Renewed FOCUS

Fieldmans Waste fast-tracks circular economy ambitions with a new recycling plant

FEATURES

Plastics payload

Safety by choice

Flip the narrative on mattress waste Munich calling

PROUDLY SUPPORTED BY:

Fieldmans Waste fast-tracks circular economy ambitions with a new recycling plant

FEATURES

Plastics payload

Safety by choice

Flip the narrative on mattress waste Munich calling

PROUDLY SUPPORTED BY:

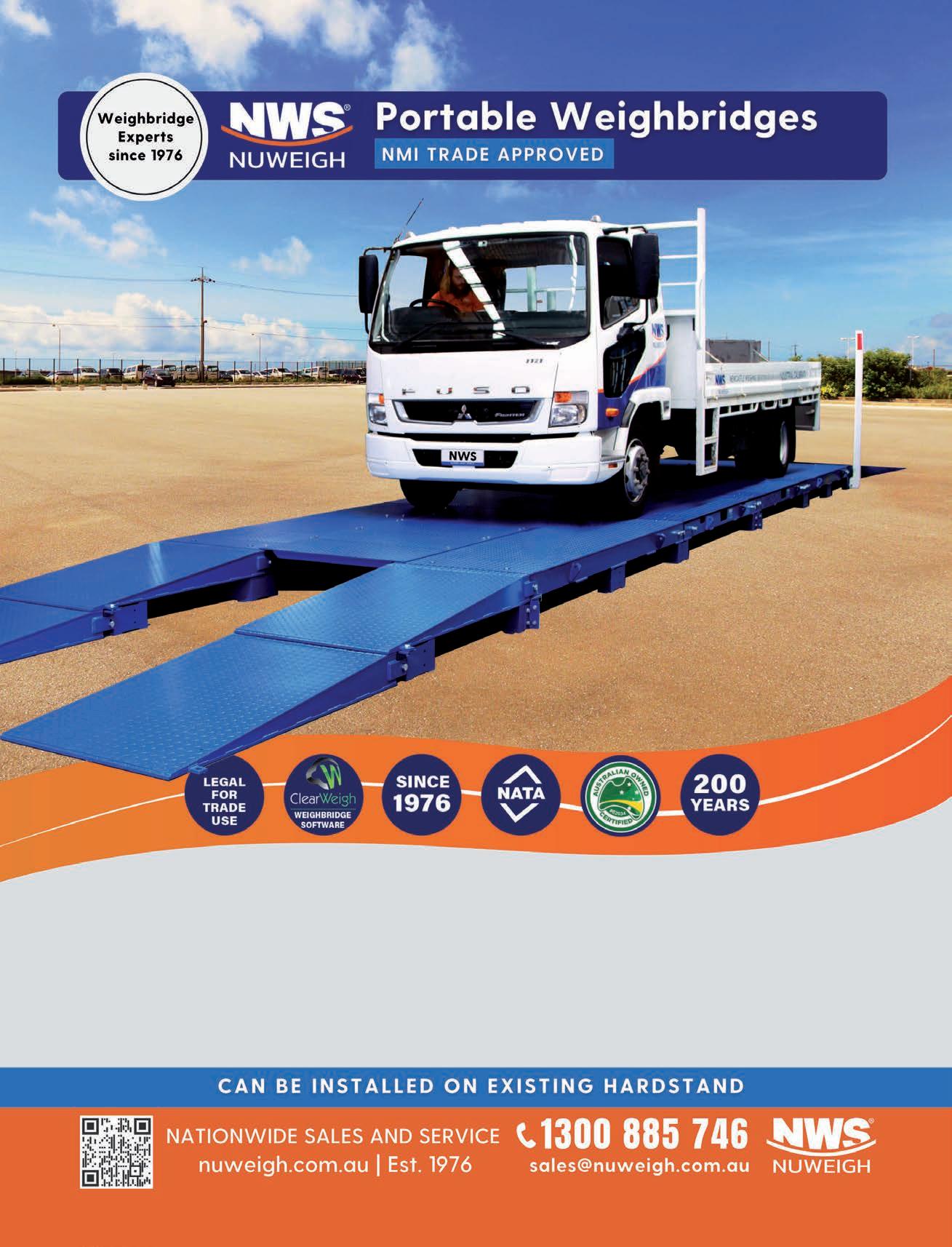

Quality and versatility you can rely on

This machine is truly an all-rounder.

Komatsu’s WA270-8 Wheel Loader offers customers an outstanding combination of stability, breakout power and tractive effort. Perfect for waste and recycling applications, you can enjoy the benefits of first-class comfort and safety.

06

Should Australia introduce a tax on plastic packaging waste that is not recycled?

13

How technology is transforming the recycling industry.

17

Altero pelletising lines are designed to balance efficien, costs, and service for plastics recyclers.

20

Closing the loop on post-consumer and difficult to ecycle plastics.

23

Aerofloat suppots clients through its specialised after sales service.

27 BODY

Ground-breaking technology offer hope of ridding national waterways of PFAS.

31 ACCELERATING THE EFW REVOLUTION

Veolia is set to play a key role in Australia’s energy from waste operations, with three facilities coming online in 2024.

A new construction and demolition recycling plant fast tracks the circular economy ambitions of a Victorian business.

“WE’VE BEEN ABLE TO RECOVER MORE OF THE WASTE STREAMS WE ALREADY HAD, CREATE EFFICIENCIES WITHIN THE BUSINESS AND A BETTER ENVIRONMENT FOR EVERYONE WORKING IN THE YARD.”

- Dylan Mansfield, Fieldmans Waste

Veolia is set to play a key role in Australia’s EfW operations.

34

Introducing Ecobatt’s battery safety bin for mixed household batteries, power, efficiency andersatility.

36

Why Allu buckets are a key element in Enviropacifi’s remediation applications.

38

Liverpool City Council flips th narrative on mattress waste.

41 PARTNERING FOR SUCCESS

A look at the long partnership between Komatsu and Cleanaway.

44

RecycleSmart continues to evolve, developing new solutions for current problems.

The nwest machinery and technology from Komptech CEA will be on display at IFAT Munich 2024.

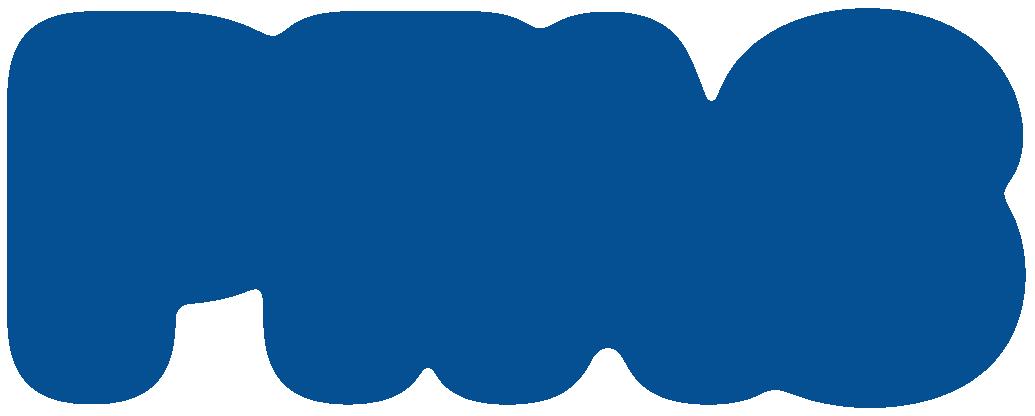

Taking weighing systems to the next level.

51 INVESTING IN VOLVO

A look at Wanless Waste Management’s journey with Volvo Construction.

54 WASTE EXPO AUSTRALIA

Are you ready for Waste Expo Australia 2024?

Regulars

54 PRODUCT SPOTLIGHT

57 LAST WORD

After years of reporting on the challenges of single-use plastics in the industry, Prime Creative Media is playing a proactive role in it, by taking its first step in educing its own use of the troublesome waste stream.

The company is the firstustralian publisher to send paper-wrapped magazines at scale, in partnership with its printing and mailing supplier FSG.

Based in Bayswater, Victoria, FSG purchased the country’s first eer paperwrapping mailing machine in January this year. Its ability to wrap publications in paper will eliminate plastic wrapping for several Prime Creative Media titles including Waste Management Review.

