Fuel in FOCUS

BINGO Industries is opening the gateway to the alternative fuel market.

FEATURES

Australia’s first incinerator bottom ash plant ready to run

Setting new standards for e-waste ESG

Taking waste equipment to the next level Meet the ‘landfill whisperer’

PROUDLY SUPPORTED BY:

PMS 380 PMS 376 PMS 355 MARCH 2023

19 FIRE IN THE BELLY

FUEL IN FOCUS

BINGO Industries is opening the gateway to the alternative fuel market with new green technology that will push its material recovery rate towards 90 per cent.

“BY SOLVING OUR RESIDUAL WASTE STREAM, WE CAN PRODUCE SIGNIFICANT ECONOMIC, ENVIRONMENTAL AND CARBON BENEFITS.”

In this issue

Features

Resource Recovery at forefront for REMONDIS.

46 THE NEXT LEVEL

Tutt Bryant goes to the next level with the acquisition of 600 Cranes.

48 THE GOOD FIGHT

The changing face of Isuzu’s packaging push.

50 $280M DEAL

Veolia signs long-term contract with the City of Gold Coast.

52 INVESTING IN QUALITY

Why the latest WEIMA Powerline shredder is worth the investmen

54 ORGANIC PARTNERSHIP CEA and Thoeni lay the groundwork for better value solutions in organics recycling.

56 OLD INDUSTRY, NEW TRICKS

An ASTEC high-frequency screen helps build a circular economy.

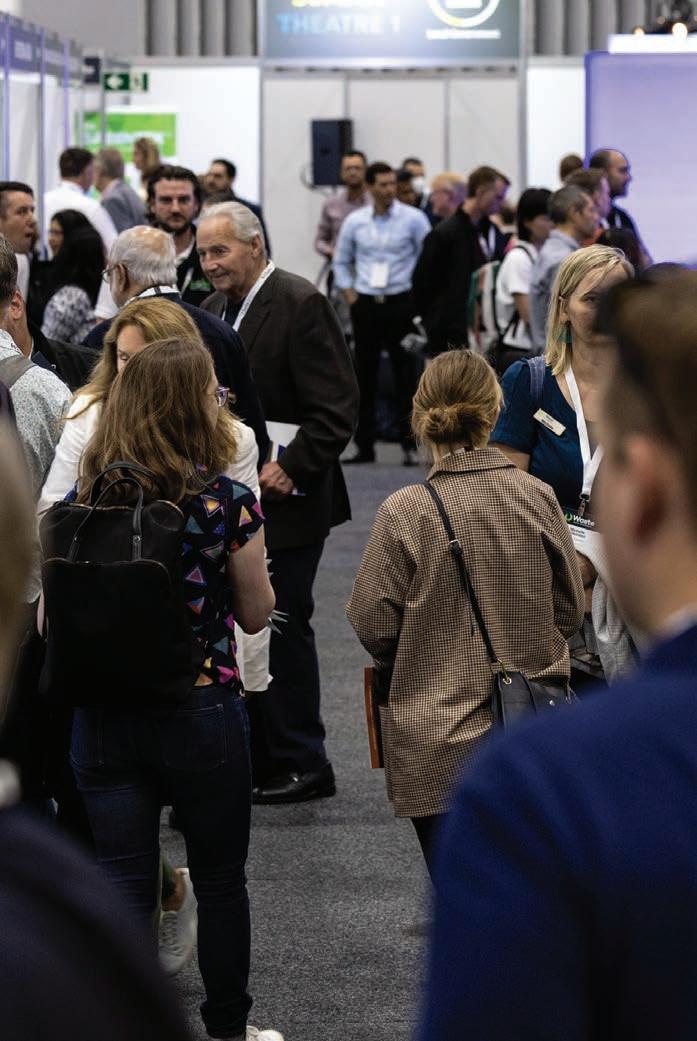

58 THE FUTURE OF WASTE

Waste Expo Australia 2023 to tackle the future of waste and recycling.

61

Australasian Waste and Recycling Expo expands its program.

64 WORKING TOGETHER Waste 2023 builds industry connections.

Regulars

67 PRODUCT SPOTLIGHT

69 LAST WORD

14 FUEL IN FOCUS BINGO industries pushes to tackle the last 20 per cent of waste to landfill. 19 FIRE IN THE BELLY Blue Phoenix’s world-first Incinerator Bottom Ash facility is complete. 23 POWERFUL SOLUTIONS Eneraque offers powerful solutions for waste gas. 26 NEW RESEARCH Monash University brings the science to waste processing. 28 MASTERING ORGANICS Mastershred tackles organic waste and carbon emissions. 31 LEADING THE FIELD LGI’s Scott Prior is the ‘landfill whisperer’. 34 BETTER INFORMATION Green Technology Recycling harnesses the power of data science. 36 A SHRED OF HOPE Shred-X has e-waste solutions built for sustainability.

TECH IN SCIPHER

39 MORE

TECHNOLOGIES

PUSHING

Setting new standards for ESG reporting. 43

THE BOUNDARIES

IN THE ZONE

COVER

14

STORY

- Simon Sherwood, BINGO Industries General Manager of Operational Development

4 / WMR / March 2023

After three years of development work, Blue Phoenix’s first Australian Incinerator Bottom Ash processing facility is ready to flick the switch.

GENOX’S NEW SHREDDER IS A PLASTIC PIPE’S WORST NIGHTMARE. THAT’S APPLIED THINKING. Call: Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au genoxmachinery.com.au Genox’s new J-Series pipe shredder is specificially designed for HDPE plastic pipes. With a unique multi-rotor design and long life counter knives, it quickly shreds different diameter and sized pipes. Like all Genox equipment it comes with the support and back up that only a true local machinery partner can provide.

Warranty is subject to the conditions outlined in the IAL New Vehicle Warranty. For further information please visit isuzu.com.au or contact your local dealer. FSA/ISZS1339 Keep your business moving. We know how important it is to keep your business on the road. That’s why we’re o ering a 6 year factory warranty and 6 years of 24/7 roadside assist on Isuzu trucks.

From the Editor

Renewed energy

Energy-from-waste (EfW) has been a successful and critical component of the waste hierarchy for many years overseas.

While Australia may have been slow to adopt the technology, a pipeline of projects is changing the nation’s waste landscape.

Many industry insiders hope that Australia’s first EfW facility, currently being built in Kwinana, Western Australia, will quell the naysayers and highlight the benefits it can bring as the nation transitions to a circular economy.

The chance to be involved in the landmark project was enough to entice Ian Lynass out of semi-retirement. An industry veteran and now Blue Phoenix Australia, Managing Director, Ian has taken a leading role in constructing Australia’s first incinerator bottom ash (IBA) processing facility.

He says it’s a timely and responsible approach for the technology now to be included in Australian waste strategies for the long-term (Page 19).

As this edition of Waste Management Review highlights, the value of residual waste as fuel is being unlocked across multiple platforms as the world transitions away from traditional energy sources.

In this month’s cover story, (Page 14) Simon Sherwood, BINGO Industries General Manager of Operational Development, explains how a new division is opening the gateway to the alternative fuel market and helping the company conquer the last mile –finding a solution to divert the last 20 per cent of its waste from landfill.

In 2022, Queensland-based Eneraque propelled Australia’s gas-to-energy sector to the next level – upgrading biogas to biomethane that will power heating, hot water and cooking for thousands of Sydneysiders (Page 23).

Meanwhile Mastershred, is hoping a new easily deployable plant will provide greater opportunities for an EfW solution for organic waste (Page 28).

While technology is advancing, these projects wouldn’t be successful without the people driving them. We talk with Scott Prior, LGI’s “landfill whisperer”, whose knowledge of landfill management is helping regional councils capture biogas to abate carbon emissions, improve local air quality and, in some cases, generate renewable energy. (Page 31).

While it still might be some time before everyone embraces EfW, it appears Australia is on the cusp of some exciting changes.

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

GROUP MANAGING EDITOR

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Leon Cranswick leon.cranswick@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGN

Louis Romero, Kerry Pert

BRAND MANAGER

Chelsea Daniel-Young chelsea.daniel@primecreative.com.au

p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. The rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Lisa Korycki

8 / WMR / March 2023

The missing piece for Australia’s

E-WASTE CRISIS

The missing piece for Australia’s

E-WASTE CRISIS

Did you know that approximately 54% of all e-waste in Australia is collected, with around 80% of this going to low efficiency recycling?

Did you know that approximately 54% of all e-waste in Australia is collected, with around 80% of this going to low efficiency recycling?

ReSource has invested in the solutions needed to process e-waste safely, efficiently and in an environmentally friendly manner

ReSource has invested in the solutions needed to process e-waste safely, efficiently and in an environmentally friendly manner

Scale & LocationEfficiencyFire & SafetyEnvironmentTechnology

Australia's first large scale e-waste recycling facility covering 15,000m2.

Australia's first large scale e-waste recycling facility covering 15,000m2.

Strategically located only 15mins to the port and within 60km of three quarters of Victorian residents

Strategically located only 15mins to the port and within 60km of three quarters of Victorian residents

E-waste specific processing equipment to maximise efficiency and recovery rates leading to better environm

lental outcomes

E-waste specific processing equipment to maximise efficiency and recovery rates leading to better environm

lental outcomes

Implement industry leading fire prevention/ protection and safety controls using over a dozen thermal cameras and multiple thermally activated Al powered water cannons

Implement industry leading fire prevention/ protection and safety controls using over a dozen thermal cameras and multiple thermally activated Al powered water cannons

Advanced dustand emissions collection system able to capture VOC's and airborne heavy metals and site fully powered by solar

Scale & LocationEfficiencyFire & SafetyEnvironmentTechnology

Advanced dustand emissions collection system able to capture VOC's and airborne heavy metals and site fully powered by solar

Australian first Al-powered x-ray battery sorter and battery to fertiliser processing capabilities

Australian first Al-powered x-ray battery sorter and battery to fertiliser processing capabilities

info@re-source.net.au www.re-source.net.au

www.re-source.net.au

info@re-source.net.au

EXTRACTING MAXIMUM VALUE FROM WASTE

HIGHLY ROBUST DESIGN

QUICK & EASY SET UP

LOW CAPITAL OUTLAY

Obtaining the quickest return on your capital investment depends on how quickly operators can be up and running, and the volume of commodities that an operator can recover from their waste stream. EDGE Innovate’s range of mobile solutions are tried and tested, are quick and easy to set up, require no on-site civil works, represent a low capital outlay and are proven to achieve high commodity recovery levels.

