All night long: Queensland’s oldest and largest sewer was upgraded while the city slept

Read on to learn how we rehabilitated this 100-yearold sewer

All night long: Queensland’s oldest and largest sewer was upgraded while the city slept

Read on to learn how we rehabilitated this 100-yearold sewer

ISSUE 77 FEBRUARY 2023

TRENCHLESS PIONEERS

ProjectMax Company Director and Principal Engineer Steve Apeldoorn

UNDER NEW SOUTH WALES

New South Wales’ operators open doors to share and collaborate

NEW TECHNOLOGY

Voeu keeps an eye on the evolving water sector

Adapting, improving, and leading the way in liner systems

Collaboration results in new drilling machine – AdaptX

Proof in the UK pudding

RELINING

Providing the right technology to succeed with pipe rehab and repair

Aussie Trenchless steering future pipe rehabilitation

Smart Lock’s Shane Curren reveals the company’s full support capacity

McRobert restores PST channels at Woodman Point

Putting the best solution forward for corrugated pipe installations

MICROTUNNELLING

DJ MacCormick Contractors completes seven drives on Iron Bridge Project

How Pezzimenti Trenchless overcame challenges using microtunnelling

HDD

The future of HDD: daunting, thrilling, and important Diversified partnering with Ditch Witch CEA for over 30 years