“It’s the evolution of the mailing industry to abolish the use of single-use plastics in mailing magazines,” says Michael Murphy, owner and director of FSG Mailing.

Murphy came across this technology through his supplier UK company Norpak, who previously supplied his plastic wrapping machine.

“They intoduced us to the idea because they saw what was happening in the European Union with the phase out of single-use plastics,” Murphy said. “With the Australian Government making similar moves towards a full phase out of single-use plastics, we think that this machine will be the catalyst to push the movement along in the mailing industry.”

It’s not just the mailing industry that is pushing the movement along. As this edition highlights, technology is transforming the waste and resource recovery industry right across the supply chain. We talk with some of the decision makers who continue to innovate and work toward better outcomes.

Better outcomes are also a primary focus for brothers Jake and Dylan Mansfield who have commissioned a new recycling plant for construction and demolition waste at their Victorian site.

Raising the stakes in Victoria’s transition to a circular economy, the brothers share their plans for the future in our cover story.

Happy reading

Lisa Korycki

Lisa Korycki

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Chris Edwards chris.edwards@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGN

Louis Romero, Kerry Pert

BRAND MANAGER

Chelsea Daniel chelsea.daniel@primecreative.com.au

p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

ACCOUNT CO-ORDINATOR

Marina Milisavljevic marina.milisavljevic@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

P: +61 3 9690 8766 enquiries@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. The rights of efusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. The ditor reserves the right to adjust any article to conform with the magazine format.

COVER

Cover image: Prime Creative Media

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The ditor welcomes contributions but reserves the right to accept or reject any material. While every effot has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. Th opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

THE

The Breakdown is a monthly column giving industry leaders and decision makers a chance to share their views on topics central to the sector.

This month we asked: : “Should Australia follow Europe’s lead and introduce a tax on plastic packaging waste that is not recycled?”

A plastic tax in isolation is not considering the systems wide transformation that needs to happen to create circularity for plastic packaging. Let’s prioritise fixing the economics, as they drive action. Investment is crucial for system transformation, and this needs to be backed by policies and regulation. In the absence of mandated obligations on recycled content, the linear economy remains more profitable, and so will continue. We need both the “carrot” (incentives) and the “stick” (a disincentive) to drive action. Whether the stick is a plastic tax (like the UK) or mandated recycled content in packaging (like the EU), Australia needs to consider the whole value chain, both investment and policy, to drive meaningful change. Industry requires clear mandates to unlock investment capital and we need new technology and infrastructure, such as advanced recycling, to unlock a circular economy for plastic packaging

Australia will miss at least two out of the four 2025 National Packaging targets, so a strong market signal is needed to increase levels of recycling and the use of recycled content in plastic packaging. To meet our targets, we also need to secure self-sustaining end markets for recycled content and incentives to produce that outcome, whether a tax levy or fee in a mandatory product stewardship scheme.

Any fee or tax should be varied according to weight, whether an item is disposable or recyclable, how much recycled material it contains, or other qualities that will encourage recycling markets.

The reason this levy makes sense is when we make packaging recyclable, we reduce costs to local authorities who foot the bill for waste services, landfilling and cleaning up litter. Dealing with our waste according to best global practice means reducing cost of living pressures.

Plastics add great value to our society. However, the escape of plastic (and often single-use plastic packaging) to the environment is a real problem. Stopping plastic pollution requires four key actions: bans to eliminate unnecessary plastic packaging, better collection and recovery options (e.g. CDS systems), significant increases in pollution fines and enforcement and international aid to assist other countries to collect and safely dispose/recycle plastic waste. Financial incentives are always the most economically efficient ways to drive behaviour change and system reform. So, as long as the funds raised by a plastic levy, are directed to these four goals, then it would help reduce plastic pollution.

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2024, please get in touch with Editor, Lisa Korycki lisa.korycki@primecreative.com.au

Richard Kirkman Chief Executive Officer Veolia

Andrea Polson General Manager – Stakeholder Engagement & Communications Licella

Dimitris Dimoliatis MRA Consulting

Richard Kirkman Chief Executive Officer Veolia

Andrea Polson General Manager – Stakeholder Engagement & Communications Licella

Dimitris Dimoliatis MRA Consulting

A new construction and demolition recycling plant is fast tracking the circular economy ambitions of a Victorian business.

Jake Mansfield describes Fieldmans Waste Management as a small family business, but he and brother Dylan are thinking big.

In September 2023, Fieldmans Waste commissioned a multi-million-dollar recycling plant for construction and demolition (C&D) waste.

The static plant y M&K Recycling Systems adds to the growing number of

successful C&D and construction and industrial processing systems operating in Australia.

Within months the plant has increased timber recovery by about 50 tonnes per month and non-ferrous metal recovery has doubled. And it’s opened more market opportunities.

“It’s exceeded expectations,” Dylan says. “We’ve always had a handful of

external customers who bring waste to us, but we didn’t realise how much this plant would speed up processes.

“We need more waste than what our trucks can collect.”

Every year in Australia, the building industry produces 27 million tonnes of waste, according to the National Waste Report 2020 – equal to 44 per cent of all waste generated throughout the country.

Based in Dandenong South, Fieldmans Waste provides construction, demolition and commercial rubbish removal to building and construction companies throughout Melbourne.

Recovered materials, including masonry, clean timbers, cardboard, plasterboard, metals and soil, are separated and sent offsite to end processors.

Jake says an increase in the need for sustainable waste solutions, and the potential to recover vital resources, drove the decision to invest in new infrastructure.

He and Dylan looked at what was being achieved overseas and say they didn’t want to sit idle. They eached

out to specialist equipment supplier FOCUS Enviro to design, construct, and commission a new waste recycling plant that would increase the waste they could process and provide opportunities to grow.

FOCUS Enviro has been involved in some of the largest resource recovery projects in Australia and has a reputation for providing turnkey, tailored solutions. Jake says FOCUS

Enviro’s expertise gave them confidence they were going down the right path.

“We’ve had a good relationship with them right from the start,” he says. “It was evident that the level of detail and what we could achieve was just as important to them as it was for us.”

Following multiple site visits to gain an understanding of the project, and using 3D animation and drawings, FOCUS Enviro custom-built a

plant that not only suited Fieldmans Waste requirements but was able to fit within the constraints of its existing site.

Key considerations for Jake and Dylan were the flw of materials, machinery and trucks around the plant, and the health and safety of staff

Prior to the plant being commissioned, staff ere working on the floor of the shed, manually picking up and sorting waste. With the new plant, staff ae positioned in a purposebuilt sorting cabin, standing up and sorting the waste as it comes by on a conveyor belt.

A better working environment, it’s also helped improve recovery rates. Dylan estimates the plant will process up to six times more waste than currently handled. While he’s aiming to run the plant fie days a week, it’s now operating three times a week because they’re running out of waste.

“Before one load might have taken half an hour to 45 minutes to sort through, now as quickly as we can load the waste into the machine it’s being processed,” he says.

“Previously we were losing a lot of non-ferrous metals because they were getting lost in diffeent streams, but this machine is picking up every nut and bolt.

“We’ve been able to recover more of the waste streams we already had, create efficiencies within the business and a better environment for everyone working in the yard.”

The bothers say the M&K product stood out because of the quality of the build and safety aspects such as walkways, access points and operator control systems. All components are also made in house by M&K – from start to finish – steamlining the process but also ensuring all components are compatible.

The plant arried in about 16, 40-foot shipping containers and was pieced together onsite while Fieldmans Waste continued operations.

“To watch it come together is astonishing,” Jake says. “Every piece fits perfectly. It doesn’t have anything on it that doesn’t need to be there.

“It’s compact and does everything we need it to.”

The plant was seeral years in the making, from start to commission, and Jake says that over that time Fieldmans Waste and FOCUS Enviro have a strong relationship that goes beyond a typical

sale. Both he and Dylan are impressed by the team at FOCUS Enviro for its knowledge in the product, after sales support and investment in their future.

The FOCUS nviro team was on site when the first waste was un through the plant and continues to be a phone call away. Since the plant was commissioned, it has arranged several interstate visits to see the plant in operation.

“The’ve gone beyond what they had to,” Jake says. “FOCUS Enviro saw our growth potential and helped us unlock it. The’ve opened a new window for us

because of what the recycling plant is capable of.

