GROUP DOUBLES DOWN IN AUSTRALIA AS PIPELINE PROJECTS BOOM – 10

Work with a team that understands e ective risk management is the

› Pigging

› Inline Inspection

› Live line dig ups

› NDT, including verification by phased array

› Leak detection

› Welding and field joint coating repair

› NATA pressure testing up to 70,000 kPa

› Flexible set-ups for remote and limited footprint locations

› Fast emergency response

Taddam: 0432 666 917 taddam@pipetek.com.au

Myles: 0417 707 729 myles@pipetek.com.au

|

EXCAVATORS |

|

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

|

‘Everything we do begins and ends with our customers’

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

- Michael Benson, Austrack MD

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

‘Everything we do begins and ends with our customers’

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

‘Everything we do begins and ends with our customers’

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

- Michael Benson, Austrack MD

Managing the building of major pipelines is challenging, complicated and expensive.

- Michael Benson, Austrack MD

Managing the building of major pipelines is challenging, complicated and expensive.

- Michael Benson, Austrack MD

Managing the building of major pipelines is challenging, complicated and expensive.

- Michael Benson, Austrack MD

Managing the building of major pipelines is challenging, complicated and expensive.

- Michael Benson, Austrack MD

Managing the building of major pipelines is challenging, complicated and expensive.

Managing the building of major pipelines is challenging, complicated and expensive.

Managing

Managing the building of major pipelines is challenging, complicated and expensive.

Managing the building of major pipelines is challenging, complicated and expensive.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Managing the building of major pipelines is challenging, complicated and expensive.

Managing the building of major pipelines is challenging, complicated and expensive.

Managing the building of major pipelines is challenging, complicated and expensive.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Managing the building of major pipelines is challenging, complicated and expensive.

Managing the building of major pipelines is challenging, complicated and expensive.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

One

Managing the building of major pipelines is challenging, complicated and expensive.

Managing the building of major pipelines is challenging, complicated and expensive.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Managing the building of major pipelines is challenging, complicated and expensive.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Managing the building of major pipelines is challenging, complicated and expensive.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Our people bring ‘at the coalface’ hands on experience to get your project moving.

Our fleet of 300+ machines and 700+ attachments can deploy to anywhere in

Our fleet of 300+ machines and 700+ attachments can deploy to anywhere in

Our fleet of 300+ machines and 700+ attachments can deploy to anywhere in

Our fleet of 300+ machines and 700+ attachments can deploy to anywhere in

Our fleet of 300+ machines and 700+ attachments can deploy to anywhere in Australia

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Our people bring ‘at the coalface’ hands on experience to get your project moving.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Our people bring ‘at the coalface’ hands on experience to get your project moving.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Our

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Our people bring ‘at the coalface’ hands on experience to get your project moving.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Our fleet of 300+ machines and 700+ attachments can deploy to anywhere in Australia

Our people bring ‘at the coalface’ hands on experience to get your project moving.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

One call to Austrack and instantly WE become part of YOUR team. We save you all the stress involved with hiring equipment.

Our people bring ‘at the coalface’ hands on experience to get your project moving.

Our people bring ‘at the coalface’ hands on experience to get your project moving.

Our people bring ‘at the coalface’ hands on experience to get your project moving.

We have you covered on all fronts with:

Our people bring ‘at the coalface’ hands on experience to get your project moving.

Our people bring ‘at the coalface’ hands on experience to get your project moving.

We have you covered on all fronts with:

We have you covered on all fronts with:

Our people bring ‘at the coalface’ hands on experience to get your

Our people bring ‘at the coalface’ hands on experience to get your project moving.

We have you covered on all fronts with:

• Reliable equipment

• Reliable equipment

• Reliable equipment

Our people bring ‘at the coalface’ hands on experience to get your project moving.

We have you covered on all fronts with:

• Reliable equipment

Our people bring ‘at the coalface’ hands on experience to get your

• Best Brands

• Best Brands

Our people bring ‘at the coalface’ hands on experience to get your project moving.

Our people bring ‘at the coalface’

• Best Brands

• Best Brands

Our people bring ‘at the coalface’ hands on experience to get your project moving.

We have you covered on all fronts with:

We have

We have you covered on all fronts with:

We have you covered on all fronts with:

• Superior service

We

• Superior service

We have you covered on all fronts with:

•

• Superior service

• Reliable equipment

We have you covered on all fronts with:

We have you covered on all fronts with:

• Superior service

• Reliable equipment

• Reliable equipment

• Putting safety first

•

• Putting safety first

• Putting safety first

• Best Brands

•

•

• Reliable equipment

•

• Best Brands

• Reliable equipment

• Putting safety first

• Best Brands

• Reliable equipment

•

• Best Brands

• New technology

•

• New technology

• New technology

• Best Brands

• New technology

•

• Superior service

• Superior service

• Great Rates

• Great Rates

• Great Rates

• Superior service

• Superior service

• Putting safety first

• Superior service

• Putting safety first

• Putting safety first

• Putting safety first

•

•

•

•

• Putting safety first

• Putting safety first

• Putting safety first

• New technology

•

• New technology

• New technology

•

•

• Great Rates

• Great Rates

• Great Rates

•

CEO

John Murphy COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au EDITOR

Timothy Bond tim.bond@primecreative.com.au

JOURNALIST

Vivien Topalovic vivien.topalovic@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

Jake Niehus

jacob.niehus@primecreative.com.au

ART DIRECTOR

Michelle Weston michelle.weston@primecreative.com.au

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

DESIGNER

Daniel Truong

COPYRIGHT

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2021

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Printed by: The Precision Group

83-89 Freight Drive, Somerton VIC 3062

Ph: (03) 9490 1500

The Australian Pipeliner brand comprises: six editions a year, a news website, a weekly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

20,000+ website views each month 16,500+ e-newsletter subscribers

13,700+ social media followers magazine subscribers 3,300+

Want to find out more?

Contact our business development team to discuss how you can grow your business with The Australian Pipeliner. Call 0466 929 675 or email jacob.niehus@primecreative.com.au

Head Office

379 Docklands Drive, Docklands VIC 3008 Ph: (03) 9690 8766

Sydney Office Suite 303, 1-9 Chandos Street, Saint Leonards NSW 2065 Ph: (02) 9439 7227

enquiries@primecreative.com.au www.primecreative.com.au

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry.

The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

• First to move the vacuum reservoir from the excavator stick to the counterweight

• First to use the excavator hydraulics to power the vacuum pump

• First to remove radio remote control

• First to introduce dedicated excavator operator controls

• First to introduce 360˚ rotation

• First to develop an in-trench pipe assembly apparatus

• First to develop an hydraulically assisted multiple o ring jointed pipe assembly tool

• First to develop a remote controlled in pipe inspection tool

• First to develop a VacLift that will only release a pipe when the pipe is on a solid surface

• First to increase the range of diameters able to be handled by each pipe shoe

• First to develop a fully adjustable attachment pickup.

We know the industry better than anyone, talk to us about all your pipeline plant hire needs first.

Iam pleased to welcome you to the 2024 Convention and Exhibition edition of The Australian Pipeliner. I am also welcoming many of you to the beautiful city of Adelaide, where you can immerse yourself in insightful business sessions, network with industry peers, and explore this vibrant city.

We have prepared an enriching and informative program for the Convention, where members of our industry will provide invaluable insights into emerging trends, best practices, and future projections. As an industry, we thrive on collaboration, creative thinking, and the pursuit of excellence. Our keynote speakers, including Dean Boxall, following his team’s multiple gold medal triumphs in Paris, are a testament to our industry’s excellence. The soldout exhibition hall is a result of our collective efforts, a platform we have built to foster collaborations, share knowledge, and drive advancements within the pipelines and gas sector. Let’s take pride in what we have achieved together.

This edition features many of our exhibitors, focusing on providing NDT, pipeline equipment, integrity and maintenance services, HDD, and rehabilitation and repair.

Since my last President’s message, we have started to see a shift in the public debate as gas’ role in the energy transition is becoming more widely understood and accepted. We have continued to work diligently through our enhanced advocacy program, and the recent release of the Federal Government’s Future Gas Strategy is a strong demonstration of the changing narrative – an acknowledgement of the central role natural gas plays in firming renewables and powering our essential industries where alternative energy solutions are not yet available.

The Strategy also underscores the need for new gas supply sources to meet demand during Australia’s transition, requiring investment in new energy sources and its associated infrastructure. The recent announcement of Senex’s Atlas East Gas Project should encourage us that further investment is coming when delivered in the right policy environment where

we will all benefit from the unlocking and transporting of our abundant gas resources, especially in Queensland and regions such as the Beetaloo Basin.

Beyond gas infrastructure, I am sure most members are involved in ongoing and upcoming water pipelines and infrastructure. Several large water pipelines are being delivered in Queensland and New South Wales, and future ‘mega’ projects are planned in other states, including South Australia, where the Northen Water project will require a 600km pipeline to connect the Spencer Gulf to northern SA. As an industry, we transfer our skills and knowledge between sectors while always focusing on the safety of our people.

I want to thank the Secretariat for their efforts in preparing for the Convention and Exhibition, thank our exhibitors for committing their time and resources to share their latest innovations, technologies, and services, thank our speakers and presenters for taking the time to prepare and having the courage to stand up and share their knowledge and experience, congratulate the individuals and companies that have won Awards in recognition of their services to our industry and finally thank the membership as a whole for your commitment to the industry and Association. As APGA’s mission says, we look to foster innovation and collaboration, provide valued services, and represent the collective interests of our members. I hope your experiences here in Adelaide have delivered on this mission.

Stay safe, and I look forward to seeing you in Adelaide.

