West Coast Edition (CA, OR, and WA)

West Coast Edition (WA, OR, and CA)

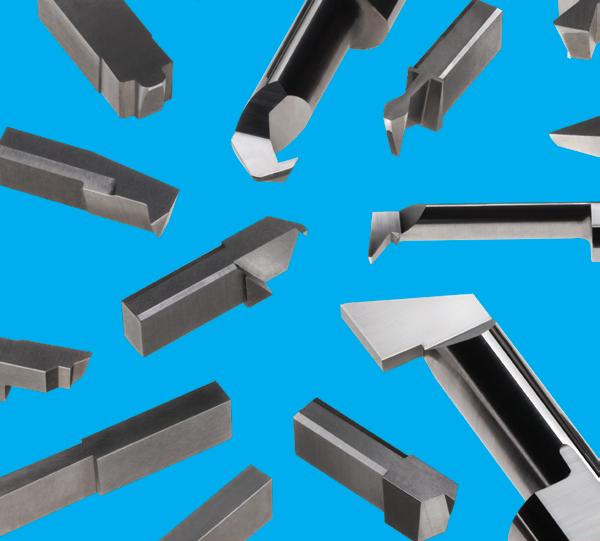

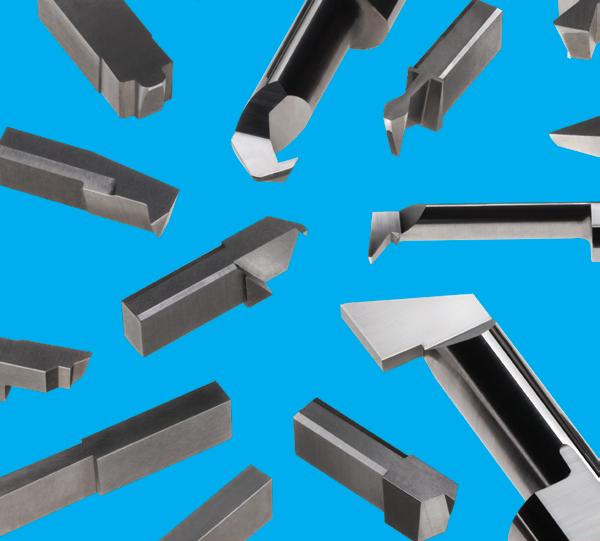

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING

West Coast Edition (CA, OR, and WA)

West Coast Edition (WA, OR, and CA)

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING

Materials Research Engineer Bryan Harder examines coatings deposited on silicon carbide parts in the Plasma Spray-Physical Vapor Deposition Rig at NASA Glenn. Credits: NASA Advancing the efficiency of aircraft engines can be improved significantly by increasing the temperature at which they operate. Engine components today are made of super alloys, but operating conditions take these materials to their fundamental limits. In order to further improve fuel efficiency, a new class of ceramic materials made from silicon carbide, are being incorporated into engines. These materials are lighter and can withstand higher temperatures than the super alloys being used today. However, these ceramics erode in combustion environments due to the presence of water vapor.

To solve this problem, scientists and engineers at NASA’s Glenn Research Center have pioneered a process that applies thin, smooth ceramic coating materials to protect the silicon carbide parts.

It all happens in the Plasma Spray-Physical Vapor Deposition Rig, a 10 by 6 foot stainless steel chamber. Materials Research Engineer Bryan Harder explains how it works. “The torch creates a high-powered plasma that vaporizes ceramic material and deposits it onto parts very precisely to create durable, longlasting coatings to protect the components from environmental attack.”

Harder and a team of materials researchers and engineers at NASA Glenn are currently developing the next generation of coatings to allow for operation of turbine engine components up to 2700°F and beyond.

The applications of this game-changing technology are far reaching according to Harder. “Using this high temperature process, we can potentially create coatings rapidly with varied architecture and composition for fuel cells, batteries and sensors, as well as a host of other technologies including space applications,” he says.

NASA Glenn is maturing and developing this technology while making direct contributions to NASA’s aeronautic mission.

Nancy Smith Kilkenny, SGT Inc.

NASA’s Glenn Research Center

“Managers should always take care of their team before they take care of themselves — the supervisor is there to serve his team — not the other way round.”

– Elon Musk

If you have worked for a bad leader, you already have the answer as to why good leadership matters. Good leadership can make the difference between enjoying your job and tolerating your job until you find a better one.

The human costs of bad leadership are just as bad and include low employee morale and decreased job satisfaction and poor performance. Most times, bad leaders are the difference between a job you love and a job you are trying to leave. Good leaders bring many benefits to their teams and organizations, like increased profit, customer satisfaction and employee retention, according to the Center for Creative Leadership.

When a highly intelligent and highly skilled individual was promoted into a leadership position they failed at the job of leading their team. And, likewise someone with solid but not with extraordinary intellectual abilities and technical skills was promoted into a similar position and then soared to great heights as a leader. Good leaders possess self-awareness, earn credibility, focus on relationship-building, have a bias for action, exhibit humility, empower others, stay authentic, present themselves as constant and consistent, become role models and are caring and are competent.

A great number of small business are started by people with great technical skills, they’re smart, capable, they know their business well and often start the business as a one man/ woman band, so to speak. Let’s say they are a great machinist, programmer, and they have a work ethic like no one working 40 hours a week because they work 100-120 hours a week to get things done.

These people are great at what they do and figure they can go out on their own and start the ‘American Dream’ from their double car garage and they do. And, as they grow they realize their forte is not in accounting, marketing, sales, human resources, or customer service. If they can be a good leader and an solid example to their team and walk the walk and teach their team to be better at what the company expects from them, the team can find fulfillment in their work and look forward to improving and following the examples of leadership.

Some are not meant to lead. In this case the owner of the business would do well to hire a good General Manager with good leadership skills. This does not take the onus off the Owner of the business to be the example of what team members need to do to fit the business model.

In closing we wish you continued prosperity and above all health and happiness.

We would like to do an in depth ‘Cover Story’ on your business. A ‘Cover Story’ with a two page article includes an in depth interview and pictures of your facility. Please contact us for more information on being the cover story for one of our regional manufacturing magazines.

Thank you!

God Bless Our Troops!

Kim Carpenter

PUBLISHERS/EDITORS

Kim Carpenter & Linda Daly Kim@A2ZManufacturing.com

Mail Address: PO Box 459 Higley AZ 85296

Telephone: (480) 773-3239

Website: www.A2ZManufacturing.com E-mail:Kim@A2ZManufacturing.com

Linda Daly, Stephen Hannemann

Published bi-monthly to keep precision manufacturers abreast of news, contracts, trends, and to supply a viable supplier source for the industry.

Circulation: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

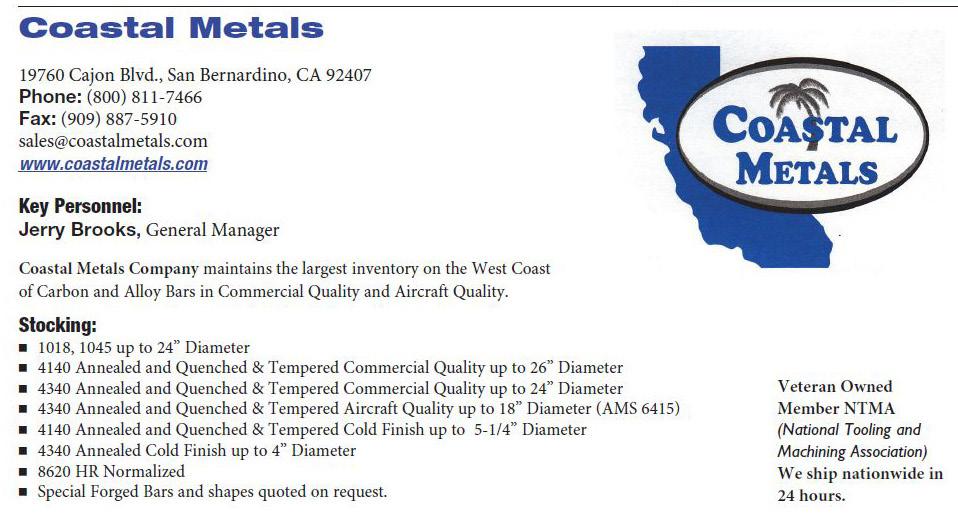

Northwest Machine LLC is a newly formed home based company in Pasco, Wa specializing in production turn/mill work.

*CNC lathe with live tooling: Up to 2” diameter bar feed capacity and up to 11.5” swing for chuck and faceplate mounted turning.(23” diameter)

*CNC milling: 15.5” x 19.7” machine capacity.

*Manual machining capabilities.

Please contact us for a quick competitive quote.

Email: services@northwestmachinellc.biz

Phone: 425-870-0018

Owners: Mark Underwood-Manufacturing Engineer/ Machinist, Michelle Schrindel

MASIC Industries Continues to Grow to Serve It’s Customer’s

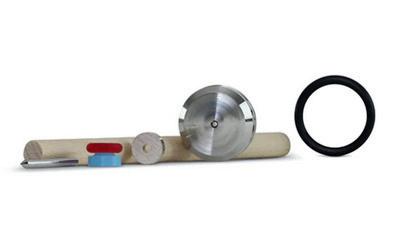

MASIC Industries, an ISO9001certified special processing entity, offers Certified Applicators of Premium Thin Film Ceramic Coatings, Physical Vapor Deposition (PVD), Diamond-Like Carbon Coating (DLC), and Powder Coating.

