NIGELKEEN

Foot Forward: Reshaping the Culture of Running and Consumption

Nigel Keen

Foot Forward: Reshaping the Culture of Running and Consumption

Nigel Keen

1. Introduction

2. Statement of Thesis

3. Personal Glossary

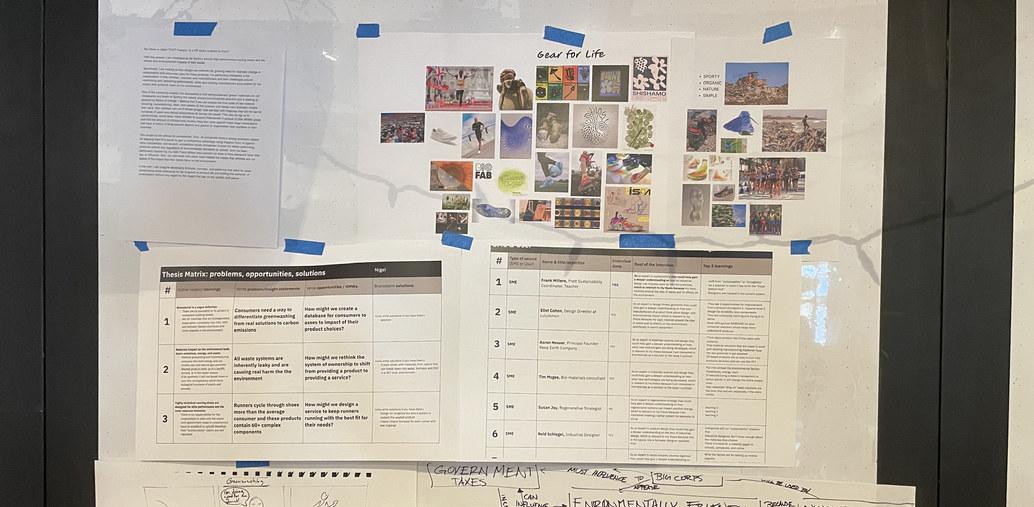

4. Source Research Section I: Finndings

5.Ideation & Prototyping

6. Audience/Market

7. Design Principles

8. Thesis Projects

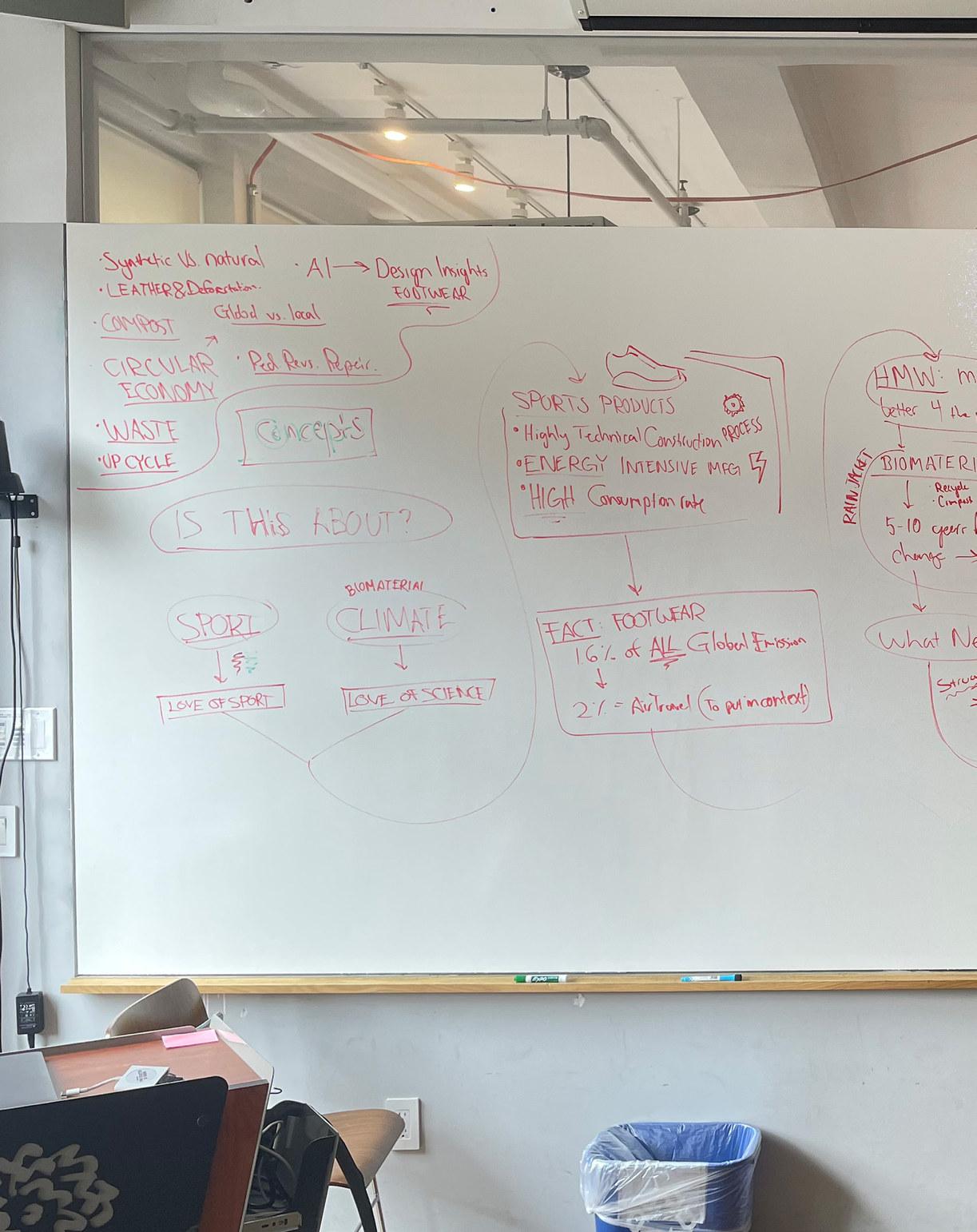

My thesis, Foot Forward: Reshaping the culture of running and consumption, investigates the intersection of performance footwear and sustainability. Globally, over 22 billion pairs of shoes are thrown away on a yearly basis. And if we look at the amount of emissions produced by the footwear industry, it’s 1.4 percent of all greenhouse gas emissions.To put this into perspective, the aviation industry accounts for 2 percent of the global emissions.

As an athlete, I’ve always been fascinated with footwear’s ability to shape my physical and emotional experience with sports. However, knowing that the products I enjoy and my decisions cause real harm to natural ecosystems, social dynamics, economic structures, and more, it’s hard for me to grapple with this cognitive dissonance. And so my goal with this work was to try and parse these two conflicting ideas in my head and create something that addresses this.

Due to its popularity and impact globally, I decided to focus on runners as my primary user group.With numbers around 621 Million people globally the impact and scale of the equipment industry for runners is one of the largest industries of consumer goods. An industry which needs to change if we as a population have a chance at changing our broken relationship to the environment.

End-consumer rate of consumption, material innovation, waste, and high performance sports products were the primary areas of focus for my thesis work. With an ever growing manufactured need for more and more stuff, I sought to try and combat this by researching better systems of product use, care, and longevity.

In my research, it became abundantly clear that all products are made from fossil fuels, none of the materials are biodegradable, and products are highly engineered but wear fast. This corporate climate perpetuates a system that has led to the loss of bivodiversity, increasing climate, destruction of land, and pollution of the global ecosystem. Because we have clear empirical evidence and loads of it dating all the way back to the 1970s, it is no longer acceptable for upcoming product designers to ignore these facts. I feel that in order to create the change we need to fight for better quality design, materials, and systems.

When looking at the carbon footprint of performance shoes, materials account for 70 percent of the total emissions. Interested in new innovations in materials, I researched the hundreds to thousands of material startups focused on creating better alternatives to traditional fossil fuel based materials that are heavily relied upon today. And initially I sought to answer the question: Is it possible to make zero-waste regenerative footwear?

To find out if this was possible I interviewed subject matter experts in the areas of material developers, footwear designers, climate tech strategists, and more.

After speaking further with these experts, I found that high performance materials can have long production life cycles and may take 10 to 20 years to reach a scale that would meet the current demand.

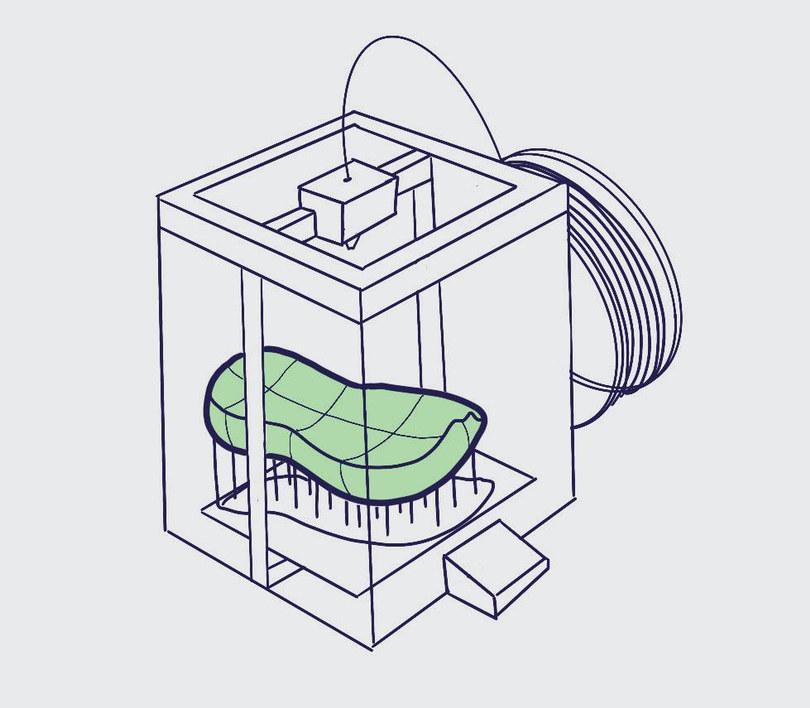

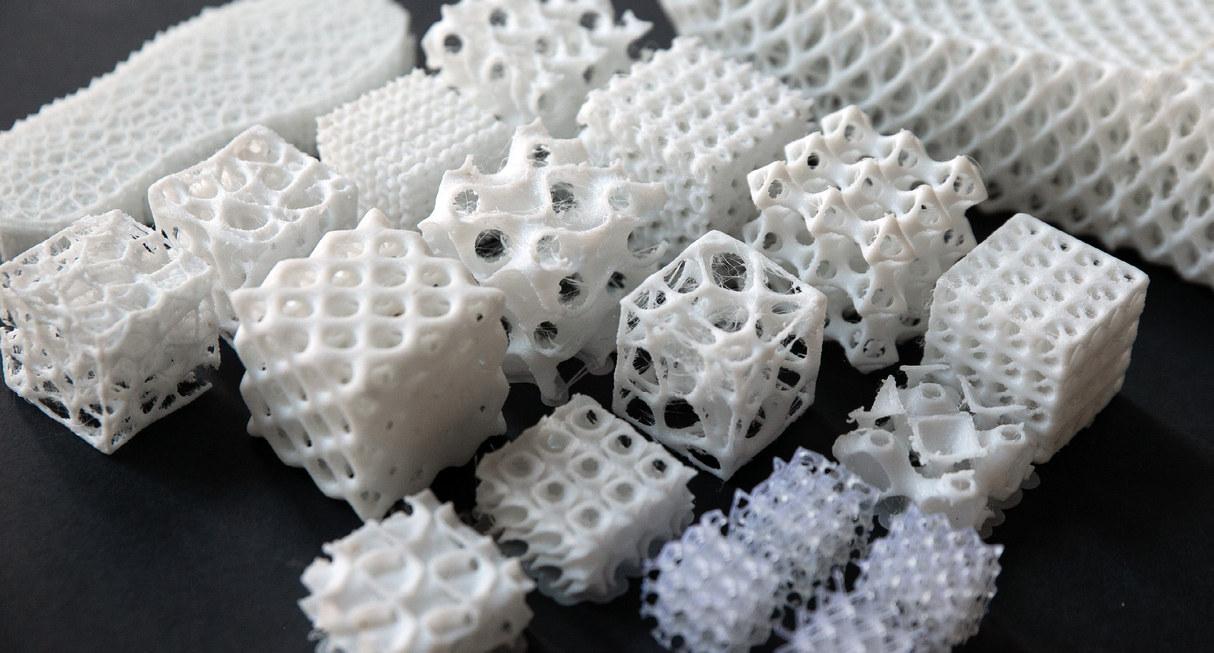

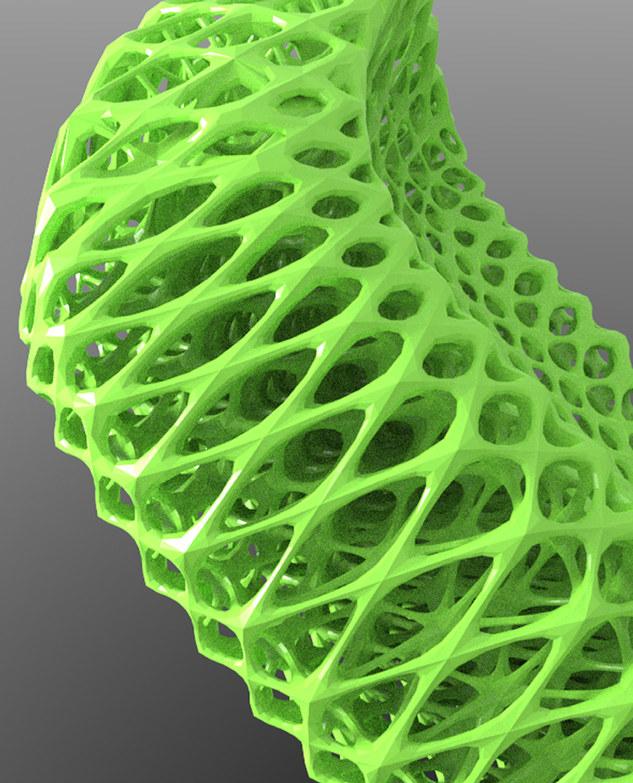

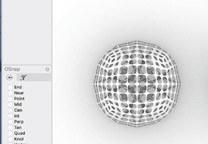

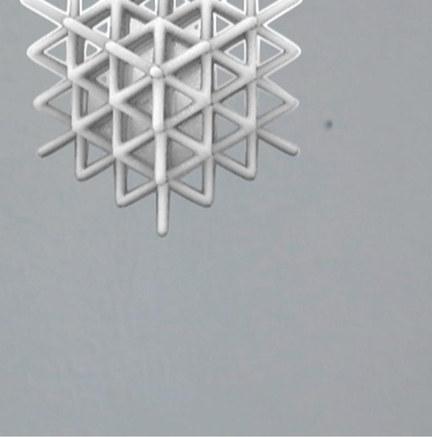

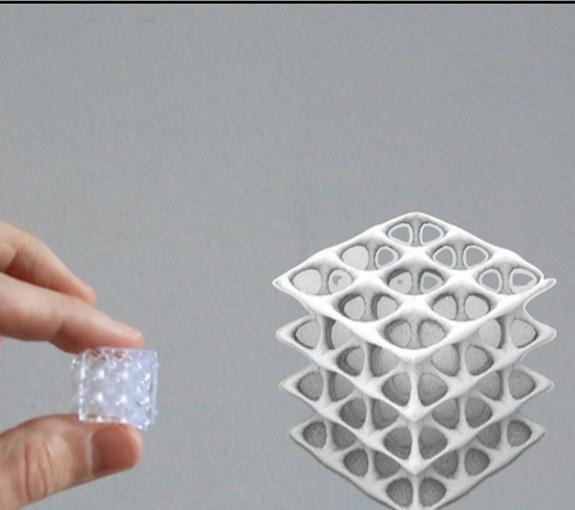

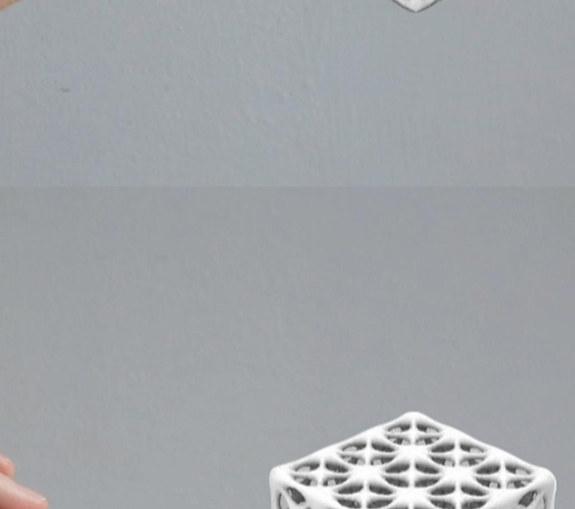

This refers to the process of adding layers together using methods like 3D printing. This process allows for complex geometries that cannot be achieved by other methods of manufacture like injection molding. It also has significant advantages like the ability to create one off designs. The space and energy requirements are also lower than traditional methods of manufacturing. However, the disadvantages include low rates of success in printing, and longer production times. The scalability of these processes is an important factor to consider from a business perspective

This term is used to explain the ability of a substance or object (material) to break down when exposed to different bacteria or organisms. Often this term is used to describe if a product is “sustainable”, however this term is not specific enough. Biodegradability should state in what environment the material will decompose, and how long it will take for the decomposition to occur.

