“WHATEVER IT TAKES!”

Attitude Helped Erickson Metals Corporation Achieve 50 Years In Business

“WHATEVER IT TAKES!”

Attitude Helped Erickson Metals Corporation Achieve 50 Years In Business

Are you concerned about employee turnover —particularly in losing your best employees? If so, do you know if your employees actually like working at your business?

According to a Global Workday report, while 34% of manufacturing employees feel engaged, a disconcerting 38% feel disengaged and 27% feel actively disengaged. The less engaged employees feel, the more likely they are to look elsewhere for a new position — a serious concern given manufacturing’s ongoing labor shortage.

The term “employee engagement” was coined by William Kahn, a professor of organizational behavior at Boston University, in the 1990s. Kahn stated that in order to feel fully engaged — employees require three things:

• Meaningfulness: A sense of purpose in one’s work

• Safety: The ability to be one’s full self in the workplace without risk or fear of negative repercussions

• Availability: The necessary energy and resources to do the work

It should always be a workplace goal to create a happy and healthy workplace environment and to provide the best possible experience to its workers. Improving employee engagement is a key part of this. And as an added bonus, employee engagement can positively impact your bottom line:

• A Gallup report shows that companies with high employee engagement saw substantially better customer engagement, higher productivity, better employee retention, fewer accidents and a 21% increase in profitability.

• Gallup’s State of the Global Workplace report also found that businesses that actively engage their employees see an 18% decrease in staff turnover.

• According to Manufacturing Digital, engaged employees have productivity rates that are 70% higher than those of non-engaged workers. They also enjoy a 78% higher safety record, 70% lower employee turnover, 86% greater customer satisfaction and 44% greater profitability.

• Have a well-trained leadership team. For many employees, having the right manager can make all the difference in their overall experience. Without a leadership team that’s invested in their continued growth and success — employees may feel less engaged in their work.

• Provide regular training: Without proper training, workers struggle to complete certain tasks, understand organizational goals and meet performance expectations. Provide training resources and foster a culture of continuous learning and improvement.

• A lack of flexibility: Shopfloor employees may not be able to work from home the same way office workers do, but that doesn’t mean manufacturing managers should deprive them of flexible scheduling. In fact, flexible scheduling is proven to improve workers’ work-life balance and overall morale, both of which have a direct impact on engagement.

In closing, God bless our troops and I wish you continued business success. Running your business is much less stressful with low employee turnover.

‘WHATEVER

TAKES’ Attitude Helped Erickson Metals Corporation Achieve 50 Years In Business

Published

keep precision manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z Manufacturing has compiled and maintains a master list of approximately 6500 people in the Rocky Mountain states actively engaged in the Precision Manufacturing Industry. It has an estimated pass on readership of more than 18,000 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to www.azManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

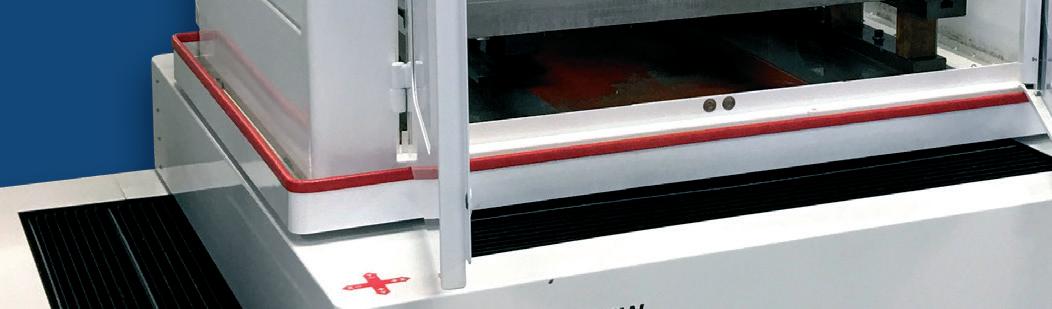

Nothing is sweeter than the sound of a spindle making chips, especially when it’s the high-performance spindle found on one of our NHP Series of Compact Horizontal Machining Centers. These workhorses can handle whatever you throw at them, and are always asking for more.

That’s where our Linear Pallet System (LPS) comes in. It feeds the NHP around the clock, which leaves nothing but pallets upon pallets of precise, ready-to-ship parts. And if floor space is a concern, the Rotary Pallet System (RPS) will fit right in.

√

√

T. J. Snow Company of Chattanooga, TN is now stocking a variety of a water chillers for industrial applications under its new Industrial Water Chiller (IWC) division.

T. J. Snow originally entered the chiller market many years ago to provide recirculated cooling water for its line of resistance welding machines. However, the company soon started selling chillers for a diverse range of applications.

IWC sells, services, supports and stocks chillers and spare parts from its Chattanooga, TN headquarters. An experienced service and engineering group is ready to assist nationwide.

Chillers in stock for quick delivery range from ½ ton to 20 tons. Larger sizes are also available, as are custom-engineered plant-wide systems.

Industry veterans Don Joyce, Jim Kirchoff and Billy James have joined the team in support of IWC sales and service.

For sales or service inquiries, visit www.IndustrialWaterChiller. com or call (800) 934-0785.

Cavendish Scott is a full-service ISO organization focusing on quality management system implementation, internal auditing, and ISO training. We are the ISO experts and have been working with ISO and quality management systems (QMS) since 1985.

Our team of expert consultants/auditors have decades of industry experience and audit internally year-round. We also lead and teach several Internal and Lead Auditor courses throughout the year as an IRCA (International Register of Certified Auditors) approved training partner. We have a true passion for quality and continuous improvement. Our

We Specialize in Close Tolerance Precision Grinding and Small Parts Manufacturing Celebrating 28 Years In Business

Grinding Capabilities:

√ OD,ID Centerless Plunge and Thru Feed (OD Between Centers up to 72” L x OD Swing up to 24”) (ID - 9” depth x 10” LD)

√ Surface, Angled and Blanchard

√ Long Bar Grinding for Screw Machines

√ We grind all types of Industrial Blades

Announcing AS9100

Revision D Certification!

WE’RE GROWING! We Added a 2nd Supertech CNC Universal Grinder, We’ve Hired New Machinists and More!

consultants bring real world experience, expertise, and professionalism and make a positive and value-added impact for our clients every day.

We help our clients prove and demonstrate their competitive advantage not only by helping them to achieve certifi cation, but in the tangible benefi ts from the management systems we help design, develop, and implement. Our solutions aren’t template based but are customized to truly refl ect your organization and how you operate.

Our strength lies in our ability to make ISO fi t your organization, and not the other way around. This results in a low maintenance management system that reduces waste, increases productivity, and better prepares your organization for growth.

We are excited to help companies and organizations of all sizes improve the quality of their operations. Please contact us to see how we can help!

Contact: Tommy Nguyen;Cavendish Scott Business Management/Development tommy@cavendishscott.com

(303) 480-0111

So�ware

LKMetrology'sALTERACcoordinate measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

IntegratedTech

muchanticipated open house on June 9, 2023. The Erickson Metals Colorado team was joined by Troy Erickson, EMC President, Robert Stiles, EMC V.P. of Operations, Marlyn Poznanski, Chief Financial Operator, Corey Bayer, Director- EMC Minnesota, and Michael Medina, Director- EMC New Mexico.

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

Over 100 valued customers, vendors and public fi gures gathered with Erickson employees in the spacious 60,000 square foot facility. Attendees were able to meet the sales, production and shipping teams who take pride in Erickson Metals products.

AllCMMso�warepackagesand op�onsavailablefromLKMetrologyare availablewithALTERAC

Mul�-sensorTechnology

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

Contactustodayat (810)263-6100 or sales.us@lkmetrology.com

So�ware

ALTERAC

Trustworthytechnologyforprecise measurementatanaffordableprice!

1963 2022 59 years

Mul�-sensorTechnology

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

CompactFootprint

LKMetrology'sALTERACcoordinate measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

IntegratedTech

Contactustodayat

op�onsavailablefromLKMetrologyare availablewithALTERAC

Mul�-sensorTechnology

Mul�-sensorTechnology

AllCMMso�warepackagesand op�onsavailablefromLKMetrologyare availablewithALTERAC

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

Mul�-sensorTechnology

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

(810)263-6100 or

(810)263-6100 or sales.us@lkmetrology.com

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

www.LKmetrology.com

Some meeting for the first time in person, some reuniting with familiar faces. Erickson Metals believes that the insights shared, and the connections made, will greatly benefit the attendees and are excited to see the positive impact it will have on our industry.

Come visit their new location at: 3559 N. HIMALAYA ROAD, SUITE 100 AURORA, CO. 80011

You can also visit their website: www.ericksonmetals.com

MarZee Cutting Services is pleased to announce its lastest machine acquisition, the Eagle iNspire 20kW Fiber Laser Cutter. Ed Wenz, owner of the company, says, “The iNspire series of cutting machines are state of the art, extremely precise, and amazingly quick. They excel at the most demanding mass

production applications with their rigid composite base and lightweight carbon fiber bridge as well as the long-life eVa cutting head.”

He adds, “We chose the Eagle iNspire line because they are the fastest and most efficient laser machines in the world.”

As a family-owned and operated business, located in Phoenix, AZ. MarZee is the industry leader for WaterJet, Forming, and Laser cutting with our CNCcontrolled state of the art machines. To learn more about how MarZee can help you with waterjet, forming and now laser cutting, contact them at: 877-885-1059, email: marzee@marzee.com or visit marzee.com

T.J. Davies Company, Inc. was started in 1965 by Thomas Davies. Tom originally named the company Deb-Sher Machine after his two daughters, Debra and Sherry. He later changed the name to T.J. Davies Company.

