13 minute read

Women in Glassmaking: Courtney Calahoo

(Above) Dr Calahoo pouring glass in her current laboratory at Genics Inc.

An Indigenous woman in glass

The study of glass not only helped Indigenous scientist Dr Courtney Calahoo* interact with Indigenous communities, she believes it could also aid in bringing these communities and wider society closer together. Jess Mills met with Dr Calahoo to discuss further.

While in academia, Dr Calahoo was surprised to discover that glass helped her to bridge the gap between science and Indigenous communities. Outreach programmes with a focus of glassmaking allowed her to speak with Indigenous students on their experiences in a neutral, low-stress environment. She therefore believes glass science and technology could be an ‘objective way’ to interact with Indigenous communities.

There is still a lot of mistrust between Indigenous communities and wider society, not to mention the scientific community. In worst cases, anthropologists have taken sacred artefacts and not returned them, disregarding their cultural significance. Dr Calahoo believes the relationship can be healed, but it will require organisations to be patient and listen to the people within Indigenous communities on what needs to be done.

“It’s great that the Canadian government is trying to form a strategy and is acknowledging these communities. But it’s not going to be easy to overcome that sort of history.”

Dr Calahoo, who is of Mohawk and Cree descent, grew up in Alberta, Canada. Like many Indigenous families, her family was forced onto a reserve; they needed permission to leave and sell

crops. Children were often taken away to residential schools (Fig 2), where they were forced to speak English or French, and siblings were separated.

Fig 2 . A residential school in Canada – eight of Dr Calahoo’s family members are in this photo.

Getting into glass

As a child, Dr Calahoo said she could often be found out in the country or in the woods playing with frogs. Much to her mother’s frustration, she also had a fascination with combining all the liquids in the house, hoping something would happen. This led to her childhood nickname of ‘messmaker’ and ignited her interest in science and chemistry.

After completing her Bachelors of Science at McGill University, Dr Calahoo was unsure of where she wanted to go next. As she was interviewing for PhD positions in 2010, she met with Professor Joseph Zwanziger, a glass scientist. Prof Zwanziger discussed the many unique uses of glass, such as encasing material for solar cells, and how using different glass formers with lower melting points, specifically phosphate glasses, could contribute to a reduction in greenhouse emissions and energy usage.

Coming from a province where oil and gas “are king”, Dr Calahoo said she couldn’t help but be intriguied: “I was allured by a project that had clear green impacts and environmental sustainability. Up to that point, I definitely thought glass was just for windows and screens, so it was eye-opening to hear about this whole industry.”

From there, Dr Calahoo uncovered the wonders of the industry, and hasn’t looked back since. She said she has found the scientific glass community extremely welcoming, which was highlighted for her at the recent International Year of Glass (IYOG) Opening Ceremony.

“I think we’re really lucky that we have this option to be scientists in a university and to be researchers in the glass industry. We all go to the same conferences and we really talk to each other […] I have found that people are really welcoming and just want to talk about glass.”

In her work, Dr Calahoo said she enjoys exploring whether glass could be a solution for long-standing issues within other industries, such as preserving construction materials.

“I think people think that we’ve made glass. We’ve made float glass and windowpanes and now we’re done. But they don’t realise that even a small company like Genics is innovating and coming out with new glass products.”

Genics

The majority of Dr Calahoo’s research has focused on uncommon glass formers, such as ionic glasses, metalorganic frameworks and inorganic glass composites.

She is currently working with Canadian manufacturer Genics as part of her postdoctoral fellowship at the University of Alberta. The company works with forestry and utility organisations to preserve the lifespan of wood, and is also planning to expand into agriculture and construction.

At Genics, Dr Calahoo has been working on a dissolvable glass technology that preserves wooden structures such as telephone poles. Currently, the process involves drilling a hole into the wood and inserting a glass rod (Fig 3), which then takes the water from the ground, as well as fresh rainwater. Dr Calahoo described the process as follows: “[The water] slowly dissolves the glass over about two months. And when the dissolution products, like the chemicals, go into the wood, they actually stay there.”

Fig 3. A dissolvable glass rod is inserted into wood to prevent rot.

