OFFSITE

SUSTAINABILITY IN STEEL LIGHT GAUGE FRAMING OPTIONS AND REDUCING ENVIRONMENTAL

A

A

Developers before we became manufacturers, we’re committed to protecting choice in the design process and to offering hybrid solutions that combine traditional with modern methods of construction.

There are just two things we’re not flexible on. Precision manufacturing to your exact specifications and our “fabric first” approach, that radically reduces energy use in the construction of buildings and in their operation.

UNisystem panels, walls and floors are suitable for much more than simply house, mid-rise and high rise apartments blocks. They are readily adaptable for student accommodation, education, healthcare and commercial projects, of all sizes.

Designers and developers have complete control over architectural features and have the option to manufacture basic or “fully dressed” panels for internal and external walls and floors. The light gauge steel at the core of UNisystem is dressed with board, insulation, fire stopping and external cladding to your exact design specifications.

Champions of precision, born to build 137,000 sq ft second factory open for business

Our hybrid solutions bring traditional and modern methods of construction together, in alignment with your individual ambitions and needs. We’re here to support you at every stage of your transition to offsite, from as early as pre-planning, with land optimisation and logistics consultancy, as well as pre-planning design.

Our precision manufacturing and fabric first approach to construction save energy by making sure it isn’t needed in the first place. We manufacture panels that create air tight, highly insulated buildings that use less energy in operation.

Our UNipanel significantly outperforms the requirements of current Building Regulations (ADL2021), and UNiSystem is expected to outstrip the requirements of the Future Homes Standard which comes into operation in 2025.

So let’s start the conversation about your project, using the flexible UNisytem product range that’s leading the way on build quality and energy efficiency standards.

FRONT COVER

voestalpine Metsec

PRINTED ON:

FSC Mix paper by Buxton Press

PUBLISHER:

Offsite Magazine is produced and published by Offsite Media Ltd

101 Longden Road, Shrewsbury, Shropshire, SY3 9PS

T: 01743 290001 www.offsitemagazine.co.uk

©Offsite Media Ltd.

SUBSCRIBE TO RECEIVE OFFSITE:

This magazine is a bimonthly publication and the annual subscription fee for UK postage is £29.70 plus VAT for all six issues (£4.95 per copy). Visit www.offsitemagazine.co.uk

ADVERTISING ENQUIRIES PLEASE CONTACT:

Julie Williams // T: 01743 290001

E: julie.williams@offsitemagazine.co.uk

SEND US YOUR NEWS:

Gary Ramsay // T: 01743 290001

E: gary.ramsay@offsitemagazine.co.uk

BACK ISSUES VISIT: www.offsitemagazine.co.uk

FOR OFFSITE ENQUIRIES PLEASE CONTACT:

E: info@offsitemagazine.co.uk

DISCLAIMER: The content of Offsite Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. Content including images and illustrations supplied by third parties are accepted in good faith and the publishers expect third parties to have obtained appropriate permissions, consents, licences or otherwise. The publisher does not accept any liability or any loss arising in the absence of these permissions for material used in both physical and digital editions. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

KEEP

Welcome to the new edition of Offsite Magazine and as befitting the one that will be distributed at Offsite Expo, it is a bumper one full of companies and comment on what is making the industry tick right now.

When Offsite Expo comes around it tends to be a landmark for various reasons. Not only is it the premier show for all those working in and around the offsite/MMC arena plus the opportunity to meet, network, socialise and do business. But it acts as something of a milestone and pause for thought. One year on from the last show and what has changed – which individuals have moved on, what new products are on the market and does the industry still have the same allure, the same impetus?

The last 12 months has seen some notable exits from the offsite sector that don’t need detailing here – each organisation had their own specific issues compounded by wider economic and business problems –suffice to say, that many suffered from the illusion that entry into the world of factory manufacture was going to be relatively straightforward, depending on how much investment money was

available. The general gist of what I hear from industry insiders is: you design and create a special product then build a factory to manufacture it. Not build a lovely big factory then try and figure out what you are going to fill it with. A simplification I know, but it highlights a universal truth that many ignore.

Enough from me. Amongst the many highlights to read inside are three particular ones. Firstly, Trina Chakravarti from Building Better, heads up a team that is making a compelling case for MMC in the world of social housing and told me why demystifying the process for clients is key. Secondly, a roundtable discussion hosted by VOLUMETRIC™ had much to say about supply chain collaboration and why sharing knowledge and data can make your project a smoother process. Thirdly, the MPBA’s Richard Hipkiss offers a refreshing view of the merits of Pre-Manufactured Value and how you measure it.

Thanks to all our contributors, advertisers and supporters for their help this issue. I hope to see many of you in Coventry at Offsite Expo and the Offsite Awards!

Gary Ramsay Consultant Editor

Email: gary.ramsay@offsitemagazine.co.uk

•

•

•

•

•

A central hub for heating, ventilation, water management, communications and electrical services.

Arrives on site fully assembled, rigorously tested and certified, ready for simple ‘plug and play’ installation. WWW.VOLUMETRIC.CO.UK/MEP-PODS

With the built environment being responsible for a significant proportion of global greenhouse emissions, the construction industry needs to adopt practices which minimise carbon emissions and promote sustainability. Deciding whether to adopt such processes may not be entirely voluntary either, as central government and local authorities are already putting policies in place to encourage a greener approach – a trend which seems likely to continue in the future.

Net zero carbon forms part of the government’s procurement policy, with the Cabinet Office’s Action Note PPN06/21 stipulating how government departments need to take account of suppliers’ Net Zero Carbon Reduction Plans when procuring for major government contracts.

Together with other environmental initiatives, such as the London Plan 2021 requiring medium- and

large-scale construction projects in London to have an Environmental Product Declaration (EPD) and carbon footprint statements as part of the planning application, these policies place increased pressure on architects to design buildings which can be constructed using sustainable materials and methods.

The green credentials of Light Gauge Steel Framing (LGSF) are recognised throughout the industry and include:

• Reduction in a structure’s embodied carbon by using less steel

• Less embodied carbon than traditional construction methods

• Zero waste in manufacturing and on-site

• Reduced weight reduces concrete in foundations or podium structures

• Fewer, and lighter deliveries to site

• High recyclability/reuse.

Leading the way towards a more sustainable future in the steel framing arena is voestalpine Metsec plc. As part of the multi-national steel and technology group, voestalpine AG, the company is committed to the group’s target of achieving net zero carbon emissions throughout its Metal Forming Division by 2035, placing sustainability at the core of the company’s operations and providing designers with absolute confidence that Metsec systems, and their efficient installation, are as environmentally responsible as possible.

“The construction industry will come under increasing pressure to meet environmental targets,” says Chris Holleron, Sales Director for voestalpine Metsec’s Framing Division. “Which encompass the entire design, construction and ultimate demolition of a building, including reuse of the materials from which it has been constructed.

“The sustainability credentials of steel framing systems and relatively low environmental impact achieved through the efficiency of their installation by modern methods of construction (MMC) are well documented, with Metsec systems delivering at all levels. We believe that our net zero carbon initiative sets new standards in the industry by committing us to verifiable targets which will have real benefits for the environment and provide designers with total assurance of the sustainability credentials of our construction systems.”

Achieving this industry-leading target requires a focused effort within voestalpine Metsec together with the co-operation of suppliers and others in the value chain. The company has

With all parts of the economy under increasing pressure to become more sustainable in their operations in the international push towards net zero carbon, the use of light gauge steel framing (LGSF) can provide many answers.

created its own ‘Roadmap to Net Zero’, which establishes targets and strategies for achieving net zero carbon across all its operations in the UK. The multi-faceted approach includes investigating areas where energy can be saved and processes optimised, as well as exploring ways to source green electricity and even generate its own renewable energy.

