® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE JUL Y 2023 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY ISSN 1838-2312 9 771838231003 06 JULY 2023 $10.00 INDUSTRY INNOVATORS NEWS WOMEN IN INDUSTRY WORLD MAP ECONOMY WEIGHING SYSTEMS RELIABLE NETWORKS End results that count

PUBLISHER

John Murphy

john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

ASSISTANT EDITOR

Peter White peter.white@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Tom Anderson

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher.

Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Officially endorsed by the VTA www.trailermag.com.au

Fit for a King

Outstanding Australian citizens from all walks of life, including road transport, were recognised last month as part of the King’s Birthday 2023 Honours List. This year, 1,192 individuals were awarded for their achievements and service to the country. They were also congratulated by His Excellency the Honourable Governor-General, David Hurley, who spoke of optimism, noting that the wide-ranging service of recipients spanned almost every field of endeavour imaginable. Sure enough, four familiar names were honourably listed: Duncan Gay, Sal Petroccitto, Julie Russell and Kevin (Mick) Pattel.

National Heavy Vehicle Regulator (NHVR) Chairman and former New South Wales Minister for Transport, Duncan Gay, was recognised for his significant service to the people, parliament and community of New South Wales. To our readers he has also been an advocate for improving road safety. Last year, he said there is nothing more important than ensuring heavy vehicle drivers get home safely to their families.

Meanwhile, NHVR CEO, Sal Petroccitto, was awarded for his service to the transport industry. Having met the man, he is passionate, committed and is driving positive outcomes for both business and community. It was

his presentation five years ago at a summit that I had the pleasure of attending that demonstrated his genuine, heartfelt approach to improving our lot. Fielding an onthe-spot question about delays with PBS access approvals, he seized the opportunity to do better on behalf of the regulator and to investigate the matter personally. Since that time, he has overseen a transformation of the organisation’s administration practices and streamlined the PBS process with the support of his team.

It takes team players like Julie Russell of Russell Transport to drive meaningful change, too. She is a Director of both NHVR and Australian Trucking Association Boards and was also awarded for her service to the road transport industry.

As for the former President of the National Road Freighters Association, Kevin (Mick) Pattel, he was also presented with the OAM in the General Division. He is also the owner operator of Pattel Transport.

Julie once told Trailer that she highly valued the time she worked alongside her grandmother who taught her about family duty, commitment to a cause greater than yourself and resilience.

From the Editor’s desk

4 Trailer Magazine JULY 23

AAA Ian (General Manger) 0477 000 011 - ian@aaatrailers.com.au www.aaatrailers.com.au - 02 9188 3222 - 159 Walker St, Helensburgh, NSW 2508 Dan 0429 160 094 – Dan@aaatrailers.com.au – Perth WA TOP QUALITY AND FIT FOR PURPOSE WITH A FOCUS ON SAFETY AND RELIABILITY. DROP DECK CURTAIN SIDE STRAIGHT SIDE TIPPER

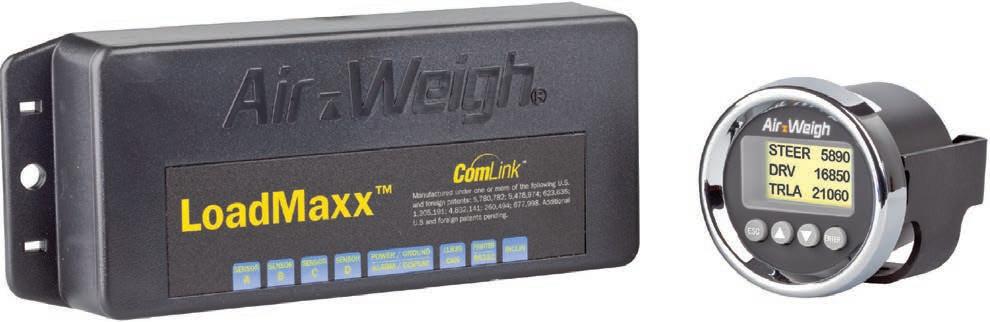

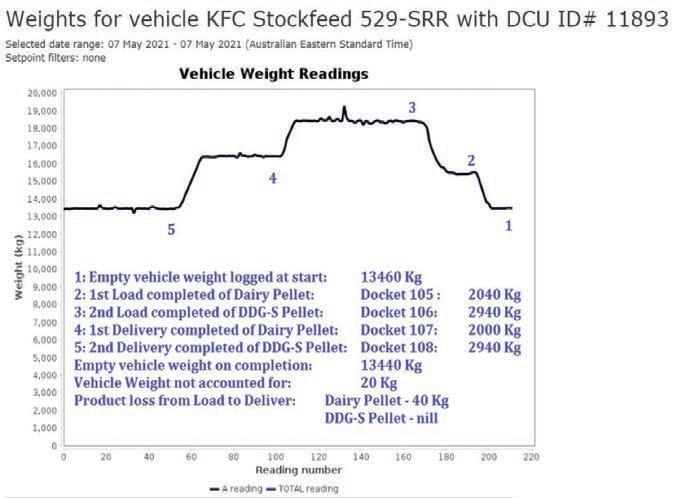

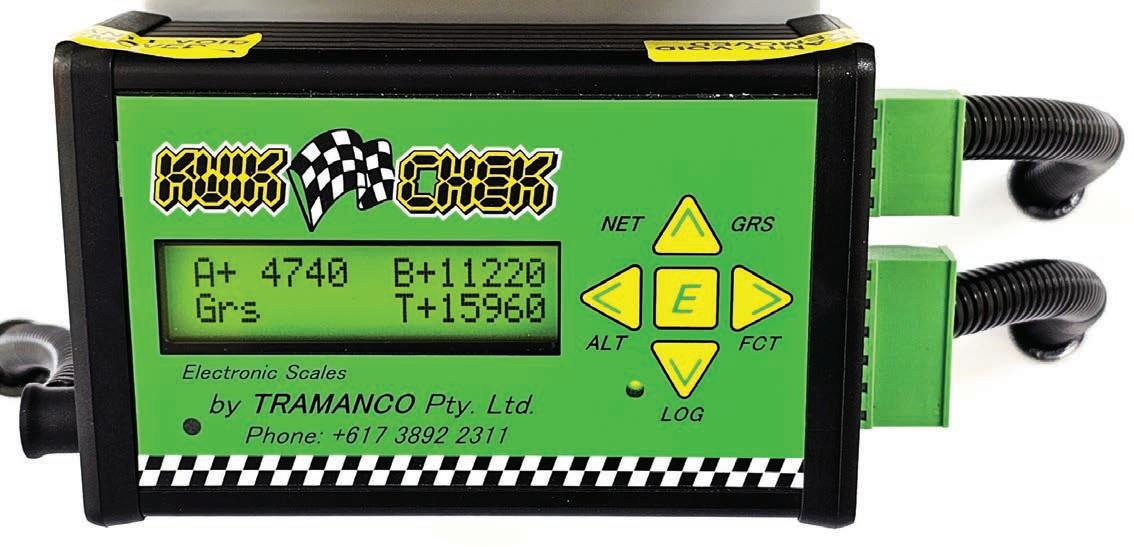

6 Trailer Magazine JULY 23 8 Industry news The latest news and industry developments. 32 Economy A look at vital freight routes. 34 Refrigerated transport equipment See the latest cold chain technologies in road transport. 42 Trailer builder Australia’s trailer manufacturing industry is as strong as ever. 48 Weighing systems Remain competitive and compliant with these on-board weighing system options. 54 Trailer building materials/components A showcase of the products and services that keep trailers on the move. 62 Women in industry Our wrap of the 2023 Women in Industry Awards. 64 World map Intelligent production with Fuwa. 66 Fleet of the month Owner-operator, Bruce Andersen, talks about his latest DAF. 68 Industry Innovators Meet Jackson Heil of Smedley’s Engineers. 70 What’s on Upcoming shows and field days.

2023 36 54 34 44 52 62

July

certified

southbound and northbound exit ramps, installing signs at the western roundabout, line marking, asphalting, installing safety barriers and removable kerb, vegetation removal, utility and pavement drainage adjustments and other associated works. The work will also include concrete grooving, which is a proven method to reduce noise coming from the road surface.

to a range of safety improvements for the M1 Pacific Motorway.

“Safety is the NSW Government’s top priority, and this work will improve safety for about 30,000 motorists who use the interchange daily,” she said.

“We are committed to ensuring every motorist and passenger experiences smoother and safer journeys and makes it home safely to their loved ones.”

Master Code of Practice to be updated

An update to the widely used Master Code of Practice is now underway according to the National Heavy Vehicle Regulator (NHVR).

The Master Code is a registered industry code of practice that was first developed by the Australian Trucking Association (ATA) and the Australian Logistics Council (ALC) in consultation with industry and registered by the NHVR in November 2018.

As a practical guide to assist in achieving the standards of heavy vehicle safety and compliance required under the Heavy Vehicle National Law (HVNL), it provides information for parties in the Chain of Responsibility (CoR) about hazards and risks which may arise from their heavy vehicle transport activities, and the control measures they can use to reduce those risks.

NHVR Director Regulatory Standards and

Policy, Paul Daly said the review of the code is an opportunity for industry and stakeholders to have their say on what should be added or updated.

“We invite industry to provide feedback for the current version and comment on whether the hazards, risks and controls in the code are still relevant, or to suggest new issues, safety methods or techniques,” he said.

“The Master code is a great regulatory tool that we can use to improve safety for all road users. We want the code to continue to remain an authoritative source of information for safety in the heavy vehicle transport industry.”

Since 2018, the industry has significantly matured in its understanding of primary duties and the skills required to manage safety. This review of the Master Code is intended to further support parties in the

days a week.

