Atotal of 33 fire events were averted this fire season in the Green Triangle due to the sophisticated work of Australia’s largest network of smoke detection cameras with plans progressing to expand the infrastructure to cover more blackspot areas for future seasons.

The Green Triangle Fire Alliance’s (GTFA) network of 14 cameras, provide a 360-degree scan of the landscape 24 hours a day seven days a week, using AI technology, to monitor 1.3 million hectares of land, across 10 local government areas.

Operated by AI specialists Pano AI Pty Ltd, the cameras acted as the first point of detection before the human eye on several occasions and positively identified 24 planned fuel reduction burns for a total of 57 detections for the season. This was in addition to the detection of thousands of private permit burns late in the season.

South-west Victoria’s seven cameras, which are located at Dergholm, Lake Mundi, Digby, Dartmoor, Rennick, Nelson and Hicks Hill, near Macarthur, successfully captured 14 unplanned blazes. South Australia’s seven cameras are located in Mt Benson, near Robe, Elad Road and The Bluff in Wattle Range, Furner, Mt Burr, and Carpenters Rocks.

Green Triangle hardwood plantation companies ABP (Australian Bluegum Plantations), SFM and PF Olsen are among nine GTFA member companies which invested

in the new technology to provide rapid detection and real-time intelligence to inform on-the-ground decision making for optimal use of fire resources.

SFM chief operating officer Mike Lawson said the cameras had brought a new level of sophistication to fire management since being installed three years ago, supporting greater protection of the plantation estate, surrounding landholders, the broader environment and community.

“These cameras have been instrumental in strengthening fire management across south-west Victoria and importantly we know that year on year these results are going to continue to improve as the AI becomes more sophisticated,” Mr Lawson said.

“The cameras have been installed in blackspot zones in CFA (Country Fire Authority) Regions 4, 5 and 17 that were not well covered by traditional fire towers. The results, which are fed live to forest managers and fire authority digital devices, have been impressive with the cameras detecting fire up to six minutes before another detection source.”

PF Olsen GT regional manager Andrew Matheson said the camera data, which was identifying fire up to 30km away, was shared directly to Victorian fire management authorities to support informed decision making and quick firefighting responses.

“Fire detection in the region has been further strengthened by the planta-

tion industry’s subscription to the Ororatech satellite fire detection service which is particularly useful overnight to support identification of overnight lightning strikes and burnt-out vehicles,” Mr Matheson said.

“Matched together, this AI-camera and satellite technology provides an additional layer of coverage to ensure we are protecting our hardwood plantation estate, our agricultural neighbours and the broader community and environment.”

ABP general manager operations Darren Shelden said it was critical to invest in more cameras to support the extensive fire tower network and mitigate the increasing risk of bushfire due to climate change.

“Plantation companies have fully funded all the cameras in south-west Victoria. Four locations have been identified as new camera sites, including CFA towers at Mount Rouse and Mount Dundas and new sites at Tyrendarra and Nareen,” Mr Shelden said.

“We are seeking to attract government support for this broader roll-out which will take the camera network to 11 in south-west Victoria.”

Green Triangle Fire Alliance manager Anthony Walsh said the alliance looked forward to continuing strong collaboration with CFA and Forest Fire Management Victoria to best use the new technology.

“The Green Triangle Fire Alliance is proud of these excellent results and the outstanding effort of our

Applications are now open for research projects that will advance research and innovation in Australian forest and wood products.

The first of four $5 million national open calls for forestry research projects are aimed at establishing new high-value wood products, developed in Australia.

more than 300 trained forest firefighters who work tirelessly alongside state agencies to keep our assets and broader region safe,” Mr Walsh said.

“Our industry helicopter and new investment in floating collar tanks to supply water in areas with limited surface water have further increased the level of aerial firefighting capacity in the region, mitigating the risk of a large fire spreading.”

Pano AI is the leading provider of bushfire detection technology in Australia, operating 28 stations overseeing more than 2 million hectares of the country’s forests, farmland, and renewable energy sites. Andrew Prolov, head of Pano AI Australia GTM, emphasized the growing importance of new technologies, such as AI and ultra-highdefinition cameras, in bolstering Australia’s defenses against increasingly intense bushfire seasons.

“Our cameras go beyond detection and alerting authorities,” Mr Prolov said.

“They provide crucial imagery and information about the fire’s location and movement, empowering landowners, first responders and fire agencies to make informed decisions to determine the best response strategy,” he said.

“We provide an additional layer of intelligence for the Green Triangle, contributing to the protection of lives, livelihoods, infrastructure, and the environment from the devastating impacts of bushfires.”

The funding is part of the Federal Government’s grant agreement with the University of Tasmania to establish and manage the $100 million Australian Forest and Wood Innovations (AFWI). The annual national open calls are open to applications from all Australian-based researchers supporting the forest and wood product industries, and is not limited to the AFWI research centres.

Minister for Agriculture, Fisheries and Forestry, Murray Watt said the open call will allow industry and researchers to undertake projects that will make a positive impact on Australia’s forest and wood product industries.

University of Tasmania Deputy Vice-Chancellor (Research) Professor Anthony Koutoulis said this funding presents an opportunity for researchers to develop novel and impactful ideas that support the sustainable production of wood products.

“AFWI is committed to fostering innovation and empowering researchers to enhance the research capacity and capability in the forest and wood products sector now and into the future,” he said. “Encouraging collaboration between researchers and industry is vital for impactful projects.

“With robust industry support and anchoring research on what really matters, research outcomes become readily applicable."

Project applications close on 12 July, 2024. For further details refer to the relevant Grant Guidelines and Application form template on the AFWI website.

