THE FIRST PRIORITY FOR AUSTRALIA’S MINING INDUSTRY

ISSUE 1 - JANUARY-FEBRUARY 2020

Innovation at work Mangoola CHPP sets safety standards Technology

Tyre management

Risk management

Training

Comment A new year brings new opportunities for safer mining AS 2020 BEGINS, THE MINING INDUSTRY IS GIVEN A FRESH START FROM A SAFETY PERSPECTIVE. BUT HOW WILL COMPANIES TAKE ADVANTAGE OF THIS?

BEN CREAGH

W

hat are your safety goals in 2020? For most mining and METS (mining equipment, technology and services) companies a new year simply means a continuation of treating safety as their No. 1 priority. But 2020 will also provide an opportunity for a fresh start in some respects. In Queensland, for example, it will be the first full year since the safety reset took place across the state. Following a number of tragic incidents early last year, almost every mine worker in Queensland participated in a reset that aimed to improve the safety performance at mines and quarries. Time will tell how effective the process has been. Safety initiatives in 2020 will also focus on the health and wellbeing of workers as awareness of the mental impact that the industry can have in some areas grows. The fly in, fly out (FIFO) debate re-emerged in 2019 as activity in remote areas ramped

SARAH BUCKLEY Tel: (03) 9690 8766 Email: sarah.buckley@primecreative.com.au

PUBLISHER CHRISTINE CLANCY MANAGING EDITOR BEN CREAGH Tel: (03) 9690 8766 Email: ben.creagh@primecreative.com.au JOURNALISTS SALOMAE HASELGROVE Tel: (03) 9690 8766 Email: salomae.haselgrove@primecreative.com.au

VANESSA ZHOU Tel: (03) 9690 8766 Email: vanessa.zhou@primecreative.com.au CLIENT SUCCESS MANAGER JANINE CLEMENTS Tel: (02) 9439 7227 Email: janine.clements@primecreative.com.au SALES MANAGER JONATHAN DUCKETT Tel: (02) 9439 7227 Mob: 0498 091 027 Email: jonathan.duckett@primecreative.com.au

up to levels not seen since the mining boom early last decade. With more FIFO miners across the industry, workers in vast states like Western Australia are increasingly living away from their families over long periods. Mining companies and contractors have done a great job over the past decade to set up stronger programs that support workers in these positions. The need for these programs will only intensify as operational activity ramps up even further. Safety now also increasingly goes beyond mine sites and company workforces. The safety, health and wellbeing of key stakeholders, such as the local communities surrounding operations and even society in general, now figure prominently on the radar for companies. In the pursuit of sharing value with its stakeholders, mining companies are partnering with suppliers and industry groups to develop innovative methods that reflect modern demands. They inevitably improve safety

DESIGN PRODUCTION MANAGER Michelle Weston ART DIRECTOR Blake Storey GRAPHIC DESIGNERS Kerry Pert, Madeline McCarty, Jo De Bono SUBSCRIPTION RATES Australia (surface mail) $140.00 (incl GST) New Zealand A$148.00 Overseas A$156.00 For subscriptions enquiries please call 03 9690 8766

SAFETOWORK.COM.AU 3 JAN-FEB 2020

performance, but also benefit workforces and communities by being more diverse, responsible when sourcing materials and environmentally friendly. These areas are set to have a major role in company strategies in 2020 and beyond.

Ben Creagh

Managing Editor

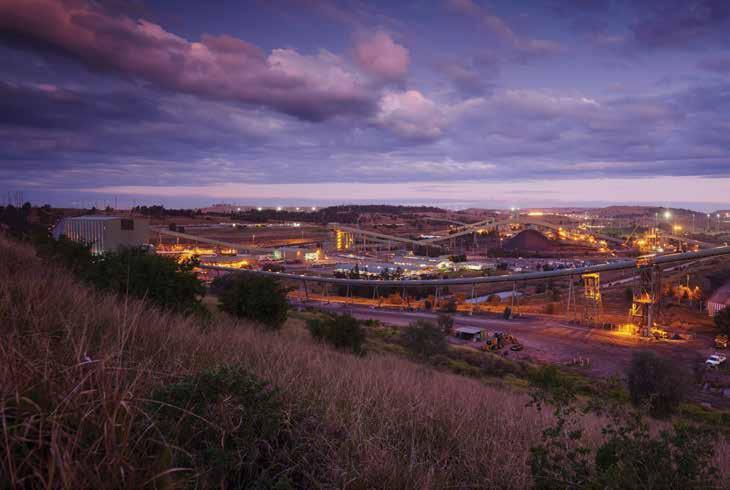

FRONT COVER The Mangoola CHPP, winner of the safety, OH&S award at the 2019 Prospect Awards. Image: Glencore.

PRIME CREATIVE MEDIA 11-15 Buckhurst St South Melbourne, VIC 3205 Australia www.primecreative.com.au © Copyright Prime Creative Media, 2016 All rights reserved. No part of the publication may be reproduced or copied in any form or by any means without the written permission of the p ublisher.

In this issue Features 16 Compete for safety

Victorian rescue competition sounds

20

the alarm

18 Merging of technologies

Hummingbird Electronics deciphers safety signals

20 Tyre changes go down under Kal Tire lifts focus on underground tyre management

22 180-degree view

Bollé Safety lends unparalleled vision

24 Awarding safety innovation Prospect Awards recognises Glencore CHPP

26 A leader’s journey in safety Epic safety plans for Industree

28 Mining’s biggest concerns

The challenges of social licence

Automation peered from the lens of social licence

36 The gender debate

Mining leaders consider the pros and cons

40 Coal’s place in green future

Miners deliver Queensland-wide reset

45 The transition towards renewables

Gold Fields and Anglo American take action

46 Preparing for summer season

Industry gets together for emergency response

Whitehaven Coal, South32 and Adani weigh in

42 Fighting the drought

30 Time to reset

32 Friends or enemies?

24

Miners reveal their water management strategy

16

REGULARS

6 NEWS

12 PRODUCTS

SAFETOWORK 4 JAN-FEB 2020

50 EVENTS

Photos : F. BOURCIER

ATION 2019

News BHP to mobilise autonomous trucks in Queensland

BHP mine manager at Goonyella Riverside, Sean Milfull.

BHP Mitsubishi Alliance (BMA) is set to introduce autonomous haulage at the Goonyella Riverside coal mine in Queensland this year in an effort to reduce exposure to safety risks. The move will not involve any forced redundancies, but is anticipated to increase truck hours and deliver more consistent cycle times. Goonyella Riverside will be the first BMA site to implement autonomous haulage, with the first trucks expected to be operational in the first half of 2020.

The coal miner will undergo a staged conversion of 86 converted Komatsu trucks over the next two years. BMA asset president James Palmer said the decision resulted from the site’s extensive engagement with the workforce, community and government. The company has prepared its workforce for the change and talked about the potential for increased automation for several months before making the announcement.

“While the first autonomous vehicles will not operate at the site until 2020, and full roll out will take around two years, we want to give people in our workforce and the community as much notice as possible of this change,” Palmer said. “Autonomous haulage will help us improve safety and productivity performance, and it is our people who will be at the centre of making this change a success.” BMA plans to deliver more than 40,000 hours of training to help prepare for Goonyella Riverside’s autonomous future. While BMA understands that automation represents a significant change, Palmer believes it offers a unique opportunity for people to gain new skills. BMA has also recruited new permanent positions in operations and created new roles in preparation for autonomous haulage. The company hasn’t made any further decisions to implement autonomous haulage at its other Queensland coal sites. These decisions will be made on a site-bysite basis, according to BMA.

Anglo American commits workers to safety talks Anglo American has included more than 5000 Queensland-based workers in its Global Safety Day program and dedicated safety discussions. Every Anglo American site marked and took part in the company’s Global Safety Day in October last year. Anglo American’s focus was on ensuring there was no gap “between what we say and what we do when it comes to safety,” according to Anglo American’s Metallurgical Coal business chief executive Tyler Mitchelson.