They are, to their knowledge, one of the few special processing facilities in all of the Western USA that offers production-capable Cerakote coating, and they have been an approved Cerakote applicator for the past decade. Cerakote is a polymer-ceramic composite that’s designed to improve a material’s Abrasion and wear resistance, Corrosion resistance, Chemical resistance, Impact strength, and Hardness. Cerakote can be applied to a variety of materials, including metals,

plastics, polymers, and wood.

The company, based in a suburb of Portland, Oregon, got its start shortly after WWII when Russ Leininger launched the company as a metal polishing entity. Many of Russ’s family members were integral members of the company, and today Russ’s grandson’s Chris and Matt Sicilia, run the company with partner Butch Mason, a Navy Veteran. Chris’ 2 sons and Butch’s two sons are the newest family members participating in the business.

Chris says, “When Matt, Butch, and I took over the business, we wanted to retain many of the best attributes our parents, uncles, and grandfather had made integral to it, including treating your employees well and for our customers, ‘Doing what we commit to do.” He adds, “We also wanted to take the business to the next level, and this meant looking at every aspect of the business and surveying customers to find ways to continuously improve.”

During Covid, the company had zero employee absences, and in fact, they found themselves venturing into a new and emerging market – low Earth orbit satellites. Chris says, “We had no idea that the space and satellite industry was so extensive, but we were fortunate to participate in several projects, which helped expand our business.”

Last year, the company successfully certified to ISO9001: 2015, with the help of its Director, Dean Brito. Chris says, “Years ago, Dean was a ‘difficult’ customer of ours more than 15 years ago, and he pointed out how our quality manual was not up to ‘quality standards.’ While this was unpleasant to hear, Dean was right, and we hired him in 2023 to make a world-class quality process for us.” The company will be audited early in 2025, and Chris says, “We have no reservations about passing with flying colors.”With a diverse team, Chris says that the MASIC Industries systems are written in three languages, including Spanish, English, and Vietnamese

Last year, the company shipped 1.2 million parts, and they had ~2400 returns, an impressive .002% defect rate. With a Quality and OnTime delivery rate with ‘A’ scores, the company’s best sales force is its customers, who regularly refer others to MASIC Industries for their special processing needs.

Quality Assurance:

Chris says, “We go above and beyond what our customers require in testing. Our customers require First Article Inspection, and this is what many in our industry adhere to. At MASIC, we’ve implemented an extremely rigorous quality process for every order. We then maintain comprehensive data for every job, not just first articles.” Extensive Testing Procedures: • Color and Cosmetic

• Coating Thickness

• Specular Gloss – a measure of the light reflected by the surface of a material.

• Crosshatch Adhesion – evaluates the adhesive strength of coatings applied to metallic substrates.

• Pencil Hardness Gauge (or scratch) Test - a method used to assess the hardness of a coating by dragging pencils of varying hardness across its surface, with the hardest pencil that can scratch the coating indicating its relative hardness level; also known as the Wolff-Wilborn test

• Solvent MEK or Acetone Rub Test – is a quality control method used to assess the cure level of a coating, typically a powder coating, by rubbing a surface with a cloth or cotton swab saturated with either Methyl Ethyl Ketone (MEK) or Acetone to see if the coating softens, removes, or shows signs of improper curing; essentially, it checks how well the coating has bonded to the substrate by applying a solvent to see if it can be easily rubbed off.

• Mandrel Bend Test - enables assessment of the resistance of a coating to cracking and/or flaking from a metallic substrate.This involves coated and scored sheets of metal being bent over a conical mandrel with the aid of a test device.

Chris says, “We are required to meet 10% testing, and since we do 100% testing, it has opened doors for us with engineers on R&D programs, where we analyze the limitations of coatings and establish reasonable expectations. Currently, we’re collaborating with many talented young engineers who are not familiar with coating processes. We engage at the design level to assist in developing specifications.”

For production, the company processes approximately 5,000 knife blades per week, and overall, they perform special processing on over 100,000 parts monthly,

Chris says, “We focus heavily on detailed masking. Approximately 90% of the knives we coat involve some form of masking, and 100% of the satellite products use it. We utilize plotters to print die-cut stickers for masking, eliminating the need for trimming.”

The MASIC dedicated workforce comprises 36 employees, and the company is open 5 days a week, 16 hours per day. Of its team, only a handful (less than 5) have less than 5 years of tenure with the company. One-third have more than 15 years with the company, and the remainder have 5-10 years of tenure. “We are very proud and grateful to have such a dedicated staff here to support our customers”, Chris says. What’s Next:

The company is in the process of implementing the

system, which is planned to go live in 2025.

The company wants to help bring new technologies to the industry, As an example, today they are participating in R&D endeavors with thinfilm ceramic companies, particularly focused on advancing ceramics for firearms.

Chris says, “We plan to expand systematically by solving our customers’ problems. In the past, we’ve introduced new lines when customer demand arises. As an example, we purchased an off-the-shelf PVD/ DLC (Diamond-Like Carbon) machine when one of our customers lost its supplier.

Landmark Solutions Announces Three New

Landmark Solutions is excited to announce new partnerships with three leading machinery manufacturers to provide a broader equipment offering:

• Ocean Machinery: Quality structural steel solutions designed in collaboration with Peddinghaus

•

• OTC Daihen: World leader in robotic arc welding and weld cell technology

•

• Wintersteiger: Premium Flattening Line by KOHLER: the Peak Performer

Landmark, with a tradition of providing best-in-class equipment and support to its customers, is proud to add these three manufacturers to its family of brands and looks forward to jointly serving the metal fabrication industry. Contact a member of your Landmark Solutions team to learn how to leverage these new partnerships to your benefit! (714) 393-3783 | info@landmarksolutionscorp.com

LANDMARK SOLUTIONS LAUNCHES METAL FABRICATION MARKETING BRANCH

Landmark Solutions has announced an industry-specific marketing service offering, making meaningful brand storytelling more accessible for fabricators across the country. Combining 100+ years of industry expertise with proven modern marketing processes, Landmark aids customers in showcasing their identity, expanding outreach, and earning more business. Services include Logo/Brand Design, Website Design, Print Design, Social Media Content & Management, Web Ads, Email Automation, and more.

(253) 266-5592 | info@landmarksolutionscorp.com

Once the Pentagon lifted its hold on receiving new Joint Strike Fighter jets last summer, the defense giant managed

Lockheed Martin reported that more than 100 of the Joint Strike Fighter aircraft were delivered during 2024, fulfilling its estimated delivery rate of 90-110 jets for the calendar year. That target had been revised upward from 90-110 aircraft last summer after a yearlong hold on deliveries was lifted by the U.S. Dept. of Defense.

Reports estimate that Lockheed and the expansive F-35 supplier program that it heads are delivering about 20 new F-35 jets per month. The program has completed more than 1,000 jets since the program started full-rate production in 2006.

The F-35 is a series of fighter jets deployed for ground attack and combat, and available in three variants – for the U.S. Air Force, U.S. Marine Corps, U.S. Navy, and for the defense forces of more than a dozen other nations.

It is by far the largest and most expensive U.S. defense program, with hundreds of program participants and suppliers.The jets’ reported unit costs range from $82.5 million for the F-35A, to $109 million for the F-35B, to $102.1 million for the F-35C.

Last month the Department placed a new contract modification worth $11.76 billion to deliver a total of 145 aircraft in the Lot

18 production series, to be completed by June 2027.

The Pentagon stopped accepting deliveries of new aircraft in July 2023, explaining that the aircraft had been built and outfitted with hardware suited to the Technical Refresh 3 initiative, though TR-3 software had not yet been approved. TR-3 is a package of advanced software, improved data-processing capabilities, greater computer memory, and enhanced graphical displays that will be installed across the F-35 fleet in expectation of an upcoming Block 4 upgrade to the aircraft, to advance electronic warfare capabilities.

As

of completed F-35 aircraft with TR-3 hardware capabilities. In June 2024, the DoD’s F-35 Joint Program Office lifted the hold on deliveries, allowing that a preliminary version of TR-3 software was acceptable for service.

A new $615-million award will cover full-rate production of the F-15 PAWSS technology, to detect, identify, and counter incoming threats to U.S. Air Force fighter jets.

The U.S. Dept. of Defense granted $615.7 million to Boeing Defense, Space & Security for full-rate production of the F-15 Eagle Passive Active Warning Survivability System, an electronic warfare technology developed to detect, identify, and counter incoming threats to the U.S. Air Force fighter jets.

The system integrates radar warning, geolocation, situational awareness, and self-protection capabilities in a common platform to notify a jet’s flight crew with identification and location details for potential threats in contested air space.

The contract covers material and component procurement, system engineering program management, and interim contractor support lay-in material.

The F-15 is a twin-engine fighter aircraft developed and manufactured by McDonnell Douglas Corp. from 1972 to 1997, and now supported by Boeing Defense, which absorbed McDonnell Douglas in 1997. The aircraft are primarily used by the USAF and the air forces of Israel, Japan, and Saudi Arabia.

Work for the project will be performed at Boeing Defense locations in St. Louis and Nashua, N.H.

US 300-megawatt boiling water nuclear reactor gets coalition support for deployment

The coalition is led by the Tennessee Valley Authority (TVA), and it includes multiple other partners.

GE Hitachi Nuclear Energy (GEH), a business of GE Vernova, has joined the coalition of utility companies that are working to accelerate the deployment of BWRX-300 small modular reactors in the United States.

The coalition is led by the Tennessee Valley Authority (TVA), and it includes partners such as Bechtel, BWX Technologies, Duke Energy, Electric Power Research Institute (EPRI), GEH, Indiana Michigan Power – an AEP company, Oak Ridge Associated Universities, Sargent and Lundy, Scot Forge, other utilities, and advanced nuclear project developers and the State of Tennessee.

