Engineering, Construction & Maintenance WATER | SEWER | ELECTRICITY | GAS | NBN www.utilitymagazine.com.au Issue #4, November 2014 SMART

GOES

PIPELINES

GRIDS, SMART CITIES HDD

MAINSTREAM

OUR ENERGY BACKBONE GAS

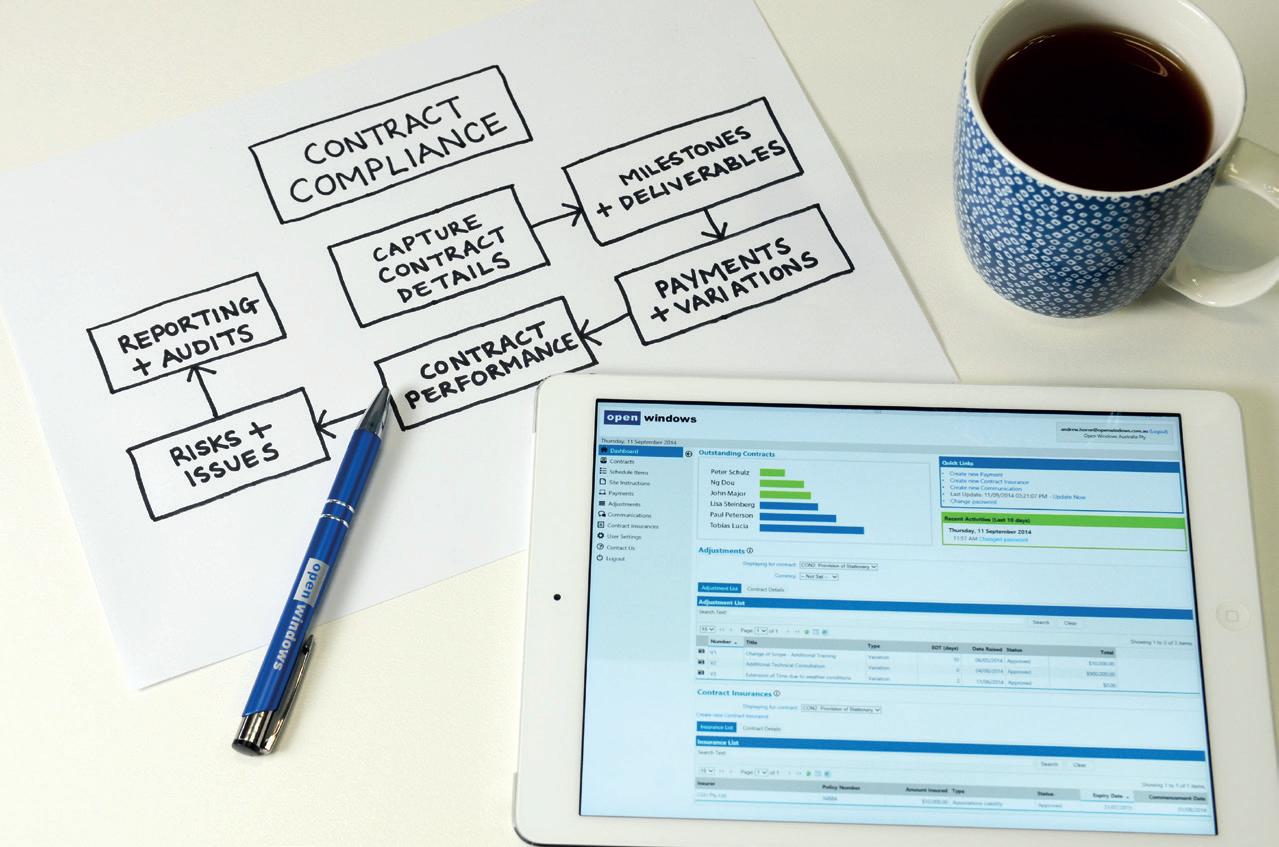

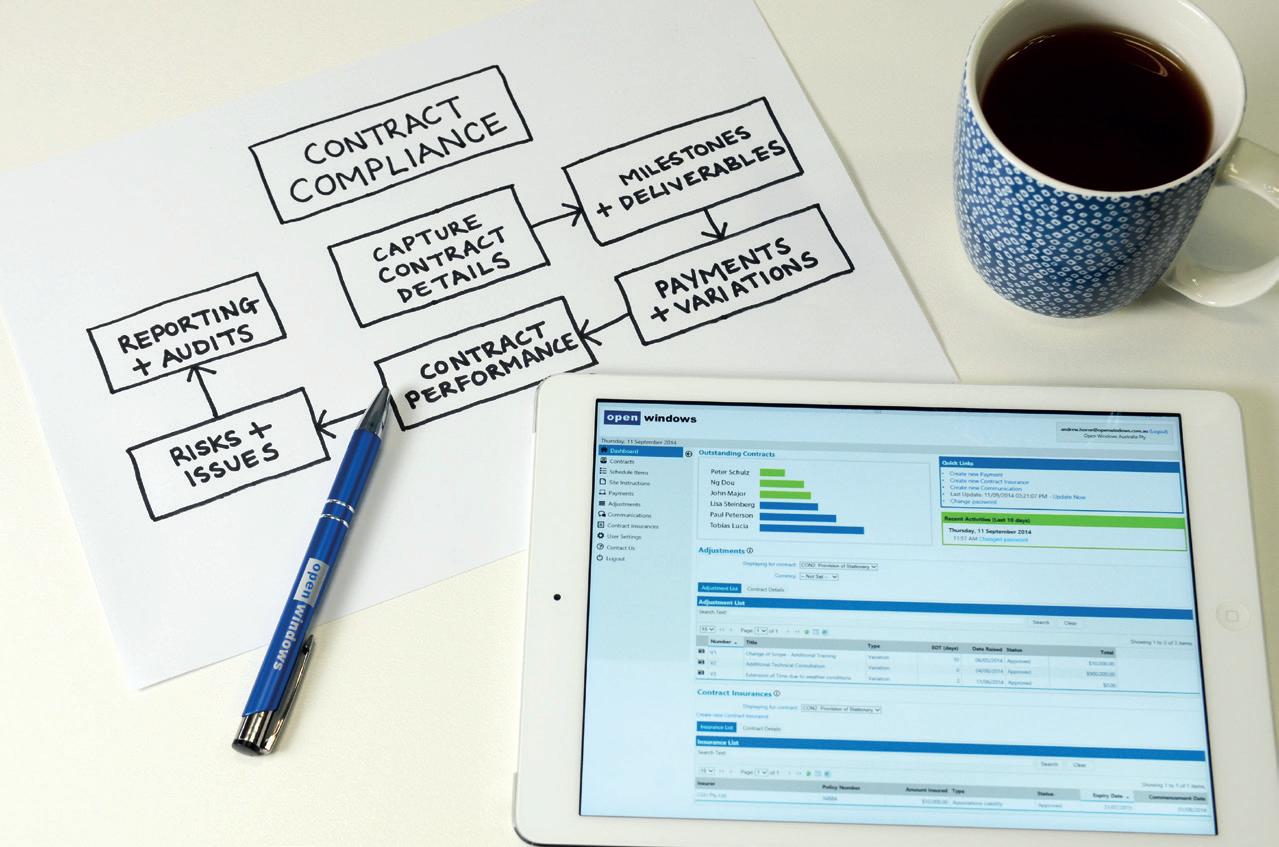

Contract Management Solutions for Utilities

Contracts repository

Strategic sourcing

Contractor management

Business process workflow

Capital program management

Payment management

The preferred choice for many of Australia’s utilities companies, extract more value out of your agreements while reducing risk and increasing compliance. A comprehensive suite of contract and contractor management modules in Open Windows CONTRACTS ensure that the contracts being signed are the contracts being delivered.

Modules include tender management, KPI management, payment and variation management, insurance management, risk determination and mitigation, as well as program management tools and external CONTRACTS Portal. Open Windows CONTRACTS can be integrated with your ERP, document management and financial management systems.

openwindows.com.au

Published by

Monkey Media Enterprises

ABN: 36 426 734 954

PO Box 3121

Ivanhoe North VIC 3079

P: (03) 9440 5721

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au

utilitymagazine.com.au

info@utilitymagazine.com.au

ISSN: 2203-2797

FROM THE EDITOR welcome

The gas pipeline industry has experienced an extraordinary decade of growth and in this edition we take an in-depth look at one of the biggest projects of recent times, the Australia Pacific LNG project.

APLNG is one of three mega CSGLNG projects currently being developed in Queensland, taking advantage of the state’s massive CSG reserves and exporting it as LNG. These three projects have been a major focus of the gas industry for a number of years.

Our in-depth feature article on APLNG takes a close look inside the project, with a focus on the construction of the gas pipeline associated with the project.

As these three CSG-LNG edge closer to first LNG deliveries, we’ll start to notice a shift in focus for the gas pipeline industry. While there is plenty of construction work still ‘in the pipeline’, the industry is also increasingly focusing on the integrity and maintenance of the existing network. Turn to page 30 to read our article on the importance of maintaining our large network.

It’s great to be able to share this edition with readers at the Australian Pipeline Industry Association (APIA) Convention this year. I attended my first APIA Convention in 2003 and look forward to attending many more. There is no event quite like it in the way it brings together all stakeholders in the pipeline industry, and creates a forum where all pipeliners can share an honest discussion across all job levels and between competitors. I look forward to talking to as many as you there as possible.

Another key focus for this issue has been the continual drive towards smart utilities. The recently released Smart Grid, Smart City report contained fascinating data obtained from a fouryear trial of Australia’s first commercialscale smart grid rollout. Read ENA Chief Executive Officer John Bradley’s thoughts on the report on page 6, and see our article covering the findings of the trial on page 62. This edition of Utility will be distributed at Australian Utility Week, where the findings of the report will no doubt be under the microscope.

Another interesting report covered in this edition, is the Water Services Association of Australia’s flagship report for 2014, Improving economic regulation of urban water. It’s a comprehensive report which calls for independent, light-touch regulation.