REHAB & REPAIR

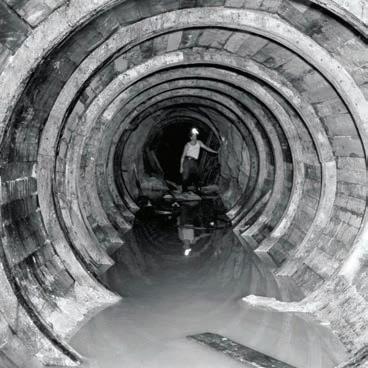

How Queensland’s oldest and largest sewer was upgraded while the city slept

VACUUM & HYDRO EXCAVATION

Sustainable excavation for trenchless applications

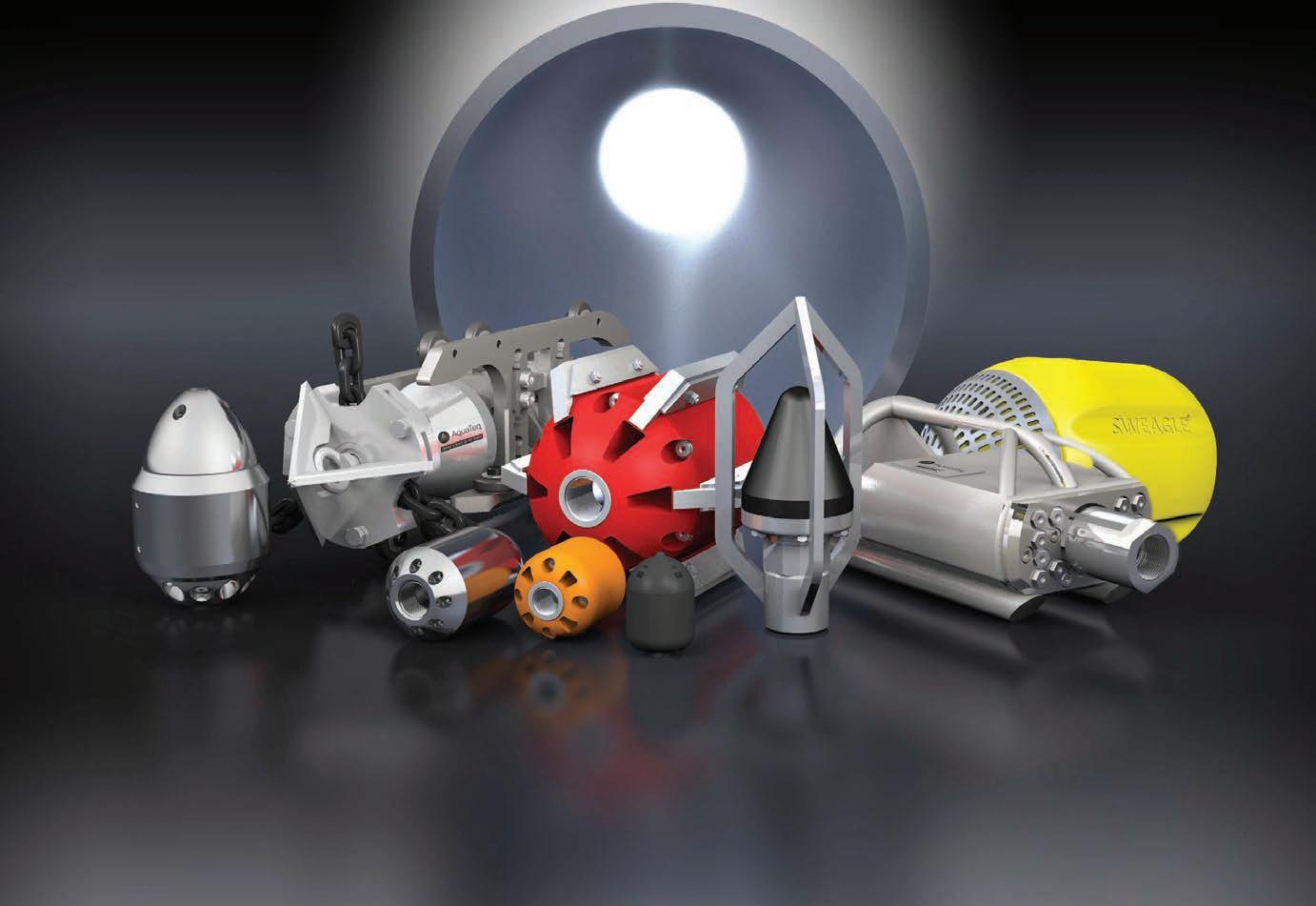

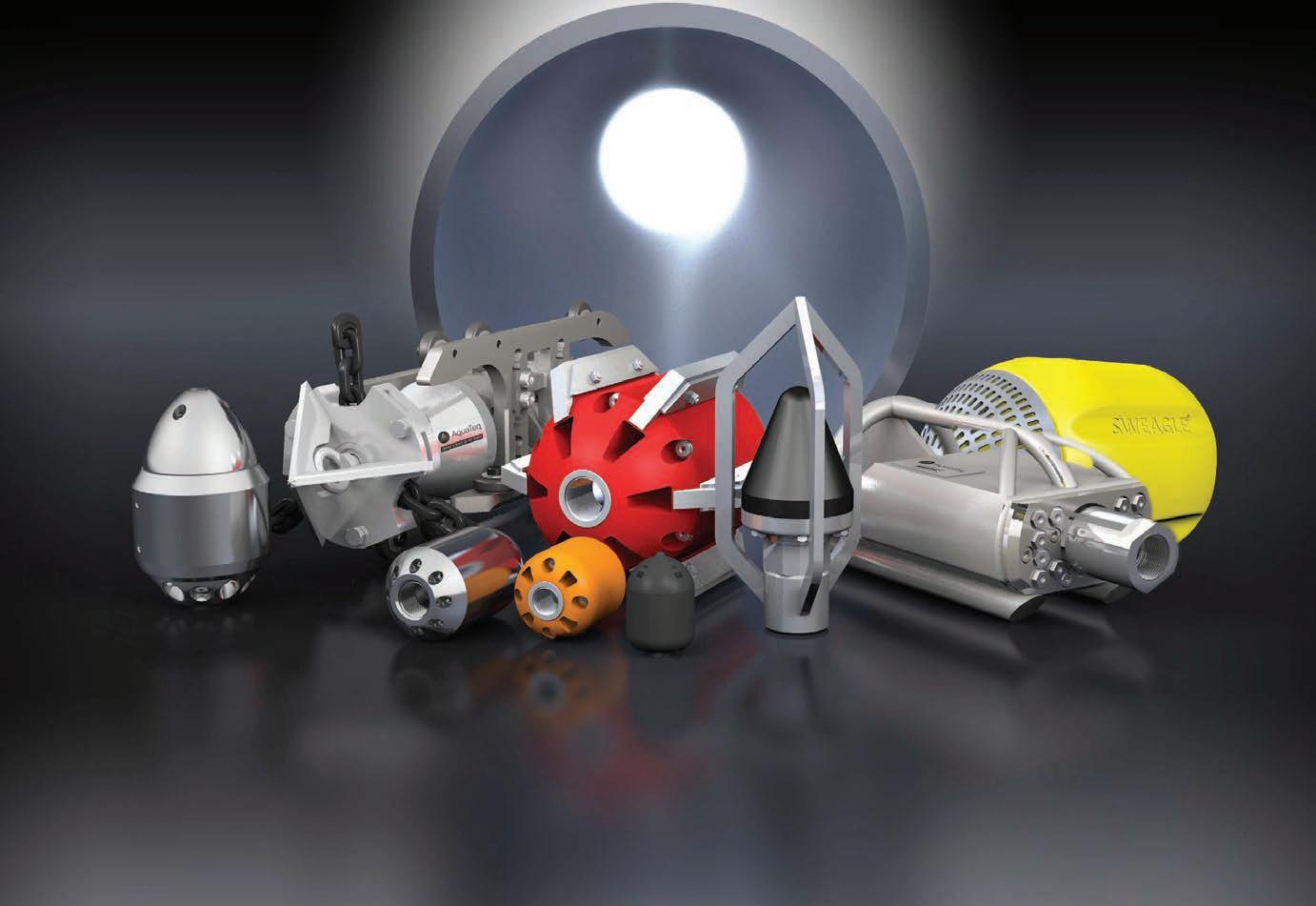

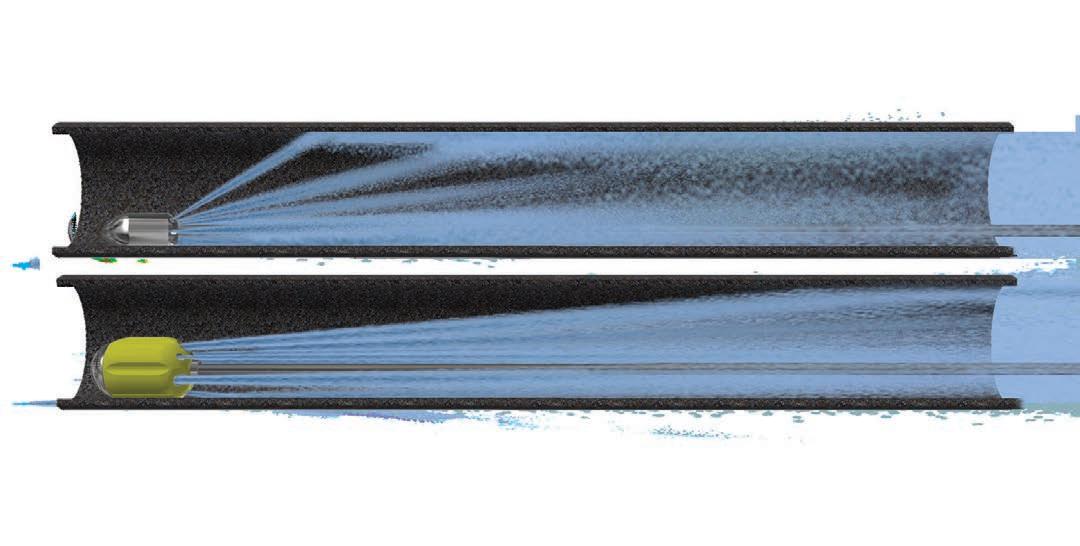

The science behind jetting nozzles

WASTE MANAGEMENT

CDE and Enviropacific close the loop on wet waste in Melbourne

REGULARS

Editor’s Letter

From the President

From the ASTT Secretary News in brief

No-Dig Down Under ASTT Corporate Members

People on the Move

This magazine is the official journal of the Australasian Society for Trenchless Technology (ASTT) and is distributed to members and other interested parties throughout Australia and the Asia-Pacific. It is also available on subscription.

The publishers welcome editorial contributions from interested parties. However, neither the publishers nor the ASTT accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or the ASTT. Neither the publishers nor the ASTT accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

Unless explicitly stated otherwise in writing, by providing editorial material to Prime Creative Media (PCM), including text and images, you are providing permission for that material to be subsequently used by PCM, whole or in part, edited or unchanged, alone or in combination with other material in any publication or format in print or online or howsoever distributed, whether produced by PCM and its agents and associates or another party to whom PCM has provided permission.

Cover image Left: Asset Survey Solutions is pushing the constraints of the underground mapping service sector. Image: Asset Survey Solutions.

We provide infrastructure and construction projects with unique solutions based on our full range of applications, including:

• 3D Laser Scan inspections

• Sewer Access Chamber and Pump Station refurbishment

• PVC and polyethylene welding

• High pressure jet pipe cleaning

• CCTV inspections of piping and sewage systems

CEO

John Murphy

COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITORIAL

Christian Alphonso, Jenna May

BUSINESS DEVELOPMENT

Nick Lovering nick.lovering@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGNERS

Kerry Pert, Tom Anderson, Louis Romero

COPYRIGHT

Trenchless Australasia is owned by Prime Creative Media and published by John Murphy. All material in Trenchless Australasia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trenchless Australasia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive, Docklands VIC 3008 Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065, Australia Ph: (02) 9439 7227

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

Welcome to the first edition of Trenchless Australasia for 2023. It is great to join you again this year to bring another year of the latest industry news, technology and projects around Australasia.

This edition we focus on new technology in the trenchless sector and where it is heading in years to come. As an industry that is forever evolving and adapting, it is an exciting time to see what is on the horizon.

Jason Marshall, Managing Director and Principal Consultant at Voeu, has 35 years experience in the construction and infrastructure industries. In an interview with Trenchless Australasia, he offers a unique and valuable insight into the current state of the gravity drainage market, with a vision towards the future and how new technologies may impact the industry.

Similarly, childhood friends from the UK and business partners, Darren Dean and Sean Henry took what was a gap in the market and brought their surveying knowledge and expertise to Australia to create Asset Survey Solutions. By working in a niche market, and the company’s long history of adapting innovative technology

on high profile infrastructure projects, it has provided the company with an exceptional amount of experience in delivering surveying solutions for the trenchless industry.

With a growth mindset, technology has resulted in new machines being built, which have the ability to adapt methods quickly and save contractors time and money.

OptionX Group has launched the AdaptX range – a fully adaptable drilling machine made in Australia. Stuart Harrison, the inventor of the Vermeer AXIS laser guided boring system, says the machine has a maximum thrust of 125 tonnes and a rotation torque of 180,000 ft lbs, and is primed to revolutionise the drilling industry.

In addition to this theme, other unique features in the next edition include Horizontal Directional Drilling, Rehabilitation and Repair, Microtunnelling, Relining and Vacuum and Hydro Excavation.

Happy Reading!

Molly Hancock

Editor

molly.hancock@primecreative.com.au

With a focus on safety, innovation and collaborative delivery over the last 30 years, Rob Carr has achieved outstanding outcomes in water, wastewater and energy infrastructure projects in both Australia and overseas. Rob Carr is part of Soletanche Bachy a world leader in foundation and soil technologies and subsidiary of VINCI, a global player in construction across more than 100 countries. With outstanding capabilities to manage the complexities of any project, Rob Carr has the people, knowledge and experience to deliver success.

THE AUSTRALASIAN SOCIETY FOR TRENCHLESS TECHNOLOGY

ABN 43 893 870 966

18 Frinton Place

Greenwood, WA 6024

www.astt.com.au

jeffpace@astt.com.au

President: Ben Crosby

Secretary: Jeff Pace

Vice President: Blair Telfer

COUNCILLORS

Western Australia: Trevor Gosatti

Queensland: Ben Crosby

New South Wales: Matthew Boyle

Victoria: Justin Shepherd

South Australia: Shaun Melville

New Zealand: Blair Telfer

Northern Territory: Vacant

Tasmania: Vacant

Sudipta Basu

Anew year is upon us, and I will take this opportunity to wish you, your families, and businesses a safe and prosperous 2023.

The ASTT closed 2022 off well and now we’ve all had a well earnt break, we turn our focus to the new year and what we have instore for 2023 is exciting.

2023 is our exciting conference year and at least the first half of this year will be dominated by the planning and organisation of what will be another great No-Dig Down Under Conference.

This year the conference is held in Brisbane between 12 September and 14 September under a slightly different and condensed program. By popular request, we have opted to remove the usual final day where the exhibition hall is open for a half day before bump out commences. This part of the conference is usually the quietest time and the foot traffic has slowed due to the previous two days in addition to the conclusion of the technical papers.

The theme this year is “Better Outcomes Through Trenchless” which we hope will stimulate conversation and influence the papers, the exhibitors, and the panel discussion on improving the service industry with better design, better method selection and better overall solutions.

I encourage you to be creative in the exhibits that you are planning, and we’d really encourage you to showcase your new products and services in the exhibition hall. I also implore you to celebrate your successes, challenges, and developments in the technical

portion of the conference. We had a great technical and case study paper presentation at No-Dig Sydney, and we’d love to see more in Brisbane this year.

The call for abstracts is now open and we encourage you and your colleagues to submit an abstract in the pursuit of being approved to submit your paper. We seek knowing how Council will continue to work through the all important key actions during 2023 as listed:

• The roll out of our Strategic Action Plan

• The finalisation of our Liner Design Specification

• The delivery of the Trenchless Technical Stream at Water New Zealand Oct 2022

• The finalisation of the Liner Design Training Package

• The continuation of the updates to our NASTT licenced training packages

• The compilation of the report: The State of the Industry (Trenchless)

• The partnership with AusJet

• The partnership with WSAA (Water Services Association of Australia)

All these initiatives are designed to deploy the membership resources to benefit the industry and the membership in one way or another. A reminder to our members; if there is something that you feel we as the peak trenchless body should be working on, please reach out and contact either myself or your local Councillor.

Ben Crosby ASTT PresidentWe are a

We are the world’s leading manufacturer and supplier of fiberglass reinforced liners for trenchless pipe rehabilitation, Cured-In-Place-Pipe (CIPP) solutions.

