A concerning trend observed in Laborled state governments in Australia - the locking up of productive state forests - raises questions about the relationships between bureaucrats, inner-city Labor MP’s and the activist class – and the poor understanding they have of rural communities, according to Forest & Wood Communities Australia executive officer Mick Harrington.

ernments to convert productive state forests into National Parks has been disastrous.”

Mr Harrington said that these forests, which could be utilized for sustainable timber harvesting – alongside healthy and productive past times such as hunting, fishing, prospecting and horse-riding etc – were increasingly being placed off-limits to everyday Australians.

“This policy shift raises questions about the relationships between bureaucrats, inner-city Labor MP’s and the activist class – and the poor understanding they have of rural communities,” he said.

“One of the key issues at hand is the impact on local economies that heavily rely on the sustainable native forestry and timber processing sectors.

Mr Harrington said that whether it was the attempt to lock-up many of the most productive parts of the New South Wales public land estate with the “Great Koala National Park” or the signalled move of Victorian Labor to lock up a further 335,000 Hectares in poorly managed National Park – the potential immense harm to regional, rural and remote communities was deeply concerning.

● Poorly managed parks also contribute significantly to out-of-control wildfires.

with almost unmanaged fuel loads,” he said.

“These industries have long played a vital role in supporting employment and local businesses.

“However, the tendencies for state Labor gov-

“These poorly managed parks also contribute significantly to out-of-control wildfires across the landscape and terrible outcomes for biodiversity – as well as posing significant threats to small at risk rural and remote communities that often are surrounded or nearby parks

“The argument here is not against real environmental conservation. It’s about finding a sustainable middle-ground that does not include the biased voices of a few elitist activist academics that currently pervade the national public land management conversation – alongside the willingness to actively manage the public land estate.”

Sustainable forest management practices had been developed to ensure the long-term health of ecosystems while supporting the economic needs of communities.

“By locking up productive state forests, we risk neglecting the potential for a harmonious coexistence between conservation and industry,” Mr Harrington said.

“Moreover, it is disheartening to observe that some environmental ‘charities’, through public donations, are supporting actions not necessarily focused on saving endangered species or rehabilitating environments. Instead, these actions are engaging in green lawfare cases against honest, hardworking Australians – with the end aim to destroy their sustainable industries, families and

communities. While environmental protection is crucial, it’s essential to distinguish between legitimate concerns and cases that are driven more by extremist ideological agendas rather than actual ecological preservation.” He said stakeholders from all sides should be invited to participate in constructive discussions.

“Unfortunately, this is often not the case – with the NSW Labor Government refusing to allow Forest and Wood Communities Australia a seat at the table on the Great Koala National Park Industry Advisory Panel.”

Australia’s forestry and timber industry breathed a collective sigh of relief after the decision of the Australian Federal Court to reject a challenge to the validity of the Intergovernmental North East Regional Forestry Agreement.

The Court examined the agreements that were made in 2000 and extended for 20 years in 2018 and confirmed that the technical requirements for extending the RFA were met.

The North East Forest Alliance case against the

Commonwealth of Australia and the State of NSW argued that the RFA should not have been renewed without assessment and approval under federal environment laws.

The decision handed down by Federal Court

Justice Melissa Perry was that the technical requirements for extending the RFA were met but the Court was unable to assess the evidence of the impact caused by native forest logging and that such matters were wholly political.

The Environmental De-

fenders Office (EDO) argued the Commonwealth was required to assess environmental values and principles of ecologically sustainable management when it was renewed but failed to do so.

The EDO stated that these included impacts on endangered species, climate change and old growth forests.

“A regional forest agreement provides an alternative mechanism by which the objects of the (federal) Environment Protection and Biodiversity Conserva-

tion Act can be achieved by way of an intergovernmental agreement,” Justice Perry said.

“As such, the question of whether or not to enter into or vary an intergovernmental agreement of this nature is essentially a political one, the most of which are matters for the government parties and not the courts to determine.”

Therefore, the agreement handed the responsibility for matters of national environment significance to NSW.

NSW’s native hardwood forestry industry is worth $1.8 billion to the economy and employs 9,000 people, more than half of them in the state’s north-east in communities built on the sector.

Timber NSW chair Andrew Hurford said that this Federal Court decision paved the way for those serious about ecological sustainable forest management and a sustainable timber industry.

Issue 1 – Volume 35

Established 1991

News 3 - 13

My View 10

Haulage 18 - 20

Forest management 15

Conferences 23

Haulage 23

Mill profile 28

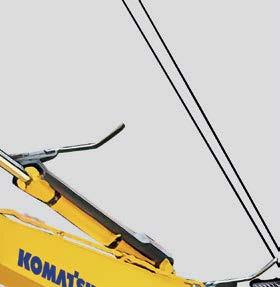

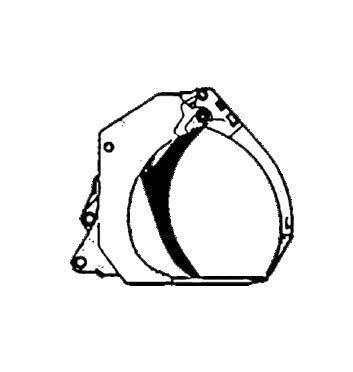

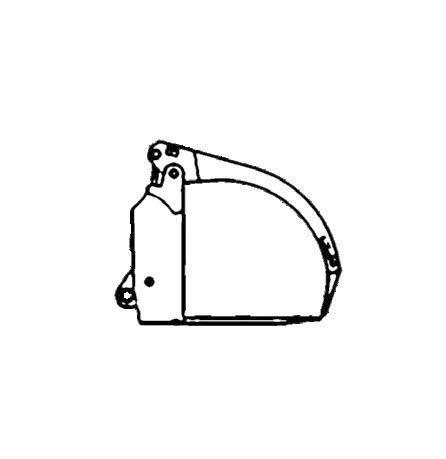

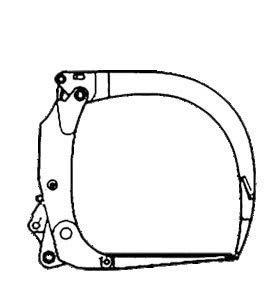

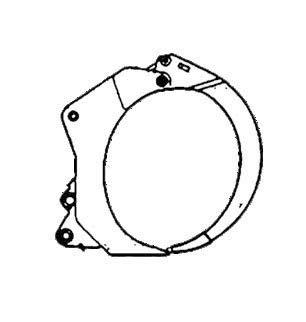

Front Cover:Orana Enterprises in Tasmania has a fleet on Tigercat skidders after discovering some years ago that cheap machines were only cheap to purchase.

Page 20

Publisher and Chief Executive: Hartley Higgins

General Manager: Robyn Haworth

Editor: Bruce Mitchell

b.mitchell@ryanmediapl.com.au

Adelaide Office: (08) 8369 9521

Advertising: Jon Andryciw j.andryciw@ryanmediapl.com.au

Adelaide Office: (08) 8369 9517

Creative Services: Sudapa Rattanonda

Publication Design: Sudapa Rattanonda

Trader classifieds: Jon Andryciw

Adelaide Office: (08) 8369 9517

Subscriptions: subs@forestsandtimber.com.au

Adelaide Office: (08) 8369 9522

Subcription rates

One-year (8 editions) $59.50

Two-years (16 editions) $103.50

Accounts:

Adelaide Office: (08) 8369 9555

Postal Address: 630 Regency Road, Broadview South Australia 5083 Phone: (08) 8369 9555 Fax: (08) 8369 9501

Melbourne Office: Suite 2262, 442 Auburn Rd, Hawthorn VIC 3122

Phone: (03) 9810 3262

Website www.timberbiz.com.au

Printed by Lane Print, Adelaide, SA

By anyone’s standards, Victorian axeman Laurence O’Toole had a very good 2023.