Biomaterial or Bio-based Material

Are plant-based raw materials such as cotton, wood, silk, or lab made materials using biological processes or plant substances to create materials like plastic and rubber. This term is also not specific and needs additional clarification to determine a material’s impact on the environment. The factors that affect the impact of a material include its degradability (time + environment), any chemical treatments, dyes, or finishes included in the production, and its sourcing methods.

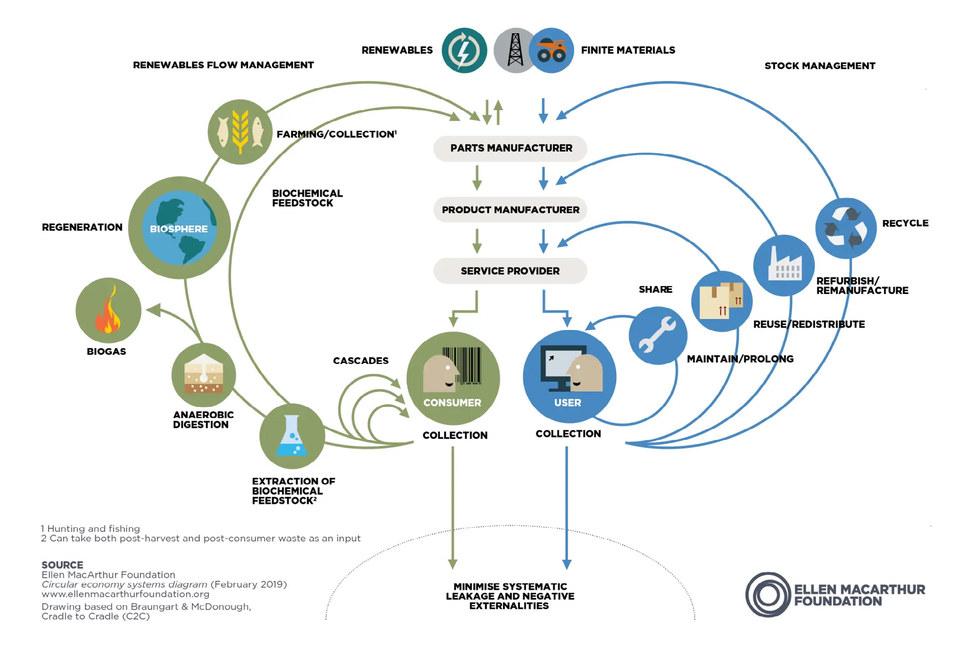

“an economic system based on the reuse and regeneration of materials or products, especially as a means of continuing production in a sustainable or environmentally friendly way.”

- Oxford Languages

This framework is the basis for my design interventions.

A carbon footprint is the total amount of greenhouse gasses (including carbon dioxide and methane) that are generated by our actions.

The average carbon footprint for a person in the United States is 16 tons, one of the highest rates in the world. Globally, the average carbon footprint is closer to 4 tons.

This concept of thermodynamics states that all matter goes from a state of organization to chaos over time. When speaking about products and waste, this means that as a result of the products manufacturing energy is lost in the form of heat and emissions. Additionally, over time as the product breaks down over time, small particles break off into the environment and the product itself will slowly break down over time. However, the polymers used will not break down for thousands of years, and these particles cause harm to humans and ecosystems.

Threw a Spark

Home compostable refers to a product’s ability to compost in a home composting environment such as a worm farm, dug in a hole in the ground and traditional composting. These home composting environments must provide optimal environments for composting to occur such as microorganisms, ideal temperatures, ideal moisture levels, oxygen levels and nutrient ratios.

The golden standard for home compostable products is certification AS 5810 which means that a product has been tested to prove:

min. 90% min. biodegradation in 180 days

90% disintegration into less than 2mm pieces within 12 weeks

no toxic effect to compost, plants and earthworms

Vital de Source

Products that can degrade in an industrial composting environment where temperatures, microorganisms, air, and moisture are controlled.

The golden standard for industrial compostable products is certification AS 4736 which means that product has been tested to prove: min. 90% biodegradation in 12 weeks under industrial conditions and disintegration after 6 months under industrial conditions.

Amuptatium qui doluptae volupid elenducitate exerrum lab imi, sequibus. Genet faciatisciet uta sitatissit autata vidit.

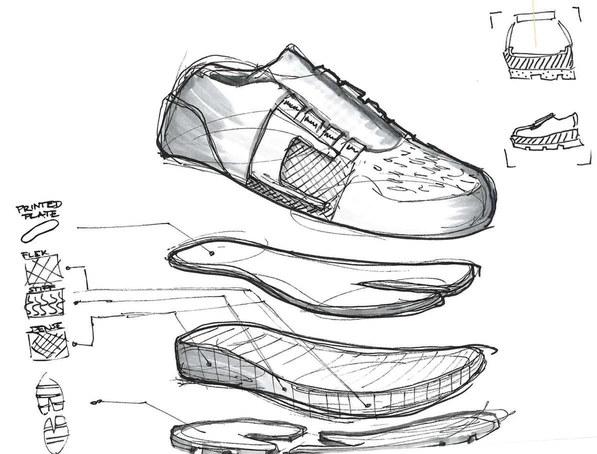

The inner part of a shoe that gives the runner a feeling of softness or comfort while wearing. In some cases this part is removable and can be replaced with an orthotic. In other cases, this part is glued directly to the lasting board.

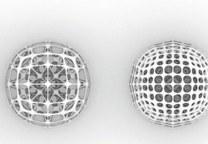

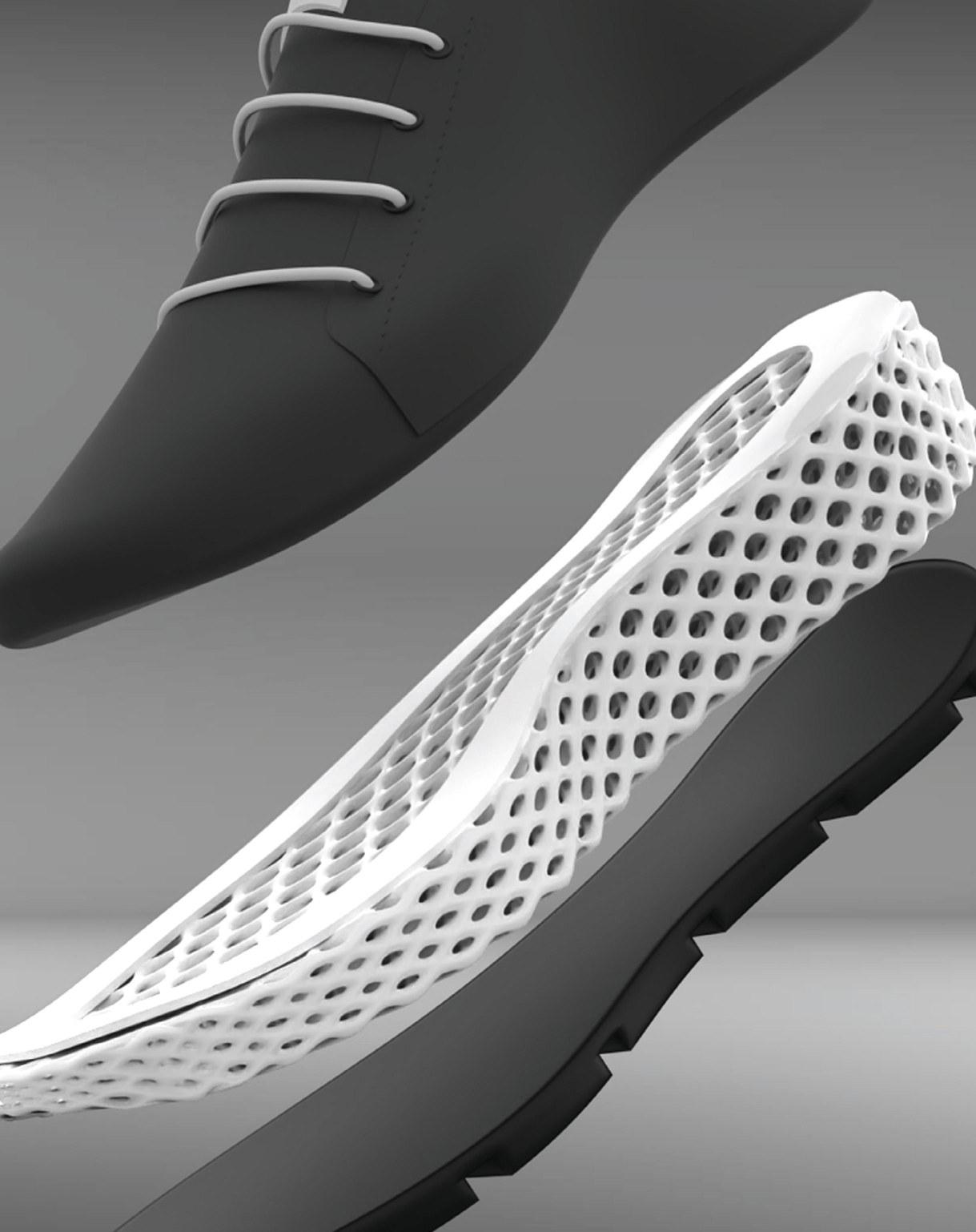

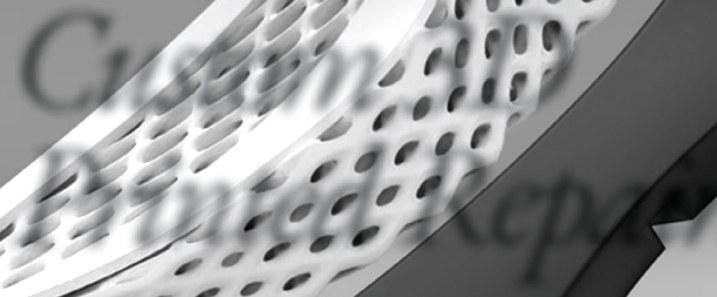

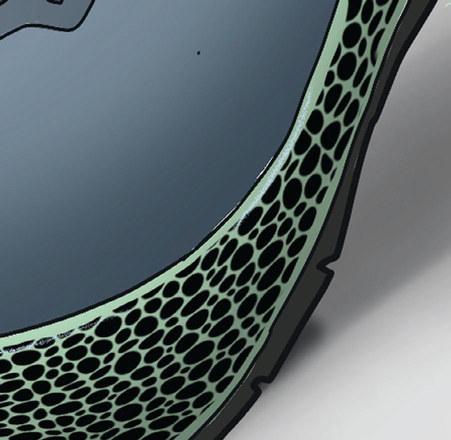

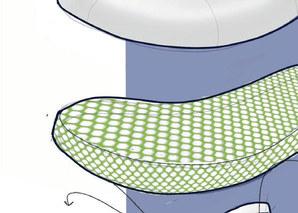

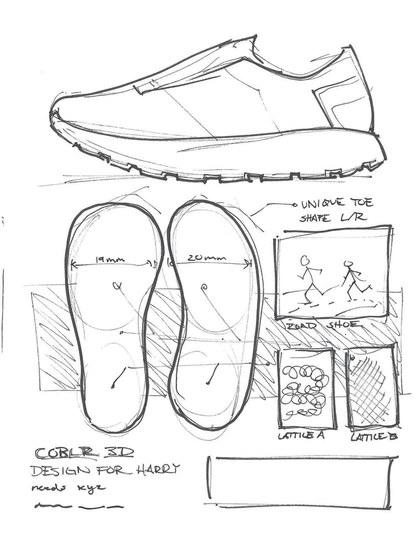

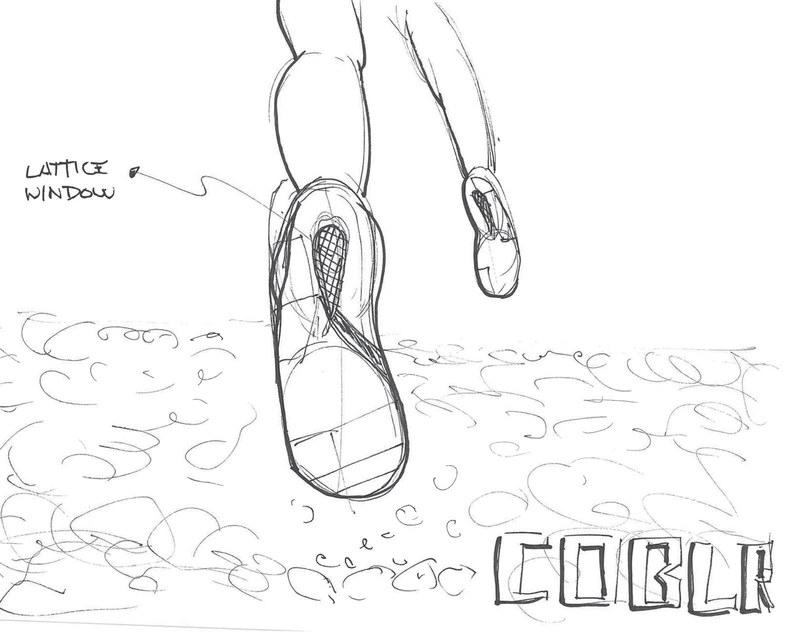

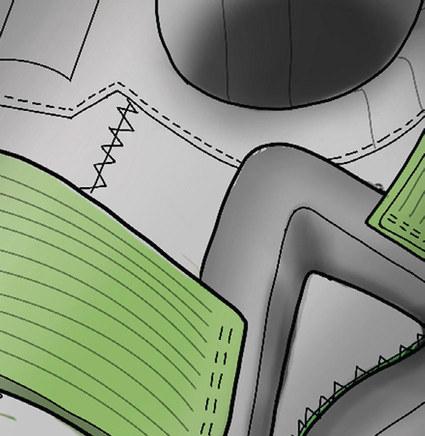

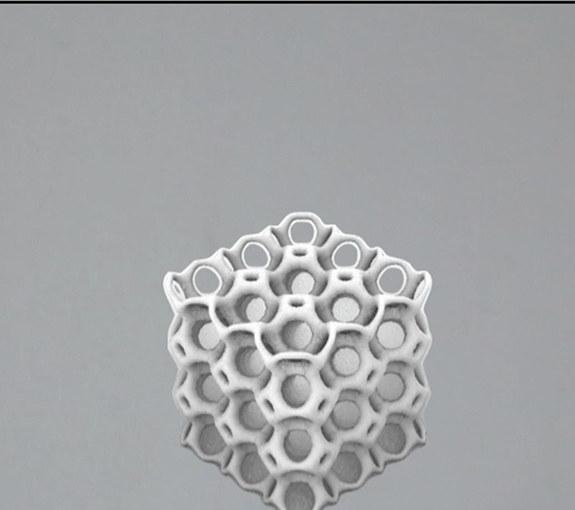

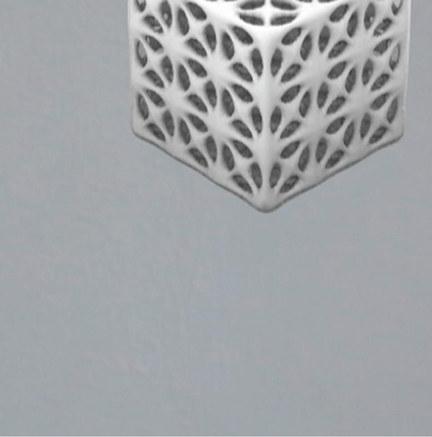

Photo from Adobe StockAn arrangement of nodes and beams in three dimensional space. This is the basis for 3D printing midsoles that can compete with traditional methods of manufacturing like injection molded foam midsoles.

