STRUCTURAL TIMBER

The latest in structural timber building design and technologies STRUCTURALTIMBERMAGAZINE.CO.UK

CUNDALL TIMBER HITS THE HIGH NOTE AT KING’S COLLEGE SCHOOL

WIMBLEDON’S NEW MUSIC SCHOOL

P24

Volumetric Timber Housing

Developer Urban Splash and Japan’s biggest housebuilder are set to develop more modular timber homes.

P26

Biophilic Design

Healthy construction and how timber can improve occupant’s physical, mental and social health.

P60

Harris Academy

The UK’s first Passivhaus secondary school sets a precedent for low carbon, high performance buildings.

AUTUMN 2019 | £4.95

DESIGN TECHNOLOGY SUSTAINABILITY INTERVIEWS NEWS ANALYSIS CASE STUDIES

Call us on 01304 842 555 to request a brochure on cavity barriers or email sales@envirograf.com CAVITY

UP TO 240 MINUTES PROTECTIONFIRE

ENVIROGRAF OFFERS THE LARGEST RANGE OF PASSIVE FIRE PRODUCTS, ESPECIALLY FOR CAVITY BARRIERS AND CAVITY FIRE PROOF TRAYS.

l Complying to EN1361-1&2, and also 1363-1&2

l Easy to install

l Suitable for different cladding types

l Allows free air movement

l Provides up to 240 minutes fire protection

l Vertical and horizontal solutions

l Moisture resistant

ALL

Envirograf

®

CLADDING PROVIDINGSYSTEMS

BARRIERS FOR ALL TYPES OF

MEMBER 2016

OF OUR PRODUCTS ARE TESTED TO BRITISH & EUROPEAN STANDARDS

RANGE

BARRIER

BARRIER

BARRIER RANGE RSF CAVITY BARRIER RANGE BRITISH MADE PRODUCTS

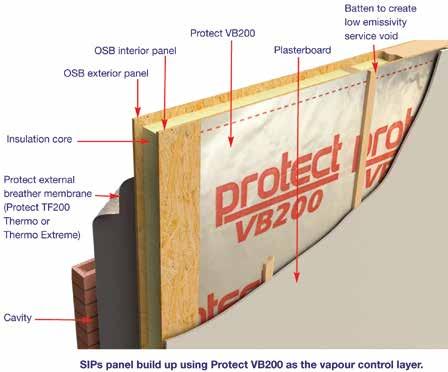

SEALED CAVITY TRAY (SCT) SILVER SCT WITH MESH PROTECTION RS/WB/CV CAVITY BARRIER RS/VWB CAVITY BARRIER CV STRIP WBS CAVITY BARRIER

FAST FIX CAVITY

FB/TS CAVITY

RSM CAVITY

FOLLOW US ON TWITTER UNDER: twitter.com/STMagUK

ADVERTISING ENQUIRIES PLEASE CONTACT:

ANDREW TANSELL // T: 01743 290002

E: andrew.tansell@structuraltimbermagazine.co.uk

BACK ISSUES VISIT:

www.structuraltimbermagazine.co.uk

SUBSCRIPTIONS VISIT:

www.structuraltimbermagazine.co.uk

FRONT COVER:

King’s College School, Wimbledon - Cundall Courtesy Janie Airey

PRINTED ON:

PEFC 16-33-576 paper stock by Buxton Press PEFC/16-33-576

PUBLISHER:

Radar Communications Ltd, 5 Darwin Court, Oxon Business Park, Shrewsbury, Shropshire. SY3 5AL

.pefc.co.uk

Welcome to the autumn edition of Structural Timber Magazine that reports on the successes of the Structural Timber Awards 2019 and also looks at the ways that timber is providing natural and healthy environments to live and work.

T: 01743 290001 | www.radar-communications.co.uk

©Radar Communications Ltd.

RELATED EVENTS:

www.structuraltimber.co.uk/events www.timbertalks.co.uk

www.structuraltimberawards.co.uk

www.offsite-expo.co.uk

DISCLAIMER: The content of Structural Timber Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

PRODUCTION

ADVERTISING & PR

CIRCULATION

PRODUCTION

ACCOUNTS

There is no doubt that using timber brings something special to a building. Not only is structural timber technology constantly refining and expanding, it is undoubtedly the most aesthetically appealing of any building material. It also brings a dimension all if its own – its organic and natural qualities can deliver a sense of wellbeing and improve our physical and mental health, like no other. The notion of wellbeing and biophilic design is explored in more detail in this issue by TRADA. Not only is wood associated with thermal and acoustic benefits, it can reduce stress and improve productivity – plus it’s ‘exclusive’ qualities can aid patient recovery and boost student performance.

Timber also brings massive energy efficiency benefits with all the cost savings and carbon reduction levels that brings. We have two fantastic schemes in this issue that demonstrate what can be done with timber and a single-minded approach to delivering low carbon learning and living. We feature the UK’s first Passivhaus secondary school – the £40million Harris Academy in Sutton. This inspirational school hopes to set a precedent for low carbon, high performance educational facilities with ambitious sustainability targets providing

a comfortable environment for students and staff. Goldsmith Street perhaps needs little introduction. You can find out more about the 2019 RIBA Stirling Prize winner inside. The revolutionary social housing development for Norwich City Council grabbed many headlines and received huge plaudits for its low energy aspirations. However, not mentioned in many places, was that at the centre of Goldsmith Street’s Passivhaus approach was a highly insulated timber frame structure.

Speaking of Award winners. The Structural Timber Awards 2019 have just come and gone. With 16 categories, nearly 250 entrants and over 70 companies shortlisted, this year’s judges had an onerous job. The big winner on the night was BlumerLehmann AG, Gilbert Ash and Marks Barfield Architects for Cambridge Mosque who scooped the Project of the Year and overall Winner of Winners – a round-up of the night is inside as well.

Many thanks to all our contributors, advertisers and supporters.

Gary Ramsay | Consultant Editor E: gary.ramsay@structuraltimbermagazine.co.uk

Andrew Tansell 01743 290002 andrew.tansell@structuraltimbermagazine.co.uk

Elle Pugh 01743 290040 elle.pugh@radar-communications.co.uk

Catherine Bodley 01743 290001 design@structuraltimbermagazine.co.uk

Debra Brooks 01743 290016 debra.brooks@structuraltimbermagazine.co.uk

Approved national and international products to protect the building envelope. The only UK cavity tray manufacturer awarded European Technical Approval. Performance warranty for the benefit of Architect, Builder & Client.

CAVITY TRAYS specialism • experience • service

WELCOME

enquiries@cavitytrays.co.uk www.cavitytrays.co.uk Yeovil • Somerset • BA22 8HU BRAND NEW PRODUCT GUIDE AVAILABLE NOW

PEFC Certified

This product is fr sustainably managed forests and controlled

Whatever you ask of it, a JJI-Joist has the answer every time. No ifs. No buts. No matter how complex or awkward the job, we have built the ultimate can-do joist. By manufacturing to the highest specification our I-Joists are light, strong, thermally efficient, BIM compatible, FSC and PEFC certified and PAS 2050 accredited (to cut a long list short). But it’s also the back-up we offer that no one can equal. Our expert team of designers, engineers and regional technical support is always there to say ‘yes we can’.

WEB: www.jamesjones.co.uk/ewp EMAIL: jji-joists @ jamesjones.co.uk

2019SPONSOR

THIS ISSUE...

P6

COVER STORY - CUNDALL

Barney Jordan, Structural Engineering Partner at multidisciplinary engineering firm, Cundall, discusses the triumph of timber in musical education and how the award-winning King’s College School, Wimbledon’s state-of-the-art new music school is an achievement of client vision, innovative architecture and structural design.

P08UK INDUSTRY NEWS

A quick round-up of some recent news stories from the timber and construction sectors that you may have missed including a new EU consortium targeting the reduction of CO2 emissions through increased use of timber, the BWF appoints a new President and BoKlok targets Bristol.

P22OFFSITE EXPO 2019

The inaugural Offsite Expo launched in Coventry to universal acclaim with positive feedback from exhibitors, visitors and speakers. With timber well represented, all agreed this was the offsite event that the construction industry has been waiting for.

P24A NEW PARTNERSHIP: A LONG-TERM VISION

Earlier in 2019 Urban Splash announced a deal to bring Japan’s biggest housebuilder – Sekisui House – to the UK, helping the developer create more modular timber homes. Urban Splash’s Director of Delivery Chris Shaw talks through the partnership, the company’s adoption of modular and plans for the future.