The coalition has submitted an application for $800 million in funding from the U.S. Department of Energy’s Generation III+ SMR program. A Generation III+ SMR is defined as a nuclear reactor that uses light water as a coolant and low-enriched uranium fuel, with a single-unit net electrical power output of 50-350 MW.

Key Milestone For The Rapid Development Of Affordable,

“These long-range solid rocket motors will allow the U.S. Army and allies to strike farther and faster than anything our adversaries have in their arsenals,” said Tom Laliberty, president of Land and Air Defense Systems at Raytheon. “This long-range rocket motor technology fills the essential role of providing affordable precision fires, while increasing range, safety, and magazine depth.”

“The Ursa Major team has utilized additive manufacturing to complete motor development, manufacturing, and testing in unprecedented timelines, resulting in nearly 300 static test fires this year,” said Ursa Major CEO Dan Jablonsky. “The innovative manufacturing techniques we employ are yielding agile solid rocket motor solutions with the design flexibility needed to expand the capabilities of the U.S. military.

Ursa Major is poised to scale the production of higher-performing solid rocket motors at the pace and volume the country requires and at a price the country can afford.”

Raytheon has selected Ursa Major’s advanced propulsion technology as a key enabler to provide affordable solutions for the U.S. Army at extended ranges. During the next phase of the program, Raytheon and Ursa Major will incorporate manufacturing improvements, leading toward additional flight tests in 2025 and qualification in 2026.

In 2023, RTX Ventures invested in Ursa Major to explore new rocket motor technologies and help address this national security requirement. Together, Raytheon and Ursa Major are responding to the U.S. Army’s urgent need for affordable precision-guided munitions by rapidly developing a new generation of smart munitions, via investments in rocket motor development and testing to prove design stability and maturity.

About Raytheon

Raytheon, an RTX business, is a leading provider of defense solutions to help the U.S. government, our allies and partners defend their national sovereignty and ensure their security. For more than 100 years, Raytheon has developed new technologies and enhanced existing capabilities in integrated air and missile defense, smart weapons, missiles, advanced sensors and radars, interceptors, space-based systems, hypersonics and missile defense across land, air, sea and space.

The U.S. Air Force awarded $3.5 billion each to GE Aerospace and Pratt & Whitney for design, analysis, rig testing, prototype engine build and testing of adaptive cycle engine technologies, as part of the Next Generation Adaptive Propulsion program.

The U.S. Air Force issued a total of $7 billion to two manufacturers working on the prototype stage for their respective roles in the Next Generation Adaptive Propulsion (NGAP) program. The GE Edison Works, a part of GE Aerospace devoted to research and development of military aircraft engines; and Pratt & Whitney Engines, have drawn separate awards of $3.5 billion, “for technology maturation and risk reduction services” in executing the prototype phase of the anticipated

fighter jet engine technology.

Both awards are structured as modifications to previously awarded contracts, and assign the contractors to design, analyze, rig test, build and test prototype engines, and define weapon system integration, with their work expected to be complete by July 13, 2032.

The NGAP program is a USAF initiative seeking to identify adaptable jet engine technology for the “Next Generation Air Dominance” (NGAD) program, a parallel effort to define and develop a new fighter aircraft.

The objective of the NGAP program is to establish technologies that will provide superior fuel efficiency, greater engine thrust during combat maneuvers, and enhanced survivability based on an ability to adjust engine performance according to flight conditions. The USAF’s vision is of a common jet engine that is versatile enough to be used in different combat situations, thanks to the use of “adaptive cycle” technology by which an engine’s air-compression ratio can be modified according to flight situations.

Ohio-based Component Repair Technologies will repair engine cases, rotating components, and other large parts for airlines, other engine

builders, and third-party MRO providers.

Safran Aircraft Engines finalized its takeover of Component Repair Technologies (CRT), an aircraft-engine parts repair operation center in Mentor, Ohio. The value of the acquisition was not announced.

CRT is a 450-employee organization that will be Safran Aircraft Engines’ “center of excellence” in the Western Hemisphere for repair of engine cases, rotating components, and other large engine parts.

Safran Aircraft Engines designs and manufactures commercial and military aircraft engines. The commercial aircraft engines – notably the LEAP and CFM56 high-bypass turbofan engines – are produced through CFM International, Safran’s joint venture with GE Aerospace.

CRT will perform engine parts repair for airlines with service contracts and other engine makers and third-party MRO companies.

Announcing the CRT acquisition in September 2024, Safran explained it is part of an estimated €1-billion investment program to expand its global engine maintenance/ repair/overhaul (MRO) capacity.

G E T T O K N O W U S

Servicing our industry and trade customers in intelligence heat treating for over 60 years.

Real Time Live Job Tracking

10+ Processes Performed

50+ Furnaces

AOG and Line Down

Services

Over 10+ Prime Approvals

24/7 Processing

602-258-7751

cs@phxht com

“We are delighted to welcome CRT teams onboard to strengthen our MRO expertise,” stated Safran Aircraft Engines CEO JeanPaul Alary. “This major acquisition perfectly reflects our industrial strategy of providing a world-class repair facility on each continent located as close as possible to needs in order to best serve our airline customers, and at the same time reduce our carbon footprint from these activities.”

www phoenix-heat-treating com

“Funding from this grant would play a critical role in the path forward, and we look forward to working with TVA and this strong team of utility and supply chain partners to accelerate the roll-out of small modular reactors in the United States.”

TVA has selected the BWRX-300 SMR for potential deployment at the Clinch River Site near Oak Ridge, Tennessee. If the funding is approved,TVA plans to accelerate construction of the first SMR, with commercial operations planned for 2033.

“Nuclear power has a key role to play in reaching a cleaner and more secure energy future,” said Scott Strazik, CEO, GE Vernova.

GEH also said that Duke Energy has entered into an agreement to invest in activities to advance the standard design and licensing of the BWRX-300 SMR technology. Further, American Electric Power (AEP) has selected the BWRX-300 for potential deployment at the Indiana Michigan Power Rockport Plant in Spencer County, Indiana.

“On the heels of the significant progress that is occurring with the deployment of the first BWRX-300 at Ontario Power Generation’s Darlington site, these announcements signify the growing confidence the industry has in our SMR technology,” said Mavi Zingoni, CEO, GE Vernova’s Power businesses.

Raytheon Technologies Corp., Pratt and Whitney Engines, East Hartford, Connecticut, is awarded an $186,044,155 cost-plusincentive-fee contract.This contract provides for material and support equipment for depot maintenance facilities; program administration for non-recurring sustainment activities; supplies, services, and planning for depot activations; and unit level support equipment in support of sustaining the F135 engines in F-35 Joint Strike Fighter aircraft for the Air Force, Marine Corps, Navy, Foreign Military Sales (FMS) customers, and non-U.S. Department of Defense (DOD) partners. Work will be performed in East Hartford, Connecticut (54.7%); Cherry Point, North Carolina (8.9%); Oklahoma City, Oklahoma (8.7%);Windsor Lock, Connecticut (4.5%); Indianapolis, Indiana (2.2%); Fort Smith, Arkansas (1.96%); Jacksonville, Florida (1.2%); various locations within the continental U.S. (3.7%); and various locations outside the continental U.S. (14.14%), and is expected to be completed by February 2028. Fiscal 2024 aircraft procurement (Navy) funds in the amount of $21,596,210; fiscal 2023 aircraft procurement (Air Force) funds in the amount of $64,751,806; fiscal 2023 aircraft procurement (Navy) funds in the amount of $41,344,488; FMS customer funds in the amount of $22,971,323; and non-US DOD partner funds in the amount of $35,380,328 will be obligated at the time of award, $106,096,294 of which will expire at the end of the current fiscal year. This contract was not competed. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity (N0001925C0075).

Raytheon Co., McKinney, Texas, is awarded a $48,552,948 cost reimbursement, level-of-effort job order made under basic ordering agreement (N0016425GJQ19) for the procurement of the JANUS II systems, including the multi-mission optical sensor and multispectral targeting system pedestal enclosure system and ancillary hardware and software to support the systems. This contract action was a sole source action in accordance with 10 U.S. Code 3204 (a) (1), only one responsible source and no other supplies or services will satisfy agency requirements. Work will be performed at Raytheon facilities in McKinney, Texas. Work is expected to be completed by February 2030. Fiscal 2025 operations and maintenance (Navy) funds in the amount of $4,169,000 will be obligated at time of award. Naval Surface Warfare Center, Crane Division, Crane, Indiana, is the contracting activity (N0016425GJQ19).

Raytheon Technologies, Tucson, Arizona, is being awarded a noncompetitive firm-fixed-price contract. The total value of this contract is $99,000,000. Under this contract, the contractor will procure and deliver SM-3 Block IB parts that are manufactured, assembled, and tested in accordance with the SM-3 Block IB specifications. The work will be performed in Tucson, Arizona; and Huntsville, Alabama, with an expected completion date of March 31, 2026.The period of performance is from Feb. 19, 2025, through March 31, 2026. Fiscal 2024 procurement funds in the amount of $49,437,643 will be obligated at the time of the award. The Missile Defense Agency, Huntsville, Alabama, is the contracting activity (HQ085124C0001).

Flash Steelworks Inc., Washington, Michigan, was awarded a $90,000,000 firm-fixed-price contract to for develop low-cost, ultrahigh-strength alloys. Bids were solicited via the internet with one received.Work locations and funding will be determined with each order, with an estimated completion date of Feb. 12, 2030. Army Contracting Command, Aberdeen Proving Ground, Maryland, is the contracting activity (W911QX-25-D-0001).