“We know we’ve got some good power behind us to go and look at other avenues to service our recovered materials and target a whole diffeent division of the market.

“With Australia transitioning to a circular economy and shifting away from landfill, e can stand proud that we’re doing something legitimate about this and it’s just the beginning.”

For more information, visit: www.focusenviro.com.au

The static recycling plant streamlines the sorting process of construction and demolition waste streams.Odour optimised, energy efficient, recyclable. And for specific applications: super clean and food contact compliant. Recycled pellets of the future can do more. Get more out of your post consumer material flow with innovative EREMA technologies featuring digital assistance systems. More quality, more productivity. For a better end product. Take the new energy saving dual filtration solution INTAREMA® TVEplus® DuaFil® Compact, for example, as well as proven ReFresher anti odour technology and the smart predictive maintenance tool Predict:On. Enter this future right now with EREMA. Enter the new era of recycling.

OFFICIAL AUSTRALIAN DISTRIBUTOR:

39 Arbor Way, Carrum Downs, VIC 3201 info@cemactech.com

+61 ( 0 ) 3 8400 6066

cemactech.com

Technology is transforming the recycling industry right across the supply chain. The latest balers ensure waste is no longer dead weight.

Sophistication in recycling and resource recovery has grown exponentially in Peter Jessup’s 10 years at Wastech Engineering.

The usiness Development Manager for Victoria and Tasmania says people now have a greater appetite for recycling.

“Awareness around the importance of recycling continues to grow across all facets of waste,” he says. “And we’ve seen greater production of those products that come from recycling.

“Given the importance of the industry, innovation within it has grown enormously. Certainly, the ability to deal with the various waste streams in an efficient way is ineasing all the time.”

Peter says one of the best aspects of Wastech, which has been at the cutting edge of Australian engineering innovation for the past 30 years, is that it can provide

advice and componentry to handle every waste stream – from plastics to glass and aluminium.

It’s built a reputation on technologyenabled solutions, driven by the goal of environmental sustainability. But technology is not all about producing a better recycled product. Peter says the need for efficiency is opelling advancements right across the supply chain, including storage and transportation.

One of best ways to be efficient whe transporting recyclable waste is to bale it.

“With a compaction rate of up to 5:1, the efficiencies gainedy baling are enormous,” Peter says. “We have a huge challenge in Australia in that we produce enormous amounts of waste, but the tyranny of distance works against us – you have to be able to transport the waste to infrastructure that can process it.

“The costs of transpot – fuel, maintenance, labour – are increasing all the time. Baling waste means you optimise truck loads.”

Bramidan balers, he says, are the Rolls Royce of balers.

As the exclusive distributor for Bramidan in Australia, Wastech has sold about 2000 balers into the national market, earning global recognition from the Danish manufacturer.

The balers, designed to handle plastics, cardboard and paper, are favoured by large retailers in Australia because of their quality, safety, and longevity.

“The’re very easily installed and commissioned, easy to use, are very safe and a very consistent piece of engineering,” Peter says.

“The engineering that goes into these is second-to-none. The flo, or welding

won’t split, and the cylinders used are of the highest quality.

“The’re extremely efficient at oducing a very solid bale. They will gie you the exact bale weight every time, all you need to do is keep loading it.”

Peter says Bramidan continues to improve its balers from every angle –structure, price point, and efficiency – an adapts to market requirements.

In the past fie years he’s seen the plastics recycling industry change from accepting clean feedstock only, to transforming contaminated plastics into new products, and balers developed to cope with harder plastics.

Typically, soft permeable plastics are ideal for baling and compacting because they have very little memory and will stay compacted. By comparison, a polymer with a ‘strong memory’ can spring back into shape.

Peter says he’s seen a Bramidan baler create an ingot out of scrap aluminium.

“It’s a relatively simple piece of machinery but they’re improving it all the time,” he says.

“The ery first balers would’t have had the power that these ones have. One of the largest B50 models today will provide 750-kilogram bales. That puts it at the pinnacle of weighted bales in Australia.”

Robotics are also adding a new level of quality and consistency. Bramidan has introduced an electronic mobile interface that can track the activity of each baler by site, ensuring a high level of safety and ease of use, and to make them attractive to large-scale operations that have multiple sites.

Key metrics such as what balers are performing well and how many are being produced is sent to a central database that owners can dial into. If a company is running 20 balers around the country it’s important to be able to ascertain how much waste is coming into each facility, identify any changes and why.

But not everyone needs the Rolls Royce. Wastech works with customers to

“With a compaction rate of up to 5:1, the efficiencies gained by baling are enormous.”

Peter Jessup, Business Development Manager for Victoria and Tasmania, Wastech.

ensure they get the right baler for the job. Consultation is non-negotiable for Peter.

“Our customers need something that’s easy, efficient to use and is the righ size for their job but the fundamental requirement is for them to be able to get their waste out to market,” he says.

“We need to understand what their waste needs are before we even start to think about what machinery they need. Tha’s where Wastech expertise and advice in our products comes in.”

That advice extends beond the initial sale. Wastech has a 24/7 help desk and can set up automated scheduling agreements for machine servicing. It will also send a service team to a site as soon as possible if necessary. Case in point, a technician was on site to help a customer

on Christmas Day, something Peter says is not unusual.

“It’s what we’ve got to do,” he says. “It’s a growing part of the business because we understand peoples’ needs and how critical it is to be able to deal with their waste efficiently.

“The people e deal with, recyclers, manufacturers, schools and even hospitals, have an expectation of an immediate turnaround and service because once they stop dealing with their waste, it can back up their production line.

“Waste is a consequence of growth; you must be able to deal with it. If you have the right equipment, you can.”

For more information, visit: www.wastech.com.au

The new plastic manufacturing paradigm: The success story of a reuse and recycle strategy.

In an era where sustainability defines the future of manufacturing, the plastic industry faces a pressing challenge: how to make production processes not only more efficient and ofitable but also environmentally responsible.

A transition towards higher-value, easily recyclable plastics is a key plank of the National Plastics Plan 2021, a roadmap to addressing the plastics challenge and reducing waste to landfill.

According to the plan, Australia is missing out on an estimated $419 million of economic value each year by not recovering all polyethylene terephthalate (PET) and high-density polyethylene (HDPE).

Recognising a need to increase resource recovery and reduce a reliance on virgin products, the Recycling Modernisation Fund (RMF) was established to support investment in new infrastructure to sort,

process and remanufacture materials such as mixed plastic, paper, tyres, and glass, and implement technologies necessary to close the gap in the circular economy.

Realising this need and opportunity, MECBIO was established with the aim to help clients achieve their sustainability goals through advanced technology and industry-specific envionmental services.

MECBIO designs, builds, and services mechanical and biological waste recovery facilities to convert wastes, including plastics, organics and construction and demolition waste, into new streams of use. The team has woked on some of the world’s most advanced treatment facilities and counts Soilco, Repurpose It, Western Composting Technology, and City of Newcastle among its clients.

It also provides a range of global best

practice sorting and processing lines, as well as specialist recycling equipment, to the local market.

“We partner with some of the world’s leading suppliers to assist Australian and New Zealand entities transition to the circular economy,” says Dean Dowie, Managing Director and Chief Executive Officer

One of those partnerships is with Spanish company Altero Recycling Machinery, which specialises in pelletising lines for waste plastics.

Altero machines are optimised to process a range of plastics from pre-washed agriculture film, to flexible packaging, contaminated post-consumer film, granulated plastic losses from injection, blowing and extrusion machines and food grade applications.

Dean says Altero’s line has revolutionised the production processes of Spanish plastic fabrication company Moyaplast, highlighting a future where sustainability and industrial success go hand in hand.

The journey began with the manufacturer’s ambitious goal to eliminate waste from its operations. In the competitive field of injection moulding, where precision and quality are paramount, the Moya brothers Manuel and David sought not only to reuse their internal scrap but also to enhance their product line by incorporating post-consumer recycled (PCR) materials, thereby contributing to a circular economy.

Moyaplast, with more than 40 injection moulding lines and a robust international presence, faced the dual challenge of managing industrial scrap and aligning with global sustainability trends.

The primay goal was to find a solution that could repelletise 100 per cent of their production scrap, thereby reducing waste and enhancing material use.

