P22

PERFORMANCE

P66

25% BY 2025

Streamlining and the seven steps to offsite and modular building with Balfour Beatty

P74

The

P22

PERFORMANCE

P66

25% BY 2025

Streamlining and the seven steps to offsite and modular building with Balfour Beatty

P74

The

Masonry homes provide superior performance benefits, both in construction and in use.

The thermal performance of concrete and masonry homes can provide homeowners with the lowest energy bills because of the superior insulation, airtightness and thermal mass.

Purchasing a home is a major investment and the inherent performance of concrete and masonry provides robust and secure homes that will last for many generations.

Concrete and masonry are non-combustible protecting life and property safety for occupants. During construction, these properties also protect the developer and surrounding community from spread of flame.

Masonry walls can support precast floors which do not squeak: 48% of homeowner noise issues raised with NHBC for detached homes were creaking floors (NHBC Foundation Report NF56).

Homes built from concrete and masonry suffer less damage because they are robust, dimensionally stable and do not rot.

Visit www.modernmasonry.co.uk for:

-

-

-

FOLLOW US ON TWITTER UNDER: Twitter.com/ExploreOffsite

ADVERTISING ENQUIRIES PLEASE CONTACT:

Julie Williams // T: 01743 290001

E: julie.williams@offsitemagazine.co.uk

BACK ISSUES VISIT:

www.offsitemagazine.co.uk

FRONT COVER

Creagh Concrete

PRINTED ON:

PEFC 16-33-576 paper stock by Buxton Press

PUBLISHER:

Offsite Magazine is produced and published by Radar Communications: ©Radar Communications Ltd.

Radar Communications Ltd, 5 Darwin Court, Oxon Business Park, Shrewsbury, Shropshire. SY3 5AL

T: 01743 290001

www.radar-communications.co.uk

For offsite enquiries please contact: E: info@offsitemagazine.co.uk

DISCLAIMER: The content of Offsite Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

Welcome to the latest edition of Offsite Magazine. This issue will be doing the rounds at UK Construction Week where offsite technology will be on show and under discussion as part of The Build Show and Timber Expo.

Having spoken to many disparate offsite industry insiders in the last few weeks about where they feel offsite manufacture sits in the grand scheme of Construction UK, the feedback has been overwhelmingly positive, while still openly acknowledging that hurdles to total acceptance remain from a cautious marketplace. Times are changing though. The level of interest in all methods of delivery –precast concrete, light gauge steel, engineered timber and volumetric modular – seems to be at an all-time high.

The recent Construction Sector Deal may not have satisfied everyone but its support for offsite construction was clear enough and a pivotal way to: “minimise the wastage, inefficiencies and delays that affect onsite construction and enable production to happen in parallel with site preparation – speeding up construction and reducing disruption.” Ultimately offsite manufacture is pivotal to improving construction productivity, efficiency and overall quality.

The future of offsite productivity and performance are at the heart of two industry discussions in this issue. One

hosted by Etex Building Performance delving into the world of housing and PRS and another hosted by Futurebuild – where the Offsite Hub in 2019 will be an important gathering ground for the offsite industry. More of these discussions in the following pages.

For a further peek into the future of construction we have a special feature from the Manufacturing Technology Centre – one of the dynamic centres of excellence in the UK – and the ways in which they are responding to the construction industry and standardisation, robotics and Design for X – that’s design for manufacture, assembly, maintenance and disassembly. The future is already here.

Finally, Balfour Beatty recently published a key policy statement. While many companies are beginning to consider ‘offsite and modularisation on a case-by-case basis for new schemes’, Balfour Beatty has made it a core part of its strategy with commitment to reduce onsite activity by 25% by 2025. It is hugely encouraging that a Tier 1 contractor has made a major declaration to adopt more ‘industrialised construction methods’ to boost productivity and plug skills shortages.

As always special thanks to all our contributors, advertisers and supporters.

Gary Ramsay Consultant Editor Email: gary.ramsay@offsitemagazine.co.uk

Creagh Concrete are championing the use of precast concrete in the UK and are at the forefront of cutting edge offsite manufacture with its Rapidres fastrack build system, that is presently revamping central Birmingham with the Arena Central development.

Andy Ormerod, Balfour Beatty Managing Director, Plant and Fleet Services is leading Balfour Beatty’s commitment to reducing onsite activity by 25% by 2025. He explains how the new generation of industrialised construction methods has the potential to transform the way the building industry operates.

08 | Industry News

News and developments from across the UK offsite industry and wider construction arena including: ZEDpods chosen for keyworker housing, a new wave of suppliers announced for Fusion21’s modular framework and Saint Gobain place offsite as a key ‘emerging reality’ in a new industry report.

P22 |

OFFSITE: SUPPLY CHAIN ENGAGEMENT AND INTEGRATION FOR

When and how to engage with the offsite supply chain to get the most value from it is always a hot topic for discussion. Etex Building Performance recently hosted a Roundtable Event to discuss issues surrounding this and the burgeoning private rented sector (PRS) approach to housing.

74

Mark Farmer said, ‘Modernise or Die’ and whilst this message has generally been accepted by the construction and infrastructure industry, it may not be clear what ‘modernisation’ actually means. Mark Ireland, Chief Engineer, Construction at the Manufacturing Technology Centre (MTC) explains more.

28 | UKCW Embraces Offsite

Offsite is due to make its mark on UK Construction Week (UKCW) by showcasing all its advantages in its very own dedicated Offsite area within the Build Show alongside an additional presence at Timber Expo.

30 | Offsite: Essential to Sector Deal

After some delay, the Government finally launched its much-anticipated Construction Sector Deal (CSD) in July, with a vison to develop an industry able to respond to the pressures of changing demographics, technological change and sustainable building.

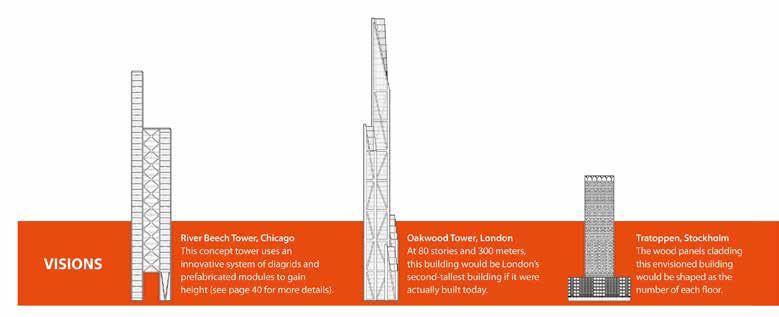

34 | A Rising Global Profile

In the past few years, the tall building industry has become increasingly interested in the use of timber as a major structural element in skyscrapers. We hear from Daniel Safarik, Senior Editor at the Council on Tall Buildings and Urban Habitat (CTBUH) on what the future may have in store.

42 | Influencers and Disruptors

As Managing Director of Cogent Consulting, Darren Richards is well placed to comment on how the world of offsite manufacturing has gained traction over the past 12 months. Here he shares his views on how the market is developing and which factors are influencing the sector.

44 | Precast Revamp for Police HQ

Lancashire Constabulary’s new divisional HQ has reached completion and features offsite precast technology to provide one of the UK’s largest custody suites, with innovative design and a more secure environment for officers and those in custody.

52 | The Power of Steel – delivering cost and programme certainty

Driven by the demand for more predictability throughout the construction process, EOS are geared up and ready to bring new systems to the market. Managing Director, Steve Thompson discusses the benefits of light gauge steel (LGSF) for load-bearing applications.

68 | Futurebuild Think Tank

After a turbulent few years, confidence is returning within the construction world with interest in offsite construction in particular on the rise. Futurebuild and Offsite Magazine recently hosted a special ‘think tank’ session to discuss progress and understand what the future may hold.

