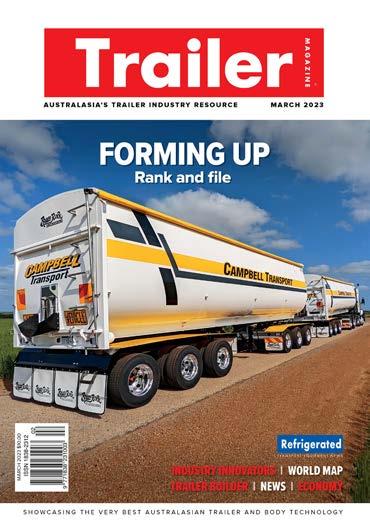

® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE MA Y 2023 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY ISSN 1838-2312 9 771838231003 04 MAY 2023 $10.00 TRAILER BUILDER INDUSTRY INNOVATORS BRISBANE TRUCK SHOW SPECIAL REPORT WORLD MAP FIRST FUEL QUAD TRAIN FIRST FUEL QUAD TRAIN

PUBLISHER

John Murphy john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Peter White peter.white@primecreative.com.au

Anjali Behl anjali.behl@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Tom Anderson

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher.

Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Some people just want to watch the world burn

Despite that damning 2019 Netflix documentary about the greatest party that never happened, word on the street is that Fyre Festival II might be happening after all. For those not in the know, Billy McFarland was convicted of wire fraud for his part in financing what became a notoriously horrendous fail of a music event back in 2017. Hyped attendees were sold a dream and found themselves, unfortunately, stranded and without adequate food or shelter on a remote Bahamas island. The entire saga is a masterclass in how not to coordinate and manage an event. It is essential viewing for the numerous lessons there are to learn from the chaos that ensued. Of course, the organisers sold tickets based on bold promises – the best food, art, music and access to celebrities –

and ultimately failed in execution on every front. Disgruntled ticketholders took to social media in droves, their testimony dismantled the fantasy. Instead of luxury accommodation and meals there were busted tents and barely enough potable water to go around. And where were the famous people? It is understood that some high-profile musicians bailed on the festival due to a lack of payment but it would seem many of those involved, including workers in the Bahamas, are still out of pocket.

How McFarland, who served four years in prison and is reported to owe creditors about $26 million USD, can whip up a media frenzy and attempt the same scam twice is absolutely wild. His response to the naysayers: ‘it’s in the best interest of those I owe for me to be working’.

From the Editor’s desk

Officially endorsed by the VTA www.trailermag.com.au

4 Trailer Magazine MAY 23

AAA TRAILERS Jeffrey 0414 671 969 - Jeffrey@aaatrailers.com.au www.aaatrailers.com.au - 02 9188 3222 - 159 Walker St, Helensburgh, NSW 2508 Neil 0418 880 077 – sale1@aaatrailers.com.au – Perth WA TOP QUALITY AND FIT FOR PURPOSE WITH A FOCUS ON SAFETY AND RELIABILITY. DROP DECK TANKERS EXTENDABLE CURTAIN SIDE DROP DECK B DOUBLE CURTAIN SIDE STRAIGHT SIDE TIPPER WIDENER

6 Trailer Magazine MAY 2023 50 72 52 56 58 88 8 Industry news The latest news and industry developments. 46 Economy An initiative aims to end dairy tanker rollovers. 48 Brisbane truck show A glimpse of what to expect at this year’s grand event and more. 88 Trailer builder Learn more about a world first road train innovation and the latest trailer designs rolling out across Australia. 100 Trailer building materials/components A showcase of the products and services that keep trailers on the move. 116 Special report What you need to know about this year’s VTA State Conference. 128 World map A review of Breakbulk Middle East 2023. 130 Fleet of the month Easy Truck Rental on hybrid electric trucks. 132 Industry Innovators Adam Ritzinger talks about pushing boundaries in the heavy vehicle industry. 134 What’s on Upcoming shows and field days.

Vawdrey Victoria Ph: (03) 9797 3700 Vawdrey New South Wales Ph: (02) 9421 6444 Vawdrey Queensland Ph: (07) 3273 6156 Vawdrey Western Australia Mob: 0448 901 126 Vawdrey South Australia Mob: 0447 343 579 IN FAMILY WE TRUST vawdrey.com.au

CROUCH

• Tailored for every application • Emphasis on safety and efficiency • Exceptional speed to market • Custom design and fabrication • High productivity combinations • Industry leading technologies • National spare parts and support • Australian owned and operated

I’ve been dealing with Vawdrey personally for 25 years and I have never had any issues. It’s always been run on the basis of mutual respect and ensuring that the high values and ethics of our companies are upheld for mutual benefit.

RON

TRANSPORT EXECUTIVE DIRECTOR, Geoff Crouch.

Toll launches ‘Curiosity in Motion’

A brand refresh and campaign for Toll will support brand awareness and repositioning as it expands across Australia, Asia and the US markets with $1.2 billion of investments planned over the next four years.

Toll Group unveiled ‘Curiosity in Motion’ last month which is reported to capture how the transport and logistics company delivers value for businesses in an era of change and disruption.

Toll Chief Corporate Affairs & Marketing Officer, Zed Ivankovic, said the new brand positioning and campaigns are a fresh, bold expression of how Toll makes an impact for businesses.

“Throughout Toll’s 130-year history, curiosity has been at the heart of our brand and the way we work,” said Ivankovic.

“Our new brand and campaign highlights how we at Toll push beyond the status quo to find new and better ways to deliver value for our customers.”

Informed by both external and internal research, the campaign creative ‘Think outside the box’ centres on how Toll makes an impact for customers.

The three creative variations show how Toll is creating solutions across three big supply chain areas: fast e-commerce logistics, supply chain visibility and simplifying complex shipping.

“At Toll, we know our brand and we understand the power of great ideas and creativity in the ever-changing supply

chain sector,” said Ivankovic.

“With our new brand identity and campaign, our people play a starring role, bringing their curiosity and spirit of progress to life with curiosity in motion.”

The campaign will run across social media in markets covering Australia, Asia and Europe.

Land earmarked for freight terminal operations in Melbourne’s north

A long-awaited freight terminal in Melbourne’s northern suburbs is one step closer to being realised thanks to Federal Government-owned National Intermodal Corporation exercising an option to acquire land.

The 1,100-hectare parcel has been identified as a suitable site for the Beveridge Intermodal Freight Terminal (BIFT) which will connect to Inland Rail on the Tottenham-to-Albury section.

Once developed, the site will offer double-stacked services for 1800-metre freight trains to Perth and, upon completion of Inland Rail, to Brisbane.

Early planning is looking at ways to support potential interstate rail services at Beveridge as soon as possible, with full terminal and precinct warehouse operations expected by 2028/29. The

precinct will also see upgrades to key road corridors.

Moorebank Intermodal Company CEO, James Baulderstone, said acquiring the land at Beveridge was an important milestone in the development of Melbourne’s modern, efficient intermodal terminals.

National Intermodal is also pushing the project forward by teeing-up large-scale support. It’s announced the signing of a Memorandum of Understanding with Aurizon, Australia’s largest freight operator, as the foundation customer for the pending terminal.

Meanwhile the City of Whittlesea is celebrating the news. It has been advocating to both Federal and State governments for funding, keen to see the plans get the green light.

Council Chair Administrator, Lydia Wilson, said the project will not only provide full terminal and precinct warehouse operations, and support interstate railway services, but also contribute $3.5 billion to the economy each year and create 20,000 jobs in construction and operations.

Image credit: ArliftAtoz2205 / Shutterstock.com 8 Trailer Magazine MAY 23 XXX News

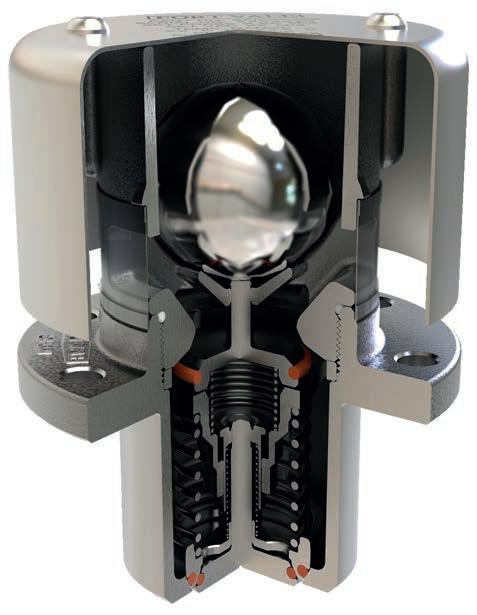

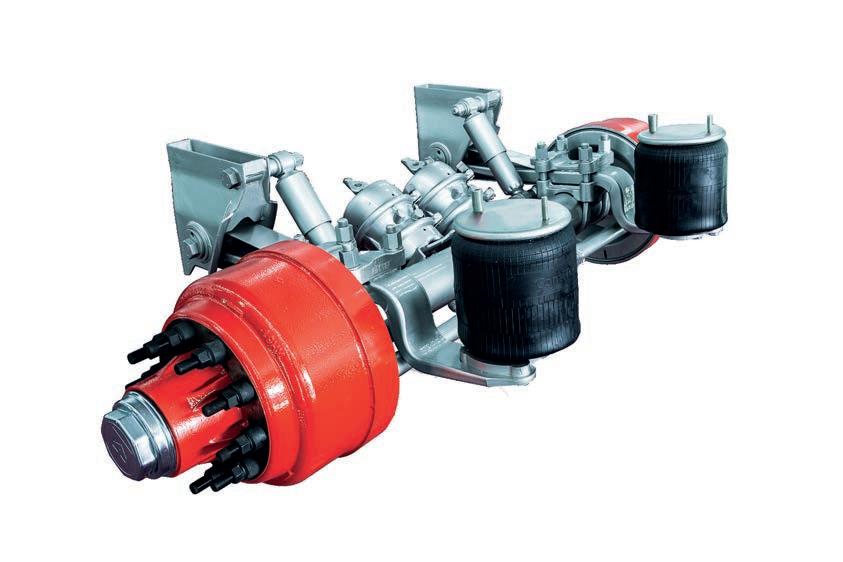

www.safholland.com.au SAF-HOLLAND (Aust.) Pty. Ltd Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763 SAF-HOLLAND (Aust.) QLD Ph: (61-7) 3375 7033 Fax: (61-7) 3375 7044 SAF-HOLLAND (Aust.) WA Ph: (61-8) 9353 1720 Fax: (61-8) 9353 1730 SAF-HOLLAND (Aust.) NSW Ph: (61-2) 9672 1950 Fax: (61-2) 9672 1994 Specify SAF- HOLLAND INTRADISC & INTRADRUM. + Frame bracket symmetry – no shocker bracing needed + SAF drum brake with quick release spherical anchor + No Ubolts + More uptime + Low maintenance + Patented composite rotor + Long life disc brake technology SAF INTRA SAF-HOLLAND (Aust.) Pty. Ltd SAF-HOLLAND (Aust.) QLD SAF-HOLLAND (Aust.) WA SAF-HOLLAND (Aust.) NSW SAF-HOLLAND (Aust.) SA Ph: (61-8) 8346 7035 Fax: (61-8) 8346 3583 Specify SAF- HOLLAND INTRADISC & INTRADRUM. + + + 1 MILLION KM OR 6 YEARS* On-road warranty on bearings, shock absorber & pivot bushes *WHICH EVER OCCURS FIRST OFF-ROAD WARRANT Y 3 YEARS / 500,000KM* SAF INTRA www.safholland.com.au SAF-HOLLAND (Aust.) Pty. Ltd ABN: 79004371215 | Sales: 1300 131 613 Email: sales@safholland.com.au Visit us at the Truck Show STAND 82 FOYER

Schmitz Cargobull partners with MaxiTRANS

International trailer builder, Schmitz Cargobull, has invested in the MaxiTRANS business.