The next step of the initiatie was to take back manufactured products from customers once their lifecycle ended to recycle them and make new products, again embodying the essence of a circular economy. This pocess not only minimises waste but also maximises resource efficien.

According to Marc Costa Dalmau, Sales Director of Altero, ALTERO VELOX120 plays a crucial role in this cycle, allowing for the integration of both material sources into a constant stream of quality pellets. These pellets ae then reused in their injection lines, closing the loop in the production cycle and reducing their environmental footprint.

Marc and Dean agree the VELOX line, designed for versatility, efficien, and superior performance, stands out for its ability to process a range of materials, including both industrial scrap and PCR plastics. They say that by facilitating the integration of postconsumer PP (polypropylene) and HDPE

from washing plants, the VELOX line allowed Moyaplast to take a significant step towards circular economy practices and enhanced sustainability operations.

By choosing pelletising over shredding, Moyaplast avoids numerous challenges associated with the latter, such as dust generation, heterogeneous particle sizes, and feeding interruptions. Furthermore, the pelletising process introduces additional benefits, including impoved filtration, degassing, and the ability to add additives – enhancements that are not possible with shredding alone.

“This compehensive approach allows Moyaplast to improve injection cycles, overall performance and quality control.”

Altero’s plastic pelletising technology allows for the creation of high-quality recycled plastic products, contributes to a reduction of industrial plastic waste disposal costs, and creates added value in the form of a saleable product.

“This success stoy serves as a powerful model for the industry, demonstrating that it is possible to balance operational efficien, profitabilit, and environmental responsibility,” Dean says.

“The pessure and targets demanded by national and state regulations and industry standards in regard to environmental protection and waste minimisation efforts have

changed the playing field.

“Our mission is straightforward: To provide plastic recyclers and manufacturers with a solution that balances efficien, costs, and service without a hefty price tag and operational costs.”

MECBIO acts as Altero’s local partner in Australia, bringing best practice technologies and costeffectie solutions for plastic recycling requirements.

“Thee is no one-size-fits-all solution” Dean says.

“We adapt our machines to fit the unique requirements of customers, ensuring they get the most out of their investment while achieving their sustainability goals.”

For more information, visit: www.mecbio.com.au

New technology is closing the loop on post-consumer and difficult to recycle plastics.

An additional 650,000 tonnes a year of waste, including plastic, paper, glass, and tyres, will flood Australia’s recycling industry when the full waste export ban comes into effect in mid-2024, according to the Library of Congress.

Landfill will likely be the destination for many of the plastics, particularly film, without mechanical driers for a circular economy

Eric Paulsen, Managing Director CEMAC technologies, says the latest EREMA technology, the INTAREMA TVEplus, closes the loop on postconsumer plastics such as low-density polyethylene (LDPE).

“It’s the most advanced technology to take post-consumer and post-industrial

use film back to high end materials for reuse,” Eric says.

“While clear plastics and post-industrial plastics are relatively easy to recycle; contaminated industrial and postconsumer plastics can be difficult.ue to the specific design using continuous melt filtration and if need be, double filtration the extrusion process of the INTAREMA TVEplus can handle a much more difficult infeed, in combination with th correct sorting and washing technology.

“It can take a high level of difficul materials and process them back into other products.”

Heavily printed films, LDE washed flakes, polethylene (PE) film with paper labels, PE washed film flakes an pallet wrap can all be recycled with

the INTAREMA TVEplus. Serbian waste process Brzn Plast is using the technology to recycle film collected fom household waste to produce new films for various applications including for the construction industry.

Brzn Plast processes only LDPE and linear low-density polyethylene (LLDPE) waste. One hundred per cent of the recycled pellets are then used in the company’s own blown film line to produce PE film fom 35 to 500 micrometres.

“We don’t consider this to be waste, but raw material we can use again to make high-quality products, so it doesn’t end up in landfill or being incinerated” says owner Dejan Simic. “Of course, that only works with the right technology,

which we found in terms of extrusion at EREMA.”

Eric says the patented INTAREMA TVEplus extruder system with double filtration is a class of its wn when it comes to recycling heavily contaminated material otherwise be difficult to ocess.

Feeding is automatic and according to customer requirements. In the preconditioning unit the material is cut, mixed, heated, dried, pre-compacted and buffeed. Next the extruder is filled continuously with hot, pecompacted material.

In the extruder screw, the material is plasticised and degassed in reverse. At the end of the plasticising zone, the melt is directed out of the extruder, cleaned in the fully automatic self-cleaning filte, and returned back to the extruder.

The final homogenisation of the mel takes place after the melt filte. In the subsequent high performance degassing zone, the filteed and homogenised material is degassed. The melt is then conveyed to the respective tool, such as a pelletiser, at low pressure.

Additional technology such as pellet flusher and the efresher technology can be linked to the machine to eliminate the odours that can occur

when recycling post-consumer plastics, making the product suitable for consumer applications.

The INAREMA TVEplus is in use across Australia producing pellets for film plastic and non-bag applications. But the benefits go beond technological. Cost savings include reduced energy consumption – up to 25 per cent at Brzn Plast compared to operating its old recycling machinery – and less waste because of the quality of the recycled pellets.

“It’s the next step in plastics recycling and sets an example of the quality of recyclate that is possible,” says Eric.

“Post-consumer plastics is a big headache for recyclers. This is one piece of

the puzzle to avoid sending it to landfill. The eality is, you can make money with recycling, and you can save energy.”

CEMAC technologies, a distributor of EREMA products, brings together 30 years’ experience in engineering and supplying resource recovery technologies to Australia and New Zealand.

It can supply end-to-end solutions for varied waste streams including plastic, paper, metals, organics, wood, and industrial wastes.

A Melbourne warehouse supplies essential spares, engineering solutions and services across Australia.

For more information, visit: www.cemactech.com.au

The Coffs Waste Conference is the leading industry event for the waste management and resource recovery sector and is the one you must attend in 2024!

During this 3-day conference, you will be inspired, motivated and educated...all in a learning environment that can be tailored specifically to suit your needs.

• Hear from national and international industry experts

• Visit the extensive indoor and outdoor exhibition

• Network with other like-minded waste professionals during 3 social events over 3 days

• Watch the live broadcasts in real time, or at a time convenient to you

• Participate in interactive workshops and panel discussions

• Learn from our exhibitors and see their equipment in action

Mark your diary and register today. Numbers are limited!

www.coffswasteconference.com.au

(02) 6583 8118 | 0474 629 908

Major Sponsors: Hosted By: Organised by:

Supported by:

INTAREMA TVEplus extruder system with double filtration. Image: EREMA

INTAREMA TVEplus extruder system with double filtration. Image: EREMA

Obtaining the quickest return on your capital investment depends on how quickly operators can be up and running, and the volume of commodities that an operator can recover from their waste stream. EDGE Innovate’s range of mobile solutions are tried and tested, are quick and easy to set up, require no on-site civil works, represent a low capital outlay and are proven to achieve high commodity recovery levels.

Have you needed strong aftercare support and service after your wastewater treatment plant is built? Wastewater treatment specialists Aerofloat has made a name for itself in this space with satisfied clients across Australia.

General Manager of Aerofloat, Michael Anderson is proud of his team’s work in supporting its clients through its specialised Aftercare arm

“We design and construct wastewater treatment plants (WWTPs),” says Michael. “Following installation comes the necessary operations and maintenance requirement for that plant.

“While some of our clients have an experienced team with past knowledge of wastewater treatment equipment, we have clients for whom WWTPs are a new entity.

“We support our clients from that design process right through to the maintenance of their system.”

Aerofloat suppots its clients through scheduled servicing, asset-specific chat groups, remote monitoring, and onsite maintenance. The extent to which it supports each client is dependent on their needs and wants.

“Our servicing support extends beyond that technical advice and servicing,” Michael says. “We also have a comprehensive suite of chemicals and parts to ensure optimal performance of the WWTP. We can also operate the WWTP on behalf of a client, allowing them to focus on the production end of business.”

Michael says that the idea of providing a comprehensive Aftercare program

came about from supporting the assets Aerofloat built for its clients. owever Aerofloat is nw being sought out by companies housing non-Aerofloat WWTPs needing better servicing support, training for their staff and reliable chemical supply.

“Our growth has been exponential in recent years with clients requesting better chemical supply, WWTP upgrades and general wastewater infrastructure support,” he says.