JOHN STUART-ROBERTSON APGA PRESIDENT

T: +61 2 6273 0577

E: apga@apga.org.au

W: www.apga.org.au

Chief Executive Officer

Steve Davies

Corporate Services Manager

Michelle Wickson

National Policy Manager

Jordan McCollum

Communications Manager

Lawrence Shelton

Engagement Manager

Gayle Burns

Membership Officer

Katy Spence

Policy Manager

Catriona Rafael

Government Relations Manager

Paul Purcell

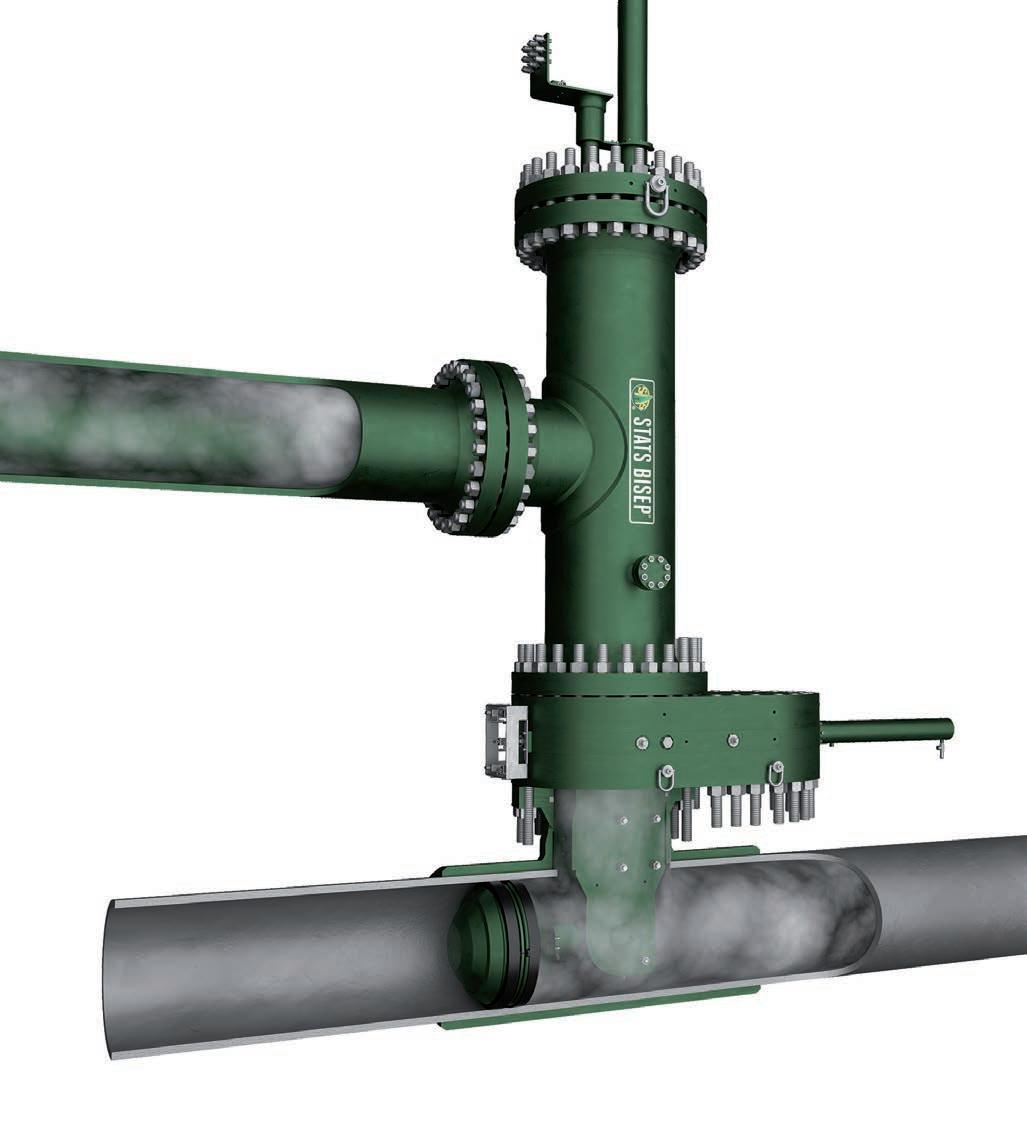

integrated bypass maintains production during isolation

Double Block & Bleed Isolation

Isolated Pipeline

Monitored Zero-Energy Zone

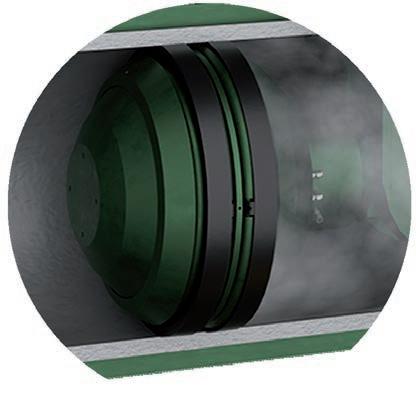

The BISEP® has an extensive track record and provides pioneering double block and bleed isolation while

dual seals provide tested, proven and fully monitored leak-tight isolation, every time, any pressure.

revenue increasing to £75 million ($145 million) while earnings rose to £12.1 million ($23.4 million), its latest annual accounts show.

“The group has delivered an excellent trading result for the year, reflecting our ongoing commitment to develop and invest in localised operations in key international markets,” STATS Chief Executive Officer Stephen Rawlinson said.

year in all our markets.

“Revenue is anticipated to be higher than that achieved in 2023 and staff levels are again expected to increase to meet the anticipated growth in demand.”

As part of its localisation strategy and to help support growth in Australia and the wider Asia-Pacific (APAC) region, Hafiz Kareem recently joined STATS as Sales Manager APAC, based in Brisbane, Australia.

clients in the transition to a low carbon future,” Kareem said.

Paulo Basto has also joined the growing team as Operations Manager for the region based in Perth, Australia.

“STATS is a leading player in the pipeline intervention and isolation industry with a wide range of cutting-edge proprietary technologies, it’s an exciting time to join the company as they increase market share and grow its footprint in Australia,” Basto said.

STATS Regional Manager for APAC Gareth Campbell said the company recorded a number of important operational milestones.

“We have made significant progress establishing strong relationships in key markets, differentiated with our market leading technologies that will continue to drive future growth in market share,” he said.

The successful delivery of significant projects included a 24-inch launcher Door Plug and bespoke grabber tool for a client in the Bass Strait. The novel technology allowed the successful retrieval of an inline inspection (ILI) module from the pipeline.

The challenging project required equipment to be engineered that ensured the pipeline remained pressurised while the ILI module was recovered first time in a single deployment. The project returned the pipeline to a piggable condition, allowing essential cleaning and inspection activities to continue.

STATS recently manufactured a SureConnect subsea mechanical pipe connector for installation on a 24-inch pipeline offshore Brunei. Additionally, multiple isolation and intervention projects for onshore and offshore deployment have been conducted in Australia, Malaysia and Papua New Guinea, with the sale of BISEPs to an operator in New Zealand as part of a multi-year master service agreement.

As STATS continues to expand its presence in the region, its track record is quickly growing with work scopes also completed in Indonesia, Vietnam and China.

With global oil and gas operators looking to support the energy transition and net zero carbon emission targets, STATS is in a strong position to help clients repurpose existing assets and piping infrastructure for future use in hydrogen, carbon capture and storage (CCS) and other decarbonisation projects.

For more than 25 years, STATS has played a central role in numerous pipeline

that, in the future, may be repurposed.

APAC’s operators and contractors are looking to the future and exploring ways

For more information, visit statsgroup.com

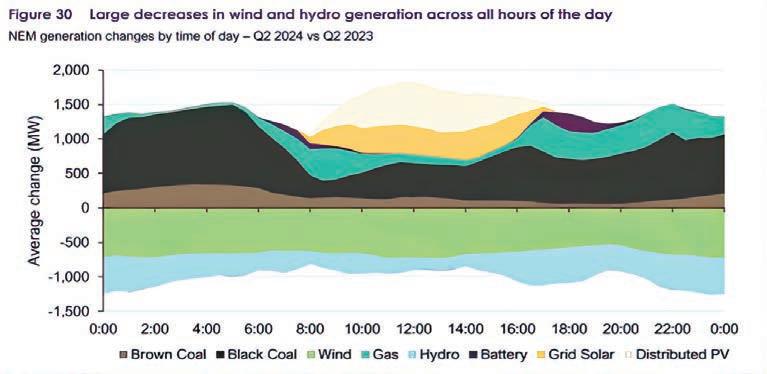

AEMO finally gets it – gas-powered generation is key to net zero

APGA National Policy Manager Jordan McCollum dissects AEMO’s latest report, which cements the critical role of gas in the energy transition.

Written by APGA National Policy Manager Jordan McCollum

After years of underestimating the need for gas-powered generation across the coming decades, the penny has finally dropped for the Australian Energy Market Operator (AEMO).

In its media release published alongside its Q2 2024 Quarterly Energy Dynamics report, the market operator stated:

“[Q2 2024] highlights the important role of flexible gas-powered generation as the ultimate backstop for the National Electricity Market (NEM) during periods of reduced renewable generation.”

To be fair, key people within AEMO have always known this, and modelling produced by AEMO has been demonstrating this fact more and more clearly over the last 24 months. But the market operator has appeared to be hesitant to publicly emphasize gas-powered generation’s crucial role.

This statement comes off the back of record renewable droughts which have led to a 20 per cent reduction in wind generation and an 18 per cent reduction in hydroelectric generation. At the same time, an increase in baseload coal generation saw NEM emissions increase year-on-year for the first time since FY2015.

Critical to energy security during this period was gas-powered generation which kicked in predominantly during the peak morning and evening demand periods. Had this gas-powered generation capacity not been available, the NEM could have been at serious reliability risk during this still, dry period.

