® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE JUNE 2023 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY ISSN 1838-2312 9 771838231003 05 JUNE 2023 $10.00 TRAILER BUILDER NEWS WORLD MAP HYDRAULICS SHOWCASE ECONOMY INDUSTRY INNOVATORS SUPER STACKED SUPER STACKED Pushing the boundaries Pushing the boundaries

PUBLISHER

John Murphy john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

ASSISTANT EDITOR

Peter White peter.white@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Tom Anderson

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766

subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher. Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

National security

There were some notable omissions for the road transport industry in the Federal Budget announced last month. We take a deep dive in this edition’s economy report.

Last year, at the IAA Transportation event in Hanover, Germany, JOST promoted its KKS fifth wheel automation innovation and cleverly tied it in with a science fiction theme. After all,

it does look a little like the USS Enterprise from Star Trek Jump back in time to 2015, when Senator John Madigan said: submarines are the spaceships of the ocean. He supported a vibrant and localised manufacturing sector even if it was specifically shipbuilding in Adelaide.

It was only two years ago that Australia joined the UK and the US in a trilateral security pact to pursue the acquisition of nuclear-powered submarines under the guise of collective security.

The national conversation of late has turned to matters of security. Manufacturing across all modes of transport intersect in this regard.

We’re told by Government officials

that Australia’s fuel supply is of the utmost strategic importance, and it is one of the reasons, according to Defence Minister, Richard Marles, why we have to spend $368 billion on submarines. Surely, trucks and trailers must factor in as well? This is the prevailing concern that we address in our review of the Budget. In response to questions about the Strategic Defence Review, specifically the reduction in strategic warning times and the risks nations face over the next three years, Marles talked about the biggest conventional military build-up that the world has seen since the end of the second world war as well as an increased reliance on economic connection with the world. It can be argued that one such important economic connection is the fuel supply most of which (at least liquid fuels) are almost all imported from overseas, predominantly Singapore. What happened to the formation of the National Fuel Council?

In the next three years the solution is to shell out $368 billion on submarines the likes of which probably won’t be ready for up to a decade from now.

From the Editor’s desk

Officially endorsed by the VTA www.trailermag.com.au

4 Trailer Magazine JUNE 23

AAA Ian (General Manger) 0477 000 011 - ian@aaatrailers.com.au www.aaatrailers.com.au - 02 9188 3222 - 159 Walker St, Helensburgh, NSW 2508 Neil 0418 880 077 – sale1@aaatrailers.com.au – Perth WA TOP QUALITY AND FIT FOR PURPOSE WITH A FOCUS ON SAFETY AND RELIABILITY. DROP DECK CURTAIN SIDE STRAIGHT SIDE TIPPER

June 2023 38

8 Industry news

The latest news and industry developments.

34 Economy

A look at the Federal Budget and its impact on our industry.

36 Trailer builder

The latest trailer designs rolling out across Australia.

32 Trailer building materials/components

A showcase of the products and services that keep trailers on the move.

64 Hydraulics showcase

Our annual listing of where you can source truck and trailer spec hydraulic equipment.

80 World map

What you need to know about TPMS in Europe.

82 Fleet of the month

Oakdare Holdings take delivery of new Kenworths.

84 Industry Innovators

After returning to Australia from Malta as a child, Maurice Azzopardi settled in Greystanes, New South Wales where he was raised on a farm. Fast forward 50 years and he is still very active, continuing to play a major role in Muscat Trailer’s operations today.

86 What’s on Upcoming shows and field days.

6 Trailer Magazine JUNE 23

52 40 44 48 60

Cleaner, Greener. Lower-carbon aluminium for your projects.

Choosing lower-carbon aluminium in your next project can reduce the embodied energy of your aluminium products by up to 75%* LocAl® Green (8kg CO2e/1kg AL) and LocAl® SuperGreen (4kg CO2e/1kg AL) are the responsible choice for a locally extruded, lower-carbon option in your next project.

FOR MORE INFORMATION VISIT lowcarbonaluminium.com.au

POWERED

* When compared with global average CO2e for primary aluminium production, Scope 1 and Scope 2 ex smelter.

BY

Toll announces $200M automated distribution centre

Toll Group has announced a $200 million investment to open a new automated retail distribution centre in Kemps Creek, Sydney.

The facility will be Toll’s largest Australian omni-channel facility, spanning 67,626 square metres.

It features $75 million of advanced automation technology and has been designed to support both e-commerce and retail store fulfilment.

The facility will have storage capacity of close to one million cartons, and through the use of automated picking stations and connected zone-routing stations, it will be capable of dispatching 37 million items each year.

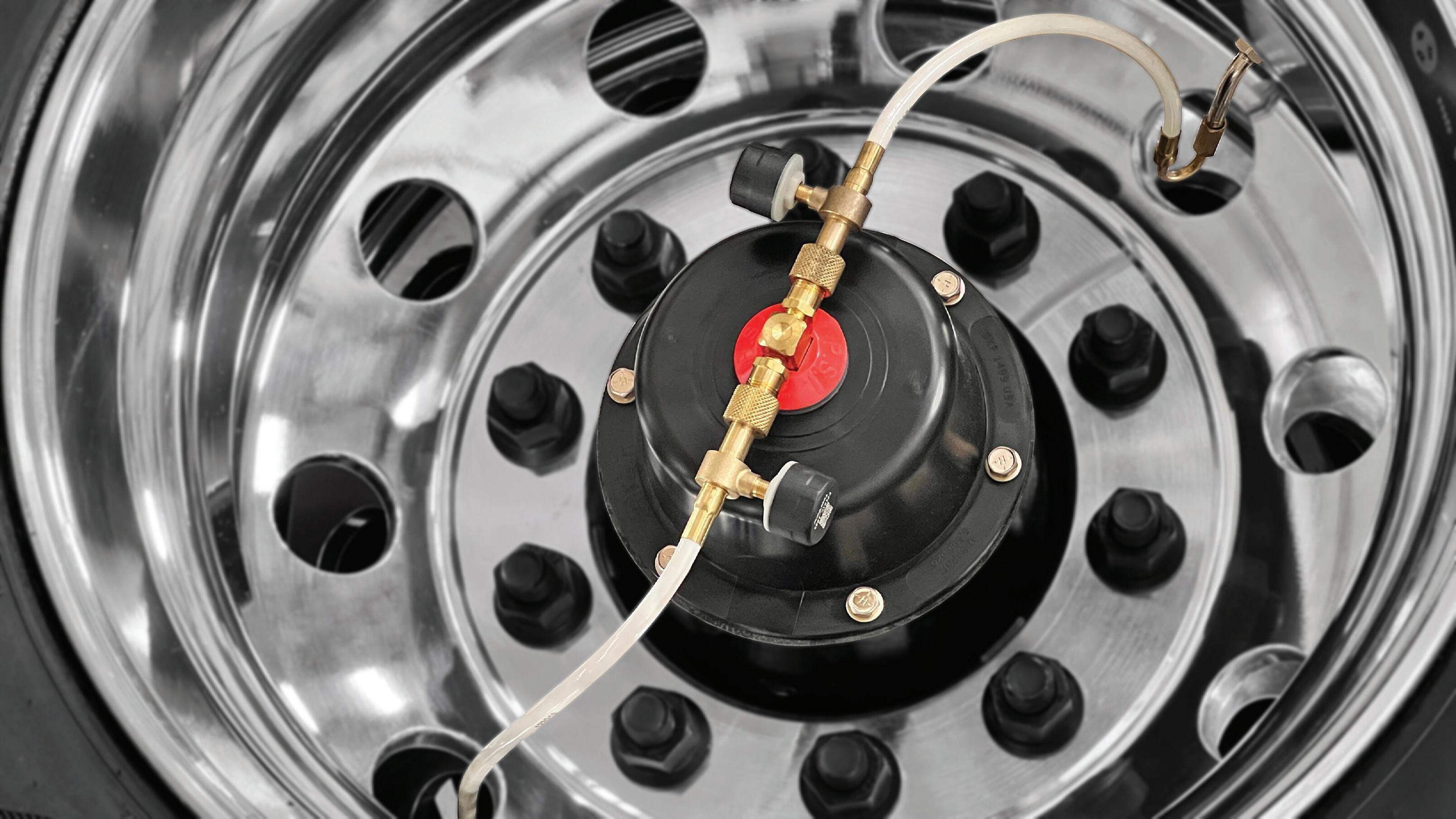

Toll President Retail & Consumer, Nick Vrckovski, said the investment shows Toll’s leadership in developing leading solutions for the retail industry.

“We’re seeing huge demand from our retail customers for fast, flexible warehouse solutions that meets the needs of Australia’s savvy online and retail shoppers,” he said.

“Our newest facility will give our customers fast, flexible fulfilment that integrates multichannel order management for immediate and accurate deliveries across all of Australia.