The Komatsu-sponsored champion picked up seven titles across Australia last year including the Stihl Timbersport’s Australian Champion for 2023 held at Glenelg in South Australia.

Throughout the year his remarkable success in wood chopping competitions, showcasing unparalleled skill, determination, and sportsmanship making him an ideal ambassador for Komatsu Forest and the timber industry. Hailing from a family with a rich tradition in the sport, Laurence learned the art of wielding an axe at an early age and has honed his skills over the years. It became evident that he possessed a unique combination of strength, precision, and strategy that set him as one of the best in his sport.

It became evident that he possessed a unique combination of strength, precision, and strategy that set him as one of the best in his sport.

“I’ve been using axes since I could crawl,” said Laurence.

“My grandfather was a world champion woodchopper as was my father and uncle, so naturally I followed in their footsteps,” he said.

“I won my first world championship in 2003 when I was twenty-two, which made me the youngest world champion at that stage by about six or seven years,” said Laurence.

Last year saw a series of victories and records that solidified his status as a wood chopping legend. Setting new benchmarks in various events, he showcased not only his technical proficiency but also his mental fortitude under pressure.

Whether it was the underhand chop, standing block chop, or the exhilarating hot saw competition, Laurence consistently demonstrated a mastery of the craft that left an indelible mark on the wood chopping community.

His major 2023 achievements included:

• Adelaide Stihl Australian Trophy, held over four disciplines (March).

• Sydney Royal World Underhand (April).

• Sydney Royal World Standing-Block (April). (In woodchopping this is called the “Double” It’s his first time achieving it.)

• Grafton NSW Australian Open Hotsaw (May).

• Mt Larcom QLD Nationals Open Hotsaw (June).

• Melbourne Royal Golden Axe Award (Sept).

• Jarradale WA Australian Standing-Block (Oct) Laurence also competed at over 20 small shows in Victoria, Queensland, NSW and WA winning state and show championships.

The Chopperoos - Laurence O’Toole (Stocksaw), Brayden Meyer (Underhand), Brad Delosa (Single Buck), Mitch Argent (Standing Block) with Jamie Head (Reserve) - claimed an unprecedented fourth consecutive win. Laurence has been a key member of the Chopperooos during their eight wins since 2011.

Laurence O’Toole’s success in wood chopping events during the year is a testament to his unparalleled skill, dedication, and sportsmanship. Showcasing his success is not just about winning competitions but also about embracing the journey, respecting the community, and continuously striving for excellence in one’s chosen field.

It’s time Federal Government funding of the Environmental Defenders Office was turned off.

Just last month it lost the case brought by the North East Forest Alliance (NEFA) against the Commonwealth of Australia and the State of NSW with its lawyers arguing that the RFA should not have been renewed without assessment and approval under federal environment laws.

And it lost a landmark case against Santos’s $5.3bn Barossa LNG project, with

claims the company’s proposed 262km pipeline would cause irreparable damage to First Nations people and their sites being rejected.

The EDO, which again began receiving money - $10 million - from Labor last year after a 10-year funding drought initiated by the Abbott government, is carrying out four additional cases in the Federal Court

– one involving Woodside’s $16.5bn Scarborough offshore gas field and another relating to the federal government’s $13bn MurrayDarling Basin water plan.

AFPA chair Joel Fitzgibbon told The Australian this week that legal aid for activists was “hurting” the Australian economy, and called on the federal government to scrap taxpayer funds from the service.

Mr Fitzgibbon said legal aid for green activists “makes no sense, there is

no case for public funding”.

He also wants the EDO to disclose a list of its donors.

It echoes a call by Senator Jonno Duniam and Senator Susan McDonald who late last year said in a joint statement that alarm bells should be ringing for the Albanese Government to defund the EDO.

All three are of course right.

There is no doubt about that. No doubt at all.

Australia is home to vast natural resources, including 134 million hectares of forests, which cover approximately 17% of the country’s land area.

Within these forests, an estimated 10.5 billion tonnes of carbon are stored, with 98.8% held in native forests, primarily dominated by hardwood species.

It’s essential to understand that of the 132 million hectares of native forest, 2 million is plantation and only 5 million hectares are accessible for timber harvesting, accounting for a mere 3.7%. Each year, a nominal 78,000 hectares are carefully harvested, representing just 6 in every 10,000 trees. This selective harvesting occurs exclusively in approved areas and is followed by meticulous regeneration efforts, often involving replanting native species in much higher numbers than was removed.

The Australasian Timber and Flooring Association (ATFA) is actively addressing the complex challenges posed by the Timber Harvesting Dilemma across multiple fronts in Victoria (VIC) and New South Wales (NSW). This encompasses the permanent closure of forestry operations in VIC by January 1, 2024, and the suspension of forestry operations in NSW to establish 106 Koala Parks.

ATFA has been actively engaged, supporting submissions from entities like Timber NSW and VicForests, contributing to the critical dialogue around native forestry’s economic, social, and environmental importance. This proactive stance aims to counter misinformation while advocating for responsible forest management.

Environmental groups have propagated misleading narratives surrounding native timber harvesting, prompting ATFA to respond with factual information. This includes clarifying aspects such as wildlife protection, carbon

sequestration, and the sustainability of timber products. Specifically, timber is an exceptional carbon sequester, maintaining carbon storage in products like timber flooring and furniture throughout their lifespan. With careful canopy management and forest renewal practices, younger trees thrive, contributing to healthy microclimates and stronger habitats. Native timber, a renewable resource, contrasts starkly with non-renewable alternatives like concrete, bricks, and steel.

Collaborating with many other Forestry and Timber associations, ATFA seeks to counter misleading claims and advocate for responsible forestry practices.

For example, VicForests is committed to upholding stringent standards based on sustainability, and careful State forest management curtails soil erosion and protects water runoff, ensuring such sustainable practices extend to plantations.

The native timber industry is a significant economic

contributor, generating $2.9 billion in gross revenue in NSW alone.

The industry plays a pivotal role in job creation, supporting regional communities and bolstering Australian sovereignty in timber supply. The Timber Harvesting Dilemma necessitates a nuanced understanding. Native timber harvesting plays a pivotal role in Australia’s sustainable forestry practices, effectively harmonising economic development with environmental preservation.

ATFA urges stakeholders and policymakers to consider the multifaceted dimensions of this issue, ensuring a balanced approach that safeguards both our environment and the livelihoods of many Australians dependent on this industry. Over the next four years, both Federal and State Governments are allocating over $300 million to support the country’s forest industries, underlining their significance.

This unified release encapsulates the diverse facets of the Timber Harvesting Dilemma, emphasising ATFA’s proactive involvement in addressing misconceptions, engaging with authorities, and advocating for balanced and sustainable forestry practices

Global nature-based real assets manager

New Forests is selling four of its New Zealand forestry assets.

The four estates, located across New Zealand’s North and South Islands, are being sold as the fund manager completes the term of the second round Australia and New Zealand Forestry fund (ANZFF2).

in both Victoria and New South Wales. ATFA asserts that the native timber industry is a responsible, sustainable, and essential part of Australia’s ecosystem and economy. Understanding these facts is crucial to fostering informed decisions and preserving our natural heritage.

The Australasian Timber Flooring Association (ATFA) stands as a beacon of sustainable forestry practices and environmental stewardship in Australia, passionately navigating the complexities of Australia’s timber harvesting dilemma.

Our unwavering commitment to responsible timber harvesting and management extends beyond the timber industry, impacting downstream sectors such as construction and building, renewable energy, interior design, flooring, furniture manufacturing, craftsmanship, paper and pulp production, and various allied industries. It is indisputable that Australian native timber plays a pivotal role in crafting spaces of timeless beauty and environmental consciousness.