“Companies that have systems that weren’t designed or built by Aerofloat come to us for upgrades to their existing infrastructure, optimising their WWTPs and creating a remote, online system to enhance operations.”

The chemicals erofloat supply via its Aftercare department meet the needs of WWTPs but also meet requirements beyond the wastewater industry.

“We’ve started selling chemicals for other parts of our clients’ facilities,” Michael says. “This is paticularly true for plastics recycling. We manufacture anti-foams and other chemicals that support the washlines, production end business and other facilities.”

Finding a gap in the market for chemicals optimised for wastewater treatment, Aerofloat ceated its own proprietary blends. Its chemical engineers have invested in significant

research and development in the wastewater chemical space, ensuring optimal chemicals for its clients including identifying new coagulant and flocculant blends that seve specific types of wastewater treatments.

“Our brand of flocculants is called AeroFloc,” says Michael.

The erofloat team prides itself in designing high-quality WWTPs with robust equipment and long operational life. It wants to be known as a provider of repute by installing longlasting equipment. However, there is equipment that has a shelf life.

“For example, we use a lot of helical rotor pumps,” Michael says. “Some components within those pumps need replacing regularly, such as the rotors. Even with our precise flw rates through those pumps, components need replacing.”

An aspect of the Aftercare service is having the stock to replace highwearing parts. Not only is Aerofloat an engineering office, but it also has me than 1000 square metres of factory space to manufacture and store its products. Michael says they have spare parts for every plant Aerofloat has built during the past 14 years.

The poper operation and maintenance of a WWTP is vital. It’s resulted in Aerofloat continuing to gow, with 35 staff nw on board, bringing with them a wealth of experience. These include automation experts, electrical, process and mechanical engineers, plumbers, electricians, and wastewater technicians.

“Our client retention rate is excellent as is our internal staff etention,” says Michael. “The erofloat team looks largely the same, just bigger. Everyone wants to be part of the journey with us, and we continue growing the business aggressively.”

This aggessive growth is geared toward cross-functional knowledge and giving staff the oppotunity to move up the pyramid. This generates moe understanding within the organisation.

“Whilst we grow our staff internall, we also bring in fresh ideas and experience from outside of Aerofloat. We recently hired an engineer with 20 years of membrane experience,” Michael says. “While the treatment of membranes is not a major part of our business, his knowledge of water filtration will be an impotant asset for us. While the core of our business is biological WWTPs, chemicals and DAF (dissolved air flotation), this nw team member can help us expand into new areas.”

Aerofloat has ecently received a large service contract for one of Sydney’s major road networks, where it provides chemical supply, technical support and consumables.

“Our staff ae doing routine checks of the assets in place,” Michael says. “Our remote monitoring systems are incomparable to others on the market and highly sought after. We can predict chemical usage to ensure a smooth re-ordering for clients. We also provide onsite support, with our service technicians using our optimised

apps to ensure all checks such as sample points, looking at probes, calibrating instruments, and checking pressure are captured at every service, along with any unusual activity.”

Both Aerofloat and the client eceive automatically generated field eports, so the right people know what is happening on site.

“Tha’s just the first step of our Aftercare service,” says Michael. “We also have chat groups connecting technicians with engineers and operators. If there is ever a problem, it can be solved quickly.”

Michael hopes that Aerofloa’s nimble and multidisciplinary support team will continue to put it at the forefront of decision-making for current and future clients.

“We understand the complexities of different WWTPs across industries” he says. “We can identify problems and solve them quickly. Working with Aerofloat means that clients can tap into our collective experience, and choose from a range of services to suit their needs. It’s just part of what Aerofloat does”

For more information, visit: www.aerofloat.com.a

Komptech CEA is a leading supplier of machinery and systems for the treatment of solid waste through mechanical and mechanical biological treatments, as well as the treatment of biomass as a renewable energy source. Komptech CEA is proud to provide innovative solutions for handling waste and biomass.

Komptech CEA’s extensive range of products cover all key processing steps in modern waste handling. At Komptech CEA the focus is always on innovative technology and solutions ensuring maximum benefit o the customer.

Like to know more? why not speak to one of our team today?

Where Function Meets Technology

A slow-running, single-shaft shredder suited to all types of

Screening with a Star

Makes waste wood and biomass processing highly efficit.

Less Fuel, More Power

Ideal for shredding all types of wood and green cuttings.

Robust and Reliable

Combining the practice-proven virtues of its predecessors with new solutions for even greater performance.

The Ideal Combination of Performance and Design

With a sturdy frame, powerful hydraulics and large drum, the Topturn X is ready to handle any work situation.

Enhancing the quality of the recyclable output.

Providing effective removal of plastic film fom screen over flow.

1300 788 757

komptechcea.com.au

Groundbreaking technology developed by The Environmental Group Limited (EGL), and Victoria University offers hope of ridding national waterways of PFAS.

The persistence and potential toxicity of per and polyfluooalkyl substances (PFAS) have attracted growing concern around the globe.

Dubbed a ‘forever’ chemical, PFAS has been used in numerous applications over time. Because they don’t break down naturally, they’re present in low levels almost everywhere in the environment, including the human body. Increased levels can be found near sewage treatment plants, landfill, and places where fie-fighting foams hae been used.

Several commonwealth departments in Australia have investigation and management programs in place, while state and territory governments are undertaking their own inquiries.

Australian subsidiary EGL Water, part of The nvironmental Group Limited, with research partners Victoria

University, has developed a technology that is more than 99 per cent effectie in extracting regulated PFAS species from water.

Known as PFAS Separation, the patented technology extracts PFAS in a concentrated form using foam fractionation.

Jason Dixon, EGL Chief Executive Offic, says the technology provides new capabilities and integration possibilities.

“Remediation of PFAS contaminated water and soil has just got a lot easier to deal with,” Jason says.

“The EGLWater system can be incorporated into existing wastewater treatment systems such as those seen at landfills, municipal wastwater facilities, airports or just about anywhere with a PFAS problem.”

EGL Water has a unique understanding of the water treatment

market, combining experience in the field with technology and esearch and development. It aims to develop low-cost technologies in response to emerging water treatment issues including in heavy industry or water recycling systems.

Jason says PFAS Separation has many advantages in treating PFAS, including low operating cost, small footprint, savings on transport and waste disposal costs, and a range of applications spanning wastewater, leachate, groundwater, and soil.

Importantly, it requires minimal or no pre-treatments when compared to PFAS absorption technologies, which again reduces the cost.

Absorption processes to remove PFAS from a water stream require a subsequent incineration process. PFAS Separation destroys the PFAS, converting it to a non-toxic chemical.

“Absorption technologies require high labour demand and extensive and costly pre-treatment. The contaminated media also needs replenishment and thus incurs considerable disposal of filtration materials,” Jason says.

“The EGLWater system also offers higher throughput volumes compared to existing technologies, while maintaining its effica.

“Using this technology, longstanding PFAS contaminated soil and water discharging sites can now be cost effectiely remediated and made safe for future generations and avoid lingering legal liabilities.”

An EGL Water PFAS Separation Plant has been commissioned and is in full operation at Reclaim Waste, a hazardous liquid waste disposal company in Victoria.

The original design for the plant was to extract PFAS concentration of less than one part per billion (ppb)

from 20 cubic metres of leachate wastewater. Jason says the plant has met all Greater Western Water’s targets for PFAS separation.

Based on commissioning batches, the plant processed leachate wastewater at a throughput of about 22.5m3/hr. Recycled water achieved a throughput rate of 12m3/hr.

“It’s worth highlighting that the leachate water and recycled water had higher ratios of Perfluoohexanesulfonic acid (PFHxS), one of many compounds collectively known as PFAS, which is typically the less common type of contamination and the more difficult t remove with this technology,” Jason says.

“This suggests that higher process throughputs could be achieved with a more typical PFAS contamination profile”

Reclaim Waste, with assistance from EGL and Victoria University, is now looking at extending the PFAS

Separation technology to remove PFAS from the recycled water generated from Reclaim’s on site contaminated soil washing process.

Victoria University is screening and evaluating numerous PFAS contaminated soils and biosolids to clearly show the expected PFAS extraction efficiency that could b achieved on site.

Jason says the aim is to reduce PFAS from the environment and establish PFAS Separation units in waste management plants across Australia.