Continued page 12

“Productivity is a top notch, well-trusted machine tool company offering the highest degree of honesty, integrity, and responsiveness. We are happy and excited for this final step. While our name is changing, we are still the same people customers trust to support their metalworking needs.”

Mark Smith

Vice President and General Manager

Mark Smith

Vice President and General Manager

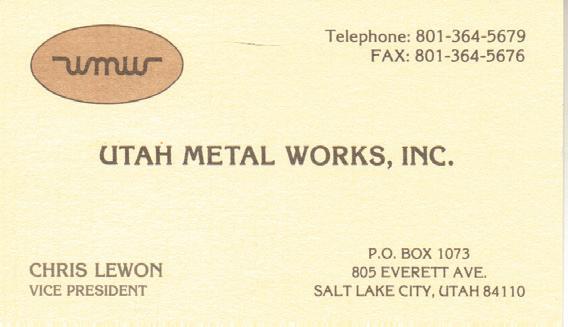

www.umw.com

Tollfree: 866-434-5679

Local: 801-364-5679

At Utah Metal Works, recycling industrial-related scrap metal is one of the things we do best. You simply wonʼt find more knowledgeable, capable partners for your scrap handling and recycling efforts anywhere. We are known in the industry for our honesty and integrity, and you can be sure you are always getting a competitive return along with superior service. We make it easy for you to cash in on non-ferrous metals from:

Industrial/Manufacturing Scrap

Currently, they offer over 500 different styles of retention knobs and add new knobs as new machines or technology is introduced. If someone has a machine and is unsure what knob they need, they are the company they call. Additionally, they make custom knobs for older machines that no other company makes. They have full-time Programmers and a full-time Mechanical Engineer on staff who can assist with your custom retention knob needs.

• Punchings

• Solids of any metals

• Turnings and borings

• Skeleton plate

• Machine Shop/Fabricator

• Solids of any size or type

Aircraft/High Temperature Alloy Scrap

Stainless, titanium, Inconel, Hastelloy, Monel, cupronickel, aluminum;state-of-the-art metal analysis conducted on site; Mixed or contaminated items are accepted and sorted

Easy Access To I80, I15, and I215 Detailed Directions On Our Website 805 West Everett Ave • Salt Lake City, UT 84116

Soon after Tom finished his service in the United States Navy, he moved his family to Cleveland, Ohio, where he took a position with Swagelok, a well-established fittings manufacturing company. After working briefly at Swagelok, Tom’s parents gave Dad a small loan to start his company. Fred A. Lennon, Tom’s boss and founder of Swagelok, contracted with the new company to manufacture parts for them. After serving in the Vietnam War, Uncle Russell (one of Tom’s younger brothers) joined the company.

The company started as a “job shop,” making various products, including retention knobs for Mazak.

About 45 years ago, they began to produce retention knobs on lathes. T.J. Davies Company was the first to use this production method to manufacture retention knobs.

In August 2018, Tom passed away, leaving the business to the next generation. Although Tom is no longer here, the company’s values, mission, and vision remain the same. His daughters have been making strategic changes to grow the business. The first order of business was to purchase a much larger building so they would have room to grow; the move was completed in December 2021. Next, a new website was launched, updated branding, and a new 132-page catalog. The book is available spiral-bound as well as an electronic flipbook that links to their website that can be kept on your smartphone.Call them if you are looking for excellent customer service, inventory in stock, and same-day shipping for orders received by 3:00 PM EST.

Occasionally, to support Utah businesses, the Legislature allocates grant funding and programs to our office. If you have any questions about Office of Economic Opportunity grants, please get in touch with us. https://business.utah.gov/ grants/

Continued next page

Air & Water Innovation Grant FY24

Opens: June 30, 2023

Closes: July 13, 2023

The grant is an $8 million initiative for Utah-based nonprofit or forprofit organizations with projects that improve air quality in the state or more efficiently utilize or conserve water resources.

Utah Manufacturing & Modernization Grant FY24

Opens: June 30, 2023

Closes: July 13, 2023

The $10 million grant incentivizes Utah businesses to modernize, establish, relocate, retain, or develop manufacturing in the state.

Rural Employment Development Incentive (REDI) Grant

Open on a rolling basis until the funds are used. Designed for businesses creating new high-paying jobs in rural Utah communities.

Utah Technology Innovation Funding

Open on a rolling basis until the funds are used. A program to support small Utah companies in their efforts to develop novel technology and products

By: Matt WardleJD Machine NUNTMA Workforce Development ChairA s we look ahead, the future of AI in CNC machining holds tremendous potential for further advancements and transformative impacts on the manufacturing industry. With ongoing research and development, we can anticipate even greater precision, efficiency, and automation in CNC

machining processes. AI algorithms will continue to evolve, enabling CNC machines to analyze complex data, adapt to dynamic conditions, and make autonomous decisions with heightened accuracy.

The integration of AI with robotics and IoT technologies will further streamline operations and create interconnected smart factories. As the symbiotic relationship between AI and CNC machining deepens, we can expect a future where manufacturing becomes increasingly intelligent, agile, and productive.

The above paragraph was written by Chat GPT. Although I would write things differently, it captures the essence of the topic of AI’s impact on the future of machining. You’ve probably heard of how AI will change the world. I’ve tried

Continued next page

We have added a number of improvements over the standard Fast Wire Edms including:

• Cutting capacity of 625 x 625 mm

• Panasonic AC Servo motors and drivers

• Hiwin Linear Guideways

• Build in Cad System

• Two filters

• Increased height side walls to reduce splashing

• View windows to see the wire progress

• Automatic spent wire spooler

• Optional build plate support fixture

• Optional Anti Electrolisis (AE)

We set containers for:

• Machine, welding & fab shops • Manufacturing facilities

• Demolition projects • One-time clean-ups

• Containers: 1 to 60 yards • Flatbed, cargo trailers, rolloffs

• Small boxes on wheels • Locking Lids • Leakproof boxes

Top prices paid for:

• Aluminum • Copper • Brass • Stainless • Steel/Iron

• Alloys • Lead & more

Convenient drive-in recycling:

• Easy acces from I-25, I-70 and Commerce City

• Fully paved • Se Habla Espanol ~

Collins Metal Finishing (CMF) opened its doors in 1968 in response to the plating needs of the burgeoning manufacturing scene of the Phoenix area at the time. It was the brainchild of businessman Robert Wilkinson and electroplater John Collins.

Over the years, CMF grew in both size and complexity, finding its niche in Anodizing and Electropolishing supplemented by a variety of similar, “less complex” services. Despite its growth, CMF has never strayed from its family roots.

In the late 90s, John’s son, Mike, took over his position while Robert’s daughter and son-in-law, Kathy and Chuck Garcia, took over his responsibilities.

Under the direction of these three, CMF left its original location— a shack built during the WWII era— and opened a 5,000 sq. ft. facility with modernized equipment and environmental protections.

Grandson of Kathy and Chuck, Gavin Garcia (now 26 years old), grew up often accompanying his grandfather to work. Intrigued with how the various processes worked and enamored with the finished products, he began working at the shop the day after he turned 16. Gavin is pictured above.

With brief stints working various other jobs, he always worked either full or part time at CMF until the time he graduated ASU in 2021.

A couple of weeks later, he began training to take over for Chuck and Kathy amid Chuck’s battle with cancer. On May 10, 2022, Chuck passed away at the age of 69, two days shy of his 70th birthday.

From then on, Gavin began his tenure as Director, working to continue the legacy of his grandfather.

Over the course of the last year, with Gavin at the helm, CMF has introduced a new logo, modernized their system, and expanded their electropolish services by introducing a brand-new line to satiate the demand of the semiconductor and medical industries.

Fully operational as of April of this year, the new EP line has cut lead times by more than 50% and supported their mission to keep prices as affordable as possible.

Recently, Kathy passed her role as President on to her son, Marc Garcia. Together, Gavin and Marc are looking to continue to grow

CMF in its support of the semiconductor, medical, aerospace, and defense industries.

To learn more about how CMF can support your plating needs, contact them at : 602-275-3117 or email Gavin at gavin@collinsmetalaz.com

A Denver-based company is investing to make money from precious metals production at a pair of mines in Brazil positioned to extract gold and supply the electric vehicle and battery industries.

Royal Gold Inc. struck a deal to spend $250 million acquiring royalty rights giving the company years of revenue tied to the metal’s production coming from the two mines in the coastal states of Alagoas and Bahia, Brazil.

The deal, expected to close this summer, involves Royal Gold in helping finance the mines and a new

group of industrial partners, said Bill Heissenbuttel, company president and CEO.

“This proposed acquisition meets our strategic criteria for investment,” continued Mr. Heissenbuttel, “as the royalties will provide predominantly precious metals revenue on producing mines that we believe have excellent long-term potential, are run by experienced local operating management complemented by seasoned corporate leadership and are located in a mining-friendly jurisdiction.”

Royal Gold acquires royalties from precious metals mines and makes its money from the portfolio of payment streams, but it doesn’t acquire physical assets or operate mines. Its royalties generated $603.2 million in revenue and $239 million in profits for Royal Gold last year.

The Santa Rita mine is one of the world’s largest open-pit nickel sulfide mines, which was brought out of bankruptcy in 2018. Serrote is a new open-pit copper and gold mine.

Both nickel and copper are in high demand globally due to the need for those materials in construction of renewable energy infrastructure and batteries.

Royal Gold’s acquisition of royalties from the Serrote and Santa Rita mines comes as the mines themselves are being sold by London-based Appian Capital Advisory LLP, an investment

Continued next page

fund, for just over $1 billion to a group named ACG Acquisition Company Ltd.