TO FIND OUT MORE CALL OR EMAIL

+61 24 365 4 24/7

info@focusenviro.com.au

focusenviro.com.au

HIGHLY CUSTOMIZABLE

Consultation begins on WA e-waste to landfill ban

Western Australians can now have their say on the rollout of an e-waste to landfill ban from 2024.

The ban would include televisions, mobile phones, computers, screens, data storage, white goods, batteries, medical devices, lighting and lamps.

Future phases of the ban would capture small household appliances such as kettles, toasters and vacuums, photovoltaics including solar panels, as well as monitoring and control equipment.

The ban is a state government election commitment and would complement existing national product stewardship schemes, support the local e-waste industry and focus on recovering high value materials such as metals.

Funding of $14 million will support the implementation of the ban. More than $10 million will go towards infrastructure grants to boost the state’s collection, storage, processing and recycling network capacity.

Environment Minister Reece Whitby said e-waste is a rapidly growing stream of waste containing valuable and rare materials that are critical to reduce, reuse and recycle.

“Reducing waste to landfill not only moves WA closer to its goal of a circular economy, but provides jobs, builds local industry and protects the environment.

“Having your say will help us understand any industry or community concerns to help shape the e-waste ban to ensure it is practical, workable and effective.”

The public consultation period for the e-waste to landfill ban is open until 31 March, 2023.

News OFFICIAL AUSTRALIAN DISTRIBUTOR Robust & Reliable Shredding Machinery for any application Carrum Downs, VIC 3201 +61(0)3 8400 6066 cemactech.com More than 1,200 machines delivered annually worldwide 40k+ machines sold

NSW soft plastics crisis hits council recycling facility

Hornsby Shire Council has introduced proof of residence and quantity limits for people using the Community Recycling Centre (CRC) as it struggles to cope with increased demand of its soft plastics recycling services following the suspension of REDcycle.

The council’s Mayor, Philip Ruddock has called on both the state and federal governments to do more to urgently address the soft plastics crisis.

Hornsby council’s CRC has a viable soft plastics recycling service, however the amount of soft plastics dropped off has more than doubled since REDcycle suspended its service from supermarkets in November 2022. Based on the increasing trend, the council estimates the CRC facility will accept about 50-80 tonnes of soft plastic material over the next 12 months.

The council has a partnership with Plasmar, a plastics recycling specialist, which sorts soft plastics, pelletises them and then makes a range of products including posts, boards, sleepers, bollards and other construction materials. It said Plasmar’s Sydney factory has a limited capacity to accept soft plastics generated by the community and, with the increasing demand on its services, has capped the quantities accepted.

“Restricting our reception of soft and hard plastics and

Styrofoam to residents of Hornsby Shire is the first lever we have to pull in an effort to ensure that our recycling processes are not overwhelmed,” said Hornsby Shire Council’s Manager, Waste Management.

Council’s Mayor, Philip Ruddock said it was critical that further funds are invested in recycling services that allow the sorting, processing and remanufacturing of soft plastics into beneficial products that can be used in a circular economy.

“It is time that government looks to regulate the packaging industry and to heavily invest in the necessary remanufacturing facilities that can turn our waste into useful resources”.

Ruddock said that following on from the Global Recycling Crisis caused when China and other countries ceased accepting plastics from western countries, it was critical that onshore recycling

and remanufacturing capacity was developed to ensure Australia’s waste does not need to be exported again.

“If our recycling systems are going to meet community demand, state and federal governments must invest in the rapid expansion of soft and hard plastics sorting and remanufacturing facilities such as Plasmar.”

Residents need to show they reside in the Local Government Area in order to recycle soft plastics, hard plastics and Styrofoam. Quantity limits for residents of one normal shopping bag full of soft plastics (40cmx40cm bag) per week have also been introduced.

The new rules came into effect as of 8.30am on Friday, 27 January 2023. CRC facility staff will accept either a Hornsby Shire Council issued rates notice or driver’s license proving residence in Hornsby Shire.

12 / WMR / March 2023 News

The amount of soft plastics taken to Hornsby Shire Council’s recycling centre has more than doubled since the REDcycle program was suspended.

60-80%

Potential to reduce a Council's carbon footprint by

Did you know that your landfill can actually help reduce local greenhouse gas emissions? If not captured, biogas from landfills can account for 60-80% of a local council’s carbon footprint.

Even small (open or closed) landfills can produce enough gas to support financially viable biogas extraction. Some sites will produce enough gas to create dispatchable, renewable energy for decades.

LGI’s biogas extraction systems capture and combust the methane-rich biogas converting it into less harmful carbon dioxide. Every tonne of CO2 equivalent that an LGI system prevents your landfill from emitting, could earn Australian Carbon Credit Units.

Don’t underestimate the value of your landfill. Biogas extraction from landfill is proven technology and is available now to drastically reduce your carbon emissions.

Fulfil community expectations

Meet decarbonisation targets

Pathway to renewable energy

LGI provides best practice biogas systems, often at no cost to Councils! Contact us today to discuss carbon abatement opportunities for your landfill.

www.lgi.com.au 07 3711 2225

Fuel in FOCUS

BINGO INDUSTRIES IS OPENING THE GATEWAY TO THE ALTERNATIVE FUEL MARKET WITH NEW GREEN TECHNOLOGY THAT WILL PUSH ITS MATERIAL RECOVERY RATE TOWARDS 90 PER CENT.

Waste will play a critical role in supporting the clean energy transition, says Simon Sherwood, BINGO Industries General Manager of Operational Development.

As the world transitions away from traditional energy sources, Simon says the value of residual waste as fuel is being identified and unlocked.

And as heavy industries move to reduce their emissions profile because of sustainability concerns, resource preservation and increased costs –waste is at the forefront as an alternate green fuel source with a circular economy benefit.

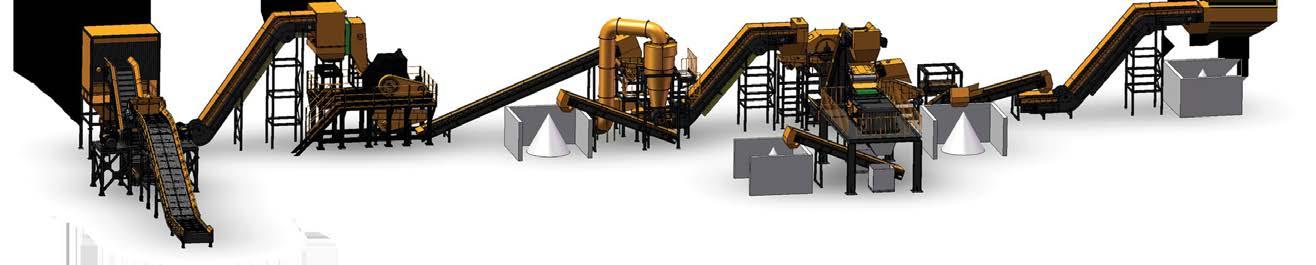

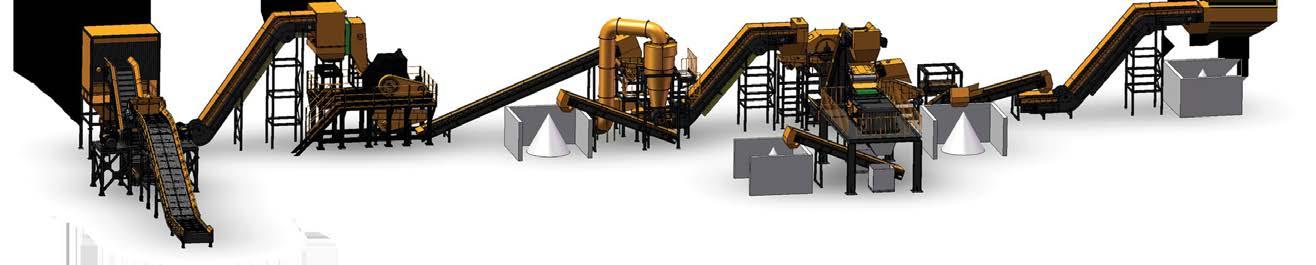

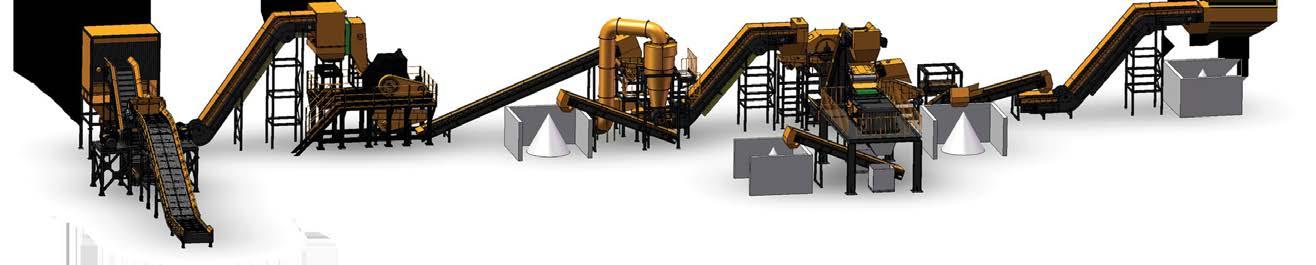

In collaboration with FOCUS Enviro, BINGO has taken delivery of an

UNTHA XR3000C shredding system to develop new alternative fuel products from waste.

