POSITIVE VISION

Ecocycle’s Tyson Ord details a national solution for a problematic waste stream.

FEATURES

Plastic-munching microbes

PV upcycling

Breaking the mould

Waste liquid, not fuel

PROUDLY SUPPORTED BY:

PMS 380 PMS 376 PMS 355 APRIL 2023

In this issue

Features

48

SOLAR FLAIR

Research by a Melbournebased team is the catalyst for a first-of-its-kind PV upcycling facility in the state.

POSITIVE ACTION

E-waste recycler Ecocycle is providing a national solution for a problematic waste stream.

“A LOT OF WORK IS BEING DONE BY GOVERNMENTS REVIEWING WHAT COULD AND SHOULD BE INCLUDED IN THE SCHEME, WHICH WILL ADD TO FURTHER TONNES OF E-WASTE BEING RECYCLED.”

- Tyson Ord, Ecocycle National Sales Representative

42 CELL RESPECT

Eriez-Australia has solutions for the unique challenges of battery recycling.

44 CHARGING AHEAD

B-cycle reflects on a positive first 12 months and the challenges to come.

46 PURE INTENTIONS

Pure Environmental breaks the mould when it comes to battery recycling.

48 SOLAR FLAIR

Research by a Melbourne-based team is the catalyst for a first-of-its-kind PV upcycling facility in Victoria.

50 RISE AND SHINE

Blue Phoenix Group helps Australia’s energy-from-waste industry take its first steps toward a circular economy.

52 RECYCLING REVELATIONS

RecycleSmart looks behind the curtain of two partners to highlight what happens to the waste it collects.

54 CRUSHING COMPACTION

Martin Hay and the MH Earthmoving team beat the drum for the Tana H380 landfill compactor.

56 FULL CIRCLE

ResourceCo takes on Australia’s offroad tyres with a new multimillion-dollar processing plant.

58 IT’S EASY BEING GREEN

Komptech’s Crambo shredders and Topturn compost turners go together like rock and roll.

60 COUNCIL IN FOCUS

Macedon Ranges Shire Council shares how the shire’s residents have become waste warriors.

Regulars

63 PRODUCT SPOTLIGHT

65 LAST WORD

16 THE BREAKDOWN Industry leaders have their say on current issues. 25 SLUDGEBUSTERS Sludgebusters’ DAF fleet of trucks covers a lot of ground across Central Victoria. 29 A NEW LEEF An Australian-designed wastewater treatment system tackles PFAS. 32 UP AND AWAY Global knowledge and a local workforce drives REMONDIS. 34 FOR GOOD MEASURE VEGA measuring tools are on the radar of municipal councils. 36 TAKING IT TO THE MAX CDE’s D:MAX wastewater processing plants set the standard for removing solids from liquid wastes. 38 PREDICT AND PROTECT ifm’s AI-assisted maintenance tool provides real-time insights. 40 BATTERY-POWERED Australia’s battery recycling sector is establishing itself as an innovation hub.

COVER STORY 19

www.wastemanagementreview.com.au / WMR / 3

From the Editor

Flushed with success

Keep your wipes out of pipes … stick to the three P’s – pee, poo and paper … are you flushing kidding me?

I admit to having a chuckle at media campaigns to draw attention to pipe works under pressure. I’ve also joined the collective ‘ewwws’ while watching television reports of giant fatbergs (a build-up of paper products along with fats, oils and grease that people pour down the drain), being pulled out of a sewer.

Whether you liked or loathed it, Sydney Water’s use of toilet humour did the job – it had people talking about a serious issue – wastewater.

Since the first civilisations were built next to water sources so rivers formed a natural sewage disposal, through to 1843 when the world’s first modern centralised sewer system was built in Germany, humans have recognised the importance of maintaining the health and wellbeing of the water environment.

These days the wastewater industry encompasses biological and chemical treatments, removal of contaminants, technology, and Artificial Intelligence.

Measurement technology is becoming more intuitive as production processes for wastewater treatment becomes more complex, particularly in municipal and industrial plants. There’s also an emphasis on processes and procedures that drive efficiencies.

This edition of Waste Management Review looks at just some of the players in an ever-changing landscape, from those on the road servicing rural communities and the equipment suppliers behind them, to the Australian team unlocking ground-breaking solutions for the global challenge of PFAS.

The Water and Carbon Group’s LEEF (Low Energy Evaporative Fractionation) System has proven so successful WCG is taking the solution to the United States market.

Tackling another global problem on home soil is specialist e-waste recycler Ecocycle.

The company has emerged as a major player in recycling within Australia and has invested heavily in best practice across the entire group to ensure it is well prepared to tackle rising e-waste streams. In this month’s cover story, Ecocycle Director Doug Rowe shares the company vision for long-term solutions and greater resource recovery.

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

GROUP MANAGING EDITOR

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Leon Cranswick leon.cranswick@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR Blake Storey blake.storey@primecreative.com.au

DESIGN

Louis Romero, Kerry Pert

BRAND MANAGER

Chelsea Daniel chelsea.daniel@primecreative.com.au

p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. The rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Lisa Korycki

4 / WMR / April 2023

GENOX’S NEW SHREDDER IS A PLASTIC PIPE’S WORST NIGHTMARE. THAT’S APPLIED THINKING. Call: Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au genoxmachinery.com.au Genox’s new J-Series pipe shredder is specificially designed for HDPE plastic pipes. With a unique multi-rotor design and long life counter knives, it quickly shreds different diameter and sized pipes. Like all Genox equipment it comes with the support and back up that only a true local machinery partner can provide.

Reviving soft plastics recycling

The Soft Plastics Taskforce has released a Roadmap to Restart, outlining the steps needed to launch a new supermarket soft plastic collection scheme, and the current state of play in the Australian recycling industry.

The Taskforce, made up of major supermarket retailers ALDI, Coles and Woolworths, has been tasked with developing an interim solution to restore community access to soft plastic recycling following the suspension of the REDcycle program.

Under the current plan, an initial in-store collection pilot is anticipated to launch in select stores in late 2023 – provided that REDcycle’s existing soft plastic stockpiles can be cleared prior. The new program would then be gradually rolled out nationwide next year.

While the Taskforce is working to launch in-store collections urgently, it is constrained by Australia’s limited access to domestic soft plastic recycling which can manage the “mixed polymer” soft plastics that are deposited by the public in supermarket collection bins.

At present, it would not be possible to recycle the volume of household

soft plastics collected in a supermarket program using domestic infrastructure. The Taskforce has plotted out the projected gradual increase in Australian soft plastic recycling capacity over the next year, as new operators launch, and existing processors expand.

From late 2023, the Taskforce will start a staged re-introduction of instore collections so that the volume of incoming household soft plastics does not exceed the amount that can be recycled.

A spokesperson for the Taskforce said: “For the vast majority of Australian households, the only avenue to recycle their soft plastic waste has been through the REDcycle bins available at Coles and Woolworths supermarkets.

“Restoring public trust in soft plastic recycling is paramount, and the Taskforce will reintroduce soft plastic collections when it can be confident that it will be properly recycled. We owe it to consumers to get this right.

“The best way to accelerate nationwide access to soft plastic recycling is through continued investment in recycling facilities to bring forward existing plans to expand domestic capacity.”

The current timeline to launch an in-store collection pilot by late 2023 is contingent on the ability to clear REDcycle’s existing stockpiles of soft plastic, which Coles and Woolworths have been granted control of.

Should new domestic processing capacity be taken up by the estimated 12,000 tonnes of stockpiled material for at least a year, the recommencement of in-store collections will be delayed.

Over the coming months, the Taskforce hopes to engage other retailers, e-commerce platforms and consumer brands that generate soft plastics to contribute to the development of the new in-store collection program.

The Australian Packaging Covenant Organisation estimates that less than five per cent of consumer soft plastic was collected by the REDcycle program. The Taskforce recognises the need for a long-term national soft plastic recycling strategy beyond its interim program.

The National Plastics Recycling Scheme (NPRS) outlines a new kerbside model to collect more household soft plastics. It has been developed by the Australian Food and Grocery Council with funding support from the Australian Federal Government’s National Product Stewardship Investment Fund.

The scheme is based on a model which would involve food and grocery manufacturers paying a levy to support the recycling of the soft plastics they create. It is currently being trialled in select areas.

News

6 / WMR / April 2023

Coles and Woolworths have made multimillion dollar commitments to a Soft Plastics Recycling Contribution Fund.

ENGINEERED FOR A CIRCULAR ECONOMY

CDE is here to transform waste materials into valuable recycled products. Our innovative wash plants give you the power to divert tonnes of waste from landfill and create new revenue streams. Move into new, high-value markets, like certified, in spec concrete sand, recovered from CD&E waste.

Visit cdegroup.com

brings us closer to reaching our target of diverting 80 per cent of waste from landfill by 2030,” Stitt said. So far, more than 50 projects across the state have

have prevented more than 55,000 tonnes of waste going to landfill and created 60 jobs.

Overall, the government has invested $515 million

waste and recycling system and a Victorian container deposit scheme.

Victorian councils and Alpine resorts can apply for grants.

8 / WMR / April 2023

Screening Output: up to 200 m3/hr

Engine: 55KW Diesel Motor

Trommel Length: 5500 mm

Trommel Screen

Screening Output: up to 180 m3/hr

Engine: 55KW Diesel Motor

Trommel Length: 4550 mm

Trommel Diameter: 2000 mm

Hopper Capacity: 6 m3

Up to 200 m³/hr

Speak to us today! 02 9457 9399 www.gcmenviro.com info@gcmenviro.com.au

GCM Enviro is a leading distributor for the latest in waste management equipement including state-of-the-art screeners, shredders and compost turners. GCM Enviro has a strong reputation for quality machinery and product support of top

quality equipment from word-renowned manufacturers.

Downer plant delivers more recycled materials for roads

The Tasmanian Government is expanding the use of recycled materials for roads around the state as a commitment to waste reduction in Tasmania.

Michael Ferguson, Minister for Infrastructure and Transport, said Tasmania has been using recycled rubber from truck tyres in road resurfacing on several resurfacing sites in the north of the state, including on the Bass, East Tamar and West Tamar highways.

“We know that about 1.3 million tyres reach the end of their life each year in Tasmania, most of which ends up in landfill or stockpiles. Some of these tyres are now being processed into crumb rubber and blended with bitumen for use as asphalt in the

state road maintenance program,” Ferguson said.

