® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE JUNE 2024 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY TRAILER BUILDER WORLD MAP LIFTING EQUIPMENT ECONOMY AXLES & SUSPENSIONS HYDRAULICS SHOWCASE ISSN 1838-2312 9 771838 231003 05 $10.00 ISSN 1838-2312 9 771838 231003 04 Local manufacturing stands the test of time TRANSPORT PIONEERING

PUBLISHER

John Murphy

john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

EDITOR

Peter White peter.white@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Alejandro Molano

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher.

Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every e ort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

O cially endorsed by the VTA

From the Editor’s desk

Trailer Magazine Editor

Bang on budget

The 2024-25 Victorian Budget unveiled last month was welcomed and praised by the Victorian Transport Association (VTA) as the one we needed to have to “start to rein in debt and in consideration of the persistent economic headwinds we face”.

The Budget, first and foremost, will look to make our roads safer while at the same time transforming our transport network. As part of a 10year, $6.6 billion investment, a total of $964 million will be spent to maintain Victoria’s road network this coming year alone – including an extra $100 million in funding to clean up damage from the flooding and storms of this past summer period. This is nearly double the average spend of $493 million between 2010 and 2014.

Meanwhile, the Victorian Government will fork out $752 million to ‘switch on’ the Big Build, funding key road infrastructure projects under construction including the North East Link and the West Gate Tunnel projects. The package will also support additional network improvements, such as works to keep rail freight moving across Victoria with $104 million (which will include encouraging operators to take up rail to reduce trucks on local roads) in addition to $17 million to improve metropolitan Melbourne roads and intersections throughout Dandenong North, Greensborough, Brunswick and Coburg. Regional Victoria will also benefit from this with $62 million to make regional roads

safer. This takes into account the Princes Highway East upgrade as well as improvements for several freight routes throughout the region.

In addition, the Budget detailed that the Government will provide $233 million for activities to prepare for the opening of the Metro Tunnel next year, such as recruiting and training drivers, timetabling, completing final testing, preparing customer information and education and training a dedicated customer service team.

$10.2 million towards new camera technology, it was revealed, will also enforce the Government’s legislated 24/7 truck bans on roads across the inner west communities – taking 9,000 trucks off local roads.

In an uncertain economic environment characterised by persistent inflationary pressures and higher interest rates, VTA CEO, Peter Anderson, believes the 2024-25 Victorian Budget commits the State Government to maintaining and growing investments in road and rail infrastructure used by the freight and logistics industry.

“Through its commitment to road and rail infrastructure investment and maintenance”, he said, “the Government has recognised the importance of the freight industry to maintaining supply chain continuity and integrity.”

Peter White

Peter White

4 Trailer Magazine JUNE 2024 C M Y CM MY CY CMY K

Business partnerships, people movements, developments that bolster freight productivity and more.

22 Economy

Engineers Australia has welcomed the Australian Government’s commitment to environmentally responsible practices.

24 Rigid bodies

With over 30 years of experience in manufacturing, Scully RSV can create rigid bodies to suit any chassis.

26 Axles & suspensions

Centurion is deploying 10 Vawdrey combinations fitted with BPW Transpec axles and suspensions.

28 Lifting equipment

Hydreco Hydraulics celebrates its 65th anniversary.

30 Agriculture equipment

Brimarco’s ‘Tough As’ trailers are designed to withstand the toughest conditions in transport.

32 Trailer builder

Australia’s trailer manufacturing industry is as strong as ever.

40 Trailer building materials/components

A showcase of the products and services that keep trailers on the move.

51 Hydraulics Showcase

Our annual listing of where you can source truck and trailer spec hydraulic equipment.

72 Infrastructure Spotlight

What you need to know about Australia’s biggest road projects this month.

74 World map

Researchers are working on a way to use heavier duty trucks as mobile generators.

76 Fleet of the month

Campbell’s Fuel Service remains an independent family-owned petroleum products business.

78 What’s on Upcoming shows and field days. June 2024 24

6 Trailer Magazine JUNE 2024

8 Industry news

DHL enters 10-year partnership with Mattel

DHL Supply Chain Australia has again partnered with global toy company, Mattel, to form a 10-year warehousing agreement.

The long-term agreement follows a successful five-year relationship between the companies and has provided the opportunity to upgrade Mattel’s warehousing with improved sustainability measures.

DHL has relocated Mattel’s warehouse operations to a new 31,000-square-metre site in Truganina, Victoria, which provides the space required to cater for growth.

The Truganina site has also been upgraded to achieve Green Star accreditation.

Its features include a 200kWp rooftop solar array, rainwater collection, Water Efficiency Labelling and Standards (WELS) rated water fittings, energy efficient

high-volume low-speed fans and rooftop lighting which uses sunlight to illuminate the building.

DHL Supply Chain ANZ CEO, Steve Thompsett, said the new agreement demonstrates Mattel’s confidence in DHL’s capability.

“We enjoy a great relationship with Mattel and we’re thrilled to have entered this 10-year agreement and have their warehousing operations running from this new site,” he said.

“It’s a real honour for us to be helping Mattel bring their brands into people’s lives – such as Barbie, Hot Wheels, Fisher-Price and others – which have brought joy to children and fans in Australia for generations.

“We’re also pleased to help Mattel reduce operational costs and boost the sustainability of their warehousing with

significant upgrades to their operation, delivered thanks to DHL’s global focus and expertise in this field.”

Mattel Asia Pacific Senior Vice President and Managing Director, Paul Faulkner, said the new long-term agreement solidifies Mattel’s great partnership with DHL over the past five years.

“This agreement ensures we have the operational infrastructure and expertise in place to secure our growth plans for the future,” he said.

“In our mission to deliver innovative products and experiences that inspire fans, entertain audiences and develop children through play, certainty and precision in our supply chain is vital.

“This expanded partnership with DHL ensures we can continue to improve the delivery of these experiences across the Australian marketplace.”

8 Trailer Magazine JUNE 2024 News C M Y CM MY CY CMY K

Victoria 13-21 Bliss Court, Derrimut VIC, 3026

Tel -(03) 9369 0000

Queensland 1/15 SeeanaPlace, Heathwood QLD, 4110

Tel -(07) 3372 2223

Western Australia 5 Freight Road, Kenwick WA, 6107

Tel -(08) 9350 6470

Register your attendance for Women in Industry 2024

Tickets are available for the 2024 Women in Industry Awards night, which this year will take place in Sydney on Thursday 20 June.

The 11th annual Women in Industry Awards will once again provide the opportunity to recognise and celebrate the achievements of outstanding women, with several award categories covering a range of industrial sectors including transport, logistics, mining, manufacturing, engineering, bulk handling, waste management, rail, construction and infrastructure. The award categories include:

• Rising Star of the Year

• Business Development Success of the Year

• Industry Advocacy Award

• Mentor of the Year

• Safety Advocacy Award

• Excellence in Transport

• Excellence in Manufacturing

• Excellence in Engineering

• Excellence in Mining

• Excellence in Construction

• Woman of the Year

Building on the list, a new ‘Excellence in Energy’ category has also been announced for this year’s line-up.

Prime Creative Media Event Manager, Chloe Armstrong, said the Women in Industries Awards night is a great way to get all of Australia’s essential industries involved, including transport.

“The annual Women in Industry Awards night allows us to bring people together in a way which shows the dedication and contributions of the women within Australia’s thriving sectors,” she said.

“Following the success of last year’s event, the 2024 Women in Industry Awards will be no different.”

Last year’s event saw Coralie Chapman from Humes Concrete Products receive the Excellence in Transport Award.

Chapman has always had a passion for promoting the various roles in the transport and logistics industry as well as safety around heavy vehicles.

She is passionate about encouraging women to choose transport as a career path, and strongly advocates for diversity and inclusion for people pursuing ‘nontraditional’ careers.

With limited venue space and time remaining, those interested in attending this year’s event are encouraged to register now.

10 Trailer Magazine JUNE 2024 News

JOST Australia Adelaide branch marks anniversary

JOST Australia is celebrating the 10th anniversary of its Adelaide branch in Wingfield.

The branch has significantly grown since opening in 2014, expanding JOST’s presence in the South Australian and Western Australian markets.

One of its key milestones includes the development of a new paint booth as well as in-house fit-ups and certification to meet evolving market needs.