Simon describes it as conquering the last mile – finding a solution to divert a substantial component of the company’s last 20 per cent of waste from landfill.

“We have a vision for a waste-free Australia and are passionate about leading the change,” he says.

“We are actively driving for a circular economy by further increasing our recovery rates as well as the quality of recovered products.

“By increasing diversion of our residual waste stream from landfill, we can produce significant

economic, environmental and carbon benefits.”

Simon has 17 years’ experience within the waste industry and has expertise in optimising recovery from a broad variety of waste streams.

He moved straight into a leadership role at a young age, supervising a familyowned steel recycling yard and small waste transfer station in the UK.

As the business expanded, he operationalised a new organics processing facility that is now a successful anaerobic digestion enterprise.

Simon arrived in Australia in 2011 for a working holiday and was quickly sponsored by a waste management company. Working his way into a site

COVER STORY 14 / WMR / March 2023

The UNTHA XR3000C shredding system will allow BINGO Industries to develop new alternative fuel products.

operation managers role he oversaw operations of BINGO’s Eastern Creek Recycling Ecology Park, which can accept up to two million tonnes of waste per year.

As part of a BINGO acquisition of Dial-A-Dump Industries in 2019, he moved into the General Manager Resource Recovery role, overseeing all 10 New South Wales sites – a mixture of transfer stations, resource recovery facilities and landfills.

He now helps lead BINGO’s major recycling projects, including the recent end-to-end delivery of BINGO’s Material Processing Centre 2, a $150 million, 300 tonne per hour construction and demolition and commercial and industrial recycling facility, capable of achieving a more than 80 per cent diversion from landfill and the largest C&D advanced recycling facility in the southern hemisphere.

Playing a part in the initial design stages and leading the commissioning, Simon says the project was particularly challenging as the plant was installed and commissioned through the COVID-19 pandemic.

He’s excited by the next challenge –developing a new division for BINGO that he says will improve recovery rates to more than 90 per cent.

BINGO diverts more than two million tonnes per annum of construction and demolition (C&D) and commercial and industrial (C&I) waste from landfill, by producing clean separated materials and recycled products that are then sold to large-scale developments and infrastructure projects to close the loop.

Simon says BINGO achieves an industry-leading recovery rate of circa 80 per cent through its advanced recycling facility, MPC 2, resulting in about 20 per cent of the company’s entire waste network ending up as residual waste in landfill.

With operations along the entire East Coast, it’s this 20 per cent the new division will target, converting it into Refuse Derived Fuel (RDF). RDF is residual waste that has undergone

processing and shredding to ensure it satisfies industry specifications. Many heavy industries including cement kilns, power stations, paper mills, steel manufacturing, sugar mills and energyfrom-waste facilities (EfW) can use RDF as a substitute for coal to meet their emission reduction targets.

Simon says BINGO’s foray into alternative fuels has been in the pipeline for several years, but the project has been restricted by an inability to supply locally.

That changed in 2022, when opportunities to supply alternative fuel to heavy industries arose.

“Dealing with this volume is the perfect introduction for BINGO to ensure it can meet all the quality standards required,” Simon says.

“There are very strict specifications around the materials that can and can’t be used.”

When it comes to processing those materials, BINGO is working with specialist waste and recycling equipment provider FOCUS Enviro.

“We’re committed to enhancing diversion of waste from landfill through creating sustainable products

www.wastemanagementreview.com.au / WMR / 15

Simon Sherwood, BINGO Industries General Manager of Operational Development; John McGuinness, FOCUS Enviro State Manager and Edward Malouf, Production Manager BINGO.

from problematic waste streams,” Simon says.

“I have worked with (State Manager) John McGuinness and the team from FOCUS Enviro for many years. When the opportunity to enter the alternative fuels market was on the horizon I knew John had the experience and processing technology to match.

“Following a trial of the machine on site we knew straight away that the UNTHA was the right machine that could process our material into the specification required and the business would benefit from the unique low operating costs this machine delivers.”

When manufacturing biomass-based fuel BINGO was previously processing wood using multiple shredding steps –slow speed into high-speed systems to try and achieve the fraction size – but this was not commercially viable longterm. The machine breaks down and operational downtime due to tramp material in the feedstock was part of daily routine.

“The switch to a single-step electric drive mobile shredder from UNTHA means BINGO can now transform about 30 tonnes of wood waste per hour with less than six per cent fines and 20 per cent more uptime,” John says.

Simon adds: “We are recovering a further 16 tonnes of clean metals from the magnet belt per week for recycling and resale. The combination of UNTHA’s shredding, backed by FOCUS Enviro’s

service, make this the perfect machine to assist BINGO enter new markets.”

FOCUS Enviro only works with experienced manufacturers and suppliers that specialise in the waste industries and understand the challenges of processing material in these sectors.

John says that as a growing number of opportunities for the manufacture and supply of alternative fuels into local markets become a reality in Australia, he is not surprised to see Simon and the team at BINGO at the front of the pack.

“Previous attempts to produce a specified size piece from hard to shred materials using a diesel-driven mobile shredder was outdated.

“This switch to an electricdriven alternative design, proven in these applications, reduced energy consumption by more than 60 per cent and cost savings of about $185,000 a year,” he says.

“The ongoing journey with BINGO and FOCUS Enviro in commissioning the new shredding system is proof that

16 / WMR / March 2023 COVER STORY

“By increasing diversion of our residual waste stream from landfill, we can produce significant economic, environmental and carbon benefits.”

Simon Sherwood BINGO Industries General Manager of Operational Development

Simon Sherwood, BINGO Industries General Manager of Operational Development, says the new division is finding a solution to divert the company’s last 20 per cent of waste from landfill.

much more efficient and profitable solutions can be delivered while at the same time adhering to the high environmentally conscious principles that are part of the culture at BINGO.

“It has been a pleasure to work with Simon and we are honoured that we have been selected to work on these projects.”

Simon says when he first started working in Australia’s waste industry it was like “stepping back in time”. The standards were well below those of Europe and the UK.

Over the years he’s seen Australia close the gap with the rest of the world, driven by legislation aimed at reducing waste to landfill and achieving a circular economy.

He says it’s rewarding to have contributed to BINGO’s journey in developing new products that are now being sold to customers as alternatives to virgin materials such as BINGO’s Eco-Product range comprising recycled mulches, aggregate and sands.

“Our RDF will assist us in solving for the last mile.”

For more information, visit: www.focusenviro.com.au

www.wastemanagementreview.com.au / WMR / 17

BINGO is aiming to push its material recovery rate to close to 90 per cent.

BINGO is driving for a circular economy by further increasing recovery rates and the quality of recovered products.

DELIVERING A GREENER FUTURE

Komptech CEA is a leading supplier of machinery and systems for the treatment of solid waste through mechanical and mechanical biological treatments, as well as the treatment of biomass as a renewable energy source. Komptech CEA is proud to provide innovative solutions for handling waste and biomass.

Komptech CEA’s extensive range of products cover all key processing steps in modern waste handling. At Komptech CEA the focus is always on innovative technology and solutions ensuring maximum benefit to the customer. Like to know more? why not speak to one of our team today?

SHREDDERS TROMMEL SCREENS STAR SCREENS WINDROW TURNERS

1300 788 757

TERMINATOR

Where Function Meets Technology

A slow-running, single-shaft shredder suited to all types of waste.

CRAMBO

Less Fuel, More Power

Ideal for shredding all types of wood and green cuttings.

TOPTURN X

The Ideal Combination of Performance and Design

With a sturdy frame, powerful hydraulics and large drum, the Topturn X is ready to handle any work situation.

MULTI STAR

Screening with a Star

Makes waste wood and biomass processing highly efficient.

NEMUS

Robust and Reliable

Combining the practice-proven virtues of its predecessors with new solutions for even greater performance.

AXTOR

Shredding and Chipping Made Easy

One of the most versatile machines around for processing wood and green cuttings.

komptechcea.com.au

Fire in the belly

AFTER THREE YEARS OF DEVELOPMENT WORK, BLUE PHOENIX’S FIRST AUSTRALIAN INCINERATOR BOTTOM ASH PROCESSING FACILITY IS READY TO FLICK THE SWITCH.

The opportunity to join Blue Phoenix Group to construct and operate an Australian-first incinerator bottom ash (IBA) processing facility was enough to entice Ian Lynass out of semi-retirement. Three and a half years and several favours later, the industry veteran and now Blue Phoenix Australia, Managing Director, is proud of the successful completion and commissioning of the plant.

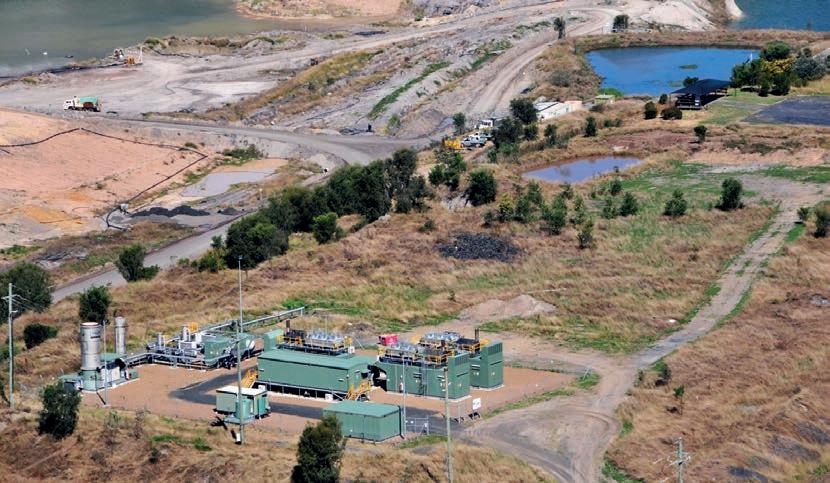

The $11.3 million IBA project at Hope Valley in Kwinana, Western Australia is the first in Australia, and the world, to bring all Blue Phoenix technology together in the one plant.

