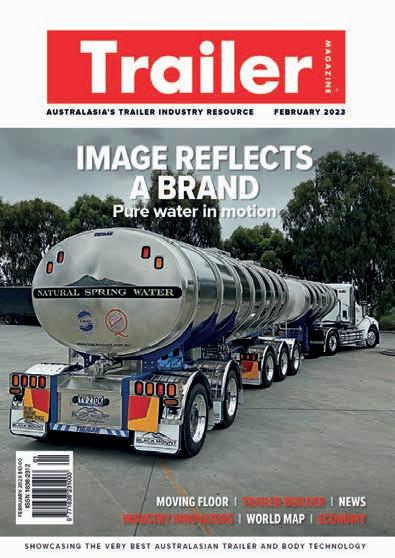

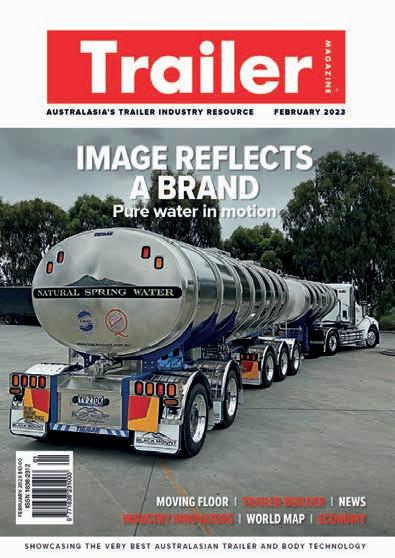

® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE MARCH 2023 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY ISSN 1838-2312 9 771838231003 02 MARCH 2023 $10.00 TRAILER BUILDER NEWS WORLD MAP ECONOMY INDUSTRY INNOVATORS FORMING UP FORMING UP Rank and file Rank and file

PUBLISHER

John Murphy john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Peter White peter.white@primecreative.com.au

Anjali Behl anjali.behl@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Tom Anderson

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS 03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher. Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Honouring the greats

An advocate for transport and logistics was among those recognised in this year’s Australia Day Honours List.

Professor David Alan Hensher has been named a Member of the Order of Australia for significant service to transport and supply chain management.

He has been the founding Director of the Institute of Transport and Logistics Studies since 1990. This Institution aims to contribute to the design, management and optimisation of infrastructure, transport, logistics and supply chain initiatives around the world. It is reported to provide impartial, evidence-based research on key facets of Australia’s economic competitiveness, environmental prosperity and social wellbeing, with a view to informing the management and policy directions of industry and government.

Since 2011 Hensher has been an advisor to statutory body, Infrastructure Australia, a member of the Reference Panel on Public Transport since 2011 as well as a member of the Smart Cities Research and Academic Institutions Working Groups since 2018.

He has held several appointments with Transport for NSW over the years since 1996 and has also been active in other transport institutions. His research interests include discrete choice analysis, transport economics and transport strategy and policy.

David Hurley, the GovernorGeneral of Australia, said the recipients of these awards have had a significant impact at the local, national and international level.

Last year, Dr Alan Finkel was awarded Companion of the Order of Australia for eminent service to science, to national energy innovation and research infrastructure capability, to climate change and Covid-19 response initiatives, and to science and engineering education.

The Order of Australia, which recognises outstanding achievement and service, was established on 14 February 1975 by Queen Elizabeth II with signoff from the Prime Minister of Australia, Gough Whitlam. Australians prior to this received British honours.

From the Editor’s desk

Officially endorsed by the VTA www.trailermag.com.au

4 Trailer Magazine MARCH 23

AAA TRAILERS Jeffrey 0414 671 969 - Jeffrey@aaatrailers.com.au www.aaatrailers.com.au - 02 9188 3222 - 159 Walker St, Helensburgh, NSW 2508 Neil 0418 880 077 – sale1@aaatrailers.com.au – Perth WA TOP QUALITY AND FIT FOR PURPOSE WITH A FOCUS ON SAFETY AND RELIABILITY. DROP DECK TANKERS EXTENDABLE CURTAIN SIDE DROP DECK B DOUBLE CURTAIN SIDE STRAIGHT SIDE TIPPER WIDENER

March 2023

8 Industry news

The latest news and industry developments.

32 Economy

Is this latest move by the Government a steer in the right direction?

34 Refrigerated transport equipment

See a selection of the latest cold chain innovations for road transport.

40 Trailer builder

This month we take a closer look at what Bruce Rock Engineering, CIMC and Graham Lusty Trailers are up to.

46 Trailer building materials/components

These are the suppliers that keep Australia’s heavy vehicles operating safer and more productive.

56 Trailer builder showcase

A list of Australian manufacturers across all major categories from general freight to heavy haulage to tankers.

64 World map

BPW debriefs on last year’s IAA Transportation.

66 Fleet of the month

Ausway Transport on 60 years of operation.

68 Industry Innovators

Daniel Smith-Thompson talks bulk haulage.

70 What’s on Upcoming shows and field days.

6 Trailer Magazine MARCH 23

40 48 34 38 44 52

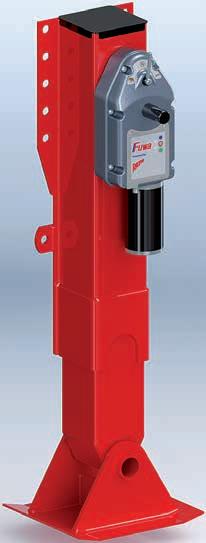

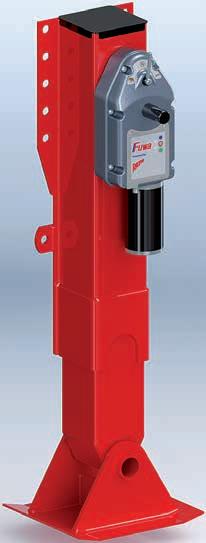

RUNNING GEAR FOR ALL APPLICATIONS AND ENVIRONMENTS FUWA K-HITCH www.khitch.com.au MELBOURNE 13-21 Bliss Court Derrimut VIC 3030 p: 03 9369 0000 f: 03 9369 0100 melb@khitch.com.au PERTH 77B Kurnall Road Welshpool WA 6106 p: 08 9350 6470 f: 08 9350 6570 perth@khitch.com.au BRISBANE 41 Moreton Street Heathwood QLD 4110 p: 07 3372 2223 f: 07 3372 1022 qld@khitch.com.au FOR ALL YOUR EQUIPMENT AND OE SPARE PART REQUIREMENTS, YOU CAN TRUST KHITCH

Works to commence for $400M intermodal terminal in Melbourne

A new $400 million intermodal site in Melbourne’s north is due to begin construction soon.

Intermodal Terminal Company (ITC) will be building the Somerton Intermodal Terminal which is expected to be a key node in the Australian and Victorian governments’ $58 million Port Rail Shuttle Network.

The terminal, the Federal Government claims, will create jobs, remove thousands of truck movements from suburban roads, reduce carbon emissions and increase efficiency as well as safety for producers, farmers, freight operators and exporters.

When at capacity, ITC expect the Somerton Intermodal Terminal to take 500,000 truck trips off Melbourne’s roads – equivalent to 454 million truck kilometres. Each year, it will also save 451 million litres of fuel and reduce carbon emissions by 189,000 tonnes.

“ITC is delighted to announce the Somerton Intermodal Terminal as the first independently constructed, maintained and operated terminal in our portfolio,” said ITC founder and CEO Mishkel Maharaj.

“We’re especially pleased that once operational, the terminal will deliver additional benefits to the people of Melbourne every single day of its operation – through reduced carbon emissions and air pollution, reduced road congestion and improved road safety.”

By 2050 the Port Rail Shuttle Network is expected to move 30 per cent of Melbourne’s containers by rail from Somerton, Altona and Dandenong South to the Port of Melbourne, avoiding thousands of truck trips on roads each year.

The Port Rail Shuttle Network will enable trucks to deliver or pick up containers from these hubs in outer metropolitan Melbourne instead of driving to the Port of Melbourne, which is in turn investing $125 million for on-dock rail infrastructure to cater for these shuttle trains.

“The Port Rail Shuttle Network will not only enhance the strategic importance of local freight and logistics operators – it will also deliver efficiencies and costsavings for businesses,” said Federal Minister for Transport and Infrastructure, Catherine King.

“The shuttle network will also deliver a huge safety boost for motorists by moving freight off the roads and onto rail. I’m thrilled to see this private sector backing for the landmark, project.”

The Somerton Intermodal Terminal will be built at the Austrak Business Park and is forecast to create 190 jobs during

construction and a further 50 permanent jobs for Victorians once the terminal is operational in 2025.

ITC was launched in December 2022 and is backed by one of Australia’s super funds, Aware Super, which last year also entered into a joint venture operation with the Victorian Government to operate the registration and licencing and custom plates businesses for VicRoads.

“The Somerton Intermodal Terminal is a city-shaping project – this private investment will supercharge job creation and support our commitment to move more freight by rail to port,” said Victorian Minister for Ports and Freight Melissa Horne.