According to JOST, the Adelaide branch has also played a key role in its national customer service initiative.

In 2014, it was announced that the office would service the whole SA region with a complete range of JOST products as well as a wide range of other products.

Going forward, JOST said it will continue to provide these offerings to the SA market.

“As we look forward, we’re excited to

keep pushing boundaries with advanced products such as JOST core products, Razor, sensor technologies and Quicke agricultural products, ensuring we meet evolving customer needs and safety standards,” the company said in a statement online.

“Thank you to our team, partners, and clients for a decade of trust and collaboration.

“Here’s to continuing our legacy of excellence and innovation.”

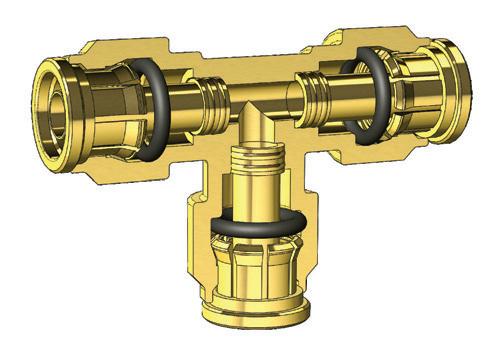

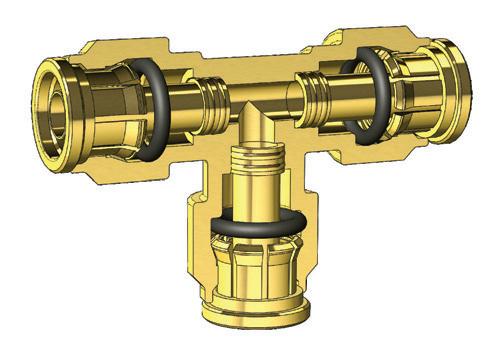

AIR BRAKE FITTINGS

UNCOMPROMISING PERFORMANCE

Image: JOST Australia.

Australia’s BIGGEST range and stockist of Metric / Imperial Push to Connect and Compression Style D.O.T Air Brake Fittings D.O.T / S.A.E STANDARDS CONFORMANCE GP TRUCK PRODUCTS available from Truck & Trailer parts outlets Australia wide. Compliant Standards: ADR-38/05 & DOT Lockable Fitting Cabinet Mobile Fitting Stand Emergency Break Down & Glove box kits Brass Fittings Full range of Brass fittings designed to suit North American and European Truck & Trailer Air Brake systems. Phone +61 3 9580 1811 sales@gptruckproducts.com.au www.gptruckproducts.com.au SCAN CODE FIND OUT MORE Huge range available. Approved to meet: Australian Design Rules ADR-38/05 DOT FMVSS 571.106, SAE J2494/3, SAE J1131 blanking plugs.

NHVR releases footage of ‘world-first’ Rollover Stability Control testing

The National Heavy Vehicle Regulator (NHVR) has shared the results of its Rollover Stability Control (RSC) testing on an A-double combination.

The testing was recently conducted during a rigorous four-day program, where NHVR Chief Engineer, Les Bruzsa, provided technical oversight while a specialised A-double was subjected to high-speed dynamic manoeuvres used in Performance-Based Standards (PBS) assessments.

The project showcased the significant safety improvements that RSC technology

can offer upon implementation.

“The project provided invaluable real-world data to support the NHVR’s engineering capabilities and initiatives, inform modern regulatory practices, drive development of the PBS scheme and contribute towards a safer future for all

road users,” the NHVR said.

“The successful trial marks a landmark achievement in heavy vehicle engineering and safety, demonstrating the game-changing benefits that RSC technology can provide to heavy vehicles.”

News

Image: National Heavy Vehicle Regulator. BUILT TO LAST Double action valving system in bump & rebound High Temp resistant hydraulic fluid Hydraulic lock-out piston for improved safety Single bonded bushing for improved durability With over 100 years of experience in every shock absorber, you know they’re built to last. monroe.com.au

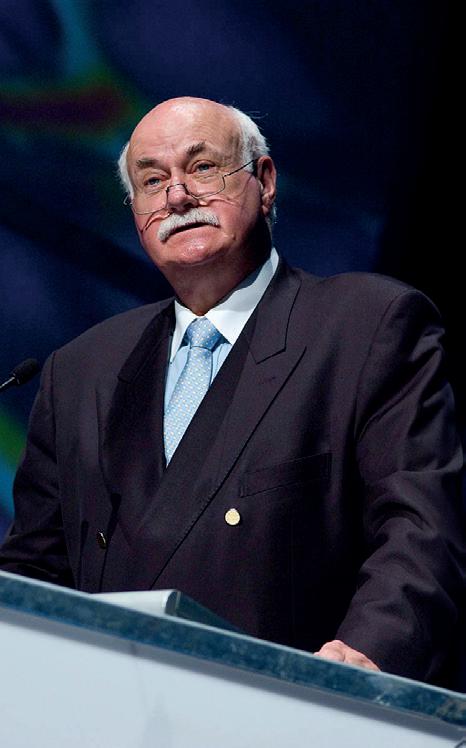

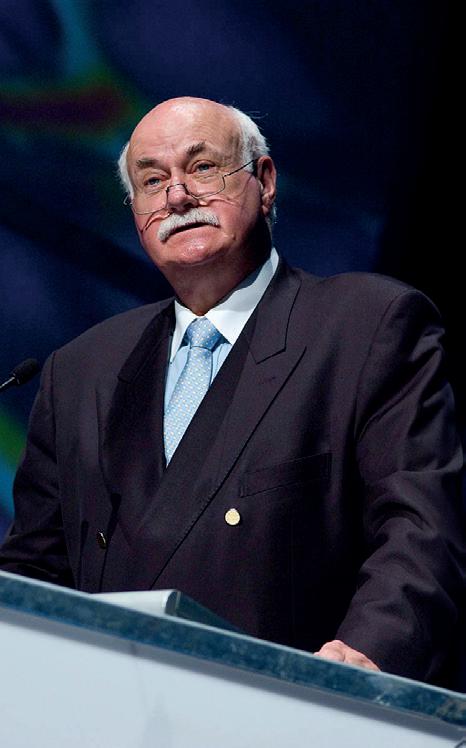

Vale Trevor Martyn

Former Victorian Transport Association (VTA) President and FBT Transwest Managing Director, Trevor Martyn, has passed away.

Martyn had an outstanding career in the Australian transport industry where he made a number of selfless contributions for more than 50 years.

Initially, Martyn was the Managing Director of FBT Transwest for 38 years from 1969 to 2007. He was the lead negotiator in the takeover of Transwest Bulk Haulage to become FBT Transwest.

During that period, he also held positions on various association representative bodies.

Martyn was Chairman of the National Bulk Tanker Association (NBTA) which achieved many industry safety initiatives in road and workplace safety, and his company was also an integral part of the Victorian Waste Management Association.

acknowledges a great leader, a fine gentleman and a doyen of our industry,” he said.

“Our thoughts and condolences are with Judy, daughters Miranda and Sally and all of the Martyn family.”

In 2018, Martyn was presented with a Medal of the Order of Australia in the General Division of the Queen’s Birthday Honour’s List.

At the time, Anderson said he couldn’t think of “anyone worthier and more deserving” of the Medal than Martyn.

Away from the industry, Martyn was active in numerous organisations and charities.

He was a member of Rotary International for 35 years and a past President of three Rotary Clubs, and he was also the Chairman of the Mayflower Brighton Aged Care Homes.

From 1998 to 2005, Martyn served on the VTA Executive Council which included his position as President from 2002.

During his term as President, Martyn oversaw the VTA develop many unique activities such as the Young Executive Program, the Freight Congress and Awards night and the Victoria President’s Dinner which is now into its 22nd year.

VTA CEO, Peter Anderson, said Martyn was widely regarded as a true leader in all parts of the transport industry due to his commitment, time and effort.

“The Victorian Transport Association

In addition, Martyn was passionate about the issue of mental health. He supported The Haven Foundation which raises funds and provides permanent, affordable and integrated housing for people with mental illness.

At NBTA Bulk Tanker Day last month, FBT Transwest Managing Director, Cameron Dunn, took the time during his speech to commend Martyn for his contributions.

“I just wanted to give my condolences to the family of Trevor Martyn,” he said.