Schmitz Cargobull has today become a minority shareholder (26 per cent) in the Australian Trailer Solutions Group (ATSG), in a partnership that will continue to set the MaxiTRANS business up for long term success in the Australian market.

ATSG comprises a group of investors, including a number of Ballarat locals. Since ATSG purchased the MaxiTRANS trailer business in September 2021, its primary focus has been on supporting Australian manufacturing, its people and delivering a high-quality product for its customers.

“We are extremely thrilled to have Schmitz Cargobull onboard with MaxiTRANS as a partner,” said MaxiTRANS Executive Chairman, Greg L’Estrange.

“Schmitz Cargobull has a great reputation for high quality, innovative design and durability across its expansive product offering. To have a company with such an international reputation see value in our plans for the MaxiTRANS business is testament to our people and the on-going support of our customers who have helped continue to build the business since ATSG came onboard.”

The partnership with Schmitz Cargobull will allow the businesses to partner on technology, scalability and processes that can then be implemented into the MaxiTRANS operation.

“The backing of Schmitz Cargobull, coupled with our own investment into the business, will allow us to streamline our processes, deliver global supply chain

benefits and allow MaxiTRANS to continue to focus on delivering outstanding quality and support for our customers,” said L’Estrange.

“In addition, it provides access to worldwide trends and technology that we can utilise and leverage in the Australian market.”

Schmitz Cargobull CEO, Andreas Schmitz, said: “Our investment in MaxiTRANS offers great potential to unlock manufacturing synergies and introduce advanced technologies to support and contribute to the Australian trailer industry.

L’Estrange added: “We look forward with great excitement at the future of the MaxiTRANS business as we work together with our investment partners and continue to support our customers for the life of our product.”

Schmitz Cargobull Australia Managing Director, Les Lange, told Trailer this investment is a good fit for both businesses and is bound to have a positive impact on the Australian trucking industry.

“There is so much activity in the industry at the moment,” he said.

“With increasing demand for the timely and safe delivery of perishable goods, among other commodities and critical cargo, fleets are on the lookout for stateof-the-art trailing equipment that will best serve their customers and keep supply chains moving.

“We see a brilliant synergy in motion between Schmitz Cargobull and MaxiTRANS and will leverage our combined expertise and technologies to empower fleet owners and operators.”

Qube manages lead-silver concentrate shipment

Logistics service provider, Qube, has coordinated the first shipment of lead-silver concentrate from the Abra Base Metals mine for Galena Mining to Geraldton Port.

A pioneer in the containerised bulk supply chain, Qube deployed a system for rotating container tippers with integrated lid lifters.

In addition to achieving productivity gains with this technology, it also allows concentrates to be transported and loaded into vessels without creating a dust hazard and minimises the risk of spillage.

Qube said it facilitated the loading of the Papora Wisdom vessel in April with 5,019 dry metric tonnes of the concentrate bound for Asia.

“The Abra Base Metals Mine is a globally significant lead-silver project located in the Edmund Basin in the Gascoyne region of Western Australia (situated between the towns of Newman and Meekatharra),” Qube said in a statement.

“It is approximately 100km due west of the Great Northern Highway, which connects the remote towns of Meekatharra and Newman. Leadsilver concentrate produced at Abra is transported by road to the port of Geraldton in the mid-west of WA, where it is then prepared for export.”

10 Trailer Magazine MAY 23 XXX News

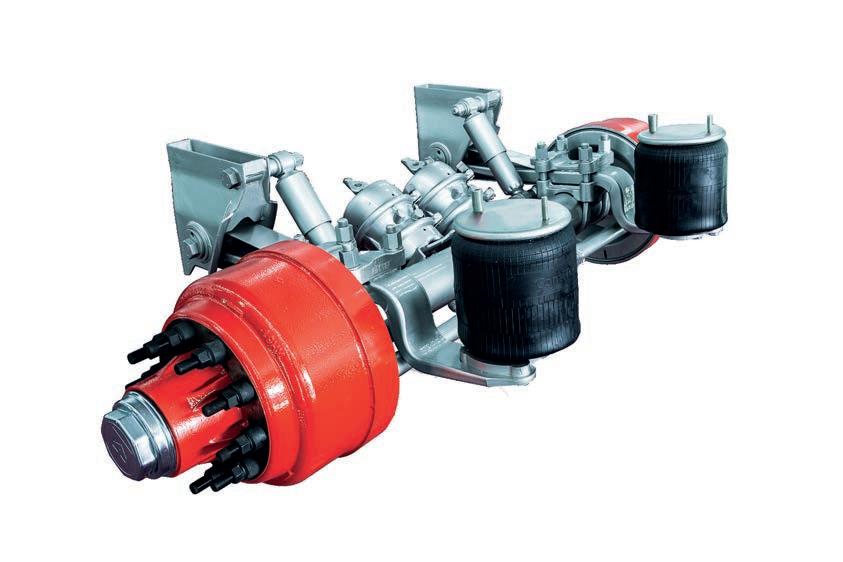

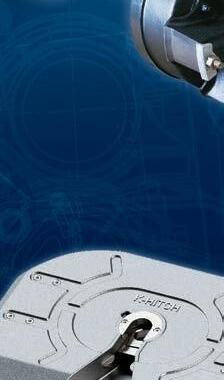

RUNNING GEAR FOR ALL APPLICATIONS AND ENVIRONMENTS FUWA K-HITCH www.khitch.com.au MELBOURNE 13-21 Bliss Court Derrimut VIC 3030 p: 03 9369 0000 f: 03 9369 0100 melb@khitch.com.au PERTH 77B Kurnall Road Welshpool WA 6106 p: 08 9350 6470 f: 08 9350 6570 perth@khitch.com.au BRISBANE 41 Moreton Street Heathwood QLD 4110 p: 07 3372 2223 f: 07 3372 1022 qld@khitch.com.au FOR ALL YOUR EQUIPMENT AND OE SPARE PART REQUIREMENTS, YOU CAN TRUST KHITCH

Coles bolsters milk supply security

Coles Group has agreed to acquire two automated milk processing facilities from Saputo Dairy Australia (SDA) for consideration of approx. $105 million.

Each facility has the capacity to process around 225 million litres a year and they are predominantly used today to process Coles Own Brand 2L and 3L milk. The processing facilities are located in Laverton North (Victoria) and Erskine Park (New South Wales) close to Coles’ distribution centres.

“These facilities are state-of-theart, delivering exceptional production efficiency and quality through highly automated processes,” said Coles CEO, Steven Cain.

“Whilst improving security of our milk supply and our supply chain resilience in the dairy sector, these facilities also have sufficient capacity to facilitate further growth opportunities through new product innovation.

“The acquisition will build on the strong relationships we have developed with our dairy farmers since launching our direct sourcing model in 2019. Around 90 dairy farmers supply milk direct to Coles, allowing these farmers to invest for the future and ensuring the long-term sustainability of their farms.

“These processing facilities will complement our existing investments in

our Own and Exclusive brand portfolio and manufacturing capabilities in areas such as convenience meals and meat.”

SDA site-based employees at both facilities will be offered employment contracts with Coles.

Coles and SDA will also enter into customary transitional services arrangements to ensure a smooth handover to Coles.

Coles will continue its direct sourcing model and relationships with existing dairy farmers, with no expected impact on current arrangements.

Other examples of Coles bringing manufacturing in-house include:

• the construction in 2015 of a highly automated retail-ready meat and poultry manufacturing facility in Erskine Park (NSW) to secure supply and improve shelf-life of meat products.

• the acquisition in 2020 of the Jewel Fine Foods (now Chef Fresh) ready-made meals facility in Mascot (NSW) to expand the convenience meals range available to Coles’ customers. Additional automation has subsequently been added to this site.

To further its commitment to the dairy industry, in March, Coles announced a $3 million investment through the Coles Sustainable Dairy Development Group. Dairy farmers can apply for grants of up to $50,000 per year with funding to be

used on projects which enhance the sustainability of farms.

This grant funding builds on $2.2 million already provided through the Coles Sustainable Dairy Development Group for projects including heat stress research and foot-and-mouth disease guidance, as well as a roll-out of defibrillators on farms.

The acquisition will be funded from Coles’ existing debt facilities and is expected to exceed our investment return hurdles within three years.

The acquisition of these sites is subject to Australian Competition and Consumer Commission (ACCC) approval and other customary closing conditions and is expected to be completed in 1H FY24.

According to financial results for 1H 2023, Coles Group reported total sales revenue growth from continuing operations of 3.9 per cent to $20.8 billion.

Meanwhile, Perth-based conglomerate, Wesfarmers, has sold all of its remaining interest in Coles Group.

Last month, Wesfarmers confirmed the sale of its remaining 2.8 per cent. It has gradually reduced its shareholding in Coles since the demerger in November 2018.

Wesfarmers and Coles will reportedly continue the Flybuys joint venture, with both groups retaining a 50 per cent interest in Flybuys.

12 Trailer Magazine MAY 23 XXX News

B-DOUBLE DROP DECK CURTAINSIDER

• Full mezz deck

• Hanging gates, toolboxes & provision for tow coupling

• Locally supplied curtains

B-DOUBLE FLAT DECK CURTAINSIDER

• Rear doors

• Gates, toolboxes & provision for tow coupling

• Locally supplied curtains

45’ Drop Deck with BiFold Ramp

• 12V Power Pack

• 3 Way Twist locks

• Machinery tie-down points in floor

13.7-21.5m Extendable Flat Top

• 3 Way Twist locks

• Pneumatic warning flags

• Provision for tow coupling

40’ DROP DECK SKELETAL TRAILER

• 3 way twist locks

• Dangerous goods rated

• Container tilt airbag fitted

40’ 3 WAY SKELETAL

• Standar & lightweight designs

• Side loader pads

• Provision for tow coupling

• CIMC has a long term commitment to Australia by investing in infrastructure to provide high quality products, support and service.

• Local production capacity for Semi-Trailers and Tankers with CNC cutter, welding machines and start-of-the-art heated paint shop.

• Comprehensive parts store stocking genuine CIMC parts, along with additional OEM sourced items.

• Dedicated service & repairs workshop.

• Total site area 51,000 sqm, with a 13,000 sqm workshop.

Melbourne CIMC TRAILERS 1300 202 462 20 Whitfield Blvd, Cranbourne Brisbane CIMC TRAILERS 0423 795 649 68 Tile Street, Wacol Perth GTE 08 9352 4000 159 McDowell Street, Kewdale Sydney JRB GROUP 02 9355 3400 26 Bosci Rd, Ingleburn 19 Hale Street, Botany ENQUIR E NOW 1300 202 462 www.cimc.com.au | sales@cimc.com.au GLOBAL LEADERS WITH LOCAL KNOWLEDGE Your semi-trailer experts.

