motorway.

In response to feedback, the State Government developed a Diverging Diamond Interchange (DDI) as the preferred option for the interchange at Picton Road and the M31 Hume Motorway.

The preferred option provided the least impact to the surrounding area while improving safety, reliability and efficient travel when compared to other options.

The diamond design is also expected to allow free flowing turns when exiting and entering Picton Road, meaning fewer traffic light phases, making the interchange safer and more efficient for motorists.

The Picton Road and M31 Hume Motorway Diverging Diamond Interchange is the second to be proposed in NSW, with one currently proposed for Australia

Avenue, Homebush.

Member for Wollondilly Nathaniel Smith MP says the NSW Government has responded to community feedback calling for improvements on Picton Road and has spent the past 12 months developing a preferred option for the interchange.

The NSW Government has allocated $44 million over four years for the planning of the upgrade of Picton Road and the Australian Government has committed $95.6 million to the planning of the upgrade of Picton Road and Picton bypass projects.

The proposal is expected to improve safety, reliability and efficient travel. Image courtesy of the NSW Government.

QLD TRAINS TO RECEIVE REPAIRS AFTER 16 YEARS OF SERVICE

Following 16 years of service, a number of Queensland trains are set to receive a major multi-million-dollar overhaul, supporting 90 train maintenance jobs in the region.

64 trains will be progressively overhauled over a six-year period, with the repairs and upgrades set to improve the safety, accessibility and reliability of services.

Engineering works will include load bearing structures, traction converters and high-voltage systems as well as customer enhancements including refreshed passenger seating, flooring and air-conditioning and new digital screens onboard.

The upgrading of Queensland Rail’s

Interurban and Suburban Multiple Unit (IMU/SMU) trains will form part of the State Government’s $300 million Strategic Partnership Agreement between Downer and Queensland Rail.

Queensland Rail CEO Kat Stapleton said

The upgrades are expected to improve the safety, accessibility, and reliability of services. Image courtesy of the Queensland Government.

the overhaul would provide customers with significantly improved accessibility to SEQ rail services, and support the public transport requirements for upcoming events such as the 2032 Brisbane Olympics and Paralympic Games.

10 ROADS DECEMBER 2022

NEWS

Puma bio Bitumen Literally paving the road to NET ZERO Puma Energy Bitumen 1800 24 88 66 bitumen.au@pumaenergy.com pumaenergy.com/en/web/bitumen/ Your journey towards net zero starts NOW with our next generation biogenic road binder. Trees capture atmospheric CO2 Integrated with our global supply network Bio bitumen extraction Bio roads become perpetual CO2 vaults

TWO MORE LEVEL CROSSING REMOVALS ANNOUNCED FOR VIC’S SUNBURY LINE

Two more level crossings will be removed from the Sunbury Line in Victoria by 2026, making the rail line level crossing-free.

Four level crossings on the line are already gone, with construction underway on the removal of two more.

Two additional level crossing removals have also been announced by the Victorian Government for the Old Calder Highway, Diggers Rest and Watsons Road, Diggers Rest.

Around 6300 vehicles travel through these

crossings each day, with up to 27 trains keeping boom gates down for nearly 36 minutes of the morning peak.

Early engineering assessments indicate that new road bridges will be the best designs to remove the level crossings at Old Calder Highway and Watsons Road, Diggers Rest.

Constructing road bridges over the rail line is expected to provide better connections for people travelling around Diggers Rest

and to the Calder Freeway, while preparing the area for growth and development.

These additional removals complement the recent level crossing removal at Gap Road, Sunbury where a new road underpass and rail bridge separating trains and cars is already unclogging a major bottleneck. Planning is also underway to get rid of the level crossings at Calder Park Drive and Holden Road in Calder Park by 2025.

MAJOR WORKS UNDERWAY, FIRST TBMS NOW ON SITE FOR THE SYDNEY METRO WEST PROJECT

Major excavation works are now underway on the Sydney Olympic Park Metro Station in New South Wales, one of nine underground railway stations which will form part of the 24-kilometre Sydney Metro West line.

Sydney Metro West is a new 24-kilometre metro line with stations confirmed at Westmead, Parramatta, Sydney Olympic

Dock, The Bays, Pyrmont and Hunter Street in the Sydney CBD.

When Sydney Metro West opens in 2030 it will double rail capacity between Greater Parramatta and the Sydney CBD, link new communities to rail services and support employment growth and housing supply. The project is expected to create about 10,000 direct and 70,000 indirect jobs during construction.

Work is now underway to excavate 468,000 tonnes of rock and soil. The commencement of major works coincides with the arrival of the first tunnel boring machines at The Bays Station site, which will carve out 11-kilometre twin tunnels from The Bays to Sydney Olympic Park.

Once launched, the newly arrived TBMs will excavate an average of 200 metres per week, with around 15 workers per shift operating each TBM 24 hours a day, seven days a week. The TBMs are due to start tunnelling from The Bays in the first half of 2023 and will arrive in Sydney Olympic Park in late 2024.

Excavation of the station is expected to take around 13 months to complete and will include the installation of 114 active anchors and 467 passive bolts, and 2151 rock bolts to support the station box structure, as digging progresses to a depth of around 27-metres.

Sydney Metro West is fully funded by the NSW Government, which is investing $12.4 billion over next four years, including $3.2 billion in 2022-23 to support major construction.

12 ROADS DECEMBER 2022

NEWS

Once launched, the newly arrived TBMs will excavate an average of 200 metres per week. Image courtesy of the NSW Government.

The Sunbury Line will be level crossing-free by 2026. Image courtesy of Victoria’s Big Build

NEVER SETTLE NEVER STOP NEVER IDLE

It takes a different kind of brain behind the brawn. Fired up like a turbo diesel. Gears constantly churning. Hardwired beneath hard hats to solve problems, or avoid them altogether. With you and your crew at the helm, and Deere at your back. The workarounds, ideas and innovations that move earth, and your business, forward. Because that’s what it takes to win in the dirt. And that’s what it means to be Never Idle.

As one of Australia’s largest construction materials testing providers, we’ve been delivering testing services to the transport infrastructure, public utility, residential and commercial development, oil and gas, and mining industries for over 60 years.

We have an extensive network of permanent and site-specific testing facilities located across Australia, including in some of Australia’s most remote locations.

coffeytesting.com 1300 175 531 SOIL CONCRETE AGGREGATE SPECIALITY

CONSTRUCTION UNDERWAY ON DARWIN’S TIGER BRENNAN DRIVE OVERPASS

Works are powering ahead on the overpass at the Tiger Brennan Drive and Berrimah Road intersection in Darwin’s east.

Northern Territory business Sitzler was recently awarded stage two of the contract for $127.8 million to complete the detailed design and construction of the project, which will be delivered over the next two years.

The project is jointly funded by the Federal and Northern Territory governments, and is expected to support 150 jobs at the peak of construction.

Close to 20,000 vehicles travel on Tiger Brennan Drive each day, and the busy intersection has been the location of multiple crashes and fatalities.

The construction of the new overpass will separate the major flow of traffic on Tiger

Brennan Drive from the traffic movements on Berrimah Road.

The overpass will also enable the continuous flow of traffic along Tiger Brennan Drive, and is expected to reduce traffic delays during peak hours, shorten travel times and improve connectivity for freight transport to East Arm Wharf.

Works on the project include a grade separation that will see Berrimah Road pass over Tiger Brennan Drive; the realignment of Tiger Brennan Drive; entry and exit ramps connecting Tiger Brennan Drive and

Berrimah Road; improvements to Berrimah Road to cater to road trains; earthworks, drainage works, pavement construction and asphalt works; street lighting, line marking and road safety barriers; traffic signals on Berrimah Road; and improved access for pedestrian and cyclists.

Works will be undertaken in stages, with consideration given to minimising impact for road users.

Larrakia Nation has been engaged to coordinate expressions of interests for artwork at the overpass.

$180 MILLION ANNOUNCED FOR CENTRAL STATION RAIL NETWORK UPGRADE

The New South Wales Government has committed an additional $180 million for works to modernise and upgrade the rail network at Central Station’s Grand Concourse.

The modernisation works are expected to provide more frequent and reliable services for commuters while reducing wait times and overcrowding.

