4 minute read

Prime Drilling supporting compact HDD rigs with customisation and knowledge

One of Prime Drilling’s compact HDD units with a custom wrap for a European client.

Prime Drilling, which is sold and supported locally through TRACTO TECHNIK Australia, is one of the world’s leading manufacturers of horizontal directional drilling (HDD) technology. Trenchless Australasia speaks to the company’s Ralf Kiesow about the new range of compact machines setting new standards in their class.

With 25 years’ experience and expertise in the design and construction of large HDD rigs, Prime Drilling prides itself on its ability to work with customers to enhance and customise its directional drilling equipment. The company is

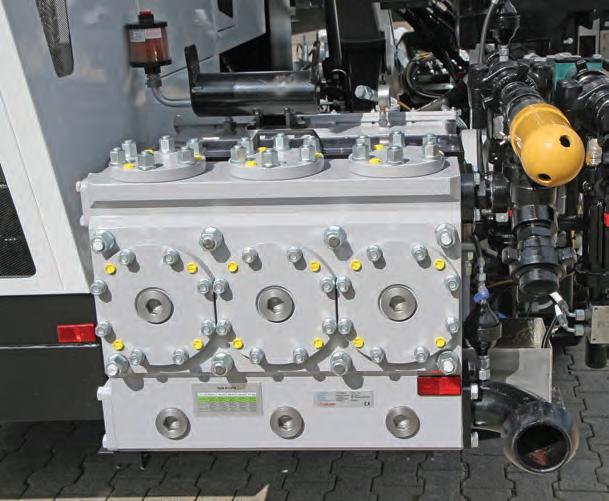

The on-board bentonite delivery pump on one of Prime’s rigs. committed to producing precise and high-quality machines, based on continuous innovation.

Prime’s International Sales Director, Ralf Kiesow, says the company utilises its knowledge of drilling techniques and high-quality materials to develop a low-maintenance, robust and reliable drilling rig.

“These are the outstanding benefits for our customers and the pillars of our company’s success,” he says.

“All the rigs we have built to date are still running today. There isn’t a single unit that isn’t still working in the field.

“Customer focus is a key part of our ongoing service commitments and we remain in contact with each and every client that has purchased equipment from us, even after 20 years.”

Every rig which leaves Prime’s factory is tailor-made for the customer to meet their specific requirements. The company offers its customers over 200 optional features with only one objective: to manufacture a unique drill.

“From our inception up to the present day, commitment and enthusiasm is what has enabled us to become one of the leading manufacturers of HDD rigs,” Kiesow says.

“Driven by the desire for perfection we take pride in presenting our comprehensive range of successfully operating horizontal drilling rigs. The merging of technology and knowledge results in unique products of absolute premium class.

“Prime Drilling machines are unrivalled in performance, high production quality and perfect service.”

Following feedback from customers who wanted rigs that were smaller and faster, Prime set about developing its next generation of compact HDD machines which set new standards in the category. The perfected design and optimised components, in both weight and size, means transport and set-up costs have been reduced to a minimum.

The PD 30/12 CU and PD 45/19 CU both have a mounted CAT 7.1 ACERT power plants which incorporate the latest emission standards and adjustable cooling systems to minimise fuel consumption.

When designing the new machines, Prime undertook a detailed

development program and selection process for components, and materials, designed to get the maximum efficiency out of every part of the machine.

“All elements of the machine’s design guarantee fast, uncomplicated and economical operation,” says Kiesow.

“Such as the inclusion of a fully automated drill pipe magazine capable of holding 32 pipes or the incorporation of a new hydraulic system enabling improved performance of the rig.”

“As a result of the powerful on-board mud pump, these machines are capable of larger diameter holes and ready for big jobs. In addition, we remain in continuous consultation with our customers and their requirements.”

Whenever the company builds a new rig it builds three at a time, which are usually sold before they are produced due to the high demand. However, Prime has large storage areas and can react quickly, efficiently, and flexibly to customers’ wishes to ensure they can source equipment when required.

Offering a comprehensive after-sales service – through TRACTO in Australia - customers can easily procure spare parts on the local market and carry out necessary repairs by themselves.

Kiesow says Prime encourages its customers to come with a ‘wish list’ when buying a rig.

“Our design team tries to meet those needs, going back and forth, until everyone is happy with the final design,” he says.

“This ensures the customer gets exactly what they want and allows for us to create something new and bespoke to the clients’ requirements. Our technicians and designers then go out in the field and see how things perform, talk with the drillers to make sure our customers are truly satisfied.”

Prime has also introduced a remote analysis function in its rigs to allow users to see a problem before it affects production on site. Mr Kiesow says its service team is available at short notice and its remote maintenance service can be accessed at any time.

“This means if a problem comes up the user is able to pin-point where the issue is and see what has to be replaced,” he says.

“If the customer can’t find the problem, they can call us on our 24/7 hotline where the technician is able to see what the driller is seeing and find the cause of the problem,” he says.

The PD45 compact machine.

For more information visit www.prime-drilling.de/en/

The Next Generation in Trenchless Technology

> Still the market leaders in laser guided microtunnelling > Bore diameters from 325mm up to 2800mm

> Specialists in ‘free bore’, sleeve boring and pipe jacking in all sizes > Used for gravity sewers, water mains, storm water, gas and electrical conduits.

Unit 2 / 85 Heatherdale Road, Ringwood Vic 3134 | PO Box 2500, North Ringwood Vic 3134 P: (03) 9872 4596 | F: (03) 9872 3293 | E: info@pezztrenchless.com.au