® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE MARCH 2024 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY ISSN 1838-2312 9 771838231003 02 $10.00 AGRICULTURE EQUIPMENT ECONOMY SPECIAL REPORT TRAILER BUILDER WORLD MAP ISSN 1838-2312 9 771838231003 02 Dependable and manufactured to precision GAINS Ambient TRANSPORT EQUIPMENT NEWS

PUBLISHER

John Murphy

john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee

luke.applebee@primecreative.com.au

EDITOR

Peter White

peter.white@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Louise Surette

louise.surette@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Tom Anderson

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston

michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766

subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher.

From the Editor’s desk

Future nostalgia

Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Tzaneros, addressed the current state and potential future of Australia’s supply chain industry. He suggests we all need to be appropriately prepared.

Following the return of those who took time off for the Christmas and New Year’s period, Tzaneros is anticipating the global supply chain to experience many varying challenges in 2024. Shortages in skilled labour, local road closures, pallet accessibility, industrial disputes, shipping delays in the Red Sea and a possible Covid-19 comeback, he outlined, are all valid threats.

“With all these potential issues at hand, proactive planning in this current global logistics climate is absolutely critical,” said Tzaneros. “Increased inventory, higher shipping rates, storage of FCL or palletised goods, access to stock is cheaper than a loss of customer.”

However, despite the challenges of 2023, and escalating geopolitical tensions into 2024, business leaders are remaining surprisingly optimistic according to new research from Economist Impact and port operator, DP World.

The primary driver is a growing belief that technology will transform the efficiency and resilience of supply chains. Unveiled at the World Economic Forum in January, the global survey of 3,500 company executives found technologies which improve supply

chain efficacy and resilience to be the main source of optimism for business leaders when asked to assess the future of global trade.

Interesting enough, at the centre of this view is the widespread adoption of Artificial Intelligence (AI), which 98 per cent of respondents reported are already using to revolutionise at least one aspect of their supply chain operations. A third of businesses are also utilising AI to deliver a reduction in overall trade operation costs and the same amount to enhance resource and supply chain planning.

On the other hand, the results found concerns that political instability, rising trade friction and global fragmentation could hamper growth are increasing. A fifth of businesses are distressed with higher tariffs, or uncertainties around tariffs, in key markets they export to or import from.

To prepare for what may be to come, Tzaneros said it is absolutely imperative that importers and exporters start changing their behaviour for supply and start thinking and acting in line with Covid-19 times.

“Business became resilient during these testing times,” he said, “and it became very clear that ‘just in time’ was an outdated model, and ‘just in case’ was the new norm.”

4 Trailer Magazine MARCH 2024

Officially endorsed by the VTA

C M Y CM MY CY CMY K

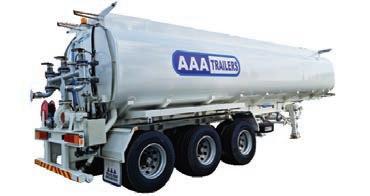

TRAILERS

DROP

DECK

TRAILERS

FLAT DECK

TRAILERS

TIPPERS TANKERS PRIORITISING �UALITY AND SAFETY IN TRAILER INNOVATION CALL 1300 333 888 reception@aaatrailers.com.au www.aaatrailers.com.au Locations in Perth, Brisbane, Sydney, Melbourne, Darwin and Adelaide

�UAD AXLE LOW LOADERS CURTAINSIDER

SIDE

March 2024

8 Industry news

Business partnerships, people movements, developments that bolster freight productivity and more.

26 Economy

Decarbonisation, diversification and digitalisation are the ‘Three Ds’ the Federal Budget should invest in according to Ai Group.

28 Refrigerated transport equipment

See the latest cold chain technologies in road transport.

34 Trailer builder

Australia’s trailer manufacturing industry is as strong as ever.

42 Agriculture equipment

Croplands Equipment is introducing a new line of 13,000-litre boom sprayers in collaboration with BPW Transpec.

44 Trailer building materials/components

A showcase of the products and services that keep trailers on the move.

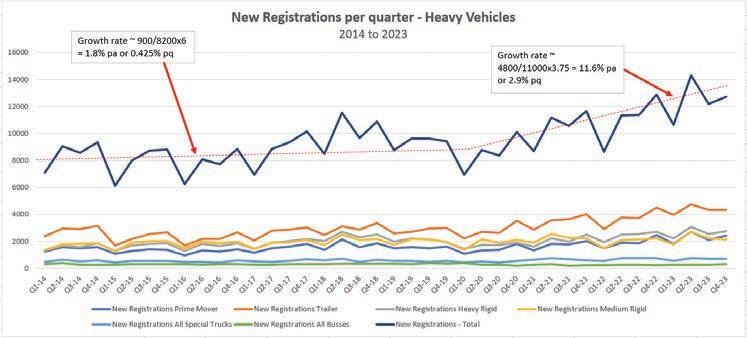

64 Special report

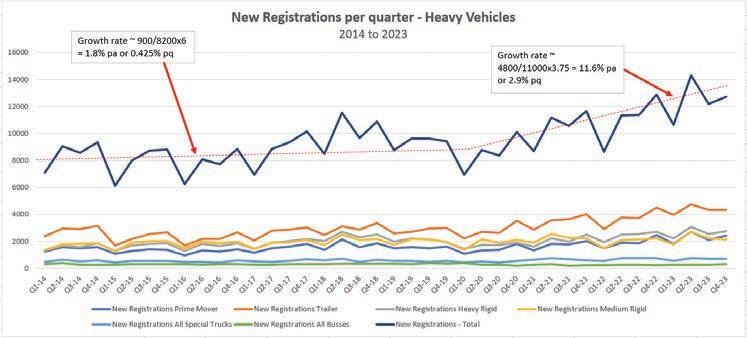

ARTSA-i Data analytics reflects on the past decade of heavy vehicle market data.

66 Haulmax Tyres Trailer Builder Showcase

A list of Australian manufacturers across all major categories from general freight to heavy haulage to tankers.

76 Infrastructure spotlight

What you need to know about Australia’s biggest road projects this month.

78 World map

There are plenty of opinions as the American trailer industry assesses the future.

80 Fleet of the month

Wickham Freight Lines maintains an enviable reputation among its peers as a steadfast and reliable long-distance carrier.

82 What’s on

Upcoming shows and field days.

6 Trailer Magazine MARCH 2024

28

30 32

60

44 42

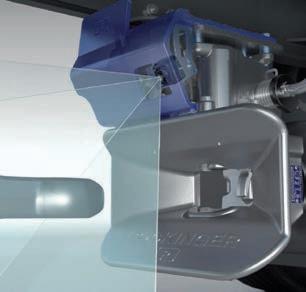

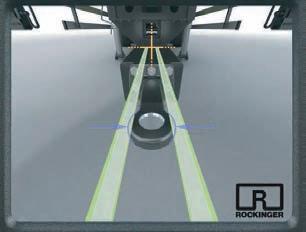

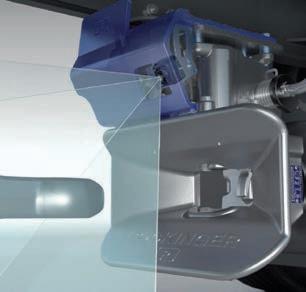

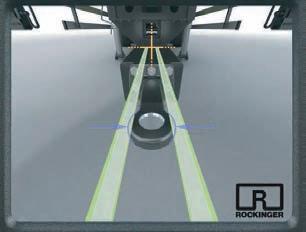

Easily Retrofit to the Popular HOLLAND

FW351E & FW331

Fifth Wheel

FLASHING RED WARNING LED LIGHTS FOR FAILED COUPLING ATTEMPT

HIGH INTENSITY WHITE LED LIGHTS FOR SUCCESSFUL COUPLING ATTEMPT

FAILED COUPLING – In the case of a failed coupling attempt, bright red flashing LED lights assist the driver to quickly recognize a potentially costly mistake.

helps drivers GET IT RIGHT!

SUCCESSFUL COUPLING – A successful couple triggers highintensity white LED lights, strategically aimed at the kingpin and lock for enhanced visibility during the inspection process, especially in poor weather and low-light conditions.

Robust electrical components: sealed one-piece harness, long-life LED lights, durable inductive sensors, and steel encased logic module ensure reliable operation in the toughest conditions.

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

Email: sales@safholland.com.au

www.safholland.com.au

Queensland Govt shifts heavy vehicle compliance to NHVR

Tasman Logistics Services announces joint venture

The Queensland Department of Transport and Main Roads (TMR) is transitioning heavy vehicle regulation services to the National Heavy Vehicle Regulator (NHVR).

Currently, regulation for heavy vehicles is managed by TMR.

However, under the changes these services will transition to the NHVR, resulting in a more consistent approach to compliance and enforcement nationally.

This is part of a national reform program to ensure the regulation of heavy vehicle movements throughout Australia is safe and efficient.