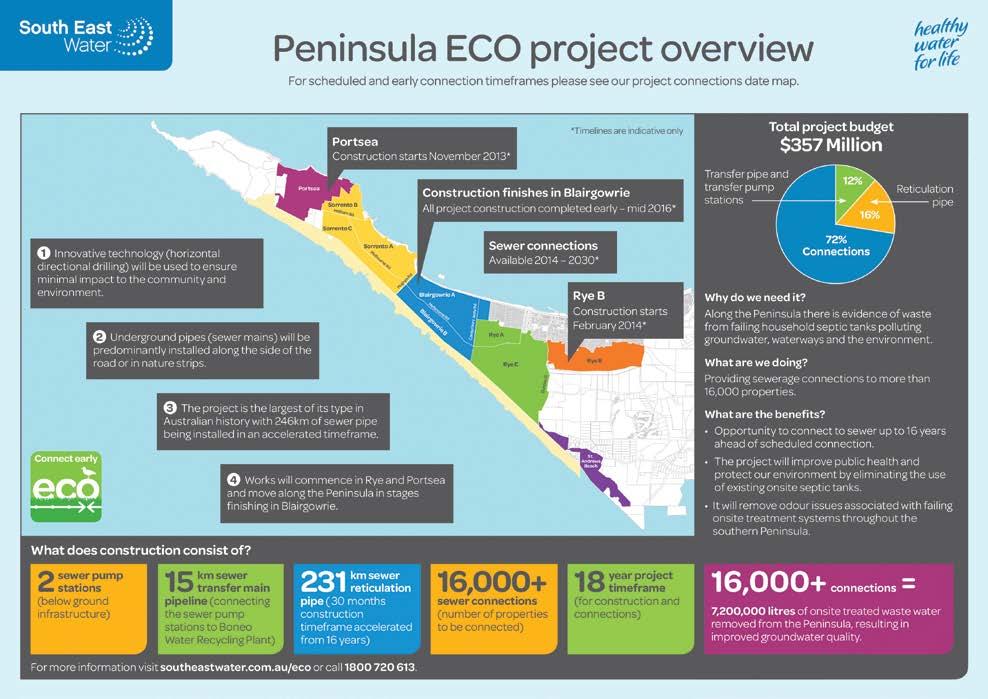

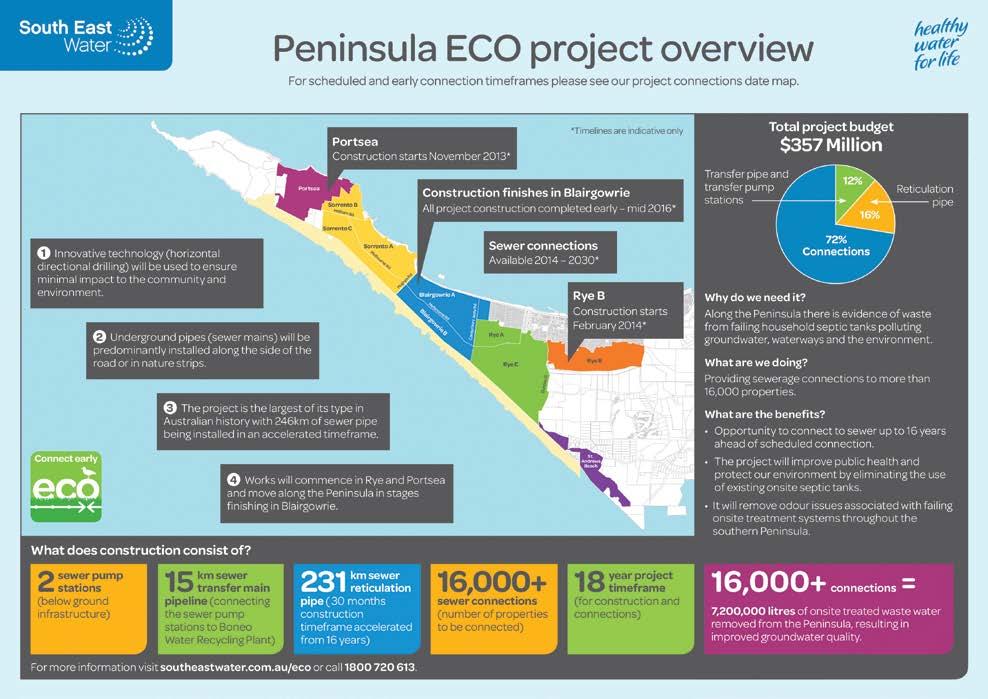

Another topic that is dear to my heart is horizontal directional drilling (HDD). My involvement with the HDD industry traces back to 2004. HDD was once a novel technology, and over the years it has become more advanced and commonplace, having been used on projects such as APLNG, the NBN rollout and the Peninsula ECO sewerage connection project in Victoria.

Work is being done to establish standards and best practice in HDD, which we cover in this issue. HDD is being used by all utilities, and it’s important to continue to promote the economic, social and environmental benefits HDD can provide to ensure this growth continues.

Chris Bland Publisher and Editor

November 2014

ISSUE 4

ONE CRAWLER, Engineering, Construction & Maintenance WATER SEWER ELECTRICITY GAS NBN www.utilitymagazine.com.au Issue #4, November 2014 UTILITY MAGAZINE NOVEMBER 2014 SMART GRIDS, SMART CITIES HDD GOES MAINSTREAM PIPELINES OUR ENERGY BACKBONE GAS

and

Managing

Publisher

Editor Chris Bland

Editor Laura Harvey Associate Editor Michelle Goldsmith Marketing Consultants

Aaron White

Cynthia Lim Creative Director

Sandy Noke Jim Cresham completes the final ‘golden weld’ on the APLNG gas pipeline.

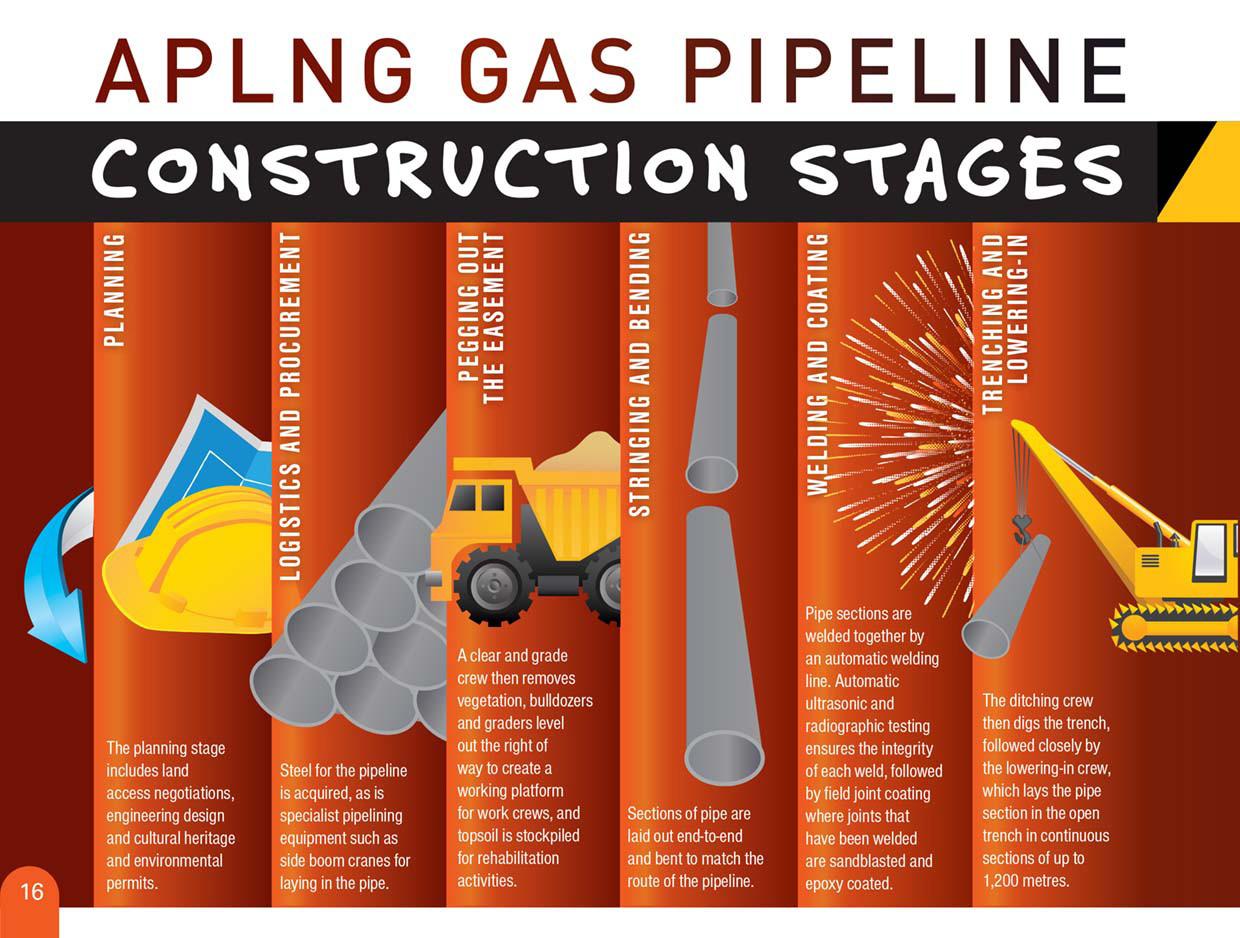

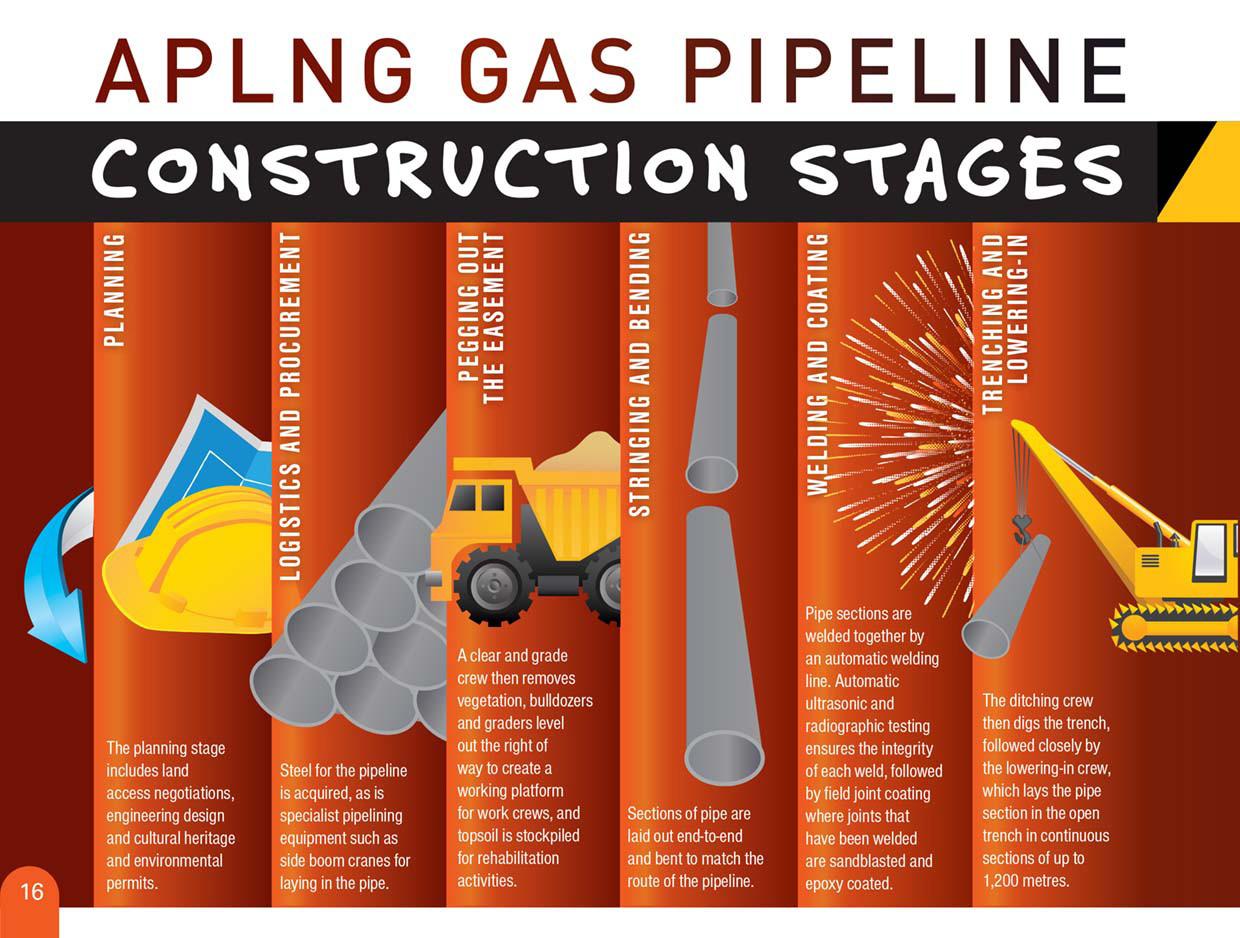

recently completed 530 km APLNG gas transmission pipeline has occupied much of the Australian gas pipeline industry for several years. We take a look at each stage in the construction of this world-leading gas pipeline project.

