4 minute read

Bormioli Pharma

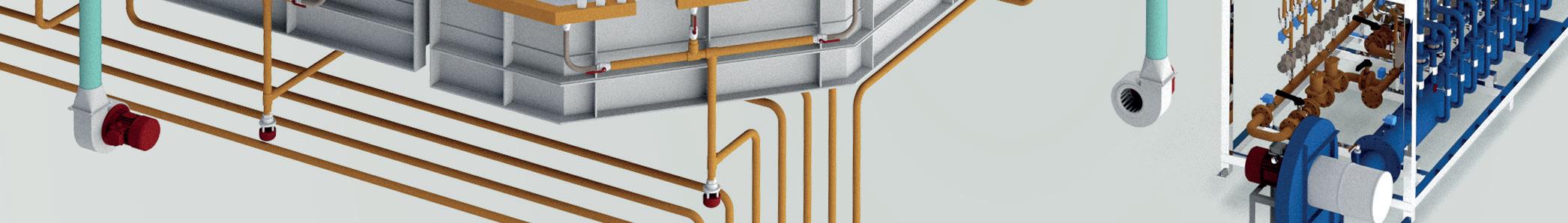

An advanced furnace for pharma An advanced furnace for pharma glass production glass production

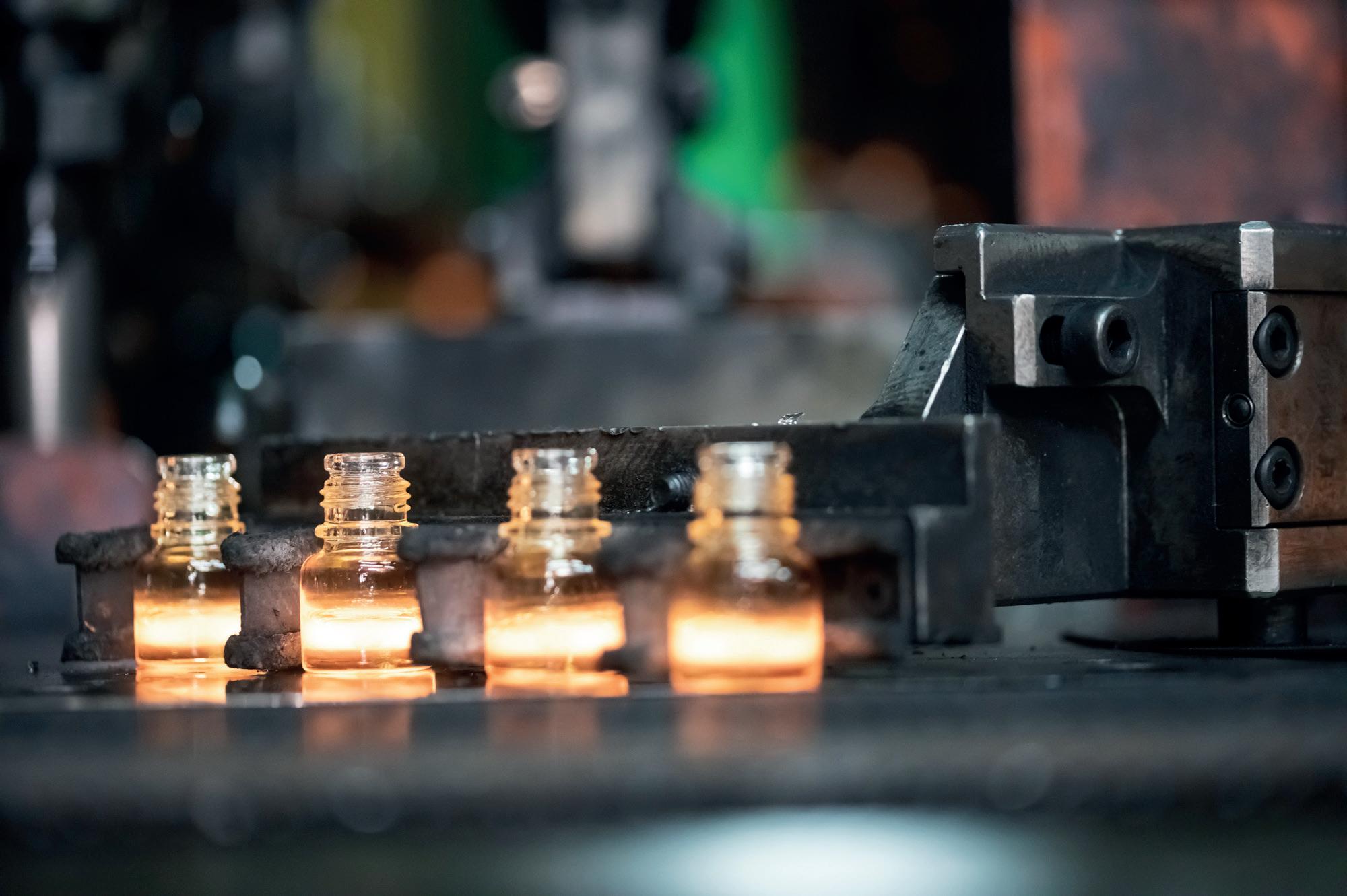

Italian pharmaceutical glassmaker Bormioli Pharma recently completed the refurbishment of its Bergantino, Italy furnace, which is dedicated to the production of type II glass containers. Davide Faverzani, Head of Engineering at Bormioli Pharma, discusses the project.