“These direct rail connections will get trucks off roads, increase safety, reduce emissions and cut the cost of doing business for producers, farmers, exporters and operators.”

Trailer Axles and Suspension

Trailer Axles and Suspension

Intra Series

Intra Series

Trailer Axles and Suspension

Trailer Axles and Suspension

Duratrac Series

Duratrac Series

8 Trailer Magazine MARCH 23 News

PARTS ON DEMAND

SAF-HOLLAND is one of the leading global manufacturers and suppliers of high-quality axles and suspension systems, fifth wheels, kingpins, coupling products and landing gear to the commercial vehicles industry.

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

Email: sales@safholland.com.au

www.safholland.com.au

Coupling & Lifting Technologies Trailer Axles and Suspension Systems Trailer Axles and Suspension Systems Couplings Powered Vehicle Available in disc and drum Available in disc and drum Intra Series Duratrac Series FW351 Mark V OC50FS2 PH300 50mm–90mm E551B0M Coupling Trailer Axles and Suspension Systems Trailer Axles and Suspension Systems Couplings Available in disc and drum Available in disc and drum Intra Series Duratrac Series FW351 E551B0M Coupling & Lifting Technologies Systems Systems Couplings Powered Vehicle Suspensions Available in disc and drum Available in disc and drum OC50FS2 50mm–90mm E551B0M TOWING SYSTEMS TOWING SYSTEMS

YOU

IT Coupling & Lifting Technologies Systems Systems Couplings Powered Vehicle Suspensions Available in disc and drum Available in disc and drum FW351 Mark V OC50FS2 PH300 50mm–90mm E551B0M

HOLLAND

WHAT

NEED, WHEN YOU NEED

SAF

ORIGINAL PARTS

Missing radioactive capsule recovered

Emergency services secured the Caesium-137 source which fell out of a truck earlier this year.

The search, led by the Department of Fire and Emergency Services (DFES), spanned 1,400 kilometres from the outback to metropolitan Perth and yielded success in just seven days.

The tiny capsule (6mm in diameter, 8mm tall) was located two-metres off the northbound roadside edge of Great Northern Highway yesterday morning.

It was discovered by a vehicle search crew which was using specialised radiation equipment.

The capsule was securely transported in a lead container to Newman for secure storage last night and has been taken to a WA health facility in Perth.

Fire and Emergency Services Commissioner, Darren Klemm AFSM, commended the extraordinary efforts of all agencies and personnel involved in the operation.

“We have essentially found the needle in the haystack,” said Klemm.

“When you consider the challenge of finding an object smaller than a 10-cent coin along a 1,400-kilometre stretch of Great Northern Highway, it is a tremendous result.

“I want to thank everyone involved in the search – we called on a large number of agencies to assist and this was a great example of working together to achieve an outstanding result.”

Western Australia’s Chief Health Officer and Chair of the Radiological Council, Dr Andrew Robertson, said the chances of anyone being contaminated by the source were extremely remote.

“As I have mentioned previously, to be at risk of radiation exposure you need to be close to the source for a period of time,” said Dr Robertson.

“If you were one metre away from the source for one hour, that would be the equivalent of receiving the radiation dose of 10 X-rays.

“This is a great result for the community of Western Australia.”

Update on Princes Highway freight efficiency upgrade

Transport for NSW has released the preferred option for a major safety and efficiency upgrade of the Princes Highway.

The upgrade will take place from Jervis Bay Road to Hawken Road, between Falls Creek and Tomerong.

A Transport for NSW spokesperson said the $500 million Princes Highway upgrade program will deliver a more efficient and connected transport network.

“Upgrading the Princes Highway between Jervis Bay Road and Hawken Road will improve safety for all Transport customers, improve traffic and freight efficiency, as well as connections to regional centres and services,” the spokesperson said.

The upgrade will feature a realignment of the existing highway and widening from two lanes to a four-lane divided highway with median separation, as well as a major intersection at Hawken Road.

“The preferred option will provide greater connectivity for the local community

and visitors, featuring an s-type grade separated intersection (or overpass), as well as service roads to connect properties,” the spokesperson said. A report outlining how the preferred option for the upgrade of the Princes Highway between Jervis Bay Road and Hawken Road, including the intersection type for Hawken Road and the Princes

Highway, is available here.

The report summarises the options that were considered and the criteria used to select the preferred option.

Transport for NSW is encouraging the community to provide feedback on the preferred option to help refine the design and prepare the Review of Environmental Factors (REF).

10 Trailer Magazine MARCH 23 News

INDUSTRY LEADERS IN ROAD TRANSPORT EQUIPMENT, DESIGN, MANUFACTURE & MAINTENANCE

AT BRUCE ROCK ENGINEERING WE ARE SPECIALISTS IN ROAD TRANSPORT EQUIPMENT DESIGN AND MANUFACTURING.

All our trailers are manufactured right here in WA, ensuring 100% quality control throughout the whole build process. Our focus on continuous improvement as industry leaders mean we thrive on innovation and the ability to deliver quality custom and Performance Based Standard designs.

Skel trailers

Evolution side tippers

Road train dollies

Flat tops, drop decks

Deck wideners and extendables

End tippers, bulk and TaREX quarry bodies

Wabash National refrigerated and dry vans

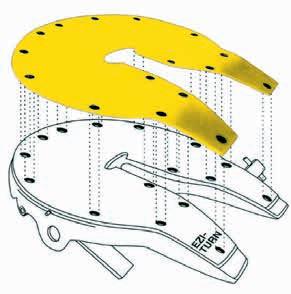

Etnyre live bottom trailers

Titan walking floor and belly dumper trailers

PBS specialis: super quad & super triple

BRUCEROCKENGINEERING.COM.AU

EXTENDED

With

support. For more information email admin@brucerockengineering.com.au or call us on 1300

253

OUR

RANGE INCLUDES:

nationwide sales and

611

NSW WestConnex M4-M5 link open

Transport for NSW has opened an underground connection ahead of schedule as part of the third stage of WestConnex.

The new extensions of the M4 and M8 motorways are now open to the public.

The 7.5 kilometre underground tunnels have been connected to the two motorways, providing a seamless link between Haberfield and St Peters – while cutting travel times by up to 40 minutes between Western Sydney and Sydney Kingsford Smith Airport.

“This is a $3.2 billion project, part of

the $16.8 billion WestConnex, Australia’s largest road infrastructure project, being delivered in partnership by the NSW and Australian governments, Transurban and their partners,” a Transport for NSW spokesperson said.

Transport for NSW Deputy Secretary, Infrastructure & Place, Camila Drover, said the WestConnex project would encourage the development of other projects in the state.

“WestConnex is a major project, a real game changer for Sydney, and it’s also a catalyst for other projects that we’ve

got in delivery,” said Transport for NSW Deputy Secretary, Infrastructure & Place, Camila Drover.

Later this year the Rozelle Interchange will be delivered, completing WestConnex.

Greater Sydney Chief Operations Officer, Howard Collins, said the project’s final stages of construction is underway.

“When we eventually open up the Rozelle interchange, that will connect the Iron Cove and the Anzac Bridges together, bringing in that massive interchange which we open in a years time,” he said.

News

12 Trailer Magazine MARCH 23

QUALITY. RELIABILITY. FLEXIBILITY. SERVICE. TECHNOLOGY.

AUSTRALIA WIDE

Scully RSV Provides Australia’s Largest Dedicated Fleet of Refrigerated

1800 728 559 www.scullyrsv.com.au Info@scullyrsv.com.au Scully RSV offers quality, reliable, and flexible truck and trailer solutions for businesses nationwide. From short & long term hire to new and exfleet sales, and customisation services, we have everything you need to succeed. With cutting-edge technology and a commitment to customer service, make Scully RSV your partner for business growth.

National plan prioritises heavy vehicle rest areas

A national road safety action plan agreed upon by government officials is reported to focus on delivering measurable actions, including the development of heavy vehicle rest areas, over the next three years.

The National Road Safety Action Plan (2023–2025) for the National Road Safety Strategy 2021–30 outlines nine priority areas. Important actions include:

• Improving regional and remote road safety through targeted road safety infrastructure programs.

Fatigue exemption supports emergency service operations

Emergency service agencies will soon be able to manage vehicle operations more effectively while preparing for emergency situations according to the National Heavy Vehicle Regulator (NHVR).

The Regulator has partnered with the Australasian Fire and Emergency Service Authorities Council (AFAC) to deliver a fatigue exemption notice.

NHVR CEO Sal Petroccitto said the National Heavy Vehicle Volunteer Emergency Services Work Diary and Record Keeping Exemption Notice 2023 (No.1) – which comes into effect on 1 February – will exempt drivers of fatigueregulated vehicles from Heavy Vehicle National Law (HVNL) work diary and record-keeper requirements when they are performing an emergency management activity for emergency services.

“Recent events have clearly demonstrated the importance of preparing for emergencies, and this notice will help by cutting administrative red tape for drivers of these vehicles, who are often volunteers,” said Petroccitto.

“The exemption provides efficiency benefits in non-emergency situations, such as relocating fatigue-regulated heavy vehicles pending deployment to an emergency event, or for training and maintenance.