ACG has supply deals and connections to PowerCo, a batterymaking division of automaker Volkswagen; to commodities giant Glencore; and to automaker Stellantis N.V., the parent company of Fiat and Peugeot, the companies said.

Those partner companies have agreed to invest $100 million each toward developing the mines’ production, ACG said.

Arizona-based vehicle maker Nikola Corp. quietly purchased nearly 1,000 acres in the Phoenix metro at the end of September for $16.5 million, according to Maricopa County records.

Nikola acquired the 920-acre site through Phoenix Hydrogen Hub LLC from Hardison Farms on Sept. 30, real estate database Vizzda shows. George Quinif of Peak Group LLC represented Nikola in the sale.

“The Glencore, Volkswagen and Stellantis partnerships are particularly notable, underlining the growing need for EV commodities and the demand for robust, transparent and traceable supply chains from western automotive OEMs, industry and other stakeholders,” said Michael Scherb, founder and CEO of Appian, in a press release about the sale.

The massive site is located at 28702 W. Patterson Road in south Buckeye just west of State Route 85 near the Arizona Department of Corrections Lewis Prison, which is one of the largest prisons in the state and houses more than 4,400 inmates.

Royal Gold plans to use cash and its line of revolving credit to pay for its royalties acquisition, which is contingent on the ACG purchase of the mines closing expected by August, the company said.

The sale comes after Nikola made multiple announcements that it planned to break ground on a hydrogen production hub in Arizona. The company’s CEO said in August that Nikola would start construction on the new facility by the end of this year but did not disclose the location.

The Denver company expects about 60% of its royalty payments from the mines to be from gold output, 25% from platinum and palladium, 5% from nickel and the rest from other metals, Royal Gold said.

The deal in Brazil follows a pair of Royal Gold deals in the past

According to the Arizona Corporation Commission, Corey Hessen and Omar Khayum, senior vice president and vice president of Canada-based TC Energy, respectively, are the managers of Phoenix Hydrogen Hub LLC. Oil and gas giant TC Energy partnered with Nikola last year to develop large-scale hydrogen production hubs across the U.S. and Canada.

12 months in which it spent $729 million acquiring royalty rights to gold production from the massive Nevada Gold Mines operation, in Nevada. The mine complex is owned by a joint venture between Denver-based Newmont Corp. and Canadian gold giant Barrick.By Greg Avery – Denver Business Journal

Nikola hasn’t confirmed, though, whether it plans to build a hydrogen production hub in Buckeye. Nikola said it has no comment about the Buckeye land sale or its plans for the property. The city of Buckeye said nothing has progressed with the company beyond negotiations.

The automaker is currently producing battery electric vehicles and has produced several alpha prototypes of its fuel cell electric vehicles, which run on hydrogen. Nikola is planning to build out a hydrogen fueling network to support its vehicles. Its first three locations will be established in California.

Colorado rocket company United Launch Alliance won business launching six military spacecraft into orbit in coming years for the U.S. Space Force. It’s a contract award splitting a dozen missions with SpaceX.

The U.S. Space Force’s Space Systems Command on assigned the half-dozen launches to be handled by Centennialbased ULA’s newest launch vehicle, the Vulcan rocket.

In addition to the fueling stations, the

The awards are part of the National Security Space Launch Phase 2 procurement program. The first phase of the program split launches 60% to ULA and 40% to Elon Musk’s SpaceX Falcon 9 rockets.

“We partner closely with our launch service providers and mission customers to deliver critical payloads to orbit precisely, on time and without failure,” said Col. Chad Melone, SSC’s chief of the Launch Procurement and Integration Division. “ULA and SpaceX continue to provide outstanding launch services with their reliable and innovative launch systems, and we are confidentin their ability to maintain the unprecedented 100% program success for the NSSL missions assigned for launch in [the 2025 federal fiscal year].”

No value was assigned to the awards issued. But, based on the average value of previous program task orders for Vulcan launches, the new missions represent several hundred million dollars of revenue if not more than $1 billion to ULA.

Four of the launches added to ULA’s future manifest are for Space Force satellites and spacecraft. Two are procured by the military branch for the National Reconnaissance Office, which buys satellites and launch capabilities for intelligence agencies.

The phase 2 award also involves three launches from ULA’s western launch site at Vandenberg Space Force Base, on California’s central coast. ULA has not completed updating its launchpad infrastructure at the West Coast complex for Vulcan rockets.

ULA has yet to fly its Vulcan rocket. Its debut flight is expected this

summer, flying a NASA robotic lander mission to the moon.

The company successfully tested flight engines on the company’s Cape Canaveral, Florida launchpad last month.

Tory Bruno, CEO of ULA, indicated in a tweet that the test-firing of the Vulcan’s BE-4 engines appeared to go as planned.

Completing the six-second firing leaves Vulcan 98% cleared to launch on its debut flight, the company said. It’s awaiting the completion of an investigation into a testing mishap with the company’s upper-rocket stage engine before finalizing the date for Vulcan’s maiden launch.

Getting that mission completed is vital to ULA catching up to its growing number of Space Force national security launches.

The U.S. Space Force had to start from scratch when it prepared to teach large numbers of its own personnel how to fly spacecraft in hostile circumstances.

The military’s space branch, carved off from the Air Force in late 2019, lacked a system to train for combat in space because the need had never really existed.

Three years later, the demand to train more guardians in the techniques of flying satellites and evading potential attacks is large enough that Even Rogers launched a startup to do it.

His company, True Anomaly, is investing in the ability to train guardians — what the Space Force calls its space professionals¬ — in Colorado Springs. It’s also building training satellites at the company’s Centennial offices. The first pair is slated to launch in October to serve as practice spacecraft to fly instead of training people on virtual simulators.

“We think this is the future of aerospace talent, and it’s in Colorado. That’s one of the reasons we set up shop here,” Rogers said.

Rogers, like many others at the company, has a military background. He served in the Air Force for a decade and worked in satellite operations, which brought him to Colorado. What he sees in the space industry now is a different military view of space: no longer the peaceful domain where the U.S. is presumed dominant and its satellites fly uncontested. Rival space programs in Russia and China are understood to be building capabilities

not just to thwart U.S. satellites but possibly engage and destroy — to fight humanity’s first battles in orbit.

The assumption that the next shooting war between the U.S. and a world power could extend off the planet is common across military planning.

By Greg Avery – Denver Business JournalWelcome Jenean Goodsell!

The NUNTMA Board is happy to announce Jenean Goodsell has been hired as the next NUNTMA Chapter Executive!

Jenean has been highly involved in the chapter for the past decade and brings her years of manufacturing and organizational expertise. Please join us in giving her a warm welcome! Jenean also wants to thank Maddie Dahl for all her work as past NUNTMA Chapter Executive!

Established in 2010, the NUNTMA is a gathering place for machine shops in Northern Utah.

Where: Stonebridge Golf Course

4415 Links Dr, West Valley City, UT 84120

To ensure that the tournament surpasses your expectations, we kindly request your participation in a brief RSVP survey. Please take a moment to click on the following link to access the RSVP survey: https://www.surveymonkey.com/r/NJ6PWZD

REGISTRATION REQUIRED FOR ALL EVENTS. VISIT: NUNTMA.ORG/UPCOMING-EVENTS

The Manufacturing Revolution; by: Broc Bryson MSC Industrial Supply; NUNTMA Membership Chair

Let’s spend a moment to thank our beloved Maddie Dahl as she steps away from NUNTMA to more fully dedicate her time to her family more. Maddie on behalf of every single person that has connected with NUNTMA in the last 9 years we are grateful for your efforts. Thank you for your total commitment to the cause. Thank you for helping to direct the orchestra or the chaos that is NUNTMA and our industry. Your contributions are too numerous to count. Know that we so appreciate the impact that you have made in the role of Chapter Executive. Thank you, Maddie!

In a major theme of NUNTMA we are working desperately to recruit and retain a younger workforce that can help our companies thrive in the current and fast-changing marketplace. Who among us thought we’d be asking young people to take these jobs as opposed to having it be the other way around? Look around our industry too. How old are your peers? How old is your workforce? What happens if we don’t get some people moving NOW to be able to take over for those sure to step aside?

Industry 4.0 technologies are here. Many will figure out how to adapt and use these technologies for our betterment – and some will not.

So now “what”? I can with some confidence tell you what I think the machining industry will do. They will adapt, overcome, adjust, and thrive. “Why?” That is who we are and what we do. We work in a very complicated business that is getting more complicated. We moved from manual to CNC. From 3 Axis to 5

Axis. From lathes to turn/mill machines. From .250” thick tooling catalogs to 8” thick books to an infinite internet. From Cast Iron to Inconel. Our success is literally based upon our adapting to new technologies.

Specifically to the “How” we each have a choice. We we can band together and spread the load of some of the shared and more complicated things. Together the cast of characters that brought about our most successful Skills USA contest yet - happened because there were a whole bunch of people coming together to make it happen. Can next year’s contest be better? Of course it can and it will be if we all keep working together.

So the time is now and the chance and privilege are ours. Are there other good people already involved? There sure are. Do we need more good people? We sure do. Do we need you to jump in and help row the boat in any way that interests you and that you can shove into your busy life? We so do!

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

“This is going to be one of the premier facilities in the world, certainly here in the state of Arizona, bringing thousands of good paying jobs that you can actually raise a family on and that do not require a

Intel spokeswoman Linda Qian declined to disclose whether the company is on track for meeting its previously announced timeline for opening the fabs in 2024.

NASA awarded a Blue Origin and Lockheed Martin Space team a $3.4 billion contract to build a second, reusable lunar landing system that will ferry astronauts between a waiting spacecraft and the surface of the moon.

