Hire

Australian Designed and Built industry leading VacLifts and Pipe Handling systems deliver more features and benefits than any other machine available. Made by Pipeliners’ for Pipeliners’. Your machine or ours, our extensive range of VacLift equipment covers from poly pipe to large diameter steel pipe weighing 15Tonne.

We can engineer a solution to suit your project needs

Not just a hire company, our extensive industry experience will match the best equipment to your project needs. We are continually adding new machines to our fleet broadening the type, range and quantity.

Fully Equipped Heavy Plant Hire ONE CALL - PROBLEM SOLVED 1300 367 046

www.pipelineplanthire.com.au

CEO John Murphy

COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITORIAL

Clemence Carayol clemence.carayol@primecreative.com.au

Vivien Topalovic vivien.topalovic@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

Nick Lovering nick.lovering@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

Kerry Pert, Louis Romero

COPYRIGHT

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

The Australian Pipeliner brand comprises: a quarterly magazine, a news website, a fortnightly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

3,300+

magazine subscribers

16,500+ e-newsletter subscribers

20,000+ website views each month

13,700+ social media followers

Head Office 379 Docklands Drive, Docklands VIC 3008 Ph: +61 3 9690 8766

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry.

The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

Ok, can we hold up…we are already half-way through the year and there is still a ton of stuff to do. Not that we haven’t achieved already as an industry. Two large pipeline projects have come to an end; FMG’s Iron Bridge Project and APA Group’s Northern Goldfields Interconnect (NGI), Kurri Kurri, Port Kembla, Big Lake, The Western Outer Ring Main (WORM) all in full swing, plus a host of other projects we are getting busy on.

It is work that brings us together but it’s the people that make our industry. The Annual Convention in Perth from 14 to 17 October 2023 is coming up. This year’s theme is ‘Power of the Present, Force of the Future’. I know I don’t have to sell it because you know how the magic happens when we all come together.

So, this is a plug to get in early and get your early bird discount. More monies to spend at the coffee shop if you buy now, and with it being in Perth you should really plan and get in a few side trips like Busselton, Margaret River, or Rotto if you have the time. Should you go to Margaret River, I’ll gladly have you bring back a sample or two for me from the ‘coffee shops’ down there.

The focus for this edition is Women in the Industry - a topic dear to my heart because well, I am a woman. I have been very fortunate in my career to work with some amazing people of both genders. But in truth, the delivery of equality in the workplace, and mentoring has all been organic.

This edition will deep dive into how different companies are more formally managing this and how we can nurture and support safe spaces to grow and excel. For businesses, part of the model is also understanding the value of the return of these programs have, and how it might translate to your own business, or the one you work in, might make for interesting reading.

Other topics in this edition include features on pipelayers and side booms, integrity, safety, fabrication, transport, logistics and social license.

Continuing the conversation on the energy transition, I recently read a Bloomberg report that details for Australia to reach it commitments to the Paris Agreement 2oC, carbon capture and storage (CCS)and renewable gases are needed to achieve it, but we must gain policy support.

It is only one analyst’s point of view, but this report says that without it, on the current economic transition pathway, by 2050 our climate landing will be 2.6C°. We all want Australia to reach net zero by 2050 so why would allowing pathways that include ‘carbon originating’ projects make sense?

Put simply, there are industries that can’t decarbonise without it and if we want to maintain our quality of life that has come about since the industrial revolution and get to net zero at the same time, then they’re needed in our energy mix.

It's hard for those not in our industry to wrap their head around this but somehow, we need to bring the paths back together as we are all wanting the same goal. APGA has had some recent media success in changing the conversation around renewable gases and our policy team is working hard for our members in this space.

Lastly, a big shout out to Dean Bennett who has decided to leave APGA to pursue a role back in industry on the business development side. He joined APGA when events took a complete u-turn on themselves with COVID-19 changing the way people want to, and have time to, engage. We are still figuring it out in part and any thoughts on this, please talk to myself or one of the Secretariat.

As I said earlier, getting together is where the magic happens, and it is what makes our Association unique from any other. Outsiders feel it when they enter our family. Let’s work together to keep that. We wish Dean all the best in his next adventure, but at least we got him back from Canada!

I look forward to seeing you at the next event.

ABN: 29 098 754 324

APGA Secretariat Registered Office: 7 National Circuit, Barton ACT 2600 (PO Box 5416, Kingston ACT 2604)

T: +61 2 6273 0577

E: apga@apga.org.au

W: www.apga.org.au

Chief Executive Officer

Steve Davies

Corporate Services Manager

Michelle Wickson

National Policy Manager

Jordan McCollum

Communications Manager

Lawrence Shelton

Engagement Manager

Dean Bennett

Membership Officer

Katy Spence

Events Coordinator

Matthew Freeborough

Policy Manager

Catriona Rafael

Government Relations Manager

Paul Purcell

DONNA MCDOWALL APGA PRESIDENTReference 1. ‘New Energy Outlook Australia’, Bloomberg Finance May 2023

TURNKEY ENERGY INFRASTRUCTURE SOLUTION PROVIDER

CAPABILITIES

Pipelines

Renewables

Defence Facilities

Power CSG Gathering

nacap.com.au

+61 3 8848 1888 (Melbourne, Head Office)

+61 7 3328 8800 (Brisbane)

+61 7 3029 1111 (Brisbane, PNG Project Office)

+61 2 6884 7878 (Dubbo)

+675 321 1001 (Port Moresby)

◊ TRANSMISSION PIPELINES

◊ CSG GATHERING AND WELLHEAD CONNECTIONS

◊ ABOVE GROUND AND BURIED FACILITIES

◊ REFINERY FACILITIES INCLUDING BROWNFIELD SITES

STRIVE TO BE BETTER

Energy has come out on top in this year’s Federal Budget, with the government investing a further $4 billion in Australia’s plan to become a renewable energy superpower and help burgeoning its renewable gas market.

Outlined in the announcement on Tuesday, 9 May, the government’s total investment to becoming a renewable energy superpower has exceeded more than $40 billion.

Among these, is the $2 billion Hydrogen Headstart, which aims to accelerate large-scale renewable hydrogen projects for the nation and bridge the commercial gap for early-stage projects, and position Australia to be a world leading hydrogen producer and exporter.

The Australian Pipelines and Gas Association (APGA) warmly welcomed the $2 billion allocated to the Hydrogen Headstart as it will aim to help further develop Australia’s burgeoning renewable gas market.

“Through this Budget, the Federal Government has demonstrated that renewable gases like hydrogen and biomethane are an important part of Australia’s holistic decarbonisation strategy,” said APGA Chief Executive Officer Steve Davies.

“As of today, the only organisations producing and delivering green hydrogen to Australian businesses and homes are gas infrastructure companies, and the industry has strong

The Northern Territory government has announced the finalisation of the regulatory framework for gas production in the Beetaloo Sub-Basin.

All 135 recommendations of the 2018 scientific inquiry into hydraulic fracturing

have been finalised, enabling safe and sustainable development of the basin.

“Having considered the system reform undertaken as a complete package, the NT Government is now satisfied that the risks identified by the inquiry have been sufficiently mitigated and is confident that applications for onshore petroleum production licences may now be accepted for consideration by the new regulatory regime,” the Final Implementation report concluded.

Deputy chief minister of the Northern Territory Nicole Manison announced the final report and outlined the benefits of the developing the sub-basin.

“Along with our world-class renewable resources, our highly prospective onshore gas resources will support our energy

SA Water has started installing around 990m of new water main at Port Vincent to prepare future growth for the area.

The new pipe is part of SA Water’s four-year $155 million water main management program and is being laid beneath Lime Kiln Road, Kent Road, Alma Street and Correll Street.

SA Water General Manager of Sustainable Infrastructure Amanda Lewry said the works will involve upgrading a key section of pipe which transports water to residents and businesses around Port Vincent.

