Assembly/Kitting and Top Level BOM Solutions EDM - Wire - Sinker - Small Hole Elastomer Molding - Rubber to Metal Bonding - Cloth Reinforced Diaphrams - Mechanical Assemblies CNC Machining - Milling 3,4, & 5 Axis - Turning Design For Manufacturing Over 50 Years of Precision Manufacturing Excellence West Coast Edition For: WA, OR, and CA Vol. 12, No. 5 OCT / NOV ‘22 Cover Story pages 20-21 a2zMFG.com

® HIGH QUALITY CUSTOM TOOLING EXCELLENT PERFORMANCE MILLIONS OF STANDARD TOOLS SUPERIOR CUSTOMER SERVICE FAST DELIVERY THINBIT.COM

Editor’s Corner

Song verse by HankWilliams Jr.

man

it’s

Mississippi River, she’s a-goin’

song was released 41 years ago and the same things are going on today that were sung about then. The world is still ending even after the Mayan calendar expired, the Mississippi seems to be pretty dry, interest is up, the stock market is down, and when was the last time you were down town?

Even though all this doom and gloom seems to come back to us like a bad penny, history will teach you things can’t stay bad forever and the economy along with every good thing comes back around. It’s about what we’re doing today to invest into a bright future and have a decent day in the present. We do this by being the pebble in the still pond and creating a nice ripple so the entire pond will eventually feel our energy. We do this by investing into today so that tomorrow will be a good time to raise a family and grow a business or just a safer place to reside.

We are told there is a major divide in our ‘land of the free and home of the brave’, but we may be looking at this all wrong. When opposites attract, when competition is healthy and fun, when opposing sides realize they are “complimentary forces” we realize the principle of Yin and Yang is on purpose and created by the great spirit and dipped in eternity.

Yin and Yang evolved into the idea that all things in the universe exist as inseparable and contradictory opposites, for example, female-male, dark-light and old-young. The pairs of equal opposites attract and complement each other. Less like “opposing forces”, and more “complimentary forces”.

How could I be me, without you?

What would the night say if it was sunny all day?

Why do the left and right fight, do they forget they are of one body? If the left hand washed the right, but the right wanted to fight, which gets clean?

One hand washes the other because it is mutually beneficial. Nature will teach us the strong survive, but we are all entwined.

In closing I would like to encourage you all to keep the faith, faith in humanity, faith in the power of love, and to allow one hand to wash the other to a cleaner, brighter, mutually beneficial day.

Thank you!

Micro-Tronics

50

of Precision

Excellence

Kim Carpenter

Published by: A2Z Manufacturing West Coast

PUBLISHERS/EDITORS

Kim Carpenter & Linda Daly Kim@A2ZManufacturing.com

Mail Address: 1538 E. La Vieve Ln. Tempe AZ 85284

(480) 773-3239 Website: www.A2ZManufacturing.com E-mail:Kim@A2ZManufacturing.com

CONTRIBUTORS

Linda Daly, Eugene Wirth, Stephen Hannemann, Hugh Taylor

Published bi-monthly to keep precision manufac turers abreast of news, contracts, trends, and to supply a viable supplier source for the industry.

Circulation: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

Cover

Telephone:

Announcements/Releases ................... 6-14 Feature Articles ........................... 1,10, 20-21 Buyers Guide Equipment Services ..... 32-38 Buyers Guide Processes ...................... 39-45 Card Gallery ........................................ 32-45 Index Of Advertisers ............................... 46 Editorial .................................. Throughout A2Z MANUFACTURING WEST COAST • 4 • OCT - NOV ‘22

Over

years

Manufacturing

The preacher

says

the end of time And the

dry The interest is up and the stock market’s down And you only get mugged if you go downtown This

September Manufacturing PMI® at 50.9%

“The September Manufacturing PMI® registered 50.9 percent, 1.9 percentage points lower than the 52.8 percent recorded in August.This figure indicates expansion in the overall economy for the 28th month in a row after contraction in April and May 2020. The Manufacturing PMI® figure is the lowest since May 2020, when it registered 43.5 percent. The New Orders Index returned to contraction territory at 47.1 percent, 4.2 percentage points lower than the 51.3 percent recorded in August. The Production Index reading of 50.6 percent is a 0.2-percentage point increase compared to August’s figure of 50.4 percent. The Prices Index registered 51.7 percent, down 0.8 percentage point compared to the August figure of 52.5 percent. This is the index’s lowest reading since June 2020 (51.3 percent).

The Backlog of Orders Index registered 50.9 percent, 2.1 percentage points lower than the August reading of 53 percent. After a single month of expansion, the Employment Index contracted at 48.7 percent, 5.5 percentage points lower than the 54.2 percent recorded in August.The Supplier Deliveries Index reading of 52.4 percent is 2.7 percentage points lower than the August figure of 55.1 percent.

This is the index’s lowest reading since before the coronavirus pandemic (52.2 percent in December 2019). The Inventories Index registered 55.5 percent, 2.4 percentage points higher than the August reading of 53.1 percent. The New Export Orders Index contracted at 47.8 percent, down 1.6 percentage points compared to August’s figure of 49.4 percent.This is the index’s lowest reading since June 2020, when it registered 47.6 percent. The Imports Index remained in expansion

territory at 52.6 percent, 0.1 percentage point above the August reading of 52.5 percent.”

Fiore continues, “The U.S. manufacturing sector continues to expand, but at the lowest rate since the pandemic recovery began. Following four straight months of panelists’ companies reporting softening new orders rates, the September index reading reflects companies adjusting to potential future lower demand. Demand eased, with the (1) New Orders Index returning to contraction, (2) New Export Orders Index in contraction for a second consecutive month, (3) Customers’ Inventories Index remaining at a low level but as close as it’s been to an ‘about right’ reading since early in the pandemic and (4) Backlog of Orders Index approaching contraction. Consumption (measured by the Production and Employment indexes) declined during the period, with a combined negative 5.3-percentage point impact on the Manufacturing PMI® calculation.The Employment Index returned to contraction after one month of expansion, and the Production Index increased by 0.2 percentage point, staying in growth territory, but at a modest level.”

Many Business Survey Committee panelists’ companies are now managing head counts through hiring freezes and attrition to lower levels, with medium- and long-term demand more uncertain. Inputs — defined as supplier deliveries, inventories, prices and imports — accommodated growth. The Supplier Deliveries Index reached an appropriate tension level, and the Inventories Index increased as panelists’ companies continued to manage the total supply chain inventory. The Prices Index decreased for a sixth straight month and is not far from contraction territory, and the Imports Index modestly grew.