Flex Contract Logistics acquires Doug Hayes Transport

Flex Contract Logistics acquired Doug Hayes Transport (DHT) last month.

The acquisition is part of Flex Contract Logistics’ five-year strategy to become a leading player within the transport and logistics industry.

With warehouses in Melbourne, Sydney and Brisbane, the DHT acquisition will allow Flex Contract Logistics to transport less-than-full truck loads with one-pallet to 36-pallet options.

Flex Contract Logistics Managing Director, Lachlan Boyd, said the acquisition will give the company a strategic advantage in its growth plan.

“It provides us with an expanded footprint along the eastern seaboard, much needed additional equipment and the ability to now provide customers a full service offering for interstate requirements,” he said.

“There are existing customers in both the DHT and Flex businesses who can now access a wider range of services.

“This is just one of the synergies we expect to extract from the acquisition and we are confident this will fast track our growth over the next 12-18 months.”

DHT Director, Doug Hayes, has agreed to stay on board and support the integration of the two businesses.

According to Boyd, this will play a major role in the growth of the business.

“Having Doug stay around is beneficial to the entire Flex business, and we will ensure that everyone gets the opportunity to spend time with him and learn as much

as possible,” he said.

“Through continued investment in our people, technology and safety, Flex will

Sturt Highway upgrade takes next step

The ongoing Sturt Highway Corridor Upgrade has now set its sights on the 55-kilometre stretch between Annadale and Shea-Oak Log in South Australia.

Pavement rehabilitation works will be undertaken at multiple locations along the highway and are expected to be complete by late 2023.

Rest areas will also begin construction and upgrading this quarter and should be complete by the end of the year.

Minister for Infrastructure, Transport, Regional Development and Local

Government, Catherine King, said the Government’s funding is key in ensuring SA’s road network is as safe and efficient as possible.

“The Australian Government is addressing the need to improve safety for motorists and freight transport operators at multiple locations on the Sturt Highway,” she said.

“This project demonstrates our Government’s commitment to supporting more efficient, resilient and safer traffic and transport solutions for

continue to grow with our customer base and continue to go the extra mile to ensure our customers are well looked after.”

South Australians.”

SA Minister for Regional Roads, Geoff Brock, said there are plenty more improvements to come.

“The South Australian and Australian governments remain committed to improving safety, freight efficiency and supporting regional economic growth along this vital stretch of road,” he said.

Other related projects are taking place north-east of Nuriootpa, which will be followed by works west of Truro and northeast of Gawler.

14 Trailer Magazine MAY 23 XXX News

Heysen Tunnels overhaul to improve road safety in SA

A refit of the Heysen Tunnels in South Australia will improve road safety, traffic management and incident response capabilities for the 50,000 vehicles that use the tunnels daily.

The project addresses current tunnel elements that are at the end of their service life, to improve safety, traffic management and incident response capabilities.

Works include: upgrading the tunnel lighting to a new LED system; installing a new automated fire suppression system; upgrading the tunnel ventilation system; repairing the tunnel lining and installing monitoring equipment; upgrading the Intelligent Transport System (ITS) equipment, including thermal incident detection systems, new and replacement CCTV, electronic speed and messaging signage and over-height vehicle detection; upgrading the traffic management system to restrict access to the tunnels in the event of an emergency incident; and upgrading emergency communication systems, including public address, radio rebroadcast, in-tunnel signage and help phones to improve safety and network reliability.

More than 50,000 vehicles travel through the tunnels each day, around 10 per cent of which are heavy vehicles.

McConnell Dowell Constructors (Australia) Pty Ltd has been appointed as the Managing Contractor for the works and where possible, local sub-contractors and suppliers will be engaged to deliver packages of works.

The Australian and South Australian governments have jointly committed funding towards the Heysen Tunnels Refit and Safety Upgrade Project, with the Australian Government contributing $120 million and South Australian Government $30 million, as part of a broader South

Eastern Freeway Upgrade, which also includes Stage 2 of the Managed Motorway Measures project.

Initial upgrades, including additional investigation works and the start of tunnel lining repairs, will kick off from Sunday, 19 March 2023, for a period of around two months.

To minimise the impacts to road users, works will be carried out at night from Sundays to Thursdays between 8pm and 6am.

The Crafers-bound tunnel will be closed during these periods, with the Adelaidebound tunnel to accommodate traffic in both directions.

During works, speed will be restricted to 40km/h in both directions on the approach to the tunnels and through the down-track tunnel.

Traffic will return to normal operation, with usual speed limits, for both carriageways each morning from 6am.

It is not anticipated that works will be undertaken on Friday and Saturday nights, or on public holidays, however advance notice will be provided via onsite message boards, project updates and social media if this changes.

Access for emergency service vehicles and to all safety ramps will be maintained at all times during these works and there is no change to public transport services. Both tunnels will reopen if required in an emergency.

“The Australian Government investment in this project will ensure people can continue to reliably and safely use this crucial and modern traffic link for years to come,” said Federal Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King.

“This project demonstrates our Government’s commitment to supporting

more efficient, resilient and integrated traffic and transport solutions for South Australians.”

Minister for Infrastructure and Transport, Tom Koutsantonis, said: “The Heysen Tunnels have served South Australia well for more than 20 years now, but with technology evolving these upgrades are necessary to keep them operating as effectively as possible.

“The technology in these tunnels was cutting edge when they opened in 2000, but with much of it now reaching the end of its service life, we’re able to install modern, state-of-the-art equipment.

“With safety of the South-Eastern freeway a priority for the Malinauskas Labor Government, we are taking steps to future-proof the Heysen Tunnels, so that they can keep operating safely for decades to come.

“McConnell Dowell has delivered some key projects for South Australia; among them the Seaford Rail extension, O-Bahn City Access project and Granite Island Causeway.

“These works will cause some disruption to traffic, so it will be important that people plan ahead, check for updates, allow extra travel time where necessary and obey any of the temporary speed or traffic restrictions in place.”

There are two Heysen Tunnels running side-by-side. One is city-bound and the other is hills-bound.

Each tunnel is 500 metres long and 10.5 metres wide; has three lanes, each 3.5 metres wide; has a 90 km/hour speed limit, and takes about 20 seconds to drive through; has incident detection cameras that detect stopped or slow moving vehicles – these alert the Traffic Management Centre to any problems; as well as roadside emergency telephones every 50 metres along the tunnel wall.