Looking deeper into the data there were weeklong renewable generation droughts three to five times in the May to July window across each of the three south-eastern NEM regions. Three of these renewable droughts affected two or more states at the same time. This is aside from numerous two- to three-day windows of similar low renewable supply.

During each of these windows, it was predominantly gas power generation which stepped in to fill the supply gap and keep the lights on.

Of course, as Australia’s pipeline industry knows, gas-power generation doesn’t do this alone.

Amidst renewable droughts, gas power generation can fill the supply gap.

It’s the gas storage and throughput capacity of Australia’s pipeline networks that allows gaspowered generation to run hard when it’s needed and sit idle when it’s not, supplying relatively flat gas production profiles into highly variable generation demand.

With this context in mind, let’s turn the clock forward by a decade. The majority of the NEM’s coal generation fleet has retired, and we are left with a majority renewable generation NEM. Now the availability of gas-powered generation is critical.

Batteries and pumped hydro will support intraday and day-to-day time shifting of renewable supply respectively. But neither have the capacity to supply the NEM across five consecutive week-long renewable droughts, as seen in Q2 2024.

This is no longer a theoretical risk but a lived reality.

In a coal-less future, NEM reliability beyond a 48-hour window is solely the domain of gas-power generation. The capacity and flexibility of gas infrastructure enables generation to ramp in line with demand, while long-term underground gas storage and a robust gas market provides a source of enduring supply for weeks on end as required.

But this only happens if the necessary investment is committed this decade.

Gas-powered generation, while being critical to future NEM reliability, is excluded from every from of electricity subsidy today.

While the renewables and batteries required to replace coal on a good day received subsidies, the gas-powered generation to maintain supply on a bad day does not.

While every other form of electricity generation and infrastructure is subsidised, it will be virtually impossible for investments in new gas power generation to reach FID. This means one of two things to ensure necessary gas-powered generation investment occurs: governments need to either start subsidising gas-powered generation or stop subsidising everything else.

The AEMO Integrated System Plan identifies over 16GW of gas-powered generation will be required to firm the NEM into the future and notes:

“As coal-fired power stations retire, renewable energy connected with transmission and distribution, firmed with storage, and backed up by gas-powered generation is the lowest-cost way to supply electricity to homes and businesses through Australia’s transition to a net zero economy.”

Now is the time for state and federal governments to step up and ensure the necessary gas-powered generation investment occurs this decade. Else we may yet find out what happens if gas-powered generation isn’t there when the wind doesn’t blow, the sun doesn’t shine, and the rain doesn’t fall.

+61 2 6884 7878 (Dubbo) +675 321 1001 (Port Moresby)

Host Sponsors:

Sponsors:

Major Sponsors:

Horizontal Directional Drilling

• Multiple NASTT Project of the Year awards

• Australia-based operations with local resources

• Extensive experience with intersects and long crossings

• Successful 4.7km HDD under waterway

Direct Pipe

• Foremost Direct Pipe Contractor

• Outfalls and shore approaches

• Pipe Installations up to 1.5m

• Completed first of multiple 2,250m HDD’s with 590m elevation change

• Longest HDD intersect completed in Australia

• Record breaking HDD for combined elevation change and length

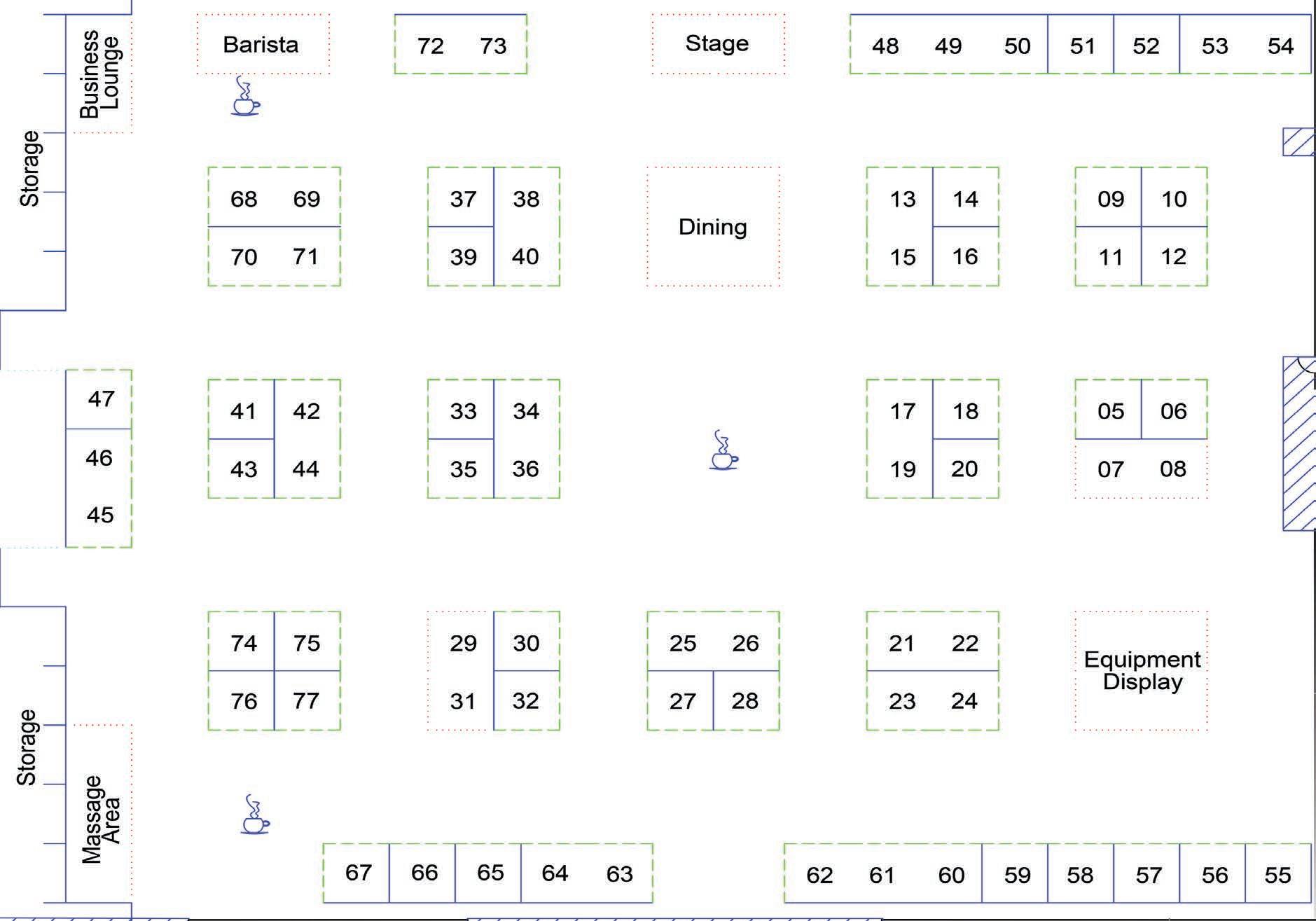

APGA Convention Program

Monday 14 October 2024

8:00 AM ARRIVAL & REGISTRATION

9:00 AM Convention Opening John Stuart-Robertson APGA

9:10 AM Welcome to Country TBC

9:20 AM State of the Industry Steve Davies APGA

9:40 AM Keynote – Industry Hon Tom Koutsantonis MP

10:00 AM APGA Awards Steve Davies | John Stuart-Robertson APGA

10:30 AM MORNING TEA

11:00 AM PANEL: Leaders Steve Davies & Guests APGA

11:40 AM Keynote – Motivation Topic: Future Fuels

12:00 PM Building the next phase of renewable gas research David Norman FFCRC

12:30 PM LUNCH BREAK

1:45 PM Towards Best Practices: Assessing and Managing Process Safety Risks for Future Fuels

Thomas Jackson | Sam Hatwell GPA Engineering

2:05 PM Bridging Industries for Sustainable Energy

Jarad McInnes | Brent Davis Jemena

2:25 PM Hydrogen Park South Australia’s performance (May 2021 – May 2024) Owen Sharpe AGIG

2:45 PM An Invitation to the Renewable Generation James Roberts GPA Engineering

3:15 PM AFTERNOON TEA Topic: Projects

3:45 PM Pipeline Engineers versus AI: Who would win a match in ‘Competence’? Michelle Unger ROSEN

4:05 PM

A Contractor’s perspective on the many challenges and lessons learned from the construction of the Western Outer Ring Main (WORM) pipeline on the outskirts of Melbourne.

Leigh Smith Spiecapag

4:25 PM New Energy Solutions: The challenges of connecting and future-proofing an LNG Import Terminal

Justin Anderson Jemena

4:45 PM Moomba CCS, from inception to operations – CO2 Pipeline – Ready for Operation Owen Lucas | Alex Donald SANTOS

5:05 PM CONVENTION CLOSE – Day 1

7:00 PM Fancy Dress Dinner ACEC

11:00 PM Happy Hour

APGA Convention Program

Tuesday 15 October 2024

8:00 AM ARRIVAL & REGISTRATION

9:00 AM Convention Opening Topic: Future Pipelines

9:10 AM

9:30 AM

9:50 AM

Bridges and pipeline integrity engineering – what do they have in common? An EPRG perspective

Marion Erdelen EPRG / ROSEN Group

Compatibility of Type B Appliances for Use on Hydrogen Blends (HyP MV Case Study)

Carina Nixon | Robert Davis GPA Engineering

Repurposing Existing Natural Gas Pipeline Infrastructure – A Case Study in a Phased Approach to Assessment and Planning for Hydrogen Conversion

Klaas van Alphen APA

10:10 AM The Ammonia Challenge

James Czornohalan Worley Consulting

10:30 AM MORNING TEA

11:00 AM PANEL: Leadership: Leadership in the industry Topic: ESG, Steve Davies | Gretchen Gagel

11:40 AM Are hard spots a stable threat in Hydrogen-blended pipelines

Isya Muhajirin Quest Integrity

12:00 PM

Discussing sustainability in the pipeline industry through the establishment of a Code of Practice

Mitch Pearce CNC Project Management

12:30 PM LUNCH BREAK

1:45 PM YPF Panel APGA

2:25 PM

Gender Diversity in the Pipelines Sector: Part 2 of Opportunity and Career Development for all.