A2Z MANUFACTURING WEST COAST • 5 • OCT - NOV ‘22

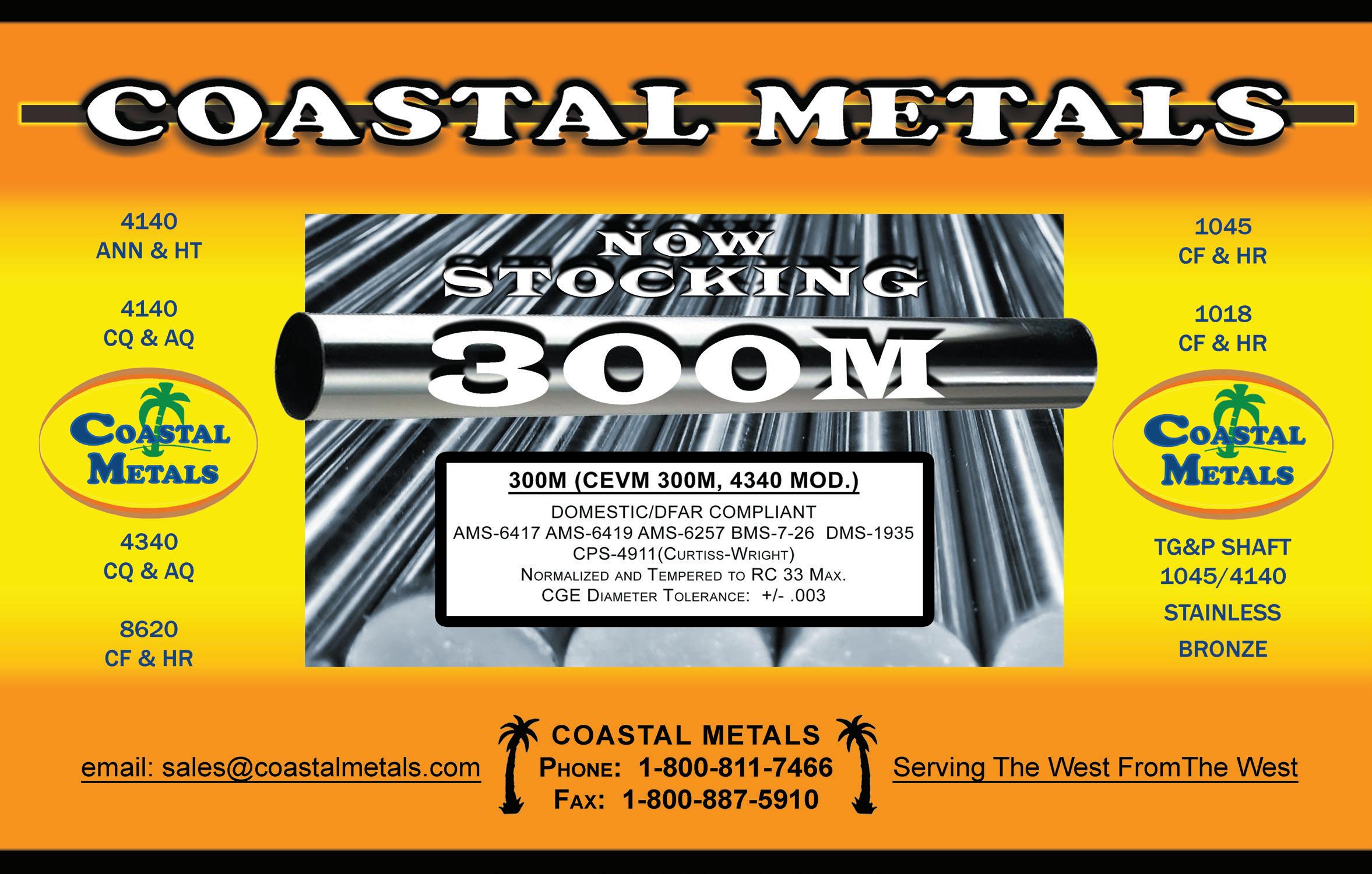

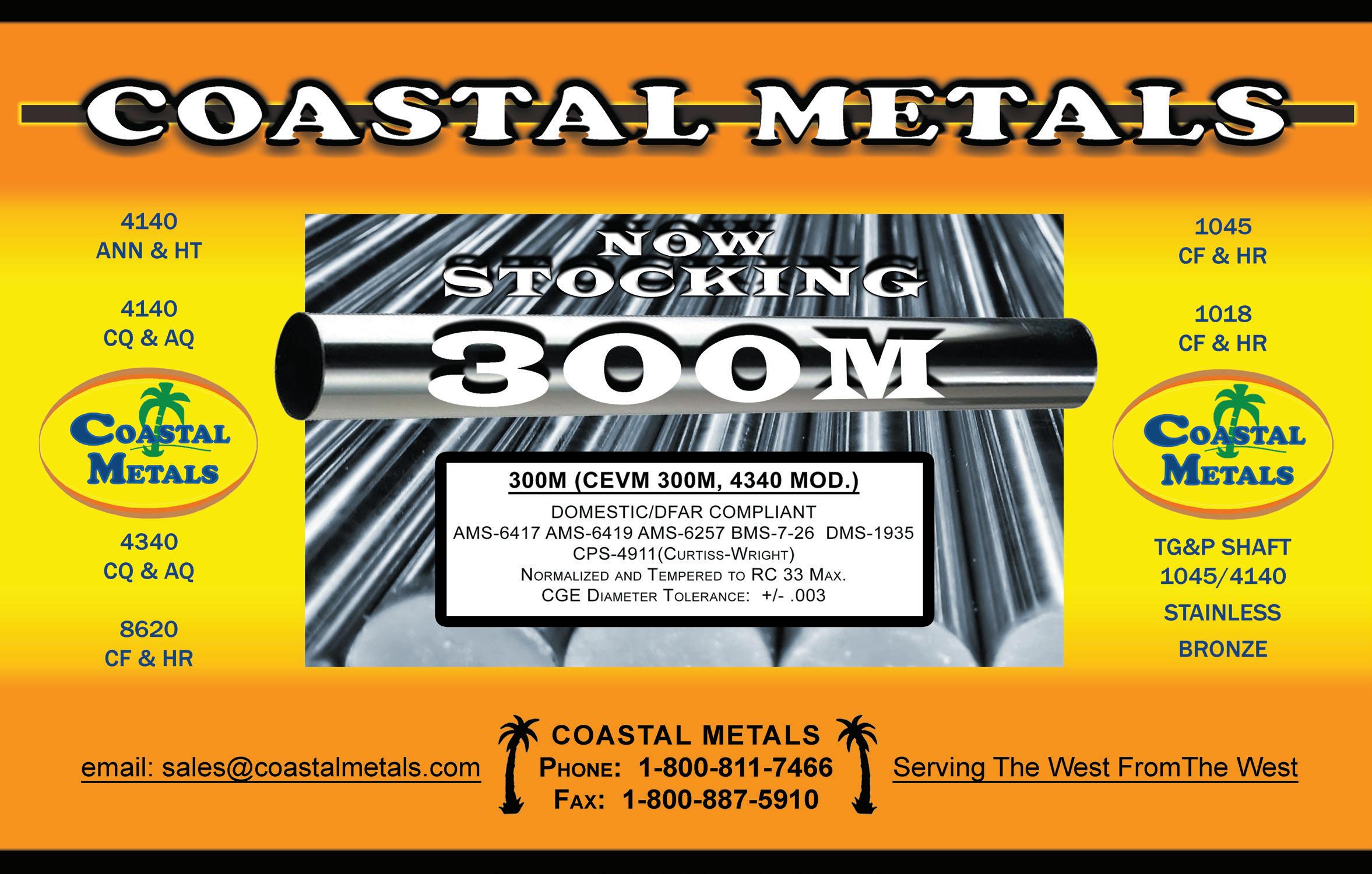

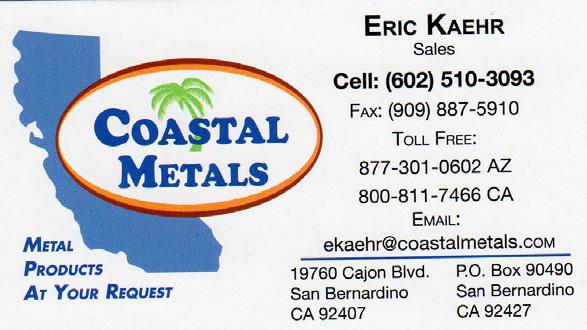

Fab Innovations Appointed Exclusive Western Us Dealer For Dne Fiber Lasers

Fab-Innovations and DNE Global have joined forces to service and support the stateof-the-art DNE technology for the Western US. DNE lasers offer a full line of cost effective fiber lasers.The new DNE LC3 is a fast and reliable cutting machine with an attractive price-performance ratio.The systems are made in the USA and offer laser output of up to 6kW with local service and support. Fab-Innovations is a division of Landmark Solutions, for more information visit fab-innovations.com.

For more information on Landmark Soltions Corp Contact: Fred R. Mooneyham, President Landmark Solutions Corp. Best Choice Parts Corp. Cell – 909-815-5757, fred@ landmarksolutionscorp.com

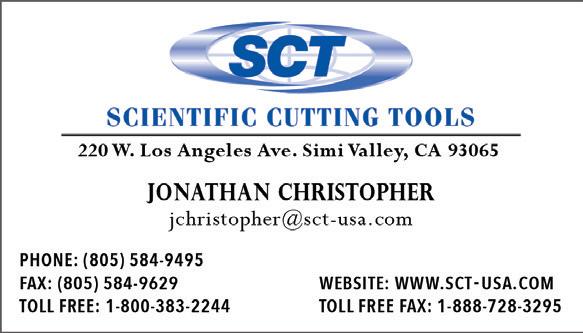

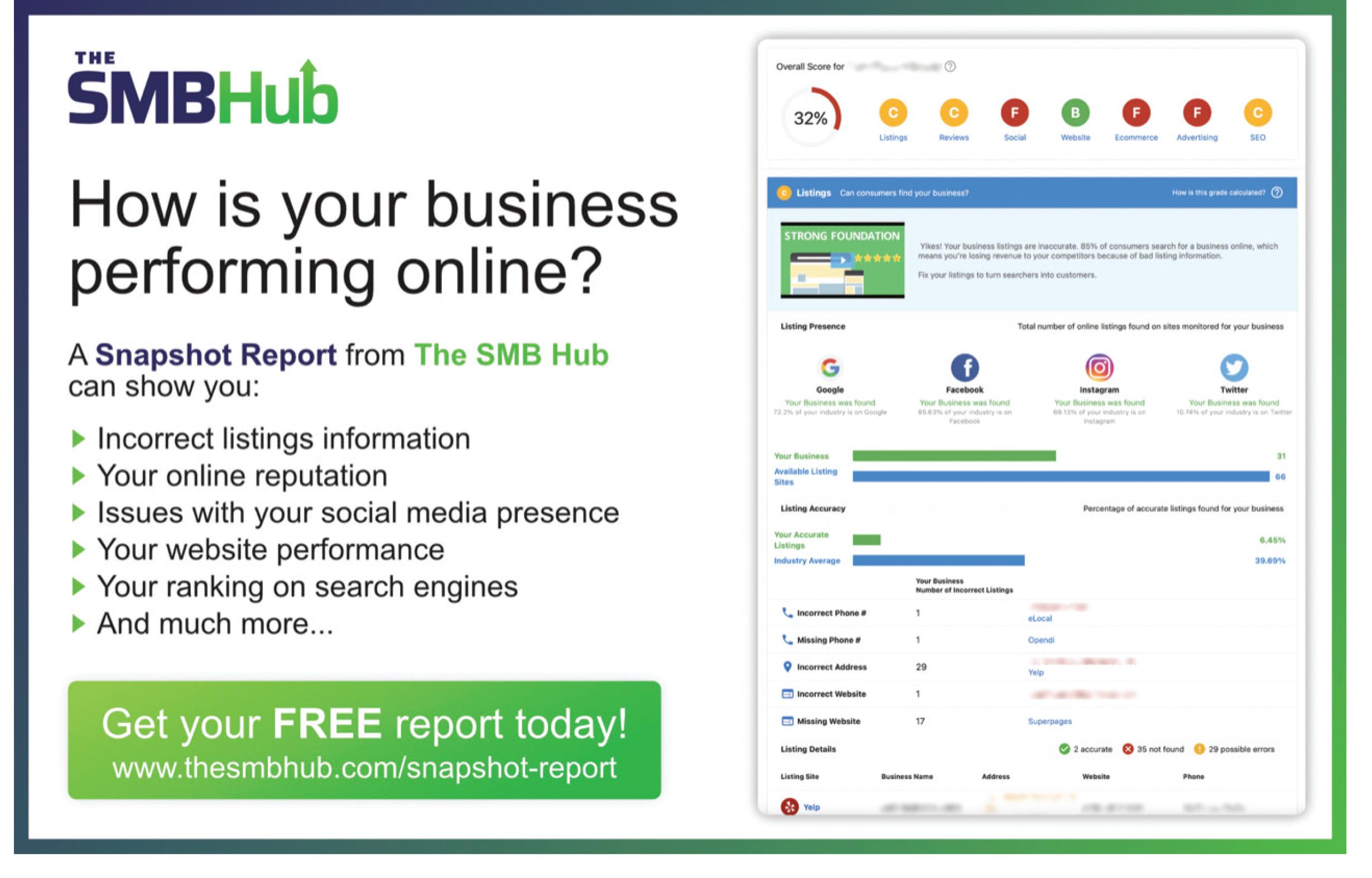

s Tech Financial Services New Employee, Equipment Finance Partner, and Tax Credits

by Mark Charlton

by Mark Charlton

Tech Financial Services, a industryleading equipment finance company, introduces Mandy Leman. Mandy joins the Tech team with 15 years’ experience in the banking industry and will lead marketing initiatives.

“Tech is a family owned and operated company whose values of honesty and customer advocacy align with my own values, I knew right away I wanted to work at Tech,” says Mandy. Mandy has an entrepreneurial spirit and passion for financial education, “sharing the benefits that financing equipment can make for growing and established businesses is just one of the many responsibilities we hold at Tech.”

Tech Financial is more than an Equipment Finance company, we’re a financial partner. We’re set on helping manufacturers, distributors, and resellers at every stage of growth by offering personalized service and flexible payment plans.

Growing shops need two lenders to maintain profit margin: a traditional bank and an equipment finance company. Leasing through a finance company allows you to preserve your lines of credit with your bank and gives you the ability to treat your monthly payments as a business expenses versus company debt. A finance company also allows you to leverage borrowing capacity. We offer a variety of payment and buyout options, as well as tax incentives. Most importantly, as an equipment finance company, we have machine knowledge, so our leases offer purchase options that best fit your company needs and growth.

As year-end rapidly approaches be sure to take advantage of tax deductions like Section 179, an immediate expensing of qualified asset purchases. Qualified equipment purchases made before January 1, 2023, may be eligible for a 100% first-year immediate deduction. Please consult with your accountant to confirm eligibility for tax benefits.

Tech Financial makes the equipment financing process easy and hassle-free. Please join us in welcoming Mandy to the team and be sure to think of Tech Financial when it comes to financing your equipment.

For more information visit www.techfin.net, phone 414-224-0242, email markc@techfin.net

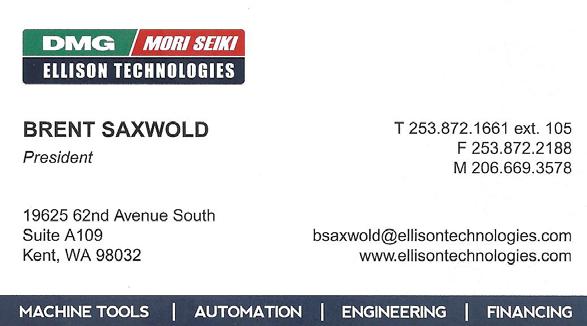

Bramac Machinery Adds Two New Lines To Its Portfolio, NEXA3D & Danobat

Bramac Machinery, Inc. is pleased to announce that it recently added two new manufacturers to its product line - Nexa3D and Danobat.

Bramac CEO Martyn Bramhall says, “We selected Nexa3D for our additive manufacturing product because they make the world’s fastest polymer 3D printers accessible to businesses of all sizes. Their printers are capable of continuously printing at speeds of up to 8 liters per hour. This represents up to 20x productivity gains over all current state additive products and is comparable only to injection molding economics.”

He added, “We also added the Danobat line to our portfolio. Danobat is a manufacturer of cutting-edge, ultra-precision high value-added manufacturing solutions for external cylindrical grinding, internal grinding, centerless grinding and finish hard turning. Danobat is well positioned to provide “turnkey solutions” with full automation.” The company is headquartered in Spain and has manufacturing facilities in Spain,

A2Z MANUFACTURING WEST COAST • 6 • OCT - NOV ‘22 Announcements & Releases

Germany and the Netherlands. Danobat has a 65 year track record with over 6000 machines installed world-wide.

Bramac Machinery provides world class equipment to the Plastics, Metal Working & Metal Fabrication Industries. They support customers thorughout Southern California, Arizona, Southern Nevada and the bordering Maquiladora Region of Northern Mexico. For more information, visit bramacmachinery.com or call 951-383-4195.