Green electricity

To date, this initiative has seen voestalpine Metsec move its electricity requirements to 100% renewable sources, resulting in a 67% reduction in its carbon footprint, from 1500 tonnes of CO2 to 500 tonnes of CO2 per year. Further measures include the installation of solar panels on the roofs of the company’s manufacturing facilities. Arrays totalling more than 4600 photovoltaic panels and covering some 9300sq m of roof space will generate up to 1.4MWh of electricity per annum.

In total, the solar panels are expected to provide 40% of voestalpine Metsec’s total electricity requirements. They will not only reduce the company’s reliance on electricity from the National Grid but will also return unused electricity to the Grid at times when the facilities are not in operation, such as evenings, weekends and bank holidays.

More energy-saving

Further measures aimed at reducing the company’s impact on the environment and achieving net zero carbon include a host of energy-saving schemes throughout its operations. These include, replacing company

cars with hybrid and electric vehicles, the introduction of fully electric fleet vehicles, installing charging points across the company site, reducing gas consumption and investment in sophisticated, state-of-the-art energy management systems.

Green steel

At the core of the voestalpine business, an investment of around €1.5billion is being made into constructing electric arc furnaces at each of the group’s two steel production sites in Austria. As part of its ‘greentec steel’ plan, construction will start in 2024, and commissioning of the two units will take place in 2027. This will allow the voestalpine group to reduce its CO2 emissions by up to 30% from 2027.

Supporting these industry-leading initiatives, and underlining voestalpine Metsec’s commitment to providing designers and specifiers with unequivocal information on which they can base their design and specification decisions with confidence, is the company’s publication of an Environmental Product Declaration (EPD) for its purlins and framing systems.

The EPD encapsulates the quantifiable environmental impacts of a product’s lifecycle, from manufacture and transport to end of life, in a single, comprehensive report. It includes a lifecycle assessment and environmental impact data comprising core environmental impact indicators, use of natural resources and end of life information.

“As construction industry regulations increasingly incorporate requirements for sustainability,” adds Chris. “Building design together with the materials and processes used in construction will need to meet ever more rigorous standards. Along with other parties invested in the project, materials manufacturers will need to state and prove the environmental credentials of their products and systems.

“As the UK’s largest designer and manufacturer of constructional steel systems, we have always been at the forefront when it comes to setting, adopting, maintaining and verifying the most rigorous standards across all of our operations. Our net zero carbon initiative, together with EPDs and other environmentally responsible measures puts sustainability at the very heart of our operations, assuring designers and specifiers can be confident in the green credentials of voestalpine Metsec products and systems.”

For more information visit: www.metsec.com

Images: 01-04. The road to net zero carbon is one that every business is travelling including voestalpine Metsec which has a range of green initiatives including the installation of solar panels on the roof of the company’s manufacturing facilities

The Hill Group has formed an Investment Partnership with Gravesham Borough Council to accelerate the delivery of affordable homes for local people in Gravesend and the surrounding area. The Gravesham Community Investment Partnership (GCIP) will identify locations and develop suitable sites for new councilowned homes, in a bid to help reduce the number of households on the borough’s Housing Register, which currently stands at more than 1,000.

Cllr John Burden, Leader of Gravesham Borough Council, said “We have long-held ambitions to build hundreds of new council homes, in order to provide real social housing for those with demonstrable roots in Gravesham, thus reducing the number of people on our Housing Register.

“However, we are a local council, and while we have succeeded in directly developing 200 new council-owned homes in the past four years, we recognise our limitations and the fact that bringing a specialist private sector housebuilder with investment, commercial, and financial expertise on board will greatly accelerate the progress we want to achieve.”

Andy Hill, Group Chief Executive of The Hill Group, said: “We are proud to have formed an Investment Partnership with Gravesham Borough Council and are looking forward to working closely together to expand the delivery of affordable homes for local communities in the area. Work now begins to identify suitable sites where we can apply our significant experience and expertise for the swift delivery of much-needed new homes for Gravesham.”

Recognising the need to tackle homelessness in the borough, Hill is donating eight purpose-built SoloHaus homes to the Council. Created to provide safe, secure, and quality accommodation for the most vulnerable people in society, these modular homes will be donated as a part of Hill’s Foundation 200 initiative. Launched to mark Hill’s 20th anniversary, Foundation 200 is a £15million pledge to design and donate 200 modular homes to local authorities and homelessness charities by 2025.

“We are so grateful to Hill for their generous offer to donate these modular homes that will help prevent people from becoming homeless,” said Cllr

JennyFollowing an extensive overhaul, the Offsite Hub is being relaunched during Offsite Expo at Coventry Building Society Arena on 19-20 September 2023. Offering an invaluable source of information on the offsite sector, the new website will have a sleeker design with easy navigation, plus up-to-date news and views.

The Offsite Hub aims to create a singular online destination for professionals and experts, as well as clients, developers and specifiers wanting to explore the sector in more depth, including the analysis of industry challenges and acknowledge the successful achievements of offsite construction. Users can expect to see new and emerging technologies, informative articles and opinion pieces from leading industry figures. The Offsite Hub will showcase awardwinning projects and businesses and will bring a new

Wallace, Gravesham Borough Council’s Cabinet Member for Housing Services. “We are currently identifying suitable council-owned land where we can install them and are working to have them in use as quickly as we possibly can.”

Andy Hill added: “We are also delighted to further the partnership by donating the first purposebuilt modular homes in Gravesham, reflecting our commitment toward making a positive social impact in the areas in which we work. We designed SoloHaus to aid vulnerable individuals with nowhere to call home, and I am confident that once this scheme has been delivered, these innovative modular homes will have an incredibly positive impact on the lives of the most vulnerable people in the area, for many years to come.”

Gravesham Borough Council is now working to identify suitable Council-owned land within the Borough to situate the SoloHaus homes.

Source: www.solohaus.co.uk

dimension to how offsite information is published and perceived.

Registration is completely free and gives users access to a supplier directory listing, a comprehensive library of resources and downloads, and exclusive content from Offsite Magazine, the Offsite Awards and Offsite Expo. The Offsite Hub offers a highly visual platform for businesses keen to demonstrate their innovation, cutting-edge products and projects. There will be multiple opportunities to contribute articles or news to the Offsite Hub, putting your business in front of a wider audience of offsite specialists. The team behind the revamp will be revealing further features and added benefits of the Offsite Hub during Offsite Expo.

You can register for free access to the Offsite Hub at: www.offsitehub.co.uk

Modular specialist Elements Europe have been awarded a central Birmingham build-to-rent (BTR) residential contract. Acting as both the main contractor and offsite manufacturer, Elements Europe will deliver a full turnkey solution to the scheme. The four-acre island site will be transformed into a residential destination, branded Smith’s Garden, with 550 spacious one, two and three-bedroom apartments in six separate blocks centred around one acre of private garden, the tallest block being 26-storey.

The design and procurement teams at Elements Europe will work closely with the client, Goodstone Living, a leading UK real estate investment manager in the rental sector and architects – Darling Associates. This project represents a significant milestone in the construction sector, incorporating innovative techniques and technologies to enhance efficiency, sustainability and affordability.

The majority of the superstructure will be constructed by offsite manufactured room modules, minimising environmental effects and disruption thanks to fewer site deliveries, reducing noise and pollution. The 1143 modules needed for the project will be manufactured in Telford between November 2023 and January 2025. Construction activities started on the Birmingham site in July 2023 and phased handover of the six blocks will be between September 2024 and January 2026.

With its exceptional design and attention to detail, this residential community sets a new standard for modern living in Birmingham. The scheme will be sustainably built with +50% reduction in operational carbon and a +30% in embodied carbon (vs. current UK building regulations).

“Elements Europe is dedicated to innovation and excellence. With a commitment to sustainable practices and cutting-edge technology, we strive to transform the construction industry and create lasting, impactful structures,” said David Jones, CEO for Elements Europe. Martin Bellinger, Principal at Goodstone Living, added: “Smith’s Garden is one of the largest and most exciting Build to Rent residential projects in the UK and is testament to the evolution of this sector over the past 15 years.”