We are reliable solution partners at all times, and commit ourselves to the highest future-proofed quality and to environmentally conscious conduct.

Australia-Wide

Wherever you're based, we're ready to help.

Environmentally Conscious

Our activities are always resource-saving and environmentally conscious.

Globally Trusted

IMPREG CIPP liner systems for UV curing are used and trusted all over the world.

Our warehouses are fully stocked. Contact us today to secure your pipe rehabilitation project this summer. sales-apac@impreg.com

www.impreg.com

On behalf of the ASTT, I extend a warm welcome to the following new members.

Michael Ellenrieder from IMPREG (Australia) Pty Ltd

Devan Russell from Aussie Drill Kings Pty Ltd

Individual Members – Australia

Aaron Gilboy from Stantec

Individual Members – New Zealand

Howard Simpson from Christchurch City Council

Salve Velasco from Christchurch City Council

The call for nominations to Council was emailed to all ASTT Members on 5 January 2023. The same notice was also published by Prime Creative Media on the Trenchless Australasia website on 12 January, 2023 also it was mentioned in the e-news dated 19 January 2023. The results will be published in the next issue and all positions will be ratified later this year at the AGM.

In early December, the majority of the membership would have received their tax invoices for the 2023 membership year through our new automated database system. These fees were due to be paid on 1 January 2023. It was pleasing to see that the number of members that renewed their memberships on time was an increase from last year. The PayPal method is now the most popular. For those that have still not paid, can you please expedite thus avoiding cancellation of your membership. Also, all members that change their email address or postal address are requested to let me know so that the ISTT and ASTT databases can be updated, these are the databases that amongst other things deter-mine distribution of the magazines. For those of you that no longer work for the companies that pay your membership renewals, can you please let me know that you have left and also who the replacement person is for your membership.

For those members living outside Australia that need to pay the annual membership renewal fee in Aus-tralian dollars will in most cases experience an international transaction bank fee. It is important to ensure that you add this fee to your transaction thus avoiding not paying the nominated amount. An international transaction fee is charged to you, the consumer, by your bank whenever you acquire something in a foreign currency. While all of these charges are applied to you the members, they are also to be added to your transaction when you make a purchase online from a foreign vendor. In most cases the general fee the banks are charging is $10. For example, in some cases your membership renewal fee for someone living in New Zealand is AUD$540, when you do the bank transfer the bank charges you $10, which means the ASTT only received $530. It is up to you to ensure the bank fee is added to your international bank transfer.

In September 2020, Blair Telfer your New Zealand Councillor established our second Special Interest Group (SIG) on the basis that this SIG represents the linings group in general. One of the original objectives of the group was to develop specifications for pipe lining that the industry, clients, consultants, asset owners, can use with confidence to ensure a quality product and that are appropriate & applicable to Aust & NZ conditions. Non-members can get a feel for the contents covered by this Specification by referring to our website, refer: https://www.astt. com.au/guidelines/. All ASTT members, as a membership benefit have full access to the entire 32 page document by accessing it through https://astt.wildapricot.org/ ASTT-Guidelines. The ASTT wishes to thank Blair and all those that contributed to the development of this specification.

It has been a long time since we developed the 2010 versions of HDD, pipe bursting,

microtunnelling Guidelines, Standards and Specifications onto our website. In 2020, we introduced our comprehensive Microtunnelling Design Guidelines Sewer (MDG-S) and now it is time to completely review the other documents we have on the ASTT website as listed at https://astt. wildapricot.org/ASTT-Guidelines.

No doubt most of you are aware that we are now back to our regular biannual frequency of holding our National Conferences now that COVID-19 seems to be under control. To this end our next National Conference and Exhibition will be held over September 12 to 15, 2023 at the Brisbane Convention and Exhibition Centre. I’m pleased to confirm that the organising committee has approved the conference theme of “Better out-comes through trenchless”. The call for abstracts is now out and submissions will close on 31 March 2023. In my previous report I mentioned that both sponsorship and exhibition space was progressing well ahead of schedule. When I last looked the exhibition was approximately 80 per cent sold and I am confident that the remaining spots will be taken up quickly. Exhibition sales are still available so if you are interested in exhibiting and do not want to miss out, then please contact Nick Lovering at nick.lovering@primecreative. com.au. More information is also available on the event website, refer: https:// nodigdownunder.com. There are now limited opportunities available with the following locked in thus far. Rob Carr as the Platinum sponsor. Vermeer as a gold sponsor, Wilmott Pipelining, Interflow and Rockpecker as the Silver sponsors. Sponsorship provides companies highly visible branding opportunities in Australia, New Zealand, and the global trenchless community, with packages that include exhibition space and conference tickets, as well as unique sponsorship.

Jeff Pace ASTT Secretary secretary@astt.com.au

Watercare’s tunnel boring machine for the Central Interceptor project in New Zealand completed its undersea crossing of Manukau Harbour. Hiwa-i-te-Rangi, the tunnel boring machine (TBM) bored a 1500 m stretch of 4.5 diameter tunnel between 15 and 20 metres below the seabed.

The TBM required 15 crews on a 24/7 schedule working underground to make the 11-week crossing smoothly.

Watercare’s executive program director, Shayne Cunis, says that the successful crossing is due to the expertise of the tunnelling teams.

“It’s a big relief to get this done successfully, and the fact that it comes just before Christmas means everyone can enjoy a well-earned holiday break,” he says.

Trelleborg Group has finalised its acquisition of the business operations of I.S.T. Innovative Sewer Technologies (I.S.T.) as of the beginning of December 2022.

Based in Germany, I.S.T. is a globally active manufacturer and distributor of a range of cutting-edge sewer rehabilitation products. The company’s range includes several milling robot models for pipes with internal diameters from 100 to 700 mm, as well as mobile UV, steam and hot water units.

Jean-Paul Mindermann, President of the Trelleborg Industrial Solutions business area, says that the market for trenchless rehabilitation using UV light curing technology and glass fibre is growing rapidly.

“This acquisition is, therefore, a strategic addition that strengthens Trelleborg’s position in the pipe repair market. The acquired operation complements Trelleborg with its broad service offering, strong focus on R&D and entrepreneurial working methods,” he says.

I.S.T. has offices in Germany, Europe and North America, and works with an expansive global network of independent distributors. Mindermann said that both companies are excited about the acquisition, and that it aligns itself well with Trelleborg’s current momentum in sales and production.

Since beginning its crossing in August 2021, Hiwa-i-te-Rangi has travelled more than four kilometres from the Māngere Wastewater Treatment Plant to its breakthrough on the far side of the harbour. The first link sewer for the Central Interceptor also recently hit a milestone, with micro TBM Domenica achieving its third breakthrough in November.

Only 330 m of tunnelling remain for the first link sewer before Domenica begins the second next year.

The proposed extension of the Central Interceptor project is awaiting consent applications which are due to take place early in 2023.

Rob Carr has taken home the 2022 national award for Civil Construction at the National CCF Awards in Canberra.

The microtunnelling specialist won the award in the $5 to $10 million category for its Gnangara Branch Sewer section 2 project, located in Western Australia.

The project, undertaken on behalf of client Water Corporation, involved installing a new pressure main to an existing sewer section. The company’s expertise in microtunnelling saw it overcome several challenges for the project, including in-ground infrastructure and a limited time frame.

Teams completed four drives reaching a total 500 m of microtunnelling, and managed to construct a DN1000 glass reinforced plastic, 259 m microtunnel in 10 days.

The Gnangara project was automatically nominated following Rob Carr’s win at the CCF WA Awards in September.

Managing Director Damien Maitre received the award on behalf of the company.

Central Highlands Water’s Ballarat Sewer Build will commence stage 2 of its duplication in 2023 with microtunnelling beneath Humffray Street South.

For stage two of the Ballarat Sewer Build, a microtunnelling machine will bore a 700 m, 1200 mm diameter tunnel beneath Humffray Street South, with a pipe to be constructed parallel to the existing sewer infrastructure.

Minor repairs and sewer pipe relining for the existing pipes will co-occur during tunnelling operations.

Stage one of the project saw 1 km of pipe laid beneath the city’s CBD. The project represents a $25 million investment from utility company Central Highlands Water and will bolster the city’s two largest sewer lines – the Ballarat East and Ballarat South – which were constructed almost 100 years ago.

Since the original pipes were laid, Ballarat’s population has grown by more than five times to 117,000 people.

Once all stages are completed, two large interconnecting sewer lines will run beneath the streets of the city, approximately 6 km in length. The third and final stage of the project is currently in the planning phase.

Unitywater has reconnected water to White Patch in Queensland after it was washed away in February 2022.

A rain bomb destroyed a 20 m section of the White Patch Esplanade, including the water main that ran beneath the road, in White Patch –a small community in Bribie Island.

Local utility provider Unity Water enlisted a specialist contractor to build a temporary water supply. This was completed in three days.

Unitywater Executive Manager Sustainable Infrastructure Solutions Daniel Lambert says that it was critical for the company to restore the water supply to full service.