Equipment Finance Industry Confidence Lower in October

The Equipment Leasing & Finance Foundation (the Foundation) releases the October 2022 Monthly Confidence Index for the Equipment Finance Industry (MCI-EFI) today. The index reports a qualitative assessment of both the prevailing business conditions and expectations for the future as reported by key executives from the $1 trillion equipment finance sector. Overall, confidence in the equipment finance market is 45, a decrease from the September index of 48.7.

When asked about the outlook for the future, MCI-EFI survey respondent David Normandin, CLFP, President and CEO,Wintrust Specialty Finance, said, “I am optimistic about our industry and our customers finding solutions to manage challenging economic conditions. As the rate of change increases, I think that our industry is well positioned to adapt and continue to find ways to win.”

The overall MCI-EFI is 45, a decrease from the September index of 48.7.

When asked to assess their business conditions over the next four months, none of the executives responding said they believe business conditions will improve over the next four months, a decrease from 3.6% in September. 62.5% believe business conditions will remain the same over the next four months, down from 75% the previous month. 37.5% believe business conditions will worsen, an increase from 21.4% in September.

8.3% of the survey respondents believe demand for leases and loans to fund capital expenditures (capex) will increase over the next four months, a decrease from 10.7% in September. 66.7% believe demand will “remain the same” during the same four-month time period, a decrease from 71.4% the previous month. 25% believe demand will decline, up from 17.9% in September.

4.2% of the respondents expect more access to capital to fund equipment acquisitions over the next four months, down from 14.3% in September. 87.5% of executives indicate they expect the “same” access to capital to fund business, an increase from 71.4% last month. 8.3% expect “less” access to capital, down from 14.3% the previous month.

When asked, 29.2% of the executives report they expect to hire more employees over the next four months, up from 28.6% in September. 66.7% expect no change in headcount over the next four months, an increase from 64.3% last month. 4.2% expect to hire fewer employees, down from 7.1% in September.

8.3% of the leadership evaluate the current U.S. economy as “excellent,” an increase from 7.1% the previous month. 66.7% of the leadership evaluate

the current U.S. economy as “fair,” down from 71.4% in September. 25% evaluate it as “poor,” an increase from 21.4% last month.

None of the survey respondents believe that U.S. economic conditions will get “better” over the next six months, a decrease from 7.1% in September. 41.7% indicate they believe the U.S. economy will “stay the same” over the next six months.

Manufacturing Program Helps Train and Certify Tesla Employees

Western Nevada College (WNC) and Tesla have partnered to provide training to 62 Tesla employees through WNC’s Manufacturing Technician program. This program is funded by Project SANDI and the Governor’s Office of Workforce Innovation (GOWINN).

A total of 47 of the students received grant funding for the Technology Level 1 (MT1) certification program and 15 received funding for the Mechatronics Technology program at WNC. Both programs help Tesla employees with training to expand their experience and career knowledge in mechanical technology and engineering.These programs are not specific to Tesla trainings and can be utilized by all individuals in this workforce area.

“The MT1 course has helped to provide basic theory knowledge to my Junior technicians so they can understand automation processes and develop methodical troubleshooting methods; while the Mech Tech course has propelled some of our veteran technicians to sharpen their troubleshooting skills and find greater career paths at Tesla,” said Nicholas Schafer, Tesla Production Engineering Supervisor.

Marcus Mathis, a SANDI grantee and MT1 certified student, says the MT1 course has had a massive impact on his day-to-day role at Tesla.“Electrical and mechanical troubleshooting has been one of my natural skills, yet I find myself referring back to class and lab applications when troubleshooting and installing. I would highly recommend this course to anyone that takes what they do seriously and is looking to go beyond the scope of their current position,” said Mathis. “I look forward to building upon these skills in the future with the other programs that are offered through the WNC and Tesla collaboration.”

Tesla’s partnership with WNC emphasizes the importance of continued education in Nevada’s workforce and job pipeline.

“We understand that providing continued education and supportive resources for our employees directly influences the morale of our team and the future of Tesla,” said Nicholas Schafer,Tesla Production Engineering Supervisor. “We want to see our team members succeed and strive to level-up in their positions and we have seen positive results of this occur directly from the courses offered at WNC.”

The plan for the SANDI grant is to invest in 1,700 Nevadans by next fall. The WNC and Tesla partnership is one of the several organizations across the state to receive SANDI grant funding to help those who were adversely affected by the pandemic, modernize Nevada’s workforce system, and expand remote access to short-term training for in-demand occupations using a digital platform.

A2Z MANUFACTURING WEST COAST • 7 • OCT - NOV ‘22

By: Earl van As

Technology

is a driving force behind operational innovation

and is rapidly altering how companies do business. Faced with growing pricing pressure as customers demand more for less and more quickly, supply chain professionals are seeking new solutions

to optimize operations and retain their competitive edge.

Recognized by many industry experts as the next step in automation, robotic process automation (RPA) is revolutionizing process efficiency and productivity. Many manufacturing, transportation and logistics companies are implementing it to improve efficiency and reduce costs.

How it works

Using machine learning to imitate user actions, RPA can execute decisions that streamline workflow. To put it in simpler terms, RPA learns on the job to mimic how employees carry out a task, and then automates it. This means that robots can manage the routine and laborious tasks to allow human workers to advance more value-added capabilities. As a result, the key to selecting the right RPA initiative is to pinpoint where employee involvement delivers the most value and where RPA could step in to release staff time.

One process that is considered timeconsuming and repetitive is manually entering data from transactional documents such as sales orders, invoices or bills of lading. It is a back-office task that causes inefficiencies throughout the supply chain and, therefore, is primed for automation. This an ideal example of a smaller-scale initiative to test RPA.

Optimizing such seemingly unimportant and mundane processes can create positive impacts across an organization’s workflow and bottom line:

Eliminating bottlenecks. Time is of the essence in distribution.With so many repetitive tasks demanding employee attention, the amount of time left for them to complete revenue-generating duties is perilously low. In addition, routine tasks are susceptible to human error, which can seriously affect the bottom line. Adopting the more physical roles and automating labor-intensive tasks with precision, accuracy and speed, RPA positions supply chains to gain the greatest possible ROI.

Delivering business insight. Understanding customer habits is key to building long-term relationships and enables distributors to provide value-added services and products tailored to buyer needs. RPA can rapidly collect and analyze enormous sets of data. With this insight, decision-makers can then pinpoint patterns and trends that enable

A2Z MANUFACTURING WEST COAST • 8 • OCT - NOV ‘22

Robotic Process Automation for Repetitive Back-Office Tasks

CNC AND MANUAL MACHINERY SINCE 1979 New - Used -Appraisals - Auctions Our Showroom At: 3305 Edison Way, Fremont, CA 94538 Is Open Monday - Friday From 8am To 5pm BOB KROHA ROB KROHA CONTACT US TODAY: 510-249-1000, PERMACH.COM

strategic planning and forecasting. For instance, a hardware distributor may find that a certain customer buys a bulk number of power tools every year around the same time. It can then offer tailored incentives to increase the customer’s order or crosssell complementary items, such as safety gear, when the customer is most likely to be interested in the products. In this way, distributors are able to personalize their interactions with each customer and expand value-added services.

Securing scalability. Every supply chain faces peaks and quiet periods. While seasonal staff can assist when demand is high, their recruitment is expensive, especially considering the lost investment in training when they leave.This makes scaling staff for shifting demands a significant and costly challenge. For example, an HVAC distributor most likely will experience peak sales season in summer months, creating a need for more staff to process incoming purchase orders. RPA can scale up to handle the increased workload, while maintaining consistent quality and output without hiring additional employees.

Smart microrobots walk autonomously with electronic ‘brains’

Source: Cornell University

Cornell University researchers have installed electronic “brains” on solar-powered robots that are 100 to 250 micrometers in size -smaller than an ant’s head -- so that they can walk autonomously without being externally controlled.

While Cornell researchers and others have previously developed microscopic machines that can crawl, swim, walk and fold themselves up, there were always “strings” attached; to generate motion, wires were used to provide electrical current or laser beams had to be focused directly onto specific locations on the robots.

“Before, we literally had to manipulate these ‘strings’ in order to get any kind of response from the robot,” said Itai Cohen, professor of physics. “But now that we have these brains on board, it’s like taking the strings off the marionette. It’s like when Pinocchio gains consciousness.”

The innovation sets the stage for a new generation of microscopic devices that can track bacteria, sniff out chemicals, destroy pollutants, conduct microsurgery and scrub the plaque out of arteries.

The project brought together researchers from the labs of Cohen, Alyosha Molnar, associate professor of electrical and computer engineering; and Paul McEuen, professor of physical science, all co-senior authors on the paper. The lead author is postdoctoral researcher Michael Reynolds. The team’s paper, “Microscopic Robots with Onboard Digital Control,” published Sept. 21 in Science Robotics.

The “brain” in the new robots is a complementary metal-oxidesemiconductor (CMOS) clock circuit that contains a thousand transistors, plus an array of diodes, resistors and capacitors. The integrated CMOS circuit generates a signal that produces a series of phase-shifted square wave frequencies that in turn set the gait of the robot. The robot legs are platinum-based actuators. Both the circuit and the legs are powered by photovoltaics.

“Eventually, the ability to communicate a command will allow us to give the robot instructions, and the internal brain will figure out how to carry them out,” Cohen said. “Then we’re having a conversation with the robot. The robot might tell us something about its environment, and then we might react by telling it, ‘OK, go over there and try to suss out what’s happening.’”

The new robots are approximately 10,000 times smaller than macroscale robots that feature onboard CMOS electronics, and they can walk at speeds faster than 10 micrometers per second.

A2Z MANUFACTURING WEST COAST • 9 • OCT - NOV ‘22

D o os a n M a c h i n e To o l s i s n ow The lineup of ver tic al machining center s at DN Solutions is ver satile, compac t and born to make incredible par t s for as long as you need them to Get your ideal VMC , then get ready for the ver tic al leap. Talk to your loc al DN dis tributor or visit dn solutions com DEM: entr y level par t producer S VM: swif t and s trong DNM: global best seller BVM: premium powerhouse MILL S & THRILL S The versatile VMC lineup at DN Solutions is enough to get anyone excited. www.ellisontechnologies.com | SALES (866) 567-2580 SERVICE (800) 994-0146 PARTS (888) 207-2787

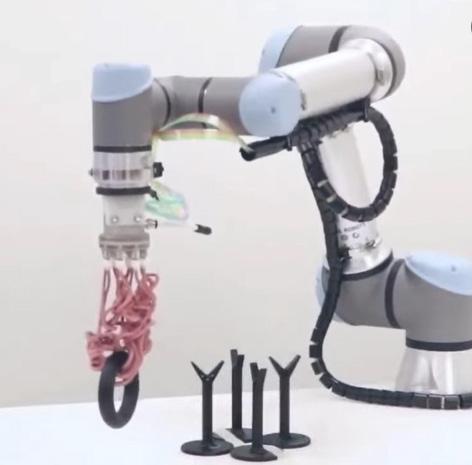

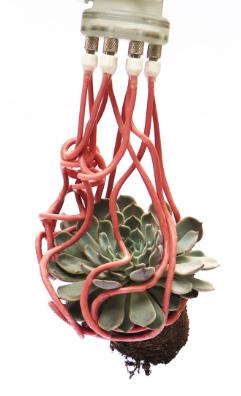

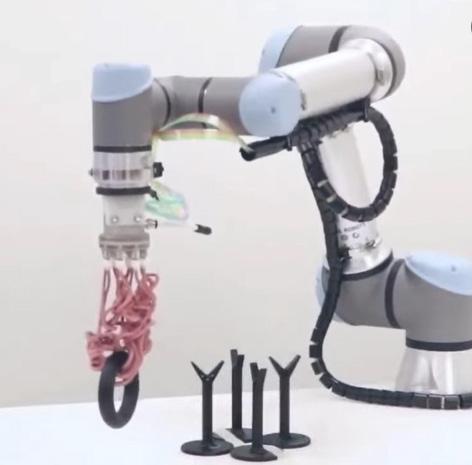

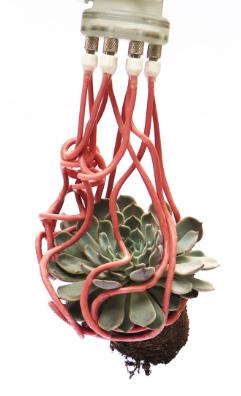

Tentacle Robot Can Gently Grasp Fragile Objects

Jellyfish-like soft gripper mimics the mechanics of curly hair

Source: Harvard John A. Paulson School of Engineering and Applied Sciences

Taking inspiration from nature, researchers designed a new type of soft, robotic gripper that uses a collection of thin tentacles to entangle and ensnare objects, similar to how jellyfish collect stunned prey. Alone, individual tentacles, or filaments, are weak. But together, the collection of filaments can grasp and securely hold heavy and oddly shaped objects.The gripper relies on simple inflation to wrap around objects and doesn’t require sensing, planning, or feedback control.