Incinerator bottom ash, the endproduct of the Energy-from-Waste (EfW) incineration process, is due to be received

and processed by the facility in late 2023 when the Avertas EfW plant is completed. Testing material is now being recycled through the IBA plant weekly to enable Blue Phoenix Western Australia to meet its maintenance regime.

“To see this system running with IBA is an exciting period,” Ian says. “The team and I are looking forward to when we can showcase to Australia a proven, sustainable and responsible way to recover and reuse materials otherwise lost to landfill.”

EfW has been a successful and critical component of the waste hierarchy for many years overseas. Ian says it’s a timely and responsible approach for the technology now to be included in Australian waste strategies for the

long term. He says it’s prudent that ‘best in class’ technology is introduced to Australia to ensure a sustainable process is used to liberate the residual metals and aggregates that will contribute value to the nation’s communities.

Blue Phoenix operates IBA processing facilities globally, providing the EfW sector with a responsible and sustainable solution for bottom ash that has been proven over the past 20 years.

The Avertas EfW is expected to process 400,000 tonnes of municipal solid, commercial, and industrial waste under agreements with local governments and other providers in Perth’s greater metropolitan area when it’s commissioned later this year.

www.wastemanagementreview.com.au / WMR / 19

FEATURED TOPIC – ENERGY FROM WASTE

The Hope Valley IBA plant is the first in the world to incorporate all Blue Phoenix technology.

Blue Phoenix will process 100 per cent of the IBA – about 80,000 tonnes per annum – from the plant, recovering metal down to minus two millimetres and returning the residual aggregates into bound and unbound civil applications.

Ian says the process seeks to liberate agglomerated slags and metals to allow for further refinement and valorisation, but importantly the residual minerals are recovered to provide a proven aggregate for reuse in the civil construction industry.

“This facility will also be available to help educate local communities about the recycling of waste and the responsible recovery of construction materials that until now simply end up increasing the landfill debt for future generations,” he says.

For the past 20 years, Blue Phoenix Group in Europe has recovered and safely reintroduced 15-million tonnes of aggregates, predominantly into road base, with no detrimental environmental effects.

It’s a track record Ian and Blue Phoenix are proud of. Ian believes it stems from the company’s commitment to give ash a new life.

He says having all Blue Phoenix’s processing technology in one plant is

unique and in the long-term will allow the company to refine and introduce new technology to achieve greater recovery of metals and improve the quality of aggregates for use in alternate markets.

It is the technical excellence of Blue Phoenix, and a desire to be involved in an Australian-first EfW and IBA project, that appealed to him.

“Coming out of semi-retirement to do this was very meaningful for me,” he says.

“Living locally where these facilities are being built, I was very much focused on making sure things were done the Australian way and done properly with a reliable and responsible company that can assist with continual development.

“The calibre of Blue Phoenix, its leadership and technical ability is renowned. It gave me a lot of confidence in what we were building and who we did it with.”

Ian has lived and breathed the project for three-and-a-half-years from concept to build. He’s proud to have delivered it on time and budget, despite a global pandemic, labour shortages and escalating shipping costs.

The project has used local materials and skill wherever possible and will

be operated for the next 25 years by a local workforce.

Ian is full of praise for the Western Australian contractors who worked on the project and says without them, Blue Phoenix would still be waiting for the contract to be finished.

Kerman Contracting provided the structural design as well as the structural, mechanical and electrical installation. Stantec provided civil design and engineering support and MACS Australia did all civil works. Mechwest and Peritas provided engineering design and 3D modelling.

“They’re fantastic partners,” Ian says. “They were highly flexible, very professional and had a great engineering pedigree and excellent resources in Perth which meant we could get things done.

“Their people on the ground made the difference. They’re dynamically technically astute and delivered with a ‘can do attitude’. This made the difference when issues arose because everyone had a voice and their experience was invaluable.”

Ian says every plant around the world is built to different geographies and technical standards. The Kwinana plant had to account for wind and seismic loading and exacting Australian Design standards, which required more structural steel. This meant that all offshore equipment had to be quality checked and assessed to meet these standards before being delivered to Fremantle.

“Getting this right in WA, which is a tough environment, means we can use this as a benchmark to allow new developments of EfW plants elsewhere in Australia to have a proven partner already operating in the country,” Ian says.

“We expect our next opportunity to partner with a developing EfW to come from the east coast. I’m very excited to see how this unfolds over the coming years.”

For more information, visit: www.bluephoenix-group.com

20 / WMR / March 2023 FEATURED TOPIC – ENERGY FROM WASTE

Testing material is being recycled through the IBA plant weekly to enable Blue Phoenix Western Australia to meet its maintenance regime.

Department of Chemical and Biological Engineering

Monash University

Our motto: Academic excellence and R&D for practical solutions and commercialization

Ranked number 1 in Australia and 48 in the world for Chemical and Biological Engineering

Academic staff with industry and international experience

Internationally recognized research strengths in:

• Bioprocessing and biomaterials

• Catalysis

• Critical metals recovery

• Energy transformation and storage

• Food engineering

• Membrane separation

• Nanomaterials

• Particle technology

• Process design, modeling, and optimization

• Rheology

• Solar cells and DNA-directed nanofabrication

• Waste processing to fuels, chemicals, hydrogen, and metal recovery

Our graduates are employed globally in governments and in industries

• Biotech, Bioprocessing, Pharmaceuticals

• Beverages and Food

• Consultancies

• Chemical, fer tilizers

• Energy, Minerals Processing, and Mining:

• Environment and Water

• Hydrogen, Fuel cells

Welcome Linkedin

Powerful solutions

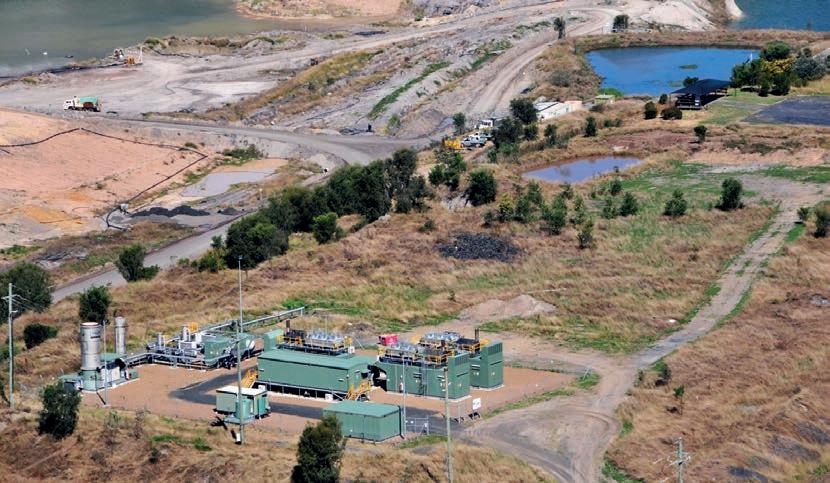

QUEENSLAND-BASED ENERAQUE IS ON A MISSION TO TRANSFORM AUSTRALIA’S ENERGY SECTOR BY HARNESSING THE POTENTIAL OF WASTE GAS.

The future is here. For the past 40 years, waste gas-to-energy specialist Eneraque has designed, built and operated turnkey waste gas-to-energy systems for a range of commercial applications.

In 2022, it propelled Australia’s gas-to-energy sector to the next level –upgrading biogas to biomethane that will power heating, hot water and cooking for thousands of Sydneysiders.

Jeremy Pringle, Eneraque Director, says the first-of-its-kind biomethane project at Sydney Water’s Malabar Wastewater Resource Recovery Plant is a sign of things to come.

“It’s super exciting,” Jeremy says. “I think it’s the start of some very interesting projects moving forward. We’re definitely at the start of a large curve of projects, mirroring the uptake of biogas technology in Europe.”

Advances in renewable energy technology have made it possible to convert what was once considered waste into a recovered, usable energy source, including the development of landfill gas to-energy systems.

Landfill sites typically use a combination of physical, chemical, and biological processes to manage waste gas disposal. Jeremy says these traditional waste management practices can have negative environmental impacts, can be complicated and expensive, and do not make the most of the waste gas as a potential asset.

“Landfill gasto-energy

technology not only provides sustainable energy for the operation, but its gas capturing methods reduce the release of greenhouse gases into the atmosphere, reduce landfill odour and improve air quality,” he says.

“They can also provide the operation with a return on investment when the resultant energy is used to power the operation or can be converted to electricity and returned to the grid.”

Waste gas-to-energy technology includes biogas power generation, biogas scrubbing and polishing; biogas flaring; biogas storage; biogas upgrading; CO₂ liquefaction; bio-CO₂; and biogas to hydrogen.

Jeremy says there has been increasing interest in gas-to-energy projects throughout the past 20 years as businesses focus on carbon neutral targets and emissions.

In 2022, the Federal Government passed the Climate Change Bills,

FEATURED TOPIC – ENERGY FROM WASTE www.wastemanagementreview.com.au / WMR / 23

Gas-to-energy technology can include biogas scrubbing.

legislating Australia’s emissions reduction target of 43 per cent and net zero emissions by 2050.

“A lot of clients want to, and are, thinking differently about the way they emit,” Jeremy says. “Emission targets are a critical point on a lot of company agendas.”

Eneraque was approached by one of Australia’s leading mega-dairies to provide a bespoke system to convert on-farm waste to energy. The project harnessed the energy value of cow manure to generate electricity, providing the farm with 100 per cent of its energy needs while handling on-farm waste disposal.