72 | Building Skills for Offsite Construction

The development of skills in offsite construction could revolutionise the construction industry and help provide a solution to the UK’s housing shortage. Ben Lever, CITB Future Skills Manager outlines how.

MODULAR MATTERS conference and exhibition will create a platform to learn directly from leading sector designers, engineers, architects and manufacturers on how to apply innovative volumetric modular technology and also dispel the myths on design constraints.

The event provides a dynamic and interactive learning experience for all visitors and a fantastic business development opportunity for exhibitors and sponsors.

ONLY A FEW DELEGATE TICKETS REMAINING

Creagh Concrete are championing the use of precast concrete in the UK and are at the forefront of cutting edge offsite manufacture with its Rapidres fastrack build system, that is presently revamping central Birmingham with the Arena Central development.

A collection of high and low-rise shops, offices and residential buildings are emerging around the existing Alpha Tower, a Grade II-listed office built in the 1970s and one of Birmingham’s most well-known architectural landmarks.

Main contractor Galliford Try is now two-thirds of the way through a £40million 323-apartment Private Rented Sector (PRS) scheme for client Dandara Living, one that will significantly boost the number of homes available in close proximity to Birmingham’s city centre. Comprising two blocks of 17 and 22 storeys linked by bridges at each level, the

1development will feature studio, onebed and two-bed apartments with balconies across all elevations.

The building is located within the footprint of a subterranean car park that used to serve the Alpha Tower and hotel behind. That car park was a two-level facility built below ground with an open central section. The new building has been launched largely through that central void, with the reinforced concrete car park broken away in areas to accommodate the new development. The building ties into the remaining sections of car park to provide spaces for its residents.

“Some of the car park has been incorporated into the design for the development,” says Aidan Smith Project Manager, Galliford Try. “Our temporary works department had to look closely at the design of the car park to accommodate the different loading on the structure during the demolition process, as well as tying it back into the new building as it came up from the ground.”

The structural frame from Creagh

Concrete for the new dual-block building is largely precast concrete with a cast in-situ reinforced concrete basement and ground floor featuring a 1.8m-thick transfer slab – cantilevered across the south-east corner. A precast concrete frame springs from this slab from levels 1-22 on block A and 1-17 on block B.

The decision to use precast concrete systems for the bulk of the building’s structural frame, cladding and balcony units was taken at an early stage on the project, with Dandara wanting a robust finish on the building, which would limit the amount of ongoing maintenance required.

With Creagh’s precasting facilities in Northern Ireland able to provide both the structural units and the acid-etched finished architectural cladding units for the facade, the Galliford Try team was quick to bring the firm in as main supplier on the project. “We did lots of due diligence,” adds Adrian Smith. “We felt Creagh could deliver and complete the work on-time and we liked its in-house design capability. The team there spent months perfecting the mixes to make sure it could manage to consistently produce the dark grey of the facade.”

The scheme uses the Rapidres fastrack build system. The bulk of the Arena precast panels measure 8m in length, with the floorplan based on a similar 8m grid. They arrive onsite from a holding point just outside the city and are lifted directly into position. The inner wall panels are formed from 180mm thick solid concrete and arrive with a perfect surface that just requires a few coats of paint. The insulated structural facade panels are 300mm thick and require no further treatment onsite.

The exclusive Forbes Place development at Stoneywood, Aberdeen comprises of four apartment blocks – two with seven storeys and two with five storeys –providing a total of 276 apartments. Each apartment block has underground parking for approximately 80 cars. Forbes Place is one of the first Build to Rent (B2R) developments in Scotland, built by premium contractor Dandara to address a critical lack of high standard accommodation for professionals in the city of Aberdeen.

Dandara turned to Creagh Concrete to use their innovative offsite fastrack build system ‘Rapidres’ for the site. ‘Rapidres’ is ideally suited to multi-storey projects where the layout is replicated consistently across each floor. While most projects will have variation of layout in mixed use spaces on the ground floor, this is routinely dealt with by the use of a structural podium which forms the base for the offsite structure. The total frame solution comprises of structural walls and solid hollowcore flooring, with construction speed far greater than alternative systems. Creagh designed, manufactured, and installed the complete structure from foundation to roof level. Units were manufactured offsite at the factory in Toomebridge and delivered to Forbes Place for installation over a 40-week build period. Units included external sandwich precast panels, precast columns, hollowcore floors, internal cross walls, lift shafts, stair-flights, landings and external brick-clad retaining walls.

You can view more on Rapidres here: http://bit.ly/2rRH2AN

The building’s design features one stair and lift core in the taller block, which provides access and emergency access for both blocks. Like the rest of the building, this is formed of cast in-situ concrete to the first level and then precast concrete beyond.

Precast concrete had always been the material of choice for the frame construction and cladding. The project team looked at various different options for the structure and its subcontractors, before settling on the team at Creagh Concrete to deliver and install the frame panels, cladding sections, balconies and floor slab. The hollowcore floor slabs are lifted into place with reinforcing steel rods used to stitch the sections together, before a final screed is placed to address any level differences and deliver the final slab level.

“We knew we wanted the robustness that precast concrete offers and spent a lot of time researching our subcontractors,” says Adrian Smith. “Creagh has the capability and experience to deliver both the hollowcore floor slab and the architectural precast concrete that we wanted. The screed that we place on top of the floor slab is there just to iron out any changes in level. It gives us a little wriggle room.”

The placing of each level is based on a turnaround time of just 10 days. Prefabricated bathroom pods, manufactured in Hull, are lifted directly into position at each level as the building edges further towards completion.

“We are seeing strong interest in our rapid build concrete systems because developers now understand the true value of slashing programme times,” says Creagh Concrete’s CEO, Seamus McKeague. “Investors not only benefit from revenue gained by the early occupation of units but, also, from the mobility of their capital resource. Quite simply, shorter build times mean developers can complete more projects with the same pot of finance. The market for custodial accommodation has also been open to offsite for some time now and we are engaging there too.”

For more information visit: www.creaghconcrete.co.uk or email: structures@creaghconcrete.co.uk

Images: 01-03. Arena Central during construction with 8m panels being raised into position

The McAvoy Group has been awarded its first contract in the residential sector following the announcement of its expansion into offsite housing. The £4.7 million contract for Clanmil Housing Association will be the first offsite housing scheme to be built in Northern Ireland. The use of the McAvoy offsite housing solution will reduce the build programme by around 60% to just 40 weeks.

Designed by Knox Clayton Architects, the Joymount development in Carrickfergus will provide 40 much needed homes to help address the severe shortfall in social and affordable housing in Northern Ireland. It will feature eight one and two-bedroom apartments for couples and families, 17 two-bedroom apartments for active older people and 12 two-bedroom houses for families. There will also be three detached bungalows specifically designed for individual families with complex needs. The scheme is due for completion in spring 2019.

The homes will be manufactured and fully fitted out offsite at McAvoy’s production centre in Lisburn, Northern Ireland. McAvoy will manufacture 111 steel-framed building modules and the homes will be installed onsite, complete with bathrooms, kitchens, partitions and glazing.

Carol McTaggart, Group Director of Development at Clanmil, said: “We have been exploring different delivery models for social housing to help address the rising cost of building materials, the shortage of skilled labour in the construction industry in Northern Ireland, and the uncertainty created by Brexit. There are currently 24,000 households in housing stress in Northern Ireland. We want to be able to deliver new homes more quickly for people on the housing waiting list whilst still maintaining our high standards of design and build quality.