Transitioning from a merchant to a manufacturer of steel systems and components was said to have been a ‘stroke of genius’ and instrumental in the growth of the Frameclad business. After 15 years and driven by customer demand, Frameclad now design, manufacture and supply a complete range of steel frames for the construction industry across the UK.

Founder Mark Munns knows that success is built by people and is on a mission to attract ‘premier league’ talent to the Frameclad team. “Our customers are ‘king’ and we believe they deserve the best,” says Mark. “I’m therefore chuffed to announce that Dan Payne will be joining us as Regional Sales Manager for the South. With his ‘can do’ attitude and vast experience, this is a top signing for the Frameclad team. This industry is in his DNA – he knows his stuff and I can’t wait to introduce Dan to the wider team and our much-valued customers in the south of the country.”

Elements Europe are majority owned by GS E&C who took a controlling interest in 2020. As an international company with headquarters in Korea, GS E&C are a $9.5billion a year organisation that is supporting both this project and Elements Europe’s growth as one of the main offsite manufacturers and turnkey modular main contractors in the UK.

Source: www.elements-europe.com

Frameclad operate as a close-knit community, but it is their customers that are at the heart of the operation. “We are known for versatility and agility, but we have learnt this business from the ground up and we understand the market,” added Mark. “We strive to meet our customers’ demands – asking the right questions, listening and reacting. We don’t take a one system fits all approach – we meet our customer’s requirements – they don’t have to meet ours. From ‘off the shelf’ standard infill systems to bespoke developments such as Concord Street, a nine-storey apartment block in central Leeds – projects large and small get the same high-quality products, attention to detail and dedicated services.”

Source: www.frameclad.com

Following the success of previous years’ partnerships, the Structural Timber Association (STA) is proud to once again be an Industry Partner with Offsite Expo, taking place on the 19-20 September at the Coventry Building Society Arena. Playing host to leading offsite manufacturers and suppliers over a two-day event, Offsite Expo is focused on supporting those that are driving change in the construction sector.

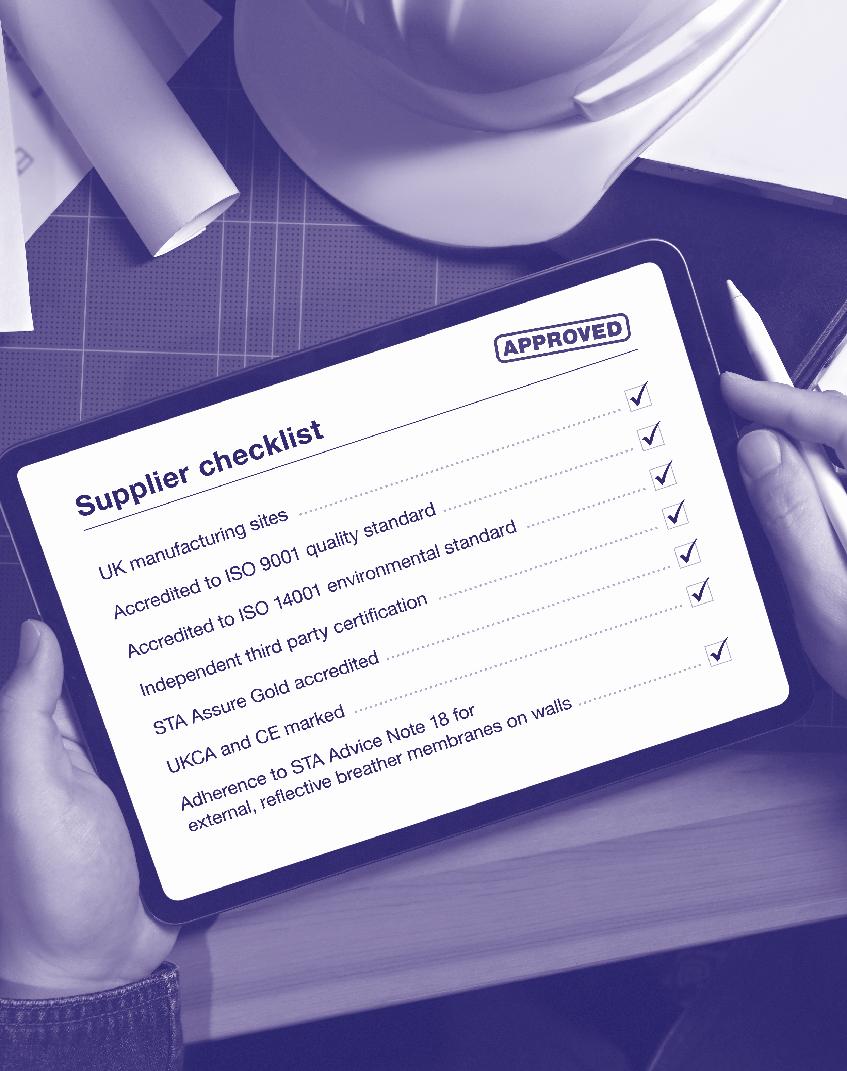

As the largest UK trade association within the structural timber sector, the STA will be exhibiting on stand F10 to highlight its mission to promote the use of structural timber in construction, as timber presents the best opportunity for meeting the UK’s net zero commitments by 2050. As such, the quality and standards of timber construction must be to the highest degree; making accreditation crucial to providing investors and insurers with evidence that companies are held to high standards.

At the event, the STA will explain how its STA Assure scheme provides solid reassurances to the construction community that members meet or exceed current legislation and regulatory requirements. Recognised by warranty providers, as well as other key stakeholders including insurers, STA Assure ensures that we remain on top of the

NG Bailey has announced a raft of contract wins worth over £150million for its engineering business, in the last quarter, as it continues to build on its industry-leading expertise in the mechanical, engineering and plumbing (MEP) sector. The series of wins spans sectors including healthcare, education, film and television and rail. This includes a £68million project for the University of Bristol’s Temple Quarter Enterprise Campus, a two-year contract which will see NG Bailey act as the MEP supply chain partner for the project.

The campus, which will sit at the heart of the city’s vibrant new Temple Quarter, will offer a new academic and scientific research hub, featuring six floors of teaching areas, learning zones, academic offices, research and computer labs, and innovation spaces. NG Bailey will be providing a range of MEP installations on the project, including water source heat pumps, heat recovery units, PV panels and LED lighting as well as connecting the building to the Bristol City district heating network.

Other recent project wins include a £8.5million project with Transport for London to provide complete

constantly evolving changes to quality and standards. The team will also be there to discuss how structural timber systems and offsite construction combined can support carbon neutral goals.

The Offsite Expo is also host to the Offsite Awards, which take place in the same venue on the 19h September; with the STA’s Andrew Orriss again on the judging panel. Additionally, the STA are also sponsoring the ‘Best Use of Timber Technology Award’ for this year’s event. The awards celebrate companies and projects that are at the forefront of the industry in terms of innovation and expertise.

Andrew Orriss, from the STA, said: “It’s always an honour to be part of this event and I’m very pleased to have been invited to return to the judging panel for the 2023 Offsite Awards. The standard of entries

has been exceptionally high this year and it’s very encouraging to see the progress and achievements that are being made across the industry. Awards like this are an excellent way of ensuring this innovative thinking is recognised and replicated.”

STA Chief Executive, Andrew Carpenter, will be leading a Q&A Session as part of the Masterclass seminar programme. Held in Seminar Theatre 1, at 10.30 am on the 19 September, Andrew will be on hand to answer any questions about integrating structural timber into offsite construction projects.

Source: www.structuraltimber.co.uk

You can also visit the STA at Offsite Expo on Stand F10

MEP and communications services to a new maintenance facility building at Beckton Depot, which will service TfL’s new fleet of trains. The business has also been awarded two projects with Shinfield Studios, a new UK film, TV studio and production hub in Reading which will encompass over 1million sq ft of purpose-built sound stages, workshops, contemporary offices and post-production facilities, with NG Bailey delivering all MEP services.

