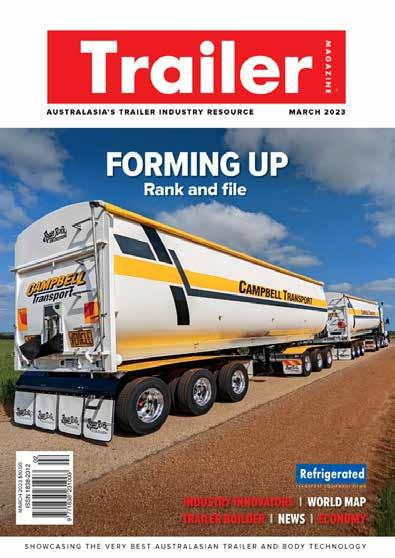

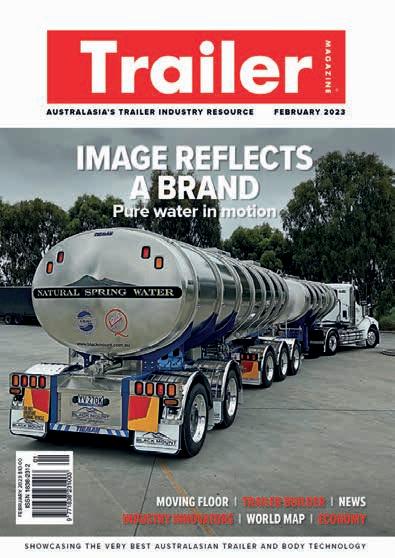

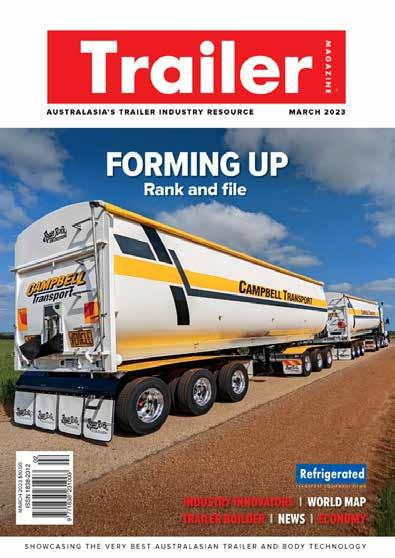

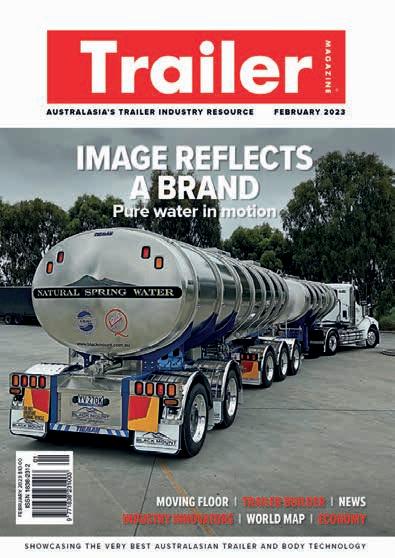

® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE APRIL 2023 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY ISSN 1838-2312 9 771838231003 03 APRIL 2023 $10.00 TRAILER BUILDER NEWS EVENTS TOW COUPLINGS ECONOMY INDUSTRY INNOVATORS STRIVING FOR SUCCESS STRIVING FOR SUCCESS The path without end The path without end

TOP QUALITY AND FIT FOR PURPOSE WITH A FOCUS ON SAFETY AND RELIABILITY. DROP DECK TANKERS EXTENDABLE CURTAIN SIDE DROP DECK B DOUBLE CURTAIN SIDE STRAIGHT SIDE TIPPER WIDENER www.aaatrailers.com.au - 02 9188 3222 Jeffrey 0414 671 969 - Jeffrery@aaatrailers.com.au - 159 Walker St, Helensburgh, NSW 2508 Daniel 0429 160 094 - Sales4@aaatrailers.com.au - 7 Coulson Way, Canning Vale, WA 6155

AAA TRAILERS Jeffrey 0414 671 969 - Jeffrery@aaatrailers.com.au - 159 Walker St, Helensburgh, NSW 2508 Daniel 0429 160 094 - Sales4@aaatrailers.com.au - 7 Coulson Way, Canning Vale, WA 6155

PUBLISHER

John Murphy

john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Peter White peter.white@primecreative.com.au

Anjali Behl anjali.behl@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Tom Anderson

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS 03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher. Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

End of an era

When Scott’s Refrigerated Logistics entered voluntary administration last month the news came as a shock to many. For a business 70 years strong, comprised of 1,500 personnel and a modern fleet of trucks and trailers, along with a sizeable warehouse portfolio, this was not the end the iconic fleet deserved.

At the time of writing, I’ve seen nothing but praise for those directly impacted. Their commitment to quality, working hard, has been celebrated online in the hopes that those suddenly without employment find a new opportunity in the nation’s essential service.

Peter Anderson, the CEO of the Victorian Transport Association, said the collapse of Scott’s is sad but tangible evidence of the challenges facing freight and logistics. He said this should be a wake-up call for governments both state and federal where industry has reached the ‘tipping point’ when it comes to fuel, infrastructure, labour and business

costs. Without genuine relief, he contends that other operators may face a similar fate. Regardless, Anderson is resolute that a longterm solution will emerge.

In 2020, Automotive retail Group, AP Eagers, sold Automotive Holding Group Refrigerated Logistics for $100 million to Australia-based private equity firm, Anchorage Capital Partners. The sale included the Rand, Harris, Scott’s and JAT businesses. It is understood as part of this 2020 deal the Scott’s Refrigerated Logistics business was purchased for $75 million.

To add to the conversation, the Transport Workers Union agrees that the fall of Scott’s is a tragedy of a suppy chain crisis but caused by wealthy clients squeezing transport contracts and profiting from ‘razorthin’ margins of operators.

Michael Kaine, the TWU National Secretary, agrees that other businesses may be at risk without action.

Officially endorsed by the VTA www.trailermag.com.au

From

the Editor’s desk

4 Trailer Magazine APRIL 23

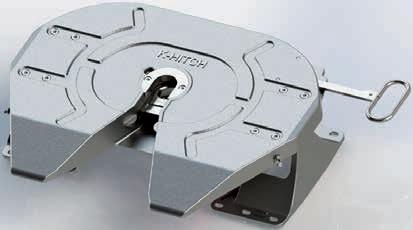

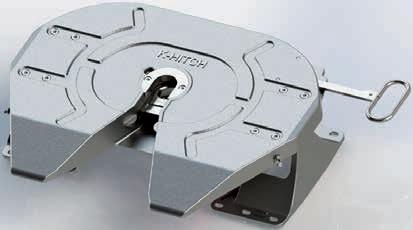

RUNNING GEAR FOR ALL APPLICATIONS AND ENVIRONMENTS FUWA K-HITCH www.khitch.com.au MELBOURNE 13-21 Bliss Court Derrimut VIC 3030 p: 03 9369 0000 f: 03 9369 0100 melb@khitch.com.au PERTH 77B Kurnall Road Welshpool WA 6106 p: 08 9350 6470 f: 08 9350 6570 perth@khitch.com.au BRISBANE 41 Moreton Street Heathwood QLD 4110 p: 07 3372 2223 f: 07 3372 1022 qld@khitch.com.au FOR ALL YOUR EQUIPMENT AND OE SPARE PART REQUIREMENTS, YOU CAN TRUST KHITCH

April 2023

See what Liquip and Lucidity are contributing to Australia’s road tanker industry today.

36 Trailer builder

This month we take a look at the latest trailer deliveries and even celebrate a milestone.

44 Tow couplings

Hyva and JOST showcase their tow coupling developments.

48 Trailer building materials/components

Familiarise yourself with these prominent suppliers. They keep this industry moving in the right direction.

68 World map

California here we come – learn a little about US-based trailer builder, Hyundai Translead.

70 Fleet of the month

Tempus Group has strengthened a new business unit.

72 Industry Innovators

Made possible by Smedley’s Engineers, Industry Innovators is a series dedicated to honouring the individuals who are transforming the commercial road transport industry.