“Significant time savings can be achieved with offsite construction. Offsite manufacture avoids delays caused by poor weather and it improves both quality and health

and safety – with less impact on the environment. By partnering with McAvoy on this pioneering project and using advanced offsite construction technology, we believe we can reduce the build programme for these 40 new homes by around 56 weeks which is crucial to reducing waiting lists.”

Eugene Lynch, Managing Director of The McAvoy Group added: “It is fantastic to see such a progressive provider of social and affordable housing as Clanmil who are looking at more innovative ways of delivering high quality new homes, more quickly to address the housing shortage in Northern Ireland.

“This scheme is the first to use our new modular housing solution and successfully demonstrates its application for apartments, detached and semidetached homes. It also illustrates our capabilities as a principal contractor. We are not just supplying building modules on to a pre-prepared site but are responsible for the full range of services for Clanmil – from site preparation and clearance of this brownfield site to design, manufacture, factory fitting out, building installation, landscaping and infrastructure. We look forward to creating a much needed and vibrant new community for this area.”

Following extensive product development and collaboration with Queen’s University Belfast, McAvoy has developed a steel-framed offsite housing solution for multi-storey apartments, detached, semi-detached and terraced family homes. The new homes are designed in accordance with Lifetime Homes and Secured by Design standards.

McAvoy will work as principal contractor on its housing projects, taking responsibility for design, manufacture, fitting out, installation and external works. This will mean easier procurement, fewer management resources, greater cost efficiency, and improved quality control for developers and housing providers.

Source: www.mcavoygroup.com

An innovative unitised facade, combining handmade bricks, aluminium, triple glazing and precast concrete, was developed for University College London Hospitals (UCLH). The unitised facade is part of an offsite solution for the new centre for ear, nose, throat and dental services.

Created by a team led by main contractor Mace and architect Pilbrow & Partners, the facade’s design aims to reduce onsite health and safety risks, improve quality and slash months off the programme – up to five of these panels will be installed a day, and the entire envelope should be complete and watertight in just 13 weeks. Most of the 248 panels are hybrids that combine traditional handmade bricks, chosen to blend with the historic context, with precast concrete, aluminium and glass. The heaviest weigh 11 tonnes.

Nicola Scammell, Senior Project Manager at Mace, says: “Prefab is often considered uncreative and repetitive but with the hospital being in a largely brick-built conservation area, a lot of work has gone into the fine detailing to ensure it is respectful to the architectural surroundings, but delivered in a modern and efficient way. Building the facade traditionally, by hand-laying bricks, would have taken 40 weeks; by unitising the panels we managed to reduce that to 13 weeks. It takes various activities off the critical path, we simply get panels delivered ‘just-in-time’ to go straight onto the building.”

The large bays on Huntley Street are the most complex and include a perforated brick element, orientated south west to increase solar shading, a triple-glazed window element, and a precast concrete element. Each panel on levels one and two is around 5.5m wide by 4m tall, while slightly taller panels feature on the upper levels.

The idea of modularising the facade was first mooted by Mace at bid stage and subsequently taken forward when it won the design and build contract and started on site in summer 2016. The new centre, which brings together services from the Royal National Throat Nose and Ear Hospital and Eastman Dental Hospital, is due to open in 2019.

Source: www.techrete.com

Central Bedfordshire College and a private developer have chosen ZEDPods, ready-made, quality starter-homes for a new development of 23 homes on college land.

The one and two-bedroom houses, a break-through development in low cost, low carbon and high-quality homes are fabricated offsite. Their modular construction allows them to be rapidly erected on pieces of land not generally considered suitable for housing. With a variety of design options covering single or multi-occupancy sites, ZEDPod homes can be tailored for a range of accommodation needs, offering a viable, affordable solution to the keyworker housing crisis.

Designed and developed by RIBA award-winning architect Bill Dunster, the ZEDPods are designed to take advantage of existing city centre car park locations and hard standings across the UK, either on the ground or assembled on raised platforms. Homes are built to higher standards than conventional houses, being super-insulated, triple-glazed, with heat recovery ventilation, low carbon technology and lots of daylight.

While the company is busy working on several new developments following the launch of the concept, this is the first ZEDPod project to go into planning. Bill Dunster, Director of the new ZED Pods company says: “We understand that Savills has reported ‘the identified requirement for affordable housing is greater than could be delivered through the planning system’ and that there is a ‘need to explore other ways of providing affordable housing’ so we look forward to working constructively with planners across the UK in explaining our new technology.”

Ali Hadawi, Principal, of Central Bedfordshire College said: “We are delighted that Central Bedfordshire College is able to support the local area needs and ZEDPods with the creation of environmentally friendly housing solutions. We look forward to working with ZEDPods to develop new courses teaching on modern forms of construction utilising the most cutting edge, eco-friendly construction techniques to our learners and to seeing the benefits that this innovation will have on our community.”

Local MP, the Rt Hon Andrew Selous is enthusiastic about this first development, which will offer affordable homes to Dunstable’s nurses, teachers and firefighters saying: “Bill Dunster set out a compelling case for affordable zero energy bill homes that people want to live in. There is a huge demand for affordable housing and I will do what I can to keep this matter at the top of the Government’s list of priorities.”

Bill Dunster added: “As the pods are constructed from quality fireproof, durable and robust materials, they are designed to last as long as a traditionally built home. The pods’ solar roofs generate more energy than the houses consume, so they will also have the lowest possible running costs.”

ZEDPod owners will have their own balcony and front door, a kitchen and dining table, a bathroom, a lounge with stairs leading to a mezzanine floor bedspace, with home office desk, double bed, wardrobe and storage. ZEDPods will be sold with a ‘Q Assure’ mortgageable warranty.

Source: www.zedpods.com

Architectural practice, astudio, has launched a revolutionary modular housing partnership in the hopes of reducing the cost of modular housing, providing high-quality homes and offering a potential solution to the UK’s housing crisis.

amodular, is astudio’s proprietary modular building method with Be First, the London Borough of Barking and Dagenham’s pioneering regeneration company. The innovative volumetric modular construction method developed by astudio enables the expedited assembly of low-energy homes, fitted-out, completed and manufactured offsite to provide robust, high-design modular housing.

astudio’s homes are supplied on a turnkey standardised production basis. Costs are minimised through bulk purchasing of materials and components. The small selection of standardised modules speeds up production and reduces the potential for defects during build. Multiple fixtures, fittings and cladding options both internally and externally are available, enabling each building to have a distinctive look and feel.

Working in collaboration with Be First and offsite modular manufacturer Rollalong, astudio’s pioneering approach is being implemented in two new developments in the borough, at Mellish Close and Sugden Way in Barking. Consisting of eight council flats in Mellish Close and 13 in Sugden Way, the homes

The first prototype homes manufactured using an innovative 3D injection printing process, and incorporating technologies inspired by the automotive and aerospace industries, are due to begin production by the end of the year.

Prefabrication specialist RDA Modular developed the technology behind the low rise homes and apartments, which will be produced in large monolithic panels, up to 16.5m long and 3.5m wide. The firm recently launched an investment and fundraising round to build its first production facility, capable of manufacturing a minimum of 2,000 homes in its first year. The long-term plan is to build several factories capable of manufacturing 6,000-8,000 houses each.

Romy Jardine, Chief Technology Officer at RDA Modular, said: “We’ve been working for the past couple of years on some brand new technology that hasn’t been used in construction, including housing or modular. We build the walls and floors in single massive pieces then ship them flat-packed standing upright,

will be built in complete accordance with building and health and safety regulations, more sustainably, cost-efficiently and within an accelerated time-frame of 60 weeks from design to handover compared to the 24-30 months it would take for traditional builds, saving the council vital resources.