FULL STORY

If you’ve ever played the claw game at an arcade, you know how hard

it is to grab and hold onto objects using robotics grippers. Imagine how much more nerve-wracking that game would be if, instead of plush stuffed animals, you were trying to grab a fragile piece of endangered coral or a priceless artifact from a sunken ship.

Most of today’s robotic grippers rely on embedded sensors, complex feedback loops, or advanced machine learning algorithms, combined with the skill of the operator, to grasp fragile or irregularly shaped objects. But researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have demonstrated an easier way. Taking inspiration from nature, they designed a new type of soft, robotic gripper that uses a collection of thin tentacles to entangle and ensnare objects, similar to how jellyfish collect stunned prey. Alone,

A2Z MANUFACTURING WEST COAST • 10 • OCT - NOV ‘22

individual tentacles, or filaments, are weak. But together, the collection of filaments can grasp and securely hold heavy and oddly shaped objects.The gripper relies on simple inflation to wrap around objects and doesn’t require sensing, planning, or feedback control.

The research was published in the Proceedings of the National Academy of Sciences (PNAS).

“With this research, we wanted to reimagine how we interact with objects,” said Kaitlyn Becker, former graduate student and postdoctoral fellow at SEAS and first author of the paper. “By taking advantage of the natural compliance of soft robotics and enhancing it with a compliant structure, we designed a gripper that is greater than the sum of its parts and a grasping strategy that can adapt to a range of complex objects with minimal planning and perception.”

Becker is currently an Assistant Professor of Mechanical Engineering at MIT.

The gripper’s strength and adaptability come from its ability to entangle itself with the object it is attempting to grasp. The foot-long filaments are hollow, rubber tubes. One side of the tube has thicker rubber than the other, so when the tube is pressurized, it curls like a pigtail or like straightened hair on a rainy day.

The curls knot and entangle with each other and the object, with each entanglement increasing the strength of the hold. While the collective hold is strong, each contact is individually weak and won’t damage even the most fragile object. To release the object, the filaments are simply depressurized.

The researchers used simulations and experiments to test the efficacy of the gripper, picking up a range of objects, including various houseplants and toys. The gripper could be used in real-world applications to grasp soft fruits and vegetables for agricultural production and distribution, delicate tissue in medical settings, even irregularly shaped objects in warehouses, such as glassware.

This new approach to grasping combines Professor L. Mahadevan’s research on the topological mechanics of entangled filaments with Professor Robert Wood’s research on soft robotic grippers.

“Entanglement enables each highly compliant filament to conform locally with a target object leading to a secure but gentle topological grasp that is relatively independent of the details of the nature of the contact,” said Mahadevan, the Lola England deValpine Professor of Applied Mathematics

in SEAS, and of Organismic and Evolutionary Biology, and Physics in FAS and co-corresponding author of the paper.

“This new approach to robotic grasping complements existing solutions by replacing simple, traditional grippers that require complex control strategies with extremely compliant, and morphologically complex filaments that can operate with very simple control,” said Wood, the Harry Lewis and Marlyn McGrath Professor of Engineering and Applied Sciences and co-corresponding author of the paper. “This approach expands the range of what’s possible to pick up with robotic grippers.”

The research was co-authored by Clark Teeple, Nicholas Charles,Yeonsu Jung, Daniel Baum and James C. Weaver. It was supported in part by the Office of Naval Research, under grant N00014-17-1- 206 and the National Science Foundation under grants EFRI-1830901, DMR-1922321, DMR2011754, DBI-1556164, and EFMA-1830901 a

A2Z MANUFACTURING WEST COAST • 11 • OCT - NOV ‘22

Flatline Fabrication Inc. THERE’S NO JOB WE CAN’T TACKLE, NO MATERIAL TOO TOUGH!!! Laser cutting – Forming – Certified Welding – Finishing – Kitting & Flat Pack, Full Assembly & Installation Contact us today 503-477 7566, www.flatlinefabrication.com Production and Custom Fabrication WE MAKE MAGIC!

AutoFlight Takes Flight

AutoFlight believes 2023 will be an exciting year for the eVTOL company, due to its steady progress and unique aircraft design

By Treena Hein

AutoFlight is one of only two winged eVTOL companies worldwide that has publicly demonstrated successful transition from vertical hover to horizontal forward flight with a full-scale aircraft.

In November 2021, AutoFlight received US$100 million in funding for expansion, and in January, its new main engineering hub opened in Augsburg, Germany, headed by Mark Henning, former project manager for the H145 Airbus helicopter.

The company holds more than 200 patents for various technologies, including electric motors, electronic control systems, and lightweight carbon-fiber composite materials.

It’s also one of only two winged eVTOL companies worldwide that has publicly demonstrated successful transition from vertical hover to horizontal forward flight with a full-scale aircraft — in AutoFlight’s case, hundreds of times with its Prosperity I eVTOL.

“Our top priority in the coming months is to establish a U.S. test flight regiment and achieve regular transition flights of Prosperity I over U.S.

soil,” Bar-Yohay said. “This is a key milestone in our ongoing progress toward type certification with the European Union Aviation Safety Agency [EASA] ahead of planned passenger flights in 2026.”

In June, AutoFlight released its latest video of Prosperity I, showing off the new design with upgraded lift and cruise capability. The eight lifting propellers for vertical take-off remain, but in the new design, the previous two pushing propellers located on either side of the aircraft have been replaced with one center propeller with twin motors.

Bar-Yohay said those remaining refinements happening now, before the final Prosperity I design is released in early 2023, are small. They are focused on optimizing payload and minimizing operating sound, among a few other areas.

AutoFlight

AutoFlight welcomed new chief commercial officer, Chad Cashin, and

A2Z MANUFACTURING WEST COAST • 12 • OCT - NOV ‘22 www.renishaw.com/nc4blue usa@renishaw.comRenishaw Inc., West Dundee, IL 60118 © 2022 Renishaw Inc. All rights reserved. Your partner for innovative manufacturing Short in wavelength, long on accuracy Introducing NC4+ Blue—the new standard in toolsetting, significantly increasing accuracy for even the smallest tools. Add NC4+ Blue into your automated machining operations along with our on-machine and mobile apps—it’s all part of the entire family of smart factory machine tool solutions available from Renishaw. NC4+ Blue A2Z 10_2022.indd 1 8/22/22 2:58 PM

new president, Omer Bar-Yohay, who will be based at the company’s new U.S. office in Napa, California. AutoFlight Image Design details

The Prosperity I is designed for urban air mobility (UAM) and regional flights, with a cruising speed of 200 kilometers per hour (125 miles per hour), and range of 250 kilometers (155 miles). It is just over three meters (10 feet) tall, with a length of 10.3 m (around 34 ft), and a wingspan of 12.8 m (42 ft).

It is powered by lithium-ion batteries, but Bar-Yohay said other batteries, such as lithium metal, could be easily used in the future. He expects that battery technology will advance and while the AutoFlight team will monitor all developments with battery and hydrogen, the batterypowered system of the Prosperity I is not considered to be an interim measure that will be replaced by a hydrogen system anytime soon, if ever.That’s similar to what other eVTOL developers are doing, in terms of power, he said.

What sets AutoFlight apart from all others, Bar-Yohay said, is Prosperity I itself.

“The simplicity of the design means that we will offer the market the best safety at an affordable price,” he explained. “A simple design, without a tilting rotor or anything else like that, keeps costs down. We have also designed for cost-effective manufacturing, and we’ll have

component manufacturing in China where we can leverage the supply chain infrastructure for batteries and everything else. Then, final assembly and testing will be completed locally at every major market, catering to different regulatory requirements and locally-made systems.”

Simplicity also drives safety, Bar-Yohay said. As mentioned, he said there is no complex tilting rotor mechanism, for example, “which can be prone to fail and also adds weight.”

Prosperity I weighs only 1,800 kilograms (about 4,000 pounds) and will carry three passengers and a pilot.

Autonomy to come

Passengers riding in Prosperity I will see the pilot and be able to interact with him or her.

“Visually blocking off the pilot to have passengers comfortable with no pilot as we move to automated flight, in my thinking, is irrelevant at this stage,” Bay-Yohay said. “I also think the interaction with a pilot is very important to have passengers feel confident in their safety, to have that willingness to climb aboard. That confidence is what will be needed, day-in, day-out, to grow the industry.”

At the same time, Bay-Yohay believes it would be naive to think UAM will scale up to expected future volumes with the current regulations requiring a pilot. But while it will be piloted for the foreseeable future, the Prosperity

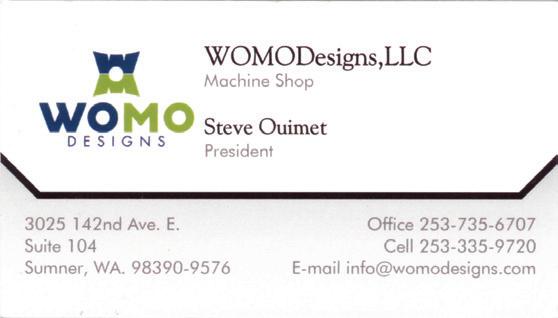

* Prototyping * 5 Axis Machining * Design Consulting * 3D Printing * Low-Limited Production womodesigns.com Call Today: 253 735-6707 info@womodesigns.com A2Z MANUFACTURING WEST COAST • 13 • OCT - NOV ‘22

Why Do You Need An Industrial Robotic Arm?

Do you like working with your hands? Do you have an interest in robotics and automation? If so, you may wonder what an industrial robotic arm is and how it could benefit you.

Contrary to popular belief, industrial robotic arms are not just for large manufacturing companies. There are many applications for these versatile machines that can benefit everyday people.

What is an industrial robotic arm, and what are its uses?

An industrial robotic arm is a type of robot designed explicitly for use in industrial settings. These robots are typically used for welding, fabricating, and assembly tasks. Industrial robotic arms are also often used for quality control, as they can be programmed to perform detailed inspections.

Many different types of industrial robotic arms are available on the market, each with unique features and applications. Some of the most popular brands include FANUC, ABB, and KUKA.When choosing an industrial robotic arm, it is crucial to select a model that is well-suited for the specific needs of your business.

How does an industrial robotic arm work

Industrial robotic arms are electronic and programmable machines that can automate tasks in factories, warehouses, and other industrial settings. These machines are designed to work with high precision and speed and can be programmed to perform repetitive tasks such as welding, cutting, or painting.

While industrial robotic arms have been in use for several decades, they have become increasingly sophisticated in recent years.Today’s industrial robots are equipped with sensors and cameras that allow them to navigate their work environments and avoid obstacles.