“We are seeing more recycled materials being used in road resurfacing and it was exciting to see construction well and truly underway at Downer’s $10.5 million asphalt manufacturing facility in northern Tasmania.”

Ferguson said construction of the asphalt plant has reached a critical point, with all establishment work complete and the main components being assembled. The components, weighing a combined 356 tonnes, were transported to the Mowbray construction site over two days thanks to 40 truckloads.

“It’s great to see this project well and truly coming to life. It’s a solid

commitment from an ASX Top 100 company to a long-term future in Tasmania which is wonderful for our state,” Ferguson said.

Since 2018 Downer has laid 11,079 tonnes of Reconophalt in Tasmania resulting in diversion from landfill of 9,503,000 plastic bag equivalents; toner from 277,300 toner cartridges; 2,652,000 RAP (recycled roads) used; 1108t of recycled asphalt paving material and 10.74 tonne of CO2e carbon saved.

Ferguson said the government would continue to work with industry to look for further opportunities to use sustainable products on Tasmanian roads.”

The new plant is on track to be commissioned in April 2023.

10 / WMR / April 2023 News

The new Tasmanian plant is on track to be commissioned in April 2023.

The ifm moneo platform goes beyond monitoring and detection, it gives you full visibility over your assets allowing you to perform maintenance at optimal times.

You don’t need a data scientist or analytics expert to know the condition of your machinery. moneo is a self-service tool that enables successful predictive maintenance programs through the help of AI methods.

Pump stations and submersible pumps face many challenges causing unplanned breakdowns. The moneo solution can detect the following issues:

n Predictive monitoring of bearings, gears and electric motors

n Rotating pump parts

n Pumps rotor and valves

n Water pressure, temperature and flow rate at the pumps outlets

n Faulty or damaged bearings

n Faulty or damaged seals

n Wear issues and rub issues

n Imbalance

n Cavitation

n Looseness

n Unusually high signatures in grinders and macerators 1300 365 088

| www.ifm.com/au

sales.au@ifm.com

Are you relying solely on historical data to inform decisions at your treatment facilty? Stand out from the rest with livestream analytics.

IT DOESN’T JUST MEASURE VALUES. IT HAS VALUES. THE 6X ®. AVAILABLE NOW! The VEGAPULS 6X: A radar level sensor that is not only technically perfect, it also takes the user into account. It’s easy to set up and at home in virtually any process or industrial environment. Made by a company that bases its decisions on values that are good for everybody. VEGA. HOME OF VALUES. www.vega.com/radar

Microbes dine out on plastic

CSIRO RESEARCHERS ARE ON THE HUNT FOR NEW RESOURCES IN NATURE TO TAKE ON PLASTIC WASTE.

Plastic waste management is a global crisis. Even some of the most remote places on Earth have been touched by plastic pollution.

About 6.3 billion metric tonnes of plastic waste is estimated to have been generated globally between 1950 and 2015, according to a 2017 peerreviewed article by R. Geyer and others in Science Advances

Of this, about 79 per cent has ended up in landfills or the natural environment, about 12 per cent has

been incinerated, and only about nine per cent has been recycled.

While there’s a growing social movement to address the overproduction of plastic, the sobering fact is that the amount of plastic waste being produced every year is continuing to grow at an ever increasing rate.

The CSIRO’s Ending Plastic Waste Mission is focused on changing the way we make, use, recycle and dispose of plastic and finding new resources in nature to break down plastic waste.

Dr Bronwyn Campbell, a postdoctoral fellow with the CSIRO, is working on developing plastic-munching microbiomes for biorecycling.

Her research is in CSIRO’s Environment Business Unit with support from the Environomics Future Science Platform, which applies genomics to environmental science issues such as detecting species, determining the ages of fish, and cleaning up waste.

FEATURE NEWS www.wastemanagementreview.com.au / WMR / 13

Soils and sediments that have been impacted by plastics, such as soils around landfills or sediments in urban streams, will be sampled for wild microbes.

Microbes hold vital roles in ecosystems, including decomposition.

“They have a lot to offer us humans and could help with challenging problems such as repurposing plastic waste,” Bronwyn says.

“My hope is that in the future, plastic waste can be broken down by microbes in large-scale bioreactors, and then used to make new products that are of equal or greater value to the plastics that went in.”

Bronwyn says that dozens of species of plastic-degrading microbes have already been isolated by other research teams, but the downside to using only one species is that it limits the range of plastics and plastic waste contaminants able to be recycled by them.

For example, a bacterium named Thermobifida cellulosilytica can degrade PET (polyethylene terephthalate) and PLA (polylactic acid); types of plastic that are often used as soft drink bottles or food packaging plastics, but it’s not able to degrade many other types of plastics.

“Plastic waste is usually mixed and contaminated. Sorting, where possible, adds time and cost to the recycling process,” Bronwyn says. “Thus, a

microbial community capable of filling different niches within the mixed plastic waste and supporting one another has the potential to reduce the need for waste sorting.”

Bronwyn will start field work this year to collect wild microbes within Western Australia, ideally within the Greater Perth region. She’s planning to sample soils and sediments that have been impacted by plastics, such as soils around landfills or sediments in urban streams.

Once she’s sampled environmental microbial communities, Bronwyn will grow them on different types of plastics in the lab to see how they respond.

Both the microbial communities and the plastics that they’re degrading will need to be analysed after incubation. This will involve methods such as DNA sequencing, which can determine the abundances of all the different microbes in the communities, and help predict their roles in consuming the plastic.

From what she’s heard from other research teams working on plastic biodegradation, Bronwyn expects the main challenge will be getting the rate of degradation to be fast enough and complete enough to make it

an economically viable option for waste management.

“Microbes are amazingly diverse and resourceful, but they don’t give a toss about profit expectations and deadlines in the waste management industry,” she says. “I expect the communities will need plenty of coaxing and manipulation if they’re ever going to reach that stage.”

Bronwyn says although research such a biorecycling is exciting, at this stage it’s more excitement than reality, and in any case, will not be a silver bullet solution for the world’s plastic pollution.

“The focus needs to remain on reducing the rate of plastic waste production where possible, as well as encouraging better end-of-life management of plastics by improving regulation of production and use.”

This research project is project is taking place on Whadjuk Nyoongar country at the CSIRO Floreat, Perth site. It is funded by CSIRO and Bioplatforms Australia and led by Dr Anna Kaksonen, with CSIRO collaborators Dr Andrew Warden, Dr Colin Scott, Dr Janet Reid, Dr Roger Mulder, and Dr Toni Reverter-Gomez. External collaborators on the project are Professor Richard Gross, Dr Yosephine Gumulya, and Professor Gene Tyson.

14 / WMR / April 2023 FEATURE NEWS

Collected wild microbes will be grown on different types of plastics in the lab to see what happens to the plastics.

Dr Bronwyn Campbell, a postdoctoral fellow with the CSIRO’s Environomics Future Science Platform.

The Breakdown

Waste Management Review introduces ‘The Breakdown’ a new monthly column giving industry leaders and decision makers a chance to share their views on topics central to the sector.

This month we asked: ‘What is the biggest challenge facing the industry in 2023?’

There is a fundamental lack of alignment between Australia’s environmental protection policies and broader circular economy principles, underpinned by a fragmented regulatory framework that identifies recyclable material as pollution rather than a resource. A nationally harmonised definition of ‘end of waste’ is essential, to support investment confidence in the recycling sector, encourage innovation and scale, and provide a more level playing field with virgin materials. At the same time, it is vital to ensure end markets for recycled material, without which the recycling system is not viable. This should include regulatory measures to support uptake of recycled content.

The biggest challenge facing the Australian organics recycling industry (AORI) in 2023 is the establishment of collaborative and consistent policy (including regulatory) settings. For the AORI to be successful and sustainable, government policy, legislation and regulations governing organics industry processors must be aligned to national and state strategic objectives for landfill and waste reduction. This must include consistency and fairness in the management of contaminants including forever chemicals (e.g., PFAS), plastics and other potential problematic contaminants. It should, ideally, include clear and consistent guidelines (supported by regular and consistent communication and education) for what can go into the green organics bin and what cannot, especially with the increasing rollout of FOGO by local government jurisdictions

Every corner of this industry has its own special challenges but I think it can be summed up in one word, Education; whether that be:

• the general public to know what is recyclable and what isn’t or what bin to put their item in.

• organisations understanding the new regulations, their requirements especially when submitting permissions

• the regulators understanding the industry and processes they are trying to regulate. There is so much greenwashing and misinformation floating around within industry and the general public, even then most well-meaning and knowledgeable waste professional can become misguided due to misinformation and greenwashing.

As an industry, we face many challenges, but one challenge we can all impact is building public sentiment on recycling. Our research shows that 30% of Victorians think their recycling ends up in landfill, and 88% of Victorians state they don’t know enough about how recycling is conducted.

We can all positively impact this. We can create educational resources and content to show the community how we recycle their materials, so they have trust in the industry. Together, we can help people have a better understanding of the work we do.

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2023, please get in touch with Editor, Lisa Korycki lisa.korycki@primecreative.com.au

Suzanne Toumbourou Chief Executive Officer Australian Council of Recycling

John McKew National Executive Officer Australian Organics Recycling Association

Brett Lemin Executive Officer Victorian Waste Management Association

John McCluskey GM Commercial Repurpose It

Suzanne Toumbourou Chief Executive Officer Australian Council of Recycling

John McKew National Executive Officer Australian Organics Recycling Association

Brett Lemin Executive Officer Victorian Waste Management Association

John McCluskey GM Commercial Repurpose It

OPINION 16 / WMR / April 2023

The LH 26 M Industry

Litronic

Robust, compact and extremely fuelefficient, the LH 26 delivers tremendous performance in various areas of material handling. Equipped with our latest engine and hydraulic technologies, the all rounder is available in numerous configurations and adaptable to all environments.

www.liebherr.com

Visit us at COFFS WASTE CONFERENCE 09 – 11 May 2023 Opal Cove Resort, Coffs Harbour, NSW Booth 11

Treasure hunter

machine Liebherr-Australia Pty Ltd • em-sales.las@liebherr.com • www.facebook.com/LiebherrConstruction www.linkedin.com/company/liebherranz • www.liebherr.com.au

Material handling

THE PHOENIX HAS LANDED IN AUSTRALIA

The Phoenix is an extraordinary mythical creature. At the end of its life when just ashes remain, something magical happens. New life merges out of something that seems lifeless. What we consider to be the end, suddenly transforms into a new beginning. We give ash a new life in the real world.