“Replacing water mains which are nearing the end of their operational life with new pipes made of modern materials minimises the

potential for leaks and breaks, which can happen due to a variety of reasons such as the condition of the soil, temperature of the ground and water pressure changes,” Lewry said.

“As regional communities see population growth, demand for services, including water and wastewater, are increasing.

“We’re planning and preparing for this future growth to ensure we can continue to provide reliable services to our regional customers.

Lewry said SA Water's water mains have a lifespan of up to 100 years.

The majority of what it installs is part of its replacement program which is made of PVC. This material is known for its flexibility and

interest in working with third parties to share our insights and help facilitate the adoption of renewable gases rapidly and at scale.”

security during the transition to renewables – and will improve living standards for all Territorians,” Manison said.

The Australian Pipelines and Gas Association (APGA) voiced its support of the decision, indicating the commercial and environmental benefits of the move.

“These projects in the Beetaloo Basin will deliver much-needed supply to gas-power generators, which work in tandem with renewables to ensure the NEM is secure, and energy prices are affordable,” APGA chief executive Steve Davies said.

“The rapid but necessary exit of coal-fired generation, combined with delays to Snowy Hydro 2.0, makes clear the role that gas needs to play to keep the lights on, and gasfired generators need dependable and affordable supply in order to fulfil that job.”

resistance to movement, compared to fibrocement. Construction is expected to take nine months to complete, with works occurring Monday to Sunday between 7am and 5pm.

HDI Lucas has shared information about the Chatswood Sewer Amplification Project it delivered as part of Sydney Water‘s Sewerfix Program in 2003.

To this day, this project still holds one of the Australian records for an inclined bore by horizontal directional drilling (HDD) technique – 1830m in length at a 1 per cent positive grade.

The Chatswood Project comprised a network of new street sewer lines and a new sewage main which needed to be a gravity main to avoid pumping stations. Trenching was virtually impossible because the route follows Victoria Avenue, the area’s main East-West artery. Sydney Water originally proposed a mix of HDD and microtunnelling.

HDI Lucas was responsible for the design,

construction, and installation. While this would have achieved the same outcome, the community impact would have been unacceptable – requiring pits up to 17m deep, 6m long and 2m wide, which would have created lengthy noise, safety, and traffic problems.

A single 1810m directional drill, eliminating the need for pits along with their risks, congestion, compensation, and liabilities, was proposed as a solution by HDI Lucas. Although longer and more precise than any other HDD gravity sewer installation in the world, HDI Lucas was confident of its solution and provided comprehensive engineering analysis and demonstrated its experience in many of the world’s longest HDD sewer and water installations in Sydney, the Blue Mountains and Hong Kong.

Australian engineering services company Verbrec is set to carry out the pre-feasibility study for the Mid-West Shared Infrastructure project (MWSIP) in Western Australia (WA).

Awarded by the Australian Gas Infrastructure Group (AGIG), the study will develop a costing model associated with the development of infrastructure for the export of iron ore, from the Yilgarn region of the Mid West of WA.

Funded by Mindax Ltd and in part AGIG, the study will specifically cost the capex and opex of a base case shipment of 30 million tonnes per annum (MTPA) of magnetite iron ore.

It will also include factored estimates for 60 and 90 MTPA in order to verify a

robust business case to further develop the infrastructure bringing high quality magnetite from the Yilgarn, to market. The pre-feasibility study will also include

the work areas of energy and power, concentrate transportation, return and top up water, end of line facilities, port, and marine.

We have the tools, electrify everything: this is the catchcry of many energy decarbonisation advocates. But the scientists at the Intergovernmental Panel on Climate Change (IPCC) disagree. The science is in – and electrify everything is out.

The recent IPCC Assessment Report on the Mitigation of Climate Change indicates that far from electrifying everything, a diverse and interconnected energy system is needed to limit global warming 1.5°.

As the preeminent international authority on climate change, the IPCC regularly assess and reports on mitigating climate change. Chapter six of the most recent Sixth Assessment Report goes into detail about how the global energy system is anticipated to change across four net

zero emission scenarios.

Not one of the IPCC scenarios proposes 100 per cent electrification of energy demand for any sector.

In fact, IPCC scientists anticipate that electricity use will account for less than 50 per cent of final energy use on average in 2050. Far from being an absolute conclusion, this average sits amongst a range that spans from 30 per cent to 64 per cent of final energy demand across all four scenarios. Not even residential and commercial energy demand is anticipated to fully electrify in IPCC net zero scenarios. Counter to much public commentary, the IPCC also sees a substantial quantity of natural gas remaining in net zero 2050 scenarios. While on average gas use declines to half that of today, IPCC uncertainty on gas use is substantial, with scenario outcomes ranging from 10 per cent to 115 per cent of current natural gas demand in a net zero energy future.

This large natural gas use appears to stem from lower-than-expected estimates of hydrogen utilisation and virtually no mention of biogas or biomethane. This is despite the European Union targeting 35 billion cubic metres of biomethane supply and 20MT of hydrogen supply by 2030.

The IPCC’s conclusions follow in the footsteps of the 2021 International Energy Agency (IEA) Net Zero Emissions Roadmap which clearly depicted a net zero energy system with a diverse array of no- and low- emissions energy sources.

The IPCC could foreseeably transition to even lower levels of fossil fuels with greater

consideration for renewable gases as was seen in the 2021 IEA report which identified renewable gases as the backstop to possible shortcomings of a future carbon capture and storage industry.

Time and time again, when the international climate and energy scientists project pathways to achieving net zero emission ambitions, the conclusions far from advocate for electrifying everything.

Instead, international climate and energy scientists advocate for measured action to create resilient energy systems which are supported by a diverse combination of energy sources.

Much like the resilience of today’s energy system has been secured by a diverse combination of energy sources, the net zero energy system of tomorrow will also need a breadth of supply options to be resilient. Yes, the science is in – and electrify everything is out.

Intergovernmental Panel on Climate Change Climate Change 2022 Mitigation of Climate Change (Assessment Report 6) available at https://www.ipcc.ch/report/ar6/wg3/

downloads/report/IPCC_AR6_WGIII_ FullReport.pdf

The global leader in the measurement, quantification, and reduction of methane emissions.

PIPELINES

Over the past year, there has been significant investment in Queensland (QLD), with many projects improving energy and water security as the state moves towards a renewable future.

In early 2023, the Federal Government pledged $70 million to support the development of a renewable hydrogen hub in Townsville. Similarly, the Australian Gas Infrastructure Group (AGIG) received development approval from the Gladstone Ports Corporation for its hydrogen park site in Gladstone.

In other energy investment news, construction began on a new Queensland SuperGrid Link between Cairns and Townsville as part of the Queensland Energy and Jobs Plan.

As for pipelines, the state’s government officially signed off on funding for the Toowoomba to Warwick Pipeline, supporting more than 400 jobs in the southwest regions.

Comet Ridge and Jemena reached an agreement for a new gas pipeline connection from the Mahalo North Project into the domestic gas market.

The competitive Townsville Region Hydrogen Hub program will deliver funds towards projects that accelerate the development of a hydrogen industry in North Queensland.

Prime Minister Anthony Albanese said that a thriving hydrogen industry in North Queensland would be critical for Australia’s push to becoming a renewable energy superpower.

“The hub will help secure jobs and economic growth in Queensland, delivering on one of our key commitments, and could also pave the way for exports to our valued trading partners in Japan, South Korea and across Asia,” Albanese said.

The new project is set to deliver up to 10 per cent by volume renewable gas blended with natural gas to local businesses and homes connected to AGN’s Gladstone gas distribution network.

AGIG Chief Executive Officer Craig de Laine said it is an important step in decarbonisation.

“This is an exciting project that raises the benchmark for the domestic hydrogen industry of the future, building on our experience of safely and reliably delivering blended renewable hydrogen to our customers,” de Laine said.

“Hydrogen Park Gladstone is the first step in delivering the low carbon future of domestic gas supply in Queensland.”