Transport and Main Roads Minister and Minister for Digital Services, Bart Mellish, said the transition will improve road safety outcomes for Queensland road users.

“The transition of heavy vehicle compliance activities to the national regulator will ensure a consistent approach to compliance and enforcement and will deliver a best practice regulatory approach across all jurisdictions,” he said.

“TMR has been working closely with the NHVR, to ensure a seamless transition for our people and our customers.

“Following the transition TMR will continue to be directly responsible for delivering regulatory and compliance

activities for light vehicles including passenger vehicles and tow trucks under 3.5 tonne.”

The change will come into effect on 20 April 2024.

NHVR CEO, Sal Petroccitto, said the transition of services in Queensland is a significant milestone for the NHVR as it finalises its 10-year journey in becoming a national regulator.

“I am thrilled we are a step closer to achieving our aim, of having a consistent approach to compliance and enforcement from the roadside to interventions, borderless operations and delivering timely, national responses to critical compliance issues,” he said.

“I look forward to working with our industry and government partners as we move into a phase of harmonisation to embed national consistency within the heavy vehicle sector across regulatory processes, compliance and enforcement standards.”

Queensland is the final jurisdiction to transition these services to the NHVR.

New South Wales, South Australia, Victoria, Tasmania and the Australian Capital Territory have already transitioned.

Western Australia and the Northern Territory have not adopted the Heavy Vehicle National Law.

A new integrated supply chain company has emerged.

Tasman Logistics Services has partnered with Aviva Prime Philippines to launch Aviva Tasman Corporation.

“Our new partnership specialises in sourcing food products direct from farmers and distributing across all of the Philippines through our facilities and logistics network in a manner not seen before,” said Tasman Logistics Services CEO, Ivan Vanis.

“I am so proud of our combined efforts to put all of this together. Following the successful completion of our first food project together, which was done with absolute precision and quality exceeding all of our customers expectations.”

Last year, Tasman Logistics Services acquired Ryans Group.

Also, Katharina of Tasman Logistics Services was presented with the Female Leadership Award at the 2023 Australian Freight Industry Awards (AFIAs)

Vanis was the recipient of the Young Achiever of the Year Award at the 2020 AFIAs.

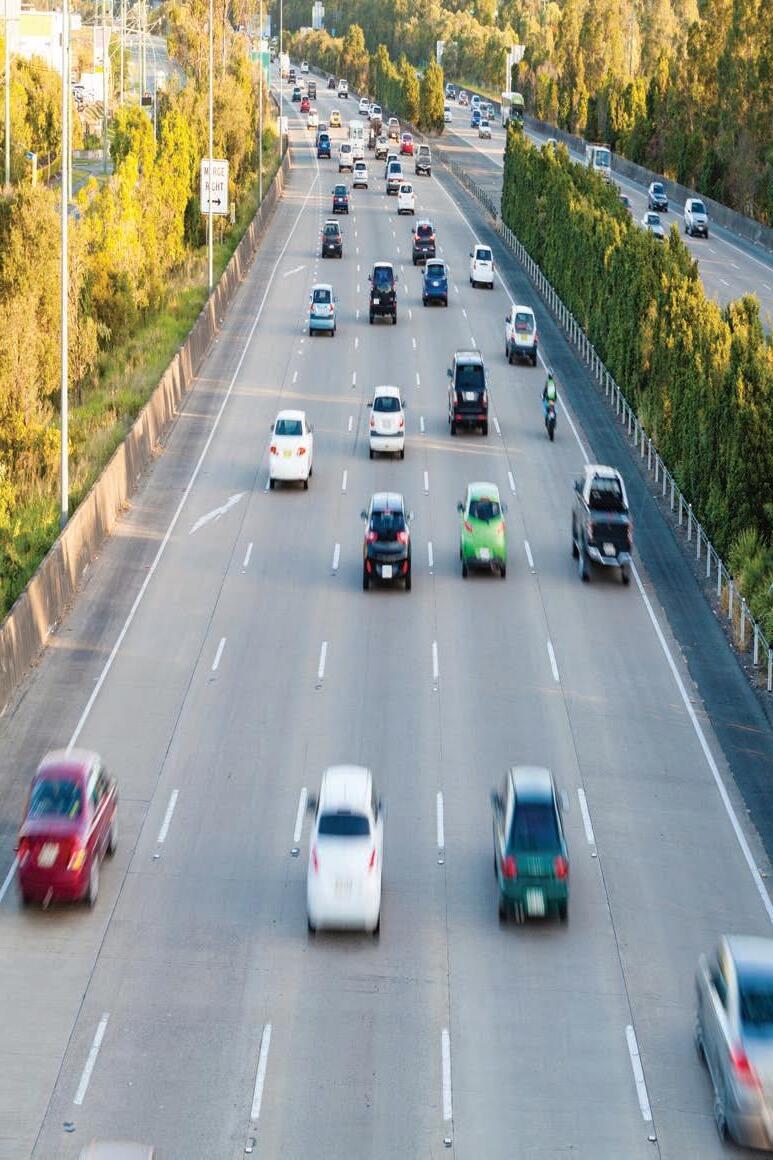

Image: serge/stock.adobe.com. C M Y CM MY CY CMY K 8 Trailer Magazine MARCH 2024 News

Image: Tasman Logistics Services.

Victoria

13-21 Bliss Court, Derrimut VIC, 3026

Tel -(03) 9369 0000

Queensland

1/15 SeeanaPlace, Heathwood QLD, 4110

Tel -(07) 3372 2223

Western Australia

5 Freight Road, Kenwick WA, 6107

Tel -(08) 9350 6470

Urgent call for level crossing reform

Rail operator, Pacific National, has called on industry and government to convene a national summit on level crossing safety.

The call for action follows a fatal collision on New Year’s Eve at a level crossing on the Barrier Highway at Bindarrah in South Australia (near the New South Wales border) that resulted in the the tragic deaths of two experienced Pacific National train drivers, Mick Warren and Kevin Baker, when the locomotive they were driving was struck by a heavy vehicle.

This is in addition to hundreds of near miss incidents that occur at levelcrossings each year, weighing on train and vehicle drivers’ mental health and putting everyday Australians seconds from death.

There are more than 23,000 level crossings in Australia many of which involve constant interactions between rail operations, road traffic, cyclists and pedestrians. Excluding trespass and suicide, accidents at level crossings

account for the largest number of railwayrelated fatalities involving members of the public.

Proposed topics for discussion and immediate action at the summit include a full audit of the nation’s level crossings to identify at risk locations, industryled solutions to improve behaviour and safety around level crossings, increased investment in technology and infrastructure, increased penalties for blatant indiscretions and joint industry public education campaigns to protect drivers, among other measures.

In addition, on behalf of the families impacted by the tragic collision on New Years Eve, Pacific National has committed to a public advertising campaign to further educate the community and road users on railway level crossing safety. This builds on existing industry and government campaigns that run annually.

This follows calls from the Rail, Tram and Bus Union (RTBU) to introduce a zerotolerance approach to level-crossing

safety, with cameras at all level-crossings nationwide.

“On Friday, I spent time with the families of Mick and Kevin, and what’s abundantly clear is no person should have to experience this type of grief,” said Pacific National CEO, Paul Scurrah.

“Tragedies at level crossings devastate entire communities and the message isn’t getting across loud enough. Losing concentration or being reckless about safety at a level crossing can kill.

“We are calling on federal and state governments to engage with industry on improved protections. This isn’t about pointing the finger at drivers or pedestrians but working together to overcome complexities and simply do better. If we don’t, more Australians will be subjected to senseless deaths.

“It can take up to 2km for a fully loaded freight train to stop. It takes a vehicle or a pedestrian a moment of clear thought and mere seconds to stop. Slow down, stop and cross with care.”

JCT Transport & Logistics announces new venture

Dedicated same day haulage specialist, JCT Transport & Logistics, has launched a new business division.

The JCT Express Haulage venture involves the expansion of its service profile which will include ad hoc services alongside the dedicated, permanent hire, and contracted logistics options it already provides.

This marks JCT’s competitive entry into the general freight sector where it aims to offer customers premium service

options ranging from couriers to taxi trucks and right through to semi-trailers and B-doubles.

“With many years of expertise and a team of dedicated transport professionals, we are well-equipped to provide clients with top-tier transport solutions which through careful consultation, we tailor to the unique and specific needs of our clients,” said Shaun O’Connor, JCT National Transport Manager.

With a focus on dedicated, permanent hire, and contracted solutions, JCT will continue to offer premium crane truck services as it expands and enters the general freight market this year.

“Our commitment to quality, safety, and excellence remains unwavering, and we look forward to continuing to serve our much-valued customers and transport partners with the highest level of service across both divisions throughout 2024 and beyond,” said O’Connor.

10 Trailer Magazine MARCH 2024 News

Image: jmimages/stock.adobe.com.