Eneraque custom-built a closed-loop power generation plant that feeds directly back to power the farms’ operation, with any extra power capable of being exported to the grid.

At a landfill site in New Zealand, Eneraque was asked to find a more sustainable, cost-effective and streamlined solution for the disposal of waste gases.

The landfill gas will be collected from decomposing waste and sent through a gas conditioning system incorporating biological scrubbing and dehumidification. This gas is then sent through to a reciprocating gas engine to produce electricity that can be used on site or used

in the local electricity network. Jeremy says this system is capable of producing 1.5MW of power and is an example of the renewable technology that is making waves in the sector.

He says that as an Australian owned and operated business, with a manufacturing hub in Brisbane, Queensland, Eneraque is uniquely placed to build world-class equipment designed to perform in the Asia-Pacific (APAC) region’s climate and to Australian standards.

The company portfolio includes a list of waste gas-to-energy projects for commercial applications including agriculture, food and beverage, and waste management – such as landfill sites and wastewater management. Some projects are achieving a return on investment for their clients in as little as five years post build.

The end-to-end service includes consultation, design, engineering, manufacturing, installation, commissioning, operation and maintenance of a site – meaning the client can work with one provider for the entire project. This manages cost, time and creates a seamless delivery of the project.

Jeremy says many clients choose to have ongoing operation and maintenance of their plant performed by Eneraque’s

operation’s team to provide support on a long-term basis.

The company has diversified into gas powered generators, gas flares, gas compression and other gas-related products. Further developments in the sector grew into gas handling opportunities with a focus on natural gas and biogas power generation for remote power, water treatment plants and commercial power generation applications.

As projects have developed, Eneraque has attracted local and international talent, and has built up an in-house engineering team.

Jeremy says the local connection within the APAC region is important for anyone considering a gas to energy project.

“Clients need a partner who understands and is not biased with regards to equipment selection for their project,” he says. “They need to have a partner based in the region that understands the relevant standards and requirements to deliver gas systems into the APAC market.

“What can be purchased as an ‘off-theshelf’ system from overseas won’t meet stringent Australian standards.

“We have to deliver a biogas project to the same standards as a project for a tier one client that is delivering compressor stations across the nation, as an example.”

Jeremy says while turnkey projects ensure an adherence to quality standards, keeping the design responsibility, delivery and final sign-off onshore also helps Australia’s manufacturing industry and employment.

“Eneraque is the gap between what’s working overseas and what can be delivered and developed in the APAC region,” he says.

“I see us as the gap for the end client. They’re not having to work out what products are compliant. We take on that full design responsibility and delivery from start to finish.”

For more information, visit: www. eneraque.com

24 / WMR / March 2023 FEATURED TOPIC – ENERGY FROM WASTE

An Eneraque landfill gasto-energy power plant.

Your E-Waste, Our Responsibility Alex Samsudin alexsamsudin@greentechnologyrecycling.com.au | www.greentechnologyrecycling.com.au

Backed by science

WASTE PROCESSING IS A GROWING AREA FOR MONASH UNIVERSITY’S DEPARTMENT OF CHEMICAL AND BIOLOGICAL ENGINEERING, SANKAR BHATTACHARYA, PROFESSOR AND INTERIM HEAD, EXPLAINS.

With the worldwide emphasis on sustainability and circular economy, there is an increased research and development focus on processing of feedstock and extraction of energy and high-value components from waste materials.

Sankar Bhattacharya, Professor and Interim Head of Monash University’s Department of Chemical and Biological Engineering, says waste processing is now a large part of the department’s portfolio.

Sankar specialises in processing of wastes such as plastics, tyres, paints, optical fibres, e-wastes and agroresidues, as well as extracting chemicals and hydrogen from solid fuels, including biomass.

He sees a future where waste processing is part of mainstream industry as it moves toward circular economy principles and less reliance on imported metals.

“The economics are favourable when compared to disposal to landfill which is becoming increasingly expensive,” Sankar says.

“Wastes of any kind are essentially low-cost feedstock with embedded energy that can be extracted. Some have high-value metals in concentrations comparable, or higher, than in mined minerals and can be extracted by using renewable or low-emission solvents.”

RESEARCH-DRIVEN

The Department of Chemical and Biological Engineering at Monash University is the highest ranked in

Australia and 48th in the world. It is active in education and research and has an international reputation for its research programs and postgraduate

training. The department has 26 academic staff, and more than 150 postgraduate students and prides itself on fundamental and industry-focused

FEATURED TOPIC – ENERGY FROM WASTE 26 / WMR / March 2023

Monash University’s Department of Chemical and Biological Engineering has patented a process for plastics and tyre co-conversion.

research. It has internationally recognised research strengths in bioprocessing and biomaterials, particle technology, process design and optimisation, food engineering, rheology, energy transformation, sustainable processing, nano materials and particle technology.

Sankar came to academia in mid-2009 after two decades in the energy and fuel industry – at the International Energy Agency in France, Anglo Coal Australia and CRC for Lignite in Australia, and Development Consultants in India.

He says the sustainable acquisition, processing, and use of fuels and other energy sources is at the heart of the chemical and biological engineering mission at Monash University.

“In the past, fuels such as coal, oil and wood were burned in air to produce heat and power with little regard to environmental effects. In the future, this unsustainable method will simply not be acceptable,” he says.

Sankar currently leads a group of 16 PhD students and researchers working on gasification of solid fuels, processing of wastes and CO2 to liquid fuel and chemicals, chemical looping for CO2 capture, and high-value platform chemicals production from biomass.

INDUSTRY COLLABORATION

The waste processing research involves reactor design, full process simulation, both small and large-scale experiments and analysis of feedstock and products including solids, liquid, and gaseous.

Apart from a few blue-sky fundamental research, most of the projects to date have been funded by the industry and have involved the processing of end-of-life mixed

polymers, bioplastics and tyres, waste biomass, automotive shredder residues, electronic wastes, battery wastes, waste paints, powder coat paints, spent optical fibres, sub-sea umbilicals, and legacy wastes such as fly ash and CO2 conversion.

The end objectives included fuel and chemicals production, monomer recovery, extraction of metals such as titanium, silicon, and germanium, and increasingly, rare earth and other critical metals.

Sankar says one company is now in discussion to start larger-scale processing of waste plastics because of the department’s research.

“I firmly believe in the processing of end-of-life waste plastics in the shortterm,” he says. “Waste paints and waste biomass will follow.”

Based on the experimental work, process simulation and the technoeconomics analysis, Sankar, and the department, believe there is a future

application for processing end-of-life tyres into liquid fuel.

“The liquid fuel is combustible but not suitable for chemicals production per se,” he says. “A dedicated supply chain needs to exist to make pyrolysis plants viable at defined locations.

“Also, defined regulatory policies in support of pyrolysis process will facilitate the introduction of pyrolysis plants that are technically not complicated.”

Lina Goodman, Chief Executive Officer of Tyre Stewardship Australia (TSA), says TSA has invested in many projects to further tyre recovery and opportunities within Australia, including pyrolysis products.

“We have yet to see large-scale uptake of these processes in Australia. If pyrolysis products reach largescale commercialisation in the future, we are confident the research we have conducted with Monash University will play a role in better understanding the market and its success,” she says.

The Monash University research team is interested in working on more collaborative projects with industry.

For more information, contact: Sankar.bhattacharya@monash.edu

www.wastemanagementreview.com.au / WMR / 27

A waste processing rig designed by Monash University.

Metals recovered from waste paint.