For more information, to become a member of ATFA, or if you require any advice, please call ATFA on 1300 361 693 or visit www.atfa. com.au/consumer-services/ species/

The four estates are located across New Zealand’s North and South Islands in established forestry regions of Blenheim, Southland, Taupo and Wairarapa and have a combined gross area of almost 16,000 hectares. All the estates apart from Taupo, are freehold, New Forests noted.

New Forests has engaged UBS New Zealand Limited as financial adviser to assist with the potential sale process. The forestry assets also present future carbon market opportunities with around one quarter of the plantations established on post 1989 land which is registered in New Zealand’s Emissions Trading Scheme (ETS). All four forestry assets have been third-party certified for sustainable forest management.

New Forests has already sold a Tasmanian forestry estate to UniSuper and a consortium of European pension funds. UniSuper, the UK’s Pension Protection Fund (PPF), and APG Asset Management N.V (APG) on behalf of its Dutch pension fund client ABP have bought Forico and a 170,000-hectare plantation forestry estate in Tasmania. Under the agreement, the three investors will each own 33% of Forico and the forestry estate. New Forests will be retained to provide investment management services.

Forico is Tasmania’s largest private forest management company and the estate itself is one of Australia’s largest plantation hardwood estates by productive area.

Forest & Wood Products Australia has launched a softwood Timber Market Index to further support planning, growth and investment across the industry.

The Timber Market Index is a representative directory of historic price movements for different categories of softwood products, to be published quarterly. The data used to calculate the index is collected anonymously to ensure data security and accuracy.

The TMI has been developed with strong support from industry and is a collaboration between FWPA and the Australian Forest Products Association (AFPA). In 2017, AFPA commissioned a Timber Market Index report, which reviewed the opportunity to establish a new

and best-practice approach to an index.

The report recognised that establishing a TMI based on the existing FWPA softwood weighted average data series is part of a best practice approach and could be

used to form the basis of new indices for the Australian softwood industry. Governance for the index will be overseen by an industry committee and independent Chairperson, which will provide ongoing management of the tool.

“The Timber Market Index is a powerful new tool in tracking industry price movements and trends over time.” said Kevin Peachey, Head of Built Environment Programs at FWPA.

“It’s exciting to see this great initiative launched

With operations on crown-owned Queensland native forestry subject to understandably complex regulatory obligations, Timber Queensland has released an online resource with a suite of easy-to-follow tools to help operators and permit holders safely and effectively navigate compliance.

The Queensland Native Forestry website (www.QldNativeForestry.com.au) has been created in line with the

Native Forest Operations Capacity Building Project, delivered by Timber Queensland with funding support from the Queensland Government’s Department of Agriculture and Fisheries. The work is part of a project to build greater capacity in compliance and improved management systems for operators in the state based native hardwood and cypress sectors.

Timber Queensland Chief Executive Officer, Mick Ste-

phens, said that while the forest and timber industry prides itself on working within a well-regulated environment and wholeheartedly supports modern sustainable forest management practices, often the complexity and layering of numerous Codes, Guides and Standards can make compliance a challenging prospect.

“Across the industry, people want to do the right thing. It was important that we put something in place

to help operators and permit holders alike understand their obligations – for the future of the forestry industry, and the forests we work in,” said Mr Stephens.

Designed for easy access via computer, phone or tablet, the website has been built to help operators (including harvesters, haulers and wood processing permit holders alike) to understand and meet their obligations through a suite of easy-tofollow training plans. Infor-

and to be able to support our industry with increased transparency and confidence in tracking industry trends” Kevin continued.

“The development of the Timber Market Index is a great example of collaboration and will help support industry analysis as well as business planning” said Andrew Leighton, CEO of FWPA.

The TMI is independently audited by consultants to ensure that all inputs are correct, providing assurance for all parties. The index may be used by the industry and its consultants to help track price movements.

Learn more: https://fwpa. com.au/new-timber-market-index-to-track-pricemovements-of-australiansoftwood-products/

mation is shared via downloadable guides and other resources with an emphasis on clarifying requirements across environmental, sustainable forestry, cultural heritage and workplace health and safety obligations.

With more training materials underway, further updates will be released on the website over the coming months and updates announced across Timber Queensland channels.

ALEADING Australian forestry expert has resigned from Bendigo Bank over its policy not to support the harvesting of native forest.

Rob de Fegely, who has had many senior roles in his 40-year career in forestry, has resigned from the board of his local Community Bank due to its parent Bendigo Bank’s policy of not supporting native forest harvesting.

Mr de Fegely, a director of Margules Groome Consulting, chair of Sustainable Timber Tasmania and a nonexecutive director of Forestry Corporation of NSW, emphasised these were his personal views and not those of any of the organisations he works for.

“Despite numerous exchanges with the chief executive, Marnie Baker, and the head of corporate affairs and ESG, they have not provided any justification for their policy, which is contrary to the United Nationals International Panel on Climate Change recommendations for managed forests,” he said.

“I respect anyone’s right to have an opinion but if it affects others then it must be well researched and reasoned.”

Mr de Fegely said he joined

the local Community Bank in Pambula because he felt they had a great model for local banking and had supported the local community “which I hope they will continue to do”.

“However, the parent company is trashing their community brand as the forest industry has been operating on the far south coast of New South Wales since the early settlers arrived in the 1830s and thanks to the efforts of our early foresters, the bulk of our forests especially on public land still exist today,” he said.

“What is poorly understood is that harvesting contractors provide the skills and equipment to fight bushfires and without them more of our precious flora and fauna will be destroyed.

We all know the Black Summer bushfire killed more wildlife and released more carbon into the atmosphere than any other event in our recent history.

“It astounds me that a bank whose origins are in rural and regional Victoria could take a policy position without consulting its community bank directors or even formally notifying them. In my opinion it is unethical.

“Refusing loans to harvesting contractors while offer-

ing support to processors is simply hypocritical.”

Mr de Fegeley said he had told the CEO that finger pointing or cancel culture was an inappropriate way to resolve the complex challenges of sustainably managing Australia’s natural forests. “Timber harvesting not only provides needed wood products but also funds much of the management of our multiple use forests,” he said.

“I don’t know if the Bendigo Bank policy had any impact on the Victorian government’s decision to end harvesting in its natural forests, but I hope their board and senior management reflect this Christmas on the future for the estimated 2.5 thousand plus people who have lost their jobs because of the decision. Most have no prospect of finding alternative employment in their home communities like Heyfield, Swifts Creek and Orbost.

ForestWorks CEO ForestWorks has appointed Angela Bell as interim CEO following the resignation of Chief Executive Office Michael Borowick.

Angela joins ForestWorks with extensive experience in the not-for-profit sector, including CEO of Ethical Clothing Australia from 2017 to 2021.

The recruitment process for a permanent CEO began in mid-January.

PFT’s new chair

Private Forests Tasmania has appointed a new Chair and two directors to the Board.

The new chair is Jim Wilson who replaces Mr Evan Rolley.

Bob Rutherford has been appointed as a new Director for three years, coming onto the Board with extensive expertise in forestry and related natural resources sciences while Alice Herbon has been reappointed as a member representing non-industrial private forest growers for a further term of one year.

Cyclone concerns

New Zealand’s Forest Industry Contractors Association says it is hugely concerned about the viability of forestry contracting businesses in the aftermath of Cyclone Gabrielle.

“I cannot see how this meets Bendigo’s goal of sustainable and resilient communities.”

Mr de Fegely said the senior management team of Bendigo also seemed oblivi-

ous to the fact that Australia is the sixth most forested country in world. “We have over 10 times the world average area of forest per person, yet we are not selfsufficient with a current import bill of $6 billion per year which could increase to $10 billion within a decade,” he said.

“Other countries could easily regard us as arrogantly selfish by being indifferent to the harm we cause forests in other countries and not skilfully utilising and protecting our own forest resources.”