“AFAC members already implement fatigue management policies and controls

that replicate or are more restrictive than standard hours under the HVNL, so the exemption does not pose any additional safety risks.”

AFAC Director Standards and Strategic Procurement Russell Shephard welcomed the exemption.

“AFAC facilitates resource sharing of emergency service personnel, fleet and equipment, enabling a national and, where required, international response to largescale emergency events,” said Shephard.

“A consistent, nationally agreed vehicleissued management log, in place of individual issue work diaries, has been developed alongside this exemption, which captures required information to satisfy the exemption.

“This will be beneficial when using other emergency services vehicles during interstate deployments.”

AFAC Fleet Technical Group Chair Tim Smith (Manager Fleet Operations for the Country Fire Authority, Victoria) supported the move and the associated safety measures.

“The new exemption notice helps improve efficiency for all emergency service operations, without compromising safety,” said Smith said.

“AFAC Members have rigorous systems in place that manage and mitigate risks to public safety related to the use of fatigueregulated heavy vehicles.”

• Progressing the uptake of new vehicle safety features and technologies through new Australian Design Rules.

• Building and upgrading heavy vehicle rest areas.

This follows extensive consultation between the Australian, state and territory governments, the Australian Local Government Association, and a broad range of road safety stakeholders. An annual progress report against the action plan will be provided to infrastructure and transport ministers and publicly released each year, providing transparency on the road safety activities of all governments.

Local governments manage 75.3 per cent of all roads across the network. This action plan includes actions from the Australian, state and territory governments to support and build the capacity of local governments to deliver stronger safety outcomes on their networks.

It also recognises the importance of robust road safety data, committing the Australian, state and territory governments to developing a National Road Safety Data Collection and Reporting Framework. This framework is expected to provide a clearer way to build a national data set for road safety that provides insights into where serious injuries and deaths are occurring and their contributing factors.

The plan also includes the development of a National Research Framework to improve coordination, test new concepts and ideas, develop best-practice approaches and consider emerging issues. This process will commence with a review into the research, funded by the Australian Government, which is currently being undertaking by institutions across the country.

News

Image credit: Nils Versemann / Shutterstock.com 14 Trailer Magazine MARCH 23

OUR CUSTOMERS TRANSPORT MORE PRODUCT

• Winner of the HVIA National innovation award - HighVolume Side Tipper (HVST)

• Equipping the Agriculture, Bulk Transport, Mining and Waste Industries

• Combinations are engineered to run at max mass across PBS networks in each state – with certification

• The latest Manufacturing technology supports the GLT craftsmen, to increase safety and improve product quality

• Marine grade Aluminium alloy bodies

• 700 grade steel chassis

• World class axles, suspension & brake systems

• Over 75% of GLT trailers are built for repeat customers

• 100% Australian manufactured

1300 731 442 sales@gltq.com.au

grahamlustytrailers.com.au

WA terminal key to new cargo route

A new cargo shipping link connecting Australia and Asia began operating last month, which comes with a $35 million investment to transform a terminal in Western Australia.

ZIM Integrated Shipping Services (ZIM) has chosen DP World’s Fremantle Terminal for the new cargo service linking Western Australia with its trading partners in Southeast Asia. The inaugural service arrived at Fremantle on January 30 and it is anticipated to heavily expand the capacity for imports and exports from Western Australia.

The new ZIM Thailand-Fremantle Express (TFX) connects Ho Chi Min City (Vietnam) – Laem Chabang (Thailand) – Port Klang (Malaysia) – Sydney –Melbourne – Fremantle – Port Klang – Ho Chi Min City.

Along the route, the TFX will call at two

DP World terminals – Laem Chabang and Fremantle terminal.

The new service is recognition of DP World Australia’s $35 million investment to transform the Fremantle Terminal to deliver additional capacity with improved performance, reliability, and operational efficiency. Over the next 12 months, the terminal will introduce new equipment such as quay cranes, reach stackers, forklifts, internal transfer vehicles, as well as upgraded IT infrastructure and operating systems to enhance terminal capabilities and boost trading opportunities for the west coast.

“Our investment into the Fremantle business will help us build a diverse and flexible operating model to service the Western Australia market,” said Glen Hilton, CEO & Managing Director for DP World Pacific & Australasia.

“The new ZIM TFX service is a further boost to these efforts as we look to unlock opportunities for our customers and partners by transforming port

operations and connect Australian businesses to new emerging markets.”

DP World are a provider of worldwide smart end-to-end supply chain logistics, enabling the flow of trade across the globe. Their comprehensive range of products and services covers every link of the integrated supply chain – from maritime and inland terminals to marine services and industrial parks as well as technology-driven customer solutions.

“As a strategic link to the Western Australian economy, DP World is committed to improving trading opportunities that will support and meet the needs of our customers and contribute to local economic growth and competitiveness, said Andrew Adam, CEO, DP World Australia.

“We are proud to be partnering with ZIM on the new TFX service, which will further bolster trade connectivity between Western Australia and emerging markets in Asia.”

DP World deliver these services through an interconnected global network of more than 300 business units in over 75 countries across six continents.

16 Trailer Magazine MARCH 23 News

Hardox® In My Body equipment is light, strong and cost-effective to operate, with high load capacity and long service life. Smart design and the latest grades of Hardox® wear steel makes it all possible. Hardox® steel is constantly developed to deliver unmatched combinations of wear resistance and structural performance. hardoxinmybody.com

Contact SSAB Brisbane. Melbourne. Perth G1, 28 Balacalva Street Woolloongabba, QLD 4102 australia@ssab.com hardox.com Taking quality to the next level

LEVEL UP YOUR DUMP BODIES

FoodBoss accepts 10th Schmitz Cargobull trailer

New South Wales-based refrigerated transport company, FoodBoss Transport, has taken delivery of a new Schmitz Cargobull refrigerated trailer.

The trailer is the 10th of its kind in the fleet, and will travel around NSW delivering frozen and chilled foodstuffs to its clients.

iNSTRUCKTA! safety project launches in WA

TRANSAFE WA officially launched its iNSTRUCKTA! safety truck initiative project at a gala event last month.

iNSTRUCKTA! is the name of TRANSAFE WA’s custom truck and semi-trailer combination which is spec’d to deliver innovative educational road safety programs.

The gala took place on 25 January at the banks of the Swan River in Western Australia at Burswood On Swan, and was attended by 170 guests who were the first to experience the virtual reality (VR) learnings, touch screen quizzes and the projection wall.

At the event, TRANSAFE WA announced that iNSTRUCKTA! was ready to tour schools and community events throughout WA.

TRANSAFE WA Executive Officer, Robin Sharpe, said the team was pleased to launch the vehicle.

“After many years of consultation, planning and construction, TRANSAFE WA’s Committee of Management and Staff are very proud to have been able to reach the milestone of launching our dedicated safety truck,” he said.

“Our aim is to encourage all road users to interact safely with trucks on the road to help reduce number of unsafe incidents.

“This will be done via virtual reality immersion, touch screen quiz learnings,

video clips and also by giving our participants a chance to physically sit in the cabin of our truck to see what a truck driver can and can’t see when interacting with other road users.”

The vehicle has 10 truck seats which allow participants to be immersed into the truck’s cabin via VR headsets.

As part of the experience, participants can learn about overtaking trucks, turning trucks, cutting-in and blind spots.

There are also 10 wall-mounted tablets where participants can complete a touch screen road safety quiz and a projection wall that plays road safety messages.

In addition, all users who take part in the program are encouraged to pledge to interact safely with all trucks on the road.

National Heavy Vehicle Regulator (NHVR) CEO, Sal Petroccitto, was privileged to attend the launch.

“It’s a been a while since I’ve been able to travel to the West Coast, and so I really enjoyed being in Perth to celebrate the launch of TRANSAFE WA’s iNSTRUCKTA! yesterday,” he said.

“iNSTRUCKTA! is a great initiative that will further educate young drivers on how to drive safely around heavy vehicles, through their customised semi-trailer mobile classroom.”

The project was made possible with the support of the NHVR’s Heavy Vehicle Safety Initiative (HVSI) which was

FoodBoss Transport Managing Director, Ian Gibson, told Trailer that the quality of Schmitz Cargobull’s products and its exceptional lead times led to the new addition.

“We ordered the first one around five years ago and we were pretty happy with their delivery times which is why we’ve thrown our business their way,” he said.

The new trailer features Schmitz Cargobull’s double loading system with loading bars capable of sliding to the roof, which Gibson said has been very useful as it prevents operators from physically handling them underneath the trailer.

“The safety factor with the double loading bars is a big plus,” he said.

“They all slide to the roof, and when we need them we can easily bring them down.”

Gibson said he has seen Schmitz Cargobull’s refrigerated trailers capable of holding their temperatures extremely well over the years which also sealed the deal for him.

“I’m very happy with them,” he said. “Their thermal qualities are as good if not better than anything else on the market. And the team at Schmitz Cargobull have been great to work with.”

supported by the Federal Government, WA’s Road Safety Commission and other industry partners.

In December last year, TRANSAFE WA announced that CBH Group had become its newest Gold Safety Partner.