Mastering organics

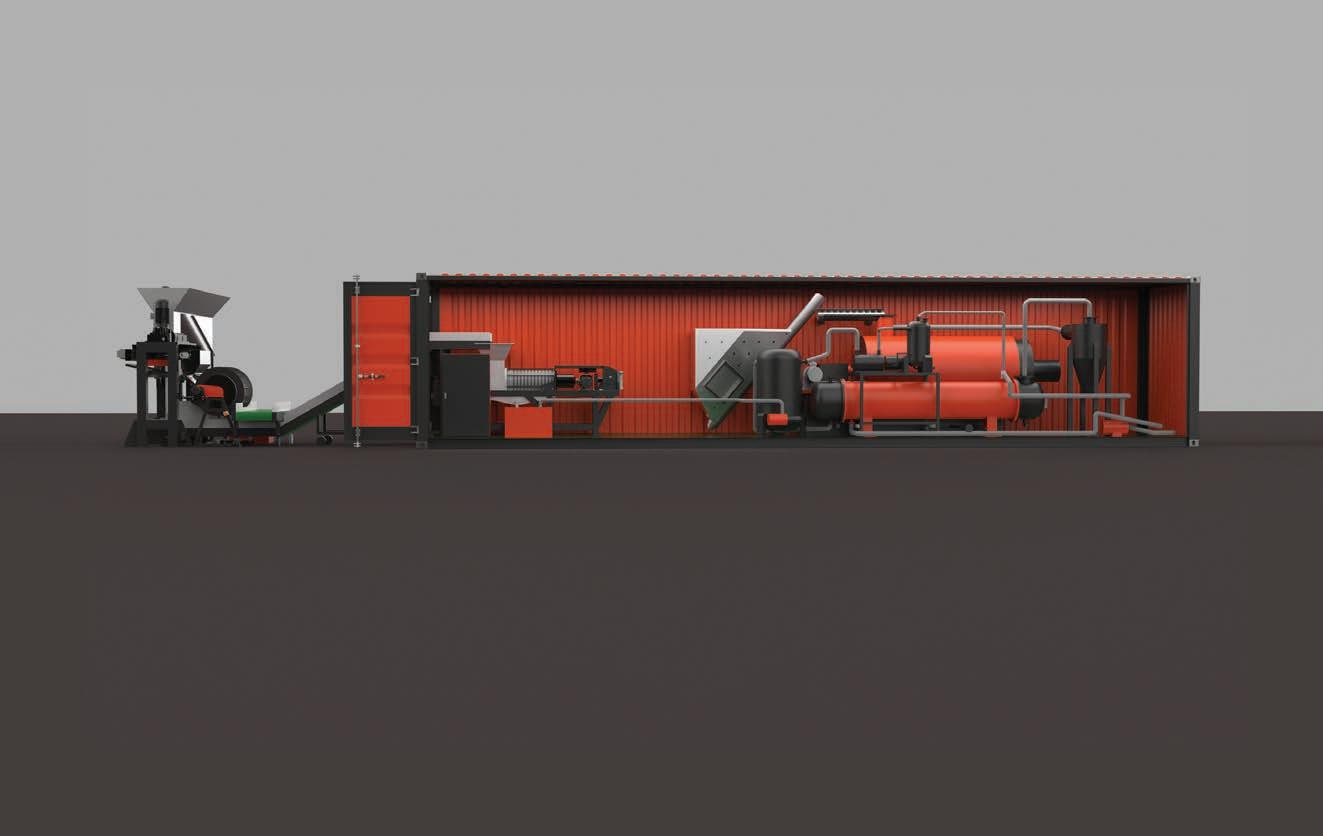

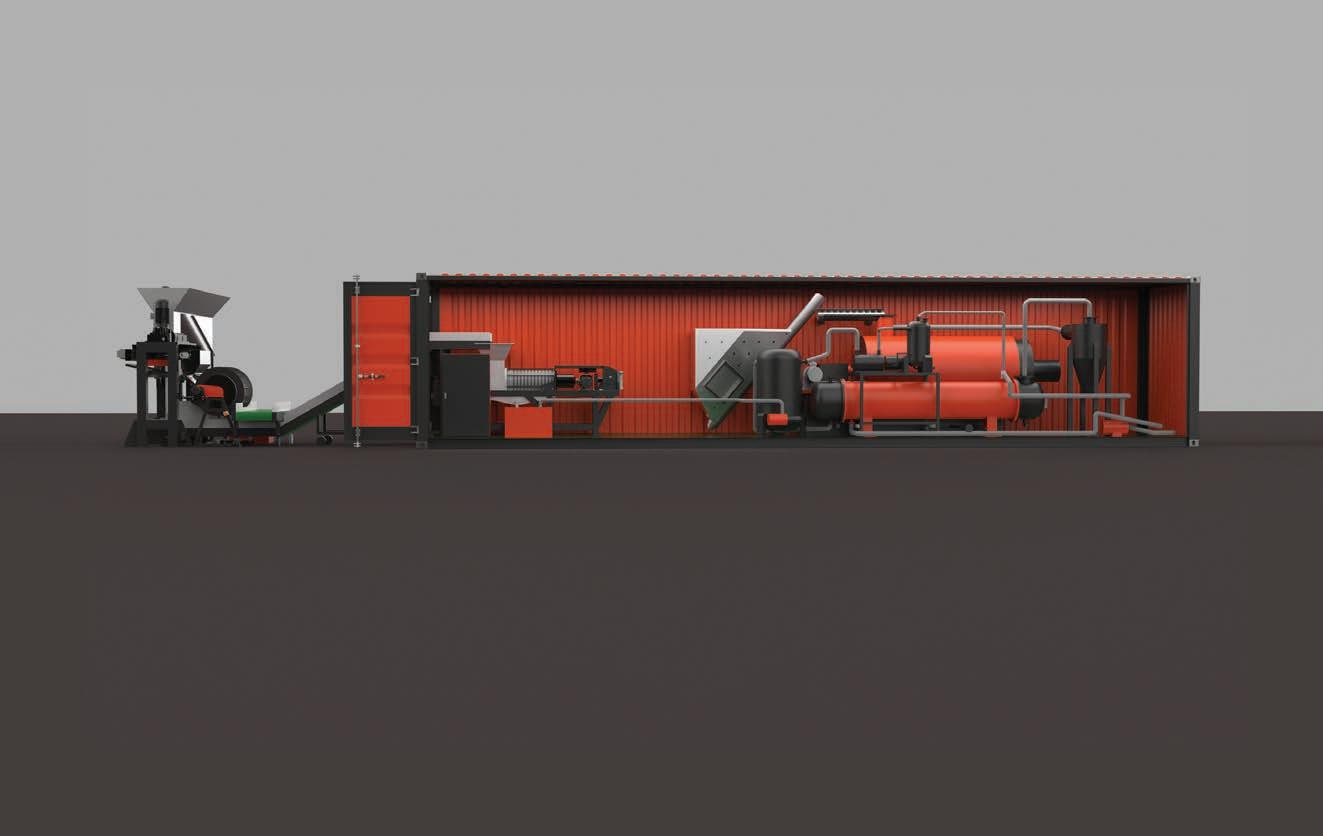

A NEW EASILY DEPLOYABLE PLANT WILL PROVIDE GREATER OPPORTUNITIES FOR AN ENERGY-FROM-WASTE SOLUTION FROM ORGANIC WASTE.

With the global shift to ‘going green’, waste minimisation and recycling equipment provider Mastershred is turning biowaste into an energyfrom-waste solution that is good for the environment.

Tim Killen, Mastershred Sales Director, says the new Mastershred Organic Waste to Energy (OWE) plant addresses the need to remove load from the power grid by providing a behind the meter decentralised energy solution while reducing carbon emissions.

The result of years of research and development, the OWE plant uses a novel milling and squeezing process to get the most out of biowaste.

The compact plant – the size of a shipping container – is being hailed as an organic waste solution for regional and remote areas.

“This will bring an organic waste and energy solution that is small and deployable,” Tim says.

Australia’s national waste targets aim to halve the amount of organic waste by 2030.

Tim says that the majority of organic waste that doesn’t go to landfill is currently being processed in commercial compost facilities.

While it’s good that organic waste is being diverted, and well-designed commercial compost facilities greatly reduce methane emissions, he says

emissions, particularly CO2, in these settings continue to be a challenge.

“What we’re saying is, we can use that organic waste to create a greater energy source without the same emissions,” Tim says.

“Essentially, to support population growth the world needs more power, and to protect the planet we need less CO2 in the atmosphere. One way to achieve this is through addressing the CO2 generated from our biowaste streams and, where possible, generate additional energy from these streams.”

Mastershred was launched in Australia in 2005 to address a need for waste reduction and recycling equipment that was environmentally responsible and tackled rising costs of waste disposal.

A pilot plant designed at the Mastershred office in Heubach, Germany, was installed at a nearby recycling plant in 2020. With the system fine-tuned for three years the books are now open for orders.

FEATURED TOPIC – ENERGY FROM WASTE 28 / WMR / March 2023

Bio-briquettes can be used to process climate-neutral fuels.

The Organic Waste to Energy (OWE) plant offers a solution that is small and deployable.

Tim acknowledges Mastershred is not the first to develop an energyfrom-waste solution for organics waste. However, he says the previous solutions required a lot of space and supporting infrastructure.

“OWE is a containerised solution,” he says, “it’s decentralised and easily deployable.”

He says the main beneficiaries will be local councils, small and medium-sized industrial operators, wastewater treatment plants and even cruise ships –anywhere that has an excess supply of organic waste and a power generation requirement.

One of the added benefits of OWE is that it’s modular and scalable. Each individual part of the process has its own material recycling stage that removes any impurities such as metal and microplastics.

The first process – milling and squeezing – produces an organic liquid that has a high calorific value suitable for use in anaerobic digestion plants.

Following that, rapid dehydration of the material creates a biomass which, with further amendment, is suitable

for composting, soil improvement or peat substitution. Next, a bio-briquette is created that can be used to process climate-neutral fuels.

The bio-briquettes can be converted into thermal and electrical energy via a gasification process. Mastershred is also investigating the use of briquettes in bioplastics.

Tim says, as the OWE is a closedloop system, any excess gases created from the gasification process are funnelled back into the drying

process, rather than dispersed out to the environment.

When development of OWE started the main goal was organics waste in, electricity out. But researchers found that extracting the liquid not only created another energy source, it reduced the weight of the remaining material, and ultimately CO2 emissions, during transport.

It’s very good technology,” Tim says. One of the added benefits of OWE is that it is adaptable to client requirements. Each stage can be used individually or as an entire process for a full organic energy from waste solution.

“You can process organic liquid, send it to an anaerobic digestor and leave it at that,” Tim says. “But you can also take it to the end process and create power from it.

“It’s also scalable. You can start with one plant and if your volumes increase you can add another container.”

There are several working installations of OWE overseas. A 3D model of the plant will be on show at the Waste 2023 Conference in Coffs Harbour in May in preparation for an Australian launch.

For more information, visit: www.mastershred.com.au

www.wastemanagementreview.com.au / WMR / 29

“Essentially, to support population growth the world needs more power, and to protect the planet we need less CO2 in the atmosphere. One way to achieve this is through addressing the CO2 generated from our biowaste streams.”

Tim Killen, Mastershred Sales Director

Each stage of OWE can be used individually or as an entire process to create organic waste energy solutions.

CRANAB RZ18 with a Marrel AL16 Si54 Hooklift

Cranab RZ18 crane has been designed to provide you with the stability, precision, and efficiency that you need for your everyday handling of scrap or other materials. Cranab are driven by a genuine passion for forestry, recycling and road clearance technology.

Thanks to their booms, they can work close to the carrier and over an increased work area, as well as provide optimum height and lifting capacity.

Coupled with a Marrel AL16 Si54 Hooklift attached, it will allow for more equipment versatility, optimisation, rear hydraulic body locking, tilting frame that acts as a power multiplier and so much more.