“Despite significant improvements, we still have not been able to eliminate fatalities from our industry,” he said. “This is something we are focussed on every hour of every day, and at every level of our business.” Anglo American operates five metallurgical coal mines in the Bowen Basin region in Queensland. The company’s Global Safety Day ensures that every employee is “united and aligned” on safety. It was an important part of the company’s SAFETOWORK 6 JAN-FEB 2020

dedication to eliminating fatalities from across the business, Mitchelson added. Anglo American undertook a full safety reset at all its sites last year as part of a broader initiative within the Queensland mining industry. This entailed over 50 sessions and an attendance of more than 5400 people. The coal giant has also introduced a program called ‘Elimination of Fatalities’, which is addressing critical safety risks by drawing from best practice knowledge and safety innovations.

Fortescue autonomous fleet achieves milestone Fortescue Metals Group has hit a milestone with more than one billion tonnes of material moved safely by its fleet of autonomous haul trucks in Western Australia. The autonomous fleet covered 33.5 million kilometres, or in excess of 1.2 million kilometres a month in 2019 – a distance equivalent to travelling around Australia 2.6 times every day. By mid 2020, Fortescue’s haulage operations are set to become the first in the world to be fully autonomous, according to Fortescue chief executive Elizabeth Gaines. She said the introduction of the autonomous haulage technology (AHS) had delivered improved safety outcomes for its team members. This was achieved through reduced interaction between heavy equipment and people in mining areas. “Our autonomous fleet has not only moved more than one billion tonnes of material, it has also delivered a 30 per cent improvement in productivity and

An autonomous truck at Solomon Hub. Image: Fortescue Metals Group

reflects our commitment to increasing operational efficiency through industry leading technology and innovation,” Gaines said. Fortescue was the first in the world to deploy Caterpillar’s AHS on a commercial scale at the Solomon Hub operations in Western Australia. This fleet has since expanded to Fortescue’s Chichester Hub, with 137 autonomous trucks now in operation. Fortescue will also convert a total of 175 trucks to autonomous technology

by mid-2020, making it the world’s first iron ore company to have a fully autonomous haulage operation. “As we expand our autonomous haulage fleet, our focus remains on ensuring that our workforce is prepared for the changing industry landscape through our training and redeployment program, which has successfully transferred or upskilled employees to new roles across the business, resulting in no forced redundancies,” Gaines concluded.

SA to launch mining-backed clean energy centre South Australia will host an industrybacked training ground for minerals industry experts in the sensing and data science areas. BHP, OZ Minerals, Boart Longyear and other stakeholders have supported the initiative with $12.5 million in funding. The ARC Training Centre for Complex Resources will facilitate postdoctoral researchers and PhD candidates’ education by Adelaide and Curtin Universities and the University of South Australia (UniSA). UniSA’s Future Industries Institute foundation fellow Marta Krasowska said the goal of the centre was to increase the value in mining by

developing “leaner and cleaner” processing capabilities. “A major part of our role is to bring our work in advanced sensors for mineral processing into this centre, to connect with data analytics and process control,” Krasowska said. “The students and researchers we train will learn how to apply cutting edge science, engineering and mathematics to an industry that will underpin the transition to clean energy in the global economy.” Deputy director of the training centre William Skinner is confident the South Australian universities, together with Curtin, can bring relevant research and

SAFETOWORK.COM.AU 7 JAN-FEB 2020

development (R&D) training outcomes across the mining value chain. South Australia has shown rapid developments in new technologies and scientific innovation in the sector that are among the best in the world, according to Skinner. “This new centre will ensure that culture of sustainable and best practice innovation continues,” Skinner said. The centre has been supported with $3.7 million from the Australian Research Council and a further $8.8 million in cash and in-kind from Maptek, Orica and Sandvik, to name a few.

News Alcoa boosts training program with virtual reality Alcoa has followed in the steps of the army, navy and air force by using virtual reality (VR) to undertake training for high-risk tasks at its alumina refineries in Western Australia. The guided training module simulates how to safely and correctly isolate electrical switches to avoid arc flash incidents in a safe environment. This takes place in a virtual replica of Alcoa’s refinery sub-station, where the trainee is surrounded by equipment, sound and personal protective equipment (PPE) found in the workplace. Alcoa has also incorporated free-play environments that include events and risks to mitigate, replicating what could occur in real life. Pinjarra refinery manager Mark Hodgson said it was a step change for Alcoa in the way training was delivered and a key enabler in increasing safety. “With safety being our top priority, this training allows our employees to experience high-risk hazards

Alcoa operator Ben Curtis tests out the arc flash isolation simulation at Pinjarra refinery.

and the steps to mitigate them in a safety environment, so they can take what they have learned back to their workplace,” Hodgson said. The team is working on deploying similar training modules for several high-risk tasks, including working on or near energised equipment and high-voltage isolation.

Alcoa’s global refining operations personnel have benefitted from this training since it started in October last year. The company believes VR training could provide a learning retention rate of 75 per cent, compared with 20 per cent with standard computer-based point-and-click training.

Rio Tinto to drive Tom Price operations with automation Rio Tinto expects 50 per cent of its haul truck fleet to operate autonomously by the end of 2020 following the announcement of a $1 billion investment in its Greater Tom Price operations in Western Australia. As part of the investment, Rio Tinto will fit its haul truck fleet with autonomous haulage system (AHS) technology in the Western Turner Syncline Phase 2 (WTS2) from 2021. Rio Tinto, now the world’s largest owner and operator of AHS trucks, stated that its autonomous haul trucks were operated by a supervisory

system and a central controller, rather than a driver. The trucks use pre-defined GPS courses to automatically navigate haul roads and intersections and know actual locations, speeds and directions of other vehicles at all times. Rio Tinto Iron Ore chief executive Chris Salisbury said the company’s iron ore business continued to deliver “industry-leading margins as we drive performance from our mines.” “This significant investment in the Greater Tom Price hub is one of a

SAFETOWORK 8 JAN-FEB 2020

pipeline of high-quality, low-cost options that will underpin production of our flagship Pilbara Blend product well into the future,” he said. Rio Tinto’s investment in the WTS2 mine is set to sustain the workforce at the Greater Tom Price production hub, with its construction workforce expected to exceed more than 1000 people at peak. Production of high-quality Brockman ore will support the company’s flagship Pilbara Blend, the preferred baseload product for Chinese steel mills.

WA tables workplace safety laws The Western Australian Government has introduced the Work Health and Safety (WHS) Bill in Parliament, laying a groundwork for future modern workplace safety laws that apply to all industries. Due to an outcry of public concern, the new legislation is set to include industrial manslaughter provisions carrying a maximum penalty of 20 years’ imprisonment for an individual and a fine of $10 million for a body corporate. The new laws will make it illegal for insurance companies to indemnify

entities against monetary penalties imposed under workplace health and safety laws. Western Australian Industrial Relations Minister Bill Johnston said the health and safety of workers were a priority for the government. “This bill will modernise Western Australia’s laws and bring us into line with other states,” Johnston said. “The current legislation is spread across multiple Acts and regulations – this update will bring the resources sector and general industries under the same act, but with separate regulations.”

The WHS Bill defines health as both physical and psychological health, and is aimed at the importance of considering psychological health in the design and management of work. It will also serve as a reminder that risks to psychological health must be considered alongside risks to physical health. “The community has high expectations that every worker has the right to come home safely after each shift, having a strong deterrence in this legislation completely accords with these expectations,” Johnston concluded

BMA lifts safety with original invention

BMA owns and operates mines in the Bowen Basin, Queensland. Image: BHP.

BHP Mitsubishi Alliance (BMA)’s Saraji team in Queensland has invented an alternative way of pulling mobile equipment to reduce a manual handling risk. The award-winning synthetic lightweight couplings have proven to be a “clever alternative” to the 110-kilogram combined weight of a pull ring and metal shackles used in pulling heavy equipment. BMA overburden supervisor Josh

Leppard, a sailor on his days off, used his knowledge of the marine industry to develop this practical solution. Leppard and the team worked with the marine coupling manufacturer in New Zealand to “super-size” the technology to suit the mining industry. “Being a yacht racer for many years, we moved away from using metal shackles four or five years ago and now only use synthetic couplings

SAFETOWORK.COM.AU 9 JAN-FEB 2020

that are made specifically for marine purposes,” Leppard said. “These couplings are lightweight but provide exceptional strength as you would expect to be needed on offshore race yachts.” The soft couplings weigh around eight kilograms and are made of Dyneema, one of the world’s strongest and most reliable fibres available, according to BHP. They are then braided with Technora, which gives them high heat and chemical resistance, as well as protecting against chafe – the same product used for bullet proof vests and firefighting clothing. The team worked with independent testers to verify and strength test the shackles so they could be used on site. “We hope that by creating the ‘soft couplings’ we’ll not only reduce the risks associated with heavy lifting and manual handling, but also remove the physical barriers that may prevent some men and women from completing the task,” Leppard concluded.