“Amazing effort by TRANSAFE WA and all supporters to put this together,” said Toll HSEQ Manager, Kate Martin. “Looking forward to seeing this out and about, raising awareness about road safety around heavy vehicles.”

18 Trailer Magazine MARCH 23 News

8.25 x 22.5 Aluminium 10 Stud 285 PCD REEFER TRAILERS IN STOCK NOW! FULL CHASSIS 12 PALLET A TRAILERS 22 PALLET B TRAILERS 26 PALLET PBS TRAILERS SHORT CHASSIS 22 PALLET 24 PALLET Vertical Double Load System Flush Mounted - Extra Width 3 – Tube Air Chute 1200mm Powder-Coated Toolbox Fitted with Swirl Plate Fitted with Road Train Cross-member, provisions for inatallation of tow coupling Schmitz Cargobull Premium Reefers B-Doubles, PBS Trailers, Semi-Trailers Load Securing Rail Horizontal Load Restraint System Flush Mounted - Extra Width CONTACT US TODAY TO FIND OUT MORE: 03 8794 6000 www.cargobull.com LUKE HARDEMAN 0467 001 515 SIMON HAKVOORT 0478 848 292

Port of Newcastle expands in empty containers

The Port of Newcastle’s container ambitions are continuing to grow, with container operations now forming part of the Multipurpose Terminal’s services at the Mayfield 4 Berth.

The Empty Container Park compliments Port of Newcastle’s Multipurpose Terminal container capability and growth, which is located adjacent to the Multipurpose Terminal – minimising additional landslide movements.

Port of Newcastle CEO, Craig Carmody, said over 60 per cent of New South Wales container exports in the financial year ending 30 June 2022 were empty containers.

“Empty container management is a vital function for efficient container trade operations,” he said.

“Empty container parks aid in managing

the imbalance between imports and exports that exists within Australian container operations by assisting container flow.”

Port of Newcastle Senior Manager of Business Development, Kate McArthur, said access to a ready supply of empty containers will allow farmers to export more produce in the future.

“Having access to empty containers aids speed to market, which allows exporters to take advantage of opportunities and capitalise on good prices,” she said.

“We are hopeful by working with farmers, business owners and other key stakeholders we can continue to develop infrastructure to better serve the needs of our future customers.”

According to McArthur, a challenge for

agri-businesses in the last few seasons has been accessing empty containers to fill and send back to port.

“With growth of our operations and capabilities, we aim, over time, to fill this gap in the market and ensure our farmers and agri-businesses have every opportunity to take full advantage of large harvest seasons and export their product effectively and efficiently,” she said.

Back-of-berth hardstand expansion works are currently underway at the Multipurpose Terminal, with waterside works to begin later in the year to accommodate larger vessels.

Once complete, the Multipurpose Terminal will be able to accommodate 85 per cent of container vessels that arrive in Australia.

20 Trailer Magazine MARCH 23 News

certified

Australia Day Honours for transport and logistics specialist

An advocate for transport and logistics has been recognised in this year’s Australia Day Honours List.

Professor David Alan Hensher has been named a Member the Order of Australia for significant service to transport and supply chain management.

He has been the founding Director of the Institute of Transport and Logistics Studies since 1990.

This Institution aims to contribute to the design, management and optimisation of infrastructure, transport, logistics and supply chain initiatives around the world.

It provides impartial, evidence-based research on these key facets of Australia’s economic competitiveness, environmental

prosperity and social wellbeing, with a view to informing the management and policy directions of industry and government.

Since 2011 Hensher has been an advisor to statutory body, Infrastructure Australia, a member of the Reference Panel on Public Transport since 2011 as well as a member of the Smart Cities Research and Academic Institutions Working Groups since 2018.

He has held several appointments with Transport for NSW over the years since 1996 and has also been active in other transport institutions.

His research interests include discrete choice analysis, transport economics and transport strategy and policy.

Hensher has also been the recipient of

JOST promotes National Employee of the Year winner

Equipment specialist, JOST Australia, has announced the promotion of Kirsty Dragon to State Manager QLD.

According to JOST, Dragon has been working tirelessly behind the scenes in an operational role where she will meet an extensive customer base, focus on further developing strong relationships and improving customer experiences.

“With her vast background in business development, customer service management and operations & warehouse management, the Queensland

branch and its customers are in great hands,” said JOST.

Dragon was the recipient of JOST’s National Employee of the Year for ‘Delivering the Promise’, which recognised her excellence in providing the best solution for customers’ needs.

“With her dedication and commitment to anything she tackles backed by the support of a great team, we know she will continue to drive high-quality customer experiences for our JOST customers,” said JOST.

other awards and recognition over the years including:

• John Shaw Medal, Roads Australia, 2019.

• Inaugural University of Sydney Vice Chancellor’s Outstanding Research Award, 2016.

• Transport Profession Award, Institute of Transportation Engineers, 2014.

• Smart 2013 Premier Award for Excellence in Supply Chain Management.

• Lifetime Achievement Award, International Association of Travel Behaviour, 2009.

• Outstanding Contribution to Industry Award, Bus NSW, 2009.

• Transport Medal, Engineers Australia, 2006.

Team Global Express announces new facility

Team Global Express is developing a new 9,970 square-metre, purpose-built facility in Altona North, Melbourne.

Team Global Express announced that it has partnered with Aliro Group and ISPT for the construction of the facility, which is strategically located on a 41,000 square-metre site in Melbourne to service the company’s complete intermodal offering across rail, road and sea.

With easy access to road, port and rail networks, the facility will provide important supply chain benefits for its customers.

Construction is underway and is expected to be completed in the second half of 2023.

Image credit: aiyoshi597 / Shutterstock.com 22 Trailer Magazine MARCH 23 News

B-DOUBLE DROP DECK CURTAINSIDER

• Full mezz deck

• Hanging gates, toolboxes & provision for tow coupling

• Locally supplied curtains

45’ Drop Deck with BiFold Ramp

• 12V Power Pack

• 3 Way Twist locks

• Machinery tie-down points in floor

45’ DROP DECK TRAILER

• 3 Way twist locks

• Toolbox, tyre carrier and load racks

• Provision for tow coupling

13.7-21.5m Extendable Flat Top

• 3 Way Twist locks

• Pneumatic warning flags

• Provision for tow coupling

40’ DROP DECK SKELETAL TRAILER

• 3 way twist locks

• Dangerous goods rated

• Container tilt airbag fitted

40’ 3 WAY SKELETAL

• Standar & lightweight designs

• Side loader pads

• Provision for tow coupling

• CIMC has a long term commitment to Australia by investing in infrastructure to provide high quality products, support and service.

• Local production capacity for Semi-Trailers and Tankers with CNC cutter, welding machines and start-of-the-art heated paint shop.

• Comprehensive parts store stocking genuine CIMC parts, along with additional OEM sourced items.

• Dedicated service & repairs workshop.

• Total site area 51,000 sqm, with a 13,000 sqm workshop.

Melbourne CIMC TRAILERS 1300 202 462 20 Whitfield Blvd, Cranbourne Brisbane CIMC TRAILERS 0423 795 649 68 Tile Street, Wacol Perth GTE 08 9352 4000 159 McDowell Street, Kewdale Sydney JRB GROUP 02 9355 3400 26 Bosci Rd, Ingleburn 19 Hale Street, Botany ENQUIR E NOW 1300 202 462 www.cimc.com.au | sales@cimc.com.au

WITH LOCAL KNOWLEDGE Your semi-trailer experts.

GLOBAL LEADERS

Western NSW road upgrade to enhance agriculture supply chain

The agriculture supply chain is set to benefit from upgrades to a key freight route in New South Wales following a $5 million boost.

The NSW Liberal and Nationals Government are injecting $5 million into the project which is expected to improve safety and freight efficiency

Minister for Regional Transport and Roads, Sam Farraway, said the funding would upgrade a major section of Bourke Shire Council’s Bourke to Milparinka via Wanaaring Road project.

Government to complete upgrades along the vital route,” said Farraway.

“We are building the infrastructure that matters and this additional funding will deliver increased resilience, capacity, and improved reliability of freight movements from western NSW to major centres and inland ports across the state.

“The funding will go towards sealing the remaining 28 kilometres of road from Bourke to Wanaaring and replacing Cuttaburra Creek Bridge with a doublelane, three-span bridge.

Bourke Mayor, Barry Hollman, said the funding will build on the work already done by Bourke Shire Council and will enhance the agriculture and broader supply chain within western NSW.

“This upgrade will bring greater social and economic benefits to the community, farmers and businesses across the region by providing a more resilient and reliable access route between Bourke and Wanaaring,” said Hollman.

“Having a hardier, sealed surface

Goujon / Shutterstock.com 24 Trailer Magazine MARCH 23 News

Image credit: Serge

also allows us to bundle this offering with our domestic and global transportation solutions delivering considerable value to our customers,” said AFS Logistics CEO, Sam Eid.