16 Trailer Magazine MAY 23 XXX News

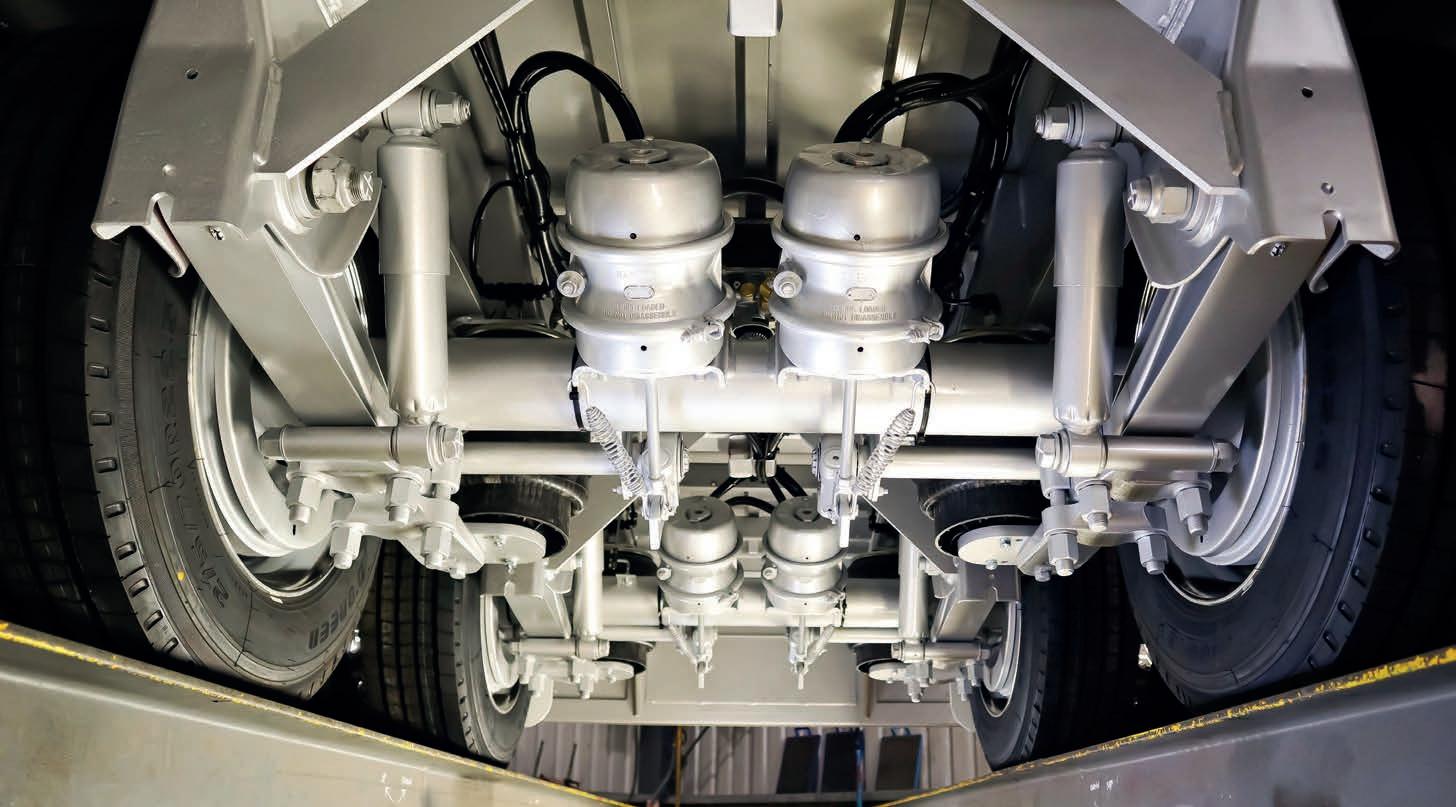

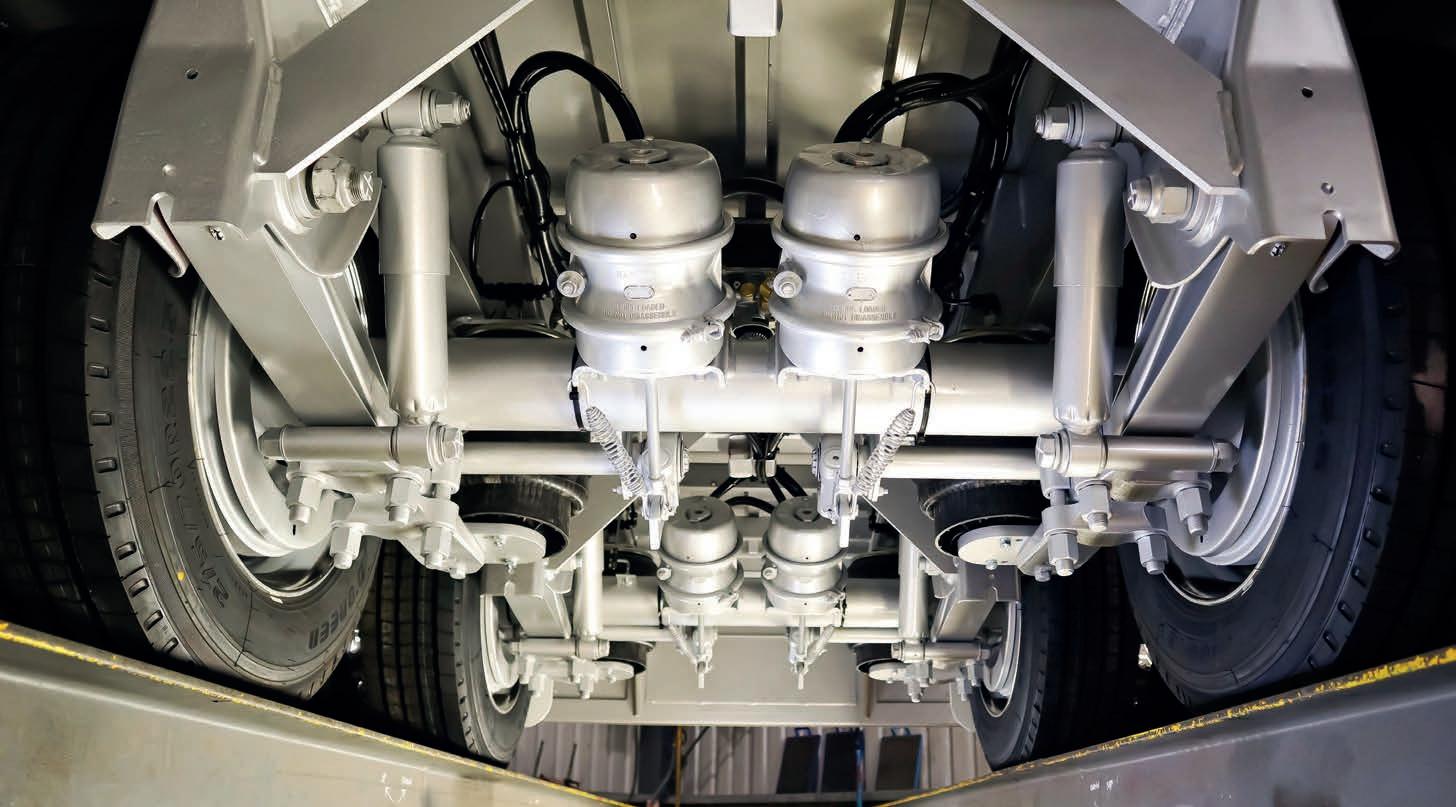

COME AND VISIT OUR UNIQUE STAND AT THIS YEARS BRISBANE TRUCK SHOW AND SEE ALL THINGS KRUEGER AS WE CELEBRATE 25 YEARS OF OUR AUSTRALIAN DESIGNED ROAD FRIENDLY SUSPENSION.

CELEBRATING 25 YEARS OF AUSTRALIAN DESIGNED ROAD FRIENDLY SUSPENSION CELEBRATING 25 YEARS OF AUSTRALIAN DESIGNED ROAD FRIENDLY SUSPENSION

krueger.com.au APRIL 18 - 21

BRISBANE CONVENTION CENTRE | STAND 155

|

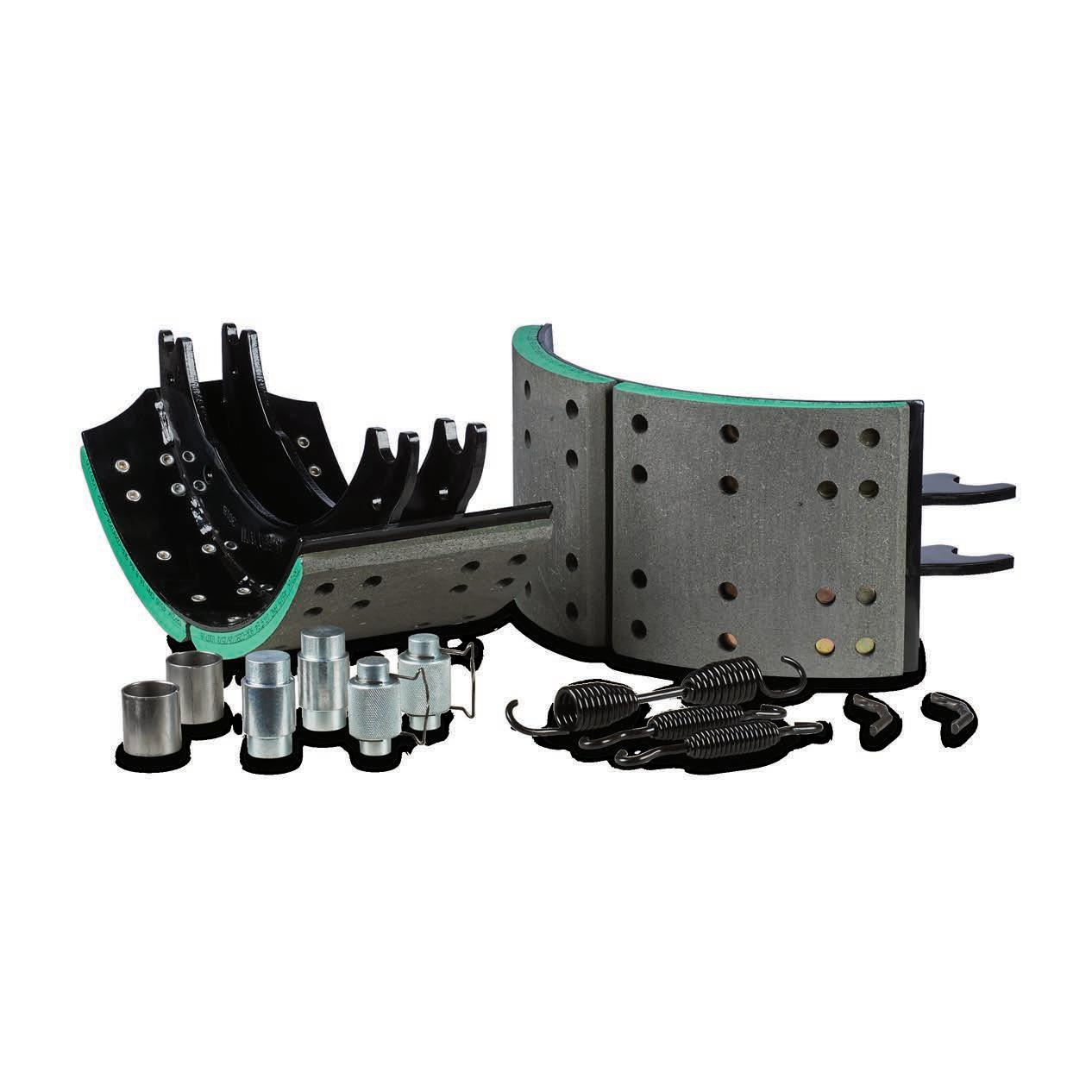

BPW Transpec welding team pass with flying colours

All seven members of BPW Transpec’s welding team have successfully passed the transport equipment manufacturer’s welding standards test.

BPW Transpec Product Manager, Steve Civelle, said the nature of the equipment that BPW Transpec manufactures, as well as its high durability and reliability standards, means specific welding knowledge is required.

“Because we manufacture trailer axles and suspensions, if the welding isn’t done correctly, cracks could appear in the product,” he said.

The company decided last year to unify their welders by coming up with an in-house standardised test and qualification. The test included a hands-on demonstration and safety quiz.

ACFS to proliferate B-triple use

Following successful trials of ACFS Port Logistics’ B-triple at the Brisbane AAT Terminal, the business is ramping up its high-productivity operations.

With permit consent from the Port of Brisbane Road Manager, ACFS Port Logistics has been running trials at the Brisbane Multimodal Terminal (BMT).

“ACFS will continue to run trials at other depots over the coming weeks with the aim to have approvals across more terminals,” ACFS Port Logistics said in a statement.

“The successful introduction to the B-triple in Brisbane has been widely accepted.

The welders were assessed by an external provider.

To recognise their achievement, the welders were presented with certificates.

“They were really pleased,” said Civelle. “They all passed and it’s been acknowledged that they’ve achieved a high standard and we appreciate their work.”

18 Trailer Magazine MAY 23 XXX News

ADDS VALUE EVERY DAY, EVERY TRIP, EVERY LOAD

Strenx® performance steel can meet the challenges facing the transport industry, which is constantly looking for ways to increase payload and improve fuel efficiency. Strenx® is a high-strength structural steel with extremely consistent properties, making it perfect for designing trailer chassis and other transportation products that are stronger, lighter and safer. That’s why we call it performance steel.

Explore the world of Strenx®

SSAB Brisbane. Melbourne. Perth G1, 28 Balacalva Street Woolloongabba,

australia@ssab.com

Contact

QLD 4102

strenx.com

Construction of WA Fitzroy River Bridge advances

Design work for the new Fitzroy River Bridge is progressing well, with the bridge scheduled to be operational by mid-2024.

Flooding caused by Tropical Cyclone Ellie last December and this January caused significant damage to the Fitzroy River Bridge along with 500 metres of road, cutting off access to communities east of the Fitzroy River and the East Kimberley and Northern Territory, a major agricultural region.

Along with the permanent restoration of connectivity between the east and west Kimberley, the bridge replacement project will also see significant investment into Western Australia’s economy.

Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said the construction is an important step to the region’s recovery.

“Reconnecting the community is an important part of recovery and the start of the work to that will allow freight to move again and reconnect supply chains,” she said.

Meanwhile, the first temporary Fitzroy River low-level crossing has opened to traffic, with construction now completed.

The crossing was constructed with more than 10,000 tonnes of rock and will initially provide access for four-wheel-drive vehicles only.

According to the Western Australian Government, access may be expanded to heavier vehicles, such as single-axle trucks, if weather conditions remain stable.

Federal Minister for Emergency Management, Murray Watt, said the second low-level crossing would provide a vital connection for the Kimberley region.

“The destruction of the Fitzroy River

Bridge has isolated much of the West Kimberley and cut off the East Kimberley, a major agricultural region, from its supply centres and markets in Perth for at least five months,” he said.

“The Albanese and McGowan

Governments are working together to support communities impacted by supply chain interruptions by rebuilding this low-level crossing and through a $42 million ongoing freight assistance package.”

Work will also start on a second temporary crossing suitable for higher traffic volumes and larger vehicles that are expected over the upcoming dry season.

The two-lane, temporary low-level crossing will have sealed approaches to cater for freight vehicles, caravans and campers.

20 Trailer Magazine MAY 23 XXX News

INDUSTRY LEADERS IN ROAD TRANSPORT EQUIPMENT, DESIGN, MANUFACTURE & MAINTENANCE

AT BRUCE ROCK ENGINEERING WE ARE SPECIALISTS IN ROAD TRANSPORT EQUIPMENT DESIGN AND MANUFACTURING.