The works will form part of the New South Wales Government’s More Trains, More Services program. The $5.3 billion program represents a range of improvements across the states train network to create extra rail services.

The next stage of the program will deliver railway infrastructure works to station platforms to accommodate the new fleet and allow up to 15 trains every hour to access rail platforms at Central

Station’s Grand Concourse.

Minister for Transport, Veterans and Western Sydney David Elliott said the multimillion-dollar investment would create high capacity, ‘turn up and go’

services for commuters.

The More Trains, More Services program has already delivered 41 new Waratah Series 2 trains and more than 1700 additional weekly services since 2017.

roadsonline.com.au 15 NEWS

An Artist’s impression of the overpass. Image courtesy of the NT Government.

Central Station Metro Northern Concourse. Image courtesy of Sydney METRO.

AGAINST ALL ODDS

SAMI BITUMEN TECHNOLOGIES IS CELEBRATING A ONE MILLION-TONNE MILESTONE FOR ITS PORT OF BRISBANE BITUMEN IMPORT TERMINAL. ROADS & INFRASTRUCTURE SITS DOWN WITH SAMI’S SENIOR MANAGEMENT TO UNDERSTAND WHAT THE MILESTONE MEANS.

Since 1978, SAMI Bitumen Technologies has been a big player in bitumen supply for Australia’s road construction and maintenance industry. Since then, it has undergone expansion right across Australia including in Victoria, New South Wales and Western Australia.

In 2010, the company paved the way for what would be a foothold in the Queensland market.

As Queensland State Manager Phil Stevens explains, the opening of SAMI Bitumen Technologies’ Port of Brisbane Bitumen Import Terminal occurred against the industry’s tide.

“SAMI started as an independent bitumen supplier, and at that time we were pitching against the big oil companies,” Stevens says.

“We were very much the independent importer trying to procure bitumen against all odds. For me, that was one of the biggest challenges the company faced.”

Through its Port of Brisbane Bitumen Import Terminal, the company started with small sized

SAMI Bitumen Technologies market share in Queensland continued to grow.

The bitumen import terminal provides additional storage capacity and processing capabilities for SAMI’s network, while also providing a platform for the creation of a range of bituminous products and binders.

This year, the Port of Brisbane Import

16 ROADS DECEMBER 2022

SAMI Bitumen Technologies’ Port of Brisbane Import Terminal team.

SAMI Bitumen Technologies Queensland State Manager Phil Stevens.

Terminal team has celebrated a significant landmark, with the facility reaching the one million tonne milestone of

Stevens says the growth of the SAMI Bitumen Technologies and supported facilities in Queensland is indebted to the

“We always have kept an entrepreneurial spirit. Such spirit has been reinforced when the company came under Colas in 2008. The global group always ensured that SAMI kept its specificity, dynamism and creativity. Today these attributes remain anchored in the core

the country,” Stevens says.

“It can be a real logistical challenge.”

SAMI Bitumen Technologies General Manager Sebastien Chatard says the one million tonne achievement marks a “significant milestone” for the company, given that this is more than the annual bitumen consumption in Australia.

Gnanaseelan says the company’s expertise helped to establish SAMI Bitumen Technologies Queensland as a pioneer in bitumen importation in recent times.

The journey to the one million-tonne milestone has not been without its challenges Stevens says. Not only during the initial construction and establishing of the facility, but also through the last few years.

He says if it wasn’t for impacts on the global markets, such as international conflicts and the COVID-19 pandemic, the SAMI Queensland team would’ve already achieved the one million-tonne milestone.

“It goes without saying that we would’ve reached that milestone sooner if it wasn’t for the pandemic and the weather. There’s a whole list of things that need to come together in order to bring bitumen into

“SAMI is increasing its facilities and supply in the market. It also shows that SAMI can ensure continuity of supply for clients. To be relevant in the market you need to show continuity to increase the confidence throughout your client base,” he says.

“We have had some challenges since 2010, such as COVID-19, which affected our suppliers. But we’re always looking to make sure that the product that we’re bringing in is the best.”

“When you’re in the bitumen market, the sector is always evolving and changing, such as rules and regulations. It’s very important for us to have consistent quality bitumen for customers, by maintaining sources of supply.” Bitumen Technical Manager Gerard

“In many ways, we were one of the first importers of bitumen, rather than relying on a local production. Many others followed our method soon after,” Gnanaseelan says.

Stevens says the company’s existing knowledge in the industry helped to steady the ship during the facilities formative years. He adds that the company’s know-how, as well as the contributions from staff helped to overcome logistical challenges.

“The business has been around for a long time, so there was already a level of expertise which surrounded the facilities foundation,” he says. “Our technical experts were amongst the very first to put these foundations in place.”

QUALITY OVER QUANTITY

Stevens says maintaining and improving assets is crucial for the sustained success

roadsonline.com.au 17

COVER STORY

The Port of Brisbane Import Terminal provides additional storage capacity and processing capabilities for SAMI’s network.

“WE’RE A MAJOR BITUMEN SUPPLIER AND BINDER MANUFACTURER FOR THE ROADS INDUSTRY AND WE’RE RELIED UPON. AS SUCH, WE INVEST IN RESEARCH AND DEVELOPMENT (R&D) TO BE AN INNOVATIVE SUPPLIER. AND WE’VE GOT THE RIGHT PEOPLE IN THE BUSINESS TO ACHIEVE THAT.”

of any operation.

“We’re always looking to improve the quality of the bitumen. These achievements aren’t just about quantity and that’s not the only metric we live by. Our milestone represents one million tonnes of high-quality bitumen,” he says.

“We’re a major supplier and binder manufacturer for the roads industry and we’re relied upon. As such, we invest in research and development (R&D) to be an innovative supplier. And we’ve got the right people in the business to achieve that.”

Using the backing of its parent company the COLAS Group, SAMI Bitumen Technologies

is, and has remained, as one of the industry’s leaders in innovative R&D.

These innovations have led to the highquality manufacturing of products such as EME2 bitumen, as well as a host of sustainable alternatives for road construction.

“We want to push the boundaries, to explore new products and opportunities with our customers,” Stevens says. “At the Port of Brisbane Import Terminal, we bring in one class of product. From there we can support the production of many different varieties of bitumen. This allows us the flexibility to market changes as well.”

SAMI’S SATISFACTION

Stevens says the one million-tonne milestone for the Port of Brisbane Import Terminal clearly demonstrates SAMI’s growing capabilities on both a state and national level.

“We live in a time of uncertainty,” he says. “One of the first questions we were asked as a supplier throughout the pandemic was ‘is your supply going to run out?’.

“We’ve demonstrated right from the outset that continuity of supply isn’t an issue. Our customers know that we stand behind our processes and our quality. Reliability and continuity of supply have been common themes for this facility since 2010.”

Stevens says he’s proud of the Queensland team, who go “above and beyond” to ensure the successful operation of the terminal.

“Something that I’ve noticed at SAMI is the dedication of our team members. There’s a real commitment and willingness, which is really important for a facility like this one. We’re talking about shipping logistics, which is a really dynamic field,” he says.

“That’s a testament to the culture we have at SAMI. What I’m most proud of is that our team doesn’t just watch the clock, they care. And that goes from the bottom of the business, right to the top.”

MOVING FORWARD

While Stevens says the SAMI Queensland team doesn’t have a set target in its sights for the future, he believes the main objective will be to maintain and improve the quality and quantity of the Port of Brisbane Bitumen Import Terminal.

“We like to distinguish ourselves from our competition; that’s the mantra of SAMI Bitumen Technologies. I believe this gives us a competitive advantage and this milestone is a demonstration of that. We want to maintain our integrity and spirit of innovation,” Stevens says.

18 ROADS DECEMBER 2022

COVER STORY

Queensland State Manager Phil Stevens says the milestone reflects SAMI’s commitment to innovation and its clients.

The facility supports the development of products such as EME2, as well as sustainable alternatives to conventional bitumen.

SAMI Bitumen Technologies’ Port of Brisbane Import Terminal opened in 2010.

“WE’RE ALWAYS LOOKING TO IMPROVE THE QUALITY OF THE BITUMEN. THESE ACHIEVEMENTS AREN’T JUST ABOUT QUANTITY AND THAT’S NOT THE ONLY METRIC WE LIVE BY. OUR MILESTONE REPRESENTS ONE MILLION TONNES OF HIGH-QUALITY BITUMEN.”