The project to establish a permanent solution took eight months, including geotechnical analysis, consultation with residents, local

council, and Kabi Kabi representatives.

A new 250 mm diameter pipe was installed using horizontal directional drilling.

“These were complex works that carried a level of risk, especially as some of the drilling occurred underwater,” says Lambert.

Rhett Duncan, Unitywater Executive Manager Customer Delivery, acknowledged a rough year for the residents of White Patch.

“Unitywater and our partners demonstrated what it means to work as a team during adversity, coming together to

In a bid to celebrate the achievements and growth of the trenchless industry and the ASTT, Trenchless will be running a new question and answer segment: Steve Apeldoorn, Company Director and Principal Engineer of ProjectMax. This is his story.

In your own words, how would you explain what the trenchless industry is?

The trenchless industry is a community of extremely skilled people and incredible technology that enables the construction and renewal of underground infrastructure that in many cases could not otherwise be built or would be hugely impacted and detrimental on the community.

How did you become involved in the trenchless industry?

In early 2000 I had the opportunity to manage a relatively small team replacing wastewater pipes in Waitakere City using pneumatic pipe bursting equipment and we also had small pit drill. But even well before that, in the mid 90’s we would use thrusting gear to install small diameter pipes where we couldn’t get excavators in or couldn’t disrupt the ground surface. By 2002 pipelining was really taking off and I had founded ProjectMax with some other colleagues. For the last 20 years we have helped Councils determine the best methods for rehabilitating and replacing their underground infrastructure.

What is a standout trenchless project or milestone you have been involved in? Can you elaborate more on this?

I have been involved in many challenging trenchless projects but what I am most proud of has been my involvement in the ASTT itself and what we have been able to add to the industry itself. In 2009 I had the privilege of becoming the NZ Councillor for the ASTT and between 2014 and 2016 the honour of being elected the President/Chair. Over that time, we extended the Trenchless Technology Forums, that we originally started in Auckland in 2007, to a number of states in Australia and introduced the special interest

groups, including the Microtunnelling and Pipe Lining Special Interest Groups. These have been hugely successful in providing opportunities for member engagement within the industry and promotion and education on trenchless technology with the wider public and infrastructure community.

What is the best part of trenchless technology? And how has it evolved since you first became part of the industry? Trenchless technology enables the installation or rehabilitation of underground infrastructure that would otherwise not be possible to construct or be very disruptive and cost prohibitive. Overtime what has been possible to achieve and continuously improved – size, length, bends, you name it.

Which form of trenchless technology do you think has had the most transformation and why?

I don’t know if I can identify a single trenchless method. In all areas we have continued to see outstanding, and sometimes mind-blowing achievement, that seem to continuously break records.

Where do you see the trenchless industry in the next 10-20 years?

At the 2015 conference opening address I made a statement along the lines that trenchless technology is no longer an alternative technology, but now part of how infrastructure is constructed. This will continue and as we move forward, the technology, the skilled workforce, and capability will continue to grow and it will be what delivers the significant infrastructure challenges that we will be facing over the next 20 years with aging infrastructure, climate change and our growing communities.

With trenchless technology having a strong ability to reduce the impact on the environment, what more do you believe the industry needs to do in order to further reduce emissions and the impact on the environment? I think that the industry is naturally continuing, through competition and growing capability, generating the equipment and technology to reduce the impact that constructing infrastructure produces. The capability to install longer lengths from a single site in itself has significant impacts. More efficient engines and electric motors, low carbon materials and waste material recycling are continuously being developed and we need this to continue to happen. The ASTT can play an important role advocating and promoting ongoing improvements, and vitally to continue to educate the public and wider industry on the environmental benefits that trenchless technology already brings over the alternatives.

This edition of Trenchless Australasia has an overall theme about new technology. How has the industry progressed in this and also being more diverse?

The amazing thing about the trenchless industry is that there seems to always be new technology emerging every day. This is being developed within Australasia and all around the world. The ASTT has for more than 30 years been the community in this part of the world that collectively has enabled asset builders and owners to adopt this technology so widely. I strongly believe that with out the ASTT that the development and use of the technology would not be so advanced. We need to Acknowledge the massive contribution that Jeff Pace has made to the ASTT. Jeff was one of the founding members of the society and has continued to help maintain and build the society to this day.

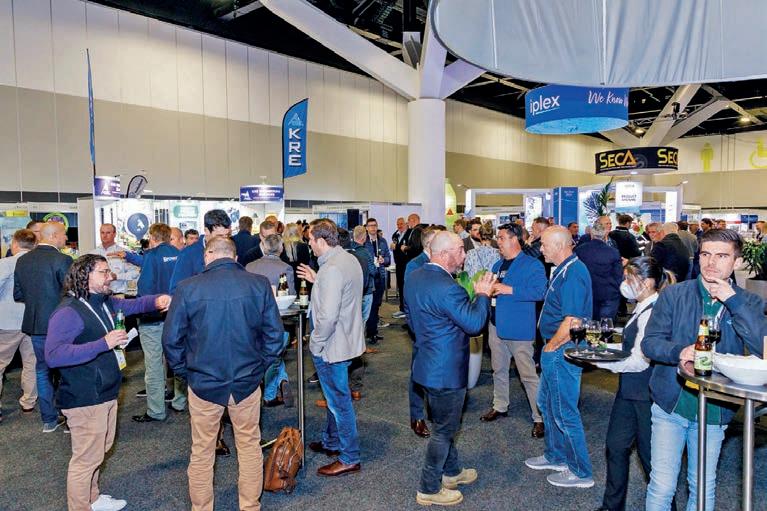

Trenchless operators in New South Wales have shown a strong sense of community, sharing product knowledge, technology, and expertise to ensure success and development in no-dig projects and asset management.

Trenchless industry operators across New South Wales have shown the true value of sharing innovations in the industry by opening its doors to anyone who might be interested.

In December, KOR Equipment Solutions held a networking and demonstration day at its Mt Druitt facility in Sydney. The event came following the company’s open day held in Mulgrave earlier in 2022.

The event brought together industry operators, with KOR putting its capabilities on full display. Attendees were able to see showcases of the company’s Cappellotto and Schwarze units, as well as KEG nozzles, TST

protective gear and products from Vanguard. Both events proved the value of networking and collaboration to the industry.

In November 2022, leading industry supplier SECA also opened its doors.

The company’s open day attracted operators from across Australia, some from as far as the Northern Territory, who descended on SECA’s Sydney warehouse.

Over the course of the day, the company held information sessions covering the latest advancements in CCTV inspection camera, Chemical-free pipe repair solutions with Quick-lock products, and how the latest software updates for cutting edge asset management program WinCan work to

eliminate the risk of human error in field operations.

Other suppliers from Kaiser, Asset Training and Switzerland’s ENZ were invited to join in, offering customers first-rate product knowledge and advice and showcasing the quality of products that SECA offers.

People pushing through Award-winning company Interflow was engaged by Sydney Water to rehabilitate central and northern rising mains using DN500 Primus Line solution in Marrickville.

Primus Line was installed from the sewer pumping station to the discharge points near Illawarra Road.

The company’s team pulled together to overcome a series of challenges for the project. Both of the existing rising mains required extensive cleaning and grinding works, while the crew were only able to access the line from a limited number of viable access points. To add

to the difficulties, the alignment also included a series of both vertical and horizontal bends.

The Primus Line was winched through the alignment before being inflated and then installed with end connectors. Finally, the line was pressure tested before repeating the process at the next section.

In executing the project successfully, Interflow has added at least 50 years to the service life of both rising mains.

Collaboration between major utility company Sydney Water and the University of Technology Sydney has resulted in new artificial intelligence (AI) technology to detect potential water main leaks and breaks, avoiding costly pipe failures.

Sydney Water’s new technology utilises acoustic sensors that can be located in water mains across the city. The cutting-edge detection equipment transmits signals to computers systems that run an AI program which is able to translate acoustic information into information about the condition of the infrastructure.

The effectiveness of the new technology has been studied over four years, and researchers have confirmed that it can predict the likelihood of a water main failure with 80 per cent accuracy at a range of 200 m.

The world-first AI water leak protection initiative has been rolled out in collaboration with the University of Technology Sydney and has saved an estimated 10,000 megalitres of water over a 30-month trial period.

The collaboration with technology developers vastly improves Sydney Water’s ability to detect faults early, which greatly reduces the

risk of catastrophic infrastructure failures and safeguards the city’s drinking water.

German-based IMS Robotics has partnered with KRE Engineering and UVR Hire to enter the Australian and New Zealand trenchless markets.

IMS, a leading developer, manufacturer and supplier of sewer rehabilitation technology, has established an affiliate company, IMS Robotics Australia, with its head office in Sydney.

KRE Director Keith Edmundson said the company is excited by the partnership and the opportunities it represents for the trenchless industry.

“We are very excited about the opportunity to represent the product portfolio of IMS Robotics and look forward to rendering the same level of services to the market, as we used to do for other brands, and of course, our own robotic cutting equipment,” he said.

The partnership looks to accelerate the market for main line cutting robots and UV curing technology in Australia and New Zealand and has acknowledged KRE’s existing presence in Australia as a specialist in the development and distribution of main line cutting robots.