Richard Hyams, Co-founder and CEO of astudio, said: “We are delighted to be working in close partnership with Be First and the London Borough of Barking & Dagenham to help address the critical housing shortage in the borough, using our amodular proprietary production method. It is vital that landowners, developers, local councils and the community collaborate if we are to free up land and develop innovative solutions to address the critical

shortage of housing in this country. It makes sense that one of those innovations is modular housing. We believe that in the very near future, building will become like car production, with houses becoming quality manufactured products.”

Iain Ferguson, Commercial Director for Be First, added: “At Be First we are determined to increase the pace and quality of development in Barking and Dagenham. So, we are excited to be working with astudio on this ground-breaking scheme which we expect to reduce costs and deliver top-class housing in a fraction of the normal build time.”

Source: www.astudio.co.uk/modular

like an Ikea system for apartments and big housing developments. Using modern materials means we can make much stronger and lighter panels that are more eco-friendly and close to Passivhaus standards. The main cost saving comes from factory automation and reducing labour by 95% compared to traditional construction.”

The prefab elements are a form of ‘superior SIPS panel’ but plug and play and are extremely lightweight. They comprise two layers of OSB with all mechanical, electric and plumbing services sandwiched in between. The homes and apartment blocks will be built up to four storeys high and located outside London, either

in the suburbs or in new garden cities, towns and villages proposed as a way to meet the current housing shortfall.

RDA Modular is working with companies in Italy and Germany to apply existing production technology, used in the aerospace, automotive and defence sectors, to construction. The company has already ordered some machinery and plans to start production for testing and certification purposes and to develop initial prototype houses by the end of the year.

Source: www.rda.global

Offsite construction specialist, Sigmat, has launched its biggest hunt yet to find Yorkshire’s ‘Hidden Talent’, as it recruits for an elite Academy to develop some of the region’s brightest individuals. The ‘Detailing Academy’, will provide opportunity for a diverse range of people from all backgrounds.

Chief Finance Officer for the company, Matthew Jowett, said: “Sigmat is the UK market leader for offsite light gauge steel framing which, in layman’s terms, means we design, manufacture and assemble steel frames for buildings in our production facility before installing them onsite, taking significant time and cost out of construction projects. Consequently, we have grown rapidly over the last few years as our technology has established itself in the UK building sector, prompting the need for more professionals to support our continuing expansion.”

Recognising that the right sort of people were hard to find, Sigmat decided to launch its pioneering ‘Detailing Academy’, with the aim of recruiting men or women returning to work after a career break, those with an interest in the ‘built environment’ or simply bright individuals looking for a career change.

“The labour market has been volatile in recent years, driven in part by the Brexit debate, so we decided to take a pro-active approach,” added Matthew. “Due to continued growth in our business we want to recruit either ready-made Structural Detailers or people looking for a new challenge, even if they have no experience.”

There are a few mandatory requirements, essentially a keen eye with excellent attention to detail, a flare for all things technical and the determination to see projects through to the end. Technical Director, Clive Webberley, added: “We have designed a unique programme to enhance existing or dormant skills within those people selected, and successful candidates will be trained in an academy-based environment and taught

the necessary skills to become a Structural Detailer, including software and 3D modelling.“

Academy graduates will eventually join Sigmat’s Detailing Team and develop their career as a Structural Detailer, using their new skills to support Sigmat in delivering some of the UK’s most exciting construction projects.

Anyone interested in learning more can email: recruitment@sigmat.co.uk or visit: www.sigmat.co.uk

Three storeys of office and welfare space have been installed over four days at Wembley Park. Construction workers on the development site will have use of the industry’s highest quality site accommodation solution as Portakabin provides almost 800m2 of welfare and office space.

McLaren was awarded three building contracts by developer Quintain, for the Wembley Park development plot, which will provide around 30,000m2 of residential and retail space. The 10-storey and 15-storey buildings constructed by McLaren will include 490 build-to-rent units with associated common spaces, commercial office space and ground floor retail units.

For the duration of the construction project, Portakabin installed a three-storey site accommodation building adjacent to Wembley Stadium. Thirty modules were carefully craned into place, over just four days, on the site next to Olympic Way, known to fans the world over as ‘Wembley Way’ which welcomes more than 11.5

million visitors a year. This minimised disruption to the site and also ensured there was no risk to public safety.

The building will be in use for 120 weeks in total and provides 795m2 of space for McLaren office staff and construction workers. The space includes three large open plan offices, two meeting rooms, an induction room, bathroom facilities on each floor, two kitchenettes, a large canteen and professional kitchen plus a drying room and reception for visitors. The white modular building, with black exterior staircases at either end, provides a clean, modern appearance for the iconic stadium site – challenging the perception of traditional site accommodation products.

Karl Salter, Logistics Manager, McLaren Construction at Wembley Park said: ‘’We used Portakabin knowing we would receive a high level of service and the McLaren team on the Wembley projects were not let down. They provide great temporary office and welfare facilities

finished to a very high standard and their customer service is excellent, from start to finish. The installation of the facilities was completed on time and in a very safe and professional manner, I can honestly say they exceeded our expectations here at Wembley. The team at Portakabin are a pleasure to work with, and I’m sure we will be working together again in the near future.’’

David Griffiths, General Manager at Portakabin added: “We worked closely with the McLaren team to achieve a solution that worked for them. Portakabin offers the highest quality site accommodation solutions and for a site and team of this prominence, quality and finish were most important. We were able to exceed that level of quality, delivering the building safely and quickly with minimal disruption.”

Credit: Quintain/High Level Photography

Source: www.portakabin.co.uk

Fusion Building Systems has completed its works on three residential housing projects in the south of England for Barratt Developments. St Mary’s Place, Felpham, West Sussex, New Quarter, Bordon, Surrey and Cane Hill Park, Couldson, Surrey, are the first schemes to be delivered by the offsite manufacturer since it successfully completed a trial project for Barratt in Southampton in 2017.

Across the three sites – working on almost 200 units – Fusion adapted existing Barratt house types as well as developing bespoke multi-storey designs, to make them suitable for use with its light gauge steel panelised system. The work was completed on each site over the past 12 months, but was the result of almost three years of intense integration and education at all levels across both companies, exploring how offsite systems could be used as a viable alternative to traditional methods of construction.

Rotherham Metropolitan Borough Council is recruiting specialist housing suppliers for a new series of modular low-cost, single-person ‘pod’ homes. The project will deliver 10 pilot pod homes across two tight urban sites. Each 22m² unit will be expected to feature a bedroom, living space and shower room. The team or teams chosen for the estimated £400,000 contract will use offsite construction to deliver a pilot programme of innovative affordable council houses which could be rolled out across the region on a larger scale if successful. In its brief, the council says it: “has ambitions to significantly increase the number of new homes built in Rotherham. To help

“Our system was proven to work on a small number of houses for Barratt’s trial 18 months ago, so it’s exciting now for us to see how we can scale up to deliver a much larger number of units,” said Robert Clark, Fusion Head of Business Development.

The three sites were very different in their requirements however, from two, three and four-bedroom standard house types, to non-standard designs with challenging ground conditions and four-storey apartment buildings. “Each site put our design and engineering teams to the test,” added Robert. “With the successful delivery of each, from concept through to installation onsite, reliant on effective collaboration and communication throughout the supply chain. The early phases on site once again presented a learning curve for each company, but as each development progressed, all parties worked well together and were ultimately convinced offsite was the future for volume housebuilding.”

achieve this, the council is piloting the use of modern methods of construction as a swifter and more efficient way to deliver new homes.