Teledyne FLIR Defense Inc., Elkridge, Maryland, was awarded a $74,226,486 hybrid (cost-no-fee, cost-plus-fixed-fee and firm-fixedprice) contract to integrate sensors onto the M1135 Flat Bottom Hull Stryker. Bids were solicited via the internet with one received. Work will be performed in Elkridge, Maryland, with an estimated completion date of Feb. 2, 2029. Fiscal 2024 procurement, defense-wide funds and research, development, test and evaluation, Army funds in the amount of $16,813,554 were obligated at the time of the award. Army Contracting Command, Aberdeen Proving Ground, Maryland, is the contracting activity (W911SR-25-C-0012).

AEG Group Inc.,* Grayslake, Illinois, is awarded a $49,742,406 firmfixed-price, indefinite-delivery/indefinite-quantity contract. This contract procures Motorola ultra-high frequency, very high frequency, and multi-band radios and accessories for the Naval Air Warfare Center Aircraft Division (NAWCAD) Webster Outlying Field Special Communications Mission Solutions Division in support of Commander, Navy Installations Command Enterprise Land Mobile Radio technical

refresh of first responder equipment. Work will be performed in Saint Inigoes, Maryland, and expected to be completed in February 2030. No funds will be obligated at the time of award; funds will be obligated on individual orders as they are issued. This contract was competed with seven offers received. NAWCAD, Lakehurst, New Jersey, is the contracting activity (N6833525D0005).

Apex Technology Inc., Culver City, California, was awarded a $45,900,000 firm-fixed-price contract for multiple space vehicles to operate in two space orbits. This contract provides the Space Force funds to advance the deployment of space vehicles capable of operating across various orbital regimes. Work will be performed in Culver City, California, and is expected to be complete by September 2032. Fiscal 2024 research and development funds in the amount of $22,000,000 are being obligated at the time of award. Space Systems Command, Kirtland Air Force Base, New Mexico, is the contracting activity (FA8809-25-C-B005).

Northrop Grumman Systems Corp., Plymouth, Minnesota, was awarded a $23,516,359 modification (P00102) to contract W15QKN13-C-0074 for precision guidance kits. Work will be performed in Plymouth, Minnesota, with an estimated completion date of May 21, 2028. Fiscal 2025 ammunition procurement, Army funds in the amount of $23,516,359 were obligated at the time of the award. Army Contracting Command, Newark, New Jersey, is the contracting activity.

Chevron and Engine No. 1 will form a JV to develop scalable power solutions for US-based data centers running on natural gas. Mikaila Adams GE Vernova.

“The partnership will work directly with customers to develop power generation that is dedicated to and co-located with data centers. The power generators will leverage Chevron’s natural gas capabilities and utilize turbines manufactured by GE Vernova,” Chevron chief executive officer and chairman Mike Wirth said in a post to his LinkedIn account Jan. 28.

Wirth cited artificial intelligence as “one of the most important technological breakthroughs in recent history, igniting productivity gains across our global economy,” but pointed to the “massive amounts of 24/7 power” needed to scale.

A December 2024 report produced by Lawrence Berkeley National Laboratory and presented by the US Department of Energy estimates that data center load growth has tripled over the past decade and is projected to double or triple by 2028.

The report finds that data centers consumed about 4.4% of total US electricity in 2023 and are expected to consume about 6.712% of total US electricity by 2028.

“Meeting this demand is forecasted to require significant investment in power generation capacity, while managing carbon emissions and mitigating the risk of grid destabilization,” he said.

The first of the projects, to be managed by Chevron New Energies, are expected to serve co-located data centers in the US Southeast, Midwest, and West regions, leveraging seven GE Vernova 7HA natural gas turbines. The companies said the projects are to be designed with flexibility to integrate carbon capture and storage (CCS) and renewable energy sources, Chevron and Engine No. 1 said in a joint release Jan. 28.

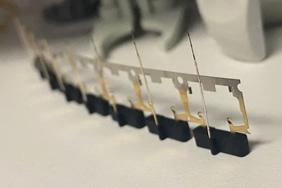

3D can provide design assistance and work with existing products to produce them more economically.We are a ‘UL Certified’ molder offering low to high quantity production runs.

We produce many of our customer’s products with metal and plastic sub-components molded in. It is very common to use threaded inserts, bushings, contacts, and plastic substrates.

As power generation is not designed to flow initially through the existing transmission grid, the risk of increasing electricity prices for consumers is reduced, the companies said, but noted that the model, “over time… is designed to sell surplus power to the US power grid, through future interconnects, supporting broader energy demands while keeping costs low.” President Donald Trump has made US energy resources a key focus of his second term in office, as noted by Chevron’s Wirth.

“We are proud to play our part in bringing to fruition President Trump’s vision for a new American golden age, powered by our enormous energy resources and unrivaled workforce. President Trump’s pro-American energy policies and commitment to energy and AI dominance give us the confidence to invest in projects that will create American jobs and strengthen our national security.”

In a note to investors Jan. 28, TD Cowen analysts said execution may be contingent on securing power purchase agreements, and that “recent DeepSeek developments could result in more tempered market reception than this would otherwise receive.”

That said, Chevron “should have capacity to support capex” for the venture within its $14-16 billion consolidated capex budget announced in December “given declining spend in major project regions such as Permian, Kazakhstan, and Gulf of Mexico,” the analysts continued, citing Chevron’s then-plan to allocate $1.5 billion to “lowering the carbon intensity of its operations and growing New Energies.”

Kick Off Year with Global Increases

Worldwide business aviation operations were up 7% YOY in January

Netjets Gulfstream G550

Large-cabin fractional operations saw the biggest jump in January, year over year, up 18.2% in North America, while large-cabin operations were also up the most overall in Europe

By Kerry Lynch

The year kicked off on an upswing for global business aircraft flight activity, jumping 7% from last January, while all regions saw an increase last month, according to industry data and safety analyst Argus International. In North America, activity climbed 4% year over year (YOY), while Europe saw a 1.8% gain, and the rest of the world combined for a 22.9% leap, Argus said, citing its TRAQPak analytics.

However, Argus sees mixed results heading into this month, with Europe— which saw precipitous declines in 2024—remaining positive with a 0.2% edge while North America is predicted to see a 3.9% decline.

In North America, all categories of aircraft saw YOY gains last month in flight activity, led by midsize jets, up 6.5%.This was followed by turboprop activity, up 4.3%; light jets, +3.1%; and large-cabin jets, +0.2%.

Fractional activity in North America once again paved

the way for the gains, up 11.1% YOY in January. Part 135 flight activity appeared to rebound a bit with a 5.9% improvement, but Part 91 flying was down 0.2% with large-cabin jet operations in that segment dipping the most at -5.7%. Conversely, large-cabin jet fractional operations drove the biggest increase in that market segment, up 18.2%.

In Europe, all three jet categories flew more: large-cabin jets by 6.4%, midsize jets by 3.5%, and light jets by 0.2%.Turboprop activity, however, dipped by 3.4%.

In other regions of the world, turboprop activity surged by 38.6%, followed by midsize jets, +20.8%; light jets, +14%; and large-cabin jets, +6.1%.

“January started off about as well as it could for business aviation.We don’t expect to see gains like this all year, but we do expect 2025 overall to finish positive by the time the year closes out,” said Travis Kuhn, senior v-p of software at Argus. “In the short term, Part 91 activity continues to be an area we are watching closely, especially in a month where everything was positive except that segment. It seems that Part 135 activity has hit its bottom but Part 91 activity still seems to have a little ways to go.”

RoboDrills make quick work out of any MILLING, DRILLING OR TAPPING jobs.

RELIABILITY has also been addressed in all areas of the machine design. Coupled with the latest FANUC 31 i -B5 PLUS CONTROL , the ROBODRILL IS THE PREFERRED MACHINE IN ANY MANUFACTURING FACILITY .

December 2024 US Cutting Tool Orders Total $179.5 Million, Down 0.6% Year to Date From 2023

Shipments of cutting tools, measured by the Cutting Tool Market Report compiled in a collaboration between AMT and USCTI, totaled $179.5 million in December 2024, down 2% from November 2024. Shipments totaled $2.43 billion for 2024, down 0.6% from 2023. by Christopher Chidzik

Shipments of cutting tools, measured by the CuttingTool Market Report compiled in a collaboration between AMT – The Association For Manufacturing Technology and the U.S. Cutting Tool Institute (USCTI), totaled $179.5 million in December 2024. Orders decreased 2% from November 2024 and

were down 4.3% from December 2023. Shipments totaled $2.43 billion for 2024, down 0.6% from shipments made in 2023. The year-to-date growth rate declined every month in 2024 beginning in April.

“Our industry continued to feel the effects of a stagnated aerospace market as we ended 2024, and this sets us up for a rather uneven first and second quarter,” stated Steve Boyer, president of USCTI. “Cutting tool markets still tended to perform better than other markets through the end of 2024 and start of 2025 but have noticeably softened. Adjusted lower outlooks for this year in the transportation, automotive, aerospace, and defense sectors will project a slower rebound.”

Alan Richter, editor-at-large of Cutting Tool Engineering,

added: “With economic and market uncertainties, such as tariffs, supply chains, and inflation, coupled with ongoing and new geopolitical tensions swirling with the election of a new U.S. presidential administration, manufacturers that use cutting tools continued to decrease their tool consumption in December, albeit at a slower rate than November. However, more encouraging reasons for the slide include toolmakers developing cutters that last longer while running at higher machining parameters, productivity gains with automation and AI, and increased efficiency from implementing advanced, or ‘smart,’ technologies.”

The Cutting Tool Market Report is jointly compiled by AMT and USCTI, two trade associations representing the development, production, and distribution of cutting tool technology and products. It provides a monthly statement on U.S. manufacturers’ consumption of the primary consumable in the manufacturing process, the cutting tool. Analysis of cutting tool consumption is a leading indicator of both upturns and downturns in U.S. manufacturing activity, as it is a true measure of actual production levels.