She said Intel is making a “tremendous amount of progress” on the fabs, which will be complete within three to five years from the initial groundbreaking date.

shipped to customers, said Jason Bagley, government affairs director for Intel Corp.’s U.S. Southwest region.

excellence as the world’s top space program and maintaining that excellence for decades to come,” Nelson said.

The fabs will support growing demand for Intel’s products and be a provider for Intel Foundry Services. The two fabs, when complete, will bring the total to six fabs on Intel’s existing Ocotillo campus.

“I almost can’t stress enough how important these wafers are to our economy,” Kelly said. “Semiconductor chips go in everything from cellphones, vacuum cleaners and cars to the most sophisticated fighter jets in the world.”

The pandemic exacerbated a global shortage of semiconductor chips, most of which are produced in Asia.

The space agency’s selection ends a two-year effort by the National Team, led by Jeff Bezos’ Kent, Washington-based Blue Origin, to have its lander included in NASA’s Artemis moon missions.

The lander will fly astronauts from a NASA-funded outpost in lunar orbit, known as the Gateway, down to the moon’s surface and then back. Blue Origin’s system, dubbed the Blue Moon lander, is being designed to carry four astronauts and 20 tons of cargo to the surface for missions. Developing the lander for the first missions will cost close to $7 billion, possibly more, based on the public-private model NASA is pursuing.

NASA had previously selected SpaceX to build a lander slated to land the first Artemis astronauts — and the first woman — on the lunar surface as soon as 2025.

The fabs will have more than 250,000 square feet of clean room space and will produce wafers, which are thin slices of semiconductor material used for fabrication of integrated circuits. Each wafer can hold hundreds or thousands of chips, depending on size.

Intel will send the wafers to an assembly testing center where they’ll be cut via lasers into individual chips, packaged and

The space agency awarded a second lander system contract to encourage the participation of other aerospace industry partners and spur more innovations to help establish a lasting presence on and around the moon, said Bill Nelson, NASA administrator. “This is about maintaining our

“We’re at a point now where we need to change the balance of the semiconductor industry supply,” Bagley said. “We are actively working on these two new factories here as part of that strategy to shift some of that production capacity back to the U.S. and back to Europe, so we have more of a fifty-fifty division between Asia, the U.S. and E.U. These efforts are critical to the ability of this country to continue to innovate and continue being a global leader in the semiconductor space.” By Amy Edelen – Reporter, Phoenix

Industry partners will invest at least as much of their own money as NASA will pay toward the lander, said John Couluris, head of Blue Origin’s lunar lander program.“Blue Origin is contributing well north of $3.4 billion,” he said.

Business JournalThe National Team’s 52-foot-tall

Blue Moon is scheduled to land astronauts on the fifth Artemis program mission in 2029. Lockheed Martin Space is already the prime contractor building the Orion capsules, deep-space spaceships that NASA will use on all of its missions flying astronauts from Earth to lunar orbit.

The Orion capsules have twice fl own successful test missions without crew, most recently completing a month-long Artemis 1 test flight around the moon last fall.

Companies teamed up to propose landers under earlier bidding. NASA made the surprise decision in April 2021, to award a single, $2.9 billion lunar lander contract to SpaceX.

Elon Musk’s company proposed using the Starship spacecraft it’s developing to serve as the landing craft that astronauts board at the Gateway.

Blue Origin plans to test parts of the Blue Moon lander’s systems in launches in coming years that will use the company’s massive New Glenn rocket, which is under development now.

A series of test missions, some of which will be to the moon, will culminate in 2028 with a test version of the final Blue Moon lander flying to lunar orbit without crew on board, landing on the moon’s surface and returning to lunar orbit, Couluris said.

An identical Blue Moon lander will be built for the following year’s Artemis mission with astronauts.

The Blue Moon landers are being designed to remain in

lunar orbit for years and, with refueling, be able to dock with Gateway and fly astronauts or cargo to multiple sites on the lunar surface, he said. Blue Origin is working on technologies that will let it use hydrogen fuel in orbit and enable a long-term, reusable lander presence around the moon, Couluris said. The company has been drawing interest from other users of the landers, not just NASA, and expects there to be commercial uses for them, too, he said.

Nelson noted that President John F. Kennedy promised the first lunar landing mission 61 years ago, famously saying the nation chose to pursue it because it was a hard challenge. The Artemis program is pursuing the moon landings for similar reasons — to master the difficult engineering feats necessary to sustain a human moon presence and do that with an eye on the harder challenge of sending astronauts to Mars.

“The great adventure of humankind pressing out into the cosmos is happening, and this is part of it,” Nelson said. By Greg Avery – Denver Business Journal

Experience cleaner, quieter cutting and better looking parts with HYDROBLOC waterjetbricks. The flat, even, honeycomb surface keeps parts from falling into the tank and drains water away to minimize splash back. HYDROBLOC’s laminated high-density polyethylene layers are welded and screwed together for unrivaled durability.

• Cleaner Cutting • Quieter Operation

• Better Looking Parts • Recyclable Watch the video to learn more at barton.com/hydrobloc

Hubs program will create ecosystems of innovation to strengthen economic opportunity in communities around the country that have historically been overlooked.

“We’re going to do that by supercharging our existing innovation foundations, bringing together our premier research institutions with world class companies to create good-paying jobs in these communities, and ensuring the technological advances that define the next century are made in communities across America,” Raimondo said.

Out of the first round of applications, the Commerce Department will winnow down the group to around 20 or more, and the funding that each group eventually gets will depend on their vision and the path they lay out to becoming globally competitive.

He stressed the ability to leverage the government money with philanthropic groups or other entities would help stretch the grant money and give it more impact. Those that don’t get picked can hopefully use the plans they have created to solicit state or other dollars to help kickstart that process, graves said.

BARTON INTERNATIONAL USA/Canada 800-741-7756

518-798-5462 • info@barton.com • barton.com • store.barton.com

The Commerce Department’s Economic Development Administration has launched its $500 million Tech Hubs grant program — and it’s looking for applicants.

The Tech Hubs program, part of the CHIPS Act passed by Congress in 2022, aims to identify potential tech hubs around the country outside of the typical tech epicenters such as Silicon Valley, Boston and New York and provide the funding they need to grow.

The official notice of funding opportunity is the first step in that process. Applications are due by Aug. 15, 2023.

The program could provide a significant infusion of money for emerging innovation ecosystems around the nation — many of which are rolling out strategies to capitalize on opportunities created by the CHIPS Act. U.S. Secretary of Commerce Gina Raimondo said in a statement the Tech

But this grant program is just one of several contained within the CHIPS Act, which aimed to boost American manufacturing and innovation. That includes tax credits as well as specific programs for semiconductor production. It also includes a $1 billion “Recompete Pilot Program” to “target long-term comprehensive economic development and job creation in selected areas by supporting workforce development, business development, and infrastructure activities.”

Essentially, areas previously left out of economic growth can apply.

There are also still loan programs and tax credits small businesses might be unaware of.

• The USDA Business and Industry Loan Guarantee Program, part of an umbrella loan program offered by the USDA under its OneRD Guarantee Loan Initiative, offers loan guarantees of up to 80% on everything from purchasing a building, modernizing equipment, working capital or acquiring a company. It also only applies to eligible areas — essentially rural areas not in cities or towns of more than 50,000 — although businesses based in larger cities are eligible as long as the project is in a rural area.

• The Inflation Reduction Act includes a tax credit for qualifying electric vehicles of up to $7,500 for vehicles weighing less than 14,000 pounds, and up to $40,000 for vehicles that weigh more than that, subject to certain

limitations. The credit is slated to last until the end of 2032, according to the legislation.

• The act also doubled the research and development tax credit from $250,000 to $500,000. The tax credit is refundable and applied against payroll taxes and includes expenditures for a wide variety of expenses, including the improvement or development of products, processes, techniques or even software.

Here are some other tax credits small businesses might want to take a closer look at. Amazon.com Inc. and eBay are among companies that are offering small business grants you can apply for right now.

By Andy Medici – Senior Reporter, The PlaybookConstruction has officially started on a 732-mile electrical power transmission line project being built by a company owned by Denver billionaire Phil Anschutz to link a massive Wyoming wind farm to southern California.

A groundbreaking for the $3 billion project attracted U.S. Interior Secretary Deb Haaland and U.S. Energy Secretary Jennifer Granholm to a ceremony outside Sinclair, Wyoming,

capping more than 13 years of work to make the TransWest Express project happen.

Both women hailed the high-voltage powerlines as a vital addition to the country’s renewable energy infrastructure.

“The TransWest Express Project will play a major role in our nation’s energy security, ensuring that home-grown clean energy can form the backbone of our electric grid as we rebuild a stronger, more resilient transmission system,” said Granholm in a press release about the groundbreaking.

The transmission lines will connect utilities serving population centers in southern California to the largest onshore wind power project being built in the U.S., a wind farm with more than 600 turbines on Anschutz’s Wyoming ranch and federal Bureau of Land Management property.

The TransWest Express route runs southwest from the gusty southern Wyoming prairie, cutting across northwest Colorado, crossing mountains and desert to a southern terminus outside Las Vegas where it connects to the electrical grid reaching California. The lines are designed to carry enough wind power to serve hundreds of thousands of homes.