Paul Aulton, Managing Director Regions at NG Bailey said: “These recent contract wins demonstrate the continued demand for our engineering expertise, and

fully support our growth across strategic sectors. As a business we have a long track record of delivering offsite manufacture and installation of complex mechanical and electrical solutions. We are looking forward to working together with both new and existing partners to continue delivering outstanding work for some of the UK’s most exciting projects in infrastructure and the built environment.”

Source: www.ngbailey.com

Mid Devon District Council received the prestigious Client of the Year award in the South West’s Constructing Excellence Awards, whilst being shortlisted for further regional accolades. The standout projects that led to this recognition were the zero carbon developments, being built in partnership with innovative, modular house contractor ZED PODS.

Set to be installed on council-owned sites in St Andrews Estate, Cullompton and Shapland Place, Tiverton, both developments are set to be zero operational carbon, making this one of the first social housing projects of this type within the district. The judges were extremely impressed by the Council’s approach to meeting their requirements whilst adopting a framework to support Modern Methods of Construction (MMC). The Council was also recognised for embracing the future and inviting neighbouring authorities to share their experiences.

Councillor Simon Clist, Deputy Leader and Cabinet Member for Housing & Property Services said: “This recognition is a testament to the hard work and dedication of our team, who consistently strive for excellence. We take great pride in our work, and this award reaffirms our commitment to delivering sustainable housing for our community.”

Tom Northway, Chairman of ZED PODS, added: “The council’s team have been focused on delivering exemplar net zero projects. Together, we overcame numerous barriers – from demystifying perceptions of modular housing to unlocking brownfield sites for development including a scheme in a Flood Zone –one of the first in the UK.”

The awards were run by Constructing Excellence South West which forms part of the Constructing Excellence Regional Partnership (CERP) and exists to improve industry performance in order to produce a better built environment. With this win, the Council automatically becomes a finalist in the same category at the National Constructing Excellence Awards Programme, to be held on 23 November 2023 in London.

Both sites will be completed with triple glazing and solar panels, have their own private communal green space as well as separate storage for residents’ bins and bicycles – with plans for new homes to be built on land previously occupied by garages and car parking. “As identified within our Housing Strategy,” added Simon Clist. “There is a need for more social rented housing within the district. These ready to move homes and our long-term programme of housing look to positively address this – these new zero carbon, energy-efficient homes are a way forward and will help towards the Council’s net zero ambitions.”

Source: www.zedpods.com

www.middevon.gov.uk

Connect Modular and Cunninghame Housing Association (CHA) were delighted to host Scottish Government Minister for Housing, Paul McLennan MSP along with Provost Jim Todd to welcome CHA’s first residents to their first volumetric modular, affordable housing development at Shortlees, Kilmarnock.

The properties are manufactured offsite by Connect Modular and the Minister began his day with a tour of their manufacturing facility in Cumnock, East Ayrshire, where he met some of the team responsible for designing and manufacturing the housing modules and to see firsthand the benefits that volumetric-modular construction provides. The tour provided insight into the efficient manufacturing process and rigorous inspection routines delivered by Connect Modular in the production of these new homes to exceptional quality for Cunninghame Housing Association. This process delivers particularly significant improvements in waste reduction, environmental outcomes, and programme certainty.

Connect Modular has returned employment to the former carpet factory, creating and sustaining jobs within the local, East Ayrshire economy. Following the tour of the manufacturing facility, the Minister travelled the short distance to the Shortlees site where he was joined by Provost, Jim Todd, and the

first

Linda Anderson, Acting Chief Executive Officer at Cunninghame Housing Association, said “The Association is committed to delivering high quality homes for rent and it’s been exciting to see this fantastic modular housing development take shape. The handover of these first completed houses to the new tenants is an important milestone in the delivery of 101 new homes in an area where demand for housing is much needed. We’re excited to continue our successful partnership with Connect Modular through to Summer 2024 when the site will be fully complete.”

The collaboration between Connect Modular and Cunninghame Housing Association represents a shared commitment to addressing the pressing need to deliver affordable housing quickly and efficiently. The completion of the first houses is just the beginning of a wider initiative that will ultimately deliver 101 purpose-built modular homes, positively impacting the lives of many individuals and families. Housing Minister Paul McLennan said: “The partnership between Connect Modular and Cunninghame Housing Association, supported by £10.5million of Scottish Government funding, will

deliver 101 affordable new homes at Shortlees. This means that more households will live in a home that meets their needs. Partnerships like this will help us to deliver at least 110,000 affordable homes across Scotland by 2032. At least 70% of these will be for social rent and 10% will be in remote, rural and island communities.”

Connect Modular has a strong pipeline of affordable housing projects, including a second phase of homes with Cunninghame Housing Association and is delighted to bring innovation to support the Scottish Government’s target of delivering 110,000 new homes by 2032.

Richard Reid, Acting Chief Executive Officer at Connect Modular, said: “We are absolutely thrilled to see the completion and handover of the first homes in this 101 modular housing development. This project demonstrates our dedication to delivering innovative, sustainable, and affordable housing solutions for our local communities. We’re delighted to be working with Cunninghame Housing Association on this development and look forward to the continuous handovers of our homes over the next year.”

Source: www.theweehousecompany.co.uk

Just landed! Our NEW pre-painted OSB is a blank canvas, perfect for applying marketing messages and graphics. With all the inherent properties of our popular OSB3, SterlingOSB Zero PrimedPlus has a primed textured finish, and is designed for hoardings, screening, exhibition stands and walkways etc, inside or out. SterlingOSBZero.com

Leading modular and offsite building solutions brand Algeco has introduced a new post-handover electrical testing service for its full range of site accommodation. Alongside this is an extended choice on Algeco 360 turnkey climate control and site Wi-Fi. The new electrical testing element of Algeco 360 turnkey service provides customers with peace of mind that the site accommodation meets all requirements post-handover and includes an NSI certificate just five days after testing.

Under the Health & Safety Act 1974 (HSWA) and the Electricity at Work Regulation (EAWR), employers have a legal duty to ensure the workplace is a safe environment. Algeco electrical testing service provides customers with an electrical installation condition report for all its site accommodation solutions. The condition report is carried out in compliance with BS7671 2018 IET Regulations for Electrical Installations and IET (Institute of Engineering and Technology) Guidance Note 3 Inspection and Testing.

Electrical testing on-site is important because once site accommodation is delivered, customers will connect to a local/generator electrical source. These new connections require re-testing to ensure

everything is safe for use. Algeco units, as is all site accommodation modules, are only tested for delivery and not after on-site installation or on obligatory annual service.

The climate control offering means Algeco customers can reduce energy consumption within their site accommodation by up to 65% – potentially saving hundreds of pounds or more each year – as wells as CO2 emissions. Functionality is extended on climate control to user needs as well as providing yearround climate control, heating, air conditioning and dehumidifier, all in one unit. Being more responsive means that Algeco climate control heats and cools workplaces quicker, whilst reducing electrical load. This means it can be used as an on- or off-grid set up. Remote control and optional Wi-Fi allow temperature to be managed to a fine degree.

The Wi-Fi element of the extended Algeco 360 turnkey service allows customers to stay connected on construction sites with new 5G broadband and large antenna added to the range. These blend the latest technology with expert support to create a bonded cellular connection with the UK’s leading carriers.

Customers can continue to choose either Plug ‘n Play or professionally installed and managed Wi-Fi service. Algeco has link up with a professional installation partner that can install and remotely manage the system wherever the site is located. Algeco Wi-Fi products can be securely connected to corporate networks, enabling site teams to access cloud applications securely. Both ‘plug-and-play' and professionally installed Wi-Fi packages have access to tech support over the telephone between the hours of 09:00 and 17:00 (Monday – Friday).