What we do

The ash in our line of business comes from the new Energy-from-Waste facility Avertas Energy. Incineration of municipal solid waste (MSW) is an effective way to reduce waste volume and reduce our reliance on fossil fuels for energy.

How we do it

We process the remaining ash and extract valuable resources. With our state-of-the-art technology we recover metals to produce a secondary aggregate used for civil construction work. Environmental protection is at the forefront of our day-to-day operations. We assure the proper use of aggregates, limiting the impact on the environment.

Why we do it

We believe our work is only valuable if it contributes to a better future. We prevent landfilling and the negative impacts associated with the extraction of virgin raw materials by producing a secondary aggregate that contributes to the circular economy.

Mr Ian Lynass, Managing Director Ianlynass@bluephoenix-group.com

Mr Ian Lynass, Managing Director Ianlynass@bluephoenix-group.com

Blue Phoenix Australia

Blue Phoenix Australia

0418 290 080 | www.bluephoenix-group.com

Proof positive

E-WASTE RECYCLER ECOCYCLE IS PROVIDING A NATIONAL SOLUTION FOR A PROBLEMATIC WASTE STREAM.

E-waste is growing at three times the rate of any other waste stream, fuelled by consumer demand for the latest technology.

The Global E-Waste Monitor 2020 reported that e-waste increased by 21 per cent in the five years to 2019. A figure that will grow exponentially in the years ahead, according to Doug Rowe, Director of specialist e-waste recycling company Ecocycle.

Doug says that while there’s mounting evidence of the environmental impacts of e-waste, only 17 per cent is recycled globally.

Part of the challenge is the diverse product range that falls under the e-waste banner.

“The challenges are immense with mixed materials, the influx of batteries into all sorts of e-waste, and the vast range of shapes and sizes of material that has to be handled,” he says.

Ecocycle has emerged as a major player in recycling within Australia with the establishment of Ecobatt – recycling all types of household, portable, electric vehicle and storage batteries; and Eco E-waste – a specialist recycling company for electrical appliances, computers, televisions, monitors and laptops.

The company has expanded its investments in the mining, gas, and petroleum industries with further work being carried out in Western Australia, including a new site chosen for expansion in the state.

And Ecocycle is the only company to be fully licensed by the environmental protection agencies of each state to handle the entire process of recycling waste containing mercury.

Doug says mercury needs to be respected, but few mercury fluorescent tubes are treated correctly and the televisions, monitors and laptops that

they come from are not processed as they should be or recycled correctly.

He has praised Australia for signing up to the Minamata Convention, which now requires all mercury to be retired, which means it can no longer be sold or reused. In a step forward, a plant is being built overseas and will be commissioned in Western Australia during the first half of 2024, to convert elementary mercury into a product that can be retired.

SHOW OF CONFIDENCE

In July 2022, Ecocycle was included in the National Television and Computer Recycling Scheme (NTCRS); established in 2011 to give households and small businesses free access to industry-funded collection and recycling services.

Tyson Ord, Ecocycle National Sales Representative, says having the NTCRS backing shows confidence in

COVER STORY www.wastemanagementreview.com.au / WMR / 19

Eco E Waste has a national reach with trucks purposebuilt for transporting e-waste.

Ecocycle’s national reach, and its ability to responsibly collect, process and separate the various grades of e-waste. It was important for the group becoming involved, as well as helping increase its presence in this field.

“A lot of work is being done by governments reviewing what could and should be included in the scheme, which will add to further tonnes of e-waste being recycled,” Tyson says. “The South Australian government banned e-waste going to landfill in 2013, the Victorian government in 2019 and the Western Australian government is looking at a ban to landfill as we speak. We believe other states could be following.

“Ecocycle looks forward to working closely with the NTCRS and ensuring we stay at the forefront of technological developments to keep us that one step ahead.”

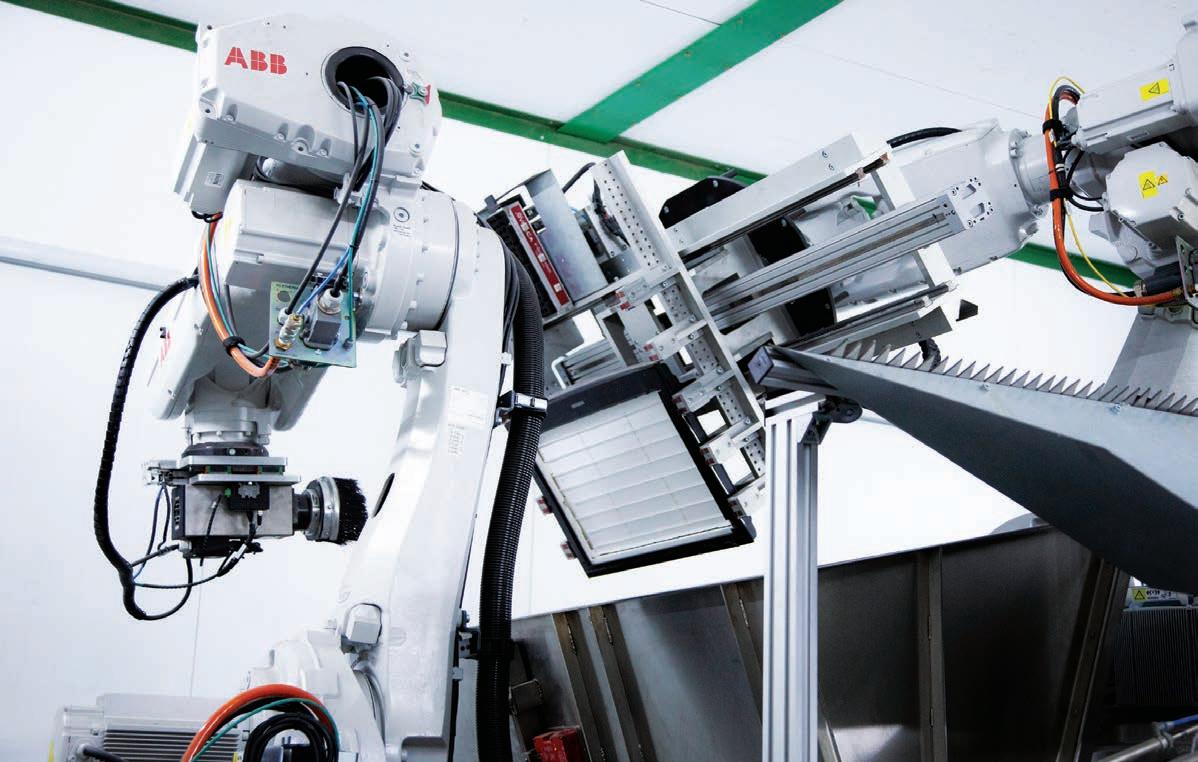

TECHNOLOGY-DRIVEN

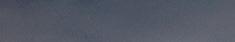

While older technology such as eddy currents still has a place, Doug says processes for sorting e-waste are advancing with robotics, Artificial Intelligence (AI), laser induction (LIBS) and X-ray.

These new, specialised systems can recover metals down to one millimetre and sort the metals into their various grades – 300 series stainless-steel from 316; aluminium extrusion and cuttings from aluminium castings; copper from brass, PVC cable, zinc, and printed circuit boards. The list goes on.

“Even one-and-two-dollar coins can be separated and recovered,” Doug says.

Ecocycle has introduced advanced technology to its purposebuilt e-waste processing and separation plant. Set up over three levels

and about 150 metres long, 40 metres wide and 16 metres at the highest point, it’s a huge up-front investment but one the company felt was needed to ensure it is as efficient, productive, and cost-effective as possible.

“Ecocycle is here for the longterm,” Doug says.

“Running consistently at 25 tonne per hour we have the capacity to process large tonnages with the highest possible non ferrous and precious metal recoveries.

“With the possibility of further e-waste to come onto the market in 2025, we wanted to be well prepared and have a sophisticated separation line that can handle the tonnage and recover all metals down to the smallest of fractions.”

20 / WMR / April 2023 COVER STORY

E-waste is growing at three times the rate of any other waste stream.

In July 2022, Ecocycle was included in the National Television and Computer Recycling Scheme.

NATIONAL APPROACH

Tyson says Eco E Waste is unique in that it has a national reach with trucks purpose-built for transporting e-waste.

Every state will have a 14-pallet tautliner truck with an automatic mezzanine deck, designed to simplify the loading process and double the carrying capacity. In some states there’ll also be semi-trailers with auto mezzanine decks.

The trucks were ordered more than nine months ago and when they are rolled out in August 2023, will boost Ecocycle’s fleet to more than 75 vehicles, including semis, crane and hook-on trucks, tailgate loaders and vans.

Most of the vehicles are Environment Protection Authority licensed and registered to transport dangerous goods. The drivers are dangerous goods registered.

“All these vehicles are tracked and traced with fleetmatics so at all times we know where our drivers are, where they have been and the route taken,” Doug says.

“We get alerted as to driver behaviour and pride ourselves on having clean ‘green’ trucks that portray a professional image.”

It’s not just the trucks, but bins, people, and systems that need to be recorded, controlled, and balanced in every state.

The various government bodies around Australia are doing more than ever to ensure e-waste, and indeed all waste, is transported, handled and recycled correctly.

Regulations change from state to state, resulting in different licensing, financial assurances, controls, and conditions across the country.

“The commitment is monumental when you consider the infrastructure and back-up required to operate an efficient, professional Australia-wide operation,” Doug says.

It’s a commitment, he says, worth pursuing.

A MIXED BAG

Ecocycle aims to be involved in some form of processing of e-waste in every state. It has set a target to remove and recover all steel, which can account for up to 50 per cent of the weight, from all e-waste it collects. The balance will be further processed to recover non-ferrous and precious metals and plastics.

Doug says mixed plastics are challenging to recycle, requiring a large commitment and investment to do it efficiently and successfully. While there are some rudimentary pieces of plant and equipment available, he says more is needed to be done in this space.