Work will also take place from 7am to 6pm from Monday to Friday and 8am to 1pm on Saturdays, weather permitting.

Short-term lane closures and traffic control will be in place for some construction activities, which will result in minor delays to traffic at the interchange, on M1 Pacific Motorway and Pacific Highway and Burns Road.

Chain of Responsibility and provide current and reliable information to make transport activities safer.

“The ATA and ALC consulted extensively on the original development of the Master Code. It was a huge job; we’re delighted that the Code is now used so widely,” said David Smith Australian Trucking Association Chair.

“This long-planned review will ensure that the Code remains up to date as the industry continues to improve its safety.”

The review of the code will consist of six phases, requiring input from stakeholders in multiple phases.

According to the NHVR, the review will commence in June 2023 and will use a variety of channels to seek industry feedback and comments.

The NVHR anticipates that the review will be completed by March 2024.

8 XXX Trailer Magazine JULY 23 News

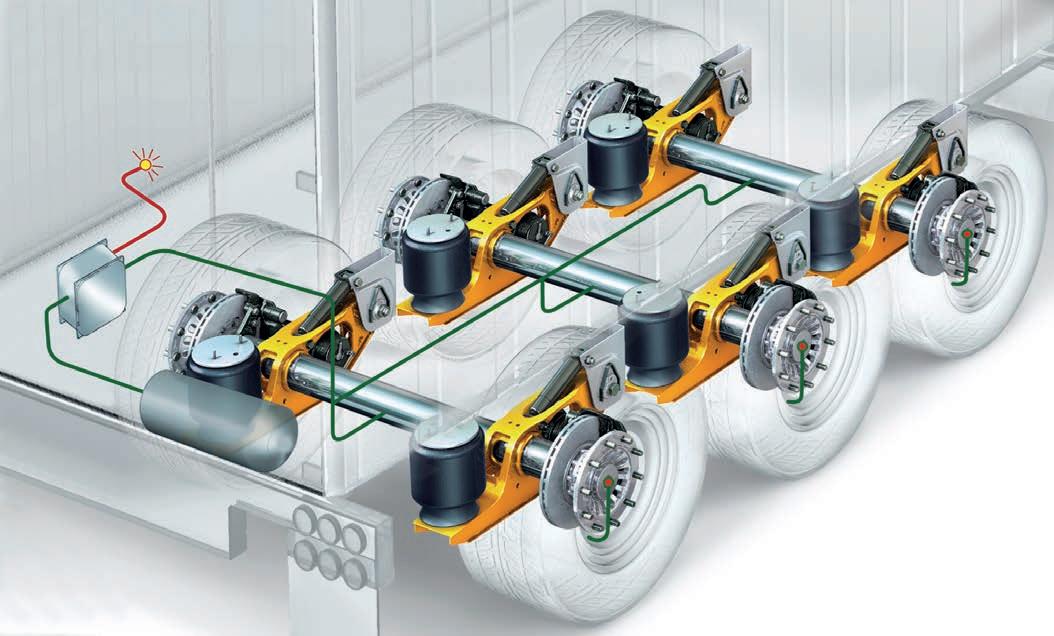

SAF TIRE PILOT SAF-Holland tyre inflation system

Regulates the preset tyre pressure permanently and reliably Automatically inflates the tyre as Maintains the minimum pressure in event of run-in damage

• Proven in Australian conditions since 2016

• Available for rigid or steerable axles

• Operates independently of the truck

• Allows easy tyre change

• Reduces tyre wear

The efficient system by SAF HOLLAND for monitoring and maintaining the preset pressure in the trailer tyres

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

Email: sales@safholland.com.au

www.safholland.com.au

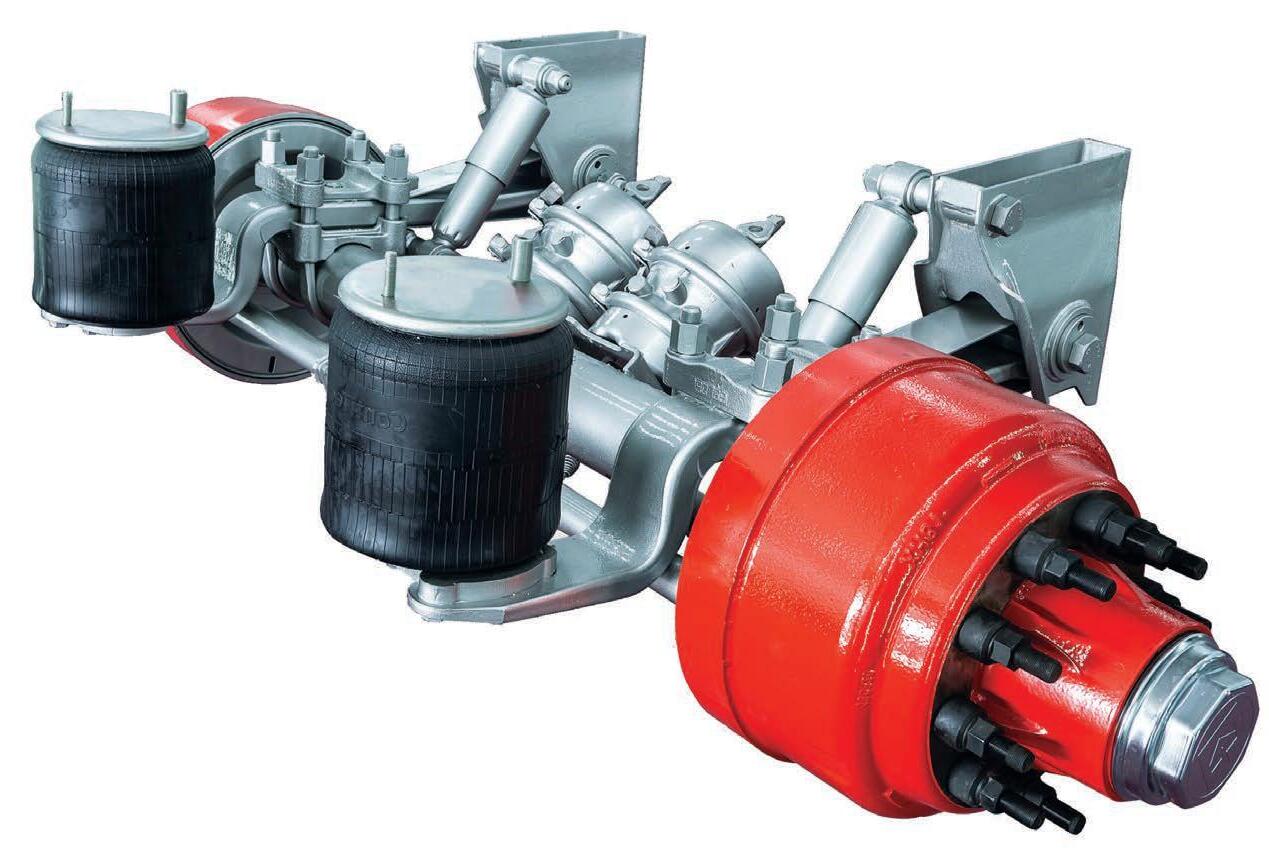

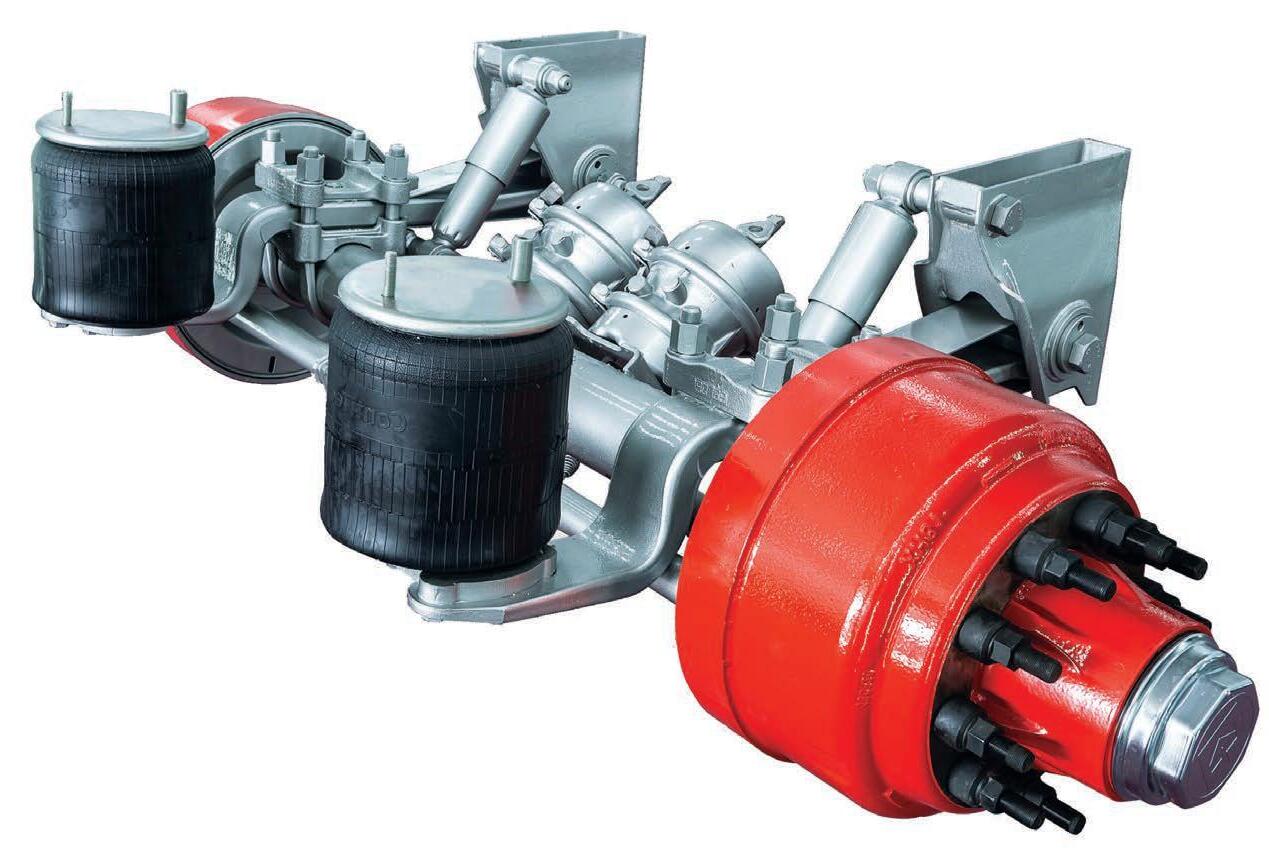

300,000th axle in Australia

BPW Transpec is celebrating the production of its 300,000th axle in Australia.