Issue 3 – Volume 35

Established 1991

News 3 - 12

Silviculture 13

Forest management 14

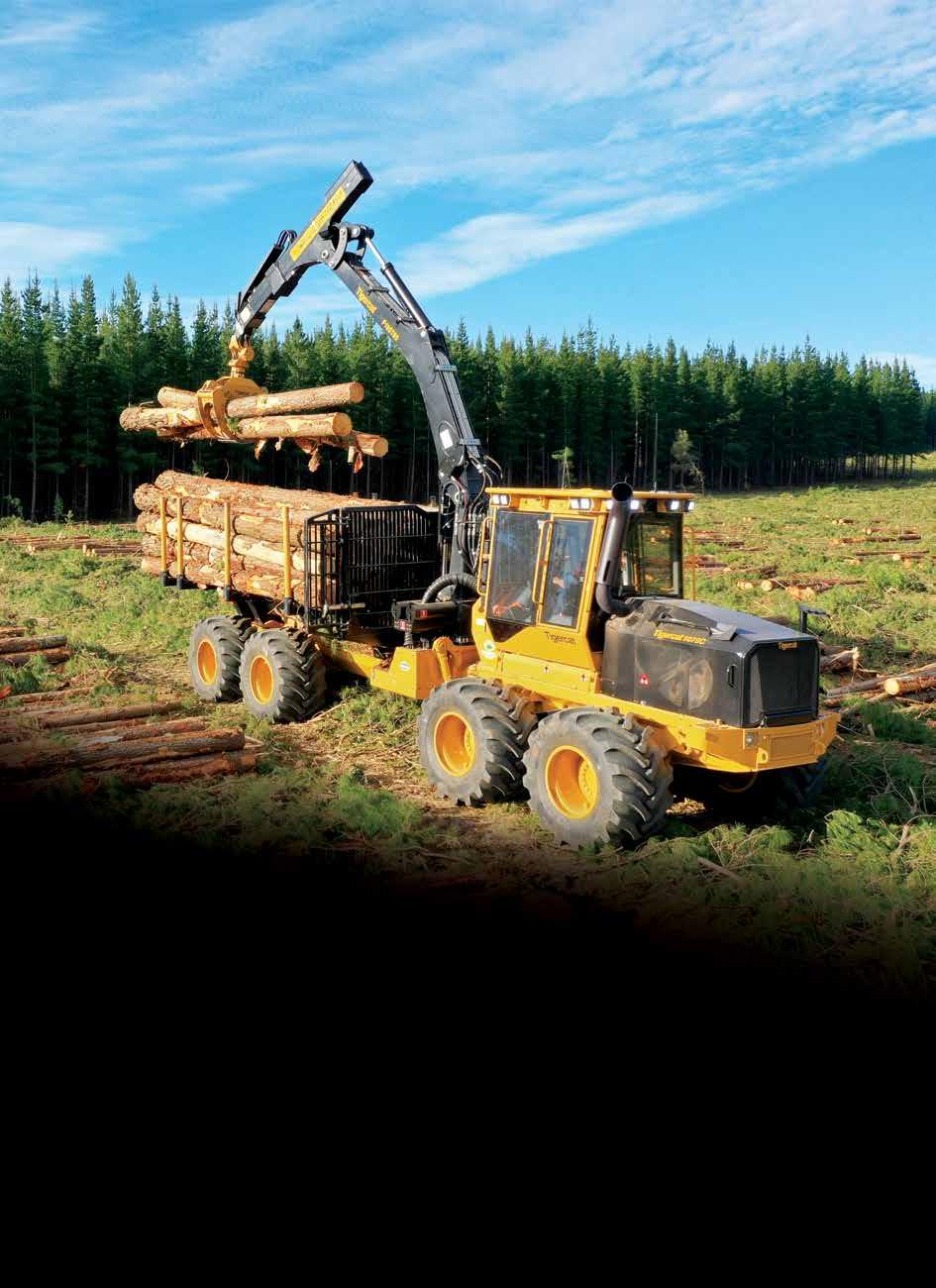

Harvesting heads 18-19

Forwarders 21-22

Training 19

Harvesters 20 - 21

Haulage 26

Mill profile 28

Front Cover:

Triple H Contracting's Komatsu 895.2 at work in Tasmania. Story Page 22.

Publisher and Chief Executive:

Hartley Higgins

General Manager: Robyn Haworth

Editor: Bruce Mitchell

b.mitchell@ryanmediapl.com.au

Adelaide Office: (08) 8369 9521

Advertising: Jon Andryciw

j.andryciw@ryanmediapl.com.au

Adelaide Office: (08) 8369 9517

Creative Services: Sudapa Rattanonda

Publication Design: Sudapa Rattanonda

Trader classifieds:

Jon Andryciw

Adelaide Office: (08) 8369 9517

Subscriptions: subs@forestsandtimber.com.au

Adelaide Office: (08) 8369 9522

Subcription rates

One-year (6 editions) $44.65

Two-years (12 editions) $77.65

Accounts: ar@winetitles.com.au

Phone: (08) 8369 9500

Postal Address:

630 Regency Road, Broadview South Australia 5083

Phone: (08) 8369 9555

Fax: (08) 8369 9501

Melbourne Office: Suite 2262, 442 Auburn Rd, Hawthorn VIC 3122

Phone: (03) 9810 3262

Website www.timberbiz.com.au

Printed by Lane Print, Adelaide, SA

Conditions

Gippsland forestry workers displaced by the Labor government’s forced closure of the native timber industry have had their compensation payments frozen.

The Allan Government agreed to pay native timber worker and Heyfield resident Jeff Coster due compensation in February.

The deal has been stalled, and no payment has been made – despite the government issuing a test payment of 20 cents into Jeff’s bank account.

Seeking a resolution, The Nationals Member for Eastern Victoria Melina Bath called on Labor in state parliament to honour its commitment and pay the due compensation without delay.

Ms Bath said, “After working in the industry for 30 years Jeff lost his livelihood as a direct result of Labor’s appalling decision to close the timber industry - a solution must be found.

“Over the past month I and The Nationals, along with the Costers have had discussions in good faith with the Minister for Agriculture and her Forestry Adviser, despite sympathetic noises, no payment is forthcoming.

Ms Bath said that the Costers were not alone, forestry workers operating under

a subcontracting arrangement face the same unacceptable predicament.

“The Allan Government is morally obliged to recognise time, toil and investment in the industry by subcontractors,” said Ms Bath.

“Labor’s hastily designed forestry compensation scheme failed to consider the federal tax implications, resulting in many workers being either rejected or left to pay huge tax bills.

“Some subcontractors who received a payment have now shockingly been asked to repay their compensation back to the state government.

“The Labor Government was so fixated on fast tracking the closure of the industry it hasn’t considered the ramifications of applying the redundancy payments to subcontractors.”

Ms Bath said the stalled payment is a bitter pill for Jeff to swallow given he has used his expertise to fight every major bushfire over the past 30 years.

“Jeff spent decades protecting forests, properties, and lives from the ravages of bushfire– it’s time the Labor Government delivered support to him and his family.

“The Allan Labor Government agreed in writing to pay due compensation to all

forestry workers – it must end the stalling and create a pathway to provide the money owed to impacted subcontractors.

“Labor’s bungling of the forestry workers compensation scheme is evidence it has abandoned workers and can’t manage money.”

To say that the money spent on the Green Triangle’s network of smoke detection cameras was well spent is an understatement.

That at least 33 fire events were averted in the most recent fire season is nothing short of amazing.

The system also positively identified 24 planned fuel reduction burns for a total of 57 detections for the season as well as the detection of thousands of private

permit burns late in the season.

This meant fire brigades were not sent on time consuming wild goose chases.

The Pano AI system was installed in south-east South Australia as part of the South Australian Government’s $2.346 million upgrade of the region’s fire tower network, with $1 mil-

lion targeting the new technology. The program also received significant support and funding from forest industries.

Spanning 14 locations

Pano AI offers a comprehensive turnkey solution that integrates high-definition cameras, satellite feeds, artificial intelligence, and modern cloud software to detect and pinpoint new ignitions and alert fire professionals within minutes.

The key to keeping fires

small and limiting the impact on industry and the community is through rapid response and the worldleading actionable intelligence helps fire crews get to the scene faster and safer. It’s relatively cheap, and will get cheaper, and it will in the long run save money, time, jobs, and most importantly, lives.

Midway managing director Tony McKenna has a simple philosophy for the way the company sees the timber industry.

“We’d like to see more trees in the ground,” he said.

“We’re committed to try to grow the estate where it makes sense.

“And I believe that there is country where it would benefit from having trees in the ground.”

Midway is a leading Australian forestry company with a head office in Geelong, Victoria, founded in 1980. Midway has business units across Australia and is involved in all aspects of forestry, with a lead focus of woodfibre processing and exporting, plantation project management and carbon abatement projects.

To encourage the development of plantation forestry and expedite sequestration of atmospheric carbon, Midway has developed a Carbon Project Agreement, a commercial offering for

Landholders who are keen to support commercial forest production and participate in Australia’s expanding carbon reduction market through the generation of carbon offsets.

Midway sources hardwood plantation and softwood plantation from Victoria and the Green Triangle region in South Australia.

Midway Tasmania sources native regrowth and hardwood and softwood plantation across Tasmania.

Plantation Management Partners sources hardwood and softwood plantation from the Tiwi Island Forestry Project on Melville Island in the Northern Territory. Wood is sourced from Responsible Wood, FSC certified suppliers and noncertified suppliers.

Combined the group manages over 90,000 ha of plantation estate.

“The hardwood plantation estate peaked at around 970,000ha in Australia in 2010, and a lot of that was driven by the MIS,” Mr McKenna said.

It is currently chipped in field at sites such as Myamyn north of Portland, and in Geelong.

The bulk of the product is exported out of Portland.

“There’s very little being used domestically,” Mr McKenna said.

He said there was some replanting.

Aseries of information initiatives aimed at advising potential farmers and landowners in South Australia interested in the on-farm forest plantation sector is now available as part of Trees on Farm initiative.

This includes a toolkit, developed by the South Australian Government, in tandem with the Green Triangle Forest Industries Hub (GTFIH), featuring expert information and printable fact sheets to support and guide landholders in their commercial plantation investment.

In addition to the toolkit, other information for perspective growers is also available from five research reports and associated seminar videos conducted under the Trees on Farm initiative from both the PIRSA and GTFIH websites.

Barriers to harvesting and processing of small private plantation resources are identified and discussed in the report, including plantation location relative to markets, plantation scale, log sale process, and harvesting contractors.

The GTFIH website also includes an interactive web map that allows users to explore the estimates of saleable wood and carbon credits, in agricultural areas within South Australia and Western Victoria.