4 CONTENTS 14 26 36 62 70 GAS PIPELINES Building a gas pipeline: the APLNG story ......................... 14 The

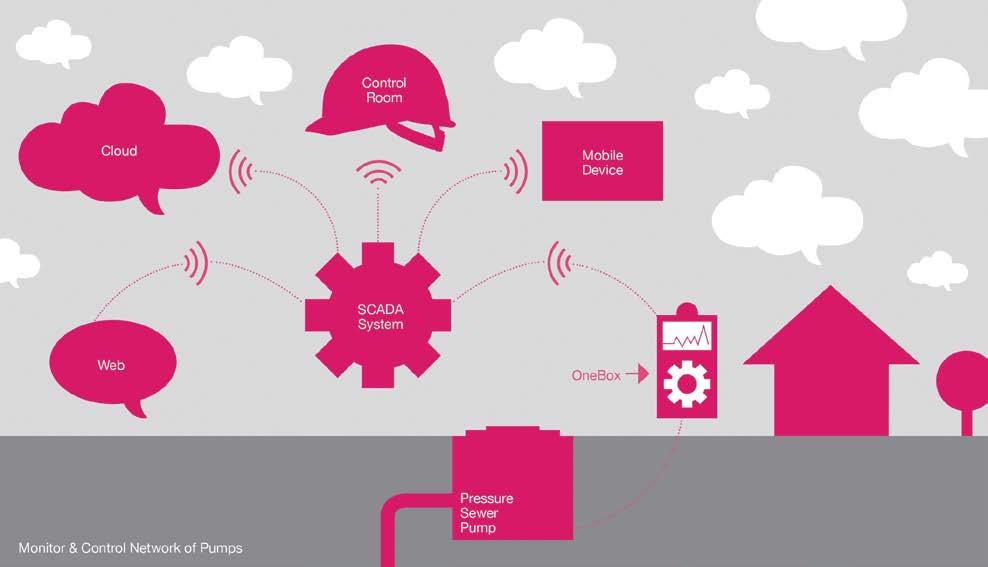

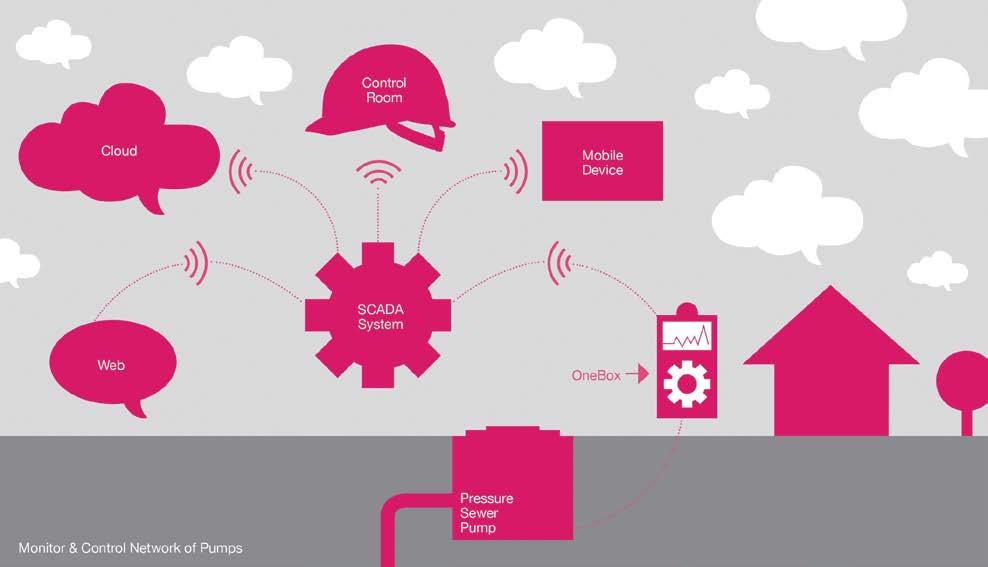

Gas pipelines: where to now? .... 22

Community engagement key to pipeline industry legacy 26 PIPELINE INTEGRITY Ensuring our energy supply ...... 30 Coatings assessment facility crucial to pipeline infrastructure............ 32 Applying coating in the field...... 34 HDD Easing the pressure on the peninsula ..36 Melbourne water retailer South East Water is at the helm of one of the largest pressure sewerage constructions in Australian history, bringing its awardwinning innovative sewerage control and monitoring systems to residents of the Mornington Peninsula. HDD and the NBN: opportunities for collaboration 42 SMART GRIDS Smart grid, smart city ................. 62 Bringing about the power of choice 68 TRANSFORMERS & SUBSTATIONS New lease of life ......................... 70 Electricity infrastructure to underpin regional growth 73 72 Utility magazine’s experts answer your questions ............................ 76 7676

LAND ACCESS

The National Broadband Network is currently undergoing its transition between rollout models. The past few months have been a time of decisions, change, trials and reviews for the project, while in the background the network continues to take shape.

The Water Services Association of Australia recently released its flagship report for 2014, ‘Improving economic regulation of urban water’. This report supported recent calls from customers, the water industry and the private sector for better economic regulation of the urban water sector. NBN

November 2014 ISSUE 4 5 46 50 59

Unified call for better urban water regulation 59

WATER

Change and

the NBN project

46

transition: an eye on

..........................

COMMUNICATIONS 2G network closes ....................... 48 ASSET MANAGEMENT Strategic asset management with ISO 55001 50 Pipe, culvert and tunnel maintenance: replace or renew? ....................... 54 DESALINATION Desalination plants: the insurance policy we have to have............... 56 79 COMPANY NEWS Inspecting gadgets for managing assets ........................................... 79 In each issue Editor’s welcome .................................................. 1 A word from the ENA .......................................... 6 News briefs ........................................................... 8 Advertisers’ index .............................................. 80 Editorial schedule .............................................. 80

A WORD FROM THE ENA

JOHN BRADLEY CHIEF EXECUTIVE OFFICER – ENERGY NETWORKS ASSOCIATION

At some point in the last five years, Australia’s energy policy debate started to feel more like an episode of Jerry Springer than the 7.30 Report.

From carbon policy to renewables, from claims of gold-plating to utility death spirals, energy policy debate in Australia is too divisive to advance the long-term interests of consumers. After all, the electricity system represents both one of our most important economic inputs and our society’s largest machine, providing an essential service in real time to almost all businesses and households.

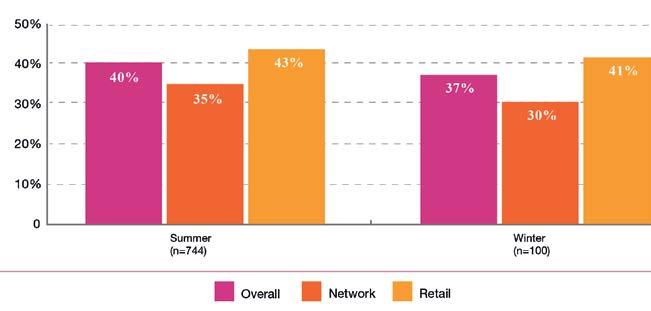

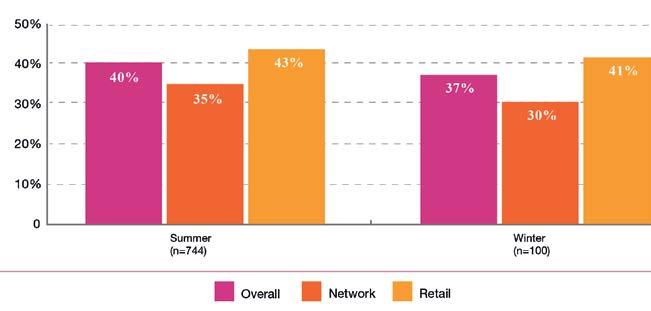

Little wonder then, in this shouty environment, that the recent release of one of the world’s most comprehensive assessments of the energy future was largely ignored by the mainstream media. Australia’s $100 million, taxpayer-funded Smart Grid, Smart City report analysed smart grid energy technology, consumer behaviour and pricing reforms over four years, involving 17,000 electricity customers.

Given the focus on electricity bills, you might have expected wider coverage of the report’s findings – that a smart grid could lower the average bill by $150 per year. Surely, it was major news that without reforms to current electricity pricing structures some electricity customers could end up subsidising others by $420 per year? Well, no.

The Report finds Australia’s current tariff structures and electricity meters may doom consumers to pay $10 billion more than necessary by encouraging over-investment in one part of the system – onsite generation (like solar panels) and storage. This is because today’s volume-based tariffs result in some users paying less than the cost of their network

service and so others pay more. Without time-varying tariffs, unfair outcomes also arise if customers add disproportionately to the peak, through large air-conditioning use or in future use of electric vehicles and battery storage.

There was a strong reaction from solar advocates to the Report’s analysis, despite the fact the analysis shows Australian solar panel capacity would increase massively even if fairer tariffs are put in place to protect other users. In fact the study found that the installed capacity of solar panels would increase by 17,000 megawatts in 20 years to be six times the current installed capacity. This outcome represents 90 per cent of the solar increase which occurs without reform but it avoids consumers paying $10 billion more than necessary during the period. While that seems a good policy outcome, cost-reflective pricing is shouted down as ‘anti-solar’ in today’s polarised energy debate.

In another Jerry Springer moment, some energy commentators suggested last year the easy way to lower costs to consumers would be to write down network investments due to declining energy demand. In that episode, no evidence or analysis of the flow-on consequences for electricity customers was provided.

The first detailed economic analysis has been undertaken by the Energy Networks Association and shows that calls for write downs are a chimera for customers. The report WrittenDown Value? – Assessing Proposals for Electricity Network Asset Write Downs shows that far from reducing customer prices, asset write downs could see consumers pay over $320 million more per year.

Australia could ruin its hard-won reputation with investors without

delivering lower electricity bill outcomes for customers. The research paper conservatively estimates that electricity network charges could increase by up to 7 per cent based on current network investments. In addition, financing costs for future network investment could be $1.8 billion higher over the next decade.

Even in extreme write-down scenarios equivalent to writing off 20 per cent of network assets, the increased cost of financing outweighs any savings to consumers intended from a lower asset base and lower depreciation charges. This conservative analysis does not factor in the potential that investors may require a sovereign risk premium if the current regulatory regime is retrospectively abandoned.

Regulatory write-downs provide more threats than opportunities to consumers, by reversing the other downward pressures on network cost of capital and network prices. By doing so, write-downs are likely to increase, not lower, any risk of a utility ‘death-spiral’ leaving both consumers and investors worse off.

To provide efficient, reliable outcomes for consumers, Australia’s changing energy system needs clear economic signals and neutral market frameworks more than any time in its history. This means an evidence-based policy and regulatory framework which avoids picking winners or plumping for simplistic solutions.

Perhaps it’s time to change the channel.

John Bradley, Chief Executive Officer, Energy Networks Association

6

Select Solutions has a wideranging knowledge and experience base providing optimal foundation for delivering specialist Asset Management services.

Select Solutions provides specialist technical solutions and services to support the ongoing maintenance and management of utility network assets and operations.

As a division of AusNet Services, we have a unique understanding of the challenges facing utility network owners to reduce costs, achieve regulatory compliance and capture greater levels of data to better maintain ageing network assets.

Our solutions and services to the utility sector include:

Asset Management Advisory (ISO 55001)

Smart Asset Inspection Techniques & Technologies

Condition Monitoring & Diagnostic Testing of HV Assets

Vegetation Management Solutions

Metering & Meter Data Management Solutions

New Water & Gas Connections

NATA Accredited Electricity, Water & Gas Asset Testing

Materials Procurement & Distribution

Servicing the electricity, gas, water, telecommunications, transport and government industries

Servicing the electricity, gas, water, telecommunications, transport and government industries.