The 300,000th product is a 10 Stud 285 PCD Brake Drum axle, which is going to Exodas Transport.

BPW Director, Achim Kotz, who was visiting from Germany was able to present the Australian production team with a sign to congratulate them.

BPW Transpec Production Manager, Steve

Civelle, told Trailer he was privileged to celebrate the product’s milestone.

“We started assembling axles in Australia in 1987, so it’s taken 36 years to get to the 300,000th axle,” he said.

According to Civelle, a lot has changed since he joined the BPW Transpec team 46 years ago.

“We started with a small crew of three people in the assembly area to now around 35 people,” he said.

“We were doing around five or six axles a day at the start, to now averaging around 50 a day.

“The assembly process back then was very basic compared to today – we had standalone workstations and all manual torque tools, whereas now it is fairly automated.”

Exodas Transport will be taking delivery of the new combination with the 300,000th axle fitted in the coming months.

Final Newell Highway upgrade announced

Work is underway on a new overtaking lane along the Newell Highway in New South Wales, as part of a final upgrade project to deliver travel savings and safety improvements.

The project, which construction crews have already started on, will see the construction of a southbound overtaking lane at Bundidgerry.

Work has already commenced or been completed on 38 new overtaking lanes along the full length of the Newell Highway, south from Tocumwal to Narrabri in the north.

In addition, overtaking lanes already under construction at Mirrool and Daroobalgie will be completed this week,

with work at the Pilliga rest area to be completed by the end of June.

According to the Federal Government, these new overtaking lanes are expected to reduce travel times between the Victorian and Queensland borders by around 30 minutes.

Federal Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said the upgrade will improve safety for freight transport operators and motorists.

“The Australian Government has been working with the New South Wales Government to deliver these overtaking lanes on the Newell Highway, delivering smoother and wider road surfaces for

more efficient journeys along this key inland route,” she said.

“Our funding is key to ensuring the NSW road network is as safe and as efficient as possible.”

NSW Minister for Regional Transport and Roads, Jenny Aitchison, said the $236.8 million investment is on the home stretch.

“The Newell Highway is a key regional route linking the south and north of our state, used by thousands of motorists every day,” she said.

“This is a particularly big benefit for freight operators who can more accurately plan their journeys and move valuable goods more efficiently.”

10 Trailer Magazine JULY 23 News

B-DOUBLE DROP DECK CURTAINSIDER

• Full mezz deck

• Hanging gates, toolboxes & provision for tow coupling

• Locally supplied curtains

B-DOUBLE FLAT DECK CURTAINSIDER

• Rear doors

• Gates, toolboxes & provision for tow coupling

• Locally supplied curtains

45’ Drop Deck with BiFold Ramp

• 12V Power Pack

• 3 Way Twist locks

• Machinery tie-down points in floor

13.7-21.5m Extendable Flat Top

• 3 Way Twist locks

• Pneumatic warning flags

• Provision for tow coupling

40’ DROP DECK SKELETAL TRAILER

• 3 way twist locks

• Dangerous goods rated

• Container tilt airbag fitted

40’ 3 WAY SKELETAL

• Standar & lightweight designs

• Side loader pads

• Provision for tow coupling

• CIMC has a long term commitment to Australia by investing in infrastructure to provide high quality products, support and service.

• Local production capacity for Semi-Trailers and Tankers with CNC cutter, welding machines and start-of-the-art heated paint shop.

• Comprehensive parts store stocking genuine CIMC parts, along with additional OEM sourced items.

• Dedicated service & repairs workshop.

• Total site area 51,000 sqm, with a 13,000 sqm workshop.

Melbourne CIMC TRAILERS 1300 202 462 20 Whitfield Blvd, Cranbourne Brisbane CIMC TRAILERS 0423 795 649 68 Tile Street, Wacol Perth GTE 08 9352 4000 159 McDowell Street, Kewdale Sydney JRB GROUP 02 9355 3400 26 Bosci Rd, Ingleburn 19 Hale Street, Botany ENQUIR E NOW 1300 202 462 www.cimc.com.au | sales@cimc.com.au

LEADERS WITH LOCAL KNOWLEDGE Your semi-trailer experts.

GLOBAL

JOST Australia hosts Toll Group training

Equipment specialist, JOST Australia, recently held training sessions at the Toll/Woolworths Michinbury, New South Wales, site for Toll Group’s drivers and management team.

The training session covered everything from the maintenance and operational aspects of JOST’s turntable systems to optimising their performance.

Toll Group Operations Support Manager, Mark Haworth, thanked JOST for partnering with Toll Group on this initiative.

“We’re grateful to JOST for partnering with us to provide these invaluable training sessions, and we’re confident that our drivers and management will benefit from the training they provided,” he said.

“We consider it our top priority to invest in the professional development of our drivers and management team to ensure that our customer receives the highest level of service and quality that they expect and deserve.

“These training sessions present an excellent opportunity for our team to learn

from the best and enhance their skills and knowledge.”

JOST Australia Managing Director, Guy Locke, expressed his gratitude to Haworth and Toll Group.

“Thank you Mark and Toll for taking the time to acknowledge the team and support the JOST product and service,” he said.

NSW Government announces Spring Creek Bridge upgrade

The New South Wales and Federal Government have committed $12.1 million to replacing Spring Creek Bridge on the Kamilaroi Highway, west of Narrabri.

Spring Creek Bridge is an important link for road users travelling on the Kamilaroi Highway between Narrabri and Wee Waa, as well as for the local community and agricultural industry.

The NSW Government is planning to replace the existing culvert structure with a new, wider bridge that meets modern design standards.

Upon completion, the new bridge will result in improved access for freight and increased safety for road users.

Plans to demolish the existing bridge are already underway, and construction of a temporary side-track is scheduled to commence in September.

ACCC opposes Woolworths’ proposed acquisition

A proposed acquisition has been opposed by the Australian Competition & Consumer Commission (ACCC) due to the impact it could have on lessening competition in the supply of groceries in New South Wales.

The proposed acquisition of SUPA IGA in Karabar and its co-located Liquor Boss store would, according to ACCC Chair, Gina Cass-Gottlieb, would see Woolworths operate three of six supermarkets in the local Queanbeyan/Jerrabomberra area. Consumers would be left with one Coles and two ALDI stores as alternatives.

Woolworths already operates two supermarkets in the neighbouring suburbs of Queanbeyan and Jerrabomberra. The SUPA IGA is the only independent supermarket in the local area.

“The more supermarkets or grocery stores there are, the better outcomes for local consumers, who can change where they shop based on the most competitive offerings for their particular needs,” said Cass-Gottlieb.

The retail supply of groceries in the Queanbeyan and Jerrabomberra area is already highly concentrated and replacing the SUPA IGA with another Woolworths owned store would further increase this concentration.

The proposed acquisition will also affect the various suppliers who currently supply SUPA IGA, particularly those who provide those products that are not stocked by Woolworths.

The ACCC’s analysis found that the SUPA IGA Karabar, which is independent and locally owned, offers a different shopping experience to Woolworths, Coles and ALDI. This differentiated shopping experience generates competitive tension in the local area that would be lost if it was acquired by Woolworths.

“Supermarkets compete not just on the price you pay at the checkout, but the frequency and types of promotions they run, the range of products they sell,

the quality of these products, and the level of service delivered at the store,” said Cass-Gottlieb.

“The local SUPA IGA competes with its different product mix, service offering and store amenity, and different promotional cycles.

“It also has the ability to make decisions locally, and to dynamically adapt and respond to changes in tastes and preferences of local customers.”

The ACCC’s decision was informed by data analysis of the spending habits of local consumers, including how often and how much local consumers spent at different supermarkets in and outside the local area.

Throughout its review, the ACCC engaged with a range of businesses and industry bodies. The ACCC also received feedback from consumers, with over 700 responding to survey questions or providing written submissions.

News

12 Trailer Magazine JULY 23

RUNNING GEAR FOR ALL APPLICATIONS AND ENVIRONMENTS FUWA K-HITCH www.khitch.com.au MELBOURNE 13-21 Bliss Court Derrimut VIC 3030 p: 03 9369 0000 f: 03 9369 0100 melb@khitch.com.au PERTH 77B Kurnall Road Welshpool WA 6106 p: 08 9350 6470 f: 08 9350 6570 perth@khitch.com.au BRISBANE 41 Moreton Street Heathwood QLD 4110 p: 07 3372 2223 f: 07 3372 1022 qld@khitch.com.au FOR ALL YOUR EQUIPMENT AND OE SPARE PART REQUIREMENTS, YOU CAN TRUST KHITCH

Study looks to improve DG movements

Delivery, Gavin Hill, said the new initiative builds upon the success of an earlier data sharing arrangement with NBTA.