74 What’s on Upcoming shows and field days.

6 Trailer Magazine APRIL 23

38 54 32 36 46 60

Vawdrey Victoria Ph: (03) 9797 3700 Vawdrey New South Wales Ph: (02) 9421 6444 Vawdrey Queensland Ph: (07) 3273 6156 Vawdrey Western Australia Mob: 0448 901 126 Vawdrey South Australia Mob: 0447 343 579 IN FAMILY WE TRUST vawdrey.com.au

RON CROUCH

• Tailored for every application • Emphasis on safety and efficiency • Exceptional speed to market • Custom design and fabrication • High productivity combinations • Industry leading technologies • National spare parts and support • Australian owned and operated

I’ve been dealing with Vawdrey personally for 25 years and I have never had any issues. It’s always been run on the basis of mutual respect and ensuring that the high values and ethics of our companies are upheld for mutual benefit.

TRANSPORT EXECUTIVE DIRECTOR, Geoff Crouch.

Rising costs driving fleet management

A new survey of more than 1,800 global fleet operators has revealed the foremost challenges today facing businesses in the industry.

The survey conducted by telematics company, Teletrac Navman, confirmed that rising fuel costs (39 per cent), disruption due to the impact of Covid-19 (32 per cent), and supply chain pressure (31 per cent), remained the biggest obstacles for transport companies worldwide.

“The past 12 months have created new complexities for fleets, but fuel cost rises are the number one concern for operators globally,” said Alain Samaha, President and CEO of Teletrac Navman.

“As the cost per gallon of fuel spiked throughout last year, many operators looked to overcome the rising costs with driver behaviour programs and EV transition plans,” he said.

As rising fuel costs and the global response to reducing carbon emissions continued to build, fuel conversion (23 per cent) remained a key challenge with EV supply, alongside purchase price and charging infrastructure concerns.

A third (32 per cent) of respondents said that the conversion to next generation fuels is one of their largest areas of expense (second to purchasing new vehicles).

Conversion is also high on the agenda for fleet owners due to concerns about their environmental impact.

More than a third (41 per cent) of those surveyed said environmental impact was their biggest concern.

Outside of transitioning to next generation fuels – of which 30 per cent were looking to transition to EVs in the next 12 months – maintenance of existing fleet continued to be the largest expense

for 39 per cent of those surveyed.

“With supply chain issues continuing to impact EV vehicle availability and cost, some fleets are struggling to start the transition and are having to find ways to safely extend vehicle life through preventative maintenance and more conscientious use on the road,” said Mayank Sharma, Head of Global Product Management & UX.

“However, those with the available Capex to be early movers to EVs could gain a competitive advantage as they won’t be exposed to any further rising petrol or diesel costs, they’ll be reducing their environmental impact which is coming more into play in customer contracts, and will likely benefit from government grants and subsidies that will later be removed,” he said.

Intra Series Duratrac Series News

Over the course of 2023, fleets are looking to make investment in expanding their offering through technological integrations (48 per cent), while also using technology to aid compliance (39 per cent). Improving customer experience (39 per cent) and recruiting and retaining drivers (31 per cent) were also high on the list of planned investment for the next 12 months.

As with the start of any new year, the market experiences emerging opportunities and technologies that will benefit fleets.

In terms of emerging technologies, fleets are focusing on implementing more digital workflows (39 per cent) and video telematics (38 per cent), as they seek to increase efficiency and manage the top three fleet business costs (fuel, payroll, and maintenance).

On the technology front, nearly all (98 per cent) respondents said they were using

either a sourced or manufacturer-provided telematics solution across their fleet.

While vehicle tracking (43 per cent) was understandably the number one reason for utilising telematics, managing driver performance (33 per cent) was the next priority, followed by using it for proof of service/job completion (32 per cent), and of course monitoring fuel usage (30 per cent) in tough economic conditions.

Trailer Axles and Suspension

Trailer Axles and Suspension

Regarding driver performance, improved driver safety (37 per cent) was the biggest benefit of using telematics, with nearly a quarter (24 per cent) stating it helped prevent fatigue on the road.

Moreover, 89 per cent of those surveyed used telematics to benchmark behaviour, with 91 per cent also seeing a reduction in accidents and 24 per cent implementing new driver behaviour to help navigate the high fuel costs.

While 31 per cent of global fleets were concerned about increasing wage demands in a cost-of-living crisis, 37 per cent are using benchmarking to provide performance-based bonuses in a bid to retain drivers.

Trailer Axles and Suspension

Intra Series Duratrac Series

“Driver performance benchmarking is a great method of inspiring drivers to perform better and safer on the road,” added Sharma.

“With the growth in mobile applications it has never been easier for drivers to see how they are performing against targets and peers. In fact, 40 per cent of our respondents say that implementing telematics has helped to build a safe driving culture within their organisations.”

Increasingly strained fleets have been turning to smart technology in order to maintain productivity while putting driver safety first.

Trailer Axles and Suspension Trailer Magazine APRIL 23 8

PARTS ON DEMAND

SAF-HOLLAND is one of the leading global manufacturers and suppliers of high-quality axles and suspension systems, fifth wheels, kingpins, coupling products and landing gear to the commercial vehicles industry.

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

Email: sales@safholland.com.au

www.safholland.com.au

Coupling & Lifting Technologies Trailer Axles and Suspension Systems Trailer Axles and Suspension Systems Couplings Powered Vehicle Available in disc and drum Available in disc and drum Intra Series Duratrac Series FW351 Mark V OC50FS2 PH300 50mm–90mm E551B0M Coupling Trailer Axles and Suspension Systems Trailer Axles and Suspension Systems Couplings Available in disc and drum Available in disc and drum Intra Series Duratrac Series FW351 E551B0M Coupling & Lifting Technologies Systems Systems Couplings Powered Vehicle Suspensions Available in disc and drum Available in disc and drum OC50FS2 50mm–90mm E551B0M TOWING SYSTEMS TOWING SYSTEMS

YOU

IT Coupling & Lifting Technologies Systems Systems Couplings Powered Vehicle Suspensions Available in disc and drum Available in disc and drum FW351 Mark V OC50FS2 PH300 50mm–90mm E551B0M

HOLLAND

WHAT

NEED, WHEN YOU NEED

SAF

ORIGINAL PARTS

Driver health boosted by new partnership

A new partnership between Healthy Heads in Trucks & Sheds (HHTS), Prime Creative Media (PCM) and Australian Truck Radio (ATR) has been announced.

As part of a joint statement PCM and ATR said they were proud to support HHTS for the great work it continues to do within the transport industry.

HHTS is a registered not-for-profit charitable foundation, created to improve mental health and wellbeing across the road transport, warehousing and logistics industries in Australia.

“People who work in the road transport, warehousing and logistics industries have long faced challenges relating to mental health and wellbeing,” stated the media release.

“Risk factors varying from long hours, shift work, fatigue, isolation, social disconnection, high job demands, and potential exposure to trauma and critical incidents are all contributing factors,” the statement continued.

“The stigma surrounding mental health is an added component that leads to poor uptake of existing resources and support services, such as Employee Assistance Programs (EAP).

“As a result, the sector is ranked the lowest of 19 sectors in Australia

when it comes to thriving workplaces, according to Superfriend’s Thriving Workplace Study in 2021.

HHTS CEO, Naomi Frauenfelder, said the stigma around mental health in this sector is a key risk factor and barrier for help-seeking.

“As such, the primary objective of many of our resources and programs is to drive a reduction in mental health stigma and improve access to information,” she said.

“This invaluable partnership with Australian Truck Radio provides a medium for us to connect directly with those on the road and the broad range of people in our industry working 24/7 to keep our supermarkets stocked, our cars fuelled, and our packages delivered,” said Frauenfelder.

“It’s important for everyone to know it’s ok not to be ok, and that we can all seek help, information, and support when we need it. All levels of industry need to have the knowledge and skills to be able to look after their own mental health and wellbeing and to support others when they need it.”

Getting the word out to drivers on the road through Australian Truck Radio was important according to Prime

Creative Media CEO, John Murphy, who said PCM was proud to be working with HHTS.

“It is a great way to reach a large number of those working on the road and they can listen anywhere and anytime,” he said.

“We can also share where they can obtain the resources available to assist on their road back to better mental health,” said Murphy.

This partnership aligns with PCM’s values of growth and humility by supporting HHTS and the support it provides those in need in essential service roles.

B-triple road trains boost efficiency for ACFS

Container freight specialist, ACFS Port Logistics, is now operating B-triple road trains at the Port of Brisbane.

With a combined length of 42m, these B-triple road trains can carry six 20′ containers or three 40′ containers.