Ecocycle sister company Recycal has plans to install a plastic to diesel plant in Rocherlea, Tasmania to handle the mixed material within the plastic chain.

“We have started talking with a supplier of plastic recycling equipment that has the technology to deliver a complete plant that will separate and convert recovered plastics with a higher return into valued-added end products for industry,” Doug says.

“It is a large and sophisticated plant with moulding and extruding

www.wastemanagementreview.com.au / WMR / 21

Inside the mercury plant in Western Australia.

equipment to manufacture very clean, separated and known products.”

The various plastics found in e-waste makes the recycling process problematic with brominated flame retardants (BFR) needing special attention. Plastics with BFRs, mixtures of man-made chemicals that are added to products to make them less flammable, have presented challenges both overseas and locally as regulations regarding their recycling have changed.

Several eco-efficient waste management options, such as incineration with energy recovery, are popular solutions being adopted throughout Europe. While energy-fromwaste plants are currently not commonplace in Australia, there is progress. The first plant is being built in Kwinana, Western Australia and there are others at the planning stage.

Doug believes they could be an answer for some of the BFR plastics moving forward but he’s aware any sustainable outcome for recycled plastics is a longterm prospect. Any plant built must also be able to handle a range of fillers, fibres and powders used in the making of various plastic products.

“The plant design can take months with lots of back and forth,” Doug says. “From the agreement stage, it can take up to 12 months to get the equipment in Australia, several months to install and wire, and then weeks of commissioning.

“It’s not something that will happen tomorrow.”

Doug says the investment in best practice across the entire Ecocycle group will give clients assurance they are dealing with an organisation that handles their waste material without

using third and fourth parties. Because material is recycled using shredding and milling, there is also no chance recycled equipment will find its way back onto the market or in Third World countries that may have exposure to slavery challenges.

“We have great reporting and a new and exciting ability to chat about carbon insetting,” Doug says.

“We would welcome the larger importers of e-waste into Australia to visit Ecocycle and see everything we do.

“It might cost a bit more, but they can rest assured knowing they’re dealing with a company that can give them the comfort of a complete end-to-end recycling solution with great reporting.”

For more information, visit: www.ecocycle.com.au

22 / WMR / April 2023 COVER STORY

Ecocycle has invested in best practice across the entire group.

Pure unites people and technology to transform the circular economy through advanced resource recovery.

We strive to be Australia’s leading resource recovery specialist, providing viable solutions to meet our customers needs.

pure-environmental-pty-ltd 10/333 Queensport Rd North, Murarrie QLD 4172 T: 1300 652 774 E: info@purenv.au W: purenv.com.au pure transforming the circular economy

Waste liquid, not fuel

SLUDGEBUSTERS HAS BEEN KEEPING REGIONAL VICTORIA SLUDGE-FREE SINCE 1989. FOUNDER GREG BUTLER DISCUSSES THE BUSINESS, AND THE FLEET OF DAF TRUCKS POWERING IT.

Greg Butler’s family first entered the liquid waste game back in 1966 when they purchased their first vacuum tanker to service the family piggery.

Greg took this to the next level in 1989 when he started Sludgebusters, which has grown into one of Central Victoria’s leading liquid waste businesses.

“Servicing domestic septic tanks was what we started off with, and that’s still the core of the business,” Greg says. “But today, if you have any liquid waste issues, we can sort it out.”

Now with 10 employees – including Greg’s son Harrison – Sludgebusters offers a full range of liquid waste and related services including septic and water tank cleaning, servicing and cleaning of domestic wastewater treatment systems, hydro excavation, and under shearing shed clean outs.

Whatever the job, the primary tool of the liquid waste trade is the vacuum tanker. Sludgebusters now runs a fleet of six of these tankers, which are mounted to DAF trucks supplied by PACCAR Australia.

Greg says he was introduced to DAF trucks through the team at Vacuum Truck Supplies in Mansfield, Sludgebusters’ vacuum tanker supplier.

“Adam at Vacuum Truck Supplies told us DAF were well suited to their builds,” he says. “And we quickly figured out that they suited our application too.

“We purchased our first DAF about 10 years ago, and had a really good run with it, and good support over the journey. That’s why I’ve kept purchasing them.”

The latest models in the fleet are two DAF CF450 FAT 6x4 rigid trucks, of which Greg says Sludgebusters has another soon to be delivered, and another on order.

THE DAF DIFFERENCE

Greg says there are a range of reasons Sludgebusters has stuck with the DAF brand in recent years.

“One thing that really stands out with DAF is the fuel economy,” he says.

“Good fuel economy is always the first thing that DAF salespeople want to spruik – but that’s because it’s true.”

With the CF450, this is achieved in part by PACCAR MX-11 Euro 6 engine, as well as the CF range’s lighter tare build of the DAF CF range.

“Our vacuum tankers are pretty heavy, and that’s before you put 10 tonnes of waste in them,” Greg says. “But the lighter tare you start off with, the better off you are.”

Greg says Sludgebusters has always endeavoured to keep ahead of the technology curve as far as tracking data – something he says is becoming more the norm across the waste industry.

FEATURED TOPIC – WASTEWATER www.wastemanagementreview.com.au / WMR / 25

One of Sludgebusters’ DAF CF450s fitted with a liquid vacuum tanker.

“Like with all parts of this industry, rules are getting tighter –things have to be trackable, and we’re expected to be more accountable,” he says.”

One way DAF trucks supports customers in this regard is through the PACCAR Connect-powered Driver Performance feature, which coaches drivers on driving behaviours to help optimise fuel efficiency.

“We can keep track of how drivers are managing fuel economy on a particular journey,” Greg says. “We can closely

monitor fuel usage, which can also help us work out pricing.” Greg says given the ground Sludgebusters covers across Victoria, this can make a big difference to the bottom line.

Safety is another theme that runs through the DAF CF truck range. Drivers can enjoy the peace-of-mind offered by newly optimised side mirror placement, as well as side cameras to cover any blind spots when changing lanes.

“Having good backup support is also important,” Greg says. “The few times

we’ve had something go wrong with a DAF, we’ve been able to sort it out quickly and get back on the road.”

Greg says that while many waste streams in Australia are evolving and changing, the business of liquid waste isn’t likely to dry up any time soon –particularly in regional areas.

“Once people have septic tanks installed, they often stay there for 50 or 60 years,” he says.

“The only big change that has come in over the past 20 years is home wastewater treatment systems. They’re bigger and a bit more complex, but they still need de-sludging every three or four years.

“So, as long as people keep flushing, we’ll be there. Your waste is our bread and butter.”

For more information, visit: www.daf.com.au

26 / WMR / April 2023 FEATURED TOPIC – WASTEWATER

“Good fuel economy is always the first thing that DAF salespeople want to spruik – but that’s because it’s true.”

Greg Butler Sludgebusters Founder

Sludgebusters’ DAF fleet covers a lot of ground across Central Victoria.

BC 773 RB-5: THE MULTITOOL

AMONG REFUSE COMPACTORS

The BC 773 RB-5 compactors have been specifically designed to conquer the extreme conditions found on landfills – which makes them your perfectly reliable and efficient partner on site.

Our intelligent machine concept sets new standards in its class: All compactors come with a multitude of smart major and minor features that make work easier and more efficient, such as a hydraulically operated engine hood and high air intake.

Additionally, our new RS variant offers you a real multitool among compactors, with high lift capacity, fitted with a 4 in 1 combination trash bucket. It enables all-in-one compaction, loading and transporting –saving you valuable time and costs.

Brisbane | Sydney | Melbourne Adelaide | Perth tuttbryant.com.au 1300 658 888 Follow us on:

Sept 2023

Melbourne’s leading construction and major infrastructure event

Inside Construction Expo will deliver

Targeted messaging in over 19 industry-leading publications that reach more than 80,000 decision makers across multiple sectors

Digital communications to 28,000+ engaged readers

Premium networking opportunity with industry leaders at the Foundation Awards gala dinner

insideconstructionexpo.com.au

EXHIBITION SPACE NOW ON SALE

Melbourne

20-21

Convention and Exhibition Centre

Turning over a new LEEF

A WASTEWATER TREATMENT SYSTEM DESIGNED BY AUSTRALIA’S WATER AND CARBON GROUP IS SET TO TACKLE THE GLOBAL PFAS CHALLENGE HEAD-ON.

Australian environmental engineering and construction firm, the Water and Carbon Group (WCG) has developed a treatment system proven to remove PFAS (per- and poly-fluoroalkyl substances) from wastewater.

The LEEF (Low Energy Evaporative Fractionation) System® is centred around foam fractionation to remove PFAS contaminants by harnessing air, and the chemical properties of PFAS itself, all while using minimal energy, no chemicals or consumables.

Jai Sudholz, Water and Carbon Group Pre-Contracts Manager, says

the system is a remedy to a growing but still widely under-recognised contamination problem.

“Our treatment system is designed to make a lasting, positive difference to people and environments, while helping operators and industries meet the PFAS challenge head on,” he says.

Often dubbed the ‘forever chemical’, PFAS is a global pollution challenge. Widely used for its water, oil and stain resistant properties, PFAS chemical chains don’t break down easily, and hence bioaccumulates in the environment and human bodies. They have been detectable in the bloodstream for years

after exposure, and are linked to a range of health risks in humans, with the longterm ecological and intergenerational effects being a cause for alarm.

Backed by a team of process and ecological engineering specialists, as well as environmental scientists, project and construction managers, WCG has been at the forefront of sustainable engineering within the wastewater, environmental and remediation industries since 2007.

Jai says the LEEF System was initially developed to address PFAS contamination in landfill leachate but the technology is both scalable

www.wastemanagementreview.com.au / WMR / 29 FEATURED TOPIC – WASTEWATER

The LEEF System is scalable and adaptable to a range of PFAS contaminated waste streams.

and adaptable to a range of PFAS contaminated waste streams.

The landfill leachate showed high concentrations of a range of contaminants that rendered conventional removal methods such as granular activated carbon (GAC), ion exchange resins, and reverse osmosis (RO) ineffective or cost inhibitive.

“The concept of the LEEF System is to enable a cost-effective treatment method that reduces the production of waste at a lower energy consumption rate than other methods,” Jai says.

The key to the LEEF System solution is that PFAS are surfactants that can produce a stable foam when mixed with air and water. This characteristic is the reason PFAS is effective as a firefighting foam to suppress certain types of fire.