Carol Bond RMIT University

2:45 PM Operationalising a low emission future

Allyson Woodford APA

3:15 PM AFTERNOON TEA Topic: POG

3:45 PM Navigating Stress Corrosion Challenges in Aging Infrastructure.

Matthew Clark | Ben Parkin APA

4:05 PM 10 Years On – Operation Post Rupture

Lauren Beynon | Josh Row EPIC ENERGY

4:25 PM SANTOS pipeline incident – lessons learned “Big Lake”

Rhys Ward SANTOS

4:45 PM

First Measurements of the Influence of Hydrogen on the Fracture Toughness of a X65 Gas Transmission Pipeline Steel

Andrejs Atrens The University of Queensland

5:05 PM CONVENTION CLOSE – Day 2

7:00 PM Gala Dinner ACEC

11:00 PM Happy Hour

We make life flow.

As the leading pipe systems and solutions manufacturer, Vinidex is at the forefront of innovations reshaping the Natural Gas industry. From water and gas transfer solutions to custom-made fabricated fittings, we’re pushing the boundaries of performance with products that are lighter to use, faster to install and easier to recycle.

Learn more about our offering in the Natural Gas market at vinidex.com.au

STAND 72 & 73

No two jobs are the same, and to tackle a wider variety of trenching projects, contractors need unique machinery that can adapt to any specific job, task or challenge.

Job sites and projects aren’t always flexible, so it’s important for contractors to have configurable, adaptable equipment that can tackle whatever requirements a jobsite throws their way.

In the world of customisable pipeline and utility trenchers, the Vermeer T755III stands out as a powerhouse and is designed to tackle a broader range of jobs with precision and ease.

Whether you’re working in rugged landscapes or challenging soil conditions, Vermeer’s T755III provides an impressive blend of configurable options and durability, combined with cutting-edge technology to maximise productivity and performance.

A key feature of Vermeer’s T755III is its versatility and the ability to adapt to project requirements. The range of options and additional features of the T755III trencher mean the equipment can be tailored to meet the specific demands of different job sites.

Central to the trencher’s adaptability is a range of optional length sectionalised boom sections. This allows operators to set the machine’s boom length to suit the depth requirements, trench spec and conditions of the job at hand, overall maximising the machine’s performance.

“It’s worth noting that the machine has a maximum digging depth range anywhere from 1.5m to 3m deep, depending on what sectional boom option the machine has installed,” Vermeer Product Specialist Steve Batchelor said.

“Adding to this is the ability to set the machine's cutting width from 40.6cm to 91.4cm wide, along with varying cutting teeth styles to tackle ground conditions ranging from sticky clays right up to seriously hard rock formations.”

Depending on the machine’s digging boom specification, the machine’s weight will range between 22,000kg to 34,000kg, which contributes to the tractive effort needed to tackle the hard rock conditions.

The onboard conveyer offers further versatility through its ability to distribute material to either side of the machine at varying distances, and the optional LRC 25 loading conveyor

The T755III features a tilt track and Auto Level undercarriage, allowing the machine to maintain a trench even on slopes up to 12°, ensuring smooth operation on a wider variety of terrains including uneven ground, without compromising the trench quality.

The SmartTEC electronic control system helps increase productivity with real-time machine

elevating operators cab,” Batchelor said. “This is to assist in keeping the operator’s environment dust free, preventing dust ingress which could be harmful to their health and safety.

Vermeer offers an optional extended warranty coverage of up to five-years/5000-hours, giving contractors the peace of mind that their machines are backed by an experienced and knowledgeable team of experts at Vermeer Australia.

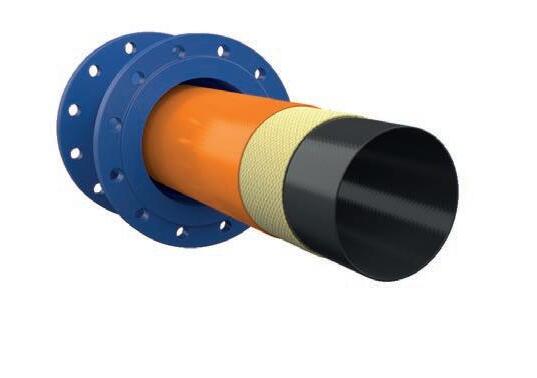

Part of the comprehensive gas distribution systems offering from TDW, the revolutionary POLYSTOPP® Quick Connect system makes it easy to safely perform tapping, plugging and branching on polyethylene (PE) pipelines — faster than other methods of isolating and using significantly less excavation space.

One person lift. | For 4-inch through 8-inch pipelines. Pressure rated to 10 bar (150 psi). | Covers multiple standard dimension ratios. 2-inch bypass capable. | Plugging or branching fittings available.

How much faster is it? Watch the speed comparison video:

7, 8 & Equipment Stand

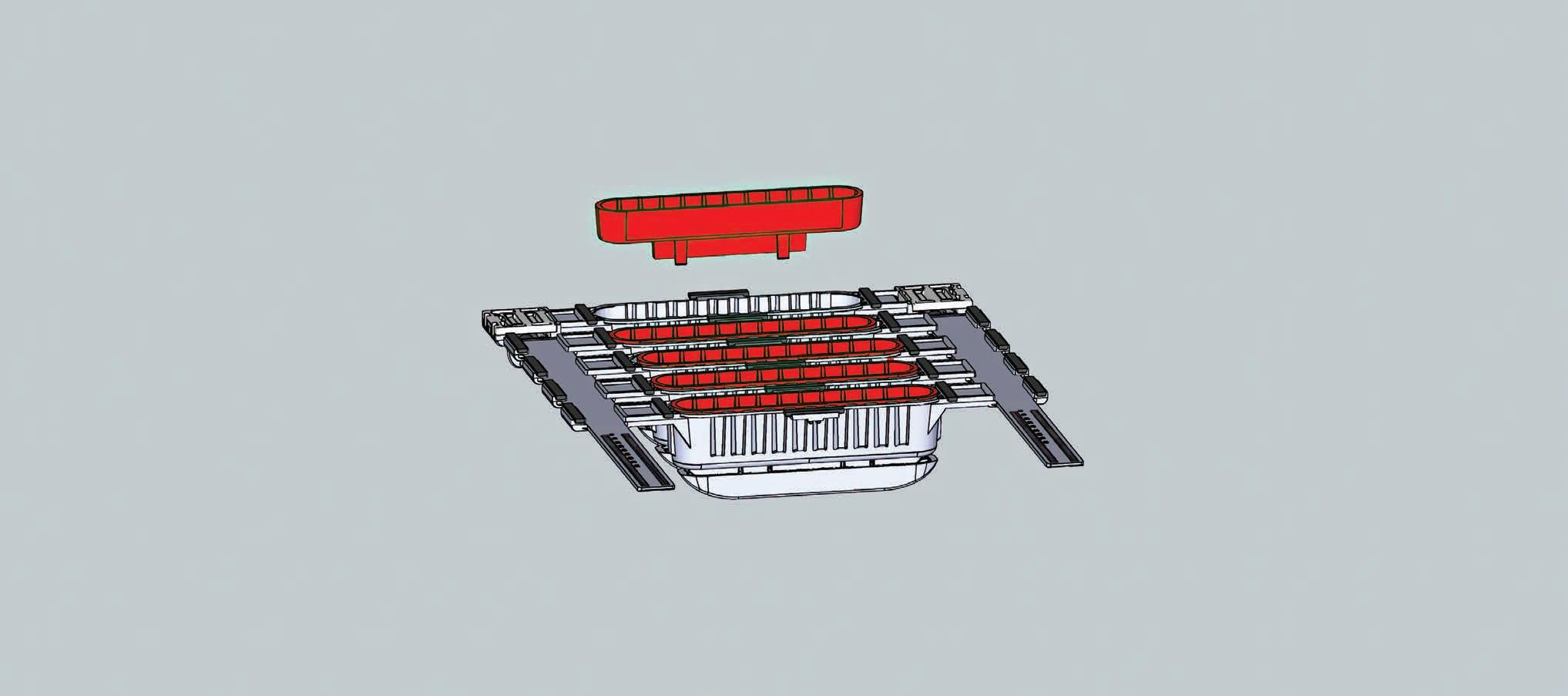

Austrack Equipment’s SafeVac Lifting Systems, known for efficiency and safety, has just added another string to its bow: adaptability.

As Austrack Equipment launches into its second full year of production of its SafeVac Lifting Systems SV400 pipe vacuum lifter, the company isn’t resting on its laurels.

Austrack’s latest adaption of its vacuum lift is hard at work at Brisbane Airport’s Legacy runway. The terrain at the airport is certainly a change of scenery for the SV400, swapping the remoteness of typical pipeline projects for the close confines of an international airport runway.

Against the backdrop of Brisbane’s central business district, the SV400 is hard at work lifting four-tonne sections of old runway scheduled for replacement.

The individual sections of this 40-year-old runway are 4m long, 1m wide and 0.5m thick. Compounding the challenge is the grooved surface of the runway, calling for a very spongy seal to ensure compression and integrity of lift. But paradoxically, unique challenges are nothing out of the ordinary for Austrack, and the project is going off without a hitch.

