11 minute read

Speeding Up Design of Bearing Arrangements

Engineers can now design complex bearing arrangements more quickly and easily, thanks to a simplified version of powerful simulation software from SKF.

Bearings are a fundamental part of any machine: designing the moving parts properly can mean the difference between an efficient machine and one that continually wears out and breaks down. For this reason, bearing manufacturers are keen to help their customers get this part of the design absolutely right. This takes many forms, from providing up-to-date online catalogues (including direct support from application engineers) to developing software to help them design their products more effectively.

Advertisement

One way that SKF has done this is to take their in-house software called SimPro Expert, which it uses to develop and design highly complex bearing arrangements, and make it far more user-friendly for customers. SimPro Expert can be used to model an entire gearbox, in order to see the influence of one shaft on another, to determine the supporting properties of the housing, and to understand the detailed bearing behaviour for the given conditions. “Our application engineers have grown up with this software, but you need to be a relatively frequent user and have a good level of bearing knowledge to get the most from it,” says Francisco Serrano, Manager for Product Line Engineering Tools at SKF.

Solid knowledge

“Although design engineers within OEM companies should have a solid knowledge of bearings, many may not consider themselves “experts”. They may not be designing bearing arrangements all the time, as SKF application engineers would do – with long intervals between individual bearing projects. Also, they cannot devote the time and effort to learning complex simulation software in detail.” This is one of the reasons why SKF has developed SimPro Quick – a stripped-down version of its more specialised bearing design programme. This software has the same core as more advanced products such as SimPro Expert and SimPro Spindle, and retains many of their advanced features, but is far easier to use. While customers were demanding more advanced analysis of their bearing designs, they wanted to be able to do it in an intuitive way, using tools that were not excessively complex. SimPro Quick is a single-shaft bearing simulation tool that was developed to quickly evaluate the design of bearing arrangements and their field performance, based on relevant application requirements and conditions.

Catalogue link

A key feature of the software is that it ties in with SKF’s new online Roller Bearing Catalogue, which

is a live database of products. This means that anything incorporated into a design will be a current product. “If we were still using a paper catalogue, it would go out of date on the day it was printed,” says Francisco. “Now, with the software, it’s live so any product that is selected will be available and up to date.” A fundamental part of a design engineer’s job is to design to a budget. The link with the live database not only gives the latest products, but also allows them to be selected according to specific criteria such as whether it has high availability (and is therefore more cost efficient).

“A design engineer might come up with four different designs, then ask which one is the most economic, as well as making a choice based on key technical attributes.”

Model building

SimPro Quick builds a complete model in three steps: components; boundaries; and lubrication and clearance. In the first step, the model is built using common components such as bearings, springs and spacers. These are all incorporated into the model by ‘dragging-and-dropping’ them onto the shaft. Bearing types can be searched based on dimension, designation as well as whether it is a ‘popular item’. Other elements such as gears can also be ‘dragged’ onto the shaft. The second stage is to set applicable boundary conditions. Factors such as shaft rotational speed, radial and axial forces and gravity can be added to the model. Force, power input and moment are all applied using ‘drag-and-drop’, while other boundaries are added with an icon click. The third part is to apply the lubrication and fit conditions. SimPro Quick allows the user to define the lubrication method and type, oil viscosity and contamination level. All lubrication properties affect outputs, such as relubrication interval for greases and bearing friction.

Analysis

Once these steps have been completed, SimPro Quick carries out an analysis of the model. Here, users can run a single data set analysis (single analysis) or several conditions at once (a load cycle analysis) based on defined operating boundaries. A time weight portion can be applied to each step, which is useful when determining bearing life over several different operating conditions. The output of the analysis includes data tables and visuals that enable the user to create a preferred template set-up for the report. These might show factors such as bearing loads, operating internal clearances, friction, misalignment, deflection and SKF rating life. Other features include visual plots and animations, including a shaft deflection plot.