“Trevor was certainly an icon of our industry. He was the Managing Director of FBT Transwest, the Chair of the NBTA,

“He will be sorely missed, but he will always be remembered.”

Heavy Hydraulics’ experienced team can provide you with the best solutions using quality hydraulic components for trucking applications.

With five state-of-the-art, purpose based facilities across Australia – with capabilities of supporting remote teams – Heavy Hydraulics are the perfect solution when you need help with your truck’s hydraulic system, whether providing parts, customised design or service and repair – get in touch today!

We’re Heavy and we’re here to

help.

President of the VTA and President of the Australian Trucking Association (ATA).

Trevor Martyn. Image: Australian Trucking Association.

President of the VTA and President of the Australian Trucking Association (ATA).

Trevor Martyn. Image: Australian Trucking Association.

1800 022 831 • Adelaide • Brisbane • Melbourne • Perth • Sydney

NHVR begins heavy vehicle compliance in Queensland

The National Heavy Vehicle Regulator (NHVR) has assumed responsibility for the delivery of heavy vehicle on-road compliance and enforcement services in Queensland.

Queensland Minister for Transport and Main Roads, Bart Mellish, said the transition of services in Queensland promises a streamlined approach to regulation across Australia.

“The Department of Transport and Main Roads (TMR) has been working closely with the NHVR to ensure a seamless transition of heavy vehicle regulatory services, to establish a safer road network in Queensland,” he said.

“This marks the end of a significant reform program, and is a step forward for industry, who now have a single point of interaction for consistent information about the Heavy Vehicle National Law (HVNL) and any issues they face as drivers or businesses.

“We look forward to the productivity

and safety benefits of having a single regulator for the heavy vehicle industry, with Queensland the final participating jurisdiction to transfer these regulatory services to the NHVR.”

By having a borderless operating model, Mellish said the NHVR will be able to address the greatest risks on roads, improving safety for everyone.

According to NHVR CEO, Sal Petroccitto, the integration simplifies compliance for drivers by providing a more unified approach to heavy vehicle regulation, in addition to strengthening Australia’s position as a leader in transport, safety and innovation.

“By taking the wheel in the ‘Sunshine State’, the NHVR will provide nationally consistent education and enforcement across participating jurisdictions and will undertake more complex Chain of Responsibility and primary duty investigations into duty holders across the

supply chain,” he said.

“The Queensland transition is a pivotal moment in Australia’s transport landscape, and by centralising regulatory functions under one authority, we can accelerate regulatory compliance harmonisation across state borders, and drive a safer, more efficient heavy vehicle industry.”

Petroccitto said there will also be a renewed on-road presence of NHVR safety and compliance officers across Queensland, particularly in regional and remote areas.

“Our new operations head office is located in Townsville, expanding our reach and enabling us to boost compliance and improve road safety outcomes in North Queensland,” he said.

“The NHVR’s on-road officers have authority to stop heavy vehicles and check compliance against the HVNL, and importantly, provide information and education to industry where it’s needed.”

Image: Zstock/stock.adobe.com. 14 Trailer Magazine JUNE 2024 News

Revolutionise your transport operations with Lucidity Australia's OMP system, the ultimate solution for streamlined electrical connectivity in the transport industry. Say goodbye to time consuming installations and hello to effortless plug-and-play technology, designed to meet the diverse needs of truck drivers, fleet owners, and manufacturers alike.

Scan me!

0392194074 sales@lucidity-au.com www.lucidityaustralia.com.au

hydreco-hydraulics Sydney 02 9838 6800 MORE INFORMATION Perth 08 9377 2211 1300 HYDRECO CALL NOW! ELEVATE YOUR PRODUCTIVITY TO NEW HEIGHTS: DISCOVER OUR RANGE OF CYLINDERS AND TELESCOPIC HOISTS TODAY

www.hydreco.com

Two Silver City Highway rest areas in NSW upgraded

Two rest areas on the Silver City Highway in New South Wales have received major upgrades for the convenience of freight operators and motorists.

Work on upgrades at the Curlwaa rest area, about four kilometres west of Wentworth, and the Seven Trees rest area, 82 kilometres north of Wentworth, started in December last year and have now been completed.

Transport for NSW Regional Director West, Alistair Lunn, said the upgrades would make trips on the Silver City Highway safer and more comfortable for the many freight operators that travel the road each day.

“Both rest areas provide access for both heavy and light vehicle travelling in both directions and are delivering great bang for our buck,” he said.

“Crews have been working hard since December 2023 to replace the single waterless composting toilets at each site with two new flushing toilets for each rest area, complete with disabled access.

“Previously there was no lighting at either site so these upgrades also include the installation of solar-powered lighting for the toilet block and surrounds to improve safety for all users, along with new picnic shelters for motorists looking to take a short break from what can be very long trips in this part of the state.

“The rest areas have remained open during construction with temporary toilet facilities brought in for motorists’ convenience, but we know all drivers who use this section of the Silver City Highway are looking forward to the completion of this work.”

Transport for NSW has carried out the upgrades at Curlwaa and Seven Trees rest areas with $850,000 in funding through the Heavy Vehicle Rest Stop Improvement Program.

www.trailermag.com.au 17

Image: Scott Donkin/stock.adobe.com.

Metcash acquisition likely to proceed unhindered

Wholesale distribution company, Metcash, is set to make a ‘Superior’ purchase.

Metcash’s proposed acquisition of SFG Group Holdings, which trades as Superior Food Services, has not been opposed by the Australian Competition & Consumer Commission (ACCC).

Where Superior distributes to food service businesses (restaurants, convenience stores and hospitals), Metcash supplies grocery and fresh foods to independent supermarkets and retailers. Metcash also operates Campbells which also wholesales food and food adjacent products to retailers.

“We conducted extensive market inquiries with customers, suppliers, competitors and industry

In addition to its proposed strategic acquisition of Superior for an estimated value of $412.3 million, Metcash also plans to purchase Bianco Construction Supplies (a construction and industrial supplies business that services the South Australia and Northern Territory trade market) and Alpine Truss (a frame and truss operator in Australia).

“We are delighted to announce three strategically aligned, synergistic and financially compelling acquisitions that accelerate our growth strategy,” said Metcash Group CEO, Doug Jones.

“The acquisitions unlock substantial shareholder value and build on our track record of disciplined and accretive capital allocation. They also deliver further

procurement savings, range expansion and extends our purpose of championing successful independents.

“Food distribution to independents is a business we know well. This, together with our proven integration track record, provides confidence in our ability to unlock value through the immediate scale that this acquisition provides in such a high-growth and fragmented space.”

Superior Food founder and CEO, Craig Phillips, said: “Superior Food has achieved significant growth, evolving into a national foodservice provider of scale with the loyal support of our staff, customers and suppliers. Metcash’s capabilities and focus on supporting independents uniquely places them to continue our growth. We

News

Boral announces Booyal Quarries acquisition

Construction materials company, Boral, has acquired Booyal Quarries in Queensland.

The strategic acquisition will provide security of supply to Boral’s Wide BayBurnett customers and integrated network, including asphalt and concrete plants at Hervey Bay, Bundaberg and Maryborough.

It will also see the continued employment of skilled workers at Booyal as they transfer to Boral.

Boral Executive General Manager, Concrete & Quarries North, Paul Noakes, said the acquisition will provide the company with a competitively strong quarry position to meet the infrastructure and development needs of the rapidly growing region.

“The strategic acquisition of Booyal Quarries in Queensland will underpin Boral’s ongoing commitment to servicing to the high-growth Wide Bay region,” he said.

“Booyal Quarries will play a crucial role in providing quarry materials to Boral’s local downstream asphalt and concrete operations to supply construction materials for the region’s robust infrastructure and development pipeline.

“Importantly, we look forward to welcoming Booyal Quarries’ staff who will continue their employment as part of the Boral team.”

The 75-hectare hard rock quarry is located

60km southwest of Bundaberg in the Wide Bay-Burnett region.

Noakes said Booyal Quarries is a highquality and well-established business in the region which, with significant quarry rock reserves, provides security of supply to Boral’s local operations.

“The hard rock quarry currently supplies a full range of products including Transport

and Main Roads certified aggregates and road bases,” he said.