Jai says the LEEF System takes advantage of the way PFAS coats air bubbles in a process called foam fractionation. By adding air in a controlled setting, PFAS compounds will attach to bubbles and rise to the top where they can be skimmed off and separated from the wastewater.

“By using foam fractionation, the LEEF System has been shown to remove PFAS compounds up to the limits of detection,” Jai says. “The system typically does not require pre-treatment for direct PFAS removal, while zero chemicals or consumables are used throughout the process, resulting in a simple-to-operate, low-maintenance system.

“Another advantage of the LEEF System is its modular design, which can be easily scaled and customised to meet any volume requirements.”

The Shoal Bay Waste Management Facility receives more than 180,000 tonnes of waste each year from 164,000 residents who live in the greater Darwin region.

Due to the region’s rainfall, the facility also generates large volumes of leachate that must be treated and kept out of the surrounding environment, which includes ecologically important eucalypt woodland, coastal wetlands, and wildlife habitats.

In 2019, the City of Darwin awarded WCG a $13.2 million contract to design, construct, and operate a leachate treatment plant solution for

30 / WMR / April 2023 FEATURED TOPIC – WASTEWATER

The Water and Carbon Group PFAS removal system harnesses air and the chemical properties of PFAS itself.

DO YOU KNOW A DRIVER OF CHANGE?

WOMEN IN INDUSTRY NOMINATIONS ARE NOW OPEN. Now is your chance to nominate an industry leader who you believe is advocating for positive change and deserves to be recognised.

WOMENININDUSTRY.COM.AU

THURS 8 JUNE 2023

The Women in Industry Awards recognise outstanding women leaders from across Australia’s industrials sector.

MHD Supply Chain Solutions PROUDLY PRESENTED BY

SPONSORED BY Australia

Up and away

REMONDIS’ WASTEWATER MANAGEMENT IN AUSTRALIA IS GOING FROM STRENGTH TO STRENGTH, DRAWING ON A GLOBAL BANK OF KNOWLEDGE AND A LOCAL WORKFORCE.

Ayear might seem inconsequential when you’ve been at the forefront of global wastewater management for many decades, but there have been milestones aplenty for REMONDIS in Australia over the past 12 months.

Since its commissioning in May 2022, REMONDIS’ wastewater treatment facility at Northgate in Brisbane has gone from strength to strength. The facility is licensed to process J120 waste oil/water, hydrocarbons/water mixtures or emulsions and has recently commenced accepting waste oil from third parties with capacity for 11.5 million litres per annum.

The Northgate facility operates alongside REMONDIS’ existing waste transfer station. Servicing south-east Queensland, its configuration allows for treatment of standard commercial wastewaters with scope for growth into complex categories of commercial and industrial wastewater.

As with REMONDIS’ installations globally, emphasis has been placed on

processes and procedures that drive efficiencies from the word go, with flexibility to ramp up as time progresses.

It has also been fertile ground for learning and development, with REMONDIS drawing on international expertise to strengthen local knowledge of world’s best practice in commercial wastewater treatment, enabling local teams to extract the most out of the plant, thereby delivering cost-efficient outcomes for clients and maximum environmental benefit.

“In the past few months, we’ve been undertaking detailed checks and audits to see how we can make the facility even more efficient,” says Sebastian Weil, REMONDIS Aqua Australia Director.

“Striving for efficiency at such facilities is business as usual for REMONDIS, a job that never really finishes.

“There’s an onus on everyone from engineering through to operations to look for improvements as the site evolves.

Such team efforts are already resulting in more efficient unloading times, higher throughput, improved effluent quality and better separation of waste oil – it’s been a great team effort.”

GLOBAL KNOW-HOW

One REMONDIS advantage is being able to draw on expertise and synergies from other arms of the entire REMONDIS group, including REMONDIS Australia’s Integrated and Managed Services division (REMONDIS IMS), an environmental managed services provider for complex waste management, specialist recycling and commodity streams, site remediation and special projects.

Local collaborations have delivered a wider suite of services to REMONDIS’ water management service clients, that include Gladstone Regional Council and Aurizon.

Globally, REMONDIS is a leading provider of municipal and industrial water

FEATURED TOPIC – WASTEWATER 32 / WMR / April 2023

REMONDIS Aqua wastewater treatment plant in Cottbus, Germany. (©U.Mertens)

management services, providing sustainable water supply, wastewater treatment and sewage sludge recycling solutions. Innovative solutions include the awardwinning TetraPhos Process for recovering phosphorus from sewage sludge.

Research and development are constantly being driven throughout the REMONDIS Group.

“There are many emerging ideas and technologies we can cherry-pick, from across Australia and from our global network,” Sebastian says.

“The more we can tap into our bank of know-how the more we can look at passing cost savings onto customers, delivering better environmental outcomes, and strengthening our position in the market generally.”

An area of focus at the Northgate facility is expansions to meet market demand for the handling of difficult-to-treat industrial wastewaters and sludges. On this front, the team is making plans to commission new treatment lines at the facility by the end of 2023.

“As industry becomes more conscious of its environmental footprints, the

demand for local science-based solutions for complex industrial wastewaters grows,” says Thomas Hallam, REMONDIS Aqua Australia Operations Manager.

“Gone are the days of wastewater disappearing into the back blocks or being hauled long distances by road to be dumped in rural areas. REMONDIS’ clients require a progressive, proactive approach.”

‘HOME-GROWN’ TRAINING

Another priority is ensuring skilled workers are on hand to keep the facility and future facilities running, amid a national worker shortage that is affecting many parts of industry.

To address that problem, REMONDIS has looked within, going all out with inhouse training programs.

“Another benefit of being a big global player is that we can tailor-make and mobilise training initiatives to sites such as Northgate,” Thomas says. “Determined to be part of the skills shortage solution, we’ve established an on-site operator training program that is supervised by senior operators and engineers.

“We’re currently sponsoring two trainees who will end up with certification in water and wastewater treatment operations, leaving them with a strong combination of hands-on experience and e-learning.

“Once these first round of trainees have completed their courses, they’ll take up full-time operator roles at other sites, where their training can continue as the business continues to grow. The ‘home-grown’ approach to training is a big win-win for our employees and our clients.”

REMONDIS Australia’s wastewater team provides water supply and wastewater treatment solutions for public and privateowned infrastructures – including all aspects of operations and maintenance, engineering design concepts, processing methodologies and regulatory compliance.

Across Australia, REMONDIS has more than 100 on-road liquids assets, ranging from mini liquid tankers to B-double liquid tanker combinations, and heavy industrial vacuum equipment for hydro excavation and drain cleaning.

For more information, visit: www.remondis-australia.com.au

www.wastemanagementreview.com.au / WMR / 33

REMONDIS Australia’s Northgate water treatment plant was commissioned in May 2022.

For good measure

VEGA MEASURING TOOLS ARE ON THE RADAR OF MUNICIPAL COUNCILS KEEN TO SIMPLIFY COMPLEX WASTEWATER TREATMENT PROCESSES.

Wastewater treatment plants have traditionally relied on ultrasonic transmitters, bubblers, and floats. But what were once considered cutting-edge technologies, are being superseded.

As production processes become more complex in municipal and industrial wastewater treatment plants, it’s important that measurement technology used to control and monitor the processes is understandable and intuitive, says John Economos, VEGA Business Development Manager.

He says VEGA has set itself the goal of developing measurement technology that is easy to install and operate and offers maximum safety and reliability.

“Wastewater treatment plants around the world rely on VEGA measurement technology because they place importance on high plant availability, maintenance-free operation and accurate measurement data as the basis for automatic control of the various process stages,” John says.

“We’ve been supplying level and pressure sensors for containers, pipelines, filters, and reservoirs for decades.

“For more than 60 years now, solutions to demanding measuring tasks are being conceived and brought to realisation.”

VEGA’s pioneering approach to water treatment and industry technology is making waves across multiple municipal areas, as highlighted by a project at Talwood Water Treatment Plant for the

Goondiwindi Regional Council. John says the project was an example of a collaborative working relationship that has developed since 2015 when VEGA technology helped the treatment plant out of tight spot.

Goondiwindi Regional Council, in the Darling Downs region of Queensland, operates seven water treatment plants, five sewerage plants and 19 sewerage pump stations, all of which now have VEGA instruments installed.

The instruments are used for level and pressure reading at new and upgraded pumping stations, sewerage pumping stations, chemical tanks, and solids detection in liquids. Items include free-to-air radar sensors, hydrostatic transmitters, vibrations sensors and pressure transmitters.

John says the VEGABAR 38, is used extensively across Goondiwindi’s water treatment plant, and is a universal pressure transmitter with ceramic measuring cells for measuring gases, vapours and liquids up to 130°C.

While Goondiwindi previously used hydrostatic readers at its pump stations, the council began a process to replace them will radars. John says the radars provide simpler installation and maintenance, with accurate and up-todate readings.

Goondiwindi also operates several VEGAPULS 31s, ideal for non-contact level measurement of liquids and bulk solids in simple applications.

“It is particularly suitable for use in water treatment, storage tanks with acids, lyes and additives in all industrial areas, or for measuring levels

FEATURED TOPIC – WASTEWATER 34 / WMR / April 2023

The VEGABAR 38 is used extensively across Goondiwindi’s water treatment plant.

in plastic tanks from the outside through the tank wall,” John says.

He says VEGA technology too continues to evolve, evidenced by the introduction of Bluetooth wireless adjustments that allow instruments to be configured remotely.

Bluetooth integration also removes the need to download package software onto a laptop.

“Operators used to have to take their laptop to the instrument, use a devise to unscrew the head of the primary devise and run a small mini-USB port and cable into the laptop,” John says.

“With Bluetooth, however, operators can access their device remotely. It allows parameterisation, display and diagnostics from up to 25 metres, thus saving time and avoiding safety hazards.”

VEGA is active in more than 80 countries with a network of subsidiaries and distributors. The company and its products have all the necessary certificates and approvals for worldwide application including technical safety as well product and service quality.

For more information, visit: www.vega.com

The association for the battery recycling industry

Driving an Australian battery circular economy through recycling and reuse

For more information on commercial battery recycling services for any battery type including EV batteries visit our website www.batteryrecycling.org.au or email secretariat@batteryrecycling.org.au

AUSTRALIAN BATTERY RECYCLING INITIATIVE

“For more than 60 years now, solutions to demanding measuring tasks are being conceived and brought to realisation.”