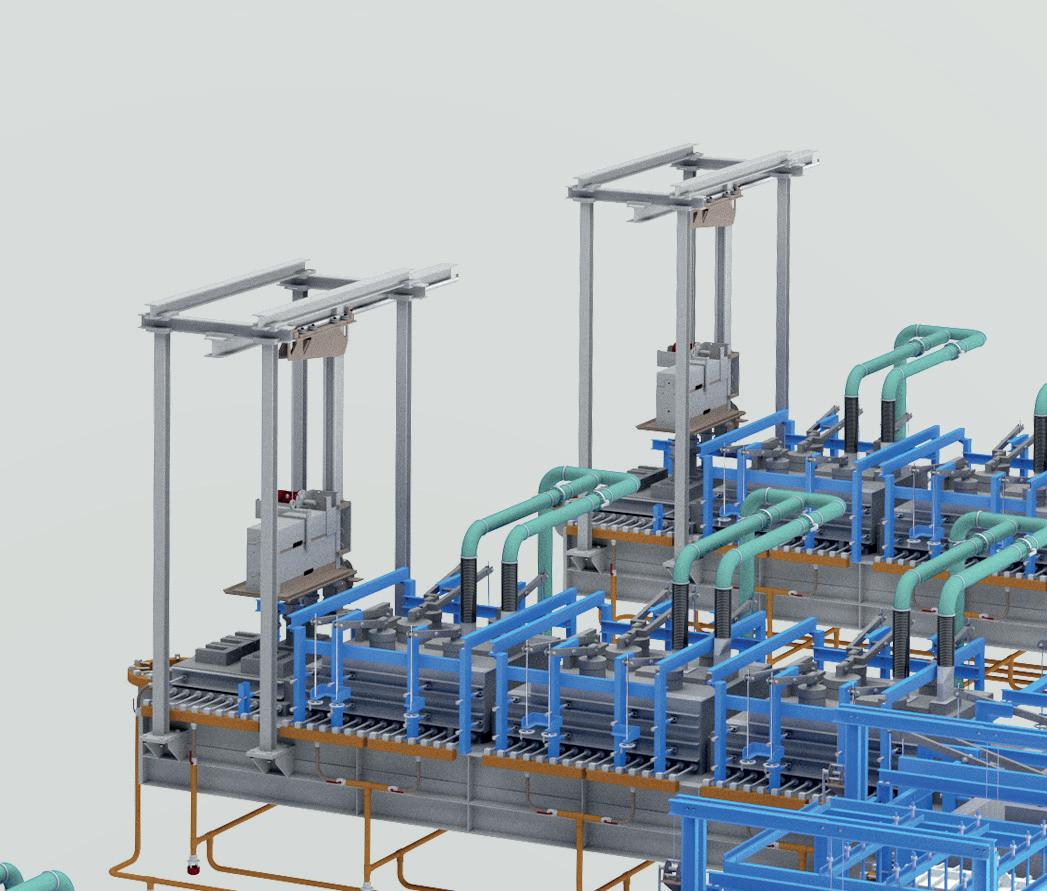

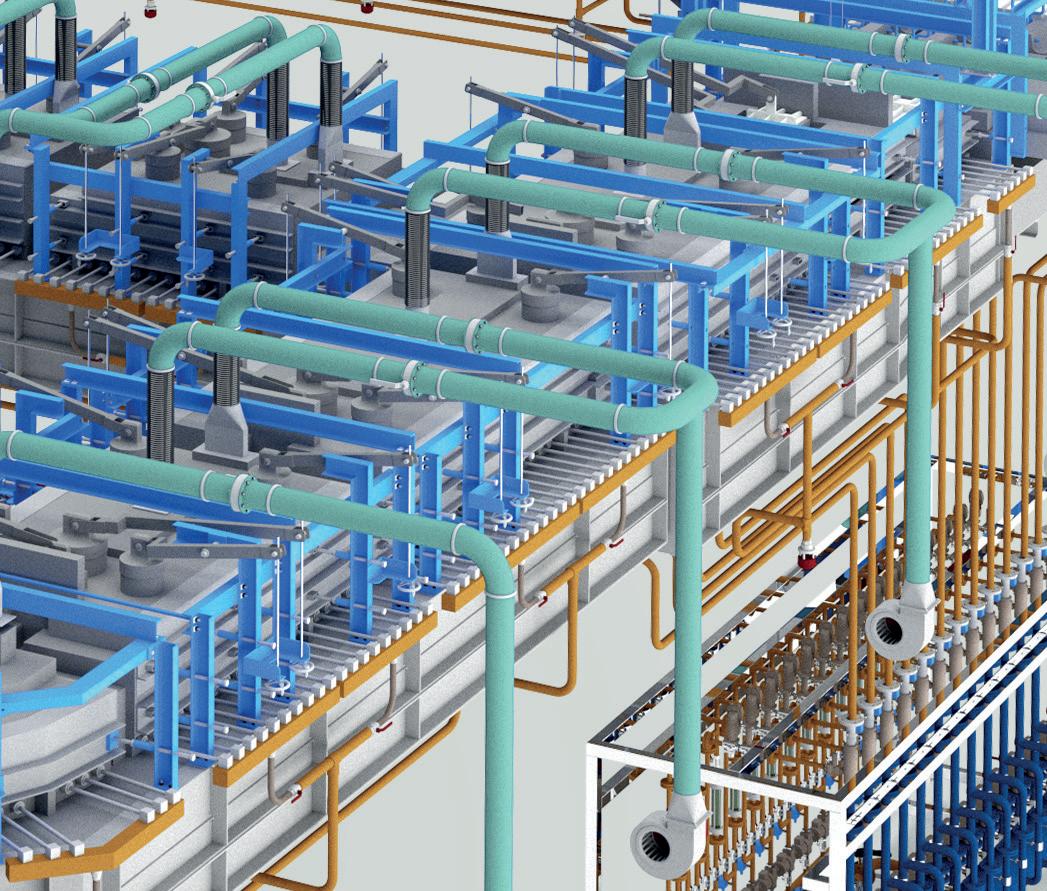

The Bergantino furnace refurbishment took 60 day from glass to glass. The project started with the complete demolition of the old furnace, together with the dismantling of two production lines and the cullet conveyor system.

After this, we continued with the construction of the new furnace, the installation of the new lines and the most advanced vision systems.