“Whether it’s opening up new channels, offering more delivery options, or

increasing warehouse capacity, our fulfilment solutions can adapt to the changing needs of retailers.”

Intra Series Duratrac Series XXX News

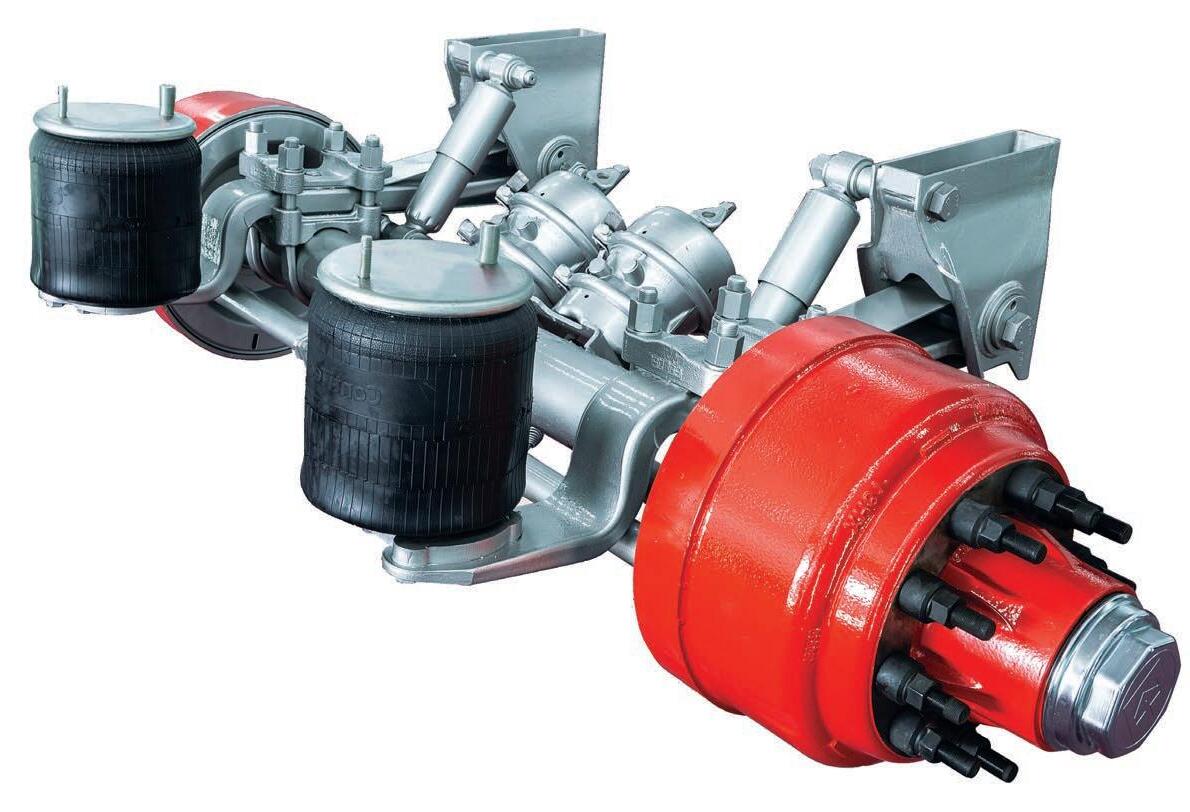

Trailer Axles and Suspension

Trailer Axles and Suspension

In addition, the facility will meet Toll’s sustainability requirements with a 5 Green Star Design and As Built rating.

It will largely be powered by renewable energy through extensive solar panels, supported by battery storage.

Construction at the Kemps Creek site is due to commence in August 2023, with the facility expected to be fully operational in 2025.

The investment is part of Toll’s broader strategy to grow the business with $400 million of new investments planned over the next four years.

Qube makes logistical move into New Zealand

Australian logistics company, Qube Holdings, has acquired a 50 per cent stake in a New Zealand group of companies, as well as 100 per cent of bulk logistics company, Kalari.

Acquiring Wellington-based Pinnacle Corporation will allow the company exposure to the New Zealand container logistics market for the first time, with longer-term organic growth opportunities a possibility, the company said. The dual purchase of Pinnacle and Kalari is worth $145 million.

Qube Managing Director, Paul Digney,

said the joint venture is consistent with Qube’s strategy for growth and geographic diversification within the company’s core strategic focus.

Pinnacle Corporation operates both port-based and stand-alone facilities in nine locations throughout New Zealand and employees about 300 people. It provides a range of services, including container storage and handling, refrigerated container maintenance and repair, container transport and warehousing.

Meanwhile, the acquisition of

Trailer Axles and Suspension

Intra Series Duratrac Series

Kalari Proprietary Limited from Swire Investments is expected to enhance Qube’s existing resource logistics offering and deepen its exposure in Australia.

Kalari, based in Melbourne, is a leading logistics provider to the Australian mining and resources industry, specialising in on-road and remote bulk haulage predominately across Queensland and South Australia.

The acquisition of both companies will be funded via Qube’s existing undrawn debt facilities in Australia and New Zealand.

Trailer Axles and Suspension 8 Trailer Magazine JUNE 23

PARTS ON DEMAND

SAF-HOLLAND is one of the leading global manufacturers and suppliers of high-quality axles and suspension systems, fifth wheels, kingpins, coupling products and landing gear to the commercial vehicles industry.

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

Email: sales@safholland.com.au

www.safholland.com.au

Coupling & Lifting Technologies Trailer Axles and Suspension Systems Trailer Axles and Suspension Systems Couplings Powered Vehicle Available in disc and drum Available in disc and drum Intra Series Duratrac Series FW351 Mark V OC50FS2 PH300 50mm–90mm E551B0M Coupling Trailer Axles and Suspension Systems Trailer Axles and Suspension Systems Couplings Available in disc and drum Available in disc and drum Intra Series Duratrac Series FW351 E551B0M Coupling & Lifting Technologies Systems Systems Couplings Powered Vehicle Suspensions Available in disc and drum Available in disc and drum OC50FS2 50mm–90mm E551B0M TOWING SYSTEMS TOWING SYSTEMS

YOU

IT Coupling & Lifting Technologies Systems Systems Couplings Powered Vehicle Suspensions Available in disc and drum Available in disc and drum FW351 Mark V OC50FS2 PH300 50mm–90mm E551B0M

HOLLAND

WHAT

NEED, WHEN YOU NEED

SAF

ORIGINAL PARTS

Bruce Highway upgrade completed at Deception Bay Road

Safety and improved travel times have received a boost at the Deception Bay Road interchange, with the Bruce Highway upgrade now fully open for use.

This $163.3 million project, jointly funded by the Australian and Queensland governments, is now complete, with all six traffic lanes opened for the very first time.

The major interchange upgrade included replacing the old, four-lane bridge over the Bruce Highway at Burpengary with two larger, wider bridges to accommodate six lanes of traffic on Deception Bay Road.

The intersections at either end of the interchange were upgraded, along with improved highway entry and exit ramps, including new loops.

Turning lanes across the highway and new connections are also open following the completion of significant construction works.

“Improved safety and efficiency, particularly at Bruce Highway access points, are the key benefits of this interchange upgrade,” said Federal Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King.

Deputy Premier and Acting Minister for Main Roads, Steven Miles, said these critical upgrades have made Queensland’s

road network better and safer.

“There has been a lot of progress made over the last 12 months as we’ve seen the two larger, wider bridges come together before our eyes,” he said.

Over the coming months, final works will be carried out to surface the road, install Intelligent Transport Systems and relocate the Heavy Vehicle Interception Site closer to the interchange.

The project was announced in September 2020. At the time, Federal Member for Petrie, Luke Howarth, said with the Bruce Highway being a major freight transport corridor, increasing the road capacity would deliver industries greater efficiency transporting goods and produce to and from markets.

“The new overpass is welcomed by Deception Bay residents as it will reduce travel time for small and family businesses and help people crossing the highway from Narangba, Burpengary East and Deception Bay,” he said.

“Anyone who knows the existing bridge, that is decades old, knows that it is in urgent need of an upgrade and as the Federal Member who fought to get this funding, I am very happy that it is now becoming a reality.”

• Targeted funding through the Roads of Strategic Importance program to improve the long-term climate resilience of freight networks.

10 Trailer Magazine JUNE 23 News

Attention to detail is paramount when managing demanding and diverse freight tasks which is why we invest in Australian made, safety optimised and durable equipment from Vawdrey.

Vawdrey Victoria Ph: (03) 9797 3700 Vawdrey New South Wales Ph: (02) 9421 6444 Vawdrey Queensland Ph: (07) 3273 6156 Vawdrey Western Australia Mob: 0448 901 126 Vawdrey South Australia Mob: 0447 343 579 TAKING THE LEAD vawdrey.com.au “

“

FREIGHTERS

K&S

MANAGING DIRECTOR AND CEO, Paul Sarant.

Major upgrade set for SA’s national freight routes

An upgrade of three major highways in South Australia will improve freight productivity of national freight routes.