Each unit is designed and built, to specific customer needs, in ustralia by The nvironmental Group Limited with ongoing Australian-based support. Units can be easily incorporated in line with existing processes such as ammonia removal.

The system can operate 24/7 and is automated and remotely monitored, preventing human intervention.

“EGL Water’s vision is to protect and preserve access to clean water,” Jason says. “Tha’s what drives our innovation efforts.”

For more information, visit: www.egl.com.au

The technology can be incorporated into existing wastewater treatment systems such as those seen at landfills or municipal wastewater facilities. Image: EGL Water

The technology can be incorporated into existing wastewater treatment systems such as those seen at landfills or municipal wastewater facilities. Image: EGL Water

Veolia is set to play a key role in Australia’s energy from waste (EfW) operations, with three facilities coming online in 2024.

Veolia is at the cutting edge of energy from waste in Australia because of its global experience in the sector, according to Craig Barker.

The Chief perating Officeresource Recovery says successfully operating 65 EfW facilities around the world gives the company significant adantages in personnel, skills, experience, and expertise.

Skills that, he says, are needed more than ever if Australia is to meet climate and circular economy targets set by the federal and state governments.

“EfW facilities will be vital to achieve those goals,” Craig says.

Veolia has three EfW projects coming online this year – operating new plants at Kwinana and East Rockingham, Western Australia, and the reopening of an upgraded anaerobic digester and energy recovery facility, EarthPower, at Camellia in Sydney’s West.

It’s also moving to expand its footprint further in the EfW landscape over the coming years, in a consortium to develop an EfW plant in Maryvale, Victoria. At the same time it’s proceeding through planning and consultation stages for the construction and operation of an Advanced Energy Recovery Centre

(ARC) at its Woodlawn facility in New South Wales.

Commercial EfW plant, EarthPower is the first cab off the rank. Th facility uses a digester to convert solid and liquid food waste into nutrient-rich fertiliser and biogas that produces enough electricity to power 4300 homes.

EarthPower adds to Veolia’s existing bioreactor capacity in New South Wales, joining the Woodlawn Bioreactor Facility, which manages about 20 per cent of Sydney’s waste, capturing methane to generate clean energy for up to 30,000 homes.

Craig says this is likely to be just the beginning for bioreactor facilities across Australia with modelling commissioned by Veolia showing that at least 17 organics processing plants with a capacity of 250,000 tons will be required to meet the national waste plan target of an 80 per cent average recovery rate from all waste streams by 2030. This is expected to generate 3947 jobs.

Importantly, EarthPower’s reopening will be a cost-saving boon for its New South Wales customers because it offers lower gate fees than landfill for solid or liquid food waste, accepting with less than fie per cent contamination per load. These customers ae expected to include commercial kitchens, food manufacturers and processors, local councils, waste management services and more.

The upgraded facility also offer an environmentally sustainable way of disposing of food waste in terms of its processes and end products, leading to reductions in greenhouse gas emissions compared to other disposal techniques. At a time of increasing regulatory pressure, including the recently proposed federal legislation for climate-related financial disclosues, this is of growing importance to business and government.

Craig says similar legislative pressures at state level are also behind the

proposed $600 million development of the New South Wales Woodlawn Advanced Energy Recovery Centre (ARC), in the Southern Goulburn Mulwaree Precinct. This is one of the four regions in the state set aside for EfW infrastructure.

Once completed, the ARC is expected to generate up to 30 megawatts of electrical energy – enough to power 40,000 homes a year – from about 380,000 tonnes of residual waste feedstock annually. It will also recycle about 25 per cent of the waste into aggregates and metals rather than going to landfill

“The AC will be a crucial piece of infrastructure for New South Wales, which has set very ambitious goals in its effot to attain a circular economy and reduce greenhouse gas emissions,” Craig says. “The eality is that the only way to achieve the state’s 10-year goal of an 80 per cent average recovery rate from all waste streams by 2030 is with EfW facilities. Without this critical infrastructure being supported by regulatory authorities and government, we will continue to see large amounts of New South Wales’ non-recyclable waste go to landfill and our ambitious targets will fall by the wayside.”

Craig says that as the first poject of its kind in New South Wales, the ARC has to overcome regulatory hurdles,

of Planning in 2025.

For more information, visit: www.veolia.com

The Environmental Group Limited Engineering a Sustainable Future

Ecobatt is a pioneer in the Australian battery recycling industry, offering solutions to address the growing challenge of battery waste in Australia and the preservation of critical resources.

Founded on the principle of environmental stewardship, Ecobatt employs latest technology to ensure that batteries are recycled in a manner that minimises environmental impact and maximises resource recovery.

The company has emerged as a trusted name in household, micromobility, electric vehicle, and energy storage battery recycling of all chemistries.

Though advanced sorting and recycling processes, Ecobatt engages

with downstream processors to recover valuable materials from alkaline and lithium-ion battery streams including lithium, cobalt, nickel, zinc, manganese, and a range of other metals, diverting them from landfills and eintroducing resources as green metals, in a rapidly growing circular economy.

The national ecycling rate is estimated at 12 per cent for used household batteries. Ecobatt’s Zoltan Sekula says incorrect disposal of lithium-ion batteries in residential waste bins is believed to cause about three fies a day nationally.

However, Environment Protection Authority sources indicate that it is likely that small lithium-ion battery fies are under-reported.

“Kerbside waste collection vehicles, Material Recovery Facilities (MRFs), transfer stations, and landfill operations are at a higher risk of thermal runaway events,” Zoltan says.

The Bxing Day 2022 fie that destroyed Canberra’s recycling plant, and a recent fie at a warehouse owned by French battery recycling group SNAM in Viviez, north of Toulouse, highlight the risk posed by lithium-ion batteries when accidently damaged.

“Kerbside waste compactors are at particular risk of adverse events, and public education must continue for the proper diversion of used household batteries from landfill” Zoltan says.

“The safe storage and transpotation of bulk mixed used household batteries in appropriately certified bulk storage boxes, like Ecobatt’s range of ASP 600/800 galvanised steel boxes, can offer a safe solution in educing the risk of battery fies developing into major adverse fie event.

“When talking about collecting, storing, and transporting hazardous materials, there’s no room for compromise in safety.”

Ecobatt, with its range of products, provides safe collection and removal methods for not only the public, but also the industrial and local government sectors.

Designed to meet the stringent demands of storing and transporting mixed household batteries, Ecobatt’s ASP 600L/800L galvanised steel

containers with lockable lids are not just battery safety bins but are certified intermediate bulk containers tailored for mixed lithium-ion batteries within packing groups as defined under the Australian Code for the Transport of Dangerous Goods by Road and Rail (ADGC).

Zoltan says Ecobatt’s commitment to safety extends to its battery receptacles. The obust, hot-dip galvanised steel receptacles are constructed to German DIN 30741 standard, ensuring they are anti-sparking and non-incendiary – a crucial feature for the storage and transport of mixed lithium-ion batteries.

“This cetification establishes them as the premium go-to solution in Europe for the packaging of mixed household batteries, encompassing all types of battery chemistries and cell groups referenced in the ADGC,” Zoltan says. “The ASP 600/800 4AX containers are certified as a steel bx. This type of packaging is suitable for all groups of

lithium batteries and cells mentioned in 4.1.4.1 of the ADR (guidelines for packaging).”

Ecobatt’s battery safety bins are weatherproof and permitted for active and passive storage when kept on a solid surface. The easy-opening lid with hinge-supported springs is lockable at two opening angles – 70 degrees and 270 degrees – for access, and can be secured with optional padlocks. The bins are stackable and movable by forklift or crane.

“Whether it’s transporting batteries for storage or recycling, handling bulk lithium-ion batteries can be problematic when their historic use is unknown,” Zoltan says.

“To ensure the safe transit of lithium-ion batteries throughout the supply chain, our bulk containers stand ready to deliver. Adverse battery events are contained within the container. In the rare case of a thermal runaway, a thermal temperature indicator is added to assist in first

response situations of measurable temperature events.

“When used correctly, our ASP containers are designed to contain a fie until it is extinguished and preventing it from spreading to other areas.”

He says the ASP600 containers are preferred for retail deployment as they offer a 600-lite capacity, while the ASP800, with 800-litre capacity, is intended for industrial applications, transfer stations, landfills, and MRFs

“With our containers, hazardous battery storage and safe transport becomes not just a necessity, but a seamlessly secure endeavour,” Zoltan says. “When you opt for Ecobatt, you’re choosing more than just a product –you’re choosing a partner dedicated to safeguarding your operations and ensuring the highest standards of safety.