The organisation says pressure has been exacerbated by the cyclone which hit New Zealand in February, but that pressure comes on the back of a tough three years characterised by Covid-19, fuel hikes, high inflation, and continuous wet weather.

Further restrictions

Firewood, fence post and specialty timber cutters will be banned from harvesting standing and fallen timber from February 5 –five months ahead of the planned mid-year cut-off. Fifty licensees, who operate under Victoria’s community forestry program, were told last May they had until June 30 this year to wrap up their operations, with some likely to gain exemptions to continue beyond that date.

Stronger and reliable connectivity in the Limestone Coast is now guaranteed with the Federal Government unveiling its $15 million investment into a national first program to boost coverage within the Limestone Coast that has brought together the State Government, six of the seven local governments, the South Australian Forest Products Association along with Telstra.

“This announcement is the last piece of the puzzle and represents a huge win for the Limestone Coast region which has received the backing of the already pledged $5.5 million by the State Government, along with financial investments from majority of the Local Governments of the Limestone Coast, Telstra and the South Australian Forest Products Association, who have all worked together to deliver this historic project,” SAFPA said Nathan Paine, Chief Executive Officer Nathan Paine said.

“Once delivered, the Limestone Coast will be the most connected up region in the nation, as 27 new

mobile base stations will be installed throughout the region, expanding the 4G coverage by almost 2,500 square kilometres,” he said.

“This a momentous day for the region and the forest industries who have worked incredibly hard with all levels of Government, corporate entities and industry groups to improve the livelihoods and public safety of those living or travelling through the regions.”

The project will improve regional equity, productivity and increase the resilience of communication services and public safety. It will be bridging the gap between metropolitan and regional South Australia, and will drive economic growth, social equity and ensure everyone in our regions has access to information and digital opportunities.

“For forestry, connectivity and quick access to data will not just improve the productivity levels of forest and timber industries but will drive the next generation of technological advancement, whether that

be autonomous vehicles, better mapping our estate, improved fire detection or increased domestic manufacturing to name just a few – essentially embracing a future of digital forests,” Mr Paine said.

“This is not only crucial for road users and public safety, but for the forest industries in the event of a bushfire. Connectivity adds another layer of bushfire protection for the South East agricultural industries, who can act quicker in their response to bushfires and minimise the risk to surrounding communities.

“This is a historic milestone for the South East, and would not be achieved without the collaborative efforts of Minister Clare Scriven with support from Member for Mount Gambier, Troy Bell and Member for MacKillop Nick McBride. Their support for this program which has been driven by Michael Patterson, State Manager for Telstra has helped bring this concept into reality. This really is a perfect Christmas gift for those living in the regions.”

The Green Triangle’s timber plantation companies continue to invest in additional aerial firefighting capacity in the region to protect its plantation estate, the broader community and the natural environment this fire season.

The Green Triangle Fire Alliance (GTFA) operated a Squirrel helicopter from the Casterton airfield for the last two fire seasons and has contracted a larger Bell helicopter, with a greater water carrying capacity, for the next three fire seasons. The helicopter has been contracted through the Victorian Government, and forms part of the Victorian aerial fleet. The GTFA’s nine

forest grower member companies are providing funding for it to be positioned in the region.

GTFA General Manager Anthony Walsh said the helicopter’s 1250 litre bucket could draw water from a variety of sources close to the fire line. GTFA members have also invested in floating collar tanks that supply water to the helicopter in areas where is limited surface water.

“This helicopter is highly complementary to the fixed wing fire bombers that operate in the region.” Mr Walsh said.

“While the fixed wing bombers carry a greater load, the advantage of a helicopter is that it can find

water in close proximity to a fire which enables very short turnaround times.

“Other aircraft may leave the region to attend fires elsewhere across Victoria and South Australia, but this helicopter will remain at its Casterton base for the 14 week service period until March 2024.”

Mr Walsh said that while the helicopter has been contracted through the Victorian Government, arrangements are in place for it to operate in South Australia as well.

The helicopter extends the industry’s extensive investment in fire management which amounts to $15 million per year. The Green Triangle plantation indus-

try collectively has 100 fire appliances with 300 trained fire fighters available, ready to rapidly respond to fires throughout the fire season.

“This helicopter provides a further layer of support to our Forest Industry Brigades that work tirelessly over the summer months to not only defend our forest estate, but to protect our broader communities,” Mr Walsh said.

South Australia did it in 2012. Victoria managed it back in 1998, Queensland in 2010, Tasmania in 2017. Only WA and NSW have held on to their pine plantations as commercial businesses.

Why have most States decided to relinquish these massive estates…and realised significant financial windfalls through privatisation?

More than 50 years ago across Australia governments took the lead in expanding plantations with financial assistance form the Commonwealth.

Softwood was a new industry, and the scale of the investment was large.

Even as the industry developed, the Federal Government maintained its primary role as the plantation grower while timber processors focused on developing their plant, technology and markets.

Fast forward 50 years, and despite the industry having fully matured, the WA Government continues to take responsibility for supplying the wood.

It is now time to question whether the industry should take this responsibility, including the privatisation of the existing trees.

The blue gum industry has been operating in total private ownership, there is no reason why the same shouldn’t work for pines.

There are good reasons for WA citizens to ask the question “is it time for the government to let go?”

Local government is not impressed.

The shires of Nannup and Boyup Brook have raised serious concerns about the fire provisions surrounding the plantations when being asked for development approval. Their concerns seem reasonable — their communities are at risk and local volunteer brigades are the front line when it comes to first attack in many areas.

At present growing trees looks like a poor investment.

This year the Forest Products Commission is predicting that it will provide an unimpressive return of -5.7% (that’s right — minus 5.7%) on our equity on the forestry business.

While this is going on, the State Government is ploughing $350 million into expanding this poor business operation. Why?

The only public information on the Government’s plans comes from its press release on September 8, 2021.

In the subsequent two years there hasn’t been a business plan, a cost-benefit analysis or even a substantial policy statement to explain the proposal.

Examination of the FPC’s website is enlightening about community activities (bike riding, painting competitions and grants) but no detail about its plans to invest $350 million.

Five years ago, Nannup Shire residents suffered from a fire emerging from one of FPC’s plantations. No consultation

The lack of a planning process means no consultation and concerns from councils, industry, community stakeholders and the public have not been heard.

Instead, the Government’s response indicates it doesn’t need Shire approval, claiming exemption under the Public Works Act.

This suggestion should have everyone outraged. All developers need to follow the rules.

Why should the Government get a free pass? Isn’t the Government a signatory to the Competition Principles Agreement?

By avoiding accountability to local government, it is gaining a significant advantage over other timber investors.

Unfortunately, although $350 million is an exciting prospect for the future

of the softwood industry, most of it is being spent in buying dirt, not planting trees.

Since the announcement land prices have skyrocketed to around $15,000 per plantable hectare, reducing the achievement from “at least 33,000ha” to 25,000ha.

Other more cost-effective methods of achieving the plantation expansion have been dismissed.

What are the outcomes being sought from this massive investment?

Additional sawlogs are urgently needed by industry now, but these new trees won’t provide any sawlogs until after 2045, so they aren’t the saviour for our current industry.

Growing these trees won’t employ many people but will face a significant fire and climate risk.

For the first four-and-ahalf years of the current State Government it had no interest in forestry.

During this time, the area of State Government-controlled plantations reduced by 4500ha.

The Commonwealth announced in December 2020 that it would allow existing plantations to qualify for carbon credits, seemingly awakening WA’s interest.

Recent announcements by Premier Roger Cook said WA will not meet greenhouse gas reduction targets, the only State to fail to achieve a reduction.

There is little wonder that the opportunity to use the offsets through forestry was

pursued with such fervour. It’s possible that the primary motive for these trees is the carbon they will sequester, not the wood.

Industry should seek independence from the Government timber monopoly. Politically expedient

The treatment of the native forest industry is one case in point, when it becomes politically expedient it was sacrificed.