Booyal Quarries’ employees were welcomed to the Boral team on 1 May with activities on site, including a BBQ breakfast hosted by the company and a visit from Noakes and Boral Executive General Manager, People and Culture, Sam Toppenberg.

Delta delivers 100% integrity, finished within a 1000th of an inch. 177-199 Stoney Rise Rd Devonport, Tas 7310 | Phone: 03 6420 6900 Fax: 03 6424 6983 | Email: jfwhite@delhyd.com.au Australian engineered, Australian precision

an 7310 engineered, precision

Image: Postmodern Studio/stock.adobe.com.

NTRO releasing free data sets to improve road safety

As part of its commitment to National Road Safety Week, the National Transport Research Organisation (NTRO) made its Road Safety Intelligence Toolkit (RSIT) available to all local governments throughout Australia, free of charge.

RSIT is a data-driven solution the NTRO has developed for the benefit of the Australian community that relies on data supplied by transport agencies across Australia.

It can analyse how dangerous a road is as well as how roads compare to each other in terms of safety.

It also breaks crashes down by location, gender, age and a range of other demographics.

The toolkit will be available to all local

governments until 30 June 2024.

“We want Councils and local communities to see for themselves exactly how safe their roads are, how they compare to other local government authorities, and where the improvements need to be made on their road networks,” a NTRO spokesperson said.

“We hope that by making RSIT available on a free trial to Councils, that it can kickstart the change towards using better data and innovation to create safer roads.”

Formerly known as the Australian Road Research Board (ARRB), NTRO has the tools and skills necessary to analyse and understand the impacts of the road safety data to give effect to positive changes on roads.

“We are able to advise road managers where they should prioritise their investment to save lives, and who is most at risk, and where,” the spokesperson said.

According to NTRO, innovative and datadriven solutions can help shape a new future free of fatalities across Australia’s road networks.

“Lives are lost and irrevocably changed every single day on Australia’s roads,” the spokesperson said.

“People make what should be a routine journey to work, school, or the shops, but don’t make it home safely to their families and loved ones.

“Data and innovation can save lives on our roads. The tools are there. It’s time to start using them.”

News

20 Trailer Magazine JUNE 2024

The National Heavy Vehicle Regulator (NHVR) has released its Removing Roadblocks to Reform paper, calling for swift reform of the Performance-Based Standards (PBS) scheme.

NHVR Chief Safety and Productivity Officer, David Hourigan, said the paper calls on industry and governments to work alongside the regulator to create positive change for the road transport sector.

“The Removing Roadblocks to Reform paper outlines how we can work hand-inhand with our partners to remove barriers to the productivity potential of the heavy vehicle industry,” he said.

“This will help us accelerate the transition to a younger and less polluting heavy vehicle fleet, and most importantly, save lives.

NHVR calls for fast reform of the PBS scheme SEKO Logistics appoints APAC President

An established leader with a diverse international logistics background has been promoted.

SEKO Logistics Managing Director, Paul Good, has accepted the role of APAC President, effective immediately.

From his role as Managing Director, Good comes equipped with expertise and knowledge which has enabled him to successfully navigate challenging marketing conditions throughout his career. His experience that he acquired through his time at organisations like Agility and Kuehne + Nagel and proficiency in P&L management has led him to achieve

“Right now in Australia, the safest, most productive, and lower emission heavy vehicles face more barriers to get on the road than a standard ‘prescriptive’ heavy vehicle, and as a result, we are seeing higher emissions, loss of productivity benefits and most concerningly, more fatalities.”

According to Hourigan, the PBS scheme needs to be modernised which will require the Heavy Vehicle National Law (HVNL) to be changed.

“We seek to work with government and industry to reset the PBS scheme’s policy settings and update the PBS standards,” he said.

Hourigan said that while the PBS scheme had proven to be popular, it was initially designed to act as a pathway for innovative

designs and technologies to be safely developed and deployed.

According to Hourigan, it is now failing to operate as originally intended.

“Rather than allowing for new truck designs, it is dominated by more or less of the same vehicles,” he said.

“Of more than 20,000 PBS combinations on Australia’s roads, almost half consist of one vehicle type – the truck and dog combination.”

Through the Removing Roadblocks to Reform paper, the NHVR is calling for amendments to the HVNL to allow for mature and proven PBS vehicles to transition to the prescriptive vehicle fleet.

The NHVR will reportedly continue to engage with industry and government to seek commitment to enact positive change.

substantial revenue growth and improved profitability across Australia and South Asia.

As APAC President he will assume all regional leadership responsibilities while also maintaining his role as Managing Director.

SEKO Logistics APAC President, Paul Good.

To bring further stability and to extend his strategic direction, Good’s time will be split between his home base in Australia as well as Hong Kong in order to achieve maximum impact on the region.

“I’m delighted to be taking on this new role and I look forward to working with

the Asian country organisations to ensure SEKO remains a significant contributor and enabler to the broader SEKO network,” said Good.

President and CEO, James Gagne, welcomed the promotion.

“I’m incredibly grateful for the opportunity to work alongside our APAC team during this transition period. It has been an absolute pleasure to collaborate with such a dedicated team,” said Gagne.

“Under Paul’s leadership, our APAC region will continue to treat challenges as opportunities, enhance optimisation, to thrive and achieve new milestones.”

Image: beeboys/stock.adobe.com. Image: Martin/stock.adobe.com. www.trailermag.com.au 21

The Environmentally Sustainable Procurement Policy (ESPP), which will take effect next month from 1 July, aims to ensure that government officials purchase goods and services that are environmentally friendly, reducing greenhouse gas emissions and promoting sustainability. That being said, the ESPP will guide the Australian Government in purchasing products that minimise greenhouse gas emissions to ensure they are safe for the environment and last longer.

Engineers Australia CEO, Romilly Madew, said the scale of these procurements presents a unique opportunity to make a substantial impact on Australia’s sustainability and net zero ambitions.

“Sustainable procurement isn’t just about buying products; it’s about shaping markets, driving innovation and creating jobs,” she said.

“Prioritising sustainable products and services will help drive demand for new technologies, materials and processes that are environmentally friendly, socially responsible, and economically viable.”

The Circular Economy Ministerial Advisory Group (CEMAG) Interim Report offers crucial direction for Australia’s shift towards a circular economy, with a strong emphasis on enhancing materials efficiency, reducing energy demand, minimising waste and achieving net-zero emissions.

It outlines 20 recommendations including priority suggestions such as establishing

circular economy provisions in sector plans, setting circularity requirements to fill regulatory gaps, leveraging government procurement power to create circular markets and promoting voluntary sustainability reporting aligned with international standards.

Madew said Engineers Australia supports the call for urgent regulatory reform and coordinated action outlined in the Interim Report’s preliminary recommendations.

“We advocate for regulatory frameworks that foster circularity, addressing priority issues like strategic policy setting and economic leverage for circular markets,” she said.

“Engineers will play an increasingly critical role in transitioning to a circular

economy by implementing principles that promote materials efficiency, reduced energy demand, waste minimisation, and achieving net zero emissions.

“We commend the government’s commitment to environmentally responsible practices and look forward to seeing the positive outcomes of this work.”

According to Madew, both initiatives will also look to create ‘tangible benefits’ for everyday Australians.

“By transitioning to a circular economy and environmentally sustainable procurement, we are safeguarding our planet for future generations while driving economic prosperity for everyone,” she said.

22 Trailer Magazine JUNE 2024

0 -2 -4 -6 -8 May Jan Sep Nov Mar Jul

CONFIDENCE

AUSTRALIAN CONSUMER

vawdrey.com.au Proudly & 9 – 20 “

Scully RSV has been manufacturing rigid bodies and refrigerated vehicles for more than 30 years. Working with industry leading OEMs and utilising customer feedback throughout this time, it has refined its processes over and over to make them best suited for Australian conditions and its unique operating conditions.

Because of this relentless dedication, Scully RSV has truly become a partner of choice for refrigerated and rigid fleet solutions, says Scully RSV CEO, Andrew McKenzie.

“Something that we really pride ourselves on is our ability to be able to work with, customise, develop and deliver a wholeof-life solution for customers,” he says. “We don’t just take a standard product and try to rent it to people, we do offer them the full package.

“Whatever their issues are, we don’t say no. There are always ways that we can help people and try to add value to their businesses. So, as an Australian designer and manufacturer, we’ve got unlimited capacity to be able to fully customise the product that we offer.”