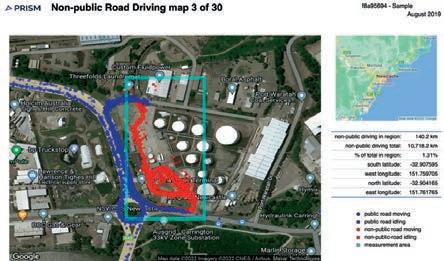

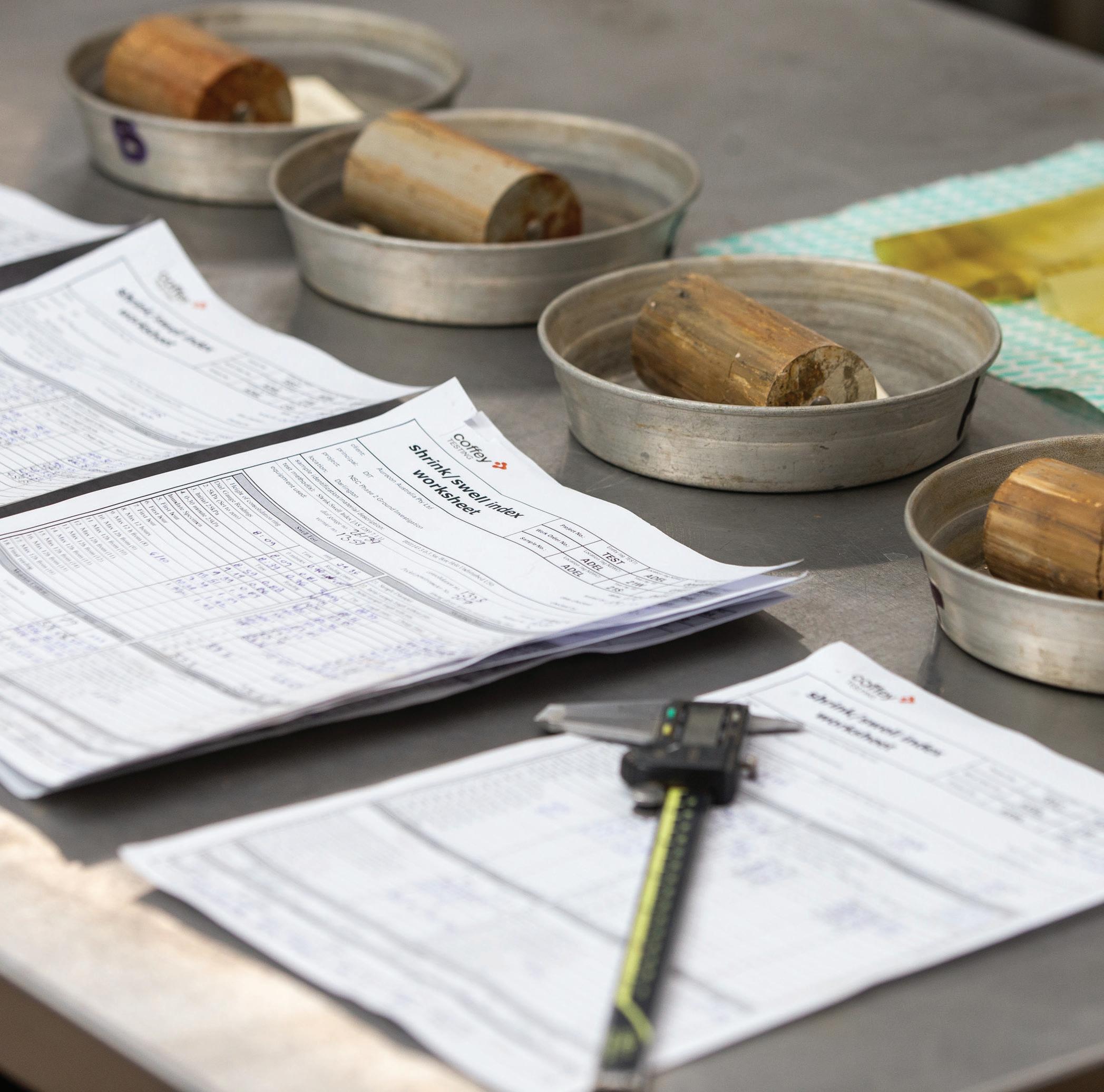

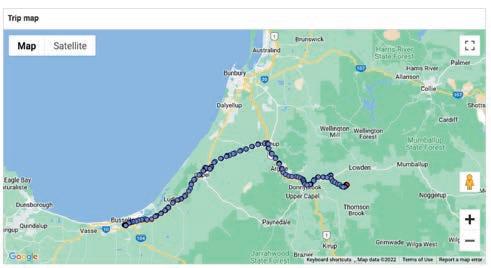

Precise

Transparent

Adaptive

Benefits of FTC automation +61 (02) 7209 2907 prismapp.com.au

detailed GPS data, mapping and spatial analysis provide the most accurate fuel apportionment available.

Highly

telematics integrations and advanced analytical processing deliver results at the start of the month, every month.

Fast Automated

analysis and audit support tools provide a complete view of all activity contributing to your results.

Unique

We continually work to keep Prism up to date with changes in infrastructure, location classifications and vehicle technology. Maximise your Fuel Tax Credits, the smart way Maximise claims and minimise risk with precise identification of off-road activity across your entire fleet. Increase the accuracy, efficiency and transparency of your claims.

ROADS REVIEW

THIS MONTH, WE ASKED

THE INDUSTRY DECISION-MAKERS, ‘WHAT CAN

DR M. REZA HOSSEINI – ASSOCIATE HEAD OF SCHOOL (RESEARCH), DEAKIN UNIVERSITY

Judging from current trends, the industry will look forward to two major transitions in 2023 and upcoming years. The first one would be a noticeable increase in the automation of construction processes, enabled by artificial intelligence (AI) and machine learning, mostly propelled by start-ups. The second major one would be a growing interest toward green and sustainable practices. There will be a considerable effort for managing the episode of change for a shift towards making construction deeply intertwined with environmental, social, and governance (ESG) concerns. We will therefore see a rise of AI along with a shift towards green construction in 2023.

BUCKLEY – GENERAL MANAGER, RATINGS AND DELIVERY, INFRASTRUCTURE SUSTAINABILITY COUNCIL

As the Federal Government starts to shift its focus to 2030 and 2050 climate targets, and its implications for infrastructure spending, it is important that industry looks to embed sustainability and consideration of carbon into all decision making. The Infrastructure Sustainability Council will be releasing to market two tools that will provide guidance to industry, and assurance to government on sustainability outcomes. The Planning Rating tool will support strategic and detailed planning and business case development, and the IS Essentials Digital Rating tool will allow for the scaling down of objectives within smaller projects (less than $100m).

ALLEN GARNER – CHIEF EXECUTIVE OFFICER, MAJOR ROAD

PROJECTS VICTORIA

20 ROADS DECEMBER 2022

OWEN

It’s a demanding and exciting time for Australia’s roads infrastructure industry and this will only intensify next year. Our flood recovery effort along the eastern seaboard needs immediate support and long-term strategy to build resilience into our road infrastructure. Major Road Projects Victoria will expand our successful Program Delivery Approach model – where road upgrades are awarded to pre-qualified contractors – and we’ll grow our use of digital engineering to boost delivery efficiency. We’ll use Victoria’s massive investment in roads infrastructure to keep progressing social procurement initiatives and push our state to view waste as a vital construction resource. THE INDUSTRY

LOOK FORWARD TO HEADING INTO 2023?’

2023 is showing signs of being a transition year with business returning to a more normal state. While supply chains remain impacted, we hope to see those impacts start to correct themselves over the next 12 months, particularly for parts and vehicles. Managing our business to normal timeframes and dealing with the backlog of orders for customers is a priority. In addition, labour shortages should start to ease. The Federal Government’s permanent migration cap increase will help, and as the world returns to a pre-pandemic norm, we should see skilled migrants wanting to again move to Australia for employment and its climate. This will ease capacity pressures on the construction and infrastructure industry. As these factors begin to normalise, we’ll see demand increase across all sectors. To meet this demand, Australia will rely on a strong transport and logistics sector as the backbone of an economic upswing, ensuring orders for everything from vehicles to goods and commodities are met across the country.