Protecting people and property since 1982

• Members of Structural Timber Association.

• Extensive experience of applying STA guidance and research.

• Determination of category of frame needed.

• Advice on appropriate solutions to reduce the risk of fire spread to surrounding buildings.

• Use of advanced computer modelling techniques to analyse timber frame proposals and provide a cost effective solution.

P26 THE ROLE OF WOOD IN HEALTHY BUILDINGS

Health and wellbeing is an umbrella term that refers to the indistinct categories of physical, mental and social health. Timber can potentially improve all three, TRADA’s Rupert Scott explains more.

P28 COMPETENCY IS CRUCIAL IN ACHIEVING FIRE SAFETY

Andrew Orriss, Director of STA Assure for the Structural Timber Association (STA) outlines the many ways to mitigate risk in timber construction and the role of quality management systems.

P32 CHAMPIONING THE WORLD OF WOOD

Stora Enso recently started production at its new €45million CLT facility at Grüvon in Sweden. Eve Dennehy reports on how Stora Enso maintains leadership in the global mass timber industry.

P36 STA ADVICE NOTE 18 – WHAT DO SPECIFIERS NEED TO KNOW?

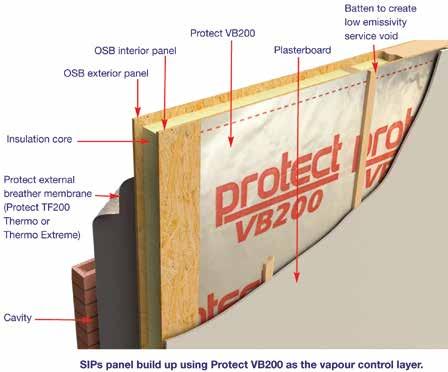

John Mellor, Product Manager at Protect Membranes, explains the STA’s new Advice Note 18 and the key recommendations for breather membranes installed to structural timber walls.

P44 STRUCTURAL TIMBER AWARDS 2019

Officially sold-out and packed to the rafters, the 2019 Awards took place once again during UK Construction Week at the National Conference Centre, Birmingham. Who was a class above?

P56 A TRIUMPH IN TIMBER

Featuring at the Timber Talks event – The Import Building in East India Dock, London is an exceptional example of the use of cross laminated timber (CLT) and glulam.

P58 ENERGY EFFICIENT TO THE CORE

The 2019 RIBA Stirling Prize was recently awarded to a revolutionary social housing development for Norwich City Council with a highly insulated timber frame structure.

P60 LOW ENERGY LEARNING

The UK’s first Passivhaus secondary school – the £40 million state-of-the-art Harris Academy has opened its doors and sets a precedent for low carbon, sustainable buildings.

The multi-disciplinary team comprises both chartered and graduate engineers, with specialist experience in fire protection and fire engineering, and experienced fire safety professionals with backgrounds in local authority fire and rescue services.

For further information visit our website: www.cstodd.co.uk

Tel: 01252 792088 Email: office@cstodd.co.uk

CONTENTS

Certificate Number 860 ISO 9001

FIRE ENGINEERING CONSULTANTS

HITTING THE TIMBER HIGH NOTES

Barney Jordan, Structural Engineering Partner at multi-disciplinary engineering firm, Cundall, discusses the triumph of timber in musical education and how the award-winning King’s College School, Wimbledon’s state-ofthe-art new music school is an achievement of client vision, innovative architecture and structural design.

Key to the project’s success has been the integrated approach between the architect, engineers, the school and the wider project team. Showcasing specially designed American white oak-lined ceilings in both the concert hall and rehearsal room, timber was the obvious choice of material in the design of the new music school.

The multi award-winning structure, which opened late last year, is part of the school’s ongoing development masterplan and is the result of a clear vision by both the school and the architect, supported by superb engineering.

The Hopkins Architect’s designed music school is arranged over three floors. The basement level comprises

loud practice rooms for instruments such as percussion, drums and brass, while the ground floor is home to the stunning 200-seat concert hall which can accommodate a 70-piece orchestra, a new porters’ lodge and staff administration space. The top floor consists of an orchestra rehearsal room, additional practice spaces and the porter’s residence. Both the concert hall and the orchestra rehearsal room have specially designed American white oaklined ceilings, which create a wonderful acoustic and reveal the exposed triangulated structure of the building.

The project team, comprising the architect, engineer, fabricator and contractor, went through extensive deliberation before arriving at the choice of timber as the dominant

STRUCTURALTIMBERMAGAZINE.CO.UK w 6 COVER STORY CUNDALL

02

01

03

structural material. During the concept design stage, concrete and steel were evaluated for the roof structures but they didn’t meet the structural honesty that Hopkins aimed for in their vision for the buildings and would not have been as aesthetically pleasing.

In the end, timber was chosen for its good compression qualities, which suited the requirements of the triangulated roof design, its sustainability credentials and its ability to achieve the architect’s aesthetic requirements to integrate the structure with both the interior and exterior finishes.

The shape of the main concert hall roof and the smaller orchestra rehearsal room roof – affectionately known by the design team as ‘the baby roof’ – are governed by the acoustic requirements of the spaces. The elegant glulam diagrid structures of these roofs not only result in a very efficient way to create the required geometry but also provide a support system for the integrated timber acoustic panels.

American white oak soffit lamella glulam beams were selected to match the American white oak veneer of the acoustic panels. The diamond structural grid matched both the interior acoustic panels and the external tile pattern, providing a cohesive and ultimately quite beautiful design, which contributes to the space functionality.

The main challenge Cundall faced was joining the timber diagrid members together, as the design required the six pieces of timber to come together at a single point. Both Cundall and Hopkins spoke to multiple timber fabricators to find an appropriate solution, eventually selecting a steel node to join each of

04

the pieces together and designing each diagrid to withstand the different forces across the roof. This meant close collaboration with both the contractor and fabricator to ensure each piece was built to the correct requirements and assembled appropriately.

To keep the overall thickness of the roof to a minimum, some of the glulam elements are designed to be working close to their strength capacity, which made the connection details even more challenging. The roof design and the node connections are just one part of a very well-conceived and engineered project, but they exemplify the collaborative and detailed design process that was experienced by the whole project team.

The timber components were prefabricated offsite following close collaboration between the engineer, architect and timber contractor to ensure fine tolerances, low wastage and a cohesive and resilient design and installation. This meant less waste, as materials are not being cut down or amended on site. The timber selected was also PEFC and FSC-certified, meaning the construction material has a lower embodied carbon, compared to other standard materials and has been responsibly sourced from well-managed forests.

Close liaison was required with the timber contractor from tender through to construction, to make sure the components met the requirements and allowed for the triangulated timber diagrid design to have structural integrity and match the design details of the rest of the structure. Since the timber was prefabricated, the design could not be altered once construction had begun.

Timber is a natural insulator, and it provided a thermally efficient structure and building envelope for the music school. This meant lower running costs and increased resistance to the unregulated changes in air, water, heat, light and noise transfer from the outside environment. Using timber to satisfy the acoustic requirements in this way meant it could be integrated into the build-up of the envelope and resulted in an elegant and environmentally efficient design.

The entire design team worked hard to meet the vision of both King’s College School and the architect, to ensure the design was fully co-ordinated ahead of fabrication. The process was collaborative through to final completion and has resulted in a beautiful and functional structure that will nurture a love of both music and building design for generations to come. IMAGES:

www.cundall.com

AWARDS

RIBA London Award 2019

RIBA National Award 2019

Structural Timber Awards 2019 –Education Project of the Year

New London Architecture Award

2019 – Commended

Education Acoustics Award 2019

The Institution of Structural Engineers Awards 2018 –Regional Winner

COVER STORY CUNDALL STRUCTURALTIMBERMAGAZINE.CO.UK w 7

01-02. The Concert Hall

Interior acoustic panels with diagrid node connections

school at King’s College School, Wimbledon.

images courtesy

03.

04. The new music

All

Janie Airey

CLIMATE ACTION FROM UK ARCHITECTS

Waugh Thistleton Architects has been selected as the only UK partner in a new EU consortium targeting the reduction of CO2 emissions through increased use of wood for multi-storey buildings. Build-in-Wood is a €8.6million project awarded by Horizon 2020.