To achieve this, Scully RSV takes

advantage of its coast-to-coast network of branches, top-tier engineering resources and locally sourced materials such as Australian body panels, while collaborating with its customers and their customers through the production process.

“It’s really a 360-degree tripartite arrangement where we look at the problem we’re trying to solve, the new technologies we can use and what solutions are out there that we might be able to help them with,” Andrew says. “Be it efficiency or safety, there’s lots of different elements to look at and to consider.”

Scully RSV’s refrigerated bodies and vehicles are heavily featured across several industries such as the logistics, dairy, meat and food sectors, and can be manufactured either to custom or standard fleet specifications. According to Andrew this means the options are endless for Scully RSV manufacturing, no matter the application.

“We just built some trucks that had more side doors than they had walls,” Andrew says. “They also had steps which could all fold out, allowing the customer to have 270-degree access to the vehicle.

“We’ve got a bunch of really heavy-duty meat hangers going through the factory at the moment for hung meat off the roof as well. They’ve got steps that integrate into the floor of the truck, and there’s also stairs up into the body of the truck which seal off and create a thermal barrier. There are lots of cool things we do that sit alongside our standard product range which we put into our fleet, and ones that customers still buy as well.”

The key to getting to this point, Andrew says, has been through constant innovation and adaptation.

“We’ve tried, we’ve failed and we’ve improved every day over the past 30 years,” he says. “There’s not a day that goes by where we don’t look back at history and say, ‘We tried that once, we did that once, that did work but if we did it again this is how we’d change it and this is how we’d do it.’ With the meat hangers that we’re doing today, we’ve taken what we have done historically and we’ve developed and evolved the product, taking into account the feedback from our customers that have bought meat hangers from us previously.”

With every truck, body and integration

24 Trailer Magazine JUNE 2024

being different, Scully RSV’s ability to engineer and design bespoke solutions to suit any truck in any configuration is critical. Because of this, its business model also has great flexibility. Scully RSV can work with any chassis, and as Andrew explains, customers often bring in their own chassis for Scully RSV to source their requirements and build to their specifications.

“We offer the best of both worlds,” he says. “Customers can come to us and buy a truck, trailer or fridge as an integrated solution. They can pick their truck or fridge brand and we will build that for them and hand it to them as a completed final product offering. For other customers that want to source their own product, we work in with them and their chosen OEM for an integrated solution in that aspect as well.”

In its latest project for one of its longterm customers, Scully RSV built a custom rigid body for a Hino Hybrid Electric truck. The process itself, which saw it collaborate with the OEM’s engineering

team throughout the fabrication process, is just one example of the ways Scully RSV can cater directly to the end user’s requirements.

Due to these vast manufacturing abilities, Scully RSV, according to Andrew, has recently seen a surge in demand for custom manufacturing for a range of customer types. It’s now building at “near record volumes” which are expected to grow further as Scully RSV pushes towards a total rigid body output of 60 units a month at its new 12,000-squaremetre Rocklea, Queensland, facility.

“Our ability to be able to turn bespoke solutions around in six to eight weeks continues to be a big reason why we’re incredibly popular in the marketplace and

why we continue to receive orders faster than we can ramp up and build them,” he says. “We continue to locally look for the best available talent, and having local on-the-ground experience in Brisbane, Melbourne, Sydney and Perth means that we are able to tap into those local markets to understand the local requirements.

“Along with local service, what’s most important to us is our commitment to our customers and that we are supporting them through their business cycles with the right solution.”

Contact

Scully RSV

Ph: 1800 728 559

Web: www.scullyrsv.com.au

www.trailermag.com.au 25

Ten new Vawdrey Performance-Based Standards Super B-doubles with BPW Transpec axles and suspensions will look to increase productivity levels within Centurion’s east coast shuttle network.

The fleet of national transport and logistics company, Centurion, is entering a new phase of higher productivity with the help of two widely recognised industry OEMs. 10 specifically designed PerformanceBased Standards (PBS) Super B-double drop deck combinations from Vawdrey, featuring axles and suspensions setups from BPW Transpec, are the main ingredients to the recipe.

The B-double sets, featuring mezzanine decks throughout and lightweight composite gates, are made up of two double drop deck trailers which offer significantly higher carrying capacities. Each combination measures in at 30m in length and 4.6m in height, and the

B-doubles are also Dangerous Goods (DG) compliant.

Centurion’s choice of suspension for the B-doubles was BPW Transpec’s self-tracking steerable axles. The fleet spec’d two steerable axles on all of the lead trailers as well as one steerable axle on all of the end trailers in their rear axle groups.

“They’re all identical PBS combinations that are designed for use on our east coast shuttle network,” says Centurion Executive General Manager – Operational Services, Khali Lake, who explains the trailers will travel extensively across the eastern seaboard including to all of Centurion’s regional depots such as

Townsville and Mackay in Queensland carrying a mix of specialty and general freight. “They are all sitting on the same PBS approvals. They’re a higher productivity vehicle, so we’re looking to effectively carry more freight on that lane per driver.”

The combinations, Khali says, will enable Centurion to increase efficiency for its customers Australia-wide. With higher payload and cubic capacities per combination, the Super B-doubles can carry more freight per vehicle meaning the fleet can also reduce the number of trucks it puts on the road.

With eight of the 10 sets now in the fleet, Khali says Centurion has achieved

26 Trailer Magazine JUNE 2024

productivity gains of about 35 per cent.

“They’ve all got brand new Daimler trucks in front of them as well which are highly efficient with low fuel burn, exceptional safety systems and driver amenities,” he says. “From a footprint perspective, we’re just trying to do more with less. Resources are limited and the price of operating costs are increasing, so we just want to make sure that we’re as efficient as we can be on our lanes.”

Vawdrey, Khali says, was chosen for this particular application due to its expertise and high-quality product. The Super B-double, he explains, was a proven concept that resided well with what Centurion was trying to achieve.

“Vawdrey is really a one-stop shop for us,” he says. “We can basically go there with a concept and they’ve got everything in-house to design the trailer, source the approvals and work with the regulator on our behalf.”

The reasoning behind the decision to spec BPW Transpec on these units, Khali says, was very similar.

“We’re of the opinion that BPW Transpec’s steerable axle in particular is the best,” he says. “I think that is wellproven not only in road-going performance but also with lifetime cost of assets,

maintenance costs and warranty support.”

Having over 12 years of experience with BPW Transpec products himself, Khali is very confident about how the steerable axles will perform on the B-doubles.

“As the history would suggest, I expect the BPW Transpec components to be low maintenance,” he says. “They will perform exactly the same every time. Both the mechanical components and the braking components should not give us any grief.

“They’re a stable platform. The steering mechanism in itself and the simplicity of it is the brilliance of BPW Transpec’s engineering. That simplicity translates to effectiveness, so I’m expecting our drivers in particular to notice a big difference between the steering and the manoeuvrability of those combinations, given that they’re 30 metres long compared to a traditional B-double. I think these units look big but they’ll go places that I don’t think the drivers will expect them to go initially.”

Over the past 15 years, Centurion has typically picked BPW Transpec axles and suspensions for condition-specific tasks like heavy-duty or off-road applications where a lot of weight or harsh environment is involved. This has been seen especially in Centurion’s heavy haulage business

which transitioned the fleet’s suspension to BPW Transpec equipment.

For these specific requirements, Centurion also leans on BPW Transpec’s technical team to come up with different concepts. The cooperative arrangement means BPW Transpec can fulfil Centurion’s exact requirements with direct technical support.

“BPW Transpec has really good parts and technical support in the country,” Khali says. “They have got a very good staffing base and they have people on hand when you need them as well.

“When conditions are expected to be tougher than normal, we will typically spec BPW Transpec exclusively – for example with our desert fleet or our heavy haulage business where we’re looking at really specific applications. So, if we’re keeping an asset for a long period of time, we’ll find that although the upfront price of BPW Transpec will be higher, the life of asset costs is significantly lower. That’s the long-term benefit of using BPW Transpec.”

Contact BPW Transpec Ph: 03 9267 2444 Web: www.bpwtranspec.com.au

www.trailermag.com.au 27

Lift off

Hydreco Hydraulics, a renowned specialist in the design and production of hydraulics and lifting equipment, is celebrating its 65th anniversary.