John Economos VEGA Business Development Manager

VEGA equipment is used across all Goondiwindi Regional Council’s water treatment and sewerage plants and sewerage pump stations.

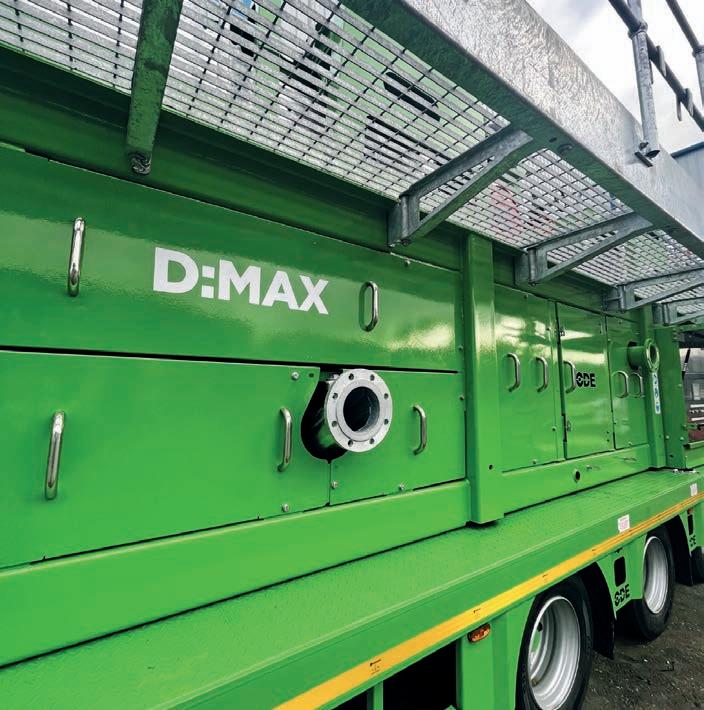

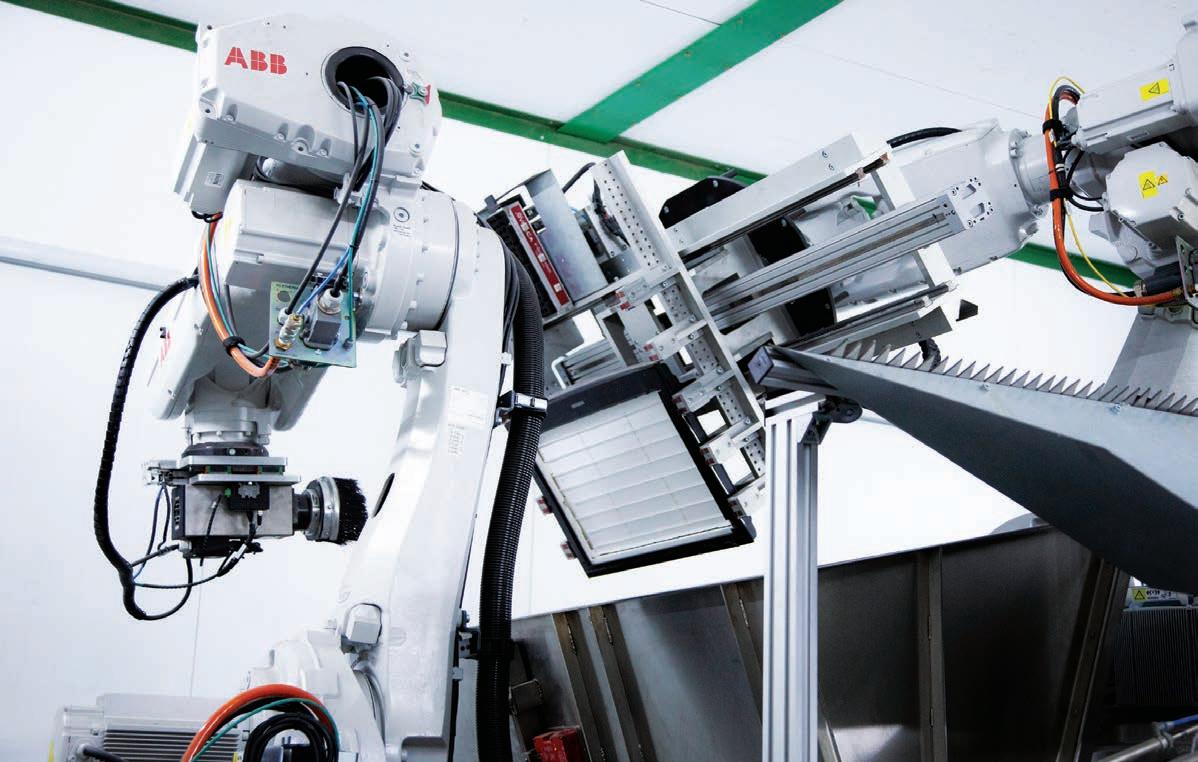

Taking it to the max

CDE’S D:MAX WASTEWATER PROCESSING PLANTS SET THE STANDARD FOR REMOVING SOLIDS FROM LIQUID WASTES IN-SITU.

CDE has been delivering wet processing solutions for 30 years and has more than 2000 systems in operation worldwide.

With a sole focus on wet processing, the company has earned a reputation globally for delivering game-changing solutions that empower customers to maximise their natural resources. The range of wastewater processing plants includes the MSU10, S:MAX, G:MAX and the D:MAX.

Mark Malone, Business Development Manager, CDE, says the D:MAX technology ensures maximum solids removal and dewatering of waste across a variety of troublesome waste streams in a highly mobile, trailermounted configuration.

“When you talk about the industry standard solution for the removal of solids from liquid wastes in-situ, the D:MAX mobile screening and classification system has been delivering for utilities and contractors for more than 15 years,” Mark says.

“The use of the D:MAX has a huge impact on the volumes of waste sent to landfill, it also means that the material that must go to landfill is safer and easier to handle and assists in protecting our water infrastructure.”

The D:MAX units are designed to remove contaminants such as Rag, a generic term for the fibre, paper and plastic-based materials; and Grit, a generic term for sand silt and stone material, that enter wastewater treatment from domestic, industrial, and urban sources. They use high frequency vibrating screen and hydrocyclone technology to separate both rag and grit contaminants.

ON THE MOVE

The D:MAX is a mobile, trailer-mounted, multi-stage separation and recycling solution used to process a variety of materials from the water and wastewater treatment process.

The contaminated wastewater is delivered to the D:MAX by means of a pump or by bucket via the onboard hopper and fed directly onto the first of two onboard high frequency vibrating screens.

Mark says this first screen is typically fitted with six-millimetre aperture media.

It separates the rag material as well as dewaters it and then discharges it directly at the end of the screen, typically into a collection bin.

The wastewater that passes through the first screen reports to a collection sump prior to being pumped to a specially configured hydrocyclone that diverts any remaining solids/grit material from the wastewater and onto the second of the high frequency vibrating screens.

The vibrating screen catches and dewaters this finer material before it too is discharged into a collection bin.

FEATURED TOPIC – WASTEWATER 36 / WMR / April 2023

The D: MAX is a mobile, trailer-mounted separation and recycling solution,

“Depending on the application, these discharged materials can be rinsed prior to being dewatered and collected as recyclable material in whatever grade is determined by the mesh size used in the screens,” Mark says.

“The overflow from the hydrocyclone is made available as recovered water to be reused in the process, returned to the main treatment plant, or to be further processed by a separate CDE water management system that includes aquacycle thickeners, buffer tanks and centrifuge/filterpress.”

Mark says the D:MAX plant features an ADR compliant trailer, is self-powered with an on-board generator, and incudes CDE hydrocyclone technology, CDE Infinity high frequency dewatering screens, a telescopic product conveyor, a modular, non-bolted, polyurethane screen media in both screens, efficient vibrating motors and an on-board panel.

The D:MAX has been successfully used by wastewater maintenance and drain cleaning contractors, and water utility providers for de-gritting of raw sewage; feeding screening and de gritting of tank/ digester clean outs, etc and de-gritting of lagoon sludge prior to digesters.

BENEFITS TO THE MAX

Mark says reduced operations costs are

just one of benefits for companies using the D:MAX.

“Carbon footprint and transport costs are reduced because the D:MAX can be easily moved around several sites if required, facilitating processing in-situ at a variety of locations. This minimises the transport movements required to bring waste material to a processing site and recovers 80 per cent of grit, meaning less waste to dispose of,” he says.

“Operations are accelerated by separating waste solids from liquid on site rather than transporting all waste off site.”

Mark says reduced solids passing through pumps, tanks and cyclones reduces wear and, as a consequence, the requirement for unnecessary maintenance. Grit, sand, and plastics are removed in the pre-treatment stage, maintaining capacity in tanks further down the treatment line for biomass power generation.

RETURN ON INVESTMENT

The D:MAX produces a dewatered grit product suitable for a variety of further applications. This material can represent up to 90 per cent of the total waste. Mark says recovery of this material alone has a huge impact on the volumes of waste to be sent to landfill.

“This dewatered grit from the D:MAX creates new markets for classified and dewatered products,” he says.

Mark describes the D:MAX as adaptable and easy to operate.

He says variable speed drives conserve energy and ensure the D:MAX system can adapt to accommodate surges of rag or grit and variation in feed material. It also comes equipped with its own onboard generator for ease of operation; providing additional flexibility on site to run ancillary equipment.

The telescopic product conveyor, which can be deployed on either side of the D:MAX, gives the D:MAX an added degree of flexibility to cope with the individual requirements of the site it is operating on.

Other features include standard compliant walkways to ensure quick, easy, and safe access for maintenance. The walkways and safety lights retract for transport.

CDE has an extensive network across Australasia of engineering and support professionals. They provide maintenance and technical support to customers operating the D:MAX and all other products within the CDE portfolio.

For more information, visit: www.cdegroup.com

www.wastemanagementreview.com.au / WMR / 37

Grit output from the D:MAX.

Mark Malone, Business Development Manager, CDE.

Predict and protect

IFM’S AI-ASSISTED MAINTENANCE TOOL PROVIDES REAL-TIME INSIGHTS TO HELP SAFEGUARD WASTEWATER TREATMENT PLANT ASSETS.