Austrack General Manager Donna Owens said that it was precisely this reputation that helped

sourced from Holland in Europe. The actual vacuum generation and supply remains an unmodified standard SV400 system.

“The reconfigured system worked perfectly and

“Last year was our first year exhibiting at the annual APGA event and we were both surprised and delighted to be awarded ‘Best Exhibit’,” Owens said.

“This year we have taken one of the equipment areas as well as a double booth, so we have raised the bar and given ourselves a challenge.

“We are feeling a certain pressure to perform, but performing under pressure is par for the course at Austrack.

“We are very busy putting the finishing touches to the machine that will feature in our equipment display area at Adelaide.”

Owens was cautious about spoiling the surprise but hinted that the company has continued on its vacuum lifter journey.

“What we are planning to bring to Adelaide is going to mean a visit to our display at the show will be well worth the trouble,” she said.

“I can also advise that Austrack have just been appointed as exclusive agents for Australia and New Zealand for a European excavator bucket manufacturer.

“World shipping routes obliging, we plan to have the best of our new business partners quality products on display in Adelaide – yet another compelling reason to visit our display.”

APGA Corporate Affairs Manager Paul Purcell discusses the role of biomethane in the energy transition.

Written by APGA Corporate Affairs Manager Paul Purcell

South Australia has long been a national leader in action to combat climate change, and today generates more than 70 per cent of its electricity from renewable sources – a major accomplishment as the state works toward its goal of 100 per cent net renewable electricity by 2027.

But it’s a common misnomer that solving electricity generation means solving the energy transition. Currently, electricity makes up just 25 per cent of total final energy consumption in Australia.

Plainly, we’ve got a long way to go to decarbonise the rest of our economy.

But it is imperative to do so without policies that result in economic demand destruction, the offshoring of domestic enterprise and associated carbon leakage, or an erosion of living standards.

Which brings us to the lowest-hanging fruit still waiting to be plucked: Biomethane.

The domestic gas infrastructure industry is committed to net zero by 2050 through the decarbonisation of its assets, helping deliver a sustainable future for households, businesses, and industry. In 2024, APGA and its members commissioned comprehensive studies to assess the biomethane potential from anaerobic digestion of organic waste and residues in the catchment areas (within 50km) of gas networks across NSW, South Australia, Victoria, and Queensland.

Given it will be home to APGA’s convention this year, let’s focus on South Australia.

The state consumes 301 petajoules (PJ) of energy each year, which is approximately 16 per cent renewables, 27 per cent natural gas, nine per cent coal via the Victorian interconnector and about 47 per cent oil – predominantly used in light passenger vehicles as well as heavy transport.

In terms of a hierarchy for economically efficient emission reductions, the overwhelming priority should be to expedite the displacement of coal-generation, particularly Victorian brown coal.

To illustrate, the Yallourn brown coal power plant has an emissions intensity of 1316 kgCO₂/ MWh, compared with Pelican Point gas-fired power station which is 474kgCO₂/MWh – 64 per cent lower.

But if we were to move down the priority list to decarbonising gas, how would we do it?

In the first instance, it should be through expediting biomethane production. In the most

recent 2024 biomethane potential report by Blumony, it found there is up to 33PJs of carbonneutral biomethane supply in South Australia alone. To properly contextualise the emission reductions opportunity, the avoided CO2 emissions of approximately 1,651,800 tons is equivalent to taking 360,000 passenger cars off the roads, or about 31 per cent of the cars registered in South Australia.

This is significant.

Additional benefits for South Australia include the diversion of nearly 500,000 tonnes per annum of organic waste from landfills, production of 1.2 million tonnes of nutrient-rich digestate which can be used as natural fertiliser in agriculture, as well as thousands of local jobs.

This is just the start and there is significant potential to grow even more. But how do we get there?

Today, the National Greenhouse and Energy Reporting rules do not currently recognise biomethane as distinct from fossil-derived natural gas when it is injected into the existing gas grid. This lack of differentiation means that the environmental benefits of biomethane, such as its lower carbon footprint, are not acknowledged or incentivised within the reporting and accounting framework.

The existing NGERS framework lacks mechanisms for tracking and verifying the volume and origin of renewable gas once it enters the common-use infrastructure. Without such mechanisms, it becomes challenging to ensure that the reported emissions reductions or renewable energy credits are accurately attributed to

between renewable and fossil gases within common-use infrastructure, there are no specific incentives for gas producers or consumers to switch to biomethane. This misalignment of incentives limits the economic attractiveness of biomethane projects, reducing the motivation for companies to invest in its production.

APGA has been engaging with the Federal Government, and state governments, to help address this oversight, and expedite the amendment of NGERS to recognise biomethane while also advocating for a fast-tracking of a market-based method to provide a framework for tracking and reporting.

That’s the first step.

From there, it will be imperative to set a national target of renewable gas for 2030, and 2035 – which will be predominantly supplied via biomethane to help signal national ambition for renewable energy development, boosting investor confidence and the development of a nascent market.

And finally, we must establish a target price for biomethane to make it cost-competitive with other energy sources.

These steps are crucial for bridging the gap between our current reliance on fossil fuels, particularly coal, and a sustainable future. By addressing these challenges, South Australia can continue in its role as a national leader in reducing emissions and setting a precedent for the rest of Australia.

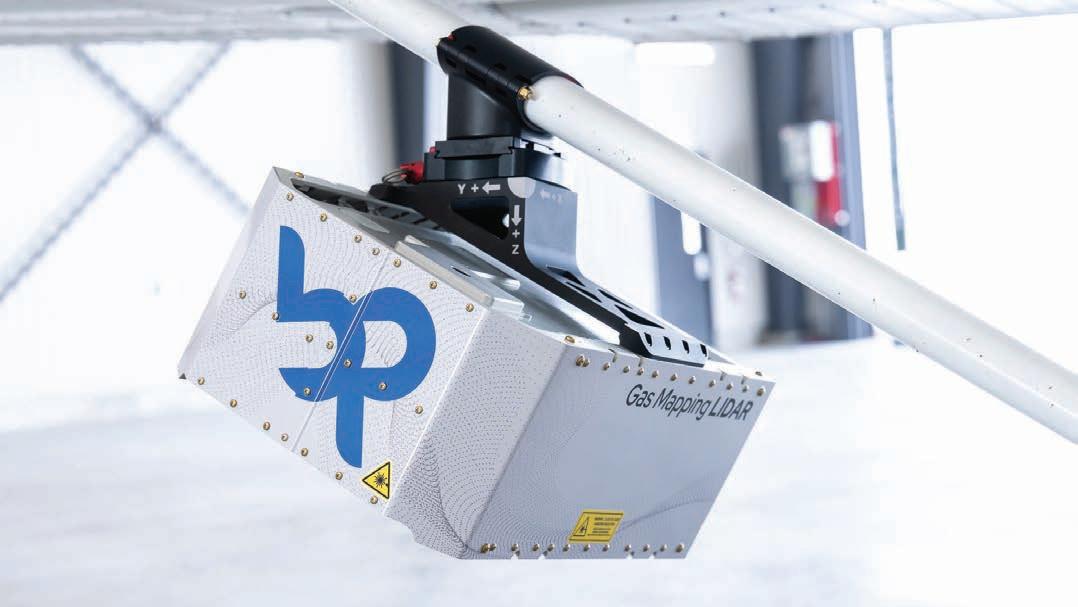

As methane emissions take spotlight across the globe, oil and gas operators are seeking ways to detect, locate, and reduce methane emissions.

In Australia, new advanced technologies are emerging to help operators take on the unique challenges that come with operating in Australia.

One such technology is Bridger Photonics’ Gas Mapping Light Detection and Ranging (LiDAR). To learn more, The Australian Pipeliner sat down with Bridger Photonics Vice President of Sales Ryan Stewart.

What is Bridger Photonics’ mission in the oil and gas sector?

Our goal is to empower the industry to achieve greater environmental stewardship by providing actionable insights that help reduce methane emissions, improve safety, and enhance operational efficiency.

Bridger Photonics’ Gas Mapping LiDAR, or GML, uses laser technology to detect, locate, and quantify methane emissions across the full value stream, from production to distribution of natural gas. We attach a GML sensor to a small aircraft, which collects methane data over oil and gas facilities to detect and image methane emissions.

We then analyse that data and provide the client with maps and information about detected emissions, including pinpoint source location, emission rate, plume imagery, emission persistence, max path-integrated concentration, and more. This data can allow oil and gas companies to characterise their emissions at a system level and develop plans that manage fugitive and operating emissions more efficiently and effectively.

The GML uses laser technology to detect, locate, and quantify methane emissions.

What attracted Bridger Photonics to the Australian market?

We’ve worked for a lot of the global majors and our track record has generated interest in Australia, with many operators seeing the gaps we could bridge versus existing technologies. Our interest in the Australian market was fortified through early conversations with operators who expressed a clear demand for advanced emissions detection solutions that would help them overcome the many challenges they are facing. Australia’s strong commitment to safety and sustainability aligns perfectly with our core values and expertise.

What are some of the challenges Australia faces with methane emissions?

What we’ve heard from our partners is that there are three main challenges operators face in this industry.

First, the sheer scale and remote nature of operations in Australia pose significant difficulties. The expansive and rugged terrain makes it both time-consuming and heavily resource-intensive to detect and manage methane emissions.

Secondly there are risks to the safety of employees while carrying out these critical activities. Due to the remoteness of many sites, ground crews often spend considerable time traveling and operating on hazardous sites, sometimes only to find that there are no emissions to address. This not only comes at a considerable operational cost but also raises safety concerns due to the extensive travel and site exposure required.

Finally, operators need technologies that can accurately characterise emissions at scale across Australia’s vast and complex infrastructure to ensure emissions reduction programs are efficient and effective.