Backed by $40 million in local Government funding, the publicly owned Powerlink project will upgrade part of the existing 132 kilovolt (kV) coastal transmission line to permanently operate at 275kV capacity.

Minister for Energy, Renewables and Hydrogen Mick de Brenni said the new SuperGrind Link improves renewable energy reliability for North Queensland.

“This Queensland SuperGrid link between Cairns and Townsville will improve the reliability, security and affordability of energy supply to North Queenslanders, and unlocks up to 500 megawatt (MW) of additional renewable energy capacity on this third circuit to the far north,” de Brenni said.

“It means we can pump more renewables into the Queensland SuperGrid and create more good jobs in our publicly owned energy system for workers in North Queensland.”

The new pipeline will carry raw water from Wivenhoe Dam and connect with Toowoomba Regional Council’s existing water infrastructure to deliver water to Warwick and will be an opportunity to deliver treated water to the Toowoomba region communities of Cambooya, Greenmount, Nobby, and Clifton.

The pipeline also provides drought contingency for residents of Southern Downs Regional Council.

Premier Annastacia Palaszczuk said the cabinet had locked in the final funding amount of more than $370 million.

“This is fantastic news for the people of Western

Queensland, with a pipeline of good, quality jobs just around the corner,” Palaszczuk said.

“We know that water security is vital to these local economies, as well as the liveability of our Queensland communities.”

In addition to the pipeline, the funding also includes upgrades to the Wivenhoe Pump Station to boost existing capacity, construction of new water treatment facilities to service communities along the pipeline route, and installation of network monitoring to reduce losses and improve water security for Southern Downs.

As part of the memorandum of understanding (MOU) and a preliminary front-end engineering and design (pre-FEED) agreement, Jemena will immediately undertake a pre-FEED study of a high-pressure gas transmission pipeline of 73km from the Mahalo North Gas Project to Jemena’s Queensland Gas Pipeline.

Jemena Managing Director Frank Tudor said the agreement is a key step in providing regional Queensland with additional gas.

“The announcement means we will be able to leverage our experience and understanding of regional Queensland to conduct a pre-FEED study with a view to constructing a 73km pipeline which is capable of delivering around 25 terajoules of gas per day to the domestic market,” said Tudor.

“It is also good news for local communities in regional Queensland who stand to benefit from an influx of jobs and local contracts throughout the planning, construction, and commissioning of the proposed pipeline and broader development as part of Comet Ridge’s Mahalo North Project.”

Growing from installing 10km of high-pressure pipeline from a gas field in the 1920s to becoming a leading global contractor in pipelines and associated facilities, Spiecapag is celebrating 100 years of constructing gas pipelines in 2023.

Being a leader from the early years, and able to remain at the forefront of the industry certainly helped, as does our global presence, which can open exciting doors for our staff to work on. Many innovative approaches to project construction learned on one continent have been quickly applied elsewhere, and have continually honed our methodologies.

Many of us can imagine a not-too-distant future involving hydrogen and other future fuels, and we are seeing projects designed with larger and heavier pipelines, pushing the welding away from manual and into auto welding. That plays to our strengths.

The Australian Pipeliner sat down with Spiecapag Managing Director John Walsh to talk about the significant milestones over the past 100 years, the changing landscape of the industry and where the company is heading.

In the late 1800s and early 1900s our founding company SPIE was best known for constructing electrical metro tram lines and railways. In fact, that’s the origin of the name – the “IE” is for industrialisation and electrification.

In 1923, it expanded into other infrastructure projects, building France’s first high-pressure gas pipeline. While it was only a 6-inch line running about 10km, the pipeline connected France’s first onshore gas field development at Vaux en Bugey to the nearby town of Ambérieuen Bugey.

Over the decades, SPIE continued to play a major role in European oil and gas pipeline construction, and in 1977, it merged with CAPAG, another well-known pipeline constructor who had been active in pipeline construction since the 1930’s and became SPIECAPAG. Eventually, we dropped the hyphen.

Our reputation is being the constructor who gets the challenging projects built.

Looking back at projects across the world, the 42-inch and 46-inch AGT pipelines for BP (BTC and SCP) in Georgia and Azerbaijan (2002-2006) saw Spiecapag crews crossing

mountains at 2500m altitude in temperatures as low as -30 degrees C, and over very steep terrain.

Subsequent projects such as the Trans Adriatic Pipeline in Albania and Greece, as well as the recent Coastal Gas Link pipeline across the Rockies in Canada, show we don’t shy away from a challenge.

Coming back into our region, just to Australia’s north, the 1990’s Kutubu oil pipeline and the 2013 PNGLNG gas pipeline opened up hydrocarbon export in Papua New Guinea (PNG). These were built through some of the most varied and challenging terrain imaginable, and at a time when there was no supporting infrastructure or road networks in PNG – true pioneering construction.

Our first project here was the Sydney-Newcastle Pipeline in 1982, where a major focus was minimising the environmental impacts on the Hawkesbury River. Since then, we have seen lots of open trenching and trenchless construction projects across the country. There were plenty of other challenges, and many working on the project will remember the rocky sections and some of those steep sections with large boulders.

We delivered several other large projects including the 756km Tenneco pipeline (SouthWest Queensland Pipeline) in the 1990s, which was memorable for its hundreds of kms of rock. Other milestone projects include the SEA Gas pipeline in 2004, entailing 687km from Victoria to Adelaide, which was commissioned and online just days before an incident at Moomba cut the original gas supply line to Adelaide.

We have been delivering large auto-welded gas pipelines for over 30 years and understand the stringent requirements and the logistical challenges to build pipelines to this standard.

We also play an active role in pipeline standards and research. It makes sense to understand and participate in how pipelines are likely to be designed in the future, because that allows us to be ready for when they are built.

You mentioned future fuels, is this where do you see the industry heading?

I don’t think anyone can say with certainty where the industry will be heading short-term, but gas is certainly part of that. On other fuels, there are trends, but also lots of challenges to be resolved, and which technology proves the greatest scalability, affordability and reliability is yet to be confirmed. That said, longer term we can see greater

volumes of gases being used in low-carbon mobility and increasing use of emerging nonhydrocarbon fuels.

Supply and demand could drive an increase in import terminals to ease shortages seen on the east coast, specifically in the southern states, although government intervention through artificial price controls is having an impact on that. Without oversimplifying it, it makes sense that Australia continues to play to its strengths while incubating future export industries and net-zero technologies such as carbon capture and sequestration, and demonstrates its support for gas exploration and production, as consistency on that front will send the right signals to investors.

Longer term there is an ever-growing number of hydrogen and/or ammonia projects all around Australia taking advantage of cheap renewable energy and the potential high value export markets in our region.

Throughout all of this, our population continues to grow, and that means that not only energy needs to be transmitted, but also water, and Australia has plenty of challenges on that front too.

It’s a fascinating time for our industry, and we are excited to be part of that. We prize our local and global experience building all kinds of pipelines for utilities and dom-gas/LNG, and hope that will serve our clients well as we explore this path in the coming years, decades and, dare I say it as we celebrate our first 100 years, centuries ahead.

We are currently weathering a perfect storm - An aging workforce departing the industry

combined with a post COVID-19 boom resulting in an influx of new staff, which results in a skills shortage and has the potential to impact project safety. Working through this is an unerring focus for us.

The workforce challenge is compounded by how the hydrocarbons sector is negatively perceived in some quarters, reducing the potential graduate pool. We are thankful that our global presence allows us to draw on highly experienced experts from around the globe to support our projects and mentor the next generation of pipeliners in Australia and our region.

While uncertainty can be caused by many factors, in pretty-much all scenarios in the global fuel mix, Australia can continue to play an important role in producing low-carbon fuels. That said, there is a cycle to our industry, and short-term dips in investment have always been a factor, so we are thankful to be active across several sectors including energy, water, utilities, and future fuels, using a variety of methodologies including horizontal directional drilling. This allows us to retain and develop the skilled teams we need to deliver major projects as well as continue to develop capable staff.