The cost of air compressor leaks can be significant for any wastewater treatment facility – not only is compressed air wasted, but the energy bills and toll on the equipment can be expensive.

Leaks trigger a drop in system pressure, preventing compressors from providing the necessary suction pressure for effective removal of wastewater. Additionally, leaks will cause an air compressor to cycle more regularly, incurring more maintenance and potential unplanned downtime.

Which is why Freddie Coertze, National IoT Business Manager at ifm Australia, says the modern treatment facility needs predictive maintenance tools to get the insights required to protect assets.

“Why does the modern facility need data science tools to prevent compressed

air waste? Because a compressor doesn’t run on load all the time,” says Freddie.

“It runs on variable load depending how much the facility needs. To fully understand how the asset is performing, data needs to be collected from the equipment and analysed – but this is where there is a difference between solutions available.”

The ifm moneo platform has been designed to provide real-time insights using artificial intelligence (AI) and other in-built smarts.

“This is an AI-assisted, self-service predictive maintenance tool,” says Freddie. “It makes it very easy to harvest the data from a complex system, putting the power back into the hands of the business so they can achieve better productivity at their plant.”

To elaborate on his point, Freddie refers to a real example of where moneo has been used to monitor and improve an air compressor.

“All that is required for this set-up is the moneo platform, which comes in the form of an IPC unit that we provide,” he says.

“This is very easy to install and doesn’t require going via an IT network to install device software. This links to an IO Link master which collects data from the sensor devices, and on this air compressor example we have flow meters, humidity, temperature, pressure and vibration sensors as well as a current transmitter to see how hard the compressor is working.”

According to Freddie, the moneo software will draw on historical data to create set parameters in which the compressor should be working, along with the live-streamed data to provide an analysis. It does this through the use of AI algorithms and machine learning.

“In the case where we monitored an air compressor at a site, the moneo platform determined that the compressor was running at a loss and consuming more energy than it should, which was especially evident when the plant was shut for the weekend,” says Freddie.

“Because the solution gives a holistic picture of the whole asset, we were also able to predict a future failure. This was easily remedied without any major consequences.”

While an air compressor is a strong example of where efficiency gains can be easily obtained, Freddie says that the moneo data science tool will provide greater predictability of all assets in a plant. Importantly, he notes that the moneo

FEATURED TOPIC – WASTEWATER 38 / WMR / April 2023

The moneo platform is agnostic and can be integrated with existing systems.

platform is agnostic and can be integrated with existing systems.

“To protect, you need to predict, but the difference is that now we can harness the benefits of AI to make this a simpler process for any wastewater treatment or processing facility,” he says.

“With moneo, we provide a prepackaged self-service kit that you can expand on, depending on your changing requirements.

“Significantly, this platform is a middleware that can sit between your sensor level and a higher end system such as Scada. And with the in-built AI and automated machine learning, you don’t need to involve a data scientist to get realtime, actionable insights.”

For more information, visit: www.ifm.com

REUSE REPURPOSE UPCYCLE Elecsome 14a Velore Road, Kilmany, VIC, 3851 (+61) 3 9041 2829 info@elecsome.com elecsome.com World's First Nano Engineered Concrete Aggregate A company leading the way in recovering and upcycling of decommissioned solar panels Developed through CRC Research collaboration with University of Melbourne & RMIT

Predictive maintenance tools can help protect wastewater treatment plant assets.

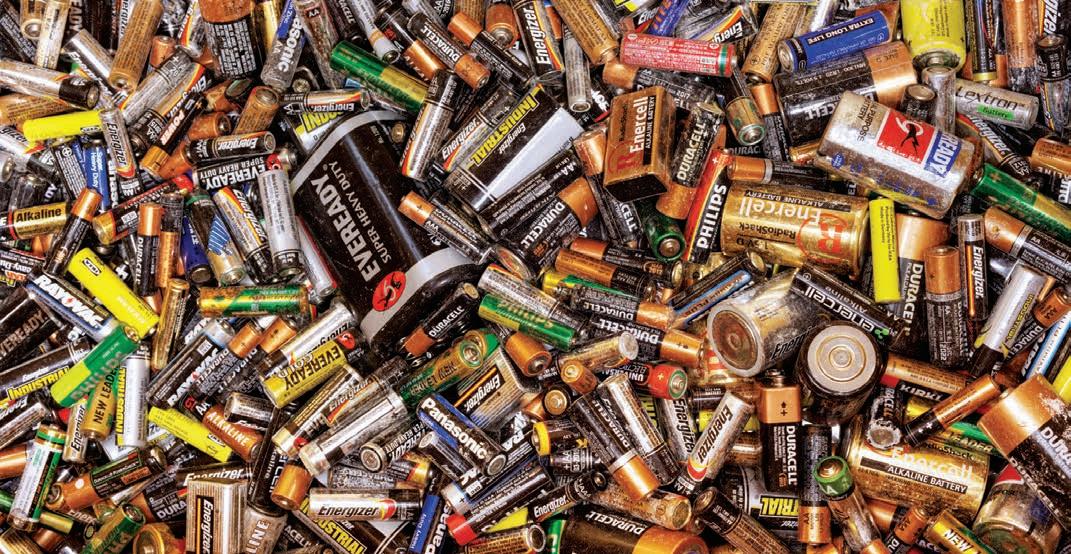

Battery-powered

Recycling is the starting point in achieving a circular economy for battery manufacturing, says Katharine Hole, Chief Executive Officer of the Australian Battery Recycling Initiative (ABRI).

Katharine says industry innovation and increased investment in processing used batteries, research and development, and technology to transform recycled materials to cathode materials, is evidence of the importance of a strong battery recycling sector in Australia.

These trends are being mirrored overseas where they are supported by large-scale public sector funding.

“It’s the bridge between mineral and cathode recovery from used batteries through to chemical refining and active materials manufacturing for batteries,” Katharine says.

“Materials produced from recycled lithium and nickel metal hydride batteries have 38 per cent lower greenhouse emissions than virgin materials. While spent batteries require significantly less resources to obtain one ton of battery-grade cobalt or lithium.”

Australia’s battery recycling sector is quietly leading the charge to establish itself as an innovation hub, and ABRI is a key part of the revolution.

ABRI was formed by a group of battery manufacturers, recyclers, retailers, government bodies and environment groups to promote the collection, recycling, and safe disposal

of all batteries. It now has more than 50 members committed to the battery circular economy journey, including nine companies in lithium recycling – from fully operational through to start-up – six lead acid battery recyclers and two zinc carbon/alkaline battery recyclers. These companies operate across Australia.

And yes, there is recycling of EV and energy storage batteries to recover critical minerals including cobalt, copper, nickel, graphite and lithium.

Katharine says battery recyclers, vehicle and battery original equipment manufacturers (OEM), renewable energy investors, mining and mining equipment, technology and services (METS) companies, and the university research sector are collaborating on research and proof of concept to expand battery recycling and reuse.

“These companies recognise the groundwork needs to happen immediately to deliver their circular economy and zero emissions goals,” Katharine says.

She says the launch of B-cycle, Australia’s battery stewardship scheme, was the first step change for the industry. In the first year of operation the collection rates for small batteries increased from eight per cent to 16 per cent.

The next step change is readiness at scale to recycle the projected 3600 per cent increase in lithium battery volumes over the next decade coming from EVs and energy storage systems.

Katharine says ABRI’s growing membership base includes those who recycle lithium, lead acid, alkaline and zinc carbon batteries for use in new batteries and other materials such as lead, zinc, and green cement.

There’s also collaborative work across ten Australian universities and research centres to improve the sustainability of recycling processes and develop patents to provide quality alternates to virgin mined materials.

At the same time, ABRI members are developing solutions for battery reuse – refurbishment of ten failed nickel metal hydride batteries can return six or seven of these batteries to the road. Companies are also working on reuse of lithium EV batteries to create energy storage systems.

But while industry is preparing for a clean energy future, Katharine says there are challenges emerging, including the need to invest now to be ready at scale when batteries come through over the next decade.

AUSTRALIA’S BATTERY RECYCLING SECTOR IS ESTABLISHING ITSELF AS AN INNOVATION HUB. KATHARINE HOLE, CHIEF EXECUTIVE OFFICER OF THE AUSTRALIAN BATTERY RECYCLING INITIATIVE, PROVIDES A RUN-DOWN OF THE LATEST DEVELOPMENTS.

FEATURED TOPIC – BATTERY RECYCLING 40 / WMR / April 2023

Katharine Hole, Chief Executive Officer, Australian Battery Recycling Initiative.

ABRI hopes the National Battery Strategy, which was opened for consultation in early 2023, will recognise the critical role of the sector and prioritise recycling of batteries in Australia where there is available capacity, underpinned by locally developed technology and innovative processes.

ABRI members hope the strategy looks at minimising regulatory costs and red tape, where it’s safe and sustainable to do so. Katharine says a current ABRI member survey shows that inefficient and conflicting regulatory processes are currently a barrier for business.

Funding for research and proof of concept work, including capital expenditure to support commercialisation of technology in sustainable metals recovery processes and secondary industries, is also key.

“The battery recycling sector is driving innovation in packaging, fire safety, monitoring, AI and robotics,” Katharine says. “The sector has broader manufacturing opportunities than solely undertaking metals recovery.”

She says consistency with policy developments and regulation overseas, such as producer responsibility and battery material traceability rules, should be considered to maximise and leverage existing opportunities. And Australia should be promoting the availability of Australian recycled critical minerals and battery materials for use as recycled content in new batteries in other countries such as Europe and India.

“Australia has a unique opportunity to drive the battery recycling revolution,” Katharine says.

“Cross sectoral collaboration and investment is naturally emerging as sectors bring their skills and technical knowledge to take advantage of opportunities arising from batterydriven electrification.”

She says the collaboration is already resulting in a growing relationship between mining/renewable energy companies and battery recyclers; as well as emerging commercial relationships between OEMs and battery reuse businesses to lead repurposing of grid connected energy storage batteries from EV batteries.

Battery recyclers and research institutions are developing proprietary recycling processes and supporting technologies such as AI, robotics, and fire safety.

“Companies are applying for patents and looking for opportunities to commercialise research locally and export,” Katharine says.

“Companies in the scrap metal collection industry sector are building recycling facilities and drawing on their existing networks

to safely and sustainably collect and recycle batteries.”