Chris Coxon, Head of Marketing at Algeco, said: “Our new and extended 360 turnkey services have been welcomed by busy contractors on-site that are tired of managing multiple suppliers, purchase orders and communications. Now, with just one point of contact, our 360 turnkey services does all this for them. And with the extended options on climate control and Wi-Fi, plus new electrical testing, it really couldn’t be easier – a full turnkey solution, including social enterprise options, providing you with everything you need from just one supplier.”

Source: www.algeco.co.uk

Steel fabricators are facing a challenging market, with price rises, increased client demand and a renewed focus on sustainability. With this in mind, Trimble has released a new eBook with the aim of demonstrating how digital technologies can help relieve some of the pressures faced by those in the industry.

Material shortages, fluctuating prices and increased client demand have combined to create a complex landscape for steel fabricators to navigate, who are not only looking to protect their all-important profit margin and continue providing customers with highquality work, but to also meet key sustainability aims. This has, understandably, left many in the industry feeling overwhelmed as to how they can overcome these challenges, whilst remaining profitable, productive and efficient.

Trimble’s latest eBook: ‘A Guide to MIS for Steel Fabricators’ aims to help those in the steel industry to streamline their workflows. Available to download for free online, the eBook covers each individual stage within the steel fabrication workflow (from estimation and procurement through to fabrication, reporting and delivery) and explores the value that a digital management information system (MIS) can bring to businesses, along with cloud-based collaboration tools and a 3D modelling workflow – meaning there is something for everyone.

Providing specific examples of how digital technology can help streamline the fabrication workflow, such as the ability to create more accurate tenders, deliver a traceable flow of up-to-date and accurate data and co-ordinate deliveries to meet with on-site construction schedules (to name just a few). The guide also features a range of customer testimonials and case study examples, to better illustrate the effect digital technology has had for other steel fabricator companies.

Chris Gatehouse, Detailing & Manufacturing Specialist at Trimble, says: “We recognise that the steel industry is a challenging one to work in currently, with a highly volatile landscape to navigate. However, we want steel fabricators and detailers to know that there are many digital tools and technologies available to them, which

can help to streamline their workflow and make their businesses more efficient, profitable and productive. It is our hope that this eBook will truly bring the power to steel detailers and fabricators, allowing them to arm themselves with the knowledge of what digital technologies can do for them and how they can get more from their software, guiding them through this challenging period.”

With cloud-based connectivity and model-driven workflows covering every section of fabrication and construction, Trimble offers interconnected solutions that unite the digital and physical worlds, helping you to build faster, cheaper, greener, and safer.

Source: www.tekla.com/uk

Shaun brings 35 years of experience in the construction industry and an outstanding track record in project delivery. He joins from international construction firm Mace, where he spent 17 years as a Director and was the driving force behind launching and running a business unit focused on maximising offsite pre-manufacture value and assembly.

During his long career, Shaun has led major construction projects across residential, commercial, education, biopharmaceutical, and medical facilities, and many more sectors. He thrives on complex construction schemes and has been central to delivering challenging, award-winning, technical solutions. At Reds10, Shaun’s expertise will be instrumental to setting the foundation for the next phase of the company’s growth trajectory. This includes building on its successful platform approach, harnessing more production and delivery methodologies, bringing innovative solutions to a wider client base, and driving operational efficiencies and social value.

Together, we will continue to challenge and push what the construction industry can and should be, with MMC and technology at its core.”

Shaun Tate (pictured) COO of Reds10, added: “I genuinely believe that our industry is at a crossroads, and we have a unique opportunity to redefine how the built environment is delivered. Offsite construction methods offer an opportunity to drive more intelligent solutions that will enable clients to benefit from a far more predictable and controlled construction delivery experience. Our clients deserve far better from our industry and Reds10 offers the repeatable, predictable consistent outcomes that enable them to achieve higher performing buildings with full confidence in delivery every time.

Vertically integrated offsite construction specialist Reds10 has welcomed Shaun Tate as Chief Operating Officer (COO), to support and accelerate its ambition to become the leader in a new breed of Tier 1 contractors. The appointment follows the third consecutive year of turnover and profit growth for the company, which recently reported an annual 32% revenue and 17% profit increase, attributed to Reds10’s continuing commitment to investing in its products and people.

Portakabin has added three new leaders to its executive team as the company bolsters its dominant position in the offsite industry. With the recent acquisition of healthcare specialist Darwin Group, Portakabin is making serious inroads in asserting pressure on other players in the modular market. With 283,900sq m of manufacturing space across three sites, and over 80 customer locations across Europe, it remains the largest supplier of modular buildings in the UK alone.

Dan Ibbetson, CEO comments: “There are many elements required to not only make a business successful but to also make it a great place to work; a clearly defined strategy, excellent governance and amazing people certainly helps. Gavin, Simon and Kim are the final pieces in the puzzle for us and I’m incredibly excited to see where they’re going to take us.”

Kim Panton joined in August 2022 as People and Culture Director from Rolls-Royce where she has spent the past 20+ years working with one of the world’s most reputable brands. Her strategic HR skillset has ranged across the group’s business units and brings considerable experience in people and organisational development. Kim said: “Portakabin is a fantastic business with brilliant people and

Matt Bennion, CEO of Reds10, said: “We are delighted that Shaun has joined the Reds10 team. Like us, Shaun is passionate about changing our industry and is a real innovator in the delivery of high-quality offsite construction. His major project experience and drive will help us to accelerate our ambition to become the leader in a new breed of Tier 1 contractors, so that clients have a viable and sustainable alternative to traditional delivery.

“Reds10’s platform approach, focus on product innovations that meet client needs and vertically integrated model are unique in our industry and mean that we control every step of the production process and our own destiny when it comes to delivery, by driving a production mindset and deploying the right technology through ever more powerful digital platforms. To be part of a team with a shared vision of a better future and an insatiable desire to drive our industry and lead a revolutionary change for the better, is something that genuinely excites me, and I can’t wait to get started.”

Source: www.reds10.com

represents an exciting new challenge for me. I’m delighted to have joined the team and I’m looking forward to supporting the organisation as it grows and develops.”

Simon Thomson joined in January 2023 as Company Secretary and General Counsel from Aggreko and has quickly become a strategic partner to stakeholders both within the legal function and throughout the wider organisation. Simon comments: “I’m incredibly proud to be part of this organisation; it has a fantastic heritage, and our people strike the right balance between being commercially minded and customer focused. I’m looking forward to realising the outstanding potential for future growth and success with Portakabin.”

Gavin Urwin joined in March 2023 as Chief Financial Officer from Smart Metering Systems PLC (SMS) and brings considerable experience of working within both PLC and family-owned businesses along with his ability to manage multiple stakeholder groups. “There’s never been a better time to join a market leading brand name such as Portakabin,” said Gavin. “It’s a growing and ambitious business, both in the UK and Europe, has fantastic people working for it and I’m delighted to be part of its future.”

L-R Gavin Urwin, Kim Panton and Simon Thomson

Source: www.portakabin.com

THROUGH OUR MODERN METHODS OF CONSTRUCTION NEW HOMES (NH3) FRAMEWORK

Our frameworks are procured in accordance with The Public Contracts Regulations 2015 and are free to use. They provide public sector organisations with easy access to procure works, products and services for the construction, refurbishment and maintenance of social housing, schools and public buildings.

LHC Procurement Group strives for excellence in the services provided to their clients and aims to deliver the best solution to suit every project’s individual needs.

Our dedicated Client Support and Project Support teams are on-hand to assist throughout the life of the project.

For more information on how our frameworks can work for you, get in touch.

www.lhcprocure.org.uk

HELPING YOU TO BE MMC READY

A 32-bed short-stay ward for Northwick Park Hospital London is being created above the existing A&E department by MTX in one of the most complex build programmes ever undertaken by the company. More than 50 structural steel modules manufactured offsite will be used to construct the new ward on a steel deck installed on existing concrete stub columns that were part of the original A&E department build.