“A good part of it was in the Green Triangle in Western Victoria more generally. And a lot of that was driven by MIS, but not all of it.”

Since then the plantings have decreased by 250,000ha with some of the best country reverting to primarily grazing agriculture.

The hardwood timber harvested in Western Victoria goes to paper mills in China and Japan, making renewable recyclable products such as paper products and plastic replacement packaging.

“There’s a couple of things happening with the economics around a little bit of improved longer term demand for the woodchips and the carbon story,” he said.

“Carbon generates another source of income from a plantation And that helps in country that’s really marginal agricultural country.”

Midway doesn’t do any of its own harvesting and haul operations, relying on local contractors.

Logs are generally harvested, cut to length, and then brought into Midway’s static mills.

“Having the infrastructure there makes it cheaper for us to do it that way,” Mr McKenna said.

Combining the technical nature of taxation with a need for clear examples, the report makes use of case studies to demonstrate principles and concepts with a caveat that any specific implementation will need to seek specific and current professional advice.

The two year, $650,000 Trees on Farm initiative, jointly funded by the Australian and South Australian Governments, is aimed at boosting the growth and development of the on-farm forest plantation sector, particularly in the Green Triangle region.

For further information visit www.pir.sa.gov.au/ trees-on-farms and www.gtfih.com.au/trees-on-farms

INNOVATIOIN is at the heart of any successful business.

Radial Timber in Yarram, with a strategy already in place for its mainstream timber operation, has embarked on a new approach to using its wood waste that takes the company deeper into the heart of the sustainable, circular economy.

Radial has installed a pilot plant that uses pyrolysis technology; organic material, in this case wood residues, is burnt at high temperatures without oxygen to produce biochar, a stable solid that is rich in carbon and can fertilise and endure in soil for thousands of years.

“The plant can also produce heat and energy, and wood vinegar – a liquid, potentially usable in agriculture, also in cooking,” said Radial’s managing director, Chris McEvoy. The heat will play a crucial role in running the timber mill, with a potential heating source for the local community.

The $1 million pilot continuous biochar maker is the result of three years’

John and Linda Ballis.

“We have a pure resource, most of the biochar plant around the world are working with waste, plastic waste, arboreous waste –green leaves, different species and densities; the product that comes out is not that uniform,” said Chris.

“Our timber is all dense class, one or two timbers, all exactly the same shape.

er is you can put through much larger volumes. Take the biochar and put it into degraded soil’s to improve it – I love this circular economy story.”

Earth Systems, the technology provider based in Port Melbourne, was originally an environmental consulting firm founded in 1993.

“For about a decade, we

take off. There is a lot more interest in biochar,” said Ricky Dent, Earth systems’ environment technology specialist.

Chris McEvoy will assess how the biochar plant fits in with Radial’s current operation. Having lost access to VicForests’ native hardwood timber, Radial’s plan is to use its own hardwood

line is part of the peeler plant, which can peel a small log down into veneer sheets, which are dried, glued and pressed. This engineered timber can theoretically be used to make mass panels

“We could not run the peeling plant we want to run because of the requirements to heat the logs before they are peeled. Once peeled, you must dry the veneers through this big dryer; doing that on gas and electricity, you would never afford it.

“We can’t put a peeling plant in without a bio-plant. If we put the full LVL plant in, we need a lot of heat.” That may require the use of technology called ROC – a Rakin cycle engine that produces electricity off waste heat from the pyrolysis plant.

“What’s really exciting –solar is only good in summer or daylight; no sun – no solar. The idea of the biochar plant and this ROC - I believe no one in Australia is doing this – is to have a solar system and a renewable recharge system that is not solar. The idea there is

Private Forests Tasmania has launched an interactive knowledge hub for Tasmanian landowners to learn about the positive impact integrating commercial trees can have on their properties.

The Tree Alliance Knowledge Hub and its content have been developed in consultation with a broad scope of state and nationally-renowned forestry, agricultural and biodiversity experts to ensure landowners can glean the best advice and support from the information resources.

The $400,000 project was supported by the TAS Farm Innovation Hub through funds from the Australian Government’s Future Drought Fund, PFT and supported by 10 other stakeholder project partners.

The Knowledge Hub, developed by Walker Designs and Cavalletti Communications, consolidates accessible and user-friendly information and tools that highlight how integrating trees on farms through whole-farm planning can improve farm resilience through environmental and economic shocks such as droughts.

People can visit the hub to:

• Discover how to integrate trees into your farming operations to maximise productivity, and generate economic, ecological and societal benefits

• Learn about the experiences of farmers who have successfully planted trees on their land

• Explore the results of Tasmanian case studies measuring the productivity and environmental impacts of trees on farms

• Access tools that support decision-making from carbon estimation to forest mapping, to species selection

• Find practical step-bystep resources backed by the latest research, market insights and industry knowledge

• Gain information and

advice from leading forestry professionals on each aspect of the tree-growing process

• Begin planning their own tree-growing journey for a thriving future

Included in the hub is PFT’s new Farm and Forest Mapper tool to help simplify the farm-planning process for landowners, consultants, planners, contractors and land agents.

The Farm and Forest Mapper, developed by Esk Spatial, in consultation with Private Forests Tasmania and the Forest Practices Authority, is a FREE set of mapping and decision support tools and calculators where users can easily plan, map and manage their properties to expand their plantation estate and leverage the multiple benefits that trees on farms can provide.

PFT Chief Executive Officer Dr Elizabeth Pietrzykowski said the Knowledge Hub would be a key resource for many Tasmanian landowners to learn more about the benefits of trees on their farms and then find what help is available to enable them to make the best decisions for their enterprise.

“The Knowledge hub is an extension of PFT’s strate-

gic program Tree Alliance, which works with forestry, agricultural and environmental stakeholders to raise awareness of farm forestry and the benefits of trees on farms,” she said.

“Longer-term, we hope the outcomes of this project will be more trees of the right type, in the right places across the agricultural landscape, improved farming businesses’ drought resilience and better carbon and other natural capital asset outcomes.

“We know farmers are interested in integrating trees into their whole farm plans, however, in many cases, they don’t know how or where to start.

“This Knowledge Hub, developed by the forestry and agricultural sector, will provide them with key information and direction of the process and who to talk to make sound economic and environmental decisions.”

Director of the TAS Farm Innovation Hub Sandra Knowles said the project supported the hub’s aim of helping farmers access information and drive innovation in their business.

“As our climate changes and becomes more variable, we need to build cli-

Forestry Corporation has reached an important milestone to explore the potential for windfarms within public pine plantations to contribute to the NSW transition to renewable energy.

Chief Executive Officer Anshul Chaudhary has announced that Neoen, Iberdrola Australia, TagEnergy and Mainstream Renewables Power and Someva Renewables joint venture have been awarded permits to investigate wind farm opportunities in some pine plantations in the Central West and Southern Inland regions.

mate resilience into communities, economies and environments at all scales,” she said.

“We know that a critical part of this is ensuring farmers are able access information they need to make the best decisions for the future.

“The Knowledge Hub will be a fantastic resource as it uses a variety of methods to show farmers how integrating trees on farmers and whole farm planning can improve their financial, social and environmental resilience to drought and climate variability.”

The TAS Farm Innovation Hub is one of eight hubs nationally funded through the Australian Government’s Future Drought Fund. The hub is based at the Tasmanian Institute of Agriculture (TIA) at the University of Tasmania and delivered through a network of industry and community partners.

The Tree Alliance Knowledge Hub can be explored at pft.tas.gov.au by clicking on the Tree Alliance tab in the top right-hand corner or call PFT’s free Helpline on 1300 661 009.

Mr Chaudhary said the permits will enable the proponents to investigate windfarm opportunities in pine plantations in the State Forests around Bondo, Orange, Black Springs and Sunny Corner.

“(The) announcement marks the start of the investigation phase under what will be a comprehensive and considered planning process,” he said.

“A permit is not a consent to proceed with a project, but it will allow the proponent to start the detailed studies to see if a project is viable within each investigation permit area. Each company will need to conduct detailed wind farm feasibility studies, which will commence with the installation of wind and weather monitoring equipment on meteorological masts.