The HACCP certified site features 8,600 square metres of floor space, which

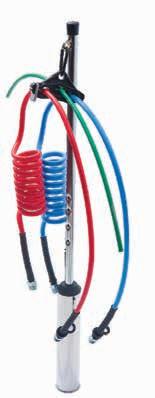

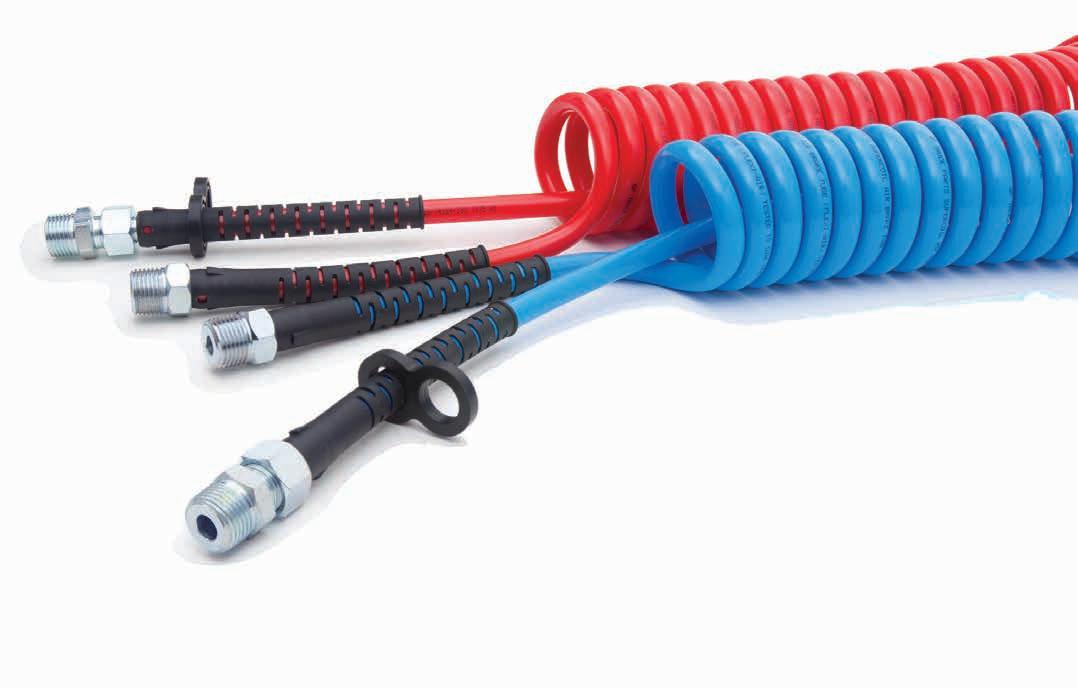

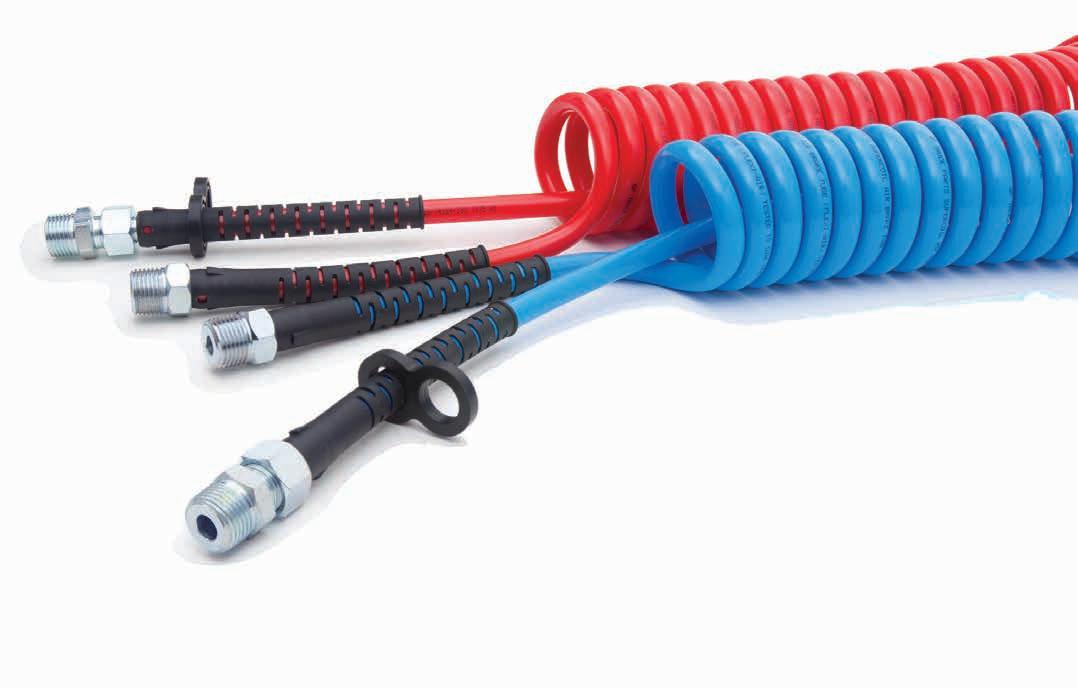

ANTI KINK SUZI-COIL

and next day delivery services as well as providing more bespoke value add services like kitting and returns management,” said McDonnell.

The business was founded in 1995. It currently supports more than 80 leading brands across Australia and abroad.

TEC-CLAMP

SUZI-COIL CLAMP

The new 4 hole TEC-CLAMP allows you to lock in your lines and go! No tools or hardware needed for fast, easy installations!

Versatile design can be used with both rubber air hose or coiled tubing hook-ups.

3 hole NEW 4 hole

GP-9889

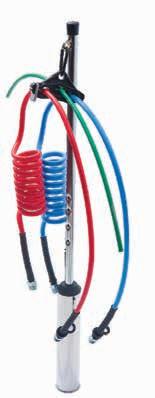

POGO STICK & TECCLAMP COMBOS

Part# GP-925-C

Chromed steel heavy duty Pogo Stick

Part# GP-925-C3

Chromed Pogo Stick with 3 hole

Tec-Clamp

Part# GP-925-C4

Chromed Pogo Stick with 4 hole Tec-Clamp

GP AIR COUPLINGS TRUCK & TRAILER

Huge range of Air Couplings & Adaptors to suit your truck or trailer. GP Air Couplings & Adaptors are designed & manufactured to conform to the Australian Design Rules ADR-38/05, Australian Standards AS4001.3-2003.

GP TRUCK PRODUCTS available from Truck & Trailer parts outlets Australia wide. Compliant Standards: ADR-38/05 & DOT Phone +61 3 9580 1811 sales@gptruckproducts.com.au www.gptruckproducts.com.au UNCOMPROMISING PERFORMANCE

Couplings - Male, Female, Sealing & Non sealing. Adaptors - Male, Female, Sealing & Non sealing. Dust covers, Adaptor plates, Trailer coupling locks

Partnership bolsters growth opportunities for women in transport

Prime Creative Media (PCM) has formalised its support for Transport Women Australia Limited (TWAL) by becoming a Gold Partner.

This follows a strong history of collaboration and shared values between both organisations.

For John Murphy, PCM CEO, strengthening the partnership with TWAL simply ‘made a lot of sense’.

PCM, through its suite of industry magazines, digital platforms, events and Australian Truck Radio, has been involved in the transport industry for more than 20 years.

Murphy admires the dedication and innovation of TWAL and had seen firsthand the value of the work it does for

the transport industry, and in particular its role in encouraging more women into the industry.

“This association certainly walks the walk,” he said.

“They do what they say they’re going to do.

“They are just so professional in their approach.

“We think this is a great opportunity to support one of the most important associations in this industry.”

TWAL Chair, Jacquelene Brotherton, said the announcement of this exciting partnership would help her group to continue to grow its offerings and further support the transport industry.

Brotherton said PCM’s support for

TWAL over many years has helped the organisation to build its membership base and boost the visibility of women working across the many varied roles within the transport sector.

She said the Gold Partnership agreement would serve to strengthen the existing relationship with PCM and provide TWAL with greater certainty of funding into 2023 and beyond.

TWAL was formed in 1999 by eight women working in the transport industry who were determined to see women given a stronger voice in the industry they love.

The work has continued to this day with TWAL hosting regular conferences and networking events, conducting detailed research and providing training, scholarships, awards, advice and

Brotherton, who has been involved in the transport industry for more than 50 years, said it had a great story to tell, but traditionally was not very good at telling it.

TWAL’s latest initiative on the storytelling front takes the form of its

The campaign aims to promote a positive image of the transport and logistics industry and highlight the camaraderie of the people in it.

A key element of the promotion is the Living the Dream song and music video co-written by brand agency Branthem

The song has proven to be popular with listeners on Australian Truck Radio, where it has been played since its release and TWAL hopes to further extend its audience by releasing it on Spotify and Apple Music in the coming months.

In 2018, as part of the fifth annual Women in Industry Awards, Brotherton received the ‘Excellence in Road Transport’ accolade for her efforts with improving the Australian road transport

Brotheron joined the transport industry in 1970 and has worked for several major transport companies with more than 20 years in livestock transport and roles in fleet management, general and refrigerated transport operations as well

26 Trailer Magazine MARCH 23 News

Followmont’s Brisbane Convoy for Kids trailer hits the road

Followmont Transport’s 2022 Brisbane Convoy for Kids trailer has been on the road for more than three months.