Real example

In one case, a manufacturer of high-end textile machinery used SimPro Quick to increase the speed and accuracy with which it designed bearing arrangements. Here, running accuracy of the bearings is critical to the overall performance. Using SimPro Quick helped the company to speed up its design process, while also evaluating an optimal bearing arrangement, without external help. This was due in part to the user friendliness of the software, combined with its advanced analysis capabilities. An integrated e-Learning module allowed the user to quickly start modelling relevant bearing arrangements.

Next steps

SimPro Quick was first launched towards the end of 2017, and has had a good response, says Francisco. It is now being rolled out more extensively. “There are two ways to get hold of it: one is to contact your local SKF contact to request a licence; the other is to register through our website, after which the request will be passed on to a local SKF representative. “If you are known to SKF, you will then be able to download SimPro Quick from a link. And if we don’t know the requester, we would very much like to,” Francisco quips. The programme has an embedded ‘e-Learning’ module within it, making an intuitive piece of software even easier to understand. For now, all modelling is done within the programme itself. SKF has added a CAD import functionality, allowing users to import a CAD design into SimPro Quick. “We will develop the tool in the direction of what users want,” he concludes. “This software is for all design engineers working with bearing arrangements.” Machine designers know how crucial it is to get the design of their bearing arrangements absolutely correct, but without having to master complex software programme. SimPro Quick has proved to be an efficient way of doing this, combining an intuitive interface with powerful simulation to produce designs that can be validated quickly and effectively.

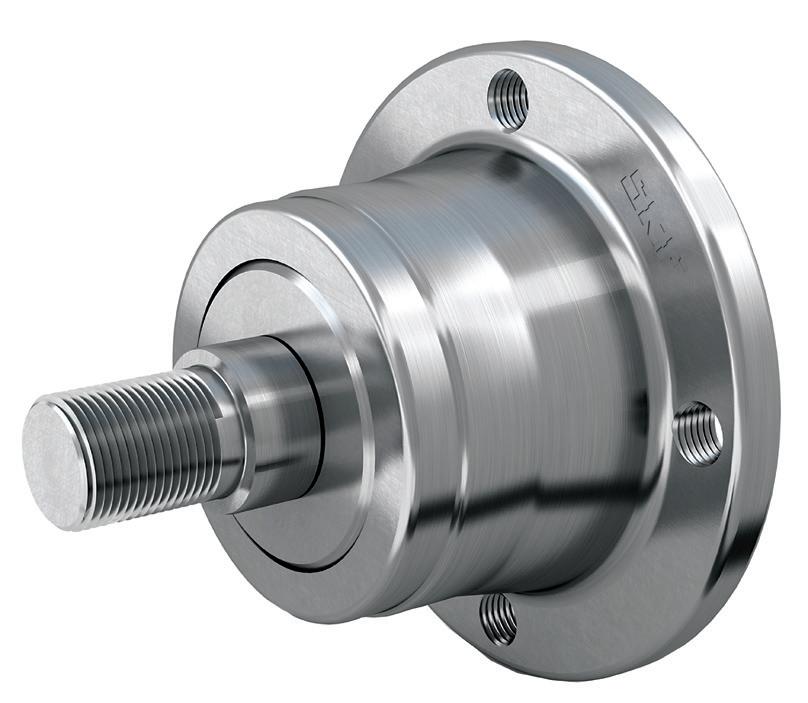

Agri Hubs solution with a bearing and seal integrated in one housing for disc Plough.

Agri Hubs solution with a bearing and seal integrated in one housing for seeding

Agri Hubs solution with a bearing and seal integrated in one housing for tillage.

Advanced and Efficient Equipment

“A critical part of our service to the sugar sector is in equipment design: from the front-end cane off-loading, cane preparation and juice extraction, through to processing, sugar drying and refining. “Our research and development team works closely with associate sugar consultants and technologists around the world, to develop high-performance equipment. Every system is designed to meet the client’s requirements for cost-efficiency and improved productivity. “Although new equipment is designed, combining the latest technologies and advanced manufacturing trends, we incorporate tried and tested technologies favoured by clients into new designs.” Over the past 20 years, the Bosch Projects Equipment division has developed an extensive range of sugar processing equipment, which includes its patented chainless diffuser and continuous vacuum pan.