In addition, many industrial robots can now work collaboratively with human workers, increasing their efficiency. As industrial robotic technology continues to evolve, these machines will likely play an even more significant role in manufacturing.

The benefits of using an industrial robotic arm

Industrial robotic arms offer some advantages for businesses. They can work tirelessly for long periods without getting rest and can be programmed to perform precise tasks with great accuracy. This can result in a significant increase in productivity and improved product quality.

A2Z MANUFACTURING WEST COAST • 14 • OCT - NOV ‘22

In addition, robotic arms can often be used in dangerous or demanding environments, such as those involving high temperatures or toxic substances. This can help to create a safer working environment for employees.

The cost of owning and operating an industrial robotic arm can vary depending on several factors, including the size and capabilities of the arm, the industry in which it will be used, and the country in which it is purchased. However, some general trends can be observed. In general, larger and more complex robotic arms will be more expensive to purchase and operate than smaller and simpler ones.

Additionally, robotic arms used in manufacturing are more expensive than those used in other industries, such as healthcare or agriculture. Finally, robotic arms purchased in developed countries are typically more expensive than those purchased in developing countries.The cost of owning and operating an industrial robotic arm can be high, but the exact amount will vary depending on many factors.

You’ll need to decide what type of arm you need.There are two basic types of arms: fixed and articulated. Fixed arms are great for simple tasks, while articulated arms are more versatile and can handle more complex tasks. You’ll need to consider the payload capacity of the arm.This is the amount of weight that the arm can lift safely.

You’ll need to choose a power source for the arm. The most common options are electric or pneumatic power.With these factors in mind, you should be able to choose the right arm for your needs.

Let’s look at some frequently asked questions.

How do they move so precisely?

The answer behind how an industrial robot arm moves precisely is actually quite interesting. It lies in the design of the arm itself, which features a series of interlocking joints that allow for a wide range of movement.

How can they lift heavy objects?

The answer to this question also lies in the design of the arm, which features a powerful motor capable of generating a large amount of force.

Do they damage the products?

Many industrial robotic arms are equipped with sensors that help to prevent them from damaging the objects they are handling. These sensors can detect when an object is getting too close to the arm and will automatically adjust the arm’s position accordingly. As a result, industrial robotic arms can easily handle even the heaviest objects.

A2Z MANUFACTURING WEST COAST • 15 • OCT - NOV ‘22

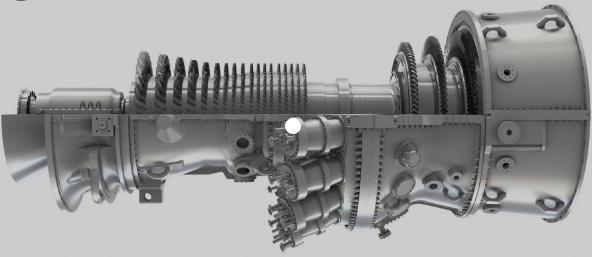

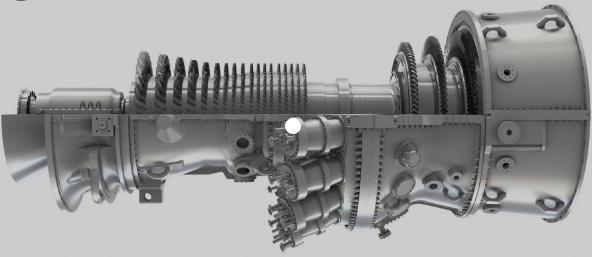

GE has announced the successful completion of the award negotiation phase for the company’s proposed project “Advanced Mixed Mode Combustor for Hydrogen F-Class Retrofit.” GE will receive $6.6 million in federal funding from the US Department of Energy’s Office of Fossil Energy and Carbon Management to accelerate the transition towards a 100% hydrogen combustion future for its F-class gas turbines. This funding will allow GE to develop and test breakthrough technologies to burn higher levels of hydrogen in its F-class gas turbine fleet, presently the company’s largest installed base with more than 1600 units in the world. GE Gas Power’s project was part of the six selected projects announced by the DOE on May 19 this year, which also includes a GE Research project focused on

the study of the operation of hydrogen-fuelled turbine components.

GE’s negotiations were aided by the receipt of letters of support for its proposal from 10 US utility companies with an aggregate 240 GW of total installed generation capacity, and a letter of support from an undisclosed US-based independent, non-profit organisation that conducts research and development related to power generation. Many utilities expressed interest in potentially contributing to technical reviews during the project period, while two other utilities expressed interest in hosting future H2 projects with GE’s next generation H2 combustion technology.

Jeffrey Goldmeer, Emergent Technologies director at GE Gas Power commented: “Our objective is to develop and test a retro-fittable F-Class staged combustor module with fuel capability ranging from 100% natural gas to levels up to 100% hydrogen.”

As part of this programme, the project team will address the challenges associated with highly reactive hydrogen combustion dynamics, starting with the study of micro mixer and axial fuel staging technologies. Both technologies, from the HA-Class combustion system, enable great load flexibility and have excellent premixing and operability over a range of fuels including up to 50% hydrogen. The concepts will be tested at the Center for Advanced Turbomachinery and Energy Research facility at the University of Central Florida and then validated at GE Gas Turbine Technology Laboratory in Greenville, South Carolina.

A2Z MANUFACTURING WEST COAST • 16 • OCT - NOV ‘22 We are a fullservice job shop, providing asmuch or aslittle projectinvolvement as required – from tooland die design to finishing and assembly. Precision aluminum and zincdie casting, machining and finishing. tvtdiecast.com ▼ 800 280 2278 ISO 9001:2008 Certified Qu ali t y, Reliabili tyand Service Ge Awarded $6.6 M To

Develop

100% H2

Combustion In F-Class Gts

The

Italian energy company Plenitude, a subsidiary of Eni, has inaugurated its El

in

Located in the region of Castilla La Mancha, the 104.5MW

equipped with 19 GE

turbines.

to develop the El Monte project.

Azora Capital had previously been involved with the Eni subsidiary in developing solar photovoltaic (PV) and wind projects in the country.

Plenitude CEO Stefano Goberti said: “El Monte wind farm will contribute to the gradual decarbonization of the electricity sector in Spain, contributing to the energy transition process undertaken by Eni and to Plenitude’s ambitious goals of achieving carbon neutrality by 2040 and supplying 100% decarbonised energy to all its customers.

“The development of the wind and photovoltaic sectors is key to Plenitude’s growth strategy, which aims to reach more than 2GW of installed capacity from renewable sources by the end of 2022, scaling up to over 6GW by 2025 and over 15GW by 2030.”

increased Plenitude’s renewable energy generation capacity in Spain.

Plenitude is also active in the Spanish energy and gas sales market for household customers, as well as small, medium-sized and large enterprises.

The facility has the potential to generate

of clean energy a year, which is enough to power 100,000 households in the region.

Plenitude collaborated with Azora Capital, its strategic partner in Spain,

Under this partnership, Plenitude acquired a 65% stake in Infrastrutture’s subsidiary Hergo Renewables, which has a 1.5GW project portfolio across the two countries.

The first solar photovoltaic plant developed by the two companies will be located in Italy’s Montalto di Castro region and have 37MW of capacity.

A2Z MANUFACTURING WEST COAST • 17 • OCT - NOV ‘22 (800) 481-6271 www.pmplating.com We Are The Noble Partner With The Personal Touch! Precious Metals Plating Co., Inc + Gold Plating + Silver Plating + Nickel Plating + Electroless Nickel Plating + Tin Plating + Heat Treat With Plate + Nadcap Approved Processes + Boeing Approved Processes + Expedited Turnaround + X-ray Fluorescence Thickness Verification + In-House Laboratory With Atomic Absorption (AA) + Expanded Capacity In Vibratory Plating Eni Subsidiary Plenitude Inaugurates 104.5Mw Wind Farm In Spain

El Monte wind facility will generate 300GWh of clean energy a year.

Monte wind farm

Spain.

wind farm is

wind

300GWh

GE Announces H-Class Gas Turbine Order from ENEVA to Support Energy Transition in Brazil

GE’s highly efficient, reliable, and advanced H-Class combined cycle power plant is the most responsive and flexible in the industry

Eneva’s Azulão GE 7HA.02 power plant will deliver up to 350 megawatts (MW) of reliable reserve power to help stabilize the grid and support renewable growth in Brazil

Advancements in hydrogen-based fuels and carbon capture and sequestration (CCS) solutions enable gas turbines to represent a long-term investment

Atlanta, GA, October 13 2022— GE (NYSE: GE) today announced it has secured a H-Class gas turbine order from Eneva, the largest private natural gas operator in Brazil to support the energy transition and enhance renewable energy growth in the country.

GE will supply a 7HA.02 gas turbine for Eneva’s new Azulão reserve power plant to help stabilize the grid.

“The use of renewable energy sources is continuously being expanded in many countries around the world, but the grid infrastructure still requires highly efficient gas turbine technology to stabilize and support these variable technologies,” said Eric Gray, President and CEO of GE Gas Power. “Rapid renewable energy growth presents system operators and energy providers with the increasingly difficult task of continuously ensuring stability of the

grid and a reliable power supply. GE’s H-Class gas turbine technology has earned a reputation for flexibility, output, environmental performance and high efficiency that has led to its rapid growth and maturation as a fleet worldwide, and we’re honored to add a new customer to our HA fleet.”

Eneva’s Azulão power plant, Brazil

For the new 350-Megawatt (MW) Azulão power plant, GE will provide a GE 7HA.02 gas turbine powering a H65 generator to give Brazil extra flexibility to manage its renewable-rich grid and its growing utilization of non-dispatchable energy sources. The country counts on approximately 70% of its power generation from renewable energy and this plant will help support the grow of intermittent power from hydro (without reservoirs), solar and wind resources. According to the National Grid Operator, wind and solar generation will grow from 15.6% (27.8GW) in 2022 to 21.1% (42.1GW) in 2026 of the grid’s total installed capacity.

The construction of the new reserve power plant, located near Manaus, will start in late 2022, targeting the start of commercial operation by 2026. The installed capacity will be available to the National Grid Operator to help ensure grid stability with high efficiency. In addition, the increased power available on the open electricity marketplace could help reduce average cost of electricity in the country.

Eneva trusted GE’s advanced HA technology and turned to GE based on a longtime collaboration between the two companies, built on more than half

A2Z MANUFACTURING WEST COAST • 18 • OCT - NOV ‘22 WWW.NORTHSOUTHMACHINERY.COM | (800) 460-9014 | CA • OR • WA • AZ • NV LEAN. MEAN. 100% GREEN! • 100% Electric Precision Press Brake • 110 US Tons x 10.2’ • EC10 Touch Screen Control (EC20 Optional) • CNC X-Axis, R-Axis, Y1/Y2-Axis • Manual Z1/Z2-Axis (CNC Optional) • Mechanical Tool Clamping (Hydraulic Optional) • Tool Lighting on Front • 2x Front Support Arms • 2x Backgauge Stops • Installation & Training Included SAFANDARLEY E-BRAKE STANDARD FEATURES:

a dozen of GE 7F gas turbines reliably powering Eneva’s power plants across Brazil for almost a decade.

In Brazil, Eneva owns and operates a 1.9 GW-generation complex integrated to proprietary gas production. Expanding the use of natural gas will support Eneva’s continuous investment in renewable energy: the company is now in the Brazilian renewables industry with the recent acquisition of Focus Energia. The carbon footprint of Eneva’s power generation portfolio will drop significantly as this new capacity becomes operational, with coal power plants targeted to be phased out by 2040.

GE’s H-Class gas turbine technology is the most responsive and flexible in the industry. It has also set combined cycle efficiency records at both 50 Hz and at 60 Hz and is engineered to reduce carbon emissions below those emitted by prior gas turbines.

GE Aviation Successfully Tests Another Engine On 100% Sustainable Jet Fuel

Alex Schroff

ASTM International has approved Sustainable Aviation Fuel blends to date up to 50%, so GE and its competitors are looking to the future with 100% SAF.