News ICMM to release strict tailings standards The International Council on Mining and Metals (ICMM) will be releasing the international standard for tailings management this year. It builds on a draft standard that was open for public consultation until December 31 last year. The draft standard was convened by the Global Tailings review, the United Nations Environment Program (UNEP) and the Principles for Responsible Investment (PRI) in response to the catastrophic tailings dam collapse at Brumadinho in Brazil. It proposes a range of measures including an engagement with projectaffected people at all stages of a tailings facility lifecycle, and linking remuneration to the integrity of dams. An independent expert panel takes into account the perspectives of local communities, civil society groups, regulators, investors, insurers and the mining industry in developing the standard.

“While there is still much work to be done before the standard can be finalised, ICMM’s membership is committed to engaging in an open and transparent discussion, and providing feedback through the consultation in order to ensure the final standard is both feasible and effective in meeting our shared goal,” ICMM stated. “I encourage all interested people to do the same.”

The public consultation was firstly done online via a survey, which was available in seven languages, followed by in-country consultations across mining jurisdictions in the northern and southern hemispheres. “The standard makes clear that extreme consequences to people and the environment from catastrophic tailings facility failures are unacceptable,” the draft standard reads.

New Century Resources processes tailings at the Century mine.

Five key trends influencing drone development in mining Drone technology is affecting the global metals and mining industry, with unmanned aerial vehicles (UAV) increasing in popularity in recent years. GlobalData’s survey shows that more than 200 mine sites have shown substantial uptake of drones across regions such as Australasia and Africa. Rio Tinto, BHP, Anglo American, South32, Alcoa and others have led the trend by adopting the technology. Drones are being employed to inspect mining equipment, which is an expensive and time-consuming process, requiring a highly-skilled workforce, according to GlobalData in its report ‘Drones in Mining – Thematic Research’. Aside from the UAV’s popular use

in monitoring and inspection, mines also employ drones and a drone pilot, instead of a piloted plane, to collect unlimited aerial data while saving around 90 per cent of the cost per hour. GlobalData also reported that one of the greatest challenges facing companies while managing stockpiles was their extreme height and area. “Drones can enable mining companies to generate aerial terrain models of the inventory. Further, deploying drones frequently could ensure companies consistently keep track of stockpile movement,” GlobalData said. The use of drones has also penetrated the haul road network, which GlobalData said needed to be constantly monitored. SAFETOWORK 10 JAN-FEB 2020

Drones can facilitate this process by collecting a large amount of aerial data, covering wide areas more precisely for assistance in planning, designing, construction and maintenance activities. GlobalData’s survey shows the use of drones extends to the measurement of tailings dams, which helps eliminate the risk of manual surveying. “There is no need for manual interference within the proximity of the dump when drones are around,” GlobalData stated. “By analysing the captured data on a digital platform, mining companies can maintain the structural integrity of the tailings dam, design expansion and avoid failure.”

Epiroc, Orica to develop semi-automated explosives system Orica and Epiroc are working to bring automated blasting to mines by 2020, as they join forces to develop a semiautomated explosives system. The companies are working together to develop a system that enables safer and more productive blasting operations in underground mines. Together, the companies will combine Orica’s wireless initiating system WebGen and Epiroc’s automation strategies in the first steps to achieving their automated drill and blast vision. The companies expect the first prototype system this year, with the first commercially available systems to come into service in 2021. “This promising collaboration with Orica is an important first step on an exciting journey toward automating the whole drilling and explosives charging process,” Epiroc senior executive vice president for mining and infrastructure Helena Hedblom said. “It is a vital part of both Epiroc’s and Orica’s vision of making the mining

operation as safe, productive and cost efficient as possible.” As mine operations go deeper and ore bodies become more remote, implementing blasting automation becomes more necessary to address the growing demand from customers mining in increasingly hazardous underground conditions. Orica chief commercial officer and technology officer Angus Melbourne

said the partnership would leverage the exclusive WebGen wireless initiating system to deliver the first crucial steps towards the automation of drill and blast operations. “Automation is a key pillar of our technology strategy and supports our vision of transforming drill and blast to unlock mining value by creating safer and more sustainable operations,” Melbourne said.

Epiroc is partnering with Orica to deliver blast automation.

Tech transition to disrupt jobs, boost safety Embracing technology in the resources industries could add $74 billion to the Australian economy by 2030 and create over 80,000 local jobs, according to a report commissioned by METS Ignited and National Energy Resources Australia (NERA). Australian Minister for Industry, Science and Technology Karen Andrews said the use of analytics and robotics provided significant safety and environment benefits, while rapidly increasing job opportunities. The report, which was prepared by consulting firm AlphaBeta, suggested potential job losses in mining and oil

and gas could be more than offset by an increase in employment in Australia’s domestic supply chain supporting those sectors. Job losses in heavy vehicle driving could potentially be replaced by increasing jobs in the primary firm, in the supply chain and the wider economy. The benefits also include workforce development and higher paid employment in digital technology enabled positions. These benefits would be lost to importers if Australian equipment, technology and services suppliers fail to support miners and energy

SAFETOWORK.COM.AU 11 JAN-FEB 2020

producers in automating their operations, the report stated. Australia’s domestic supply chain alone has the potential to generate an estimated $32 billion of benefits and 265,000 jobs from this tech transition. “This kind of technology opens up new, unexplored opportunities for the resources sector and what this report shows is the huge economic opportunity if new technology is embraced,” Andrews said. “The new jobs will be created across the country, including many in the regional areas where mining already exists, which will ensure the continued vibrancy of these communities.”

Products BLUNDSTONE GIVES WOMEN’S INJURIES THE BOOT Blundstone has launched a new range of safety boots specifically designed for women working across a number of trades. The boots bridge the gap between safety and style, providing support, protection and comfort for the toughest work sites. The women’s boots, which come in two styles; #892 and #897, build on the features of all Blundstone boots such as moulded TPU bump caps, built-in steel shanks, impact-resistant steel toe caps and rubber outsoles to increase slip resistance. The women’s models also include Blundstone’s XRD technology, providing repeated impact protection, absorbing up to 90 per cent of energy with every step taken. blundstone.com.au

STRATA SECOND-GENERATION MINER COMMUNICATOR Strata has updated its StrataConnect wireless system for underground communication, tracking, remote monitoring and control.

The second-generation communicator, or MC2, was redesigned and enhanced to simplify usability and expand the device functionality. Specifically designed for the harsh environments of the mining and tunnelling industries, MC2 provides users with two-way text communications, real way tracking and critical alert and response functions. Modelled on smartphones, the MC2 has a full, hard-button QWERTY keyboard, large display screen with multiple character sizes and an easy-to-use navigating system. Other features include one-on-one or group texting, access to a full contact list and data storage for up to 500 messages. For emergency situations, the MC2 provides critical alerts and response capabilities. The MC2 is available to buy now. strataworldwide.com

INDUSTREE DELIVERS EPIC TRILOGY SERIES Industree Group’s Morphlex gloves are designed for unparalleled performance based on workplace needs. This latest series of protective gloves are based on four key design innovations: Polymerix, a range of light weight fibres, thermally activated coating technology; TACT, which reacts to the wearer’s body temperature and adapts to provide a customised fit for workers; EPICFIT glove shaping technology to provide the most comfortable fit; and EPICFLOW, an engineered cooling system, allowing heat and sweat dispersion. These four design factors come together to bring Industree Group’s most comfortable and personalised fit of glove yet, while featuring the level C cut protection of its predecessor models. industree.com.au