AirRoad founder to enter semiretirement

AirRoad Group founder, Tim Paine, recently celebrated his 80th birthday and will step down from his position as Chairman.

He started the logistics company with a single depot in Sydney in 1989.

Today, AirRoad provides national road freight distribution, express and specialised transport and supply chain management services.

To bolster its delivery performance, the organisation has national offices in New South Wales, Victoria, Queensland, South Australia and Western Australia.

It also has strategically located freight terminals in Sydney, Melbourne, Brisbane, Adelaide, Perth, Canberra and Townsville to deliver to metropolitan, regional and rural areas Australia-wide.

Going forward Paine will continue to

serve on AirRoad’s Board of Directors.

“Thanks for everything you have done Tim,” the company said in a statement. “We wish you all the best.”

Matahari Logistics Director, Ian Pemberton, praised Paine for being a true gentleman who built a passionate and successful business: “Congratulations on a well deserved retirement.”

Direct Freight Express Managing Director and founder, Joe Catania, wished Paine a long and healthy semi-retirement.

“You have built a beautiful business,” he said. “Congratulations to you and your team.”

AirRoad is backed by Senko Group following its investment as a majority shareholder in 2021.

UNCOMPROMISING PERFORMANCE AIR BRAKE FITTINGS Australia’s BIGGEST range and stockist of Metric / Imperial Push to Connect and Compression Style D.O.T Air Brake Fittings D.O.T / S.A.E STANDARDS CONFORMANCE GP TRUCK PRODUCTS available from Truck & Trailer parts outlets Australia wide. Compliant Standards: ADR-38/05 & DOT Lockable Fitting Cabinet Mobile Fitting Stand Emergency Break Down & Glove box kits Brass Fittings Full range of Brass fittings designed to suit North American and European Truck & Trailer Air Brake systems. Phone +61 3 9580 1811 sales@gptruckproducts.com.au www.gptruckproducts.com.au SCAN CODE FIND OUT MORE Huge range available. Approved to meet: Australian Design Rules ADR-38/05 DOT FMVSS 571.106, SAE J2494/3, SAE J1131 blanking plugs.

Image: AirRoad Group.

NSW Government announces freight reform program

New South Wales Minister for Transport, Jo Haylen, has announced a policy reform program to address key issues facing the state’s freight industry.

The Freight Reform Program will deliver prioritised and practical policy reform focused on the key current and emerging challenges facing the NSW freight network.

It will also look to identify short, medium and long-term actions for Government to support the ongoing improvement of freight transport across NSW.

The policy reform will focus on the different parts of the supply chain, with ports, rail, road and intermodal facilities all considered as part of a coordinated supply chain to determine the right policy framework to optimise safety, sustainability and productivity.

According to Haylen, NSW’s freight network is still too disjointed and inefficient, with policy and infrastructure bottlenecks right across the supply chain.

“Safe, sustainable, and productive freight

transport is critical to support the people, businesses and industries of NSW,” she said.

placed to lead us through this significant reform in freight transport policy.”

“A more productive freight sector can deliver reduced costs for businesses and lower retail prices for ordinary people right across NSW.”

The program will be led by Transport for NSW under the leadership of an Independent Advisory Panel of experts, all who have deep experience in the freight and logistics sector.

The panel, consisting of Dr Kerry Schott, Lucio Di Bartolomeo and Dr Hermione Parsons, will report to Haylen who will assist in the development of a new freight strategy.

“The appointment of the Independent Advisory Panel will work with my department and provide independent and expert advice on the Program,” Haylen said.

“I have confidence that with their diverse expertise in their fields, the Panel is well

Immediate priorities for the panel will include consideration of the determination of compensation to be paid by the Port of Newcastle for increasing container operations as part of NSW port policy.

The panel will also review and consult with industry on the recommendations made by Ed Willett’s review of the port regulatory framework and the regulation of the movement of containers at Port Botany.

Willet is the Independent Reviewer for the Ports and Maritime Administration Act 1995 and Port Botany Landside Improvement Strategy Review.

There will be a comprehensive stakeholder consultation undertaken as part of the program.

It is intended that the first phase will follow the release of a Discussion Paper and is expected to occur in in the first quarter of next year.

Team Global Express backs NHVR safety campaign

Team Global Express is actively participating in the National Heavy Vehicle Regulator’s (NHVR) We All Need Space campaign.

The NHVR’s We All Need Space campaign focuses on simple yet vital tips to increase safety around heavy vehicles. It looks to raise awareness on overtaking trucks and caravan etiquette, while encouraging light vehicle drivers to remember that trucks have much larger blind spots and need more space to stop.

By placing the campaign’s stickers on its vehicles, Team Global Express is aiming to educate light vehicle drivers on the critical importance of maintaining safe distances with trucks on the road.

“Through our efforts, we embrace the message that everyone, regardless of their profession, needs space to ensure safety on the roads,” a Team Global Express spokesperson said.

“This initiative underlines our commitment to promoting road safety and

fostering a safer driving environment for all.”

A study conducted by the NHVR surveyed 1,000 drivers across Australia and found that half of motorists (51 per cent) experience anxiety or nervousness when driving near heavy vehicles. The survey revealed that although drivers believe they have some understanding of how to safely share the road with heavy vehicles, just 32 per cent feel very knowledgeable about the rules.

12 Trailer Magazine MARCH 2024 News

Image:

Ines Porada/stock.adobe.com.

STOCKNOWAVAILABLE CONTACT US TODAY TO FIND OUT MORE: 03 8794 6000 www.cargobull.com Australia’s Most Fuel Efficient Reefer Trailers LUKE HARDEMAN 0467 001 515 SIMON HAKVOORT 0478 848 292 Refrigerated B-Doubles PBS-Trailers Semi-Trailers

Linfox builds on 34-year partnership with Myer

Transport and logistics company, Linfox, and department store chain, Myer, have extended their partnership for an additional seven years.

Linfox reportedly became Myer’s preferred carrier in 1989. It currently provides transport services from Myer’s distribution centre to all Myer stores across every major city in Australia except for Northern Territory and Tasmania.

For more than 30 years, Linfox has upheld supply continuity amid periods of unplanned demand, environmental

challenges and economic changes.

“Myer is committed to getting our product to customers in the quickest and most efficient way and Linfox, our domestic freight partner, is instrumental in ensuring we deliver against this key strategic pillar,” said Myer Executive General Manager Supply Chain, Tony Carr.

“Myer and Linfox have a longstanding and trusted relationship built on their leading service, reliability and innovation that ensures we are stocking stores and

DCs in the most efficient and productive way.”

Andy Gissing, General Manager Merchandise Linfox Retail, has been committed to this partnership for more than 20 years.

“Linfox and Myer have a unique and inspiring history,” he said.

“The deep level of trust that has developed over the years is the cornerstone of this relationship. We look forward to continuing our journey and supporting Myer into a safe and sustainable future.”

Board appointment to bolster Qube operations

An executive with experience across agribusiness, mining, manufacturing and the chemical industry has joined Qube.

James Fazzino has been appointed to the Qube Holdings Board of Directors effective 22 February 2024.

In particular, Fazzino was Chief Financial Officer, Chief Executive

Officer and Managing Director at industrial chemicals manufacturer Incitec Pivot Limited where he led the successful globalisation of the business including the construction of two large chemical plants in Australia and the US.

Fazzino is a Non-Executive Director of energy infrastructure business APA

Group and Chair of its Sustainability Committee. He is also a NonExecutive Director and Chair (elect) of Rabobank Australia Limited, Chair of Manufacturing Australia and a former Chair of Tassal Limited.

Qube Chairman, Allan Davies, welcomed Fazzino to the Board.

“James has broad executive management and board experience and deep financial and relevant industry knowledge,” said Davies. “James’ mix of skills and experience will be valuable to Qube’s operations and strategy and I look forward to his contribution.”

Fazzino graduated from La Trobe University with a Bachelor of Economics (Hons). He is a Vice-Chancellor’s Fellow of La Trobe University, a fellow of CPA Australia and was a past co-convenor of the Energy Group of the Champions of Change Coalition.

14 Trailer Magazine MARCH 2024 News

James Fazzino. Image: Qube.

Skel

Evolution side

Road

Flat tops, drop decks

Deck wideners and

End

Coldcore

Etnyre

Titan

PBS

INDUSTRY LEADERS IN ROAD TRANSPORT EQUIPMENT, DESIGN, MANUFACTURE & MAINTENANCE

trailers

tippers

train dollies

extendables

tippers, bulk and TaREX quarry bodies

refrigerated and dry vans

live bottom trailers

walking

belly dumper trailers

floor and

specials: super quad & super triple OUR EXTENDED RANGE INCLUDES: With nationwide sales and support. For more information email sales@brucerockengineering.com.au or call us on 1300 611 253 BRUCEROCKENGINEERING.COM.AU

Rio Tinto announces $375M deal

A Rio Tinto joint venture has entered a sales agreement to enhance operational efficiencies in the Pilbara.