HOGAN AUSTRALIA

High-quality, efficient transport systems built off long-lived infrastructure assets are among the key building-blocks that support communities to prosper. For long-term success, asset-owners need to ensure that ambitions for new capital investment to grow the capacity of the transport system are better matched to increases in sustainment capital that ensure whole-of-life performance of the existing asset base can be realised. Increases to maintenance funding, improvements to strategic asset management and realisation of value for money, productivity and sustainability through competitively outsourced operations and maintenance should be forefront in the thinking of asset owners and the supplychain for 2023 and beyond.

SIMON SQUIRE –

DIRECTOR

AND JUNIOR VICE PRESIDENT, AIQS

Continued volatility and multiple fractured trajectories is the short-term outlook. The market is then expected to ease to a new high norm. However, in saying that, there are several big caveats; that the conflict in Ukraine eases, rising inflation globally subdues and China gets back to pre-pandemic production levels – all these issues could have further surprising impacts that we just can’t forecast currently. Additionally, while escalations may ease, the focus will then shift to certainty of supply and delivery. Even if you’ve budgeted for higher prices, you can’t always guarantee product availability. Shipping rates may be easing but certainty in delivery will be the issue. Preplanning therefore is expected to be a 2023 industry buzzword.

ROADS REVIEW roadsonline.com.au 21

STEPHEN COWAN – CHIEF COMMERCIAL OFFICER, COATES

GRAEME JOHNSON – CHIEF EXECUTIVE OFFICER, FULTON

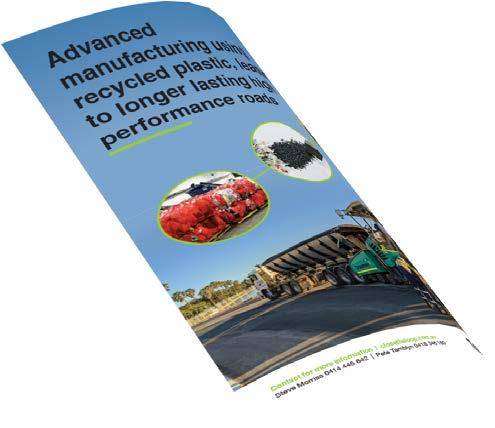

ARLOS RIAL – CHIEF E XECUTIVE OFFICER, AUSTRALIAN FLEXIBLE PAVEMENT ASSOCIATION

It is an exciting and challenging time for the roads industry, heading into 2023. We are facing the big build in the civil roads sector, full (effectively) national employment levels and a new Federal Government set to tackle the real challenges of inflation, increased cost of energy and sustainability – reducing our carbon foot print and emissions. All of this during a sustained period of major weather events affecting roadworks delivery and also showcasing the lack of resilience in Australia’s road network. While this is a challenge, it is an extremely exciting time. We are seeing a Federal Government committed to addressing our transport networks resilience to disaster events. We are hopeful as a sector that this finally means we will see our roads maintained – eliminating the ever growing national road maintenance backlog and ensuring our roads are safe, resilient and built to last. The flexible pavements industry is ready to respond to this need. As an industry we are excited to support the commitment towards carbon zero and have outlined our road map to do our part. The flexible pavements industry is already doing its part to help address Australia’s waste challenge, incorporating end of life tyres, glass and soft plastics into roads that not only reduce waste but provide longer lasting roads.

Optimize

Profits

Asphalt Control

22 ROADS DECEMBER 2022

* Repeatable

* Recipe

* Full

* 24/7

* Customised

* Mobile and tablet interface * Real time

* Standard

* Modular

* Seamless

Production &

With The Genius

Systems Tired of inaccurate and slow weighing processes, limited production reports and not being able to maximize your plants efficiency with your current systems or technology? What makes the Genius Asphalt Control Systems so powerful and affordable… The Genius Asphalt Control systems, developed by our own software engineers, offers a fully automated cost effective solution to meet the demands of production while accommodating budgets for process improvements and future requirements. * Complete asphalt plant control - docketing, blending, batching, drum control, outloading, truck time slot scheduling, remote monitoring

batch weigh accuracy

based blend control

product traceability

support & built-in diagnostics to minimize downtime

reporting

batch data via internet

PC hardware

hardware & software, allows for ease of future expansion

interface to ERP or other software packages “Gordyn & Palmer provided great service from end to end in our recent Maryborough upgrade; scoping, quote, installation, commissioning and post commissioning support. They were very professional with the operators extremely pleased with the upgrade and service. The new Genius system has better reporting capabilities and visibility of cost to assist with supporting and driving sustainability ambitions.”

Joel Cowen Group Asphalt Industry Asset Manager Colas Australia

Complete Electrical & Automation Solutions Head Office: 46 Melverton Drive, Hallam, VIC, 3803 Telephone: +61 3 9703 2477 Email: sales@gordynpalmer.com.au Internet: www.gordynpalmer.com.au If you or someone at your organisation is an industry leader and would like to be a

this monthly column

2023, please get in touch with Editor, Tom O’Keane:

Gordyn & Palmer

part of

in

tom.okeane@primecreative.com.au

ROADS REVIEW

HEAD ON FACING THE CHALLENGE

THE PLANT AND MACHINERY AND CONSTRUCTION INSURANCE INDUSTRIES ARE EMBRACING CURRENT CHALLENGES, WHILE REMAINING OPTIMISTIC FOR THE FUTURE. STAN ALEXANDROPOULOS UAA GROUP CHIEF OPERATING OFFICER AND MECON INSURANCE CHIEF EXECUTIVE OFFICER GLENN ROSS EXPLAIN.

Global impacts, enduring from the economic damage caused by COVID-19 lockdown, as well as the on-going conflict in Ukraine, continue to affect essential resources for Australia’s infrastructure and construction space.

Businesses ranging from sub-contractors to major infrastructure providers have been forced to re-evaluate how they operate. The insurance sector is no exception.

Stan Alexandropoulos, Underwriting Agencies of Australia (UAA) Group Chief Operating Officer, says the plant and machinery insurance sector is still working through these significant challenges.

“Supply chain issues are a major challenge for everybody at the moment,” Alexandropoulos says. “And that actually translates back to insurance as well, because

that’s causing what we call ‘claims inflation’. Every time we have a claim, it’s probably costing at least 30 per cent more than it was 12 months ago. Increased weather and catastrophe claims just add to the challenges.”

MECON Insurance Chief Executive Officer Glenn Ross agrees. As he tells Roads & Infrastructure magazine, rising costs is a challenge shared between the construction, and plant and machinery insurance industries.

“There are commonalities between both industries, especially for challenges such as inflation. With unexpectedly high inflation, more than ever, we’re paying for today’s claims with yesterday’s dollars, and that’s never been truer than for late-reported workplace injury claims,” Ross says.

“We also have the COVID-19 runoff issues, such as materials delay, parts supply and

repairs, all of these are being faced across the construction, and plant and machinery insurance industries.”

LENDING A HAND

UAA and MECON Insurance are amongst the leading providers of insurance in their given industries. Both companies recently agreed to merge, combining their expertise in the mobile plant and machinery, and construction insurance industries respectively.

Now UAA and MECON Insurance provide insurance brokers with claims advice and technical knowledge, during what Ross refers to as “uncertain times”.

“Our clients challenges are our challenges,” Ross says. “Whether it be inflation, delays, fixed price contracts, or labour related problems. The consequence of most of

roadsonline.com.au 23

FORWARD PROJECTION

UAA and MECON Insurance’s merger is set to provide clients with a one-stop solution for plant and machinery and construction insurance.

these challenges are lengthy delays and cost over‑runs.”

“Delays in repairs and getting parts in can often leave equipment to deteriorate, like the seals hardening and then leaking for example. We’re often dealing with some form of consequential loss on the back of the original loss, the likes of which we haven’t seen in the past.”

Both UAA and MECON Insurance are working with insurance brokers to develop practical solutions to on going impacts.