“WHATEVER IT TAKES!” Attitude Helped Erickson Metals Corporation Achieve 50 Years In Business

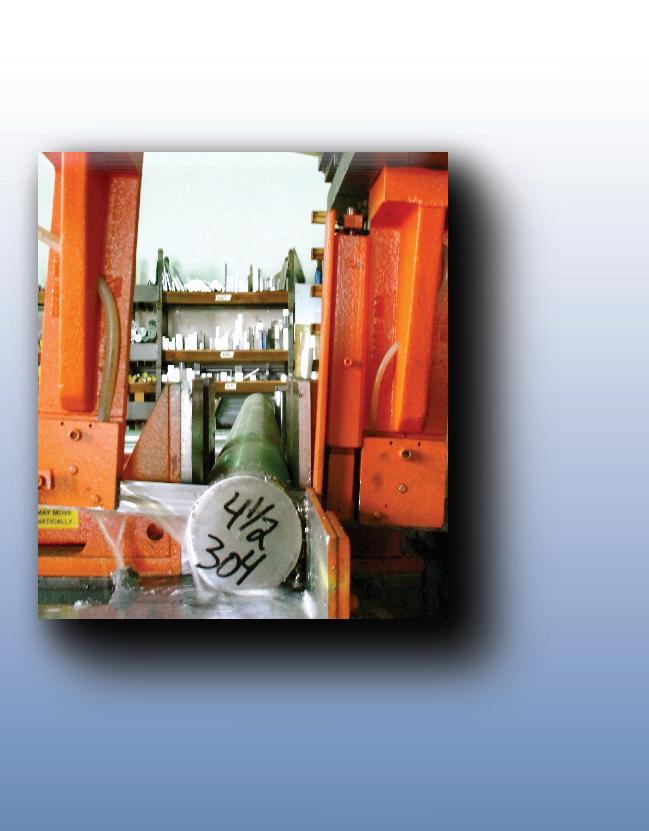

Erickson Metals ju st celebrated their 50th year in business last year. What a feat! To put this into perspective, the U.S. Census Bureau reports that only about 12% of companies are older than 25 years. And their celebration of a half century in business coincided with a major expansion of their Colorado division. The company’s new state of the art facility, completed just months ago, is 60,000 square feet, more than double the size of their previous facility. In the building, the company stocks an inventory of more than 2 million pounds of aluminum.

The aluminum supplier entity, with facilities in Aurora, Colorado, Coon Rapids, Minnesota, and Santa Teresa, New Mexico, maintains a complete stock of aluminum products to give their customers quick turn-around on all deliveries. The team at Erickson Metals works closely with customers to design practical packaging methods. Whether a shipment needs custom skids, special wrapping or spacing materials, they do “whatever it takes” to ensure safe delivery.

Randy Adkisson, General Manager for Colorado, with 37 years tenure at the company, says, “Our new facility is truly state of the art, and our improvements were all intended to make the experience of buying materials from us better than ever. For customers, the additional footprint meant that we are able to increase our efficiencies dramatically. In fact, just months after completing the move, we have reduced our time to process orders by 50%.”

Erickson Metals is a family-owned business. Founded by Richard (Dick) Erickson in 1972, today the company remains under ownership by the Erickson family, and son Troy is the company president. But Erickson Metals isn’t just a ‘family’ business because of the Erickson family members — in fact, one of its greatest assets is the 50+ extended family members who have helped run the company, and many for decades.

Randy’s 37 years with the company isn’t an

anomaly — Bob Stiles, VP of Operations, has 35 years with the company, Angela Rupoli, Director of Sales, has been with the company for 24 years, Julie Flinn, who works as an Outside Sales Representative, has 30 years of tenure with the company, and Randy says that the lead ‘Cut to Length’ Operator, Darryn Wright, has also been with Erickson Metals for 3 decades.

Randy says, “Angela, our Director of Sales, started at the company as a receptionist.” He added, “We are always looking for superior, loyal people to join our team and participate in our growth. At Erickson, we do an outstanding job of promotion within our company, and this is just one of the reasons our employees remain with us for decades.”

Bob Stiles, Vice President of Operations, says, “All of Erickson Metals’ employees are empowered to pursue a “Whatever It Takes” philosophy. We support an atmosphere of consistent betterment in communications, creativity, teamwork and mutual respect. By working together, we can develop and maintain partnerships with our customers and suppliers to improve all aspects of business, including efficiency on all levels, excellent responsiveness, and fast turnaround times.”

He continued, “Superior customer service is something nearly every company talks about, but it truly is something we live and breathe at Erickson Metals — it’s the little things that we do on a daily basis that matter to our customers. It’s a live person who answers the phone when they call, it’s the regular face to face contact our customers get from our sales team; it’s our delivery trucks and the drivers who customers always compliment for their professionalism, it’s our quick turnaround on quotes, just to name a few, that make a difference to our customers.”

Randy says, “We track on-time delivery on a daily basis, and are scores are consistently >98%, which is certainly above industry standards, but still we’re working on getting to 100%. We also track material return rates, and this metric is less than 1/10th of 1%.”

Angela adds, “Our customers value the services we can provide,

above just selling them aluminum. We offer saw cut plate, cut-to-length sheet, shearing and slitting, all done in-house, and we can precision saw up to 10” thickness plates, and achieve tolerances up to .005” for up to 12’ x 12’ material size. Our precision services incorporate multiple saws to cut through hollow and solid shapes. All three locations have the capabilities of leveling aluminum sheet of various thickness and lengths, as well as large and small pieces, with quick turnaround on your request each time.”

Randy says, “Additionally, our trucks offer delivery on a daily basis from Fort Collins to Colorado Springs. For our ‘Will Call’ customers, we take the time to package their materials very well, so that we help to minimize any damage to the customers’ purchase.”

Erickso n Metals specializes in aluminum, including sheet, plate, rod, bar, tube, as well as structure shapes and custom extrusions. Randy says that plans are in place to add aerospace grade metals to their product line, and that this is expected to be available in the next 12 months. “We will strengthen our aerospace customer base once we offer these new materials, adding to our ~500 customers today who are in such varied industries as signage, transportation, precision sheet metal, communications, technology, medical, amongst others.” Angela adds, “We proudly support customers who are ‘mom and pop’ shops all the way to multi-billion dollar corporations.”

While nearly a requisite for machine shops manufacturing precision parts, ISO certification is not a ‘must have’ in the metal service industry. Still, to best ensure processes are in place, Erickson Metals has been ISO 9001 certified since 1997, Bob says, adding, “ISO certification establishes credibility and trust among our clients and business partners. In today’s international marketplace, it validates that we adhere to global standards of quality assurance, manufacturing and business. It’s just another thing we do to make sure that we are offering superior products and services to our customers.”

Are you getting best in class service from your aluminum service provider? Is the quality and on-time delivery consistently outstanding? If you are manufacturing aluminum products, whether sheet, plate, rod, bar, tube, structure shapes or custom extrusions, you absolutely should contact Erickson Metals Corporation. Ph: 303-373-0820; Email: SalesCO@EricksonMetals.com

When you call, prepare to be pleasantly surprised by a real voice on the other end of the phone!

“Erickson is my #1 supplier for aluminum, bar none. My father started using them more than 30 years ago, and at the time he purchased from Randy’s father. Today, I use them, and I purchase from Randy. The customer service is outstanding - they deliver aluminum to me dailyeven if I need just one bar. Their prices are competitive and they are just such a pleasure to work with.” Machine Shop Owner, CO

“You get unprecedented customer service when you buy aluminum from Erickson Metals. Not only is their pricing good, but delivery times are also outstanding. If we need aluminum same day, Erickson Metals takes care of us. When the lead time from our customers is 4 weeks, we can’t have our materials delivered in 1 week - that eats into 25% of the time we have to deliver to our customers. We keep an eye on costs with all of our vendors, but we have never had a reason to look at another supplier for our aluminum. It is

just Erickson - Angela, Randy and the team are just that outstanding.” Operations Manager, Machine Shop, CO

“I have been buying from Erickson Metals for 15 years now, since 2008. For all these years, Julie and Angela have been my contacts. 15 years! It is quite unusual for you to have a supplier and you’ve had the same team supporting you!

Erickson Metals is different than many of metals suppliers for a number of reasons:

1) They answer the phone — I don’t get an answering machine to leave a voice mail.

2) They deliver on time, and if there is ever an issue, they communicate it to me. There are no surprises.

3) Pricing is always competitive and often better than other suppliers.

Of my metals suppliers, and I probably have a dozen, Erickson is #1.” Purchasing Manager, Precision Machine Shop, CO

“Julie and Lindsey do a really good job supportining us, and we’ve been working with the Erickson team for more than 7 years now. They help us with rush orders, credit us when needed, and they are helping us to reduce prices as we order metal in larger quantities. They are obviously doing a great job for their customers as they are continuing to grow — in fact they just completed a major expansion with their new building.” Procurement Manager, Canyon City, CO

“Lindsey is a Rock Star and so is our delivery guy! We’re a new business, having opened in 2021, and Erickson has been phenomenal about helping a start up with little credit. They are prompt, they do delivery, which saves us time and money, and they do our cut and shear to size. We’ve worked with them so that now they house all the alumunim that we need.

It is so great to work with a company that is so willing to help a young company such as ours. Erickson is the best.” Business Owner, Manufacturer, CO

A company making a solar and batterypowered travel trailer plans to manufacture the product out of new space it leased in the Denver metro area and hire dozens of people for the plant.

Lightship Energy Inc. announced it has signed a lease agreement for what will become the company’s Broomfield production facility for its newly launched Lightship L1 trailers.

“This is a big milestone for Lightship and a stepping stone to ultimately producing thousands of vehicles in the future and helping to introduce electrification to a pastime enjoyed by millions of American families,” said Toby Kraus, Lightship co-founder and CEO, in a press release. “I grew up in Colorado and am thrilled for Lightship to set up its first production facility and contribute to the growing ecosystem of climate tech and hardware manufacturing in my home state.”

The company is based out of San Francisco and Boulder. It is adding a 32,000-square-foot space in the Baseline Innovation District, part of a development off Colorado Highway 7 just west of Interstate 25. It will make the Lightship L1 trailers there.