“Each company will also undertake extensive community consultation and work with local communities to consider and address potential concerns around environmental impact, noise, landscape and visual impacts, traffic and transport issues, hazard and risks, heritage, water and soil impacts and waste management.”

The combined investigation, consultation, planning and approval stages could be expected to take between three and six years.

The future of forestry has been unveiled at OneFortyOne’s Glencoe Nursery in the Green Triangle following the completion of an $8m redevelopment project for the site.

South Australian Minister for Forest Industries Clare Scriven joined OneFortyOne Board Director Angie Davis and CEO Wendy Norris in officially opening the upgrades and witnessing the new state-of-the-art handling systems in action.

The three-year redevelopment project includes undercover automated handling lines, new irrigation and ergonomic systems and major infrastructure upgrades, which will improve employee safety and wellbeing at the site.

Also in attendance were Member for Mount Gambier Troy Bell, Member for MacKillop Nick McBride, Rob Robinson, Director of Forest Industries, Department of Primary Industries, Regions, Shadow Assistant Minister for Regional South Australia Ben Hood and Green Triangle Forest Industries Hub Executive General Manager Tony Wright.

South Australian Forest Products Association CEO Nathan Paine and the Australian Forest Products As-

of the nursery’s workforce was a major factor in the decision to upgrade the facility, helping enhance the safety of people and making it a better place to work, Ms Davis said.

“The infrastructure upgrades are not a replacement for workers but are designed to complement our existing nursery workforce.”

Ms Scriven heralded the redevelopments as “significant for the future of the Green Triangle forestry sector”.

Almost 2.5-million hardwood and softwood seedlings are being dispatched from Forestry Corporation’s Grafton Nursery to be replanted in state forests across New South Wales.

The Grafton Nursery grows a mix of eucalyptus and pine seedlings, which are replanted in state forest timber plantations that have previously been harvested for renewable timber products.

sociation CEO Di Hallam also attended the event.

OneFortyOne Board Director Angie Davis said the redevelopment demonstrates OneFortyOne’s “commitment to innovation, sustainability, and the future of forestry in the Green Triangle”.

“The Glencoe Nursery has been a cornerstone of the region’s forestry operations for 40 years, growing 7.5million trees annually to support not only OneFortyOne, but other forest growers in the region,” she said.

“Innovation and safety are the key drivers of this rede-

velopment with a new state of the art undercover handling system that enhances seedling growth whilst reducing chemical and water use. “We can now grow an additional 4 million seedlings per season, significantly bolstering our capacity to meet the demand for timber resources in South Australia and beyond.”

Ms Davis also commended Nursery Manager Craig Torney, for his long-term vision for the site and for leading the project over the last three years.

“The safety and wellbeing

“This region is the powerhouse of the Australian forest industry with 140 years of innovation and experience in growing and producing world recognised products,” she said.

“The Glencoe Nursery, which supports both OneFortyOne and other local growers, is at the very heart of a supply chain which sustains multiple major industries, from construction to plantations and logistics, which, in turn, supports the jobs of thousands of South Australians.

“Today, in seeing these new systems in action and streamlining traditional operations, we are seeing the future of our forestry sector – a major economic driver for our state.”

Next year’s Green Triangle Timber Industry Awards will mark the culmination of newly implemented changes informed by the valuable feedback from sponsors, attendees, and award nominators from our previous events.

As part of the changes the nomination process will be streamlined and partnerships forged with local organisations to enhance the experience for all stakeholders.

In addition to these enhancements, the committee is also exploring avenues to

further elevate the recognition of nominees and winners, particularly through the esteemed Legend Award.

“By continually refining our approach, we aim to ensure that every deserving individual receives the acknowledgment they rightly deserve,” committee chairman Adrian Flowers said.

“As we embark on this exciting journey, we would like to acknowledge and thank our sponsors, suppliers and regional representatives for their unwavering support. Without the sponsorship team, the awards

night would not be possible – our success is a direct result of industry backing,” he said.

“As we look forward to the next chapter, the GTTIA Committee remains dedicated to fostering growth and ensuring that the awards continue to serve as a flagship event for the region’s timber sector.”

Since its inception, the GTTIA has evolved into a platform that not only celebrates the achievements of nominees and winners but also highlights the diverse industries within the timber sector.

Mr Flowers said that by shining a spotlight on the myriad job opportunities and career pathways available, the awards played a pivotal role in inspiring future generations and fostering innovation.

Furthermore, the GTTIA served as a testament to the timber industry’s positive impact on environmental sustainability, carbon emissions reduction, and the integration of transformative technologies.

The 2025 awards night has been scheduled for October.

“These seedlings will be planted and grown for around 30 years to supply renewable timber for the next generation’s homes and infrastructure,” Forestry Corporation’s District Manager for Grafton Lyndon Orpwood said.

“After timber harvest operations, state forests in New South Wales are regrown or replanted to continue the forest cycle into the future,” Mr Orpwood said.

“Timber is the ultimate renewable resource and is crucial to the Australian construction industry.

“Almost 100 million seedings have been raised at the Grafton nursery over the past two decades, ultimately helping to build people’s homes and to replenish vital public infrastructure including power poles, marine piers, bridges and platforms,” he said.

Forestry Corporation’s pine and native hardwood seedling nursery at Grafton employs a permanent workforce of 13 staff, who are assisted with the annual dispatch by a seasonal workforce.

When in full production, the Grafton Nursery produces around 50,000 seedlings a day with all stock grown from seed.

The eucalypt and pine seedlings are being dispatched from the Grafton nursery across the state for replanting schedules in plantation forests.

For plantation forests in southern NSW, Forestry Corporation produces seedlings at its Tumut Nursery.

Find out more about Forestry Corporation at www. forestrycorporation.com.au

In today’s world, where environmental conservation is at the forefront of global concerns, ensuring the responsible management of our forests is paramount.

One crucial tool in achieving this goal is the PEFC (Programme for the Endorsement of Forest Certification) certification. This certification plays a vital role in safeguarding our forests and promoting sustainability. But what exactly is PEFC and Responsible Wood certification, and why does it matter for our forests?

PEFC certification is a globally recognised standard for promoting sustainable forest management. It provides assurance to consumers that wood and paper products bearing the PEFC label come from responsibly managed forests. The PEFC and Responsible Wood certification process involves rigorous assessments of forest management practices against a set of strict criteria, including environmental, social, and economic aspects.

One of the key reasons why PEFC and Responsible Wood certification matters for our forests is its focus on sustainability. Sustainable forest management aims to balance environmental, social, and economic considerations, ensuring that forests can continue to meet the needs of present and future generations. By adhering to PEFC standards, forest managers commit to preserving

biodiversity, protecting water resources, and minimising the environmental impact of forestry operations. Moreover, PEFC and Responsible Wood certification contributes to the fight against deforestation and forest degradation. By promoting responsible forest management practices, PEFC helps combat illegal logging and encourages the conservation of valuable forest ecosystems. This is particularly significant in regions where deforestation poses a severe threat to biodiversity, climate stability, and local communities.

Another crucial aspect of PEFC and Responsible Wood certification is its emphasis on stakeholder engagement and social responsibility. PEFC standards require forest managers to engage with local communities, indigenous groups, and other stakeholders to ensure that their interests and concerns are taken into account. This inclusive approach fosters transparency, accountability, and trust within the forestry sector, ultimately benefiting both people and forests.

Furthermore, PEFC and Responsible Wood certification supports the market demand for sustainable wood and paper products. As consumers become increasingly aware of environmental issues, there is growing demand for products that are sourced from responsibly managed forests. The

PEFC label provides assurance to consumers that they are making a sustainable choice, thus driving market demand for certified products and incentivising more forest managers to adopt sustainable practices.

In Australia, where forests are not only valuable ecosystems but also integral to the cultural identity of indigenous communities, PEFC and Responsible Wood certification holds particular significance. By promoting sustainable forest management practices, PEFC helps preserve Australia’s unique biodiversity and ensures the long-term viability of its forestry industry. Moreover, PEFC and Responsible Wood certification aligns with Australia’s commitment to sustainable development and environmental stewardship, contributing to the nation’s efforts to mitigate climate change and conserve natural resources.