Alexandropoulos says UAA and MECON Insurance have “very comprehensive policy wordings, specifically designed to cover the exposures in our respective industries.”

“There’s already a number of policy enhancements within our policy wordings,” he says. “For instance, on the UAA plant and machinery policy, we spoke about inflation issues and increased downtime following a claim due to supply chain delays.”

“We have an appreciation clause within the policy wording already, which allows for a 25 per cent increase in the market value of an insured item within the period of insurance. So that’s an additional benefit that’s automatically in there. We also have financial protection covers and options within our policy that can reduce the impact of increased equipment downtime to the business.”

UAA and MECON Insurance are also providing additional education for clients, helping them to weather the storm of enduring impacts on the insurance market.

“On the construction side, we’ve been sending out quarterly emails. Recently targeting fixed price contracts for residential

buildings, helping to ensure that our clients are remaining vigilant. Our brokers will then pass that information onto their clients,” Ross says.

Alexandropoulos says that while UAA and MECON Insurance do not have direct influence over a lot of issues affecting the insurance industry, both companies are trying to play their part in giving back.

“We deal with our insureds via their insurance brokers who are effectively our customers. We’re really trying to push every single broker and our mutual clients at renewal time to go through their insurance schedules to make

He says the partnership is exemplified by the motto “two brands, one family”.

“We’re both experts and leaders in our industries and have been for a long time. The merger gives us more scale and resources to package up policies for clients,” Alexandropoulos says.

“Our clients can get the best of both worlds, as we can offer construction and plant machinery insurance expertise in the form of one industry powerhouse.”

Ross agrees, saying the two companies’ approach and specific industry knowledge is a differentiator in the market.

“We handle all claims ourselves, which differentiates us from other agencies. We’re visible and available with not only underwriting but also claims, and you don’t often get that with the large companies,” he says.

OPTIMISM FOR THE FUTURE

Both Alexandropoulos and Ross remain optimistic for the future of their respective industries, despite current challenges.

“I think from a plant machinery perspective, it’s pretty exciting times,” Alexandropoulos says. “Compared to what we’re currently facing now the future certainly is bright. There’s certainly plenty of work out there for everybody at the moment, which is super positive.”

“With challenges such as inflation and supply chain issues we’ll hopefully feel some

sure that they’re fully updated and their sums insureds have been reviewed,” he says.

“This is especially important, because prices are appreciating so quickly. One of the things we do is to have a look and compare it to the previous year to make sure that some adjustments have been made. If those adjustments haven’t been made, we try to educate the broker and our client on the importance of doing this in the current climate.”

STRONGER TOGETHER

As Alexandropoulos explains, the merger between UAA and MECON Insurance this year will allow both businesses to further support clients and industry, as the insurance sector looks ahead to 2023.

sense of normality soon. I think there’s a silver lining, particularly when it comes to the development of technology in the mobile plant and equipment sector and the industries they work in.”

For Ross, it’s the dynamic and ever changing nature of the industry which excites him about the future of the sector.

“One thing that’s always excited me about the construction industry is that it’s constantly evolving and adapting. You never repeat the same thing all day, every day. Whether it’s design, materials, or legislation. We’ve seen a raft of changes,” he says.

Both say UAA and MECON Insurance will be looking to continue to expand their capabilities and policy wordings of both companies leading into 2023 and beyond.

Stan Alexandropoulos, Underwriting Agencies of Australia (UAA) Group Chief Operating Officer.

24 ROADS DECEMBER 2022 FORWARD PROJECTION

MECON Insurance Chief Executive Officer Glenn Ross.

“WE HANDLE ALL CLAIMS OURSELVES, WHICH DIFFERENTIATES US FROM OTHER AGENCIES. WE’RE VISIBLE AND AVAILABLE WITH NOT ONLY UNDERWRITING BUT ALSO CLAIMS, AND YOU DON’T OFTEN GET THAT WITH THE LARGE COMPANIES.”

resourceco.com.au TOMORROW’S SOLUTIONS. TODAY • Construction and Demolition Waste • Commercial and Industrial Waste • Tyre Recycling • Energy from Waste • Complete Material Solutions • Circular Economy Carbon Abatement Since 1992, we have repurposed over 60 million tonnes of waste. We are in the business of resource recovery –transforming waste into usable products. Find out what we can do for you.

FROM ARRB TO NTRO: A VISION FOR THE FUTURE

SITS

For more than 60 years, the Australian Road Research Board (ARRB) has delivered innovative solutions for Australia’s roads industry and transport agencies.

As transport systems across the world have become increasingly integrated, the overlaps between these services, and the needs of the industries that support them, have also grown.

Which is why, on 1 December 2022, ARRB officially transitioned to the National Transport Research Organisation (NTRO), signalling an evolution from a roadsfocused entity to one encompassing Australia’s entire transport network.

Michael Caltabiano, NTRO Chief Executive Officer, says this major transition has been in the works behind the scenes for some time.

“Our board has been working on this plan since 2017,” he says. “And this year, we’re seeing the culmination of all of that effort.”

Caltabiano says the process has been measured within the organisation, with ARRB’s staff transitioning over several years, from a focus on roads, to a much broader

whole-transport-system methodology.

“We’ve been operating that way for the last three years or so,” he says. “The word ‘road’ no longer appears within our functional business groups – nobody’s fixated on one mode of transport anymore.”

One of the first big changes involved ARRB’s Transport Infrastructure Product Evaluation Scheme’s (TIPES) evolution into the wider-reaching NTRO Certification.

“ARRB has been running the TIPES process since 2015, and that focused on product certification for the roads sector,” Caltabiano says. “In transitioning to NTRO, we’ve expanded our offering to a road, rail, ports, and airport certification service. And, in doing so, we’ve also broadened the scope to include not just product, but also process, people, and services.”

“We intend for NTRO to be the central point through which certification happens for the transport sector across Australia and New Zealand.”

But what of ARRB’s decades-long legacy in the Australian transport landscape?

Caltabiano says ARRB will live on as one

26 ROADS DECEMBER 2022

ROADS & INFRASTRUCTURE

DOWN WITH MICHAEL CALTABIANO TO LEARN ABOUT THE NEWLY LAUNCHED NATIONAL TRANSPORT RESEARCH ORGANISATION (NTRO), AND ITS ROLE IN THE FUTURE OF AUSTRALIA’S TRANSPORT INDUSTRY.

of two sub-divisions of NTRO – the other being the Australasian Centre for Rail Innovation (ACRI), which came on board with ARRB in July this year.

DRIVEN BY INDUSTRY

Caltabiano says his organisation’s evolution into NTRO has been largely driven by industry and transport agency members, who have been seeking an independent portal to access certified resources for the sector.

“The industry has been craving a central location to have their innovations certified by a trusted third-party, so they can offer them to government,” he says.

“Being owned by transport agencies means that when NTRO certifies a product, process, person or service, these agencies can have absolute confidence that what’s being certified is fit for purpose, does what it says it’s going to do, and can therefore be accepted in construction projects.”

CIRCULAR MATERIALS

As the demand for sustainable and recyclable construction materials has steadily ramped up across the sector, so too has the need for appropriate certification processes.

According to Caltabiano, innovation in this area will play a big part in NTRO’s near future.

“The circular economy outcomes that both industry and government is seeking

A NATIONAL HUB

With a presence in almost every other state and territory in Australia, Canberra was chosen as the location for the NTRO national office. Caltabiano himself recently relocated to Canberra with his family to lead the organisation’s transition from the front lines.

“We opened the Canberra office in March this year – it’s the first NTRO-branded office in Australia,” he says. “It’s also our

“The work we’ve done with them so far has been really positive,” Caltabiano says. “The reception we’ve had from their staff has been wonderful.”

A new office in New Zealand is also in the pipeline for 2023, and NTRO has also committed to extending its physical presence to the one remaining piece of the Australian puzzle, the Northern Territory.

“We do a lot of work for the Northern Territory,” Caltabiano says. “Getting people on the ground to further support the Territory’s transport and infrastructure department is very important to us.”

MOVING FORWARD

need a certification pathway to be accepted,” he says.

Caltabiano says the laboratories at the ARRB facility in Port Melbourne – now NTRO co-branded – have put a lot of testing into such products, from new crumb rubber blends to special plastics blends for incorporation into bitumen.