Our vision is centred on the concept of “Build Better Together”, the same concept that drives our parent company, VINCI Construction.

Build: We share a passion for building, finding solutions and delivering infrastructure for communities. This guides us in developing our staff, utilising cutting edge innovation, and sharing our experiences to improve.

Better: Our constant focus on continual improvement because you can always find a better way to do the job.

Fostering a culture of autonomy and trust, empowering the projects to make the decisions that are needed.

Together: Because people come first. Whether it is focusing on our employee’s safety and teamwork, or our clients to ensure positive outcomes, or the wider community, delivering a legacy that lasts long after the project construction has completed.

Our communities in Australia and our region, are growing, and these three simple words will work well to serve our ambitions as a company, an industry, and a broader community. Let’s Build Better Together the world we live in.

To learn more visit www.spiecapag.com.au

The Women in Pipelines Forum (WPF) was established as an outcome of the APGA Women’s Leadership Development Program, with the purpose of promoting the collaboration, contribution, celebration, and empowerment of women in the pipeline industry across Australia and New Zealand.

Since its official launch at the APGA Convention in 2021, over 150 women have joined the Forum. The WPF consists of many subcommittees which include our Development, Research and Advocacy committees, as well as state-based committees.

All of these committees are led by amazing women in our industry. Here we introduce two of our stars - Elizabeth Wheeler and Siew Shan Foo.

Elizabeth Wheeler: Lead Project Engineer NSW, APA Group (Brisbane), Chair of the WPF Advocacy Committee

What’s your role in the Pipeline industry?

I’m currently looking after a team of project engineers who deliver complex Stay-in-Business projects for APA’s NSW assets. We keep the assets improving and growing so that APA can continue transmitting energy across the East Coast.

Why did you join the industry?

I’ve been in the industry since graduating from university in Canberra, when there was a strong recommendation from my pipeliner father to apply for an open position at APA.

What do you love about your job?

I love the people in the Engineering and Planning team, and my own team. I love getting out and seeing the country we live in and serve.

What drew you to the WPF?

15-odd years of experiences (many stories) being a Woman in Pipelines with no organised network for us. As soon as I heard about WPF I was in without hesitation.

What do you hope to achieve in your subcommittee?

I want to advocate for all the women in our industry to make working in Pipelines a diverse and safe career choice for all people, to the point that we no longer need advocacy within the industry, and we can join our colleagues

advocating for the industry.

What do you do in your spare time?

I have two young daughters and a never-ending laundry basket! I love spending time with my family doing absolutely anything.

Siew Shan Foo: Engineer –Facilities Gas Distribution, Jemena (Sydney), Chair of the WPF NSW subcommittee and member of the WPF Development Committee

What’s your role in the Pipeline industry?

I am a facilities engineer at Jemena, the largest gas distributer in New South Wales. I am responsible for all our high-pressure stations in NSW and ACT, ensuring gas is supplied to our customers safely and reliably, whilst maintaining asset integrity. I provide asset management, engineering and technical services to the business.

Why did you join the industry?

I have always been interested in Mathematics and Science, so Engineering seemed a logical career to pursue. I was recruited by the Natural Gas Company for their graduate program whilst completing the final year of my Engineering degree. I was thrilled to join an industry that directly impacts so many people’s lives and have never looked back. With the increased focus and rapid advancement in renewable energy, it is an exciting time to be in the industry.

What do you love about your job?

I love the variety of tasks I undertake as part of my job. One week I could be driving out to the regional areas doing risk assessments on our assets, the next I could be in the office developing Engineering Assessment for a project, reviewing design documentation etc. I love that after 20 plus years, I am still learning and growing.

What drew you to the WPF?

Joining the male-dominated industry back in the 90s as a shy female engineer, I understand what it is like to feel a little out of place. The WPF provides a unique environment for women in the industry to network, collaborate and grow.

What do you hope to achieve in your subcommittee?

In the NSW sub-committee, we coordinate events to bring women in the industry from NSW together, to network and to learn from each other. We have already had a couple of successful networking events. Moving forward, on top of networking events, we are looking to get involved in social initiatives (such as promoting uptake of STEM among girls in school) as well as site visits.

Since its launch, the members of the WPF has organised networking events, attended development sessions, launched an industry research project, and created material for raising the profile of women in the industry. If you would like to join in, please get in touch.

The leading innovator supplying cutting-edge integrity solutions. Together we can ensure sustainable decision-making. Our combination of advanced inspection systems and expert consultants delivers a comprehensive understanding of asset safety, lifetime, and performance.

The Women in Industry Awards recognise outstanding women from a range of industrial sectors. The Australian Pipeliner talked to some of this year’s winners and what it means to work in a predominately male industry.

Taking place on 8 June 2023, women were put in the spotlight and recognised for their achievements and skills in the resources, transport, manufacturing, engineering, logistics, bulk handling, rail, construction, and infrastructure sectors.

The Women in Industry awards comprised of 11 prestigious categories.

This category recognises an individual who has created new growth opportunities that has allowed their organisation to expand and generate greater revenue. The winner this year is Stefanie Frawley from TMX Global.

This prestigious category singles out an individual who has made a positive contribution to one of the many facets of the construction industry. This year’s recipient is Trudy Grimshaw (Department of Finance, Western Australia).

“It's a real honour to be able to deliver services to the community,” Grimshaw said.

“It's an absolute delight to see so many young women up here and to see how our industry is moving forward.”

This category recognises an individual who has shown leadership in engineering, technological excellence and innovation.

Meet this year’s winner, Elsa Antunes from James Cook University.

“This isn’t just about women, it is about how we are making an impact in this society,” she said.

This award is about recognising an individual who has thought ‘outside the box’ to implement an outstanding personal contribution to their manufacturing business and the wider manufacturing community. Kristi Riordan from Harvest B is this year’s winner.

“Thank you to Women in Industry for your 2023 awards night, and the work you do to recognise the important role of women across highly technical industries,” she said.

“Moments such as this re-energise me with the potential for the future we can create.”

This award singles out an individual who has made a positive contribution to one of the many facets of the mining industry. This year’s winner is Ashara Moore from BHP, who said this wouldn't have been possible without her team.

“I have a fantastic team of engineers working with me” Moore said.

“I couldn't be here without them today.”

This award is all about recognising an individual who has gone above and beyond to improve and positively impact the Australian transport industry.

In 2023, this special individual was Coralie Chapman (Humes Concrete Products).

“I hope that instead of saying this industry is male-dominated, which can sound threatening, and especially for young women, we can change it to predominantly male," she said.

“If we can learn to change our language when we're talking to women and to younger people in the industry, I think it's a big step towards getting more women into any predominantly male industry.”

This category is about singling out an individual who has helped shape a positive view of their industry and/or helped to create a policy change that benefits those working in the sector. Jemma Walshe from Fulton Hogan was the most-deserving recipient of the award this year.

Walshe thanked her co-workers and her mentors upon receiving the prestigious award, adding she wouldn’t be there if it wasn’t for them as well as their ability to strive and push everyone to do better.

“I just want to say a big thank you to the leaders that I look up to,” she said.

This category recognises an individual who has demonstrated a commitment to developing female talent within their organisation or wider industry. Meet Teagan Dowler (The BCW), this year’s Mentor of the Year.

“I just want to thank every single person who has believed in the work that we do to support

women in our industry, and particularly in the personal development space and the mentoring space,” she said.

“I do want to do a special shout out to all of the other finalists because your work is so impactful in creating change in this industry.”

This is about recognising an individual who has shown significant promise within their chosen industry or who has reached new goals at the start of their career. Sophia Kurianski from Jinolo is this year’s award recipient.

“The one person I'd really like to think in this whole journey is my mother, because she has just shown me the incredible example of a strong female leader both in the workplace and in normal everyday life,” she said.