AMT – The Association For ManufacturingTechnology represents and promotes U.S.-based manufacturing technology and its members – those who design, build, sell, and service the continuously evolving technology that lies at the heart of manufacturing. Founded in 1902 and based in Virginia, the association specializes in providing targeted business assistance, extensive global support, and business intelligence systems and analysis. AMT is the voice that communicates the importance of policies and programs that encourage research and innovation, and the development of educational initiatives to create tomorrow’s Smartforce. AMT owns and manages IMTS – The International Manufacturing Technology Show, which is the premier manufacturing technology event in North America.

The United States Cutting Tool Institute (USCTI) was formed in 1988 and resulted from a merger of the two national associations

A2Z-TM8MYi-Nov2024.indd 1 10/8/2024 2:24:30 PM

representing the cutting tool manufacturing industry. USCTI works to represent, promote, and expand the U.S. cutting tool industry and to promote the benefits of buying American-made cutting tools manufactured by its members. The Institute recently expanded its by-laws to include any North American manufacturer and/or remanufacturer of cutting tools, as well as post-fabrication tool surface treatment providers. Members, which number over 80, belong to seven product divisions: Carbide Tooling, Drill & Reamer, Milling Cutter, PCD & PCBN, Tap & Die, Tool Holder and All Other Tooling. A wide range of activities includes a comprehensive statistics program, human resources surveys and forums, development of product specifications and standards, and semi-annual meetings to share ideas and receive information on key industry trends.

Ellison Technologies is a provider of advanced machining solutions to North American metal-cutting manufacturers and their global affiliates.

As a family of companies we are committed to the survival and growth of the American manufacturing industry. Independent offices provide us a local market focus and the flexibility to advocate the needs of each of our valued customers.

Our priority is to introduce technologies that strengthen our customers’ ability to compete in the markets they serve. Whether the solution involves a stand alone machine, multi-process equipment, or an integrated manufacturing system with robotic automation, our goal remains the same; to optimize throughput and quality at the lowest per-part manufacturing cost.

Our team of engineers, equipment and automation specialists, and project management professionals, are dedicated to helping manufacturers get the most from their technology investments. Service and parts engineers provide post-installation support aimed at optimizing machine availability, productivity, and cost of ownership.

We strive to make every customer worldcompetitive. Whether our customer competes globally or not, Ellison Technologies brings its full mastery of advanced manufacturing technology to provide the most comprehensive and productive solutions the industry has to offer.

Whenever you add a new technology, there’s bound to be a learning curve. At Ellison Technologies, we act as an extension of your operation as you get up to speed. If you have any questions – whether before, during or after the machine install – we’re here to help you identify the best way to do things.

There are Ellison branches all over the United States, and all of our employees bring experience (and a willingness to share it) that’s simply unmatched. No matter how new your machining adventure is to you, we’ve seen it, and we’ve solved for it already. It’s a welcome dose of peace of mind as your journey begins.

Our mission is clear: at Ellison, we equip American manufacturers to compete and win, both locally and globally. If you can’t shake the feeling that there’s a better way to do things, we are ready to help you increase quality and efficiency, win more work and increase your profits.

For more information on Ellison Technologies contact them at: 866-567-2580, www.ellisontechnologies.com

Lockheed Martin Rotary and Mission Systems, Syracuse, New York, is awarded a $551,012,019 cost-plus-incentive-fee, fixed-price incentive (firm-target), and firm-fixed-price, indefinite-delivery/indefinitequantity contract for engineering and technical support and production of the submarine AN/BLQ-10 electronic warfare systems on newconstruction and in-service submarines. This contract includes options which, if exercised, would bring the cumulative value of this contract to $1,365,790,743. Work will be performed in Syracuse, New York, and is expected to be completed by January 2030. Fiscal 2025 shipbuilding and conversion (Navy) funds in the amount of $2,000,000 will be obligated to satisfy the minimum guarantee and begin engineering efforts under delivery order N00024-25-F-6260 and the funds will not expire at the end of the current fiscal year. The requirement was competitively procured through full and open competition via System for Award Management (SAM.gov) with one offer received in response to this solicitation. Naval Sea Systems Command, Washington, D.C., is the contracting activity (N00024-25-D-6211).

Lockheed Martin Space, Littleton, Colorado, was awarded an $86,700,000 cost-plus-incentive-fee, undefinitized contract action (N0003022C1025P00062) for the procurement and delivery of advanced payload modules. Work will be performed in Denver, Colorado (52%); Huntsville, Alabama (36%); Sunnyvale, California (8%); Michoud,

Louisiana (2%); Stennis, Mississippi (1%); and at various other locations (1% total). Work is expected to be completed on Sept. 30, 2027, once the contract is definitized. Fiscal 2025 other procurement (Navy) funds in the amount of $43,350,000 will be obligated on this award. No funds will expire at the end of the current fiscal year. This contract was awarded on a sole source basis pursuant to 10 U.S. Code 3204(a)(1) and was previously synopsized on the System for Award Management (SAM.gov) online portal. Strategic Systems Programs,Washington, D.C., is the contracting activity.

Raytheon Co., Tucson, Arizona, is awarded a $75,125,477 costplus-fixed-fee modification to previously awarded contract N0002423-C-5410 to exercise options for Standard Missiles 2 and 6 (SM-2/6) engineering and technical support. Work will be performed in Tucson, Arizona, and is expected to be completed by March 2028. Fiscal 2024 research, development, test, and evaluation (Navy) funds in the amount of $21,754,175 (76%); fiscal 2025 research, development, test, and evaluation (Navy) funds in the amount of $2,782,000 (10%); fiscal 2024 weapons procurement (Navy) funds in the amount of $2,683,000 (9%); Foreign Military Sales (FMS) (Spain) funds in the amount of $581,500 (2%); FMS (Netherlands) funds in the amount of $553,500 (2%); and FMS (Germany) funds in the amount of $398,400 (1%), will be obligated at time of award, of which, $21,754,175 will expire at the end of the current fiscal year. Naval Sea Systems Command, Washington, D.C., is the contracting activity.

BARTON’s Transfer Hopper holds up to 4,400 lbs. of garnet eliminating the need to handle individual bags of abrasive.

• Saves time and labor

• Increases worker safety

• Minimizes clogs

• Reduces waste

Interested in learning more?

Call 800-741-7756 or email info@barton.com

BARTON INTERNATIONAL USA/Canada 800-741-7756 • 518-798-5462 info@barton.com • barton.com • store.barton.com

The Navy has awarded an indefinite-delivery/indefinite-quantity multiple award contract to 1,023 businesses in multiple locations across 43 of the 50 United States, Puerto Rico, and Washington, D.C., for future competition of support service requirements to be solicited by Department of the Navy activities under Rolling Admissions of the SeaPort Next Generation (SeaPort-NxG) multiple-award contract vehicle. All work under the contracts will fall under two categories (engineering support services and program management support services), which are further divided into 23 functional areas. The government estimates approximately $5,000,000,000 of services will be procured per year via orders issued under the SeaPort-NxG multiple award contracts.These contracts have a four-year period of performance and were competitively procured via Federal Business Opportunities (FedBizOps), with 1,106 offers received. No contract funds will be obligated on the basic awards. Naval Sea Systems Command, Naval Surface Warfare Center, Dahlgren Division, Dahlgren, Virginia, is the contracting activity (N00178-24-R-7000). (Awarded Jan. 2, 2025)

Lockheed Martin Corp., Lockheed Martin Aeronautics Co., Fort Worth, Texas, was awarded a $678,442,004 modification (P00009) to a costplus-fixed-fee, firm-fixed-price order (N0001923F0002) against a previously awarded basic ordering agreement (N0001919G0008). This modification adds scope to procure various material modification kits, special test/tooling equipment, and associated seed assets to support

the F-35 Joint Strike Fighter aircraft retrofit and modification efforts for the Air Force, Marine Corps, Navy, non-U.S. Department of Defense (DoD) F-35 program partners, and Foreign Military Sales (FMS) customers. Work will be performed in Fort Worth, Texas, and is expected to be completed in December 2028. Fiscal 2024 aircraft procurement (Air Force) funds in the amount of $163,792,190; fiscal 2024 aircraft procurement (Navy) funds in the amount of $163,078,071; fiscal 2023 aircraft procurement (Navy) funds in the amount of $22,586,072; fiscal 2023 aircraft procurement (Air Force) funds in the amount of $20,809,905; non-U.S. DOD participant funds in the amount of $281,331,708; and FMS funds in the amount of $26,844,058, will be obligated at the time of award, none of which will expire at the end of the current fiscal year. The order and contract being modified were not competed. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Raytheon Co., Tucson, Arizona, was awarded a $333,281,489 firmfixed-price and cost-plus-fixed fee contract for Standard Missile-6 (SM-6) full rate production requirements, spares, and round design agent. This contract includes options which, if exercised, would bring the cumulative value of this contract to $908,144,803. Work will be performed in Tucson, Arizona (74%); Huntsville, Alabama (19%); Andover, Massachusetts (5%); and Dine, New Mexico (2%), and is expected to be completed by October 2027. If all options are exercised, work will continue through September 2030. Fiscal 2024 weapons procurement (Navy) funding in the amount of $333,281,489 was obligated at time of award and will not expire at the end of the current fiscal year.This contract was not competitively procured in accordance with 10 U.S. Code 3204(a)(1) (only one responsible source and no

other supplies or services will satisfy agency requirements). Naval Sea Systems Command, Washington, D.C., is the contracting activity (N00024-25-C-5409). (Awarded Dec. 20, 2024.)