SAFETOWORK 12 JAN-FEB 2020

SANDVIK RELEASES NARROW VEIN DRILLS Sandvik Mining and Rock Technology has released its latest range of narrow size drills, aimed for mining ores in veins three or less metres in length. The 2711 model drill is protected under falling object protective structures (FOPS) and has enhanced mobility and safety, particularly within small mining drifts and tunnels. Sandvik’s narrow size drills are equipped with fleet data monitoring systems, which enables remote operation, removing workers from potentially hazardous environments. The new model also features electro-hydraulic systems which can be used with Sandvik’s entire range of underground drills, loaders and trucks. There are three drill types available for different drilling methods: the DD2711 for development drilling, the DS2711

for rock support bolting and the DL2711 and DL2721 for long hold production drilling. www.rocktechnology.sandvik

CTRACK EN ROUTE TO SIGNIFICANT SAVINGS Ctrack’s latest product Ctrack Route is a routing and optimisation solution that improves time management and safety. Ctrack Route allows fleet managers to plan and optimise routes rather than doing this processing manually, which can save as much as half a day’s worth of time. The solution meets not only the needs of fleet managers, helping them to efficiently plan routes but also compliance requirements, both current and requirements anticipated in the future. Ctrack Route also allows for better time management across existing fleets, resulting in cost savings per route as well as the potential to use existing resources to make more deliveries. ctrack.com

VEGAPULS 69 MAKES ROCK CRUSHING SAFER VEGA has released its latest non-contact, continuous level measurement system VEGAPULS 69, which is a safe and versatile way to measure bulk solids for rock crushing. Placed above the crushing system, VEGAPULS 69 can accurately measure feeds to the rock crusher despite extreme noise and dust generation thanks to its high-quality signal focussing. VEGAPULS 69 has a measuring range of 120 metres, app integration and is available in two variants: a plastic antenna for lighter applications or a stainless-steel flange for heavier applications. VEGA believes the VEGAPULS 69 will offer improved cost efficiency, convenience and reliability for its operators. vega.com SAFETOWORK.COM.AU 13 JAN-FEB 2020

Products BOLLÉ ULTRA-PANORAMIC 180 GOGGLE Bollé Safety has launched its new ultra-panoramic 180 goggle, a combination of safety and comfort thanks to a flexible bi-material ventilated frame. The goggles feature an indirect vent that uses covered vents to increase air flow, providing better protection from splashed liquid and dust. As well as improved air flow, this model features Bollé’s signature platinum coating on both sides of the lens, giving it high scratch resistance and delays fogging beyond the minimum required standards. Providing all-round vision, the 180 goggles also feature a wide, adjustable strap, are compatible with respirator masks and fit over prescription glasses. store.bolle.com.au

FENNER DUNLOP CONVEYORS SAFELY TRANSPORT BULK The SADA Group contracted Fenner Dunlop to design a low-cost train unloading conveyor to safely receive and transport bulk materials directly under rail cars. Fenner Dunlop’s design incorporates two identical systems that operate in parallel, moving the product 4.5 metres vertically from the rail car, streamlining SADA’s unloading process. The train unloader conveyor is a safe and cost-effective alternative to traditional unloading methods, with its compact yet robust design that suits a range of material types, particle sizes and densities. With Fenner Dunlop’s unloader, SADA is able to deliver hassle-free solutions for every project without a hitch. fennerdunlop.com.au

X MARKS THE SPOT FOR DYNA CONVEYOR GUARDS DYNA’s high-density polyethylene (HDPE) conveyor guards are revolutionising conveyor systems. The new guards are 40 per cent lighter, easier and quicker to move, rust and corrosion free, chemical resistant and don’t require painting, making them a safer and more cost-effective alternative to their conventional steel counterparts. DYNA has implemented a unique X shaped design, increasing the guard’s strength up to 60 per cent more than standard guards, well above Australia’s minimum standard. Installing and removing the HDPE guards takes just minutes, reducing the amount of time spent around the conveyor system, which is considered one of the highest risk areas of a mine site, lowering the number of accidents occurring during maintenance. dynaeng.com.au SAFETOWORK 14 JAN-FEB 2020

GATES POWERGRIP GT3 BELT MAKES OPERATIONS SAFER Gates’ PowerGrip GT3 timing belt allows for safer resources operations, by minimising the likelihood of fires in refineries, where it is a high safety risk due to the products being processed. The GT3 belt is anti-static, meaning it does not cause sparks or damage on sites, taking one risk out of the equation when it comes to fires in refineries. Gates’ anti-static properties also mean there is no need for custom-made fire retardant as with other models. Unlike other rubber components which set off static charges, the PowerGrip GT3 belts are designed and built to limit all static activity, making them superior to the

conventional synchronous belts. The GT3, which is an update from Gates’ previous GT2 can last 12 to 18 months and requires less belting than previous models, while producing more power. gates.com

MOBILARIS LAUNCHES MOBILE RADAR FOR MINE SAFETY Epiroc subsidiary, Mobilaris, has launched Mobilaris Onboard, a mobile application that allows high accuracy positioning in underground mines without any positioning infrastructure. The technology acts as a mobile radar showing oncoming

traffic, while also making miners aware of the whole realtime situation in the mine. Mobilaris Hybrid Positioning allows users to know the position of a vehicle with five to 10 metres accuracy. The technology increases transparency and safety while decreasing traffic congestion by helping users avoid vehicles or giving miners warning when meetings occur. Epiroc global business manager Ulla Korsman-Kopra said Mobilaris had made large strides in terms of safety, productivity and smooth traffic flow by visualising the traffic situation from inside the cabin of vehicles and mobile mining machines. The Boliden Kristineberg mine was the first operation to adopt the Mobilaris Mining Intelligence system and it will be the first to upgrade to Mobilaris Onboard. mobilaris.se

GREASEMAX DELIVERS ELECTRIC MOTOR LUBRICATION IMPROVEMENT GreaseMax lubricators can significantly increase the reliability of electric motors. This continuous lubrication provides the best lubrication results and helps improve bearing life. Re-greasing the motor when it is running delivers a more effective and controlled result. Lubrication is a major factor when it comes to preventing bearing failure, which could lead to premature motor failure. Lubricants have a finite life so re-lubrication is essential for long-term motor reliability. Meanwhile, manual re-lubrication brings in human error factors, such as applying the wrong grease, too much grease, or lubrication being missed. Manual greasing also carries other disadvantages. It is often

done when equipment is stopped and the motor is cold. Under these circumstances, older and colder grease may block the entry of new grease into the bearing. The grease may instead go into the motor internals. With GreaseMax, bearing life is improved, and the possibility of excess grease being applied and contaminating the motor’s internals is reduced. greasemax.com.au

SAFETOWORK.COM.AU 15 JAN-FEB 2020

Emergency response

Cadia Valley operations team competes in the fire fighting category in the Victorian Mine Rescue competition. Image: Minerals Council of Australia.

Miners sound the alarm at Victorian rescue competition ANYONE PASSING YALLOURN MINE IN VICTORIA’S LATROBE VALLEY DURING OCTOBER MAY HAVE THOUGHT THERE WERE A NUMBER OF SERIOUS INCIDENTS OCCURRING WITH ALL OF THE CHAOS GOING ON. SALOMAE HASELGROVE EXPLAINS WHAT WAS REALLY HAPPENING.