Similar things have already happened to plantations.

When the dropping water table on the Gnangara Mound was causing consternation, pine trees were the scapegoat, even though the primary causes were the public and private abstraction and reduced rainfall.

The wood was sold under contract but once harvesting started concerns over Carnaby’s cockatoos emerged and there was again an outcry.

As a result, many trees (that have been sold) are now retained … leaving the industry short of timber.

It’s time for the State Government to change its methods for encouraging plantation forestry and follow eastern Australia — pass the pine plantation baton on to the private sector and, with government support, let it take control of its own destiny.

Gavin Butcher is a forester and a former Forest Products Commission director.

Ten forestry organisations have signed an accord to establish a pan sector body, called the New Zealand Forest & Wood Sector Forum.

The NZFWSF will engage on issues of common interest or concern to the national industry and act as a spokesperson and point of contact for the industry with the government and other relevant bodies where appropriate.

The NZFWSF aims to improve communication throughout the forestry supply chain to pursue and ensure continued growth and to manage issues with the interest of the whole sector in mind.

Forestry Industry Contractors Association CEO and NZFWSF spokesperson Prue Younger said the NZFWSF’s collective advocacy will be for policies that are socially responsible, environmentally and ecologically sustainable, internationally competitive, and profitable.

“The greater and longterm goal for the pan sector initiative is the desire to improve the coordination and collaboration of the sector and make it communicate, promote and improve the total value chain,” she said.

“The benefit of a common and collective ‘whole of industry’ voice, with direction and future opportunities, stands to be shared with the industry and government providing credibility that the ‘whole of industry’ is backing the content.”

The pan sector group was an outcome of a meeting held on July 26 in Rotorua. The hui provided a shared understanding of the problems and opportunities the sector faced in a 15-year crisis for the forestry industry.

“Collective discussions were had around what change would look like to generate a sustainable operating model that we don’t currently have,” Younger said. “This collective direction setting can better guide decisions for the future and define what can be done more effectively, more efficiently and potentially what can be rationalised or minimised.”

Forestry Australia has poured water on the latest bushfire research that suggested prescribed burning could make Australian forests more flammable.

Nokian Forest King F2

belts and prescribed burns are highly beneficial most of the time.

Nokian Forest King TRS 2

“Scientific consensus amongst bushfire scientists confirms that prescribed burning is a key tool in managing bushfires,” Forestry Australia Science Policy Adviser Dr Tony Bartlett (AFSM) said.

“While there is no panacea for reducing the impacts of catastrophic bushfires, prescribed burning is a scientifically proven part of the solution. Simply, reduced fuel levels in forests will reduce the severity of bushfires on all bar the most catastrophic fire weather conditions.

“Any criticism that prescribed burning can make Australian forests more flammable is misguided. Criticising prescribed burning is like dismissing the value of seat belts in cars because people still die in car accidents. Both seat

“Forestry Australia’s view is that using cool burning to reduce fuel hazards is critical to good forest fire management and very consistent with the way Aboriginal people managed these forests for thousands of years.

“Reducing the risks from bushfires in forest areas should include wellplanned, risk-based strategic programs of prescribed burning, silvicultural management, fuel breaks and track maintenance, with appropriate public consultation.

“Importantly, Australia’s bushfire management is based on decades of on ground research and lived experience. While new ideas on how to improve bushfire management are always welcome, it is essential that untested theoretical concepts are carefully considered in light of the existing knowledge on how wildfires behave in Australian forests.”

“Increased investment in prevention and preparedness is essential to achieving enhanced management of fire and to address the increased risk of more fre-

quent and severe bushfires.” Dr Bartlett added that “the claim that further investment in drone technologies can contain bushfires has not been proven.”

Western Victoria’s hardwood plantation sector has engaged respected regional advocate and communications specialist Liz McKinnon to act as its shared external affairs manager to coordinate communication with government and community stakeholders.

Global forest companies

Australian Bluegum Plantations (ABP), Midway Limited and New Forests, who control about 90 per cent of western Victoria’s hardwood (eucalyptus globulus) estate, have engaged the recognised government figure to manage its aligned external affairs.

The contract role will coordinate strategic communication, government relations and policy development, aimed to enhance and support the work of existing industry advocacy groups.

Ms McKinnon has extensive industry experience as the founding CEO of the Green Triangle Forest Industries Hub prior to taking on the role of South Australia’s first Cross Border Commissioner, acting as an advocate for the state’s border communities.

She joins the hardwood collective with more than two decades experience in media and communications, including senior management experience in government relations and stakeholder management.

With growing interest from investors and government, ABP CEO Russ Hughes said the companies recognised the value of engaging a “communications specialist” to promote the hardwood sectors focus on plantation investment and domestic value-add, including trials to create new hardwood struc-

tural timber products and use of hardwood in the creation of biofuel.

Mr Hughes said a key emphasis of the role was building closer partnership with the broader agriculture industry in western Victoria, promoting the value of the carbon market and the sector’s sustainable management practices.

“Liz has worked across jurisdictions dealing with complex policy and challenging stakeholder management environments. She has a strong understanding of the industry’s strategic direction and business operations ensuring she is well positioned to promote the hardwood sector’s future, building trusted relationships, and recognising areas for new partnership,” Mr Hughes said.

Midway Limited managing director Tony McKenna

said Ms McKinnon would be responsible for identifying, managing, and facilitating coordination of key issues, with an initial focus on investments in the Geelong, Otway and Heytesbury regions.

“Our relationship with the media, broader industry, government, and community stakeholders is important to growing our business. This collaboration will support a more consistent and transparent voice for the plantation hardwood sector in western Victoria,” Mr McKenna said.

New Forests global head of asset management Matt Crapp said a primary focus of the external affairs role was community education, supporting greater understanding of the sector’s sustainable management practices and focus on new domestic-value add.

“Liz will play an important role managing the coordination of messaging for our three companies, reflecting how we can better align our public engagement to enhance the economic, social and environmental understanding of the role our sector plays not only to the local economy but the nation’s economy,” Mr Crapp said.

Ms McKinnon has been employed in the role as a contractor via her business EHM Advisory.

Since the mid 60s, Ensign has been designing and building some of the world’s toughest log forks and supplying them to customers all over Australasia. Clamps, kickers, pivots, locks, high lifters… you name it, if it’s a feature that’ll help you pick up and put down stuff easier, faster or safer you can guarantee we’ve already built it.

So whether you're in the market for the biggest and baddest or something a bit more modest give us a call and we’ll build your perfect log fork.

Forestry Australia

President Dr Michelle Freeman welcomed the Federal Court’s Decision to uphold a Regional Forest Agreement in New South Wales as did Forest and Wood Communities Australia (FWCA) and the Australian Forest Products Association (AFPA).

“Commonsense has prevailed … native forestry can have a strong future in Australia,” Dr Freeman said.

“Forest managers, growers, scientists and workers will breathe a sigh of relief that the challenge by the North East Forest Alliance to the Regional Forest Agreement covering North Coast NSW native timber harvesting operations has been dismissed.

“Our Regional Forest Agreements (RFAs) time and time again have proven to be a successful way of sustainably managing Australia’s forests for all their values, and the Federal Court has confirmed this today.

“In public native forests that are available for timber harvesting, our RFAs have protections in place for conservation and heritage. This adaptable multi-layered approach ensures key forest types and biodiversity are managed and conserved across the landscape.

“The findings of the Federal Court … confirms that RFAs achieve what they set out to do, with Justice Per-

ry confirming the Court’s view that the RFAs provide an alternative mechanism through which the objectives of the national environmental laws can be achieved through a rigorous framework agreed by State and the Federal governments.

“It is clear, RFAs strike the right balance between the sustainable harvesting of timber and providing rigorous environmental protections.

“Our forestry sector, its workers, families and communities that depend on it, can now move on with certainty in their future.