IMS Head of sales and executive board member Konstantin Wolf said the new affiliate company will promote the group’s full product portfolio. He says that, besides the main line cutting and UV curing technology, IMS Robotics Australia also promote the brands and products of other IMS Robotics Group companies.

“We are certain that we can add more value to the trenchless industry down under, and look forward to the next steps,” he said.

At L&D Micro Tunnelling we specialize in laser guided boring. Our Tunnel bore machines use a vacuum extraction system where all spoil is sucked into interceptor tanks for easy disposal with no mess. All our heads are hydraulically driven and guided by a high accuracy laser to achieve precision over long distances.

Jason Marshall is the Managing Director and Principal Consultant at Voeu. With 35 years’ experience in the construction and infrastructure industries, he offers unique and valuable insights into the current state of the gravity drainage market, with a vision towards the future and how new technologies may impact the industry.

As the trenchless technology industry continues to mature, Marshall says that there are still challenges, and opportunities, for asset owners and delivery providers within the gravity drainage renewal market.

“Trenchless technology has been used in the renewal of gravity drainage across Australia for more than 30 years. No-dig operations have become the preferred method used by asset owners for renewal of aging gravity drainage infrastructure,” he says.

According to Marshall, the replacement value of publicly owned drainage networks

A specialist water sector advisory and consulting practice, Voeu delivers commercial advice and improvement projects for infrastructure owners, operators, and delivery providers.

are valued at more than $200 billion, with an estimated $450 million spent annually on asset renewals.

These figures include the value of pipelines and structures that make up wastewater, stormwater, and culvert gravity drainage systems, along with associated costs incorporated into renewal programs.

“The renewals market for gravity pipelines is typically divided three ways; 70 per cent wastewater, 10 per cent stormwater, and 20 per cent culverts, though this varies by region,” says Marshall.

“Stormwater pipelines are underrepresented in trenchless renewal because they are typically laid shallowly, making them easier to replace using open cut methods.”

“Significant changes continue to occur within the renewals market as asset management priorities evolve, innovative technologies continue to be developed, and new delivery providers emerge,” he says.

Marshall says that the industry is steadily increasing its focus on asset condition assessment and planning, which has resulted in asset owners improving their understanding of the condition of their existing assets. This information has been used for strategic asset management targeted at optimising the performance and whole-of-life cost of the drainage systems.

“Early adopters of trenchless technology are realising operational improvements from long-term renewal programs. Reduction of chokes, wet weather overflows, discharge to waterways, and critical asset failures are examples where program objectives are being achieved,” he says.

There is, Marshall says, an emerging trend that sees pipeline renewal being incorporated into larger capex and opex programs. A trend that he believes is likely to continue, especially with larger authorities. These programs incorporate maintenance, design, and renewals

where the delivery provider is accountable for performance outcomes and risk.

“When it comes to the benefits, and risks, of an evolving industry, it’s primarily delivery providers who are in the thick of it,” he says.

A broad category itself, delivery providers can be further divided into four main groups:

• Large specialist renewal contractors that provide a wide range of products and services across the water sector in multiple regions.

• Small specialist renewal contractors that provide a limited range of products and services usually to a specific region or customer group.

• General renewal contractors that provide a limited range renewal products and services in addition to their core business, for example; civil contracting or drain cleaning.

• Specialist contractors such as plumbers who have entered renewals in small diameter pipelines or provide specialist services such as patching or junction sealing.

There is a high level of competition between large specialist contractors as they typically compete for larger contracts and have greater insight to each other’s operational costs and productivities. Contractors usually focus on delivering larger contracts to enable continuity for their lining crews and on larger diameter projects that are typically more profitable.

The product groups used in trenchless gravity drainage renewal have not changed radically

over the last 30 years. These products include:

• CIPP lining

• Die reduction lining

• Fold and form lining

• Lateral lining

• Patching

• Pipe bursting

• Protective coatings

• Slip lining

• Spiral wound

• Spray linings.

Technological advancements in renewal products and services are usually enhancements made to existing products, or alternative versions of current products from new suppliers.

“A CIPP lining system that use UV or LED lights to cure the liner instead of heated water is an example of a product enhancement, while new equipment suppliers providing forms of spiral wound lining systems –products with patents that have lapsed – to the market represent an alternative version of a current product,” says Marshall.

Gravity drainage renewal is a highly

competitive market, partially because the barriers for the entry of new competitors is so low.

“There are multiple versions of products available from suppliers with equipment that can be leased or rented prior to purchase,” Marshall says. “Training and technical support is provided by suppliers during bidding and through project delivery.”

“There is also a clear path for new operators – a healthy demand for operators on smaller projects in regional areas to build operational credentials and experience,” he says.

The changes within the drainage renewals market provide opportunities and challenges for the industry as innovative technologies emerge and new competitors enter the market.

“There are significant opportunities for the industry given the current unprecedented spend in the infrastructure sector, offset by the risk of cost increases and shortages in the supply of materials, equipment and skilled labour,” says Marshall.

The evolution in asset management needs to be acknowledged and considered by industry operators, as priorities shift inexorably towards strategic asset management over renewals programs.

“As a company specialising in advisory and consulting services for the water industry, Voeu uses its industry experience and commercial expertise across the water sector to partner with organisations to help them grow and become more profitable,” he says.

For more information visit www.voeu.com.au

IMPREG finds its origin in the regional south of Germany, not far from Stuttgart. The area is known for global, high-quality brands and IMPREG is no different – leading the way in trenchless pipe rehabilitation through high-tech cured-in-place pipe liner systems for UV-curing.

Clients have come to expect outstanding quality from IMPREG. After installing an IMPREG liner, pipe systems are securely protected for decades, withstanding the most demanding loads.

IMPREG proves its innovation through its cured-in-place pipe (CIPP) solution; one of the leading technologies within the industry that is adaptable to various project scales.

IMPREG not only meets and accelerates global standards, but its liners are innovative especially for dimensions between DN 1200 and DN 2000. With the GL 16 liner, IMPREG hits the nail on the head – creating a liner so versatile and effective, it’s a favourite for projects.

The liners are developed with specific impregnations which are cured using UV light. This method has a clear advantage – speed. Up to three pipes per day are capable of being installed. The pipes are functional immediately after being cured and the technology is environmentally friendly thanks to its high energy efficiency, this makes IMPREG’s CIPP liners the economical solution on any project.

Outside the installation process, clients can store IMPREG liners for up to three months at normal temperatures of 25°C, without additional cooling.

IMPREG CIPP liners come well packed in a specially made, stable transport box made from wood. The inside of the transport box is additionally lined with a UV-resistant foil which provides a further protection against premature curing. Upon request, IMPREG can also use wood treated to IPPC standards to construct the transport boxes. The experienced team can provide support at any time with customs clearance and import into the destination country.

With over 20 years of experience in the industry, IMPREG has been a trusted partner for a variety of projects. Core to the business is the notion that consistent quality and timely innovations

are never achieved through shortcuts.

high-quality and specifically selected raw materials through a certified production process. All liners in IMPREG’s product range have been awarded through German National Technical Approval (DIBt, Berlin), further highlighting the ingenuity of the products.

The company leaves nothing to chance when it comes to ensuring the consistently high quality and very best material parameters for its CIPP liners. Impregnated with innovative resin systems under strictly controlled and monitored conditions, the liners are held to the most current quality standards.

IMPREG’s liners are made using specially designed and high-tech material. This material is reinforced by glass fibres making it permanently resistant to corrosion. Due to its design, the liners possess the optimum properties of high strength and durability, low intrinsic weight, and a long lifetime.

As the world continues to look towards the

important that IMPREG’s liners not only last for decades to come but also limit the use of chemicals.

Notably, when using IMPREG’s liners for a project no chemicals need to be handled on site to install the liners. Additionally, following pipe installation chemical reactions can take place in complete isolation from the environment with no contact to groundwater or soil.

Depending on the use and task, IMPREG can individually optimise resin systems of the liners to ensure additional safety for each individual project. Exclusively DIN-standard unsaturated polyester resins are used across all products within IMPREG’s range. High performance vinyl ester resins are used for waste waters that experience heavy chemical pollution and at high temperatures works to minimise environmental impact.

As IMPREG continues to work on expanding within the Australian market, the company is looking forward to working on many more projects across the country in the years to come.

Edge Underground is a precision microtunnelling contractor that operates in Australia and the USA. With a focus on innovative technology and expertise, Edge Underground designs and enhances the performance of trenchless equipment. Full factory backing here in Australia means solutions can be created when they’re needed most.

PART OF THE

optionxgroup.com.au

optionxgroup.com.au

OptionX Group is launching the AdaptX range – a fully adaptable drilling machine made in Australia. With a maximum thrust of 125 tonnes and a rotation torque of 180,000 ft lbs, this new machine is primed to revolutionise the drilling industry.

Manager Tom Chart was instrumental in production.”

To ensure the AdaptX has the features the industry needs, Harrison and his team took the time to further consult experts, including Tom Chart, now OptionX Group’s Head of Manufacturing. After working for many years at Bournedrill, Chart has the working knowledge to bring a new concept to completion. The AdaptX is made in Bournedrill’s Queensland workshop, securely under Chart’s supervision.