Dampier Salt – which is a joint venture between Rio Tinto (68 per cent), Marubeni Corporation (22 per cent) and Sojitz (10 per cent) – is purchasing the Lake MacLeod salt and gypsum operation in Carnarvon, Western Australia, with privately owned salt company, Leichardt Industrials Group.

This deal is expected to close by this year’s end.

“The sale of Lake MacLeod will enable Dampier Salt to focus on enhancing

operational efficiencies at its remaining two Pilbara operations, while allowing the new owner of Lake MacLeod to maximise its potential,” said Rio Tinto Managing Director Port, Rail & Core Services, Richard Cohen.

He added that until the completion of the sale, the Dampier Salt leadership team will focus on safety, deliver on their plan and maintain respect for all people at Lake MacLeod and in the Carnarvon community.

“We are pleased Leichhardt has committed to retaining all Lake MacLeod employees, ensuring continuity of operation and providing job stability to the

130-strong workforce,” said Cohen.

Lake MacLeod is one of three solar salt sites owned by Dampier Salt, which also includes operations in Dampier and Port Hedland. It is located within Baiyungu country in the Gascoyne region of Western Australia, 70 kilometres north of the town of Carnarvon, including a ~1.5 Mtpa salt operation, ~1 Mtpa gypsum operation as well as a deepwater port at Cape Cuvier.

Dampier Salt is reported to be the world’s largest seaborne salt exporter with annual production capacity of approx. 10 million tonnes.

Team Transport & Logistics celebrates award win

For the third consecutive year, Team Transport & Logistics has been awarded for its unparalleled dedication and exceptional performance.

Global logistics firm, Expeditors, has presented Team Transport & Logistics with a Service Provider of the Year award.

This win, according to Team Transport & Logistics, is the result of building strong foundations, understanding Expeditor’s needs, aligning with their goals and consistently delivering ‘top-notch’ service.

The partnership reportedly thrives on tailored solutions where Director Steve Skinner and Operations Manager Troy

Nankervi analysed Expeditors’ logistical needs and challenges. They developed strategies to address specific pain points and contributed to the success of the supply chain.

Team Transport & Logistics General Manager, Kylie Wilkinson, said that shared success is sweeter than individual success.

Dean Penrose, Team Transport & Logistics Sales Manager, added it was an honour to be named Expeditors’ Service Provider of the Year once again.

“This award is a testament to the dedication and passion of our team, and it reinforces our commitment to providing exceptional service to our clients. A wonderful achievement for all our staff,” he said.

Expeditors, founded in 1979, is a Fortune 500 company, headquartered in Seattle, Washington, US. It operates in 346 locations and 101 countries and has more than 19,000 employees. Core services are supply chain, transportation, customs and compliance and warehousing and distribution. In 2022, this organisation reported revenue of more than $17 billion USD.

Image: Adwo/stock.adobe.com.

16 Trailer Magazine MARCH 2024 News

Image: Team Transport & Logistics.

Premium Quality, Optimised Performance, Reliability & Safety Your Greatest Investment Deserves the Silver Lining Visit E -Plas for QuickSilver Truck Lining System Australia Wide Distribution & Service Ph: 1800 806 475 www.eplas.com.au Discover More QuickSilver App Q uic k Si l ver Silver® Truck Line rs Discover More

Trailer publisher first to use paper-wrapping mailing machine

Prime Creative Media is Australia’s first publisher to send paper wrapped magazines at scale, in partnership with its printing and mailing supplier, FSG.

FSG, based in Bayswater, Victoria, purchased the country’s first ever paperwrapping mailing machine in January this year.

Imported from UK supplier, Norpak, the machine’s ability to wrap publications in paper will eliminate plastic wrapping for several Prime Creative Media titles, including Trailer

“It’s the evolution of the mailing industry to abolish the use of single-use plastics in mailing magazines,” said FSG Mailing owner and Director, Michael Murphy.

“This follows the government’s move to get disposable plastics out of our Australian systems.”

Up until this technology was in place, the only alternative option to plastics for publishers was paper envelopes.

Murphy said this was cost prohibitive for many clients, because the price of producing and printing the envelopes was high – in addition to the labour of

either hand inserting magazines into the envelopes, or using very expensive equipment to insert into the envelopes and seal them.

This added a significant increase to mailing costs.

Although mailing houses like FSG have experimented over the years with bioplastics and recy-clable plastics, Murphy said the technology never quite worked out.

“We tried to use bioplastics but the settings on the machines – which use heat to seal them – make it very difficult,” he said.

“Even for those companies who worked out how to mail them, it was a challenge for consumers to separate the plastics at the end of the process, or find appropriate disposal.

“Eventually, we saw that the only real option was paper.”

Murphy came across this technology through his supplier UK company, Norpak, who previously supplied his plastic wrapping machine.

“They introduced us to the idea because

they saw what was happening in the European Union with the phase out of single-used plastics,” he said.

“With the Australian Government making similar moves towards a full phase out of single-use plastics, we think that this machine will be the catalyst to push the movement along in the mailing industry.”

Murphy noted that in Europe, where it was put into commercial use 18 months ago, it has al-ready taken off.

“The first person to use the machine really took a leap in the dark,” he said.

“Now he has 13 of these machines, and those plastic wrapping machines are sitting there not being used – they are becoming museum pieces.

“That will be the future in Australia now that this machine has arrived.”

An additional environmental benefit to the machine is that because the addresses are printed directly onto the paper wrapping, it eliminates the need for flysheets – the paper that lists the addresses and is placed onto a magazine.

18 Trailer Magazine MARCH 2024 News

FSG owner, Michael Murphy, and Prime Creative Media COO, Christine Clancy. Image: Prime Creative Media.

This improves efficiency, as it limits the printing and transportation of flysheets.

It also means that only a small amount of more paper is being used in with the new system, once you take into account the paper used in flysheet printing. And of course, this opens up a vast array of options in using recycled and sustainable paper products.

The only drawback, Murphy said, is that the paper is less weather-proof. In Europe many people live in apartments instead of houses, and magazines are delivered in post boxes or through slits in doors.

He said it will be interesting to see how the paper stands up to Australia’s climate, but is confident it will work well.

That being said, he noted the price of an occasional damp magazine is one worth paying to save thousands of tonnes of plastic wrapping from going to landfill every year.

Prime Creative Media COO, Christine Clancy, was on site at FSG in Bayswater to witness the first publications being sent out in paper-wrapping.

“It’s such an honour to watch history in the making, to see our publications make this first step in reducing single use

plastics in our environment,” she said.

Clancy said the company has long been involved in supporting the growth of the waste management industry, through its publications Inside Waste and Waste Management Review, along with its annual Waste Awards.

“After years of reporting on the challenges of single-use plastics in the waste industry, it’s so wonderful for us to play a proactive part in it by reducing our own use,” she said.

“We’re fortunate to have FSG as a partner to help make this happen.”

New update on $1.7B Rockhampton Ring Road project

The Australian and Queensland governments have shared an update on the $1.73 billion Rock-hampton Ring Road project.

Prime Minister Anthony Albanese and Queensland Premier Steven Miles recently celebrated construction progress on the project, which is now fully funded by both levels of government.

The full 7.4-kilometre Rockhampton Ring Road will be delivered with an increased Australian Government commitment of $1.2 billion and an increased Queensland Government commit-ment to $530 million.

Upon completion, the Ring Road is expected to transform Rockhampton and will be a critical new artery for Central Queensland and the broader Bruce Highway.

According to Miles, it will also benefit the transport sector by allowing more productive travel for operators moving freight around the state.

“When complete, big trucks will avoid 19 sets of traffic lights through the middle of Rockhamp-ton, which has long been regarded as the pinch point for travel on the Bruce Highway,” he said

“That is critical for Queensland’s economic growth.”

The Rockhampton Ring Road project was announced last year, and according to the Queensland Government, is a once in a lifetime opportunity.

“Late last year the Australian and Queensland governments confirmed construction would be underway on the Rockhampton Ring Road by the end of 2023, and here we are two months into construction to deliver this

essential infrastructure project for Central Queensland,” Albanese said.

“This significant investment by the Australian and Queensland governments is a long-term, vi-sionary project for Queensland’s biggest highway, the lifeline for the state of Queensland that will unlock future economic growth, build flood resilience, reduce travel times, improve road safety and support jobs.”

Construction on the first $280 million package of works started in November 2023.

Both contractor joint ventures mobilised to site in November to start construction at key work locations in Parkhurst and on Rockhampton-Ridgelands Road in West Rockhampton.

Construction on this phase of the Rockhampton Ring Road is expected to take up to two years to complete.

www.trailermag.com.au 19

Image: Zstock/stock.adobe.com.