PEFC and Responsible Wood certification helps foster collaboration and knowledge-sharing within the forestry sector. By bringing together stakeholders from government, industry, academia, and civil society, PEFC creates a platform for exchanging best practices, innovative ideas, and scientific research. This collaborative approach enables continuous improvement in forest management techniques, leading to more effective conservation efforts and better outcomes for

Forico appointment

Tasmania’s largest private forest and land asset manager Forico will welcome a new Chief Financial Officer (CFO), Chris Oddie, from June 24.

Chris Oddie is a Chartered Accountant with over thirty years’ experience in senior executive finance, commercial and operational management, gained across the agribusiness, construction, community services, financial services and logistics sectors both in Australia and overseas.

Most recently he has occupied CFO and Company Secretary roles with Regional Livestock Exchanges, Li-Ve Tasmania, and Spectran Group, where he shaped business growth and successfully managed company transformation and change.

both forests and communities.

Additionally, PEFC and Responsible Wood certification enhances the competitiveness of forest products in the global market. With growing awareness of sustainability issues, many businesses and government agencies around the world require certification as a prerequisite for purchasing wood and paper products. By obtaining PEFC and Responsible Wood certification, forest managers gain access to these markets and can command premium prices for their certified products. This not only benefits certified forest owners but also incentivises others to improve their practices to remain competitive in an increasingly sustainable marketplace. Ultimately, PEFC certification helps drive positive change throughout the forestry supply chain, from forest management to product manufacturing and distribution, ensuring a more sustainable future for our forests and planet.

PEFC and Responsible Wood certification plays a crucial role in ensuring the sustainability and responsible management of our forests. By adhering to PEFC standards, forest managers demonstrate their commitment to environmental stewardship, social responsibility, and sustainable development.

The all-party South Australian parliamentary select committee which is inquiring into the exporting of wood fibre and other Limestone Coast timber matters has been granted yet another extension to its deadline.

The Legislative Council sub committee was due to report last November however the revised deadline is now November 24.

The New Zealand Forest Owners Association has elected Matt Wakelin as its new President replacing retiring president Grant Dodson.

Portfolio manager for New Forests, Mr Wakelin has extensive experience stemming from a lifelong career in forestry – managing forest estates, port services operations, log supply and residues sales for log processing facilities and offering his sector expertise in an executive and corporate capacity.

New Forests has appointed Yida Kemoli as Managing Director, Africa.

Yida will be responsible for driving the strategy for New Forests’ African business, fund raising for African forestry strategies, leading the team on the ground in Nairobi, and delivering investment returns and impact outcomes for clients.

Nearly 250 hectares of trees will be planted and the carbon outcomes researched as part of a new grant program supporting Tasmanian farmers.

Private Forests Tasmania is excited to announce the recipients of a $450,000 co-investment to support farmers on private land in Tasmania to plant and grow more commercial trees on their properties.

regimes.

The Stems for CO2 Program - supported by the State Government’s Renewables, Climate and Future Industries Tasmania - will directly support three Tasmanian farmers with upfront establishment costs to successfully integrate commercial trees into their agricultural enterprise.

PFT Chief Executive Officer Dr Elizabeth Pietrzykowski said the successful applicants were chosen due to their demonstrated ability to meet the assessment criteria and program objectives.

PFT launched the grant on February 2, 2024 with applications closing in March.

An independent assessment panel comprising of individuals with experience in carbon, forestry and agriculture assessed the applications received, with their recommendation going to the PFT Board for final approval.

The three recipients who will establish about 249 hectares of commercial tree plantings are Alison Napier at St Marys, Julian Devery at Riana and Dougal Morrison at Oatlands.

The Tasmanian Government committed $10 million for new actions that will maintain Tasmania’s net-zero emissions status into the future in 2023 and $600,000 was awarded to PFT to deliver this program.

Aseries of information initiatives aimed at advising potential farmers and landowners in South Australia interested in the on-farm forest plantation sector is now available as part of Trees on Farm initiative.

This includes a toolkit, developed by the South Australian Government, in tandem with the Green Triangle Forest Industries Hub (GTFIH), featuring expert information and printable fact sheets to support and guide landholders in their commercial plantation investment.

In addition to the toolkit, other information for perspective growers is also available from five research reports and associated seminar videos conducted under the Trees on Farm initiative from both the PIRSA and GTFIH websites. The research projects, focussed on short rotation silviculture, include topics such as:

• Development of rotation silviculture – which explored current and alternative Tasmanian bluegum (hardwood) and radiata pine (softwood) management (silviculture) regimes. By considering expected time frames for harvest, the farm

property plan, and intended markets, there is potential to match a range of forest management regimes to an individual farmer’s property and production system.

• Enhancing commercial viability via logistics and processes - includes a snapshot of Green Triangle softwood processors and hardwood woodchip exporters, tables of indicative softwood and hardwood harvest yields, indicative harvesting and haulage costs, approximate roading costs, and typical mill door prices.

Barriers to harvesting and processing of small private plantation (SPP) resources are identified and discussed in the report, including plantation location relative to markets, plantation scale, log sale process, and harvesting contractor availability.

• Spatial analysis of suitable land areas for trees into farming - Four plantation management regimes are modelled using the Agricultural Production Systems Simulator (APSIM), and likely forest wood harvest volumes generated at thinning and final harvest across the project area are shown on the map.

The map also shows the to-

tal Australian Carbon Credit Units (ACCUs) that could be available under the Tasmanian bluegum and radiata pine regimes, as well as ACCUs that could be available under a permanent environmental planting.

• Comparison of the Emissions Reduction Fund methods - primarily compared the ACCU Scheme plantation forestry method (Schedule 1), which focuses on new plantation forests for commercial harvest, with the farm forestry method, which incorporates both harvest plantation projects for saleable forest products and permanent planting projects. Among the conclusions, the analysis suggests the plantation forestry method is likely to be a better option if a plantation is established for harvesting wood products.

• Development of taxation treatment in a farming framework - provides a distilled account of trees, taxation and superannuation and comprehensive appendices with information sourced from the Australian Taxation Office (ATO) and other sources. The analysis does not seek to provide specific treatment and outcomes but rather demon-

strate what may be possible subject to a range of considerations.

Combining the technical nature of taxation with a need for clear examples, the report makes use of case studies to demonstrate principles and concepts with a caveat that any specific implementation will need to seek specific and current professional advice.

The GTFIH website also includes an interactive web map that allows users to explore the estimates of saleable wood and carbon credits, in agricultural areas within South Australia and western Victoria.

The two year, $650,000 Trees on Farm initiative, jointly funded by the Australian and South Australian Governments, is aimed at boosting the growth and development of the on-farm forest plantation sector, particularly in the Green Triangle region.

For further information on the Trees on Farm initiative including the toolkit, research reports and videos and interactive map visit www.pir.sa.gov.au/trees-onfarms and www.gtfih.com. au/trees-on-farms

In a groundbreaking collaboration, the Materials & Embodied Carbon Leaders’ Alliance (MECLA), Hyne Timber, XLam, Forestry Corporation of NSW, and Responsible Wood joined forces to organise a transformative field trip focusing on certified sustainable forest management and ethical supply chains.

The event, held across New South Wales and Victoria, provided attendees with invaluable insights into the intricate processes behind responsible forestry practices.

“Events like these are crucial for fostering a deeper understanding of sustainable forestry practices,” Sustainability Manager at Responsible Wood Matt De Jongh said.

“By witnessing firsthand, the efforts put into maintaining our forests, participants gain a renewed appreciation for the importance of ethical and responsible supply chains.”

The field trip offered participants a multifaceted experience, where attendees

had the opportunity to witness sustainable forestry practices in action, gaining insights into forest regeneration, biodiversity conservation, and responsible harvesting techniques.

“For over 140 years, Hyne Timber has prioritised delivering industry-leading products while ensuring the preservation of our natural resources,” Katie Fowden, General Manager of Stakeholder Engagement at Hyne Timber, highlighted the company’s commitment to quality and sustainability, said.

“This field trip underscores our dedication to promoting sustainable forestry and driving positive environmental impact.”