The company claims these high productivity trailers, manufactured by Vawdrey Australia, will boost efficiency by approx. 33 per cent and also reduce the carbon emission footprint per container by 33 per cent.

“ACFS will be working with the terminal operators at the Port of Brisbane to ensure that this vehicle configuration is widely accepted, in order to achieve the

above stated benefits,” the company said in a statement.

“All ACFS depot facilities and empty parks are configured correctly to accommodate, as is Australian Amalgamated Terminals as a terminal, whilst DP World and Patrick discussions are progressing well. Hutchison is not in a position to adopt the new triple configuration.”

ACFS Port Logistics has thanked Nicola Murray from Port of Brisbane, Andrew Rankins, Wayne Jenkins, National Heavy Vehicle Regulator Chief Engineer, Les Bruzsa, and driver/ operator Michael Zunker for their key

involvement in the B-triple road train initiative.

Performance-Based Standards vehicles, according to Bruzsa, are significantly safer than the prescriptive fleet. He also recently told Trailer that B-triples are among the safest trucktrailer configurations on the road today.

The container logistics operator is committed to innovations that introduce smarter processes that reduce carbon emissions and increase productivity.

Last year, ACFS Port Logistics announced it was using Vawdrey A-double Titeliners along the East Coast of Australia.

10 Trailer Magazine APRIL 23 News

Naomi Frauenfelder, HHTS CEO.

A game-changing delivery system

By popular acclaim, the SWIFT Delivery System from Liquip is the industry’s simplest, lightest, smartest and – yes –fastest fuel-delivery solution.

The SWIFT’s innovative metering delivery system uses level gauging to accurately and conveniently deliver multiple products through a single pump – whether the method of delivery is gravity-fed, bulk-drop or hose reel.

Make the SWIFT Delivery System the star of your fuel-delivery production!

SWIFT DIGITAL DISPLAY

PNEUMATIC

DFV SWIFT CONTROL

SWIFT MAC BOX

CONTROLS

liquip.com | sales@liquip.com Liquip International Pty Ltd 148 Newton Road, Wetherill Park · Sydney NSW Australia 2164 Tel: +61 2 9725 9000

Team Global Express calls for decarbonisation

Team Global Express, among other freight companies and vehicle manufacturers, is calling for stronger government support for decarbonisation in Australia.

According to the Australian Government’s latest Quarterly Update of Australia’s National Greenhouse Gas Inventory, transport accounted for 18.6 per cent of Australia’s total emissions for the year to June 2022.

National emissions for the June quarter increased by 0.3 per cent in trend terms on the previous quarter, which was driven by a 2.8 per cent increase in diesel consumption, a 2.3 per cent increase in petrol consumption and a 42.7 per cent increase in domestic jet fuel.

Team Global Express ESG Director, Heather Bone, said Australian policy around transport is actively impeding progress.

“There is no policy framework encouraging the use of low emission fuels and there is an inherent conflict of interest that fossil fuels are such a huge income source for government,” she said.

Bone explained that bio-derived fuels such as biodiesel and renewable diesel are available now, but the Australian Government’s single biggest source of income is still fuel excise from fossil fuels.

“Indeed under current tax guidelines, if you use renewable diesel, it’s still considered to be 100 per cent fossil fuel for tax purposes.

“We would be using renewable diesel now if we could get it in bulk in Australia and our customers are absolutely demanding low carbon solutions.”

Australia is also limited in its biodiesel use to 20 per cent for the fuel tax credit, according to Bone.

“Not because our engines can’t take a higher blend, but we are limited by our fuel tax credit regime,” she said.

Bone said the path to decarbonisation may contain another hurdle, in the move to electric trucks.

“They are great fun to drive, but you can’t overstate how this is going to be the biggest change to our industry since the internal combustion engine was invented,” she said.

News

12 Trailer Magazine APRIL 23

QUALITY. RELIABILITY. FLEXIBILITY. SERVICE. TECHNOLOGY.

AUSTRALIA WIDE

Scully RSV Provides Australia’s Largest Dedicated Fleet of Refrigerated

1800 728 559 www.scullyrsv.com.au Info@scullyrsv.com.au Scully RSV offers quality, reliable, and flexible truck and trailer solutions for businesses nationwide. From short & long term hire to new and exfleet sales, and customisation services, we have everything you need to succeed. With cutting-edge technology and a commitment to customer service, make Scully RSV your partner for business growth.

M1 Pacific Motorway transformation approved

One of the Hunter Region’s biggest infrastructure projects, the M1 Pacific Motorway extension to Raymond Terrace, has been approved by the Australian Government.

The $2.1 billion project will deliver a 15-kilometre extension of the M1 Pacific Motorway from Black Hill to Raymond Terrace, New South Wales, including a 2.6-kilometre bridge over the New England Highway and Hunter River.

The surrounding network will also be upgraded, including the Hexham Straight Widening of around six kilometres of the Pacific Highway/Maitland Road to three lanes in each direction between the Newcastle Inner City Bypass at Sandgate and the New England Highway at Hexham Bridge.

Minister for Regional Transport and Roads, Sam Farraway, said the upgrade will cater to the transport industry.

“This project is also set to create better access for key employment areas and support freight servicing the Hunter Valley mining industry, the Port of Newcastle and interstate freight – meaning it will have local, regional and national economic benefits,” he said.

“The 15-kilometre extension includes a four-lane divided motorway with two lanes in each direction, four new interchanges and a 2.6-kilometre viaduct over the Hunter River and floodplain, the Main North Rail

Line and the New England Highway.

“We now have the official planning approval to get on with the job of delivering one of the biggest infrastructure projects the Hunter region has ever seen to make daily life easier for families, businesses and truckies.”

John Holland Gamuda Australia Joint Venture has been announced as the contractors for the southern section of the project, covering a 10-kilometre section extending from Black Hill to Tomago.

Seymour Whyte Constructions will deliver the northern contract, completing the five-kilometre section that will bypass Heatherbrae.

Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said the M1 Pacific Motorway extension to Raymond Terrace will be a key link in Australia’s infrastructure.

“Demand on the road network in this area is only expected to increase as local populations grow,” she said.

“We know that extending the M1 will provide improved traffic flow and increased connectivity.

“Getting the official tick to move forward is exciting news for the community as we continue to build the infrastructure that communities in regional NSW deserve.”

The project is expected to be open to traffic in mid-2028, weather permitting.

Freight upgrade for key Katunga intersection

Works are underway to improve a key freight intersection in the farming community within Katunga, Victoria.

The intersection of Numurkah, Sandmount and Hendys Road is being upgraded to two new simplified T-intersections.

The works will see the northern stretch of Hendys Road closed, a new right turning lane added on Numurkah Road, the relocation of the Sandmount Road intersection to meet Numurkah Road and improved signage and line marking.

Member for Northern Victoria, Jaclyn Symes, said the upgrade will benefit heavy vehicle operators in the region.

“Katunga is in the heart of the Goulburn Valley’s rich farming region, so this upgrade will help our farmers, freight operators and suppliers travel safely and easily navigate the intersection,” she said.

The project is being delivered as part of the Australian and Victorian Governments’ jointly-funded Targeted Road Safety Works (TRSW) Program, with $105.7 million invested to deliver infrastructure projects and urgent road safety improvements in Victoria.

“We’re upgrading this intersection at Katunga to improve road conditions for motorists as they travel through the area, and to help make sure that locals get home safely,” said Victorian Minister for Roads and Road Safety, Melissa Horne.

The works are expected to take 14 weeks to complete, weather permitting.

News

14 Trailer Magazine APRIL 23

www.omfbpacific.com OMFB Pacific Pty Ltd Phone: 1300 040 600 Email: sales@omfbpacific.com •Power Take-Offs • Gear Pumps • Piston Pumps & Motors •Control Valves • Control Systems • DC Powerpacks •Oil Tanks • Hand Pumps • Winches, and more... Backed by dedicated local product support and expert technical knowledge and assistance we’re focussed on providing the most durable solution for your on-road application. With over 70 years of innovation and thousands of customers in over 100 countries, OMFB has become a worldwide manufacturing leader of hydraulic components suited to Transport, Agricultural, Mining, Industrial, Marine, Oil & Gas and Mobile applications. Complete Hydraulic Solutions Tippers Bin trucks Vacuum trucks Truck-mounted cranes Waste management trucks

Wiseway reports positive rebound in first half of FY2023

Integrated freight and logistics operator, Wiseway Group, has released its financial results for the six months ended 31 December 2022 (1H2023).