“Importantly, Australia’s entire forestry sector can keep on doing what it does best; sustainably managing our forests for their environmental, social, cultural and economic values.”

AFPA NSW CEO James Jooste said that the decision was a vindication that sustainable native forestry operations in NSW are well governed by the federalstate regulatory framework.

“The Federal Court decision is a vindication for the sector and the contribution it makes to the economy, environment, communities and society in NSW, Australia and internationally. It’s also a message to activists that the RFA framework stands, and the native forestry sector has a right to operate without their irresponsible legal meddling

in the daily lives of timber workers and their families.

“The decision is also a major win for the climate, easing cost of living pressures and sovereign capability with so many renewable, sustainable and essential products created by the NSW native forestry sector.

“I call on the Minns Government to continue recognising the importance of native forestry to the state and to work with us as plans progress for a Great Koala National Park on North Coast. Without the sector, we face a future of more timber and wood fi-

bre imports from countries without Australia’s high regulatory standards, fewer quality job opportunities in our regions, increased cost of living and a stalled progression on emissions reduction.

“The industry will now continue to get on with the job it’s there to do.”

Forest and Wood Communities Australia said in a statement that the decision of the Australian Federal Court – throwing out a case brought forward by extremist “environmental” group North East Forest Alliance (NEFA), was a welcome victory for timber commu-

nities all over New South Wales.

In making the ruling, Federal Court judge in charge – Justice Perry, noted that RFAs “are an alternative mechanism to deliver the EPBC requirements through the states” and that “whatever happens after the judgement will be a political decision, not a legal one”. FWCA Executive Officer Mick Harrington said that anti-rural and anti-forestry tendencies of groups like NEFA are now plainly in the view of everyday Australians with the Regional Forestry Agreement.

The decision in the Federal Court was a definitive statement on the legal and administrative arrangements supporting our sustainable, renewable native timber forestry industry in New South Wales, the Australian Forest Contractors Association said.

Welcoming the result AFCA General Manager Tim Lester said the Court’s findings confirmed that Regional Forest Agreements between the Commonwealth

and States support the protection of environmental assets while allowing for this sustainable industry to operate.

“The Federal Court has confirmed that RFAs provide an alternative pathway for delivering environmental protection of forests and biodiversity rather than creating a regulatory void,” Mr Lester said.

“The Regional Forest Agreements are based on striking the balance be-

tween environment responsibilities and the needs of our society and community. RFAs improve management of the forest and therefor biodiversity and forest health by creating the space for a well-regulated, efficient and effective industry that optimises forest functioning, the protection of high value environmental assets and productivity now and for future generations.

“Native hardwood timber is critical as a source of

power poles, wharf timbers, high quality architectural features and are increasing being used in mass timber construction to us lower the carbon footprint of the built environment.

“As an industry we provide a win-win solution that manages and maintains forest landscapes, enables biodiversity to flourish and provides the best integrated climate and emissions solution available today. This industry is also incredibly

for creating sustainable and high quality jobs in rural and regional areas, supports local economies and is quite literally helping to build the nation.

“We welcome the judgement that confirms the regulatory environment is robust. Questions should now be asked about the role of the Commonwealth in funding for both sides of this case and whether that is the best use of taxpayer dollars,” Mr Lester said.

As leaders in the timber sales industry, we pride ourselves in having the most knowledgeable customer service staff in the business.

We have always been in favour of applying the highest standards to our industry.

According to the Forest Industry Advisory Council (FIAC), who were commissioned by the Australian Government to prepare a document on the state of the timber industry, the entire industry could use better training if we are to compete on an international stage in the future.

As global technology advances further, the timber industry will need a workforce that is equipped with the skills to handle both current and emerging positions. The industry will have to increase efficiency, productivity and innovation. This will require a skilled and flexible workforce that is able to meet the demands of the industry.

The concept is simple: in order for the Australian timber industry to maintain or increase its competitiveness on a global and domestic scale, training

and education are going to have to rise accordingly.

As in any industry, the timber industry is reliant upon the skills of its labourers, managers, engineers and executives. The sector requires expertise in a wide range of jobs, including transport, forestry, engineering, timber harvesting and manufacturing. it is also important that the fields of market analysis and scientific research continue to grow with the industry.

It is important that the timber industry begin to identify the skills that will need to be developed in the future, both short-term and long-term. It will be important to implement effective training and recruit people who can take the industry into the 2020’s and beyond.

In November 2023, the employment data for Agriculture, Forestry & Fishing in Australia stood at 308.982 persons. This was an increase from the previous

figure of 298.269 persons reported in August 2023. The recorded data reached its peak at 453.668 persons in November 1990 and reached its lowest point at 279.973 persons in August 2013.

Presently, an increasing array of universities and TAFEs throughout Australia are expanding their range of undergraduate and postgraduate courses focusing on topics related to the for-

estry industry. By 2023, six universities and five TAFE courses have established pathways for forestry training.

Forestry Science degrees and VET are not the only educational requirements of the timber industry. There is a high demand for those who can manage value chain relationships, implementation of technology and logistics. In addition, advances in technology

are requiring workers with the ability to operate more high-tech equipment, especially in the development and production of more innovative products.

In April 2023, the Queensland government revealed that Timber Queensland secured a funding application of $980,000 for a one-year period to launch a program titled ‘Canopy,’ which is a training and career hub for the forest and timber industry.

Clarissa Brandt, Strategic Relations and Communications Manager at Timber Queensland, clarified in a press release that the hub aims to bring together industry stakeholders, employers, training institutions, and employment agencies. The goal is to provide training, career education, and work experience opportunities for school leavers, unemployed individuals and those seeking to enhance or retrain their

For you and for us, it is important that the timber industry is able to meet the demands for future efficiency, innovation and delivery of timber products. Otherwise, Australia may lose ground in the constant battle for supremacy in the

Professor Francis E Putz

and Dr Claudia Romero

Logging typically degrades tropical forests. But what if logging is carefully planned and carried out by welltrained workers?

While public campaigns to end logging dominate both the popular press and highprofile science journals, a transition from “timber mining” to evidence-based “managed forestry” is underway. Given poor logging practices are likely to continue in about 500 million hectares of tropical forest, efforts to promote responsible forestry deserve more attention.

In our new report we recommend five ways to improve tropical forest management. This work was funded by the United States Agency for International Development (USAID) and the US Forest Service International Program.

Fortunately, these practices are compatible with management for non-timber forest products such as fruits, fibres, resins and medicinal plants, as well as biodiversity conservation. They would also reduce carbon emissions and increase carbon removal in cost-effective ways.

Five ways to improve forest fates

Research shows biodiversity is mostly retained in well managed, selectively logged forests. Especially if hunting is controlled and lower-impact logging practices are employed, carbon stocks remain high.

Harvesting 5–10% of the trees does temporarily reduce the total amount of carbon stored in the forest, but these stocks recover quickly if damage to young trees and soils is kept to a minimum.

Here are five ways to smooth the transition from “timber mining” and clearfelling to managed forestry featuring selective harvesting:

1. Improve logging practices. Planned harvest operations – carried out by trained workers suitably

rewarded for the proper application of lower-impact logging practices – result in less soil erosion, fewer worker injuries, and half the carbon emissions of conventional logging.

2. Waste less wood. Workers can be trained to maximise the recovery of wood from harvesting and processing. For instance, if trees are felled properly, stumps are low and fewer logs are broken.

3. Allow time to recover.

Sustaining timber yields often requires leaving forests alone for longer between harvests (reducing harvest freqency) and/or limiting the amount that can be harvested per unit area.

Harvest intensity (that is, the numbers of trees or volumes of timber harvested per unit areas) can be reduced by increasing the distance between harvestable trees or by increasing the minimum size of trees that can be felled.