“The council is seeking tender returns from housing providers using MMC to deliver a pilot project which will consist of 10 small ‘pod’ type homes for single-person households requiring affordable accommodation. This is identified as a pilot scheme which the council hopes to roll out as a larger programme, depending on the success of this pilot. The new homes will be added to council stock and will be developed on council land.” The first sites revealed for the project include Chatham Street in the town centre, close to the site of the new University Centre Rotherham on Doncaster Gate. Six units are envisaged here. At Vine Close in Masborough, four units are proposed. Two bungalows at Hounsfield Road and Hounsfield Crescent, East Herringthorpe and

Oliver Novakovic, Technical and Innovation Director, Barratt Developments, added: “Fusion has now successfully delivered full scale pilots on three sites with our Southampton and Southern Counties divisions. We have seen a real improvement in speed as predicted and are now continuing to work closely with the Fusion team to roll this technology out further. We believe the work we have done over the last two years on things like standard details and the construction approach really supports the application of the Fusion system into our private housing market.”

Source: www.fusionbuild.com www.barratthomes.co.uk

eight bungalows at Symonds Avenue, Rawmarsh are proposed.

If the pilot proves to be successful, it could provide a delivery route for many of the other 200-300 small sites in the borough. The overall number of homes in the borough increased by 479 units in the 2017/18 financial year, below the Council’s target of 641 units.

Source: www.rothbiz.co.uk

www.rotherham.gov.uk

Hallsville Quarter is one of the most significant regeneration projects in London and forms part of the £3.7 billion Canning Town and Custom House Regeneration Programme. Working with developer Bouygues and specialist cladding contractor Facade Concepts Ltd, Aquarian Cladding Systems have supplied over 8,000m2 of its offsite-manufactured Gebrik insulating brick cladding system for two 15-storey residential tower blocks, which were built in just seven months.

With a desire to achieve a brickwork façade using mast climbers, Bouygues’ design team identified that Gebrik would allow the brick cladding to be incorporated within other trades using mechanical access, enabling a quicker build programme without the need for scaffolding. Gebrik’s BBA certification also ensured warranty provider NHBC would approve its use over 18m, provided the entire build-up met the tested conditions in accordance with BS8414:2.

With the building footprint effectively the site footprint, storage space was at a premium, and so all deliveries were made on a ‘just-in-time’ basis. With fewer deliveries and less storage than conventional brickwork, this meticulously-timetabled project proved more straightforward and Gebrik’s swift installation meant that when materials arrived, they were used within a few days.

“We believe Gebrik installation is generally easier than brickwork,” explains Guillame Simon, Project Manager for Bouygues UK, “Its installation is typically less affected by weather conditions, it needs less storage and load space onsite than brick, and it can be installed safely from mast climbers. Its adaptability also made it possible to co-ordinate with GRC features, which would have been difficult using traditional brick.”

Source: www.aquariancladding.co.uk

Saint-Gobain UK and Ireland’s new report ‘Emerging Realities in the Construction Industry’ curates statistics and opinion from independent contributors on aspects of construction facing imminent disruption – and what it means for the future of the industry. This report covers the trends, technologies and approaches in their infancy which will change our industry now and in the immediate future. Four key topic areas facing disruption are explored: economic, technological, socio-demographic and environmental realities. The report features independent opinion from organisations across the industry including from The Carbon Trust, SNC-Lavalin’s Atkins, The Royal Institution of Chartered Surveyors, Mott MacDonald and The Manufacturing Technology Centre.

Offsite manufacture is referenced several times as a technology and innovation megatrend stating: “There’s a big link to manufacturing. You can get better productivity offsite. It’s about cross-sector learning – for example, about processes, which are about creating more structure for people to work within. We are trying to drive horizontal innovation and are learning a lot from discussions with the manufacturing, aerospace and automotive sectors. We are redrafting the narrative of our sector. It should be seen as being built asset manufacturing, rather than construction. This approach can benefit so much of what our society depends on – housing, schools, hospitals, roads and railways. It will enable us to build more, to a higher quality, with less resources.”

Mike Chaldecott, CEO of Saint-Gobain UK and Ireland said, “I’d like to thank all of the contributors who took part in the formation of this report. Business thrives on foresight and I hope this report helps spark a debate about the future of our industry. Specifically, how we all might prioritise our thinking and activity across our industry to maximise the opportunities at our fingertips and capitalise on the vast potential of our sector.”

Offsite manufacturing is a progressive step that challenges outdated assumptions –the construction sector has been advised to ‘modernise or die’. This technology will generate savings in the long term, but the overwhelming message has to be – get involved sooner rather than later, or risk being left behind.

Spotlight on Offsite brings together distinguished speakers from a broad spectrum of pioneering organisations representing clients, construction professionals and suppliers.

The combined conference and exhibition will showcase ground-breaking offsite construction solutions and focus on the latest developments, innovations and investments in the offsite sector across a range of vertical markets.

Get involved as an exhibitor for the two-day event from as little as £1500 + vat.

Please contact:

julie.williams@radar-communications.co.uk

01743 290042

If you are working within the offsite sector and believe that you can present some leading-edge ideas or some ground-breaking case studies and would like to share your insight with an audience of over 300 interested delegates - then please get in touch with:

grace.baker@radar-communications.co.uk

Fusion21 has announced the suppliers successfully appointed to its Modular Building Framework following an expansion worth £175 million over a four year period. A total of eight highly skilled firms have secured a place on the framework which is designed to service the blue light, health and leisure sectors, in addition to providing buildings for educational purposes and wider public use.

With a full turnkey solution for the Design, Manufacture and Installation of Buildings of Modular construction the framework worth, a total of £400 million, offers Fusion21 members including schools, academies, colleges and universities, temporary or permanent quality modular buildings, which are compliant with all building regulations and present lower carbon emissions than traditional builds.

Nick Verburg, Procurement and Supply Chain Manager at Fusion21, said: “Modular offsite construction is an innovative and cost-effective way to deliver buildings for the 21st century, and we are delighted to have expanded this flexible procurement solution in response to market demand and member feedback.

“Fusion21 members accessing this framework from the education sector will benefit from significant efficiency savings and social value, whilst accessing a range of sustainable building solutions specific to their building needs and requirements. Members can also enjoy the advantages of prefabricated construction including reduced labour and onsite costs, and a faster turnaround – which is ideal when classrooms are urgently required.”

Fusion21 provides procurement services and OJEU compliant frameworks to the public sector, and is committed to making a difference in communities across the UK. To date the firm has saved its members more than £177 million through the procurement process, created more than 5,100 jobs and generated £76 million of community impact.

The successful suppliers appointed to Fusion21’s national Modular Buildings Framework include: Danzer, MTX Contracts, Wernick Buildings, Elliott Group, Qube Structures, Western Building Systems, Integra Buildings and REDS10 (UK)

Source: www.fusion21.co.uk

be announced early next year, now that the Heathrow team has completed visits to all 65 longlisted sites Last year, Heathrow invited organisations across the country to showcase how their area could contribute to the delivery of one of the UK’s largest infrastructure projects. An initial 121 expressions of interest were whittled down to a longlist of 65 potential sites, all of

which have been visited by Heathrow representatives over the past six months. The nationwide tour concludes in the Midlands with the Heathrow team visiting sites from Balfour Beatty, SEGRO and Prologis located in Tamworth, Derby and Daventry.

The hubs are integral to the airport’s plans to ensure every corner of the UK benefits from the expansion of Heathrow, helping to spread job creation and economic benefits up and down the country. Offsite construction will also help to make the project more affordable and sustainable – by transporting assembled components in consolidated loads. Heathrow expansion is an opportunity to consider a new approach to the construction of major infrastructure and will be the first of this scale to use this method – with the objective of encouraging other major projects to explore offsite construction.

“Heathrow expansion is much more than the delivery of Britain’s new runway, said Emma Gilthorpe, Expansion Executive Director at Heathrow. “Expansion is a once in a generation opportunity to transform British construction as the country prepares for life post-Brexit. This nationwide tour has shown us the possibilities offsite construction offers and we’re looking forward to announcing the shortlist early next year.”