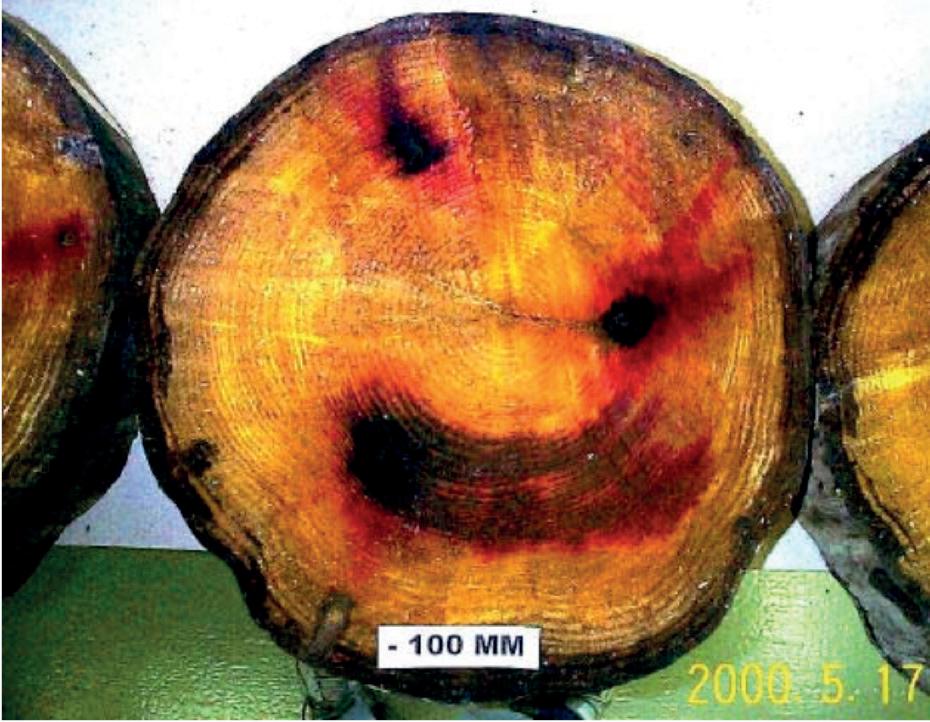

The chemicals, copper and borate, become a biocide (chemical mixture) when they are dissolved into the water (Fig 4). This mixture is antibacterial and prevents rot. Further advantages include the controlled rate in which the glass dissolves: “You don’t need to worry about one mineral suddenly becoming more soluble and overwhelming its surroundings.”

Fig 4. Boron and copper distribution in – 100mm section after two months.

Future applications of the technology could see the glass being applied to wood as a wrap, “like a Band-Aid”, to avoid the time-consuming drilling process. However, Dr Calahoo said that the dissolvable nature of the glass can be frustrating to study, which is perhaps why it hasn’t been investigated much outside of the medical field.

“If you have something that you know is going from a nice hard glass to something that is gelling overnight, then you’re always concerned that your measurements are wrong because it’s taking on water.”

She further commented that the soluble nature of the technology goes against the traditional attributes of glass staying “clear and beautiful”. She believes most companies wouldn’t want glass that’s going to dissolve or leak chemicals when it encounters water. Although, for the forestry industry, the technology has saved countless hours and dollars: “Even if you extend the lifetime of the wood by 50%, it’s still millions and millions of dollars being saved.”

Sustainability

Dr Calahoo believes that Genics has ‘ended up’ as a sustainable company: “When you triple the lifetime of wood you’re helping to create a carbon sink. You are reducing the amount of trees, reducing the energy it takes to install the wood. A lot of these telephone poles are in the middle of nowhere, especially in Canada, so it’s a big amount of effort to go out there and replace them every 20 years.”

However, Canada’s dependency on oil and gas can complicate matters. In Alberta, the oil and gas sectors are the main sources of power for most industries; nine percent of Canada’s GDP is from oil, which all comes from the province. Dr Calahoo said: “I do think that we’re trying to be sustainable in many fields and industries, but it’s hard with oil and gas.”

She has also discovered that introducing more sustainable technologies to new industries can be challenging, as no one wants to be the first to try a product.

“One of the bigger issues we have is getting anybody, like a construction industry, to take on innovation […] Let’s say they’re using a product that they know works. They don’t want to go and test the new product. They don’t want to be the ones to try it, because if it doesn’t work, then it’s their problem.”

Dr Calahoo said a solution could be to create more associations between the glass industry and scientists to fund sustainable technology. She suggested that having an impartial organisation between the two would provide a safety net for initial collaborations before a trusting business relationship is built.

Indigenous glassmaking

At the IYOG Opening Ceremony, Dr Calahoo discussed the similarities between Indigenous techniques for sculpting natural glasses, like horn and antler, and the skills for traditional glassmaking from Egypt and Mesopotamia.

She believed the straightening procedure used by the Inuit to shape musk ox horn, an animal native to the Arctic, was equivalent to the skills needed for lamp working and glass blowing: “There is quite a bit of overlap because the horn material is made out of keratin, which does have a glass transition in exactly the same way that an amorphous material does.”