The challenging location amid the busy hospital site requires the use of the UK’s largest crane to lift the modules into place and MTX is currently constructing additional site infrastructure including high strength concrete foundations and piling to support the crane.

MTX has huge experience working on hospital sites and the team pride themselves on being able to deliver contracts with minimum disruption to the vital services provided by the medical staff. At Northwick Park this means maintaining safe access to the A&E Department for both pedestrians and ambulances throughout the build programme. They also prioritise the safety of their own staff and contractors which in this case entails building a pedestrian bridge over a busy road on-site to enable access to the build location.

Modular building specialist Integra Buildings has announced a £1million programme of investment at its East Yorkshire site to reduce the carbon footprint of its operations. Integra is driving down emissions at its headquarters in Paull, East Yorkshire, with an ambition to become a carbon neutral business by 2038.

Key sustainability projects on-site include the installation of more than 70 rooftop solar panels on Integra’s office building, with a further 150 panels fitted to one of the factory units. Integra has also reduced the volume of waste leaving its site by almost 20%, thanks to a compactor which cuts the number of lorry trips to the processing facility and saves on carbon emissions. The business has also secured ISO 14001 Environmental Management accreditation as it sets out a roadmap to carbon neutrality.

Integra CEO Gary Parker said: “We’ve done a huge amount of work to firstly understand our carbon footprint and then identify the priority areas and key actions we can take to become more sustainable.

The programme includes designing and installing mechanical modules pre-manufactured offsite to control the ventilation and the environment of the wards, with a dedicated integrated plant facility provided within the new building as part of the M&E specification. The new first floor construction will link to the existing hospital buildings via a 20m-long suspended connecting corridor. It will also link to two existing stairwells to provide access for staff and visitors.

Northwick Park Hospital is situated on the outskirts of Harrow in North West London and managed by the London North West University Healthcare NHS Trust. The new £20million state-of-the-art short-stay ward is designed to enhance the quality of care provided to patients at Northwick Park, and is part of an NHS

England initiative to meet the growing demands for general and acute beds across the country.

MTX Managing Director David Hartley explains: “We have worked with the Trust on previous projects, and we are immensely proud to have been awarded this contract to deliver the new facility. Our team at MTX recognises that these new beds are urgently needed at Northwick Park, and we are working closely with the Trust to progress the build programme as swiftly and safely as possible. With such a major development within the busy hospital site there will inevitably be some disruption to existing access and traffic management arrangements but our close collaboration with the Trust team aims to ensure it is kept to a minimum and mitigate any impact on patients and staff.”

Source: www.mtxcontracts.co.uk

Construction companies like us face significant challenges in reducing their emissions and becoming carbon neutral, but we’ve taken significant steps forward and we’re committed to working with our suppliers, clients and partners to share ideas and help each other on the decarbonisation pathway.”

The first phase of Integra’s solar installation saw 72 panels on the roof of the office building expected to reduce annual energy bills by over £80,000. Since then, an additional 150 panels have been fitted to the roof of one of Integra’s factory units. The two installations combined will generate close to 200,000 KW of clean electricity every year. All the modular buildings Integra manufacture are 100 per cent re-usable and can be relocated. Should the building ever be disassembled, timber and steel products can be easily recycled.

Simon McGeachy, SHEQ (Safety, Health, Environment and Quality) Manager at Integra, added: “Our sustainability work also extends into the local community. We’ve been supporting the Humber Wood Recycling Project for a number of years, donating our surplus wood which is used to create outdoor furniture for Dove House Hospice.”

Integra is carrying out further work to understand its scope two and three emissions, including those produced throughout its supply chain and operations offsite. Integra’s environmental approach is to only consider carbon offsetting as a last option where there is no possible outcome of achieving net zero.

Source: www.integrabuildings.co.uk

Smartroof has successfully completed a groundbreaking project at Claremont Garden Centre in Essex. The Claremont Garden Centre project in Woodham Mortimer marked an exciting milestone for Smartroof, as it was their first venture into the commercial sector and the first time the company has installed its panelised roofing system to a steel portal frame instead of masonry.

Overcoming unique challenges posed by the project's size and requirements, Smartroof's offsite ‘room in roof’ system has been employed to create a new cafe, office, staff room, and greenhouse. Partnering with architectural firm Acanthus and client English Auberge, Smartroof demonstrated their expertise and adaptability, providing an exceptional roofing solution for this new multi-use garden centre building.

Drawing on their expertise and recommendations, Smartroof collaboratively enhanced the designs, incorporating their ‘room in roof’ system seamlessly into the architectural vision. The project’s scale presented a remarkable feat for Smartroof, leading them to manufacture their largest panelised roof panels to date – each an impressive 13m long. Rigorous planning and precision during the design and manufacturing stages ensured a smooth process for both the factory and logistics, ultimately resulting in a flawless installation.

The Smartroof system offers a complete roofing solution for builders and developers seeking to unlock a building’s full potential by creating functional spaces within the roof space. Comprising a series of factory-produced panels, including insulated roof panels, spandrel wall panels as well as dormers, roof windows, decorative chimneys, soffit, and fascia where required the system is expertly delivered and craned into place on-site. Smartroof’s offsite fabrication facility in Derbyshire provides a controlled environment that enables the technical team to achieve the architect's vision with millimetre precision in both cutting and fabrication.

In an era demanding faster construction methods and heightened energy efficiency, the offsite fabrication of roofs at Claremont Garden Centre delivered substantial benefits to all stakeholders. From improved health and safety to accelerated construction speed,

and exceptional quality control, Smartroof's innovative solution was tailored to this bespoke design and resulted in estimated savings of up to three weeks when compared to traditional on-site methods of roof construction.

Ian Dean, Operations Director at Smartroof said: “We take immense pride in delivering cutting-edge roofing solutions that are custom-tailored to meet the unique requirements of each project. Our collaboration, along with our vast design and fabrication experience, played a pivotal role in the success of the Claremont Garden Centre project. With a genuine passion for efficiency and an unwavering pursuit of perfection, we are the ideal partner when it comes to the creation of superior quality buildings.”

Source: www.smartroof.co.uk

Theory, practice, experimental campaigns: putting it all together on screws takes years of lectures, workshops and construction sites. We make it available to you in 70 pages that are extra catalogue. Because our experience is in your hands.

O’Keefe is carrying out the second phase of groundworks and infrastructure works for a new residential development by modular offsite specialist TopHat. The project is part of a larger scheme that will see TopHat deliver almost 300 new volumetric modular homes over three phases on the 4.8-acre Kitchener Barracks site.

O’Keefe is the groundworks contractor on the current second phase, which started with enabling works in January 2022 followed by the main works package in March 2022. The company was principal contractor on the first phase of the scheme, completed in early 2021. The site knowledge gained by the team on that phase has assisted greatly when dealing with the construction element of the phase two works.

The Kitchener Barracks project involves the construction of three four-storey blocks of modular apartments which will comprise 96 oneand two-bedroom homes. On this phase, some 240 modular sections were assembled on-site, and cassette corridor sections were then installed at the upper levels between the rows of apartments.

O’Keefe’s role includes part-construction of foundations, drainage and services for the modular apartments, plus access roads and external finishings. Although the apartment modules are manufactured

offsite, they still require foundations and services to be built in-situ. The foundations are mass concrete strip footings bedded a minimum 200mm into the underlying chalk strata. One of the biggest challenges for O’Keefe has been to ensure the on-site works perfectly align with the factory-built modules. Working to exacting tolerances, O’Keefe has formed upstands to receive the prefabricated modular units.

“Co-ordination is vital when offsite manufacturing and site build foundations are carried out,” says Project Manager Daniel Gough. “It is essential that precise as-built surveys are carried out to ensure that the position and levels are within the specified tolerance and any drainage pipes are located correctly.”