“I'd like to say thank you and congratulate every single woman in this room. You're doing really amazing things and I'm just so honoured to be in a room full of such amazing women in this industry.”

This category recognises an individual working actively to improve safety for their industry.

This year’s winner is Giselle Phillips from Fredon QLD.

“This is a celebration not only for me but for the team as well because we are making change in our field,” said Phillips.

“Advocate for yourself. If you don't have a seat at the table, I recommend you create a seat at the table.”

This year’s Woman of the Year is also the remarkable Giselle Phillips from Fredon QLD.

Upon receiving this most prestigious award, it’s with emotion that Phillips thanked all the women in the room and in her life.

“I have advocated for them, I have listened to them, and we're all in the same boat” she said.

“We are not in competition with each other. We are needing to advocate and help each other to get where we need to be.

“So, this [award] is not only for me, but this is also for every woman that is in the room.”

Australian Mining, PACE, Manufacturers’ Monthly, MHD Supply Chain Solutions, Prime Mover, Inside Construction, Waste Management Review, Inside Water, Rail Express, Roads &

Infrastructure Australia, Energy Today, The Australian Pipeliner, Trenchless Australasia, Quarry and Australian Bulk Handling Review are partnered to acknowledge the exceptional women who have achieved success through their invaluable leadership, innovation, and commitment to their sector.

All pictures were taken by photographer James Thomas.

program, who have found useful tools in expanding their skillsets.

In addition, ERIAS has benefited from the career experience of their senior staff, such as ERIAS Principal Julie Crawford, who has extensive resource industry experience across multiple commodities.

She has led remote teams to deliver environment, health, safety, and community functional excellence. Much of Crawford’s experience has been working in remote locations in predominantly male industries.

Crawford first joined ERIAS in 2022 to lead the multi-disciplinary field teams for the Papua LNG export pipeline pre-construction surveys in the remote Gulf Province of Papua New Guinea. Here, she leads teams of up to 30 local, environmental and social scientists.

Across her extensive career within the energy and resource sectors before joining ERIAS, Crawford has experienced many challenges with gender inequality.

“About eight years before joining ERIAS, as a member of a senior management team, male members of the team would exclude me from several social events,” she said.

“In the first instance they redirected me to another task in another location, subsequently, I found out about the event occurring and thereafter there was no attempt to conceal activities that were specifically designed for the men to enjoy.”

While this was not her only experience of gender inequality, Crawford said it has brought her a long way, to a more positive environment at ERIAS.

ERIAS is an environmental and social impact assessment consulting business that has recognised that diverse teams bring value to an organisation.

Fostering an inclusive work culture is a company imperative. As a result, ERIAS strives to empower and create an inclusive environment for all staff by promoting gender equality and respect across their workplaces.

Gender equality is something that is broadly recognised across ERIAS as a key to success and has been encouraged organically within the business.

In particular, the streams of environmental and social sciences embrace a sense of nurture and natural gender balance, which has resulted in a spread across the business of 57 per cent females and 43 per cent males.

The company has a number of senior female role models, providing its graduate and junior staff with the opportunity to work with female mentors and scientists who, in turn, foster the development of graduates.

The Australian Pipelines and Gas Association’s (APGA) Women's Leadership Development Program (WLDP) provides a much-needed framework for developing female leadership within the pipeline industry. For ERIAS, it has provided an opportunity for women to network and develop skills that has enabled their continued development and success in their careers generally.

ERIAS has embraced the WLDP from the outset and enrolled several of its female leaders in the

“I have 19 years’ experience working in remote areas which historically have had low female participation rates,” she said.

"ERIAS has a great gender balance, and I have received off-site support by talented women.”

In her role, Crawford manages the field survey programs, with each being a month long and involving significant jungle treks to collect scientific data.

“Upon commencing the role in PNG my family raised concerns for my safety based on media reports of kidnapping, remoteness, lack of females on site, and camp living,” Crawford said.

“Remote working in camps can feel like an extended family where the values of respect trust and genuine care are practiced.

“Such camps can be very protective of such culture and if this is threatened, those that disrupt the harmony are quickly called out.”

ERIAS Group’s Julie Crawford, Melanie Brown, and Luci David share their career experiences and how theAPGA women’s

leadership program has shaped them as leaders and inspired future trailblazers.ERIAS team take time out from export gas pipeline pre-construction environmental surveys in the Gulf Province, PNG. ERIAS pre-construction environmental and social survey team comprising ecologists, botanists and archaeologists.

Crawford said this is how she views her current base, as it encompasses a diverse and accepting environment.

“I have never received (and voiced) so many daily ‘good mornings’ accompanied by a big smile,” Crawford said.

“When I return from break, the good mornings are replaced by ‘Hey Julie, welcome back!’ and fist bumps.

“It is a sense of belonging and every human has that need for belonging and purpose. I have conveyed this to my family and alleviated their concerns.”

Seeing the positive outcomes of the program, ERIAS will continue to rely on the APGA WLDP and engage with staff to effectively listen and act to cultivate an inclusive and empowering work environment.

A positive experience taken from the program is through ERIAS Principal Melanie Brown, who praised the program’s tailored experience of growth.

“Unlike any other leadership course I’ve done, the WLDP really does go with the flow, which is its

strength,” Brown said.

“The program has helped me grow into my own brand of leadership and find connections with other women who I know will continue to support each other beyond the program’s completion.”

ERIAS Principal Luci David attended the inaugural APGA WLPD and enjoyed learning from the experiences of other leaders.

“The program has helped me to reflect on the type of leader that I am, the type of leader that I want to be and how this affects the way I work,” David said.

“I have been able to draw on many aspects of the leadership program in my roles both within project teams and within ERIAS.

“I have really valued being part of an expanding network of women who have been involved in the program.”

Through these fruitful experiences, the ERIAS employees who attended the program have opened a constructive dialogue to engage with management on discussions to develop the careers of female employees of the company.

Like many businesses and organisations that make up the APGA membership, ERIAS will

continue to work to foster an inclusive, respectful work environment that supports equality in all respects.

Key to this is fostering a culture that provides a safe workplace in all regards, where equality is fostered, such that we can look forward to a time when equality and respect are universal norms, and these conversations are a thing of the past.

The vacuum excavation company has a remarkable and valuable team of women helping make James Vac Solutions what it is today. They sat down with The Australian Pipeliner to chat about their daily life in the industry.

James Vac Solutions, founded in 2021, is all about putting women first – the company’s owner and Director is a woman herself.

Dannielle James is her name. With her now husband Jason James, they decided to start their very own directional drilling company 10 years ago.

“In 2013 we started Pipe Pro Drilling which is now a leading rock drilling company in Victoria,” she said.

Jason was at that time a directional driller on the same roster as Dannielle (working together in FIFO roles in the Pilbara, WA), their passion for the pipeline industry cemented their will to embark on this adventure together.

“During this time, we invested in a vacuum excavation truck to work alongside our drilling crews to safely identify and locate underground services and dig in more sensitive areas where traditional excavation methods could not,” Dannielle said.

“As more and more people began to see the benefits of our vacuum excavation truck, they started to enquire about hiring.

“As we were using it every day, Jason and I saw a gap in the market where we could hire out our services.”

In 2020, Jason set out with the help of local mechanics to custom build a larger 10,000L vacuum truck. By the end of 2021 it was ready to start work. That was the genesis of James Vac Solutions.

“Since then, with the help of our Manager, Jim Mackay, we have grown our fleet to six vacuum excavation trucks and our street sweeper to meet the ever-growing demand for our services in Western

Victoria,” Dannielle said.

In her 13 years working in the pipeline industry, Dannielle has seen it evolve for the better.

“In the beginning I did not know any other women and as much as I would have loved to employ more women a decade ago, I wasn’t seeing any applying for the jobs we were advertising,” she said.

“I started following organisations such as National Association of Women In Construction (NAWIC) and Tradeswomen Australia just to network and connect with other women in the industry as I felt very isolated.