“What we found from the previous study was that many dangerous goods transport operators had not necessarily seen a macro view of their vehicles’ footprint across the network,” he said.

A new data sharing initiative between Transport Certification Australia (TCA) and the National Bulk Tanker Association (NBTA) is aiming to provide better understanding of vehicles transporting Dangerous Goods (DG) and bulk liquids.

Study collects regular telematics and associated data from freight vehicles to better understand DG movements across Australia.

Based in Victoria, FBT Transwest is one of the companies that has already signed up for participation in the study.

“This is required so we can have an informed discussion about network access with the Department of Transport and Planning Victoria.”

Speaking at the Bulk Tanker Day 2023, TCA General Manager of Strategy and

Steel deal to boost NSW manufacturing

Planning approval for a $182 million upgrade of three berths at Port Kembla will help to guarantee the supply of Illawarra steel for transport infrastructure.

Minister for Planning and Public Spaces, and Member for Wollongong, Paul Scully, said the move would help rebuild the domestic manufacturing industry in New South Wales and support more than 14,500 jobs.

“Our construction industry is the largest user of Port Kembla’s steel, using more than 70 per cent of the site’s total output,” said Scully.

“This approval provides more capacity to import coking coal for steelmaking and keep production flowing when local coal supplies are scaled back from 2028.

“It’s an investment in jobs, training, and the Illawarra community, but importantly it’s a vote of confidence in NSW manufacturing and construction, providing the locally sourced steel they need to build the homes, hospitals and transport infrastructure NSW needs.”

Minister for Illawarra and the South

Coast, and Member for Keira, Ryan Park, said the revamp of three berths would mean more local steel used for major NSW Government projects, supporting thousands of local jobs.

“Illawarra steel contributes around $10.3 billion to the NSW economy each year, and this decision secures the continued direct employment of around 4500 people, together with another 10,000 people in the supply chain,” said Park.

“Steel-supply certainty is vital for the home building industry as we work to fast-track ways to supply new homes in the Illawarra, in Sydney and across the entire state,” he said.

Member for Shellharbour, Anna Watson said the berth upgrades were essential to enable BlueScope to handle coal brought in from Queensland after 2028.

“BlueScope uses a unique blend of coal to operate the blast furnaces used to make steel and needs this type of product to be shipped into Port Kembla,” said Watson.

“The berths are more than 50 years

“So, instead of leaving that as a oneoff study, we’ve decided to launch an evergreen study, where we’ll work with the industry to make sure they get true benefits out of it.”

A key aspect of this new initiative is that the types of DG being carried by vehicles will be collected.

When combined with vehicle movement data, the collection of DG types will provide valuable insights into the movement of DG on the road network.

“We recognise that different operators may collect this information in different ways, and we’ll work with individual operators to ensure there’s streamlined process to share dangerous goods load information with us,” Hill said.

old and need improvements to meet the expected increase in steel demand as NSW continues to grow.

“The project will create 100 immediate construction jobs as the steelworks continues to support hard-working local families as it has for generations,” she said.

BlueScope Australia Chief Executive, Tania Archibald, said the planning approval demonstrates the NSW Government’s commitment to secure the future of steelmaking in Australia.

“BlueScope operates five berths at Port Kembla to import a range of raw materials such as iron ore, coal, limestone, recycled steel scrap, and export steel products to customers, and the continued supply of these raw materials is critical to the operations of the steelworks,” said Archibald.

“This infrastructure upgrade represents a significant investment to secure the asset for the long-term whilst supporting future technology options for lowemissions steelmaking.”

News

14 Trailer Magazine JULY 23

Leading the way in vehicle safety and performance

Scully RSV is on a mission to have the safest vehicles on the road. Every day.

Scully RSV and SafetyCulture have partnered to develop an industry leading initiative for transport safety. The digital safety inspection captures the performance of Scully RSV vehicles each and every time they are used on our roads.

The SafetyCulture platform enables a more efficient and optimised inspection capture and reporting system for vehicle compliance and safety. Delivered via a QR code scan, users can launch and complete the vehicle inspection in less than 30 seconds.

Scully RSV is proud to be bringing this initiative to market with Safety Culture and leading the way in keeping our communities and their families safe. It’s another great example of delivering on the customer promise, that Scully RSV fleet is managed to the highest levels of quality, safety and reliability.

FLEXIBILITY TECHNOLOGY RELIABILITY SERVICE QUALITY 1800 728 559 info@scullyrsv.com.auwww.scullyrsv.com.au

Amazon new facility expected to boost capabilities

Construction of Amazon Australia’s new purpose-built fulfilment centre (FC) in Perth is nearing completion and is set to open this year.

The new FC spans around 20,000 square metres with capacity to house over three million items sold on Amazon. com.au, ranging from smaller to medium items like health, household and personal care products to larger items like TVs and gardening equipment.

Located in the Jandakot Airport Commercial Precinct, the new centre is more than double the size of the company’s existing site near Perth Airport which it will replace when it opens.

As a result, it is expected to increase Amazon’s operational footprint in Western Australia by more than 60 per cent.

According to Amazon Australia, it will also increase the storage capacity available to sellers by 500 per cent.

Director of Operations at Amazon Australia, Mindy Espidio-Garcia, said the company is investing in its Perth operations as part of an ongoing commitment to improve selection and delivery outcomes for customers throughout the state.

“Many Prime members in greater Perth will have already enjoyed free next day delivery from Amazon and the opening of this site will increase the selection of items

that can be shipped to local customers quickly,” she said.

“Nearly 1,000 construction jobs were created during the build and fit out, and we look forward to welcoming a team of more than 200 people working at the FC once it’s fully up and running.

“People are at the heart of our

safe and positive work environment and the opportunity for them to build their skills and grow their careers.”

More than 200 jobs will be based at the new FC once fully operational.

This includes around 100 new job opportunities in addition to roles filled by existing workers transferring to the new

Reforms in review for safer freight vehicles

The Australian Government has released reform proposals in hopes of reducing barriers in the uptake of safer technology in heavy vehicles.

According to the proposed Safer Freight Vehicle (SFV) reforms, any vehicles exceeding 2.50 metres in width would need to be fitted with a mandatory technology package.

This technology package includes features such as: Advanced Emergency Braking (AEB); Improved rear vision mirrors and systems; Lane Departure Warning; Side Underrun Protection (SUP); and improved conspicuity markings.

Once finalised in Europe, blind spot information systems and advanced systems that detect pedestrians and

cyclists on the passenger side of heavy vehicles will also be required as part of the mandatory technology package.

Following the announcement, the National Heavy Vehicle Regulator (NHVR) has released a Discussion Paper on how to implement the SFV reform proposals, including increasing the width of heavy vehicles fitted with modern safety technologies.

NHVR Chief Regulatory Policy and Standards Officer, David Hourigan, said the reforms would support the uptake of safer heavy vehicles.

“The proposed SFV reforms would increase the fitment of safety technologies to new heavy vehicles by aligning local width regulations with those

in major markets such as Europe,” he said. “These reforms will give industry access to a greater range of heavy vehicles fitted with the latest safety technologies.

“We want to hear from industry and further unpack how to implement these Australian Design Rule (ADR) changes into the Heavy Vehicle National Law (HVNL).”

While the Australian Government is still finalising the details of these reforms, the NHVR is proactively considering how these changes might affect the HVNL.

“The heavy vehicle industry and truck manufacturers are ready for this next generation of safer trucks. The NHVR wants to make sure the HVNL is prepared to get these safer trucks on our roads.”

16 Trailer Magazine JULY 23 News

INDUSTRY LEADERS IN ROAD TRANSPORT EQUIPMENT,

MANUFACTURE & MAINTENANCE Skel trailers Evolution side tippers Road train dollies Flat tops, drop decks Deck wideners and extendables End tippers, bulk and TaREX quarry bodies Wabash National refrigerated and dry vans Etnyre live bottom trailers Titan walking floor and belly dumper trailers PBS specials: super quad & super triple OUR EXTENDED RANGE INCLUDES: With nationwide sales and support. For more information email admin@brucerockengineering.com.au or call us on 1300 611 253 BRUCEROCKENGINEERING.COM.AU We are

Australian

Refrigerated/Freezer trailers and

vans.

engineered for Australian conditions.

DESIGN,

the sole

distributor of USA’s largest manufacturer of

Dry

Custom

CRL Express opens new VIC warehouse

CRL Express has opened a brand new purpose-built warehouse in Dandenong, South Victoria.

The 11,500 square-metre facility features over 7,000 pallet bays of racking and a 2,500 square-metre super awning to facilitate allweather cross-docking and operations.

In a statement online, CRL Express said the state-of-the-art warehouse represents a fresh

chapter in its story.

“As a five-year-old business, this announcement of our new warehouse in Melbourne signifies our dedication to delivering exceptional service and surpassing your expectations,” it said.

“It’s been a year in the making, filled with both triumphs and challenges.

“We couldn’t have achieved this significant

VTA slams plan to eliminate freight access

The Victorian Transport Association (VTA) has criticised the City of Melbourne’s proposal to redesign the Hoddle Grid and further restrict freight access to key routes.

Under the Future Streets Framework proposal voted on last night, key freight routes in Melbourne CBD such as Flinders Street, Bourke Street and Spring Street would be closed to motorists.

Meanwhile, public transport users, bicycles and pedestrians would be prioritised for access.

VTA CEO, Peter Anderson, said the plan has a complete disregard for freight as well as small businesses and city traders

relying on the transport industry.