Business & Industry Minister Richard Harrington said: “We want the UK to lead the bytes and mortar revolution within the built environment and our Construction Sector Deal lays the foundation to take advantage of these opportunities – boosting productivity, creating better jobs and increasing new offsite manufacturing technologies to speed up construction. The Heathrow Logistics Hubs have the potential to be an example of this modern construction in action, embodying the principles of our Industrial Strategy and benefitting millions by allowing businesses across the UK to harness the strengths of their own regions to deliver a landmark infrastructure project.”

Marie-Claude Hemming, Director of External Affairs at the Civil Engineering Contractors Association (CECA), added: “CECA has long argued that expanding our airport capacity is vital in securing future economic growth across the UK, and we are fully supportive of Heathrow’s development of a third runway. As strong advocates of rebalancing the economy, we welcome Heathrow’s decision to use logistics hubs which will drive project efficiencies, improve site welfare and will also contribute to growing the economy for the long term outside of London and the South East.”

The next stage of the selection process will be a pre-qualification questionnaire (PQQ) which opens in autumn this year. A shortlist of potential Logistics Hubs will be announced early in 2019, before the final four sites are announced later in the year, with construction set to begin at these sites in 2021.

Source: http://mediacentre.heathrow.com

Hadley Group have announced the appointment of Ben Towe (pictured) as Group Managing Director while Stewart Towe becomes Executive Group Chairman. In line with Hadley Group’s strategic 2020 vision, Ben Towe has been appointed Group Managing Director leading the day-to-day worldwide activities of Hadley Group and Associates. As Executive Group Chairman Stewart Towe will continue to promote, drive and support the strategic intent of Hadley Group.

Ben will continue to drive the company’s growth strategy while Dr Michael Castellucci will take the reign as Group Engineering Director responsible for all technical and operational functions. Michael was instrumental in the development of Hadley Group’s patented UltraSTEEL® process – a groundbreaking steel strengthening technology.

Stewart Towe, Executive Group Chairman, Hadley Group, said: “I have really enjoyed my role as Chairman and Managing Director of Hadley Group over the past 12 years building highly effective Board members and a successful business. My new role will give me the opportunity to pursue activities within the wider business community while still supporting the pursuit of Hadley Group’s strategic business development

and investment activities globally.” Jonathan Jaggar continues as Group Sales Director and Richard Neale as Group Finance Director.

Hadley Group recently acquired EWS (Manufacturing) Ltd. In a move that reaffirms its commitment to support the construction market, both in the UK and internationally, Hadley Group announced the acquisition of EWS (Manufacturing) Ltd with Stewart Towe, commenting: “I am delighted to confirm the addition of EWS into the Hadley Group. The company greatly complements our wide range of value added construction products. We look forward to supporting

EWS as they continue to progress in the markets they serve.”

EWS produces in excess of 25 million metres of cold roll-formed sections annually and is the market leader in window and door steel reinforcement with core strengths in other construction market products. The Wolverhampton-based manufacturer will now form part of Hadley Group’s global chain of manufacturing locations.

Source: www.hadleygroup.com

Hadley Group is a world leader in advanced cold rolled steel technology, with manufacturing facilities in Europe, the Middle East and Southeast Asia, delivering innovative solutions across sectors as diverse as construction, industrial and agriculture.

Our technical, structural and design abilities, coupled with our unsurpassed expertise in cold rollforming, have resulted in an extensive range of innovative products. From steel profiles and steel framing to innovative, market leading solutions like our purlin system, ceiling grids and SFS panelised bolted frame; we work hand in hand with our industry partners to deliver products designed to streamline construction, enhance performance and maximise sustainability.

www.hadleygroup.com

When and how to engage with the offsite supply chain to get the most value from it is always a hot topic for discussion. Etex Building Performance recently hosted a Roundtable Event to discuss issues surrounding this and the burgeoning private rented sector (PRS) approach to housing.

Arguments about how to deliver the vast quantities of newbuild housing required in the UK over the next decade to fuel demographic demand are complex. But what most people can agree on is that a new breed of affordable, flexible and purposebuilt housing is needed that appeals to discerning tenants and anxious investors alike. New commercial and technology models are shaping the ways of delivering construction quality and consistency.

The role offsite construction has to play – not just in delivering new housing –but across all building types has never been more important and over the last 18 months in particular, offsite has seen its status at an all-time high. But problems still surround lack of early engagement – when in any project cycle are clients engaging with offsite suppliers and how could the process be improved?

“Procurement behaviour needs to change, says Rory Bergin Partner, Sustainable Futures, HTA Design LLP. “There is still a struggle with people trying to procure new things in an old way and we come across that on multiple projects. There is still a maturing awareness of what products and systems are available on the market. Not everybody wants the same technology or has the same considerations, but there is a worry about limited suppliers out there. Or what is increasingly happening with these limited suppliers is that they are incredibly busy.”

Early supply chain engagement is the oft-repeated mantra and starting the process of adopting offsite at project inception means its long-term benefits are maximised. “Certainly everyone is on a different stage of the journey to understand what products and systems are in the marketplace,” says

Joe Thornton, Founding Director, Cast Consultancy. “But we are finding that far more people are ‘open’ to talking about offsite than ever before from a very early stage.”

Many clients and investors needs to widen their expectations and understand that offsite adoption is a: “business strategy first and a procurement strategy second”, and is about absorbing the culture of offsite manufacture into the business model. Confidence levels are growing about the use of offsite – but with confidence everything in long-term investment decisions – this is putting the pressure on disparate parts of the supply chain. As Brendan Geraghty, Director of Geraghty Taylor Architects says: “Funders have a profound influence on this space, on design decisions and greater control of the supply chain. They are being very strategic about

what they control and what brings less cost and ultimately what saves them money on the operational side.”

Overall the feeling is that a ‘leap of faith’ is still required into an uncertain market with challenges surrounding capacity and whether existing facilities can scale up to cater for increased delivery of systems or more products. To underpin greater confidence, better collaboration and more partnerships between contractors and the offsite supply chain are required, that make the best of both worlds. What needs to be better understood, communicated and sold as a positive, is the concept of ‘moving the value of a project away from the construction site to inside a factory’ and where the levels of quality and reliability can be controlled and streamlined. The age-old problem of overlapping trades, site snagging and endless site revisits can be made a thing of the past - for the PRS sector this is critical.

Hurdles & Barriers

With more education required on what offsite can deliver generally, what does the offsite industry itself need to do to get greater engagement with PRS clients, and what are the barriers to overcome to facilitate a better understanding over what factory manufactured building components can do?

One hurdle and a deep underlying issue is that the manufacturing and traditional construction industries are entrenched in the way they work and neither fully understand what each other does. Each have different thought processes, different histories and modes of operating. Certainly the role of precision factory engineering is at odds with the traditional construction mindset.

“There is definitely a need for precision design and high mechanisation,” says Matt Voyce, Director, Quintain. “Offsite construction is being sold as precision manufacture so more of that will give us more confidence in specifying across a range of projects.”

It is often here, where the varying quality of factory facilities and where businesses are in their business evolution is often queried. “Newer entrants have gone more towards precision engineering,” adds Darren Richards, Managing Director of Cogent

Consulting. “The newer businesses are sophisticated and starting from a blank page. The older established suppliers are having to evolve their systems, sometimes job by job.” As the quest for cutting edge technology and greater digitisation drives factory manufacture, there is a feeling that the UK is slightly lagging behind the continent with pressure from the Netherlands, Germany and Poland with large scale production of precast elements, volumetric modules and bathroom pods.