Hydreco Hydraulics started out in 1959 under the identity of Powauto, manufacturing a limited range of Power Take-Off (PTO) units and pumps in Gladesville, New South Wales. The business was developed by Australian company, EG Bishop, in an effort to bring quality PTOs and pumps to the Australian truck market. Over the last 65 years, it has delivered these solutions and much more.

While undergoing several name changes and business restructures during its time, Hydreco has continued to grow by expanding on what it can offer to its customers.

“From making just PTOs and pumps, the next step was to begin offering tipping valves in the early 1960s,” says Hydreco Hydraulics Product Manager, Geoff Ross.

Further to this, the business’ acquisition of LM Hydraulics in 1985 would bring telescopic cylinders to the Hydreco portfolio, and the purchase of Thomas Winch the following year would see hydraulic winches for 4WDs and tow trucks join the mix.

“Since then, there have been incremental changes,” Geoff says. “We’ve aligned ourselves with quality manufacturers

with good reputations to fill the gaps in our range.”

Geoff says there have been many technological advancements since Hydreco’s establishment in terms of manufacturing processes and the materials used, which have led to better equipment, higher efficiencies and increased pressure capabilities.

“In 1959, valves and PTOs were operated by a manual cable until they changed to using the truck’s air system,” he says. “We’ve since gone to electro-pneumatic action, where you push buttons and switches to operate the PTO.

“The PTOs used to be manufactured to an American standard as well, so we were making a limited number of them and using adaptors to fit to the different transmissions. Now, we manufacture individual PTOs to suit the different gearboxes.”

As the demand and quantity of Hydreco’s PTOs grew, the business was able to diversify the type of products it was creating. Hydreco began constructing a wider range of PTOs to suit various applications while it also continued to build its other offerings from the ground up to

include hoists, hydraulic tanks, piston pumps, controls, mobile hydraulic valves and much more.

Despite the various changes over the last six-and-a-half decades, one thing remains the same at Hydreco –its commitment to local engineering in Australia.

“We engineer everything here in Australia,” Geoff says. “We’re doing things on an Australian scale rather than a worldwide scale, so our response times are quicker. It also means our products are better suited to operators here because they’ve been engineered to Australian conditions.

“With our 65-year history, we’re known in the industry as the Australian PTO people. So, we have that reputation that we want to maintain and build upon. We also consider ourselves a global hydraulic and PTO player, as we are sell into and are represented in every continent in the world.”

Contact Hydreco Hydraulics

Ph: 02 9838 6882

Web: www.hydreco.com

28 Trailer Magazine JUNE 2024 Lifting equipment

Image: Hydreco Hydraulics.

Skel trailers

Evolution side tippers

Road train dollies

trailers side tippers train dollies

Flat tops, drop decks

Deck wideners and extendables

End tippers, bulk and TaREX quarry bodies

Coldcore refrigerated and dry vans

Etnyre live bottom trailers

Flat tops, drop and extendables End TaREX quarry

Coldcore dry vans Etnyre

walking floor and belly dumper trailers

floor dumper trailers

super quad & super triple

OUR EXTENDED RANGE INCLUDES: With nationwide sales and support. For more information email sales@brucerockengineering.com.au or call us on 1300 611 253 BRUCEROCKENGINEERING.COM.AU INDUSTRY LEADERS IN ROAD TRANSPORT EQUIPMENT, DESIGN, MANUFACTURE & MAINTENANCE

Titan

PBS specials:

Titan

PBS specials:

RANGE information email on 1300 611 253

triple

Brimarco’s ‘Tough As’ trailers are robust solutions that are designed to withstand the toughest conditions of Australia’s transport and agriculture industries.

Throughout Australia’s vast and varied landscapes, where agriculture shapes the horizon, the strength of a farm’s operation often hinges on the quality of its tools. With a heritage of more than 45 years, and having several variations of dependable and rugged equipment, Brimarco is an established key manufacturer and supplier in this field.

Brimarco has carved a niche by crafting some of the country’s toughest trailers. The ‘Tough As’ range stands as a testament to this, tailored not just for durability but also for the specific needs of the farming community.

Brimarco General Manager, Adam Quick, says Brimarco’s trailers are distinguished by their exceptional strength and stability, featuring a low-profile build to accommodate higher loads. Moreover, these durable Australian-built trailers hydraulically widen to accommodate larger machinery, making them uniquely suited to the diverse demands of Australian agriculture.

“Brimarco’s commitment to custom solutions allows every farmer to find a trailer that fits their unique requirements, from carrying heavy harvest machinery

to maximising payloads of hay,” he says. “The ingenuity of Brimarco’s designs shines through in its low-height tri and quad-design wideners.”

These trailers are not merely tough –they are smartly designed to transport a broad spectrum of agricultural machinery safely and legally across Australia’s diverse lands.

“Such functionality is crucial as it directly addresses the farmers’ ongoing challenge of adhering to ever-tightening transport compliance requirements,” Adam says. “And for Brimarco, compliance is more than a checkbox. It’s a commitment to farmer welfare and industry standards.”

Brimarco plans to take this commitment to the next level in the coming months through structured industry engagement with the Victorian Farmer’s Federation.

This participation will highlight the importance of transport compliance and assist with making farms safer.

In recognition of its 45-year milestone, Brimarco is also launching a ‘Heritage’ special offer designed around its Heavy Duty ‘Tough As’ tri-axle 3.5-metre Widener semi-trailer. This offer is a testament to Brimarco’s enduring legacy

and gratitude towards its clientele in the agricultural sector, enhancing the trailers’ already robust specifications.

Brimarco’s anniversary offer includes a Bisalloy flooring upgrade, an extra toolbox, premium finishes, a SAF-Holland suspension upgrade, a limited edition Brimarco ‘Heritage’ plate, Haulmax Tyres premium tyres and wheels (including free of charge access to the Haulmax Wingman 24/7 tyre support program) and an extended five-year structural warranty.

As Brimarco commemorates its 45-year milestone with the ‘Heritage’ special offer, it celebrates a legacy of excellence and reinforces its role as an indispensable ally in the agricultural sector.

“Looking to the future”, Adam says, “Brimarco is committed to further strengthening its offerings, integrating cutting-edge technologies and innovative designs to meet evolving industry standards, and continuing to support Australia’s agricultural sector as it moves forward.”

Contact Brimarco

Ph: 0409 409 576

Web: www.brimarco.com.au

30 Trailer Magazine JUNE 2024

Rentco, the first Australian Rental Fleet to bring to market the R/H Drive fully electric terminal tractor, the long awaited Terberg TY200-EV.

After testing the first 12 units to be delivered into Australia we are very happy with the results and these have proven to be the most comfortable carbon free emission option we can deliver to market.

The first four units were delivered in July of this year and have been tested by some of the counties largest freight companies in some of the busiest depots we have in Australia, with another 4 arriving this year and the remaining 4 will be delivered in Feb 2024. These 12 full electric terminal tractors will bolster what is already the largest terminal tractor fleet in the country.

Rentco takes its responsibility to a more sustainable future and reducing carbon emissions very seriously and is leading the way by delivering a ready to go true 100% electric terminal tractor to Australia’s transport industry.

For Terberg Rental enquiries, contact Paul Scott: Tel: 0407 456 463 Email: paul.scott@rentco.com.au Web: www.rentco.com.au

As Vawdrey celebrates half a century of manufacturing in the Australian transport industry, it envisions a prosperous future of further success and growth ahead.

On 27 September 1974, Vawdrey’s story began. It was when Mick Vawdrey first opened a business in Braeside, Victoria, a move that would change the game forever.

In his early working life, Mick was a plumber by day and a tow truck driver by night. He worked both jobs to generate an income until, at the age of 24, he was involved in a car accident which left him a paraplegic.

Six months later, after leaving the hospital and returning to work, Mick, with a characteristic restlessness and a fiveyear-old son to support, decided to go out on his own and create his own truck body building business. Vawdrey was born. At the beginning, Mick would spend most of his days trying to sell his equipment, and at night he would build it. And, despite being wheelchair-bound from his accident, he found strength in what others might have perceived as a disadvantage. Mick would tell his son,

Paul, that the wheelchair was an asset to the company as it made him focus on growing the business rather than losing himself in the actual production process.