General Dynamics Electric Boat Corp., Groton, Connecticut, is awarded a not-to-exceed $188,000,000 undefinitized contract action modification to previously awarded contract N00024-17-C-2100 for Construction Spares associated with the Virginia Class Block V submarines. Work will be performed in Sunnyvale, California (36%); South Yorkshire, United Kingdom (7%); Westfield, Massachusetts (6%); Staffordshire, United Kingdom (4%); McKeesport, Pennsylvania (3%); Manchester, New Hampshire (3%); Tacoma, Washington (3%); Newport News, Virginia (2%); Warren, Massachusetts (2%); Farmingdale, New York (2%); El Cajon, California (2%); Tucson, Arizona (1%); Chesapeake, Virginia (1%); Tampa, Florida (1%), Portsmouth, New Hampshire (1%); and other locations less than 1% (26%), and is expected to be completed by September 2035. Fiscal 2024 shipbuilding and conversion (Navy) funding in the amount of $188,000,000 will be obligated at time of award and will not expire at the end of the current fiscal year. The statutory authority for this sole source award is in accordance with Federal Acquisition Regulation 6.302-1(a)(2)(iii)-only one responsible source and no other supplies or services will satisfy agency requirements. Naval Sea Systems Command, Washington, D.C., is the contracting activity.

General Dynamics Electric Boat Corp., Groton, Connecticut, was awarded an $83,729,655 cost-plus-incentive-fee modification to previously awarded contract N00024-20-C-4312 for efforts related to completion of the USS Hartford (SSN 768) engineered overhaul.

Work will be performed in Groton, Connecticut, and is expected to be completed by November 2027. Fiscal 2025 operation and maintenance (Navy) funds in the amount of $81,325,569 will be obligated at the time of award and will expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity. (Awarded Dec. 19, 2024)

Kratos Unmanned Aerial Systems Inc., Sacramento, California, was awarded a $59,338,010 modification (P00008) to a previously awarded firm-fixed-price contract (N0001923C0021). This modification exercises options to procure full rate production Lot Six of the BQM-177A Subsonics Aerial Targets system to include 65 BQM-177A targets, 65 Rocket-Assisted Takeoff (RATO) attachment kits, three replacement in kind (RIK) BQM-177A targets, and three RIK RATO attachment kits for the Navy; and two BQM-177A targets and two RATO attachment kits for the Republic of Korea to support weapons system test and evaluation and fleet training.Work will be performed in Sacramento, California (50%); Dallas,Texas (20%); Fort Walton Beach, Florida (5%); Blacksburg, Virginia (4%); Santa Ana, California (2%); Newton, Kansas (2%); Concord, California (2%); Milwaukie, Oregon (2%); Chatsworth, California (2%); and various locations within the continental U.S. (11%), and is expected to be completed in July 2027. Fiscal 2025 weapons procurement (Navy) funds in the amount of $55,099,581; fiscal 2023 weapons procurement (Navy) funds in the amount of $2,543,057; and Foreign Military Sales customer funds in the amount of $1,695,372, will be obligated at the time of award, of which $2,543,057 will expire at the end of the current fiscal year. The contract being modified was not competed. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

CJ Precision Machine, Inc. is a leading manufacturer of critical parts for a wide variety of industries, including aerospace, semiconductor, medical, solar, food processing, aviation, automotive, and motorsports.

From our vertical machining centers, to our state-of-the art 5-axis mills and 7-axis lathes, we provide superior customer satisfaction from prototype to production.

CJ provides superior customer satisfaction through flexible and dependable service with timely turn-around.

Our precision manufacturing includes working with both plastics and metals in our 9,500 square foot facility in Boise, Idaho. Our machinists have more than 140 years of experience and all manufactured parts are inspected by quality control.

CJ can provide finishing including anodizing, powder-coating, chromate, various types of electro-plating, and many others as required by our customers.

Precision

1-208-908-5920

www.cjprecisionmachine.com

ISO 9001 certified

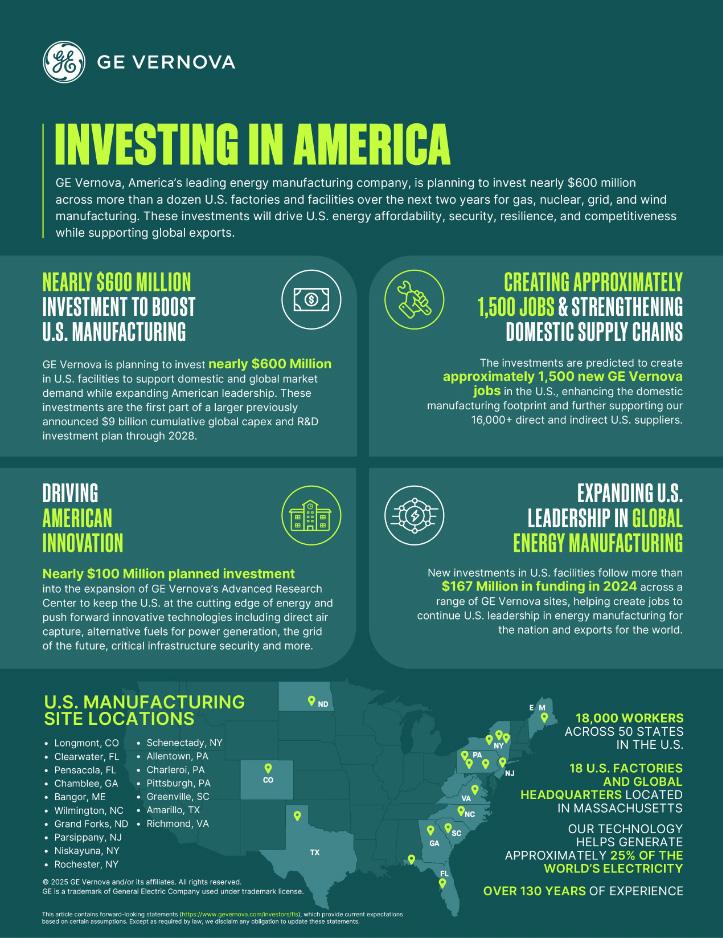

Ge Vernova To Invest Almost $600 Million In U.S. Factories And Facilities Over Next Two Years

America’s leading energy manufacturer expects to create more than 1,500 new factory and engineering jobs in the U.S.

Expansions at company’s U.S. factories and facilities will help meet surging customer demands for electricity equipment at home and abroad

Investments focus on gas power, grid, nuclear and onshore wind manufacturing sites

Company’s world class Advanced Research Center in Niskayuna, NY plans to grow as a leading energy innovation hub while accelerating cutting-edge energy technology development

GE Vernova Inc. (NYSE:GEV), America’s leading energy manufacturing company, is planning to invest nearly $600 million in its U.S. factories and facilities over the next two years to help meet the surging electricity demands around the world.

The new investments – expected to create more than 1,500 new U.S. jobs – will help drive U.S. energy affordability, national security, and competitiveness, and enable the American manufacturing footprint needed to support expanding global exports.

With worldwide energy needs forecasted to double, the substantial investments – the largest since the company’s spinoff in April – will help meet soaring customer demand, strengthen domestic supply chains, and continue developing cutting-edge American technology that helps power the world.

“These investments represent our serious commitment and responsibility as the leading energy manufacturer in the United States to help meet America’s and the world’s accelerating energy demand,” said Scott Strazik, CEO of GE Vernova. “These strategic investments and the jobs they create aim to both help our customers meet the doubling of demand and accelerate American innovation and technology development to boost the country’s energy security and global competitiveness.”

The new investments are the first part of a larger $9 billion cumulative global capex and R&D investment plan through 2028 that was announced at the company’s Investor Update on December 10. Currently GE Vernova has more than 18,000 workers across 50 states in the U.S., with 18 U.S. manufacturing facilities and its global headquarters located in Massachusetts. The company’s technology helps produce approximately 25 percent of the world’s energy and is currently deployed in more than 140 countries.

Plans to expand gas turbine manufacturing

To support our previously announced plan to deliver up to 80 heavy duty gas turbines per year, resulting in an additional 20GW of electricity globally, GE Vernova intends to invest almost $300 million in support of its Gas Power business and build-out of capacity incremental heavy duty gas turbines. The new funding is projected to create more than 850 new jobs, and support a range of new projects, including:

In Greenville, SC, the company is planning to invest more than $160 million to support capacity growth, quality, industrialization and delivery efforts, and new testing capability with hydrogen fuel.These efforts are expected to create more than 650 new jobs.

In Schenectady, NY, as previously announced, GE Vernova is planning to hire on more than 100 new jobs in 2025, and is investing over $50 million to support capacity growth and sustainability, industrialization and quality efforts.

GE Vernova is planning to invest nearly $50 million combined in its Parsippany, NJ, and Bangor, ME, locations to support capacity growth and quality, industrialization and delivery efforts.

to

GE Vernova is planning to invest a total of nearly $20 million to expand capacity at its Grid Solutions facilities in Charleroi, PA, which manufactures switchgear, and Clearwater, FL, which produces capacitors and instrument transformers.The investment is expected to result in a total of more than 260 new jobs at the two facilities. The investments are critical to meet rising demand for critical highvoltage grid equipment. The majority of the investment is planned

for the installation of new assets to create additional capacity and improve productivity.

More resources for nuclear business

GE Vernova’s nuclear business, GE Hitachi, plans to invest more than $50 million to enhance safety, quality and productivity at its Wilmington, NC, factory and to launch its next generation nuclear fuel design, a critical component to the company’s small modular reactor, the BWRX-300. The BWRX-300 reactor is the only advanced design that includes an approved, existing fuel. Expanding capacity of the fuel manufacturing operation further positions the BWRX-300 as the most ready to deploy advanced reactor on the market.