The company came up with an aerodynamic, 27-foot trailer that sleeps four to six people, and has solar panels and onboard batteries. The trailer can provide its own propulsion, making it energy-free to haul for a tow vehicle and able to provide as much as a week’s worth of electrical power for off-grid camping, the company says.

Lightship calls the trailer the first all-electric recreational vehicle. It introduced the trailers in March.

The company plans to move into the Broomfield space next year and have L1 models in production by late 2024. It expects to hire 100 people to staff the trailer factory.

Lightship was founded by two ex-Tesla employees and has hired engineers from other well-known electric vehicle companies, including Rivian, Polestar and Proterra. Pricing starts at $125,000, which would be reduced to $118,400 if applicable tax credits are used.

The company viewed Broomfield as an up-and-coming

innovation hub that will help access from the regional labor pool surrounding the Denver-Boulder area, the company said.

The Baseline development is a project of Denver and Loveland-based McWhinney. The 1,100-acre mixeduse development is projected to include 9,205 homes, a science, technology, engineering and math school, dining and commercial areas. By Greg Avery – Denver

Business Journal

A Colorado manufacturer is more than doubling the space it leases to make complex medical devices, adding a new Arvada site to its other metro area design and production locations.

ERI Group leased 34,000 square feet of Arvada manufacturing space for an expansion beyond the company’s existing sites in Genesee and Denver.

“We’re taking ERI to the next level. We’re growing up as a business,” said Tasha Bond, the company’s president and top executive.

ERI Group makes complicated electrical and mechanical devices for client companies whose names and brands go on the products.

The Arvada space should be outfitted for medical device manufacturing by late this year, allowing ERI Group to move in, she said. ERI has doubled its headcount since early 2022, topping 100 employees at its three sites, she said.

Building out the Arvada location will give the company room to expand both its production capability and, as it handles more projects for clients, expand its staff to as many as 160 people in three years, Bond said.

The company’s future growth will be focused in Arvada, Bond said.

The Mountain Gateway has attracted other advanced manufacturers, such as aerospace company Moog Inc., which expanded its Colorado presence last year.

ERI Group’s expansion comes less than a year after the business merged with Link Production Development, making ERI Group able to make complicated machines for large manufacturers, or small complex devices, like wearable, and help small companies design and prototype early products.

A Louisville company that makes communications technology for satellites is considering where to build a new factory that could employ hundreds of people. The state is offering 4.9 million reasons to open it in the Denver metro area.

The new factory would be Tendeg’s second recent expansion. The company added a second building to work out of in the Colorado Technology Center, in southeast Louisville, a few months ago.

Tendeg has been growing due to the success of the collapsible mesh antennas it designs and makes for small satellites.The antennas are made from gold-plated molybdenum strands woven together and forming a collapsible material that Freebury said feels like a fabric one might find in lingerie.

But the metal mesh, when unfurled in a frame or spread across spokes like

an umbrella, makes an effective way to catch or send communications signals from orbit.

Tendeg’s antenna technology includes gimbals to steer the direction of the antennas and software to enable communications, making its products both small and something ready for a satellite company to adapt to its larger design.

A circular mesh antenna that deploys to be three meters, or just under 10 feet, in diameter can be collapsed to take up a space just 20 centimeters in diameter, Freebury said.

That’s an advantage in an era when space companies are building fleets of many satellites and packing large numbers of them onto the same launch rocket.

Tendeg’s antennas pack into a relatively small space but, once in orbit, can unfurl to become an antenna with meters of surface area sensitive to communications signals.

The small mass of Tendeg’s antennas works well for satellites made to fit on rideshare rocket launches, where space is tight, and the technology is still effective in larger versions for satellites that are bigger.

Ten satellites using 11 of Tendeg’s antennas are in orbit now. They were made by aerospace companies that required nondisclosure agreements and Tendeg cannot name.

Lockheed Martin Space chose a Tendeg antenna for Lockheed’s self-funded TacSat mission that’s expected to launch later this year. That small satellite, about the size of a dormitory room refrigerator, is designed to test the first 5G telecommunications node in orbit that could be a dedicated advanced communications system for the U.S. military, Lockheed says.

The big aerospace company has placed several other orders with Tendeg, too, and is discussing how Tendeg’s designs can be used in conjunction with Lockheed’s radio frequency communications technologies in other national security space missions. Some of that work involves bigger antennas for larger satellites, and that’s a lot of what’s driving Tendeg’s search to open a new production facility.By Greg Avery – Denver Business Journal

Desert EDM Sales 480-816-6300

Abrasive Products

Barton International ____ 800-741-7756

Chemtool Inc.

_______ 815-957-4140

Bandsaw Blades

Roentgen USA _______ 847-787-0135

Bar Pullers

Accudyne Corp 303-991-1500

Edge Technologies 951-440-1574

Boring, Grooving, Milling, Turning Tools

Fullerton Tools 989-799-4550

NTK Cutting Tools 425-365-3613

Qualichem, Inc. 480-320-0308

Star Metal Fluids _____ 800-367-9966

Coolant Systems

Machine Tool & Cutter Grinding 435-512-4416

Dust Collectors, Filtration Equip. Star Metal Fluids 800-367-9966

EDM Materials & Supplies

Desert EDM Sales 480-816-6300

EDM Network 480-836-1782

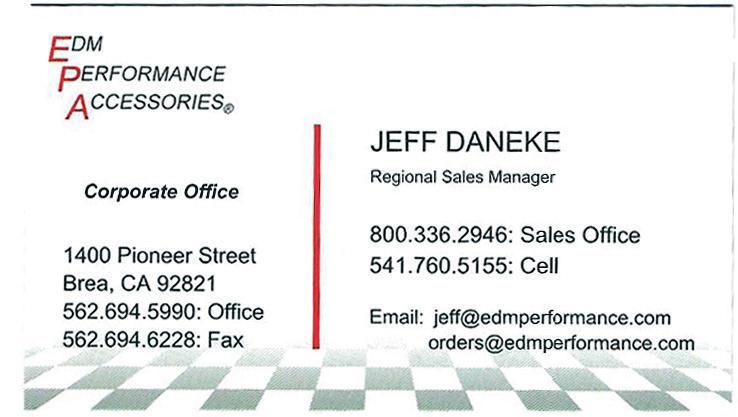

EDM Perform. Access. 800-336-2946

Global EDM Supply 480-836-8330

Star Metal Fluids 800-367-9966

EDM:

EDM Perform. Access. 800-336-2946

End Mills

Fullerton

Machine Tool & Cutter Grinding 435-512-4416

Filtermist Mist Collectors Royal Products 800-645-4174

Gage

Power Tools

Ingersoll Rand _____ 206-472-0826

R8 Quick Change Tool System

Royal Products _______ 800-645-4174

Retention Knobs

T.J. Davies ________ 440-248-5510

Robot Accessories

SCHUNK 919-602-8294

Rota-Rack Parts Accumulator

Royal Products 800-645-4174

Solvents /Degreasing Agents

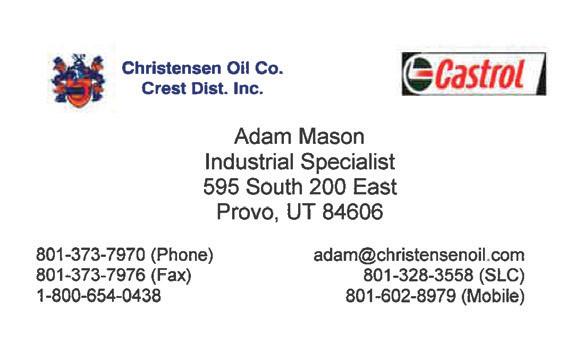

Castrol ___________ 800-894-7773

Hasco Oil __________

562-595-8491

Star Metal Fluids 800-367-9966

Spindles

GMN USA 800-686-1679

Sulli Tool & Supply 714-863-6019

Surface Plates

Starrett ___________ 949-382-4123

Toolholding

Hainbuch ________ 818-970-7874

Industrial Supply 800-288-3838

Tooling for Swiss Type Lathe

NTK Cutting Tools 425-365-3613

Vices and Vice Jaws

Desert EDM Sales 480-816-6300

Hainbuch 818-970-7874

Sulli Tool & Supply ____ 714-863-6019

Waterjet Cutting Abrasives

Barton International ____ 800-741-7756

Workholding

Hainbuch 818-970-7874

AUTOMATION

Acieta 402-650-8132

DATRON 480-826-3689

Bystronic Inc__ 702-340-6964

Hainbuch 818-970-7874

Fiero Automation 303-431-3600

KEYENCE _____720-614-9241

Measurement Systems Hexagon 303-859-7159

KEYENCE _____720-614-9241

Starrett 949-382-4123

Metrology Instruments

Gage Lab Products 801-716-2972 Hexagon 303-859-7159

Innovative Measuring Systems 602-527-5488

KEYENCE _____720-614-9241

Klontech Industrial Sales 480-948-1871

LK Metrology _______ 949-716-4440

Renishaw 847-286-9953

Starrett 949-382-4123

Total Quality Systems 720-338-2581

ACCUDYNE CORPORATION

Daniel R. Kenner

2835 S. Raritan St Englewood, CO 80110

303-991-1500 (Ph)

303-991-1921 (Fax)

Web: www.ezpullerusa.com

Zeiss Industrial Metrology

KEYENCE _____ Optical Comparators

Gage Lab Products

Hexagon

Innovative Measuring Systems

Klontech Industrial Sales

LK Metrology

Renishaw

Total Quality Systems

Sensors: Contact & Optical

Zeiss Industrial Metrology

Video Measuring Systems

Gage Lab Products

Klontech Industrial Sales

Total Quality Systems

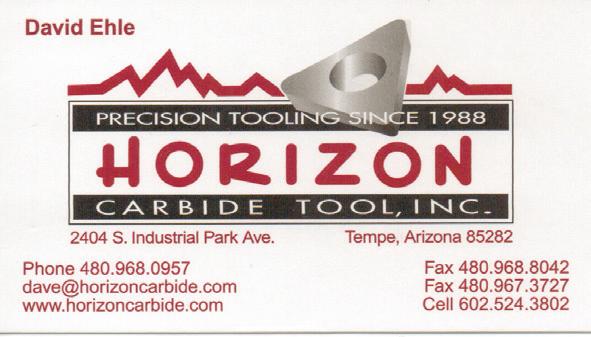

Horizon Carbide Tool

Utah Metal Works, Inc.