How can Bridger Photonics help operators overcome these challenges?

Bridger Photonics addresses these challenges with our aerial methane detection technology. By deploying our sensors via aircraft, we are capable of scanning hundreds of sites or kilometres of pipeline in a single day, safely and efficiently. Our data can provide operators with precise locations of methane emissions and, crucially, confirms where there are no emissions.

This can enable operators to prioritise their resources effectively, reducing unnecessary site visits and travel time for ground crews.

We also provide operators with aerial imagery of each site and have the spatial resolution to pinpoint emissions sources down to equipment level so they can have a better understanding of each emission source before visiting a site. This means that ground crews can arrive better prepared for repairs with the necessary tools, reducing exposure and driving efficient programs.

With advanced technology like ours, operators aren’t blind to their emissions profiles – we allow them to measure and take control. We help operators baseline and track emissions through measurement, which is increasingly important in a continuously evolving regulatory environment.

As we dove into the unique data GML provides, feedback has been overwhelmingly positive, with a special appreciation of the detailed insights we provide because it can enable more

complete emissions inventories and informed decision-making. Compared to previous technologies tested, operators have shared that we provide more detailed emissions data with better localisation which is due to Bridger’s proprietary LiDAR technology.

Since this is a relatively new area of deployment for us, we are continuously engaging with operators to ensure we deliver maximum value tailored to their specific needs.

Our primary goal is to strengthen and expand our relationships with local operators to ensure sustainable, long-term operations in Australia. We have successfully navigated many of the logistical challenges necessary to establish a strong presence here, including partnering with local flight providers. Now, our focus is on optimising these partnerships, leveraging our technology to provide the most value to operators, and contributing to the industry’s overall sustainability and efficiency.

We are impressed by the innovative thinking and proactive stance of the Australian market towards methane emissions reduction. Bridger Photonics is here to support your efforts, whether you are pursuing OGMP 2.0 standards, corporate emissions reduction targets, measurement informed inventories, or enhanced operational efficiencies. We’re excited to partner with operators and tailor a plan that’ll help achieve those goals.

Pipe Tek has been nominated for Downer’s Crew of the Quarter Award due to the safety measures the team took while investigating a 70-year-old asset in a high-density residential area.

Downer contracted Pipe Tek to complete investigative works for a pipe isolation design on a 6.5km DN910 water trunkline, operated by Urban Utilities.

The section of mild steel cement lined (MSCL) trunk water main was constructed in 1959 and forms part of the Wellers Hill reservoir water supply zone.

The pipeline is one of the two largest trunks transferring water from the reservoir to the northern part of the zone.

The proposed project to install two isolation valves will provide improved network contingency.

The contract involved investigative work at two different site locations, located in highdensity residential areas requiring significant road closures.

The pipe was exposed so assessments could be carried out on the coating and identify the best way to dispose of waste when installing the mainline valves.

Steel samples were also taken to determine the best welding procedure.

After the samples were obtained, Pipe Tek applied a Stopaq coating over the areas where coating samples had been taken before backfilling and reinstating the sites. The second stage of the project will involve isolating the pipe to allow for the construction of the new valve pit.

For the next scope of works, Pipe Tek is proposing a Peterson system for the isolation, which is currently being sourced with the help of fellow pipeline contractor Pro Pipe, which specialises in hot tapping and isolation.

As a result of Pipe Tek’s work on the project, Downer nominated Pipe Tek for its ‘Crew of the Quarter Award’ due to the precautions the team took to mitigate the risk of working in and around the live edge dig sites.

“Fostering a positive culture of open communication and feedback is crucial for promoting collaboration in safety initiatives,”

“Pipe Tek have demonstrated active listening to address improved safety by implementing changes as a need to improve safety outcomes in collaboration with the Downer supervisory site team.

“By prioritising transparency and accountability, Pipe Tek was able to adhere to the Downer standards and deliver the investigation works safely and effectively in a time frame of five days prior to the planned schedule.”

Pipe Tek mitigated the risk onsite by implementing barricades, using fall arrests and safety harnesses, and stringent safety procedures for the work area ingress and egress.

The team also placed mats under the buckets of excavators on bitumen roads and ensured that all Pipe Tek personnel upheld good onsite housekeeping.

Pipe Tek Construction Manager Jess Boulter said the team understand risk management is critical onsite.

“We’re really excited to be nominated for Downer’s Crew of the Quarter,” he said.

“We take the safety of the team onsite very seriously. We work hard to make sure that our sites are secure and we’re complying with the relevant safety regulations because we understand that effective risk management is the critical foundation of a job’s success.”

Collaborating with delivery partners Downer has a strong focus on safety, holding regular Delivery Partner Proactive Safety Forums for its contracting teams. These forums support open discussion, engagement and proactive improvements to how Downer and its delivery partners work together.

“They’re really good to attend,” Boulter said.

“By sharing the most recent key lessons learned or proactive activities and plans from each team means all Downer’s delivery partners are on the same page. Each delivery partner is encouraged to share their prestart approach and process, including expectations, what and who is involved, the questions being asked, and the information that is being captured.

“As one of Downer’s delivery partners, we’ve found the opportunity to provide input and feedback in this way is really valuable in reducing risk onsite. And as a bonus, Downer makes the workshop insights available in a slide pack so that we can easily communicate them to all our team members.”

Pipe Tek Managing Director Myles Brannelly said Pipe Tek’s approach to safety reflects Downer’s.

“We strongly believe that, by working together, we can identify and manage risks to reduce potential injury and illness,” he said.

“No job is so important that it cannot be done safely.”

DETECT, MEASURE, AND BETTER UNDERSTAND YOUR METHANE EMISSIONS WITH ADVANCED TECHNOLOGY

Industry leaders across the globe choose Bridger’s aerial Gas Mapping LiDAR™ to provide operators a more clear picture of their emissions, so they can take control.

LEARN MORE TODAY. Scan here to start the conversation.

For over six decades, the company has proudly manufactured its products right here in Australia – partnering with builders, authority bodies, and its customers to deliver innovative pipe systems and solutions, including PVC, polyethylene (PE), polypropylene (PP), ductile (DICL), and industrial pipe systems.

Providing industry-leading solutions is only the beginning. There’s so much more to Vinidex.

Its products and services have been instrumental in delivering innovative solutions for the natural gas industry that have enabled large-scale gas projects to evolve and thrive as they grow.

“We’re incredibly excited about what the future holds for us at Vinidex,” Chief Executive Officer David Bird said.

“We’re continuing to innovate our products and have an exciting pipeline of new solutions. It really is an exceptionally exciting time to be a part of this transformative organisation.”

The Vinidex difference

Vinidex understands the challenges faced across industries, such as natural gas. The need to build faster, reduce costs and deliver exceptional quality while meeting stringent compliance requirements can feel challenging at the best of times.

That’s why the company ensures its greatest asset is the knowledge and expertise its people bring to every project.

Vinidex is passionate about the role its pipeline solutions play in supporting the flow of everyday life– connecting infrastructure, industry and agriculture. 2023

Across every project, Vinidex always starts by developing a broader understanding of the overall objectives, allowing its team to find innovative solutions that are unique to that specific project.

Since starting its Toowoomba gas facility in 2013, Vinidex has rolled out in excess of 3.8 million metres of PE pipes, constructed 26,000 custom-fabricated assemblies and delivered 30,000 units across product categories.

And there’s still more to come.

Vinidex is integrating a strategically designed and located manufacturing facility close to the gas fields to support projects in the region.

Designed with sustainability in mind, the Toowoomba complex will

The company provides innovative pipe systems and solutions, including PVC, PE, PP, DICL, and industrial pipe systems.

transform its capabilities in warehousing, fabrication and recycling.

As a leader in the industry, Vinidex understands the role it plays in leading that transition to a cleaner future.

To ensure the company focuses on this important objective, the company is developing a sustainability blueprint that encompasses all parts of the business and transparently reflects its ambitions and the pathway to achieving them.

The company is moving to 100 per cent renewable electricity as of 1 January 2025 and in conjunction with PIPA and MPAQ, is proudly a part of the Queensland construction plastics recycling scheme.

Additionally, Vinidex has Environmental Product Declarations (EPDs) for a wide range of its locally manufactured products, which helps customers make informed decisions based on the environmental impact of the product.

As a local manufacturer, Vinidex is also aware of the impact on the local communities in which it operates. The company’s procurement policy ensures its partners adhere to strict Modern Slavery guidelines and supplier code of conduct programs.

Vinidex will have its products and services on display at this year’s Australian Pipelines and Gas Association Convention at the Adelaide Convention Centre.

Contractors Committee

Consultants Committee

Coals Seam Gas Committee

Health, Safety & Environment

Pipeline corridor

Pipeline Engineering Competency

Pipeline Operations Group

Suppliers Forum

Research & Standards committee

WA Chapter

Women’s Pipeline Forum

Young Pipliners Forum

As pipeline projects become more complex, there is a global need to push the boundaries of trenchless infrastructure installations. With an expanding presence in Australia, Michels is rising to the challenge.

Founded in the Midwestern United States in 1959 as a regional natural gas distribution company, Michels quickly expanded its services to meet the evolving needs of established and new customers. Twenty-six years ago in 1988, Michels entered the horizontal directional drilling (HDD) market, offering a safe, environmentally sound way to install utility lines in areas where traditional open-trench construction would not be practical or feasible.

“Keeping with Michels’ spirit of innovation, the

industry, building a reputation for completing the world’s most challenging and significant installations and for continuing to expand the capabilities of its team and its custom-designed and fabricated equipment,” Michels Trenchless General Manager Bryce Morrow said.

“Michels has completed more than 225 pilothole intersect HDD projects and drilled single crossings more than 4700m to become the world’s most experienced direct pipe contractor.”