N

o-one was actually in danger at the Yallourn mine – it was just the sounds of the 27th annual Victorian Mine Rescue competition. Nine mine rescue teams from Victorian and New South Wales operations visited the site to participate in a range of team competitions, including firefighting, first aid, search and rescue and rope rescue, all to improve their skills for real-life scenarios. While bragging rights were up for grabs, all of the teams were happy to share knowledge in their areas of expertise and embrace the opportunity to learn new skills from other mine rescue experts. Mineral Council of Australia (MCA) Victorian executive director

James Sorahan, who was running the competition for the first time, is extremely impressed with how seriously everyone took the range of highly realistic scenarios. “The scenarios are actually quite confronting, which is the aim of it, so it provides real life training,” Sorahan tells Safe to Work. “You’ll see people with blood, fake injuries and broken legs, so it’s very realistic.” The categories included safety, a fire exercise, first aid, ropes exercise, search and rescue, a skills exercise, theory and using a breathing apparatus. The event also gave the different types of mines an opportunity to excel. “There actually used to be a separate underground mine rescue competition and a surface mine competition, but

SAFETOWORK 16 JAN-FEB 2020

a few years ago they brought them together into just one competition,” Sorahan explains. “It’s great exposure to learn about all the sorts of emergency situations that can arise at the different mine types. “If you’re a coal miner, fire is much more of a risk than it would be for an underground gold mining team and for open cut mines it’s great experience to learn about underground emergency situations like the breathing apparatus scenario.” Exposing mine workers to safety training for different types of mines is also beneficial if they change careers or move to different sites with unfamiliar emergencies. The hands-on experience was supported with feedback from a team

of adjudicators, who assess the every move of competitors. They provide an oral and written feedback report after the competition, allowing teams to see what they do well and how they can improve. This year, miners also had the opportunity to learn not only about new scenarios, but from emergency services professionals and volunteers who attended the Victorian Mine Rescue competition for the first time in 2019. The mobile intensive care ambulance (MICA) paramedic team, Moe state emergency service (SES) and the country fire authority (CFA) Bendigo’s Oscar 1 unit all participated, while Victoria Police observed the competition. “There is actually a huge range of emergency services that need to work together with mine rescue teams, so that was also really useful for the mine rescue teams to learn from other emergency agencies,” Sorahan says. “The CFA in Bendigo is the only brigade in Victoria that is trained in underground mine rescue, so Bendigo and Victoria are really lucky to have a volunteer brigade with those skills.” This was particularly useful for the fire rescue scenario, in which teams assess the situation, work together to figure out how to put the fire out and treat any injuries. “The fire scenario is particularly spectacular and the other one that stood out to me was the first aid rescue,” Sorahan says. “The aim is for the teams to strategise how to put the fire out, what type of fire retardant to use and extracting people who have been injured in the fire in a safe way is part of the challenge. “In the first aid rescue there’s always a surprise thrown in, so as soon as they arrive at the scene something else usually happens during the rescue. “This year it involved a car accident on-site where somebody was thrown

through a window they had to locate and receive help from the SES part-way through the rescue.” The competition doesn’t just better prepare miners but also helps workers from other industries. For example, it provides realistic training opportunities for volunteer ambulance workers. “This competition counts as hours towards their professional development to keep their qualifications up to speed,” Sorahan says. “We’re really happy this competition provides this opportunity for some of the volunteers.” The competition also gives local communities piece of mind that the mines operating on their doorstep are safe. “Yallourn mine won the fire competition, so that’s really positive to give people in that LaTrobe Valley community the confidence that the coal miners are trained very well in dealing with mine fires, which is a critical issue at coal mines,” Sorahan explains. “When you’ve got coal mines sitting fairly close to town, the community appreciates the assurance that the mines are taking fires seriously and are adequately trained to deal with it.”

In addition to the wide range of different scenarios the miners face, there are many workers who volunteer to be a part of their mine rescue team, as anyone from diesel fitters to geologists can sign up. It’s not all serious though – the competition finishes on a fun note with the Spence Herd team building exercise. “The point of it is training, but being a competition certainly adds a fun element to it and also as a motivator,” Sorahan says. “The Spence Herd challenge is a bit of fun at the end of the long weekend, teams compete with each other in team building exercises and they really look forward to it.” With the chance to be competitive, meet new people and bring pride back to their mines, the MCA reinforces the simple but important message of the Victorian Mine Rescue competition. “Every worker deserves to go home safely, and mine rescue teams take any training they can do extraordinarily seriously,” Sorahan says. “You hope that they don’t ever need to use the skills they learn in the competition, but at least they are ready if something does happen.”

A Peak Gold Mines team member attends to a leg injury during the Victorian Mine Rescue competition. Image: Minerals Council of Australia.

SAFETOWORK 17 JAN-FEB 2020

Technology Hummingbird Electronics inclinometer screen display.

Technology made to save lives THE REDARC GROUP AND HUMMINGBIRD ELECTRONICS COMBINE THEIR UNIQUE POWER TO PROVIDE LIFE-SAVING SOLUTIONS. SAFE TO WORK WRITES.

A

bus was carrying a full load of fruit pickers from around the world when they were alerted of a safety emergency. The alarm was thanks to an audio alert system installed on the bus that could communicate and give a precise verbal command to its passengers in various languages. The rare technology not only captured their attention, but also uncovered the problem and guided them to safety. Vehicle operators often struggle to decipher a variety of warnings, lights and symbols that appear on their dashboard in the event of an emergency. These few seconds of confusion can be critical to the safety of passengers, and be intimidating to an operator that is trying to identify what the alerts mean. With the audio alert system from Hummingbird Electronics, which has been part of REDARC since 2015, the operator is clearly warned of a dangerous situation. The system is capable of transferring buzzes, alarms and lights – whether

they are positive or negative – into a voice output, making the operator aware of their situation. Warnings can also include instructions on how to rectify or respond to the issue quickly. Should there be a fire on a vehicle, the warning can tell the operator to evacuate. The verbal alerts may also point to low coolant levels, high engine temperature, open doors, an open tailgate, apply handbrake, apply seatbelt or roll over danger. Vehicle operators can even choose to have the voice of English comedian John Cleese or his Australian counterpart Dame Edna if they’re tempted. More importantly however, operators can choose to continue their operation with care or stop the journey if they are in a dangerous situation. “In the occupational health and safety (OH&S) side of things, there are often near-misses such as a crane being overextended and an excavator working on too extreme an angle,” REDARC Group national mining and industrial business development manager Scott Montgomery says.

SAFETOWORK 18 JAN-FEB 2020

“Without any form of warning for the operator, these situations can exceed levels of machine tolerances, and that’s when incidents happen.” The importance of these devices is demonstrated by the latest top line vehicles coming out with an audio system as a factory option, verbally reminding a driver to fasten their seatbelt, or informing them of high engine temperature. “A lot of the time during these situations, you can only see a warning light coming on the dashboard of the vehicle indicating that your engine temperature is too high,” he says. “Now you’ve got a verbal command saying, ‘Engine temperature too high, pull over.’” While operator safety is the key benefit of the technology, it can also save mining companies from incurring extra costs. A crane toppling over or an excavator working on too extreme an angle, and then falling on its side, will incur mining operators a steep repair cost and lost productivity with equipment downtime. Now the audio alert system gives

operators a safety luxury by doubling up its technology capability with a Hummingbird inclinometer, thanks to its compatibility with a range of Hummingbird products. The inclinometer produces a visible pitch-and-roll readout for operators and features configurable warning and alarm levels. Hummingbird’s Dual Axis Inclinometer – Elite – features advanced data logging capabilities, recording events with time, date and GPS location. This data can be used to analyse potentially dangerous conditions, or in the event of an incident, assists in evaluating the event. Montgomery says an inclinometer should be fitted on any machine that works on an angle or has a high centre of gravity. Small and large machinery in mine sites are particularly at risk, he adds. Larger machine operators can also choose to evaluate the angle of the road using a ball bank, which measures and allows for easy interpretation of roll angles up to 20 degrees. The screen will update roll measurement 10 times a second, and produce a visual warning when the roll exceeds a configured angle,

Installing an inclinometer on a machine can help keep operators safe.

prompting the ball bank to emit a sound all at once. The operator can also change the symbol displayed in the inclinometer according to the type of vehicle it’s installed in, such as an excavator, bulldozer and water truck, making the display relevant to the operation.

“Mine operators are generally pretty sensitive about safety. It’s interesting because when we first introduce this product to a mining client, they take interest,” Montgomery says. “They absolutely don’t need to wait for a big incident to happen before they take actions.”

Bespoke electronic vehicle safety solutions

Hummingbird Electronics are specialists in electronic vehicle and machinery safety solutions. We offer a suite of safety focused products designed to protect operators and equipment in the mining, civil, industrial, machinery hire and agriculture industries. Designed and manufactured in Australia to the highest standards, Hummingbird is a brand you can trust to improve safety on your worksite.

1300 155 541

Dual Axis Inclinometers

Audio Alert System

Silent Horn

We offer a range of digital inclinometers that provide machinery operators with highly visible pitch and roll measurements.

Our Audio Alert System provides clear, voice readouts for a range of customisable inputs, to serve as warnings and safety reminders.

Our Silent Horn is for machinery operating in noise-sensitive environments. Horn blasts are replaced with a wireless link, allowing for communication with no external noise.