The project is made up of a consortium of 21 partners. Its goal is to make wood the main choice of material for construction of multi-storey buildings. Kirsten Haggart of Waugh Thistleton said: “Widespread construction of multi-storey wood buildings would significantly reduce the construction sector’s CO2 emissions. Trees and are still the best method of carbon capture on earth. Our goal is to create a tall timber building kit of parts that optimises current timber

FIRE PROTECTION FOR PECKHAM APARTMENTS

A ‘shell & core’ style apartment development in one of South London’s up and coming districts is making use of Magply boards’ fire resistance and other performance characteristics, as the lining to a bespoke timber frame package.

technology. The system will be used as an exemplar of timber technology to dispel the barriers to timber adoption within the industry.”

The consortium partners represent the entire value chain from building materials to the finished structure with input from universities who will test the system and material prototypes. In addition to designing building systems, the project also involves manufacturers, end users, politicians, and local European communities to increase

The five flats are being developed on land adjacent to Peckham Rye railway station by Unboxed Homes while main contractor, Mara Build has overseen all the service provisions and creation of the sub-structure. Cambridgeshire-based White Haus is the timber frame specialist that has manufactured and erected the highly energy efficient structural envelope.

Crucially, given the proximity of the building to neighbouring properties, 9mm Magply has been used to line the timber panels, before being sprayed with a polymer-based membrane to achieve excellent airtightness. The purple finished Magply MgO boards are therefore the surface purchasers are presented with to fit out to their own specification and taste.

Project Manager for White Haus, Tony Buck, commented: “We offer clients a bespoke service for the supply and installation of high-performance timber frames to meet various specifications – right up to Passivhaus standard – building schools, hospitals and commercial premises as

the knowledge and acceptance of wood as a building material. European demand for construction of apartments is estimated at 1.6million units annually between 2020

Build-in-Wood is receiving funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 862820 and runs for four years from September 2019 to August 2023.

www.waughthistleton.com

well as domestic properties. While the timber frames normally have a plywood sheathing, we choose to use Magply internally whenever there is a requirement for fire protection as it offers up to 90 minutes resistance and meets the increasing threat of arson attacks on construction projects, as well as improving fire safety throughout the life of a building.

“Then, as with the Peckham development once the 25mm battens have been fixed to create a service cavity, we spray the surface with one of our membranes. Although this project isn’t actually to Passivhaus standard – which would require triple glazed windows and thicker insulation – the sprayed PU insulation in the walls, close-fitting Magply boards and our purple membrane will give an air permeability down at 0.6 air changes per hour to work with the heat recovery ventilation system.” www.magply.co.uk

8 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

BRISTOL READY FOR BOKLOK

BoKlok UK Ltd, the sustainable, quality and low-cost home provider jointly owned by Skanska and IKEA, has announced plans to develop 200 homes in south Bristol with Bristol City Council. Subject to planning permission, construction is expected to start in autumn 2020.

Bristol City Council, who owns the Airport Road site, has committed to pursuing the development of this partnership with BoKlok as part of the five-year Bristol Housing Festival which is trialling innovative offsite housing solutions across the city. The proposed development will be the first BoKlok community in Bristol. About 140 of the homes will be for market sale under the BoKlok brand. The remaining homes will be for social rent and shared ownership.

Marvin Rees, Mayor of Bristol, said: “At the festival’s launch a year ago, we said we would invite ideas from all over the world and be imaginative in solving the city’s housing emergency. This is exactly what

BoKlok will bring with these exciting plans. We are also exploring how Bristol City Council might acquire a number of these new homes as part of our commitment to providing more social housing.”

BoKlok has more than 20 years’ experience and has developed about 12,000 homes in the Nordics. Jonas Spangenberg, CEO of BoKlok, said: “When we entered the UK market we pin-pointed Bristol as a key city, and now we are excited to move ahead with the plans for Airport Road. We are here to stay for the long-term, making it possible for more people with average incomes to realise their dream of owning their home.”

BoKlok is jointly owned by Skanska and IKEA. Gregor Craig, President and CEO, Skanska UK said: “Skanska’s purpose is to build for a better society and BoKlok will broaden our offer in the UK with sustainable, quality homes at a low cost. Skanska has been actively involved in Bristol for many years, building or refurbishing over 50 schools in the area.

So, I am delighted that these plans for BoKlok would extend our association with the city.”

Jez Sweetland, Bristol Housing Festival’s Project Director, said: “The festival is all about re-imagining new and better ways to live in our cities. BoKlok provide creative solutions with a fantastic track record of creating great homes and strong communities, we are really thrilled to be working with them.”

BoKlok homes are built primarily from timber, using a smart, industrialised and efficient process. Homes are completed offsite in a safe and dry environment using a smart and industrialised process. This enables high quality, low and predictable costs. BoKlok, having the most satisfied customers in the residential sector in Sweden 2017 and 2018, aims to set new customer satisfaction standards in the UK market.

www.boklok.co.uk

10 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

NORBORD PROGRESSING AT INVERNESS WOOD PANEL PLANT

Wood panel manufacturer Norbord is making significant progress at its Dalcross-based factory, following a further £35million investment earlier this year. This second recent investment into the site, following a £110million expansion programme in 2018, will realise the construction of a second wood debarker and flaker, heat plant and a dryer at the Morayhill mill, increasing the production capacity. Set for completion in 2021, the development will allow the mill to meet increased consumer demand for oriented strand board (OSB) across the UK and Europe.

Alan McMeekin, Norbord Europe Managing Director, said: “The plan was always to invest further, and we are pleased that the very successful start-up, as a result of great teamwork and market, has enabled us to enhance facilities earlier than we originally anticipated. This £35million investment will increase capacity and deliver an increased level of support to our strategic customer base, further underlining Norbord’s status as the world’s number one OSB producer.”

Stuart Hendry, General Manager at the Inverness factory added: “This investment showcases our commitment to our Inverness workforce and supply chain, as well as the significant growth potential there is within the European OSB industry. I’m delighted to have been able to join the team at Inverness at such an exciting time as these developments ensure that Norbord are in prime position to deliver the best service to our customers, efficiently serving their needs across the UK and mainland Europe.”

Last year, First Minister Nicola Sturgeon unveiled the new manufacturing line at the plant following the investment, which was supported by a £12million development grant from Highlands and Islands Enterprise.

www.norbord.co.uk

HUNDEGGER ROBOT-Drive MULTIFACETED FLEXIBILITY FOR ALL TIMBER CONSTRUCTION COMPANIES

Me and my Hundegger!

Never change a winning team!

hundegger.com

JOINERY MACHINE HUNDEGGER ROBOT-Drive

Compact dimensions and modular design –the ROBOT-Drive offers maximum flexibility and almost unlimited processing possibilities for bars and panels.

With the ROBOT-Drive, a 6-axis unit performs all the necessary work steps on the part – and in a single run. The solution for all requirements including timber glue construction from 20 x 60 mm to 300 x 1300 mm.

The ROBOT-Drive is the most recent addition to the range of Hundegger joinery machines.

Hundegger UK Ltd.

Daniel Blades

Snetterton Park, Harling Road

Snetterton, Norfolk NR16 2JU

Office: +44 (0)1953 660 331

Mobile: +44 (0)7940 714 599

d.blades@hundegger.com

in

Innovation

timber engineering

RD_4c_93x267+3_GB_Daniel Blades.indd 1 02.09.2019 11:41:52

SO MODULAR REACH NEW HEIGHTS

An innovative building product developed by Wales largest specialist timber frame manufacture based in Neath, has been given the green light to be used in six-storey buildings – an important landmark as it widens the potential market for its use.

The Triso-Warm structurally insulated panel modular build system, developed by Sevenoaks Modular has been given the seal of approval by the BBA, the UK’s leading construction certification body. The Triso-Warm system is at the forefront of innovative and creative solutions within the construction industry. It allows developers to boost efficiency, sustainability and costeffectiveness across a diverse range of construction projects.

The certificate awarded by the BBA allows the company to construct six-storey buildings using the Triso-Warm product. Until recently, they could only use it up to four-storeys. The certificate was granted after the company has demonstrated the product’s efficiency, sustainability and costeffectiveness, as well as passing several tests conducted by the BBA to ensure its competence, durability and safety on higher-storey builds.

Sevenoaks Modular’s Triso-Warm product comprises specially engineered timber frame panels injected with PUR highlyinsulated foam, which expands and adheres to the inner panel, creating an airtight seal. The product is extremely thermally efficient, addressing three key issues required for excellence in thermal efficiency: very low U-values – typically 0.11 W/m2K, good performance to resist cold bridging –Y-values typically of 0.04 W/m2K; and good air permeability – as low as 1m3/m2h @50pa. The product provides economic solutions to achieve an ‘A’ rated Energy Performance Certificate.