METALS & MATERIALS

AZ Tool Steel LLC

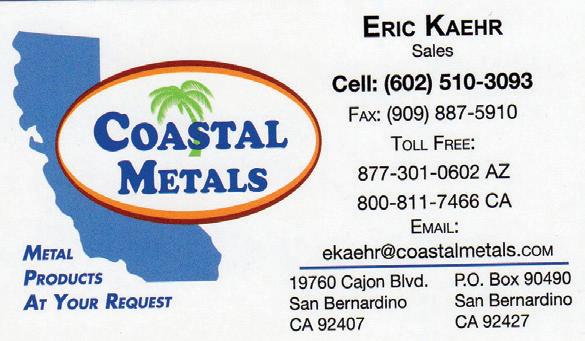

Coastal Metals

Erickson Metals

Laube Titanium

Olympic Metals

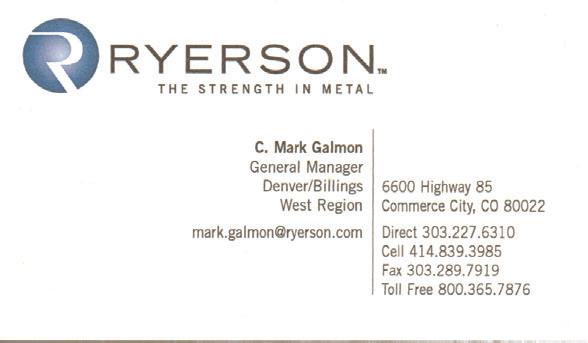

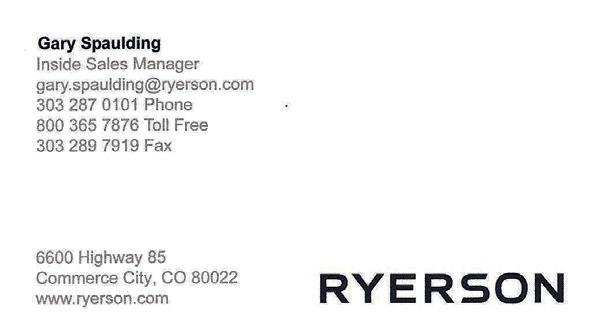

Ryerson

United Perform. Metals

Western States Metals

Affiliated Metals

Metals: Bar & Plate

AZ Tool Steel LLC

480-784-1600

Coastal Metals 800-811-7466

Erickson Metals ____ 303-373-0820

Ryerson

303-227-6310

TW Metals 800-203-8000

Mold Steel

AZ Tool Steel LLC

480-784-1600

Nickel Alloys AZ Tool Steel LLC 480-784-1600

Ryerson 303-227-6310

TW Metals 800-203-8000

United Perform. Metals 317-946-0025

Plate-Precision Saw Cut

Erickson Metals 303-373-0820

Pre-Honed Tube

Western States Metals 801-978-0562

Stainless Steel

AZ Tool Steel LLC 480-784-1600

Coastal Metals 800-811-7466

Olympic Metals

303-286-9700

Ryerson 303-227-6310

United Perform. Metals 317-946-0025 Steel

AZ Tool Steel LLC 480-784-1600

Coastal Metals ______ 800-811-7466

Olympic Metals 303-286-9700

Ryerson 303-227-6310

Ryerson 303-227-6310

United Perform. Metals 317-946-0025 Titanium

Laube Titanium___805-388-1050x124

METAL DISTRIBUTORS

Erickson Metals 303-373-0820

Coastal Metals 800-811-7466

Laube Titanium __ 805-388-1050x124

Olympic Metals 303-286-9700

Ryerson 303-227-6310

TW Metals _________ 800-203-8000

United Perform. Metals 317-946-0025

Western States Metals 801-978-0562

NEW MACHINERY 3D Metal/ Additive

Manufacturing Machines

Production Machine Tools 425-881-1200

Renishaw 847-286-9953

CHIP CUTTING

CNC Drilling/Tapping

Methods West 602-437-2220

CNC Mills

Action Machinery ______888-289-9100

AME, Inc.

DATRON

DMG Mori

Doosan

Hurco __________

J.M. Grisley

J.M. Grisley

Bystronic Inc____ ____

Cold Saws

Fullerton Tools ____

702-340-6964

989-799-4550

KNUTH Machine Tools ___ 847-415-3333

CNC Punching Centers

Latitude Machinery

602-517-7153

S&S Machinery Sales 602-368-8542

CNC Routers

Multicam _________

Drill Lines

970-218-9046

Production Machine Tools _ 425-881-1200

Fiber Lasers

Bud’s Machine Tools

385-271-6718

Multicam 970-218-9046

Production Machine Tools _ 425-881-1200

Grinding Machines

DCM Tech

Latitude Machinery

KNUTH Machine Tools

800-533-5339

602-517-7153

847-415-3333

Multitool USA 800-660-0880

Iron Workers Action Machinery ______888-289-9100

602-517-7153 425-881-1200 602-368-8542

Laser Cutters ______888-289-9100

Production Machine Tools

Shearing Machines

Action Machinery

Bystronic Inc__

Latitude Machinery

S&S Machinery Sales

DATRON

Vacuum Tables

OTHER ACCESSORIES

Grinding Accessories

Multitool USA 800-660-0880

602-368-8542

303-424-0268

Magnetic Particle (NDT) Machines

DCM Tech

800-533-5339

Pipe & Tube Benders/Notchers

Bystronic Inc__

702-340-6964

S&S Machinery Sales 602-368-8542

Plasma Cutters

Action Machinery ______888-289-9100

Bystronic Inc__ ______

702-340-6964

KNUTH Machine Tools 847-415-3333

Multicam 970-218-9046

Production Machine Tools 425-881-1200

Press Brakes

Action Machinery ______888-289-9100

Bystronic Inc__

Latitude Machinery

702-340-6964

602-517-7153

Production Machine Tools 425-881-1200

Rotary Surface Grinders

DCM Tech 800-533-5339

Sawing Machines Action Machinery ______888-289-9100

Fullerton Tools ____ 989-799-4550

Latitude Machinery 602-517-7153

Tooling Systems

Desert EDM Sales _____ 480-816-6300 USA EDM Supply 480-836-8330

PALLET SYSTEMS

Automatic Pallet Systems Midaco 847-593-8420

Automatic Door Opener Systems

Midaco 847-593-8420

Manual Rotary Pallet Systems

Midaco 847-593-8420

Robotic Part Loading Systems

Midaco 847-593-8420

PLASTICS

Acrylics And Polycarbonates

Laird Plastics 303-292-1687

Plastics: Fabrication

Laird Plastics 303-292-1687

Graphics Materials

Laird Plastics 303-292-1687

Mechanical/Engineering Material

Laird Plastics 303-292-1687

Cavendish Scott 303-480-0111

Business Forms/ Custom labels/Brochures

Pryntink 855-675-1444

Calibration Services

Advanced Coord. Tech

303-469-6161

Klontech Industrial 480-948-1871

Quality Measurement Services970-413-2438

Western States Calibration 801-466-1700

Consultant,Operational Consultant, ISO

ABS Quality Evaluations 702-371-7591

BMSC 602-445-9400

Cavendish Scott 303-480-0111

MEP ___________ 801-863-7001

Contract Inspection

Advanced Coord. Tech 303-469-6161

Klontech Measure Sol 480-626-8131

Quality Measurement Services970-413-2438

Education

Ogden-Weber Tech College_801-395-3795

Electrical: Breakers/Switches/ Starters

Denver Breaker Supply 855-4UR-BRKR

Engineering Services

Advanced Coord. Tech

303-469-6161

Financing

Tech Financial Services 414-224-0209

Univerity Federal Credit Union 801-463-3597

First Article Inspection

Advanced Coord. Tech ____ 303-469-6161

Heavyhaul

IRH ___________ 801-972-5581

Injection Molding

3D Parts To Go 801-380-7935

Inspection Services

Advanced Coord. Tech 303-469-6161

Quality Measurement Services970-413-2438

Lean Consulting

ABS Quality Evaluations 702-371-7591

MEP Center 801-587-0713

Logistics/Freight

R&R Transportation ____801-747-2607

Metrology Services

Advanced Coord. Tech 303-469-6161

Hexagon 303-859-7159

Klontech Industrial 480-948-1871

Quality Measurement Services970-413-2438

Western States Calibration 801-466-1700

Process Improvement/ Audit

ABS Quality Evaluations 702-371-7591

BMSC _____________ 602-445-9400

Cavendish Scott _____ 303-480-0111

X-Ray

Certified Inspection Service 602-267-0661

ISO9000 / AS9100 Cert.