The U.S. government has two goals for sustainable aviation fuel:

Production of 3 billion gallons by 2030 (a 600-fold increase from 2021) Production of 35 billion gallons by 2050, enough to meet the projected U.S. demand for aviation

In addition, GE Aviation has a net zero goal for 2050 and is working with Safran to create a new greener engine by 2035, as WVXU reported last summer.

GE and Honda formed a 50/50 joint venture in 2004, called GE Honda Aero Engines, based in Burlington, North Carolina.

In Peebles, the GE Honda HF120 sits inside a sphere which controls wind flow. Acting Plant Manager Jose Gonzalez walks up to get a closer look.

“This is probably a good side view, right there.You can see the engine. I don’t know if you can make it out. It’s on center line with respect to our spherical inlet conditioner and it’s operating at idle.”

Engineers accelerate the HF 120 Honda engine once we’re a safe distance away. It’s smaller than the other engine GE tested earlier this year on 100% sustainable aviation fuel, the Passport. The HF 120 is connected to a tanker which holds sustainable aviation fuel.

The tests took several days to complete. A small sample of the SAF goes to the fuel and oil lab and that’s where GE analyzes it to make sure the fuel is efficient.

On Monday, the company said in a news release preliminary test results for the HF 120 were favorable, with engine performance equivalent to Jet A fuel during the SAF run.

A2Z MANUFACTURING WEST COAST • 19 • OCT - NOV ‘22

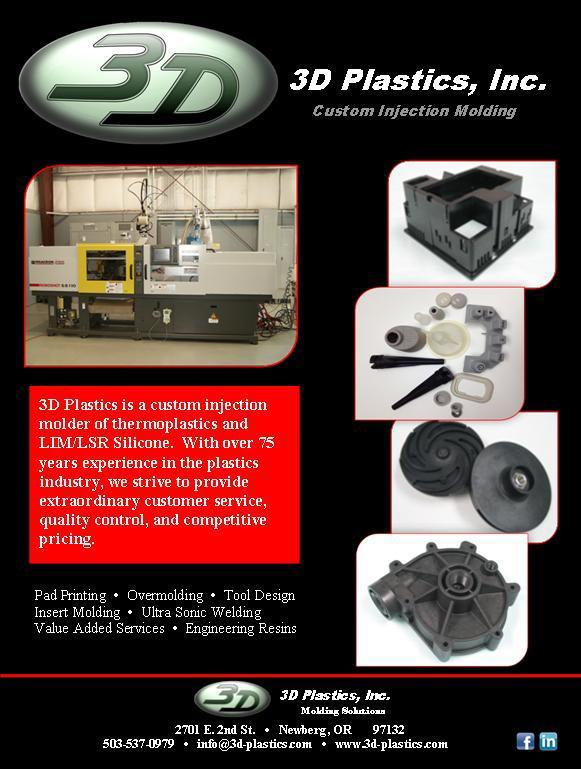

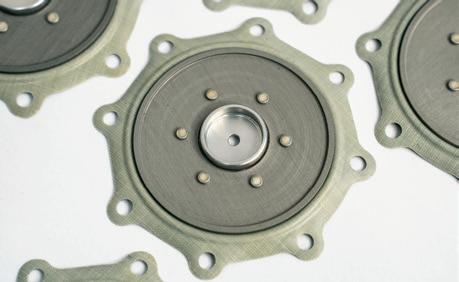

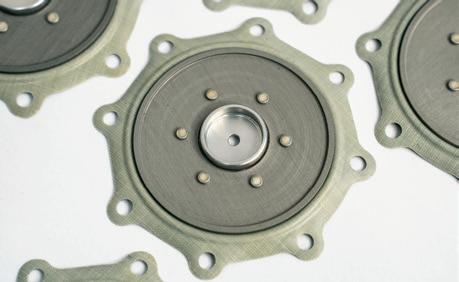

3 Generations of Manufacturing Excellence

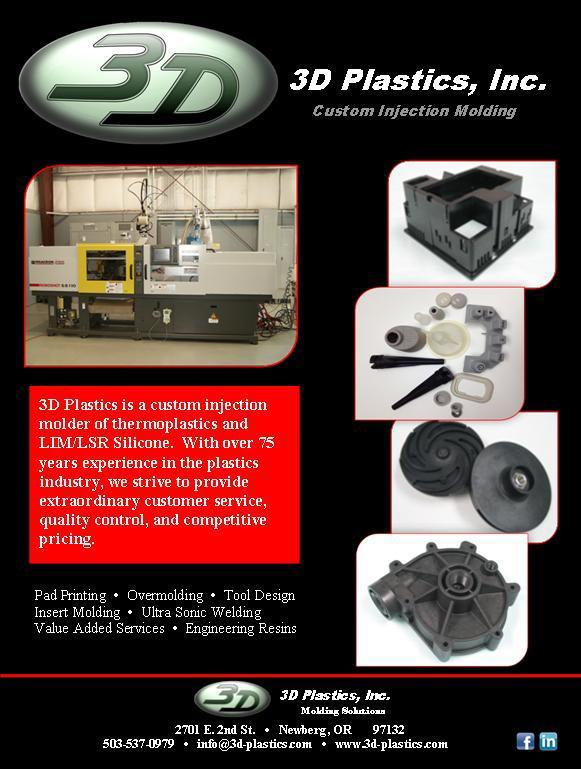

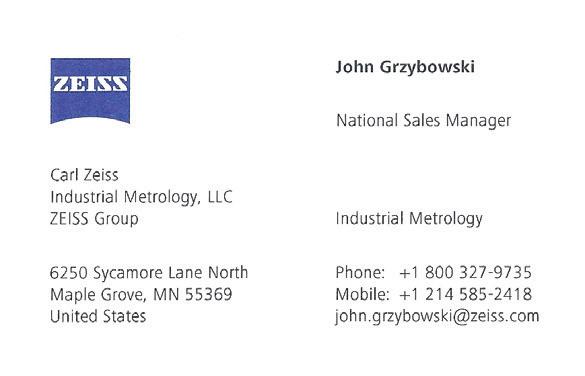

Micro-Tronics (MTI) is a contract manufacturer that is most certainly unlike any other company you are outsourcing to. Its sprawling campus headquarters in Tempe, Arizona includes 4 buildings and ~80,000 square feet of space, and it is here where its 100 plus experienced employees support customers. It differentiates itself in so many ways, but here is a snapshot.

• Woman-Owned – The company was founded by Angeline and John Marusiak, and today, John’s daughter in law Lucia Marusiak, together with her sons are the sole owners of the business. The business is in its 3rd generation of management, with Johnny and Charlie Marusiak leading the operations and business development for Micro-Tronics.

• Experience – The company is more than ½ century old, having been founded in 1968.The company brought in outside expertise to build the operation’s depth and take it to the next level of excellence. Jeff George is the current president of the company, having come on board nearly 2.5 years ago. Jeff is an aerospace and industrial manufacturing leader with over 30 years of experience, and was most recently Operations Director for SKF AB’s, multi-plant, Aerospace Business Unit. Lucia says, “Our customers directly benefit from the partnering of longevity, low turnover and experience of our team of devoted employees.”

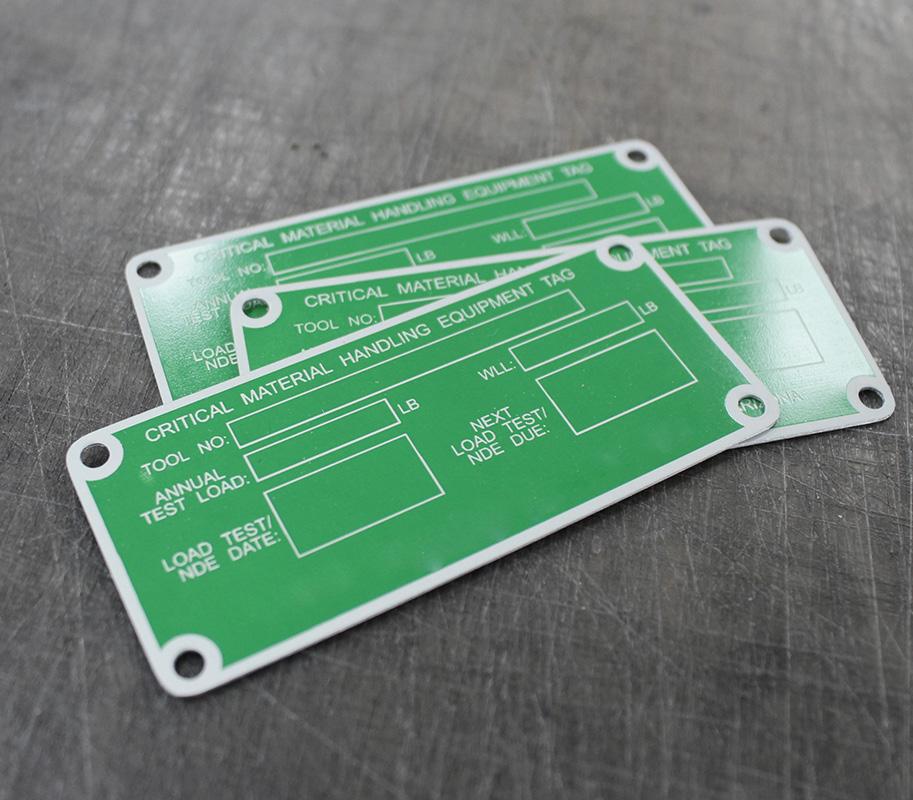

• Credentials – The company is AS9100 Certified, NADCAP Accredited for Nonconventional Machining (EDM) and Elastomer Seals (Rubber Molding), ITAR Registered and soon to be compliant with NIST Cyber Security Requirements.

• Engineering – With a team of engineers (industrial, chemical and manufacturing), the company is able to support its customers with their prototype/R&D manufacturing to ensure that the products are being designed for manufacturability, and highly competitive compressed lead times with complete in-house solutions.

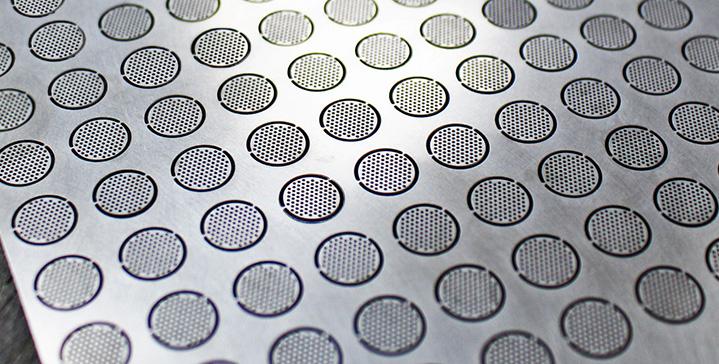

• Capabilities - They have several distinct areas of expertise to enable customers to reduce the amount of suppliers they rely on and reduce lead

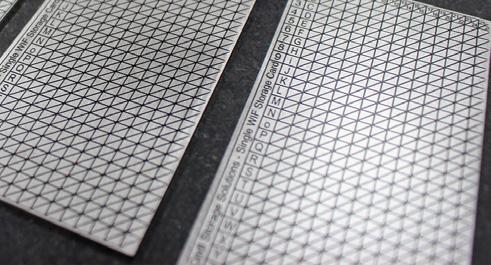

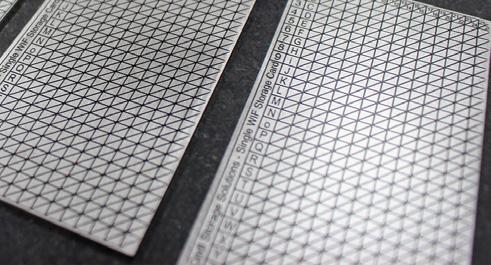

timesthese include: EDM(Wire, Sinker, and fast hole), CNC machining, full Turn key products, custom elastomer/kapton molding, bonded plate seals, custom elastomer to metal bonding, fabric reinforced elastomer diaphragms, and final assembly/kitting and shipping of complete tested top level bills of material eliminating 20 or more sub levels of processing and assembly in one facility. Beyond these capabilities, the company also offers in-house tooling and mold manufacturing, Design For Manufacturability, and proprietary laser marking.