Dr Calahoo said the horn shares a similar molecular structure to other glasses that she’s worked on, although the substance is not as ‘pure’ as glass; natural glasses often contain more than one material. Despite this, she thought the procedure used to shape the horn was still similar to the techniques used in a traditional glass working shop. (Fig 5)

Fig 5. Fishing spear (or kokiwog): John Tyman, Copyright Pitt Rivers Museum, Oxford University, 2010.

Dr Calahoo said she would like to see anthropologists explore Indigenous glassmaking, to learn how and why they created natural glass products and how their techniques differed from more studied communities. She believed Indigenous glassmaking techniques should be held in the same regard as old world methods.

“Why can we not look at the shaping of this natural type glass like horn and antler with the same fascination, and see what differences and traditions were passed down?”

Dr Calahoo also thought that studying these methods could teach modernday glassmakers the value of energy and the conservation of materials, due to the scarce resources many of these communities had. Not to mention, the importance of investing in the members of a community.

“Often, the reason that women or Indigenous people are not at higher levels is because no one has taken the time to show them. No one has seen that they are valuable and that they could be good at that position because they normally are not in that position.”

Indigenous glass scientist

Dr Calahoo believes that being Indigenous has made her more aware of the challenges that people face when entering an industry, particularly young and/or Indigenous women. She said it has made her more determined to try and help those joining the industry, as well as breaking the Indigenous stereotype.

“In Canada, we definitely have the stereotype of a drunk Indian, let’s say. And even if you don’t realise it, you do have this sort of image in your mind. […] I would say that from school and throughout my career, it has been satisfying to surprise people.”