Sevenoaks Modular is due to complete a £10million housing development in Pentland Close, Llanishen, Cardiff –where the Triso-Warm system is being implemented to meet the requirements of Wales and West Housing Association to ensure thermal efficiency is met for its future residents. The extensive project involves the build of five three-storey blocks – with large parts of the build – including installed doors and windows along with external cladding being manufactured offsite. Charlotte Hale, Director of Sevenoaks Modular, said: “This is an exciting time for Sevenoaks Modular as we

are offering a product that is much sought after in the current climate of fuel poverty in Wales – and we are happy to be able to provide a solution to help people stay warm, without it costing money that some households are unable to afford. We are thrilled to have been awarded the next level certificate by the BBA to enable us to now use the product on six-storey builds.”

Claire Curtis-Thomas, CEO of the BBA, added: “As a company it pleases us to see how JG Hale has used their BBA Certified Triso-Warm product to provide a long lasting and effective solution to the construction of offsite housing in Wales. The innovation and development displayed by JG Hale and Sevenoaks Modular in the continual expansion of their business footprint can only bring about positive changes for the industry.”

Sevenoaks Modular has been growing rapidly since it was formed in June 2018 on the back of a growing demand for modular construction solutions in the UK. This move should allow it to go from producing 1,000 homes per year to more than 3,000 per year.

12 STRUCTURALTIMBERMAGAZINE.CO.UK w

UK INDUSTRY NEWS

www.somodular.co.uk

SAINT-GOBAIN SET TO REWARD STAFF

Well-known and respected timber industry brands –International Timber, Pasquill, Roofspace Solutions and Scotframe – have collaborated to launch the Saint-Gobain Off-Site Solutions (OSS) Awards, recognising and highlighting achievements of staff across the four businesses.

Saint-Gobain recognised that construction is changing and the demand for quality, speed and productivity of build is driving customers to innovate and change their approach. In response to these new challenges and opportunities, the four brands have come together to form the new Off-Site Solutions division.

International Timber, Pasquill, Roofspace Solutions and Scotframe boast a unique combination of products, solutions and skills. Working together under the Off-Site Solutions division allows the brands to present a unique offering for customers, backed up by the wide range of Saint-Gobain assets available in the UK.

The OSS Awards are an evolution of the annual Pasquill and International Timber staff awards, which for the last four years have celebrated employees who go above and beyond. The nominations are now open and colleagues across the division are nominating their fellow colleagues and teams for a number of awards.

Accolades are to be given for the following categories: Outstanding Contribution, Best Collaboration, Outstanding Contribution to Environmental Health & Safety (EHS), Newcomer of the Year, Innovation Award, Design / Sales Team of the Year, and Operations / Team of the Year.

Ross Baxter, Managing Director - Saint-Gobain Off-Site Solutions, commented: “The new OSS Awards allow us to bring together brands to celebrate success, recognising the people who truly make a difference to our business. The old Awards have previously been a highlight of the year, and we’re excited to extend this to other brand’s employees who form an important part of the Off-Site Solutions offering.”

www.saint-gobain.com

Futureproof The Evolution of CLT

With B&K Structures, the restriction on combustible materials does not mean an end to building with CLT. We achieve highly practical, sustainable structures over 18m.

• Meeting the Latest Building Regulations

• Panelised Hybrid Approach Integrating a CLT Superstructure

• Non-Combustible Unitised Wall Panel Systems

• Structural Steel Carrier Frame & Non-Combustible SFS Infill Walling

• Factory Fitted Added Value Options

• No Impact on Cost or Programme

• Delivers a Lower Carbon Footprint Compliant System

COMPLIANT INNOVATIVE COST EFFECTIVE B&K Structures @BKStructures bkstructures www.bkstructures.co.uk B&K Structures Limited Peveril House Alfreton Road Derby DE21 4AG 01773 853400 sales@bkstructures.co.uk

TIMBER PRICES STABLE SAY BIDWELLS

Property Consultants Bidwells have released their Summer 2019 Timber Price Database which looks at the standing conifer timber prices achieved covering October 2018 to 31 March 2019.

Following dramatic increases in standing timber values seen between late 2017 and early 2018, the report results from sales suggest that prices remained fairly stable at the comparatively high levels which had been experienced since late 2017. The latest results, however, are based on returns from only 59 transactions, totalling just over 206,000 cubic metres of timber with a standing value to the grower of approximately £8.1million. Despite being a small sample, it was clear during the reporting period that demand from processers remained high as did standing prices paid to growers.

GLOBAL PRIZE FOR CLT EXPERT

Professor Gerhard Schickhofer, from the Institute of Timber Engineering and Wood Technology at Graz University of Technology, Austria was recently awarded the 2019 Marcus Wallenberg Prize for research and knowledge transfer behind crosslaminated timber (CLT).

Windblow and the high incidence of timber affected by bark beetles on continental Europe (possibly as a result of the hot, dry conditions of summer 2018) has produced an excess of imported timber looking for a home.

UK sawmillers in particular have come under pressure in terms of both price and demand for their finished products in light of this flood of imports, which has inevitably led to lower demand and price for homegrown standing timber. Raymond

Gerhard Schickhofer has laid the scientific and technological foundation for the development of CLT and his research team have played a leading role in establishing standards and Technical Approvals for CLT production and use in industrial applications of wood construction.

The purpose of the Prize is to: ‘recognise, encourage and stimulate pathbreaking scientific achievements which contribute significantly to broadening knowledge and to technical development within the fields of importance to forestry and forest industries.’

“CLT is the result of the co-operation between science and industry,” said Gerhard Schickhofer says. “It is good to know how much the construction industry has gained in importance with the product and how all over the world thousands of jobs have been created, not only in rural regions where the forest is nearby but also in urban areas. The material has radically transformed the view on construction and

Henderson, Forestry Partner at Bidwells said: “This effect is not demonstrated in these results and should be a temporary phenomenon until European timber harvesting rates return to a more normal footing. Fundamentals of the UK industry remain sound and should (despite the ongoing Brexit situation) give all connected with timber real confidence for the future.”

To view the full insights and research visit: www.bidwells.co.uk

design in the wood building industry. “Prefabrication of different modules at the factory makes the assembly time on the building site shorter. CLT is a sustainable and renewable material, that stores carbon dioxide. Thus it makes sense to pursue building with CLT in order to push the sustainability strategy of the whole construction industry to the forefront, making it more carbon dioxide neutral and contributing to the fight against climate change.”

Johanna Buchert, Chairperson of the Selection Committee of the Marcus Wallenberg Foundation said: “Gerhard Schickhofer’s passion and commitment to the field of CLT have played a key role in raising the profile of wood for the construction of massive and tall structures. His work has been seminal in interpreting the technological opportunities of CLT to architects and designers.”

www.mwp.org

14 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

Lasting beauty. Exceptional performance. Peace of mind.

FACTORY FINISHES WITH PROVEN PROTECTION AND PERFORMANCE

From protective undercoats and weathering treatments to beautiful finishes and durable topcoats, Sansin’s Precision Coat line of water-borne, factory finishes delivers the color, durability and performance that architects, engineers and builders can count on.

1-877-SANSIN-1 | sansinfactoryfinish.com

Tsleil-Waututh Administration & Health Centre, Vancouver, Canada. Photo © Ema Peter

A Proud Sponsor of the Structural Timber Association’s London Timber Talk

NEW PRESIDENT FOR BWF

The British Woodworking Federation (BWF) has appointed Paul Bailey, founder and Managing Director of European Doorsets, as its new President. He succeeds Sean Parnaby, Managing Director of West Port Timber Windows.

Paul has over 30 years’ experience in the woodworking sector. He established European Doorsets, manufacturers of bespoke performance doors, doorsets and associated joinery items, in 1990 and for a number of years has been an active member of the BWF. Paul has been integral to driving forward the BWF’s aims and ethos, having been a member of the association’s board of directors for 13 years and vice president since 2016.

Helen Hewitt, CEO of the BWF said: “We’re delighted that Paul has taken up the reigns as President of the association. He brings with him experience and knowledge of the sector, an understanding of the challenges we face as an industry and a clear sense of what we can be doing collectively to meet them head on. Our thanks go to Sean Parnaby who has played a central role in our growth. Paul is committed to continuing to drive forward Sean’s excellent work in promoting our sector and ensuring it remains attractive to young people who seek a long and rewarding career.”