Group revenue grew to $54,991 million in 1H2023 compared with $52,781 million in 2H2022.

There has been an encouraging turnaround in Wiseway’s core Australian divisions, with a reported EBITDA of $2.4 million.

The Group’s imports operations and sea freight operations have seen an over 23 per cent increase respectively, with the perishables division reporting the biggest improvement of over 79 per cent. The big growth is a result of the company’s continued efforts to diversify its revenue streams.

The company attributes the overall growth on improving business environment, strong customer relationships, a focus on cost management and margin improvement, and a diversified business model.

“Our Australian business has consistently performed and delivered profits and value for our shareholders,” said Wiseway Co-Founder and Managing Director, Florence Tong. “It is pleasing to see the company’s imports operations rebound and our perishables divisions doing very well throughout the period.”

The overseas divisions have reported mixed profitability as the company continues to invest in building its global network.

“Wiseway’s overseas operations have seen mixed results in 1H23, as the company continues to invest in building its global network. Achieving growth and profitability in Wiseway’s overseas operations will be a key focus for management in the coming months,” Tong said.

“Management believes that business performance will improve in the next 12 months as these impacts abate. Importantly, we are seeing early indications that sales volumes are rising across the board. With China’s reopening this calendar year we should see a marked pick-up across relevant sectors.

“Furthermore, management has started implementing measures to cut costs and improve productivity and margins, following investments for growth in recent years. These initiatives include rightsizing assets and staff, consolidating contracted services and exploring additional financing opportunities.

“The Group has maintained solid revenue growth in our Australian business division. This provides a springboard for Wiseway’s international business divisions to gain momentum and attract more customers, as we work towards sustainable profitability in our new growth segments.

“With the tactical investments and foundations in place, we will focus on untapped and underserviced markets in the Asia Pacific region, and gain enhanced access to the fast-growing markets in North America and Asia.

“Our diversified business model, growing customer base, strategic industry partnerships, and expanding global footprint will enable Wiseway to benefit from growing demand for returning global trade and integrated logistics solutions.”

News 16 Trailer Magazine APRIL 23

Construction on new Dubbo bridge begins

Major work is now underway to lay the foundations for the new Dubbo bridge across the Macquarie River in Dubbo.

The Australian and New South Wales Governments have jointly funded the New Dubbo Bridge project, which forms part of more than $1 billion in upgrades along the Newell Highway.

Upon completion, the upgrade will improve traffic efficiency and reduce congestion for the freight industry while improving access across the Macquarie River floodplain during extreme weather events.

Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said the project is hitting a milestone with the start of construction.

“Crews are now ready to start constructing the bridge’s permanent supports and 660 metre span,” she said.

“This will start with a drill rig that will bore holes into the bedrock beneath the Macquarie River to guide crews to drive steel tubes about 60 metres into the ground.

“From there, crews will construct the

columns that will hold up the new bridge.”

The bridge will use 123 reinforced concrete girders to provide the framework to hold the 5,000 tonne weight of the bridge deck.

“Once the 89 piles are installed, the first massive girders would be moved into place from late 2023,” said Sam Farraway, Minister for Regional Transport and Roads.

“We will really see this work start to come together in early 2024.”

Early works on the project started in August 2022, with the Brisbane Street and Darling Street intersection works now nearing completion.

During November last year a key milestone for the New Dubbo Bridge took place, with piling work on the floodplain adjacent to River Street, NSW.

The New Dubbo Bridge project is a $220.2 million investment, with major construction now starting and the project expected to be open to traffic by late 2026.

The Australian Government is providing $176.2 million for the bridge, and the NSW Government $44.0 million.

Arrow Transport announces new GM

Arrow Transport has appointed Barbara Karipis as its new Group General Manager.

After working alongside Arrow Transport Logistics & Quarantine Services Managing Director, Craig Webster, for nine years as an operational account at Chalmers, Karipis joined the team six years ago and has been involved in many roles including CFO, establishing and managing backroom offshore functions and setting up and managing the company’s centralised invoicing team. Karipis also played a key role in the development of Arrow’s internal operating system, AOS.

With Arrow now operating out of the five major ports around Australia, the board identified the importance of appointing the right Group General Manager to lead the company into its next phase of growth.

Managing Director, Craig Webster, said the business did not have to look very far. “With her natural leadership skills, industry knowledge, customer focus, true passion for the business and its success, a work ethic second to none, I think its fair to say she appointed herself! And I could not be happier,” he said.

Blank sailings see container volumes collapse

The decision to schedule a large volume of blank sailings to Australia by international shipping companies will reportedly impact on one of its largest shipping terminal operators.

The Maritime Union of Australia (MUA) has warned that the blank sailings will throw the waterfront industry into disarray and cause significant economic hardship, with the latest example of shipping company cartel behaviour bolstering the case for government intervention into Australian supply chain security.

Hutchison Ports has advised the Union it expects the impact of the

shipping companies’ withdrawal of sailings to its two terminals in Sydney and Brisbane will last four months.

The reduction in volumes will reportedly drive potential job losses and necessitate significant wage reductions and hardship for the entire workforce.

MUA said terminals operated by DP World in Fremantle and VICT in Melbourne are also affected.

“This is a prime example of persistent market failure in Australia’s supply chains, with Australian workers once again bearing the brunt of international cartel conduct on our coast and on our

waterfront,” said Paddy Crumlin, MUA National Secretary.

“During Covid, this cartel behaviour took the form of rampant price gouging and scheduling and vessel allocation manipulations that created a false scarcity amidst the global pandemic. “Now, they’re slashing sailings and leaving a massive vacuum behind to exert pressure once again on Australia’s supply chains and working people.”

The MUA said it will work with Hutchison and all affected stevedoring operators to protect job securities and manage the impact the scheduling gap will have on workers and their families.

18 Trailer Magazine APRIL 23 News

Download our Service Locator App NSW Brown and Hurley Group Coffs Harbour02 6648 2222 NSW Brown and Hurley Group Tamworth02 5778 2777 NSW Brown and Hurley Group Kyogle 02 6632 0333 NSW Commercial Brake EngineeringSydney 0419 495 764 NSW Diesel Tec Cowra 0428 429 275 NSW Doug Sutherland Truck RepairsAshmont 02 6925 2094 NSW Gilbert & Roach Hexham Newcastle02 4964 8641 NSW Gilbert & Roach HuntingwoodHuntingwood02 8825 1000 NSW HMR Australia Orange 02 6360 3380 NSW JME Engineering Pty Ltd Wollongong02 4272 7784 NSW Truck Tech Chipping Norton0415 971 322 NT Haulmark Trailers Darwin 08 8984 3533 QLD Action Mechanical SpecialistsBanyo 07 3268 6888 QLD Attitude Contracting Dalby 0429 622 747 QLD Brown and Hurley Group Caboolture07 3385 4800 QLD Brown and Hurley Group Darra 07 3363 8000 QLD Brown and Hurley Group Rockhampton07 4923 8000 QLD Brown and Hurley Group Toowoomba07 4690 7300 QLD Brown and Hurley Group Townsville07 4758 4000 QLD Brown and Hurley Group Yatala 07 3441 7000 QLD CQ Diesel Eagle Farm07 3268 2543 QLD Queensland Air Brake ConsultantsBrisbane 0412 666 982 QLD Truck & Equipment Service CoCairns 07 4035 1610 QLD Walkabout Worskshop Ormeau 07 5549 2417 SA Barry Maney Group Mt Gambier08 8721 3400 SA Haulmark Trailers Edinburgh08 8283 8585 SA Tatiara Truck & Trailer Bordertown08 8752 0077 SA Transmech Australia Pty Ltd Wingfield0478 774 093 SA TruTech Services Port Augusta0457 901 416 TAS AJL Heavy Equipment Pty LtdBurnie 0428 595 592 TAS AJL Heavy Equipment Pty LtdDevonport0428 595 592 TAS Webster Trucks Derwent Park03 6211 0550 TAS Webster Trucks Kings Meadows0419 562 820 TAS Webster Trucks Wesley Vale 0409 185 991 TAS Webster Trucks Wivenhoe0484 612 253 VIC Arkon Auto Electrical & InstrumentsWodonga02 6056 4600 VIC Banlay All Truck & Trailer RepairsDandenong South03 9794 7199 VIC GM On-Site Trailer MaintenanceMelbourne0431 084 861 VIC Graham Thompson Motors Shepparton03 5821 3977 VIC Hallam Truck Centre Hallam 03 8796 9100 VIC HM Transport Maintenance Shepparton03 5831 6996 VIC Jev’s Diesel Repairs Sunshine West 0425 838 455 VIC Marshall Group Mildura 03 5023 1701 VIC Mildura Truck Centre Mildura 03 5051 2800 VIC Ryan’s Diesel Maintenance & RepairsGippsland0438 761 462 VIC The Truck Specialists Swan Hill 03 5033 1372 VIC Twin City Truck Centre Wodonga02 6049 8888 WA EBS Perth Perth 0410 512 879 WA Flex Industries Kalgoorlie08 9068 1500 WA Flex Industries Kwinana 08 9419 1199

CouriersPlease celebrates women in leadership roles

Ahead of International Women’s Day on 8 March, CouriersPlease is celebrating the success of women in leadership and franchisee roles.