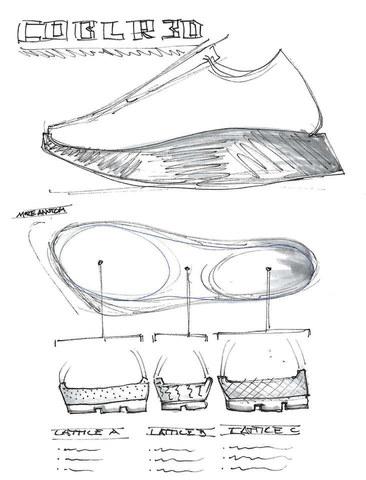

Lattice Tests

Lattice Tests

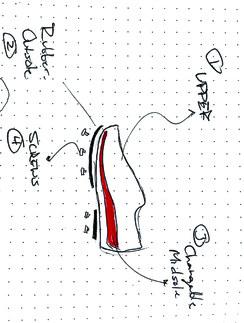

Midsole

The portion of a shoe that provides shock absorptions and propels the runner forward through their stride. The geometry and material choice is an extremely important factor when considering the experience and benefit a shoe will have for a runner.

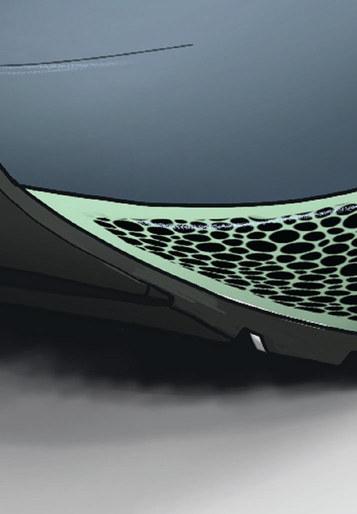

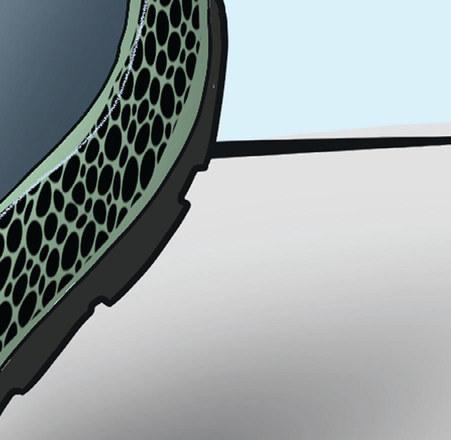

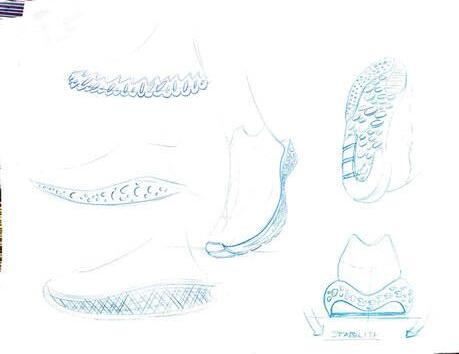

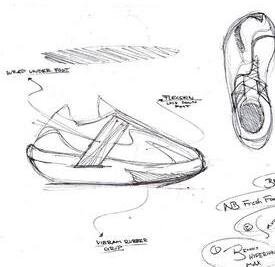

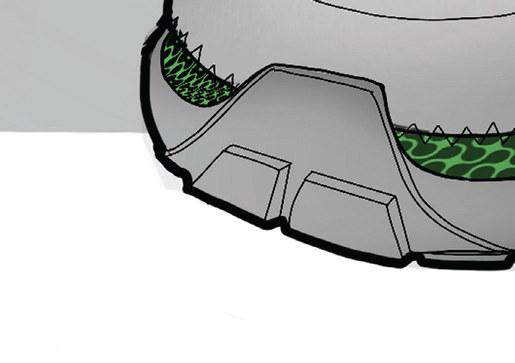

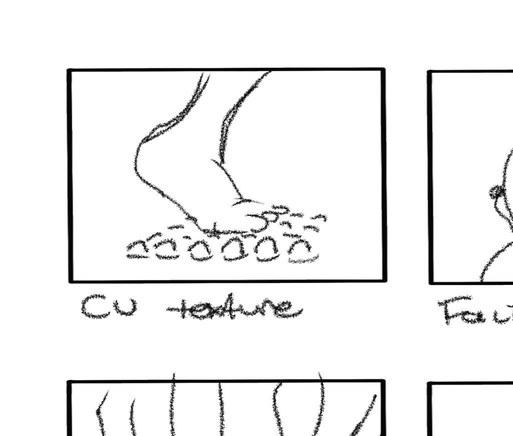

The rubber portion under the midsole that provides traction and grip to the surfaces underneath the foot.

Outsole

Outsole

The per-and polyfluoroalkyl substances (PFAS) are a group of chemicals used to make fluoropolymer coatings and products that resist heat, oil, stains, grease, and water. Fluoropolymer coatings can be in a variety of products. These include clothing, furniture, adhesives, food packaging, heat-resistant non-stick cooking surfaces, and the insulation of electrical wire. Many PFAS, including perfluorooctane sulfonic acid (PFOS) and perfluorooctanoic acid (PFOA), are a concern because they: do not break down in the environment, can move through soils and contaminate drinking water sources, build up (bioaccumulate) in fish and wildlife.

PFAS are found in rivers and lakes and in many types of animals on land and in the water.

Most sports products have heavily relied on PFAS chemicals for performance characteristics like water proofing, stain resistance, and others.

Subtractive manufacturing removes material to manufacture a part. This process traditionally uses Computer Numerical Control (CNC) machining.

Upcycling, also known as creative reuse, is the process of transforming by-products, waste materials, useless, or unwanted products into new materials or products perceived to be of greater quality, such as artistic value or environmental value.

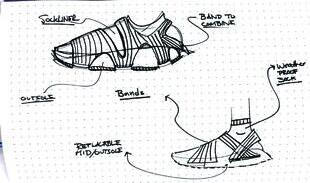

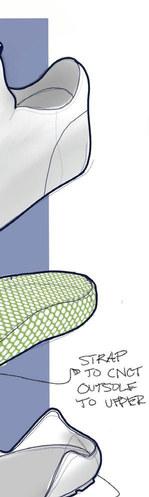

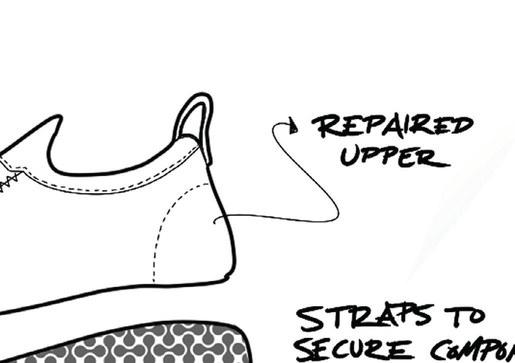

The upper is the portion of a shoe that holds the foot in place and provides structure around the foot. The upper can consist of many components to achieve this, and material choice as well as construction plays a big role in the feeling of a shoe on the foot.

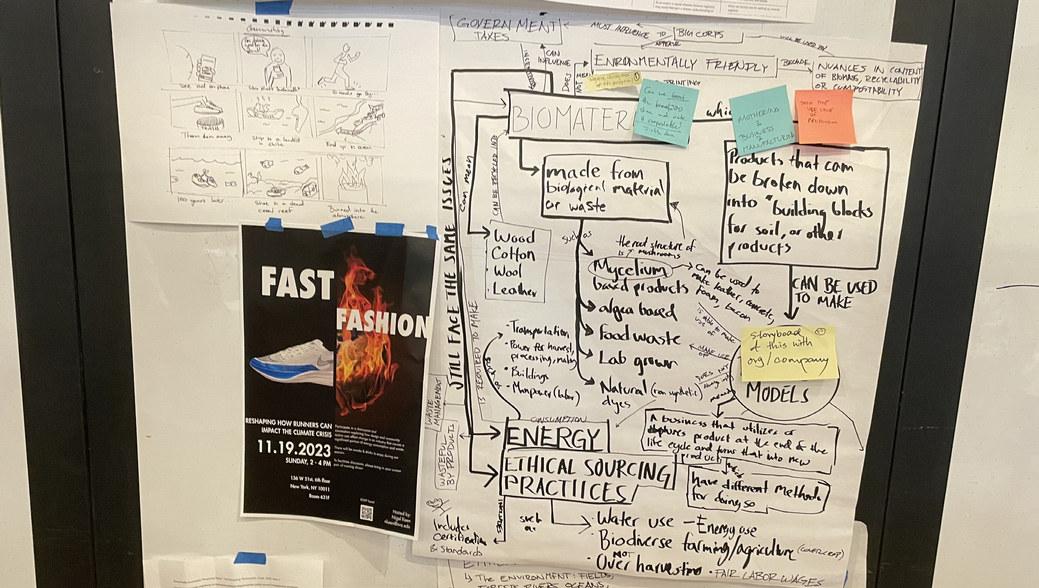

The biological innovation happening in materials science, and tons of start-ups popping up, is a testament to the diversity of options becoming available for products to be made with less waste, and return to its basic elements as opposed to its plastic counterparts. Through my research I sought to understand this new eco-system and understand what are the barriers to widespread adoption. Through my expert interviews I learned about the challenges of not only the material properties and manufacturing, but also sourcing, intellectual property, logistics, labor, waste streams, and government regulations.

The words biodegradable and compostable get thrown around a lot. With companies jockeying for position on the sustainability front, many of these terms get used to describe how they should be disposed of. Oftentimes these terms are misleading and end up making it harder for recycling systems and compost collection to properly sort items correctly. The term biodegradable means the material will break down, but for most of these plastics they do not break into basic elements that can be utilized by biological systems and have a harmful effect on the ecosystem they end up in. Compostability has been marketed as the best possible solution for materials that will end up in landfills or compost systems. But the issue here is the lack of specificity and consumer education. If a material is industrial compostable it still requires high temperatures and chemicals to break down into basic elements. Otherwise if these materials find themselves in landfills they will not break down properly like home-compostable materials. Time and environment are critical to ensuring that claims by companies are actionable and understandable to the consumer.

Choas, Disorder, and Randomness

The degradation of the matter and energy in the universe to an ultimate state of inert uniformity

Entropy is the general trend of the universe toward death and disorder.In the context of my research, this topic relates the fact that all recycling systems are inherently leaky. This means that all materials must be safe to end up in nature because one way or another, they all do.

This concept explains why PFAS are found in polar bears in Antarctica and other areas that are untouched by humans. As garments break down and deteriorate, these chemicals end up in air streams, waterways and soil, which have a detrimental effect on the health of the humans and the planet.

From

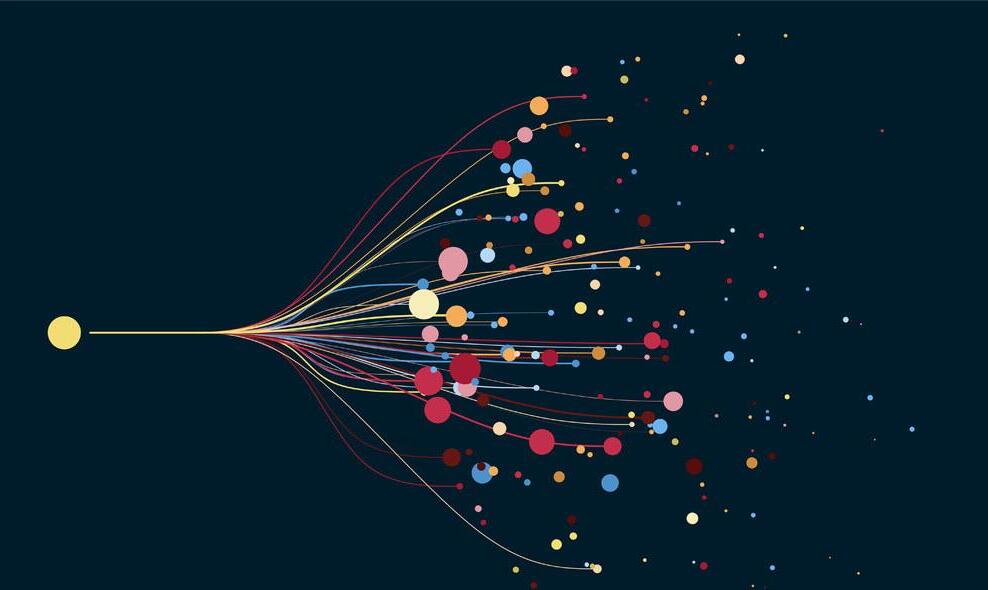

Illustration of Entropy

Illustration of Entropy

“In China, over 70% of the rivers are polluted (River Blue Documentary), meaning many of their 1.4 billion population cannot access uncontaminated water Ground water is contaminated, rendering wells unsafe for collecting water for domestic consumption. Billions of tonnes of wastewater are expelled from factories untreated, lowering dissolved oxygen within waterways to levels unable to

sustain life. For the communities surrounding China’s Li River, and the factory workers handling these chemicals, exposure to toxic, potent and potentially deadly chemicals occurs on a daily basis. Fashion Revolution: https://www.fashionrevolution.org/the-true-cost-ofcolour-the-impact-of-textile-dyes-on-water-systems/

WWater Use and Dye Process

Waterways near dye factories in China

Across the world, an estimated 24.9 million people are victims of forced labor. The lion’s share of them–16 million people–are exploited by companies for a profit, rather than by private individuals, such as in the case of sex trafficking. And according to KnowTheChain’s report, one of the largest sectors that relies on forced labor is the $3 trillion apparel and footwear industry. An estimated 60 million to 75 million people are employed in this global sector. And while most of us realize that these workers are paid very little, the reality is that some are not paid at all.