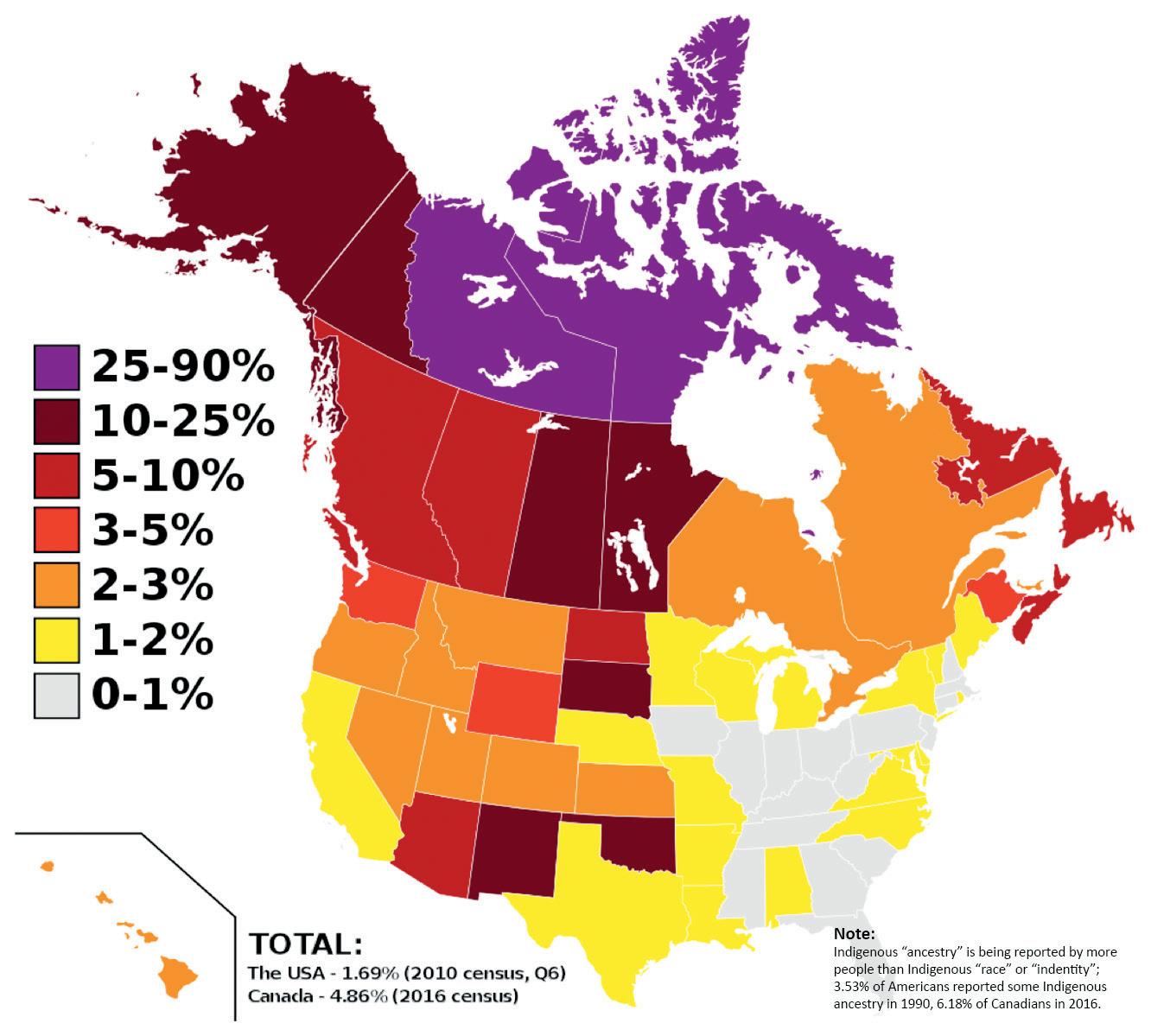

In Canada, 5% of the population is Indigenous (Fig 6), but Indigenous students only make up 2.7% of federally funded scholarships and fellowships at the undergraduate level.1 In higher education, the numbers fall off drastically – 1.9% at Master’s and Doctoral Awards and 0.4% of Postdoctoral Fellowships. [1]

Fig 6. The Indigenous population in the US and Canada.

“A lot of these Indigenous students come from poor backgrounds, so the tuition of university is quite expensive. Money is a barrier, so they can’t really imagine seeing themselves at university. No one in their family has gone to school before, so they just sort of stop thinking about it.”

To address the educational gap, Dr Calahoo has been a part of several outreach programmes for Indigenous communities. During her PhD, she was part of project that brought in highschool aged children to create sugar glass and conduct experiments on it, such as measuring its refractive index.

Whilst the objective focus was glass, the experience allowed Dr Calahoo to discuss wider issues with the students, such as university funding available for Indigenous people.

“I have considered that being a higher level in science and industry means that I could implement different initiatives or have outreaches. I can be the person that goes into Indigenous communities and talks to younger people. I can be the person that initiates some sort of programme for affirmative action. But I never really thought about that connection with glass technology, like the glass science itself, until more recently.”

Dr Calahoo believes that having an objective focus, such as glass, could help to repair the fraught relationship between science and Indigenous communities, as well as wider society.

“If we could demonstrate that the knowledge and the technology [of Indigenous communities] were equal with Romans, I think that that could go a long way to changing people’s perception of Indigenous people. There are negative stereotypes. We have negative stereotypes of ourselves as well. That’s part of the reason why being able to highlight positive things, that people can be proud of, becomes extremely important.”

Hopes

Dr Calahoo believes the glass industry is recognising change, although there is still much more to be done to ‘level the playing field’ for young women and/or ethnic minorities entering the industry. She advised that companies should invest in their employees to see them thrive in their roles, but acknowledged this could be time consuming and difficult.

“It takes so much effort to be the one that provides the resources to give everyone a level playing field. I hope that somehow industry and academia can begin to recognise that and somehow encourage their leaders to be able to give the resources to help people individually.”

Multiple studies have shown that more diverse teams lead to greater innovation and profit. Businesses run by culturally diverse leadership teams are more likely to develop new products than those with homogenous leadership, [2] and companies with more women are more likely to introduce radical new innovations into the market over a two-year period. [3]

Unsurprisingly, those in the top quartile for ethnic and racial diversity in management are 35% more likely to have financial returns above their industry mean, and those in the top quartile for gender diversity are 15% more likely to have returns above the industry mean. [4]

With an industry focused on achieving net zero carbon emissions by 2050, solutions for sustainable glass production are more crucial than ever. In Dr Calahoo own words, the industry is only going to grow: “We ourselves don’t even realise the breadth of compositions, properties and applications glass can have.” Therefore, why not encourage diversity to discover new minds and new ways of thinking for next chapter of the glass industry?

Dr Calahoo’s full talk is available via UN Web TV, please see the link below.

References

1. Figures from the Natural Sciences and Engineering Research Council of Canada (NSERC), https://www.nserc-crsng.gc.ca/ index_eng.asp

2. Max Nathan & Neil Lee (2013) Cultural Diversity, Innovation, and Entrepreneurship: Firm-level Evidence from London, Economic Geography, 89:4, 367-394, DOI: 10.1111/ ecge.12016

3. Cristina Díaz-García, Angela GonzálezMoreno & Francisco Jose Sáez-Martínez (2013) Gender diversity within R&D teams: Its impact on radicalness of innovation, Innovation, 15:2, 149-160, DOI: 10.5172/impp.2013.15.2.149

4. Vivian Hunt, Dennis Layton & Sara Prince (2015) Diversity matters. McKinsey & Company, 1(1), pp.15-29.

*Genics Inc. and University of Alberta, Edmonton, Canada https://genicsinc.com/ https://www.ualberta.ca/index.html

UN Web TV: https://media.un.org/en/asset/ k13/k13xelnyhx