“Before COVID, transport movement to and from the city for cyclists was four per cent of total trips with cars representing 20 per cent of total trips,” he said.

“Since COVID, bicycle trips remain at four per cent with cars now representing 43 per cent of all trips.

“Such inward looking, insular and isolationist perspectives are effectively telling 43 per cent of city commuters that ‘we do not want you in our city’.”

Anderson said the proposal is oblivious to the consequences that could arise.

“Over 5,000 commercial vehicles service the city every day including the

milestone without the incredible support of our valued customers and the hard work of our talented team.”

Having withstood the tumult of COVID lockdowns and its impact on the market, CRL Express has remained steadfast in its approach to providing a personal solutionbased approach and transparent service nationwide.

garbage collectors, concrete trucks, delivery vans, rigid trucks and ancillary vehicles that need access, parking, and flexibility,” he said.

“These vehicles and their drivers work under tight timelines, growing congestion, and an expectation to live a normal life.

“The freight industry is the lifeblood for thousands of city businesses, commercial developments and public transport projects and its high time the City of Melbourne recognised the value of transport operators and their workers in upholding the vitality of our once great city.”

18 Trailer Magazine JULY 23 News

8.25 x 22.5 Aluminium 10 Stud 285 PCD REEFER TRAILERS IN STOCK NOW! FULL CHASSIS 12 PALLET A TRAILERS 22 PALLET B TRAILERS 26 PALLET PBS TRAILERS SHORT CHASSIS 22 PALLET 24 PALLET Vertical Double Load System Flush Mounted - Extra Width 3 – Tube Air Chute 1200mm Powder-Coated Toolbox Fitted with Swirl Plate Fitted with Road Train Cross-member, provisions for inatallation of tow coupling Schmitz Cargobull Premium Reefers B-Doubles, PBS Trailers, Semi-Trailers Load Securing Rail Horizontal Load Restraint System Flush Mounted - Extra Width CONTACT US TODAY TO FIND OUT MORE: 03 8794 6000 www.cargobull.com LUKE HARDEMAN 0467 001 515 SIMON HAKVOORT 0478 848 292

Freight monitoring cameras to roll out across NSW

The New South Wales Government will use new counting and classifying cameras to better understand freight movements to help reduce congestion, improve road safety outcomes and encourage more efficient deliveries.

Using world-first camera technology, Transport for NSW is continuing to install machine learning traffic cameras across the state in the north.

Transport for NSW said the new technology can be used to help manage increasing freight volumes which are

expected to increase by 28 per cent in the state by 2036, over a 2018 baseline.

The new cameras will be installed at the following locations:

• Golden Highway Putty Road/Mitchell Line of Road, Whittingham

• New England Highway, Liddell

• Pacific Highway at Raleigh, 1.5km north of Bellinger River bridge

High-definition pictures of heavy vehicles are taken by the cameras, which are then

classified into the type of vehicle in transit and the type of cargo being transported.

According to Transport for NSW, the cameras will not be used for “enforcement or monitoring people or private vehicles”.

“This heavy vehicle traffic information will enable Transport for NSW to better understand freight movements with the aim of assisting long-term planning for the movement of goods in NSW,” a Transport for NSW spokesperson said. Trailer will be monitoring this development with keen interest.

Popular intersection reopens with freight upgrade

The intersection at Farm and Alexandra Streets, Queensland, has reopened following major upgrades which have improved safety and congestion for heavy vehicles.

Funded by the Rockhampton Regional Council and the Queensland Government, the intersection has undergone significant enhancements.

Road works entailed increasing the existing pavement thickness to cater for heavy vehicles, widening corners to improve safety for turning vehicles,

installing left and right turning lanes on Farm Street for turning north into Alexandra Street, a new kerb and channel, concrete footpaths, additional drainage and new asphalt surfacing.

Infrastructure Councillor, Ellen Smith, said the project will primarily benefit the freight network.

“Safety has been at the forefront of this project as this area sees high traffic usage and heavy vehicle use,” she said.

Divisional Councillor, Donna Kirkland, welcomed the completion of the project.

“With more development in the area and more heavy vehicles, this intersection will only get busier which is why we needed to make sure it could handle the increase in traffic and population going forward,” she said.

“I know that local users of this intersection will be very pleased to use this popular route again.”

Over the next few weeks, crews will work on the final touches such as completing footpath works and cleaning up the site.

20 Trailer Magazine JULY 23 News

•

E- Mail: i n fo@e-m a x.com.a u P: 130 0 85 0 5 75

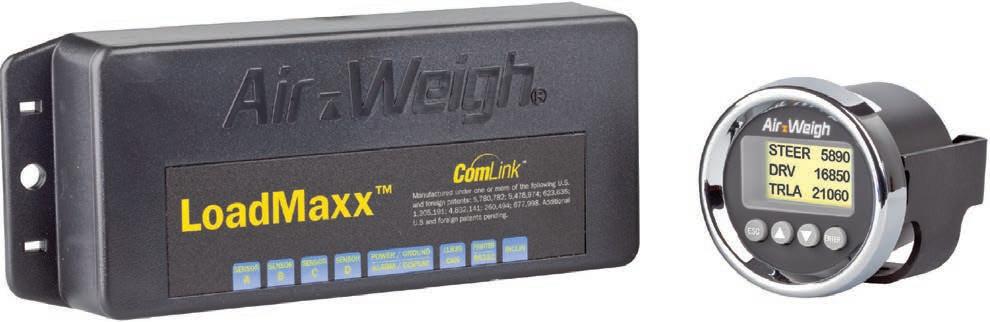

Approved for use with all TCA approved telematics devices, for Smart OBM and IAP-M • 3 year limited warranty • No manual pairing of the system needed, no extra cost or need for a third party phone or tablet, system connects automatically with no driver input required, turn the key and go. • Smart OBM and IAP-M ready today, with whatever

www.air-weigh.com.au

Khali Lake joins Centurion’s leadership team

Centurion has appointed Khali Lake as its new Executive General Manager of Operational Services.

Following his role as General Manager at The Drake Group, Lake has a wealth of industry knowledge and brings 13 years of experience in the manufacturing, OEM and mining supply industries.

In his new position at Centurion, Lake will

be responsible for leading the operational support functions on a national level. With a keen focus on assets, fleet management, procurement, marketing and properties, he will also play a vital role in enhancing Centurion’s overall operational efficiency.

Earlier this year, Centurion deployed B-triple combinations to move vital

supplies to Fitzroy Crossing and surrounding communities in East Kimberley as part of a relief effort due to floods. At the time major road access to the region was impassable as a result of record-breaking flooding. Damage to the Fitzroy River bridge, the only sealed road linking Broome with the rest of the Kimberley and Northern Territory, was flagged for extensive repairs.

ACCC green lights Armaguard-Prosegur merger

A proposed merger involving Linfox Armaguard has been authorised by the Australian Competition & Consumer Commission (ACCC).

Authorisation has been granted for the merging of Linfox Armaguard and Prosegur Australia Holdings Limited. A court-enforceable undertaking, which is a condition of the authorisation, has also been accepted.

ACCC said Armaguard and Prosegur are the two largest providers of cashin-transit services in Australia and both provide cash transport, management and processing services, which are predominantly provided to banks, retailers and independent ATM operators.

Under the Competition and Consumer Act, merger authorisation may be granted if the ACCC is satisfied that the merger is not likely to substantially lessen competition, or where the merger would or is likely to result in public benefits that would outweigh the public detriments likely to result from the merger.

“After conducting an extensive review of the transaction, we were not satisfied that the proposed merger would not substantially lessen competition,” said ACCC Commissioner, Liza Carver.

“However, we are satisfied that, provided the parties comply with the undertaking, the proposed merger is likely to result in a public benefit that would outweigh the likely public detriment.”

The ACCC’s review found that the cashin-transit industry is in structural decline due to the decreasing use of cash as a payment method across the Australian economy. However, despite this decline,

cash continues to be crucial to some parts of the economy.

“We accepted that, without the proposed merger, it was highly probable either Armaguard or Prosegur would withdraw from the declining cash-intransit market in the near future and this exit could occur very quickly,” said Carver.

“We were concerned that the rapid exit by either of these two major suppliers could cause significant disruption, including by reducing the availability of cash to their customers, and therefore the public.”

Public access to cash was an important consideration for the ACCC, particularly in regional Australia where internet access issues can limit electronic payment options and for vulnerable consumers who are reliant on cash payments.

“The ACCC concluded that the merger lessens some of the likely harms caused by the potential disorderly exit of one of the parties, and allows for a smoother transition to one provider, including by maintaining adequate access to cash,” said Carver.

The undertaking imposes obligations on the combined Armaguard-Prosegur and will be effective for the next three years. The ACCC considers the undertaking will allow time to consider whether any Government responses are needed to further regulate the industry and maintain adequate access to cash in the future.

The undertaking covers a range of obligations which together are intended to provide continuation of services,

reduce uncertainty about price and service levels and provide opportunities for other cash-in-transit providers to make use of excess equipment to expand their existing operations.

“To comply with the undertaking, the combined Armaguard-Prosegur will be required to continue offering cash-intransit services to all locations that are currently serviced,” said Carver.

“The undertaking also limits its ability to reduce service levels and raise prices for existing customers and sets minimum terms and pricing constraints for new customers.”

While the undertaking allows prices to be increased within limits over the next three years, this is against a backdrop of a declining industry with current lossmaking prices.

The ACCC considers that the undertaking appropriately balances the capacity for the combined ArmaguardProsegur to build a financially viable business against the potential impact of the proposed merger on existing and new customers.