“The AdaptX is a great concept. Edge Underground has tested the equipment and we’ve worked with them throughout the design phase to finalise the machine. It’s something new for the Australian market, but it’s been put through its paces over the last year and held up in all conditions,” says Chart.

The AdaptX modular drilling system is the culmination of work from experts across OptionX Group, with insights from Bournedrill and Edge Underground as well as input from industry leaders.

The innovation was spearheaded by Stuart Harrison, the inventor of the Vermeer AXIS laser guided boring system, who sat down to tell Trenchless Australasia how the industry will benefit from a machine like the AdaptX.

“Previously, contractors needed different equipment for vacuum, slurry, bed boring, auger boring and pipe jacking. With its modular design, The AdaptX can do all this and more,” says Harrison.

Given how often ground conditions present unexpected problems, the ability to adapt methods quickly will save contractors time and money. Other capabilities of the AdaptX include pressure air vacuum, HDD, displacement pilot, canopy tunnel drilling, pipe assist and pipe bursting. Torque and speed can also be adjusted to suit the job.

“The new AdaptX range has more than a dozen inventive features and we’ve sought protection of those features through the Australian Patent Office. We expect this to be granted in the coming years after positive

feedback. International patents will also be sought in due course,” he says.

“The team at Edge Underground has enjoyed working closely with Bert Fourie of Fourie Tunnelling Systems, and Allen Henley, who is the Senior Design Engineer at Bournedrill. As the product moved into manufacturing, Bournedrill’s former General

“Internationally, there’s already interest in the machine. When Stuart and I recently attended the Bauma Trade Fair in Germany, with all the leading manufacturers in the industry in attendance, everyone was looking for updates on the new AdaptX range.”

Along with being manufactured in Australia, having a local engineering and

production team means that any repairs or modifications needed can be completed quickly. Bournedrill’s workshop, and its team, are equipped to service the drilling, tunnelling

and boring industries, and have everything needed to continue to build the AdaptX.

Harrison says inevitable delays associated with using overseas suppliers have had a

negative impact on Edge Underground projects in the past.

“Importing replacement parts has become slower and more expensive over the last few years. Any delay on a project is costly and contractors are always keen to minimise this. We know that if a piece of equipment breaks down or needs modifications, everyone on site is keen to get it back up and running as quickly as possible.

“The faster an issue can be rectified, and the works continue, the better for everyone,” he says.

The current range of AdaptX machines includes the AdaptX Mini and the AdaptX Maxi. Both can be adapted for pit launched HDD, vacuum microtunnelling, auger boring, hammer reaming, pipe jacking and more.

The AdaptX Mini features a torque range of 10,000 to 60,000 with a max thrust of 40 tonnes. The AdaptX Maxi torque range 17,500 to 180,000 with a max thrust of 125 tonnes.

From childhood friends in the United Kingdom to business partners in Australia, Darren Dean and Sean Henry took what was a gap in the market and brought their surveying knowledge and expertise to Australia to create Asset Survey Solutions.

go-to service mapping company, Asset Survey Solutions is at that stage now where it will be recognised for its quality engineering solutions too.

“As a result, we’ve been picking up survey packages for high profile infrastructure projects, such as level crossing removals, including Webb Street at Narre Warren Station. We’ve been getting these packages off the back of that reputation,” Dean says.

Removing this level crossing will improve safety, relieve congestion on Webb Street, and allow more trains to run on the Pakenham Line, more often. The Webb Street level crossing removal is part of a $15 billion investment to upgrade the Pakenham Line, which will be boom gate free by 2025.

Darren Dean and Sean Henry saw an opportunity to grow a business in Australia, especially in the underground services mapping sector.

Today, Asset Survey Solutions specialises in being a multi-disciplined survey company.

Henry says since the company’s partnering with Rangedale in 2017, he and Dean have been able to provide effective and innovative solutions for its clients to better resource their projects.

Following a couple of years of steady growth and business, Asset Survey Solutions has really made a name for itself following works on the Westgate Tunnel Project and the Metro Tunnel Project early works.

“That’s where we really carved our teeth as a company. From there, over the last two years, we’ve just gone through a rapid rate of expansion and growth and we’ve doubled, even tripled, in size over that time,” Henry says.

“We’ve recently branched out into other states as well. We are now in Queensland and Sydney, as well as Melbourne. I think it’s safe to say we’re one of the largest servicers in terms of underground service locating and mapping along the East Coast of Australia.”

Dean says that now the business is five to six years down the line, he and Henry have become proactive in proving themselves to be a leading provider in all surveying services, not just underground service mapping.

He says that by working in a niche market, its long history of adapting innovative technology

on high profile infrastructure projects has provided the company with an exceptional amount of experience in delivering surveying solutions for construction, plant, residential and civil infrastructure projects such as roads, railways, bridges, and the trenchless industry.

“Through our extensive range of laser scanners, total stations, GPS/RTK systems and qualified surveyors, we have the capacity to provide specialist expertise, equipment and experience specific to the projects’ requirements,” Dean says.

Building off the reputation of being the

“Asset Survey are working in conjunction with site engineers deploying multiple survey disciplines aiding and supporting the construction of new car parks and train stations,” Dean says.

“Our role is to ensure that everything that is being installed is in the right place and to within the expected accuracy tolerance. The project only started in September last year, so it’s still really in its early stages.

“We had some of our team working all throughout the Christmas break, conducting track monitoring for multiple rail projects throughout the Victoria region ensuring any track movement is reported. We work closely

with our client and Metro Trains to make sure mandates and safety tolerances are met.”

Continuing to push outside the constraints of surveying, Dean and Henry are able to accumulate all information, whether it be through service locating, surveying, laser scanning, monitoring, through to one singular conduit of information. Providing a clear line of communication between Asset Survey’s data management teams and Project Design.

“As a result of our continually improving data sets and deliverable standards, lines of communication is improving essentially having everyone singing from the same hymn sheet, that flow of data to the project design team is becoming far, far more seamless,” Henry says.

The pair were also able to use their insights into Europe’s civil sector to further help Rangedale advance its offerings. Rangedale Group of companies is vertically integrated, allowing turnkey solutions utilising all in-house services.

With the scale of its fleet, personnel, industry knowledge and expertise, Rangedale Group of companies can provide solutions for drain cleaning, maintenance construction and relining, inspection, maintenance and repair, service locating, as well as mapping, service proofing, saw cutting, restoration, NDD, CCTV, civil

works, industrial cleaning, bulk liquid, and slurry waste management.

Henry says because of its relationship with Rangedale, its clients love that they only have to make one phone call and all services are available under one roof and meet Australia’s equipment standards.

“It only takes one contractor to let you down on a single project and the whole day is ruined, the costs associated with contractor standdown time can blow project budgets way out. Whereas

with our in-house connections, it’s one person that they have to contact and if there’s an issue, it’s only one person they’re chasing, and our clients love that,” he says.

“It goes without saying, obviously, the more resources available to that single point of contact for the bigger projects, the better.”

» Quality and collaborative HDD design and construct services

» Expertise to advise at the right time in the project delivery cycle

» Gas, water and sewer, rail, road, power, telecommunications, mining, residential development, renewables and hydrogen

» Maxi-rigs capable of long and wide diameter bores in hard rock and difficult conditions

» Building a future we all look forward to

SECA’s offering of trenchless pipe repair solutions brings the most advanced, up to date innovations to industry operators in pipe repairs and rehabilitation.

NBR, or silicon. As a fully mechanical system that eschews the need for any chemicals, the innovative solution removes the health, safety, and environmental risks associated with chemical-based solutions. Quick-Lock has proven itself over the last 30 years in the renovation of sewer pipes.

Wthree main technologies which are pivotal in restoring the integrity of pipes and ensuring the repair and rehabilitation is costeffective and eco-friendly.

Quick-Lock: reliably versatile

For a trenchless pipe repair solution that restores the integrity of pipes and seals out groundwater, operators need look no further than the UHRIG Quick-Lock. The product’s pneumatically expanding rehabilitation sleeve provides structural repair to the inside of pipelines. Quick-Lock is designed for point repair, prelining stabilisation works, junction capping, and as a liner end seal.

Its versatility and reliability enables it to be suitable for all pipe materials. Its patented locking system and static capabilities allow the sleeve to remain permanently in position and absorb the natural tectonic movements of the pipe.

Used for cracked systems, root intrusions, leaks, pressure pipes, junction capping, and joint displacements, the product is manufactured using long-life materials that are designed to outlast almost any other repair solution. QuickLock has revolutionised sewer rehabilitation and is the ideal choice for long-term watertight lining projects.

The patented Quick-Lock system is based on compression and durable materials –1.4404/316L stainless steel and EPDM, or

Not limited to these classic application and repair methods, the Quick-Lock system is also used for connecting pipe liner systems and for rehabilitating walkable sewers.

Trelleborg: forward-thinking

SECA is also a supplier of Trelleborg products. The Trelleborg range includes a number of ecofriendly technologies designed to service and maintain underground utilities while minimising potential disruption and now boasts a tested service life of 100 years.