CouriersPlease prides itself on a supportive culture, diverse team and a high-performing female workforce throughout its 40-year history.

The company’s senior leadership team comprises 62 per cent women, an increase from the 50 per cent that represented the team in early 2022.

Female franchise territory managers are also well-represented at CouriersPlease, with 36 per cent of those roles being held by women. These roles work directly with franchise partners, working alongside them, as well as supporting and overseeing them.

CouriersPlease COO, Janine Zammit, was appointed to the role in October 2022 and has spent more than 20-years driving success and sustainable growth for companies in the finance and logistics industries.

Zammit has extensive experience in senior leadership, operational excellence and strategic planning roles. In her previous positions at Commonwealth Bank, Citibank and Prosegur, she led the companies through transformational change, innovation and expansion into new markets.

In her Sydney-based role at CouriersPlease, Zammit will drive efficiency and create a seamless experience for customers and employees. She is also driving the company’s commitment to sustainability and seeking opportunities for its franchise partners to grow profitable businesses.

Zammit said the support and nurturing of women at CouriersPlease is inherent.

“A dedication to bringing and supporting women in the industry permeates across our company and starts at the top with our senior leadership team,” she said.

“Thanks to our hardworking staff and support from our CEOs, past and present, women are present in every facet of the

company which, in turn, encourages other women to enter the industry and build their career.”

Shannon Menzies is one of CouriersPlease’s longest-serving team members, having joined the company as a relief driver nearly two decades ago before starting her business as a franchise partner 13 years ago.

Since starting as a Franchise Partner, Menzies has maintained her run in Brisbane’s Salisbury and Robertson as a one-woman business, and completes more than 100 daily deliveries to industrial, commercial and residential areas. She delivers on behalf of small businesses and large corporations, such as Kmart, and family-owned national business Richmond Wheels.

“I’ve been in the transport and logistics industry for my entire career, as I love of driving, physically active work and the outdoors,” she said.

“I also love connecting with people in the community I service, and building strong relationships.”

Brisbane-based Franchise Territory Manager, Jasmin Ginn, manages a fleet of 28 franchise partners and depot staff.

Ginn joined CouriersPlease more than a decade ago as a customer service agent, before becoming one of the company’s most dedicated and successful Franchise Territory Managers in 2017.

Ginn has achieved numerous successes in her role, including being awarded Singapore Post Best Ambassador of the Year in 2019.

Adelaide-based Franchise Partner, Carolyn Van DeLeur, joined CouriersPlease as a relief driver five years ago, before purchasing her first territory as a franchise partner in 2021.

“I was drawn to CouriersPlease by my love of the outdoors and I absolutely love my job as a Franchise Partner,” she said.

“My ultimate goal is to continue doing this until I retire.”

Since starting her business, Van DeLeur has seen an exponential growth in parcel

volumes and now delivers to 140-190 customers a day across several Adelaide suburbs, including Blakeview, Evanston South and Elizabeth.

CouriersPlease Head of People and Culture, Hannah Dunlop, recently accepted the role after more than two years at the company as a Human Resources Business Partner and Acting Head of People and Culture.

Dunlop has been in the transport and logistics industry for her entire career and is the youngest team member at CouriersPlease to hold a senior leadership position, at age 28. In her role, Hannah leads a team of four and last year was instrumental in hiring women in key roles, supporting the company’s CEO to find key talent.

“Throughout my career at CouriersPlease, I’ve also helped initiate programs that have equally benefitted both men and women, including our graduate program in 2021,” she said.

“I designed and implemented the program, which saw two operational graduates join the team, both of which remain in permanent positions at the company.

“I was also involved in the launch of our company intranet, One Place, which contains valuable resources and information for our staff, including a Mental Health Hub, with key advice to keep employees happy and healthy.”

This year, Dunlop will also play a key role in implementing a learning management system – an online platform that will provide key information and advice to Franchise Partners, encouraging them to invest in their own self-development and upskilling.

Dunlop grew her profile as a key industry and HR thought leader, delivering presentations at two Franchise Council of Australia events in 2022, including a panel on recruitment at the Victoria Chapter Breakfast and a panel on upskilling and building a learning culture at the Franchising and Small Business Summit.

20 Trailer Magazine APRIL 23 News

Ask us about LocAl® at the Brisbane Truck Show

Cleaner, Greener. Lower-carbon aluminium for your projects.

Choosing lower-carbon aluminium in your next project can reduce the embodied energy of your aluminium products by up to 75%* LocAl® Green (8kg CO2e/1kg AL) and LocAl® SuperGreen (4kg CO2e/1kg AL) are the responsible choice for a locally extruded, lower-carbon option in your next project.

FOR MORE INFORMATION VISIT lowcarbonaluminium.com.au POWERED BY

* When compared with global average CO2e for primary aluminium production, Scope 1 and Scope 2 ex smelter.

Followmont Transport embraces growth mindset

On the back of acquiring Bradco Transport in North Queensland, Followmont Transport is exploring other strategic opportunities.

Followmont Transport Managing Director, Mark Tobin, said the business has a clear business and growth strategy which sees the company target acquisitions that add value to its customers, progressively grow and ensure service levels are maintained.

Working with Bradco owners since October last year, Followmont’s Senior Executives, identified the opportunity to leverage Bradco’s existing network and provide additional infrastructure for their produce service.

This approach has reportedly resulted in 80 per cent growth for the FNQ Solutions arm of Followmont and has meant they have been able to assist their valued customers in their own business growth and begin to build solid foundations with new customers.

Tobin said the venture had been on the cards for some time as they have a close relationship with the Bradley family.

“I have the upmost respect for Ken and everything he has achieved with his family

and through his career,” he said.

“So after many discussions on his retirement, I knew Followmont would serve his customers well, carry on the partnerships he had created and also offer future growth for Followmont’s existing customers.”

Followmont’s successful model has seen the company sustainably grow year after year and future proof their business through their property portfolio.

Strategically investing in a footprint that allows their network to offer a reach and solution that works in with their customers’ needs.

“Our property is actually the backbone of our business,” said Tobin.

“We developed Bootooloo Property in 2017 with the intention of owning our own assets, controlling our future, and driving organisational agility.

“Working alongside Bootooloo, we have secured real estate throughout Queensland and New South Wales to invest in our network and complement our business strategy.”

The significant real estate portfolio allows Followmont to leverage its property plan

and maximise return on investment.

Since July 2016, Followmont has invested over $180 million in its fleet, network infrastructure and property and has plans to invest up to $230 million more in the coming years.

The latest project in Followmont’s midst is a new Sydney development, providing the company the freedom of expansion as they continue to outgrow their current site.

Even with this large project underway, Tobin said the transport leader is on a path to source suitable bolt-on businesses, that will only strengthen their pipeline.

“We will continue to grow and are on the hunt for further mergers and acquisitions,” said Tobin.

“We will do this the right way though, and our commitment and service will not waiver.

“I am so confident with our Senior Leadership Team and the level of knowledge and passion that our entire team brings.

“I know we have the right people on the ground to continue our success and invest in the right places.”

22 Trailer Magazine APRIL 23 News

•

E- Mail: i n fo@e-m a x.com.a u P: 130 0 85 0 5 75

Approved for use with all TCA approved telematics devices, for Smart OBM and IAP-M • 3 year limited warranty • No manual pairing of the system needed, no extra cost or need for a third party phone or tablet, system connects automatically with no driver input required, turn the key and go. • Smart OBM and IAP-M ready today, with whatever

www.air-weigh.com.au

Milestone for $200M supply chain program in WA

A groundbreaking ceremony in Brookton has marked the milestone for Western Australia’s $200 million Agricultural Supply Chain Improvement Program.