Major contract awarded for Mount Ousley interchange

Registration opens for VTA State Conference 2024

The Victorian Transport Association (VTA) is now accepting registrations for State Conference 2024, to be held from Sunday 17 – Tuesday 19 March at Silverwater Resort, Phillip Island.

“The State Conference is the VTA’s premier professional development event, and I invite members, associate members, and other industry stakeholders to join us for three days of learning, networking and social engagement with fellow members, operators, and suppliers,” said VTA CEO, Peter Anderson.

Fulton Hogan has been awarded a major contract to design and build a new interchange in New South Wales.

The $390 million Mount Ousley interchange project will improve road safety by providing northbound access from Mount Ousley Road to the M1 Princes Motorway via an overpass, as well as providing better separation of cars and heavy vehicles.

When complete, the new interchange will include southbound heavy vehicle bypass lanes and safety ramps, a commuter carpark and a shared path and vehicle overpass for improved access between Mount Ousley Road, the M1 Princes Motorway and the University of Wollongong.

It has been revealed that detailed design work will start early this year. Transport for NSW and Fulton Hogan will work together throughout early work and the detailed design process to ensure the community continues to be informed about the project.

“We are one step closer to starting major work on this critical piece of infrastructure, which will not only improve travel times for motorists but also provide safer journeys and support growing freight movements to the south coast,” said Federal Infrastructure, Transport, Regional Development and Local Government Minister, Catherine King.

“This stretch of road is known for traffic queuing and delays during peak periods.

Separating cars and heavy vehicles travelling southbound is a unique feature that will provide a safer environment for everyone using the road.”

An estimated five million tonnes of freight travels the M1 Princes Motorway each year, as one of the main road freight corridors to and from the Illawarra-Shoalhaven region.

Federal Member for Cunningham, Alison Byrnes, said the investment in the Mount Ousley interchange is therefore essential.

“The M1 Princes Motorway is the only road in and out of the Illawarra capable of handling the volume and size of traffic needed to support commuters coming to and from Greater Sydney and our growing local industry,” she said.

“It is the economic artery that ensures products like new cars, trucks and buses from the Port make their way to the showroom floor and BlueScope’s world class steel can find its way to market.

“The Australian and NSW governments’ significant joint investment in this project show that we understand this is a busy and vital route for visitors to the region, locals, business and the freight industry.”

Early work will start in the coming months, including survey and geotechnical investigations, utility relocation and vegetation clearing.

Major work is expected to start later this year, with the project expected to take about four years to complete – weather permitting.

“The theme of our Conference this year is Future Freight Landscapes. Technology, artificial intelligence, and cyber-security are just a handful of issues that are upending economies, communities, and industries as we know it. And the transport industry isn’t exempt.

“We invite you to explore what you don’t know but should know about transport, with the VTA assembling experts from industry, regulators, academia, and government, to challenge our thinking and inform our discussions,” said Anderson.

Throughout the Conference, formal sessions will be interspersed with a range of networking and hospitality sessions, providing delegates with opportunities to socialise and gain new contacts from across the industry.

A trade exhibition during the Conference will feature new products and innovations from a range of industry suppliers, and we anticipate having the latest associated equipment from our domestic and international original equipment manufacturers.

“I look forward to sharing our provisional program over the coming weeks; delegates can be assured the calibre of presenters will be exceptional, in keeping with our reputation for providing a relevant, timely and contentrich State Conference,” said Anderson.

Image:

Jason/stock.adobe.com.

Image:

Jason/stock.adobe.com.

20 Trailer Magazine MARCH 2024 News

certified

Monadelphous secures long-term project with Woodside

Engineering company, Monadelphous, is extending its maintenance and shutdown services agreement with Woodside Energy.

The existing agreement has been extended for a further three-year period with an additional option for the agreement to be extended for a further two years thereafter.

The value of the extension is approx. $180 million per annum – subject to final work scope required each year. Works include maintenance, shutdown and brownfields project services at the Woodside-operated onshore and offshore gas production facilities in Western Australia (Karratha Gas Plan, Pluto LNG, North Rankin Complex, Goodwyn.

The scope of work under the agreement includes maintenance, shutdown and brownfields project services at the Woodside-operated onshore and offshore gas production facilities located in the northwest of Western Australia, including Karratha Gas Plant, Pluto LNG, North Rankin Complex, Goodwyn A platform and Angel platform).

Monadelphous Managing Director, Zoran Bebic, said the agreement extension was a testament to the strength of the company’s relationship with Woodside, and Monadelphous’ safe and reliable delivery of services.

“We are extremely proud of the relationship we have developed with Woodside over more than 20 years and are delighted to continue supporting their operations well into the future,” he said.

Earlier this month, Woodside signed a non-binding Memorandum of Understanding (MOU) with South Korea’s SK E&S to enable studies on the potential development of a lower-carbon hydrogen value chain, including hydrogen, ammonia and other related products.

Under the MOU, Woodside and SK E&S plan to jointly explore opportunities relating to long-term ammonia and hydrogen offtake arrangements, equity participation in ammonia and hydrogen production projects, and project engineering supply opportunities.

In addition, both parties will consider

Silk Logistics appoints CFO

Silk Logistics Holdings appointed a new Chief Financial Officer (CFO).

James Nicholias commenced the role on 8 January and brings more than 20 years of financial experience from industries including logistics and supply chain, recycling, banking and infrastructure.

He has held multiple roles at Bingo Industries from 2017 to 2022 including Acting CFO, Group Financial Controller and General Manager for Finance Transformation and Investor Relations.

Prior to that he was the CFO at Scott’s Refrigerated Logistics – appointed in September 2022, day zero of the reset and turnaround under private equity.

Nicholias has also worked in senior finance roles with Australian Turf Club, JP Morgan, Macquarie Group and Deloitte.

“We welcome James to Silk, and look forward to his contribution as the company plans its next phase of consolidation and growth,” said Silk Logistics Managing Director and CEO,

existing and proposed government policies of South Korea and Australia that could help facilitate lower-carbon hydrogen value chain development.

Woodside Executive Vice President New Energy, Shaun Gregory, said the MOU reflected the increasing demand for largescale decarbonised energy solutions such as lower-carbon hydrogen and ammonia from Woodside’s industry partners in the Asia Pacific region.

“With more than 35 years of experience as a world-class developer and operator of complex energy production facilities, and as a safe and reliable energy provider, Woodside is well positioned to play a key role in the development of the hydrogen and ammonia value chain for partners in South Korea,” he said.

“This collaboration will help inform our development of the new energy products and services which could support our customers’ decarbonisation, unlock new market opportunities and support the broader Asia Pacific region in their climate goals and net zero aspirations.”

Brendan Boyd.

He added that Nicholias will work through a transition program with outgoing CFO Brendon Pentland prior to his leaving around March 2024.

For FY2023 the business reported revenue of $486.6 million, a 23.8 per cent increase compared to FY2022.

As for mergers and acquisitions, the integration of Fremantle Freight & Storage is reportedly on track to complete within the first half of FY2024.

Image: Rafael Ben-Ari/stock.adobe.com.

News 22 Trailer Magazine MARCH 2024

B-DOUBLE DROP DECK CURTAINSIDER

• Full mezz deck

• Hanging gates, toolboxes & provision for tow coupling

• Locally supplied curtains

B-DOUBLE FLAT DECK CURTAINSIDER

• Rear doors

• Gates, toolboxes & provision for tow coupling

• Locally supplied curtains

45’ Drop Deck with BiFold Ramp

• 12V Power Pack

• 3 Way Twist locks

• Machinery tie-down points in floor

40’ DROP DECK SKELETAL TRAILER

• 3 way twist locks

• Dangerous goods rated

• Container tilt airbag fitted

• CIMC

13.7-21.5m Extendable Flat Top

• 3 Way Twist locks

• Pneumatic warning flags

• Provision for tow coupling

40’ 3 WAY SKELETAL

• Standar & lightweight designs

• Side loader pads

• Provision for tow coupling

a long term commitment to Australia by investing in infrastructure to provide high quality products, support and service.

• Local production capacity for Semi-Trailers and Tankers with CNC cutter, welding machines and start-of-the-art heated paint shop.

• Comprehensive parts store stocking genuine CIMC parts, along with additional OEM sourced items.

• Dedicated service & repairs workshop.

• Total site area 51,000 sqm, with a 13,000 sqm workshop.

Melbourne CIMC TRAILERS 1300 202 462 20 Whitfield Blvd, Cranbourne Brisbane CIMC TRAILERS 0423 795 649 68 Tile Street, Wacol Perth GTE 08 9352 4000 159 McDowell Street, Kewdale Sydney JRB GROUP 02 9355 3400 26 Bosci Rd, Ingleburn 19 Hale Street, Botany ENQUIR E NOW 1300 202 462 www.cimc.com.au | sales@cimc.com.au GLOBAL LEADERS WITH LOCAL KNOWLEDGE Your semi-trailer experts.

has

Program addresses gender imbalance in industry

A new round of grants are now open to drive equality in the workplace according to the Victorian Government.