Creating Value | Delivering Results

For more information about Select Solutions phone 1300 SELECT web www.select-solutions.com.au

AARON WHITE JOINS THE TEAM AT UTILITY

Aaron White is the latest team member to join Utility magazine, taking on the role of Marketing Consultant.

Aaron has more than twenty years’ experience in the Utility industry, where he specialised in working closely with his clients to tailor a solution to their needs.

Utility Publisher and Editor Chris Bland said Aaron will play an integral role in the growth of the magazine. “Aaron is an exciting edition to the Utility team. His extensive experience in utilities means he is perfectly placed to assist our clients and deliver the right solution for them.”

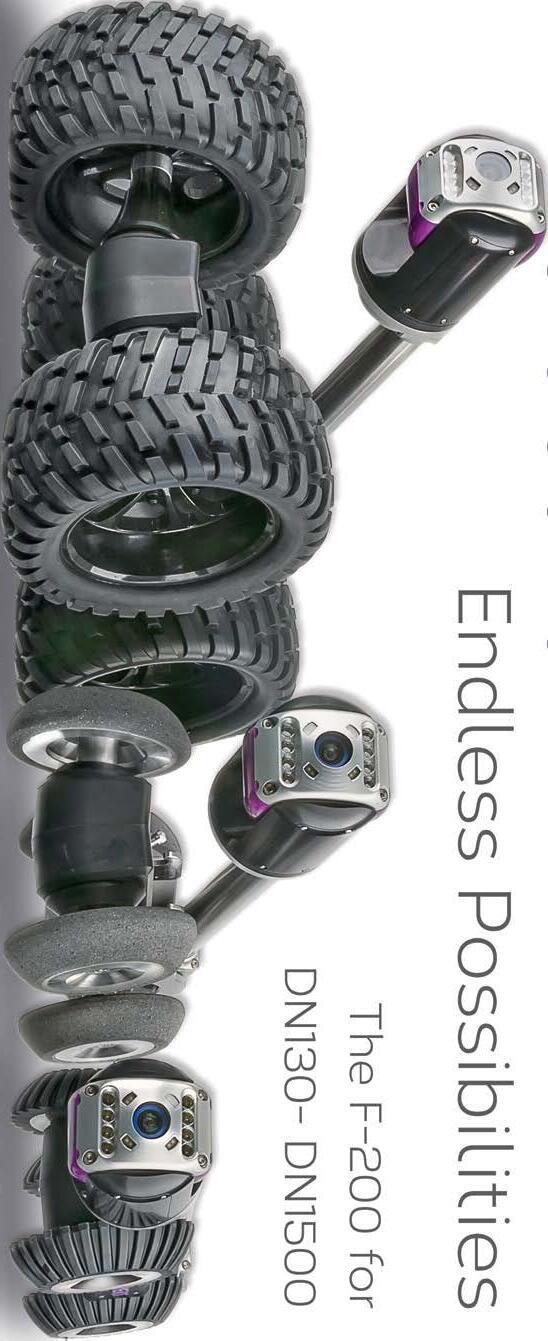

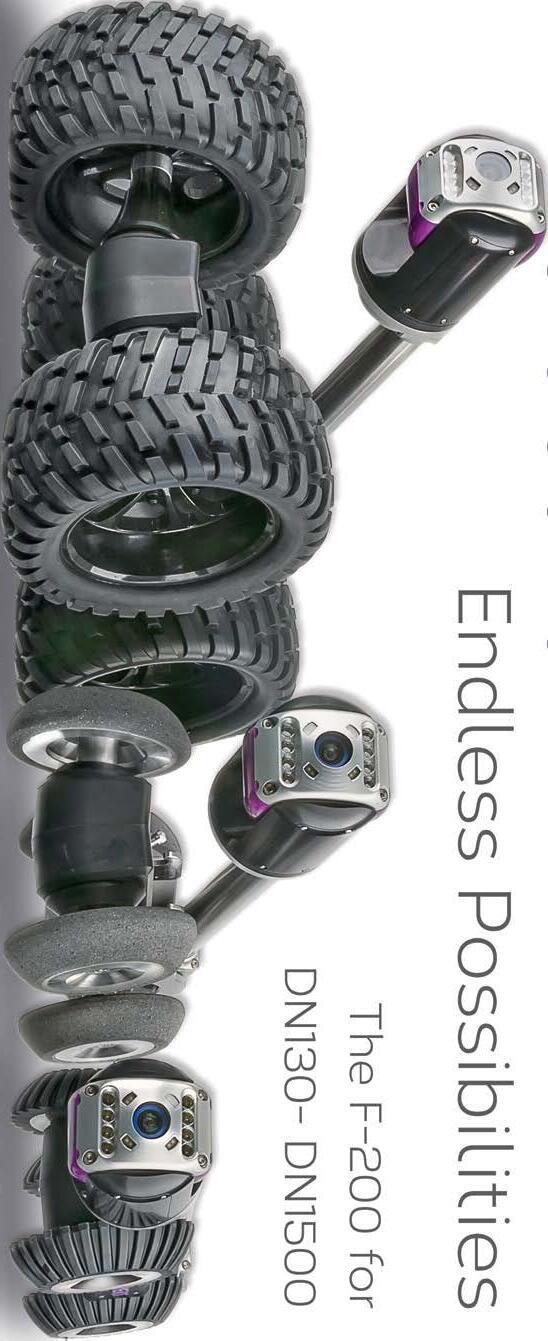

NEW APPOINTMENT AT VERMEER

Vermeer Australia has appointed Simon Coles to the position of Director of Operations, Mining and Energy. His new role encompasses operational support of all Vermeer Australia’s surface mining, oil and gas field project work, and a range of equipment including track trenchers, surface miners, mud systems and mud pumps, and large-scale drilling systems.

In the 25 years he has spent with Vermeer, Simon has gained very broad and exceptional technical and commercial experience, and as such was a logical choice for the role. He has comprehensive experience in business operations and the unique liaison between Vermeer Australia, their customers, and Vermeer Corporation that large-scale project work necessitates.

Peter Pullan, Managing Director of Vermeer Australia, said “We recognise that the continued expansion of our operations in the Mining and Energy sectors brings greater challenges in terms of service delivery and governance requirements. There is no other person in or outside our organisation who could more capably direct the expansion of this most important area of our business. It will require strategic planning based on an incisive knowledge of equipment, logistics, manpower, and risk management. This plays to Simon’s strengths.”

CSIRO REPORTS CSG EMISSIONS FINDINGS

CSIRO has released a report on greenhouse gas emissions from Australian CSG production wells.

The report, Field Measurements of Fugitive Emissions from Equipment and Well Casings in Australian Coal Seam Gas Production Facilities, involved CSIRO scientists measuring fugitive methane emissions from a number of production wells in QLD and NSW.

Key findings included the fact that of the 43 wells examined, only three showed no emissions; and while the remainder had some level of emission, generally the emission rates were very low, especially when compared to the volume of gas produced from the wells.

The report states: “As a rule of thumb, if fugitive emissions are below 1-2 per cent, natural gas has lower greenhouse gas emissions compared with coal (based on current technologies). Above

about 4 per cent fugitive emissions, the greenhouse benefits are lost. The average emissions rate for this study equated to approximately 0.02 per cent of the total gas produced.

“Although this is a very low figure, it’s important to note that this is only a pilot study, encompassing less than 1 per cent of the existing CSG wells in Australia. Another important consideration is that emissions were only measured from well pads, so cannot give a full representation of the whole-of-life emissions.

“This work will significantly add to the knowledge base about emissions in Australia and help to better characterise Australia’s CSG emission profile. To fully characterise emissions, however, a larger sample size would be required and measurements would need to be made over an extended period.”

NEW GAS PIPELINE FOR QLD

The Queensland Government has announced an $11 million investment in a new gas pipeline to supply householders and industry in the Bundaberg region.

QLD Premier Campbell Newman said the 24.7km Bundaberg Gas Pipeline could create around 100 new full-time jobs and 600 indirect jobs by attracting new industry and development to the region.

“This pipeline will encourage new businesses and industries to locate in the Bundaberg region and allow existing businesses to expand.”

The new gas pipeline will begin at the existing Wide Bay pipeline, west of Bundaberg, (Kensington Gate Station) and extend through to the Port of Bundaberg.

8

gas

“There is no GPR locating system that is as rugged and dependable”

Utility Locating made Easy... again

The MALÅ Easy Locator pioneered Ground Penetrating Radar utility locating and became the industry standard to which all later products is compared. Built on this massive success, MALÅ introduces the Easy Locator HDR (High Dynamic Range)

The MALÅ Easy Locator HDR, is faster, even easier to use, more powerful and delivers cleaner data with more detail at up to 20% better penetration depth to comparable systems.

Antenna HDR 450 HDR 450 HDR 450 System weight 21.5 Kg 34.5 Kg 22.5 Kg Depth Range* 0-4m 0-4m 0-4m Frequency Range 200 - 800MHz 200 - 800MHz 200 - 800MHz Stacks per measurements 700 700 700 Maximum Survey speed 300km/hr 300km/hr 300km/hr Flight approved Li-Ion battery Li-Ion Li-Ion Li-Ion Free Software upgrades 32bit data resolution Real-time sampling HDR Enabed In-field reporting Extended Warranty Option Rough Terrain Cart Upgrade Option Internal GPS Optional Optional External GPS port Data Post-Processing Processing Software Included In-field 3D processing Warranty 1 yr 1 yr 1 yr Easy Locator RTC Easy Locator Easy Locator PRO * Soil dependent MALA GPR Australia Unit 26, 10-18 Orchard Road Brookvale, NSW 2100 Australia PHONE: +61 438 278 902 E-MAIL: sales@malagpr.com WEB: www.malagpr.com.au

Specifications

Sales | Support | Training | Servicing | Special Projects RadioDetection Receive 20% off your RadioDetection RD7000 or RD8000 EM locator when purchased with a MALA Easy Locator. Offer ends 30.12.14

AWARDED

A large contract has been awarded for major components of the $120 million Sunraysia Modernisation Project (SMP), the biggest irrigation upgrade in the history of the Sunraysia district.

GOLD JV, a joint venture between Guidera O’Connor and Leed Engineering and Construction, has been appointed to design and build new pipelines, decommission irrigation channels at Merbein and Red Cliffs and replace the existing 1920s pumps at Merbein Pumping Station.

An enhancement to the project is also being made, which will allow the entire Merbein Irrigation District to have access to irrigation water 365-days a year.

Detailed design by the contractor is now underway and is due to be finished by the end of the year.

Site work is expected to begin early in 2015, with the entire SMP to be finished by June 2016.

For the latest UTILITY NEWS visit

www.utilitymagazine.com.au

STUDY TO REVOLUTIONISE URBAN WATER MANAGEMENT

A ground-breaking study into future scenarios for urban water management has been launched at a Committee for Sydney 2054 workshop. The results will help cities in Australia and across the world address key pressures that pose challenges to safe, secure and sustainable supply of water.

The Future of Urban Water: Scenarios for Urban Water Utilities in 2040 report highlights over 100 social, economic, environmental, political, and technology trends, outlining four key scenarios which will guide the long term planning of Sydney Water.

Each scenario sees the industry move in a new direction with various opportunities for customers, infrastructure, and governance. Some incorporate modest changes, such as the introduction of products and services using smart-water metering, real time monitoring, smart phone apps, and related technology. Others suggest more extensive changes, including self-management of water supply by local communities, a greater role for private industry in building and operating site-specific water systems, and differentiated customer billing.

Arup’s Australasia Water Leader, Daniel Lambert, said the joint planning study was one of the most imaginative

sewer NBN

YARRA VALLEY WATER COMMITS TO NEW INFRASTRUCTURE

Yarra Valley Water (VIC) has announced major new infrastructure to be built in Melbourne’s north.