Alexi Barnstone, Project Manager at MECLA, echoed similar sentiments.

“MECLA is dedicated to reducing embodied carbon in the construction industry. Collaborating with key stakeholders in initiatives like this field trip allows us to align our efforts with the Paris Agreement targets and advance the principles of the

circular economy,” he said.

The field trip offered participants a multifaceted experience, where attendees had the opportunity to witness sustainable forestry practices in action, gaining insights into forest regeneration, biodiversity conservation, and responsible harvesting techniques.

One of the highlights of the trip was a visit to a certified sustainable pine plantation managed by Forestry Corporation of NSW. Participants observed firsthand the meticulous planning and execution involved in maintaining a renewable plantation to ensure a sustainable supply of timber.

Additionally, demonstrations and presentations from industry leaders such as Hyne Timber and XLam showcased innovative solutions for sustainable construction. Hyne Timber and XLam’s expertise in engineered timber for mass timber construction exemplified how advanced technologies can enhance sustainability, increase construction efficiency, and

improve overall project outcomes.

Overall, the field trip served as a catalyst for promoting awareness and collaboration within the construction industry. By bringing together key stakeholders, it facilitated meaningful discussions and laid the groundwork for future

initiatives aimed at advancing sustainability practices.

“This field trip is just the beginning. By continuing to work together and championing sustainable forestry practices, we can pave the way for a greener, more environmentally conscious future,” Mr de Jongh said.

THE Victorian state government has defended its panel that will investigate the future of Victoria’s native forest estate, but did not comment on its lack of bushfire expertise.

The membership of the panel had been strongly criticised for its lack of a bushfire expert by a Latrobe Valley forest and business consultant, John Cameron.

The government was also asked whether the panel would consider the report by the federal-state Major Event Review Panel that investigated the impact of the destructive 2019/20 fires on the Regional Forest Agreements. The panel, which submitted its report a year ago, made 36 recommendations on future forest policy but has received no reply from the state or federal government.

A government spokesperson said the end of native timber harvesting presented new opportunities to improve forest management, balancing recreation and

tourism for Victorians to enjoy time outdoors, while protecting the environment and supporting Traditional Owner self-determination.

“The taskforce will play a critical role in engaging with Victorians to determine the best forest management practices, with each member bringing specialised knowledge from various fields such as environment, tourism, regional

development, and outdoor recreation – ensuring a comprehensive consideration of all options during the consultation process,” the spokesperson said.

“As part of this important work, the taskforce will consider a wide range of resources including the report from the Major Event Review Panel.”

The government’s Great Outdoors Taskforce, led

by the former Minister for Environment and Climate Change, Lisa Neville, will consider the future management and use of state forest previously available for timber harvesting.

Commercial native timber harvesting in Victoria ceased on January 1, 2024.

The taskforce will work alongside the Eminent Panel for Community Engagement that is currently

engaging with Victorians on the future management and uses of state forests in the Central Highlands.

The taskforce has promised to widely consult with communities and stakeholders on the options to protect the environment and support recreational, social and commercial opportunities in the forests. This includes investigating opportunities for recreation and tourism such as camping, hunting, hiking, trailbike riding and four-wheel driving.

The work will be undertaken over the next 12 months and consultation details will be released in the coming weeks.

Mr Cameron said wildfire was the single most important threat to the state’s 7.5 million hectares of native forest.

“There is a clear need for a bushfire expert to be on the Great Outdoors Taskforce,” he said.

For more information visit deeca.vic.gov.au/futureforests/immediate-protectionareas/future-forests

Having a high profile should not provide anyone a free pass to speak disrespectfully and unfairly about others.

Forestry Australia is appalled by the misinformation about forest scientists and professionals that has been perpetuated by lobbyists and anti-forestry campaigners in recent media articles. It is hard not to think that such narratives have been constructed to suit certain agendas. Statements made are not universally supported by forest scientists, and do not recognise the knowledge, expertise and credibility of Australia’s world-leading forest scientists. It is also disappointing that recent coverage has not included these other voices.

Forestry Australia is a not-for-profit, independent professional associa-

tion with 1,200 members. Our members are individuals who have high levels of scientific expertise and extensive operational experience. They operate across all aspects of forest, fire and land management, farm forestry and tree growing throughout Australia. Some of our members are current or past employees of State forest agencies responsible for timber harvesting. These forest scientists and professionals are among the most dedicated

and passionate individuals, who make significant and under-acknowledged contributions to forest management, forest conservation and provision of renewable, sustainable and responsibly-sourced timber

for the Australian public. This contribution furthers our understanding of forest ecology and forest fire management. It also includes operational expertise in active and adaptive management options that are crucial for building climate resilience and mitigating wildfires. These forest scientists make significant contributions to managing and conserving our forests for the benefit of society. They provide elite and specialised firefighting capacity to all major wildfire events, collect and apply seed to revegetate forests severely degraded by bushfires, and are at the forefront of technological advancement such as drones and sophisticated apps to record and monitor forest values. In addition, they conduct the

most comprehensive threatened species monitoring programs that exist in this country, and oversee comprehensive management plans that provide high quality, sustainable local hardwood timbers.

It is time to move on from these tiresome, divisive and outmoded forest wars. Australia needs forest management decisions to be informed by pragmatic, open minded, evidence-based and credible voices who engaged in positive dialogue regarding future forest management.

In doing so, it is only right that we recognise the immense positive contributions of the forest scientists and forestry professionals who have dedicated their careers to evidence-based care for our forests.

Anew video has documented the impact that myrtle rust has on indigenous communities and the environment, reinforcing the need to maintain momentum in breeding for resistance and monitoring its spread.

Whakakotahitanga i te Kaupapa | Unity of Purpose, released today by Scion and Rotoiti 15 Trust, is a video capturing activity from a cultural exchange in November last year that aimed to discuss the challenges posed by myrtle rust in New Zealand and Australia.

Hosted in Rotorua, the exchange welcomed representatives from the Department of Agriculture and Fisheries; Queensland and New South Wales Department of Climate Change, Energy, the Environment, and Water; the University of Tasmania; the Butchulla Nation (K’gari Queensland); the Gumbaynggirr Nation (Coffs Harbour, New South Wales) and the Bundjalung Nations (New South Wales).

It offered a unique opportunity for cultures and researchers on both sides of the Tasman to connect and learn from each other. The eight-day visit highlighted the importance of sharing traditional knowledge and Western science between indigenous communities and researchers in both countries, and how they each have a role to play in protecting our environment from exotic diseases, such as myrtle rust.

The short film weaves together First Nations’ and Māori perspectives on kaitiakitanga (guardianship) and the interconnectedness of all living things. It reveals the strong respect that both cultures have for the bush and takes viewers inside the ngahere around Rotorua, Scion’s nursery and to the trust’s marae on the shore of Lake Rotoiti, reinforcing the vital link between healthy forests and healthy people.

The film also illustrates the work that Scion is doing in partnership with Rotoiti 15 Trust to monitor the spread of myrtle rust around the lakes area and efforts to breed more disease-tolerant species, starting with ramarama, rōhutu and their hybrids.

The research is delivered through Te Rātā Whakamaru, a Jobs for Nature | Mahi mō te Taiao programme funded by the Department of Conservation – Te Papa Atawhai. With support from Scion scientists, the programme employs 10 full-time staff who have been trained as technicians (hōmiromiro) to collect field monitoring data and develop protocols for longterm resistance breeding trials.

The challenge facing researchers is the time it takes to breed for resistance. Trees are slow growing and the current research is only on small trees in pots.

A multi-year programme is required to ensure the resistance is enduring.

Both Scion and Rotoiti 15 Trust are exploring strategies for how the programme will continue after the Jobs for Nature funding contract ends in December 2024.

Scion forest geneticist Dr Heidi Dungey says there is a desire to see mana whenua (Ngāti Pikiao) and Rotoiti 15 Trust take greater ownership of the programme as part of their journey to reconnect people to nature and build a passion for conservation.

In the video trust chairman Arapeta Tahana shares his vision for the future, adding that the goal of Ngāti Pikiao is to become guardians of their own rohe and whenua.

“That essentially means that we need rangers on the ground…that are monitoring and supporting restoration efforts.”