Best-sellers

Other best-selling equipment includes rotary juice screens, juice heaters and clarifiers, cane preparation equipment, long tube evaporators and entrainment separators. The company has also recently sold sugar dryers, refined sugar conditioning silos, continuous vertical massecuite reheaters, vertical continuous crystallisers and batch pans. “Our patented Continuous Vacuum Pan (CVP) design has become the preferred system of many of the world’s biggest sugar processing groups,” adds Neil du Plessis, sector manager, Sugar Equipment, Bosch Projects. “When supplying a CVP for C boilings, we recommend to clients that we provide the full C station, which includes the CVP, the continuous vertical crystalliser and the continuous massecuite reheater. By offering the entire system, we guarantee optimum performance of the total C station exhaustion.

Reheater

“Another system that has been well-received by the sugar sector is our vertically orientated reheater, with significant performance benefits over conventional massecuite reheaters, that are horizontally orientated. The major advantage of the vertical reheater design is that massecuite rises as it is heated and

“We have served the global sugar industry for over 58 years, offering a comprehensive service to customers, encompassing strategic planning and feasibility studies, sugar technology selection, project structuring and funding, design and engineering, project delivery and operational support and training,” explains Steve Rosettenstein, sector director: sugar, Bosch Projects.

thus follows natural convection tendencies. This results in favourable plug flow through the heater, thereby minimising the purity rise across the unit.” Horizontal reheaters tend to have over-heated channels of massecuite near the top of the vessel and static cool areas at the bottom. This causes short-circuiting of massecuite inside the reheater, reducing the unit’s efficiency.” Bosch Projects has recently supplied and commissioned six vertical massecuite reheaters around the globe and has submitted proposals for another four units to clients looking to upgrade their current design to their reheater. These units are fabricated from stainless steel which minimises maintenance costs and reduces the need to treat the heating water. Clients are offered either a full turnkey installation or the stand-alone equipment can be supplied.

Clarifier

The company has also developed the lamella clarifier, especially for the sugar industry, to satisfy demand for short retention clarification. Although various lamella clarifier systems are wellestablished in water treatment applications, this technology is new in sugar processing and is especially effective for juice, s y r u p a n d

refinery phosphotation clarification. The Bosch Projects system, which utilises a series of inclined plates for fast, effective particle separation and settling, is much smaller than conventional clarifiers and substantially reduces liquor retention times.

Although various lamella clarifier systems are well-established in water treatment applications, this technology is new in sugar processing and is especially effective for juice, syrup and refinery phosphotation clarification

The design of this new settling lamella clarifier reduces the size and footprint of conventional juice clarifiers by approximately 30%, significantly lowering capital investment costs. Important features include short residence times, reduced sucrose degradation and improved turbidity removal. This highly efficient system, which operates with minimal moving parts, requires low maintenance.

Compact size

The syrup clarifier is similar in design to the lamella juice version, except that it operates as a flotation clarifier, as opposed to settling. This system can be switched on and off as desired when syrup qualities are low and it can be easily installed inside an existing factory, due to its compact size.

The Bosch Projects team works closely with its technology partners and fabricators globally, to ensure manufacture of all equipment adheres to stringent international quality standards and exact design specifications. The company has an extensive network of

The vertically-orientated reheater has been well-received by the global sugar sector. It has performance benefits over conventional horizontallyorientated massecuite reheaters. The major advantage of the vertical reheater design is that massecuite rises as it is heated and thus follows natural convection tendencies. This results in favourable plug flow through the heater, thereby minimising the purity rise across the unit.

offices in Africa, South and Central America and the United Kingdom. The company also has technology partners in the South East Asian region and the USA. Bosch Holdings (Pty) Ltd Melanie Elsworth Tel : (031) 535 6192 Email: elsworthm@boschholdings.co.za www.boschholdings.co.za

The patented Continuous Vacuum Pan (CVP) design has become the preferred system of many of the world’s biggest sugar processing groups.

TRACE due diligence solutions are based on internationally accepted best practices and our experience and familiarity with the compliance needs of multinational companies. Services range from a denied parties screening to enhanced due diligence, including TRACE Certified Due Diligence.