All our trailers are manufactured right here in WA, ensuring 100% quality control throughout the whole build process. Our focus on continuous improvement as industry leaders mean we thrive on innovation and the ability to deliver quality custom and Performance Based Standard designs.

Skel trailers

Evolution side tippers

Road train dollies

Flat tops, drop decks

Deck wideners and extendables

End tippers, bulk and TaREX quarry bodies

Wabash National refrigerated and dry vans

Etnyre live bottom trailers

Titan walking floor and belly dumper trailers PBS specials: super quad & super triple

BRUCEROCKENGINEERING.COM.AU

OUR EXTENDED

INCLUDES: With nationwide sales and support. For more information email admin@brucerockengineering.com.au or call us on 1300 611 253

RANGE

Capped road tolls and upgrades a priority for Minns government

IPL divests plant, scores ammonia supply deal

Incitec Pivot Limited (IPL) – the company that expanded its production and distribution of AdBlue last year – has agreed to sell an ammonia manufacturing facility in Waggaman, Louisiana, to CF Industries Holdings for approx. $2.5 billion ($1.675 billion USD).

Road Freight NSW (RFNSW) has welcomed the recently elected Minns government’s ministerial appointments and is buoyed by their quick delivery of key election demands.

The Labor government, headed by Chris Minns, announced a $1.1 billion package of road upgrades over the next three years, capped tolls for two years from 1 January 2024 and pledged $20 million in funding for truck rest stops around Sydney.

RFNSW had been advocating for major transport and road sector changes throughout the campaign said CEO, Simon O’Hara.

“We made it clear that our election priorities were aimed at supporting our hard-working truckies, as well as the wider community using the state’s roads each and every day.”

The new Government’s pledge to cap tolls will cut the truck toll by $8, saving a driver who does two trips a day, an average of $3,800 a year.

A review of the toll network, and the possible scrapping of an estimated $50 million in administration charges, should also result in some financial relief for truck drivers and, in turn, incentivise them back

to toll roads, O’Hara said.

Jo Haylen has been appointed Labor’s new Minister for Transport and John Graham appointed Minister for Roads.

Sweet deal for sugarcane transport route

A bridge replacement near Mossman in Far North Queensland has finished just in time for the 2023 sugarcane crush season – a welcome boost for heavy vehicle operators.

Warners Bridge, which passes over Cassowary Creek, south-east of the township, now has an increased 44 tonne load limit which can handle heavy vehicles such as sugarcane harvesters and tractors.

The previous single lane, timber bridge will remain open for passage by sugarcane trains.

Jointly funded by the Australian Government’s Bridge Renewal Program (BRP) and Douglas Shire Council, the $1.25m project is the second to have recently receive an upgrade, with the new Anich’s Bridge opening last year.

The Australian Government is encouraging state, territory and local governments to apply for funding from the BRP with applications open all year round.

IPL has also secured a 25-year ammonia supply agreement with CF for up to 200,000 short tonnes of ammonia per annum to support the Dyno Nobel Americas (DNA) explosives business. The ammonia supply agreement secures ammonia at producer cost for the DNA business.

The value allocated to the ammonia supply agreement is approx. $634 million ($425 million USD) which will be offset from the cash proceeds of the sale agreement for Waggaman.

The divestment of Waggaman remains subject to US anti-trust regulatory clearance and the completion of other customary closing conditions.

Under the terms of the sale agreement, these conditions must be satisfied within 24 months of execution of the agreement.

“The Waggaman strategic review was undertaken with our previously articulated objective of monetising the value of the excess ammonia production from the facility while retaining the strategic value of the Waggaman site to the competitiveness of the DNA explosives business,” IPL said in a statement.

“IPL has undertaken a robust competitive sales process to seek full value delivery for the excess commodity exposure and to secure a long-term cost competitive ammonia supply for the DNA business with a trusted and proven strategic offtake partner.”

22 Trailer Magazine MAY 23 XXX News

Image credit: IOIO IMAGES / Shutterstock.com

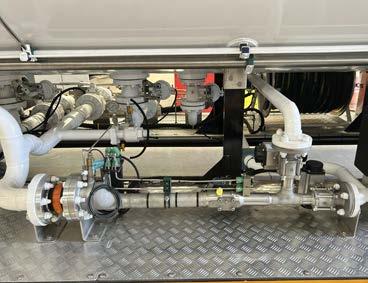

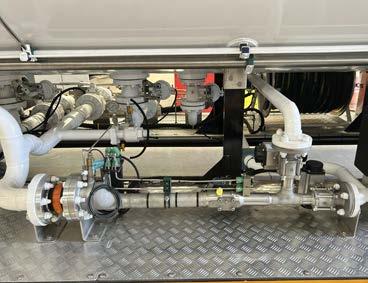

Holmwood Highgate is a 3rd generation family owned & operated business located in both Queensland and Victoria. We specialise in bulk liquid transport solutions, with a tailor made feel and personal touch experience for our customers nationwide.

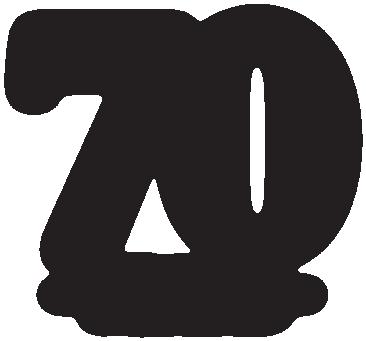

Quality is in our DNA, with our history as a company spanning 7 decades and hundreds upon hundreds of happy owners using a Holmwood Highgate tanker on the daily. We understand reliability and dependability is everything for a logistics company, thus we ensure every product we make is manufactured with reliability as a key focus to keep our tankers on the road for longer than our competition.

We specialise in multiple facets of transport, including Fuel, Bitumen, Ammonium Nitrate, Mining, Waste Oil, and more. Our capability in recent years has also seen an expansion into specialised applications such as Aviation refuellers and Military grade transport modules.

Holmwood Highgate has also expanded our capability to include the importation and distribution of LPG and Dry Bulk tankers. These new options add to our current repertoire and help us cater to more businesses needs than ever before.

Find out more at: www.holmwoodhighgate.com.au

Queensland 20-26 Burchill Street, Loganholme, QLD, 4129

Victoria 425 Fitzgerald Road, Derrimut, VIC, 3026

Queensland 20-26 Burchill Street, Loganholme, QLD, 4129

Victoria 425 Fitzgerald Road, Derrimut, VIC, 3026

Rio Tinto supports Australian business with $15.3B

Mining company, Rio Tinto, has increased its spend with Australian suppliers to more than $15.3 billion as part of its commitment to supporting communities where it operates. This was an increase of almost 9.0 per cent on the previous year and was spent with more than 6,200 businesses, including Australian owned and operated businesses and locally owned and managed branches of global companies.

The spend has reportedly helped support tens of thousands of Australian jobs and delivered a significant economic contribution to communities across the country.

As part of this spend, more than $565 million was spent with Indigenous businesses across Australia – an increase of 40 per cent on the year before.

“Supporting local businesses in the communities where we operate is a key priority for Rio Tinto,” said Rio Tinto Chief Executive – Australia, Kellie Parker.

“We strive to employ local people, buy local products and engage local services – especially from Indigenous, small and regional businesses.

“We are working hard to improve our approach to Indigenous business development and engagement in

Sweet deal for sugarcane transport route

A bridge replacement near Mossman in Far North Queensland has finished just in time for the 2023 sugarcane crush season – a welcome boost for heavy vehicle operators.

Warners Bridge, which passes over Cassowary Creek, south-east of the township, now has an increased 44 tonne load limit which can handle heavy vehicles such as sugarcane harvesters and tractors.

The previous single lane, timber bridge will remain open for passage

by sugarcane trains.

Jointly funded by the Australian Government’s Bridge Renewal Program (BRP) and Douglas Shire Council, the $1.25m project is the second to have recently receive an upgrade, with the new Anich’s Bridge opening last year.

The Australian Government is encouraging state, territory and local governments to apply for funding from the BRP with applications open all year round.

Australia, and while there is still more work to do, last year we significantly increased our spend with Indigenous suppliers.

“We couldn’t do what we do without our local supplier partners and having good relationships with them helps us find better ways to provide the materials the world needs and innovate to decarbonise our operations.”

Rio Tinto engages with more than 20,000 suppliers globally.

In 2022, Rio Tinto increased its global spend with suppliers to $22.5 billion USD, up from $19.8 billion USD in 2021.

24 Trailer Magazine MAY 23 XXX News

DP World opens refrigerated container facility in Sydney

Reefer World, adjacent to the DP World Sydney Terminal, provides refrigerated container cleaning and repair services.

This facility, according to DP World, is the largest of its kind in Sydney and is expected to enhance the quality of freshness of perishable cargo delivered to destinations around the world.

DP world has doubled its empty refrigerated container capacity following the opening of Reefer World. It now has capability to pre-trip and wash more than 100 refrigerated containers daily.

“As businesses continue to build agility, reliability and resilience into their supply chains, Reefer World will help to facilitate the timely and efficient flow of perishable goods while addressing increased export demand in the region,” said DP World Australia CEO, Andrew Adam.