O’Keefe formed the drainage connections prior to the modular sections being installed. Service entries were taken into the plantrooms situated in the two stair cores and then distributed to the modular units. Reinforced concrete upstands and slabs were constructed within the two cores and the end escape stairs and a reinforced concrete in-situ lift core constructed to each of the cores, with a steel framework installed prior to installation of the modules. O’Keefe’s contract has also involved construction of a reinforced concrete (RC) frame extension off the back of the existing Khartoum Building, dating from the 1930s.

“The complex design has been a continuous, coordinated process assisted by O’Keefe, the consultant engineers, architects and TopHat, to ensure that further survey work was carried out to slabs, roofs, cavities and foundations for the structural frame to have its final design,” added Daniel. “Underpinning was carried out on the building in the early stages of the project and then the installation and cutting back completed after the concrete had cured. TopHat and O’Keefe have worked together throughout the RC frame element of the works to monitor progress and provide live survey data to the consultant engineers and architects to assist with overcoming any issues encountered during the RC frame build.”

Andrew Shepherd, Managing Director of TopHat added: “TopHat have worked closely with O’Keefe on this complex and groundbreaking project. It was essential that we had a partner that was able to address a number of different challenges from foundations for an innovative modular project through to a concrete frame that would tie into an existing heritage building. This ongoing relationship has been formed on a process of innovation and continuous improvement, which underpins our joint approach to future projects.”

Source: www.okeefe.co.uk

www.tophat.io

Fusion Steel Framing has been brought on board as a contractor for 5-star housebuilder The Hill Group and L&Q’s large-scale redevelopment of the former Citroen garage, Kew Bridge Rise, in West London.

Fusion will be fabricating 13,720sq m of its innovative TraxTM product to form the steel frame system infill across five buildings of up to 18 storeys on the development. Kew Bridge Rise, located within the heart of the Brentford regeneration area, will deliver 441 new homes, of which 50% will be affordable. Construction of the steel frame system has already begun on-site, with the development expected to complete in 2026.

Since its foundation in 2000, Fusion has delivered more light steel residential structures than any other European producer and worked with some of the largest contractors and developers in the UK construction industry. In 2022 Fusion was acquired by Hill to advance Hill’s progress in MMC and more efficiently integrate light gauge steel frames on developments such as Kew Bridge Rise.

Mike Fairey, Managing Director at Fusion Steel Framing, said: “We are delighted to be providing our industry-leading TraxTM product on this significant residential scheme, and to support our partners at Hill and L&Q in bringing their vision for the project to life. TraxTM’s custom design, high-precision engineering, and exceptional thermal and acoustic insulation mean our product aligns perfectly with their ambition to deliver high-quality residential units across the development.”

TraxTM is a highly economical non-load bearing infill system which helps to create rapid dry building envelopes on a range of building types using steel

framing. The works at Kew Bridge Rise will involve Fusion forming the openings, applying RCM DensGlas external board, Kingspan K-Roc insulation and fitting of brick tie channels. Fusion expects to be working on-site for around 12 months.

Fusion will manufacture TraxTM at the company’s high-grade 80,000sq ft manufacturing facility in Northampton, which has the capacity to deliver over 30,000sq m of light steel each year. The company’s expert engineers will then deliver and install the TraxTM system at the Kew Bridge Rise site. The development will have a concrete frame structure and TraxTM will be used for the infill between floors, sitting on the floor slab up to the ceiling. In addition, Fusion will create the window apertures, providing a complete solution for the project.

Cain Peters, Regional Director at The Hill Group added: “The key advantage of using Fusions’ trail-blazing TraxTM system is the ability to rapidly accelerate construction projects while de-risking the process of installing a structural framework system. The system also reduces fire risk which is always at the forefront of our construction design. This extensive redevelopment project will be an impressive example of the capabilities of delivering prefabricated steel frame systems at scale.”

Hill and L&Q began on-site in Brentford in September 2022. The project also includes a new public square, alongside significant investment in local infrastructure improvements. The joint venture partnership will also provide a range of social benefits for the local area during construction, including investment in significant employment, training and community focussed opportunities.

Source: www.fusionsteelframing.co.uk

Approval has been granted by Charnwood Borough Council for the creation of a new Space4 timber frame factory – believed to be the biggest in the UK – on the edge of Loughborough. The stateof-the-art facility will bring up to 120 new jobs to Loughborough and the surrounding areas, whilst also utilising the latest automation technology as part of the manufacturing process.

The factory will produce timber frame units for up to 7,000 homes a year and is set to be in full operation towards the end of 2025. Utilising modern methods of construction (MMC) systems within Space4’s products places sustainability at the core of its build practices. Utilising timber over other materials enables the homes to be more environmentally friendly – all the timber used is from sustainable forestry sources. The factory-assembled nature of the product will also help to improve the speed and consistency in quality of the homes built, with timber frame homes being around 20% more efficient to build than other methods.

Gareth Wicks, Managing Director Designate at Space4, said: “We’re delighted to have received approval for our new Space4 facility and I want to thank Charnwood Borough Council for their support. Not only will the development deliver up to 120 new jobs, it will also further our goal to place sustainable practices at the very heart of our developments. We’re committed to creating vibrant, successful communities with the environment in mind. We’ll continue to work in partnership with the Council and other stakeholders to ensure our new Space4 factory delivers real benefits for local industry and the wider Loughborough community.”

The new Space4 facility will be placed on the Garendon Park Sustainable Urban Extension (SUE), a community of over 3,000 homes on the Garendon Park estate. Dan Endersby, Managing Director of Persimmon Homes North Midlands, added: “Garendon Park will be one of Persimmon’s flagship communities, with over 3,000 homes, employment and leisure facilities, and a range of preserved historic monuments around the site.”

Source: www.persimmonhomes.com

M-AR Offsite has partnered with Biffa, the UK’s leading sustainable waste management company, to ensure all waste generated through its manufacturing and construction operations is reused or recycled.

Through the partnership M-AR is refreshing its current waste management programme with the aim of diverting 100% of its waste from landfill. The new Biffa skips in place around M-AR’s factory have clear signage as well as being colour coded to help visually identify what waste goes in which skip. It also creates a clear central focal point for waste management in the factory, which along with M-AR’s newly appointed ‘Waste Champions’, is designed to maximise take-up among staff.

Tom Malcom and Jamie Leckenby, who are both part of M-AR’s internal logistics team, nominated themselves to be M-AR’s first ‘Waste Champions’. The role involves educating the team and communicating policy changes to the whole production team. They will both receive specialist training and support from Biffa to appreciate the benefits of segregating waste effectively.

Biffa and M-AR will collaborate on future waste reduction initiatives to implement within the business. M-AR will also be able to accurately report on waste

volumes and disposals to track ongoing progress and understand where changes may need to be made to the process through its own online Biffa portal. The signage boards placed around the factory, as well as acting as prominent reminders about segregation of waste materials, will be used to provide feedback to the factory from the data collated from the Biffa portal.

Dan Lowther, Head of Procurement and Supply Chain at M-AR said: “While this first phase covers waste management specifically relating to our manufacturing facility in Hull, our ultimate aim is to roll the programme out to all our live construction sites across the UK. This step marks a significant improvement in the reduction of waste generated on construction sites which are typically harder to regulate than a controlled factory setting and will mean that we’re able to divert all waste material from

landfill whether that’s generated in the factory or on-site. Reducing our waste materials to zero is a key part of our ongoing commitment to achieving net zero status as a company and reducing the embedded carbon of the modules we manufacture and install.”

Shaun Williams from Biffa's commercial team in Humberside, added: “We know recycling and sustainable waste management is extremely important to companies of all sizes, so we're delighted to be working with the team at M-AR to bring our knowledge and skills to drive sustainability at their factory. Small steps can make a big difference and recycling more waste means there's less consumption of raw materials and fewer carbon emissions, which all contributes to the UK's effort to achieve net zero.”