Fast Co: https://www.fastcompany.com/90279693/did-a-slave-makeyour-sneakers-the-answer-is-probably

During my interview with Aaron, we discussed the difficulty with changing the use of better materials at the product design level. This is why he know works to help start-ups gain funding because only though the development of new companies can real change be made.

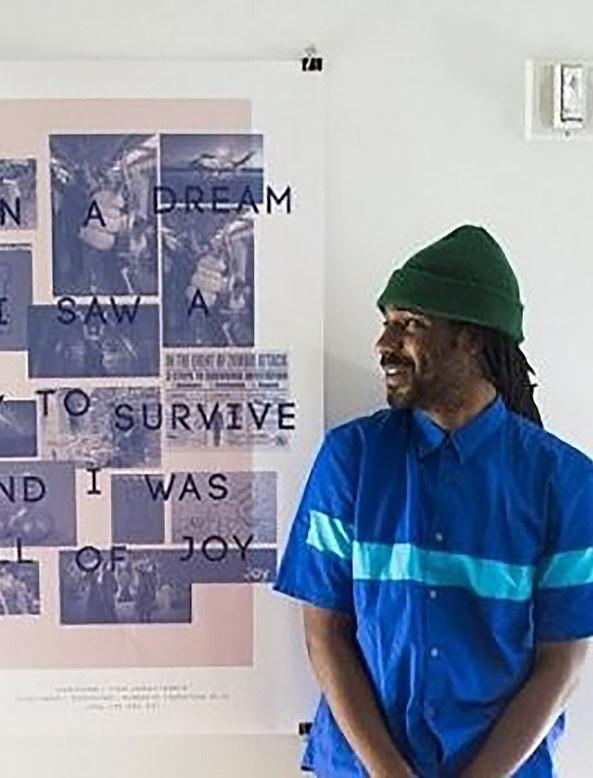

Interview with AaronKeep Earth Company, Biodesign Jobs, Material Factors

Aaron Nesser

Aaron Nesser

From my interview withi, the main insights that influenced my thesis work are to design for a specific situation that lends itself to making the sustainable choice easy. Additionaly that changing behavior and perception is a primary goal for him. He also introduced me to the idea of products as a service.

Ali El Idressi

Ali El Idressi

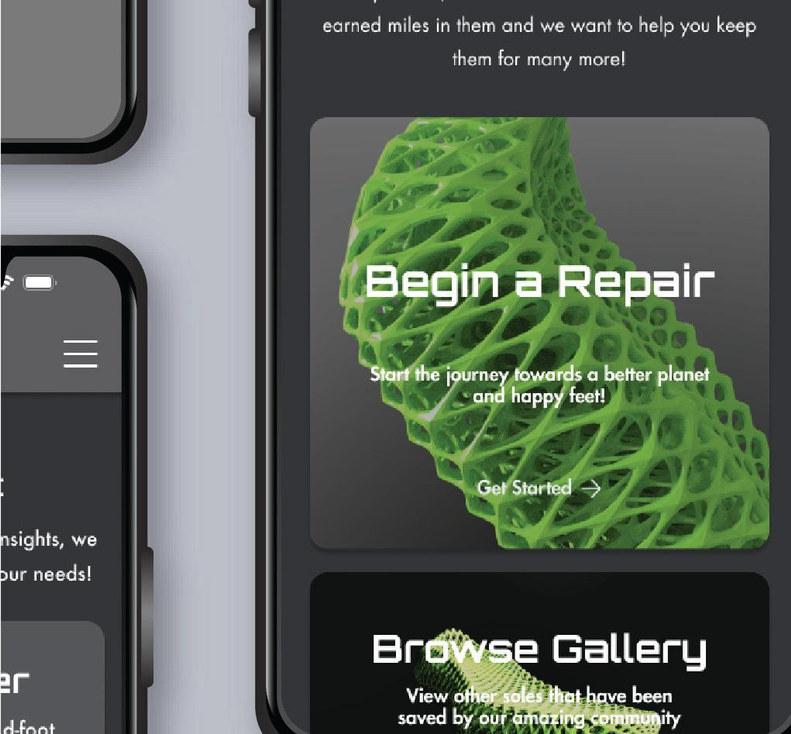

I met with Brandon twice during my design phases of building COBLR. He provided me valauable feedback to think about how to improve the branding, conceptualize the overall feeling of the brick and mortar store, and how the app could help support the physical service. With his eperience working for Reed Art department and general knowledge of street wear, it was motivating and valueable to hear his excitement and encouragement for this work.

Design Director at Reed Art Department

Brandon Washington

Design Director at Reed Art Department

Brandon Washington

Claire’s company Reath, uses software and lowtech solutions like QR codes to track products through their life cycle in order to set up reverse logistics to re-use packaging. Her framework helped me understand some the opportunities and chlllenges of trying to re-use packaging fr more sustainable economic solutions.

Interview with Claire CEO and Co-Founder of Reath Claire Rampen

Claire Rampen

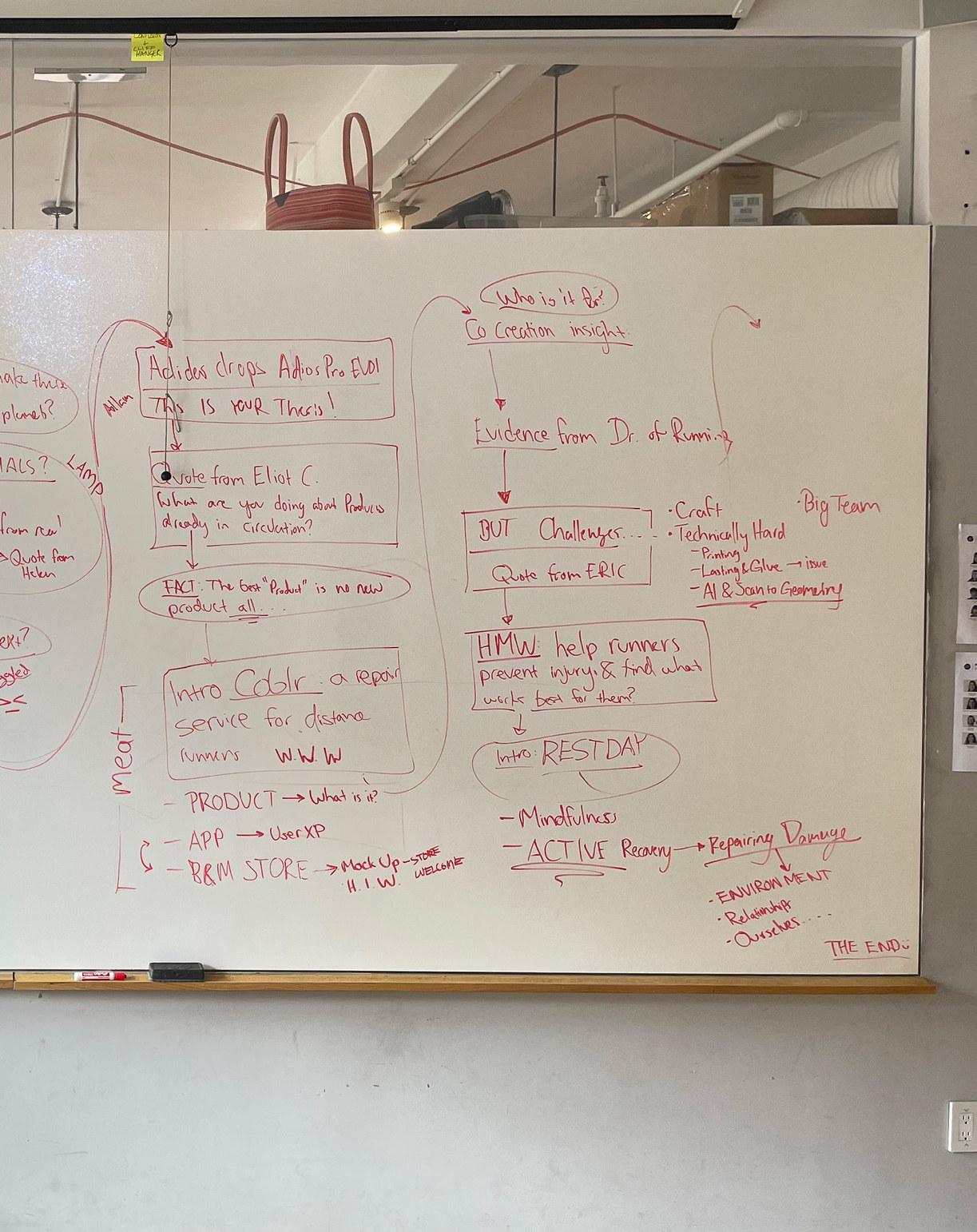

Eliot met with me on multiple occasions and really acted as an advisor for my thesis work. It was Eliots questions that led me to think about the repairability of existing products and how might we handle issue of waste and recycling. In addition to this he gave me valueable insight on how Lululemon specs materails for their product lines and work with vendors to find better alternatives to commonly used materials that are fossil fuel based.

Eliot Cohen Pirenne

Eliot Cohen Pirenne

From my interview with Frank, I learned about the ways in which he worked with local artisans across the globe to help them increase their output while minimizing the laboor. He also explained his knowledge of textiles used for home decor and how the materials choices and dye processes effect the overall impact of a product from an environmental perspective

Frank Millero

Frank Millero

In my interview with Kara, I was able to learn the challenges with recycling which include sorting, getting unrecyclable goods, not being able to sell a materia. I also learned that the machinery needs to be set up for specific goods, so for example, if a shoe gets into their machines it can break them causing down time and repairs, which are very expensive costs for the facility.

Education Director at Balcones Recycling

Kara Napolitano

Education Director at Balcones Recycling

Kara Napolitano

In my interview with Susan, she opened my eyes to a world of new potential material developments and dye processes that are al really exciting and innovative. However, she added the caveat that many of them will take 10-20 years to reach a production scale.This led me to shift the focus of my work towards something that could be implemented today.

Interview with Susan Susan Joy

Susan Joy

From my interview with Stacey, she warned me of the trap with some bioplastics companies. Many of them don’t provide a real alternative that is better for the planet. Another insight that she provided is the push from corporations to focus on circularity. By closing the loop and recapturing product, it is easier for companies to deal with the waste they produce. However, this waste should generally lowered and be made from better materials.

From my interview, Tim’s insights helped me put into context what is important to the environmental aspects of materials: Energy, Feedstocks, and Costs. In a business context: costs, performance, or unique selling point He gave me insight into the process of manufacturing, the scalability of materials, what players are doing things in the space, priorities of start-ups vs. large corporations, company views on risks and willingness to take them, government’s role in manufacturing, and end-of-life processes or problems.

Tim McGee

Tim McGee

Over the course of the year I relied heavily on the knowledge found from these two podcasts, How to Biodesign Audio Recap and Doctors of Running. I listend to hundreds of hours which pushed and pulled my work in many directions as I tried to navigate the challenging and amorphous landscape that is climate science.

Although many of the experts may argue the details, many agree that the current system of production and waste is not working. Only through large-scale reform and a paradigm shift of consumer behavior can we start to work our way out of the mess that the industrial revolution has sprung onto human and planetary health.

In the process of conducting my research on climate related issues to production and new biomaterial innovations, I decided to focus my attention towards the issue of running shoe waste because I have a particular interest in the performance and experience of running as a direct relationship between the shoe, the body, and the environment.

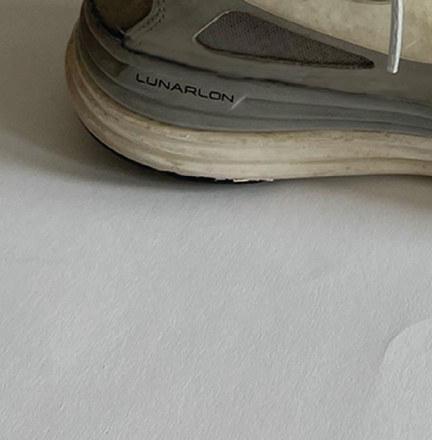

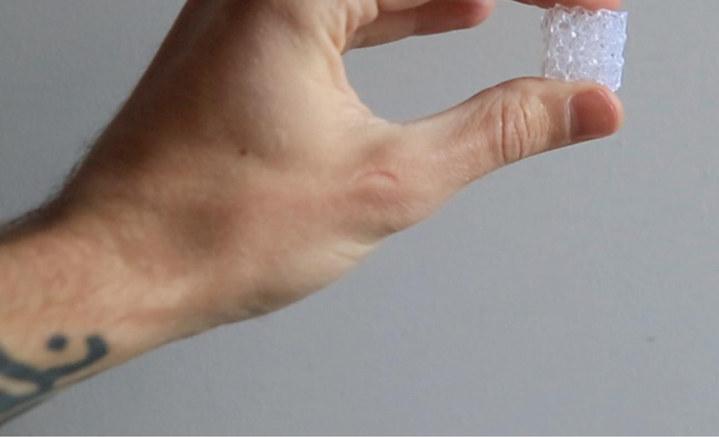

After discovering the issues with labor, energy, pollution, and waste associated with common running shoes on the market, I found that saving shoes from a landfill and giving it new life is more impactful than even the most “sustainably” made new shoe. Through the innovation in material science, parametric modeling of lattice structures, and 3D printing technology, it is possible to repair old worn out soles which saves shoes from landfills and can be recycled when the new repairs end up wearing out.

Image from Colourbox

Image from Colourbox

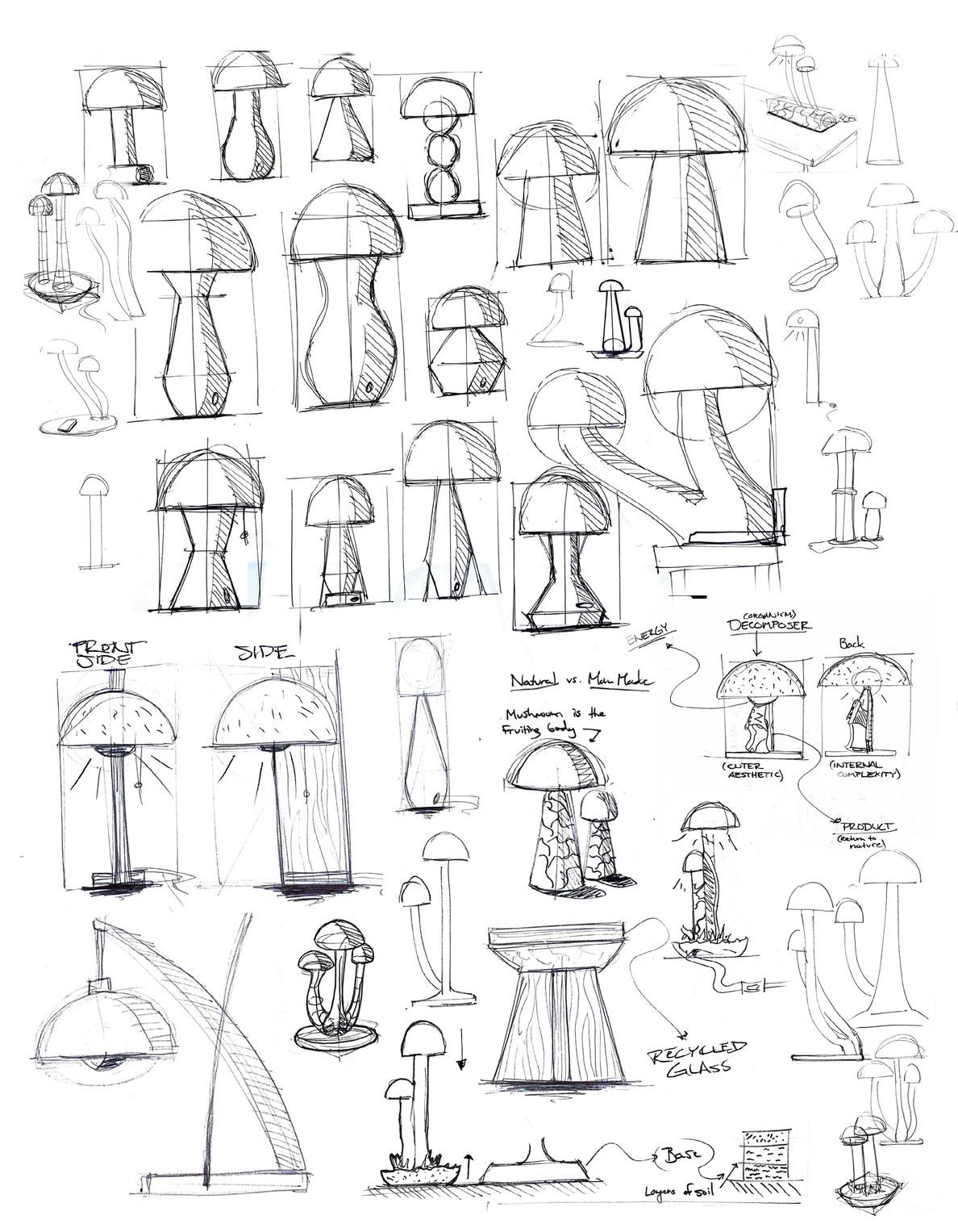

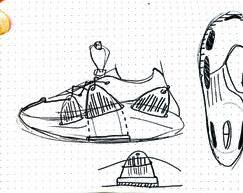

In this section, I will explore materials processes, methods of manufacture, and movement. My process involved a mixture of physical making, 3D modeling, sketching, mind mapping, growing materials, and teardowns.