Minister for Women, Natalie Hutchins, has announced a further $1.3 million is now available for organisations through the Women in Energy and Manufacturing Funding Program.

This program, according to Hutchins, will support organisations with attracting, recruiting and attaining women.

“We want women of all ages, backgrounds and identities to have the careers they want – which is why

programs like this, are so important,” she said.

“I encourage all organisations that want to help more women get the job they want in the these traditionally male-dominated industries to apply.”

The first grants round supported a range of initiatives including mentoring programs for women run by the National Association of Women in Operations through virtual group and one-onone sessions and school awareness campaigns for solar energy careers run by Australian Women in Solar Energy.

Government response to AI an intelligent first step: Engineers Australia

Engineers Australia has welcomed the Federal Government’s Interim Response to Safe and Responsible AI as a positive first step in balancing regulation and safety with innovation.

“Engineers Australia supports the Government’s commitment to a future where AI is both a force for good and responsibly managed,” said Engineers Australia CEO, Romilly Madew AO.

“We must pioneer a path that balances innovation with safety, ensuring AI’s benefits while protecting professionals, educators, students and the community.”

The Government’s announcement focused on ways to make sure the design, development, and deployment of AI in legitimate high-risk settings is safe and responsible, while ensuring that AI can continue being used in low-risk settings

largely unimpeded.

“This approach, blending regulatory and non-regulatory strategies in a risk-based framework, is not just about control – it’s about empowering responsible AI use across diverse sectors,” said Madew.

“We are particularly pleased with the announcement of an AI expert advisory body, which aligns with our recommendation for a specialised taskforce that includes engineering expertise, which is crucial in the development, implementation, integration, use and maintenance of AI systems and products.

“This advisory body should offer technical advice and expertise on AI development, adoption, and use, along with regulatory and non-regulatory options. AI regulation should strike a balance, blending risk

It also supported the Women in Trades project run by the Australian Manufacturing Union, which delivered a series of trade demonstration events, employer site visits and career expos with employers such as Nestle to attract young women to exciting careers and opportunities in the manufacturing sector.

Women are reported to account for just 32 per cent of Victoria’s manufacturing sector, and 33 per cent of the electricity, gas, water and waste services industries. The figures are even lower for women working in trades.

management and control systems. Tailoring regulation to diverse sectors, use cases, and risk profiles is crucial.”

Engineers Australia will continue to consult with government, industry, and academia, with a focus on regulatory guardrails.

“While this is a step in the right direction, we’d like to see the government working closely with engineering professionals on designing and building these systems with appropriate consideration of the ethics of AI systems, alongside the development of codes of conduct for professional practice,” said Madew.

“We will continue pushing for transparent and accountable AI development. Our call is for AI systems to be as reliable as they are revolutionary, ensuring they are tested, transparent, and trustworthy.”

Gorodenkoff/stock.adobe.com.

Image:

24 Trailer Magazine MARCH 2024 News

Dangerous Goods risk assessment update

International practice has influenced a change in the way risk is assessed for the transportation of Dangerous Goods (DG) in specific scenarios.

Austroads has proposed a new approach for assessing whether the risk resulting from the transit of DG is lower on a tunnel route or lower on an alternative surface route.

The approach, according to Austroads, largely draws on European experience where countries like Austria, Germany, France, Italy, the Netherlands, Spain and Switzerland have national methodologies that offer an official evaluation procedure.

Prior to the release of this Austroads methodology no such national method existed in Australia or New Zealand.

Austroads said the decision to restrict DG traffic through tunnels should also consider environmental and ecological risks, with community, social and economic benefits.

“Neither Australia nor New Zealand have a standardised risk assessment approach

for considering risk to life associated with how we route dangerous goods,” said Austroads Transport Infrastructure Program Manager, Ross Guppy.

“By providing this method, we address a need of road authorities to have a rational documented risk-based input to the multifacetted decisions that must be made about routing dangerous goods through tunnels.”

The Australasian approach is based on a Dangerous Goods Quantitative Risk Assessment Model (DG-QRAM) – an internationally applied software jointly developed by PIARC (World Road Association) and the Organisation for Economic Co-operation and Development (OECD).

“One of the main advantages of DGQRAM is the ability to estimate the risk of dangerous goods transport through both a tunnel and an alternative open-air route, enabling a comparative risk assessment to inform route evaluations and regulatory

decisions,” said Guppy.

The application of the methodology in the Australasian context is demonstrated in a case study of a hypothetical tunnel, illustrating the stages of the comparative assessment, with incorporation of risk mitigation measures.

The DG risk assessment guidance is provided as a series of three reports that should be read and applied together.

Image: Donald/stock.adobe.com.

Image: Donald/stock.adobe.com.

Federal Budget investments could be transformative for industry

Decarbonisation, diversification and digitalisation are the ‘Three Ds’ the Federal Budget should invest in according to Ai Group.

The national employer association recently released a submission to the Federal Budget outlining the need for government to invest for the long-term as industry navigates the challenges of uncertainty, inflation and a slowing economy.

“Australian industry enters 2024 feeling anxious and pessimistic about the immediate future,” said Ai Group CEO, Innes Willox.

“While the Australian economy continues to slow, global uncertainty is growing and inflation and labour shortage pressures appear to be persisting longer than expected.

“Yet Australian industry also has to keep an eye on longer-term transformational challenges: the ‘Three Ds’ of decarbonisation, diversification and digitalisation.

“These transformations have a longterm time horizon measured in decades, not years. But they cannot be ignored, as getting them right will be key to Australia’s future wealth and prosperity.”

Ai Group said an effective and successful 2024-25 Federal budget will help industry manage this tension between short-term challenges and long-term investment needs. It should focus on:

• Decarbonising industry by promoting investment, reforming regulatory barriers and supporting skills for energy transition opportunities;

• diversifying industry through innovation programs, trade promotions efforts and a commitment to skilled migration;

• digitalising industry through automation, AI, data stewardship and cybersecurity investments.

“Overarching these proposals is the pressing need for reform of Australia’s taxation system,” said Willox.

“This should deliver tax simplification, minimise ‘bracket creep’ and other unplanned fiscal changes, unlock opportunities for productivity-enhancing changes, and support the aspirations of

people wanting to work harder and earn more.

“Underpinning our capacity to meet our challenges in the short and long term is the need for a clear-eyed focus on developing a workforce with the skills to thrive in a decarbonised, digitalised and more diverse future.”

Ai Group’s submission is reported to highlight key areas in which deep work is still needed in order to embed a tertiary education and training sector that allows Australia to achieve its human capital potential. Recommendations include:

• A tertiary education body, including VET, with appropriate industry representation that provides national governance, analysis, expert advice and a funding model that considers the impacts on VET and drives parity of esteem between the sectors.

• The setting of new longterm targets that address overall participation and attainment in higher education into the future, in concert with VET target setting, to meet projected workforce needs.

• E xamine the level of funding for the tertiary education system to ensure it

enables quality outcomes across VET and higher education and is equitable across the sectors.

• Progress reform of the Australian Qualifications Framework.

• Provide Government support for all apprenticeships and traineeships of no less than 30% in wage subsidy across two years.

• Reinstate the fixed monetary completion incentives of $2500 to employers.

• E xtend the support currently available to apprentices in priority occupations of up to $5000, to assist in the completion of their training to all endorsed apprentices and traineeships without exception.

• Develop a national framework for skills transferability.

• Introduce a lifelong learning funding model that includes a framework of learning entitlements and income contingent loans.

“The budget should provide the framework industry needs to continue to invest and innovate for long-term transformations, even while business conditions are difficult in the short-term,” said Willox.

GDP growth rate September 2023 Unemployment rate December 2023 Interest rate December 2023 0.2% 3.9% 4.35% 10 5 0 -5 -10 Oct 2023 Jan 2023 Apr 2023 Jul 2023 -1 -1 -3 -4 6 1 1 00 -3 -8 -1 26 Trailer Magazine MARCH 2024 Economy Image: KamWing/stock.adobe.com.