Follow us on: BRISBANE | SYDNEY | MELBOURNE | ADELAIDE | PERTH www.600cranes.com.au 1300 551 075

Leading the field

COLLABORATION IS HELPING COUNCILS ACHIEVE BEST PRACTICE LANDFILL OPERATIONS AND REAP ENVIRONMENTAL AND FINANCIAL BENEFITS. LGI’S POWER GENERATION AND FIELD TECHNICIAN SCOTT PRIOR EXPLAINS.

The days when dad would go to the tip and come home with more than he took are a shared childhood memory for Generation X.

As are the mounds of split rubbish bags spilling their contents and the sour stench that clung to the air.

But the oldest and most common form of waste disposal is no longer a set and forget burial pit for waste – they’re well engineered and managed, and a modern gold mine for renewable energy.

LGI is capturing biogas formed naturally in landfills to abate carbon emissions, improve local air quality and, in some cases, generate renewable energy.

Scott Prior, LGI Power Generation and Field Technician, says there’s a science behind what happens at landfills.

“Managing the methane gas output on a landfill site is somewhere between a black art and science,” he says.

It’s his skill at mastering the black art that has Scott, widely known as the ‘landfill whisperer’ in demand to help councils optimise their landfilling practices.

Calling on the vast experience in landfill management of LGI’s workforce, he developed a structured landfill operations training program that is offered to councils. So far more than 70 councils across New South Wales, Victoria, Tasmania and Queensland have used the program.

“There’s three major issues with managing landfills,” Scott says. “Airspace, leachate, and compliance.

“It’s amazing how many people get it wrong.”

A former geologist field assistant, Scott says he fell into waste management when he was offered a winter job as an operator on a tip face. More than 35 years later he’s worked in every aspect of the industry and can’t imagine doing anything else.

“I’ve always had a role in landfill. I’ve worked it right from base level of doing the job on the ground, through to being responsible for budgets,” he says.

“I can not only explain to councils what they need to be doing, but I can show them.”

Since 2013, Scott’s role at LGI covers five landfill sites from Benaraby (Gladstone) to Maryborough, Hervey Bay and Bundaberg. He looks after a combination of gas fields with flares and some with power generators, for burning off and destroying methane to abate carbon.

The two sites with power generation engines enable electricity to be put back into the power grid, creating a dispatchable renewable energy source to displace electricity generation from fossil fuels.

Scott takes his role on each landfill site seriously. He has a plan and manages each site carefully, monitoring remotely and via planned site visits.

He says there are many variables including waste composition, climate, and moisture that impact a landfill site. However, his knowledge of each site, experience and detailed mapping enables him to tune each one effectively.

A typical day will see Scott out on a landfill checking out the gas field against its baseline measures and making minor adjustments. Always looking for ways to maximise output, Scott suggested a management process that

FEATURED TOPIC – ENERGY FROM WASTE www.wastemanagementreview.com.au / WMR / 31

Scott Prior, LGI Power Generation and Field Technician, is widely known as the “landfill whisperer”

reduces the leachate waste and enhances gas production.

He also collaborates with the councils’ landfill management team on each site to ensure planned activities are aligned.

LGI has worked with the Bundaberg Regional Council since 2013 by installing and operating biogas extraction and flaring systems on two sites – Cedars Road and University Drive.

Scott has worked with the council to help optimise landfilling practices. He says the council has increased its maximum waste density by 20 per cent just by ensuring there was a proper compaction pattern.

“Bundaberg had leachate problems in the original cell, a lot of it caused by not stripping out and covering material,” Scott says.

“You need to have a defined space of operation, compact the working face, cover material up, and put fall across the floor to drain toward surface ponds.

“We initiated things that the council hadn’t been doing and within months, anybody observing could see it was more under control. There was no more leachate, and from our perspective, increased gas extraction.”

Kerry Dalton, Co-ordinator Landfill Operations with Bundaberg Regional Council, says the council initially engaged LGI to install a flare at Cedars Road to help reduce methane levels.

In 2016, LGI proposed a biogas capture and carbon abatement project for the University Drive landfill site.

As of May 2022, the projects had captured 54 million cubic metres of biogas, resulted in 514,000 tonnes of carbon abatement, and created 251,000 Australian Carbon Credit Units (ACCUs), combined.

“The results have been really good,” Kerry says. “There’s great extraction from the landfill. For the council, it means we’re compliant and we get the added benefit of ACCUs for the project because

it’s registered under the emissions reduction fund. Rather than releasing methane into the atmosphere we’re converting it to CO2 so there are good environmental benefits.

“It’s ticking all the boxes.”

Kerry says LGI is experienced working with smaller councils and has been with the Bundaberg council every step of the project, from putting a system in place to helping manage it.

“LGI really takes the responsibility out of our hands,” she says. “A lot of councils don’t have the staff or technical expertise to manage that process in-house.

“LGI are very good to deal with.”

She encourages other regional councils to consider biogas capture from landfill, not only for compliance, but also the environmental and financial benefits. “It’s a real feel-good project,” she says.

For more information, visit: www.lgi.com.au

32 / WMR / March 2023 FEATURED TOPIC – ENERGY FROM WASTE

Bundaberg Regional Council’s Cedars Road landfill site which has a biogas extraction and flaring system.

THE PHOENIX HAS LANDED IN AUSTRALIA

The Phoenix is an extraordinary mythical creature. At the end of its life when just ashes remain, something magical happens. New life merges out of something that seems lifeless. What we consider to be the end, suddenly transforms into a new beginning. We give ash a new life in the real world.

Mr Ian Lynass, Managing Director Ianlynass@bluephoenix-group.com

What we do

The ash in our line of business comes from the new Energy-from-Waste facility Avertas Energy. Incineration of municipal solid waste (MSW) is an effective way to reduce waste volume and reduce our reliance on fossil fuels for energy.

How we do it

We process the remaining ash and extract valuable resources. With our state-of-the-art technology we recover metals to produce a secondary aggregate used for civil construction work. Environmental protection is at the forefront of our day-to-day operations. We assure the proper use of aggregates, limiting the impact on the environment.

Why we do it

We believe our work is only valuable if it contributes to a better future. We prevent landfilling and the negative impacts associated with the extraction of virgin raw materials by producing a secondary aggregate that contributes to the circular economy.

Blue Phoenix Australia

Blue Phoenix Australia

0418 290 080 | www.bluephoenix-group.com

Better information, better recycling

GREEN TECHNOLOGY RECYCLING’S ALEX SAMSUDIN IS HARNESSING THE POWER OF TECHNOLOGY AND DATA SCIENCE TO IMPROVE E-WASTE RECYCLING IN AUSTRALIA – AND HOPES THE INDUSTRY WILL JOIN HIM ON THE JOURNEY.

Alex Samsudin never set out to build a career in e-waste recycling. He started dismantling electronics as a source of income in 2009 to support his software engineering studies at Canberra’s Australian National University – and he never stopped.

Since December 2020, Alex has been Director of Green Technology Recycling’s (GTR) ACT branch – a business he started as an offshoot of GTR’s New South Wales branch, which is run by his business partner.

At GTR ACT, Alex is putting his software engineering background to

use – combining his skills and industry experience to prototype an integrated software solution that he hopes could benefit the Australian e-waste recycling industry.

“At first, I started building a system just to make my own life easier as a small business owner,” he says.

This started as a means to automate some of the menial administrative tasks involved with data destruction, warehouse management, and generating reports.

“The other problem we had from the very start, is we could find no single point of reference to help identify and manage

the many different types of materials –there’s no Wikipedia for e-waste,” Alex says.

“To recycle e-waste properly, you are also required to be able to track exactly where it comes from, where it’s going, and what’s happening to it.”

Alex says some software solutions existed for certain tasks – and some worked well – but he found using a cobbledtogether system of different software solutions cumbersome.

“Coming from a software engineering point-of-view, I knew there was a way we could make everything more integrated,” he says.

“By now, I think the processes for managing e-waste should be a lot more advanced, especially because it’s a waste stream that’s always changing.”

This combination of factors has led Alex to develop a prototype platform he calls AWESOME.

“It’s ‘AWESOME’ because it’s an Automated Waste Enterprise System that’s Online, Modular, and Easy to use,” he says.

INTEGRATED AND VERSATILE

The AWESOME platform is made up of seven primary modules, including systems for managing customer relationships; warehouse and inventory; work health safety; documents; reporting; data administration; and compliance.

Alex says AWESOME is designed to

FEATURED TOPIC – E-WASTE 34 / WMR / March 2023

The AWESOME platform integrates inventory management, downstream tracking, compliance data, and more.

be modular, scalable, and customisable; while also easy to “plug and play” for businesses, with web-based options for maximum portability.

“A business can choose to implement all modules, or just a subset of modules depending on its needs,” Alex says.

“No module relies on another, so you can plug and play as you need. If you still want to use an external document manage system, or you have a subscription to a different warehouse management system –go for it.”

Alex acknowledges that some businesses are protective of their data, and are not always comfortable using cloud services.

“We don’t take data security for granted,” he says. “If they like, a business could just run it locally in their warehouse – they don’t have to connect it to the internet.”

STREAMLINED COMPLIANCE

“Working in e-waste, there’s a lot of compliance and standards you need to follow,” Alex says.

“My platform closely follows the AS/NZS 5377 and ISO 9001 certification guidelines.”

Combined, these standards outline the minimum requirements for safely collecting, managing, and recycling e-waste material in Australia and New Zealand. These include maximising material recovery, protecting the health of workers, and minimising harm to the environment.

Alex says streamlining audit processes could be a key benefit of an integrated platform such as AWESOME.

“I’ve been through the same kind of audits for the past seven years, and they are always looking for the same things – they tend to follow the same kind of flow and structure,” he says.

These can include the downstream tracking of recycled materials, staff training, data security, and risk management, to name a few.