“Its completion further expands DP

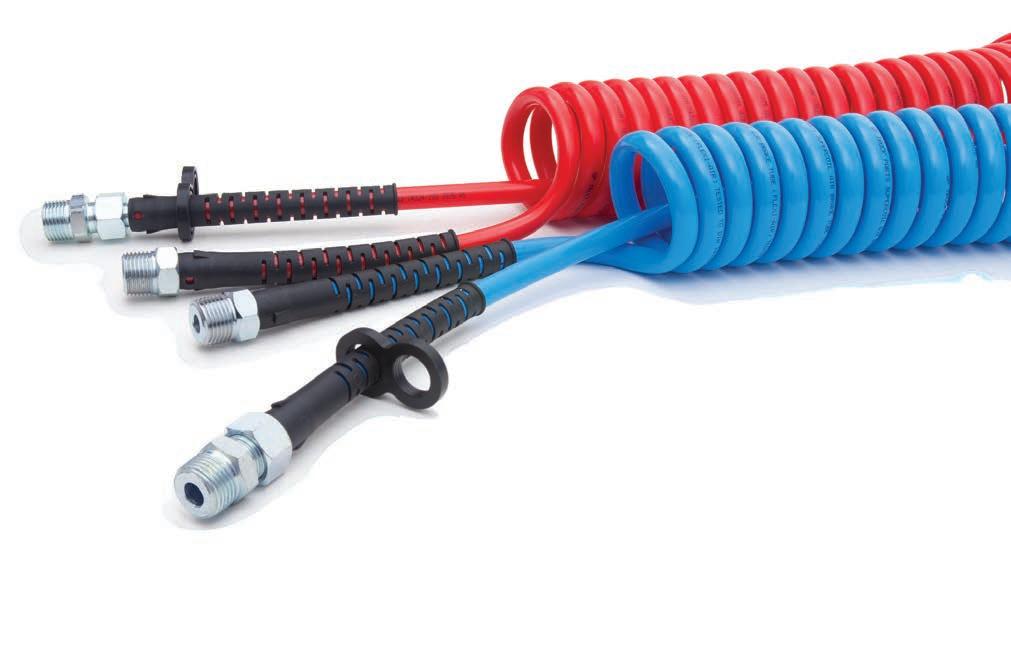

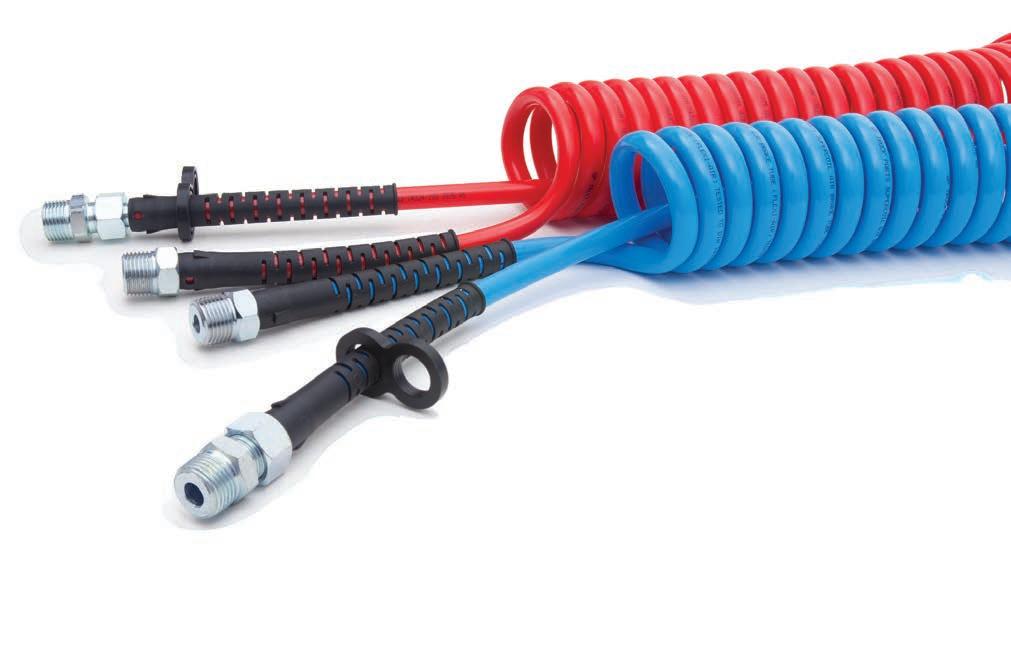

ANTI KINK SUZI-COIL

SUPERCOIL FEATURES

Compliant Standards: ADR-38/05, Tested to DIN 74323, 74324 & ISO 7375 A1

• Anti Kink Thermoplastic Polyurethane material

• Excellent abrasion resistance

• Excellent mechanical properties, combined with a rubber-like elasticity

• Oil and Diesel resistance

• High UV resistance (>4000 hours of Accelerated Testing to ISO 4982-2)

• 40% lighter than traditional Type B Suzi-Coils

• High elasticity with excellent flexibility and recoil memory.

position as the go-to partner for customers

SUZI-COIL CLAMP

The new 4 hole TEC-CLAMP allows you to lock in your lines and go! No tools or hardware needed for fast, easy installations!

Versatile design can be used with both rubber air hose or coiled tubing hook-ups.

3 hole NEW 4 hole

GP-9889

POGO STICK & TECCLAMP COMBOS

Part# GP-925-C

Chromed steel heavy duty Pogo Stick

Part# GP-925-C3

Chromed Pogo Stick with 3 hole

Tec-Clamp

Part# GP-925-C4

Chromed Pogo Stick with 4 hole Tec-Clamp

GP AIR COUPLINGS TRUCK & TRAILER

Huge range of Air Couplings & Adaptors to suit your truck or trailer. GP Air Couplings & Adaptors are designed & manufactured to conform to the Australian Design Rules ADR-38/05, Australian Standards AS4001.3-2003.

GP TRUCK PRODUCTS available from Truck & Trailer parts outlets Australia wide. Compliant Standards: ADR-38/05 & DOT

TEC-CLAMP

Phone +61 3 9580 1811 sales@gptruckproducts.com.au www.gptruckproducts.com.au

UNCOMPROMISING PERFORMANCE

Part# GP-7750 Long Tail Coil Part# GP-7000 Short Tail Coil SUPERCOIL Compact 74mm diameter coil Regular Suzi-Coil 130mm Diameter

Couplings - Male, Female, Sealing & Non sealing. Adaptors - Male, Female, Sealing & Non sealing. Dust covers, Adaptor plates, Trailer coupling locks

TAS commits $100M to freight access

Work has started on further improving freight access on Tasmania’s state road network under a new $100 million program.

The Freight Capacity Upgrade Program is a jointly funded initiative, with $80 million committed by the Australian Government and $20 million by the Tasmanian Government.

The program will increase the freight capacity of critical and regional freight routes throughout Tasmania by strengthening or replacing various bridges and improving sections of roads.

The first stage includes the strengthening of 11 bridges, replacement of two bridges and road improvements at 14 sites.

When completed, there will be an additional 224 kilometres of state roads approved for access by Higher Mass Limit vehicles.

This will greatly assist freight operators in planning for the future and give them confidence to expand their operations.

It will also extend the lifespan of critical and regional freight routes throughout the state, improving access for operators of heavy vehicles and providing benefits for the state’s agriculture, resources and manufacturing industries.

It will also minimise the long-term maintenance costs to the state.

The Tasmanian economy has been growing strongly and improving freight transport infrastructure will ensure that growth continues.

Work has already started on several road strengthening projects and tenders closed on 15 March 2023 for the first two bridge strengthening projects: Pipers River Bridge on Bridport Road in the state’s north-east and Ring River Bridge on the Murchison Highway on the west coast.

An estimated 190 jobs will be created during the construction phase of the program, with an Indigenous employment and supplier-use target of 4.5 per cent.

“The Australian Government is committed to improving road safety and freight efficiency, and this investment will ease congested roads while also creating opportunities for Tasmanian,” said Federal Infrastructure, Transport, Regional Development and Local Government Minister Catherine King.

“Our funding, by helping continue this successful economic productivity initiative for the next five years, is key ensuring Tasmania’s road network is as safe and as efficient as possible.”

Tasmanian Infrastructure and Transport Minister, Michael Ferguson, said: “The Freight Capacity Upgrade Program not only enhances the productivity of Tasmanian freight, but also increases efficiency and road safety. This investment in Tasmania great news for our community and will back local jobs while also supporting our freight industry.”

26 Trailer Magazine MAY 23 XXX News

WE ARE READY FOR ALL CHALLENGES!

The Faymonville Group is one of the leading full-range manufacturers of special vehicles for heavy load transport and special transport. The unique variety of products offered by Faymonville, Cometto and MAX Trailer have enabled the Faymonville Group to position itself as a full-range supplier in the sector of heavy load transport and special transport. The portfolio includes transport solutions for payloads from 15 tons to 25,000 tons … and beyond.

The semi-trailers, low-loaders, modular vehicles and self-propelled vehicles that we produce can be used to transport anything exceptionally heavy, long, wide or tall! Our customers value our reliability and flexibility in offering tailored transport solutions even in the face of difficult challenges. Our vehicles excel with their technical quality and sustainable production methods.

Only we manufacture everything ourselves 100% in-house, from the first sheet to the finished vehicle. As a result, we can boast a flawless level of manufacturing and effective quality and process controls. Our excellent facilities in a production space of 170,000 m² form the foundation for qualitatively unique, high-tech products.

Get advice from one of our experts!

T: +352 26 90 04 155 | sales@faymonville.com | www.faymonville.group

Our official dealer for Australia

plan for agriculture

The Low Emissions Agriculture Roadmap

2022-2032 charts a route for Queensland to achieve cleaner, greener food and fibre production as well as improved supply chains.

This Roadmap was released last month by the Palaszczuk Government and is the result of a productive co-design approach with industry, with key themes and actions identified in a CSIRO report.

Five focus pathways for a sustainable future in the state’s agriculture includes: livestock emissions, cropping and horticulture emissions, on-farm energy opportunities, carbon farming and landscape management, regions and supply chains.

“Those who implement plans to lower greenhouse gas emissions now will have fewer transition costs and disruption to their business than those who delay and find themselves urgently responding to market forces,” said Minister for Agricultural Industry Development and Fisheries and Minister for Rural Communities, Mark Furner.

“This Roadmap was written following an extensive consultation process between

the Department of Agriculture and Fisheries and key industry partners.

“The aim is to provide a structured, smooth transition, while minimising dramatic changes.

“Now is the time to take action – adopt the roadmap’s strategies and yield the benefits of secure long-term economic and social prosperity.

“But this is not a set and forget approach—we will keep refining the roadmap as over time we develop even more emissions reductions solutions.”

The Roadmap, according to AgForce CEO, Mike Guerin, will help producers by providing key areas to prioritise their focus including natural asset management, business profitability and risk management.

“Queensland’s producers recognise the importance of adopting new practices and technologies to ensure the long-term sustainability of their industry,” he said.

“As proud and responsible contributors to the state’s economy, we recognise the importance of supporting the roadmap and doing what we can to lower emissions to promote long-term sustainability.”

Queensland Farmers’ Federation CEO, Jo Sheppard, said the roadmap will assist in providing clarity to farmers about options available as they embark on their own low emissions journey.

“As Queensland agriculture strives to respond in meaningful and sustainable ways to continuing global demand for a transition to low emissions production, the roadmap will help coordinate some of the messaging in what is becoming an increasingly crowded marketplace,” she said.

“A strong agriculture sector is important to us all and we need to make sure that farmers are supported to achieve environmental outcomes whilst still being able to do what they do best in producing the world’s best food, fibre and foliage.

“It is so important that Government works closely with industry to ensure the future economy of agriculture to safeguard the future of all Queenslanders to achieve our ultimate goals of a viable, sustainable agriculture sector, sound environmental outcomes and stronger regional communities.”

CBH Group boosts urea ammonium nitrate storage capacity

Western Australian grain growers are set to benefit from CBH Group’s new Kwinana Fertiliser Facility.

Minister for Agriculture and Food, the Hon. Jackie Jarvis MLC, the Member for Brand, the Hon. Madeleine King MP, and CBH Chair, Simon Stead, officially opened the facility on 17 March.

This project marks the start of CBH’s liquid fertiliser business and expands its granular fertiliser capacity by 15,000 tonnes.

Located adjacent to CBH’s Kwinana Grain Terminal, the new facility has capacity to store 32,000 tonnes of Urea Ammonium Nitrate (UAN) and 55,000 tonnes of bulk granular fertiliser.

Stead said this is an exciting milestone which will deliver significant value to the grain growers of Western Australia.

“CBH’s new Kwinana fertiliser facility provides a new liquid offering, and bolsters our granular offering, across a wider catchment for the benefit of all growers,” he said.

“Ultimately, it enables us to reduce our handling and freight costs through efficiencies, which can be passed on to growers through competitive prices.

“Increasing our fertiliser storage capacity will also improve consistency of supply for growers when they need it most.”

CBH Chief Marketing and Trading Officer, Jason Craig, said the facility

enables the growth of the cooperative’s fertiliser business in line with grower demand.