Over the course of the year, my prototyping process involved deconstruction of the items around me to create a deeper understanding of the construction of them. Early on I was deeply inspired by the nature of grown materials such as mycelium and bioleathers. The underlying concepts explored in my prototyping process involve creating new value from discarded items. Consumption is the major problem I am trying to address with this work. My goal with this work is to shift perspectives of what it means to throw our everyday objects away and have people ask themselves if these objects are truly worth throwing away, or is there some other value that can be captured from this object?

Barners & Noeble

Barners & Noeble

How does material make a difference?

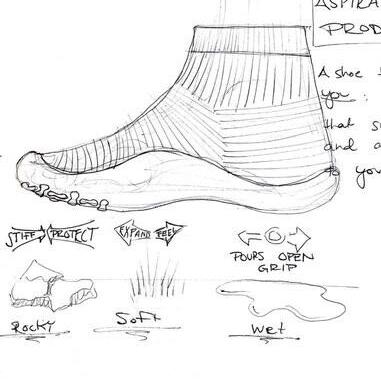

These prototypes helped me discover the different sensation of materials that can create the user experience in a shoe. I explored how my foot hit the ground and compressed while walkng, and jogging.

by Susan

by Susan

The compostable rain jacket was my first provocation and attempt to ask the question, what if we compost our clothes like we do our food scraps? How would that change our relationship to the garments we wear and how might that be better or worse than our current system of throwing items out when we no longer like the style?

I constructed this artifact with GrainPro grain storage bags and sealed the seams using a hair straightener to melt them together. The pattern for the jacket was acquired online from Glory Allen’s website. Through the process of making this piece I realized how quickly I was able to construct a garment which technically was functional (although would be unbreathable and extremely sweaty). This led me to think about how much energy, waste, labor and resources we could save if people accepted the challenge of making or repairing clothes and other artifacts with excitement. Not only are you able to save money but these pieces become much more valuable from the time and energy spent caring for or creating them.

Made in the Fall of 2023

Using GrainPro storage bags, and heat welded seams

by Susan

by Susan

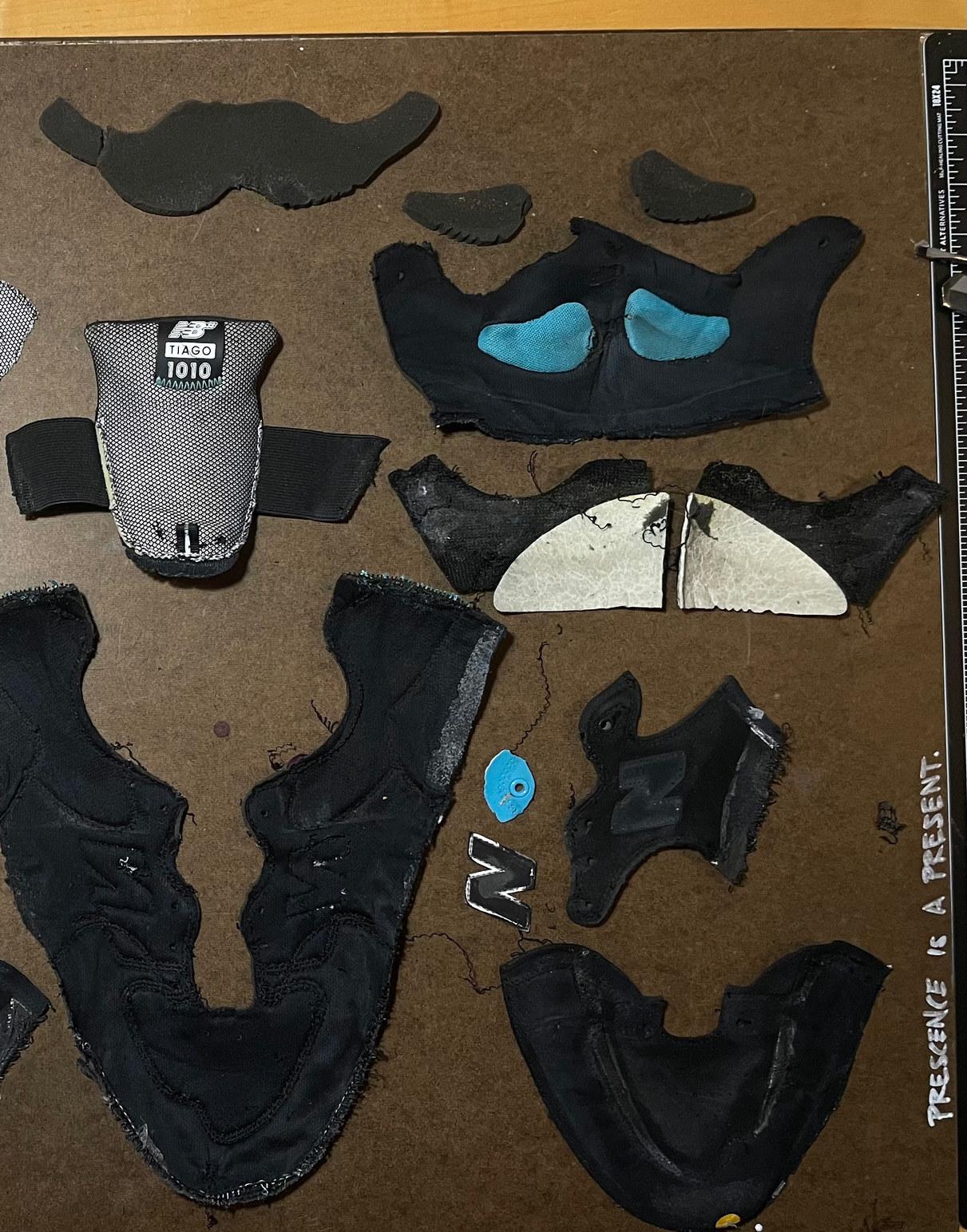

The Sole Shroom lamp shared a similar ethos to the compostable rain jacket, but the focus for this artifact was to create a juxtaposition of grown material (mycelium) and waste material (old skate shoes) into one single object that showcases these two things beautifully. I wanted to make this artifact aesthetically pleasing because I want the viewer to find beauty in something that traditionally is seen as trash (old beat up skate shoes).

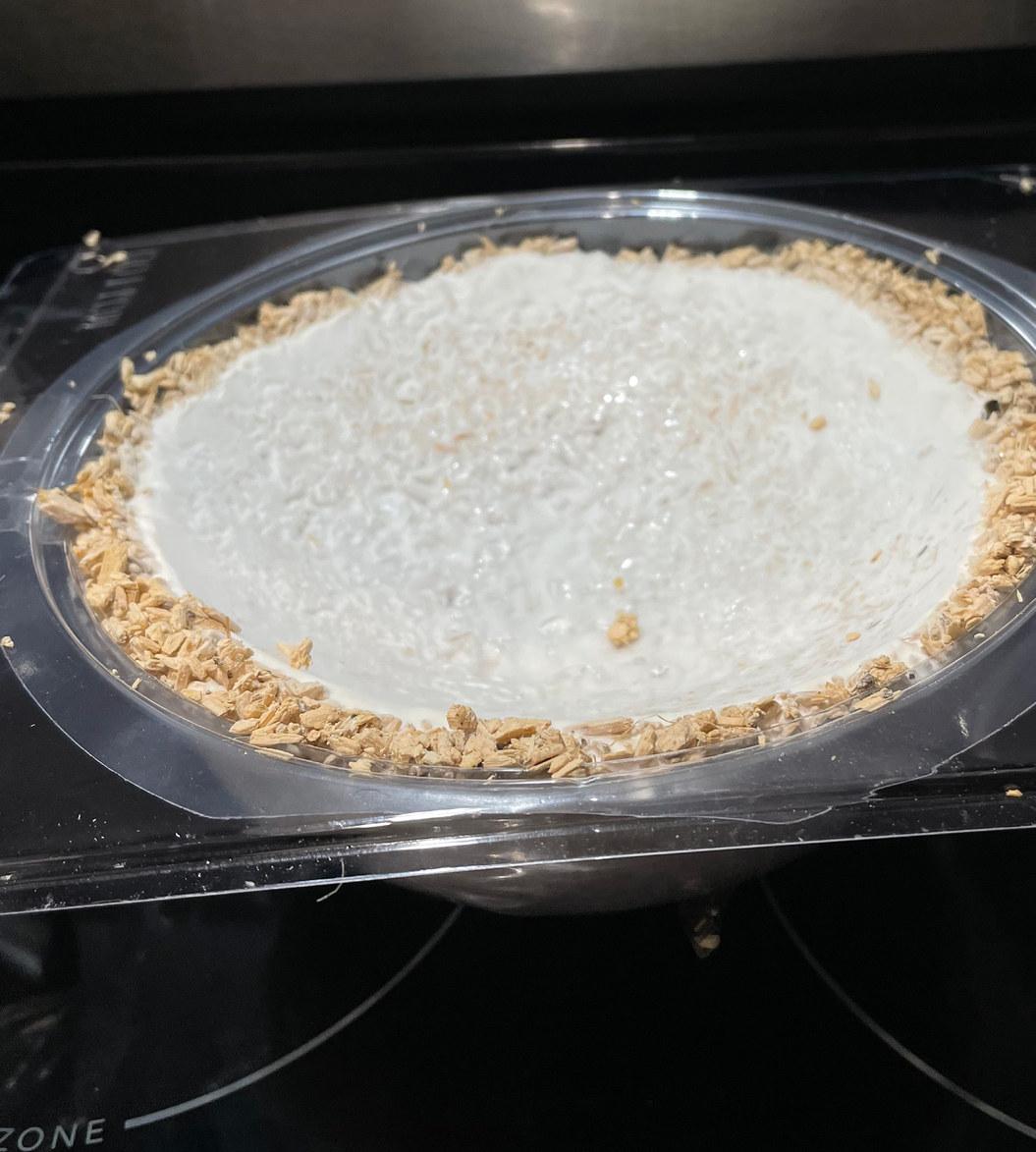

I made this artifact by disassembling two separate shoes into each individual component for two reasons. 1. To understand how many individual components are in one single shoe and 2. To understand the construction and design of how the pieces are assembled to create three dimensional structure from two dimensional parts. I then created the mycelium lamp shade by growing the material sourced from Ecovative. This included a 2 week process of growing the mycelium, placing it in a mold, and baking it to stop the mold from growing. Once I had my components ready, I used blue foam to create the base form, which I could then attach my shoe components, lamp shade and light to. I used simple tea lights from Amazon as a proof of concept.

The process of creating this lamp gave me a deeper understanding of the complexity and number of components it takes to create a shoe. In some cases, a single shoe can require 370 components, which each require sourcing material, energy, labor, water, and waste. Also in the process of disassembling the shoe, and how difficult it was, it became very apparent that they are not designed to be disassembled or repaired. These highly technical, and highly engineered products are made to be discarded and oftentimes take hundreds of years to decompose.