Source: www.m-ar.co.uk

HENCO PRO-FIT

• 100% Visual jointing control

•

•

•

• Secure non demountable function

• Ergonomic design

HENCO PK FITTING

• Chemically resistant

PVDF and stainless

steel construction

• Leak Before Press technology

• 100% recyclable

and share best practice to provide high quality new facilities, drive down carbon emissions and deliver social value to the prison community. Alliance members will also collaborate on how to support and work most efficiently with supply chain partners across the sites.

The prison places will be in new houseblocks with a standardised design and construction approach maximising quality, efficiency and sustainable outcomes through modern methods of construction (MMC). Each houseblock will include 60 singleoccupancy rooms and be supported by larger kitchen spaces and other relevant ancillaries.

A number of the sites will contain educational areas for study and light industrial units where prisoners can take professional courses such as bricklaying. All three contractors will also provide training and employment opportunities for prison leavers to support rehabilitation.

A spokesperson for the Alliance said: “This vital project will deliver much-needed prison places while also providing valuable training and employment opportunities to those leaving prison. Working in partnership together and using standardised designs, modern methods of construction, and a shared strategic supply chain enables us to drive efficiency and deliver significant value across multiple concurrent projects.

We welcome this pioneering approach from the Ministry of Justice and look forward to working with them on this programme that will see the delivery further safe, modern, sustainable, and fit-for-purpose accommodation for the Justice system.”

Kier, Laing O’Rourke and Wates have been appointed by the Ministry of Justice (MoJ) to provide up to 1,200 new prison places across the UK with a focus on safety, security and rehabilitation and will be using offsite methods.

Building on the success of the MoJ’s pioneering Alliance model, all three contractors will collaborate

This approach is fully aligned with the government’s Construction Playbook and recognises the significant benefits of Tier 1 contractors working together to drive innovation, maximise social value outcomes and create a contemporary prison estate that will deliver on the UK’s 2050 net zero carbon targets. This programme builds on the success of the Ministry of Justice’s pathfinder projects at HMP Five Wells, HMP Fosse Way, and HMP Millsike.

In addition to this programme, Kier, Laing O’Rourke and Wates are working with ISG and the MoJ in the separate Alliance 4 New Prisons (A4NP) which will deliver an additional 6,000 new prison spaces. Kier and Wates are also working as an Alliance to provide up to 2,200 places through the MoJ’s Accelerated Houseblock Delivery Programme.

The three teams will immediately commence an intensive preconstruction period. Construction work is anticipated to begin in 2024, with the houseblocks set to be operationally ready from 2025.

Source: www.wates.co.uk

With a product range specifically developed to improve the operational energy efficiency of buildings, leading manufacturer Glidevale Protect has launched several initiatives to reduce the environmental impact of its business operations.

Glidevale Protect is at the forefront of designing ‘hidden protectors’ such as specialist roofing and construction membranes and ventilation solutions, that help to improve a building’s overall thermal efficiency and airtightness, whilst reducing the risk of condensation. The manufacturer is working to improve the sustainability and operational efficiency of its business, with key projects underway including the creation of Environmental Product Declarations (EPDs), progressing towards accreditation to the ISO 50001 energy management standard and tracking recycling levels and

energy consumption across its UK based manufacturing facilities. The business is also investing in closed loop recycling of its product waste and is looking at other ways to improve the environmental footprint of its packaging.

The company has established a dedicated Group Sustainability Board and has gained a silver accreditation from the Supply Chain Sustainability School, which highlights its commitment to employee engagement and training.

John Mellor, sustainability lead for Glidevale Protect says: “Our current activities are being implemented from the front line with both internal and external customer drivers and we are not paying lip service or greenwashing with regards to reducing our environmental impact across our factory sites. Our key stakeholders within the business engage in monthly meetings to help push through positive changes and where necessary

we are consulting with industry experts who can assist us in our sustainability roadmap.”

Glidevale Protect is a UK producer and a subsidiary of Building Product Design Ltd – one the UK’s leading forces in the development of building ventilation solutions and specialist building products.

www.glidevaleprotect.com

Images:

01. L-R: Glidevale Protect’s commercial director Ben Gerry, sustainability lead John Mellor and quality technician Dean Horner holding granulated ABS, made from waste offcuts from its tile vent production line. This is then compounded, moulded, and recycled back into products.

Trina Chakravarti, Director at Building Better, took some valuable time out to speak to us about the organisation’s role and why MMC is integral to the improvement of the social housing sector.

Q: Building Better is an alliance of housing associations and local authorities committed to using more offsite manufacture in social housing – can you a say a little about its background and mission?

Trina Chakravarti (TC): Building Better was set up by social housing providers, for social housing providers. Everything we do centres around our social purpose – to provide homes that help people lead healthy, happy lives. I think that’s a real strength for us as an alliance. It’s in our gift to do something that impacts both our residents and the environment they live in and MMC supports both areas. Our mission is also to focus on sustainability in its broadest sense and the more we save by harnessing demand from other social housing organisations (we now have 32 members), the more we can all build and benefit both the climate and residents.

Q: The quality of housing generally in the UK is under a constant critical spotlight – perhaps more so in the social housing sector. Where are the main pinch points in social housing supply and how can offsite improve building at scale and give registered landlords best value for money?

TC: There’s no silver bullet here. We’re not for a second suggesting offsite alone can make up for the chronic undersupply over a generation –but it must be part of the solution. The labour crisis means there aren’t enough skilled tradespeople to build homes traditionally and layers of subcontracting encourages the passing down of risk and a lack of ownership.

Offsite and the assembly-led manufacturing process improves quality because employees (and their work) can be checked more easily –reducing downstream operational and

maintenance costs. It’s also a more attractive environment to work in – one location, safer, not exposed to the elements and appealing to a more diverse workforce. A development director recently described traditional construction as “building the retrofit of the future” and this highlights another way scaled offsite construction can give housing providers value for money. Our members are thinking about how the homes they build now will stand the test of time in terms of environmental and energy performance as well as customer comfort and affordability.

Q: How easy – or difficult – is it to convince clients that MMC is a viable route to better housing for their portfolios and residents? What objections do you often come across?

TC: We’re finding that sharing experiences, case studies and data is critical to engaging clients and

showing them that MMC is viable and will help them provide safer, higher quality homes for their residents, but also homes that will need less maintenance and retrofit down the line. Hearing first hand from other housing associations and local authorities helps to break down the fear factor around risk in the market, but also where to begin and what type of MMC is right for their homes.

Objections include cost and cost certainty. We’ve designed our procurement framework and dynamic purchasing system to provide clarity on cost. With our procurement partner, Procurement for Housing (PfH), we’ve created an MMC cost modeller that members can use to quickly find out prices by choosing from a range of housing archetypes, confirming the number of units and their location. This provides an estimated cost per square metre for a fully completed site with the opportunity to get an uplift price for net zero.

Q: Procurement, planning and pipeline are three Ps associated with many frustrations surrounding the wider growth of offsite manufacture – is that fair to say from your experience? What are the barriers to wider adoption?

TC: I’d agree on those, but I’d add a fourth: Price! MMC has got an image problem when it comes to price, with people often (wrongly) assuming it will cost more than traditional. Building Better has been tackling this head on by creating streamlined, accessible ways to procure MMC at affordable prices but also by gathering cost data from housing providers using MMC

at scale. We’ve worked with several housing providers, each delivering MMC homes, to gather their figures which you can read about on our website. This data shows that MMC costs are on a par with traditional homes when you compare like for like on specification. If there is a slight increase for MMC then it’s offset by savings from offsite where homes need less maintenance and retrofit down the line.

Q: Are any preferences being shown by the membership for MMC Categories and what level of understanding is there amongst housing associations and local authorities of the various methods and benefits behind these?

TC: We’ve seen a lot of interest in both Category 1 and Category 2 and there is some knowledge about the different processes and advantages but equally, housing organisations are really appreciative of the webinars, factory tours, workshops, case studies and other content we create that clearly explains what MMC is, the different categories and the difference within those categories.