“CBH Fertiliser continues to experience year-on-year growth and outturned a record 204,000 tonnes last year – our best result since entering the market in 2015,” he said.

“Increasing the scale of our Fertiliser business, and allowing for further expansion, reflects the ever-increasing demand for CBH fertiliser.

“It also supports CBH’s Strategy target of holding a 15 per cent market share in WA by 2033.”

CBH is expected to commence outloading UAN and granular fertiliser to WA growers next month.

28 Trailer Magazine MAY 23 XXX News

Centurion announces new CFO

Centurion has named an experienced executive to the position of Chief Financial Officer (CFO).

The company today made it public that Harry Singh has agreed to join the Centurion Executive Leadership team.

Singh brings 23 years of financial experience, having worked extensively across the oil and gas, mining services, manufacturing and logistics industries.

No stranger to Centurion, Singh previously worked for both the CFC Group and Centurion between 2007 and 2012 in senior commercial roles.

Prior to his appointment he was with energy and resources infrastructure company Altrad.

Mondiale VGL names new Chair

A major new appointment has been announced at freight forwarder Mondiale VGL.

Justine Smyth CNZM will join Mondiale VGL as Independent Director and Chair the company has confirmed.

Announced to coincide with the twoyear anniversary of the successful merger of Mondiale Freight Services and VISA Global Logistics, Smyth’s appointment will support the company’s next phase of growth in the global freight forwarding sector.

Smyth brings extensive commercial and governance experience to Mondiale VGL and is currently the Chair of Spark NZ and Chair of The Breast Cancer Foundation NZ. She was made a Companion of the New Zealand Order of Merit (CNZM) for services to governance and women in 2020.

“Having Justine Smyth join Mondiale VGL to chair our Board is another important step forward for our business,” said Mondiale VGL CEO, Ray Meade in a statement.

“Smyth’s appointment to the Mondiale VGL Board of Directors supports the firm’s strategic commitment to leveraging its increased capabilities, cementing long-term customer partnerships, and expanding its global reach,” he said.

On joining the Board of Directors, Smyth recognised the opportunities that the merger has created for the business.

“Mondiale VGL has built Oceania’s leading freight forwarder by bringing together two highly experienced industry

leaders in the supply chain and logistics sector,” she said.

“This has established solid strategic and financial foundations, with current and expected market dynamics creating further opportunity to scale,” said Smyth.

“I’m thrilled to be joining the Mondiale VGL team at such an exciting time in their expansion journey.”

The merger in 2021 helped secure the company’s place in the world’s top 30 freight forwarding services in addition to supporting the strategic acquisition of Customs Agency Services (CAS) in South Australia.

With further strategic investments in China, Spain, Germany, and India completed, Meade said it had been a significant two years for the business.

“We are seeing clear evidence of the advantages that the merger and acquisition of CAS have delivered through increased international trade lane access, enhanced technology, and the achievement of the growth milestones we mapped at the outset,” said Meade.

“Our goal was to build a global supply chain operation with its roots in the Asia Pacific region, and we are firmly on the path to achieving that with our strategic position across Australia, New Zealand, Asia, Europe, and America,” he said.

“Growth by acquisition is an important part of our strategy to build scale in our business and the merger positioned us well to take this forward.”

Meade said the acquisition of CAS, made in December 2021, had enabled the

Northline marks 40-year milestone

The unveiling of a commissioned artwork on the side of a shipping container was the highlight of Northline’s 40th anniversary celebrations in Adelaide last month.

More than 250 guests, including customers, suppliers and employees gathered at Victoria Park Social Club to mark the global logistic company’s milestone with an outback themed soiree – a tribute to Northline’s beginnings.

The traditional indigenous painting

by local artists Kelly Taylor and T’keyah Ware, which was reproduced and vinyl-wrapped onto the shipping container, depicted Northline’s historical journey.

Northline CEO, Craige Whitton, said the artwork held a special place in the business.

“[It] is a true representation of where we started and highlights the connection and strong roots we have servicing the remote communities in northern Australia,” he said.

business to consolidate Mondiale VGL’s national footprint in Australia while building further scale in the Australasian market.

“CAS has given us valuable access to the highly strategic Defence and eCommerce industry verticals and our Australian customers have benefited from greater access to contested sea and air cargo space,” he added.

Mondiale VGL has transitioned into a global entity, and today, the rapidly growing freight forwarding company employs over 1500 staff across 39 offices in Australia, New Zealand, Asia, Europe, and the USA, supported by 1000 agency offices worldwide.

Following a particularly challenging period for the industry during the COVID-19 situation and continued supply chain constraints, the forming of the new combined entity of Mondiale VGL, according to Meade, had allowed it to provide increased commercial value to customers.

“While the sector faces ongoing pressure, our united volumes, long-term relationships with carriers and suppliers, and combined 40 years of industry knowledge have enabled us to solve complex supply chain issues and innovate at pace,” he said.

“A key factor of our success has been the way our people have come together and embraced the merger. We’re thrilled to watch them grow their careers within a global organisation and have made several senior appointments to support our expansion ambitions.”

In support of those same remote communities, Northline also handed The Royal Flying Doctor Service a cheque for $40,000, raised by team members from across the country.

Founded in 1983, Northline began with specialised freight services to customers in the Northern Territory, connecting them to the rest of Australia.

Today it operates an industryleading network and has international reach into more than 100 countries.

30 Trailer Magazine MAY 23 XXX News

Port Lincoln freight route improvements get greenlight

A key freight route in Port Lincoln, South Australia will receive important upgrades as part of the latest Federal Government funding release.

The upgrades are aimed at increasing safety outcomes and productivity for heavy vehicle operations in the region.

The intersection of Porter Street, Liverpool Street and Railway Place, at the end of the Lincoln Highway, will receive traffic signals, a dedicated right-hand turn lane, improved drainage, widening and pavement works.

“Investment in segments of our roads which are well-utilised by heavy vehicles has never been more important, with many of our communities grappling with ongoing flooding and tightening supply chains,” said Carol Brown, Federal Assistant Minister for Infrastructure and Transport.

The $3.6 million put towards the project

comes from the Heavy Vehicle Safety and Productivity Program which has committed

This builds on the Federal Government’s $140 million commitment to upgrade heavy

New project approaching for Tasman Highway

Two new overtaking lanes will be included in new improvements along the Tasman Highway between Scottsdale and Branxholm.

Team Global Express partners with FIFA

Intermodal logistics provider, Team Global Express, has been named the Official Logistics Services Provider of the FIFA Women’s World Cup 2023 in Australia and New Zealand.

To support the event, Team Global Express will be utilising its lead logistics capabilities to meet the requirements of the biggest global sporting fixture of 2023.

“Team Global Express is proud to provide innovative transport solutions to best meet the requirements of the FIFA Women’s World Cup Australia & New Zealand 2023,” it said in a statement.

Team Global Express Group CEO, Christine Holgate, said the partnership further demonstrates Team Global Express’ high level of commitment to diversity and inclusion.

“As a passionate advocate for women in the workplace and the development of women in sport, I am very excited for Australia and New Zealand to host the

single biggest women’s sporting event in the world,” she said.

“We have a vision to be at the cuttingedge of the transport and logistics industry in both Australia and New Zealand and a crucial part of this is supporting women’s participation, both within the industry and further afield.

“Team Global Express and the FIFA Women’s World Cup are significantly aligned on these values.”

FIFA Secretary General, Fatma Samoura, said she was pleased to see increased commercial support for the event.

“Team Global Express has sustainability and diversity at the heart of its operations, and the FIFA Women’s World Cup 2023 looks forward to partnering with an entity that shares common values,” she said.

According to Team Global Express, its strong sustainability focus and commitment were pre-requisites for FIFA Women’s World Cup Australia and New Zealand 2023 when assessing the partnership.

The improvements, part of the Tasmanian Government’s $4 million Dorset Roads Package, will include new passing opportunities in each direction with the construction of an overtaking lane for eastbound traffic near Rocky Gully and another for westbound traffic near Billycock Hill.

Minister for Infrastructure and Transport, Michael Ferguson, has signed a contract with Launceston-based construction company, Show Contracting, which will see work begin in the coming weeks.

According to Ferguson, the upgrades will improve freight in Tasmania.

“They will contribute to making transport in the North East safer and more efficient, providing benefits to residents, freight operators and businesses and the growing tourism industry in the region,” he said.

“The improvements address local concerns about the lack of overtaking opportunities on this section of the highway and follow extensive consultation we’ve done with the Dorset community and the Council.”

Following extensive repairs to damage caused during floods last October, the Tasman Highway through the Sideling recently reopened to traffic.

The completed repairs involved the rebuilding and reinforcement of a steep embankment which collapsed due to severe rainfall, undermining the highway and requiring its closure.

32 Trailer Magazine MAY 23 XXX News

WA Government expands heavy vehicle training

The Western Australian Government is rolling out its Heavy Vehicle Driving Operations training program in Kimberley and Pilbara.

Funded as part of the 2023-24 State Budget, the expansion into the Kimberley and Pilbara regions is expected to result in more truck drivers hitting the road.

The Heavy Vehicle Driving Operations (HVDO) training program has been available in metropolitan WA since April 2021, and it was later expanded to the southwest and midwest regions over the past two years.

The program was developed in collaboration with industry to address the truck driver shortage during the Covid-19 pandemic, and provides theoretical and practical hands-on truck driver training to train job-ready workers for the transport industry.

The additional $3.5 million investment will help North Regional TAFE deliver training to around 350 participants in Pilbara and Kimberley over a four-year period.

Training Minister, Simone McGurk, said the program – the first of its kind in Australia –will help create a highly skilled workforce.

“Participants are given practical, handson experience, ensuring they’re job-ready when they complete their course,” she said.

“The Heavy Vehicle Driving Operations training program has helped hundreds of people gain employment in the heavy haulage industry, and I’m confident that success will be replicated when it’s expanded to the Kimberley and Pilbara.”

Transport Minister, Rita Saffioti, said the expansion will provide a much-needed boost to the transport industry.

“With 350 participants expected through the course over the next four years, the McGowan Government is helping to create a pipeline of skilled workers for this essential industry well into the future,” she said.

“Supporting economic growth, industry diversification and greater regional engagement, remain our key priorities.”

Since February 2023, of the 552 participants enrolled at a TAFE College to undertake the program, 282 had achieved either a Heavy Rigid, Heavy Combination or Multi Combination licence.

Why waste your valuable time polishing alloy wheels? Superchrome wheels wash clean in just 41 seconds. So, stop wasting time on wheel maintenance and get back to doing what you love. Longer wheel life | No polishing costs | Quality presentation Call Superchrome on 02 9060 1610 or visit us at www.superchrome.com.au Come and talk to us at the Brisbane Truck Show! Stand #269 on the Plaza level

Upgrade underway for TAS freight bridge

Critical work will be undertaken to bolster a key bridge in Tasmania’s metropolitan road network as the first stage of the Freight Capacity Upgrade Program gets underway.

A strengthening project will be undertaken on Charles Street Bridge in Launceston as part of the $100 million Freight Capacity Upgrade Program.