“We’ve done a lot of work with Tyre Stewardship Australia to get new specifications written across the states, including writing standards for local government in Victoria,” Caltabiano says. “They’ve been great partners in that process of offering change, and developing those standards for incorporation into practice.”

hub for rail in Australia – ACRI Chief Executive Rob Moffat and his team operate out of there as well.”

Caltabiano says proximity to both the Federal and ACT governments also factored into the Canberra decision.

“We are doing a lot of work with the Commonwealth in the certification space for heavy vehicles; as well as to assist with the journey to incorporating more recycled products,” Caltabiano says. “We’re working through exactly what that means, what they can specify, and what they can demand of their transport agencies.”

He says NTRO has also been working closely in partnership with the ACT Government on some important initiatives.

Caltabiano and NTRO will begin 2023 with some interesting challenges to deal with on the path to their vision for a more unified national transport sector.

“The reshaping of this infrastructure pipeline that the Federal Government has announced will have major implications for the sector,” Caltabiano says.

“It’s a really fascinating time for the industry. 2023 will be a seminal year, and it will set the stage for our journey over the next five years to deliver this step change that the community wants to see.

“NTRO’s vision is to enable transport agencies to give effect to that change, by providing that central portal for innovation in Australia and New Zealand. It’s a big vision, and a pretty lofty goal – but we’re up for it.”

roadsonline.com.au 27

FORWARD PROJECTION

Michael Caltabiano, NTRO Chief Executive Officer.

“IN TRANSITIONING TO NTRO, WE’VE EXPANDED OUR OFFERING TO A ROAD, RAIL, PORTS, AND AIRPORT CERTIFICATION SERVICE. AND, IN DOING SO, WE’VE ALSO BROADENED THE SCOPE TO INCLUDE NOT JUST PRODUCT, BUT ALSO PROCESS, PEOPLE, AND SERVICES.”

backhoe loader is as fresh and innovative today as when it was first conceived over 60 years ago. Since the

by JCB in 1953 it has undergone continual innovations, pushing the boundaries and providing real solutions to meet customer needs. A

of JCB’s success

that we’ve listened to what our customers want, and we’re always striving to produce the most productive, reliable and efficient machines on the market. In tough market conditions, we take the time to understand what’s important to customers and how we can make a difference to your success through features that ensure versatility, offer positive residuals, fuel efficiency and low cost of ownership. For more information on the range of JCB backhoe loaders please contact your local dealer www.jcbcea.com.au or call 1300 522 232. JCB BACKHOES THE WORLD’S NUMBER ONE BACKHOE LOADER MANUFACTURER • BEST IN CLASS ROAD SPEEDS • LOW EMISSION HIGH POWERED STAGE V ECOMAX ENGINES • IMPRESSIVE FUEL SAVINGS WITH AUTO ENGINE SHUT DOWN • ERGONOMICALLY DESIGNED CONTROLS WITH EXCLUSIVE IN SEAT CONTROLS • ADVANCED TECHNOLOGY 7” LCD TOUCH SCREEN • EFFICIENT DESIGN PHILOSOPHY • AUTOMATED FUNCTIONS WITH SELF LEVELLING STABILISERS INTRODUCING THE NEW STAGE V JCB SITEMASTER

JCB’s iconic

invention of the backhoe

large part

is

ROOM FOR OPTIMISM

InEight’s digital solutions aim to increase the efficiency of project delivery, therefore reducing impacts such as supply chain and skilled personnel challenges.

The capital projects industry is going through one of the largest changes in the sector’s history.

Still reeling from the impacts of the COVID-19 pandemic, as well as an industrywide skill and supply shortages, many businesses across the capital projects industry are looking to digital providers such as InEight for guidance.

InEight Sales Director Justin Fagents says that despite challenges, the capital project industry still has a lot to look forward to. He tells Roads & Infrastructure magazine that solutions to on-going industry problems are there for the taking.

“There’s a couple of big challenges that the industry is currently facing. The resourcing of human capital has been a real stretch. That has mainly been due to restrictions on labour coming in internationally because of the COVID pandemic,” he says.

“With less international expertise coming in, this presents an opportunity to attract a new generation and diverse workforce.

Bringing more women into the workplace for construction is going to be imperative. Creative ways of hiring, and also being able to utilise a diverse and remote workforce, are just some of the ways our clients are maintaining productivity.”

For many businesses in the modern capital

construction projects. This includes the pre-planning, design and engineering, construction, commissioning and startup and final operation phases.

Fagents says that accuracy, accessibility and flexibility can all be achieved across these construction phases, as long as the

projects industry, accuracy, accessibility and flexibility are paramount.

To counter on-going impacts to the current economy, InEight has developed a ‘digital transformation roadmap’, outlining how businesses can embrace digital tools throughout the life cycle of a construction project.

This roadmap entails the project life cycle typically associated with commercial

technology is successfully implemented.

“When we talk about the digital transformation roadmap, it really starts at the pre-planning phase. Really, it’s around that effective scope, evaluating the costs, potential risks, and creating those benchmarks and estimates,” he says.

“From the pre-planning phase, right through to the operations and maintenance phase, it’s important that

roadsonline.com.au 29 TECHNOLOGY

INEIGHT IS REAFFIRMING ITS COMMITMENT TO DIGITAL TRANSFORMATION BY PROVIDING INNOVATIVE SOLUTIONS TO ON-GOING GLOBAL IMPACTS AFFECTING THE CAPITAL PROJECTS INDUSTRY. INEIGHT SALES DIRECTOR JUSTIN FAGENTS SITS DOWN WITH ROADS & INFRASTRUCTURE TO DISCUSS.

“FROM THE PRE-PLANNING PHASE, RIGHT THROUGH TO THE OPERATIONS AND MAINTENANCE PHASE, IT’S IMPORTANT THAT YOU CAN ACCESS DATA QUICKLY AND EASILY, WHENEVER YOU NEED IT, THROUGHOUT THE LIFE OF THAT ASSET.”

InEight’s ‘digital twin’ includes realtime clash detection, helping to minimise disparities between design data and as-built data.

you can access data quickly and easily, whenever you need it, throughout the life of that asset.”

InEight provides a range of solutions to minimise risk and improve project certainty.

More than 575,000 users across 60 countries use InEight’s solutions to manage in excess of $1 trillion worth of capital infrastructure projects globally.

During the design and engineering phase, InEight’s software can support the management of engineering deliverables, while also allowing users to view scheduling impacts caused by design delays, helping to minimise the downtime and impacts to the project schedule.

“Then we move onto the construction phase, where the main components happen,” Fagents says. “Now the constructor and asset owner can use what we call the control module, which is your baseline of all of the schedules, all of the risks, all of the key suppliers, all of the procurement functions, while also managing essential documents.”

During the startup phase, project managers can manage the punch lists

and commissioning through InEight’s digital tools.

Once the structure/facility is in operation, constructors and asset owners can have access to digital project archives, which are captured by InEight’s software, providing a digital audit trail.

One such tool, which can provide an audit trail, as well as real-time clash detection, is InEight’s intuitive ‘digital twin’.

As Fagents explains, the digital twin has been designed to cater for multiple disciplines and designs on major infrastructure projects, creating a united view across all models.

“The digital twin connects the design data with the as-built data. So having that digital twin from the design phase at the beginning, and having that full replication, ensures that as the project is being constructed, clash detection is done on the fly. As you’re building the physical asset, the digital asset is also aligned,” he says.

“By having an audit trail, project managers can view clash detection, as well as any components that may have failures. Stakeholders can see what was installed,

30 ROADS DECEMBER 2022

InEight Sales Director Justin Fagents.

who the asset was installed by as well as the maintenance history, all in one platform.”

As Fagents adds, the digital twin is also useful for the on-going servicing across the life of the asset.

“For the life of the asset, it’s obviously important to have the ability to plan maintenance shutdowns and ongoing upgrades to the facility or the asset. Having a full digital twin ensures there’s going to be a better performance in terms of being able to do that plan, maintenance and shutdown, as well as being able to identify where some of those key pain points may be within the within the asset.”

In uncertain times, Fagents says the use of data is paramount.

“We’ve seen far too many major infrastructure projects failing to be

completed within their given timeframe and cost cap,” he says.