“The building industry has always been notoriously slow to pick up new technologies,” adds Kevin Wylde, Director ESA Architecture. “There is a huge amount of technology out there but we are slow to pick it up. It’s all about shifting perceptions.”

The difficulty seems to be there is often a ‘traditional approach to a technological problem’.

Technology & Collaboration

While technology is changing the ways buildings are constructed everywhere and transforming the way components are produced, the specification and design process would be far more efficient if the investor/client business requirements were more clearly articulated at an early stage to designer and architect teams and the supply chain. This would enable them to combine and collaborate and work out the optimum way to deliver client proposals. Stronger client leadership and where they see their ‘value points’ needs to be communicated better to illicit a better integrated response from the offsite supply chain.

“A lot of entrepreneurs have set up an offsite solution that works for various clients,” says Neil Ash,

Facilitator: Darren Richards –Managing Director of Cogent Consulting

Neil Ash – Managing Director, Etex Building Performance

Matt McKay – Commercial Manager Etex Building Performance

Joe Thornton – Founding Director, Cast Consultancy

Rory Bergin – Partner: Sustainable Futures, HTA Design LLP

Brendan Geraghty – Director, Geraghty Taylor Architects

Matt Voyce – Director, Quintain

Kevin Wylde – Director, ESA Architecture

Colin Westpfel – Head of Design, Balfour Beatty

Gary Ramsay – Editor, Offsite Magazine

Managing Director, Etex Building Performance. “And there is a flip side where a customer has a list of specific requirements of what they want and somehow these are not gelling together, so along the way there needs to be far better collaboration.”

A cultural shift in collaboration seems to be clear. Advice on which products and systems to use and where they would be most successful is an area where developers and clients need to know more about. The manufacturing market is a mature one and what developers would like to see is a clear presentation or proposition of what offsite systems can deliver versus a traditional approach. An oft-repeated stumbling block is the lack of statistical evidence and hard data that proves the benefits of offsite manufacture. It is very difficult to underpin the numerous benefits of what offsite can deliver without independent statistical data to prove it.

In an ideal world what is required is a thorough cost risk appraisal of a ‘traditional versus a manufactured offsite project’. Offsite manufacture is unquestionably not without risks but they are fewer and more manageable than via a traditional route. “Traditional costs are more commonly understood but there are so many intangibles in a traditionally delivered project, that to truly get a comparison would be nigh on impossible,” says

Colin Westpfel, Head of Design, Balfour Beatty.Generally, architects need to get to grips more with offsite and factory manufacture. Building design is still commonly centred on the delivery of traditional construction, with little understanding of factory-based system parameters and methods. And with the pressures of design, work-flow and supply chain integration key to success, the spotlight is on the architect, who could be best placed to be the ‘integrator’ of all these factors. “We are often in a central position between the competing bits,” says Brendan Geraghty. “From building design to interior fit out or assembly, we have to wear a number of hats but we need to know more detail to be able to make all of those competing bits work smoothly.”

Standardisation brings many cost benefits but may not always deliver wide choices. What the vast majority of clients and customers want when choosing a home is choice – and this is key to the PRS model as well. So will the focus on greater standardisation create a potential ‘turn-off’ for clients? Certainly some architects are wary of standardisation and the fear that it can stifle creativity, whereas for a manufacturer standardisation is the perfect scenario.

So there is sometimes a perception within architectural and construction circles that standardisation is a bad thing. “One of the challenges with offsite and volumetric modular is its repetitive nature,” says Kevin Wylde. “I understand that there can be lack of flexibility. Fear of standardisation is not the issue its understanding what

should get standardised. Introduction of standardisation can add real value by taking out the mundane bits and leaving you to focus on the elements that deliver true value.”

Of course the 3D volumetric modular approach is not the only one driving the PRS market. “We are very much in the thought process of looking at where the construction industry is going to change in the future,” says Matt McKay, Commercial Manager, Etex Building Performance. “We are looking to see what is required and what we can bring to the offsite market. There is a bigger role for standardisation – there is something behind that which really needs to be thought about – either at component level or as a producer of 2D panelised or full volumetric systems.”

The increased use and popularity of new technology including BIM and immersive environments such as AR/ VR and the connected world are set to bring a younger generation and different thinking into the industry with lifetime transferable skills that extend careers beyond the building site. Are they set to deliver the massive benefits that everybody says they can?

Digital has a big role to play in enabling closer supply chain integration. Once there is a better understanding of what technology can do and how companies can co-ordinate better within the digital environment, then it will make big differences. The role of digital technology can identify contractor risk

by checking small details and this can deliver huge material efficiency and potentially save millions of pounds over a major developments. These kind of cost savings for clients that are caught early ultimately reduce the risk for contractors and improve the chances of offsite acceptance.

Also, beyond the digital and software aspects of BIM, the crux of its success rests in its ability to improve project productivity and optimise the construction process and bring about lasting quality benefits that everyone along the building supply chain – from client to customer – can profit from. BIM helps reduce costs and defects onsite and instils discipline into project teams to deal with problems earlier in the design process. “Offsite needs to possibly mature to open platforms,” says Colin Westpfel. “With a range of asset tagging and intelligent graphics minimising defects, these de-risk the building process and solve problems early via digital technology not on the construction site.”

Whilst repeat footprints and standard layouts allow for massive efficiencies in the hotel and student accommodation sectors, can the same be said for PRS? It has the right attributes and footprint for low level of changes and variations with offsite systems and components in a perfect position to produce a broad range of homes consistently. The key aspect rests in that homes being ‘living spaces’ need to align with client and brand values and ultimately geographical location. Quality is

As pioneers of light gauge steel construction, EOS Facades specialise in the design, manufacture and supply of a wide range of steel sections for panelised or volumetric offsite solutions.

Through careful design detailing and value engineering, EOS Facades is able to offer the highest quality award winning light gauge steel solutions - delivering environmentally sustainable projects on time and to budget.

As an advanced high performance offsite solution, steel is a robust, rigid and dimensionally stable material that does not suffer from movement created by moisture related issues. Light gauge steel is perfectly positioned to meet construction industry demands – it is future proof and future ready.

If you have a project in mind then why not challenge EOS Facades to help value engineer the most efficient solution for you?

T: 01325 303030

E: enquiries@eosuk.org

W: www.eos-facades.co.uk

Clearer Understanding – clients, contractors and supply chain need to have a better understanding of each other’s business models to engage and work with efficiently.

PRS in its Infancy – while the use of volumetric modular is perfect for repeatability of hotel and student accommodation, the specification for PRS housing has to be more flexible.

Selling Offsite – overcoming the ‘front of house’ issue and having better client-facing teams that understand offsite manufacture and deliver a convincing proposition to the marketplace.

Technology Cultural Shift – technology is fast becoming the common ground to make client – manufacturer – customer integration easier.

Building Ownership – unlike the ‘sold’ housing model, those holding the PRS assets need to think clearly about its future development and building lifecycle.

Cost Comparisons – better and transparent industry data to show genuine cost comparisons between traditional methods and offsite manufacture.

Creativity Crunch – more efficient buildings come from the understanding of technology and focusing on how to apply this to design and supply chain integration.

Upwards Trajectory – the interest and trend for offsite manufacture is heading upwards with clients happier to invest in long-term assets than ever before.

Quality Management – the evolution of BOPAS is encouraging but warranty providers also need to understand and scrutinise the quality standards and expectations that underpin investor decisions.

Procurement Behaviour – this needs to change. Organisations are still trying to procure new products and systems with an old traditional mindset.

critical but when people buy a home it is an ‘emotional decision’, when renting it’s about ‘quality of service’ and making the rental experience a positive one. As the PRS customer becomes more sophisticated, clients and suppliers need to be more attentive to the long-term life-cycle of the building and the wider role of place-making – it is here where a large paradigm shift rests: “it’s not about the building it’s about the customer.”