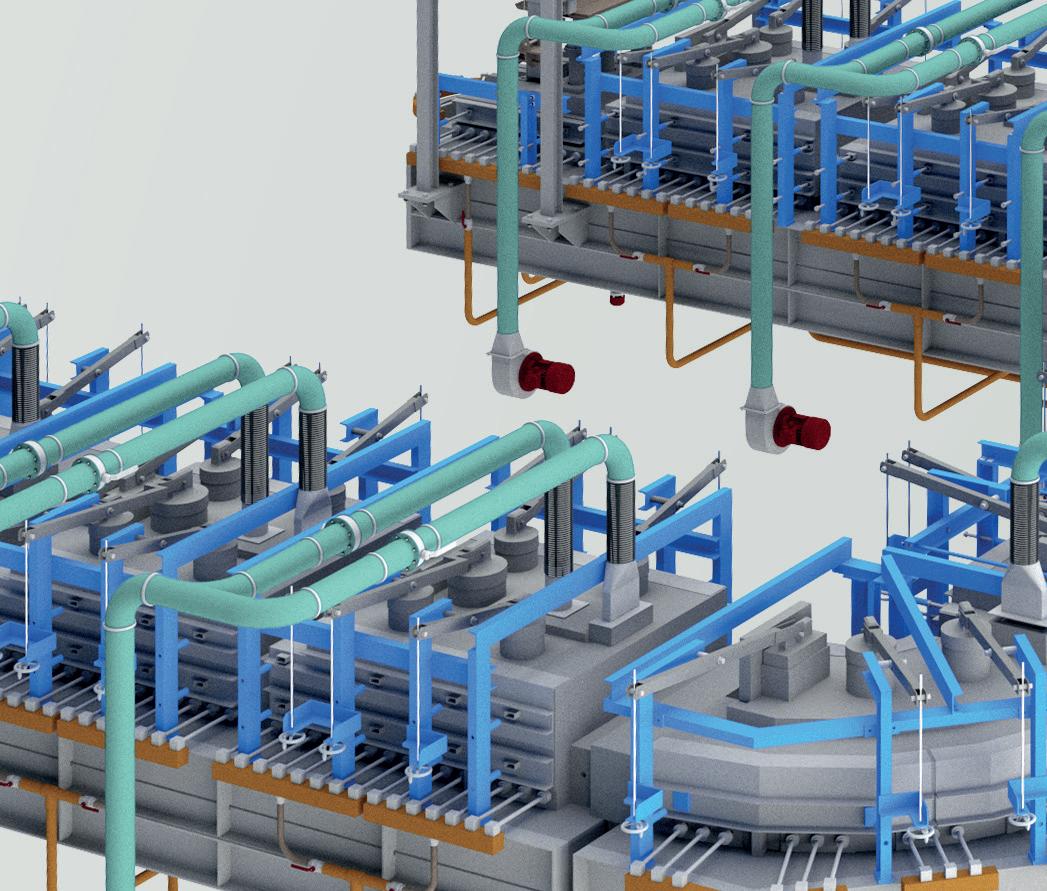

Moreover, the project included the installation of a new insulation system, which allows us to increase energy performances and furnace life.

Energy

As far as the issue of continuity of energy and gas supplies is concerned, Bormioli Pharma has taken a number of mitigating measures to keep the risk of supply interruption to a minimum, so limiting the impact also on this project.

We have binding contracts in place with international energy production and distribution companies who do not foresee the risk of a reduction in supply in the next 12 months unless highly disruptive geopolitical event occur.

Government and European Institutions are issuing recommendations aimed at limiting energy consumption through targeted actions (e.g., reduced use of air conditioning or heating systems) and, at present, there are no specific measures in place that have a major impact on industrial companies.

Moreover, the sector in which Bormioli Pharma operates, namely pharmaceutical & healthcare, has been identified, both at a National and European level, as an ‘essential’ supply chain.

Sustainability was a consideration during the works. We have installed a special insulation system which allows to reduce consumption, thus allowing for a more sustainable production.

The new furnace relies on a mixed technology, which use both electric and natural gas power. Moreover, an extra power boosting system has been introduced to guarantee the opportunity to increase the melting performance in the future.

Other investments took place within the plant at the same time.

Within the new furnace refurbishment project, we have replaced the medium voltage substation with a new monitoring

power system. Moreover, at the Bergantino plant we are revamping the parking area and the entrance building and we expect to close the project by the end of this year.

Digital technology was also a consideration during the investment. Digitalisation is an aspect we always consider when making new industrial investments. In the case of the new furnace, we have connected all the production equipment – from furnace up to palletizer – with a special Industry 4.0 supervisor system. Bormioli Pharma, Italy https://www.bormiolipharma.com/en

Demand

The new furnace will contribute to reinforce the positioning of our Bergantino plant as the biggest European production site for pharmaceutical moulded glass.

In this plant we produce 1.8 billion glass vials every year, which reach more than 100 countries. More specifically, the new furnace will be mainly dedicated to the production of modern type II glass containers, thus meeting the growing demand for this kind of product.

The first campaign started last September producing different Type II glass product formats, from small glass vials up to 1000 ml infusion bottles.

Demand in Italy’s pharmaceutical industry has been impacted by Covid-19. Going back to the 2019-2021 period, the packaging market has been impacted as the economy as a whole by the Covid-19.

Nevertheless, other than for the enormous shortage of glass vials, which has been addressed by the industry and aside from some anti-cyclical development of certain diseases (as flu and other seasonal diseases) as well as the delay in therapies due to the stay-at-home policies implemented in many countries which slow down or stopped for one year the demand for specific packaging products (such as syrups bottles), the Covid-19 only slightly affected the macro trends of the market which is projected to grow at mid-single-digit up to 2026, in line with the pharma market.

We expect that Italian market will reflect the same European trends described above. �