“As time has gone on, I am seeing many more women in roles across all sectors which makes me really proud as a woman and for the younger girls coming through school seeing that a career in civil construction is possible.”

Pipe Pro Drilling and James Vac Solutions are both success stories, thanks to their owners and directors’ unwavering passion for the industry.

Pipe Pro Drilling won two awards in the commerce Ballarat Business Excellence Awards. One in 2017 under the innovation category, and one in 2018 when it won an award for excellence in trade. James Vac Solutions was also recognised, winning the Commerce Ballarat Award for Excellence in Trade in 2022.

“In 2019 I personally won the NAWIC Victorian Businesswoman of the Year award,” Danielle said.

“Asides from the awards, I am most proud of the businesses Jason and I have created, and the opportunities we have given people.”

For her, being a woman in this industry is all

about trusting yourself and other inspiring women gravitating to it. Be confident and recognise your worth,” Dannielle said.

“If you are passionate about a career in civil construction, then do work experience or seek out other women already in the industry to act as mentors.”

And Dannielle surely knows how to surround herself with smart, dedicated and skilled female co-workers, such as Stella Boots the Office Administrator at James Vac Solutions.

Boots has been working at the company since May 2022, and it is her first position in the pipeline industry.

So far, her experience has been nothing less than positive and insightful.

“It’s interesting to increase my knowledge of all the types of work that our company undertakes,” Boots said.

“I have found my male co-workers friendly and easy to deal with.

“It is satisfying to reflect on how much I have learnt in regard to vehicles, equipment and job concepts.”

For Boots, women are assets in the pipeline industry, as they bring with them invaluable skills, remarkable expertise, and new ways of looking at the industry.

She said women have so much value to add to this industry.

“My view is that the workplace is safe and

participate in this field of work hopefully the more the role will be reflected back for other women to join.”

Georgia Crow, Vacuum Truck Operator at James Vac Solutions, said that working for the company had always been a positive experience.

“It has been very good, I really enjoy working with and getting to know all the guys and girls,” she said.

“They are already fun, easy-going and enjoyable to be around.”

Crow is proud of having passed her truck licence, because according to her, it is one of her biggest achievements as a woman in the industry.

She is also proud of realising that she is doing “pretty good” at her job and getting more and more confident in doing tasks by herself.

“Not only was I confident in doing the job by myself, but Jim Mackay, Fleet Manager at Pipe Pro Drilling, also believed in me,” she said.

Crow’s advice for women who are considering joining the industry is simple: go for it.

“I think if you enjoy working outdoors, don't mind getting a bit muddy and enjoy giving the boys a run for their money, then there's no harm in trying something new,” Crow said.

For more information visit www.jamesvacsolutions.com.au

Tell us a little bit about yourself?

Hi, I’m Megan, I’m a cartographer and a mum of three and that’s pretty much my whole life. I joined Warren King and Company (WKC) in 2010, while studying cartography, the job was advertised at my university. Now 13 years on I'm still relatively in that the same job. Although the company has changed names a few times, and I’ve had a few different positions, WKC is now Veris Australia. I have been working with the same people for a long time, and that’s mainly the reason I stay, the people at Veris are great to work with.

As I was studying the job started out as only

part time, one day while having a chat to the general manager he offered me a full-time position instead of continuing my studies. As I was a single mum at the time the idea of not studying sounded great, so I jumped at the opportunity.

Now I am the Drafting Lead - Technical and Pipelines. I am now the only pipeline drafter in Veris Australia.

I originally got into pipelines because of a mentor at WKC, Michael Arriotti, an old school drafter. He was seen as a grumpy old man who teased relentlessly all who tried working with him, but he took a liking to me. Because of that,

I was able to work one on one and learn from his 30 plus years in the industry. That mentorship built out my career in the pipeline space.

What was your favourite project?

Originally at WKC we worked on pipelines all across Australia, so I can’t think of one specifically. The ones that stick out are because of the team and the client that I worked with. Having a strong relationship with clients and a clear scope allows you to get on and do the job to the best of your ability, it's a real winner.

Recently, I worked on the East Perth Power

Station (EPPS) Relocation project, with Enscope it stands out as an enjoyable job because of those guys over at Enscope.

East Perth Power Station –tell us more.

EPPS for myself was completed late last year, I believe the project itself is still ongoing, my involvement was part of the relocation of a gas line. There was some complexity to the project when we had to consider all the variables of going through a very built-up area in East Perth and the many other services that ran through the same area. But working with friendly, smart, and good people makes even the stressful projects worth working those extra hours and days to get the job done well and quickly for them.

I got involved circumstantially when I came back from maternity leave in 2016, WKC had just been sold and was now on its way to becoming Veris. With the change in management, all the social clubs I had been part of historically had been dissolved. Wanting to still be a part of the social scene and I was looking for something to do to get out of the house and meet people.

I had attended Young Pipeline Forum (YPF) events previously as a guest of a previous WKC colleague so I knew they were a good time. I emailed Jeffrey Sneglar who back then controlled the YPF mailing list to see how I could join the YPF and perhaps help out with events.

James Matison was flagged about my interest, as he was the chair at the time, he was more than happy to assist and invited me to my first YPF meeting so yeah, that's how I got into the community. Since then, I have also joined the APGA WA Chapter Committee at the bimonthly meetings they hold with the YPF and I started volunteering for some of the APGA events they hold. Taking photos, greeting guests, that sort of thing helping out wherever I could. I officially joined in 2022 and sit on that committee as secretary.

How did you get involved and become chair?

I got more involved by attending the meetings, which are in themselves a bit of a social situation as well. Once a month we get out, have a chat. Over the years, I started doing more and more slowly everyone who had been there before me, running things, started to leave, James and Jeff left, eventually I moved up into the chair position. I've held the position of chair the last two and a half years.

Why the longevity, why stay so long?

I'm not an engineer by trade, but most others are, and I have been able to learn a huge amount that has progressed my thinking in this space. It is wonderful to get out and have an intellectual conversation, while getting to know someone new.

What do the committees offer as a budding pipeliner?

The YPF, it’s just a great way for young members to, especially when just starting out, to get them excited and interested in the industry and more involved. By being a part of the committee, even just the community of pipeliners sitting on that committee with you, you get so much from that you would not otherwise. Being kept up to date

on what’s happening in the industry, knowledge and updates on regulatory and policy issues, and how changes in the industry affect you.

Do you do you feel that the being part of the committee's has added a different dynamic to your career?

Yes, positive. Having this as an avenue in my career has helped me both with my personal development, pushing me out of my comfort zone.

Those that know me will understand how much I hate public speaking, and would rather much be in the background, being part of the committee has allowed me to develop that skill and while I still don’t like it, I am getting much better at it.

Being pat of the committee has also opened channels for me in my career, giving me access to people and organisations that I would not have had otherwise, especially on the East coast.

Most recently, internally my contribution through the committees has been noticed and my profile has benefited as a result of the work I have put in.

What would you tell anybody that's looking to join a committee?

Do it! Come along to the meetings, volunteer to participate, learn from the experience. It has been a great benefit to me, even just the opportunity to get out of the office once a month and have an intellectual conversation with like-minded people.

As the pipeline industry moves towards a more inclusive employment approach, there is still work to be done when it comes to retaining older members of the workforce.

While some progress has been made in reducing ageism in recruitment, a recent report from the Australian HR Institute (AHRI) has suggested that some employers are still reluctant to employ older workers.

Titled Employing and Retaining Older Workers, the report found that only a quarter of the nearly

300 human resources (HR) professionals surveyed were open to hiring people aged 65 and above “to a large extent”.

In comparison, 85 per cent of surveyed HR professionals said they are open to hiring from younger labour pools to “a large extent”, including people aged between 35 and 49.

Peter Norman Personnel is a recruitment agency servicing the engineering and utilities sectors.

Kate Cuic, a Recruitment Manager specialising in contractor and staff placements for pipeline projects, shared her expertise with The Australian Pipeliner.