Charles Street Bridge is among 11 bridges to undergo strengthening during stage one alongside two other bridges and road improvement works at 14 other sites.

The program is being delivered over five years with design for select Stage 1 projects already underway.

Tenders for the Charles Street Bridge strengthening, along with other bridge sites, are expected to be called during mid-2023, with construction starting later in the year.

The Australian Government has committed $80 million to the transformational program, with the Tasmanian Government set to contribute $20 million.

According to the Tasmanian Government, it will increase the freight capacity of critical and regional freight routes across the Apple Isle by strengthening or replacing various bridges and improving sections of roads.

Assistant Minister for Regional

Development, Anthony Chisholm, said the Federal Government is committed to keeping the freight transport industry moving.

“We are proud to partner with the Tasmanian Government to deliver the Freight Capacity Upgrade Program, which over the life of the program, will open up to 224km of State road and bridge network capability to increase freight productivity for critical state industries such as agriculture and manufacturing,” he said.

“This is among the first of many projects to come that will prove a game-changer in terms of building a safer, more productive transport network benefiting all Tasmanian road users.”

34 XXX Trailer Magazine MAY 23 News

Toll opens new $10M Brisbane warehouse

Toll Group has announced the opening of a new healthcare warehouse and distribution facility in Richlands, Brisbane.

The cutting-edge facility is part of a $10 million investment over the next 10 years that will support the delivery of patient-critical healthcare products to Queensland communities.

The facility, officially opened on 21 April by Queensland’s Assistant Minister for Health and Regional Health Infrastructure, Julieanne Gilbert, has a storage capacity of 4,600 square metres across ambient and cool-room facilities including ultra-low freezers for the storage and distribution of specialised vaccines.

The Richlands facility is Toll’s fifth healthcare facility in Australia and will be the primary distribution centre of National Immunisation Program flu vaccines for Queensland Health in 2023.

“This investment reflects Toll’s commitment to creating advanced warehouse management solutions to meet the changing dynamics in the healthcare sector,” said Toll President Government & Defence, Perry Singh.

“The facility provides fast, accurate and compliant delivery for our customers.”

It has been custom designed to store and manage inventory of pharmaceuticals, medical devices, vaccines and consumer health products.

Located 24 kilometres from central Brisbane and close to major highways, it is licensed with the Therapeutic Goods Administration. According to Toll, it is also the only healthcare facility in Queensland that is Good Management Practice certified.

In addition, the warehouse has a 5 Green Star Rating and features recyclable water usage, energy efficient/motion-sensor LED lighting and a roof solar power system to provide green energy.

In the statement, Toll also announced that it is investing $400

2 - 24 BURWOOD AVENUE, NTH SUNSHINE, VIC 3020 INFO@CHRISBODYBUILDERS.COM.AU WWW.CHRISSBODYBUILDERS.COM.AU PROUDLY BUILDING SINCE 1983 TIPPING EQUIPMENT BUILT TO THE HIGHEST STANDARD. WE DESIGN TIPPING EQUIPMENT TO SUIT YOUR NEEDS, FROM THE PADDOCK TO THE QUARRY.

Casino Truck Show rolls into its 10th year

Excitement is building among organisers and exhibitors as the countdown to the 2023 Casino Truck Show begins.

Celebrating its 10th year, the event will showcase transport-related products and services in Casino, New South Wales.

The show has given naming rights to local area business, North Coast Petroleum.

Last year’s event, according to Richmond Valley Council, welcomed 8,000 guests and is expecting to beat that figure this year.

Casino Truck Show celebrates a decade of showcasing industry which keeps the country moving.

“We couldn’t be prouder to host such a dynamic event, which over the past 10 years has opened up our beautiful town and the Richmond Valley to the rest of Australia,” said Richmond Valley Council Director – Service Delivery, Angela Jones.

“As a community which is passionate about its transport industry, we welcome all and sundry to Casino on Saturday 5 August.”

Online registration and market stall applications for the event open on 1 June.

MGM Bulk launches same day FIFO

To encourage driver recruitment, Western Australia commodity transporter, MGM Bulk, has announced same-day fly-in fly-out.

So that employees can return to loved ones quicker, same-day FIFO has been introduced with what MGM Bulk describes as a straight forward signup process and supportive work environment.

Flights from Cairns, Townsville and all Australian capital cities are provided and covers connections to New Zealand along with all meals, travel and accommodation.

“We know these are challenging times, but your work life doesn’t have to be,” the company said in a statement.

“As a family-owned transport and logistics business, MGM Bulk is driven to deliver competitive pay rates, upskilling opportunities, paid onsite inductions, and tailored shift patterns to suit your needs.”

This follows, as part of a driver recruitment campaign, a giveaway of 25 Matt Stone Racing Team memberships

valued at $200 each to the first 25 successful multi-combination licenced applicants.

The promotion is in conjunction with Supercars Raceweek.

MGM Bulk has been operating since

2014, however, sits within the wider stable of the MGM Group whose legacy goes back over 60 years in Western Australia.

It employs over 400 people across three sites.

36 Trailer Magazine MAY 23 XXX News

Solid sleep for transport workers only an app away

A world-first sleep and mood mobile phone app could have a big impact on the transport industry’s vital shift workers.

Melbourne’s Monash University is hoping SleepSync, an app that personalises sleep-wake cycles for shift workers, will improve their sleep, mood and overall health.

Researchers from the University’s Turner Institute for Brain and Mental Health trialled the app on 27 shift workers over a two-week period with results showing that 70 per cent reported it easier to fall asleep and more than 80 per cent reported better quality sleep.

Participants slept an average of 29 minutes longer each night.

Lead researcher, Dr Jade Murray, explained that work hours outside the nine to five standard can wreak havoc on the body’s circadian clock – something many transport workers understand well.

Shift workers, she said, report much more impaired alertness and sleepiness

compared to the general population.

“Shift workers are at greater risk of a range of long-term adverse health consequences such as gastrointestinal problems, cardiovascular disease, mood disorders and cancer, as well as the short-term increase in the risk of errors, accidents and injuries,” said Murray.

The app, the very first of its kind, is unique because it is entirely tailored to the individual user. Its functions include:

• I ncorporating a calendar for work and personal commitments.

• P roviding biologically viable recommendations for sleep, accounting for obligations.

• O ffering a daily log to record sleep/ wake times and correlating moods.

According to the research gathered from the trial, 82 per cent of participants reported the app was easy to incorporate into their daily lives.

This isn’t the first time Monash University has put its efforts into

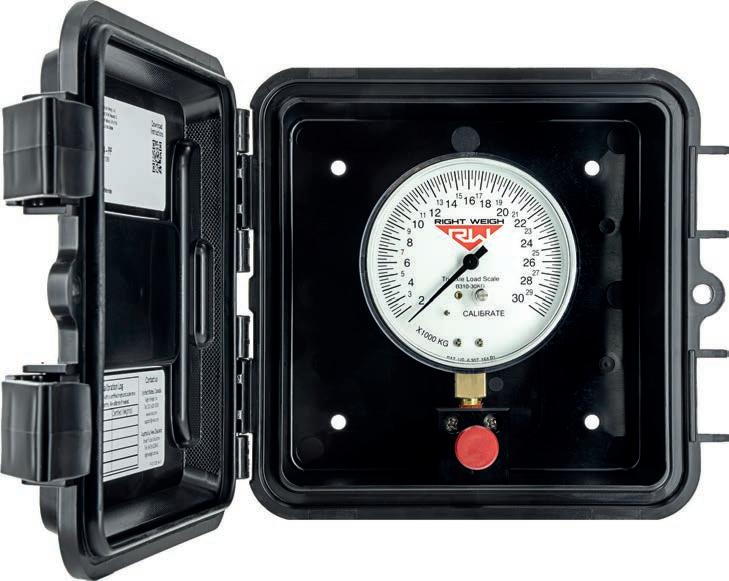

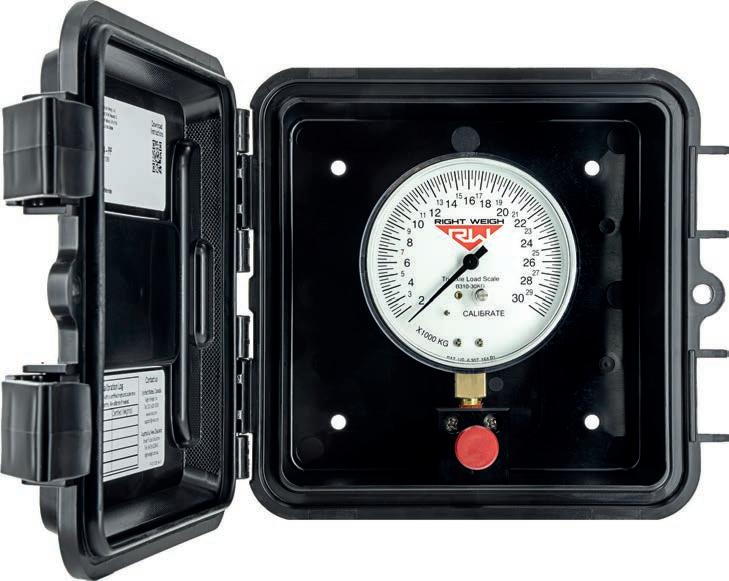

THE LOAD SCALE YOU TRUST

Right Weigh offers the most reliable scales in the industry. With the free Right Weigh App, monitor on-the-ground weight without leaving your cab. Superior customer service and 3-year product warranty ensures complete customer satisfaction.

INCREASE PROFITS

Maximise load capacity and save money on commercial fees, out-of-route mileage and overweight fines.

understanding the impact shift work has on health and well-being.

In 2018 they released findings specific to the transport industry that showed 19.9 per cent of accidents were caused by fatigue.

Similarly, a report released in 2019 by the National Truck Accident Research Centre, demonstrated that fatigue was the underlying cause of 34.8 per cent of crashes.

Meanwhile, the researchers who developed SleepSync are hoping it will aid behavioural change and provide practical advice to shift workers.

“This has the potential to improve shift workers’ health and wellbeing and how they function day to day,” Murray said.

“It also has the potential for development and integration with wearable devices, such as smartwatches and further help minimise the health costs associated with shift work to society.”

Smart Trucks Solutions Leigh: 0418 622 840 | leigh@rwlsau.com.au | Jarrod: 0488 130 481 | jarrod@rwlsau.com.au

TIME

more detours to commercial ground scales. The days of waiting in

to

SAFETY

the guess work out of driving and maintaining legal weights. KEEP IT SIMPLE Installation of Right Weigh load scales is a simple threestep process and calibration is quick and easy. Right Weigh is now OBM Type A/B Certified! Drive More. Scale Less.TM rightweigh.com.au

SAVE

No

line

rework and weigh your loads are over. IMPROVE

Remove

Coles officially opens automated distribution centre

Coles has announced the opening of its first Automated Distribution Centre (ADC) in Redbank, Queensland, which is the largest single capital investment in the retail giant’s history.

The ADC, also the largest of its kind in the Southern Hemisphere, will provide a safer, more efficient and sustainable supply chain.

The state-of-the-art facility spans 170,000 square metres, and with a building size of 66,000 square metres it’s reportedly one of the biggest and most productive ADCs in the world.