Paul Bailey added: “Political events continue to dictate the activities of businesses across all sectors and the uncertainty over Brexit has undoubtedly made it difficult to plan ahead, particularly for the joinery and woodworking industry. However, if any sector has the skills, experience and resilience to make alternative plans and get on with things, then it’s ours. I’m confident that with support from the BWF and overarching leadership from the Confederation of Timber Industries, the industry is well placed to build on the encouraging growth it has experienced over the past few years.

“There are two areas in particular that I believe are fundamental to ensuring this progress continues: attracting the next generation of talent and communicating the benefits of wood to professional audiences and the general public. I’m excited about the future as I take on the role at such a critical time for our industry. United by a passion for wood, I’m looking forward to working with my colleagues at the BWF to raise the profile of UK woodworking, tackle the skills gap and drive innovation and growth throughout the sector.”

www.bwf.org.uk

TIME FOR TIMBER AT SWATCH HQ

After a construction period of almost five years, watchmaker Swatch has opened its new headquarters in Biel – one of the world’s largest timber structures, designed by the Japanese star architect Shigeru Ban.

A timber grid shell construction forms the basic structure of the large-area façade. During the planning phase, modern 3D technology helped to define the exact shape and positioning of the approximately 4,600 beams of the timber grid shell. Using a sophisticated plug-in principle, the individual beams were fitted to each other perfectly. Since the timber grid shell of the Swatch building serves as a large office façade, it also had to meet various technical requirements.

A complex network of cables is discreetly integrated into its structure. Only timber from Swiss forests – mainly spruce – was used in the construction. While the wooden structure was still being erected, the installation of around 2,800 honeycomb timber grid shell elements, which make up most of the façade, began. Each element was meticulously tailored from up to 50 individual parts and adapted to its individual function and position.

www.swatchgroup.com/en

16 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

A stronger system for stronger floors. Simply use our enhanced moisture resistant boards, our quality joint & joist adhesive and our reliable fitting method to benefit from the EGGER Advanced Lifetime Guarantee For more information and terms and conditions, please call 0845 602 4444 or email building.uk@egger.com Egger Advanced Structural Flooring System. A lifetime guaranteed. www.egger.com/lifetime

EGGER GROUP RECEIVES ISO 38200

EGGER has implemented a new, globally valid standard for the transmission of information along the supply chain of wood and wood-based products. The ISO 38200 provides a globally valid, internationally recognised standard for the product chain of wood and wood-based products.

It regulates the transmission of information along the supply chain: from logging to delivery to the end customer. As one of the first wood-based materials manufacturers worldwide, the EGGER Group meets the high requirements of the new standard.

Sustainable procurement is a matter of course for EGGER, including compliance with national and European laws, such as the EU Timber Regulation (EUTR).

In order to live up to its responsibilities and pioneer role, EGGER has now expanded its due diligence system (DDS) to include the standards of the new ISO 38200.

ISO 38200 regulates the transfer of information along the entire product chain of wood and wood-based products. The traceability of wood or wood-based products is made more transparent, and proof of origin and legality is maintained through continuous monitoring of the supply chain. In addition to general aspects of control and inspection, the standard also categorises social criteria, environmental criteria, and DDS requirements. The new ISO 38200 standard also helps EGGER to present its sustainability indicators in an even more comprehensive and detailed manner.

Walter Schiegl, Production and Technical Group Director at EGGER, said: “Forwardthinking action, which is also geared to future generations, is based on ecological, economic, and social sustainability and has always been our established practice. With the Group-wide implementation of the ISO 38200 standard, we are setting a further step towards promoting sustainable forestry beyond meeting all legal requirements.”

ISO 38200 offers a standard that is valid worldwide and internationally recognised for the product chain of wood and wood-based products. ISO 38200 standard helps EGGER implement the United Nations Sustainability Goals (SDGs).

www.egger.com/environment

18 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

Connectors developed for modern timber construction

What can it be used for?

• Timber frame and solid timber construction

• For installation in wood and concrete

• For absorbing tensile and shearing forces

Advantages

• Many different fields of application

• High load-bearing capacity → Fewer connectors required

• Indirect fixing due to an intermediate layer (e. g. OSB)

• Optimised hole pattern

The specialist for fastening technology E.u.r.o.Tec GmbH • Unter dem Hofe 5 • D-58099 Hagen Tel. 0049 (0) 2331 62 45-0 • Fax 0049 (0) 2331 62 45-200 • email: info@eurotec.team www.eurotec.team/en

CONSTRUCTION CONNECTORS

TIMBER

Shearing plate

Shearing angle

Tension straps

Tension rod

YEARS of quality NEW

product

to our

range

MOBIE MOBILISING

The ways that homes are designed and built in the future could be completely transformed, thanks to a new project between Northumbria University, Newcastle and the renowned architect, TV presenter and campaigner George Clarke.

The University has signed an agreement with Clarke’s charity, the Ministry of Building Innovation and Education (MOBIE), to work together to drive innovation in designing and delivering homes for the future. The partnership was officially announced during the UK Construction Week event at Birmingham NEC.

MOBIE was founded by Clarke in 2017 to promote innovation in the design and delivery of homes through education and the charity currently works with a number of schools, colleges and universities. However, this is the first time that MOBIE has focused on embedding research and innovation into businesses. The new MOBIE Northumbria Homes for the Future Innovation Centre

will help businesses involved in the design and delivery of homes access the latest in research and innovation at Northumbria University to drive the transformation of the sector.

The centre will investigate new methods of construction, design, offsite manufacture, digital competencies and materials with the aim of making house building a more efficient and precise process. It will provide greater quality control, using the latest technologies, all while ensuring the needs of residents and communities are met. Over the next three years, Northumbria will offer a total of 15 co-funded PhD studentships to work with industry partners through the centre. The University will jointly fund the studentships, meaning businesses will invest roughly £10,000 per year for each of the three years.

George Clarke explained: “By partnering with Northumbria University and appointing doctoral students to work with the businesses, we can ensure we are passing

on the very latest in research and thinking into the building sector to transform the way it works. Ultimately, we want to create better quality homes that will drive a better quality of life for everyone living in them.”

Dr Paul Jones, Professor of Scholarship in Architecture at Northumbria University said: “By opening our doors to businesses, we will be able to work with them to develop truly innovative techniques that will create positive change in the industry, create high quality homes for those who need them and help businesses by driving growth.”

Recruitment is already underway for industry partners and the first PhD students, in time for the centre to officially begin operating from April 2020.

To find out more about opportunities to get involved with the MOBIE Northumbria Homes for the Future Innovation Centre visit: www.northumbria.ac.uk/mobie

20 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

Kronobuild® Fast Protect T&G

Mess happens on a building site, but now issues like spilled paint can be cleared up almost as fast as they happen. Kronobuild Fast Protect T&G boards feature a slip-resistant waterproof membrane cover that can be easily peeled away at the end of the build taking all the mess with it. What’s left behind is a pristine floor that also has a permanent secondary layer of coating for on-going protection. Certified weatherproof for 60 days, it’s engineered to perform. For samples or further information visit www.kronospan-express.com

THE QUICK CLEAN UP T&G FLOORING

OFFSITE EXPO ARRIVES IN STYLE

In its launch year, Offsite Expo certainly exceeded expectations, with universal positive feedback from exhibitors, visitors and speakers. All agreed this was the offsite event that the construction industry has been waiting for.

Industry expert and acknowledged offsite champion Mark Farmer cut the ribbon to open Offsite Expo, welcoming construction professionals from across the UK and beyond to the official launch of the inaugural event at the Ricoh Arena, Coventry.

This highly focused two-day exhibition featured 40 hours of CPD Accredited Masterclass Seminars, an International Offsite Summit and the Offsite Connect Buyers and Specifiers Forum. “It is really inspiring to see the world of offsite gathering to showcase the latest technology options and innovations within the sector,” said Mark Farmer. “Offsite Expo’s positioning, content and timing really reflects the mood within the construction sector and the buzz around the show was exceptional.”