The visit to Rotorua followed an earlier trip to Queensland and New South Wales last year by representatives from Rotoiti 15 Trust and Scion. The cultural exchange was captured in a video called Roots of Resilience released last month across all six Australian States.

Dr Geoff Pegg, senior principal forest pathologist at Queensland’s Department of Agriculture and Fisheries, says Australia’s forests are valued for their diverse ecosystems and unique biodiversity, adding that ex-

University of Queensland scientists have developed an environmentally friendly RNAbased spray to help combat myrtle rust, which has wiped out many Australian plants.

Developed in collaboration with Department of Agriculture and Fisheries forest pathologists, the spray induces RNA interference (RNAi) – a natural way to shut down protein translation – which means it could slow the spread of myrtle rust through bushland, home gardens and nurseries.

The disease affects plants of the Myrtaceae family, which includes eucalypts, paperbarks and lilly pillies, and makes up 10% of Australian plant biodiversity.

otic diseases, such as myrtle rust, were a constant threat.

“Endeavours like this cultural exchange underscore the vital importance of global collaboration and unified actions aimed at preserving biodiversity and strengthening ecological resilience.

Traditional knowledge and Western Science must walk together to protect our Country and the unique forests in New Zealand too.”

The exchange was funded by Catalyst Seeding funding provided by the New Zealand Ministry of Business, Innovation and Employment and administered by the Royal Society Te Apārangi.

Myrtle rust was first discovered on mainland New Zealand in 2017. Since then Scion scientists have been involved in a suite of research aimed at protecting our most vulnerable myrtle species from the infectious airborne fungus. The disease targets new leaf growth and repeated infection causes trees to die back, affecting natural regeneration in the forest.

The video can be founf at https://www.agriculture. gov.au/biosecurity-trade/ policy/environmental/firstnations

The disease is a slowmoving ecological wrecking ball: surveys suggest it may drive at least 16 species of rainforest tree to extinction in the wild within a generation, with another 20 species at risk.

Molecular plant biologist Dr Anne Sawyer said the team wanted to find an alternative myrtle rust control to fungicides.

“Growers rely heavily on fungicides, but they come with a lot of problems such as being harmful to humans and beneficial organisms like bees and monarch butterflies as well as water contamination,” Dr Sawyer said.

“Pests and pathogens can also develop resistance to chemicals and consumers are becoming more aware of residues on their fruit and vegetables.

“We already knew that RNA interference works against other plant pests and pathogens, and our research found rusts are very amenable to this method when we sprayed the double-stranded RNA onto the plants.”

Dr Sawyer said the early results were very positive, and further research would test the spray in more uncontrolled conditions outside of the lab and glasshouse."

two-year research project has shed light on the promising opportunities for regional New Zealand to adopt short rotation forestry (SRF) for bioenergy production.

The findings show that leveraging short rotation forestry will not only diversify regional economies, but also contribute to sustainable land management and generate environmental benefits as New Zealand looks for ways to transition to a circular bioeconomy and meet its net-zero emissions targets by 2050.

Silviculture and forest carbon scientist Alan Jones says Scion’s modelling shows that short rotation forestry as a feedstock for bioenergy has the potential to replace 6% of New Zealand’s annual fossil fuel demand from less than 1% of the land area.

“We’ve built on research from a decade ago and assessed the feasibility of rapidly upscaling bioenergy production from forests. We’ve found there are particular regions well-suited to short rotation forestry which provides a real opportunity for communities to transform their economic base and reshape New Zealand’s energy future.”

A key outcome from Scion’s research is a ‘how to’

guide for short rotation forestry targeting landowners, forest investors, and government agencies. It not only outlines the feasibility of SRF but also identifies specific regions most suitable for it in New Zealand.

Scion’s research recommends that short rotation forestry should be established on lower value land (Land Use Capability Class 5-7) in locations where transport distances to processing locations can be minimised. Regions highlighted include the Central North Island, Northland, the East Coast and Otago.

The ideal species for short rotation forestry is Pinus radiata, owing to its rapid growth rates and high degree of adaptability and disease resistance in a range of growing locations. Other options include Eucalyptus fastigata and Eucalyptus regnans for their potential to rapidly yield large volumes of woody biomass from young age trees. Trees are generally planted in dense stands and managed to intensify rates of wood production for renewable energy, such as wood pellets, torrefied briquettes or liquid biofuels for marine and aviation sectors.

SRF is a forestry practice that involves growing and harvesting trees on a short

rotation cycle which, according to Scion’s modelling, would ideally be between 12 and 18 years for the production of wood biomass. This is considerably shorter than the conventional 28-year harvesting cycle.

One of the key advantages of SRF is its ability to provide a steady supply of biomass for energy production on relatively economically marginal land, with plantations harvested multiple times. Additionally, SRF can reduce greenhouse gas emissions by displacing fossil fuels and promoting carbon sequestration in the form of sustainably harvested living trees.

Scion’s research responds to signals from the Climate Change Commission that indicate the rising importance of bioenergy from forests in the coming decade. It also presents owners of low production grazing land on steeper hill country with alternative options to maximise productive capacity and increase economic viability.

Several challenges could impede the future widespread adoption of SRF in New Zealand – primarily low value of bioenergy feedstock under present market conditions. Considerations such as land costs and trans-

portation distances further complicate the potential adoption of SRF bioenergy nationally. To address these challenges, Scion’s analysis proposes integrating the Emissions Trading Scheme (ETS) carbon value of standing trees in SRF plantations into their economic assessment, which provides additional incentives for investment.

Jones says the guide provides a glimpse of what could be possible in the future for short rotation forestry as a vehicle to scale up bioenergy production. But the benefits would go much further if decentralised processing of harvested material was promoted to stimulate regional economies and fast-track bioenergy availability.

“It’s about developing forest systems that are optimised for bioenergy. But in more economically disadvantaged regions, it also makes sense to build and establish processing facilities there because the energy itself is a lot cheaper to transport once it’s chipped and dried or transformed into liquid biofuels.

To validate theoretical findings, Scion is collaborating with the Ministry for Primary Industries (MPI) on developing designs for forest bioenergy trials. These

trials will involve rigorous testing of growth rates, optimal density, and tree health for different species, including Pinus radiata and Eucalyptus varieties. The collaboration represents a critical step in moving from theoretical models to practical implementation, addressing the complexities and uncertainties associated with on-the-ground application.

Scion researchers are also looking at optimising tree genetics and ways to optimise tree genetics by reevaluating past stock for its compatibility with bioenergy. Conventional tree breeding over the past 50 years has focused on timber quality, minimal branching and straightness. As a feedstock for bioenergy, Jones says optimal trees have very different traits.

By 2035, one scenario suggests 150,000 hectares of dedicated bioenergy forest could contribute to at least 5% of domestic fossil energy demand, displacing the equivalent of 3 Mt of CO2 emissions from oil combustion per year, or 4 Mt CO2 from coal.

Scion’s research has been funded by the Strategic Science Investment Fund.

The Vermeer chip drum offers customers versatility and consistency, allowing you to use one grinder to process both wood waste and biomass. Designed for use on HG6000TX and HG6800TX Horizontal Grinders, the chip drum changes the action of the drum from ripping and shredding to chipping – offering the flexibility to produce a more uniform, consistently-sized, chipped end product for the ever-growing Australian biomass market. Try it out for yourself by getting in contact with your local recycling specialists at Vermeer Australia.

In late September 2023, visitors to the PLC live demo event held in Washington state got a sneak peak of the new Tigercat 573 harvesting head processing logs on the end of a Tigercat 875E logger.

Since then, multiple units have been testing in far flung regions from Alberta to Australia and the results are in. The 573 is shaping up to be a high performing, reliable head for roadside processing and harvesting. Best suited to medium and large tree profiles, the 573 has a 800 mm (31 in) maximum cut capacity and offers optimal performance in 400-600 mm (16-24 in) diameter timber. The feed rollers close down to 60 mm (2.4 in), allowing the 573 to smoothly delimb and process smaller diameter trees and thus achieve higher value fibre recovery.