Site works have begun at the Wheatbelt town on the first of 11 rail siding upgrades to optimise the safe and efficient transport of WA’s bumper grain harvests to domestic and international markets.

The upgrade is part of Package 1 of the $200 million Agricultural Supply Chain Improvement (ASCI) Program, jointly funded by the State and Federal Governments.

Constructed by WA company, Multiplant, the Brookton rail sliding extension will connect to the Co-operative Bulk Handling (CBH) grain bin allowing longer trains to load grain adjacent to the Great Southern Line without causing congestion on the main line.

To complement the Government funding and further improve grain handling and loading, CBH will also invest in rapid loading bins and elevators at all 11 rail siding upgrade sites.

In addition to allocating $68 million for 11 rail siding upgrades, $60 million has been allocated to upgrade the main Midland Rail Line between Carnamah and Mingenew, and $72 million for

investigation and recommissioning of rail lines in the Narrogin-Wickepin-Kulin area.

Transport Minister, Rita Saffioti, said WA’s agricultural products contribute $8 billion annually to its economy, and are sold to more than 30 countries around the world.

“With WA’s recent run of recordbreaking grain harvests, it’s more important than ever to optimise the efficiency of our agricultural freight transport supply chains to manage the increase in product,” she said.

“As well as an economic boost, the ability to transport more grain by rail will improve community safety and decrease environmental emissions and road maintenance, by reducing the need for road freight.”

Agriculture and Food Minister, Jackie Jarvis, said the Brookton rail siding extension, combined with CBH’s new rapid loading infrastructure, will maximise value for WA growers.

“In recent years, we’ve seen recordbreaking grain harvests, and while our supply chains have stood up to the huge level of demand, we need to keep investing in projects that will support greater capacity in the future,” she said.

Vale Gary Liddle AO

Non-profit organisation, Roads Australia, mourns the passing of former Board Director and transport industry leader, Gary Liddle AO.

Liddle served the transport industry for more than 40 years.

“In that time, he occupied senior leadership positions in the sector, including as Chief Executive of VicRoads, Deputy Secretary of the Department of Transport, Planning and Local Infrastructure (Vic), Chair of the Australian Road Research Board (ARRB), Chair of Austroads, Chair of iMOVE and Chair of iRAP,” Roads Australia said in a statement.

“Gary’s passion for the transport sector and sharing his knowledge with the next generation was further reflected in his role as Enterprise Professor, Transport at the University of Melbourne.

“In 2017, Gary was made an Officer in the Order of Australia (AO) for ‘distinguished service to public administration in the Victorian transport sector through leadership in policy direction, infrastructure development, road safety and regulatory reform.’

“RA extends is deepest condolences to Gary’s wife Meredith, his family, friends and all Gary’s former colleagues across the industry.”

Former CEO of the Victorian Transport Association (VTA), Philip Lovel AM, said Liddle was a true-blue good guy.

“He helped out the VTA many times whether it be in sponsorship, speaking at our events or assisting our individual members with their issues.

“He was also a very important leader in overseas charities involved in building houses and facilities in Cambodia.”

The VTA Executive and members extend their condolences to Liddle’s family and friends.

Liddle was also a Life Member of the Australian Road Transport Suppliers Association (ARTSA).

24 Trailer Magazine APRIL 23 News

Quality aluminium solutions

Your single source product, processing and service solutions provider

As one of Australia’s leading national steel and aluminum distributors, BlueScope Distribution has the product range, processing capability, and technical expertise to deliver on your project requirements.

Our national aluminium routing capability enables us to profile complex shapes with precision, ease and accuracy. Combined with our extensive aluminium product range and experienced programmers, we work closely with your business to deliver aluminium solutions that give you the freedom to do what you do best.

Talk to our team about your aluminium processing requirement including, profile cutting simple or complex custom shapes, milling, holes, material labelling and coding, and much more!

For more information visit bluescopedistribution.com.au

13 72 82

BlueScope Distribution® is a registered trademark of BlueScope Steel Limited.© BlueScope Steel Limited March 2023 ABN 16 000 011 058. All rights reserved. Perth Esperance Adelaide Portland Ballarat Hobart Launceston Melbourne Newcastle Sydney Albury Brisbane Gladstone Townsville Mt Isa

Steel. Aluminium. Knowhow.™

Food supply shortage concerns escalate

Did you know that more than half a million Australian households struggle to meet their food needs?

Households with children have been reported to be 32 per cent food insecure over the past year compared to the national average of 21 per cent. Meanwhile, single parent households are 37 per cent severely food insecure.

The rising cost of living is the most common explanation for why people are failing to meet their household food requirements (64 per cent of food insecure households).

The cost of food and groceries is the top cause (49 per cent), followed closely by energy (42 per cent) and housing (33 per cent) costs.

Over half of food insecure households (54 per cent) had someone in paid work.

Nearly a third of households with mortgages (30 per cent) have experienced food insecurity in the last year.

The situation is even worse in regional areas (36 per cent compared to 27 per cent in metro areas).

On a typical day, 306,000 households are receiving assistance from food relief organisations.

These are the results of Foodbank Hunger Report 2022.

This pressure could be further exacerbated by the current state of Australia’s cold chain network.

Following the collapse of Scott’s Refrigerated Logistics, and the possibility of food waste as a result of insufficient storage capacity, this has potential to further disrupt the nation’s food supply.

Foodbank Australia CEO, Brianna Casey, has witnessed the rise in demand for food relief services over the past year, but even she was shocked by the troubling picture of today’s Australia exposed in the report.

“We know how important it is for people to have access to nutritious food, yet the rising costs of energy, fuel, groceries, rent and mortgages have put this fundamental need beyond the reach of more and more people with no respite in sight,” said Casey.

“These results should make everyone stop in their tracks. The numbers being reported are massive and hard to process, but they represent the harsh reality of living week to week when the cost-ofliving crisis collides with an income crisis and the household budget now lists food as a discretionary spend.”

The report signals that the problem is only set to get worse with half of all households experiencing difficulty saying that being unable to afford food is happening more often.

The report presents key findings from a survey which was conducted between 11 and 28 July 2022, through an online questionnaire of 4,024 people in Australia aged 18 years or older. The sample was nationally representative by age, gender and location (capital city / rest of state) in each major state, with stratified quotas to ensure all major states have a robust minimum sample size of n=600 or above. The data was weighted to nationally representative proportion of age, gender, state and location (capital city/ rest of state).

‘Food insecurity’ covers a range of experiences from being uncertain about getting enough food and compromising on nutrition right through to disrupted eating patterns and reduced food intake.

26 Trailer Magazine APRIL 23 News

Device Technologies to upscale national logistics capabilities

Medical technology company, Device Technologies, is building a custom, stateof-the-art national distribution centre.

Located in Sydney Business Park in Marsden Park, the distribution centre will be the epicentre of the Device Technologies’ operations, warehousing and logistics for Australia, New Zealand and Asia.

With completion slated for late 2023, the Device Technologies distribution centre is designed around the future needs of customers, logistics partners and employees.

“Device Technologies is driven by growth, and we have reached the stage where we must transform,” said Device Technologies COO, Steve Symes.

“This next phase of our evolution equips us with a custom-built, five-Star GreenStar rating facility designed around our customers’ needs in delivering lifesaving technologies to our hospitals.”

The company’s 30-year growth trajectory has seen various warehousing solutions, and the Marsden Park development will allow for streamlined logistics both within metropolitan Sydney and around Australia.

Device Technologies CEO, Michael Trevaskis, said the company will remain committed to its customers along its

growth by providing the best solutions to fit their needs.

“This extends to our logistics, where we aim to make the order, supply, delivery, and reverse logistics processes as streamlined as possible, creating more efficiencies for Australian healthcare customers,” he said.

DG

Lucidity website

Shift workers face higher illness risk

Rotating shift workers eat more kilojoules, snack more on junk food and don’t eat as many nutritious foods, increasing their risk of diet-related illness a new report has found.

The Monash University-led research published in Advances in Nutrition, found rotating shift workers, many of whom are employed in transport and logistics, had higher average 24-hour energy intake than day workers.

As part of the systematic review of dietary habit and energy intake studies it was discovered that for each recorded day of kilojoule intake, rotating shift workers ate on average 264 more kilojoules than regular day workers.