Initial works have started on an upgrade on the Stuart Highway near the Northern Territory border and along the Dukes Highway.

Other works along Port Wakefield Highway between Adelaide and Port Wakefield and on Augusta Highway around Port Augusta will also be undertaken, as part of $30 million in upgrades occurring this financial year.

Planning for the remaining program is progressing, with other works being considered such as intersection upgrades, overtaking lanes, rest areas and targeted safety treatments.

In total, $500 million has been

committed towards the upgrades by the Australian Government and SA Government.

The Australian Government’s $400 million contribution is part of the $1.5 billion National Freight Highway Upgrade Program – a 2022-23 October Budget commitment – to seal the Tanami Track in the Northern Territory and Western Australia, as well as upgrading other nationally significant freight routes including the Dukes, Stuart and Augusta highways, and Central Arnhem Road in the NT.

Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said the pandemic’s toll on Australia’s supply chain has made it vital to invest in

measures to keep freight drivers moving.

“These upgrades will also deliver reduced travel times for our truckies, ensuring a more efficient, smoother journey from the farmgate to wholesalers, retailers and on to consumers,” she said.

“Resilient and reliable transport is the backbone of the nation, and I am proud we are delivering this long-term project, which will essentially benefit all Australians.”

More than 3,200 heavy vehicles use the Stuart, Augusta and Dukes highways each day, which are vital transport corridors for freight crossing the nation. Around half of those vehicles are B-doubles and road trains.

Linfox opens facility to support partnership

Linfox has announced the completion of a new state-of-the-art facility to support its growing partnership with Fuchs Lubricants.

The new 15,266-square-metre facility, located in Derrimut, Victoria, is minutes from Fuchs Lubricants’ production site in Sunshine and is close to major freight routes.

Designed for Linfox’s customer’s unique product needs, the facility will streamline their supply chain for more efficient, safe and cost-effective operations.

Along with Dangerous Goods (DG) protection to safeguard people, products and assets, a new Linfox fleet will support transport.

According to Linfox, the facility is seeking a GBCA 5 Star Green Star rating through features like solar, LED lighting, rainwater harvesting and electric vehicle charging.

“For Linfox, growing stronger means investing in resilient, local and sustainable customer supply chains – now and into the future,” it said in a statement.

News

12 Trailer Magazine JUNE 23

RUNNING GEAR FOR ALL APPLICATIONS AND ENVIRONMENTS FUWA K-HITCH www.khitch.com.au MELBOURNE 13-21 Bliss Court Derrimut VIC 3030 p: 03 9369 0000 f: 03 9369 0100 melb@khitch.com.au PERTH 77B Kurnall Road Welshpool WA 6106 p: 08 9350 6470 f: 08 9350 6570 perth@khitch.com.au BRISBANE 41 Moreton Street Heathwood QLD 4110 p: 07 3372 2223 f: 07 3372 1022 qld@khitch.com.au FOR ALL YOUR EQUIPMENT AND OE SPARE PART REQUIREMENTS, YOU CAN TRUST KHITCH

Linfox announces partnership with TWAL

Linfox has joined Transport Women Australia Limited (TWAL) as a Gold Partner to support its commitment to provide an inclusive, safe and diverse workplace.

Linfox will partner with TWAL to provide mentoring, host networking events and contribute to Government relations and advocacy activities.

Linfox Australia and New Zealand CEO, Mark Mazurek, said the company is serious about improving its female participation rate through increased opportunities and training.

“We are proud of the progress we have made, but recognise that we still have a long way to go before we achieve the diverse and inclusive workplace we aspire to,” he said.

“We continue to roll out unconscious

Silk Logistics confirms Board appointment

Silk Logistics Holdings has announced a new member of the Board with the appointment of Cheryl Hayman as a NonExecutive Director.

Chair of the Board, Terry Sinclair, said Hayman is an experienced Director with a track record of applying a strategic focus to growth and managing challenges in geographic product and channel expansion.

Hayman is currently Director of Ai-Media Technologies, Beston Global Foods, Darlinghurst Theatre Company and not-forprofit, Peer Support Australia.

Silk Logistics announced big gains in the first half of the 2023 financial year, having increased revenue by 39 per cent to $253.6 million.

The company said this was due to new business wins, growth in existing customer volumes and acquisitions.

Hayman will stand for election at the company’s 2023 annual general meeting.

NBTA and AFAC renew MoU

bias and diversity and inclusion modules in our leadership training programs.

“We have also established reference groups and mentoring programs dedicated to influencing positive change.”

TWAL Chair, Jacquelene Brotherton, said TWAL was delighted for Linfox to join as a Gold Partner.

“We welcome the opportunity to strengthen the bond between our organisations and the benefits it will bring to both,” she said.

“Linfox has long supported increasing female participation in the transport industry.

“We look forward to the opportunity to strengthen our leadership support and the additional benefits this partnership will bring to our advocacy for industry diversity and inclusion.”

The National Bulk Tanker Association (NBTA) and the Australasian Fire and Emergency Service Authorities Council (AFAC) are renewing their Memorandum of Understanding (MoU).

The MoU was established between both parties in 2009.

On 4 April NBTA Executive Director, Anthony Germanchev, attended the Hazmat Urban Operations Group meeting chaired by Acting Fire Rescue Commissioner, Gavin Freeman.

At this meeting the renewed MoU between the NBTA and AFAC was endorsed.

“The MoU signifies our members commitment to safety and AFAC’s support for our safety initiatives including the DG101 – NBTA education and awareness program and TERP in-field testing and preparedness,” NBTA said in a statement.

The MoU will now be signed by NBTA Chairman, Justin Keast, and AFAC CEO, Rob Webb.

News

14 Trailer Magazine JUNE 23

CELEBRATING 25 YEARS OF AUSTRALIAN DESIGNED ROAD FRIENDLY SUSPENSION CELEBRATING 25 YEARS OF AUSTRALIAN DESIGNED ROAD FRIENDLY SUSPENSION krueger.com.au VICTORIA DERRIMUT (03) 8331 6128 NSW WETHERILL PARK (02) 9757 4944 QLD SALISBURY (07) 3275 1011

Port of Newcastle signs hydrogen partnership

Port of Newcastle has joined forces with ten global energy enablers to commit to the Platform Zero Global Partnership for Hydrogen Innovation.

The collaborative global partnership was announced to support hydrogen innovation.

Port of Newcastle CEO, Craig Carmody, and COO, Simon Byrnes, signed a Memorandum of Understanding (MoU) under supervision of the Dutch Minister for Foreign Trade and Development to accelerate the renewable energy transition with Platform Zero, Port of Rotterdam, the City of Rotterdam and key universities and innovation hubs around the world.

“We are delighted to be collaborating with such a strong cohort of leaders in this space and to be a leading voice for our sector and region as the only Australian Port represented among these global energy industry enablers,” Carmody said.

Carmody said the partnership is another milestone of Port of Newcastle’s diversification strategy.

“It puts Port of Newcastle at the table alongside like-minded global leaders in the sector, enabling us to work

together to develop and scale innovative hydrogen technologies and overcome key bottlenecks to enable the hydrogen and clean energy transition and trade pathways,” he said.

“As we work to bring our Clean Energy Precinct to reality, the benefits of this virtual global innovation hub will be exponential, allowing our Port and Region to learn from international Ports, researchers and clean energy producers, whilst contributing to the development of the Innovation Road Map that will enable a global hydrogen economy.”

Byrnes said partnerships like these will be key to the future enablement of a scalable clean energy trade pathway at Port of Newcastle.

“Within the Platform Zero partnership, universities will contribute through developing the relevant new technologies and solutions, where Ports, like Port of Newcastle, and innovation hubs, will develop infrastructure to support storage, transportation and scaling of innovative hydrogen technologies that enable the clean energy transition,” he said.

“As the designated NSW hydrogen hub, we are at the forefront of creating

a new economy – one which faces many technological challenges in order to make it scalable, economical, reliable and safe.

“So, collaborating with other innovators who are developing and scaling new technologies will be the key enabler for a hydrogen economy.”

Port of Newcastle was also recognised as a finalist at the World Hydrogen 2023 Awards in the Port of the Future Award Category.

As a finalist, Port has reaffirmed its commitment toward a cleaner, greener future through its work in helping drive hydrogen and clean energy production in the Hunter region.

“Although we did not win the category, the fact the world’s largest coal port is sitting alongside such progressive ports as a finalist at the World’s Hydrogen Awards, is a clear indication Port of Newcastle’s diversification journey is heading in the right direction,” Carmody said.

“Our port is changing for the future, and we remain focused on collaboration, diversification and developing clean energy trade pathways, career opportunities and jobs for generations to come.”

16 Trailer Magazine JUNE 23 News

BUILT TO GO THE DISTANCE.