“Excellence is not just a standard but a commitment.”

For more information, visit: www.ecobatt.net

Why Allu buckets are a key element in Enviropacific’s remediation applications.

“This bucket will screen anything at all – and we’re flying through it.”

Shaun Walshe, an experienced operator with environmental service provider Enviropacific, has been putting a nw ALLU screening bucket through its paces in Western Sydney and says it has boosted production.

“If it wasn’t for this bucket, I’d be using a sifting bucket on the end of an excavator, which would take us 10 times longer,” Shaun says.

Uptime and efficiency e vital to the success of any resource recovery project, and this is where ALLU’s range of material processing buckets are well suited.

The bucket is designed to sceen and separate a range of materials, including soil, sand, gravel, compost, demolition waste and biomass onsite, ready for

reuse. It classifies materials into diffent fractions, allowing for the removal of oversized or undersized particles.

Having the bucket onsite reduces the need to transport material to another processing facility, minimising costs and waste and promoting sustainable and efficient operation

Enviropacific povides solutions for waste treatment, recovery, and tracking – from soil remediation to water and resource recovery.

Rodney Gray, Enviropacifi’s National Plant and Fleet Manager, says the company specialises in site remediation, treatment of PFAS (perand polyfluooalkyl substances), asbestos and other hazardous waste management, basically any sort of remediation works.

On any given job, the Enviropacific team typically uses a range of machinery and attachments, including excavators

and wheel loaders equipped with anything from hammers to shears. But Rodney points to Enviropacifi’s range of ALLU buckets as some of the most important attachments to its operations.

“We currently have six ALLU buckets in the fleet” he says. “We’ve been dealing with them for seven or eight years now.”

The ALU range has units available to fit almost any base machine sie, from the compact DL Series that suit excavators from four to 12-tonne through to the M Series, which will fit ecavators up to 160 tonnes and wheel loaders up to 90 tonnes.

A range of blade and drum sizes are available to provide fragment sizes of 10 to 105-millimetres depending on drum and blade set-up.

Enviropacific ecently took delivery of a customised ALLU TS Screener Crusher in Western Sydney, New South Wales. A standard ALLU bucket imported from

Finland, it was dismantled and rebuilt with an axe blade configuration to suit Enviropacifi’s specific application.

The ae blade cutters were chosen in place of straight cutters to help the Enviropacific team deal with difficult cl material. The esults have been positive.

“We were having issues with other buckets getting jammed up, and we couldn’t meet production rates – but this new bucket is doing the job for us,” Rodney says. “The idea is the ae blade cutters pull the material through as opposed to letting it jam up in the bucket.”

Rodney says his team has stuck with ALLU buckets for several reasons, a big one being the support coverage on offer through the ALLU dealer network, which ensures a skilled and knowledgeable expert is never far away.

Establishing relationships for the long haul is important and an ethos that carries through the dealer network.

Enviropacific has a national pesence in most centres in Australia, so knowing its ALLU products will be looked after, wherever the job, is a key consideration.

Rodney says ALLU has repeatedly gone above and beyond in its support – especially important considering some of the time-sensitive projects that Enviropacific egularly undertakes.

“Thee’s one older ALLU bucket that we’ve had in our fleet for pobably eight years, a discontinued model, with very limited parts available for it,” he says. “We got it to an ALLU dealer, and they managed to source parts for us – even though a lot of the parts were discontinued – and do a complete rebuild.

“A lot of the work we do is on airports, so it’s critical that we have continuation of work, and that our operations aren’t held up by an issue with our equipment.

“ALLU provides us with that service, and that limits our downtime.”

For more information, visit: allu.net or find a dealer attachmentspecialists.com.au/allu

Liverpool City Council is flipping the narrative on mattress waste, turning a nation-wide problem into a regional opportunity.

It has been the villain in numerous thriller movies, gives its name to a global shoe brand, and is now the latest weapon in landfill diersion for Liverpool City Council.

‘The roc’, is chewing its way through more than 21,000 mattresses a year and is offering a egional solution to an expensive waste stream. It’s also spawned a circular economy initiative set to revolutionise local recycling.

“To achieve 80 per cent landfill diversion, as set out in the National Waste Policy, we need to start thinking outside the box,” says Tim Pasley, Liverpool City Council’s Resource Recovery Manager.

“The olume of waste mattresses is a tremendous problem, but also a tremendous opportunity.”

Across Australia, about 1.8 million mattresses are thrown out every year, according to the Australian Bedding Stewardship Council. In 2023-24, mattresses were added to

the Environment Minister’s product stewardship priority list.

Historically, Liverpool City Council collected and landfilled thousands of illegally dumped mattresses annually. The practice was expensive – up to $137 for each mattress – and unsustainable with landfill in the ydney basin expected to expire by 2032.

The cost of having mattesses taken away by a private contractor for recycling was close to $800,000 a year.

Tim says that about fie years ago the council decided there had to be a better way. A meeting with Andrew Douglas, who began Mattress Recycle Australia operating out of Cootamundra in New South Wales, set the council on a path to taking ownership of its mattress waste.

‘The roc’, as it’s affectionately known by locals, is a Tana Shark industrial shredder purchased from waste management and recycling equipment distributor GCM Enviro. It’s

the centrepiece of a mattress recycling operation at the council’s waste depot.

TheTana Shark has earned a reputation for its robust design and reliability, taking on, and winning, against challenging materials. At Liverpool, the Tana Shark’s giant jaws demolish a mattress every minute, separating the steel from the mattress flocking, eady for repurposing.

“We can’t fault the Tana Shark,” Tim says.

“The council ran an exhaustie procurement process to identify what the best in the market was, focusing on the quality of the machine, durability, ease of repair and availability of parts.

“TheTana Shark gives us best bang for buck. It maximises operational efficiency and toughput of materials in a single pass.”

GCM Enviro configued the shredder specifically for mattess waste. The team provided a training package and manuals and continues to offer back-up to ensure the council is achieving the best results possible.

The roc has been operating two days a week since commissioning in 2023. The council aims to incease to daily operations and has called for an expression of interest from neighbouring councils to use the service. Thee’s also been interest from bedding companies keen to provide an environmentally friendly disposal option for their beds.

To meet the expected demand the council has purchased a second Tana Shark. A second shredder gives the council the opportunity to increase throughput; having two of the same machines requires fewer spare parts to be stocked, there’s no need for extra training

and service intervals can be timed so there’s little to no downtime.

Tim says, ‘the Croc’ is proof of concept for a wider initiative – establishing

a circular economy centre that will include a micro factory to transform the mattress waste into tiles. The council has purchased land next to its waste facility

that will be developed over the next four years and could include up to four Tana Sharks. Presently the council is recovering 44 per cent of the metal waste from mattresses, it’s aiming for 99 per cent recovery of all waste when the micro factory is established.

“When we started on this journey, we wanted to solve the problem for our region,” Tim says. “We saw a gap in the market and thought, ‘who is better positioned to do this than us’?

“We were ripe for change and wanted to see things done better. That meant being brave and trying out new things.

“We’re already saving a couple of thousand dollars a year, now we’re really trying to bring circular practices to the fore.”

For more information, visit: www.gcmenviro.com

Komatsu and Cleanaway have had a long partnership lasting many years. What have they achieved?

Cleanaway Australia is a national waste management and recycling company that also operates the South East Melbourne Transfer Station (SEMTS) in Dandenong. With such an extensive portfolio of responsibilities, Cleanaway needs the right equipment.

Tha’s where Komatsu steps in. It has long focused on quality, reliability, insight and support for its products and machines. Though its manufacturing and technological innovations, Komatsu continues to partner with its clients to

create the solutions needed to achieve a sustainable future.

Cleanaway has a range of Komatsu machines, including loaders, excavators, articulated dump trucks and motor graders. Matthew Wentman is the National Fleet Manager – Yellow Gear and Mobile Plant. He has proven operational management, project and financial management, and delivery experience.

“I joined Cleanaway seven years ago,” says Matthew. “I moved to working

in the waste industry for an industry and career change, having previously worked in facility and manufacturing maintenance for 20 years. Since I joined Cleanaway, I have worked in the liquids, hydrocarbons and solids business. Now I’m working with the central fleet team.”