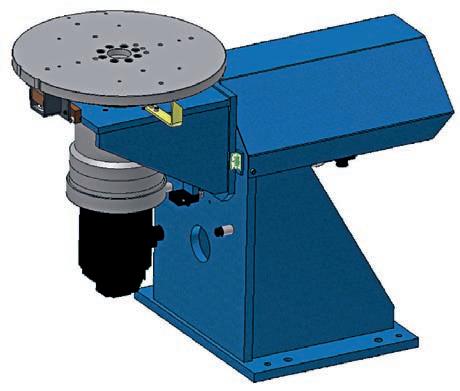

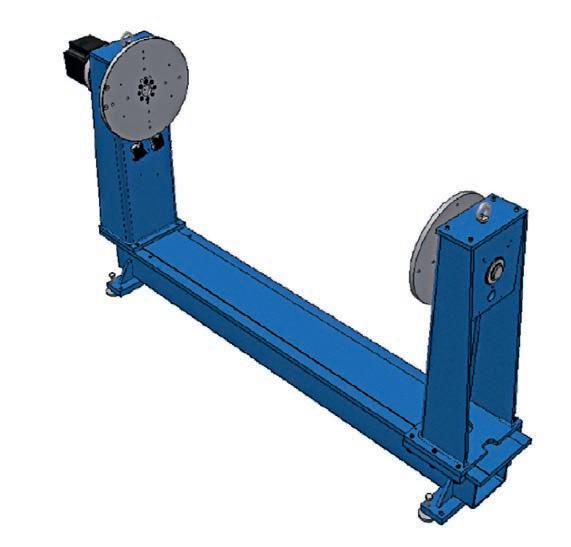

Robotic Automation Pty Ltd T. 1300 552 333 E. sales@ragroup.com.au W. www.ragroup.com.au Turn-key Solutions for Manufacturing Industries. The Home of Intelligent Automation. Established in 1988 and with over 3,500 solutions installed across Australia, our extensive experience is your best assurance of quality and value. 3D SIMULATIONS ENTRY LEVEL COBOTS NOW IS THE TIME TO AUTOMATE YOUR WELDING PROCESS LARGE SCALE SOLUTIONS

Refrigerated stash

SLR Trans has expanded its Schmitz Cargobull fleet of more than 20 combinations with the delivery of a new B-double refrigerated trailer.

Now, it will go all in as it looks to build on its collection even more.

Brisbane-based refrigerated transport company, SLR Trans, specialises in moving a range of temperature-controlled freight including dry, ambient, chilled and frozen goods. Not only that, it offers a comprehensive logistics solution designed to streamline the supply chain and reduce operational complexities by utilising its storage and cross dock facilities for these freight tasks.

As a proud Australian and family-owned and operated business, every aspect of the SLR Trans business is aligned with old-fashioned values of integrity, honesty and commitment to customer care and excellence.

This is where SLR Trans COO, Aumar Moosa, says the company distinguishes itself.

“What sets us apart from the rest is our commitment to providing superior service throughout the SLR Trans journey from start to finish,” he says. “We provide tailored linehaul, short haul, metro and home delivery temperature-controlled

transport solutions for temperature sensitive goods for businesses of all sizes.”

SLR Trans’ journey began back in 2013 as a small company averaging 200 deliveries a week. Its humble beginnings came about from the dream of founder and CEO, Jimmy Gupta, to one day own his own refrigerated transport company working as a driver alongside his wife, and now Director and Finance Manager of the company, Shubhi Aggarwal.

Jimmy’s passion for the refrigerated transport industry, combined with firsthand knowledge gained from years of practical experience within this space, is what helped him to identify a critical gap in the local service providers – a tailored refrigerated transport solution.

“He believed the ‘one size fits all’ principle prevented businesses from achieving cold chain efficiency and integrity, and this is what fuelled the inception of SLR Trans,” Aumar says.

SLR Trans’ growth has been steady, with milestones

marking almost every year since its inception. By the end of 2020, for example, SLR Trans had expanded to the point where it was completing over 45,000 deliveries per week. Today, SLR Trans credits its progress to the sheer perseverance, hard work and dedication of every team member.

“We look forward to achieving and celebrating even more milestones as we continue our steady progress towards becoming the refrigerated transport provider of choice for businesses across Australia,” Aumar says.

It was in January of 2022 when SLR Trans crossed paths with Brown and Hurley Yatala. Jimmy and Aumar were invited to the dealership by Trevor Cox to view a new European Schmitz Cargobull 24-pallet freezer capable trailer, and since

Trailer Magazine MARCH 2024 28 Refrigerated transport equipment

Images: Brown and Hurley.

It has now accumulated over 20 Schmitz Cargobull trailers.

SLR Trans’ fleet of Schmitz Cargobull trailers travel from Melbourne to Brisbane through Sydney to move bulk goods at -22°C and ambient temperatures. In these operations, Aumar says Schmitz Cargobull’s loader bars in particular have come in handy by allowing operators to double stack pallets and eliminate manual handling.

“We use the typical loader bars to double stack pallets,” he says. “They are heavy for the drivers to lift, and there is quite a lot of manual handling involved. Without Schmitz Cargobull’s vertical double loader system, the drivers would have to load and unload around 32 decking loader beams which weigh around 10 kilograms each on a B-Double load from the back of the trailers and stow away underneath the trailer. Some of the bars become rusty overtime as well, so Schmitz Cargobull’s loader bars have really helped them.”

Because of the agility, performance, user-friendliness and pleasing aesthetics of the Schmitz Cargobull product, SLR Trans purchased another two B-double refrigerated units. The first has recently arrived and is already making its mark in SLR Trans’ interstate freight tasks.

“Due to Schmitz Cargobull’s robust technology, the refrigerator doesn’t have to work as hard and the temperature

body, making fuel consumption extremely efficient,” Aumar says. “It’s good on fuel, and it’s good for double stacking pallets with the drop-down loader bar system.”

Schmitz Cargobull’s Ferroplast panel, patented in 1978, remains to be the backbone of every refrigerated or ambient trailer body sold under the Schmitz Cargobull label.

Since the product was launched, the company has delivered hundreds of thousands of Ferroplast-based trailers worldwide, indicating just how popular the technology is within the wider transport community.

Thanks to the Ferroplast thermal technology in the refrigerated Schmitz Cargobull boxes, Aumar says his bodies don’t sweat in the extreme heats faced in Australia. The technology also prevents moisture from penetrating through the body’s vapour, resulting in less fuel consumption and better performance from the A500 Thermo King unit – SLR Trans’ preferred refrigerator on all of its Schmitz Cargobull trailers.

Apart from the drop-down loader bars, Schmitz Cargobull’s fuel tanks are another feature SLR Trans is extremely fond of. Aumar says they are accessible from both sides of the trailer, carry a good amount of fuel, and distribute the weight equally across the trailer.

from Schmitz Cargobull can be seen in its use of the trailer’s multifunctional floor.

“The smooth floor is brilliant to wash out the dust and debris from the wooden pallets,” Aumar says. “It comes with a smooth non-slip barley grain patterned floor which is silent when loading and unloading goods on dolly wheels. It puts less friction on the forklift wheels as well, unlike the air flow floors, but most importantly it is very hygienic and easy to clean.”

Choosing Schmitz Cargobull for its refrigerated transportation needs, Aumar says, has proved its worth.

“Schmitz Cargobull is a big win, for sure,” he says. “It means there is one less worry for the allocator who juggles between air flow floors and flat floors depending on the load carried. We are always excited to receive a new Schmitz Cargobull trailer, and Trevor Cox does a good job keeping us up to date with the progress and upcoming deliveries.”

Going forward, the plan for SLR Trans is to stick with Schmitz Cargobull and to keep adding its trailers to the fleet.

Cargobull Australia

Unit 2, 221 Browns Road, Noble Park North 3174 VIC

Ph: 03 8794 6600

Web: www.cargobull.com.au

Contact Schmitz

www.trailermag.com.au 29

A driving force

On the back of its recent expansion, CoolWay Trans has acquired five new B-double sets fitted with Carrier Vector HE19 refrigeration units.

CoolWay Trans, since establishing around 10 years ago, has prospered in its national transportation within the temperaturecontrolled sector and Less-ThanTruckload (LTL) network. The business has grown from having one single vehicle to over 140 pieces of equipment.

Accompanied by an expanding national footprint, the company’s niche market has served it extremely well. CoolWay now runs distribution centres (DC) in every capital city in the country.

The fleet’s most recent expansion saw it relocate to a new and second site in Glendenning, New South Wales. Between the two locations, CoolWay has a total of around 9,000 square metres of DC and

hardstand storage and preventative maintenance.

CoolWay Commercial Manager, Mark Williams, says the new facility allows the business to control its own destiny.

“We have the flexibility to maintain our equipment when it suits us during times where there might be a bit of downtime,” he says. “So, we can service them, we can maintain them, and we can keep them clean and tidy. We can control the direction of the business.”

From the beginning, Carrier Transicold had always been CoolWay’s preferred refrigeration supplier for its trailer and rigid units. It has also played a big part in the fleet’s growth – Coolway Managing

“Carrier has played a major role in the success of the company, because they make sure everything gets delivered on time, in temperature, and that’s what we sell for,” he says. “They have a major role in our operations.”

CoolWay recently took delivery of five B-double sets fitted with Carrier’s diesel-electric Vector HE19 refrigeration units. The combinations, which arrived last December, have already completed multiple trips to Perth and will soon travel routes from Sydney to Perth, Sydney to Adelaide and along the east coast of Australia carrying multi-temperature LTL pallets.