“There’s a real opportunity for the construction industry to connect this data to gain real insights into whether a project can be delivered on time and on budget. We can give a project team the ability to forecast what’s coming, and then pivot, to ensure that the development of an asset doesn’t get off track.”

THE COMPETITIVE EDGE

Fagents says the construction industry is among the slowest when it comes to embracing digital transformation. He says that while the benefits of digital tools are well publicised, the sustained success of embracing digitalisation relies on internal support and objective setting.

“I think if you don’t have a clear outcome of what you’re looking to achieve, the technology itself will fail,” he says. “The first step is to be very clear on what the problem is that you’re trying to solve as an organisation.

“Organisations also need to ensure that the executive leadership team is supporting the transformation. In our experience, executive endorsement is very important from a change management perspective.

“Businesses need to embrace the technology across the whole organisation. It’s also important that your subject matter experts in the discipline are involved early in the conversation.”

As Fagents adds, InEight’s digital tools are proving to be the differentiators for organisations bidding on Australia’s next wave of major infrastructure works.

“When you’re looking from an owner’s perspective, they’re selecting the right partner based on experience in a particular sector. They’re asking, ‘how are they going to deliver projects with certainty?’ InEight is able to bring certainty to those constructors, but also to owners as well, by giving them the visibility and insight they require,” he says.

“Our clients are bidding for work using our InEight solution set as a key differentiator between themselves and their competition.”

LOOKING AHEAD

As the capital projects industry continues to weather the storm of economic impacts, Fagents says he’s optimistic for the sector’s future. He believes the influx of government spend on a federal and state level is an encouraging sign for the industry’s long-term future.

“If we look across the country, there’s plenty of projects that are coming up. The Western Sydney Infrastructure Plan, the Bruce Highway Upgrade and the Great Western Highway are just some examples of projects which are bringing jobs and millions of dollars to the industry,” he says.

“I’m incredibly optimistic and buoyant about the way the industry is tracking. There’s a lot of money being invested. The sector’s certainly not shrinking, but we’re going to need to ensure that we have the right tool sets available to the people that are delivering those projects.”

roadsonline.com.au 31 TECHNOLOGY

“THE DIGITAL TWIN CONNECTS THE DESIGN DATA WITH THE AS-BUILT DATA. SO HAVING THAT DIGITAL TWIN FROM THE DESIGN PHASE AT THE BEGINNING, AND HAVING THAT FULL REPLICATION, ENSURES THAT AS THE PROJECT IS BEING CONSTRUCTED, CLASH DETECTION IS DONE ON THE FLY.”