Alex says his platform could be used to generate any necessary data or reports with the click of a button, rather than

having to dig through a mishmash of Excel spreadsheets, emails, virtual and physical documents.

“I think any e-waste company – or any other sort of company that goes through similar certification processes – will feel the same way I feel,” he says.

OPPORTUNITY FOR COLLABORATION

Alex says his platform is still in its prototype stage, and work on it will be ongoing – but as a system designed to evolve and grow with the industries it serves, AWESOME will always be a work in progress.

He also thinks it could present an opportunity for the industry to work together for mutual benefit, and to improve the quality of e-waste recycling overall.

“Everybody wants to recycle, and

everybody wants to do it the right way,” he says. “So, we should be trying to find common ground.”

Alex says there’s a great deal that businesses could learn from each other without compromising their operations. Establishing a standardised resource for e-waste information and data could be valuable – and something his AWESOME platform could help facilitate.

“It’s all about information sharing. My system is just intended to help point people in the right direction – whether that’s a business, a governing body, an auditor, or the public,” he says.

“If they have a question to ask about e-waste recycling, they can find the answer, or at least the right direction to go to find it.”

For more information, visit: www.greentechnologyrecycling.com.au

www.wastemanagementreview.com.au / WMR / 35

“Everybody wants to recycle, and everybody wants to do it the right way. So, we should be trying to find common ground.”

Alex Samsudin, Green Technology Recycling ACT Director

Green Technology Recycling ACT Director Alex Samsudin.

A shred of hope

SHRED-X IS PROVIDING E-WASTE RECYCLING SOLUTIONS BUILT FOR SUSTAINABILITY.

Nearly every electronic or IT device a business uses contains materials that can be recycled into new product components. Almost 100 per cent of electronic devices – computers, tablets, hard drives, mobile phones and printers – can be recycled once they reach the end of their useful life if done through the correct channels.

Steven says Shred-X has partnered with Australian recyclers to divert e-waste from landfill, recovering valuable resources such as lead, copper, aluminium gold and titanium and alleviating the reliance on increasingly scarce virgin materials.

Data breaches of several top tier organisations in 2022 catapulted cyber security into the nation’s conscience.

In response, more entities are adopting General Data Protection Regulation (GDPR), designed to safeguard personal information and data. Despite extra vigilance surrounding security, redundant IT equipment can hold data that can compromise individuals, a business, its customers or employees.

Steven Batumalay, Shred-X ITAD Solutions and Relationship Manager, says more awareness of data security, from both the general public and businesses, has created opportunities for e-waste service providers.

Shred-X has built its reputation on securely destroying data. Having started in 1999 within the paper recycling industry, Shred-X evolved to provide a range of destruction and recycling solutions for a myriad of materials other than paper, including IT and data assets, media,

uniforms, dated or contraband products, used coffee cups and QSR (Quick Service Restaurant) waste, textiles and clothing, ensuring ethical landfill diversion for materials which previously had no other disposal alternative.

Shred-X’s expertise in providing IT asset disposition (ITAD) and e-waste recycling services has been sought after by many global partners within the Asia Pacific region. Expanding it’s footprint, in November 2022 Shred-X acquired RCube Solutions, an Australian-owned and managed ITAD company focused on e-waste diversion from landfill and mitigation of data theft.

“Shred-X has been one of the fastest growing companies in the e-waste and secure data destruction industry,” Steven says.

“It’s been making the right technology and resource investments to service clients and with a focus on providing sustainable and environmentallyfriendly solutions.”

It’s widely recognised that e-waste is a global problem – the United Nations estimates that only 12.5 per cent of the 20-50 million tonnes of electronic waste worldwide is recycled, with the rest ending up in landfill or cluttering up homes and offices. Those discarded in landfill not only pose a risk for the data stored, but can leak dangerous chemicals into the environment with devastating effects on local communities and wildlife.

Steven says there’s more awareness in Australia regarding how e-waste should be treated and recycled responsibly, largely due to government restrictions on exporting e-waste to developing countries, and a focus on corporate Environment, Social and Governance (ESG) policies.

“E-waste is the fastest growing waste industry not only in Australia but globally,” Steven says. “Hence there is more and more investment from local and international businesses and government, which is great for the Australian economy.”

Shred-X aligns itself with five of the United Nations Sustainable Development

FEATURED TOPIC – E-WASTE 36 / WMR / March 2023

IT asset recovery is a sustainable option to help businesses maximise their IT investment.

Goals (SDG’s), that were first implemented into the global sector in 2016. Shred-X is actively invested in these goals with one of its SDG’s being SDG 9: building resilient infrastructure, promoting sustainable industrialisation and fostering innovation.

Steven says it is part of the organisation’s ethos to help companies achieve their targets by finding a new home for waste besides landfill.

He adds that while e-waste recycling is a positive disposal method ensuring that precious metals and components are recycled, an alternative sustainable option is to repurpose or reuse IT assets. The IT asset recovery service is one of the initiatives Shred-X has implemented to help customers maximise their IT investment in technology hardware through the asset buyback program.

Steven says for electronic assets containing data, repurposing is possible

JCB WHEEL LOADERS

after a process called data sanitisation. Sanitisation involves a multiple pass data overwriting process to ensure that data cannot be retrieved through commercially available data recovery processes.

“Our e-waste repurposing alternatives deliver a compliant, sustainable solution to end-of-life asset management plan and is one that can also be integrated into a business’s corporate social responsibility project,” he says. “With a national customer base of more than

PROVEN RELIABLE AND PRODUCTIVE

20,000 Shred-X can help businesses to securely manage their e-waste and at the same time improve their bottom line by tapping into any unrealised value in their spent technology.

“The Shred-X solution promotes a circular economy, providing environmental sustainability and financial benefits to business.”

For more information, visit: www.shred-x.com.au

1300 522 232 jcbcea.com.au

Shred-X has partnered with Australian recyclers to divert e-waste from landfill.

The JCB range of wheel loaders are built to be strong, reliable and provide comfort for long days in the cab. Designed for ultimate productivity, and offering superb performance the JCB wheel loader range features best-in-class comfort, visibility, safety ergonomics and superior serviceability plus a whole lot more.

Shred-X has partnered with Australian recyclers to divert e-waste from landfill.

The JCB range of wheel loaders are built to be strong, reliable and provide comfort for long days in the cab. Designed for ultimate productivity, and offering superb performance the JCB wheel loader range features best-in-class comfort, visibility, safety ergonomics and superior serviceability plus a whole lot more.

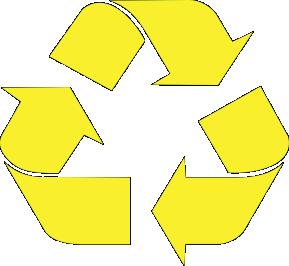

2023

A year in which anything is possible

Let’s continue inventing the world of tomorrow together...

What if...

Putting more tech in Scipher Technologies

SCIPHER TECHNOLOGIES, A LEADING E-WASTE RECYCLING COMPANY, IS SETTING NEW STANDARDS FOR ESG REPORTING IN THE INDUSTRY. EXECUTIVE DIRECTOR CHRIS SAYERS EXPLAINS.

E-waste specialist Scipher Technologies is putting the “G” into ESG (environmental, social and governance) reporting.

Scipher Technologies, with current operations in Melbourne and Perth and plans to expand to Sydney, aims to lead the way in responsible e-waste management through safe and advanced raw material recovery processes providing circular economy-driven outcomes.

The company’s newly developed waste tracking and reporting system, Sciphertech allows for full traceability of e-waste throughout the recycling process, generating transparent and verifiable reports on performance and outcomes for clients and partners.

Chris Sayers, Executive Director of the firm, says the Sciphertech system puts his company ahead of the game.

“The recycling industry is developing rapidly in Australia,” Chris says. “The provision of accurate and auditable data will help avoid the risk of green washing across the industry.

“At the core of Sciphertech is governance. We take governance and reporting seriously and are making sure that the information we release to the market, regulators and our clients is fully verifiable.

“We’re raising the bar of expectations that clients can have of the recycling industry.”

Australia is one of the world’s largest producers of e-waste per person, but most of it still ends up in landfill or is traded overseas at end-of-life.

Victoria, South Australia, and the ACT have all banned e-waste from landfill in a bid to encourage resource recovery as

Australia transitions to a circular economy. Other states are expected to follow suit.

Chris says Scipher Technologies operates some of the most advanced and commercially proven waste processing technology available.

The company works with waste management companies, councils, schools, large corporate and small-tomedium businesses to help them achieve circular-economy-driven solutions for their end-of-life products, in the form of recycling, product stewardship and material recovery targets.

He says that as investors and businesses increasingly put more emphasis on ESG aspects of their operations, clients are seeking to understand what happens to their materials after they’re sent to a recycling facility. “They want to see the outcomes,” he says.

FEATURED TOPIC – E-WASTE www.wastemanagementreview.com.au / WMR / 39

Sciphertech allows for full traceability of e-waste throughout the recycling process.

“Clients are expecting a high level of reporting and details.”

Enter, Sciphertech. Tailored to track waste through complex recycling and de-manufacturing processes, Sciphertech provides clients a detailed report that can include an analysis of different types of e-waste processed, what category and quantities of materials are recovered, where the material ends up downstream, and what that equates to in diversion from landfill.

“For every 100 kilograms of waste that we process, we reconcile back and track exactly where it ends up,” Chris says.

“We can set up tailored reports for customers to feed into their own ESG reporting requirements. We can easily capture the right data when different types of waste enter our facilities, and provide it

back in meaningful and accessible formats for clients.

“Collating, analysing and generating reports that are verifiable is critical for us.”

Chris says the Sciphertech information system was developed because there was no off-the-shelf product that could provide the level of detail the company was seeking. Management worked with a software development partner to custom build the system with the functionality needed now, but also has ability to adapt and update it as market and regulatory requirements change.