Either restriction reduces short-term profits, but ensures there will be timber to harvest in the future. Fortunately, these changes also reduce carbon emissions from managed forests, for which there should be compensation from carbon market investors seeking to compensate for their own emissions.

4. Protect young trees. If we protect and foster the growth of small trees, they will grow to a suitable size for the next harvest. This

is especially important in forests that have been disturbed by previous logging. Liberating the future crop from woody vines (lianas) is a relatively cheap way to augment future timber yields and double the rate at which carbon dioxide is removed from the atmosphere.

5. Plant more trees. In areas that lack natural regeneration of commercial tree species, enrichment planting can help. If these planted trees are regularly tended for several years, growth and carbon sequestration rates can be substantial.

Managed forestry has multiple carbon benefits

The carbon benefits of all five mechanisms described here are additional. That means they wouldn’t have happened in the absence of the intervention.

So carbon markets should support the transition away from exploitative timber mining once responsible forest management is accepted as a legitimate land use.

Managed forestry also creates jobs for professionals and supports a stable workforce. In contrast, carbon projects based on stopping logging run the risk of sending loggers elsewhere.

The long-awaited transition from tropical forest exploitation to responsible forest management requires support from governments, the private sector, and society as a whole.

Two new reports have been released by the Tasmania Forestry Hub outlining opportunities to support silvicultural interventions that could deliver additional saw log production in the next 10 years.

Governments will need to enforce their laws. Failing to do so will starve their economies of tax revenue. Meanwhile the glut of illegal timber keeps log prices at a rock bottom low.

Forest industries need to recognise the benefits of investing in all aspects of forestry including the maintenance of productive timber stands.

Society also needs to support forestry by ensuring the supply of well-trained young foresters. Unfortunately, the common misconception of forest management as a synonym for forest degradation reduces the appeal of the profession to young environmentalists.

The closure of so many undergraduate forestry degrees outside of Brazil, coupled with increased focus on plantations rather than natural forests, makes it hard to find trained and motivated people to support the transition to responsible forest management. But it will be worth the effort, because responsible forest management promises financial, environmental and social benefits.

Professor Francis E Putz is a newly appointed research professor at UniSC in the Forest Research Institute.

Dr Claudia Romero is a Professor of Tropical Forestry and Director of the Tropical Forests and People Research Centre at the UniSC.

-The Conversation

Australia faces an ongoing shortage of structural grade timber for use in the construction of houses to meet the requirements of a population which will grow to 40 million by 2050. Longer term policy settings are in place to encourage the establishment of new plantations with the aim of growing more timber to meet those requirements. However, it will be at least thirty years before additional wood is available from new plantations.

There are potential forest management solutions which could be introduced now which could result in increased sawlog production from the existing forest estate. However, in some cases those solutions are not commercially viable. There is a strong rationale for Government intervention, in the form of structured incentives, to help forest owners realise these opportunities.

The analysis undertaken for this report has demonstrated that there are opportunities for Government funded incentives to support short to medium actions which can deliver up to 650,000m3 per year of additional sawlog production by the mid-2030s, which otherwise would not be commercially viable. This represents an increase over current sawlog production of about 7 per cent.

Importantly, the proposed actions (conversion of hardwood plantations from short to long rotation and active silvicultural management of regrowth native forests) will deliver important and tangible environmental benefits.

ENHANCE PRODUCTIVITY AND EFFICIENCY WHATEVER THE CONDITIONS.

Demanding environments call for a machine that’s up to the job. And when tackling the forest, there’s none more capable than John Deere’s Tracked Harvester. Available in 5 different models with differing levels of features and horsepower, there’s one that’s right for everyone.

They’ve been designed with proven components to withstand rugged tasks such as steep slope logging and swamp logging. And they’re packed with innovative features including Intelligent Boom Control for faster, more precise operating, and Timbermatic maps and TimberManager to take the guesswork out of effective decision making.

Thoughtfully designed. Built tough. John Deere’s Tracker Harvesters have everything you need to win in the woods.

HARD WORKING FOREST MACHINES FOR EVERY DAY OF THE YEAR.

Logset is set to release new map software in 2024.

The result is a unique map software which takes further advantage of the machine’s information flow and provides the operator with a quick overview of tree species, timber quantities as well as locations.

Logset’s current digital portfolio which includes machine positioning, production follow-up and machine monitoring, gets a powerful complement through the new map software and streamlines and supports the everyday life for their customers.

John Deere is delivering enhanced customer solution for self-repair to enable customers to remotely download secure software updates directly to their equipment

Through its Equipment Mobile app, it will enable customers to remotely download secure software updates directly to embedded controllers on compatible 4G-connected John Deere equipment. This update follows the March 2022 announcement that expanded the availability to purchase Customer Service ADVISOR directly from John Deere.

New department

Komatsu Forest is focussing on sustainability and innovation, creating a development department for electrification.

Stina Drotz stepped into the role of General Manager of the department, whose main mission is to solve the challenges of electrification of Komatsu forest machines together with industry stakeholders.

Spare part finder

Komatsu Forest has made it easier to find the right spare part with its spare parts catalogue now includes all models of Komatsu Forest machines.

This is something Komatsu Forest have taken on board in the latest update of the spare parts catalogue. In addition to expanding the catalogue so that all machine models are represented, a new filter has also been introduced, which greatly simplifies the search.

Mandy Parry-Jones

Technology is everywhere, and it is nowhere more obvious than at ForestTECH where more than 250 delegates attended the conferences from places near – Australia, New Zealand, and far – Chile, South Africa, the US, Sweden, Finland among many others.

While some may have attended remotely that does not diminish the importance of the conferences’ or topics’ relevance to resource managers, inventory foresters, GIS specialists, tree crop manager and those involved in forest establishment.

As well as the conference in Melbourne, which was held in late November, there was an exhibition and conference workshops. An earlier conference was held in New Zealand.

Conference organisers FIEA stated that the key objectives were:

Mechanised Establishment & Silviculture

Lessons from two planting seasons in Victoria using a fully mechanised planting operation. Results, lessons and payback from a forest owner’s and contractor’s perspective

A new concept in mechanised planting. Results from the first Australasian trials by Pan Pac Forest Products using the Swedishdesigned and produced PlantMax mechanised planter

· Results from operational trials using remotecontrolled mechanised tree pruning

Using smartphone and drone collected data to improve the quality and productivity of Chilean mechanised thinning operations

· Using vertical farming systems (growing crops in vertically stacked layers) to meet ambitious planting targets.

Forest Inventory/Remote

Sensing/Data Capture Pre-assessment thinning inventory using dronebased LiDAR

· Monitoring forest estates for fast assessment

and recovery from fire, storm or disease

High-value, low-cost satellite imagery options available to AU/NZ foresters Australasian designed and built solar-powered stratospheric aircraft a game-changer for collecting frequent, high-resolution aerial data

The current state of satellite information in forestry – how collected data is travelling the globe

· Operational use of drone-based LiDAR for preharvest inventories in eucalyptus plantations.

Two presentations caught our attention: Steve Critchlow, Group Managing Director of Critchlow Geospatial (New Zealand) who spoke on High-value, low-cost satellite imagery options for AU/NZ foresters.

Forest change and climate change was the topic for Hamish MacPherson Busi-

ness Improvement Manager for PF Olsen in New Zealand.

High-value, low-cost satellite imagery options for AU/NZ foresters

Mr Critchlow is a founder and managing director of the Critchlow Group which includes Tula Geospatial and National Mapping Limited. He’s an experienced surveyor with a computer science qualification that led him to mapping New Zealand transport, land use, and other infrastructure over the last 30 years.

Critchlow Geospatial now represents satellite imagery providers from the US, South Korea, China, India, and Uruguay, with collectively hundreds of satellites and sensors.

For foresters satellite imagery allows them to operate more sustainably by reducing the need for physi-

cal survey and data collection on the ground which is expensive both in terms of time and cost. With satellite imagery it is possible to achieve the necessary data in a timely and automated manner.