Komatsu and Cleanaway have worked closely together for many years, including under Matthew’s leadership.

“Both businesses have national approaches, and it works well for us,” Matthew says. “They hae representatives in every state in which we operate. We work together closely to ensure we get the machine specifications correct for all applications. That makes it an excellent relationship.”

Cleanaway employs more than 60 machines from Komatsu around the country, including wheel loaders that load thousands of tonnes a day from the SEMTS site.

Cleanaway offers its customers capacity to safely collect, process, treat, recycle, or dispose of any waste. It sees all waste as a resource. Matthew says managing Australia’s waste needs isn’t a matter of asking “where does it go now?” but “what can it be next?”

Its experience and expertise in the industry means Cleanaway is always finding bette, smarter, and cleaner ways to make a sustainable future possible. The machines fom Komatsu are a key part of that impact, and the work done at SEMTS shows the effect

“SEMTS was purpose-built in 2017 as a commercial and municipal waste transfer facility,” Matthew says.

“They eceive general waste, construction and demolition waste from Melbourne’s southeast. It’s one of Cleanaway’s largest transfer stations.”

The machines woking at SEMTS have had an enormous impact on the operations there.

“Komatsu has reliable machines that can work in the harsh environment of a transfer station,” Matthew says. “They sent engineers out to wok with us to get an intimate understanding of the environment the machines would be working in. This meant that we got specific machines that ere waste-guarded to protect our staff and equipment operating at SEMTS. Being in that harsh environment means that they have to be reliable.”

The eliability that is built into Komatsu has shone through. Waste does not stop coming into SEMTS, so having machines down for planned repair, maintenance, and cleaning makes the work easier for Cleanaway.

As many individuals would reflect, having quality aftersales support is key for any significant puchase. Tha’s the same for Cleanaway, where the organisation has appreciated the

service offeed by Komatsu. “We’ve got full maintenance agreements with Komatsu,” Matthew says. “Any issues are quickly addressed, and our operators are supported with training for the correct and safe operation of our gear.”

Preventative maintenance agreements, face-to-face and technical support have been important aspects of the partnership.

“We’ve not had any issues with the machines,” Matthew says. “We can book in the machines and arrange scheduled servicing without issues. It’s great to have such an excellent partner supporting our business.”

In the future, Cleanaway will look to expand its over-the-road and off-the road fleet.

With its expanded focus on recycling and organics, Matthew hopes that Cleanaway and Komatsu can continue to work together to develop safe and reliable waste solutions.

For more information, visit www.komatsu.com.au

On-demand recycling service RecycleSmart continues to evolve, developing new solutions for current problems.

Small businesses are among the worst recyclers, not because they don’t want to recycle, but because they often don’t have the resources available, says Dr Amitoj Singh, RecycleSmart’s Head of Sales.

Traditionally many commercial businesses have a red-lidded residual waste bin, but not a recycling bin. Or the types of waste to be disposed of are recyclable but not through the current yellow bin arrangement.

Tha’s where RecycleSmart comes in.

The on-demand ecycling service has built a reputation on providing accessible solutions for hard-to-recycle waste through its Power Pickup. Residents schedule a pickup, put their recycling into any regular shopping bag and leave them outside for collection.

In June 2023, RecycleSmart introduced the Business Power Pickup to help recycle commercial waste in warehouses, construction sites and manufacturing

businesses, and also smaller businesses, retailers and head offices.ore than 700 businesses have since signed up, contributing to divert about 700,000 kilograms – or more than 16 million litres – of waste from landfill

“Business owners knew this was an area where they needed help,” says Amitoj.

“The usiness Power Pickup is helping to take a lot of waste out of the red bin, such as polystyrene, soft plastics, and uniforms, and recycling it instead.”

Increased efficien, reduced costs, traceability, and improved sustainability outcomes are just some of the benefits of the Business Power Pickup.

Following the collapse of soft plastics collection program REDCycle in 2022, transparency has become crucial, says Amitoj.

“RecycleSmart is 100 per cent transparent,” he says. “We tell businesses exactly where their material goes and what happens to it. For bigger businesses,

or those that have environmental and social governance strategies, they need to know that.”

RecycleSmart works with a variety of collection vehicles, which means getting into tight locations, scheduling pick-ups when and where they’re needed and the quantity of waste to be collected (from 60 litres upwards), is no problem.

Neither is the type of waste. All waste streams can be collected, eliminating the need for multiple service tenders and contractors, and reducing the workload on internal resources.

“In New South Wales, there are a lot of businesses with a contractor behind every single waste stream, and that takes significant internal esourcing,” Amitoj says. “They can nw have one contractor manage the entire collection.”

Soft plastic is the number one material recycled, but it’s not all chip wrappers. Commercial plastics, such as pallet wrap, can be difficult to dispose of becaus it occupies a lot of volume and is not accepted by many recyclers.

Foam, used to protect furniture, is also classed as a soft plastic but is not currently recyclable in Australia. It’s one of a few items for which RecycleSmart is working toward a solution.

And Amitoj is confident a solution will be found. As RecycleSmart’s program extends, more recyclers are reaching out for the service to provide quality feedstock. Businesses are also coming forward with waste streams that RecycleSmart doesn’t currently collect.

And it doesn’t stop there. With 24/7 live reports available and a new traceability system, RecycleSmart helps businesses and councils measure their impact.

“RecycleSmart has transformed how we handle soft plastics from our operations,” says Mary Karatasos, from Williams Logistics, a leading specialist provider of thirdparty logistics (3PL).

“It’s comforting to know that plastic from our operations are being recycled, making it easy for us to reduce our landfill contributions

Mary says sustainability in logistics, especially when servicing fashion brands, is critical so it has always been a part of 3PL do. But it has never had the ability to track like it can now.

“Reporting and finding the right patners has been the biggest challenge we have faced on our sustainability journey,” Mary says.

“Which is why it’s great to have partners like RecycleSmart that can track the impact of what we are doing. Finding the right partners has been critical to us feeling the change internally and having more belief in what we are doing.”

Amitoj says the partnership is an example of how RecycleSmart can help drive efficiency for businesse as well as getting everyone on board, for a long-term beneficial effect.

And Mary agrees: “When our team can see the impact from the data, they feel a sense of pride and it makes it easier for them to buy into what we are doing.”

The usiness Power Pickup service in New South Wales, Victoria and Queensland has provided proof of concept. The sevice is being introduced in Adelaide.\

“It’s very exciting,” Amitoj says. “We want this strategy for the entire nation, it’s just a matter of finding the right partners.

“Businesses are very fast moving. They want their resources recycled as quickly as possible, and that’s what we want as well.”

visit: www.recyclesmart.com

The newest machinery and technology from Komptech CEA will be on display at IFAT Munich 2024.

IFAT Munich prides itself as the world’s leading trade fair for waste, water, sewage and raw materials management. It is a solution platform, a networking event, and a knowledge hub bringing together key international industry representatives from politics, business and science.

Offering eciting ideas and innovative solutions for industrial and municipal challenges, IFAT Munich also provides hundreds of exhibits for visitors to experience in action and up close. This is what makes it more versatile and resultsoriented than any other trade fair.

And it’s why Komptech CEA will be in attendance.

It doesn’t matter whether you are a big player or a medium-sized company, a large city or a small municipality, IFAT

Munich places a focus on recycling and disposal for private-sector and municipal waste management companies. The aim is to identify solutions to close raw material cycles and further advance the circular economy.

Which strategy is effectie? Which process is suitable for which need? Which vehicles and machines are particularly energy-efficient?usinesses will get answers and tailored solutions for every process across the various material flws, including smart collection, new sorting and processing methods, energyefficient materials handling and AI-base software solutions.

Komptech CEA will be displaying a range of new machines, while also

providing further details about their availability in Australia.

Komptech CEA will also be offering a range of site tours for those interested in the inner workings of the organisation, both before and after IFAT Munich 024.

One set of tours includes a visit to the Komptech head office atrohleiten (northern Austria) and Factory II, the production facility in Ljutomer (northeastern Slovenia), before the IFAT event. Thee will also be an opportunity to visit a working site near Frankfurt.

For more information, visit: www.komptechcea.com.au

Recognising