The compact frame design deftly handles poor stem form and contributes to tidy delimbing performance. The triangulated feed wheel arm configuration operates in locked three-wheel drive. This, combined with

timed knife arms, provide the operator with fast picking and positive stem control for high productivity in roadside processing applications. Independently mounted, trailing-arm length measuring ensures reliable tracking and accuracy.

The top knife and lower/ back knife pivot on the same side of the chassis frame, aligning the position and flow of each stem centrally through the head. This arrangement promotes positive contact with all three feed rollers and the measuring wheel at all times. The result is better quality and accuracy, reduced fuel consumption, and greater processing speed. The orientation also provides the operator with a clear sightline to the measuring wheel.

The 573 is standard equipped with continuous rotation for ease of use and superior hose routing and protection. Quick, stable WiFi connectivity between the cab and attachment modules reduces wire rout-

ing along the boom and provides excellent command response.

The Tigercat D7 control system is available with Pri-

ority or Optimization levels and is fully compatible and compliant with StanForD Classic and 2010.

The 573 is a great fit for

the H250D, 850 and 875E for roadside processing applications and the H822E and H855E carriers for in-stand harvesting.

Entering its 56th year in business, Randalls Equipment Co is undergoing a significant transformation under its new owners, David, and Vanessa Waldron.

After taking control of the business in February 2023, David and Vanessa immediately started to work on the long-term vision.

The heritage of the business dates to 1968, when Ken Randalls manufactured attachments for construction equipment followed by a transition into manufacturing rotating grapples for the forestry industry. Over the next 5 decades the business grew organically on the back of a good reputation for manufacturing high quality grapples. Grapple sales extended to southeast Asia and along the journey Randalls managed to obtain the

distribution for Rottne and Prentice forestry machines (no longer sold in Australia), Indexator rotators, Clark tracks, SP Maskiner processing heads, Ponsse forestry equipment and SANY excavators.

Looking to the future, the new owners have developed a strategy plan focused on values-based management, sustainability, productivity, and customer service to deliver significant growth, value and performance. Since taking control early last year, David and Vanessa have quickly shifted gears focusing on improving the company’s culture, engagement, and depth. Safety from every perspective is being imbedded as our core value, employee welfare is a key element for employee engagement and every effort is being made to implement improved

conditions and benefits for our highly valued team, such as the move to a 9-day fortnight. Investing for the future has seen Randalls hie three apprentices in 12 months and undertake significant investment in employee training and purchasing our own Ponsse simulator. Our journey to build a stronger, engaged and more flexible team has just begun. As the old saying goes, “take care of your employees and they will take care of your customers, which in turn will take care of your business.” It might sound too simple to be true in this day and age when corporations are spending significant money on people strategies, but most of

the time, keeping things simple tends to be the best strategy of all!

From a product perspective, we have been busy! Building on the world class brands we already have on offer, Randalls have secured the distribution for Falcon Forestry Equipment, Risutec Planting Heads, OMEF forestry and silviculture equipment, and further announcements are just around the corner. The additional brands provide Randalls with a unique opportunity to be a one-stop-shop for our customers. From a forestry perspective, we can supply, service and support equipment for harvesting,

forwarding, loading, and replanting - full circle supply to the most sustainable industry in the world. From a silviculture perspective, we have equipment to cover shearing, pruning, stump removal, trimming and mulching. For construction equipment, we cover excavation, demolition, augering, rock breaking and rental.

Randalls Equipment is on the move, building a sustainable sales, service and support business for the future. Our focus is on delivering the best equipment, the best service, and the best whole-of-life cost for our customers. We are transitioning from a manufacturing business to a fullservice dealer with the inhouse ability to customize solutions for our customers.

Waratah Forestry Equipment has unveiled the H216 – a new two-roller head added to its 200 Series lineup. Built for hardwood, the H216 is strong enough to handle the toughest tree forms with accuracy and efficiency. Its simple design with excellent feed power, delimbing, and large cut capacity provide productive tree harvesting.

“The H216 is specially designed for hardwood,” said Brent Fisher, product marketing manager for Waratah. “This head not only provides our customers reliable performance in hardwood but is equally capable of handling softwood, debarking and everything in between.”

Optimal performance in hardwood

Weighing in at 1495 kg (3296 lb.), this 200 Series head features a two-roller design ideal for hardwood harvesting, late or final

thinnings. Floating roller arms allow for superior and easy tree horizontal movement and easy log transport through the head. High performance single or multispeed options keep timber moving quickly.

The H216 features the efficient SuperCut 100S saw unit with improved auto tensioning and easier servicing. With large sawing capacity, this head can cut logs up to 750 mm (29.5 in.) in diameter, while an optional top saw tackles heavy branching. The delimb arms provide excellent delimbing power across all diameter ranges, while drive wheel options offer maximum traction for crooked wood.

The H216 harvester head utilizes the TimberRiteTM H-16 control system for optimum head performance, productivity and measuring accuracy.

The H216 is built to tackle the toughest, crooked timber to the straightest postwood and everything in between. While also naturally capable in softwood, debarking or multi-tree handling, this head is designed for efficiency and agility in thinning and harvesting applications with quick cycle times.

A heavy-duty main chassis saw box, as well as tilt frame and guarding, provide added protection and reliability. Maintenance is simplified through one position daily servicing and easy open/ close hinges on the valve cover.

The Waratah H216 is available to customers in the United States, Canada, Europe, Australia, New Zealand, Asia Pacific, Brazil and Latin America.

For more information about Waratah, please visit Waratah.com

The Woodsman Pro range offers the ultimate blend of productivity-enhancing tech and brute strength. Designed and built in NZ with over two decades of development in the harshest forestry conditions, Woodsman Pro is now available in Australia factory-direct with total support.

Forest owners say a new report is a promising step towards addressing complex land use management issues in New Zealand but needs to recognise the value of forestry in building a more resilient environment.

The report, Going with the Grain: Changing land uses to fit a changing landscape, was released by the Parliamentary Commissioner for the Environment (PCE). It acknowledges the longstanding complexities of land use management in New Zealand and the need to shift to a more granular, mosaic approach in the face of a changing climate.

New Zealand Forest Owners Association chief executive, Dr Elizabeth Heeg, says forest owners are supporters of an integrated land use conversation.

“Unfortunately the report paints forests as part of the land use problem when the opposite is true,” she says. “It is time for the government to acknowledge the pivotal role New Zealand’s production forests have in creating a resilient landscape and for the sector to be supported in driving change.”

New Zealand’s 1.75 million hectare production forest estate currently sequesters more than half the nation’s carbon dioxide emissions each year and is arguably one of the most effective tools at the nation’s disposal to mitigate the effects of climate change.

Forest owners are concerned that the report’s suggestions to alter the Emissions Trading Scheme (ETS) and phase forestry out of the ETS, could jeopardise meeting our 2050 climate change target.

Dr Heeg says confidence in the ETS is vital for forest owners to continue to invest.

“A new scheme may add to the volatility of that market, not to mention the unnecessary complexity and overheads.”

Turbochargers are critical components used for optimizing performance of on-highway and off-highway engines.

They increase engine power, improve fuel efficiency, and help reduce emissions of internal combustion engines (ICE).

Cummins producers a range of turbochargers to support a wide variety of engine requirements used in countless applications and explain the types of turbochargers to us.

The primary types of turbochargers are Fixed Geometry Turbochargers, Wastegate Turbochargers and Variable Geometry Turbochargers. Engine manufactures consider several factors when choosing the type of turbocharger that is best for their engine and application.

Turbochargers increase air flow to the engine cylinders, allowing for greater power density of the engine which improves combustion. Turbochargers use the energy in the engine exhaust gas to rotate a turbine at high speeds. A shaft connects the turbine wheel to a compressor wheel. The rotating compressor increases the pressure and flow of fresh air to the engine.

The differences between the types of turbochargers described in this article are based on how the exhaust gas is manipulated before it reaches the turbine wheel.

The exhaust gas flows through the turbocharger turbine housing before reaching the turbine wheel. A cavity in the turbine housing is called the volute. With Fixed Geometry Turbochargers, 100% of the exhaust gas flows through the volute to the turbine wheel. The wheel of the turbine and the shape of the volute affect the turbocharger and the engine performance. The turbine housing and wheel geometries are designed to optimize performance across