This investment also seeks to expand automation at the plant, which has been manufacturing fuel since 1968 and serves much of the U.S. boiling water reactor fleet, strongly positioning it for the future as the demand for nuclear energy increases globally, particularly as several U.S. utilities restart retired plants.

More capacity for U.S. onshore wind factories

As it continues focusing on its workhorse product strategy, GE Vernova’s Wind segment is planning to invest nearly $100 million in

its manufacturing facilities in Pensacola, FL, Schenectady, NY, and Grand Forks, ND, and its remanufacturing facilities in Amarillo, TX. These continuing investments aim to strengthen the U.S. supply chain for renewable energy through factory upgrades and tooling and fixtures investments, while improving customer and employee experience through a new experience center in Pensacola and office renovations in Schenectady.

Adding U.S. manufacturing capacity to support U.S. grid, demand for solar and energy storage

GE Vernova is planning to invest more than $10 million in its Pittsburgh, PA, facility to expand capabilities across its Electrification segment.This includes planned funding to house a new domestic manufacturing line for the company’s FLEXINVERTER, a key technology for utility-scale solar and energy storage applications. The total investment is expected to create more than 270 new jobs, with the new line producing both the 1500V and 2000V FLEXINVERTER. This will help enable utilities to seamlessly connect renewable energy sources to the grid, ensuring stable and consistent energy supply for homes and businesses.

Expanding leading energy innovation research hub

At its Advanced Research Center in Niskayuna, NY, a leading hub for energy technology and innovation, GE Vernova plans to invest almost $100 million in 2025 to strengthen the center’s electrification and carbon efforts, enable continued recruitment of top-tier talent, and push forward innovative technologies including direct air capture, alternative fuels for power generation, the grid of the future, critical

infrastructure security and more. In partnership with NewYork Governor Kathy Hochul and Empire State Development, the State of New York is committing an additional $9.6 million in tax credits to the project. The company expects this investment will create 75 new research jobs. The company is also planning to fund Generative Artificial Intelligence (AI) work in Niskayuna at $15 million in 2025.

These new investments in U.S. facilities follow more than $167 million in funding in 2024 across a range of GE Vernova sites, helping create more than 1,120 jobs to continue U.S. leadership in energy manufacturing for the nation and exports for the world.

About GE

GE Vernova is a purpose-built global energy company that includes Power, Wind, and Electrification segments and is supported by its accelerator businesses. Building on over 130 years of experience tackling the world’s challenges, GE Vernova is uniquely positioned to help lead the energy transition by continuing to electrify the world while simultaneously working to decarbonize it. GE Vernova helps customers power economies and deliver electricity that is vital to health, safety, security, and improved quality of life. GE Vernova is headquartered in Cambridge, Massachusetts, U.S., with approximately 75,000 employees across 100+ countries around the world.

GE Vernova’s mission is embedded in its name – it retains its legacy, “GE,” as an enduring and hard-earned badge of quality and ingenuity. “Ver” / “verde” signal Earth’s verdant and lush ecosystems. “Nova,” from the Latin “novus,” nods to a new, innovative era of lower carbon energy. Supported by the Company purpose, The Energy to Change the World, GE Vernova will help deliver a more affordable, reliable, sustainable, and secure energy future. Learn more: GE Vernova’s website and LinkedIn.

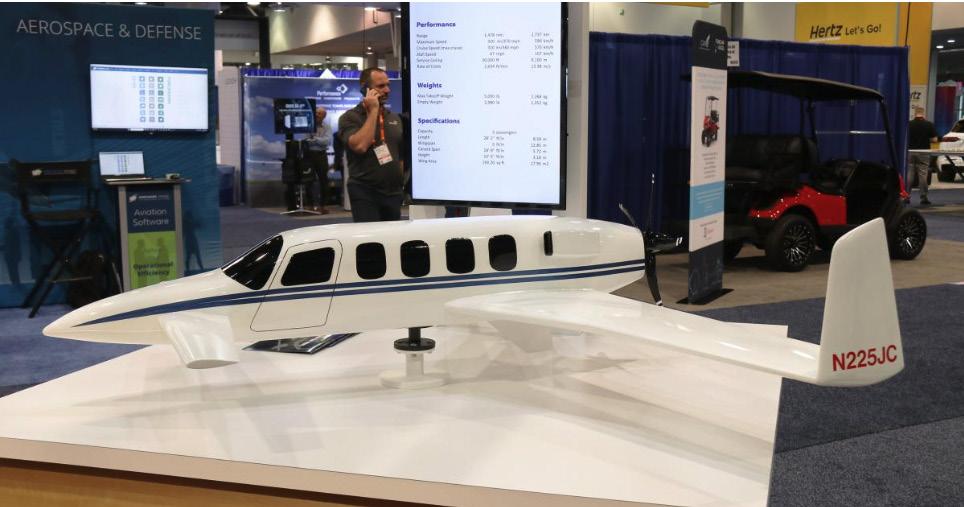

Hydrogen-electric six-seater aircraft is targeted for 2028 service entry

Jetcruzer International 500E model

Jetcruzer International revealed its plans for the electric six-seater 500E aircraft at the NBAA-BACE show in 2023. © AIN/Barry Ambrose

By Charles Alcock

Jetcruzer International has ordered a 600-kilowatt electric propulsion system (EPS) from ZeroAvia to support development of its six-seat hydrogen-electric 500E airplane.The U.S. company today announced that it will take delivery of the ZA600 powertrain in the second quarter as it works towards service entry in 2028 for the reworked 1990s-era Jetcruzer 500 pusher turboprop single.

According to ZeroAvia, this is the first firm order for the ZA600, which the company has developed to convert aircraft carrying up to 20 passengers to hydrogen power. It has previously reported preorders for 2,000 units and is also developing the two-megawatt (2,682-hp) ZA2000 unit for larger airliners with 40 to 80 seats.

Earlier this month, the FAA issued ZeroAvia with a G-1 issue paper, marking stage two of the certification process for the EPS. Featured in the equipment are four 200-kilowatt continuous power bidirectional inverters to convert DC to AC power for ZeroAvia’s direct-drive motors, which are capable of 2,200 rpm. The EPS can be configured for various aircraft powertrain architectures, including battery-electric, fuel cell-based electric, and hybrid-electric.

Jetcruzer International announced plans for the 500E aircraft, as well as for a version powered by a Pratt & Whitney Canada PT6 turboprop, at NBAABACE 2023. The original design was acquired in 2017 by Victor Tao, owner of Farrar Aerospace, after AASI shelved the program in 2004.

California-based Jetcruzer also plans to develop a 12-passenger model called the 1250E, with a target certification date in 2030. When the first ZA600 is delivered, it will be integrated with a rebuilt Jetcruzer 500 airframe that will be used as a flying testbed.

Approved Processes

+ Boeing Approved Processes

+ Expedited Turnaround

+ X-ray Fluorescence Thickness Verification

+ In-House Laboratory With Atomic Absorption (AA)

+ Expanded Capacity In Vibratory Plating

“Sustainable aviation is the future, and we are thrilled to take a leadership role in advancing this vision,” said Tao, who is CEO of Jetcruzer International. “The electrification of the Jetcruzer 500E represents a bold step forward in reducing carbon emissions while maintaining the high performance and efficiency our customers expect.”

ZeroAvia has opened a 136,000-sq-ft Propulsion Center of Excellence in Everett, Washington, to produce the propulsion systems. “It is exciting that our first sale of the 600-kW EPS as a standalone unit will support a project with simultaneously a rich history and a bright future,” said ZeroAvia chief business officer Sergey Kiselev. “Our commitment to deep vertical integration in development of our full powertrain technology is paying off as we have amassed a range of intellectual property and a portfolio of valuable fuel cell and electric propulsion components that have a strong market in their own right.”

JX Advanced Metals USA has more than 125 employees. The company previously announced plans to hire 100 additional workers by 2025, and officials told the Business Journal in 2022 it could develop equally sized phases on its Mesa site in the future, depending upon market demand. By Amy Edelen – Phoenix Business Journal

ASU lands $100 million CHIPS Act grant for advanced packaging research project

Preem is set to transition its Lysekil refinery from fossil to renewable fuels, and it has decided to use Alleima’s heat exchanger tubes made from its Sanicro 35 alloy which combines the best features of a super austenitic stainless steel and a nickel alloy.

Arizona State University has landed a multimillion-dollar federal grant to accelerate advanced packaging research and development for the semiconductor industry.

The National Institute of Standards and Technology — part of the U.S. Department of Commerce — announced Thursday it plans to award ASU a CHIPS Act grant up to $100 million to support the SHIELD USA initiative, a project led by a university research team and Deca Technologies, a Tempe-based advanced packaging technology provider.

The changeover means that Preem will no longer use fossil raw materials such as crude oil, but renewable raw materials instead.To make this possible, advanced technology is required, not least in the pre-treatment unit (PTU) that will be built. The raw materials will be pre-treated and purified at high temperatures before being used to produce renewable fuels such as Hydrotreated Vegetable Oil (HVO), diesel made from vegetable oils or plant products and Sustainable Aviation Fuel (SAF).

ecosystem of new advanced packaging service providers — or interconnect foundries — centered on molded core substrate and fan-out wafer-level packaging technologies, according to a university announcement.

SHIELD USA’s team is led by Jason Conrad, chief operating officer of the Southwest Advanced Prototyping Hub and Craig Bishop, chief technology officer of Deca Technologies.

The processes in refineries often place high demands on the materials used and renewable fuels are particularly challenging. The raw materials used usually contain chlorides, which can cause corrosion. Therefore, special materials are required that can withstand high temperatures and aggressive chemical environments without corroding.