The utility has committed $14.7 million to install water and sewer services along a major road in Craigieburn, and $20 million towards upgrading the Wallan Sewage Treatment Plant.

The Craigieburn works encompass a number of projects, including the construction of a branch sewer, a potable water main and a recycled water main in preparation for new developments in the area. The construction, which also includes 12km of pipe work, commenced earlier this year and is expected to be completed by mid-2015.

Meanwhile, the Wallan STP upgrade is due to commence in 2015, with completion expected in 2016. The works will also allow the plant to supply Class A recycled water to customers in the Wallara Waters and Mandalay area.

and forward-looking of its type undertaken by any water utility, and would help Australian water utilities to plan for and effect change on a local and global scale.

“Australia is the driest populated continent, and due to the challenges of our climate Sydney Water has successfully undertaken water efficiency and conservation programs to manage demand. As our largest city and one facing unique challenges however, it is imperative that Sydney continues to remain at the forefront of innovative thinking as to what the future of water supply may look like. This thinking should consider demand, operating models and adoption of technological innovation to ensure value is able to be realised by the community.

“Jointly with Sydney Water, Arup has been able to consider and assess scenarios that could transform the operating model for water utilities. Arup believes our population will be best served if water authorities migrate towards a hybrid model which incorporates greater decentralisation and autonomous management of water supply, greater participation of additional service providers and smarter management of the water grid.”

NBN UPDATES FTTB AND INFRASTRUCTURE COMPETITION PLANS

NBN Co has pushed back the expected delivery of its FTTB (fibre-to-the-building or fibre-to-the-basement) product until early 2015 in order to focus on its FTTP (fibre-to-the-premises) services in areas where rival provider TPG poses a competitive threat.

In a May hearing with the Senate Select Committee on the National Broadband Network, NBN Co CEO Bill Morrow and COO Greg Adcock confirmed that NBN Co intended to begin the race to connect apartment buildings by using fibre-to-thepremises (FTTP) technology until their own FTTB product is ready.

The amended FTTB release date is listed on the NBN’s Integrated Product Roadmap and states that all processes and systems for the initial FTTB services product will be released in the first quarter of 2015.

10 SMP PUMP

AND PIPELINE CONTRACT

water

ITS PipeTech Pipe Rehabilitation & Construction

Tunneline

Water Rail Road Sewer Mining & Power

● Pipe Bursting, Slip lining and Pressurelining

● Tunneline and man entry pipe refurbishment

● Berolina UV Cured pipe lining system

● CCTV pipe inspection and laser pro ling

p 02 8603 2000 f 02 8603 2001 e enquiries@itspipetech.com.au w www.itspipetech.com.au Head O ce 1/13 Stanton Rd, Seven Hills NSW 2147 BEFORE

– structural concrete lining for road culverts

A new collaboration between the Australian Renewable Energy Agency (ARENA) and the Energy Networks Association (ENA) is set to provide a one-stop-shop of up-to-date renewable energy grid integration projects and findings.

ARENA CEO Ivor Frischknecht said the new partnership would address an existing information gap and build on important work ARENA had already undertaken.

“ARENA has released a stocktake of 176 renewable energy grid integration projects from across Australia, worth more than $4 billion, including 60 key projects from overseas,” Mr Frischknecht said.

“Integrating renewables into the grid is one of the major challenges facing the energy sector and this stocktake is a vital step in helping advance this work.

“This stocktake of relevant studies, trials and demonstration projects will provide the basis for further work and get the most out of existing information and investment.”

$570M POWER STATION FOR PILBARA (WA)

Canadian-based energy company TransAlta Corporation (Australia) has signed an agreement with Horizon Power to fund, design, build and operate a 150MW combined cycle gas power station at South Hedland to meet future Pilbara electricity demand.

Fortescue Metals Group and Horizon Power are foundation customers of the new $570million power station, to be built in South Hedland’s Boodarie Industrial Estate.

WA Premier and State Development Minister Colin Barnett said the new power station would help to ensure long-term energy security for residents and businesses in the growing Pilbara region, with TransAlta’s presence also introducing much-needed competition into the market.

“This state-of-the-art energy infrastructure will be built using private, rather than State funds, demonstrating there are still innovative ways to deliver important infrastructure in times of financial constraint,” Mr Barnett said.

First power is expected to be delivered in 2016 with full commissioning expected in 2017. At a later date, the plant may also be expanded to supply power to other customers and commercial users.

ENA CEO John Bradley said the ENA would provide updates in late 2014 and 2015, to ensure there is a continuing resource of up-to-date, publicly available information for the whole sector to draw on.

“Housing the latest research, studies, findings and projects in one place will make it easier for the sector to address challenges and capitalise on opportunities involved in integrating renewables into the network,” Mr Bradley said.

“The rapid increase in distributed renewable energy is upending the traditional supply system and driving an increasing need to revisit the energy network, which was originally designed for one-way delivery.

“There are real and tangible benefits and opportunites to be gained from integrating renewables into the network, and network businesses have already facilitated the installation of more than 1.2 million roof top solar panels in Australia.

“The ENA and ARENA recognise the valuable role this stocktake will play in helping the sector to make this transition, by providing a consolidated base for information-sharing and collaboration.”

INNOVATIVE FAULT NOTIFICATION SYSTEM WINS ACCOLADES

A world-first CitiPower and Powercor project that identifies unplanned outages before customers call in the fault has won the Innovation category award at the prestigious Australian Business Awards 2014.

The Meter Outage Notification (MON) system utilises smart meter technology to notify the business of outages by identifying voltage variations in a customer’s system and sending a ‘last gasp’ signal back to the business when the power is about to be lost. This assists in reducing the duration of power outages and saves the business money through greater efficiency.

MON came into service in May 2013 and has saved CitiPower and Powercor about $7 million in the year since.

MON project manager, Luke Skinner, said the ABA100 Innovation category award was tremendous recognition of the work done by his project team.

“The world-first MON project benefits both our business and our customers by being able to detect the exact time of the outage, pinpoint its exact location, identify the exact time of restoration and reduce the need for field crews to undertake outage investigations.”

TRANSEND AND AURORA’S DISTRIBUTION BUSINESSES MERGE

TasNetworks, the new company formed through the merger of Transend and Aurora’s distribution business, is now operating.

TasNetworks CEO Lance Balcombe stated that this is an historic day for Tasmania’s electricity supply industry.

“The commencement of TasNetworks is a significant change to the Tasmanian electricity supply industry and the conclusion of a significant program of work. I would like to thank employees of both Aurora and Transend for their support getting us through that process,” Mr Balcombe said.

“TasNetworks will strive to reduce power bills for all Tasmanians. We will focus on providing outstanding customer service and drive efficiencies to reduce costs, delivering savings for the people of Tasmania.”

GRID

INTEGRATION ‘STOCKTAKE’ PROJECT

electricity

12

Leading suppliers of equipment & expertise to assess sub-surface utilities, roads, civil structures, & geophysical issues Pro’s 10 watt 4

• Ground Penetrating Radar...budget to professional.

• Cable & pipe tracing units...models for all jobs

• Superb training & support

• Concrete rebar imaging equipment

• Australasia’s trusted provider with 17 years of service!

• HOT online pricing on our top GPR and locator combos

• Best brands, best prices contact us now!

www.lordcivil.com

000

0800 485 990

BURIED INFRASTRUCTURE LOCATION AUST: 1800 128

NZ:

Noggin

freq. Rycom 8879PLS 4yr Warranty

LMX100

Advanced Noggin GPR cart system

low-cost LMX100 cart Conquest

Popular

Building a gas

THE AUSTRALIA pipeline

14 GAS PIPELINES

PACIFIC LNG PIPELINE STORY

The recently completed 530 km APLNG gas transmission pipeline has occupied much of the Australian gas pipeline industry for several years. We take a look at each stage in the construction of this world-leading gas pipeline project.

15 GAS PIPELINES

The Australia Pacific Liquefied Natural Gas (APLNG) project is one of three mega coal seam gas (CSG) to LNG projects under construction in Australia. The project is on track to have the first LNG train started up in mid-2015 and the second LNG train remains on schedule for startup in late 2015.

The main export pipeline is now being commissioned, the first gas began flowing from the Condabri Central Gas Processing Facility in June, and on Curtis Island hydrotesting of both LNG storage tanks was successfully completed in August.

Australia Pacific LNG is an incorporated joint venture between Origin, ConocoPhillips and Sinopec.

Origin is responsible for the further development of Australia Pacific LNG gas fields in south central Queensland, and the construction and operation of upstream gas field facilities and the gas transmission pipeline.

ConocoPhillips is responsible for the construction and operation of the downstream multi-train LNG facility and associated infrastructure on Curtis Island, near Gladstone. The LNG plant will be constructed using ConocoPhillips’ Cascade technology, and will have the capacity to produce up to nine million tonnes of LNG per year.

THE GAS PIPELINE PROJECT

A key component of the Australia Pacific LNG project is the high pressure

gas transmission pipeline that will transport CSG from the gas fields in the Surat and Bowen Basins of Queensland to the LNG plant on Curtis Island.

The pipeline infrastructure comprises the 530km main export pipeline and 180km of high pressure laterals connecting to Gas Processing Facilities such as Condabri and Reedy Creek.

Australia Pacific LNG Pipeline Project Manager Graeme Hogarth described the project as world-class.

“This is the one of the largest pipeline projects that’s been undertaken in Australia,” Graeme said. “The pipeline consists of over 700km of high pressure gas pipeline of which 360km is 42inch – very large, high pressure pipeline.”

GAS PIPELINES

“Just the sheer size of the project in its own right is a challenge, and we have successfully delivered construction of this world class project as planned, and on time.”

The pipelines project resources comprised Origin and its two main pipeline contractors, MCJV (a 50/50 joint venture between McConnell Dowell Constructors and Consolidated Contracting Company Australia) and Nacap, with a peak workforce of approximately 1,600 people.

MCJV was contracted to engineer, procure, construct (EPC) and precommission 510km of the large diameter pipelines on the project. The MCJV engineering scope extended to the whole of the gas pipeline system.

Origin procured all the line pipe as well as the large valves and fittings.

Nacap is constructing the infield small diameter gas pipelines that connect the various gas plants to the main export

pipeline and has constructed 40km of high density polyethylene pipeline for water transfer.

GETTING OFF TO A GREAT START

Getting the basics right at the start of the project played a key role in managing technical complexities, resolving construction and timeframe challenges, and creating a unified “one team” culture of cooperation and support across multiple sites, teams and companies.

The use of an Engineering, Procurement and Construction (EPC) contract model enabled Origin and MCJV to share ideas and expertise in design, selection of materials and equipment, and resolve potential issues with construction techniques.

While use of EPC is not unique, Mr Hogarth said the decision to also establish an integrated leadership team (ILT) with representatives from Origin,

MCJV and Nacap proved strategically important.

“The integrated leadership team made joint project-related decisions and guided project delivery, creating a clear, shared understanding of issues from each perspective,” Mr Hogarth said.

“ILT members remained objective during discussions, and developed and endorsed common project values to create a sense of cohesion and shared purpose.

“This integrated approach, developed from the outset, was fundamental for developing ‘teamwork’ and a positive workplace culture across the pipeline project.”

These shared values and goals were brought to life across the project through a range of team development activities.

For example, the ‘Game On’ team engagement program proved highly effective in building performance in

GAS PIPELINES

relation to the key project elements of Safety, Quality, Environment and Progress.

GAME ON: SAFETY, QUALITY, ENVIRONMENT AND PROGRESS

On the pipeline project, safety was recognised as the most important one of four critical elements for project delivery – alongside quality, environment and progress.

As the project moved from planning to critical construction stage, a common approach to safety and progress activity was adopted in order to encourage collaboration and best-for-project outcomes.