“They’ve been faultless,” Mark says. “With the finish on the trailers coupled up with the efficiency of the refrigeration units, they’ve been perfect. They basically haven’t stopped since we’ve taken delivery of them – from the initial install to all the pre-trip inspections that have been

30 Trailer Magazine MARCH 2024 Refrigerated transport equipment

L-R: Carrier Transicold NSW Service Manager, Dean Coffill, CoolWay Trans NSW/ ACT State Manager, Michael Mihailovic, CoolWay Trans Commercial Manager, Mark Williams, and Carrier Transicold NSW Sales Manager, Darrin Klein.

Fast fact

The Carrier Vector HE19’s use of a hermetically sealed scroll compressor and economiser helps to deliver a 40 per cent increase in refrigeration capacity during pull-down, while reducing the chance of refrigerant escape by 50 per cent.

used in a road train combination which travelled to Perth, and in an A-double combination between Sydney and Melbourne.

CoolWay has found the Vector HE19s throughout all of the 10 trailers to be extremely efficient on fuel. So much so, that its several trailer orders lined up for the near future are all set to feature Carrier’s all electric E-Drive technology.

reduces fuel consumption by up to 30 per cent, improves unit weight by 10 per cent, and brings lower noise levels with up to 15 per cent savings on maintenance costs, compared with predecessors.

“They give us that peace of mind that, whether we’re running confectionary chilled or frozen goods, they will maintain the temperature without any fault,” Mark says. “These new ones are a little bit overspecified for our setup, but they pull down quickly, they hold temperature and they’re extremely good on fuel. Once the doors are sealed up and they’re pulling down and have reached their temperature, they maintain it with the combination of the MaxiTRANS trailers.”

Carrier’s Vector HE 19 temperaturecontrolled trailer system features patented all-electric technology, which means the unit is powered by AC electricity generated by the diesel engine while in transit and also when plugged into mains power while stationary.

Since its launch, the internal architecture of the Vector HE 19 has been significantly redeveloped. Its modern design now

The high efficiency unit has been built around Carrier Transicold’s E-Drive all-electric technology, which works by removing the mechanical transmissions found in conventional belt-driven equipment and engine power into electricity via a generator, which drives the refrigeration system. This provides the benefit of a sustaining refrigerant containment for a projected average annual leak rate of less than three per cent.

The Vector HE 19 system combines the E-Drive technology with an improved multi-speed engine design, bringing fuel savings of up to 30 per cent when compared to the previous Vector 1950 – the equivalent of saving 5.4 tonnes of CO2 annually. It is also 82kgs lighter, operates at 3dB (A) lower, and has engineless options available for emissions reductions.

To CoolWay, it was clear from the start that Carrier cares about its customers. When Sunny and Anna used to work from their home office, Carrier’s NSW

Sales Manager, Darrin Klein, paid them a visit and made the decision for them for the unforeseeable future.

“He told me they treat everybody equally,” Sunny says. “To them, it didn’t matter if you buy one fridge or a hundred. It was the same.”

Now, CoolWay is replacing all of its fridges alongside Carrier.

“We are changing everything over 40,000 hours, and we haven’t had any breakdowns,” Sunny says. “Carrier has delivered and catered to all of our expectations. We are trying to be the best, and to be the best you have to partner with companies like Carrier who have the integrity and really do care about its customers.

“They’re such a big global brand and they still take care of all the little things for the small family-owned businesses, which is great. They will give you the best advice, not based on selling a product. They will give you the right product to suit the trailer, and that’s what I like about them. They’re an excellent company with an excellent product.”

Contact Carrier Transicold Ph: 1800 448 166 Web: www.transicold.carrier.com.au

www.trailermag.com.au 31

Images: Carrier Transicold.

Fleet solutions for success

Scully RSV’s hire, sales and manufacturing prowess have allowed companies like Rum City Foods to transform their business and bring their offerings to a new level.

Scully RSV, renowned for its broad solutions and ability to partner with customers throughout their journeys, has built its success on the foundation of dominant manufacturing capabilities and reliable vehicles for hire. It has been in business for over 30 years with these same values, and because of that, has developed a wealth of knowledge and experience in servicing Australia’s transport sector.

It is Australian road transport which Scully RSV CEO, Andrew McKenzie, says is one of the most arduous tasks anywhere in the world. Therefore, it is essential for Scully RSV to get it right.

“With the unique operating conditions of our environment, the distances travelled and the loads we carry, there’s no other market in the world like it,” he says. “That’s why it’s so important to maintain Australian design on our refrigerated transport, and that’s what Scully RSV has done. We don’t take European or American designs, but what we do is look to their learnings.

“The tyranny of distance in Australia is that we can’t afford for our assets to break down. In Europe or America, you aren’t more than 100 kilometres from a major capital city and yet here in Australia we have one of the most geographically isolated capitals in Perth.”

Scully RSV understands the various

nuances and tasks that exist in the refrigerated road transport space, and from milk to meat hangers, custom doors and more, it has designed and built it all.

“What sets us apart is our ability to create incredibly bespoke solutions to our customers unique operating and contract requirements,” Andrew says. “Our manufacturing process is 100-per cent customisable, allowing us to create the perfect solution.”

Ranging from utes to 14-pallet trailers, Scully RSV builds its customised solutions using panel materials from a local supplier in New South Wales. From there, it assembles and builds each and every unit in-house in Brisbane. Being a local manufacturer, Andrew says, is something the business is very proud of.

“We pride ourselves on our ability to design and build truly world class solutions here in Australia,” he says. “We don’t look to import –we source local product. Because we do this, we work with our suppliers to manufacture only the most premium products available in Australia for our vehicles.”

Working with these local suppliers also means that Scully RSV is able to support and reinforce its purpose of connecting communities. By supporting local businesses, they then employ their local communities to produce the products that

make it into Scully RSV’s trucks.

“It’s this powerhouse combination of overseas learnings, applying it with our domestic suppliers, and creating a superior product that’s made by local communities, which reinforces why we design and manufacture in Australia for Australian conditions,” Andrew says.

Based in Queensland, Rum City Foods is a family-owned and operated business which has completely leveraged its service offerings with Scully RSV’s fleet solutions. The fleet now has over 40 rigids on the road as well as a range of vehicles purchased through Scully RSV.

Following its most recent venture which saw the company branch out into fruit and vegetables, Rum City Foods turned to Scully RSV for a range of A and B trailers. Rum City Foods General Manager, Scott McIntyre, says these units have transformed his operations.

“With the savings that they’ve implemented into my business, they’re brilliant,” he says. “Instead of running two or three trucks to one region we’re just running one semi-trailer. So, they’re costsaving, efficient and reliable.”

The trailers will travel to Brisbane three days a week to pick up fresh produce at the Brisbane Markets. They will first load out of Bundaberg with fruit and vegetables to take

32 Trailer Magazine MARCH 2024 Refrigerated transport equipment

Fast fact

Scully RSV founder, Damien Scully, originally approached Rum City Foods Managing Director, Kelvin McIntyre, in hopes of getting his support after completing his apprenticeship. Rum City Foods backed Damien and Scully RSV, and it hasn’t looked back since.

to Brisbane, and then will bring loads back to Rum City Foods’ Rockhampton facility to satisfy the needs of its customers.

Rum City Foods has been dealing with Scully RSV for several decades since its inception in 1978, and over that time, has benefitted significantly from its service and reliability.

“Their product is reliable, and they listen to our requirements,” Scott says. “If we have issues with their technology in the harsher environment of north Queensland, they listen to us, they rectify and they restrengthen in certain areas. They satisfy all of our needs, and they’re there to assist our growth.”

In the event of a breakdown or a new contract, Scott says Scully RSV allows businesses to keep trading – delivering on its promise to be a full service provider.

“Because our business is growing so fast, if we pick up a new contract and we physically don’t have enough vehicles in our own fleet, they’re only one phone call away,” he says. “Every build is different, depending on the contract that you’re servicing, so then we design it with a purpose-built body to fulfil that contract.

Then when they manufacture it, we return the hire truck and pick up our new trucks.”

To Rum City Foods, Scully RSV is an insurance policy every day. Scott says he is able to continue to service his customers in full and on time, because if there is ever a breakdown or a need for more vehicles, he has Scully RSV up his sleeve.

“I can call on them, and they answer, they produce, and they provide,” he says. “Scully RSV is very diversified and they can

us in growing, we wouldn’t be here in the same position as we are today without Scully RSV.”

Contact

Scully RSV

Ph: 1800 728 559

Web: www.scullyrsv.com.au

Images: Scully RSV.

Scott McIntyre and Kodi Beeston.

www.trailermag.com.au 33

Rapid and responsive

Australian shipping company, Sea Swift ,has taken delivery of a 45’ flat top and 45’ drop deck semi from CIMC Vehicle Australia to modernise its road transport fleet as well as increase productivity.