24.6

38.4

DIGGER MODE

hmbe.com.au Hummingbird

Electronics

Electronic solutions for all vehicles

Tyre management

Innovating tyre management services underground KAL TIRE HAS PROVEN THAT TYRE MANAGEMENT IN UNDERGROUND MINING CAN BE AN INNOVATIVE ACTIVITY THAT IMPROVES THE SAFETY AND PRODUCTIVITY OF OPERATIONS. BEN CREAGH WRITES.

U

nderground mines usually fall way behind open pit sites when it comes to investment in tyre management services. Australia’s open pit sites are known to spend between $5-10 million a year on earthmover tyres. They also invest significantly in strategies that improve productivity and safety practices for workers that operate around tyres. It’s a different story at underground mines. Owners of most underground operations, in contrast, annually spend less than $1 million on their tyres. Many remote underground operations will also service their tyres in house and will not develop innovation that enhances their management practices. That’s not to say tyre management innovation isn’t possible in underground mining. Kal Tire Australia manager – sales and marketing Caleb Pullella says a number of opportunities have emerged that will improve underground mines. “The maturity of underground operations compared with surface sites just isn’t there yet when it comes to tyre management, but it

shouldn’t be overlooked,” Pullella tells Safe to Work. Underground mines have several unique attributes that make them a more challenging environment than most surface operations, reinforcing the importance of innovation. For example, fitters are often required to change a tyre on the spot of an incident, almost anywhere across an underground mine network. Fitters at surface operations, meanwhile, enjoy the luxury of moving equipment to a dedicated tyre bay or safe point to make a change. “In an underground scenario you could be in a stope or a work situation where the access to the machine isn’t great,” Pullella says. “The ground that they are working on often isn’t ideal for changing a tyre, but they can’t get the machine to a suitable location to work on it. “It is important to help them understand the dangers of changing tyres and have the workers certified, then they can make the change and understand the different risks underground environments pose.” Kal Tire works at underground sites, big and small, to introduce tyre management strategies

SAFETOWORK 20 JAN-FEB 2020

Kal Tire’s servicepeople analyse the impact that each underground site has on tyres.

for preventative repair and planned maintenance. As underground tyre changes compromise safety and slow productivity, Kal Tire helps mining companies ensure the rubber that goes to work is fit for the purpose and makes it to the next service. The Canadian company offers its Tyre Operations Management System (TOMS), a digital tool that reports on key performance indicators, and analyses and recommends actions on tyres and fleets, to support the service. TOMS has been developed to improve fleet uptime and

Kal Tire’s service team gives surface and underground sites the same focus.

productivity, but the tool can also help mining companies with predictive maintenance. Kal Tire also supports risk management with safety programs, processes and training, which is particularly helpful for smaller companies that might not have the scale to invest in their own systems. “We can provide a full solution to supply and manage all of their tyres and everything that surrounds the tyre and the wheel,” Pullella says. “Kal Tire is there to help them reduce the overall spend on the tyre, to manage them as an asset and look at them with that respect. “The programs are also set up to increase the awareness of tyres and safety around them. We will talk to the mine workers about how much each tyre costs and the impact they can have on operations when they are damaged.” Kal Tire’s servicepeople will routinely analyse the environment of each underground operation that they manage. This process enables them to identify issues affecting tyre performance and tailor preventative maintenance solutions that aid

safety and productivity. It also enables Kal Tire to find areas where innovation can be applied to underground tyre management activities. Kal Tire recommends that underground sites consider using battery-operated equipment so tyre teams don’t have to rely on mine air that can be distant or compromised because of condensation. “There is always air supply underground and you may not always have a service vehicle available when it is needed,” Pullella says. “Having battery-operated equipment certainly helps in this case

because you remove the potential for mine air with condensation, which can ruin your tools. “You can certainly access and perform all the work you need to with that sort of equipment.” Above all, Pullella stresses the importance of treating tyres as an asset that can have a major impact on the safety and productivity of an underground operation. “Tyres are not a consumable, they are an asset and innovation to improve the management of them is possible – if tyres are managed in that respect it makes a big difference,” Pullella concludes.

Underground sites offer unique tyre management challenges.

SAFETOWORK 21 JAN-FEB 2020

Eye protection

Insight into the importance of eyewear BOLLÉ SAFETY NATIONAL SALES MANAGER DAVE BYRNE SPEAKS WITH SAFE TO WORK ABOUT THE IMPORTANCE OF CHOOSING THE RIGHT SAFETY EYEWEAR FOR THE RIGHT JOB.

B

ollé Safety provides a range of safety eyewear, including glasses, goggles and face shields. For over 60 years, the company has dedicated itself to fashioning the ultimate in protective eyewear, focussing on innovative coatings and providing technological solutions to make the job as comfortable as possible, whether you’re working in a surface mine or deep underground. According to national sales manager Dave Byrne, roughly 20 to 25 per cent of work-related injuries are eye injuries, and the main cause is a lack of or inadequate protection. Using appropriate eyewear can prevent up to 90 per cent of

these injuries. So, if eye injuries are so preventable, why are they still happening? “The biggest problem with human nature is people will always take the quickest shortcut they can,” Byrne explains. “The issue with goggles is not everyone likes to wear them for a number of reasons. There’s a myriad of excuses why people think they shouldn’t wear them, such as it doesn’t look cool, it doesn’t feel comfortable, some people might feel claustrophobic or it blocks their vision.” This is why Bollé Safety has developed products that are not only safer but more comfortable than traditional safety eyewear, particularly

SAFETOWORK 22 JAN-FEB 2020

so with its new model, the ultrapanoramic 180 goggle. An improvement on the Pilot 2 model, the ultra-panoramic 180, as the name suggests, offers a better field of vision for users, making it suitable for mining work. With its flexible bi-material ventilated frame and Platinum antiscratch/anti-fog coating applied on both sides of the lens, 180 goggles can fit over prescription glasses and are compatible with a respirator half-mask. Bollé Safety also offers a range of lens solutions to suit the type of work being completed, for example a clear lens, which is suited to underground mining, versus a smoke lens for outdoor areas.

Bollé Safety’s ultra-panoramic 180 goggle provides all-over eye protection.

Bolle eyewear keeps workers across a number of industries safe.

Byrne warns workers, particularly in mining to not underestimate the damage dust can do to the eyes and it should be taken as seriously as other risks like chemicals. “When people are handling liquids or acids, they’re mostly aware they have to keep safety gear on, because they don’t want an acid burn or loss of vision,” Byrne says. “But I think with dust, people can be a little bit more relaxed, but there is still the risk of getting a ricochet or a foreign object going under or around the edges of glasses. “Goggles are more effective at protecting against hazards from entering the eye due to form-fitting facial seal. Especially when working

in the area where airborne dust and flying debris are present. “A goggle gives you a complete seal around the face so it’s less opportunity for particles like toxic dusts, aerosols, liquids and even gases to cause harm because unfortunately with traditional glasses, you can’t get that seal around the face to avoid these harmful substances.” Bollé Safety’s research and development has been based on its clients and how to improve its goggles for comfort and productivity. One of the main points of feedback Bollé Safety has taken on board is making goggles that can comfortably be worn over prescription glasses. Byrne urges those who wear prescription glasses to wear goggles over them as they do not provide the same protection as specialised safety goggles or to consider safety prescription glasses (such as Baxter and Twister sealed models) which provide sealed protection around eye sockets. As well as harmful liquids, gases and particles, Bollé Safety also has thermal risk goggles, which are suitable for people working around fire. To add to the range of different work goggles, Bollé Safety also offers various vent options, providing comfort for all kinds of environments. “In each style we have different variations on the venting and the reason behind that is we want to expel the

SAFETOWORK 23 JAN-FEB 2020

hot air or the humidity that’s building up within the enclosed goggle, out of the lens and keep that airflow through it,” Byrne explains. “There are some high volatile areas that do require the top vent closed to take the risk out of getting splash in the eyes from the top of the goggle. “By far, the most prominent model we have is the top vent open that creates that air flow through the goggle to keep your eyes protected but stop fogging.” Byrne says it is important to remember safety goggles are not a ‘one size fits all’ product and to weigh up what is the most comfortable for the individual. “This is where we start breaking it down and fitting down the person’s workload, products and chemicals to fit with the most practical product for them,” Byrne says. “People don’t really think about what it would be like to lose their eye or their vision, so it’s about making sure individuals are prepared to invest in protecting their eyesight. “Our eyesight is like an express highway in peak hour traffic, you’ve got all of this information coming through your vision into your brain, which is breaking all of that down. “Imagine if you lost your eyesight, what would that be like? It would be a pretty dark old spot.”