Using the common elements of existing safety programs from the different project partners, the pipeline project management developed the ‘Game On’ safety program to ensure a simple, consistent message to help engage work teams and supervisors in safe project delivery.

The Game On program was based on the successful Australia Pacific LNG safety program ‘Every Day is Game Day’, led by rugby league legend Darren Lockyer in his role as safety ambassador.

Game On reinforced existing contractor safety activities, promoted engagement with frontline crews on ways to improve overall project performance, and provided an opportunity to involve the entire workforce.

Pipeline Project Deputy Director John Swanson said Game On was designed to deliver three basic elements:

• combining common safety themes and messages from all three project partner companies

• introducing key performance indicators (KPIs) for safety, quality, environment and progress that extended all the way through to front line supervisors and work teams

• providing specialist ‘coaches’ to support supervisors in communicating with work teams about safety.

“The idea of Game On is really just a delivery method for these three

concepts, and it proved to be extremely effective,” Mr Swanson said.

Thanks to Game On and to every person who worked on the project, by July 31 2014 the pipeline project had reduced its rolling 12 month Total Recordable Injury Frequency Rate to an industry leading 2.42.

WORKING WITH LANDHOLDERS AND LOCAL COMMUNITIES

Cultivating effective relations with landholders and local communities was another critical aspect of the pipeline project’s success.

A team of pipeline landholder liaison officers was established to maintain relations with local landowners, community groups, and local government to provide information and listen to feedback.

These relations and communication lines were essential for managing discussion about issues such as impacts on roads, road use permits, placement of camps, land access negotiations, cultural heritage and environmental permits, and responding to feedback and complaints.

Mr Hogarth said the early stages of a pipeline project focus on the critical aspects of gaining necessary approvals, permits and land access agreements.

“The first three years of the pipeline project were all about the approvals and the engineering; about defining the route of the pipeline, and then designing the pipeline – taking into account design safety as well.”

“Gaining necessary approvals

involves securing access to land, cultural heritage clearances, environmental permits, working with stakeholders, working with landholders, working with council and working with Government.”

During the pipeline project a total of 260 landholder land access agreements were negotiated, along with numerous permits and approvals at Federal, State and local government level.

LOGISTICS AND PROCUREMENT

In parallel with planning activities, logistics and procurement functions shifted into high gear in order to secure necessary equipment and materials, particularly items with long lead times, varying from 42,000 sections of steel pipe, to specialist pipelining equipment such as side boom cranes for laying in the pipe.

Manufacturing and transporting the steel pipe for Australia Pacific LNG’s pipeline was a major logistical challenge undertaken over an 18 month period, involving project teams in three countries.

It involved a total of 42,000 steel pipes, most at 18 metres in length and half at 42 inches in diameter, and weighing around 270,000 tonnes, delivered via 45 ship movements, around 250,000 crane lifts and 330 train trips. It required close coordination with international manufacturers and shipping agencies, port operations, stevedores, Government departments, rail and road transport operators and construction contractors.

18

GAS PIPELINES

THE LAST SHIPMENT OF PIPE IS UNLOADED AT GLADSTONE PORT.

The pipe sections were manufactured in Japan by Nippon Steel for Metal One, coated in Malaysia by WASCO, transported by vessels under charter from Thoresen and Westlink, and unloaded in Australia by Patrick Stevedoring.

Port operations were managed by Gladstone Ports Corporation, with quarantine and Bio-Security services provided by the Federal Department of Agriculture, Fisheries and Forestry.

Consultation with local communities and regional councils identified opportunities to use rail transport to manage impacts of heavy freight transport on local roads, and minimise potential traffic issues.

Pipes were transported from Gladstone via rail by Aurizon Railroad to a central laydown area at Callide, near Biloela and by road to work sites for construction.

The decision to use rail to transport

KILOMETRE-LONG

the pipe sections removed around 10,000 heavy truck movements from Gladstone and the surrounding traffic corridor.

WORKFORCE MANAGEMENT

At its peak the Australia Pacific LNG

pipeline project workforce reached approximately 1,600 employees and contractors.

Due to the remote location of the project, and the fact that work locations constantly moved as work on the pipeline progressed, workforce

19

GAS PIPELINES

STRINGS OF PIPE ARE LAID IN THE OPEN TRENCH USING SPECIALISED SIDE-BOOM CRANES.

WORKING ON THE PIPELINE GANG

Once permits and land access permissions had been obtained the first steps in laying the pipeline were cultural heritage and environmental surveys, followed by pegging out the easement.

A clear and grade crew then removes vegetation, bulldozers and graders level out the right of way to create a working platform for work crews, and topsoil is stockpiled for rehabilitation activities.

Semi-trailers deliver and place pipe sections in preparation for pipe bending and the ‘firing line’ – the automatic welding line which involved over 80 people completing up to 145 welds per day, and covering a linear distance of up to three kilometres.

Automatic ultrasonic and radiographic testing ensure the integrity of each weld, followed by field joint coating where joints that have been welded are sandblasted and epoxy coated.

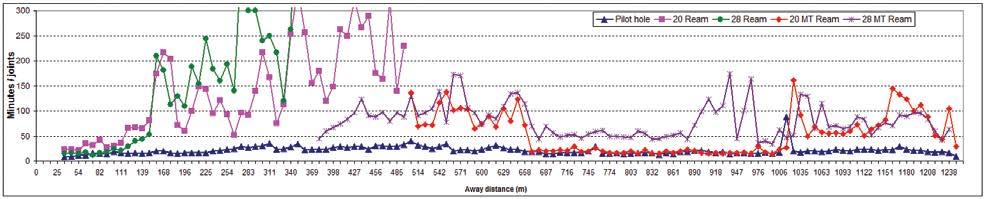

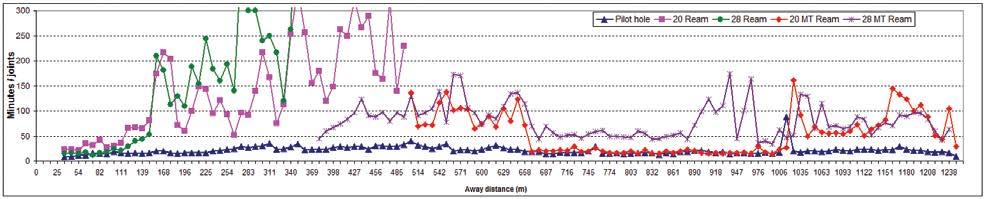

The ditching crew then digs the trench, followed closely by the lowering-in crew, which lays the pipe section in the open trench in continuous sections of up to 1,200 metres.

The two companies agreed to locate their pipelines in the same trench across the Narrows, and install the pipelines simultaneously to minimise environmental impacts. The collaborative approach resulted in the world’s first dual CSG to LNG transmission pipeline project, where MCJV successfully installed both pipes in parallel.

The Narrows crossing pipeline involved horizontal directional drilling to install the dual pipelines, construction of a temporary coffer dam to traverse the marshland section, and winching the completed pipelines through the coffer dam, and then across the open channel.

Once the two pipelines had been constructed, welded and tested, they were moved into position at the entrance to the cofferdam.

The Narrows channel was closed to shipping and a cable was towed from Curtis Island to the mainland and attached to the pipe-header.

A 450 tonne winch on Curtis Island was used to pull the twin pipe strings through the flooded marshland cofferdam and then across the channel to Curtis Island.

accommodation and transport for work teams was a major challenge for the project. Temporary accommodation facilities or camps were established.

Camp locations were planned so that drive times to and from the right of way were minimised. MCJV constructed four temporary camps at various locations, NACAP constructed three camps, and two camps managed by commercial operators were also used. Purpose-built, 18-seater four-wheel drive (4WD) buses were used to transport crews to work sites each day.

A combination of buses and commercial/charter aircrafts were used to transport personnel to Brisbane and other destinations on cycle break.

A $20 million upgrade to the Miles Airport funded by Origin on behalf of Australia Pacific LNG and completed in October 2013 helped to further reduce use of private vehicles using local roads for workers commuting.

Highly skilled specialist welding crews join the long sections, completing these final welds manually in the trench. The final ‘golden weld’ – creating single continuous pipeline stretching from Curtis Island to the gas fields – was completed by specialist welders Simon Patten and Jim Cresham on 30 April 2014.

Once the pipe is lowered in, it is backfilled and compacted, the topsoil is reinstated and seeded with locally appropriate pasture grasses.

CROSSING THE NARROWS

One of the most technically and environmentally challenging aspects of the Australia Pacific LNG pipeline project was crossing the Narrows, a channel separating Curtis Island from the mainland featuring creek, marshland and marine sections with high environmental value.

Australia Pacific LNG and Queensland Gas Company adopted a collaborative approach to the task of installing each respective company’s pipeline across The Narrows.

Conventional trench and bury techniques were used to install the APLNG pipeline from the Curtis Island winch pad to the APLNG receiver station, which will deliver the gas to the newlyconstructed LNG processing plant.

TOWARDS FIRST LNG DELIVERIES

Construction of the main high pressure gas transmission pipeline was safely and successfully completed in July, and the pipeline is now being progressively placed into service. At the same time, hydrotesting of LNG tanks on Curtis Island has been completed, and gas from the recently commissioned Condabri Central gas processing facility is now being delivered into the gas network.

These milestones play a critical role in the delivery of first LNG in mid-2015, with gas from Condabri Central delivered to Curtis Island through the pipeline system where it will be liquefied and shipped to Asia.

For more information visit www.aplng.com.au.

20

PIPELINES

TRIMMING THE FINAL SECTION OF PIPE NEAR GLADSTONE.

GAS

SOLUTIONS PIPING TOTAL

WHEN HDPE PRODUCTIVITY, RELIABILITY AND SAFETY ARE PRIORITIES, CONNECT TO ISCO AUSTRALIA FOR SOLUTIONS.

Rely on ISCO for your next project – offering the latest advances in Mobile Polyethylene Pipe Fusion Technology.

Since 1962, ISCO has put its experience to work, providing total piping solutions on the most challenging projects.

CONSIDER ISCO AUSTRALIA FIRST FOR:

• Vacuworx - Pipe Vacuum Lifting Systems

• Mustang® Pipe Squeeze tooling up to 630mm

• Specialist Pipe Fittings supplier for all project needs

• Electrofusion equipment and fittings

• High Pressure welding training specialists

• Hire equipment available up to 1200mm

• HDPE spool fabrication

• Custom HDPE fabrication

As the globally recognized leader in heavy-duty lifting technology – Vacuworx provides the most comprehensive and complete line of lifting and material handling systems on the market.

8 Rothschild Place Midvale WA 6056 +61 (0) 8 9250 110 264 South Pine Road Brendale, QLD 4500 +61 (0) 7 3881 1838

iscoau@isco-pipe.com www.isco-pipe.com.au

Mobile Hydraulic Chainsaw for safe, accurate cutting of HDPE Pipe.

ISCO CERTIFICATIONS AND QUALIFICATIONS

ISO 9001:2008-certified quality management system N-3822 N-3680

GAS PIPELINES: WHERE TO NOW?

Jim McDonald has been one of the key figures in the development of the Australian gas pipeline industry as we now know it. Founding Managing Director of the Australian Pipeline Trust, founding Chairman of the Energy Pipelines Cooperative Research Centre and three-time APIA President, Jim has now turned his attention to a new technology which has the potential to revolutionise the way gas powers heavy duty trucks and machinery and is delivered to remote industrial locations.

Jim’s career in pipelines began in 1971, when he joined Esso Australia. After 15 years, Jim made the move to NT Gas, where he took up the CEO post. This led to roles within AGL, eventually managing the company’s pipeline division – which went on to become the Australian Pipeline Trust (now APA Group), of which he was the first CEO.