Followmont Transport said in a statement: “With over 30 businesses placing their stamp on the trailers and generous families and individuals donating, this travelling billboard is a fantastic cause to get behind and one that our Followmont team are proud to support.”

Meanwhile, planning is reported to be underway for this year’s Brisbane Convoy for Kids which will be held Saturday 4 November at Redcliffe Showgrounds.

This event aims to fundraise for the selected Brisbane Children’s beneficiary.

This Trailer of Hope was deployed November last year.

The Trailer of Hope concept was introduced as part of the 2019 Brisbane Convoy for Kids.

The 2019, 2020 and 2022 Trailers of Hope are reported to be operating along Australia’s east coast.

ATRPLUS.COM.AU WINGFIELD, SA 08 8347 3434 YOUR SERVICE PARTNER IN REFRIGERATED TRANSPORT Installation, Servicing & Repairs of Refrigeration fitouts Truck & Trailer Body & Tailgate Repairs Lighting Solutions for Vehicles & Trailers Truck Sleeper Bunk AirConditioning Authorised Sales, Service and Repair Agent for Mitsubishi Heavy Industries Thermal Systems in SA TRANSPORT REFRIGERATION | AUTO ELECTRICAL | CUSTOM FABRICATION Celebrating17years!

New driver distraction laws set for Victoria

New driver distraction road rules are set to be introduced in Victoria.

These will come into effect across the state from 31 March.

According to research distraction is a key contributor to road trauma, with the risk of drivers crashing increasing when texting, browsing or emailing.

Distraction is also involved in at least 11 per cent of fatalities – equal to 20 people each year whose death is avoidable.

The new rules will extend existing mobile phone rules to cover modern technology – as one third of drivers admit to using their phone illegally while driving.

“Distraction is deadly – which is why we’re introducing these new road rules to protect the lives of Victorians,” said Minister for Roads and Road Safety Melissa Horne.

“Everyone has a role to play in keeping our roads safe, so when you’re driving, please make the right choices – pay attention and don’t be distracted,” she said.

The new laws will bring Victoria in line

with the Australian Road Rules, and cover in-built vehicle systems, mounted devices, wearable and portable devices such as smartwatches and tablets.

A two-second glance at a device means a driver is travelling blind for 28 metres while driving in a 50km/h zone – and the distance jumps to 55 metres when travelling at 100km/h.

Motorists caught driving distracted will receive penalties of four demerit points and a $555 fine.

The Victorian Government is also investing $33.7 million as part of the Victorian Road Safety Strategy 2021-2030 to introduce new mobile phone and seatbelt detection camera technology that will help catch people using their mobile phones and not wearing their seatbelts while driving.

The new cameras are estimated to prevent 95 crashes that result in injury or death per year.

Mobile phone and seatbelt detection

technologies involve AI-enabled camera systems that can capture highresolution images of passing vehicles in all conditions, including poor weather and low light levels when distracted driving is even more dangerous.

The new camera technology will be operational on Victorian roads in coming months. A three-month warning period will apply from the technology’s activation before drivers face infringement and demerit penalties.

“Too many drivers continue to put lives at risk using mobile phones behind the wheel. We’re deterring this type of risky behaviour on our roads with these new road rules, as well as phone and seatbelt detection technology,” said Minister for Police Anthony Carbines.

“We need every motorist to make the right decisions when they’re behind the wheel. When they don’t, road safety cameras and Victoria Police are there to hold them accountable.”

News

28 Trailer Magazine MARCH 23

VIC Council calls for better freight network

Baw Baw Shire Council is asking for more support from the Victorian Government to plan a better heavy vehicle road network.

In the lead up to the 2023 state budget, Baw Baw Council launched a community advocacy campaign calling for State Government action and investment to plan a better road network for Drouin and Warragul.

According to Council, with Baw Baw’s population outpacing most Victorian municipalities, the Shire’s 100-year-old arterial network is ‘out of date and not designed to accommodate today’s volume of traffic’.

“Factor in increasing residential construction, continuing population influx, growing demand for local agriculture and resources and a new West Gippsland Hospital on the way, and it is easy to see that Baw Baw’s already inadequate road network is facing unsustainable pressure,” it said in a statement.

“That’s why Baw Baw Shire Council continues to advocate to the Victorian Government to allocate $3 million to Regional Roads Victoria to plan a fit-for-purpose, future ready, arterial network.”

The recommended road upgrades would include building three new town alternate heavy vehicle routes to remove heavy agricultural and industrial vehicles from major town centres, the duplication of Princes Way between Drouin and Warragul and works to make several major intersections safer and more efficient.

Baw Baw Shire Council Mayor, Annemarie McCabe, said the region’s 100-year-old network is past its use by date.

“It just isn’t designed to cope with our region’s rapid growth,” she said.

“With more than 20,000 new homes expected to be built in the coming years we urgently need the Victorian Government to plan and upgrade our roads to accommodate our growing population.

“We need a ground swell of local voices to make sure the state government pays attention and builds the road network Baw Baw Shire needs and deserves.”

Image credit: David L Young / Shutterstock.com

Rural Road Alliance calls for $5B package

An emergency funding package totalling nearly $5.5 billion has been called for by the newly-formed Rural Road Alliance.

Representing diverse stakeholders from across regional Australia including farmers, transporters and local councils, the alliance has requested provision be made in the next Federal Budget in response to the critical challenges facing Australia’s rural road network in the wake of recent flooding and high rainfall.

The Alliance includes GrainGrowers, the National Farmers Federation (NFF), Australian Local Government Association (ALGA) and Australian Livestock and Rural Transporters Association (ALRTA).

Since January 2022, there have been 23 flood events, with 429 declarations across 277 local government areas (LGAs).

In the last two months, the ongoing east coast flooding event has seen more than 82,000km impacted by flood-related closures across New South Wales, Queensland, Victoria, and South Australia, while Western Australia has experienced the devastation of Cyclone Seroja.

The Alliance said recent flooding had taken a wrecking ball to regional roads, including the nationally significant Hume, Newell, Calder, and Western highways.

Natural disasters and extreme weather events have already cost the Australian economy $5 billion in 2022, according to Treasury estimates, as a result of

widespread disruption to key industries such as agriculture.

GrainGrowers Chair, Rhys Turton, said the rural road network was now at breaking point.

“We’re already seeing recently repaired roads crumbling. It’s thrown a challenging grain harvest into disarray as farmers and transporters struggle to move grain from paddock to port,” said Turton.

NFF Chief Executive, Tony Mahar, has labelled the damage as catastrophic.

“We’re looking for a substantial, long-term commitment. We can’t be left driving on decimated roads once the politicians and news cameras move onto the next disaster,” said Mahar.

ALRTA Executive Director, Mat Munro said the damage was already undermining productivity and safety in the regions.

“Severely damaged roads are dramatically increasing the time and cost of moving freight to and from our rural production centres,” he said.

“It’s harder on our vehicles, it’s harder on our drivers, and it’s harder on our livestock. It’s holding back development of our regional communities and undermining safety and welfare for all users of country roads,” he said.

ALGA CEO Matt Pinnegar said the ongoing impacts of severe weather

events should prompt a fundamental shift in the way Australia funds, delivers and maintains its roads.

“The flooding, fires and cyclones we’ve seen over the past few years are unprecedented. What we need now is unprecedented funding – not just to repair our roads, but to strengthen them for future events,” he said.

In the lead up to the Federal Budget, the Rural Road Alliance is calling for an emergency funding package totalling nearly $5.5 billion, including:

A one-off injection of $1 billion over four years directed at regional road and infrastructure reconstruction for councils impacted by flooding and other natural disasters to ensure the rebuild is to a standard more resilient to future disaster events; $800 million a year over four years for the Roads to Recovery Program; $300 million a year over four years to address first and last mile freight productivity; and targeted funding through the Roads of Strategic Importance program to improve the long-term climate resilience of freight networks.

The Alliance said its proposed funding package was an opportunity for the Federal Government to stem the rapid deterioration of Australia’s rural road network, and to reduce the cost to the budget of future climate events.

News

30 Trailer Magazine MARCH 23

Image credit: mastersky / Shutterstock.com

to increase freight

The Australian Rail Track Corporation (ARTC) has dismantled an existing steel single-track rail bridge and constructed a new concrete double-track bridge as part of the Botany Rail Duplication project.

The bridge works included moving and installing two 36.5-metre-long main bridge girders over Robey Street, New South Wales – weighing 330 tonnes each – during a five-day track closure.

Twenty-four planks were also installed to form the bridge deck using a 600-tonne crawler crane and a 650-tonne mobile crane working simultaneously.

The project will duplicate the remaining 2.9-kilometre section of single line track to Port Botany and construct a passing loop on the Southern Sydney Freight

Line at Cabramatta to accommodate freight trains up to 1,300 metres in length.