Cuic said that employers are doing themselves a disservice by not considering older workers.

“Many older employees offer the skills, experience and wisdom that businesses need, especially when paired with next generations for project delivery as well as for the overall development of work force diversity in each sector,” Cuic said.

“Having a work culture that supports older members of the workforce can lead to many benefits for a business such as improved productivity and client satisfaction.

“Businesses need to shift their perspective on stereotypes and embrace the fact that we are now in a time where people will work into their older years.

Research has also shown an increasing number of older workers re-joining the workforce.

According to federal government, by 2050, more than four in ten individuals in the world’s most advanced economies are likely to be older than 50.

“In our experience in the pipeline industry, we’re already there and have been for a long time because of a shortage of early career talent,” Cuic said.

“However, the sector is reaching a coming of age and now we’re faced with attrition of many mature age workers who could provide the experience that complements the skillsets of younger workers and can bring a positive influence on the workplace,” she said.

“Employers need to take advantage of this trend to address any talent gaps – particularly as the overseas talent tap was turned off in the last few years and we have seen dramatic changes to workplaces, technology and government policies.”

In fact, the four greatest advantages of recruiting

older workers in 2023 are seen to be experience, professional knowledge, age diversity and reliability.

However, for those employers who are willing to consider older candidates, the research from AHRI indicated that there are many ageist practices embedded within the recruitment process.

A total of 49 per cent of HR professionals said recruitment practices at their organisation negatively impacted older workers.

According to the AHRI report, initiatives to support older workers to remain in employment have fallen across several areas.

Fewer respondents reported organisations are offering career planning, training, development opportunities and flexible working hours.

“There are many specific initiatives that have proved to be positive in both recruitment and retention,” Cuic said.

“For employers, the Workforce Australia Services Wage Subsidy provides a financial incentive of up to $10,000 to encourage businesses to hire and retain eligible employees aged 50 years or older.”

Cuic said the Skills and Training Incentive provides up to $2200 to fund training to help employees build upon their skills to remain in the workforce.

There is also an online mature age hub that provides resources and assistance to both mature age workers and job seekers.

On the other hand, 50 per cent of respondents noted that their organisations offer flexible work locations, something which may benefit older workers.

Other measures however, such as elder care leave, grandparent leave, and specific digital capability upskilling appear to be limited across the board.

These results reinforce the need for employers to make jobs more appealing to older workers.

Ultimately, Cuic said the path forward is for employers to amend their recruitment practices and remain open to providing flexible working and development initiatives.

“Employers can future proof their businesses by providing flexible workplaces and opportunities to grow for mature age workers,” Cuic said.

“In our experience, the pipeline industry has

generally benefitted from the longevity of baby boomers.

“The nature of work is evolving, so the time is right for reinvention to harness the benefits of an age diverse workforce,” she said.

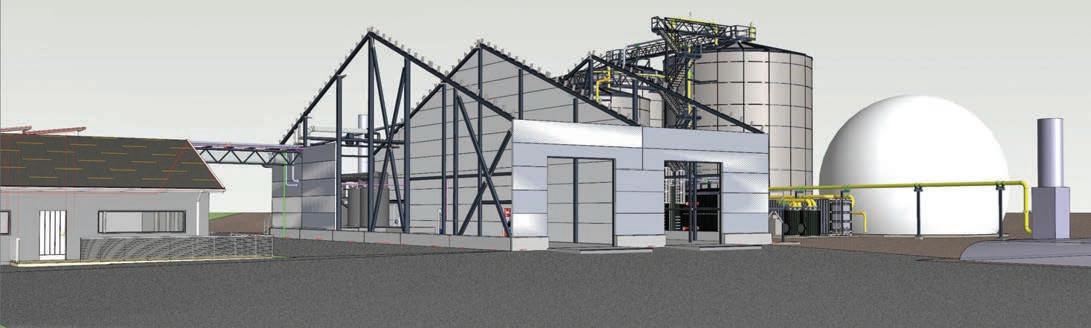

One of the leading building software providers, Vertex, is behind G4Plant, a versatile design software for all plant suppliers working with large plant models.

The G4Plant software is based on powerful functions that allows users to build an intelligent plant model in an illustrative and streamlined fashion.

In 2013, Finnish environmental engineering company, Watrec implemented the Vertex G4Plant and Vertex Flow software solutions to assist in the design and build of biogas plants. A biogas plant uses waste as its raw material, which was then digested, resulting in the

production of biogas and fertilisers.

Approximately two-thirds of biogas is methane and one-third is carbon dioxide, and can be used as fuel for heat production or burned in a gas engine to produce heat and electricity.

Solutions Director Juha-Pekka Sura at Watrec Oy said G4Plant’s user friendly system allowsfor a streamlined design of biogas plants.

“The deciding factor was G4Plant’s easy to

use piping design,” Sura said.

“We also use Vertex Flow to support G4Plant, as well as in all our project management

“We have many overlapping projects and previously we found it difficult to manage all the documentation and drawings.”

Most of Watrec’s projects are large scale ones, with physical documents for one project amounting to 20 folders of paper.

Sura praised G4Plant’s data compatibility, useful piping tools and extensive libraries.

“G4Plant is customised to our needs which makes design work easy,” he said.

“We have been very pleased with the quick response time from Vertex. Support is usually instant.

“We are also thinking of implementing Vertex Building Design software in our business.”

Jim Johnston has extensive experience across the pipeline industry and currently serves as vice-chair of the Board of Directors of the Plastics Pipe Institute (PPI). He is actively involved in many standards and industry organisations such as the International Standards Organisation, Alliance and the Americal Society for Testing and Materials (ASTM).

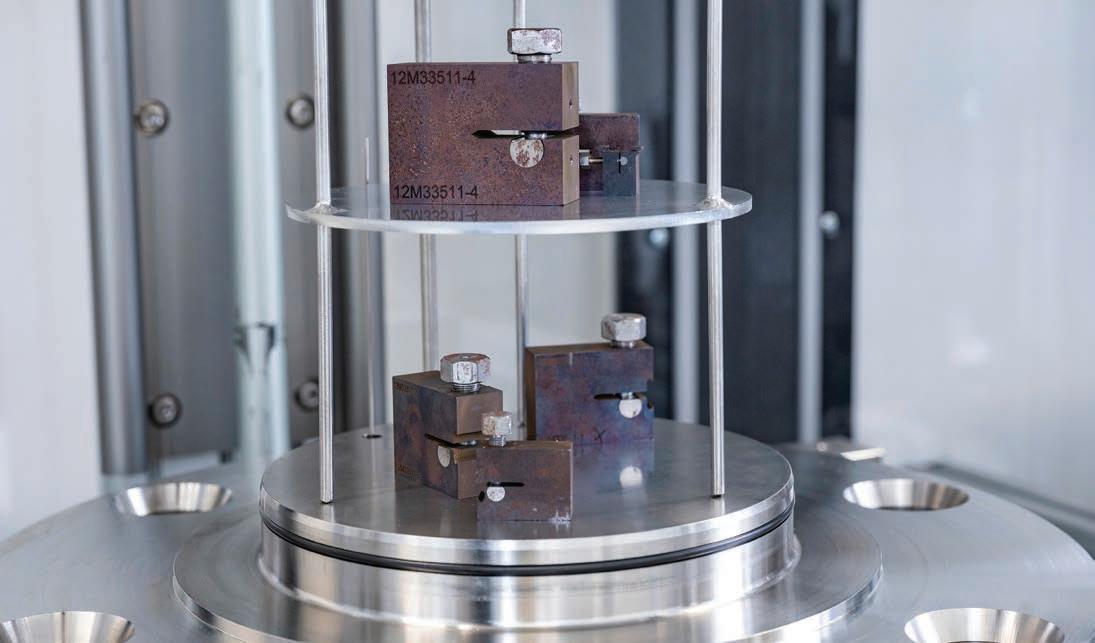

For decades, high-density polyethylene (HDPE) piping systems have proven to be a reliable and long-term option for a variety of markets, from municipal water systems and gas lines to the mining and natural gas industries.