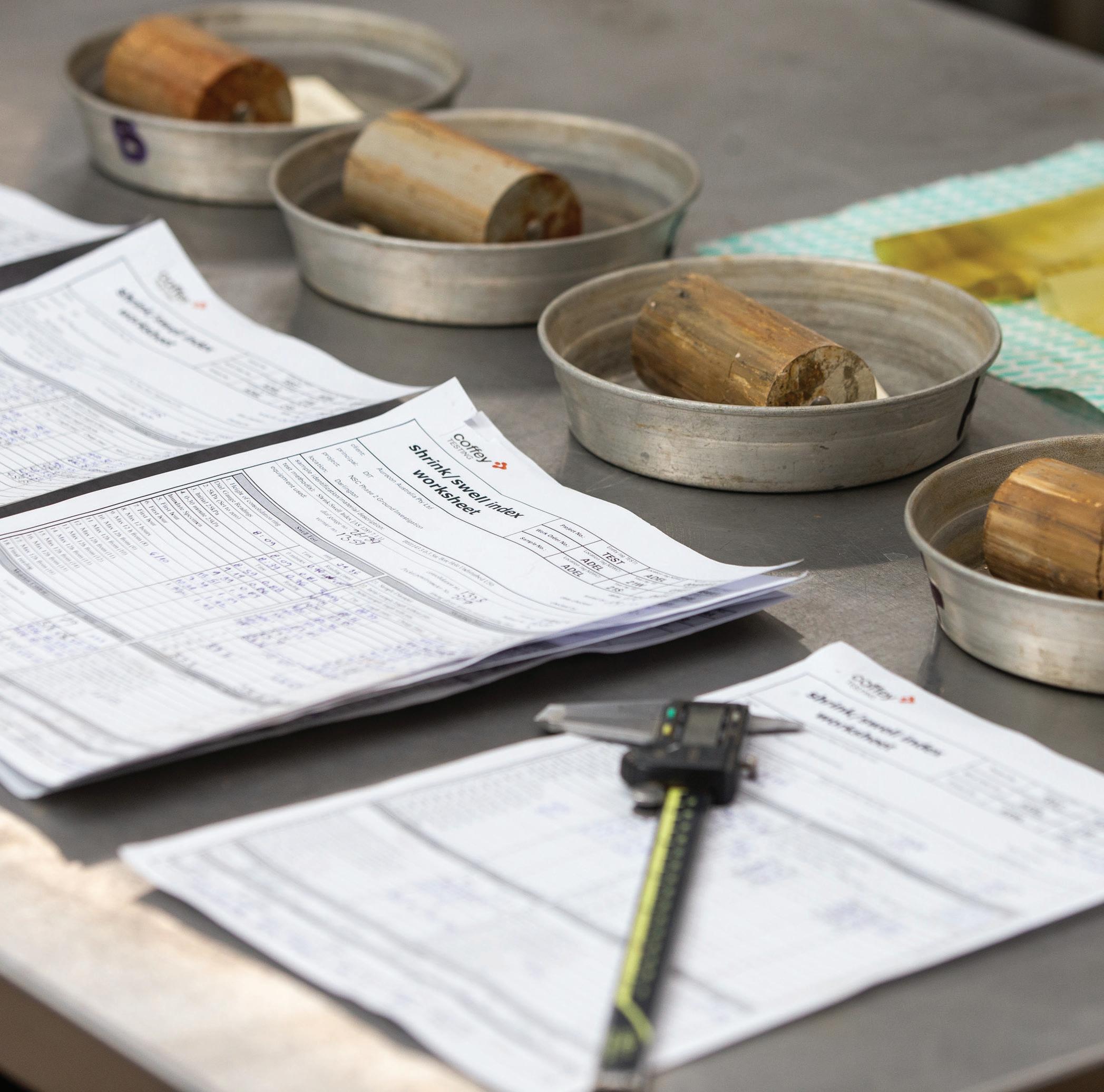

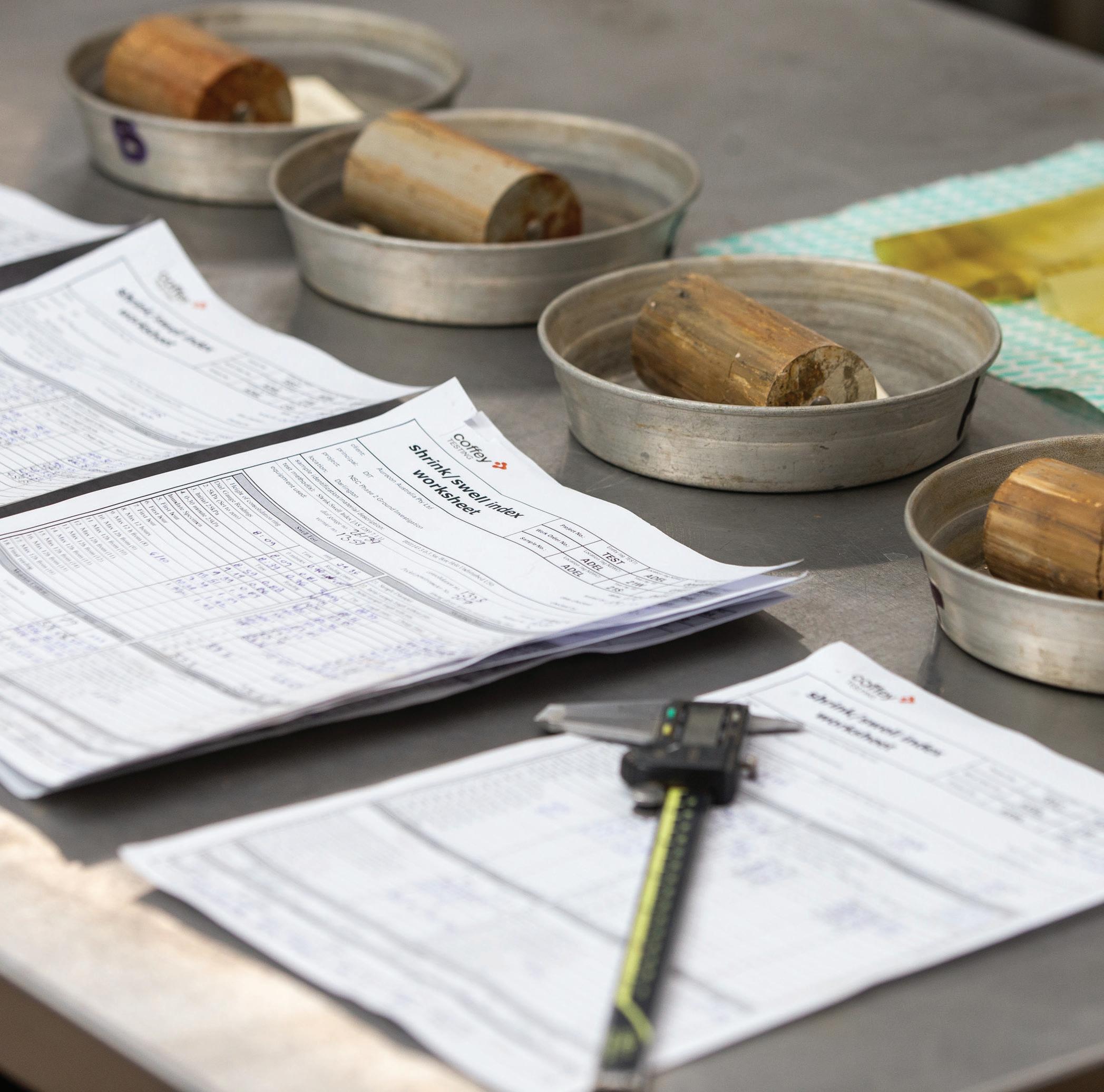

SPEED TEST

ROADS & INFRASTRUCTURE FINDS OUT HOW COFFEY TESTING’S REMOTE TESTING

LABORATORIES HAVE REVOLUTIONISED ONSITE CONSTRUCTION MATERIALS TESTING

BY ENABLING FAST, CERTIFIED RESULTS IN THE FIELD.

From houses and high-rises to roads and rail lines – any form of construction is only as solid as the earth on which it’s built.

This makes the rigorous testing of soil, concrete, and aggregate one of the most crucial steps in the construction process –especially at the very start.

Coffey Testing’s Newcastle Laboratory Manager Joe Stallard knows this process isn’t always a part of construction that contractors look forward to – but it’s one that can save time, money, and liability down the track.

In an industry where time is money, waiting days or weeks for certified test results is often not viable – especially if that result means a project needs to be delayed or completely reworked if a sample does not pass a compaction control test.

“No contractor likes to hear that one of their layers of soil has failed, because they are obligated to pull that layer out and rework it to meet the specifications,” Stallard says.

These specifications are dictated by the National Association of Testing Authorities (NATA), which is the governing body for the Australian Construction Materials Testing (CMT) industry.

NATA ensures that laboratories adhere to strict test methods and procedures, and provides certification for projects that are tested accordingly, as Stallard explains.

“When we perform tests in a laboratory, all our samples are processed in accordance with specific requirements. This includes having certain equipment calibrated to certain tolerances, and in an environmentally controlled space,” he says.

“If you’re going out to a site without those measures in place, your tests aren’t to NATA requirements, and you can’t provide that test certificate to a client. You can give them a result, but it’s only going to be an indication.”

Stallard says this is how things had to be done twenty years ago. On-site testing capabilities were limited, and could not provide NATA-certified results.

“A sample from a compacted layer would undergo basic ‘non-NATA’ testing on site,

proper certified testing,” he says. “And that’s a lot of needless double-handling.”

REMOTE SOLUTIONS

This is where Coffey Testing’s remote testing laboratories come into play.

“These are NATA-endorsed mobile facilities built into a trailer, which can be driven out to sites Australia-wide,” Stallard says. “This allows us to conduct specific testing on-site to deliver timely, NATA-certified results for our clients.”

Stallard says the trailers are set up primarily for compaction control and stabilised pavement testing, which are critical to a range of infrastructure and construction projects.

“For every 300-millimetre layer a contractor puts down, our job is to ensure that they’ve delivered adequate energy and compaction into that layer before any subsequent layers are put on top,” he says. “Because if a layer isn’t compacted correctly or sufficiently, it can cause all sorts of issues down the line.”

means each test can be turned around straight away, and – providing it passes – a NATAcertified result provided within 45 minutes.

“If the sample fails, the client is notified, and they’ll give it more work,” Stallard says. “Then, we’ll test it again – and more often than not, it will pass, and the contractor can place the next layer.”

Nowhere is this immediate turnaround more valuable than on remote rail projects, where Stallard says project crews can be isolated for up to a week.

“Works on those rail projects can involve excavating out a whole section of rail –including all the ballast and one-and-a-half metres of formation – and then put down layers of clay and gravel all the way back to the finished surface layer,” he says.

Stallard says the rail must be returned to service on time, regardless of the weather conditions.

“You could be dealing with the worst weather in Australia – it doesn’t matter,”

32 ROADS DECEMBER 2022

Coffey Testing’s remote laboratories are all NATA certified.

he says. “That rail needs to go back by the deadline, because there’s always a train coming.”

This means, without the availability of a remote laboratory, contractors would have no way of knowing for sure if any given layer had passed compaction tests until long after the layer had been buried and the tracks re-laid.

“If you have trains going over that failed compaction layer, you might find that it settles gradually over five years and the track will drop five or 10 millimetres,” Stallard says. “And then a train could derail – and who do you think is going to be liable for that?”

THE ROAD TO RESULTS

Stallard says the availability of speedy test results also make a big difference for road construction and maintenance, where the window for effective testing is often dictated by the time it takes a binder to set.

“You have a minimum working time to sample the gravel before that binder sets like concrete,” he says.

“If you’re driving three or four hours to do that test back at the lab, by the time you get back the pavement is starting to set, and its properties are changing.”

As well as compaction control, Coffey Testing’s remote labs are also set up to test for the moisture of gravel – something Stallard says is a critical factor for any infrastructure project.

“We can tell a contractor in the field if their gravel is too wet or too dry,” he says. “If they put it in too dry, we can tell them to add another two per cent water to the mix. Then, they can add it in, rework it, and we can retest it immediately.”

Stallard says these instant results can dramatically affect how such works are Coffey Testing’s remote services also allow

contractors well and truly capable of using their experience to make these judgements, obtaining NATA-certified tests can mitigate risk and save liable parties from playing the blame game if something does go wrong.

It’s this ability to minimise risk and maximise efficiency on a wide range of projects that has allowed Coffey Testing to develop a dedicated base of return customers for its remote testing services.

“We now have a group of clients who specifically request Coffey Testing because they know we have the capability to deliver results in a timely manner,” Stallard says. “And for them to deliver on certain projects, there’s no way they could do that without timely results in the field.

“Remote testing is really the way forward for construction projects, because the amount of time and money it can save is astronomical.”

roadsonline.com.au 33

Remote trailers are set up primarily for compaction control and stabilised pavement testing.

Coffey Testing’s remote labratories can help streamline project schedules.

WE LOVE RELIABLE VALUES. JUST LIKE OUR RADAR LEVEL SENSOR. THE 6X ®. OUT NOW! For over 60 years we have only had one thing in mind: making measured values ever more precise. But we also never lost sight of the need for human values, too. By combining these it makes a remarkable radar level sensor possible. The best value there is: VEGAPULS 6X. VEGA. HOME OF VALUES. www.vega.com/radar

SUSTAINABLE STORAGE SOLUTIONS

ATLAS COPCO’S NEW ZENERGIZE RANGE MAKES ON-SITE ENERGY STORAGE QUIETER, CLEANER, AND GREENER.

Energy storage solutions are becoming an increasingly vital part of modern construction sites.