• Tier One Customers – a significant number of MTI’s ~ 50 customers are in the defense and aerospace business (original and aftermarket), and the parts they manufacture go into nearly every vehicle owned by the government, from land to air and to sea. They have retained customers today that they brought on when they first opened for business 54 years ago, though the companies have typically been through several name changes and acquisitions during this half century. Their more recently targeted customers hail from the oil and gas;,medical, semiconductor, transportation, and hydraulic and pneumatic industries.

• Culture – Jeff says, “When I joined MTI, I was delighted to experience our company culture, which is one of commitment and collaboration. Our entire team rallies around customer service. As an example, during Covid we had a new customer come to us. They were in crisis mode, as their current supplier had let them down. They needed production solid elastomer parts in 5 weeks, and this included building a mold. The material they required was somewhat specialized, though close enough to what we were very experienced with. Tooling took 4 weeks, as did the material ship time. The mold and rubber came in the day before Memorial Day weekend. Without hesitation, our team worked throughout the 3-day Holiday weekend to deliver parts to our new customer on time. Our commitment to on-time delivery and to supporting this new customer with a very difficult part has resulted in them awarding us an additional 15 parts.”

EDM/CNC EDM/ Wire EDM/ Fast Hole EDM – NADCAP Accredited

Jeff says, “If you need EDM services, we’re probably the largest EDM shop west of the Mississippi. With 25 Sinker EDMs, 14 Wire EDMs and 6 Fast Hole Machines, we have the capacity to meet most all top level requirements. We can accommodate a wide variety of work pieces and configurations,

A2Z MANUFACTURING WEST COAST • 20 • OCT - NOV ‘22

and we are confident you won’t find many shops that have been doing EDM for more than a half century. We are proud that our EDM department received the highest NADCAP status at our last audit – the ‘MERIT Status’.”

The company was also awarded ‘Top Shop’ by EDM Today Magazine.

Charlie adds, “We have 3 Wire EDM machines with 4-axis indexing capability, which provides rotational cutting, which can, as is termed in our industry ‘turn and burn’. This allows for fewer setups on complex parts, allowance for more unattended burns and extends the capability of a standard machine. It has also unlocked an entirely new range of part geometries – geometries not possible to manufacture with any other machining method.

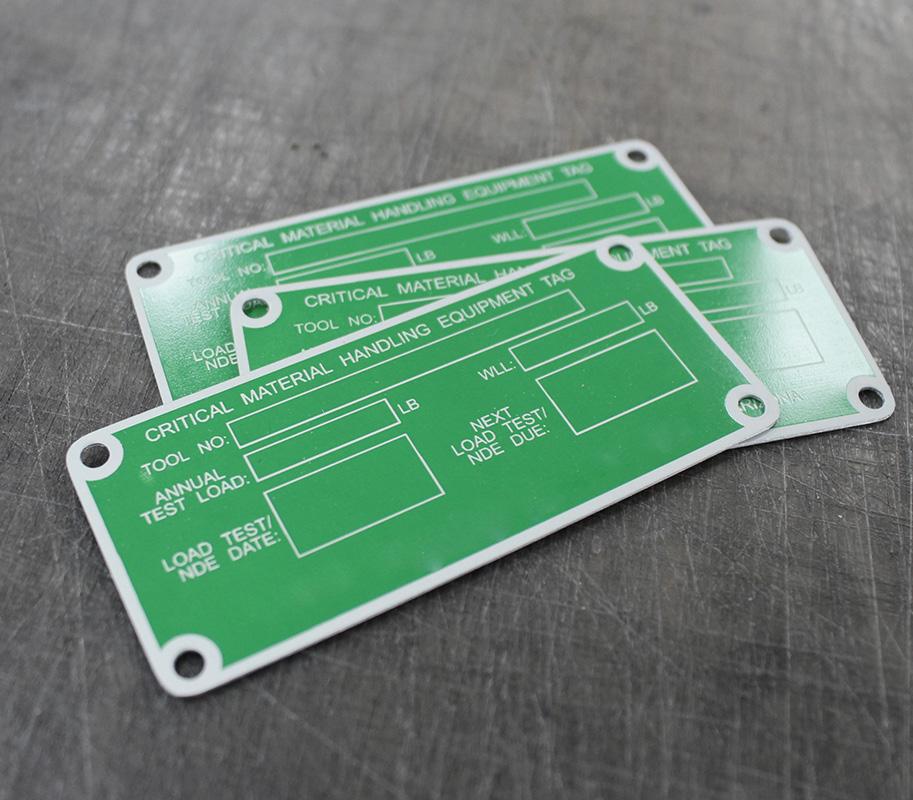

A Trusted Partner, MTI excels at Rubber and Rubber-toMetal Bonded Seals.

MTI offers a range of in-house services to their customers, including metal and rubber manufacturing, bonding, and product assembly, which allows them to cut weeks to months off startup lead times.

• MTI’s application engineering team can ensure your designs are prepared and well suited for manufacturing.

• Their machine shop enables them to machine the metal components (e.g., metal rings and plates) required for the rubber-to-metal bonding operations.

• MTI’s tool room enables them to design and build all molds and finish dies.

• The rubber formulation capabilities enable MTI to make standard or custom materials as needed.

• Their assembly shop enables MTI to mate and assemble other components to molded rubber products to create larger subassemblies as well as kit the molded rubber products with other assembly line components.

• MTI’s value-added services enable them to accommodate laser marking, bag and tag, stock programs and other final packaging requirements.

Micro-Tronics has the experience, equipment, and expertise to deliver bonded seals for many different industries and applications.With over 30 presses with tonnage that ranges from 30-400 tons, MTI offers injection, transfer, and compression molding and over 25 AMS, MIL, and or ASTM standard materials with NADCAP certified molding.

MTI can manufacture products to meet your exact specifications and standards, including AMS, MIL, SAE, and ASTM. MTI’s AS9100D- and ISO 9001:2015-certified quality management system and NADCAP certification ensures all customers receive the highest quality solution. Machine Shop – AS9100 Revision D Certified

MTI’s machine shop offers both CNC lathe and mill precision machining. In its milling department, it offers horizontal and vertical milling, with machine tools that include 3, 4, and 5 axis. MTI mills can machine parts up to 8” X 12” X 24”.

The MTI turning department is equipped with high productivity and rigid turning (including live tooling).They focus on turning parts in one operation where possible with dual spindle equipment. This eliminates costly operations like deburring and backside finishing operations. MicroTronics has also had remarkable success in unattended turning. Their record is 63 hours of uninterrupted, unattended run time.

The machine shop also offers in-house surface finishing capabilities, including grinding and honing. The latest capability brought in house, Jeff says, is laser marking. “Our customers were having difficulty with ink markings that could come off when they interacted with certain chemicals. Our proprietary technique has enabled us to mark on rubber and it doesn’t come off with chemicals. It has been so popular that we have aerospace customers who come to us strictly for our laser marking.” MTI offers laser part marking on steel, stainless, aluminum, brass, copper, magnesium, plastic, to name a few.

Charlie says that MTI opened its machining division to help reduce turnaround times for their EDM and rubber molding customers. And now its also being used to produce assembly details that are essential to the providing turn-key assemblies to their customers. “Everything we can do to help our customers through reduced turnaround times and increased consistency of quality parts, we bring in-house to control the complete process and eliminate supply chain constraints and delay issues.”

Like all areas of MTI’s manufacturing, the company focuses on increased automation. All departments are tasked with finding ways to automate tedious and repetitive tasks. This helps our machinists focus their talents on truly meaningful work.

Micro-Tronics is your complete source for all manufacturing solutions with a focal on top-level integration.

For more information on how Micro-Tronics can solve all of your supply chain drama, contact them at:

(602) 437-8995, Sales@Micro-Tronics.com,

A2Z MANUFACTURING WEST COAST • 21 • OCT - NOV ‘22

NYPA Sees Results from Green Hydrogen Project

The NewYork Power Authority, as part of a comprehensive decarbonization strategy, announced the results of a green hydrogen demonstration project showing decreased carbon emissions when using hydrogen blended with natural gas to generate power at the Power Authority’s Brentwood Small Clean Power Plant on Long Island.

The demonstration project, led by NYPA in collaboration with EPRI, General Electric and Airgas, an Air Liquide company, retrofits a natural gas facility and enables the use of hydrogen mixed with natural gas to power the plant and make electricity.

NYPA and its industry collaborators demonstrated that the plant was fully operational while safely using the hydrogen blend. The project informs New York and the power industry by demonstrating that hydrogen may be one valuable tool to help decarbonize power generation.

While NYPA and other power companies already use hydrogen for equipment cooling, this project marks the first time it was tested as a fuel blend for use in electricity generation at a NYPA generator. In July 2021, the State of New York announced its intent to explore the potential role of clean hydrogen.

Working with its collaborators, NYPA led a hydrogen fuel demonstration from the fall of 2021 to the spring of 2022, investigating the potential

Are you ready to implement or upgrade your Quality Management System to the new ISO 9001:2015 or AS9100D / ISO 9001:2015 Standard, AS9110C or AS9120B?

Special Packages available, take advantage of 20 plus years’ experience implementing and auditing quality management systems for commercial and aerospace companies!

Bretta Kelly, President and Owner of BMSC, LLC www.businessmsc.com has proven, copy written templates for ISO 9001:2015, AS9100D / ISO 9001:2015, AS9110C / ISO 9001:2015 and AS9120B / ISO 9001:2015 Standards with more than 30 companies upgraded and certified with zero to one finding results to date in their upgrade audits!

Packages Available:

Complete Electronic QMS System/Templates and 4 hours consulting Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s $3,500

Complete Electronic QMS System/Templates and online webinar of how to complete Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s $2,500

Do you need Quality Management System Software? Bretta Kelly is also President of CIS WWSG, LLC and is now offering the $3,500 Templates for FREE with purchase of CIS Software! www.cissoftware.com. CIS Software costs $5,000 upfront (one time) and $385/month license and server fees for UNLIMITED users, request a demo today!

Testimonial from BMSC Clients featured in the A2Z Manufacturing Magazine who have taken advantage of the BMSC Templates for successful upgrades: Bretta, I wanted to email you and let you know that because of the help of yourself and Debbie we completed our audit to the new revision with no findings! :) We very much appreciate all of the help that you both did for us and will recommend your company to anyone looking to get certified. Your system really makes it easy for companies like ours to stay organized and compliant to the guidelines. Kristie McKee, Gibbs Precision Machine

of substituting clean hydrogen—produced using renewable energy, including wind, solar, and hydroelectricity—for a portion of the natural gas used to fuel NYPA’s Brentwood Power Station in Suffolk County on Long Island.

Under the project, NYPA demonstrated power generation utilizing blends of 5%-40% hydrogen with natural gas to identify and document any resulting impacts on GE’s LM-6000 combustion turbine engine and the unit’s operation.The project found that carbon emissions decreased as the amount of hydrogen increased.

In addition, at steady state conditions, the exhaust stack NOx, CO, and ammonia slip levels showed that emissions could be maintained below the NewYork State Department of Environmental Conservation (DEC) Title V Regulatory Permit using the existing post-combustion emissions reduction systems, with no known detrimental effects on the gas turbine operations.This result could prove consequential for power plant operators to begin testing and using hydrogen fuels—aiming to lower a facilities’ carbon output—with minimal or no required modifications to plant systems.