The Offsite Expo exhibition was a total sell-out, with over 100 exhibitors promoting offsite systems, technologies and services but this of course, is only part of the equation. Offsite Expo was developed as a platform to network and create new business opportunities and at the heart of the event, the Offsite Connect Buyers and Specifiers Forum, which was open exclusively to exhibitors, was a hive of activity. With over 100 buyers and specifiers registering to participate including representatives from Mace, Willmott Dixon, Kier, Balfour Beatty, Galliford Try, NHS and Apex Airspace. 320 business meetings were scheduled with buyers and exhibitors via the online diary system and of those over 300 actual meetings took place and feedback from both the buyers and exhibitors has been tremendous.

Tom Fairlie from Walker Timber Group, endorsed this view saying: “Offsite Connect provided a fantastic opportunity for exhibitors to hold focused business meetings and discussions regarding the benefits of specifying timber frame technology and sustainable modern methods of construction.”

But Offsite Expo was not only about securing business opportunities –the conference and exhibition was developed to inform and inspire through knowledge exchange and opinion sharing. Getting to grips with the latest international offsite methods and smart digital technologies was high on the agenda – the Offsite Construction Summit provided a dynamic and interactive experience focusing on international offsite best practice. Knowledge share and transfer was the prime objective for the Summit and the stellar speaker line-up presented some incredible developments across the global offsite supply-chain.

22 STRUCTURALTIMBERMAGAZINE.CO.UK w OFFSITE EXPO 2019

01

02

One of the curators of the event, leading offsite expert from Cogent Consulting, Darren Richards said: “The offsite arena is an exciting place to be. The levels of investment and confidence in the long-term viability of advanced offsite methods of construction, is greater than previously witnessed. The heightened interest in all things offsite was clearly demonstrated at the event. Facilitating knowledge transfer and promoting innovation in the sector, Offsite Expo has been extremely well received.”

Over 80 speakers offered delegates the opportunity to hear from experts offering in-depth analysis and technical know-how in an extensive range of CPD Accredited Offsite Masterclasses. Presented by a host of UK pioneers in two dedicated custom-built offsite technology theatres, the Masterclasses focused on the latest innovations. “Demand was ramping up and our industry intelligence demonstrated a need for a dedicated offsite exhibition curated by sector experts that focused on cutting-edge content, complementing our Offsite Hub and Offsite Magazine platforms,” said Julie Williams, Event Director for Offsite Expo. “The response has been truly astounding and already, just days after the event, we have 68 exhibitor bookings for 2020 – 53 re-bookings and 15 new companies looking to promote offsite technologies and services at our next Offsite Expo.” *

The final word goes to Dan Soulsby, National Construction Account Manager Building Products, EGGER (UK) Ltd: “I’m sure you’ve had many comments

like this, but I just wanted to say how good Offsite Expo was! We were well impressed (but not surprised) at the quality of the organisation, the content of seminars, the exhibitors and the attendees. We had some great discussions and met with some really key people and have lots to take away with us, plus all the information we gained from the seminars – most of which were standing room only!”

KEY STATISTICS

03

IMAGES:

01. Mark Farmer & Event Director Julie Williams at the opening ceremony

02. Offsite Summit saw international experts talk about global developments

03. Masterclass Theatre built and hosted by B&K Structures DATE FOR YOUR DIARY:

• 2,874 Unique Visitors attended Offsite Expo

• 40 hours of CPD Accredited Presentations in the Explore Offsite Masterclass Sessions

• 80 UK and International Speakers in the Offsite Summit / Masterclasses

• 300 meetings in the Offsite Connect Buyers & Specifiers Forum

• 2 Launches - Offsite Construction Awards 2020 and the Construction Futures Research Centre

• 5 Feature Builds / Seminar Theatres

OFFSITE EXPO 2020

Plans are already underway for the next event taking place on 22 - 23 September 2020 at the Ricoh Arena, Coventry – Offsite Expo will again feature informative speaker content but new for 2020 will include ‘live’ feature builds, machinery demonstrations and by considerable demand – Technical Guided Tours hosted by offsite experts from Cogent Consulting.

For the first time Offsite Expo 2020 will also host the Offsite Construction Awards. This move will give the team behind the Awards room to expand the event, after a high demand for tickets last year saw many people losing out on attending the big night. The deadline for submissions is the 15 May 2020 with the finalists being announced ahead of the Award ceremony at Offsite Expo on the 22 September 2020.

For more information on getting involved in Offsite Expo 2020 as an Exhibitor or Sponsor contact Julie Williams, Event Director: 01743 290 001 email: julie.williams@radar-communications.co.uk or visit: www.offsite-expo.co.uk

*Statistic correct as of 30 September 2019

23 STRUCTURALTIMBERMAGAZINE.CO.UK w OFFSITE EXPO 2019

A NEW PARTNERSHIP: A LONG-TERM VISION

Earlier this year Urban Splash announced a deal to bring Japan’s biggest housebuilder – Sekisui House – to the UK, helping the developer create more timber modular homes.

Urban Splash’s Director of Delivery Chris Shaw talks through the partnership, the company’s adoption of modular and plans for the future.

Following a period of creating homes using offsite construction – and vertically integrating the production of those homes into our core business – the hoUSe by Urban Splash story culminated in early summer in a £90million deal with Sekisui House and Homes England. It’s a deal which is helping us produce more homes using offsite.

Urban Splash has long positioned itself as a pioneer of modular homes created using sustainable timber products – we actually started developing timber homes using modular techniques in 2012 – working with Liverpoolbased architects shedkm and offsite construction partners SIG to create

a prototype modular home for the family-housing market. Initially, we were looking at traditional construction, but then turned to offsite.

In 2016, after years of R&D and design iterations, we brought the first 43 modular homes to market at New Islington in Manchester under our hoUSe by Urban Splash brand. Core to that brand’s offering is Town House which offers customers an adaptable design template on a 1,000sq ft two-storey property or a 1,500sq ft three-storey property.

To date, we’ve created Town House at New Islington in Manchester – where all Town Houses are sold and occupied – Irwell Riverside in Salford, again all sold – as well as 24 Town Houses which are sold and occupied at Smith’s Dock in North Shields and homes at Port Loop in Birmingham – where 80% are sold following a launch this summer.

But it’s time to create so much more! A huge modular wake-up call came in 2016 with the release of Mark Farmer’s ‘Modernise or Die’ report that called for radical changes in the wake of severe traditional construction skills shortages.

With vertical integration a big recommendation in Farmer’s report, we commenced talks with SIG about buying the modular factory in which our homes to date had been created. The deal completed early in 2018 when we acquired our 85-employee factory in Alfreton in the East Midlands.

In 2019, we made an even more significant announcement – that we were partnering with Homes England and Sekisui House – and together we’re making modern homes more accessible.

24 STRUCTURALTIMBERMAGAZINE.CO.UK w VOLUMETRIC MODULAR TIMBER

01

The deal was actually more than two years in the making, during which time our team visited Japan and two of Sekisui’s factories to witness an incredible setup. Notable was the company’s 750,000sq ft R&D institute in Osaka which features a two-storey earthquake simulator reaching 7.7 on the Richter scale. Sekisui House uses this feature as a sales tool to show their customers the strength of their buildings, and a sophisticated design which absorbs the friction and heat of the earthquake, separate from the inside of the house.

Now, thanks to the deal, we’ve brought that expertise and advanced R&D to the UK market, and we’re already

applying the insight as we evolve the hoUSe by Urban Splash modular product offering. From an innovation and technology standpoint there are so many awesome things we are already looking at. The numbers are impressive. Sekisui has delivered more than two million modular homes, with around 15,000 customisable individual homes developed every year. That scalability and the deal means that now we can take a long-term view.

Our partnership’s now well-established and we’re looking at new sites and new ways of working, but there is still a gap in the industry – whose grasp of modular and offsite manufacture and delivery isn’t quite there yet. The private

sector cannot revolutionise alone. The Government – through Homes England – has realised that they need to be a catalyst, it does need public sector coercion and support, otherwise it will be vulnerable to market fluctuations and any type of downtown. It needs long-term vision.

The industry is still lacking in its adoption of modular and timber homes – industry statistics show that just 10% of homes are created offsite in this country – meaning we’ve still got quite a way to go, especially when you read that countries such as Sweden can easily lead the way, with 45% of homes created offsite.

On their arrival in the UK market, our partners Sekisui House were genuinely surprised that the UK industry was so out-dated and we could have a housing crisis. In Japan the output of homes is so enormous and the technology is so advanced – it can sense when a person is home, run a bath for a child and withstand an earthquake, all at scale.