Prospect Awards

Mangoola CHPP innovation boosts safety record FOR A SITE THAT HAS NOT SUSTAINED A LOST TIME INJURY IN THE EIGHT YEARS SINCE OPERATIONS STARTED, GLENCORE’S MANGOOLA CHPP IN THE HUNTER VALLEY HAS DEVELOPED ONE SAFETY INNOVATION THAT STANDS OUT ABOVE ALL. BEN CREAGH WRITES.

Mark Colbourn (Flexco), Chris March (Mangoola CHPP), Scott Bannerman (Mangoola CHPP) and Shaun Egan (Downer) celebrate the win.

G

lencore’s team at the Mangoola CHPP (coal handling preparation plant) in New South Wales has demonstrated how safety improvements can be effectively introduced in response to a tragic incident. Mangoola CHPP’s asset management team developed a carefully-engineered solution to the difficult task of replacing the belly plates on an ABON chain feeder after a worker at another Glencore site was fatally injured while performing the task in 2016.

The now-proven safety initiative at the Hunter Valley site was rewarded at the 2019 Australian Mining Prospect Awards with the Flexco Excellence in Mine Safety, OH&S award. Typically, working space is restricted beneath the chain feeder, and ABON’s standard replacement instructions involve dismantling of the machine from the top down. The lengthy task requires the removal of the upper floor plates, the chain and flight assembly and then removing the belly plates once each of the former components have been removed.

SAFETOWORK 24 JAN-FEB 2020

It also involves multiple crane lifts and the associated interaction of personnel in that environment. There is also the risk of the belly plates binding within the frame, making it difficult to dislodge them and inviting excessive lifting equipment loads as a result. During the 2016 incident, the work group was slinging the belly plates from the top side of the machine using manual rigging equipment. Glencore believes the group was planning the execution of the task as they went to a certain extent and it

appears that the injured worker entered the area beneath the load. With all of the bolts removed and due to the angle of the rigging, it dropped and swung rearward, crushing the worker. The Glencore CHPP asset management team was faced with the prospect of conducting the same task two years later. However, the team was instructed to “devise a method to remove and replace these components with the absolute certainty that no person would be injured,” according to Mangoola CHPP manager Chris March. Led by Mangoola CHPP maintenance supervisor Scott Bannerman, the team spent nine months devising a method based around a hydraulic trolley mounted lifting table. The trolley travels on a rail system that allows the plates to be removed and railed out. The new plates are then railed in and lifted squarely into position without any personnel being exposed to suspended loads. Mangoola CHPP completed the task without injury or incident in October 2018, but continued to add improvements to make the task safer. With the design assistance of FLSmidth ABON, the Mangoola CHPP team improved the process further by manufacturing the replacement plates at a slightly narrower profile by adding ‘shim packs’ to eliminate the prospect of binding when the next change is required. This method also enabled work to continue above the top deck as it remained in place as a hard barrier between the workers below. It meant that critical bin liner work could proceed with nil risk or impact to the involved work party. Mangoola Coal operations manager Nick Slater is delighted that the CHPP asset management team’s

Operations at the Mangoola site.

“By using a combination of rail and hydraulics, we’ve been able to take our people away from areas of higher risk.” work has been acknowledged at the Prospect Awards. “The health and safety of our workforce is our number one priority and our CHPP team has done an excellent job in designing a rail and hydraulic system for one of the higher risk maintenance tasks at the plant – replacing chain feeder plates,” Slater says. Furthermore, the hot works that were initially required in preparation for the task are no longer needed for the next changeover. In total, the job took 36 hours to complete from start to finish. However, it is expected that this time will be reduced to 24 hours with the elimination of the hot works. March believes what sets the initiative apart is the diligent application of engineering in the hierarchy of controls to deliver not only a method that eliminates the risk of serious injury, but also adds productivity benefits.

SAFETOWORK 25 JAN-FEB 2020

“By using a combination of rail and hydraulics, we’ve been able to take our people away from areas of higher risk, as well as significantly reducing the time needed to replace the plates,” March says. Glencore has also conducted the task using the Mangoola CHPP methodology at another of its operations in the Hunter Valley with the same results. The award-winning initiative reinforces why Mangoola CHPP is recognised as an industryleading operation in terms of safety, productivity and environment excellence. “We have maintained a strong focus on safety at Mangoola. In fact, our CHPP team has not sustained a single lost time injury since we started operating in 2011,” March says. “These types of innovations are designed to help us maintain that record.”

Profile

Fleming’s epic plans for Industree

Industree’s new general manager Jon Fleming is welcomed to the company by managing director Jason Stenning.

INDUSTREE GROUP HAS ALWAYS FOCUSSED ON HAVING A SINGLE SOURCE SUPPLY BUSINESS MODEL. SAFE TO WORK SPEAKS WITH RECENTLY APPOINTED GENERAL MANAGER JON FLEMING ABOUT HIS VISION FOR THE COMPANY.

J

on Fleming joined Industree in August 2019 to fulfil his goal of developing a mediumsized business on New South Wales’ central coast, a place close to his heart where he has worked and lived since 2002. Industree’s business model is single source supply, another reason Fleming was eager to join the company, as its views resonate with his own goals as a business manager. The company is also proud to have been 100 per cent certified carbon neutral since 2011, offsetting its carbon footprint by providing low emission stove facilities to African locals, which significantly reduces deforestation. Moving to Industree also allows Fleming to work with managing director Jason Stenning, someone he notes to have admired and respected within the safety industry for some years. “Joining Industree was an opportunity

for me at a stage in my life where I felt like I’d achieved and learned a lot working for global companies,” Fleming tells Safe to Work. “My experience there stood me in good stead to take Industree’s mediumsized business and turn them into a really strong player in the personal protective equipment (PPE) space. “It’s a small, central coasted-based team of likeminded people leveraging our carbon zero approach and we want to achieve the company’s mantra: ‘solutions that don’t cost the earth’.” Fleming’s time in the safety industry dates back to 1990, when he started out with global manufacturing company MSA Safety, selling products such as breathing apparatus equipment, thermal imaging cameras and gas detection products. “That’s where I really cut my teeth and started to learn about the industry to then be able to share those insights to add

SAFETOWORK 26 JAN-FEB 2020

value to customers,” Fleming says. After seven years with MSA, Fleming was promoted to a state manager for the company’s Victorian and Tasmanian offices for the manufacturing, oil and gas and construction sectors. He moved to Sydney in 2002 then left MSA in 2009. After more management stints with companies including Brady Corporation and Bunzl, which included consolidating a number of businesses into the latter, Fleming joined uvex Safety in 2017. From there, Fleming was hungry for an opportunity to lead a safety and PPE business within his beloved central coast community, when the opportunity to join Industree came up. “I really enjoy it, you wouldn’t be in safety for 30 years if you didn’t enjoy it,” Fleming says. “Being on my own terms now, being an equity shareholder in the business and choosing the types of projects we go

after, it’s become even more pleasurable.” Since joining Industree, Fleming has been busy with the company’s latest project, launching the EPIC Glove Trilogy series, including the EPIC Morphlex cut 5 level C glove. This model includes Industree’s key design innovations for the best possible performance; Polymerix light weight, high cut resistance fibres, EPICFIT glove shaping and design for optimal fit and ergonomic comfort and EPICFLOW, a purpose engineered cooling system for sweat and heat dispersion. The EPIC Trilogy series also features TACT (thermally activated coating technology), which reacts to the wearer’s body heat and adapts to the individual’s hand shape for a more customised fit for every worker. “This has been a massive project for us, we’re excited to deliver it for our clients,” Fleming says. “There has been a lot of interest around new cut protection standards and new technology and there is a lot of evidence in the marketplace that our customers are seeking higher rated cut protection gloves that are as dexterous and lightweight as possible. “They’re looking for that holy grail of high level cut protection yet wanting the feel of almost not wearing gloves and still demanding their gloves perform on the job across a variety of applications.” This project has led to another major achievement for Fleming in his first few months with the company; Industree forming a preferred distribution partnership with ATOM, a first for the company. The partnership’s primary focus will be on ATOM distributing the EPIC range but Industree is also eager to assist ATOM with its community engagement fund, which supports Indigenous employment and charities. “Our new partnership is firmly built on joint interests centred on social, environmental and safety