Made in the Fall of 2023

Made with blue foam, plywood, upcycled shoe panels, mycelium, and tea lights

Is

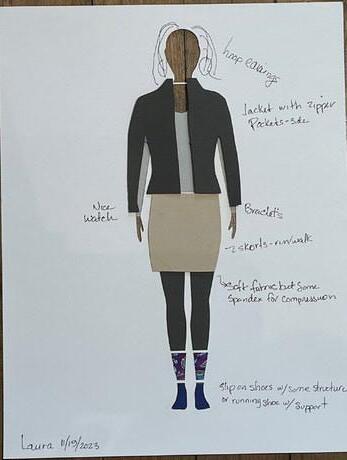

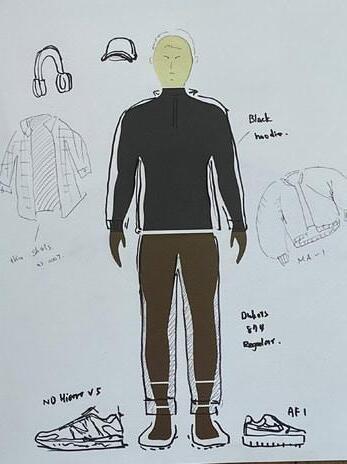

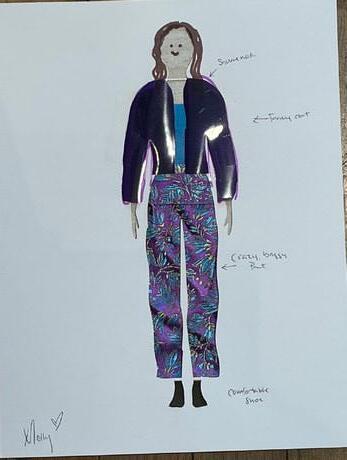

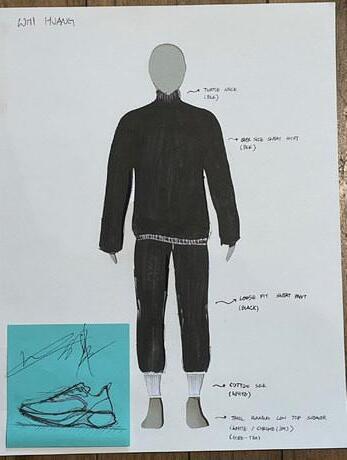

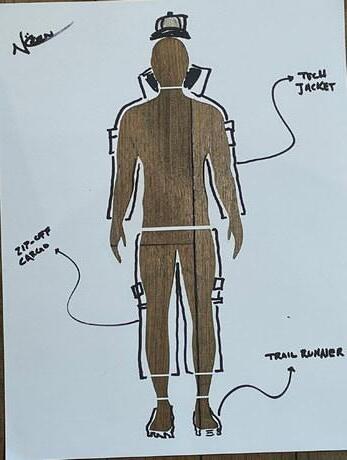

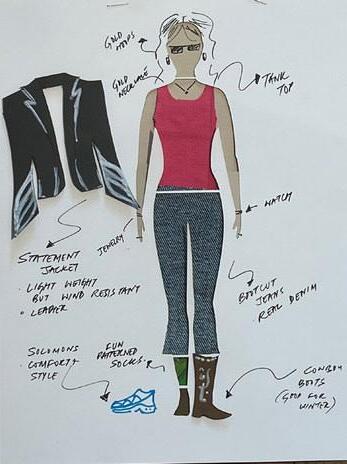

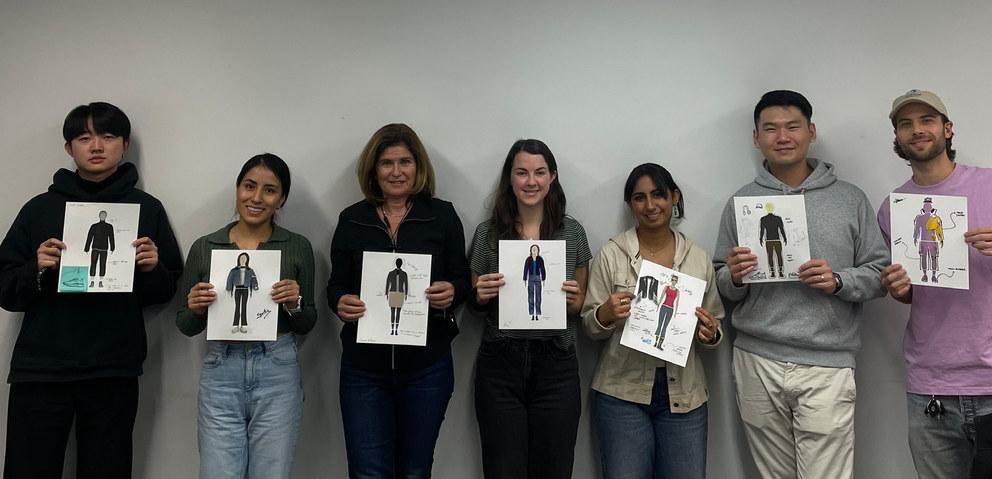

The goal of this co-creation session was to understand how sport and identity play a role in the issues we face with overconsumption and the fashion industries’ impact on climate. To start with, I presented the group with a story about the problems of fashion and sportswear as a framework to understand the point of the co-creation activity. After the opening presentation, I had the participants design their own “forever fit”, an outfit that they could see themselves wearing for the rest of their life. The purpose behind this was to have participants think about what styles and items they would need to get through 90% of their daily life. If we each think about the

actual requirements of our clothes for sports or social situations, the number is very limited. But due to identity and consumption, we often overbuy and constantly change styles to keep up with trends or try out new things. This is really where the problem of the fashion industry lies.

Held during the Fall Semester for Thesis I

The participants included 2 men and 3 women, within the age ranges of 24 - 59. Each person brought their own unique set of challenges and needs when it comes to footwear. 2 participants ran long distances (more than a mile at a time multiple times a week) and the other 3 have experiences running but don’t run on a regular basis.

In the discussion portion of the co-creation, participants with flat feet mentioned that they felt limited in the options of shoes available on the market because many shoe shapes tend to be too narrow and unsupportive for them. Other participants mentioned that width is often a factor that eliminates a lot of options when buying for them. Another theme that we touched on is style. If a shoe is really comfortable but doesn’t fit their style it can be just as wasteful as buying a shoe that doesn’t fit.

From these discussions the important insights that later influenced the design of my product and service is that shoes need to be functional and stylish. Shoes often don’t fit people that well because their feet aren’t shaped like the common mold shape. People have a hard time finding the right shoe that fits them well because there are so many options. It is expensive and time consuming to test out different styles and brands. And when they do find a great fitting shoe, the next model year fits very differently. From these insights I was able to better understand what problems the users were having with their shoes. Up until this point I had much more research and knowledge about the issues of sourcing, manufacturing, and waste.

There are roughly 621 Million runners worldwide according to AskWonder. In the US this group is 15% of the total population. What this means is that more and more people are finding the joys and benefits of running worldwide. If you put a product lens on these numbers that means more and more people are trying, and buying running shoes. With an enormous amount of options available new runners are met with an important and often overwhelming decision. What’s the best running shoe? What type of running shoe do I need? Why are they so expensive? The list goes on. The answer to these questions lies in a lot of time and energy spent researching, and testing different shoes. Not to mention, running shoes are often over $100 and can exceed $300 if you start getting into carbon-plated racing shoes.

Like in any new hobby or activity the vast amount of knowledge required to make informed decisions can feel daunting. Which is why my education is an important part of the target user for my service.

Another important factor in determining the right running shoe is comfort. If you look at most of the shoe shapes on the market, they tend to be designed with a symmetrical pointed toe box. These designs often crowd the toes together due to the unnatural shape. People with wider feet, flat feet, or even asymmetrical feet can have a really hard time fitting into these common shoe fits. This can greatly limit the options a person has when looking for a pair of shoes, and in some cases even require very expensive custom orthotics to correct the unnatural position the shoe forces a person into. This is what makes finding the right pair of running shoes such a unique experience, and especially tough for people with wide, flat, or asymmetrical feet.

Photo taken during Brooklyn Half Marathon

The main theme explored in my thesis work is recapturing value from discarded or wasted items. The primary focus of my work is to create better systems, products, and experiences aimed at reducing the significant human impact on the environment. Only by design can we shift the global crisis we face as a global society. The footwear industry, and the agriculture industry which is inevitably linked, are two major drivers behind climate change and ecosystem decline. One major factor in shifting the narrative and driving change is reducing the consumption of our culture. This starts with repairing and reusing existing products in circulation, coupled with producing new products that are not just less harmful but regenerative for the environment.

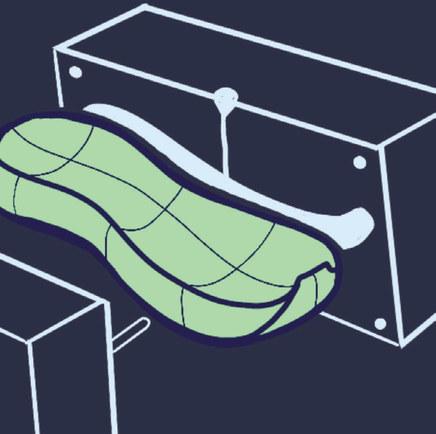

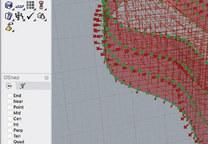

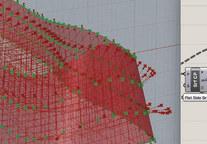

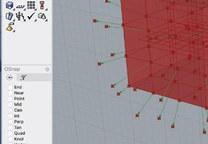

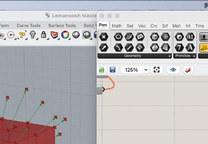

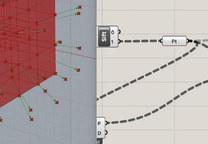

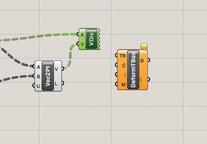

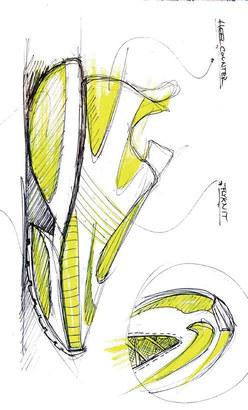

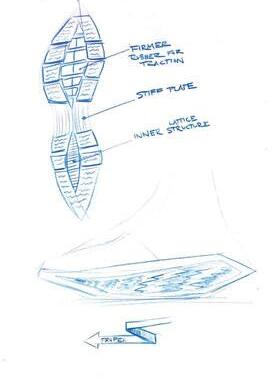

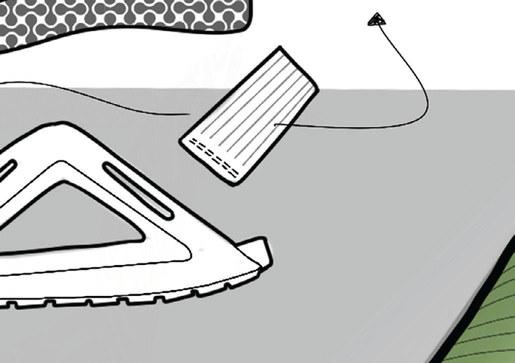

The nodes here are the basis for how the outer cage of the midsole in the image above is constructed using the point strecth method

Populating NURBS objects with voxels allows for cubic boxes to be stretch onto organic surfaces using the Grasshopper plug in in Rhino

Parametric modeling in Grasshopper shows the division of a solid geomerty into cubes which are then populated with a lattice fill type