In 2021, Michels established Michels Trenchless,

Victoria, Australia, bolstering the Michels Family of Companies. Michels Trenchless selectively specialises in delivering technically challenging trenchless installations throughout the region.

In Australia, Michels Trenchless is continuing to demonstrate its ability to succeed with technical challenges that expand the potential for trenchless construction. The team has used its skills to maintain directional control and avoid negative environmental impact while completing a 2243m-long borehole with an elevation change of a staggering 650m. By comparison, the classic HDD profile is commonly composed of five sections: a downward tangent, a parabolic arc, a flat tangent, another parabolic arc and an upward tangent ending at the exit point. In most standard HDD profiles, elevations changes of about 50m between entry and exit locations are considered significant.

The Michels Trenchless team continues to complete additional challenging drills on the same remote project in Australia.

During its foundational years in Australia, Michels Trenchless established the leadership, safety and field operation teams needed to deliver trenchless construction throughout Australia and the Asia Pacific region.

In-country teams have direct access to a large, local fleet of specialised equipment integrated with

Michels now globally experienced technical experts.

“Michels has responded to the need of expanding the region’s trenchless construction capabilities,” Morrow said.

“Michels has the skills, experience, creativity and confidence needed to plan, review and safely construct technically challenging crossings beyond what has been previously achievable by existing domestic capabilities.”

This is far from the first time Michels has completed HDD projects requiring immense levels of skill and power.

“In 2021, Michels completed a 4702m installation of an NPS-24 steel utility line in North Dakota, the likes of which had not previously been attempted at the 24-inch diameter anywhere,” Morrow said.

That same year, Michels completed a 3540m installation of an NPS-12 steel pipe under a golf course and wetland in Burlington, Ontario, the longest HDD in Canada to date. The alignment

horizontal curves along the alignment.

In 2020, Michels completed a 1041m installation of NPS-42 steel pipe under the bow River in Cochrane, Alberta, Canada. A 64.4m

For more information, visit michels.us

Michels has a long history of delivering complex trenchless projects. With a growing footprint in the country, Australian pipeline projects look set to benefit from the company’s expertise.

At this year’s Australian Pipelines and Gas Association Convention, Mipela GeoSolutions is on deck to help solve the pipeline sector’s most pressing data challenges.

The energy transition is ramping up, with more and more businesses moving away from fossil fuels to electrification to drive down carbon emissions in their operations.

As companies face mounting pressure from regulators and stakeholders to decarbonise operations, the role of data – and its value as an asset within an organisation– is increasingly prominent.

Technology is constantly evolving and is often complex. That’s why pipeline companies are turning to Mipela GeoSolutions for expert guidance in data management.

Mipela’s X-Info suite of software solutions turns data collection and analysis into a streamlined process, as it can manage, share, visualise and capture data for clients – connecting people with information.

“Mipela GeoSolutions is helping its pipeline industry customers learn new ideas to align processes and systems to automate tasks and eliminate manual processes,” Mipela Managing Director Hayden McDonald told The Australian Pipeliner.

Mipela GeoSolutions is currently undertaking a digital transformation of the X-Info suite. The phases of this project are to migrate and modernise, so the Mipela team can in turn enhance security, improve reliability, and increase performance.

“We are continuing with our digital transformation, with the migration phase of our new X-Info portal hosting platform in AWS (Amazon Web Services) now complete,” McDonald said.

Leveraging the new and improved capabilities of its X-Info suite assurance solutions, Mipela is

maintaining and aligning its processes and systems, enhancing the security of customer data, while also driving forward future of solutions with new ideas, improvements and innovations.

These solutions can digitalise core business functions, including stakeholder, project, customer relationship and asset management, geographic information, stakeholder engagement, document management systems, and much more, integrates them into a unified knowledge software solution.

“With Mipela, you can easily monitor, manage and improve the efficiency of your business processes to ensure all procedures and steps are completed on time and your projects remain on track,” McDonald said.

“Storing, maintaining, tracking and analysing information within your business has never been easier.”

Mipela will be on the ground at the APGA Convention, highlighting the latest in its suite of digital solutions.

“This year we wanted to visually highlight the race that is underway in the energy transition and the tightrope that we are all travelling along, in a way that people could easily understand in how we align the solutions and services we provide,” McDonald said.

“Whether you’re an established player or just starting out, we help clients accelerate the assurance of their day-to-day data management activities or hosting needs, no matter where they are in their journey along the tightrope.

“To help with this transition, we have decided to stage our convention stand as a psychiatrist’s office to help clients diagnose their most pressing cloud hosting or data management ailments.”

Mipela’s stand will be warm and inviting with a fireplace, chaise lounge, and decorated with the company’s animal mascots and key messages.

“At the convention, we will share how we provide secure solutions in pipeline industry,

enabling your people to be proactive and improving the lifecycle of your day-today activities.

Whether it’s digitalising business practices, environmental, social and governance

accountability, eliminating operational inefficiencies, or improving safety, Mipela has a digital solution for almost anything. The company’s suite of products is helping drive the pipeline sector into the future.

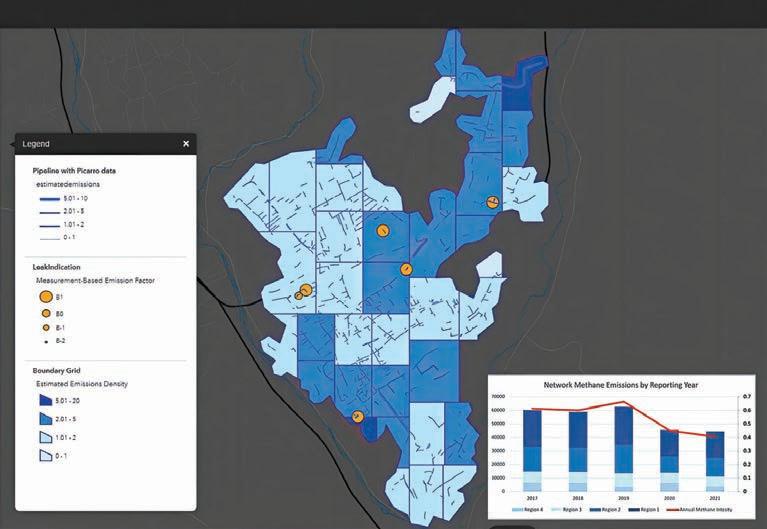

Picarro has launched the updated LISA Priority Scoring system embedded in the P-Cubed platform, a revolutionary advancement in leak management and emission management technology.

The company’s comprehensive datainformed framework, powered by Picarro’s patented data collection systems, provides timely, reliable, and actionable insights that revolutionise risk management.

As regulations evolve, operators can seamlessly manage and reduce system risks, streamline reporting processes, and make well-informed decisions to enhance network performance, delivering significant value across the enterprise.

Picarro’s team of experts has been closely monitoring the rapidly changing regulatory environments, driven by the new regulations in Australia and the European Union on methane emissions, as well as the United States PHMSA’s advanced leak detection programs.

In anticipation of these regulations, the company has also developed emissions360™ ensuring it meets current and future needs of advanced leak detection programs, emissions inventories and abatement strategies.

P-Cubed™ identifies gas emitting locations, called ‘Leak Indication Search Areas’ (LISAs), where the gas operator can then send leak investigators to find, pinpoint and address one or more potential gas leaks.

At the heart of this application is the LISA™ Priority Scoring system.

This sophisticated algorithm is a game-changer for distribution leak surveys. It allows operators to generate tailored reports based on a variety of data sources, including utility DIMP models, pipeline GIS data, and emissions source data gathered by Picarro.

By leveraging these inputs, the Priority Scoring system offers customisable results that enable companies to address the most critical indications effectively. Under this new era of leak management operators will be able to prioritise leak repair in a way that will dramatically increase safety and reduce emissions without overburdening operations with additional repairs.

Picarro Director of Gas Sales and Marketing Doug Ward highlighted the impact of the LISA Priority Scoring system as a powerful tool for leak management.

“By digesting data from diverse sources— utility DIMP models, pipeline GIS data, and

Picarro’s emissions source data—the system provides highly customisable results,” Ward said.

“This new feature from Picarro allows operators to focus on indications that matter most –focusing on risk reduction and system safety.”

With this latest release, P-Cubed provides a comprehensive solution for identifying and managing leaks with precision.

Key features of emissions360 latest release:

• Adjustable Super Emitter (SE) Threshold: A Super Emitter survey program deployed by the gas operator allows the operator to collect and aggregate gas leak and emissions data on their network while identifying only their larger more impactful emitters for follow-up leak investigations. The SE threshold is customisable, allowing users to align it with their specific operational conditions. This flexibility enhances the accuracy of SE counting on the Playbook Page, providing more precise data for decision-making.

• SE Program Planner Enhancements: The SE Program Planner now runs simulations exclusively with Super Emitter leaks. Allowing the operator to accurately plan their abatement

strategies tailored to their system metrics and operational procedures.

• Picarro Inventory Playbook Page: Follow step by step as the software guides users to truly understand their systems emissions. Increase operational efficiency and accelerate reductions by digesting data like never before.

Picarro supports natural gas operators around the globe, addressing the specific challenges they face in leak management and emissions monitoring.

With its advanced technology and user-centric features, P-Cubed offers a forward-thinking approach to managing leaks and meeting regulatory requirements.

In the evolving landscape of emissions control, Picarro is setting a new standard for excellence. By combining cutting-edge technology with a deep understanding of industry needs, Picarro is helping operators achieve significant reductions in emissions while improving overall safety and efficiency.

As the industry continues to evolve, Picarro remains committed to providing innovative solutions that support operators in navigating complex regulatory environments and enhancing their operational practices.