MERITOR MTA25 TRAILER SUSPENSION SYSTEMS

• Lightweight integrated axle and suspension package

• Innovative axle wrap design eliminates high-stress concentrations

• Simple installation backed by local support

• Industry proven Meritor Q+ or EX+ brakes

Trucks missing from National Electric Vehicle Strategy

Multiple freight and transport industry bodies have joined forces to demand the Federal Government create and enforce a zero emissions strategy with heavy vehicles in mind.

This follows the government’s first National Electric Vehicle Strategy launched recently which, critics argue, needs to go beyond light vehicles.

The freight and logistics transport sector contributes 38 per cent of Australia’s transport emissions but so far is without a clear, multi-level plan to tackle it.

“We need to move from one-off pilot projects to a strategy that enable all trucking operators to plan with certainty for low and zero emissions,” said Samuel Marks, Sustainability and Future Transport Manager for the Australian Trucking Association, adding that the country is at risk of falling behind other countries, and pointing out that financial incentives to create cost parity between electric and diesel vehicles is now common in the United States.

Fiona Simon, Chief Executive of the Australian Hydrogen Council, concurs saying the situation has now become critical.

“There is a cost of not acting,” she said. “Heavy vehicle transition is already naturally delayed, compounded by the timeframe they remain on the road and regulatory barriers. It is with absolute urgency that a comprehensive low emissions trucks strategy be developed.”

The concerned industry groups are also being backed by retailers who say a lack of support inevitably means their zero emissions delivery goals are at risk.

“We are committed to achieving 100 per cent zero emissions delivery by 2025, but we can’t do it alone,” said IKEA Australia Zero Emissions Delivery Lead, Alexandra Kelly.

“More is needed to build confidence in the sector that now is the time to electrify.”

The group of concerned sector members say even if heavy electric

Lineage Logistics appoints new CFO

Temperature-controlled logistics company, Lineage Logistics, has announced the appointment of Rob Crisci as the company’s new Chief Financial Officer. Crisci has more than 25 years of financial leadership experience in the industrial and technology sectors, the company reported in a statement.

His most recent position was as Executive Vice President and Chief Financial Officer of Roper Technologies.

“On behalf of Lineage’s management team and Board of Directors, we could not

be more excited to have Rob join us as our CFO,” said Lineage Logistics President and CEO, Greg Lehmkuhl.

“Rob is a proven public company financial leader who brings extensive operational and strategic expertise and a deep knowledge of the industrials and technology sectors.

“He will be an invaluable addition to the Lineage leadership team as we continue into our next phase of growth and expansion.”

Crisci was pleased to accept the position.

vehicles were easily accessible, the industry faces impossible barriers such as vehicle design rules, a lack of electric truck recharging and hydrogen refuelling infrastructure and higher upfront costs. They are asking the Federal Government to:

• Develop a national zero emission truck strategy.

• Sign the global memorandum of understanding on zero emission trucks, to set clear climate ambition for medium and heavy vehicles.

• Fix the regulatory barriers (i.e. width and axle mass limits) to zero emission trucks, to increase vehicle model supply.

• Increase investment in electric recharging and hydrogen refuelling infrastructure for trucks.

• Implement a purchase price incentive for zero emission trucks.

• Fund and implement an upskilling and reskilling plan to ensure the preparedness of the workforce to transition to a zero-emission fleet.

“I am thoroughly impressed with the incredible global growth Lineage has achieved over the past 10 years and look forward to leading its world-class finance team at such a pivotal point in the company’s history,” he said.

“I am excited for the opportunity to partner with Greg, the executive team, and the Board to further advance Lineage’s position as the world’s leading and most innovative temperature-controlled logistics company.”

18 Trailer Magazine JUNE 23 News

Leading the way in vehicle safety and performance

Scully RSV is on a mission to have the safest vehicles on the road. Every day.

Scully RSV and SafetyCulture have partnered to develop an industry leading initiative for transport safety. The digital safety inspection captures the performance of Scully RSV vehicles each and every time they are used on our roads.

The SafetyCulture platform enables a more efficient and optimised inspection capture and reporting system for vehicle compliance and safety. Delivered via a QR code scan, users can launch and complete the vehicle inspection in less than 30 seconds.

Scully RSV is proud to be bringing this initiative to market with Safety Culture and leading the way in keeping our communities and their families safe. It’s another great example of delivering on the customer promise, that Scully RSV fleet is managed to the highest levels of quality, safety and reliability.

FLEXIBILITY TECHNOLOGY RELIABILITY SERVICE QUALITY 1800 728 559 info@scullyrsv.com.auwww.scullyrsv.com.au

DHL Supply Chain signs cosmetics partnership

DHL Supply Chain has signed a strategic partnership with The Estée Lauder Companies Australia & New Zealand (ELC ANZ), an international cosmetics manufacturer.

In a first for ELC ANZ, DHL will manage omni-channel warehousing logistics and value-added services for 11 brands.

According to DHL, the partnership with future-proof ELC’s growth strategy, operational capability and inventory capacity.

The new Third-Party Logistics (3PL) solution will also provide greater capacity

for both B2B and B2C customers, and is designed to accommodate peak periods and increased growth.

DHL Supply Chain Australia & New Zealand CEO, Steve Thompsett, said the partnership is a significant milestone for both companies.

“We are so proud to be trusted with ELC warehousing in Australia,” he said.

“It was a consultative planning and design approach, and the new operation puts ELC ANZ in a robust position for growth.”

The Estée Lauder Companies

Managing Director Australia & New Zealand, Emmerentia Wilding, said she was pleased to be partnering with DHL.

“At The Estée Lauder Companies, we pride ourselves in delighting our consumers by providing them with the highest level of care and service, and this new era in our supply chain will ensure that we continue to do so,” she said.

“In addition, the capacity and scalability of this new solution will flex to meet with evolving needs of our consumers across Australia and New Zealand.”

Transport industry comes together for mental health

Several fleets and organisations are raising awareness for R U OK? in Trucks and Sheds Day last month.

R U OK? in Trucks and Sheds is a collaboration between R U OK? and Healthy Heads in Trucks and Sheds.

It aims to ensure people in the road transport, warehousing and logistics industries know when and how to connect and genuinely ask, ‘are you OK?’.

Heavy Vehicle Industry Australia (HVIA) has partnered with Healthy Heads in Trucks and Sheds (HHTS) as the Official Charity Partner of the 2023 Brisbane Truck Show, which will allow both organisations to utilise every opportunity to promote positive messaging around mental health and wellbeing.

The first of those is a morning tea for all exhibitors and contractors involved in the build of the event.

“We are going to take time to enjoy a cuppa, a muffin and a chat in for a very worthy cause,” said Noelene Bradley, HVIA National Events Manager.

Linfox is celebrating R U OK? in Trucks and Sheds by highlighting the importance of mental health in colleagues across the transport and logistics industry.

“From BBQs to morning and afternoon teas, teams across Linfox and BevChain sites have created space to learn how to drive conversations and meaningfully connect with others,” a Linfox spokesperson said.

“This collaboration between R U OK? and Healthy Heads in Trucks and Sheds aims to ensure people in the road transport, warehousing and logistics industries know when and how to ask ‘R U OK?’ to their peers.”

Linfox New South Wales Operations Manager, Sarah Chapman, said it’s about being able to support your peers even if you can’t help them yourself.

“We’re not all experts, but it’s about guiding them in the right direction to get the help they need to be able to be okay,” she said.

“Even if somebody is not with us physically on site, we need to make sure that they still feel valued and part of the Linfox family.”

Ron Finemore Transport also shared a statement to show its support.

“Mental health is priority within our industry,” it said.

“At Ron Finemore Transport, we prioritise the wellbeing of our team members.

“Let’s take the initiative, let’s start the conversation, let’s ask R U OK?”

Image credit: Jarek Kilian / Shutterstock.com 20 Trailer Magazine JUNE 23 News

65 YEARS OF QUALITY AND INNOVATION

65 YEARS AUSTRALIAN MADE

www.thedrakegroup.com.au

Major Victorian freight route set for replacement

One of Victoria’s most badly flooddamaged roads will be completely removed and replaced to boost freight in the region.

Minister for Roads and Road Safety, Melissa Horne, announced today that more than three kilometres of Prairie-Rochester Road will be entirely rebuilt as part of a $7.8 million package of works targeting roads in the state’s north and west.

“We’re repairing the state’s roads following the devastating floods last year, ensuring work is delivered where and when it’s needed most,” she said.

“This package of repairs is all about ensuring connectivity and safety for the

people using these roads – whether they’re farmers checking on their crops, freight operators heading to our major ports or people heading off to visit family and friends.”

Works already delivered under this package include major repairs to the McIvor Highway at the Axedale Bridge and landslip repairs at Axe Creek near Longlea.

Other roads undergoing repairs as part of the broader package include the Western Highway at Langhi Ghiran, BallaratMaryborough Road, Robinvale-Sea Lake Road and Kerang-Koondrook Road.