The Australian Government is fully funding ARTC to deliver the $400 million project, which will deliver better access to global export markets via Port Botany, improve freight supply chains across New South Wales and help reduce the number of trucks on local roads.

Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said the project will contribute towards an increase in freight within the region.

“Port Botany is a major gateway for Australia and the world, and investing in its growth is vital to the economic wellbeing of the nation,” she said.

“When completed, this project will allow

Toll rebate needed for heavy vehicles

Relief for motorists, promised by the New South Wales Opposition, from the toll system, needs to be expanded to heavy vehicles according to the National Road Transport Association.

NatRoad CEO Warren Clark said Labor’s pledge for expanded toll rebates for motorists who are heavy toll road users needs to be matched by incentives to take trucks off suburban streets.

“The Opposition says specific measures for trucks are on the way and

our response is: ‘Bring it on’,” said Clark.

“It’s great to hear that the Opposition has adopted our recommendation to a Parliamentary committee that a ‘commissioner for toll roads’ be appointed to examine the current regime’s impact on heavy vehicles,” he continued.

NatRoad, according to Clark, would welcome any such appointment.

“We note that one of the things on the commissioner’s agenda would be

freight to be moved more efficiently and effectively, ensuring we are ready for an anticipated 77 per cent increase in freight task by 2036.”

ARTC Group Executive Major Construction Projects, Mike Zambelli, said the project is on track to be completed in 2024.

“Not only will this project increase freight capacity, it will also encourage more freight movements to be made by rail – helping to shift freight away from road transport and reduce truck movements and associated traffic congestion,” he said.

“Each extra freight train travelling on the Port Botany Rail Line will take up to 54 trucks off Sydney’s roads and that will be well received by local road users.”

ways to get more freight on toll roads at night, which is something else we have pushed,” he said.

“NatRoad was invited to participate in a review of tolls by NSW Treasury and Transport but their report has yet to surface. That review needs to report now, not later,” said Clark.

“Tolls matter to heavy vehicle operators who have to use Sydney roads. We look forward to hearing from the NSW Government.”

www.trailermag.com.au 31

A steer in the right direction?

The Federal Government has finalised the membership of the Heavy Vehicle Rest Area Steering Committee as part of its $140 million initiative.

During December last year, the Federal Government announced that it would be establishing a steering committee which would give truckies a voice in shaping projects funded under the heavy vehicle rest area initiative.

The Labor Government’s first Budget delivered an additional $80 million for new and upgraded heavy vehicle rest areas, bringing dedicated heavy vehicle rest area funding up to $140 million over 10 years.

The Government has since announced that the committee – chaired by former truck driver, Senator Glenn Sterle – will

be joined by representatives of the following organisations:

• Tasmanian Transport Association Executive Director, Michelle Harwood, who will represent the Australian Transport Association;

• N ational Road Freighters Association President, Rod Hannifey, who is also a long-term truck driver and road safety advocate;

• F ormer President of the Australian Livestock and Rural Transporters Association, John Beer, who is also a veteran long-distance truck driver; and

• H ealthy Heads in Trucks and Sheds

Board Member, Paul Ryan.

The organisational representatives will be joined by five truck drivers, all of whom were selected through an expression of interest process:

• Kellie Boland: From Victoria, Boland has held a heavy vehicle license for 30 years and her family has been ownerdrivers for three generations;

• B ruce Skelton: From Queensland, Skelton has been involved in advocating for the correct use of heavy vehicle rest areas and has driven long haul trucks for 40 years;

• Frank Black (Arcidiaco): From South

Key to that success is utilising the experience, insight and knowledge of the truck drivers and road safety advocates on the committee

“ ”

32 Trailer Magazine MARCH 23 XXX Economy

Australia, Black has been the owner driver representative on the Australian Trucking Association general council for the last 20 years and has driven long haul trucks for 35 years;

• H eather Jones: From Western Australia, Jones sits on the WA Road Freight Industry Council, is the Co-Founder of the Pilbara Heavy Haulage Girls and has driven long haul trucks for more than 30 years; and

• Craig Forsyth: From New South Wales, Forsyth is a Board Member of the National Road Freighters Association and has driven heavy vehicles for 26 years. The steering committee will meet for the first time in February.

Senator Glenn Sterle said he was

thrilled to be named Chair of the Heavy Vehicle Rest Area Steering Committee.

“The announcement of the membership of the steering committee means that we can now get to work to deliver meaningful outcomes for truck drivers,” he said.

“Key to that success is utilising the experience, insight and knowledge of the truck drivers and road safety advocates on the committee and I can’t wait to get to work.

“I’d like to thank every driver who took time out of their busy schedule to complete an expression of interest to be a part of this process and offer my congratulations to those who have been selected.”

• 30 + years in the market place

• Clean, grease-free fifth wheel

• More cost effective

• Easy to fit

• Consistent steering characteristics

• Environmentally friendly

• Australian designed & manufactured

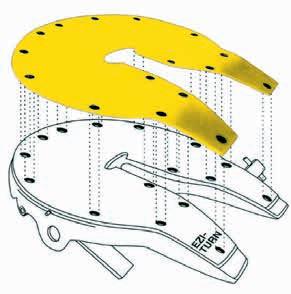

• Used by some of the most highly respected companies since 1990 EZI

Interest rate January 2023 Inflation expectations January 2023 Loan growth December 2022

Confidence 0 5 -5 -10 -20 10 15 20 25 10 10 6 5 0 -4 -1 1 13 16 3 Apr 2022 Jul 2022 Oct 2022 Jan 2022 7 IS MANUFACTURED IN AUSTRALIA BY: EZI-PRODUCTS PTY LTD 2 RUTHERFORD ROAD, SEAFORD VICTORIA, 3198 PH: (03) 9775 0766 Email: info@eziturn.com www.eziturn.com

STOCK AFTER-MARKET REPLACEMENT KITS TO SUIT MOST GREASELESS OR LOW-LUBE FIFTH WHEELS.

3.1%

5.6% 8.3%

Australian Consumer

WE

EURO 16B

JGL 37

EZI

Lineage of quality with Schmitz Cargobull

Temperature-controlled logistics company, Lineage Logistics, has taken delivery of eight 24-pallet Schmitz Cargobull trailers to serve Lineage’s customers in Victoria.

Patented in 1978, Schmitz Cargobull’s Ferroplast panel still is the backbone of every refrigerated or ambient trailer body sold under the Schmitz Cargobull label. Since the product was launched, the company has delivered hundreds of thousands of Ferroplast-based trailers worldwide, indicating just how popular the technology is within the wider transport community.

Lineage Logistics was one of the most recent transport companies to invest in Schmitz Cargobull’s innovation with its eight new refrigerated 24-pallet refrigerated trailers.

The units, which will be used for local work for Lineage’s customers in Victoria, feature Schmitz Cargobull’s latest in-built

racking system which have the capability to slide up to the roof, making the lives of owners and operators much easier.

“The roof-mounted load bars are attached to the trailer itself, so there’s no issues in losing load bars which happens in traditional equipment,” says Lineage Logistics General Manager of Transport for Australia, Justin Ryan. “This was the main reason why we decided to go with Schmitz for this order, in addition to the fact that they were able to offer us a short lead time.”

In the last two years alone, Lineage Logistics has invested over $20 million into its fleet with new trailers and prime movers. By making the decision to invest in quality manufacturers such as Schmitz

Cargobull, Lineage’s purchases have shown to prove their worth in the fleet.

“With these 24-pallet configurations we get an extra capacity per trip as opposed to an extra two spaces per trip, so in the end it helps us with high utilisation in our loads for our local distribution,” Justin says. “There was a bit of a focus on trying to get the overall weight of the trailers lower to allow for more capacity as well.”

Each of the eight trailers are fitted with Carrier HE19 refrigeration plants to give the fleet a reduction in fuel usage and CO2 emissions. They also come with a series of comprehensive GPS temperature tracking, among a plethora of safety features the trailers have

34 Trailer Magazine MARCH 23 XXX Refrigerated transport equipment

increase safety elements for our drivers and reducing our emissions as well. At the end of the day, we want to ensure that our operation is always compliant for weight and that our customers’ products are protected, while keeping our drivers and the general community safe.”

Lineage accepted delivery of the trailers just before Christmas and are already a favourite among drivers.

makes everything so much easier for them.”

This order was Lineage’s first deal with Schmitz Cargobull, marking the beginning of the relationship between both companies. By experiencing Schmitz Cargobull’s well-known positive aftersales service, Justin says it’s off to a good start.

“The follow-up on their behalf has been quite good since the implementation,”

They were quite innovative, and they were very keen to understand what we’re looking for.”

Contact Schmitz Cargobull Australia

Unit 2, 221 Browns Road

Noble Park North 3174 VIC

Ph: +61 434 743 144

Web: www.cargobull.com.au

www.trailermag.com.au 35

Carrier’s next big leap –hydrogen-powered refrigeration

Carrier Transicold’s next hydrogen fuel cell system will be an energy-efficient and environmentally responsible solution for road transport refrigeration.