Industree has launched the EPIC Glove Trilogy series, including the Morphlex cut 5 level C glove.

programs,” Fleming says. “In particular, Industree Group praises ATOM on their work to further Indigenous programs such as their expected $500,000 a year ATOM community engagement fund, to support Indigenous engagement programs and cancer charities. “This is something Industree Group will be keen to support as our partnership evolves.” Industree is also in the process of developing other PPE products, such as cut protection cargo pants and safety eyewear, but it isn’t the products Fleming wants to change in the long term; it’s how and where they are made. “I have an active interest to one day achieve developing and promoting Australian-made safety products,” Fleming says. “In the mid-term we’re not quite there yet but I do believe deep down that it is possible for a company like Industree, with the right technologies associated with the right product, to produce in Australia. “If I could do that in the next two years, I’d be proud and so would our company.” While Industree is still manufacturing in India, Taiwan, China, Korea, Malaysia, Pakistan and Vietnam, it has strict

SAFETOWORK 27 JAN-FEB 2020

regulations to ensure its workers are not being discriminated against, such as guaranteed hygienic conditions, living wages and no child labour. “Social responsibilities for our manufacturing sites are not just a fad for us,” Fleming says. In his short time with the company, Fleming has already achieved the launch of a major product and shared his goals with the company and has already been endorsed by his fellow staff for making a positive impact on the team. “Morale has always been good at Industree but since Fleming joined us there’s been a noticeable lift in everyone’s efforts,” Industree group marketing manager Mike Yanco says. “The team is pleased we have gained such an experienced businessman who knows exactly what he is doing and wants to be a part of the ride.” For Fleming, he wants to continue to grow the business and brand recognition, while working towards his eventual goal of production within Australia. “I feel like we are the best kept secret in PPE. Right now, my path is to try and create a strong recognition in the industry as a brand, continue providing a premium range of product while continuing to achieve solutions that don’t cost the earth,” Fleming concludes.

Risk management Social licence again topped the EY global risk list.

Licence to operate Australia’s biggest risk ALMOST HALF OF GLOBAL MINING COMPANIES RANK LICENCE TO OPERATE AS THE BIGGEST ISSUE FOR BUSINESS IN THE TOP 10 BUSINESS RISKS AND OPPORTUNITIES 2020 REPORT. BUT WHAT IS AUSTRALIA MOST CONCERNED WITH? SALOMAE HASELGROVE INVESTIGATES.

W

ith more than 150 global mining executives surveyed for the Ernst & Young (EY) report, spanning across every major mining region, this is the second straight year it has ranked licence to operate as the biggest concern. But what is Australia’s view on the global scale? According to EY Oceania mining and metals leader Scott Grimley, Australia’s perspective is extremely significant globally, so it is closely aligned with the rest of global opinion. The top 10 has changed in recent years, which Grimley attributes to the high-level of distraction by public

opinion regarding the Australian mining industry. Grimley worries the Australian public has less of an understanding of the industry than in decades past, meaning there is negative but misinformed commentary on the industry as a whole. “It used to be the case that pretty well every person in Australia had a family member or someone else they knew working in the mining sector,” Grimley says. “This is not the case now, so large amounts of people don’t know anything about the industry, this is especially so for those living in urban areas. “These people have a negative but very loose perception of the industry,

SAFETOWORK 28 JAN-FEB 2020

and miners recognise there are many people with a negative perception of their work, hence licence to operate continuing to rank highly. “The Australian public don’t understand how fundamental mining is to everyday needs; whether it’s the house you’re living in, the transport you’re using to get to work every day or in the mobile phone you’re using. These items all come about because of commodities that need to come out of the ground that are accessed by mines.” Grimley believes the mining industry needs the support of the Australian public and government to back it as a key industry, ensuring it has the required capital to invest in technology

to support innovative mining solutions. Jumping from seventh place to second in the report was future of workforce, as companies struggle to determine how the workforce might look in years to come, especially with the rise of technology at mine sites. Technology is clearly another worry on the radar, as digital and data optimisation rounded out the top three in the survey. Grimley urges miners to embrace technology and views it as something that creates more jobs within the industry, not the reverse. “There’s quite a bit of unhelpful rhetoric around the fact that technology and automated machines are doing people out of jobs, which is simply not the case,” Grimley says. “The need for people running mines in this new world is likely to increase, not decrease, looking at the jobs and roles based on technology implemented in the next 10 years or so, 70 per cent of roles will be enhanced or redesigned because of technology. “The people already working at the mine are the best to retrain, because they already know the business, they know the industry and there will be a range of jobs for them, they just need to be willing to adapt.” Grimley says while there will be less of the traditional jobs associated with

mining, such as driving trucks and physical labour, there will be a range of new jobs, not just within the technology sector, but also in communications. He believes these roles are essential in keeping workers in the know of how the mine is operating. There were four new risks ranking in the top 10 this year: reducing carbon footprint (fourth), high-impact risks (fifth), cyber (seventh) and replacement of production (eighth). Grimley says miners are already taking steps to reduce their carbon footprint, both for environmental reasons and out of necessity. “The focus on investigating any form of renewable sources of energy is being explored,” he says. “Renewables can be mobile and positioned remotely which is a real benefit for miners, for example, solar is definitely fitting for the 40-degree days up in the Pilbara. “The other form being explored is electrification, moving away from machines and kit operated on diesel and moving towards equipment that runs on batteries and electricity. “We’re seeing miners explore that in terms of looking to build underground mines completely based on equipment running off electricity, not dissimilar to the move around batteryoperated cars.” Despite the underlying risks that

Top 10 business and risk opportunities in the mining industry n

Licence to operate

n

Future of workforce

n

Digital and data optimisation

n

Reducing carbon footprint

n

High-impact risks

n

Maximising portfolio returns

n

Cyber

n

Replacement of production

n

Innovation

n

Rising costs

* Gathered in the Top 10 Business Risks and Opportunities 2020 report.

come with technology and public perception, Grimley is optimistic for the future of the mining industry. “The industry is best in class in a number of technical advancements, as well as the economic importance, jobs and value provided not only through the mining industry, but the supporting services to the industry,” he says. “Selling the message of the fantastic opportunities for jobs, growth and the boom mining provides regional areas is critical.”

Replacement of production emerged in the latest list.

SAFETOWORK 29 JAN-FEB 2020

Workforce management

Safety reset spurs return to top priority NEARLY 50,000 WORKERS HAVE BEEN THROUGH QUEENSLAND’S SAFETY RESET FOLLOWING A STRING OF TRAGIC MINE AND QUARRY INCIDENTS IN THE STATE. SAFE TO WORK WRITES.

Break out session at the Grosvenor mine during safety reset.

Q

ueensland’s first ever safety reset has reached more than 98 per cent of the state’s mine and quarry workers. State Minister for Natural Resources, Mines and Energy Anthony Lynham launched the reset last July in response to six fatalities in Queensland over a 12-month period. This decision was widely backed by mining and services companies, which immediately worked with government and industry bodies to implement the plan. Anglo American, one of Queensland’s leading employers, has unsurprisingly taken the reset seriously, given the company’s extensive involvement and government

discussions around safety in the state. The size of Anglo American’s workforce and operations clearly doesn’t deter the met coal giant. Its entire 5400-strong workforce has taken part in the reset by completing over 50 sessions across its sites. “Despite significant improvements, we still have not been able to eliminate fatalities from our industry,” Anglo American metallurgical coal business chief executive Tyler Mitchelson tells Safe to Work. “This is something we are focussed on every hour of every day, and at every level of our business.” With Anglo American senior leadership teams leading the sessions at its mine sites, the company’s safety reset focussed on an end of

SAFETOWORK 30 JAN-FEB 2020