Prairie-Rochester Road was one of the last state-managed roads to reopen in

Victoria following October’s devastating floods, due to the severe damage caused to the surface.

Thanks to more than $3 million in funding, the road will be given a stronger base and new surface.

This round of work will deliver a complete rebuilding of some sections of flooddamaged roads, along with large-scale asphalt patching and resurfacing.

Some of these repairs are already underway, while others will begin in the coming weeks.

The works are all part of a $165 million emergency road repair blitz announced in October 2022.

Linfox wins Wellbeing Award with Healthy Fox program

Linfox’s Healthy Fox program won the Healthy Heads in Trucks and Sheds (HHTS) Wellbeing Award at the Australian Logistics Council’s (ALC) Supply Chain Summit Awards.

Presented at last night’s ALC Supply Chain Summit gala dinner, the Award coincided with R U OK? in Trucks and Sheds Day which saw Linfox ANZ teams and the broader industry unite for mental health.

The ALC Supply Chain Summit Awards recognise outstanding work and achievements across the supply chain and logistics industry.

There are four awards, including the HHTS Wellbeing Award, which are

sponsored by Primary Connect.

The HHTS Wellbeing Award itself recognises an individual or organisation that is demonstrating extraordinary commitment to creating psychologically safe, healthy and thriving working environments.

HHTS was excited to announce Linfox as the winner.

“Congratulations, and well done to all who were nominated for this award,” HHTS said in a statement.

Since 2014, Linfox has passionately supported the health and wellbeing of employees through its Healthy Fox program.

Linfox’s award-winning initiatives

included its dedicated driver podcast, ‘The Driver’s Seat’, which features conversations about fitness, nutrition, addiction, work-life balance, sleep and finances.

“We continue to provide tools, resources and opportunities to help all our team members live healthier, happier lives,” a Linfox spokesperson said.

Also at the event, Team Global Express was announced the winner of the ESG Leader Award, sponsored by New South Wales Ports.

“Proud inaugural winners of the Australian Logistics Council’s ESG Leader Award,” said Team Global Express Director ESG, Heather Bone.

Image credit: P.j.Hickox / Shutterstock.com 22 Trailer Magazine JUNE 23 News

ONE COMPANY, A FULL RANGE Transport Hydraulic Solutions • Power Take-Offs • Gear & Piston Pumps • Control Valves • Controls • Oil Tanks • DC Powerpacks • Hand Pumps • Winches • Underbody Hoists Mobile Hydraulic Solutions • Load Sense Pumps • Gear & Piston Motors • Proportional Directional Valves • Control Systems • Joysticks • Sensors Backed by dedicated local product support and expert technical knowledge, we’re focused on providing the most durable solution for your on-road or mobile application. OMFB Pacific Pty Ltd 29 Trevi Crescent, Tullamarine VIC 3043 Ph. 1300 040 600 | www.omfbpacific.com.au

$80M upgrade completed on TAS freight link

The first stage of the $80 million upgrade to Illawarra Road, a key freight link between the Midland and Bass Highways, has been completed.

The completed first stage included widening the lanes and road shoulders between the Longford roundabout and Bishopsbourne Road and improving safety at the Bishopsbourne Road intersection.

A heavy vehicle rest area has also been created near the Longford roundabout.

Illawarra Road is a key link providing efficient access to the freight hubs between Hobart and the northern regions of Tasmania.

Tasmanian Infrastructure and Transport Minister, Michael Ferguson, said improving the efficiency and safety of transport networks is a priority for the State Government as it enhances productivity in the broader economy.

“The Tasmanian economy has been growing strongly and improving our freight transport infrastructure will ensure that growth continues,” he said.

“We are investing heavily in upgrading

key freight routes and strengthening bridges to cater for modern heavy vehicles.

“Illawarra Road is a key link between the north and south of the State. Its upgrade will benefit not only our freight operators but provide a safer, more efficient route for everyone using this road.”

Planning is progressing on the next stage of improvements, with detailed design underway on a 2.9-kilometre section at the Bass Highway end of the Illawarra Road.

Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said the completion of this road will provide a major economic stimulus to centres in the region.

“Improved infrastructure and enhanced safety will benefit all motorists travelling on this key transport link,” she said.

The project was jointly funded by the Australian and Tasmanian Governments and aims to improve productivity and efficiency in moving freight and increasing safety for all road users.

Roads Australia appoints new CEO

Roads Australia (RA) has announced the appointment of Ehssan Veiszadeh as its new CEO, effective 3 July 2023.

Veiszadeh is currently the Deputy CEO of Committee for Sydney.

He has previously served as a senior adviser to former New South Wales Premier, Gladys Berejiklian, and as a Federal and State Press Gallery journalist with Australian Associated Press.

RA President, Aneetha de Silva, said Veiszadeh was chosen after an extensive search process.

“Ehssan has deep experience across government, media and policy thought leadership, which is integral in Roads Australia achieving its next phase of modernisation,” she said.

“This appointment marks an important moment for Roads Australia’s 70-year history and comes at a time of significant transformation for our industry.

“I look forward to working with Ehssan, our Board and members on continuing RA’s strong record of advocacy on the evolution of Australia’s roads, integrated transport and mobility networks.”

Veiszadeh said he was thrilled to be joining RA.

“I’m incredibly honoured to be leading Roads Australia as we embark on a new era in transportation and for the industry itself,” he said.

“Roads Australia has played an important role in leading the conversation on key issues facing the industry such as decarbonisation, productivity, divercsity and attracting talent.

“I look forward to working with RA’s members, Board and team to build on this important work and to offer solutions to some of our biggest policy challenges.”

24 Trailer Magazine JUNE 23 News

RENTCO TO BRING AUSTRALIA’S FIRST FLEET OF TERBERG YT200-EV ELECTRIC TERMINAL TRACTORS TO AUSTRALIA

Rentco is proud to announce the long awaited arrival of the first of 12 electric terminal tractors later in June

Our journey, alongside the team at PortxGroup, Terberg Distribution Partner in Australia, is the culmination of 12 months’ work with Terberg in Europe and Asia. Both Rentco and PortxGroup are very excited to deliver the first fit for purpose R/H rental terminal tractor into Australia.

The first 4 Terberg EV units are scheduled for delivery in June 2023, the remaining 8 units all to be delivered in 2023 and will boost Rentco’s already impressive portfolio of Terminal Tractors.

In an everchanging world, the transport industry of Australia is starting to recognise and even incentivise green choices in an effort to help shape a more sustainable future. Rentco takes this very seriously and will lead the way with this order of 12 x 100% EV Terminal Tractors into Australia over the next 9 months.

Whilst many countries around the world have made significant progress in the development and introduction of EV vehicles, Australia is still a little sceptical and undecided. Despite this, Rentco decided to make a significant investment into carbon neutral vehicles. Bringing a prime mover that is green and carbon neutral into an industry is a bold and confident step forward and a commitment to a more sustainable future.

Many of our great transport partners have already showed interest in renting these carbon neutral terminal tractors and have been waiting on someone to make the investment. We see this as the pathway for many to follow as green vehicles including EVs are here to stay.

For Terberg Terminal Tractors sales enquiries, contact Kirwan Barr: Tel: 0413 097 237 Email: kirwan.barr@portxgroup.com Web: www.portxgroup.com

About the vehicle

Terberg YT200-EV is a 3rd generation product with a unique battery that has an Active Safety Design with 6 x temperature sensors. In addition, it has smoke sensor, temperature sensor, short circuit, overload and low voltage protection. The batteries utilise Freon generated liquid active cooling.

The performance of the new Terberg YT200-EV electric motor is like that of a diesel engine, it has no CO2 and NOx emissions at the point of use. The new electric drive system has fewer moving parts than a diesel engine and any previous EV generation, resulting in lower maintenance costs. The new EV drive supports regenerative braking, thus reducing energy consumption. These vehicles can operate indoors with zero emissions and a lower noise level, which is particularly relevant for Terminal Trucks.

PortxGroup is committed to investing in building technical expertise and services to support EV Terminal Trucks in Australia, including provision of specific factory training for EVs.

Commenting on the order, Peter McLean, Group CEO said, “Once again, PortxGroup has delivered an innovative and highly productive solution to meet our customers’ needs. Lowering CO2 emissions and finding sustainable solutions is increasingly becoming a critical factor and this is where our Terberg YT200-EV Terminal Tractors are able to deliver outstanding results. We are honoured to be a supplier of choice for Rentco’s EV portfolio”.

For Terberg Rental enquiries, contact Paul Scott: Tel: 0407 456 463 Email: paul.scott@rentco.com.au Web: www.rentco.com.au

New inspection station to improve freight in NSW

A new heavy vehicle inspection station will be built on the Golden Highway to make one of New South Wales’ key freight links safer.

Works have already begun on the new facility, which will be located Between Dubbo and Dunedoo on the western side of the Golden Highway.