36 Trailer Magazine MARCH 23 XXX Refrigerated transport equipment

It just keeps getting better and better with Carrier Transicold. The company has been at the forefront of diesel and electric power for refrigerated transport for many years, but with its latest leap into hydrogen fuel cell technology Carrier has entered a league of its own. The new Hydrogen Vector concept is a real breakthrough as the complete fuel cell is inside the fridge replacing the diesel engine.

Developed in close cooperation with Bosch and PowerCell Sweden AB, the fuel cell system was specifically designed to integrate within the chassis of the Carrier Vector transport refrigeration unit (TRU). The key to the success of this technology is the integration of a Bosch 48-volt automotive battery, which directly interfaces the fuel cell with the refrigeration unit, removing the need for a standalone engine or a separately mounted buffer battery system. The result is an innovative system that delivers zero direct emissions without a reduction in performance or refrigeration capacity.

It will deliver the same level of autonomy as existing diesel engines used in the standard Carrier Vector units, and by using a hydrogen fuel cell system, customers can maintain operations with the legacy products sans any of the associated emissions.

The new fuel cell system is powered by hydrogen tanks coupled with an electric power distribution unit (PDU). The PDU is used to convert the direct current provided by the fuel cell into the alternating current needed to operate the refrigeration unit. The refilling time for the new concept is equivalent to a standard diesel engine.

Following successful field tests in Europe and improvements on the demonstrator version presented in 2021, the latest system is highly advanced offering benefits such as elimination of the need for an additional battery for energy storage, and 100 per cent autonomy for installation in all types of trailers, even retrofit. The new hydrogen fuel cell technology will be coupled with Carrier Transicold’s Vector HE 19 trailer unit.

The first trailer concept was showcased at the 2022 IAA Transportation in Hanover, Germany.

It wouldn’t have been possible without the pioneering work Carrier has done over a long period of time with the Vector E-Drive™ platform and the recent Vector eCool. Competitors now have an even longer way to catch up to the level of sophisticated technology that Carrier is using currently.

Carrier Transicold is also behind France’s first electric-hydrogen powered truck with an all-electric, engineless refrigeration unit.

Carrier Transicold’s path-breaking E-Drive™ system has long been mainstay of the company’s trailer systems. The unique design of the all-electric system removes the need for the mechanical transmissions found in belt-driven truck and trailer refrigeration systems. It makes the system ideally suited to operate on the electric power derived from the hydrogen cell, delivering increased efficiency and reduced risk of refrigerant leaks.

“Carrier Transicold continues its

electrification journey, providing an electric solution in every area of the temperaturecontrolled transport market, from vans through to multi-temperature trailers,” say Kelly Geddes, Director, Product & Aftermarket Solutions, Carrier Transicold. “The new hydrogen-powered Vector concept is a major step forward for the company. We are committed to exploring every avenue to reduce emissions and deliver better sustainability for customers – and hydrogen fuel cell technology is extremely exciting.”

The new concept Vector with hydrogen integration is yet another contribution towards Carrier Transicold’s drive to help its customers avoid over one gigaton of greenhouse gas emissions as part of its environmental, social and governance goals for this year.

Contact

Carrier Transicold Australia

Ph: 1800 448 166

Web: www.carrier.com.au

www.trailermag.com.au 37

Reliability and compliance at the fore for Scully RSV

To meet an increased demand for food service distribution from their new site at Chullora, PFD Foods recently took delivery of several brand new 14-pallet refrigerated trucks from Scully RSV. The journey of PFD Foods began in Victoria, back in 1943 delivering seafood across the state. Post the Second World War, consumption of seafood grew and so too – the distribution network. According to the Melbourne Seafood Centre, Melbourne Fish Market back in those days was situated along Flinders and Spencer Streets and where PFD Foods made their first food deliveries. Conveniently accessible to the rail routes delivering fresh seafood from Adelaide, it was at these markets the seafood would begin their next journey and where PFD Foods comes in. Today PFD Foods is still headquartered in Victoria, operates over 60 distribution centres across the country and employs over 3,000 staff.

The organisation is Australia’s largest family operated food service network delivering a range of dry goods, frozen and chilled products, fresh seafood and meat and confectionery. Their clientele includes pubs, clubs, cafes, airlines, hotels, restaurants, aged care facilities and retirement villages, cruise ships, resorts and theme parks, convenience outlets, venue and field caterers, fast food outlets, schools and kindergartens, and sporting, child care and correctional facilities.

In 2018, PFD Foods consolidated its Sydney operations to a purposebuilt facility at Chullora. The site has 22 loading docks, a workshop, truck wash and a seafood processing facility. The site services New South Wales and into parts of the surrounding states, with seafood distribution state wide. With such a wide distribution network and an incredible breadth of

transported goods, PFD Foods needed a wide range of vehicles to carry out deliveries – from 14 pallet trucks to two pallet carriers. They contacted national refrigeration transport provider, Scully RSV, a partner of over five years. “We’ve been using Scully’s 14-pallet trucks for deliveries to hospitals for almost a year. Other vehicles are involved in transport in the Sydney CBD and for airline food service deliveries, while the smaller vehicles were extensively used for deliveries during the busy holiday season,” says Nashenas (Nash) Zarmati, PFD’s Chullora Transport Supervisor. “Scully have great products and we get good support from Brendan Pfitzner, Scully RSV’s NSW/ACT Business Development Manager for all the fleet and servicing needs.”

Scully RSV was established over 30 years ago in Brisbane, Queensland, and true to its roots the company

Scully RSV offers customers like PFD Food Services a huge selection of modern refrigerated vehicles and services featuring the latest technology.

38 Trailer Magazine MARCH 23 XXX Refrigerated transport equipment

continues to manufacture its range of refrigerated truck bodies from the Brisbane suburb of Archerfield. However, today the Queensland operations are complemented by its national network of company owned branch facilities. “That’s really been the secret of Scully RSV’s incredible growth story in recent years,” says Andrew McKenzie, Scully RSV’s CEO. “Scully RSV is uniquely positioned in the market as we have the network and breadth of fleet comparable to the other generalist rental companies that service the road transport industry, yet we have the depth of product offering to support the unique needs of cold chain logistics companies.”

Today the Scully RSV fleet comprises around 1,000 assets that range from a one-pallet Ute, through to road-train multi-temp trailers. “The breadth and depth of our fleet supports one of the core values that Scully RSV stands for –reliability. And for food service providers this is critical,” Andrew says. “We

don’t rent prime movers; we don’t rent curtainsiders or skels. Our customers know that if they need to rent a meat hanger to cart carcases, or a 20-pallet low height roller door distribution van on a new metro supermarket job – whatever it may be – they can ring us and as Australia’s largest refrigerated truck and trailer rental company we can help them to deliver on their promises.”

“If for whatever reason we don’t have it available today, chances we can facilitate a solution,” he adds.

However, fleet availability is just one element to Scully RSV’s success,

compliance is the other. Of course, managing a safe and compliant fleet of trucks and trailers goes without saying, but it’s the nuance of what is required to cart temperature sensitive food and medicine that sets Scully RSV apart. “Scully RSV has, and continues to, invest heavily in new technology to better manage compliance both within our business and with our customers.

All of Scully RSV’s new trucks and trailer come fitted with the latest GPS technology, but that’s hardly new or exciting,” Andrew says. “What is exciting is what we do with the data and how we can seamlessly integrate it with our customers in their day-to-day operations which is really cool, and where the operational efficiencies live for our customers.”

Contact Scully RSV Ph: 1800 728 559 Web: www.scullyrsv.com.au

“ ” www.trailermag.com.au 39

... as Australia’s largest refrigerated truck and trailer rental company we can help them to deliver on their promises.

Against the grain

Based in Western Australia, Campbell Transport has offered a wide range of logistics-related services to its clients for over 20 years.

Having begun the business with a focus on agricultural bulk haulage in 1997, Campbell Transport has since diversified its services and progressively grown to now offer clients a much wider range of services. These include bulk haulage with extensive mine site experience, off road bulk haulage in larger payload custom road trains, general freight, agricultural bulk haulage and grain handling, storage and warehousing solutions, oversized loads and heavy haulage operations, earthmoving and road maintenance tasks, and a harvesting capability for multiple commodities.

Due to its plethora of operations, Campbell Transport has gained extensive experience hauling on highway using specialised equipment such as Performance Based Standards (PBS) road trains and other combinations, depending on what is required for the job

to ensure maximum efficiency. Its fleet of over 400 trailers – mostly of Bruce Rock Engineering’s (BRE) finest tippers – is expected to grow with a further 30 on

order from the manufacturer to increase grain capacity and close to an extra 100 trailers per year.

Campbell Transport Managing Director,

Travelling the distance of the Earth’s circumference two and a half times every day and carting 500,000 tonnes of bulk commodities around Western Australia monthly is possible for Campbell Transport with Bruce Rock Engineering’s durable trailers.

40 Trailer Magazine MARCH 23 XXX Trailer builder

the best side tipper in the market for what we do,” he says. “We started dealing with BRE in 2016 because of the payload and stability on their trailers. We wanted to be able to maximise our payload, which is the most important part, and we also needed a combination that was stable and safe on the road.”

Campbell’s BRE end tippers are made of steel rather than alloy.