For applications that call for a thicker pipe wall, HDPE continues to provide longevity, durability, and the reliability of a leak-free piping system.

Heavy wall* refers to the dimension ratio (DR) of the pipe itself. The DR of a pipe is the ratio of the wall thickness to the pipe’s outer diameter. Simply put, as a pipe’s DR decreases, the pipe’s wall thickness increases.

Butt-fused HDPE pipe is a growing choice for commercial and municipal piping systems due to its multiple methods for installation, reliability, and

durability. Generally, heavy wall pipes are used in applications that will subject the pipe to higher pressure.

During the fusion process, HDPE pipe ends are faced, heated, and brought together under pressure to form a bond as strong as – or stronger – than the rest of the pipe itself. When working with heavy wall pipes, the process itself does not change, but operators and contractors should plan for longer heating and cooling times.

ISO 21307 single high pressure (SHP) fusion jointing procedure outlines the standard for polyethylene butt fusion using high interfacial pressure. The procedure defines the heating and cooling times required based on the wall thickness of the pipe being fused. Therefore, thicker walls result in longer heat time and cooling times.

As heavy wall pipe has, by definition, a higher pipe wall thickness, the amount of time required to heat soak will also increase.

ISO 21307 SHP also defines the cooling time based on wall thickness. Accordingly, higher wall thickness will mean a longer total cooling time.

Other than heating and cooling times, the fusion process itself will not change, regardless of the wall thickness of the pipe being fused.

While the procedure remains unchanged, there are several best practices that will help ensure good fusions.

Due to the nature of large-bore, heavy wall pipes, it is not uncommon for there to be variation in wall thickness around the circumference of the pipe.

While this is minimised with low slump resins, there are still variations. To limit those variations, it is good practice to align the print line and the direction of extrusion so that the ID walls of the pipe are best aligned.

Due to the large mass of the heavy wall pipe, it is recommended that the user operate their heaters at the higher end of the allowable range. For ISO 21307 SHP, this allowable range is 215 +/- 15°C.

For the interfacial pressure, best practice is to operate at the lower end of the allowable range. For ISO 21307 SHP, this allowable range is 0.52 +/0.1 megapascal (MPa).

Another important consideration when fusing heavy wall pipe is the weight of the pipe itself. As a pipe’s DR decreases (because of an increase in wall thickness), so does the amount of material that makes up the pipe. A 250mm DR17 pipe can be picked up and moved by one person, but a 250mm DR7 is an entirely different story.

When working with heavy wall pipes, additional personnel may be needed to move the pipe from one location to another. Depending on the weight and size of the pipe, heavier equipment might be needed to manipulate or move the pipe or load it into the fusion machine.

In these situations, McElroy productivity tools like the PolyHorse® and Low Profile Pipe Rollers are invaluable assets on the job site.

The PolyHorse, which comes in two sizes, is a series of adjustable racks designed to hold enough pipe for a day’s worth of fusion work. It is designed to allow a single operator to load and align pipes without the use of extra machinery.

The standard PolyHorse is for 3-inch iron pipe size (IPS) to 20-inch outside diameter (OD) (90mm to 500mm) and is available in both manual and hydraulic modes, with the latter offering a hydraulic PowerAssist to help maneuver the pipe up, down, and into the fusion carriage.

The MegaMc® PolyHorse is used with pipe from 20-inch OD to 48-inch OD (500mm to 1200mm). The MegaMc PolyHorse features a powered, tracked pipe stand operated by remote control. It offers up to 24 inches of lateral and 34 inches of vertical movement.

McElroy’s Low-Profile Rollers are modular pipe rollers designed to make 4-inch to 18-inch IPS (100mm to 450mm) pipe easier. MegaMc Rollers are also available for 12-inch IPS through 54-inch OD (900mm to 2,000mm) pipe. Rollers can be paired with other productivity tools, to greatly reduce the amount of manpower and other equipment needed to move the heavy pipe from one location to another.

When using pipe rollers, the amount of force needed to move even heavy pipe and pipe joints is reduced. Pipe rollers have the added benefit of keeping the pipe off the ground, reducing the amount of wear and tear on the pipe itself during fusion and installation.

What can users expect from using McElroy’s products?

HDPE is growing in popularity, and projects continue to grow both in size and scope.

As the number of applications for large-diameter HDPE increases, it’s reasonable to assume that the use of heavy wall pipe will increase as well. Despite the extra considerations and challenges presented by the use of heavy wall pipe, McElroy machinery and productivity tools are designed to keep the job going.

Whether fusing in a crowded metropolitan area or in the most remote and rural of locations, McElroy equipment is built for rugged reliability and is backed by a network of specialists and technicians but also by other professionals who are constantly searching for ways to further streamline the fusion process itself.

Reference

*For the purposes of this article, the definition of “heavy wall” will be a wall thickness greater than approximately 65mm.

To learn more about McElroy’s industry-leading equipment, visit www.mcelroy.com

With plastic pipes on the rise in Australia, ROTHENBERGER’s

leading plastic pipe welding solution for optimal performance and productivity.

ROWELD’s standard range is suitable for pipelines from 315mm to 1200mm in diameter, with the ability to manufacture build to order machines up to 3m diameter, designed and manufactured to perform at the highest standard.

ROTHENBERGER Australia and New Zealand Managing Director Trent Carter said the company is excited about the prospect of establishing partnerships with state distributors and service agents in the Asia pacific region.

He said they also wanted to work with local distributors working directly with the manufacturer based in Germany and China.

“Customers all over the world rely on the performance and productivity of the ROWELD system for their plastic pipe welding,” Carter said.

“Perhaps most importantly, our equipment welds in accordance with DVS 2207/ISO 12176 and other international standards and guidelines.”

The range includes butt and electrofusion welding systems which are applicable for pipe diameters from 20mm to 1200mm and on a range of plastic pipes, including polyethylene (PE), polypropylene (PP) and polyvinylidene fluoride however, distributors are required for larger butt-welding applications.

ROWELD offers both manual and CNC hydraulic butt-welding machines which are suitable for PE and PP pipes and fittings with an outer diameter from 315 to 1200 mm. The machine features hardened and hard-chromeplated guide shafts guaranteeing torsion-resistant use of the machine.

Carter said the company is looking forward to Australian companies utilising its pipe welding machines such as the ROWELD system.

“We are excited to see Australian installers use ROTHENBERGER welding machines and tools to help tackle new challenges knowing we can assist in any conditions and requirements,” he said.

Established in Germany in 1949, ROTHENBERGER is focused on developing, producing, and marketing pipe tools and machines for plumbers, pipe fitters, heating, ventilating, air conditioning, refrigeration and the maintenance trades.

The manufacturer’s tools and machines are used every day throughout the world across a variety of industries.

For more information visit www.rothenberger.com/au-en/products/installation/plastic-pipe-welding

ROWELD system is one of theThe company has a range of butt-welding solutions. The ROWELD P355 B Professional.. ROTHENBERGER’s ROWELD range includes butt and electrofusion welding systems. ROWELD offers both manual and CNC hydraulic butt-welding machines. ROTHENBERGER is searching for Australian distributors.

When looking for a spacer solution, McConnell Dowell looked no further than kwik-ZIP’s product range. Manufactured from high-grade thermoplastic, these spacers and centralisers are developed to solve centralisation challenges in many industries, including trenchless and pipeline.

On a recent water main relocation project in Victoria, McConnell Dowell utilised kwik-ZIP HDXT-58W spacers to facilitate the slip-lining of a 660mm OD MSCL Steel Mains Sintakote® carrier pipe over a 54-metre run.

McConnell Dowell Senior Project Engineer Paul Pomfret said kwik-ZIP’s spacers were the right choice for this relocation project because of their versatility and adaptability.