The project forms part of a jointly-funded $23.7 million commitment under the Heavy Vehicle Safety and Productivity Program (HVSPP) to implement a series of improvements along the highway.

As part of these improvements, the inspection station will use Intelligent Transport System (ITS) components

closed signage and network facilities.

It will also facilitate compliance monitoring and enforcement of heavy vehicles on the Golden Highway to reduce heavy vehicle overloading, fatigue-related heavy vehicle crashes and the risk of non-compliant vehicles travelling to Dubbo.

“The HVSPP provides funding for projects like this which work to make our most utilised freight routes safer for truckies and everyone using our roads,” said Federal Assistant Minister for Infrastructure and Transport, Carol Brown.

“This inspection station is one of many HVSPP projects increasing safety and

Australia while enhancing access and improve freight transport through local rural communities.”

According to Senator for NSW, Deborah O’Neill, the project will help businesses deliver and receive products and services from heavy vehicles more efficiently.

“Through this key investment, the Australian Government is improving the safety of all road users and in particular those in the heavy vehicle freight industry accessing the Golden Highway between Dubbo and Dunedoo,” she said.

Most heavy vehicles registered in NSW need to be inspected annually under the Heavy Vehicle Inspection Scheme (HVIS)

26 Trailer Magazine JUNE 23 News

CYLINDERS FOR TRANSPORT - 4 YEAR WARRANTY - MADE IN AUSTRALASIA sales@motushydraulics.com 1800 956 752 - FREE DESIGN QUOTE - FAST LEAD TIMES

The Drake Group announces new Directors

The Drake Group has announced the appointment of Sam Drake and Maggie Nilson as Directors, effective immediately.

Remaining Chair of the Board, John Drake was proud to confirm the appointments of his son and daughter.

“I believe they will continue to bring outstanding value to the business,” he said.

“Their addition inaugurates a third generation of family involvement in the management, leadership and ownership of The Drake Group.

“These well-deserved appointments follow many years of commitment and effort by Sam and Maggie both in the business and in the industry more broadly.”

Drake and Nilson bring a wealth of experience and knowledge to their new roles as Directors. Having held various positions in The Drake Group, they have experienced most facets of the business.

The Drake Group said both Drake and Nilson are excited about the opportunities their new roles will bring in allowing them to continue the growth and success of the company.

“At the same time, they acknowledge the enduring significance of The Drake Group’s strong foundational values in forging the future ahead,” it said in a statement.

Sam Drake told Trailer it has been a lifelong dream to fulfil the role as Director in his family’s business.

“Obviously, the business has been a huge part of my life growing up through to this point and I am looking forward to the future,” he said.

“Manufacturing in Australia certainly has its challenges and is becoming increasingly difficult; however, our business continues to produce market leading and high-quality products that I am proud of.

“The key to maintaining success and growing our business continues to be good design and innovation, reliable supply chain, lean manufacturing, quality control and of course our great staff and customers, all of which I am

grateful for and will continue to nurture and support.”

Maggie Nilson told Trailer she was also very privileged to accept the new position.

“I am excited to lead the business and continue to expand on the foundations of quality, innovation, and advanced

manufacturing that our business is built on,” she said.

“My father and grandfather built this business on family values and our intention is to keep it that way as we continually adapt, pivot, and grow The Drake Group as leading Australian manufacturers.”

28 Trailer Magazine JUNE 23 News

L-R: Sam Drake, John Drake and Maggie Nilson.

Road Freight NSW backs toll reductions in Sydney

An election promise not to force truck drivers onto toll roads is set to be delivered by the New South Wales Government.

NSW Minister for Roads, John Graham, this week all but ruled out forcing drivers onto the Westconnex motorway network announcing tolls on heavy vehicles would be reduced from three times the light vehicle rate to double the light vehicle rate.

The cut effectively reduces toll charges from $24 to $16.

The change in tolls will go into effect 1 January 2024 as part of a trial lasting two years.

Road Freight NSW said it was pleased the State Government had delivered on one of its election commitments.

“We commend the new NSW government for keeping their election pledge to the NSW freight industry,” it said in a statement.

Road Freight NSW has lobbied hard on the issue of tolls and sought to incentivise operators of heavy vehicles onto toll roads rather than penalising drivers by forcing them to use toll roads.

“This decision is a win for the RFNSW position of incentivising truckies onto toll roads and our past submissions and discussions around trying to make this work for the community and freight industry,” Road Freight NSW said.

“We have also advocated for off peak tolling which Professor Alan Fels will examine as part of his review and we have also proposed incentives for future vehicles like EV trucks/hydrogen vehicles.

“Additionally, given developments with technology, we can now get on board real time data from sensors showing mass and weights, we have also proposed in the review toll road price reductions for heavy vehicles carrying no loads on these roads.”

Invest In The Best

Fels along with Dr David Cousins are leading an independent review of tolling NSW. A public discussion paper will be released mid-year, followed by public hearings in the second half of 2023.

Submissions will be sought from the public and industry stakeholders.

To avoid tolls, some drivers have been going through suburban areas to avoid the M8 tunnel.

Peak hour speeds had decreased by 8 km/h with traffic increases of up to 23 per cent in places like Bexley and Arncliffe where many of these heavy vehicles are travelling.

“We’re hoping that this will bring thousands of trucks off suburban streets and into these toll tunnels,” said Minister Graham.

“The former government’s original promise that these tunnels worth billions of dollars would be used to take these trucks off suburban streets.”

With 30 years of industry experience providing customers with the best possible transport solutions, Allroads Transport Engineers are pleased to announce the addition of the Gincor Werx Live Bottom Trailer to our line up of trailer offering. Gincor’s reputation for manufacturing a premium product aligns well with our industry reputation for supplying premium built custom trailer transport solutions.

W: allroads.com.au E: sales@allroads.com.au Allroads Transport Engineers 65 Copal Road, Albany WA 6330 P: (08) 9844 3883

MODEL 323LBC-S Tridem Live Bottom Trailer

MGM Bulk launches same day FIFO

To encourage driver recruitment, Western Australia commodity transporter, MGM Bulk, has announced same-day fly-in flyout.

So that employees can return to loved ones quicker, same-day FIFO has been introduced with what MGM Bulk describes as a straight forward signup process and supportive work environment.

Flights from Cairns, Townsville and all Australian capital cities are provided and covers connections to New Zealand along

with all meals, travel and accommodation.

“We know these are challenging times, but your work life doesn’t have to be,” the company said in a statement.

“As a family-owned transport and logistics business, MGM Bulk is driven to deliver competitive pay rates, upskilling opportunities, paid onsite inductions, and tailored shift patterns to suit your needs.”

This follows, as part of a driver recruitment campaign, a giveaway of 25 Matt Stone Racing Team memberships

TWAL members make finals for awards

Four Transport Women Australia Limited (TWAL) nominees and five members have been named as finalists in the 2023 Women in Industry Awards.

The Women in Industry Awards recognise outstanding women from across a range of industrials sectors including transport, logistics, mining, manufacturing, engineering, bulk handling, waste management, rail, construction and infrastructure – all sectors that are traditionally maledominated.

It was recently announced that six of TWAL’s members were nominated for the 2023 Women in Industry Awards.

Since then, TWAL Vice Chair, Coralie Chapman, and Ann Lopez have been

named as finalists for the Excellence in Transport Award.

TWAL Director, Annastasia Denigan, has been named as a finalist for the Safety Advocacy Award.

Louise Azzopardi has been named a finalist for the Mentor of the Year Award.

TWAL’s corporate member, Viva Energy Australia, was named as a finalist in the Industry Advocacy Award.

TWAL Chair, Jacquelene Brotherton, told Trailer she was proud to see her colleagues make it as finalists.

“I am so very proud of our team members and I am looking forward to supporting and cheering them on at the Awards dinner,” she said.

“As Chair of TWAL, I am very excited

valued at $200 each to the first 25 successful multi-combination licenced applicants.

The promotion is in conjunction with Supercars Raceweek.

MGM Bulk has been operating since 2014, however, sits within the wider stable of the MGM Group whose legacy goes back over 60 years in Western Australia.

It employs over 400 people across three sites.

about having them on board.”

The 2023 Awards will be presented during a special ceremony at Aerial in South Wharf, Melbourne, on Thursday 8 June 2023.

This year’s award categories include:

• Rising Star of the Year

• Business Development Success of the Year

• Industry Advocacy Award

• Safety Advocacy Award

• Mentor of the Year

• E xcellence in Transport

• E xcellence in Manufacturing

• E xcellence in Engineering

• E xcellence in Mining

• E xcellence in Construction

• Woman of the Year

30 Trailer Magazine JUNE 23 News

Device Technologies to upscale national logistics capabilities

Two significant upgrades to key areas of the Bass Highway have been completed in Tasmania’s north-west.

The works are funded under a $100 million investment in Bass Highway upgrades between Wynyard and Marrawah.