Looking ahead to where the offsite industry is heading in relation to the PRS sector and housing generally, there is now a continuous incline and increase of interest in offsite systems but there is still a reticence to engage from a sometimes wary client base. High levels of investment and large sums of money are available, but there still needs to be a convincing argument created for offsite to be deployed. The PRS sector in particular wants more validation of products above and beyond mortgageability and warranty – people are seeking in-service performance validation. Institutional lenders have high expectations about their long term investments and this kind of thinking is underpinning procurement decisions.

So while there is as positive relationship between the offsite sector and PRS market, a lot of effort still needs to be expended on defining clearly what offsite can provide for clients and specifiers and why construction fuelled by repeatability and standardisation is ideal. Economy of scale rests in repeatability and standardisation – so this and the wider use of design for manufacture (DfMA) plus the injection of creativity from architects and building designers, can bring about the changes that the construction sector and housing sector desperately need.

Many thanks to Etex Building Performance for hosting the Roundtable Event and thanks to all participants for their time and contributions to the discussion.

For more information on Etex Building Performance visit: www.etex-bp.co.uk

For more information on offsite related activity visit: www.offsitehub.co.uk.

Product & service portfolios

Manufacturing operations

Supply-chain integration

Business processes

Management systems

Marketing strategies

Sales routes to market

Offsite is due to make its mark on UK Construction Week (UKCW) by showcasing all its advantages in its very own dedicated Offsite area within the Build Show alongside an additional presence at Timber Expo. 1

Offsite construction will help take over Birmingham’s NEC between 9 – 11 October, with more than 10,000 products and 650 exhibitors, seminars, CPD sessions and networking opportunities across nine shows: Build Show, Energy 2018, Timber Expo, Surface and Materials Show, Building Tech Live, HVAC 2018, Civils Expo, Plant and Machinery Live and Grand Designs Live. To demonstrate how effective offsite construction is becoming, a two-storey house and student apartment will be installed at the show plus a high-end hotel bathroom pod and a timber house will be on display.

With a wide and varied range of offsite exhibitors on hand there is a plethora of products to discover. Many of which are embracing new technologies that will enable faster, more efficient and better-quality buildings.

The Elliott Group will be discussing everything from telecoms packages through to fire equipment thanks to their 360 degree service package for offsite construction. REM will be showing its unique approach by using living containers to build schools, offices and showrooms. And Containex will be showcasing its new selfcontained staircase modules, which are easy to transport and install, with strong and flexible guardrails that can be repositioned anywhere.

Other exhibitors include: KC Cabin Solutions offering personalised modular and portable buildings, Kerkstoel the precast concrete experts, Extenda Line with portable flat packed storage units and Morland will be displaying its new Forever FirecheckTM fire door frame and its brand-new Water Vapour Barrier tongue and groove panels.

Visitors won’t want to miss out Michael Dall from Barbour ABI’s talk, delving deeper into the market, where he looks at the key sectors for offsite, how it will develop and grow in the next few years and which sectors it appeals to most. Stephen Wade-Palmer from Offsite Solutions will talk about specifying factory-built bathrooms, looking at the critical considerations needed to optimise efficiency in using bathroom pods. An elegant bathroom pod, which is earmarked for luxury Canary Wharf hotel, will be on display in the Offsite area.

Visitors will have access to numerous CPD sessions and seminars. Don’t miss out on the Innovation Trail, networking opportunities and the Offsite Theatre, supported by MPBA and the Structural Timber Association. Modular building specialist, Vision Built, is installing a two-storey house and student

apartment for all to experience at the Offsite Theatre. Following the event, the construction will be taken to its final location in Suffolk.

For visitors who want to learn as much as possible about the speed of modular construction, you won’t want to miss out on the following seminars:

• Building more homes, with the Central Housing Investment Consortium

• Developing your offsite strategy, with Action Sustainability

• Flexible and high-rise modular constructions, with MJH Structural Engineers.

Other essential seminars include:

• New assessment methodology and certification scheme for modular homes presented by David Gall, Associate Director, BRE

• Digitising offsite construction by David Clark, Head Of Manufacturing And Innovation, The McAvoy Group

• Routes to market for modular and volumetric housing delivered by Joanne Booth, Construction Business Manager, Lucideon.

This year’s ‘Future of Construction’ theme, there is plenty to discover for the future of offsite. The Future of Construction Hub, in collaboration with Birmingham City University, provides an immersive opportunity to discover pioneering techniques such as digital

construction, 3D printing, robotics, AI and AR and modern methods of construction. Visitors will be able to try out these new technologies first hand and learn how they will shape the built environment in years to come. An Innovation Trail uncovers products from Danosa, Hekim Yapi, Max, SFL Mobile Radio, and Velux. Plus Carwyn Lloyd Jones will be building a timber home at Timber Expo, where he will deliver lessons on natural construction techniques too.

This year also sees the launch of the UKCW Role Models Campaign to champion the existing talent in the industry and to inspire the next generation. 36 inspiring men and women have recently been shortlisted for this campaign, and the overall Role Model of the Year will be announced on 10 October.

Debates on major national and international construction issues will take place on the UKCW Stage. Speakers already confirmed include: Barbara Res, Project Manager behind Trump Tower, Lord David Blunkett, Heathrow Skills taskforce Chair, Phil Wilbraham, Expansion Programme Director at Heathrow, Bridget Rosewell OBE, Commissioner at the National Infrastructure Commission; Ben Derbyshire, RIBA President and Ruth Davidson, National Housing Federation Executive Director.

Celebrations will all be in order at the Construction Enquirer Awards,

the Structural Timber Awards and Voltimum Smart Solutions Awards, all taking place throughout UKCW.

Once inspired by the exhibitors and seminars it’s time to unwind at the Beer Festival, sponsored by Velux, with street food, rockaoke, and a gin and fizz bar. FIX Radio will be broadcasting from here throughout the event. You can also visit the Central Bar in Hall 11 sponsored by Elliott Group and the Timber Bar in Hall 9 sponsored by Germany Trade & Invest.

Keep up to date via www.ukconstructionweek.com and Twitter at @UK_CW or using the hashtag #UKCW2018.

Images: 01-03. UKCW will feature the Offsite Theatre and a range of offsite exhibitors 2 3

After some delay, the Government finally launched its much-anticipated Construction Sector Deal (CSD) in July, with a vison to develop an industry able to respond to the pressures of changing demographics, technological change and sustainable building. 1

The construction sector is central to the UK’s economic health and wellbeing yet forever seems to be tarnished by pockets of poor productivity, low quality, unpredictability and resistance to change. Talk of industry transformation, better collaboration and modernisation has been swirling around since the late Sir Michael Latham’s landmark report ‘Constructing the Team’ in 1994. The latest report to crystallise the industry’s key problems was Mark Farmer’s 2016 review, now simply known as ‘Modernise or Die’. This report was perhaps more brutal in its assessment of where things need to improve with the introduction of more offsite manufacture and the adoption of digital technology driving advanced industry and building performance.

The Construction Sector Deal – “an ambitious new partnership between the government and the construction industry” – was unveiled by the Business and Energy Secretary Greg Clark, in a speech to the Northern Powerhouse Summit in Newcastle, and set out how it will form part of the Clean Growth Grand Challenge (itself part of the wider Industrial Strategy) with the ‘Transforming Construction’ investment that is supporting lowcarbon approaches to housing.

With almost half of the economy reliant on the built environment and the services it enables, the Government is bringing together the construction, manufacturing, energy

and digital sectors to deliver innovative approaches that improve productivity and accelerate a shift to building safer, healthier and more affordable places to live and learn that use less energy.