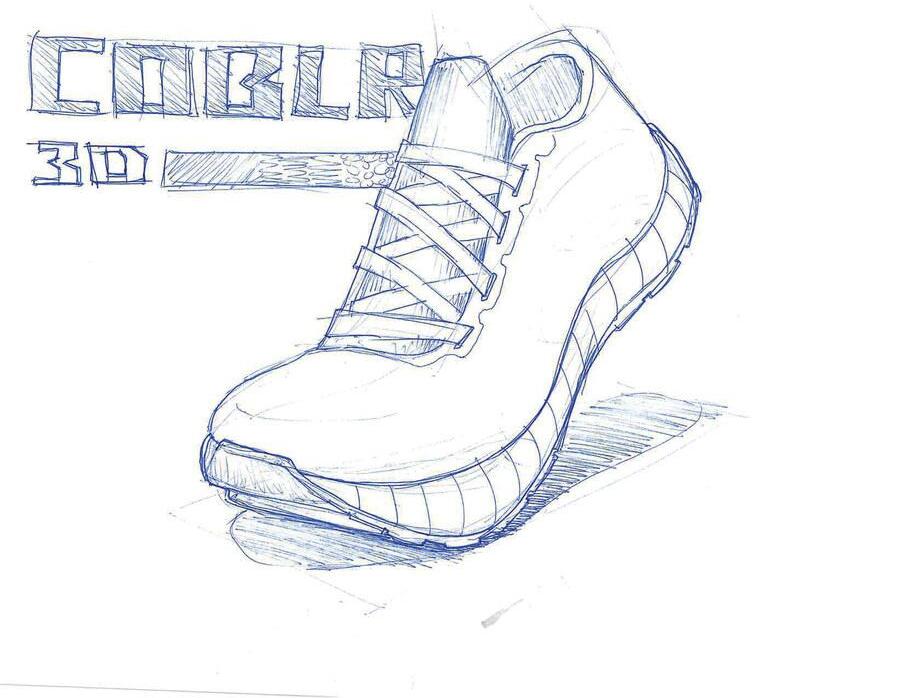

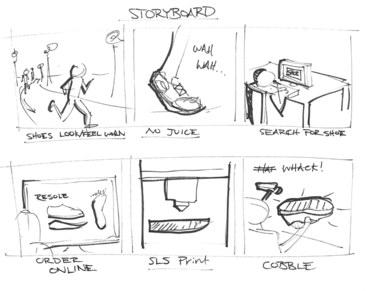

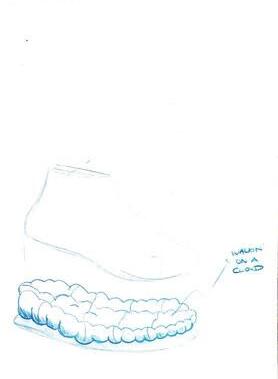

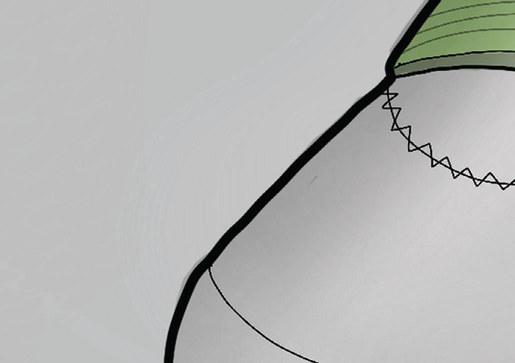

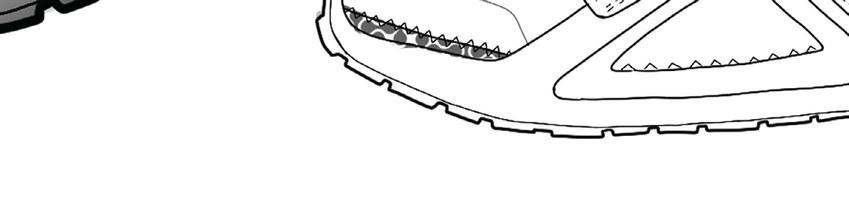

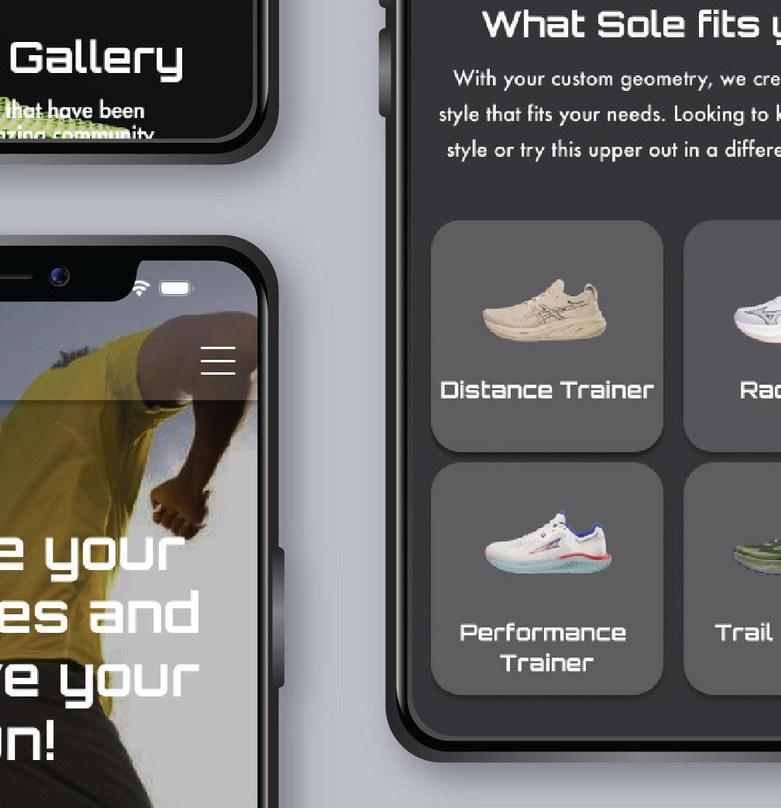

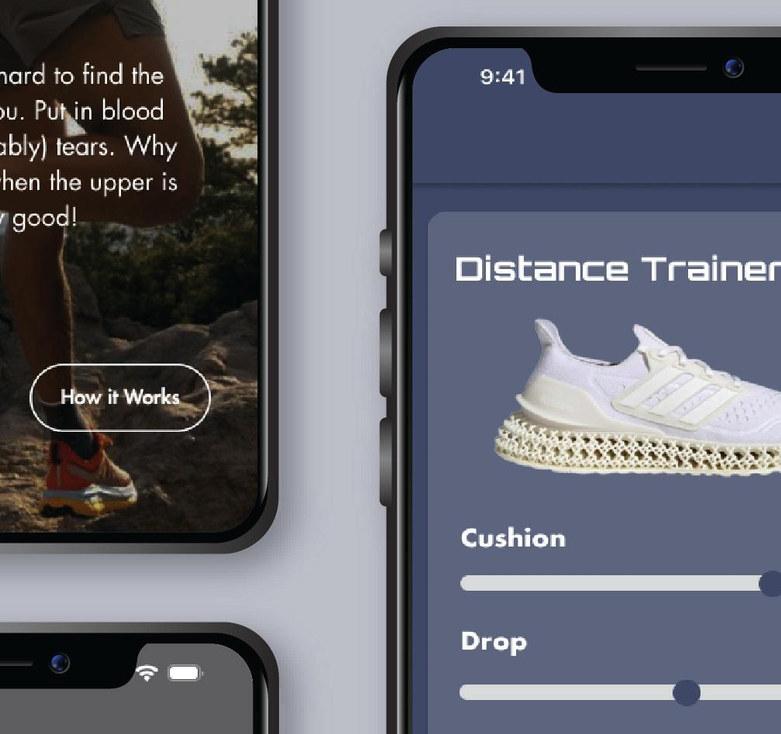

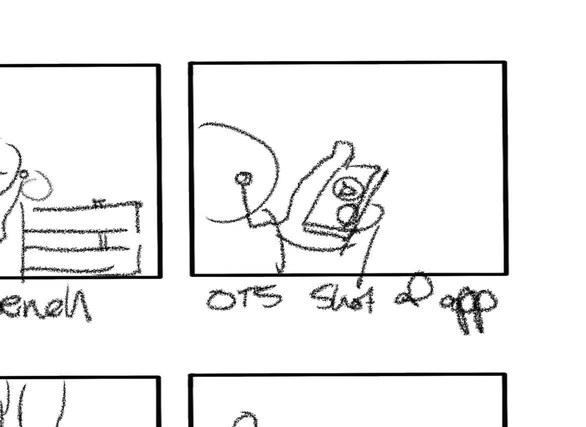

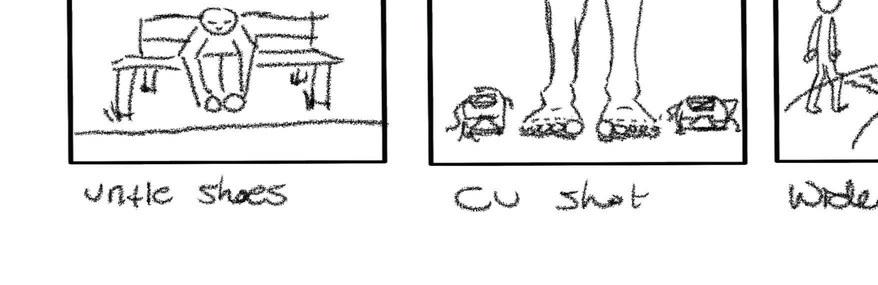

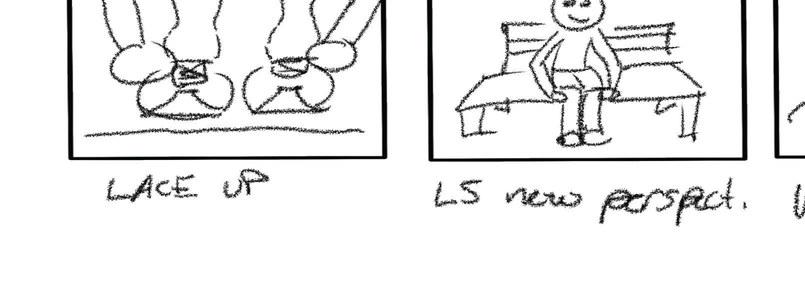

COBLR is a repair service for runners who have found a great-fitting pair of shoes and want to repair them rather than throw them away.

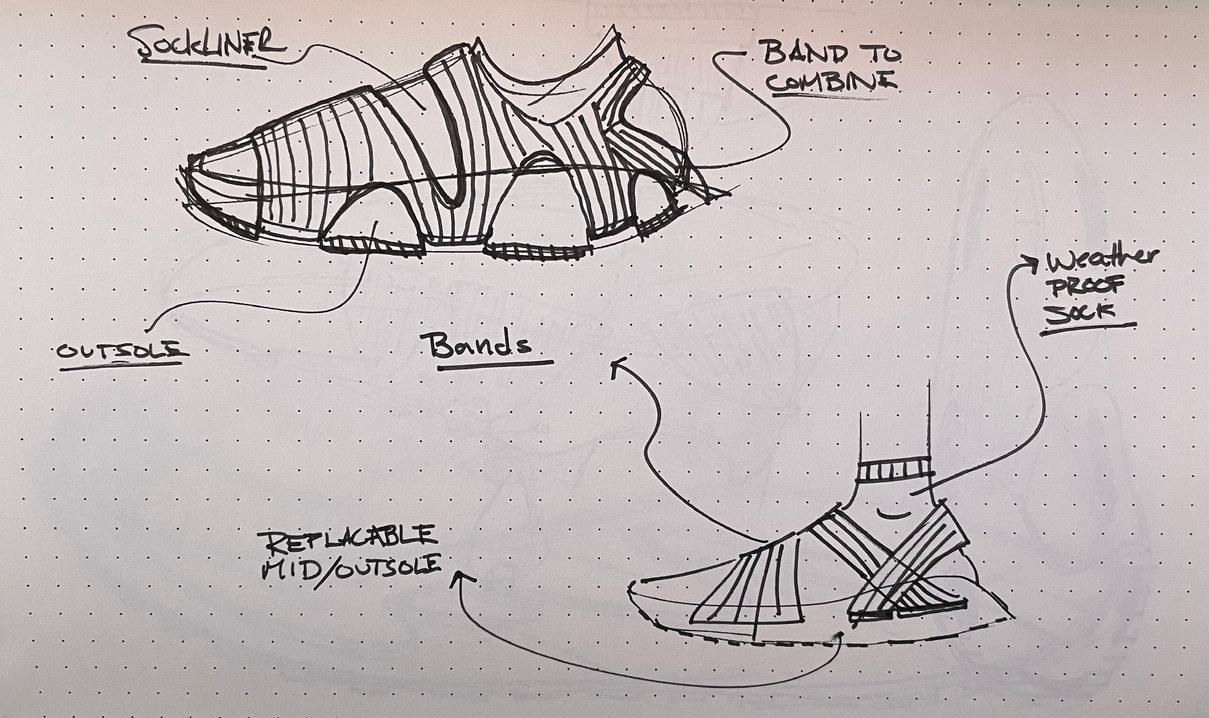

It is an exploration into the possibilities of 3D printing as an alternative to foam injection molding or subtractive manufacturing processes. There is also an added level of complexity to this project, as it aims to take individual users’ foot scans and gait analyses to redesign their existing shoe midsoles to be remade and attached to the original shoe upper.

Because each individual has unique foot attributes and biomechanics, everyone experiences footwear differently. Even over the course of a single run, a person’s mechanics change in response to factors such as terrain, level of fatigue in the body, and mental state. This product has two main goals in its design. First, to take a previously loved shoe and repair it so that the shoe fits the runner even better than before. Second, to extend the life of shoes so that runners are consuming fewer shoes over time.

When I conducted primary research, every single runner I talked to had a version of this story: “I loved this shoe by XYZ company, but when I wore through it and went to buy the next model of the same line, it wasn’t really the same. I wish I could buy the old model.” In my synthesis of user interviews and secondary research, I’ve come to the conclusion that footwear, for many, is

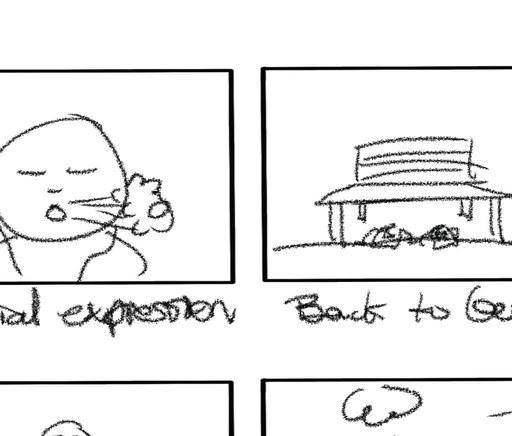

Context Drawing for 3DPD -3

a deeply emotional piece of equipment. For runners, it allows them to run long distances by protecting their feet and preventing injury. And if we look at the science of feet, they have thousands of neurons that take in sensory information from the outside world. Because of this connection, footwear has the ability to shape our perception of the external environment.

With footwear production accounting for roughly 70% of the industry’s total carbon emissions, as well as the addition of harmful chemicals and dyes used in the process, this is by far the most environmentally harmful phase of the footwear industry. As I struggled to find an entry point of design to address this problem, one of the subject matter experts I interviewed, Eliot Cohen, posed this question to me, “What could you do about the products that are already in

circulation?” This led me to think about repair as a method of slowing the rising rate of consumption. By providing an alternative to buying new shoes, I felt that this would be one way to promote better consumer habits aimed at countering increasing consumption. In my research, I found that people were receptive to this option and that, in some cases, they were willing to pay the same price as a new shoe for this service.

citation:https://www.circularonline.co.uk/features/circular-trainers-how-consumption-became-culture/

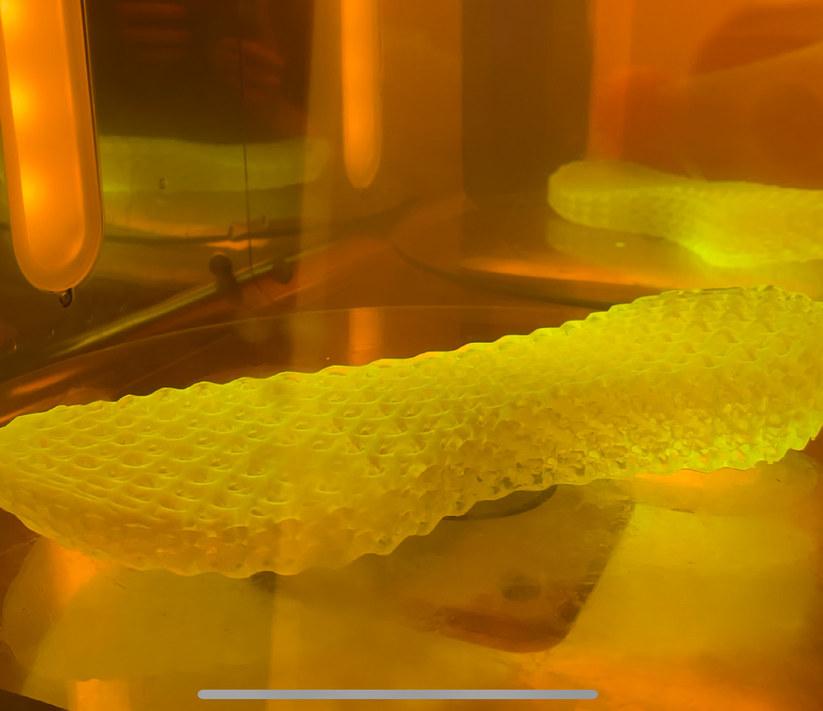

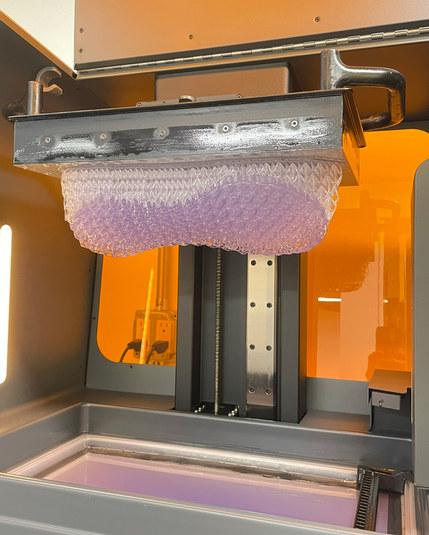

Printed on FormLabs

“What could you do about the products that are already in circulation?”

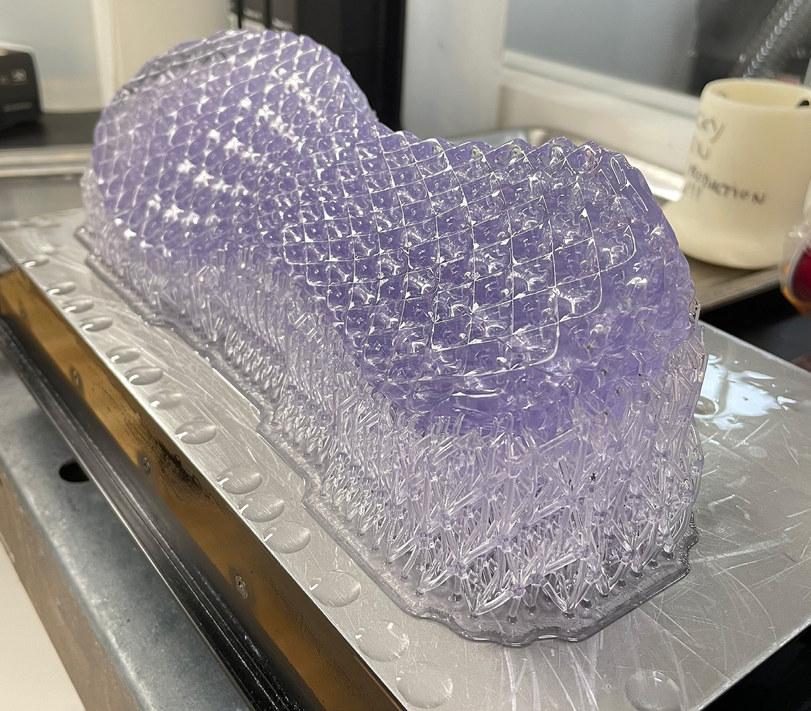

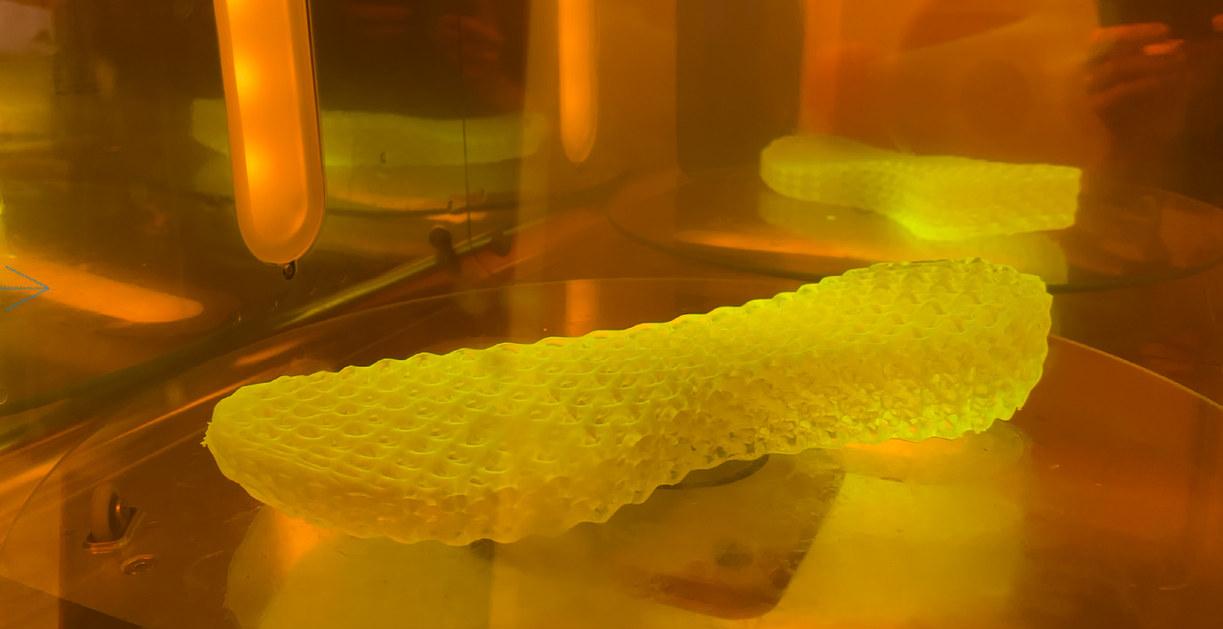

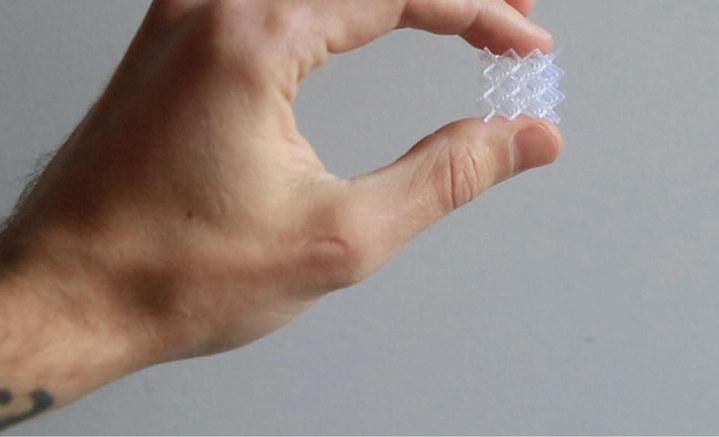

This idea builds on the innovation of Adidas and Carbon’s 4DFWD running shoe, which is a running shoe with a 3D-printed midsole designed to compress and rebound in a forward-propelling fashion, based on the geometry of the “bow-tie” lattice structure. To break this down further, the manufacturing of the midsole is a two-part process that involves first SLA (stereolithography) printing, and then a baking process onto a last that gives the midsole its curvature.