In addition, the undertaking contains a commitment to create registers of surplus sites, employees and equipment. The ACCC believes this measure may assist other cash-in-transit providers to expand, which would increase the competitive constraint on the combined ArmaguardProsegur.

“The undertaking also includes commitments that cover services to ATM operators and is therefore likely to reduce the impact of the proposed merger on independent ATM operators,” said Carver.

22 Trailer Magazine JULY 23 News

HELPING YOU DELIVER EXCELLENCE

Through our leading brands and the backing of our unrivalled aftermarket service and support network, MaxiTRANS has a solution to service your transport needs.

What sets us apart? It’s MaxiTRANS’ ongoing commitment to understanding your business needs and providing even greater access to our high quality Australian made products to help you continue delivering industry excellence. Contact MaxiTRANS today to find out why more Australian road transport operators choose us as their transport solutions partner. maxitrans.com

ACFS Port Logistics announces new Perth facility

ACFS Port Logistics has announced a brand-new 15,000 square-metre warehouse facility in Hazelmere, Perth. The multi-site warehouse will service Third-Party Logistics (3PL), freight of all kinds (FAK) and eCommerce.

It will also be supported by the ACFS Port Logistics Transport Fleet to deliver full container loads (FCL).

ACFS Port Logistics COO, Wayne Morris, said the new facility will largely benefit customers.

“We take great pride in our work and are always looking forward to creating warehousing solutions for our customers,” he said.

“Our customers products and needs are at the forefront of our initiatives, and growing our existing footprint is a testament to the loyalty our customers have shown us.

“We are very grateful for their ongoing support.”

With racking capacity to store 20,484

pallets at 1.4 metres and a FCL container depot providing 11,850 square metres of container rated hardstand, the new development will act as a hub and spoke solution for customers in the area.

It will also have a 5 Star Green rating with a 99kW solar system, as part of ACFS’ initiative to reduce its carbon footprint.

Being developed by ACFS’ strategic partner, LOGOS, the Hazelmere facility is expected to be completed by December this year.

Transport leaders acknowledged in King’s Birthday Honours List

The King’s Birthday 2023 Honours List awarded a number of influential figures in the heavy vehicle and transport industry for their services.

The King’s Birthday 2023 Honours List recognises and celebrates 1,192 recipients, including awards in the Order of Australia (General and Military Divisions), meritorious awards and recognition for distinguished and conspicuous service.

National Heavy Vehicle Regulator (NHVR) Chairman and former New South Wales Minister for Transport, Duncan Gay, was presented with the Member of the Order (AM) award in the General Division for his significant service to the people, parliament and community of NSW.

NHVR CEO, Sal Petroccitto, was presented with Order of Australia Medal (OAM) in the General Division for his service to the transport industry.

Director of both NHVR and Australian

Trucking Association (ATA) Boards, Julie Russell, was presented with the OAM award for her service to the road transport industry.

National Road Freighters Association (NRFA) Founding President, Kevin (Mick) Pattel, was also presented with the OAM in the General Division for his service to the road transport industry.

Announcing the winners in the Honours List, Governor-General of Australia, David Hurley, congratulated everyone recognised.

“Recipients have made substantial contributions and had a significant impact at the local, national or international level,” he said.

“Some are volunteers, others have had a remarkable impact in professional roles – many have done both.

“They are all inspiring and their service is valued by us all.”

Heavy Vehicle Industry Australia (HVIA) Chief Executive, Todd Hacking, also passed on his regards to each of the medal recipients.

“On behalf of HVIA and all of our members, I commend Julie, Duncan, Sal and Mick for this great and worthy honour,” he said.

“It is great to see that our industry is being recognised with honours like these.

“They recognise the importance of our industry to the community and the generous contributions so many of our industry-family make to their own communities in so many different ways.

“These recipients deserve every commendation for their work towards delivering effective reforms to the transport industry, particularly in facing down the challenges of a single national system of regulation, governance and oversight.”

24 Trailer Magazine JULY 23 News

CELEBRATING 25 YEARS OF AUSTRALIAN DESIGNED ROAD FRIENDLY SUSPENSION CELEBRATING 25 YEARS OF AUSTRALIAN DESIGNED ROAD FRIENDLY SUSPENSION krueger.com.au VICTORIA DERRIMUT (03) 8331 6128 NSW WETHERILL PARK (02) 9757 4944 QLD SALISBURY (07) 3275 1011

$50M Bass Highway realignment completed

Another major section of the Bass Highway has been upgraded to provide a safer and more efficient road for heavy vehicles between Somerset and Wynyard.

Part of the $1.2 billion Tasmanian Roads Package and Bass Highway 10 year Action plan, this $50 million project saw 3.6 kilometres of the highway realigned from west of Cape View Nursery to the Old Bass Highway intersection at Doctors Rocks.

The upgrades have made this section of the highway safer with a number of sharp bends removed and new overtaking lanes in each direction which will improve traffic flow and safety.

Senator for Tasmania, Anne Urquhart, said the upgrade will benefit operators using the key freight link.

“This project will also boost productivity along this key freight corridor, keeping truckies and our economy moving during these challenging global times,” she said.

“Upgrading the Bass Highway is all about cementing opportunities for future growth across Tasmania’s north and north west.”

The realignment is one of many upgrades planned, underway or completed on the Bass Highway

between Cooee and Marrawah.

These projects include making junctions safer, road widening and construction of more overtaking lanes.

Tasmanian Infrastructure and Transport Minister, Michael Ferguson, said he was pleased to contribute to improving safety on the Bass Highway.

“The completion of these works marks

New laws in place for owner-drivers in WA

Updated laws introduced by the Western Australian Government to safeguard the rights of owner-drivers of heavy vehicles operating in the road freight transport industry come into effect today.

The amended Owner-Drivers (Contracts and Disputes) Amendment Act 2022 passed Parliament in October last year and is the result of extensive consultation with the Road Freight Transport Industry Council and the Road Freight Industry Tribunal.

The amendments will help improve business dealings between ownerdrivers of heavy vehicles who transport freight and the people who hire them, by clarifying the regulatory responsibilities of both parties.

The changes include the introduction of minimum notice periods of 90 days for termination of a contract longer than three

months, and seven days for contracts less than three months.

The role of the Road Freight Transport Industry Tribunal has also been clarified to make sure it can deliver fair and efficient outcomes in dispute resolution between owner-drivers and hirers.

Non-compliance with owner-driver guideline pay rates will now be factored into dispute resolution decisions made by the Tribunal.

This change places more responsibility on hirers to offer fair pay for owner-driver services.

In addition, workplace right of entry provisions have also been updated to allow an authorised owner-driver’s representative to enter a workplace to investigate suspected breaches of the Act.

WA Transport Minister Rita Saffioti

a key step in our plan to upgrade the Bass Highway, which is a key link across major population centres, transport hubs and agricultural regions across the north and northwest of Tasmania,” he said.

Last month, the Tasmanian Government announced that the Bass Highway will see $2 billion worth of upgrades completed over the next four years.

said the updated laws protect the rights of small businesses and independent operators who own and drive trucks in the freight industry.

“These are the small operators who are making a big difference to our economy and our lives, by helping to keep our supply chains going and delivering goods across our State,” Saffioti said in a statement.

“Our new laws will provide them with better protection and improve their position in matters including job security and fair pay, as well as clear processes to follow to resolve disputes.

“We have consulted extensively with industry to update these laws which will result in more streamlined and reasonable business dealings between owner-drivers and people hiring their services.”

26 Trailer Magazine JULY 23 News

ADDS VALUE EVERY DAY, EVERY TRIP, EVERY LOAD

Strenx® performance steel can meet the challenges facing the transport industry, which is constantly looking for ways to increase payload and improve fuel efficiency. Strenx® is a high-strength structural steel with extremely consistent properties, making it perfect for designing trailer chassis and other transportation products that are stronger, lighter and safer. That’s why we call it performance steel.

Explore the world of Strenx®

SSAB Brisbane. Melbourne. Perth G1, 28 Balacalva Street Woolloongabba,

australia@ssab.com

www.trailermag.com.au 27

Contact

QLD 4102

strenx.com

Industry Skills Australia appointed Jobs and Skills Council for transport and logistics

Industry Skills Australia (ISA) has been appointed the Jobs and Skills Council for Australia’s transport and logistics (Road, Rail, Aviation and Maritime), Omnichannel Logistics and Space Transport industries.

Industry will, under these new arrangements, have a determinative role in identifying and prioritising its workforce development needs and designing highly effective solutions in collaboration with employers, unions, industry bodies, communities, training providers, universities, and schools.

With over 30 years of expertise, ISA is considered in a unique position to address the rapidly evolving needs and challenges faced by industry and its workforce.

“The Jobs and Skills Council for the nation’s transport and logistics industry demonstrates our commitment to strengthening Australia’s supply chains. Industry Skills Australia will play an important role in equipping our workforce with world class skills, fostering innovation, and driving collaboration between industry and stakeholders,” said Brendan O’Connor, Minister for Skills and Training.

ISA Chair Tony Wilks echoes this sentiment and emphasised the Council’s dedication to industry.

“Our model is proudly industry-owned and industry-led, and we’ve been genuinely overwhelmed with support from right across the many sectors that comprise Australia’s supply chains, from the multi-nationals right through to small business,” he said.

“Together, we’re committed to a ‘people first’ culture where a skilled workforce will enable better jobs, increased productivity and create real opportunity.”

ISA will now work to establish the Jobs and Skills Council and undertake a range of initial activities. It will be fully operational by January 2024.

Industry Stewardship which involves gathering industry intelligence to reliably represent the views and needs of industry back to the government and its decisionmakers will be one of four key roles ISA will have as a Jobs and Skills Council.