BMSC 602-445-9400

Cavendish Scott 303-480-0111

Platinum Registration 303-639-9001

Orion Registrar 303-645-4017

ISO Registrar

Platinum Registration 303-639-9001

Orion Registrar 303-645-4017

Machine Tool Rebuilding

EDM Network 480-836-1782

Nadcap Approvals - Consulting

Level III NDT Consulting 602-578-8109

Non-Destructive Testing (NDT)

Level III NDT Consulting 602-578-8109

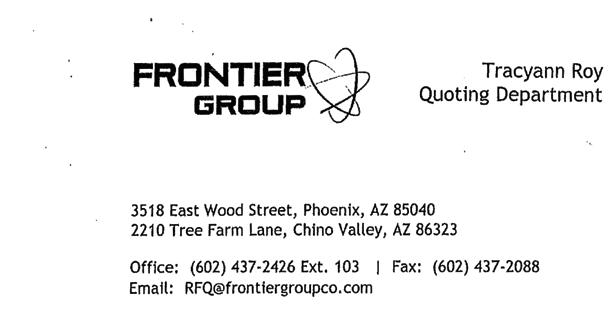

Frontier Group 602-437-2426

Phoenix Heat Treat_____602-258-7751

Process Improvement

BMSC 602-445-9400

MEP Center 801-587-0713

Reverse Engineering

Advanced Coord. Tech __ _303-469-6161

Diversified Metal Services__ 801-972-6093

Klontech Measure Sol__ 480-626-8131

Rigging & Transfer

IRH _____ _____ _801-972-5581

R&R Transportation ____801-747-2607

Transportation

IRH ____________801-972-5581

R&R Transportation ____801-747-2607

SPINDLE REPAIR

RMS Assembly & Mfg 303-777-3064

TOOLING

PrecisionToolholding Products

Industrial Supply 800-288-3838

Von Ruden Mfg 763-682-0322

Tooling Systems

Industrial Supply 800-288-3838

Von Ruden Mfg 763-682-0322

Live Tool Holders

Industrial Supply 800-288-3838

Von Ruden Mfg 763-682-0322

Static Tool Holders Industrial Supply 800-288-3838

Von Ruden Mfg 763-682-0322

TRAINING MEP Center _______ 801-587-0713

CAD/CAM Training

Blackwing Machine__ __ 801-645-4485

MultiCAM 970-218-9046

Machining Software MultiCAM___________ 970218-9046

USED MACHINERY Action Machinery _______888-289-9100

DATRON___________480-826-3689

EDM Network 480-836-1782

K.D. Capital Equipment___480-922-1674

Methods West________602-437-2220

CASTINGS Aluminum Casting Precision Enterprises 731-642-8709

Die Casting

TVT Die Casting 800-280-2278

Die Casting: Aluminum/Zinc

TVT Die Casting 800-280-2278

CHEMICAL PROCESSING

PAS Technologies 602-744-2648

COATING

Coating:Black Oxide

Phoenix Heat Treat 602-258-7751

Coating: Liquid

Pilkington Metal Finishing 801-972-2146

Coating: Nickel/ Teflon/Chrome

Coating Technologies 623-581-2648

PAS Technologies _____ 602-744-2648

Coating:Zinc & Mag.Phos.

Coating Technologies 623-581-2648

PAS Technologies 602-744-2648

COMPOSITES

S.A. Composites 970-776-3877

DESIGNCAD/CAM

CNC Machine & Design Inc 801-531-9922

DIES

Able Machining & Eng. _ 801-268-6766

EDM

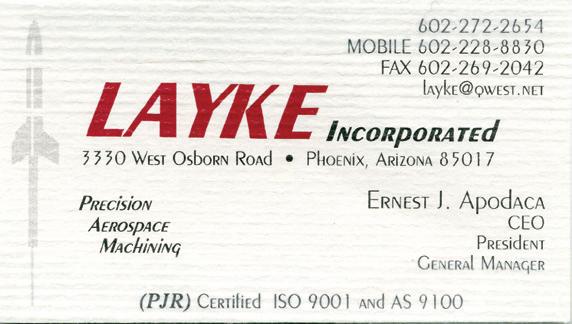

EDM: Drilling Small Hole LAYKE, Inc.___________ 602-272-2654

Micropulse West 480-966-2300

EDM: Ram-Type (Sinking)

Innovative Precision 801-334-6317

Maverick Mold & Machine _ 970-535-4604

Micropulse West 480-966-2300

Kustom Koncepts 307-472-0818

Star Precision 303-926-0559

Fabrication: Medium & Large

CAID Industries 435-890-8823

EMJD Corp 303-761-5236

EPOCS Mfg 970-535-4540

Group Mfg Serv 480-966-39528

Weiser Engineering 303-280-2778

Fabrication: SheetMetal

A1 Precision Metal 623-377-2191

Advantage Manufacturing 877-727-0281

CAID Industries 435-890-8823

Denver Machine Shop 303-295-6000

Dynamic Design & Mfg 303-652-0431

EMJD Corporation 303-761-5236

EPOCS Mfg 970-535-4540

Group Mfg Serv 480-966-3952

JD Machine 801-782-4403

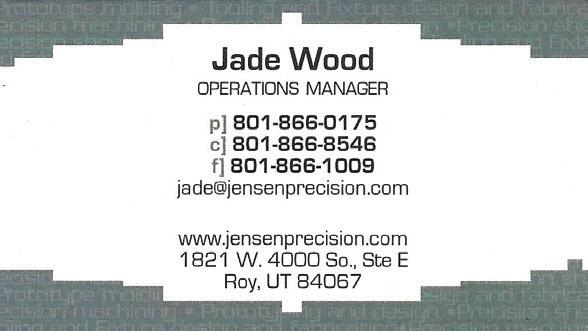

Jensen Precision 801-866-0175

Kustom Koncepts _____ 307-472-0818

Metalcraft 888-280-7080

Pillar Machine 801-965-1900

Richards Fab 801-409-0392

Star Precision 303-926-0559

Weiser Engineering 303-280-2778

Wrico 480-892-7800

Fabrication: Steel

Bandsaw LLC 303-744-7181

CAID Industries _____ 435-890-8823

EMJD Corp 303-761-5236

FINISHING

Advantage Manufacturing 877-727-0281

Coating Technologies ___ 623-581-2648

Coating Technologies

Phoenix Heat Treat ______ 602-258-7751

Iron Phosphates

Metals Finishing LLC 801-718-7969

Wasatch Powder Coating 801-718-7969

Passivation

Certified Inspection Service___602-267-0661

Coating Technologies __ _623-581-2648

Collins Metal Finishing 602-275-3117

Photochemical/Etching

VACCO Industries 626-443-7121

Powder Coating

CPCS 303-438-8328

Metals Finishing LLC 801-718-7969

Pilkington Metal Finishing 801-972-2146

Star Precision 303-926-0559

Wasatch Powder Coating 801-718-7969

Sandblasting

Metals Finishing LLC _____ 801-718-7969

Phoenix Heat Treat 602-258-7751

Wasatch Powder Coating 801-718-7969

EPOCS Mfg JD Machine 801-782-4403

FOUNDRY Precision Enterprises 731-642-8709 GAS NITRIDING Blanchard Metals Proc. 801-972-5590 GEAR CUTTING Ponderosa Ind 303-298-1801

Specialty Steel Svcs 801-539-8252

Gear Hobbing Ponderosa Ind 303-298-1801

GRINDING Diversified Metal Services 801-972-6093

GMN USA 800-686-1679

Machine Tool & Cutter Grinding 435-512-4416 PAS Technologies 602-744-2648 Prec. Mach’d Products 970-482-7676 Ron Grob Co. _______ 970-667-5320 Steel Services Grinding 800-662-0126

Grinding _____ 801-487-9700

Precision Mach’d Products 970-482-7676

Radtech 303-789-4247

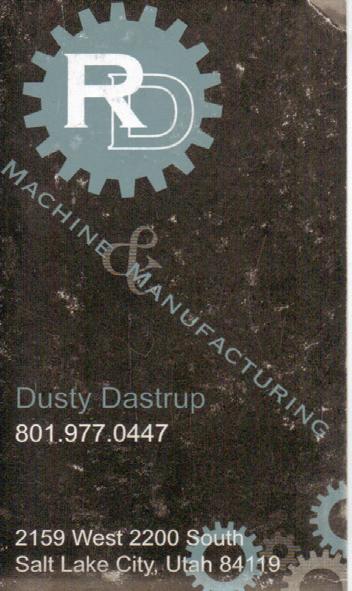

RD Machine & MFg 801-977-0447

RP Machining 719-550-1724

Skydandee Mfg 801-774-8031

Machining: Automatic

StarRex Precision 480-834-6344

Machining: Ceramic

O’Keefe Ceramics 719-687-0888

Ceramic: Sapphire, Alumina, Silicon, Aluminum, Quartz

O’Keefe Ceramics _____ 719-687-0888

Machining: CNC

A1 Precision Metal ____ 623-377-2191

Able Machining & Eng. 801-268-6766

Accutech Machine _____ 801-975-1117

American Machine & Eng. 801-973-0494

Apex Engineering ____ 435-713-0072

Auburn Tool & Machine 303-278-8769

CM Manufacturing ___ 406-543-4450

CNC Machine& Design 801-531-9922

Cornerstone Machine 801-731-8862

Denver Precision Products 303-469-1771

DMSI___________801-972-6093

Dynamic Design & Mfg 303-652-0431

EPOCS Mfg 970-535-4540

Flex-Pro 480-773-3239

GL Manufacturing 801-634-5894

H& S Machine 801-755-7627

Innovative Precision 801-334-6317

Jaguar Precision 505-242-6545

JD Machine 801-782-4403

Jensen Precision 801-866-0175

Kings Peak Manufacturing 801-337-5926

LAYKE, INC_________ 602-272-2654