However, as Mr Critchlow stated in his introduction understanding the formulas behind satellite imagery, pricing and licencing is a steep learning curve, as he personally discovered.

“Actually, what I hope you leave with today is an understanding of just what those formulas are,” he said during his presentation. “And actually, they’re not that hard. I have made a spreadsheet.”

He went on to detail his own involvement with satellite imaging companies from around the world and how he became part of that technology.

Central to his talk was things that should be considered when purchasing or using satellite imagery such as the licence types and image resolution saying that you don’t need to spend money on really high precision imagery in most cases.

His spreadsheet was shown near the end of the presentation detailing the satellite imagery marketplace in November 2023 which showed resolution versus cost; these costs varied from $0 km-2 for 10m Sentinel-2, right through to $40 km-2 for the 30cm GSD at nadir but the spreadsheet indicated that sweet spot was at the $20 km-2 mark for the 50cm KOMPSAT-3 HD, KOMPSAT-3A, EasrthScanner.

Mr Critchlow also suggested that another option to purchasing high-cost imagery was resolution enhancement processing which is available at a low cost.

● 1 - Asia Pacific Remsoft account manager Carolyn Glasson.

● 2 - Business development manager at areometrx Schalk van der Westhuizen.

● 3 - Locus client relationship manager Chris Morris with Locus business development director Ruby Donaldson.

● 4 - Forest and Wood Products Australia’s Emmy Peterson.

● 5 - Asia Pacific Trimble Forestry sales manager Aaron Ford

● 6 - Director of research and development at Swift Geospatial James Saunder with Nyasha Mureriwa, senior project manager at Swift Geospatial.

Dwayne Kerrison came to an important realisation early on in his timber harvest and haulage career.

The operator of Orana Enterprises discovered that cheap machines were only cheap to purchase.

“In the long run, high maintenance costs and retained value aren’t as good with some of the cheaper gear. They can end up costing more,” he said.

Orana Enterprises is a Tasmanian-based business that specializes in timber harvest and haulage.

As a family-owned local business, it provides services to both customers and landowners in the Tasmanian forest industry.

Orana’s services include the harvesting and hauling of timber, through to the unloading of the timber at some customer sites.

Orana’s team is currently working on an essential project that involves native forest thinning.

This active forest management and climate adaptation tool is crucial to support forest health and resilience.

The process of selective removal of individual trees is aimed at improving or maintaining the ecological value of the forest.

“They have five sites doing this kind of work, and at these operations they use a

feller buncher, harvester, skidder and log loader,” Dwayne said.

Dwayne said that they have owned other wellknown brands of skidders. However, the majority of the skidder fleet is now Tigercat with 2x 630D, 1x 632E and 3x 632H (latest model) skidders which Orana has been very happy with.

According to Dwayne, Orana’s decision to upgrade to the latest Tigercat Skidder 632H was necessitated by an older skidder that had reached the end of its serviceable life.

Considering that they were already familiar with the Tigercat range and had a large fleet of Tigercat equipment, it was an easy decision to purchase the latest model skidder.

The outdated skidder was on the verge of causing production issues and delays in the process. Dwayne emphasized that partnering with Onetrak was a smart business choice due to their extensive availability, excellent deals, and reliable backup and support.

“Our initial contact with Onetrak was around 2014/15 when we required a feller buncher and a couple of skidders to complete a high production plantation hardwood job,” he said.

“Onetrak and Tigercat provided us with excellent

● Orana Enterprises’ new Tigercat Skidder 632H which replaced an older skidder that had reached the end of its serviceable life.

solutions as we began to transition a large portion of the fleet to purpose-built products, moving away from excavators with attachments. We were, and still are, very pleased with their services,” he said.

Orana have always been aware of the reputation and superiority of Tigercat equipment within the forestry industry.

Dwayne said that starting out they didn’t have enough work or money to justify the capital outlay for a Tigercat machine initially. However, experience in the high production hardwood plantation job that commenced in 2015 proved the overall value of Tigercat

Wildfire is proving to be one of the greatest challenges facing foresters, landowners, governments and environmental organizations in the 21st century.

The summer fire season over the last several years in North America has devastated millions of hectares of forest land, destroying wildlife habitat and carbon sinks, while releasing massive amounts of carbon and particulate matter into the atmosphere.

Excessive fuel build-up on

the ground is having a devastating effect.

Tigercat recently released a mulching head designed to mount on a Tigercat LX830E carrier. This machine can tackle steep slopes and operate within dense stands to reduce build-up of woody debris as a mitigation measure to guard against future wildfires.

The new 4161-15 head has a 1,5 m (59 in) mulching swath, 130 degree wrist pivot, and a pin-on rake for added utility. Like all Tigercat mulching heads, it

is strength-to-weight optimized and fitted with large bearings. Many of the components including the bearings, sprockets, seals and timing belt are common to the Tigercat 4061 series mulching heads and thus field proven. Hydraulic hoses are routed through the open tip boom into the top of the wrist, providing excellent protection. The replaceable wear liner is field serviceable. Removable covers allow easy access to all service points.

equipment.

Dwayne said as they gained experience in those early years, they soon realised that the “cheap machines were only cheap to purchase.

In the long run, high maintenance costs and retained value aren’t as good with some of the cheaper gear. They can end up costing more.”

“We have harvesters that have been working eight years already and still on the front line, basically doubling the life expectancy of the cheaper machines. They’ll easily wear out two harvester heads.

“Our operators especially love the H model skidder. It is roomier, with turnaround seat controls, fantastic vis-

ibility and heaps of power which they love,” said Dwayne.

The biggest change in the new model is the cabin, maneuverability, low noise and comfort, which is greatly appreciated by Orana’s operators.

“Our experience with Onetrak and Tigercat has been fantastic. They are wonderful to work with, responsive to the needs of their customers and willing to have tough conversations when necessary.

If issues arise, they are quick to resolve them in a timely and effective manner, understanding the urgency of getting the job done and getting the machine up and running quickly. In addition, Tigercat’s Steve Green offers exceptional technical support in Australia,” Dwayne said.

“Dave Hazell, the Managing Director of Onetrak, is accessible if required and capable of making swift decisions. We also have other contacts within Tigercat if necessary, which makes a big difference.”

Onetrak is the official dealer for Tigercat equipment in Australia. Visit www.onetrak.com.au or call 1300727 520 to get in touch with Onetrak and the team.

Acompact track loader is one of the most versatile machines a contractor can own.

Whether as support equipment in a larger fleet or the main workhorse for an owner/operator, a skid steer and compact track loader are two of the most versatile machines a contractor can own. But what is the right loader arm and platform for each application? Contractors can follow this quick guide to set them on the right path.

Loader arm – radial or vertical: Radial lift machines are best served for ground-engaging applications as they feature better breakout, digging and prying forces. As the travel path is most similar to an arc, this configuration provides greater reach at midranges, which makes it ideal for loading and unloading

off of smaller vehicles or platforms, such as pickup trucks. Visibility also tends to be a bit better with radial configurations. Vertical lift machines generally offer greater lifting heights, greater reach at full height and slightly higher lifting capacities. The arm design keeps the load closer to the cab for added stability and capacity. The arm design also allows for more stable material handling.

Platform – tyres versus tracks: Tracked machines provide an incredibly stable platform that improves everything from grading to attachment use. The primary advantage is lower ground pressure and stable operation over uneven surfaces, as the tracks provide more contact with the ground than four independent tires. Tyred machines – the traditional skid steer loader

– give the operator greater traction and maneuverability on paved surfaces. Tyred machines are quicker and have faster top travel speeds. Tyres are also more ideal in applications where tight turning is going to be taking place. While tyres will generally wear at a faster rate than tracks, tracks are more expensive to replace. Skid steers are typically less expensive than comparable compact track loaders.