Others include workforce planning to identify industry’s current and emerging skills needs, culminating in development of a national Workforce Plan; training product development to build highquality, world-class skills for new and existing workers; and the implementation and monitoring of solutions, which involves working on the ground to support training providers, promote careers, and monitor just how well the system is meeting the needs of industry and learners.

Paul Walsh, CEO of ISA said collaboration would empower individuals to drive positive change.

“We’re genuinely honoured to be appointed by the Commonwealth Government as the Jobs and Skills Council for Australia’s transport and logistics sectors, and to have the opportunity to make a real difference to industry and its workforce,” he said in a statement.

“But we’re not alone. We believe that great ideas can come from anyone and anywhere, and that if we work together, we can drive smart, sustainable solutions right across the country.”

ISA will now work to establish the Jobs and Skills Council and undertake a range of initial activities. It willbe fully operational by January 2024.

28 Trailer Magazine JULY 23 News

Industry Skills Australia CEO, Paul Walsh.

Truckies gone to the dogs

Pippi, Prinny and Spud truly work like dogs. The three whippets love nothing more than joining their owners on weekly hauls between Gippsland and Brisbane. For partners and truckies, Carly and Adam, having them for company helps keep their mental health in check during the long, and often lonely, drives.

Adam comes from a family of truck drivers and has seen first-hand the tough mental load they have to endure. He said taking his dogs on the road with him has helped manage his own mental health during some difficult years as they offer companionship, affection and a good excuse for frequent rest stops and dog walking.

In recognition of National Take Your Dog to Work Day, Carly and Adam are teaming up with the National Heavy Vehicle Regulator (NHVR) to raise awareness surrounding the mental health issues that can impact truck drivers and how bringing a furry friend to work can help.

The NHVR said it is well-documented that pets in the workplace have calming effects on many people by reducing stress and offering a social support which in turn can improve employee health and well-being and increase productivity.

Carly and Adam say their dogs can sense when they aren’t in a good headspace and will give them a nudge.

According to a Work-Related Mental Disorders Profile by Safe Work Australia, the transport and logistics industry has one of the highest rates of claims for workrelated mental disorders, with 44.8 per cent its workers having experienced a mental health condition.

Analysis by the Coroners Court of Victoria (2008-2014) showed truck drivers had the highest number of suicides of any profession.

“We’re seeing several truck drivers, like Carly and Adam, taking their dogs to work with them for the positive impact it has on their mental, emotional, and social health,”

said NHBR Executive Director of Corporate Affairs Michelle Tayler.

“Truck drivers deal with numerous on-the-job stressors, including spending long periods of time away from family and friends which can create a sense of isolation.

“With shift work being a part of most truck drivers’ jobs, routine can be hard to maintain, so often poor diet and lack of exercise can all be contributing factors that lead to an increase in mental health conditions and suicide in the sector.”

Over the years the NHVR has partnered with charitable foundation Healthy Heads in Trucks & Sheds on several initiatives to ensure resources are available to reduce mental health issues in truck drivers.

“Transport and logistics workers are an often-invisible workforce that support the nation every day and through particularly challenging times as we have witnessed in recent years,” said Health Heads in Trucks & Sheds CEO Naomi Frauenfelder.

ELECTRONIC SCALES One WAY or the other it is CHEK-WAY® or KWIK-CHEK® Proudly Designed and Manufactured by TRAMANCO in Australia Phone: + 61 7 3892 2311 info@tramanco.com.au &

Arrow Transport opens new facility

Arrow Transport Logistics & Quarantine Services have opened its brand new Brisbane home at Fisherman Islands.

Part of the Port of Brisbane precinct, the purpose-built facility comprises a 7,900sqm warehouse, office, workshop and 35,000sqm, 100-tonne hardstand area on a 4.96ha site.

It also includes a washbay, fumigation pad and sustainable design elements including 100kW rooftop solar, recycled water and energy efficient lights and hydraulic fittings.

Construction was completed in under ten months.

This follows the Port of Brisbane agreeing to terms on a $500 million sustainability linked loan, to be financed by a syndicate of ten banks.

negotiated as part of larger $850m syndicated bank loan transaction in November 2022 and will take effect from June 2023.

The loan will be executed under the Port’s Sustainability Financing Framework and will be linked to KPIs across three key areas: Emissions reduction, biodiversity, and mental health first aid.

Port of Brisbane Pty Ltd’s (PBPL) Chief Executive, Neil Stephens, said the deal would support the port’s ongoing investment while cementing its place as an industry leader in sustainability.

“Sustainability at the Port of Brisbane is a whole-of-business strategy. Everything we do incorporates the principles

core,” said Stephens.

“Our ambitious sustainability targets across People, Planet, Prosperity and Partnerships drive not only our day-to-day business activities, but our future planning and our interactions with stakeholders.

“Tying an important part of our financing structure to sustainability sends a clear signal to investors and the community that our commitment to the global transition to a more sustainable future is deep and unwavering.”

Stephens said the port was particularly proud to include mental health first aid as a key focus area in the deal.

“We are working incredibly hard to drive down our scope 1 and 2 emissions, and we are working closely with our customer base as to how we can record and influence scope 3.

“We are also extremely proud of the role we play in managing the biodiversity of the port area. We work immediately adjacent to a Ramsar wetland site, and ensuring it thrives long into the future is a key goal of ours.

“But sustainability to the Port of Brisbane is also about the health and wellbeing of our workforce, which is why we have included ambitious goals on mental health first aid support.

“To be a sustainable business must mean having a healthy and engaged workforce, and we will be working hard to deliver on those commitments as soon as we can.”

NHVR encourages cooperation following offence surge

The National Heavy Vehicle Regulator (NHVR) is reminding heavy vehicle drivers to always carry their National Written Work Diary (WWD) or Electronic Work Diary (EWD).

At the Marulan Heavy Vehicle Safety Station (HVSS) last week, the NHVR addressed recent data which found over 120 offences of drivers not carrying their work diaries in Marulan, New South Wales during the past few months.

The latest Marulan blitz recorded 18 work diary-related offences from over 1,000 intercepts.

According to NHVR Director of Operations Central Region, Brett Patterson, this suggests that although education on work diaries is having a positive impact, there is still more work to do.

“It’s great to see the majority of drivers and operators in this latest operation doing the right thing by carrying their work diary, however there is still a small group who were not,” he said.

“We take fatigue related offences seriously and those who were not carrying their work diaries were issued a direction to stop and rest for a period of seven hours.

“As a driver, meeting your safety and fatigue management obligations, in accordance with the Heavy Vehicle National Law (HVNL), is imperative for not only keeping yourself safe, but those you share the road with.”

Other breaches recorded included 137 vehicle defect notices, with 48 per cent of

those being self-clearing and 26 to secure or adjust loads.

With a strong focus on educating heavy vehicle drivers on work diary requirements, NHVR wants drivers to know that they can carry either a WWD or an approved EWD – or a combination of both, if they are switching from using one format to the other.

“We received a number of enquires around carrying work diaries and we’d like to stress that it’s important to ensure drivers can produce records for the past 28 days,” Patterson said.

“If you change from using a WWD to an EWD, then you’ll also need to carry your WWD until which time you can show 28 days of records.”

30 Trailer Magazine JULY 23 News

$2B transformation project to follow recent Bass Highway upgrades

The Bass Highway, a major freight link for transport operators in Tasmania, will see $2 billion worth of upgrades completed over the next four years.

The Tasmanian Government recently released a strategy to improve safety and travel time between Launceston and Devonport. The Bass Highway Corridor Strategy – Launceston to Devonport identified 66 potential improvements for the 91-kilometre section of the highway from Hadspen to east of Port Sorell Road in Devonport. These include upgrading intersections to improve safety at Christmas Hills Road, Oppenheims Road and Cutting Road/East Sassafras Road, and the extension and creation of overtaking lanes at Parramatta Creek and Sassafras.

Other high priority works identified in the Bass Highway Corridor Strategy include the creation of heavy vehicle rest areas, widening shoulders, installing safety barriers and improving road conditions at various points.

Minister for Infrastructure and Transport, Michael Ferguson, said the next step will be to develop detailed designs and to construct the prioritised projects with the available funding.

“The strategy follows an extensive consultation period with key stakeholders and the local community, with the feedback received used to help determine what needs to be done and the priority,” he said. “In addition to community input, the strategy has also looked at current and future demand and the highway’s safety performance.”

The upgrades, Ferguson said, are part of the State Government’s investment in state roads and bridges.

“The Australian and Tasmanian Governments have jointly committed a total of $50 million in targeted upgrades between Deloraine and Devonport, $100 million in Safety and Freight Efficiency Upgrades between Launceston and Devonport, and $420 million for the Northern Roads Package Stage 2, which in part will fund improvements between Launceston and Devonport,” he said. “This complements the $150 million in joint Australian and Tasmanian Government funding that is currently being delivered to improve the Cooee to Wynyard and

Wynyard to Marrawah sections of the highway.”

Earlier this year in May, two significant upgrades were also completed on the highway between Wynyard and Marrawah as part of a $100 million investment. One of the completed upgrades has improved safety on the Bass Highway by removing a curve on a section between Boat Harbour Siding Road at Boat Harbour and Broomhalls Road at Sisters Creek. It has also delivered vital upgrades to the Bass Highway’s junction with Morris Road, significantly improving safety for road users.

The other completed works are located on the highway at Togari, between Pacey’s Road/Park Road and Salmon River Road. Upgrades for this stretch of the highway included shoulder widening and the improvement of the road structure between Pacey’s Road and Salmon River Road.

As well as meeting the needs of modern freight transporters, the construction of the new Montagu River Bridge has

Economy

32 Trailer Magazine JULY 23

provided training and employment opportunities for young tradespeople.