We’re conscious though that there is an overload of exciting new options and the challenge will be to be selective, work out what the UK market needs and then gradually build it up. Ultimately, our relationship with Sekisui allows us to invest even more in R&D – ensuring that we’re finding new ways to adapt our product and keep our houses at the forefront of the industry.

VOLUMETRIC MODULAR TIMBER

04 02 03

www.urbansplash.co.uk

Timber and factory manufacture bring huge low carbon and quality benefits

Modular design speeds up the delivery of new homes 25 STRUCTURALTIMBERMAGAZINE.CO.UK w

IMAGES: 01-02.

03-04.

THE ROLE OF WOOD IN HEALTHY BUILDINGS

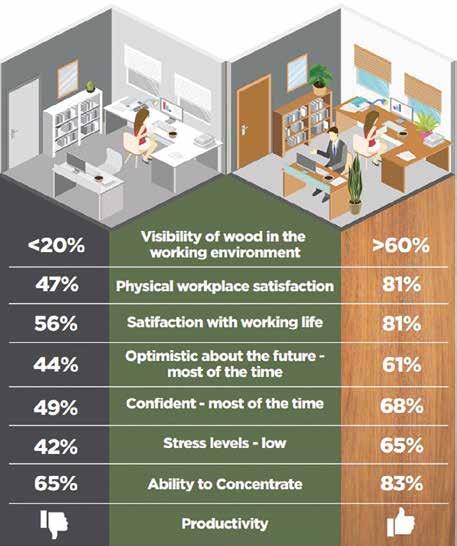

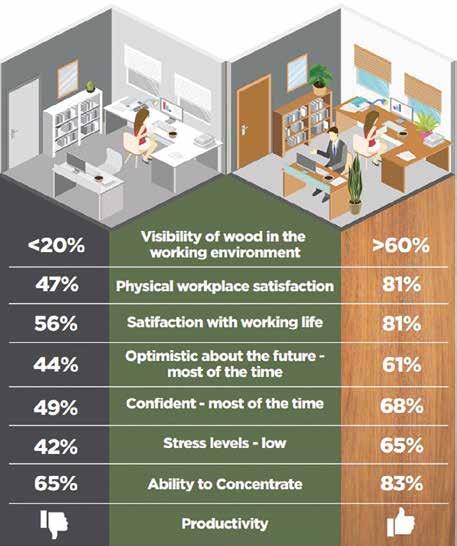

Health and wellbeing is an umbrella term that refers to the – at times – indistinct categories of physical, mental and social health. Timber can potentially improve all three, TRADA’s Rupert Scott explains more…

The impact our buildings have on how we work, heal, learn and rest is highly significant, whether it is productivity in offices, patient recovery, student performance, or our own comfort at home. We are all influenced by the indoor environment and the design, products and systems used to create and furnish our buildings.

In 1995, Hal Levin defined a healthy building as: ‘one that adversely affects neither the health of its occupants nor the larger environment.’ While there is still much to learn in the field of

healthy building science, it is commonly understood that buildings should go beyond eliminating negative impacts on our health. We should recognise the influence of buildings on our health and wellbeing by their design, build and operation. Among other aspects, this requires consideration of air and water quality, acoustics and materials.

A cookie cutter approach to healthy buildings would be both inefficient and inadequate, but functional outcomes should be dictated by building typology. Empirical studies assert that both active and passive experiences of nature may be beneficial for human health and wellbeing – suggesting that the use of natural materials, such as wood, improves the occupant experience.

Biophilic design, which refers to the inspiration and improvements that nature can provide for the spaces where we live and work, should therefore take centre stage in the movement for healthy buildings. For example, the Dyson Centre for Neonatal Care was one of the first modern timber buildings in the UK with exposed internal timber surfaces for clinical healthcare. Post occupancy evaluation showed that babies slept 20% longer, which is critical for a premature baby’s survival. Mothers’ anxiety scores dropped, visitors stayed longer and physical contact with the babies increased.

Of all materials, timber and timber products are best placed to maximise healthy building outcomes. It is a uniquely versatile material with many exclusive qualities and can feature in the main structural components of a building, the insulation, the linings, floor cassettes, floor finishes, furniture, cladding and fit-out. Wood is associated with warmth – it is a natural insulator, as well as having warm colour tones, while also possessing inherent acoustic and thermal qualities. Wood is both naturally hypoallergenic and sound-dampening and its odour is typically considered appealing. Buildings which use wood therefore have the potential to yield high levels of thermal comfort, mitigate sound and have improved air quality through humidity moderation.

26 STRUCTURALTIMBERMAGAZINE.CO.UK w TIMBER & WELLBEING

01

02

Most importantly, timber products can often be left exposed internally, maximising the biophilic impact of natural materials on occupant health and wellbeing. It has been reported that this exposure, in unison with other biophilic factors such as views of nature and indoor planting, supports faster recovery times in healthcare settings, reduced absenteeism in schools and offices, and better productivity. An Australian study found that employees take less leave and report higher levels of wellbeing, concentration and personal productivity, in buildings that have more visible wood in the working environment. Mitie’s ‘Living Lab’ experiment in The Shard also found that employees exposed to timber finishes were significantly more relaxed, happier and more productive. Additional research suggests that the visual presence of wood indoors can reduce blood pressure, heart rate and stress levels, improve attention and focus, improve emotional wellbeing and level of self-expression, enhance creativity, improve recovery and reduce pain perception.

At the same time, indoor air quality is a key area of concern as buildings are increasingly built to be airtight and energy efficient. Volatile organic compounds (VOCs) refer to the 900–1000 human-made or naturally occurring chemicals which can evaporate and enter our air. Indoor air can contain 5–10 times, occasionally up to 100 times, the amount of VOCs as air outside, which has implications

for respiratory health. A report from the World Green Building Council suggested that better indoor air quality (low concentrations of CO2 and pollutants, and high ventilation rates) can lead to productivity improvements of 8–11%.

VOCs naturally occur in wood and wood products, but many are in fact beneficial to health and wellbeing: the emission of terpenes from certain softwood species may confer health benefits, e.g. alphapinene, d-limonene and monoterpenes result in physiological relaxation and have antimicrobial, anti-inflammatory, antipruritic, analgesic and stressreducing properties.

Many wood adhesives contain formaldehyde, which is naturally occurring but associated with health risks. These adhesives are regulated through European standards, which set out permitted limits for the release of formaldehyde from a product. Timber also has other natural advantages in the area of indoor air quality. As a material, it has good hygroscopic properties and its ability to absorb moisture from, or release it back into the air, gives it the unique ability to regulate relative humidity within a building and keep it within a comfortable range. In addition, it is also vapour-permeable, which helps to maintain the indoor air quality.

In conclusion, these qualities combine to contribute to an improved sense of health and wellbeing, with the many physical, mental and social benefits

03

– yet these characteristics remain underutilised. What’s more, these characteristics remain underutilised amid a wealth of research suggesting biophilic design could help ease the burden on the NHS and our education system. Can you envision a world where the buildings we live, work, rest and learn in have a positive impact on our health?

TIMBER & HEALTHY BUILDING

You can find out more with the following free-to-download TRADA resources. Research Summary ‘Timber and healthy buildings: indoor air quality’ and TRADA Briefing ‘The role of wood in healthy buildings’. Dr Ed Suttie, Research Director at BRE, prepared the TRADA resources on healthy buildings and will be presenting on timber’s influential role in this area at TRADA’s Better Timber Buildings conference, held on 27 November 2019 at the Royal Geographical Society, London. www.trada.co.uk

IMAGES:

01. The influence of wood on wellbeing cannot be understated 02-03. Timber buildings contribute to better healthcare and education environments – Maggie’s Oldham and Cranleigh Preparatory School. Courtesy dRMM Zublin Timber and Tate Harmer

27 STRUCTURALTIMBERMAGAZINE.CO.UK w TIMBER & WELLBEING

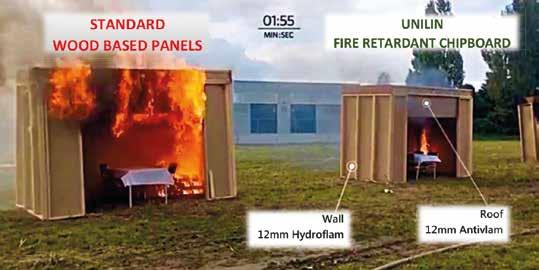

COMPETENCY IS CRUCIAL IN ACHIEVING FIRE SAFETY

There is a common misunderstanding that timber construction is more susceptible to fire than other building materials. The cause of most fires is electrical faults or peoplerelated incidents — fires very rarely start in the structure. As Andrew Orriss, Director of STA Assure for the Structural Timber Association (STA) outlines, there are many ways to mitigate risk.