NYPA collaborated with General Electric, the gas turbine equipment manufacturer which has significant experience with hydrogen and similar low-BTU fuels. GE assisted in the building of the state-ofthe art hydrogen/natural gas blending system. EPRI’s Low-Carbon Resources Initiative helped design the project and served as advisors on the technical evaluation. Airgas supplied the renewable hydrogen for the testing.

A2Z MANUFACTURING WEST COAST • 22 • OCT - NOV ‘22

www.techfin.net Tech Financial has been providing best-in-class financing to the Machine Tool Industry across the USA and Canada for over 20 years! We are committed to providing: •Hassle-Free Equipment Financing •Fast Approval Process •Flexible Financing Structures and Terms •Unmatched Industry Knowledge Isaac Leman, CLFP 541-360-1318 isaacl@techfin.net Kobe Knaak 414-213-2261 kobek@techfin.net Contact our sales team today so we can help you get the equipment you need, when you need it Sara Charlton, MBA 262-844-7571 sara@techfin.net

Engineering Research and Consulting Inc., Huntsville, Alabama, was awarded a $640,512,703 cost-plus-fixed-fee contract to support planning, conducting, analyzing and reporting the results of developmental tests, production tests and other tests conducted by the U.S. Army Aberdeen Test Center. Bids were solicited via the internet with three received.

locations and funding will be determined with each order, with an estimated completion date of Oct. 20, 2027. U.S. Army Contracting Command, Aberdeen Proving Ground, Maryland, is the contracting activity (W91CRB-23-D-0001).

Lockheed Martin Corp., Grand Prairie, Texas, was awarded a $476,814,000 hybrid (cost-plus-fixed-fee and firm-fixed-price) contract for the Guided Multiple Launch Rocket System. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of Aug. 15, 2025. U.S. Army Contracting Command, Redstone Arsenal, Alabama, is the contracting activity (W31P4Q-23-D-0003).

NAVY

Northrop Grumman Systems Corp., doing business as, Launch Vehicles Division, Chandler, Arizona, is awarded a $79,278,808 modification (P00011) to a previously awarded firm-fixed-price contract (N0001921C0005). This modification exercises an option to procure

28 GQM-163A Coyote supersonic sea-skimming targets and associated technical and administrative data in support of full rate production Lot 16 deliveries for the Navy.Work will be performed in Camden, Arkansas (43%); Chandler, Arizona (35%); Vergennes, Vermont (8%); Cincinnati, Ohio (4%); Oconomowoc, Wisconsin (4%); Lancaster, Pennsylvania (4%); and various locations within the continental U.S. (2%), and is expected to be completed in March 2026. Fiscal 2023 weapons procurement (Navy) funds in the amount of $50,964,948; and fiscal 2022 weapons procurement (Navy) funds in the amount of $28,313,860 will be obligated at the time of award, none of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Lockheed Martin Aeronautics Co., Fort Worth, Texas, is awarded a $14,909,400 cost-plus-fixed-fee modification (P00002) to a previously awarded contract (N0001921C0037). This modification adds scope to provide country-specific program support for F-35 production, modifications, logistics, and sustainment, as well as standup for a security operations center in support of integration for a Foreign Military Sales country into the F-35 enterprise. Work will be performed in Nagoya, Japan (76%); Fort Worth, Texas (13%); and Tokyo, Japan (11%), and is expected to be completed in March 2025. Foreign Military Sales customer funds in the amount of $14,909,400 will be obligated at time of award, none of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

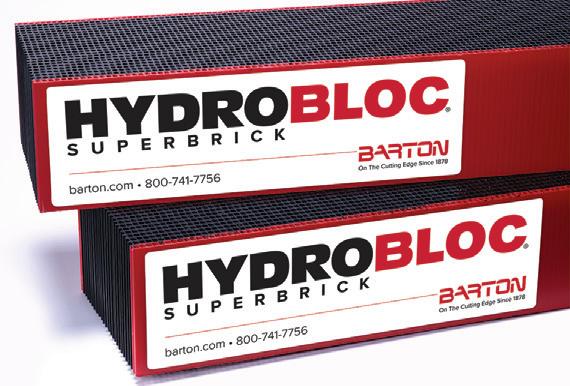

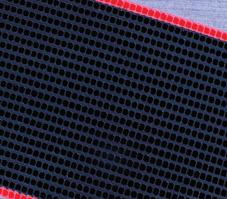

A2Z MANUFACTURING WEST COAST • 24 • OCT - NOV ‘22 OIL MIST AND SMOKE IN YOUR SHOP? Low-Cost, Highly Efficient Mist and Smoke Collectors Designed Specifically for the Metalworking Industry www.mistcollectors.com 1-800-645-4174 BARTON INTERNATIONAL USA/Canada 800-741-7756 518-798-5462 • info@barton.com • barton.com • store.barton.com The BARTON logo and our brands are registered trademarks of BARTON Mines Corporation. Experience cleaner, quieter cutting and produce better-looking parts with HYDROBLOC Superbricks. Their flat, even, honeycomb surface keeps parts from falling into the tank and drains water away to minimize splash back. The laminated highdensity polyethylene layers are welded and screwed together for unrivaled durability. • Cleaner Cutting • Recyclable • Quieter Operation • Better-Looking Parts Learn more at barton.com/hydrobloc Upgrade Your Waterjet with HYDROBLOC® ARMY

Work

Department of Defense (DoD) Awards

Lockheed Martin Corp., Fort Worth, Texas, is awarded a $12,052,847 firm-fixed-price modification (P00006) to an order (N0001921F0398) against a previously issued basic ordering agreement (N0001919G0008). This modification adds scope to procure Lot 15-16 gun pod containers in support of F-35 Lightning II aircraft ancillary mission equipment for the Navy, Marine Corps, non-U.S. Department of Defense (DOD) partners, and Foreign Military Sales (FMS) customers. Work will be performed in FortWorth,Texas, and is expected to be completed in February 2026. Fiscal 2022 aircraft procurement (Navy) funds in the amount of $11,218,945; FMS customer funds in the amount of $457,865; and non-U.S. DOD participant funds in the amount of $376,037 will be obligated at the time of award, none of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

The Defense Advanced Research Agency, Arlington, Virginia, is the contracting activity (HR0011-23-C-0002).

Nammo Defense Systems Inc., Mesa, Arizona, was awarded a $498,092,926 firm-fixed-price contract for the full rate production of M72 Light Assault Weapon variants and components for shoulderlaunched munitions training systems. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of Dec. 19, 2026. U.S. Army Contracting Command, Newark, New Jersey, is the contracting activity.

NAVY

DEFENSE ADVANCED RESEARCH PROJECTS AGENCY

Raytheon Co., Tucson, Arizona, is awarded a $55,121,826 costplus-fixed-fee modification to a previously awarded contract (N0002421C5434) for engineering and technical services in support of the Evolved Seasparrow Missile and NATO Seasparrow Missile Sys-tems programs. This contract combines purchases for the U.S. govern-ment (99%); and the governments of Japan and United Arab Emirates (1%) under the Foreign Military Sales (FMS) program. Work will be performed in Tucson, Arizona (82%); Portsmouth, Rhode Island (17%); Andover, Massachusetts (less than 1%); San Jose, California (less than 1%); Aranjuez, Spain (less than 1%); Brisbane, Australia (less than 1%); and Koropi Attica, Greece (less than 1%). Work is expected to be com-pleted by December 2022. The Naval Sea Systems Command, Wash-ington, D.C., is the contracting activity.

Northrop Grumman Systems Corp., Redondo Beach, California, was awarded a $7,755,736 cost-plus-fixed-fee contract for the Modular Efficient Laser Technology (MELT) program. MELT seeks to develop a laser tile as the building block for compact, scalable, panelized highenergy laser (HEL) sources. Work will be performed in Redondo Beach, California (85%); and Goleta, California (15%), with an expected completion date of October 2024. Fiscal 2022 research, development, test and evaluation funds in the amount of $1,428,182 are being obligated at time of award.This contract was a competitive acquisition under Broad Agency Announcement HR001122S0017 and nine offers were received.

Honeywell International Inc., Phoenix, Arizona, is awarded a $22,467,124 cost-plus-fixed-fee contract for the development, build and demonstration of the Compact Rubidium Extended

Alliant Techsystems Operations LLC, a wholly owned subsidiary of Northrop Grumman Defense Systems Inc., Northridge, California, is awarded a $35,587,641 modification (P00008) to a previously awarded firm-fixed-price contract (N0001921C0044). This modification exercises an option to procure full rate production Lot 11 of the AGM-88E2 Advanced Anti-Radiation Guided Missile (AARGM), to include the production and delivery of AGM-88E2 AARGM All Up Round (AUR) tactical missiles; AGM-88E AARGM Captive Air Training Missiles (CATMs); AARGM guidance sections; AARGM control sections; High-Speed Anti-Radiation Missiles (HARM) rocket motors; HARM warheads; HARM control sections; HARM G-Code AURs; HARM G-Code CATMs; and M-Code Global Positioning System receivers, as well as associated test equipment, containers, spare and repair parts, software, and logistical and program support for the government of Australia.Work will be performed in Northridge, California (60%); and Ridgecrest, California (40%), and is expected to be completed in March 2025. Foreign Military Sales customer funds in the amount of $35,587,641 will be obligated at the time of award, none of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Stability Timing (CREST) — a ruggedized atomic clock module with a unique combina-tion of performance and size, weight and power, capable of the abso-lute accuracy of a commercial cesium beam clock in a VPX-card-like form-factor. The CREST module will be designed to provide uninter-rupted Global Positioning System (GPS)-quality timing holdover in challenging military environments. Work will be performed in Phoenix, Arizona, with an expected completion date of Dec. 21, 2026. This contract was competitively procured under long range broad agency announcement (BAA) N00014-21-S-B001. The Office of Naval Research, Arlington, Virginia, is the contracting activity).

The Boeing Co., Mesa, Arizona, was awarded a $239,590,243 cost-plus-fixed-fee contract for the Apache Improved Turbine Engine Inte-gration Phase II. Bids were solicited via the internet with one received. Work will be performed in Mesa, Arizona, with an estimated comple-tion date of Dec. 31, 2026. Fiscal 2021 and 2022 research, develop-ment, test and evaluation, Army funds in the amount of $18,000,000 were obligated at the time of the award. U.S. Army Contracting Com-mand, Redstone Arsenal, Alabama, is the

activity.

A2Z MANUFACTURING WEST COAST • 25 • OCT - NOV ‘22 A2Z MANUFACTURING SW • 44 • March / April 2022

contracting

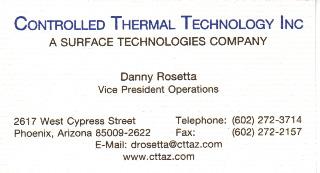

A Heat-Treating Company OFFERING Salt Bath Nitride-MELONITE®- Per AMS2753 D • GASEOUS CARBURIZING • GASEOUS NITRIDING • VACUUM HEAT TREATING • HEAT TREATING • NORMALIZING, ANNEALING, HARDENING, COLD TREATMENT STRESS RELIEVING, PRECIPITATION Serving the Aerospace/Aircraft, Military, and Commercial Industries Other Services; For More Info: Contact Tim Johnston; 602-272-3714; tjohnston@cttaz.com CONTROLLED THERMAL TECHNOLOGY (CTT) AND TS WEST 2617 West Cypress Street Phoenix AZ 602-272-3714

Honeywell Makes A Brighter Business Jet Outlook

Honeywell now predicts significant growth for business jet deliveries through 2032 after forecasting only modest increases at this time last year.

The strong pandemic rebound of business aviation has had a significant impact on Honeywell Aerospace’s industry outlook for the next decade.

On the eve of the National Business Aviation Association convention in Orlando, the company Sunday released an annual forecast that was up 15% on its key metrics from the previous year.

Honeywell now expects 8,500 new business jet deliveries through 2032 at a value of $274 billion — up from an outlook of 7,400 deliveries at $238 billion from last year’s forecast.