An increase of just 100 kilojoules each day can lead to a .5 kilogram weight gain over a year.

Shift workers also reported unhealthier dietary patterns than day workers, including irregular meals, more snacking or eating at night, less core food consumption and more eating of discretionary foods.

In Australia, 1.4 million employees (16 per cent) have shift work as their main occupation.

Rotating shifts, where schedules vary from week to week, are the most common form for women and men.

Previous studies have found that while shift work may be more convenient or pay more, it puts workers at increased risk of chronic illnesses such as cardiovascular disease and diabetes.

A contributing factor to these increased risks is the timing of eating occasions.

Consuming a greater proportion of daily energy intake at night has also been

associated with weight gain and impaired glucose metabolism.

Someone who concurs with the challenges of shift work is Tania Whalen, 51, who has done shift work off and on for 20 years, and consecutively for the last six years.

Although enjoying her work in telecommunications, Tania said when she was tired it was “too easy to grab junk food such as chocolate during a shift.

“The good part of rotational shift work is having up to four days off at a time and the work has fitted in nicely with raising a family,” she said.

“The bad part is the food and nutrition challenges, especially as I often work 12hour shifts. That’s a long time to prepare food for and keep it fresh at work.”

To better understand the situation,

News

28 Trailer Magazine APRIL 23

from the Department of Nutrition, Dietetics and Food, compared the total daily kilojoule intake of workers on rotating shift schedules with those on day

For the first time, the study revealed that rotating shift workers may be eating more kilojoules with a large proportion at night, helping to explain why they face increased risk of chronic diseases.

Clark, who works with Monash University’s SWIFt Study (Shifting weight in night shift workers) said understanding the impact of extra kilojoule consumption could go a long way towards much

needed workplace support.

She said while the disruption to lifestyle that shift work causes could not be changed, improving diets and eating patterns could make a difference.

“The study also found the diets of rotational workers tended to contain less protein and carbohydrates, and more fat than day workers,” she said.

“The foods and drinks typically consumed by rotating workers were more fried and fatty foods, confectionary, sweetened drinks and alcohol, with fewer core foods such as dairy, meat, fruit and vegetables.

“There was also a pattern of more meals per day and frequent snacking at night, with the majority of kilojoules being eaten

NO MORE POLISHING Alcoa Dura-Bright® EV Wheels

in the second half of the day.

“Adding to the complexities of night time eating, shift workers don’t have the same access to healthy food as day workers and may rely more on vending machines, takeaway and convenience foods.”

Monash University, in collaboration with the University of South Australia, is now trialling the effectiveness of three weight loss strategies for night shift workers. Funded by the NHMRC, The SWIFt Study considers the complexities of circadian rhythms and meal timing on weight-loss success.

“These workers are an important part of our society and are often working around the clock to keep our world functioning,” said Clark.

Image credit: AngieYeoh / Shutterstock.com TALK TO OUR EXPERTS 1800 955 191 durabrightevo.com.au

Alcoa Dura-Bright® Wheels clean with just soap and water, so there’s no need to polish.

Available across our range of wheels, the patented technology significantly reduces maintenance labour and time costs.

Action plans

The 2023 Heavy Vehicle Safety Strategy Action Plan, according to the National Heavy Vehicle Regulator highlights essential safety priorities for the next 12 months.

The Action Plan supports the delivery of the NHVR’s Heavy Vehicle Safety Strategy 2021-25, which outlines the regulator’s ambitions for achieving better heavy vehicle safety outcomes and reducing the number and seriousness of crashes involving heavy vehicles.

NHVR CEO, Sal Petroccitto, said the Action Plan will deliver initiatives addressing safety risks identified through feedback from our partners, and the analysis of operational data and research.

“All of the 2023 Action Plan’s deliverables are built on the theme of partnerships,” said Petroccitto.

“Through industry partnership and collaboration, the NHVR is committed to achieving better heavy vehicle safety outcomes and reducing the number and seriousness of crashes involving heavy vehicles.”

The Action Plan’s safety initiatives were refined in consultation with the NHVR’s partners at the July 2022 Industry Reference Forum.

Partner feedback was central to determining the five broad actions to improve heavy vehicle safety.

These five actions are:

1. Delivering safer and tailored fatigue risk management outcome;

2. Empowering industry to better manage safety in their business;

3. Delivering tailored regulatory interventions to drive positive safety change;

4. I nfluencing the regulatory framework to promote the adoption of safer, cleaner, and more efficient vehicles and technologies; and

5. Providing input into government policy decisions that affect the safety and productivity of the heavy vehicle industry.

Each of the above actions contains multiple safety deliverables that will enable safer heavy vehicles and road safety for all road users.

Petroccitto said the Action Plan would help guide the NHVR to continue making strides for a safer heavy vehicle industry in 2023.

30 Trailer Magazine APRIL 23

The National Heavy Vehicle Regulator announces its latest 12-month strategy, while the Steering Committee welcomes truck drivers to the decision-making table.

XXX Economy

“After a busy 2022, this year we are focused on continuing to address heavy vehicle safety risks,” he said.

“I want to thank our partners that provided valuable feedback to help shape the Action Plan and position us for a proactive and successful year to come.”

In 2021-22, the NHVR delivered several safety actions that have benefited industry, community and all road users, with highlights including:

• E xpanding the availability of Electronic Work Diaries by approving its use on multiple electronic devices.

• Delivered the 9-Step Safety Management System (SMS) Roadmap, making SMS guidance material more accessible for transport operators.

• Conducted the Don’t #uck with a Truck campaign to target young learner (L) and provisional (P) licence holders.

• Supported delivery of new Australian Design Rules for increased electronic stability controls and advanced emergency braking.

• Worked with road managers to expand the gazetted network for PerformanceBased Standards vehicles.

Steering Committee welcomes truck drivers to the decisionmaking table

Senator and Chair of the Heavy Vehicle Rest Area Steering Committee, Glenn Sterle, said heavy vehicle drivers are vital to keeping the country running.

The Committee held its first meeting in Canberra last month and was reported to be the first time that truck drivers have been at the table directly informing decisions that will impact their work through increasing access to new or improved heavy vehicle rest areas.

The four industry representatives and five truck drivers discussed their priorities for the roll-out of the Government’s $140 million commitment to the building or upgrading of rest areas for heavy vehicles. A list of representatives is provided below.

The Committee is working on the guidelines for the funding program. They aim to have the guidelines finalised in coming months so that state, territory and local governments can start applying for funding for heavy vehicle rest area projects by the middle of this year.

“Having truck drivers at the table involved in the delivery of our rest areas election commitment was a key part of the announcement made by Minister Catherine King and Senator Glenn Sterle during the 2022 election,” said Assistant Minister for Transport and Infrastructure, Carol Brown.

“It was a real privilege to attend part of the first day of the Committee’s meeting. The shared knowledge and experience of members of the Committee will deliver heavy vehicle rest areas in the most efficient locations.”

Sterle said the Australian community has a greater appreciated for the role the heavy vehicle industry plays in keeping the economy and local communities going following pandemic and recent natural disasters.

“During the pandemic when our truckies worked around the clock to ensure people across the country continued to receive the things they needed to keep them safe and well,” he said.

“Following the floods in Fitzroy Crossing, truckies took on the challenge of driving an extra 4,500 kilometres to get supplies to the flood affected communities.

“The Committee is hoping to hear directly from truckies about where they think there are gaps in the rest area network.”

Australian Consumer Confidence

0.5% 3.7% 7.8%

GDP growth rate December 2022 Unemployment rate January 2023 Inflation rate December 2022

0 5 -5 -10 -20 10 15 20 25 10 10 6 4 0 0 -4 1 15 17 3 6 Apr 2022 Jul 2022 Oct 2022 Jan 2022 8

www.trailermag.com.au 31

Fuelling growth

Based in Cairns, Queensland, Nqpetro was born in a small shed in 2004, starting with two full-time staff and a casual office assistant. Several of its major fuel installation projects over the years throughout north Queensland saw business pick up, and by supplying a quality product, Nqpetro was able to grow the team considerably in a short period of time. Within 10 years of operation the business was able to increase its staff

which allowed the company to achieve further growth.

Nqpetro Workshop Manager, Steven Gibney, says the company went from being a service company to building petrol stations and regional depots across Australia. And, with these locations requiring a large usage of Liquip equipment, it made sense to request and partner with Liquip to become a distributor for far north Queensland.