Safe and Effective Solutions for Rapid Pipe Testing & Repairs

Confidently test open-end pipe, pipelines & pressure vessels without welding, and isolate & test flange-to-pipe weld connections with GripTight Test & Isolation plugs from Curtiss-Wright.

• Patented gripper design for increased safety in high-pressure applications

• Eliminates welded end cap procedures for testing pipe spools & piping systems

• Test flange-to-pipe welds without pressurizing entire systems

• Isolate & monitor upstream pressure and vapors during hot work

• Standard pressure ratings up to 15,000 PsiG (1034 BarG)

• ASME PCC-2 Type I, III & IV testing devices

STAND 38 & 40

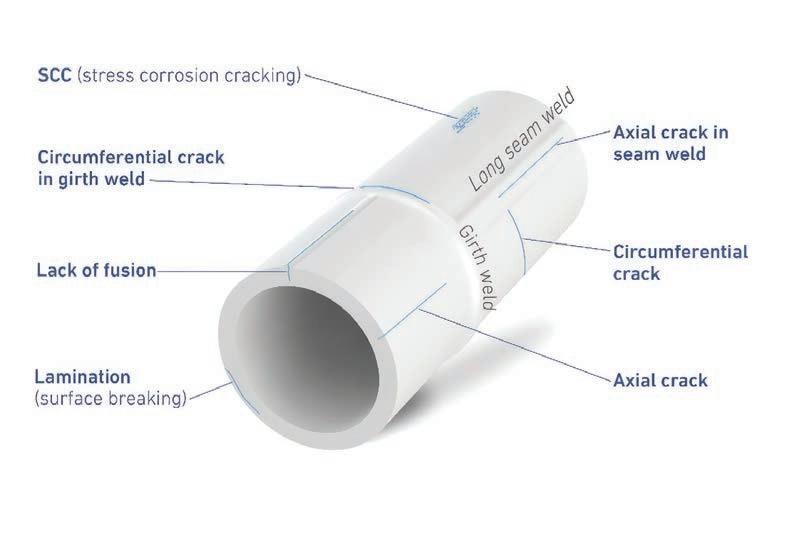

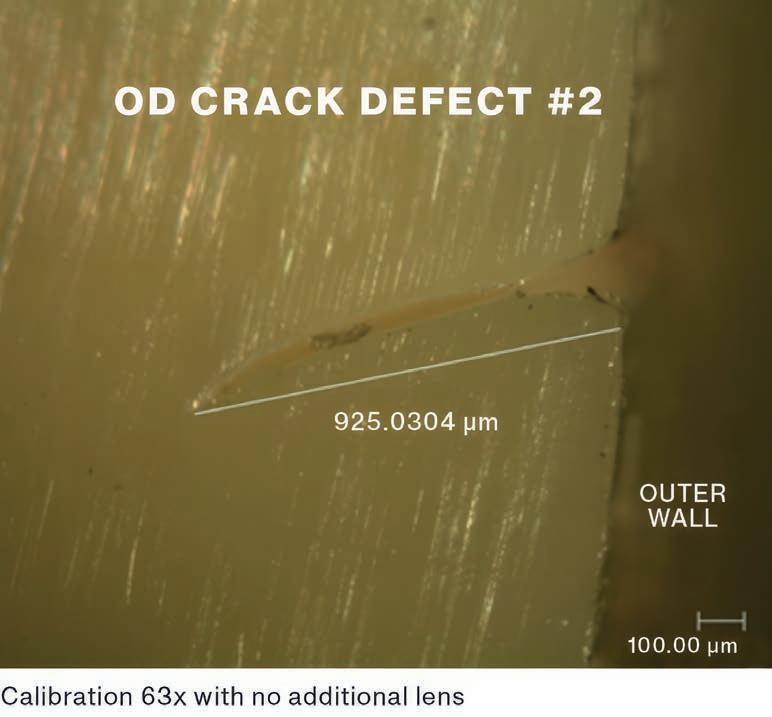

ROSEN Senior Engineer Alex Hazeltine and Principal Engineer Erwin “Erk” Gamboa discuss how data analytics can be used for advanced integrity management of pipelines with cracking.

Pipeline integrity management is critical within the oil and gas industry, where failures can lead to severe environmental, economic and human consequences.

The progress made in advanced in-line inspection (ILI) tools and data analytics fuelled by the ROSEN Integrity Data Warehouse (IDW) has revolutionised the integrity management of pipelines with cracking.

These dual aspects of integrity management not only enhance the detection and characterisation of cracks but also helps inform integrity management activities, ensuring the safety and efficiency of pipeline operations.

The ROSEN IDW is a data repository that is used to store, discover, and understand high quality historical ILI and pipeline information datasets from tens of thousands of pipelines that ROSEN has inspected over multiple decades across the globe.

As the global pipeline network ages, the threat of cracking (particularly stress corrosion cracking (SCC) and fatigue) becomes more prominent. Cracking mechanisms are often complex and can be challenging to both inspect and manage. A good understanding of the cracking mechanism, careful consideration of the inspection technology, data analysis, field verifications and integrity responses are required to ensure effective management of the cracking threat.

A recognised effective method for the management of cracking threats is ILI. Ultrasonic (UT) ILI tools are typically used for liquid lines, while electromagnetic acoustic transducer (EMAT) ILI tools are used for gas lines.

Combining multiple datasets for comprehensive insights

Effective integrity management of pipelines integrates data from various sources, offering a comprehensive view of pipeline integrity and highlighting key focus areas. Key data sources (such as those found in the ROSEN IDW) include:

inspections to identify trends in pipeline integrity. Considering multiple ILI technologies that are not directly used for crack detection but for inspecting other pipeline threats can help improve the understanding of cracking susceptibility along the line. Historical datasets may include:

∘ Corrosion or coating disbondment surveys that can identify locations with conditions suitable for other electrochemical attack mechanisms (such as SCC)

∘ Geometry and bending strain inspections that can report areas of local (dents) and global (bending strain) changes in stress; areas of increased stress are more susceptible to cracking.

• Verification and laboratory data: Destructive and non-destructive testing data is needed to determine the specific cracking mechanism present, allowing more targeted management strategies.

• Operational data: Understanding key parameters such as pressure, temperature, flow rates, and product composition is crucial for understanding possible and existing cracking threats and how to manage them.

environmental systems (including cathodic protection) integrated with inspection data help understand conditions contributing to crack formation and growth.

• Geospatial analysis: The integration of terrain and environmental data helps to identify external factors influencing pipeline integrity, which is crucial for pinpointing high-risk areas and tailoring inspection and maintenance strategies.

Availability of high-quality data is crucial in providing confidence in data analytics insights; sufficient high-quality data is often unavailable for many pipelines across the globe. Work is ongoing within ROSEN to further leverage the vast amount of data within the IDW to fill these data gaps based on datasets from similar pipelines.

The role of data analytics in integrity management

A combination of data analytics techniques and high-quality data sources, such as the ROSEN IDW, can support a robust framework for managing pipeline cracks, providing value throughout the integrity management cycle:

• Susceptibility and predictive modelling: Aggregating data from multiple sources to

• Enhanced integrity decision-making: Access to detailed, up-to-date information allows pipeline operators to make informed

insights that enhance the overall efficiency and effectiveness of integrity management programs.

Advancements in sensor technology, machine learning algorithms, and data processing capabilities are expected to further enhance the effectiveness of decision support systems at all levels. Continued research and development will be required in addressing current limitations and unlocking the full potential of data analytics for ensuring pipeline safety and reliability.

Data analytics represents an emerging opportunity to move the needle in pipeline integrity. Leveraging data analytics allows accurate detection, predictive maintenance, and monitoring of cracking threats, ultimately enhancing pipeline operations’ safety, efficiency and profitability. As technology continues to evolve, integrating data analytics into integrity management practices of pipelines with cracking will play a pivotal role in safeguarding pipelines for years to come.

STAND 70 & 71

Energy is a global market and what happens on the other side of the world is vital for the future of Australia’s pipeline industry.

Written by David Norman, CEO Future Fuels CRC

Hydrogen in Europe has taken four sigificant steps forward this month:

• Shell confirmed it will build a 100-megawatt renewable hydrogen electrolyser in Germany, producing up to 44 tonnes a day of renewable hydrogen to partially decarbonise the Rheinland refinery’s operations. This on top of their 200MW Holland Hydrogen 1 in the Netherlands.

• TotalEnergies took FID on its 350MW OranjeWind project in the Netherlands.

• EWE confirmed their 280MW CHC-EEF project in Germany.

These three new projects will significantly push forward Europe’s capability in delivering and running major hydrogen facilities. Given the ambitious emissions targets set for 2030, more announcements should be occurring soon both for hydrogen and biomethane projects and infrastructure at significant scale.

But the fourth development is even more relevant to Australian pipeliners. The first sections of the European Hydrogen Backbone are now being installed in locations such as Rotterdam, the Netherlands, incorporating capacity for longer term volumes, more than ten times the first projects needs. This project has required foresight, planning, collaboration and support from all stakeholders, especially industry and government. The role of government is crucial, especially providing policy clarity, sufficient investment certainty and financial support to allow the delivery by private sector investment.

Germany’s recent announcements clearly specifying the need for over 9000km of such pipelines for hydrogen by 2032 are yet another such indicator of the rapid recognition of the need for such infrastructure to support industrial decarbonisation, heavy duty transport and firming of the power system.

Europe is at the very initial stages of establishing new supply chains delivering hydrogen to their key industrial centres, similar to Australia’s plans under the now expanded Hydrogen Headstart program targeting heavy

industrial centres. Key is not just the supply of hydrogen but also the need for secure customer offtakes and most importantly to our pipeline community, the necessity of connecting infrastructure. High-pressure hydrogen transmission pipelines and storage is rapidly becoming recognised as an issue to be planned and executed now, not in 10- or 20-years’ time.