One of the completed upgrades has improved safety by removing a curve on a section of the Bass Highway between Boat Harbour Siding Road at Boat Harbour and Broomhalls Road at Sisters Creek.

It has also delivered vital upgrades to the Bass Highway’s junction with Morris Road, significantly improving safety for road users.

The other completed works are located on the Highway at Togari, between Pacey’s Road/Park Road and Salmon River Road.

Upgrades for this stretch of the Highway included shoulder widening and the improvement of the road structure between Pacey’s Road and Salmon River Road.

Additional safety upgrades have been

prioritised, such as the replacement of the Montagu River Bridge.

As well as meeting the needs of modern freight transporters, the construction of the new Montagu River Bridge has provided training and employment opportunities for young tradespeople.

Tasmanian Infrastructure and Transport Minister, Michael Ferguson, said reliable road connections are essential for all Tasmanians.

“These projects are among a raft of upgrades between Wynyard and Marrawah, many of which have now been completed, including four new overtaking lanes, 10 sections of Highway realignment, 66 junction upgrades and up to 60 kilometres of road-widening,” he said.

“The upgrades between Boat Harbour Siding Road and Broomhall’s Road will make all road users safer and demonstrate our ongoing commitment to improving the Bass Highway.”

Future work under the Bass Highway 10Year Action Plan near Crayfish Creek will include drainage improvements to Dunn Street, line marking and signage renewal. This project is expected to be completed in July 2023.

Delta delivers 100% integrity, finished within a 1000th of an inch. 177-199 Stoney Rise Rd Devonport, Tas 7310 Phone: 03 6420 6900 Fax: 03 6424 6983 Email: jfwhite@delhyd.com.au Australian engineered, Australian precision

Eurocold announces $100M expansion plans

Brisbane based refrigerated transport rental company, Eurocold, has announced significant expansion plans for key stakeholders at the Brisbane Truck Show. A pipeline of initiatives will be bolstered by an $100 million investment according to Managing Director, Avraam Solomon which will see expansion through new markets, including New Zealand and further development set for sister company Revora.

After it launched a Western Sydney facility earlier in May, Solomon’s vision is expansive, committing to a $100 million spend within the refrigerated transport industry with the focal point being expansion into Melbourne, Perth and ultimately New Zealand.

This commitment over the next three years will see up to 800 trucks being deployed, the initial goal being 500 trucks.

The nexus of Eurocold’s establishment

three years ago was securing the Australian rights for Isokit refrigerated bodies.

In that time, Eurocold has become one of the leading companies in the space combining decades of experience, innovation and a customer service focused approach.

Solomon and his key executives have spent significant time researching global trends in refrigerated trucking – both in person and anecdotally – and, when it comes to renting or leasing trucks, the Australian market lags in uptake when compared to global counterparts –something Eurocold wishes to change.

“I’ve spent a lot of time in Europe in the last 12 months looking at large businesses that specialise in refrigerated truck leasing and rentals,” he said.

“For example in Europe, of all the vehicles that are produced every year, we know that 58 per cent of the builds go into long

term rentals trading to leasing off balance sheet,” said Solomon.

“Currently in Australia, it is a fraction of that – the percentage of rental takeup is more like 1 to 3 per cent – so there is significant opportunity for transport fleet operators to scale with flexibility and ensure their fleets feature the latest technology, which then flows onto a second hand market.

“We see ourselves as a large participant in the industry to get rigid vehicles that are of the highest quality and standard onto the road, so we’re always using the most modern chassis’ and sourcing the best Isothermal bodies from around the world.” Revora, which was launched in March, will be a fully owned sub-brand that specialises in the rental of rigid, electrified trucks.

General Manager, Nathan Gore-Brown announced that Carrier will be a supplier

News

32 Trailer Magazine JUNE 23

of new technologies for the electric, refrigerated transport industry in Australia.

“Revora is a real investment to us. It is something that is costing us money every month, which we forecast will take 12 months or two years before starting to see significant returns,” said Gore-Brown.

“Revora (and Eurocold for that matter) are companies that really want to see the industry make a difference in the long-term sustainability of refrigerated transport – and to our environment –because we believe in it,” he said.

Gore-Brown said the usage situation for clients is what will drive the selection of chassis and body size.

“We’ve been working with our partners at Carrier to utilise its new technology designed specifically for an electrified body and we’ve progressed with suppliers in other areas when it comes to those selections of chassis, battery technology and charging units” he explained.

“It will take commitment and buy-in from the industry for Revora to get there. We acknowledge that the industry has to be willing to participate in order for us to get it to a position of profitability.”

Lindsay Australia announces new CEO

Lindsay Australia has appointed Clayton McDonald as Chief Executive Officer, effective from 17 July 2023.

McDonald has extensive leadership experience in the transport and logistics sector, and is currently Group Executive Bulk at Aurizon Limited.

He has held a number of senior executive positions at Aurizon since 2008, prior to which he was employed at Toll Group between 2001 and 2008.

McDonald holds a Bachelor of Science from the University of New South Wales and a Master of Management from Macquarie Graduate School of Management and is a graduate of the Harvard Business School Advanced Management Program.

A number of highly experienced internal and external candidates were considered following a highly competitive search process for Kim Lindsay’s replacement before the transport and logistics company settled on McDonald as CEO.

“Clay McDonald is an outstanding

operational, commercial and customerfacing roles in transport and logistics,” said Ian Williams, Chair of Lindsay Australia.

“He has demonstrated experience growing businesses both organically and through acquisitions, which aligns to Lindsay Australia’s growth objectives,” he continued in a statement.

“Kim Lindsay’s 20 years as Managing Director and CEO have built the foundations for an enduringly successful business and he leaves Lindsay Australia in a strong position to achieve our ambitions for profitable growth.”

Williams said it was testament to Kim’s contribution to the Group that Lindsay Australia has been able to attract a new CEO of Clay McDonald’s calibre to lead the business during what shapes as its next stage of continued operational improvement and growth.

“On behalf of the Board, I would like to thank Kim for his distinguished service to the business and his dedication to the

www.trailermag.com.au 33

Federal Budget leaves truckies under more financial pressure

It was the first surplus in 15 years and referred to as considered and methodical. One that balanced spending restraint, with helping those who were struggling. Treasurer Jim Chalmers’ 2023 Budget was perhaps not an outright win for the most in need, but with a focus on easing energy and medical bills, providing rental assistance and increasing employment, experts agree it was a good look for the government and an improved picture of government finances.

Chalmers offered some overall light at the end of the tunnel, predicting the economy would grow in 2023-24 by 1.5 per cent while inflation, currently at 7.0 per cent, was forecast to fall to 3.25 per cent next year. All in all, there was plenty of Labor pollie backslapping in Parliament.

But not everyone is happy. In fact, many in the transport industry say the Budget hasn’t just completely ignored them but

made their livelihoods even harder to continue. It’s a bitter pill to swallow after years of Morrison government policies which, comparatively, seemed wellreceived by the sector.

The biggest issue the outraged truckies have with the Budget is the increase to the Heavy Vehicle Road User Charge, putting, they say, even more pressure on their already strained finances. The Budget shows the government’s plan to increase the toll from 27.2 cents to 32.4 cents per litre of diesel over the next three years – a 6.0 per cent rise. This charge is typically used to pay for road maintenance and repair and the decision was made jointly by federal, state and territory transport ministers.

Australian Trucking Association Chair, David Smith, said the increase will have a major impact.

“The Australian Trucking Association

has always accepted that it must pay its fair share of road maintenance and improvements,” he said. “But the basis of determining that fair share, the so-called PAYGO system, is broken. Road user charge reform is desperately and urgently needed.”

Federal Member for Wright, Scott Buchholz, has slammed the Federal Government for hiking the charges and said inevitably it will be consumers who end of paying in the long run.

“Everything we buy, manufacture, grow and build in this country touches the back of trucks, whether it originates on a farm, from a factory, or enters the country via a port,” he said in response to the Budget. “Sadly, heavy vehicle operators will have no choice but to pass this hike in government taxes on to their customers, which will jack up the cost of everything transported by our truckies.”

Not everyone is singing the praises of this year’s surplus Federal Budget , with the transport industry gaining a win on the environmental side of business but losing out with road charges.

34 Trailer Magazine JUNE 23 XXX Economy

CYLINDERS VALVES PUMPS PTO www.hydreco.com hydreco-hydraulics Sydney 02 9838 6800 MORE INFORMATION Perth 08 9377 2211 1300 HYDRECO

Hard to follow

Since July 2016, Followmont Transport has invested more than $180 million in its fleet, network infrastructure and property. As part of a massive growth project, its latest addition to the fleet is a Vawdrey quad-quad high productivity B-double combination.

Followmont Transport began in 1984 delivering magazines out of a small office in Brisbane. Since then, it has transformed into Queensland’s largest family-owned transport company and a preferred carrier to many with over 1,000 vehicles.