Curing process requires baking with UV light

Using Rhino 3D modeling software and the Grasshopper plugin that enables parametric design, I was able to test out a conceptual 3D-printed model of what this could look like. Using different cell types and arrangements of points in three-dimensional space, beams and nodes are constructed, which provide a scaffolding to support the geometry. With this software, each beam thickness and node size allows for the mechanical properties of each lattice type to be tweaked and tailored to design certain properties of the midsole, such

as stiffness, flexibility, responsiveness, or shock absorption. These structures are known as lattice structures.

Throughout the semester, I printed different types of lattices from TPU 3D filament and Flexible 80A durometer resin filament on the FormLabs SLA printer. From these test cubes, I was able to see how changing the properties of the lattice affected its load capabilities and its ability to flex and rebound. I found the TPU to be too stiff to use as a working prototype and the 80A flexible

Foot Strike Study

filament too expensive to use on anything other than the final 3D model.

To visualize and prototype what the repair process could look like, I took an old pair of running shoes and tore the midsole from the upper. This process was challenging, as I did not use Acetone to loosen the glue holding these two pieces together. Instead, I used an exacto knifeand sliced the sole from the upper. Through this process, I learned that the lasting board is an essential component to securing the sole to the upper. Consequently, in order to create a new sole that fits the runner’s foot shape, a new lasting board would likely be needed to change the shape of the footbed.

/ / /

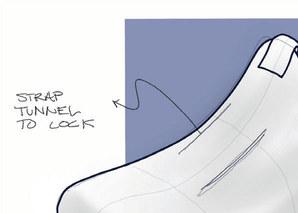

Another challenging aspect of this process is attaching the old upper to the new midsole and outsole. In my sketching explorations, I envisioned what a glueless construction could look like in order to remove the need for these toxic chemicals. If I’d had more time to devote to prototyping, I would have explored how mechanical methods construction could be possible and suit the high performance nature of running.

I also did not have as much time to focus on outsole design and materials that could be better alternatives to synthetic rubber commonly used today. However, I carried out preliminary research and found that natural rubber production, although better than synthetic rubber, leads to deforestation, biodiversity loss, and pollution. Other issues of this industry include volatile prices, impoverished farmers, the theft of land from Indigenous communities, and an international rubber cartel. I’m interested in and would love to learn more about projects that are currently producing lab-grown rubber using genes from fruit flies and other biological sources.

Through one of my subject matter expert interviews, I also discovered challenges such as the success rates of 3D printing parts. Zellerfeld, a new 3D-printed shoe company making footwear completely out of a single material, is seeing success rates of only 10% for printing. Additionally, a custom shoe last would need to be printed to accompany the custom midsole designed for each user; this is because the shoe last is one of the main pieces of equipment that gives the midsole its geometry and structure when assembling the uppers to the soles. In shoe design, the phrase ”last comes first” signifies the importance of proper last design to ensure the shoe fits correctly.

In conclusion, the feedback I received from this project was overwhelmingly positive. Many people expressed interest in seeing it evolve into an actual business opportunity. As I continue to work on this project, two areas of focus will be important to determining viability and feasibility. The first area is the requirements from a business model perspective. What people, processes, equipment, and other overhead is required to bring this to life? The second is feasibility testing and more material research. I would need to design a test run to prove out some of the assumptions made for this project. Those would be questions around construction of the repair and the necessary process required to properly assemble the repaired shoe.

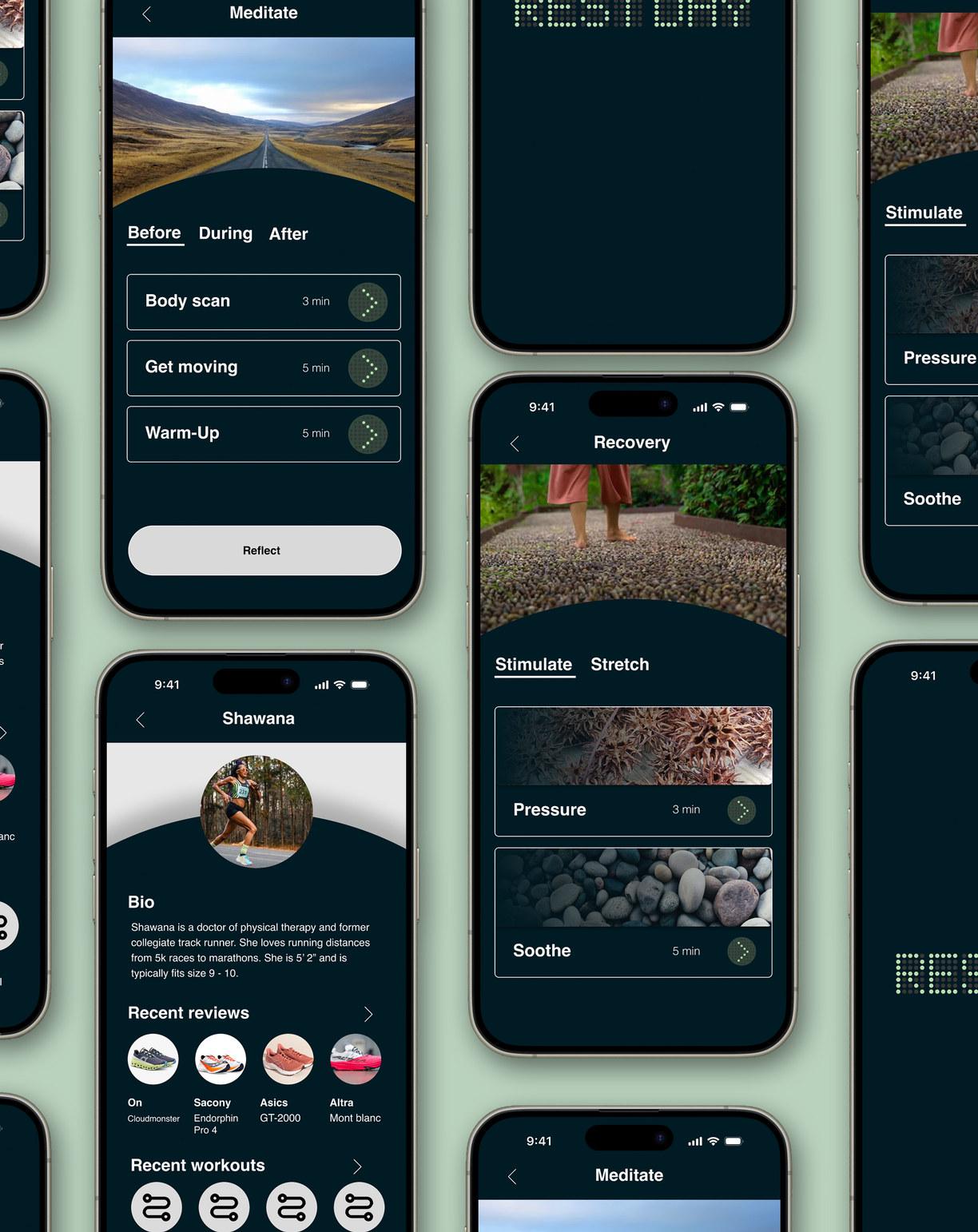

Rest Day is an experience that uses mindfulness and reflexology practices to help distance runners become more aware of the effects that footwear has on the body and how these practices can help runners find footwear that best suits their unique needs, and protect against overuse injuries by becoming more in tune with their bodies. This experience takes the form of an app that is designed to be accessible for anyone from new runners to elite professionals, and no special tools or equipment is required for these practices.

These techniques have been practiced for thousands of years, but only until recent years have they been studied by western science to produce quantifiable evidence of their results. In studying the literature of running footwear and its effects on the body, I found that long periods of standing or walking in shoes that improperly fit the individual can cause a misalignment of an individual’s bone structure, a disconnection of the external environment which has negative effects on mental health, a decrease in mobility and range of motion in the body, and decreased blood flow in the feet, which has an overall effect on cardiovascular health. Humans are also very adaptable, which is why over time an individual can start to develop pathologies that lead to injury. Without the ability to self diagnose, it can be hard to uncover that a part of the issues with recurring injuries may be caused by the footwear an individual wears.

Figma Prototypes

The reason why there are two practices included in this experience, is due to the facts that, first, one must cultivate an awareness of the feelings in the body to become better at diagnosing where the issues, like overuse injuries or pain, are occurring in the body. Second, awareness has a limited ability to treat these issues in the body. The practice of reflexology and grounding, walking barefoot on natural ground, have been shown to counteract the negative effects outlined above by stimulating the nervous system, and improving breathing, and blood flow. Other theories suggest that it relieves stress in the body that causes aches, and illness.

This experience is designed for distance runners of any level. Because these practices can be generally applied to any person and require consistent practice to remain effective, the information and techniques can be applied to any athletic endeavor or general wellness routine. However, the language of the content and the main focus of these practices are centered around improving one’s ability to handle the stresses of running long distances and foster a greater connection with the activity of distance running. Although the goal is not to improve speed or capacity to run longer distances, it may be a side effect of becoming more comfortable in the equipment an individual uses or a result in an improved mental state when performing.

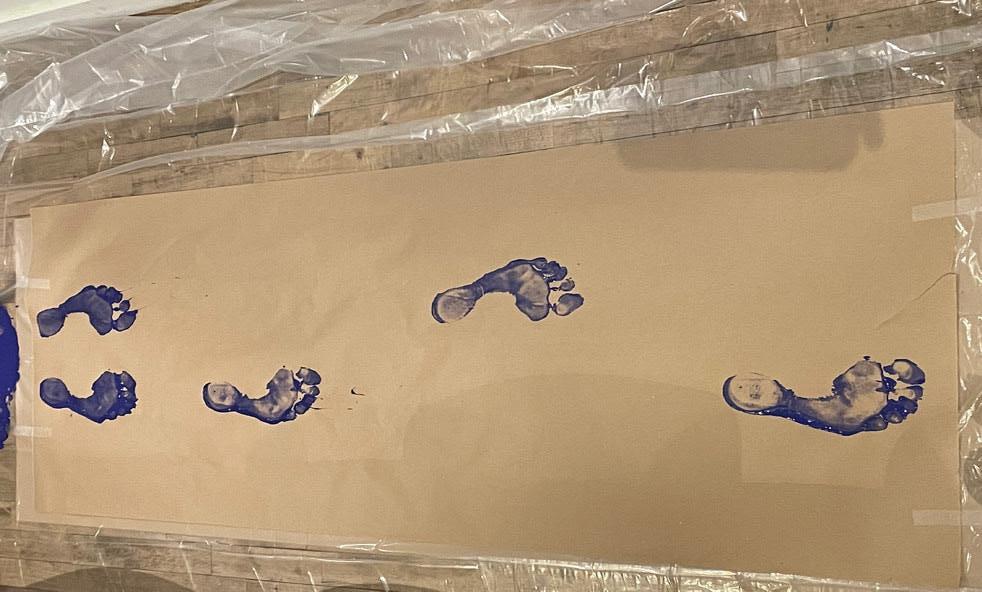

Prototyping played a large role in determining the final outcome of this project. My initial ideas included making a way for users to understand and visually see the uniqueness of their foot shape in order to show that all feet are different and require different things to perform well in distance running. Other ideas include a component of sustainable materials like compostable bioplastics to test out the feelings associated with each material and how that could potentially be used in the design of running shoes.

In my process of testing methods, I tried a paint walk where I set up craft paper with paint on one end and a wash bucket on the other. I then covered the soles of my feet with paint then walked to the other side of the paper to show my footprint. I thought it might be fun to do this with a large group of people and see how each foot shape differs as they walk across the paper. Each person gets a unique color to differentiate between people. In another test I tried using the vacuum former to create a mold in which I could make bioplastics that would be poured into those molds and cure. With these “soles” I could create thong flip flop style sandals which people could walk in to test the properties of the materials for use in shoe soles. But as I conducted my research and began working on other areas of my thesis, I found that time became very limited and forced me to pivot to the meditation and reflexology direction. I had many ideas and as I narrowed down my options, I thought this would be the best direction to serve the final output of my thesis.

The User Journey

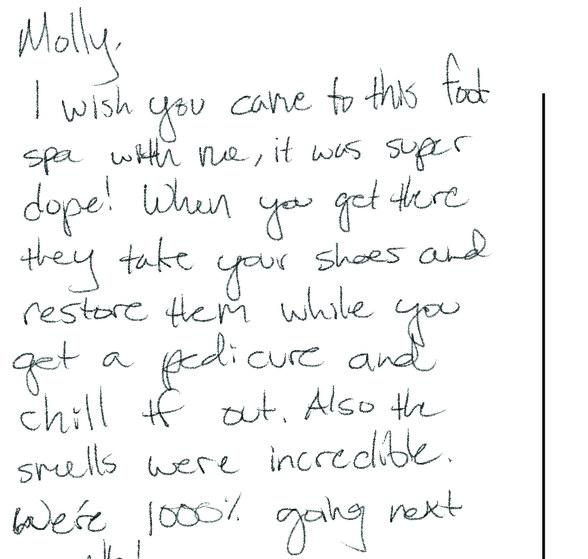

I want to thank my mother and Molly Gilligan for their support throught the entirerty of my time at Products of Design. A big thank you to the faculty and professors at Products of Design. I’ve learned so much about myself, design, among many other things by making the decision to further my education and pursue my MFA. It was the right choice and I’m exited for what’s ahead.

Nigel Keen