“To bring substrate manufacturing back to the U.S., we need to change the game. More than incremental progress, we need 10X breakthroughs,” Bishop said in a statement. “This is a fantastic example of a university working in close partnership with industry to drive innovation, and we’re excited to partner so closely with ASU and to collaborate with leading industry players in this effort to reestablish technology leadership.”

em started redeveloping its IsoCracker plant (ICR) in Lysekil in late 2024. Once completed, it will produce 1.2 million cubic meters of renewable fuels per year as well as reduce fossil carbon dioxide emissions at user level by 2 to 3 million tons per year. At the same time, Preem will reduce fossil fuel production by a corresponding amount.

Project will be based on ASU campus

“Reducing greenhouse gas emissions is one of the great challenges of our time. I am therefore proud that Preem is now making the biggest change in the company’s history. We are doing this by converting the diesel plant at the refinery in Lysekil. When the conversion is complete, we will be Scandinavia’s largest producer of renewable jet fuel,” says Tommy Johansson, project manager for the ICR project at Preem.

SHIELD USA will spur creation of a domestic

The project will be based at ASU’s MacroTechnology Works — home to the Advanced Electronics and Photonics Core Facility — where researchers will explore the commercial viability of 300 mm wafer-level and 600 mm panel-level manufacturing, a technology that does not yet exist as a

capability in the U.S.

“We are very happy that Alleima has been trusted to supply heat exchanger tubes and pipes to Preem. Alleima has a long history as a supplier of special steel to Preem’s refineries. The special alloy Sanicro 35, is an austenitic stainless-steel alloy intended for extremely corrosive environments and an alternative to the use of nickel bases in the heat exchangers for preheating and cooling the renewable raw materials in the PTU. Before a decision could be made, we conducted extensive lab tests together with Preem, which showed that Sanicro 35 can withstand the extreme conditions and process environments of the pretreatment plant. This resulted in a strong alternative to the more expensive nickel-based alloys that are otherwise used,” says Barinder Ghai, Director of Technical Marketing, New Business Development for the Tube division at Alleima.

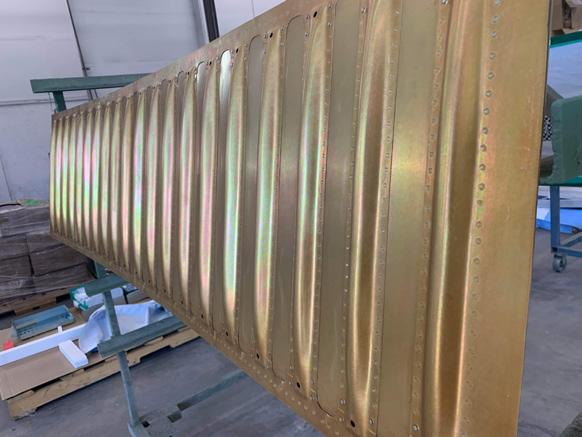

By Stephen Hannemann

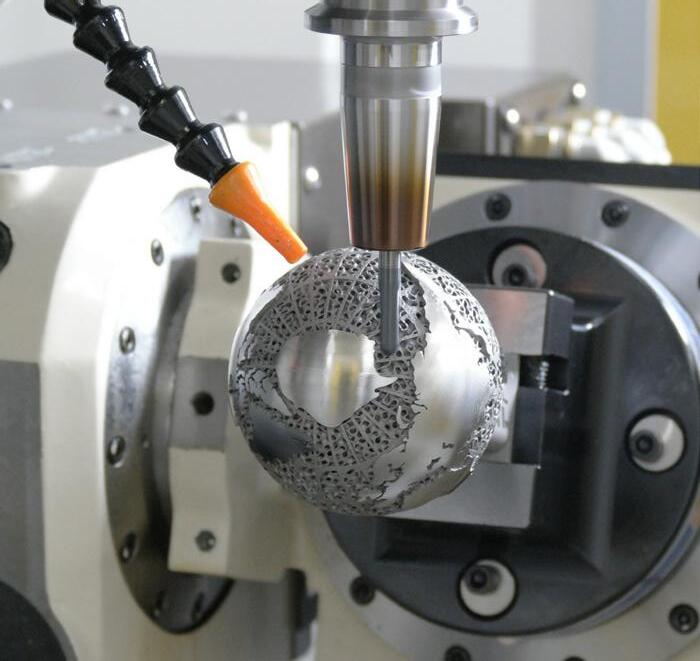

Millions upon millions of plastic injection molded parts and product components are produced every hour in this country and around the world. Plastic molded products are a key ingredient of our U.S. manufacturing economy. Injection molding is the most cost-saving process to produce plastic parts in medium to high volumes with an infinite variety of compounds that can be tailored to the product requirements.

The opportunities and uses for injection molded products are limitless. You can’t travel through a department store kitchenware section, or the hardware store tool section without seeing bright and shiny injection molded offerings.The next time you visit your dentist, doctor, or God forbid, spend time at a hospital, take a moment to look around – the exam table, bed, many of the devices used by the nurses and doctors are injection molded or are comprised of molded plastic parts. Observe the next time you fly, or take a drive in your car, there is just no escaping the value of injection molded products impacting our everyday lives.

Every one of the products mentioned above has a genesis. They evolved from an engineer, designer, or an inventor’s concept needing fulfilment. Depending upon the complexity of the product, it may go directly from the design stage to sourcing the injection mold. Or a complex part / product may need a functional prototype to first prove the concept. In either case, if you are not familiar with plastic part design, it is best to select an injection molder to aid in your design process.

Then the production process begins. When you go to the injection mold house of your choice, you will be asked a series of questions:

• What does this part do? This will determine material considerations.

• What is the anticipated annual usage and product life expectancy? This will determine the injection mold considerations such as mold heat treatment and number of cavities.

• What are the cosmetic requirements?

• What are the tolerance requirements?

• What is the expected order cycle? Answers to these questions will aid in obtaining the best part price considerations and the long-term success of the project.

Although this is an abbreviated synopsis, it gives an overall view into the process of designing for cost effective injection molding. I hope this will help you in selecting a process for your future manufacturing needs.

All the photographs in this post are courtesy of 3D Plastics in Newberg, Oregon. 3d-plastics. com.

Be sure to visit with us at the upcoming Northwest Machine Tool Expo 2525, Booth # 711 at the Oregon Convention Center in Portland – May 14 and 15. Look forward to visiting with you.

Be sure to share your unique story with a cover and 2- or 3-page article or a dynamic ad in A2Z Manufacturing Magazine - West Coast Edition. No such thing as over exposure when developing new business! Call me at 425.501.7342.

For more information about our well vetted suppliers for Injection Molding, Sand Casting, Investment Casting, True 5-Axis Quick Turn Around Machining, and Metal Fabrication, call 425.501.7342, email stephen@smhincllc.com or visit www.smhincllc.com.

1-800-645-4174 Fax: 1-631-273-1066

1-800-424-2082

orders@royalprod.com

Abrasive Systems

KBC TOOLS & Machinery___714-278-0500

Air Cleaning Guns

Royal Products 631-273-1010

Auto-Bar Feed Systems

Western Machine Center____408-955-1000

Automation and Controls

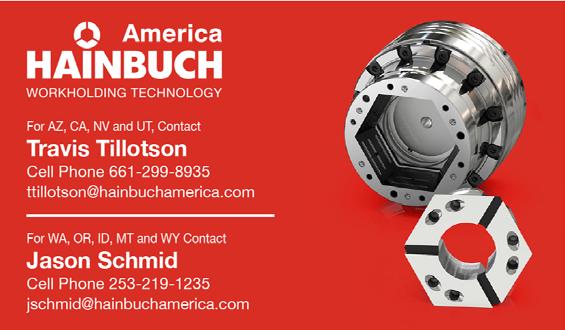

Hainbuch Workholding____818-970-7874

LANG TECHNIK-USA.

949-750-7372

Ballscrews

C & M Precision Spindle, Inc._ 503-691-0955

Band Saws/Saw Blades

Bandsaw Tech 562--419-7675

Cycle Time Solutions_____510-708-8665

Saw Service 877-738-6437

Sterling Saw Blades

800-828-11800

Band Saw Replacement Parts

Saw Service 877-738-6437

Sterling Saw Blades 800-828-1180

Band Saw Repair

Saw Service 877-738-6437

Sterling Saw Blades 800-828-1180

Bar Feeders

Spinetti Machinery 775-996-3770

Boring

THINBIT 888-844-6248

Caabinet Spray Washers

ALMCO 507-380-1009

Cams

Dayton Lamina. ________ 708-203-6684

Carbide Tools, Indexable

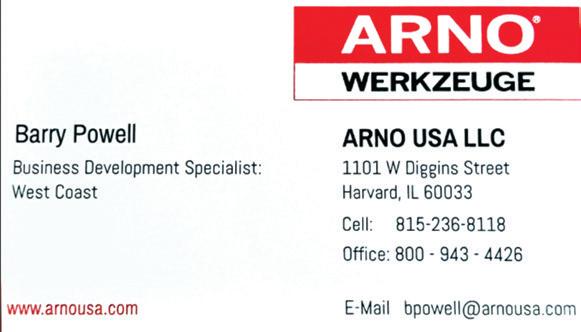

ARNO USA____________815-236-8118

Cycle Time Solutions 510-708-8665

Horizon Carbide 602-524-38028

Ceramic Cutting Tools

NTK Cutting Tools 425-365-3613

Chemicals: Ultrasonic Star Metal Fluids 800-367-9966

www.coastaluminum.com jpalmer@coastaluminum.com

Sulli Tool & Supply

714-863-6019

Cutting Tool Systems

ARNO USA____________815-236-8118

Cycle Time Solutions 510-708-8665