The Trelleborg Drain Packer is suitable for the sectional repair of damaged, still-buried gravity sewer pipes and pipelines. The Drain Packer method can be applied to the following situations:

• Leakage with or without groundwater infiltration or ex-filtration at pipe joints, pipe walls, lateral junctions.

• Offset pipes, cracks and debris, ruptures.

• Mechanical wear.

• Corrosion.

The Drain Packer repairs damage in the pipe and joint region for lengths of as little as 50 cm to 5 m and can be used even in cases of strong infiltration.

It also repairs pipes of nominal diameters from DN 50 to DN 1200 (WSA Product Appraisal 1918).

Used to repair typical circular pipes, it can also repair egg-shaped pipes across a vast range of construction material – concrete, asbestos cement, plastics (PVC, PP, HDPE), cast iron, ductile cast iron, reinforced concrete and vitrified clay.

SECA’s range of Trelleborg products also includes DrainSystems – both a pipe repair device and a method for trenchless rehabilitation of lateral connections and pipes. The inflatable

system is able to repair and seal lateral interface and connections from the main pipe.

Cherne’s point repair carriers are another pivotal part of SECA’s rehab and repair solutions. Wellsuited to most point repair systems, these carriers are available for multi-size line covers pipe sizes from 4-inch to 36-inch (100—914 mm) diameters and lengths up to 4.5 m.

Cherne’s carriers have a reputation for durability, and its flexible redesign allows for ease of transport and optimised movement. The caster wheel assembly and bypass channel has been integrated and optimised for ease of movement and enhanced ability to bypass effluent. Featuring a maximum pipe contract guides and centre line allows operators to ensure proper placement of repair medium, minimising waste and increasing productivity.

With its ever-expanding range of cutting-edge products, SECA is continuing to supply the trenchless industry with the equipment it needs to succeed at repair and rehabilitation projects with the confidence that comes from using one of the country’s most experienced suppliers.

For more information visit www.seca.com.au

POWER & STABILITY

Best suited for urban and residential utility, gas and fiber jobs, it provides 3,000 ft-lbs of toque and 24,000 lbs of thrust and pullback while maintaining a small footprint. Promoting a wider frame, the JT24 can confidently traverse uneven terrain and city curbs, offering best-in-class stability. Best of all the JT24 offers exceptional value for money

Like to know more?

The Ditch Witch® JT24 directional drill, offers outstanding power and stability.

101-gross-hp, Tier 4 Cummins® diesel engine provides unbeatable power.

Equipped with fold-out, lift-off service doors for easy access to conduct maintenance and service work.

Designed with a wider frame, the JT24 offers best in class stability without compromising on footprint.

The Ditch Witch® JT24 directional drill, offers outstanding power and stability.

101-gross-hp, Tier 4 Cummins® diesel engine provides unbeatable power.

Equipped with fold-out, lift-off service doors for easy access to conduct maintenance and service work.

Designed with a wider frame, the JT24 offers best in class stability without compromising on footprint.

Aussie Trenchless has been passionate about progressing new infrastructure opportunities and accomplishing superior outcomes since it was founded in 2014.

Aussie Trenchless Director Chris Meredith and the team are committed to pioneering state-of-the-art solutions and furthering business in the trenchless industry. As part of that innovation, the company continually offers a wide range of unique products both in Australia and internationally.

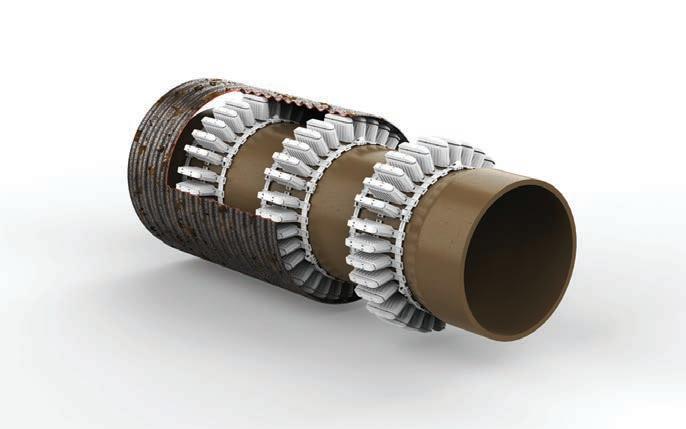

Aussie Trenchless’s SRP-EXP Spiral Lining System is designed to rehabilitate pipes from DN150 to DN1200 using a selection of six different sized profiles. The SRP-EXP system

is a close fitting structural spiral ribbed PVC trenchless pipelining system.

The SRP EXP sizes range from a profile type E7-050-5 for DN150 to DN250 pipes, E9085-6 for DN300 to DN450 pipes, E14-085-6 for DN375 to DN600 pipes, E20-085-6 for DN600 to DN900 pipes.

Wastewater and sewer pipeline networks are under stress and, as time goes by, underground pipeline networks continue to age and breakdown. Aussie Trenchless believes repairs using traditional civil open cut methods are far

too costly and disruptive on communities. Trenchless, rehabilitation techniques, Meredith says, continue to grow in volumes as they are a cost-effective repair solution.

“The SRP EXP Spiral Lining System can be installed under flow conditions, with no by-pass pumping needed it is quick and efficient, using a third-generation high quality profile to ensure ease of installation, providing a value-added outcome for the network owners,” he says.

The SRP EXP Winding Unit and Cages are a standard design. Each winding unit supplied is the same, the cages vary in diameter to suit the underground pipe size and all parts that make up the cages are standard and interchangeable on some cage sizes.

The winding machine is positioned into an access chamber or pit, then helically winds the SRP-EXP ribbed strip to produce a pipe within the existing pipeline. Aussie Trenchless’ SRP-EXP is first installed at a smaller diameter, then expanded to closely fit against the internal surface of an existing pipe.

During this initial wind-in process the spiral pipe lock holds the spiral wound pipe tight to the initial and smaller diameter.

Once the far end of the installation length is reached, the SRP-EXP Liner end is then

restrained, with the lock area sequentially released such that the SRP-EXP pipe expands in a controlled manner until it has been pressed hard against the inside wall of the pipe its being installed to.

The installation process is entirely mechanical, meaning that no chemical curing nor steam heating is utilised during the process. Not only is the system easy to install, but it’s likewise easy to remove if necessary.

The SRP-EXP system is capable of negotiating displacement and slight bends while also maintaining a relatively small site footprint. Furthermore, the system is smooth to both work with and install, with minimal and recyclable wastage.

If a client requires a special diameter cage outside of the SRP EXP product range, Meredith says the company can design and supply it.

Spiral lining and pipe segment technology is now available to all trenchless rehabilitation contractors in Australia and overseas through Aussie Trenchless.

For more information, visit www.aussietrenchless.com

Quick and easy to install

The perfect rehabilitation solution for deteriorated sewer and storm water pipelines:

SRP EXP

• An expandable tight fitting liner

• No issues with high infiltration

• Negotiates displacements and slight bends

• Small site foot print

• Smooth to work with and install

• SRP EXP pipe is made from factory produced PVC profile strip

• Profile is supplied on large steel drums which are collapsible for easy reuse

• The minimal wastage is recyclable

• For DN150 to DN1200 pipe lines

• Mechanical installation – no chemical curing or steam heating

• Easily removed if site issues encountered

+61 418 691 989

PO Box 155 Oyster Bay NSW 2225 Australia

enquiries@aussietrenchless.com

www.aussietrenchless.com

As trenchless pipe relining continues to gain favour over open-trench or relaying operations, Smart Lock is helping operators within the industry use this growth as an opportunity to adapt and improve.

Smart Lock’s Business Development Manager Shane Curren talks with Trenchless Australasia about how the company expanded its offerings to make it a stronger partner for industry operators.

How do you think the trenchless industry has changed?

There was a time when large work crews were required to live away from home, transporting one-off, custom-built equipment on trucks and offering rehabilitation slots in a yearly budget calendar.

Due to an increase in the number of professionally trained relining contractors throughout Australia, coupled with the increased availability of pipe relining equipment, drainage and water networks are in good hands. Having equipment on hand that can be hired, or purchased outright, relining solutions are becoming increasingly available, locally, in locations across the country.

Drain rehabilitation contractors can now work across many regions because they have hireable and off-the-shelf modular relining units right where and when they need them. Advanced curing and installation equipment is now abundant, and is available to all operators in the trenchless industry.

How is Smart Lock positioned in the trenchless relining industry?

Smart Lock Group has always had ability to produce the Smart Lock Liner End Seal – a simple manufacturing alteration to the standard Smart Lock sleeve which is proudly built in Melbourne.

The modern pipe reline contractor has many lining products at its disposable, some adhere to the host pipe on installation and others are known as loose-fit.

Loose-fit lining is where the mechanical Smart Lock Liner End Seal can ensure that liner specifications are achieved as promised.

Now manufactured with a life expectancy that is able to match the 100-year life of the pipe, the

Smart Lock Liner End Seal ensures that drainage engineers and asset owners don’t need to be concerned about the longevity of their renewal efforts on their sewer and stormwater networks.