ABRI is also working with the Battery Stewardship Council, the operator of B-cycle, and the Australian Battery Industry Association (ABIA). ABIA and ABRI have a statement of collaboration to drive continuous improvement in battery quality, industry standards and further development of world class circular economy practices.

A list of commercial battery recycling services is available on ABRI’s website.

ABRI will host its first battery recycling conference later in 2023. Further details will be forthcoming.

For more information, visit: www.batteryrecycling.org.au

www.wastemanagementreview.com.au / WMR / 41

Battery supply chain and feedstock from recycling.

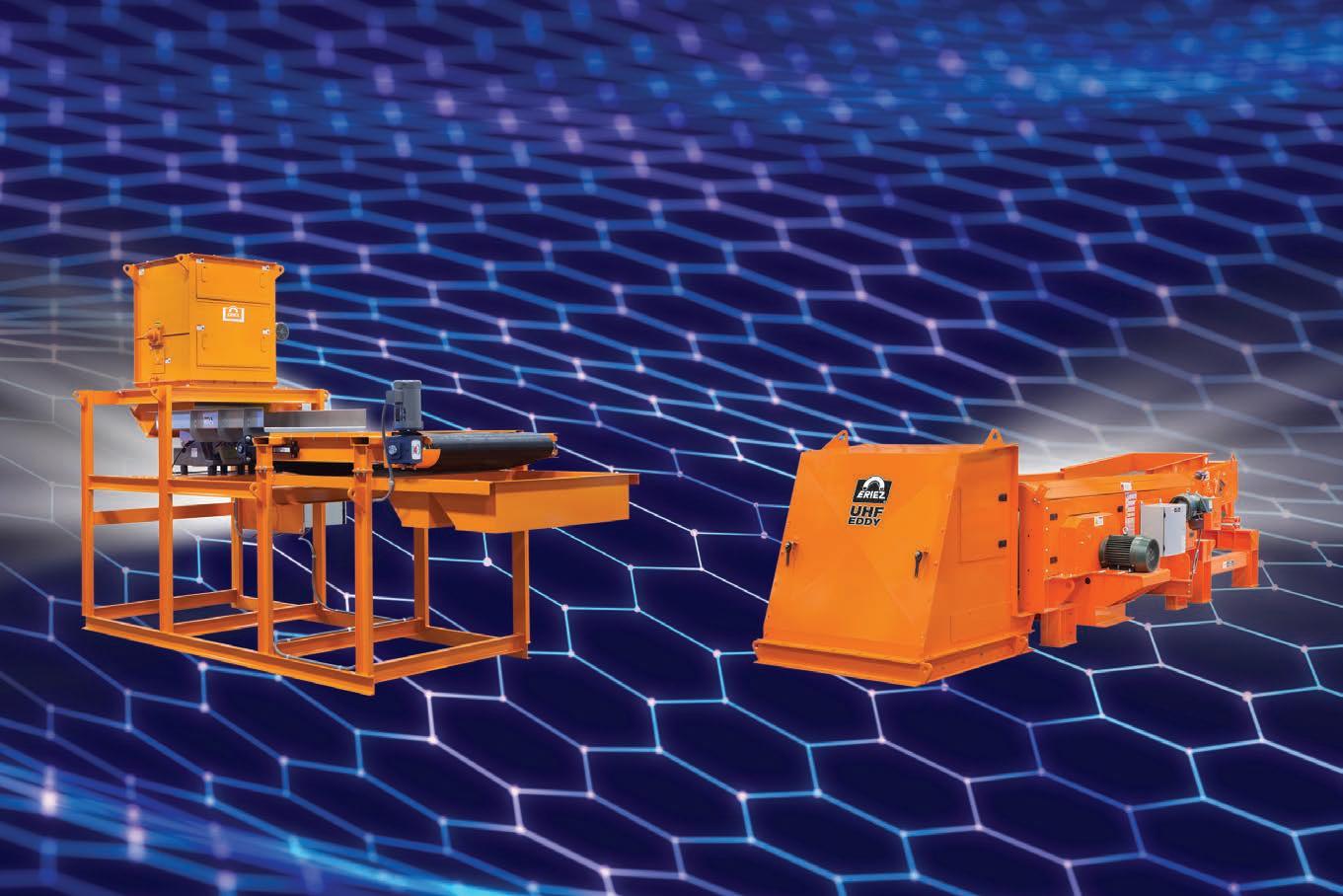

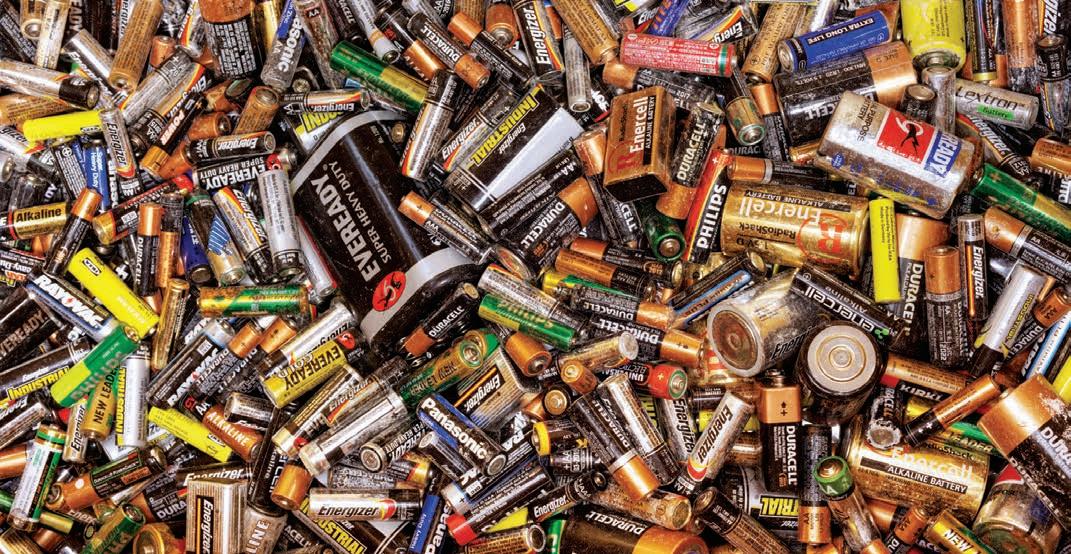

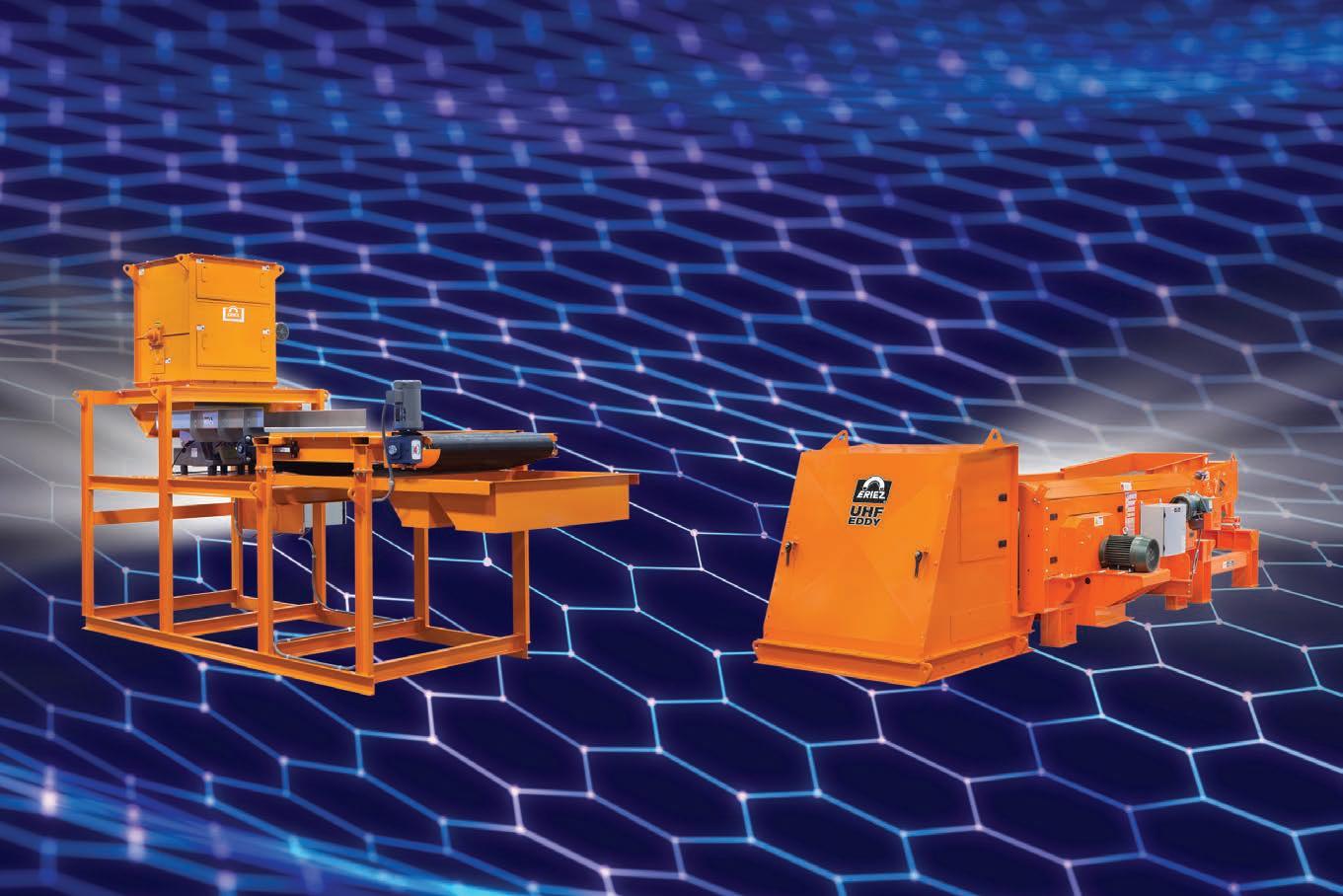

Cell respect

JONATHAN SCHULBERG OF ERIEZ-AUSTRALIA TALKS ABOUT THE UNIQUE CHALLENGES OF BATTERY RECYCLING, AND HOW ERIEZ SEPARATION EQUIPMENT CAN HELP.