Now, as he proudly watches his son guide the company through the next generation of Australian transport, it’s clear that he was right.

That being said, Mick is still very much involved in Vawdrey’s production process.

The founder continues to check every trailer combination before it leaves the yard to ensure customers are receiving the same renowned quality since he opened the business’ doors 50 years ago.

Ultimately, Mick’s true contribution to the industry lies in his commitment to people – a commitment that he passed on to his son who shares the same view.

“Everyone here has a sense of ownership for the brand and the product, and that is arguably Mick’s greatest achievement,” Paul says. “Along the way, he has ‘adopted’ so many talented

people who are now seen as part of the extended family. The loyalty people have to Mick and the company is quite special in a time like today. For Mick, Vawdrey would be nothing without his people.”

Since the early days, Vawdrey has gradually grown into one of Australia’s most prominent trailer builders while also managing to retain local manufacturing. It has become an institution of modern Australian trailer design and has paved the way for today’s revolutionary technology which is often taken for granted. Mick and his team, for example, pioneered the OH&S movement with the launch of an automatic mezzanine deck system and the development of an automatic, load-rated buckle-less curtain just over a decade ago.

Since 2012, Vawdrey also helped the Performance-Based Standards (PBS) scheme expand beyond the classic truck-and-dog segment and brought it to the general and refrigerated freight

32 Trailer Magazine JUNE 2024

market, effectively helping Australia’s road transport community cement its reputation as the most progressive in the world.

Vawdrey’s PBS journey began with the design of a Super B-double capable of hauling two 40’ containers at once, operating under strict PBS guidelines set out by Victoria’s traffic and road authority. It also rolled out a whole range of Super B-double combinations less than a year later based on the same concept, marking a major milestone in increased access for Higher Productivity Freight Vehicles (HPFV).

“Vawdrey understands the unique challenges Australian operators have to face and provides a wide range of solutions, and the company’s portfolio is constantly expanding,” Paul says. “As a specialist in the design and construction of PBS trailing equipment, backed by a solid repair and service network, Vawdrey has, time and time again, strengthened the transport capabilities of businesses to maximise payload gains and improve vehicle operator safety.”

Following the uptake in PBS-approved equipment, Vawdrey has brought several

other innovations to market as well, such as variations of the Wingliner which provides the security and load restraint benefits of a van with the flexibility of a curtain-sided trailer. On the other hand, Vawdrey’s buckle-less curtain system took load restraint to the next level by combining safety and efficiency. The load-rated curtain’s strength comes from carbon fibre straps that are connected to the roof of the trailer using a pivoting double roller system. A specially designed lower hook and tensioning system provides the tension required and flawless load restraint.

Above all else, Vawdrey provides a comprehensive product range including robust skeletal trailers that are designed to withstand heavy impact loading, Titeliner trailers, flat deck and drop deck semi-trailers, dry freight FRP vans, and, of course, its well-known Iceliner freezer trailer line. All of these trailer types are available in configurations from single applications to B-doubles, B-triples, road trains and A-doubles.

To bolster the diverse trailer portfolio, Vawdrey also adds value with innovative technologies such as the Auto Lock Deck

System which optimises deck handling safety and efficiency.

“We have built a reputation on our ability to custom build products to meet the exacting needs of our customers,” Paul says. “Our national presence continues to grow as we look after our local and international clientele. Demand from logistics businesses worldwide is on the rise for valuable safe and efficient trailing equipment branded with the Vawdrey name.”

As an integral player in the evolution of Australia’s semi-trailer building industry, Vawdrey stands unfazed with a lasting reputation based on quality, innovation and dedication. And, as the business enters the second half of a century, it’s already making strides. Looking ahead, Paul says Vawdrey is still in growth mode.

“We just bought a new facility across the road from our main plant in Dandenong South in Victoria that we’re going to be expanding on,” he says. “The state-of-theart facility will become our new service and repair warehouse, and it will be operational by the end of this year.”

Paul reveals Vawdrey’s previous service and repair warehouse will be transformed

Prime Creative Media. www.trailermag.com.au 33

Image:

into a new dedicated refrigerated trailer manufacturing plant. This, he says, will enable Vawdrey to grow its freezer trailer products while also increasing production output in its main factory.

“We’ve seen enormous growth over the last five years with temperature-controlled trailers and the refrigerated supply chain,” he says. “It’s been a massive growth area for our business, so we’ll be bringing in two more refrigerated trailer lines as well.”

Meanwhile, all of the factors which have allowed Vawdrey to become a dominant force will remain in place.

Paul says Vawdrey will continue to use Australian resources such as locally sourced steel and aluminium wherever it

can, while simultaneously making further advancements in the field of PBS.

“We will keep pushing the boundaries while continuing to focus on our customer service,” he says. “It’s an evolving industry, so we’re always learning things and changing things. We will continue to be the leaders in PBS by putting bigger trailers on the road which allow for a lot more freight to be carried.

“We are still in growth mode after 50 years, and we will continue to expand and increase our market share.”

Dyers Distribution is another Australian family business which has stood the test of time. The business, which celebrated its 90th anniversary in recent years, also has a rich and extensive history with Vawdrey which covers a significant portion of its existence.

Dyers Distribution was founded in 1932 by Leo Dyer in Sale, Eastern Victoria. Now under the leadership of Leo’s grandsons, David, Greg and Scott, the family business maintains its heritage as it approaches a 100-year milestone in the industry.

Dyers Distribution specialises in food logistics and also offers services for contract logistics, fast moving consumer goods distribution, warehousing, linehaul and 4PL. Having gained a plethora of experience since its inception, the family now prides itself on being an enduring service provider for road distribution across eastern Victoria.

For 35 years, Vawdrey has captivated Dyers Distribution. Holding an exceptional ability to manufacture high quality and lasting builds, Vawdrey, for the last quarter of a century, has also been Dyers

Distribution’s primary trailer supplier.

“Their build quality and attention to detail is without question the best,” says Dyers Distribution Director, David Dyer. The relationship between both successful businesses, David recalls, truly cemented in 2002. Dyers Distribution was awarded a new metropolitan distribution contract that required 50 trailers to be built in the span of just a few weeks, so David and his brothers turned to Mick and Paul for an immediate solution. Looking back, David says they weren’t let down, to say the least.

“It’s a great story,” he says. “It was a week before Christmas. We went in to Vawdrey and ordered the trailers on a handshake with Mick and Paul. But when we got back to our office, which is a two-hour drive, we worked out that we hadn’t made sufficient provisions for electric pallet jacks that would go on the back of the trailers. So, I rang Paul up and said to him, ‘We’ve mucked up some of the dimensions on the length, I’m just wondering whether we could change it?’ and he said, ‘I better go out and tell the guys in the workshop, they’ve already started cutting the rails.’

“By the time we got home, they had already commenced building six trailers. To not only provide that responsiveness but have faith in our organisation and be able to adhere to our timelines is remarkable. It was unfortunate that we had to change the length of the first six trailers, but we realised at that point that Vawdrey had our back 100 per cent. They were going to make sure that we met our deadlines, and we did.”

34 Trailer Magazine JUNE 2024

Dyers Distribution Director, David Dyer, and Vawdrey Director, Paul Vawdrey.

Images: Vawdrey.

The full order of trailers, consisting of a mixture of dry and refrigerated vans, were deployed for the metropolitan contract which Dyers Distribution still holds. In these operations, the fleet transports freight for some of Australia’s biggest food and supermarket giants along the eastern seaboard through Brisbane, Victoria and Adelaide, as well as in regional areas within a 400-kilometre radius of these cities.

On top of this, Dyers Distribution is heavily involved with interstate linehaul between Melbourne and Sydney, Melbourne and Brisbane and Melbourne and Adelaide.

Still powering the metropolitan contract to this day, David says, are the Vawdrey trailers purchased two decades ago.

“Some of those trailers are still being used on a daily basis 20 years later,” he says. “These vehicles have done 50,000 metropolitan loads and they’re

still operating in one of the most demanding tasks.”

Following the initial order, Dyers Distribution has accumulated a range of trailers from Vawdrey. The fleet is primarily made up of PBS units which David says have increased productivity significantly across the business due to the way they are constructed.