Fire does not respect material form and fire spread can occur in all buildings. The fact is that all materials have some vulnerability to fire, for example, steel softens and concrete cracks. The key therefore is to protect the structure to ensure that the building retains its integrity. Engineered timber technology, such as cross laminated timber (CLT), has a unique quality in that when it burns, the char that forms protect the material beneath.

Increasingly, factory-manufactured buildings are considered as the ideal modern construction method. By taking the construction process away from sites into well-managed factory environments with stringent quality control systems in place, enhances not only the quality but also delivers predictability of fire performance. All factory operations in contemporary production environments are now controlled by quality

management system such as ISO9001 or the STA’s membership and quality standards scheme – STA Assure.

STA Assure was launched in 2017, implementing an independently audited scheme for all our members classified as structural timber building system suppliers. This scheme has evolved over the years to ensure our members know how to advise customers, as construction in accordance with regulations and manufacturers guidelines, achieves building safety standards.

Competency is crucial to achieving excellent standards across all building products. In support of our STA Assure initiative, we have been working on a number of key schemes to reinforce the importance of competent installation and the use of fire protection processes and products. We have developed a

28 STRUCTURALTIMBERMAGAZINE.CO.UK w STA ASSURE

01

02

training programme in partnership with CITB and Edinburgh Napier University. In 2018 the STA implemented the Timber Frame Competency Award Scheme which was supported by a series of workshops. The scheme validates the skills and competences of experienced timber frame designers and manufacturers together with acting as a training programme for new entrants.

In conjunction, the STA also developed and implemented an Installer/Erector Competency Scheme which ensures that the STA Assure accredited quality standards for manufacturing processes, is continued throughout the onsite installation. The STA’s award-winning Site Safe policy further ensures that the process complies with strict health and safety standards and fully complies with CDM regulations.

Members of the STA sit alongside representatives from Council of Mortgage Lenders (CML), Building Societies Association (BSA), Association of British Insurers (ABI) on the modern methods of construction (MMC) definition framework, which has been developed as a specialist cross industry sub-group of the Ministry of Housing, Communities and Local Government (MHCLG). We are also working with lenders and warrantee providers to ensure that the building science and facts are fully understood

and appreciated by the financial services and insurance industries. This will enable the industry to make evidence-based decisions on levels of risk. We have seen lenders continue to support structural timber systems as a mainstream building method.

To meet the government’s targets for housing, sustainability and carbon reduction, the construction industry needs to have access to a full portfolio of building products, materials and systems. According to the Sustainable Homes research timber frame, accounts for 70% of all housing stock in the developed world and 28.4% in the UK. At a time when sustainable development is a global priority and at the forefront of the UK construction agenda with key issues such as climates change dominating our futures thinking, timber is an outstanding renewable material that offers a range of environmental benefits. Add to this energy efficiency, speed of construction and offsite manufacturing methods, alleviating the traditional skills shortages – is it important to continue to maximise the benefits of structural timber systems.

Traditional construction methods and materials account for 14-16% of world carbon emissions and whilst we accept that site-based approaches are sometimes appropriate for certain design solutions, there has to be

03

a fundamental change to the way buildings are constructed. Timber creates a natural carbon store through sequestration. The innovative use of sustainable materials can help to deliver high-quality, high-density housing without compromising the environment. It is important to raise awareness of how carbon sequestration and structural timber technology can contribute to reducing carbon emissions and help to tackle the current climate emergency.

It is essential that all materials cover every compliance requirement, not just for fire. The Hackitt Review recognised the need for all materials and construction methods to raise fire safety standards. It is mandatory for all STA manufacturing and installer members to take part in our end-to-end competency training schemes which cover design, manufacturing, installation and onsite safety.

www.structuraltimber.co.uk

IMAGES:

01-03. Staff competency and careful planning is key to the success and safety on any construction site.

30 STRUCTURALTIMBERMAGAZINE.CO.UK w STA ASSURE

www.magply.co.uk | 01621 776252 | sales@magply.co.uk A1 NON-COMBUSTIBLE BOARD TESTED AND CERTIFIED FOR ▸ Timber frame construction ▸ Spandrel panels ▸ Modular build

Rainscreen cladding

Render carrier board

High performance dry lining

Tilebacker ▸ Passive fire protection ▸ Steel frame construction ▸ Fire resistant floors and ceilings BDA CERTIFIED

▸

▸

▸

▸

CHAMPIONING THE WORLD OF WOOD

Stora Enso recently started production at its new 45 million cross-laminated timber (CLT) facility at Grüvon in Sweden. With a feasibility study underway into further investment for a fourth CLT mill in the Czech Republic, Eve Dennehy reports on the strategy and innovation helping Stora Enso maintain leadership in the global mass timber industry.

Since entering the UK CLT market in 2010 Stora Enso has delivered more than one million cubic meters of CLT for projects internationally. It is one of the world’s largest mass timber manufacturers with a current overall production capacity of 240,000m3 of CLT across its three existing CLT production facilities in Austria and Sweden and this will rise to 360,000m3 once mill number four comes online. Stora Enso’s decision to invest in the Grüvon Mill followed the opening in 2018 of the bespoke laminated veneer lumber (LVL) mill at Varkaus in Austria, with a production capacity of 100,000m3 of LVL. The significant investment of €43million into LVL production at Varkaus was a strategic move aimed at meeting growing urban construction needs and enabling Stora Enso to serve new geographic areas and markets globally.

Crucially, the combined production capability of both CLT and LVL enables Stora Enso to deliver on a key area of strategy: to develop and introduce new massive wood components that will expand the range of applications possible for timber construction.

“We are working at the cutting edge of the switch from traditional construction materials to wood,” says Mathieu Robert, Head of Building Solutions at Stora Enso. “This trajectory is based on the high sustainability agenda in international cities and the priority from investors to invest in long term sustainable targets. We believe that we can take market share where existing materials have reached their limits and replace concrete with CLT and steel with LVL.”

Gareth Mason, Stora Enso Building Solutions’ Sales Director for Western Europe, adds: “Stora Enso is a company

32 STRUCTURALTIMBERMAGAZINE.CO.UK w CLT EXPANSION

01

that is continually innovating for the future and this has been the key to our longevity. We can see the rising global demand for timber, so we have to keep growing. We’re continually developing new components that add value to our existing offering, and this is helping to change the face of construction as we see our mass timber components increasingly specified for pioneering projects around the world.”

Stora Enso’s global position gives it a unique reach that extends beyond that of other European mass timber manufacturers including a CLT supply line to Australia established in 2015. This was able to quickly respond to Lendlease’s requirements for CLT to build Australia’s first commercial mass timber building – The Library at the Dock in Melbourne. Since then they have supplied a further two multi-award winning buildings for Lendlease in Australia: International House, a sevenstorey office building providing almost 8000m² of prime commercial space at Sydney’s Barangaroo harbourside redevelopment and 25 King Street in Brisbane which, at 10 storeys, is currently the tallest and largest engineered-timber office building in Australia.

Stora Enso’s range of newly-developed components including LVL-G – a re-glued wall panel formed of sheet LVL that is vacuumed pressed to form large panels – are making it possible to build ever larger structures out of wood. LVL-G has similar properties

to CLT wall panels, but remains 15% thinner, therefore adding valuable additional gross internal floor area (GIFA) in the same building footprint. The component has recently been used at two pioneering projects in Finland. At The Lighthouse, a 14-storey student accommodation block in Joensuu, Finland, where three-layer LVL-G has been used for the walls and works together with CLT floor panels to form the superstructure. It is the first project internationally to use this hybrid system and is a trailblazer for this innovative method of construction.

At Wood City, the world’s first development to be built entirely from LVL, walls formed of LVL-G combine with LVL rib floor panels to achieve uninterrupted spans of 8.6m. The ground-breaking mixed-use development in the heart of Helsinki’s Jätkäsaari harbour district comprises two multi-storey residential buildings, along with an office building, hotel and car park. Designed by Anttinen Oiva Architects, Wood City is being jointly developed by SRV and Stora Enso for Helsinki municipal housing developer ATT. The residential buildings were completed in 2018, and the complete project is is due for completion by the end of 2019.