The fleet hit the ground running earlier this year through the acquisition of Bradco Transport, and it hasn’t stopped on its growth path since. As part of an ongoing $25 million investment into new fleet equipment, Followmont Transport has recently taken delivery of 15 new prime movers in the last six months.

Its latest purchase, which is expected to join the fleet shortly, is a quad-quad

high productivity B-double combination from Vawdrey. The unit will have 42 pallet spaces with 210 cubic metres of total space, completely fitted with mezzanine floors.

Followmont Transport COO, Ross Longmire, is working with Vawdrey on the permit process, but he says the goal is to get 77.5-tonne Gross Combination Mass (GCM) on certain lanes.

“A lot of the specs they do for these combinations are around high cubic low weight, but we’re focused on the spec while still trying to maximise weight so that the actual asset will last longer,” he says. “We’ve kept our normal spec, which

is a medium-duty spec when it comes to the manufacturing side of it, rather than going lightweight.”

According to Ross, Followmont is trying to fit as much safety features in the combination as possible.

“It’s got all the safety features that we could fit around EBS and stability control, and has axle weights and multiple steering axles as well,” he says.

Once the quad-quad arrives, it will be used to cart express freight into North Queensland and along the east coast.

Followmont has been dealing with Vawdrey for over 15 years. Like many of Vawdrey’s customers, the relationship

XXX 36 Trailer Magazine JUNE 23 Trailer builder

was built around the values of both parties. And throughout the fleet’s journey over the last 15 years, Vawdrey has always been there to support it.

“It’s very much a relationship-based scenario, and they’ve just been great to work with,” says Followmont Transport Managing Director, Mark Tobin. “You can get answers and you can get straight to the owner of the business, that’s how close we are with them.”

Mark says Vawdrey ticks the boxes in terms of quality and customer service.

“I think it’s a balance between the product and the standard to which it is delivered, and how Vawdrey works with quality control – especially with all of its units being manufactured in Australia,” he says. “They are very much about working with us around innovation, and they are always open to new ways of maximising their product.”

Throughout the dealings with dozens of Australian fleets, Vawdrey has also been known to be very easy to work with. Agreeing with this, Mark says the family

business has been very accommodating to his needs.

“Whether it be around the environment, the standard of the fleet or safety features, they’re definitely not set in their ways,” he says. “They are willing to make change to suit your application, with the best interest of both businesses.

“They’re obliging and you can do some special specs with them. In the entire marketplace, out of all the trailer manufacturers, I believe Vawdrey is at a high position at all times in regard to innovation.”

Agreeing with Mark, Followmont Transport COO, Ross Longmire, says the relationship between Vawdrey and Followmont Transport was a big factor in choosing the manufacturer for this build.

“We sit down to plan and design the unit together, it’s not just a product,” he says. “So, they actually care about our operations because of the relationship. They want to work with us, and that’s around innovation and sustainability.

They’re constantly dealing with myself and the teams on the ground to try and get a better understanding of what we need going forward, and they’ll bring suggestions to us about what we should be considering and what’s new in the market.”

With Vawdrey having a similar passion towards growth and innovation, Mark says it’s very likely the Vawdrey name will continue to power the fleet.

“Our biggest vision is to keep taking delivery of a number of different combination trailers in our business while reducing risks and reducing how many trucks we have on the road, and how can we be smarter,” he says. “The supply chain is under extreme pressure at the moment, so we’ve got to get on top of the game.”

Contact Vawdrey Australia 1-53 Quantum Close Dandenong South, VIC 3175 Ph: 03 9797 3700 Web: www.vawdrey.com.au

www.trailermag.com.au 37

Dedicated to quality

The Southbank Truck Festival at the 2023 Brisbane Truck Show saw the O’Phee ‘London’ Double Stack Container Super B-Double Skel trailer reveal itself to the transport industry, presented by Mick O’Phee.

The term ‘London’ was a code O’Phee Trailers used (based on the famous London double decker buses) during the concept, design, manufacturing and approval process of the Super B-double to keep the project under the radar. Thus, the name was given to the end result – a world-first, 32-metre Super B-double designed for innovation and productivity.

As Mick explained at the show, the combination has the ability to doublestack containers with a fully Australiancompliant load restraint system. According to Mick, it also has a 100 per

cent increase of container movements over and above the current standard B-double combinations.

“This unit has the ability to transport four 40’ containers or eight 20’ containers,” he said. “And that’s before you add a third trailer.”

The Super B-double was The Drake Group’s biggest innovation on display at the Brisbane Truck Show. Also attending to represent the business, Director, Sam Drake, said the product was initially instigated through increasing efficiencies for carrying empty containers on the port of Brisbane.

“We’ve worked with the customer, the Port of Brisbane, the National Heavy Vehicle Regulator (NHVR) and other relevant authorities to come up with an approved Double Stack Container Super

B-double Skel trailer combination that can be operated on the port precinct,” he said. “The purpose is to shift as many empty containers as possible in the most efficient way on the port precinct. So, we’re hoping that it’s something people see as a viable solution and get excited.”

Alongside ‘London’ were some of the best offerings by Drake and O’Phee, such as the Drake 4x4 Full Widener, 4x4 Deck Widener, 5x8 Swingwing, and the O’Phee Flat Top 3x4, Swinglift, Skel 2x4 and 2x8 Dolly.

“The individual models on the stand have all of the latest technology and offerings that we have, but they’re still at the core of what we do,” Sam said. “They’re proven and tested products that have matured over many years. The fundamentals of the models themselves

The Drake Group presented a selection of unique trailer combinations at the 2023 Brisbane Truck Show and Southbank Truck Festival –a testament to 65 years of innovation.

38 Trailer Magazine JUNE 23 Trailer builder

haven’t changed too much. Based on a combined effort between sales, engineering product development and customer feedback, our engineering and designing department have made improvements where needed to continually push the boundaries of payload availability whilst ensuring and maintaining the standard of quality that the models represent.”

Upon the Swingwing’s arrival in 1969 it was clear that it was one-of-a-kind. The Swingwing sets itself apart by using hydraulics to open outer decks like a pair of wings, with an increased carrying capacity between 50 and 120 tonnes. And while its standard spec has become one of Drake’s signature lines of trailers, the one on display at Brisbane Truck Show was highly spec’d to give onlookers a taste of what The Drake Group is capable of.

“This trailer was built for Mactrans Heavy Haulage and has everything you can think of on it in terms of options,” Sam said. “It has customised stainless steel pipe work and covers, full radio remote-control, additional tie downs to inner coamings, BPW axles, three beam

bi-fold ramps, hydraulic landing legs and gooseneck, additional lighting, a centre spine hydraulic jacking leg double acting suspension rams, and a bespoke paint job customised for Mactrans.”

The Drake Group’s stand itself was bigger from previous years. And with the theme of Australian road transport to highlight the family’s local builds, it was a perfect example of what Drake has stood for since establishing in 1958. Being built on the foundations of local manufacturing with extremely strong and versatile materials for ground-breaking designs, The Drake Group is celebrating its 65th anniversary this year as it continues its legacy with the original values still in place.

“We’re proud to say that we’ve been in business for 65 years, let alone being a part of Australian manufacturing for that long,” Sam said. “All the pressures that come with being in business are real –

we’ve seen ebbs and flows but we’re still here after all this time.”

Sam and his sister, Maggie Nilson, were both recently appointed as Directors to lead Drake into its third generation of success. And based on the company’s performance at the 2023 Brisbane Truck Show, it’s evident that it will continue to do what it does best.

“I am thoroughly enjoying this year’s truck show, it seems to get bigger every year,” Sam said. “It gives us the perfect platform to showcase a variety of what we do and catch up with our much-loved customers to show them some of our latest innovations.”

Contact The Drake Group 19 Formation Street, Wacol QLD 4076 Ph: 07 3271 5888 Web: www.thedrakegroup.com.au www.trailermag.com.au 39

CBB outdelivers once again

RJ & CK Trezise commenced its operations in the transport industry in 1984 with an old second-hand tip truck. Working in and out of quarries in Dunnstown, Victoria, RJ & CK Trezise would cart crushed rocks and quarry products to several road and rail projects and concrete plants, as well as taking part in replenishment work on the side.

From the first single tandem drive truck, RJ & CK Trezise slowly evolved its fleet over the years with trucks and trailers, two-axle combinations, super dog trailers

and now quad dogs and PerformanceBased Standards (PBS) combinations.

RJ & CK Trezise has continued to rely on Chris’s Body Builders (CBB) for new truck and trailer combinations since it was introduced to the product shortly after establishing almost 40 years ago. James Trezise, the son of Director, Rod Tresize, has recently taken over the fleet and

in a magazine, which had a photo of one of their trailers,” Rod says. “I thought it looked pretty good, so we gave it a go. That’s where it all started.”

Rod bought his first trailer from Chris Snr around 30 years ago which he says was CBB’s third ever unit built. Since then, all of the fleet’s orders have been PBS aluminium truck bodies with three or four axle trailers from CBB.