Retiring from APA in 2005, Jim went on to take up Non-Executive Directorships with a number of ASXlisted companies, all with a pipeline industry connection, and was also the foundation Chairman of the Energy Pipelines Cooperative Research Centre (EPCRC).

A pipeline professional of more than four decades, Jim has much to say when asked on his thoughts for the future of the pipeline industry, particularly as it moves from a phase of heady construction and into one of operation and maintenance.

“There are three major planks supporting a future pipeline industry,” said Jim. “Firstly, pipeline operations and maintenance is itself now a major industry, given the sheer size of the pipeline network, and, as capacity is absorbed, looping, compression and eventually refurbishment or replacement of ageing pipelines will add to the complexity of the work.

“Secondly, the continual addition of replacement production capacity and gathering systems for the coal seam methane LNG projects will see a continuum of work in Queensland for decades to come.

“Third, and most importantly, when the politicians wake up to the emerging energy security risk that our reliance on imported liquid fuel entails, when they understand that technology such as high density compressed natural gas (HDCNG) enables us to displace the billions of litres of diesel we presently import each year with our own natural

JIM MCDONALD.

JIM MCDONALD.

gas, and when the public realises the nonsense in exporting energy as gas for $10 per GJ whist we import energy as refined product for $25 per GJ, at a cost to our balance of trade in excess of $20 billion a year, I am confident that we will turn our attention to the vast reserves of gas, including shale gas, that undoubtedly exist in this country, and ensure that Australia’s natural gas is available for our own industries.”

AN EVOLVING INDUSTRY

It is these beliefs that have led Jim into a new phase of his career. He resigned all of his directorships over the past 12 months to focus on a job that has reignited his interest in pipelines and natural gas: as Chairman of the IntelliGas Group of companies (in which he also has a modest investment).

The founders of the business are Paul Whiteman and Derek Fekete, who were both with ASX-listed power

22

A conversation with Jim McDonald

GAS PIPELINES

technology business EDL since it was founded by Paul and Walter Pahor in 1989. IntelliGas also has a fourth investor, Ken Hall, who built Kalgoorlie Power Systems, a remote power generation business, which he sold to Pacific Energy Limited, an ASX-listed power specialist.

“IntelliGas is a natural gas technology business which has world patents pending for components and processes which enable HDCNG™ to be used as fuel in heavy duty vehicles such as highway trucks, locomotives and mining machinery. HDCNG is natural gas at pressures in excess of 350barg (5076psig), at which pressures it has twice the energy density of conventional CNG.

“The IntelliGas systems enable natural gas to be stored, dispensed and used as fuel while eliminating the problems that normally result from the heat of compression in conventional CNG systems. HDCNG enables the on-board fuel storage tanks to be filled with cool gas to name plate capacity every time, and a HDCNG equipped heavy duty B Double road train can

travel in excess of 1,100km between fuel stops.

“It is very exciting technology with worldwide application.”

According to Jim, the IntelliGas system is practically commercial-ready, and the team has commissioned the world’s first HDCNG re-fuelling station at Crestmead in Brisbane. However, a major obstacle has arisen to slow the application of the technology to heavy duty truck fleets with the withdrawal from sale of the Westport GX engine. The engine, which is a 500+HP diesel cycle engine, is ideally suited to Australian conditions. Its withdrawal means that an engine suited to Australian heavy duty conditions is presently not available. This will be resolved, but it may be a year or so before a suitable engine is on the market.

“At IntelliGas we are working with engine technology and truck manufacturers as they develop their own gas engines,” said Jim. “We have a prototype engine which develops almost 600HP running in one of our three Western Star trucks. We are also

working with fleet owners of trucks up to around 400HP where spark ignition and dual fuel gas engines are now becoming available.”

According to Jim the key target market for HDCNG is heavy duty interstate highway fleets. “Other than re-fuelling systems which will be installed ‘behind the gate’ in fleet owners premises, we plan that this fleet will be re-fuelled at strategic locations on national highways, where the highway and transmission pipelines are adjacent. Examples of such sites on the Hume Highway are Barnawartha, just west of Wodonga, and Marulan, just north east of Goulburn. Rest assured there are sufficient points on the national highway system where pipelines either cross the highway or are adjacent to it to enable dedicated prime movers to re-fuel in sync with driver rest periods and vehicle range on HDCNG.

“The heavy duty highway fleet in eastern Australia consumes in excess of 120 PJ of energy each year, and individual trucks consume up to

23

GAS PIPELINES

JIM WITH JAMES WHITEMAN AND AN INTELLIGAS TRUCK AT CRESTMEAD RE-FUELLING STATION.

REFLECTIONS ON A PIPELINE CAREER

Jim’s earliest pipeline memory is from 1964, when he and his father drove along the Princes Highway to visit a spot just east of Traralgon, where Snam Progetti had cut the highway to install the Longford-Dandenong natural gas pipeline.

“I had no idea then that pipelines would play such an important role in my life,” recalled Jim. “That didn’t happen until 1971 when I joined Esso Australia, and went on to spend 15 contented years in oil and gas production in Bass Strait. Over that time we went from two platforms to thirteen, and from zero oil production to in excess of 500,000 barrels a day. They were heady and exciting times.”

A major turning point in Jim’s career came in 1986 when, faced with a change of jobs within Esso, he chose to leave and accept the position of CEO of NT Gas, a decision that began to define his career and marked the commencement of a steep learning curve. Not long after this move, major change lay ahead for the gas and pipeline industries. In the early 1990s, Victorian Premier Jeff Kennett signed off on the privatisation of the state Gas and Fuel Corporation, which, according to Jim, sealed the fate of government ownership of gas pipelines and networks.

“A domino effect over the next several years saw all the major pipelines in private ownership, and the industry has never looked back,” said Jim.

“Privatisation also led to a major event in my career in 1994; the acquisition by AGL, Petronas and Nova of the Moomba to Sydney Pipeline and the creation of the East Australian Pipeline Company. This was the nucleus of the Pipeline Division within AGL, which in turn was the nucleus of the Australian Pipeline Trust, the subject of an IPO by AGL just six years later, listing in March 2000. I was fortunate to be the General Manager of AGL’s Pipeline Division in those growth years, and when this was spun into the Australian Pipeline Trust, now APA Group, I was offered the opportunity to be

$250,000 in imported diesel fuel per annum: now that is an untapped market for natural gas,” Jim said.

THE VIRTUAL PIPELINE

In addition to the road fleet market, IntelliGas has also developed the concept of a ‘virtual pipeline’ using HDCNG technology.

The virtual pipeline involves the transport of approximately 1,200 GJ on a B Triple Road Train – a significantly greater quantity than any conventional CNG delivery system can carry, other than a pipeline, and has enormous potential to be used to displace diesel

the company’s first Chief Executive Officer, and later Managing Director.

When asked to recall his favourite memory throughout his pipeline career, Jim was quick to name the Ballera to Mt Isa Pipeline project.

“On this project, we had a price to satisfy and a first gas date just 14 months away, with significant liquidated damages per diem for failure to deliver gas. The week we mobilised, the entire route suffered 100 year floods from cyclonic activity in the Gulf. Cooper’s Creek was 80 km wide within weeks as the floodwaters moved downstream; and Mt Isa itself was completely isolated with roads in all directions seriously damaged. Our pipe stock yard in western Queensland was under a metre or so of water, we had construction equipment stranded at Moomba, and were in serious trouble.

“We had planned to build from Moomba to Mt Isa, but were forced to turn the project upside down and regroup to build from north to south. I will not bore you with the details; suffice to say it was a daunting task with our project planning in total disarray. It was as bad as it gets in project work.

“Thanks to great work by Jeff Sheppard and Grant Bowley who were with our contractor McConnell Dowell at the time, John Bidwell who was my Project Manager, and some very serious and at times heated discussions about how a risk/reward sharing alliance project structure was supposed to work, we made it on time and on budget. From memory we set a record for construction speed, averaging something close to 8 km per day, even achieving 17 km on one day. At one time we had over 150 km of trench opened with explosives and rock saws through the hard rock country south of Mt Isa, and the welding crews almost caught up with the trenchers.

“It really was a great job.”

24

GAS PIPELINES

JIM AND BRYAN FULWOOD INSPECT AN INTELLIGAS FUEL PACK BEING FITTED TO A MILK TANKER TRAILER.

A VOICE FOR THE INDUSTRY

Throughout his career in pipelines, Jim has been a key player in growing the Australian Pipeline Industry Association (APIA) into the association it is today – one which commands respect and has political influence.

“I attended my first APIA conference in Adelaide in 1988 from memory and saw the possibility that it could represent the entire industry, not just the construction members.

“Others shared this opinion and we set about strengthening the association. It went from strength to strength, despite our being accused of hijacking it. By the turn of the century the transformation was complete, it was well funded and domiciled in Canberra, and recognised increasingly as a voice for that great fuel, natural gas.

“Through the work of APIA, the Australian pipeline industry has achieved worldwide recognition.”

Another role Jim took on following his retirement from APA was as the foundation Chairman of the Energy Pipelines Cooperative Research Centre Limited (EPCRC), the body established in 2010 to provide focused research and education to support and benefit the energy pipelines industry in Australia.

“I saw my job was to bed it down, get the research programs underway and get the governance in place to enable it to perform and report to the satisfaction of the funding providers, the pipeline industry and the Federal Government.

“There were several highlights from my time with the

at remote mine sites and towns a pipeline cannot economically reach.

Said Jim, “Of course, the first choice should always be a pipeline, but the capital for a pipeline has to be recovered over its contract life, and often this is not possible. The assets that comprise a virtual pipeline are fungible and therefore the capital can be recovered over the life of two or more contracts, or the component parts recovered and re-used in other projects. This option does not exist for a buried and welded pipeline.

“Virtual pipelines are therefore a viable option when pipeline economics do not work. As such, they will still have a positive impact on pipelines as the gas for the virtual pipeline will always be drawn from an existing

EPCRC. First, the team was successful in getting itself established due to the vision, dedication and sheer hard work of a number of members of the APIA Research and Standards committee. There is not space to name all involved; but I will give special mention to Leigh Fletcher who led the team. It would not have succeeded without his work.

“The second highlight was the appointment of Valerie Linton as CEO. I could not have wished for a better qualified and experienced person to run it. As a result, notwithstanding a bit of early wheel spin, the CRC programs were established, some issues with the university research centres were sorted, the researchers got down to their work, and we achieved a most satisfactory report from the Government at our first review.”

As Jim noted, the purpose of the EPCRC is to extend the life of existing pipelines, to maintain their impeccable safety record, and to enable the building of better, safer pipelines in the future. However, he also noted that the EPCRC cannot rely on Government funding being renewed when the present grant is exhausted in 2019 – particularly in light of recent cuts to the broader CRC program announced in the 2014 Federal Budget.

“The EPCRC has the major task of producing research of such quality, and with immediate commercial benefit from application, that the industry will have no choice but to support it beyond the present funding.

“I have no doubt that it will succeed.”

pipeline: a virtual pipeline is therefore a practical and complementary extension of a pipeline system.

“The presence of a virtual pipeline load on a pipeline, assuming the virtual pipeline load is complementary to the pipeline load factor and storage capacity, will bring further efficiencies to the pipeline. Pipeline owners will be attracted to the technology and will certainly be attracted to having a virtual pipeline take gas supply from their pipelines. They may even want to invest in this natural extension of their business.”

MINING MACHINERY ALSO IN HDCNG SIGHTS

IntelliGas is also about to commence proof of concept trials for HDCNG to

fuel mining equipment. While remote power generation is a potential market for natural gas and some sites are ideally suited to virtual pipelines for that purpose alone, the opportunity to displace diesel with HDCNG in mining machinery is immense.