How does the Smart Lock End Seal differ from other options?

Asset renewal methods using the Smart Lock Liner End Seal are low-impact, are approved for saltwater tidal conditions, and are available in standard pipe sizes with custom made options on request. They are becoming increasingly economical each year.

The relining industry is differentiating itself from the increasing civil costs and timeconsuming reinstatement works that come into play when replacing existing drainage systems.

Because of this, Smart Lock Group is also evolving as a national supplier, catering for the new needs of pipe rehabilitators all over the country and extending well beyond the Smart Lock sleeves.

Today, we can supply specialist installation equipment, fiberglass liner for longer sectional repairs and fiberglass patching for varying point repairs.

More than that, we have made a CCTV assessment coding service available to our customers so that we can provide them with the means to supply asset managers with an approved drainage assessment format, accepted nationally.

Training has evolved at the Smart Lock Group, with the Altona training facility set up to deliver advanced operational training options, rather than the basic product training offered at the time of purchase.

We have added three additional scheduled advanced training sessions, which we advertise each year, along with two VIP research and development sessions. The training is designed to benefit both experienced reliners and drain relining novices, providing them with the means to set goals and realise achievements beyond what would usually be available.

Advanced training sessions allow existing drainage rehab installers to stand out and identify themselves as high-level professionals in the field. Our improved training module provides accredited schooling in the mechanical Smart Lock product range, sectional pipe relining and advanced fiberglass patching.

The training includes student assessment, allowing operators to know exactly what to expect from the student who completes the course.

As a result, students learn the small, expert details for rehab jobs. The things that come from hard-earned experience in the field which, ultimately reduces mistakes made on the job and lowers the risk, potentially changing the outcome and cost of more difficult installation jobs.

By hosting the training at our facility in Altona, we take the onus off customers to provide the necessary equipment – appropriate pipe sections, packers – meaning the quality and efficiency of the training is consistently high.

Smart Lock Group is a valuable and dedicated partner in the drainage rehab industry, offering trenchless products and support to Australian operators who are striving to be the best.

For more information call Shane Curren on 0406630250, or visit www.smartlockgroup.com

The Woodman Point Waste Water Treatment Plant in Munster, Perth, experience deterioration of the concrete structure around its channels due to gas attack.

Fixing the damage was broken into two stages. McRobert Contracting Services (MCS) were brought in on the first stage

The success of the first stage saw Woodman Point engaging MCS to continue the work on the second stage. This required work on

and four launder channel entries on the PST channel.

MCS were called in to use its patented

and roof of the channel, up to the horizontal deck.

Before the lining could be attended, MCS undertook a thorough cleaning process using high-pressured water jet cleaning of all concrete surfaces, as well as scabbling works to improve adhesion.

MCS used layers of 12 mm high-density polyethylene (HDPE), striped to 25 mm wide and fixed to the perimeter of the channel lining. The process allowed them to extend the lining, including pouring high strength grout behind the lining and existing concrete surfaces.

A minimum of 12 mm of grout was injected into each section using and injection tubes and funnel system. This worked to both secure the lining in place, and to rebuild the existing deteriorated concrete. While rebuilding the internal concrete maintained structural integrity, the HDPE lining also provides corrosion protection.

MSC used an internal bracing and scaffolding systems to stabilise the HDPE lining while the high-density grout was injected and dried.

The entire process was undertaken in stages, lining 2.6 m sections at a time.

The Woodman Point Water Resource Recovery Facility was upgraded in 2020. The

upgrade increased the facility’s capacity to 180 megalitres per day and included improvements to its odour control system.

MCS channel lining comes before further upgrades to the Woodman Point’s sludge processing system, which is expected to commence later this year.

By upgrading the system, Woodman Point aim to recover 100 per cent of the biosolids, or ‘sludge’, in the Perth metro region.

MCS have developed a name as leaders in the fields of pipeline maintenance and plastic welding, among others.

Its HDPE patented innovations were designed with the safety of staff and clients a priority, and with interest in remaining environmentally friendly and beneficial in terms of cost.

In order to tackle the task, MCS were able to utilise a number of its innovative patents to ensure the safety of its workers and success on the project.

The work is covered by MCS’s 50 years guarantee, which will allow Woodman Point to move into the upgrades to its sludge processing system without worry.

For more information visit www.mcrobertcontracting.com.au

Designed to be compatible with all types of pipe material, kwik-ZIP’s HD and HDX/HDXT spacer system series can be used on and in corrugated pipe installations.

Manufactured from high-grade thermoplastic, kwik-ZIP’s casing spacer and centraliser products are used and recommended by pipeline and civil contractors, water and gas utilities, drilling companies and international engineering firms.

kwik-ZIP’s HDX/HDXT spacer system series are aligned with the company’s ethos to provide simple, cost-effective, and high-quality solutions. Manufactured and designed to be utilised on and in many types of pipe including corrugated pipe installations, the HDX/ HDXT series are one of the most versatile and adaptable spacers on the market.

The use of kwik-ZIP products helps contractors to comply with the numerous regulations which require casing centralisers or pipe spacers (slippers or spiders), including wastewater and sewerage codes and construction standards.

Since its inception in 2000, kwik-ZIP has been designing centralisers and spacers systems for a wide range of applications across many different industry sectors. Available in various product series (HDXT, HDX, HD, GT, 380, and 155), each series is available with varying bow/runner heights, making these highly flexible products.

pipe. The products are adaptable and versatile, able to work on corrugated pipe which is being inserted into a smooth pipe and function on a smooth pipe that’s then being inserted into a corrugated pipe.

For corrugated carrier pipe, the flat base of the HDXT and HDX runners bridge the pitch of the corrugations which allows the load to be transferred to the carrier pipe via the full length of the runners. Additionally, if the enveloper is corrugated, the HDX and HDXT flat-wear pads allow for smooth slip lining along the invert.

kwik-ZIP’s innovation when it comes to its solutions are one of the many reasons its

products are the first choice for many when looking for a versatile spacer solution.

Designed to last, expertly manufactured and compliant across guidelines

The HD series can adapt to a range of on-site scenarios. It is designed for trenchless and cased crossings, slip lining, gravel packed well screens, pump torque arrestor, water well casing, coal seam methane casing, pump riser/ submersible pump installation and piling.

Coming in four sizes, ranging from a 30 mm bow up to a 100 mm bow, the HD series can be used for both vertical and horizontal

Adaptable

kwik-ZIP’s HDX and HDXT products are suitable for installation on and in corrugated

applications.

With unique features including a curved bow spring that boasts a superior centralising force, no special tools are required to assemble the HD Series casing spacers.

Similarly, kwik-ZIP’s HDX and HDXT series spacers are designed for use on medium to heavy weight pipes in cased crossings. They can be utilised on a wide range of pipe material including steel, DICL, HDPE, concrete and MSCL carrier pipes, minimising running friction between the carrier pipe and the casing during installation.

The HDX casing spacer comes in four runner heights; 38 mm, 65 mm, 90 mm and 125 mm. Likewise, the HDXT casing spacer also comes in four runner heights of 43 mm, 63 mm, 103 mm and 153 mm. The different runner heights across the two models ensures that pipeline installers can handle a broad range of carrier pipe OD and casing (host pipe) ID combinations and customise pipe position for grade control or ‘centring’.

The HDX/HDXT series casing spacer is compatible with all types of pipe material, minimising running friction during installation, and stations the pipe to promote even grout cover. If the pipe is not to be grouted the HDX/HDXT will support and isolate the

carrier pipe plus its contents for the design life of the installation.

This highlights kwik-ZIP’s ability to provide an off the shelf solution irrespective of the requirements due to its wide range of products and options.

The HDX and HDXT models are the only casing spacers currently on the market that have been approved as compliant by WSAA.

In addition to receiving WSAA approval, other kwik-ZIP products have also been added to the Accepted Infrastructure Products

Queensland Water Supply and Sewerage Design and Construction Code (SEQ Code).

kwik-ZIP maintains a focus on price effectiveness, simplicity, and rapid on-site assembly, to ensure that its centraliser and casing spacer systems deliver significant cost, time, and operational advantages to its end user customers.

For more information visit

www.kwikzip.com

DJ MacCormick Contractors has completed the twin crossings of Humes 1000 mm reinforced concrete jacking pipe in Port Hedland, Western Australia.

To complete the project, DJ MacCormick Contractors utilised the Iseki closed face slurry shield microtunnelling system. Ground conditions on site were in wet clay and at depths that ranged from 4 m to 6 m cover.

Of the six 1000 mm drives completed, two drives of 46 m were completed under Utah Road with an additional two drives of 152 m under the BHP Rail also being completed. A further two drives of 80 m under the FMG Rail line were also undertaken. A seventh drive of 1800 mm was also completed 112.5 m under the BHP Rail, located nearby the Iron Bridge mine site.

The total distance tunnelled for the project was approximately 668.5 metres.

The launch and receival shafts for all twin drives were designed so both drives could be undertaken via a singular shaft.

Temporary designs were undertaken to accommodate the two twin drives and were signed off by DJ MacCormick’s structural engineer, including designs for the Ground Support Systems (Australia) shoring design.