“Vawdrey is very innovative with their designs, so the trailers bring a lot of efficiency,” he says. “Above all else, they are reliable and dependable. Vawdrey will basically build anything we want, and that’s probably one of their biggest strengths. Most of our orders are PBS trailers, so they are custom built for specific combinations and routes in some cases.

“Their design and engineering team are first class. With vehicle design, most of the room for innovation is in the trailer. We’ve got absolute confidence in the

Vawdrey team that they are the best supplier to achieve that innovation, and in turn, efficiency.”

In hindsight, David believes it’s hard to come by businesses that can offer bespoke equipment, and, at the same time, have an incredible dedication to their customers. This, he says, is why Dyers Distribution was fortunate to find Vawdrey.

“There are very few businesses in life that show faith in their customers like Vawdrey does,” he says. “I believe their ability to make trailers and do it so well is unmatched. Every time a trailer turns up it is built exactly how we expect it and it’s ready to work.”

As a fellow family business in the industry, Dyers Distribution commends Vawdrey on what it has achieved.

“We’re very appreciative of everything they have done for us,” David says. “More importantly, it’s just fantastic to see such an incredible story of a family business that has really succeeded in such a tough market. Vawdrey is going from strength to strength and their range is increasing. They’re doing exceptionally well.

“We understand the amount of drive, passion and overall teamwork that is required to make what they have done happen, and we’re really proud to be close enough to them to witness it.”

Contact

Vawdrey Australia

1-53 Quantum Close Dandenong South, VIC 3175

Ph: 03 9797 3700

Web: www.vawdrey.com.au

www.trailermag.com.au 35

Paul and Mick Vawdrey.

WCS Concrete, based in Western Australia, is a family-owned and operated company which supplies concrete products and services to the Wheatbelt and surrounding areas in Western Australia. Under the leadership of Managing Director, Brendan Betty, the business, established by his parents in 1996, has gone from strength to strength. From having just the one location in Wongan Hills, it has in time expanded its reach with the creation of branches in Kellerberrin, Gingin and Toodyay.

“We now have four branches, accompanied by three mobile concrete batching plants operating throughout WA,” Brendan says. “We’ve also recently completed a new satellite tower at the New Norcia Deep Space Station, so things are going pretty well for us.”

At the start of 2019, WCS Concrete

was tasked with supplying concrete from its Kellerberrin plant to Bruce Rock Engineering’s (BRE) original home base in Bruce Rock. It was this project which introduced BRE to WCS Concrete, and at the time, it was also what made Brendan’s decision that his next set of trailers would come from BRE.

“We always said that when the time came to purchase a new set of trailers, they would be from BRE,” he says. “That was definitely one of the main factors that drove us to them. We were pretty happy with the product as well, as far as how it looked and how everything stacked up. We didn’t see any need to look elsewhere.”

Brendan fulfilled that pledge with the purchase of a new TaREX end tipper made up of a 9.5m lead trailer and 9.8m dog.

While the combination is still new to the fleet, Brendan says it’s had a great start so far.

“It’s been really good, we’re very happy with it,” he says. “It’s carting out raw materials from The Lakes, as well as the sand quarries which we draw from, to our Wongan Hills, Kellerberrin and Gingin plants. It’s faring very well and it’s doing the job to our expectations.”

Outside of these tasks, the unit also travels throughout the southwestern, northern and central areas of the Wheatbelt region to transport decorative stone.

With a tare weight of 17.5 tonnes, Brendan says the TaREX end tipper has increased productivity at WCS Concrete by improving the fleet’s efficiency and capacity to move raw materials around.

36 Trailer Magazine JUNE 2024

“The weight of it is one of the most important features to us, because we can carry extra load,” he says. “We were looking to increase our efficiency when carting product out to our plants, and it’s definitely helped. We’ve been able to cart more material from the quarries with less truck movements and less fatigue on the drivers.”

BRE’s end tippers are renowned for their high-quality and light tare weights. The chassis tippers are available in a range of different heights, lengths and capacities. According to BRE Sales Manager, Peter Oliver, the biggest benefit of the range, as proven with WCS Concrete, is payload capability.

“With the tare weight of the trailers

being so light, WCS Concrete is getting a really good payload out of them,” he says. “The reason the trailers are so light is because the chassis is made with high tensile steel. The tipper bowl on the trailer is 4mm Hardox as well, so there’s a lot less wear on the material itself.”

Other features on WCS Concrete’s TaREX end tipper include a dual swinging tailgate for its quarry applications, a Right Weigh scale system, and electric tarps which have also contribute to the increased productivity within WCS Concrete’s operations.

“We went with electric tarps to allow us to get in and out of quarries quicker,” Brendan says. “We were finding before that when drivers had to stop to unwind

the tarps manually, it was costing us around half an hour or so each time. With the electric tarps we avoid that because our drivers don’t have to get out of the truck to open them now.”

When it comes to using the TaREX end tipper in different sites, accessibility is another bonus for WCS Concrete – with the unit measuring under 27.5m in length.

The trailers are locally manufactured by BRE, and in addition, and are backed by customer support throughout the trailer builder’s several service points. Thus, if Brendan ever needs BRE, he says he can get a hold of the team at any time. This assurance has set him on BRE for the foreseeable future.

“We will definitely be dealing with BRE with any business that we do,” he says. “Peter Oliver has been exceptional to deal with. He’s been really good and has helped us throughout the whole process of getting the right combination and measurements. We’ve established a pretty strong relationship with him now, and because of that, we will move forward with BRE for any future purchases.”

Contact Bruce Rock Engineering 15 Swan Street WA 6418

Ph: 08 9061 1253

Web: www.brucerockengineering.com.au

www.trailermag.com.au 37

AAA Trailers has embarked on an ambitious journey to enhance the accessibility of its services for clients nationwide.

Over the past year, AAA Trailers has achieved a remarkable feat by opening several new branches in key locations across the continent, further bolstering its position as a top-tier trailer manufacturer committed to serving customers with excellence.

With branches now established in Sydney in New South Wales, Perth in Western Australia, Brisbane in Queensland, Melbourne in Victoria and Adelaide in South Australia, the company has effectively broadened its reach, making its products and services more readily available to businesses and operators across Australia.

According to AAA Trailers Director, Daniel Bull, the decision to expand into these diverse regions is a testament to AAA Trailers’ dedication to customer satisfaction and its understanding of the importance of proximity in delivering prompt and efficient service.

“The expansion of our presence signifies more than just the physical opening of new branches,” he says. “It represents a strategic commitment to meet the evolving needs of our clientele. By strategically locating branches in key urban centres and transport hubs, AAA

Trailers is positioning itself to better serve a wider spectrum of clients, from large logistics companies to independent truck operators.”

The opening of each new branch also represents a significant investment in infrastructure, resources and personnel for AAA Trailers.

“AAA Trailers’ commitment to quality extends beyond our products to every aspect of our operations, ensuring that customers receive not only top-of-the-line trailers but also unparalleled support and service at every touchpoint,” Daniel says.

Furthermore, the expansion initiative underscores AAA Trailers’ confidence in the resilience and growth potential of the Australian transport industry.

“By investing in expansion during a time of economic uncertainty, we are not only bolstering our own footprint but also contributing to the vitality of the nation’s economy, creating job opportunities and stimulating local economies in the process,” Daniel says.

Moreover, the expansion is a testament to AAA Trailers’ forward-thinking approach and adaptability in the face of changing market dynamics. By strategically positioning itself in multiple regions, the

company is better equipped to navigate shifting industry trends, regulatory landscapes and customer preferences – ensuring its continued relevance and success in the years to come.

“As AAA Trailers celebrates this significant milestone, we invite our customers, partners and stakeholders to join in commemorating this achievement,” Daniel says. “The expansion of accessibility across Australia is not merely a triumph for AAA Trailers but a testament to the collective efforts of all those who have supported our journey thus far.”

As the company continues to forge ahead on its path of excellence, it remains dedicated to serving its clientele with the utmost integrity, professionalism and innovation.

“With its expanded accessibility and unwavering dedication to excellence”, Daniel says, “AAA Trailers is poised to redefine the standards of excellence in the Australian transport industry for years to come.” Contact

Web:

AAA Trailers Ph: 1300 333 888

www.aaatrailers.com.au

38 Trailer Magazine JUNE 2024

YOUR DUMP BODIES

hardoxinmybody.com