“I can envisage a day when a virtual pipeline has enabled a mine to convert its generators to gas, and then commence conversion of the mining fleet, creating such gas demand that a pipeline becomes feasible,” said Jim.

It’s hard not to get excited about the potential for this technology, especially when an expert like Jim can see it invigorating the gas pipeline industry in years to come.

25

An extended version of this article is available online. Go to www.utilitymagazine.com.au to read the full story. GAS PIPELINES

KEY TO PIPELINE INDUSTRY LEGACY COMMUNITY ENGAGEMENT

The rapid expansion of the Queensland onshore gas industry in recent years, and the scale of the projects involved, has been staggering. In order for these developments to have a positive legacy in the years to come, effort must be made to adequately inform and engage those affected. The expansion of the onshore gas industry over the past five years is one of the largest industrial developments ever to occur in regional Queensland.

26

LAND ACCESS

by John Cotter, Chairman of the GasFields Commission Queensland

Three major coal seam gas to liquefied natural gas projects (APLNG, GLNG and QCLNG) are currently underway and include pipelines connecting the upstream gas fields in the Surat Basin to export terminals in Gladstone.

The scale of these projects and the speed at which they have developed has been nothing short of staggering for all involved, especially for local landholders and communities.

The pipeline industry has had a key role to play in these projects, in particular the pipeline contractors. These contractors are the people who design and build these energy highways, many of which are hundreds of kilometres long and traverse many individual properties and rural businesses.

Most pipeline contractors recognise that building a pipeline is not just about meeting technical or engineering

challenges; it’s also about people. They understand that often the biggest and most important challenge is accessing land and dealing openly and respectfully with the landholders and communities along the pipeline easement.

Having travelled up and down these export pipelines dealing with numerous landholders throughout the construction phase, I have learnt a number of valuable lessons that I

27 LAND ACCESS

JOHN COTTER INSPECTS A PIPELINE EASEMENT AFTER REINSTATEMENT.

believe should be known by all involved in the industry.

GREATER CLARITY ON LAND ACCESS

Firstly, I believe more can be done by gas proponents to improve transparency and provide greater clarity to their pipeline contractors on land access responsibilities such as negotiation, operational matters and dealing with disputes.

Such land access matters must be a critical part of the contractual arrangements between the gas proponent and the pipeline builder. A blame game between project owner and contractor is no longer acceptable in this day and age.

A more coordinated and cohesive approach can not only save time and money on these multi-billion dollar pipeline projects, but can also help reduce the risk of negative publicity and the resulting impact on corporate reputations. More importantly, it can reduce the stress and heartache experienced by affected landholders and communities.

DEVELOPING A SOCIAL LICENSE CULTURE

Secondly, pipeline proponents, contractors and even their subcontractors must remain fully aware of the importance of community engagement or ‘social license’ to operate.

No matter how big or small one’s role in a project, it is critical that everyone is aware of their impact on neighbouring landholders and communities. This is particularly critical during the intensive construction phase.

The onshore gas industry already demands a strong workplace safety culture from its company and contract employees, and likewise it must demand a strong culture of social license.

Like safety, if social license and community engagement become embedded values or measurable performance indicators for individuals, teams and companies, I believe this will not only enhance corporate reputations, but will also assist project

bottom lines by reducing the delays and costs arising from disputes with landholders and communities.

PIPELINE LEGACY

Thirdly, it should be recognised that these pipelines or ‘energy highways’ have ongoing impacts well beyond the construction phase.

Issues such as erosion, subsidence, weed management and operational activities along the pipeline easement need to be handled carefully and respectfully with landholders.

After all, the rehabilitation and ongoing management of these pipeline easements in the years and decades to come represent the lasting legacy of the project.

I have inspected many of the rehabilitated areas across southern and central Queensland and spoken with impacted landholders. Some still have a bitter taste in their mouths over the way they were initially dealt with, while others have reached satisfactory outcomes.

What is clear is that the reputation of the pipeline industry and the onshore gas industry as a whole is very much dependent on taking a whole-of-life project perspective.

Whoever ultimately owns and operates these pipelines has a responsibility to respect and engage with the landholders and communities who, through no fault of their own, are living alongside these pipelines and have to coexist with them for many years to come.

QUEENSLAND LEADING THE ENERGY REVOLUTION

Queensland is leading the onshore gas industry revolution in Australia and the pipeline industry in this state will continue to grow and develop these diverse gas reserves.

A major focus for the GasFields Commission is to get out in front of this onshore gas industry expansion and provide landholders, local councils and communities with relevant information and contacts to understand their rights and opportunities.

The GasFields Commission continues to support landholder

negotiation workshops run by AgForce Queensland. Over the past couple of years more than 70 workshops have occurred, attended by some 2,000 landholders across regional Queensland.

My fellow commissioner, Don Stiller, whose family has negotiated multiple conduct and compensation agreements with resource, pipeline and utility companies, has shared his top negotiating tips as part of the Commission’s broader landholder education push.

There will be ongoing need for a community engagement and education effort, not only for the existing Surat Basin CSG-LNG export projects, but also for the number of other potential onshore gas and pipeline projects currently under consideration in Queensland.

For example, the Bowen Basin to Gladstone pipeline and other potential pipeline projects (intended to service the emerging shale gas industry stretching from Burketown in the northwest to the Cooper Basin in the far southwest), will hopefully heed the lessons of the Surat Basin experience. In order to continue to operate and grow in Queensland and beyond, the onshore gas industry must work hard to build and maintain its social license and to better explain to all consumers where their energy comes from.

28

LAND ACCESS

JOHN COTTER INSPECTING A PIPELINE ROUTE DURING CONSTRUCTION.

has

That kind of ILI experience can't be found anywhere else.

Our latest generation MagneScan 4.0 tools have inspected over 40,000 km of pipelines so far, on top of the 610,000 km with the heritage technology. We also have the data analysis and defect identi cation records to match. PII continually invests in our people and tools — pushing technologies to give our customers the highest levels of con dence, safety and productivity that science can provide. We aren’t about to stop now.

PII Pipeline Solutions a GE Oil & Gas and Al Shaheen joint venture

MagneScan™

literally been around the world BOUN D SEIRA

PIPELINE INTEGRITY: ENSURING OUR ENERGY SUPPLY

Australia is increasingly dependent on the gas pipelines that deliver this vital energy source around the nation. The construction of gas pipelines has experienced a boom in the past decade, but equally important is the ongoing maintenance work required to ensure the integrity of this critical infrastructure.

As we become increasingly dependent on energy pipelines, the potential impacts of pipeline failure have become increasingly serious. Managing this risk, and ensuring pipelines do not fail, is a major focus for all pipeline operators now and in the coming years.

MANAGING INTEGRITY

The requirements to safely operate and maintain a gas pipeline in Australia are outlined in the pipeline industry’s Standard, AS2885.

AS2885 sets out requirements for the design and construction, welding, operation and maintenance and field pressure testing of gas and liquid petroleum pipelines.

The Standard was developed by Standards Australia with involvement from the Australian pipeline industry, with contributions from pipeline regulators, engineers, constructors, managers and owners.

The Standard is continually evolving, as new technologies enter the market and new discoveries are made regarding the safe management and operation of gas pipelines.

The Standard features an integrity management, or risk management approach, which enables companies to develop their own risk-based integrity management plans applicable to their own operations. It gives them more flexibility in their maintenance programs which can provide cost savings, while maintaining quality.

THE OWNER/OPERATOR PERSPECTIVE

APA Group

APA Group states that maintaining their assets well is key to ensuring gas transportation and storage services are delivered safely, reliably and cost-efficiently for the long-term. APA has a national maintenance program for all the assets that they maintain and operate to meet technical requirements and ensure good industry practice.

Inline pipeline inspection or ‘intelligent pigging’ is one of the asset integrity management processes that APA uses to inspect and confirm the condition of a pipeline. The intelligent pigs sent through a pipeline can detect metal loss corrosion, stress corrosion cracking and other pipeline defects on both the inside and outside of a pipeline. The process is designed to minimise impact on the flow of gas in a pipeline and is normally conducted at periodic intervals of a few years.

APA uses the world’s best technology including high resolution electromagnetic and ultrasonic pigs that travel in the gas stream. The sensors in these intelligent pigs measure the size and exact location of even minute changes in a pipeline’s condition. Intelligent pigging provides a health check for a pipeline to ensure its ongoing fitness for service as well as meeting legislative and licensing requirements. By keeping detailed diagnostic records and undertaking timely repairs or preventative maintenance, APA can effectively extend the safe useable life of their pipelines.

Dampier Bunbury Pipeline

Dampier Bunbury Pipeline (DBP), owners of the pipeline of the same name in Western Australia, outline their commitment to pipeline integrity management in their ‘ZEROHARM’ health, safety and environmental policy.

A cornerstone of the ZEROHARM commitment is protecting the integrity of the pipeline. DBP monitors safety on the pipeline twenty-four hours a day, seven days a week via a dedicated control centre. Frequent helicopter patrols are conducted performing aerial safety assessments which ensure DBP is able to monitor the pipeline corridor and any works or activities happening in its vicinity.

The surface is protected from corrosion by a coating material and an impressed current system.

The pipeline is cleaned and inspected internally by a process known as ‘pigging’ approximately every ten years. This involves inserting a pipeline internal gauge ‘pig’ which is propelled through the line by the gas pressure while it scrubs the sides of the pipeline. It is followed by a high-tech tool which measures the thickness of the steel pipe wall electronically.

APLNG

APLNG has developed its integrity and maintenance plan for their gas transmission pipeline in adherence to AS2885. The key requirements of its plan are as follows:

• APLNG will assume responsibility for the safety of the gas pipeline.

30

PIPELINE INTEGRITY

• All threats to a gas pipeline will be identified and either controlled or the associated risks will be evaluated and managed to an acceptable level.

• The gas pipeline will be designed and constructed to have sufficient strength, ductility and toughness to withstand all design loads to which it may be subjected during construction, testing and operation. The design will be reviewed, assessed and approved.

• Before the gas pipeline is placed into operation, it will be inspected and tested to prove its integrity.

• The integrity and safe operation of the gas pipeline will be maintained in accordance with an approved safety and operating plan.

• Where changes occur in or to a gas pipeline or its surroundings, which alter the design basis

or affect the original integrity, appropriate steps will be taken to assess the changes and where necessary implement modifications to maintain safe operation of the gas pipeline.

• At the end of its system design life, the gas pipeline will be abandoned unless an approved engineering investigation determines that its continued operation is safe.

• Before a gas pipeline is abandoned, an abandonment plan will be developed and approved.

Jemena (Eastern Gas Pipeline)

Pipeline integrity is ensured through continuous flow monitoring (via SCADA) and the capacity to limit and isolate flow. Automated and manual shut in valves are a feature at each receipt and delivery point, and at a further seventeen locations along the pipeline. The Jemena Melbourne Control Centre monitors, on a

continuous basis, the quality of the gas entering the pipeline. The analysis is performed by the gas chromatographs installed at each receipt point, and values are fed into the SCADA system.

FUTURE PROOFING OUR PIPELINES

As the pipeline industry evolves, updates are constantly made to AS2885, and new and better ways to manage a pipeline’s integrity are brought to market. As Australia’s pipeline infrastructure ages, there is little doubt that our approach to operation and maintenance will need to adapt to meet the needs of the network.

The challenge for Standards Australia, the Australian Pipeline Industry Association and the committees involved in developing and updating AS2885, will be ensuring our gas pipeline network remains up to the task of safely delivering hydrocarbons to an energy-hungry population.

Environmental Consulting Solutions

Hydrographic Technology

Our Infrastructure team remain at the cutting edge of solutions driven technology with the use of remote sensing boat technology to deliver hydrographic mapping.

Aerial Survey Solutions

Unmanned Aerial Vehicle (UAV) Mapping