Steven says. “Liquip has the largest product offering of equipment that we would use on the tanker trucks and in the depots and terminals, and having a direct relationship with the Liquip head office has been really beneficial to us.”

As a result, what started out as relying on a few truck parts and loading arms has developed into a broad application of Liquip equipment across Nqpetro’s fuel tanker business.

Along with routine checks and inspections, Nqpetro also offers specialised technical installations, repairs and support in the transport and handling of fuels, customised storage and refuelling systems – with remote access monitoring setups from small 1,000-litre tanks to multiple 110,000-litre tanks. By continuing its relationship with Liquip and by promoting the sales of products while offering service, support and feedback to its own customers, Nqpetro is now beginning to branch out even further.

“We’re now developing custom storage solutions for mine sites, remote areas and even truck stops where there are container tanks with loading arms, pumping systems and card readers, so it’s important to us to have a supplier we can rely on,” Steven says.

Since becoming a distributor of Liquip, Nqpetro’s Cairns workshop has grown to include a dedicated threelane drive through area for trucks up to full B-doubles, along with a full

By officially becoming a Liquip distributor in 2014, Nqpetro (Cairns) was able to transform its capabilities by expanding its expertise in underground fuel tank and pipework installations to the transport storage sector.

32 Trailer Magazine APRIL 23 XXX Modern road tankers

for a comprehensive range of Liquip products to be kept in stock. Due to its size, remoteness and backing by Liquip, Nqpetro now has the ability to fully support Liquip products throughout the north Queensland area.

Before joining the team at Nqpetro, Steven was working for Liquip in its Sydney head office between 2003 and 2006. By being directly involved with the company, its processes and services, Steven was able to experience the superiority of the Liquip brand himself.

“Liquip is such a huge part of the Australian fuelling market and I am glad to be have gone full circle and be dealing with them again down the line,” he says. “It’s definitely been a good coincidence and a carry on of where I was and where I am now.”

According to Steven, the reason Liquip has been so successful is because of its ability to evolve and meet market demands.

“Their equipment has been around that much longer and there’s been a lot more research and development involved in it,” he says. “The equipment is just better designed, with better material, and there is more thought going into the process of the design. And even though Liquip takes up a large proportion of the market, they are always continuing the development of the equipment as they go.”

In addition, despite catering to most of the fuelling builds in Australia, helping out customers like Nqpetro is still a top priority for Liquip. Steven says this commitment to aftersales service was noticed in Nqpetro’s earlier dealings and it has been present ever since.

“When Nqpetro first started out doing

days and they’re still very helpful to this day. It’s not a chore for them to help out. We’ve always been able to contact them and it’s always a quick answer with a very clear and concise response as well. They have always taken on any criticisms or

Contact Liquip 148 Newton Road, Wetherill Park NSW 2164 Ph: 02 9725 9000 Web: www.liquip.com www.trailermag.com.au 33

Leading innovation

Lucidity Australia prides itself on delivering innovative designs to real world transport industry challenges and is always looking to develop engineered solutions to the many different transport sectors its customers operate in.

Lucidity is now looking to expand into the fuel tanker sector with its unique innovations. For 10 years it has been manufacturing probe overfill harnesses for the Australian tanker industry in a specialised process where each harness is complex and unique to different tanker configurations, which require a different design every time.

According to Lucidity, the manufacturing

of the probe overfill harness is not only labour intensive, but it requires unique skills to create one-off engineering drawings each time a product is manufactured. Furthermore, once all the material has been prepared for the harness, changes to the tanker specification such as length, compartment size and number of compartments can then lead to expensive rework costs.

With extensive experience in this sector, Lucidity has taken these constraints on board with the traditional probe harness design to develop a modular system which allows for flexibility in the tanker design. Because of this, it has reduced the

the Overfill Probe

need for specialist labour and bespoke engineering time – resulting in less production lead times.

Lucidity Australia President, Mathew Jenkins, says the first step was to design a purpose-built junction box specifically for the tanker industry probe overfill application.

“Typically, junction boxes used in the tanker industry for the probe overfill application are off-the-shelf commodity items with internal mounting holes,” he says. “The tanker manufacturer would then drill and tap holes in the boxes, allowing cable entry and exit. All this was then reliant on being backfilled with silicon

Lucidity is at the forefront of the industry once again with

electrical system – the first of its kind commercially available in the market.

34 Trailer Magazine APRIL 23 XXX Modern road tankers

Fast fact

Lucidity’s general electrical and wiring expertise is of great benefit to the transport industry. The Charge Plus range is ideal for protecting fridge plant batteries, while the OMP system, which allows all lighting and electrical elements of a trailer to plug into a common series of connectors, is especially handy for dangerous goods applications. Meanwhile, the Lucidity Link is a popular, durable and reliable lighting option for tippers.

with no guarantee in meeting the required IP rating, which would potentially allow water ingress and therefore make it noncompliant.”

Lucidity has designed and manufactured a probe junction specifically for this application. Its key features include a small profile design, external fastening points, water and dust-resistance to IP67, and standard industrial fittings to ensure compliance to the DG code.

Each junction box has three input/outputs to accommodate feed into the junction box, output from the junction box to the next probe position, and a probe output.

“The second step was the challenge of figuring out how to handle the probe return wiring and remembering that compliance requires no splicing while remaining competitive,” Mathew says. “We achieved this by using a proven technology taken from our IDM series of products and using a heavy duty printed circuit board (PCB) inside every junction box, which are both identical except for the probe output position on the PCB. This makes stocking these items as raw material or complete junction box assemblies very easy again, resulting in shorter product lead-times.”

According to Mathew, Lucidity has created the only off-the-shelf components series required to build, repair and maintain the critical wiring system. Designed to prevent over filling, each junction box is ordered specific to the probe location with simple point to point cables between each location, with zero

chance for assembly error.

Mat says the system was designed specifically for the tanker industry and it doesn’t require the manufacturer to have skills within the finishing area to tailor electrical components to suit an application. It also has a quick turnaround time by using specifically designed standard items, and with a fully robust and compliant design to the DG code, it’s easy to service when out in the field.

“We are extremely proud of our development here supporting the tanker manufacturing industry,” he says. “This solution delivers on cost, performance and resets the benchmark on industry best practice. Tanker OEMs are no longer walking on a tight rope of compliance from solutions not fully meeting the DG code.”

Contact Lucidity Australia 37 Paraweena Drive Truganina, VIC 3029 Web: www.lucidityaustralia.com.au Ph: 03 9219 4074 BUILT TO LAST Double action valving system in bump & rebound High Temp resistant hydraulic fluid Hydraulic lock-out piston for improved safety Single bonded bushing for improved durability With over 100 years of experience in every shock absorber, you know they’re built to last. monroe.com.au

Built different

Arthur Battle was responsible for bringing Nortrans to life following World War II, and he also played a major role in the relationship between Nortrans and The Drake Group which still exists today.

Nortrans began its journey in the transport industry in 1945 by carting milk from Malanda to Townsville, Queensland under the name Malanda Milk Transport Company. Since then, however, it has evolved to transport general freight, specialised freight, heavy freight, Dangerous Goods (DG) and refrigerated produce.

Arthur bought his first Drake trailer in the 1980s – a float and dolly – which marked the starting point of the business’ eventual path to success alongside Drake, under the guidance of his grandsons, Kent and Seeton Battle today.

By meeting with Drake’s Sales Manager, Byron Foss, seven years ago in Queensland, Kent renewed the relationship between both companies with several trailer purchases that would follow. These included a 45-metre extendable telescopic steerable and a shorter quad-axle unit, several O’Phee flat tops, a drop deck skel, and more recently,

a 4x8 Jinker coupled to a 2x8 dolly. While a number of factors have contributed to Nortrans’ loyalty to Drake, Kent says it always came down to the quality of the product.

“Byron Foss is the reason we went to Drake, and the product is the reason why we stayed,” he says. “We believe their product is the best. They’re made

in Brisbane, and when we ring and order something reasonably custom, I can talk to one of the owners or even one of the designers.”

Byron has played a major role in keeping Nortrans and Drake together for business over the last seven years. With regular visits to the Battle family whenever he was in Townsville, he was

Like The Drake Group, Nortrans is a third-generation, family-owned and operated business. And, like Drake, the value of quality trailers is highly regarded in its operations.

36 Trailer Magazine APRIL 23 XXX Trailer builder

Byron Foss and Kent Battle.

able to show Kent the care Drake is known for firsthand.