Ferguson said reliable road connections are essential for all Tasmanians.

“These projects are among a raft of upgrades between Wynyard and Marrawah, many of which have now been completed, including four new overtaking lanes, 10 sections of Highway realignment, 66 junction upgrades and up to 60 kilometres of road-widening,” he said. “The upgrades between Boat Harbour Siding Road and Broomhall’s Road will make all road users safer and demonstrate our ongoing commitment to improving the Bass Highway.”

Future work under the Bass Highway 10Year Action Plan near Crayfish Creek will include drainage improvements to Dunn Street, line marking and signage renewal. This project is expected to be completed this month.

Shortly after the Wynyard and Marrawah upgrades, the Tasmanian Government announced that the first stage of the $80 million upgrade to Illawarra Road link between the Midland and Bass Highways was also completed. The first stage included widening the lanes and road shoulders between the Longford roundabout and Bishopsbourne Road and improving safety at the Bishopsbourne Road intersection. A heavy vehicle rest area was also created near the Longford roundabout.

At the time, Ferguson said improving the efficiency and safety of transport networks is a priority for the State Government as it enhances productivity in the broader economy.

“The Tasmanian economy has been growing strongly and improving our freight transport infrastructure will ensure that growth continues,” he said. “We are investing heavily in upgrading key freight routes and strengthening bridges to cater for modern heavy vehicles. Illawarra Road is a key link between the north and south of the State. Its upgrade will benefit not only our freight operators but provide a safer, more efficient route for everyone using this road.”

Planning is progressing on the next stage of improvements, with detailed design underway on a 2.9-kilometre

section at the Bass Highway end of the Illawarra Road.

Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said the completion of this road will provide a major economic stimulus to centres in the region.

“Improved infrastructure and enhanced safety will benefit all motorists travelling on this key transport link,” she said.

The project was jointly funded by the Australian and Tasmanian Governments and aims to improve productivity and efficiency in moving freight and increasing safety for all road users.

GDP growth rate March 2023 Interest rate June 2023 Inflation rate March 2023 0.2% 4.1% 7.0% Australian Consumer Confidence 0 5 -5 -10 -20 10 15 20 25 10 4 -1 0 0 -4 1 -1 -4 -4 -1 6 8 Jul 2022 Oct 2022 Jan 2023 Apr 2023

www.trailermag.com.au 33

Decision of a lifetime

Vanstone Logistics is a family owned and operated business based in Queensland. Its original identity, Vanstone Produce, was established in Rochedale in 1912 and later relocated to Lockyer Valley in 2008. In 2021 the family saw the need for further growth and so Managing Director, Justin Vanstone, brought the transport version of the company to life for a better service level and flexibility in freighting. This is when Justin approached Brown & Hurley to build his fleet. Here he met Trevor Cox, who sourced his first trailer in the form of a Schmitz Cargobull B-double set.

“We were looking around and we were impressed by the insulation of panels with Schmitz Cargobull,” Justin says. “They seemed far superior to a lot of other makes on the temperature side, and that was very important for us.”

Since then, Vanstone Logistics hasn’t looked anywhere else when the time came for a new trailer. And while the fleet only has 18 months of experience with the Schmitz Cargobull product, it’s 18 months of an entire fleet worth.

“We’re solely Schmitz Cargobull,” Justin says. “We use different configurations and chassis, but our whole fleet is built by

them. There are two main reasons for this. Availability was definitely one and then the second was the way that their trailers are constructed, specifically the refrigerated box. We also quite like the design of the flat floor inside and it gives us a lot of flexibility with their load bar system.”

All of Vanstone Logistics’ trailers are fitted with Schmitz Cargobull’s double loading systems, which are well-known for their loading bars capable of sliding to the roof. This, Justin says, is very unique in the marketplace.

“They’re very quick to load and unload, which is critical,” he says. “It reduces driver

As soon as Vanstone Logistics expanded from a farming company to become a transporter, it made the decision to invest only in Schmitz Cargobull for its refrigerated trailers.

34 XXX Trailer Magazine JULY 23

Refrigerated transport equipment

time while doing loading activities. That system is definitely what stands Schmitz Cargobull out from the rest for us.”

The Vanstone Logistics fleet is based on four Schmitz Cargobull trailer configurations – rollback A trailers, road train-capable 22-pallet trailers, a couple of B-double specific trailers to help with weight distribution and a 24-pallet European unit thanks to its latest order.

“We only just recently took delivery of the first of three European-built, 48foot trailers,” Justin says. “We’re pretty impressed with them. They’re a bit of a different design, they’re very dock-friendly on the rear end and there’s improvements on the dimensions inside.”

There are also more units in the delivery process onsite at Brown & Hurley Yatala, which Justin is eager to get his hands on.

These units, among the others, will run between Brisbane and Sydney carting produce primarily as well as anything refrigerated. With the Schmitz Cargobull trailers being matched up with Thermo King fridges, Justin has found the product to be very efficient in their operations.

“They’ve been pretty good,” he says. “Fuel economy on the fridge side of things has been great. There are no temperature issues or anything, which is very important. Also, the way that they actually tow and sit on the highway has been very good too. They are a little bit lighter as well, which improves the payload just a bit.”

Choosing to rely on Schmitz Cargobull solely, Justin says, seems to have been the right choice.

“It’s the reliability of the temperature control, honestly, which is the biggest tick of the box,” he says. “I’ve got a lot of

faith in them – their ability to have good temperature control is definitely the biggest benefit for sure.”

According to Justin, Schmitz Cargobull meets all of Vanstone Logistics’ demands.

“Overall we’re pretty happy with the product,” he says. “They’ve stuck to their delivery schedule, and that’s why we’ve continued to take new deliveries from them.

Contact

Schmitz

www.trailermag.com.au 35

Cargobull Australia

3174 VIC

“That’s an additional A trailer just to balance us out,” he says. “Every 22-pallet of ours will have a 12-pallet to go in front of it with the delivery of the last A trailer. 144

Unit 2, 221 Browns Road Noble Park North

Ph: +61 434 743

Web: www.cargobull.com.au

Our second 48-foot trailer is also being prepared and signed up, which is another European-built trailer.”

“We’ve got to the point where there’s actually a third trailer that Brown & Hurley will deliver in the coming months, so that pretty much forms up our initial two-year plan. I haven’t sat down with Trevor to organise it yet, but Schmitz Cargobull will be a part of that growth moving forward if that continues, for sure.”

Tassie cold snap

With a growing transport business and more trucks on the road with perishables, Troy Streefland’s recent investment in refrigeration technology was a natural progression. Now his cargo isn’t just cold, but he has the data to ensure it stays that way.

36 XXX Trailer Magazine JULY 23 Refrigerated transport equipment

As summer sets in, Troy Streefland has embraced the technology involved in keeping his cargo cool. He is using the Tasmanian winter months to make sure his new Carrier Transicold equipment is ready to go.

His company, Launceston-based Streefland Logistics Solutions, supports a number of fast-moving consumer goods with beverages being the main product they deliver.

“We made a decision to improve our cold chain and have a unit that could run independent of the truck and could be operating when the trucks are stationary and we’re making deliveries,” Troy says.

Carrier Transicold’s Supra range of refrigeration units are designed for demanding distribution environments. They offer superior pull-down and accurate temperature control and are supported by a range of evaporators with electric fans, providing constant airflow independent of the engine.

Troy had previously owned some of the cold chain provider’s direct drive units that he was happy with, but they only worked when the engine was running. He decided to stick with the brand and ordered four Supra units for his rigid trucks.

“We are only a few months in, but so far the feedback from staff has been really good,” he says.

Troy’s business got its start as a country milk and bread run his parents bought in 1986. With time they added a furniture delivery business into the mix, but eventually decided to concentrate on client specific contracts. In 2008, Troy came on board helping transition the business to one that included logistics and warehousing. Today he has 40 vehicles in his fleet and more than 55 staff members.

To go with the Supra units, Troy has also acquired Carrier Transicold’s Lynx Fleet telematics system to monitor location and temperature. The Lynx Fleet digital platform offers end-to-end supply chain visibility, real-time monitoring, actionable analytics and improved sustainability for refrigerated transport operations.

“Telematics was an affordable bolt-on, allowing us to be able to monitor things remotely and ensure we remained within specification,” Troy says. “It’s an application that allows us to give our customers a safety net.”

For Troy, the winter is a good time to work with the equipment and build some data sets before the heat of the

summer set in.

“Hopefully we’ll have a good handle on what that data and information will give us ahead of our summer months and our peak periods for beverages as well.”

Troy says staying on top of advances in technology is a must in business and he’s pleased that any issues he or his staff have in learning about the new equipment is

met with timely, expert help from Carrier.

“They have a great team of contractors that look after their after sales service,” he says. “Even though we are on the island, we are well taken care of.”

Contact Carrier Transicold www.carrier.com www.trailermag.com.au 37

The right cut

If anyone knows just how important quality refrigerated transport is, it’s Rob Hawthorn. As a former butcher, he understands the value of the product his trucks are carrying as they make their way from various abattoirs around the country.

“We can have up to 20,000 kilograms

of meat on a truck at any one time and that can add up to hundreds of thousands of dollars,” he says.

Rob’s progression from butchering to refrigerated transport evolved over time. He started with small delivery trucks and now owns road trains as the Managing

Director of Southern Refrigerated Transport, which is now in its 12th year. The company, which works primarily with butchers and abattoirs, specialises in handling chilled and frozen produce.

“I’d like to think that what I’ve done in the meat industry previously has enabled me to understand things like shelf life, and allows us to set a high standard,” Rob says.